Abstract

To determine the optimal fertilizer discharging performance, a spiral fertilizer applicator was designed according to orchard agricultural requirements. The influence of different parameter combinations of the spiral speed, blade diameter, and pitch on the coefficient of variation (CV) of the fertilizer discharge uniformity was predicted using a neural-network-based model by using the Box–Behnken design (BBD) test. According to the extracted results, the neural network model has a good prediction ability, with the determination coefficient of the model and the mean relative error reaching 0.99 and 2.29%, respectively. The impact of the fertilizer discharge parameter combinations on the discharging performances was examined from both macroscopic and microscopic perspectives. During the fertilizer discharge process, the openness formed between the spiral blades and fertilizer outlet presented periodic changes with the continuous rotation of the spiral blade, thus resulting in the uneven discharge of the fertilizer particles. In addition, there are interacting force chains among fertilizer particles, which are not broken in time during the fertilizer discharge procedure, thus resulting in uneven fertilizer discharge. With comprehensive consideration of the fertilizer discharge efficiency, the fertilizer discharge effect, and CV of the fertilizer discharge uniformity, the spiral parameter combination of the fertilizer discharge after neural network optimization are as follows: rotating speed of 47.6 rpm, blade diameter of 90 mm, pitch of 60 mm, and CV of fertilizer discharge uniformity of 19.05%. Under this optimal spiral parameter combination, the fertilizer discharge effect and discharge efficiency were considered to be relatively good. Our work provides references for the design optimization of the spiral fertilizer applicator and fertilizer discharge parameter combination.

1. Introduction

Fertilization is regarded as an important factor that increases crop yield and is a significant means by which to maintain soil nutrients [,]. Accurate fertilization is beneficial to significantly increase crop growth and realize the goal of increasing fertilizer utilization, to achieve a high quality and yield of crops, and to produce a reasonable distribution of agricultural resources, among other things. The fertilization accuracy is an important index in the accurate evaluation of fertilization and a fertilizer applicator is a key piece of equipment for reasonable fertilization. As a result, improving the performance of the fertilizer applicator is of significance to the decrease in the fertilization quantity [].

A spiral fertilizer applicator is a common fertilizer applicator and it has been widely used due to its simple structure, low cost, stable single-ring throughput, and strong sealing performances [,,]. However, it has flow pulsation and leads to fertilizer waste. Hence, various studies in the literature on the fertilizer discharging performances of traditional single-spiral fertilizer applicators have been carried out in recent years. More specifically, Mondal and Ghosh [] studied the influence of spiral speed on the stability and uniformity of the spiral outlet mass-flow rate and carried out simulations and bench tests. Minglani et al. [] conducted simulations on filling rates under different spiral speeds. Zhang et al. [] improved the mass flow uniformity at the outlet by using different pitches. Zhong et al. [] performed simulations and bench tests on the influence of blade diameters on fertilizer discharge uniformity. Therefore, from the above research and analysis, it can be found that the rotating speed, pitch, and blade diameter are the key influencing factors to improve the performance of single-spiral fertilizer applicators. With the rapid development of modern dynamics, numerical methods, and computer technology, the Discrete Element Method (DEM) has become an important technical means in the field of agricultural engineering, and has been widely used to improve the performance of a single screw fertilizer drainer [,,]. Dun et al. [] optimized the fertilizer applicator design using the Box–Behnken (BBD) design by using the EDEM simulation software. The Box–Behnken (BBD) design is a common method used in surface optimization approaches and it is characterized by the execution of few tests, low cost, and acceptable results []. Artificial Neural Networks (ANN), a representative of machine learning algorithms, have the potential to determine the complex relationship between input and output, as well as high prediction accuracy and strong learning ability, and can reasonably predict and model complex system according to the obtained results to draw conclusions [,]. Based on the construction of a fertilizer discharge quantity prediction model by using a neural network, Zhang et al. [] investigated the influencing laws of the rotating speed of the fertilizer discharge axis on the fertilizer discharging performances by using the EDEM simulation technology. Although the above-mentioned works mainly focus on single-spiral fertilizer discharge performance, in the optimization of fertilizer discharge performance, the existing optimization accuracy is not high, and the impact of the spiral parameter combination on the fertilizer discharging performance has been scarcely reported. Along these lines, in this work, the BBD in response to the surface optimization approaches and ANN were combined to accurately predict the fertilizer discharge parameter combination by decreasing data size as much as possible. Moreover, the fertilizer discharge mechanism was systematically explored using EDEM simulation technology.

In this work, a single-spiral fertilizer applicator was designed. The influence of the different parameter combinations of spiral speed, blade diameter, and pitch on the CV of fertilizer discharge uniformity was thoroughly investigated through the BBD design experiment with discrete element simulation software. A neural network model was chosen for the training procedure and the spiral parameter combination was optimized to obtain the optimal fertilizer discharge effect. Moreover, the underlying fertilizer discharge mechanism was explored. The acquired research results provide references and theoretical reference values for the design of the spiral fertilizer applicator design and optimization of the fertilizer discharge parameter combination.

2. Structural Design and Working Principle of the Fertilizer Applicator

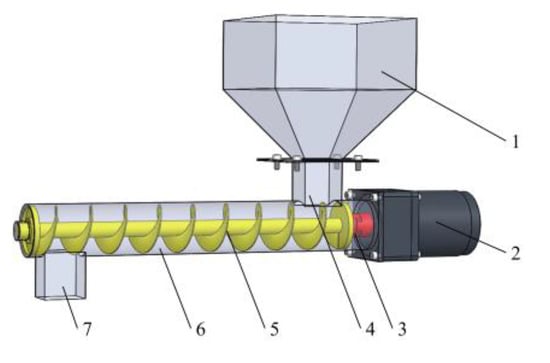

The employed spiral fertilizer applicator is mainly composed of a fertilizer tank, driving motor, coupler, fertilizer inlet, spiral, spiral shell, and fertilizer outlet (Figure 1). According to the orchard agricultural requirements, the parameters of the spiral fertilizer applicator are determined in Table 1. According to Equation (1), the highest rotating speed of the spiral fertilizer applicator was 88.54 rpm.

where is the critical rotating speed (rpm), A denotes the comprehensive coefficient of materials, while it possesses the value of 28 [], and D is the outer diameter of the spiral (100 mm).

Figure 1.

Structural diagram of the spiral fertilizer applicator. 1. Fertilizer tank 2. Driving motor 3. Coupler 4. Fertilizer inlet 5. Spiral 6. Spiral shell 7. Fertilizer outlet.

Table 1.

Main parameters of the spiral fertilizer applicator.

When this fertilizer applicator works, the driving motor drives the spiral axis to rotate through the coupler under the control of the controller. In the fertilizer tank, fertilizer particles fill in spiral spaces continuously through the fertilizer inlet under the action of gravity. Since the fertilizer particles in a spiral bear frictional resistance with the spiral shell and their own gravity, they are moved forward along the spiral under the action of the rotating spiral blade until they fall into the groove through the fertilizer outlet. This is the whole process of fertilizer discharge.

3. Experimental Design Method

3.1. The Setting of the Simulation Parameters and Construction of the Simulation Platform

As an effective numerical simulation calculation method, the discrete element method has been widely applied in agricultural machinery []. Hence, we selected the EDEM2021 software for simulating the working process of the spiral fertilizer application. If there is no adhesion among fertilizer particles during the service of the spiral fertilizer applicator, the Hertz–Mindlin (noslip) contact model is used. With references to the relevant works in the literature [,], the contact parameters between the fertilizer particles and the fertilizer applicator are determined in Table 2.

Table 2.

Setting of the simulation parameters.

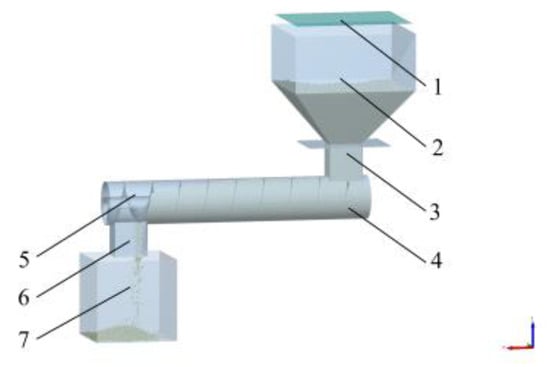

The spiral fertilizer applicator was plotted 1:1 by using the SolidWorks three-dimensional software, stored in the format of .stl, and then input into EDEM2021. During the simulation, the virtual particle factory generated 6 kg particles at a speed of 3 kg/s and all the particles fell into the fertilizer tank. When all particles fell, the spiral fertilizer applicator began to rotate (Figure 2).

Figure 2.

Simulation test. 1. Particle factory; 2. fertilizer tank; 3. fertilizer inlet; 4. spiral shell; 5. spiral; 6. fertilizer outlet; 7. Collection tank.

3.2. Test Design

According to previously reported works in the literature, we decided to optimize the rotating speed, blade diameter, and pitch under the premise that agricultural requirements are met []. The BBD test saves continuous tests and involves fewer test combinations than the other test design methods under the same factor levels. The BBD test design was applied in the simulation test and the factor level codes are listed in Table 3.

Table 3.

Experimental factor levels.

For accurate evaluation of the fertilizer discharge stability and uniformity of the applicator, with reference to the test method regulated in NY/T 1003–2006, the CV of the fertilizer discharge uniformity was chosen as the index, whereas the particle mass in the collection tank was used after fertilizer discharge was stabilized []. The average fertilizer discharge mass, standard deviation, and CV of fertilizer discharge uniformity were calculated with Equations (2)–(4).

where is the mean mass of statistical fertilizer particles after stabilization of the fertilizer discharge (g), refers to the fertilizer particle mass in the interval of time i (g), S denotes the standard deviation per unit interval (g), and CV stands for the CV of fertilizer discharge uniformity per unit interval (%).

3.3. Data Processing

The simulation test data were extracted and Excel was used for data processing. The neural network platform in JMP Pro 14.0 software was also used. The standard least square method is advantageous for quick convergence and high accuracy []. Hence, it was applied here for optimal analysis.

4. Results and Analysis

4.1. Construction of the Prediction Model

The design principle, design, and results of the BBD test are listed in Table 4. The fitting model in the JMP Pro 14.0 software and the standard least square method was applied for fitting, thus enabling the easy calculation of the unknown data and realizing the minimum quadratic sum of the error between these and the practical data.

Table 4.

Test design and results.

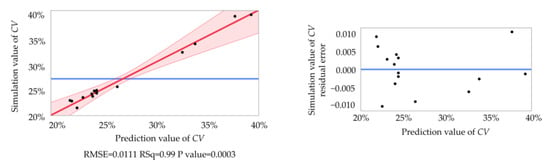

After several stages of neural network training, a three-layer neural network with a structure of 3 × 4 × 1 was adopted. It included three input neurons representing speed, blade diameter and pitch, four hidden layer neurons; and one output neuron, representing the uniformity coefficient of variation (CV). The value of each parameter was set, the number of hidden nodes was four, the verification method was “K-fold” cross-verification, fold number was five, and the reproducibility random seed was ten. The activation function is the S-shaped TanH function, the learning rate is 0.1, the model is five, the fitting option is the transformation covariable, the penalty method is the square, and the process number is five. As can be seen from Figure 3, the p < 0.05 model was significant, the root-mean-square error (RMSE) of fertilizer discharge parameters to the CV of the fertilizer uniformity-prediction value was 0.0111, the determination coefficient was 0.99, and the residual errors of the prediction value are mainly within ±0.005. In a word, this prediction model exhibited a good prediction ability.

Figure 3.

Relation map between the of the fertilizer discharge uniformity based on the fertilizer discharge parameters.

4.2. Optimization and Analysis of the Prediction Model

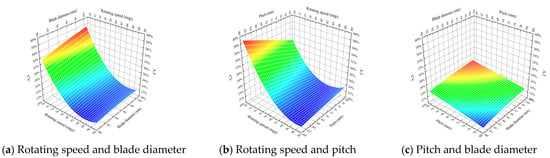

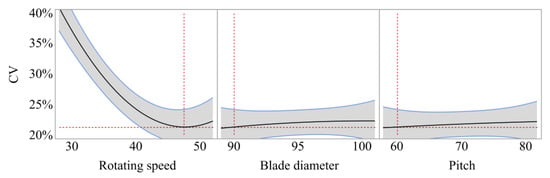

A three-dimensional surface diagram was plotted by using the surface descriptor in JMP Pro 14.0. The acquired results are shown in Figure 4. As can be observed from Figure 4a, when the pitch was fixed at 70 mm, the CV of fertilizer discharge uniformity decreased first and then increased with the continuous increase in the rotating speed. When the speed was 30 rpm, the CV of the fertilizer discharge uniformity approached the value of 0.4. With the increase in the blade diameter, the CV of the fertilizer discharge uniformity changed slightly. As can be ascertained from Figure 4b, when the blade diameter was fixed at 95 mm, the CV of the fertilizer discharge uniformity decreased with the increase in the pitch, indicating that the fertilizer discharge effect is good. Figure 4c illustrates that when the rotating speed was fixed at 40 rpm, the CV of the fertilizer discharge uniformity changed slightly with the increase in the blade diameter and pitch. To summarize, the rotating speed exerts the principal affected the fertilizer discharge uniformity, while the blade diameter and pitch had a relatively smaller influence. When seeking the spiral fertilizer discharge parameters, the fertilizer discharge uniformity increased with the decrease in the CV of fertilizer discharge uniformity, indicating the better fertilizer discharge effect. The spiral fertilizer discharge parameters were optimized by the prediction descriptor in the JMP Pro 14.0 software. The acquired results are shown in Figure 5.

Figure 4.

Impact of rotating speed, blade diameter and rotating speed on the CV of the fertilizer discharge uniformity. Notes: (a) The pitch was fixed at 70 mm; (b) blade diameter fixed at 95 mm; (c) rotating speed fixed at 40 rpm.

Figure 5.

Prediction depiction diagram of neural network.

As can be seen from Figure 5, the minimum CV of fertilizer discharge uniformity was achieved when the rotating speed, blade diameter, and pitch were 47.6 rpm, 90 mm, and 60 mm, respectively. The above-mentioned results were obtained based on the prediction model and they have to be further verified from the perspectives of macroscopic particle flow and microstructure.

4.3. Verification of the Prediction Model

In order to test the neural network model, the neural network optimization parameter group and two new factor level combinations (see Table 5) were selected for the experiment. Three groups of the test data were used as input for verification and the built prediction model was used to predict the results. The prediction results were compared with the simulation results (Table 5) to test the accuracy and stability of the prediction model. As can be seen from Table 5, the relative error between the prediction and simulation results is small and the built prediction model has good prediction ability. This prediction model can be also used to predict the fertilizer discharge parameters.

Table 5.

Comparison of the neural network model prediction and simulation results.

4.4. Mechanism Analysis of the Fertilizer Applicator

Although the spiral fertilizer applicator has a relatively simple structure, the motion state of the fertilizer particles in the applicator was relatively complicated. In this work, a qualitative analysis of the fertilizer discharging performances of the spiral fertilizer applicator was carried out by combining the prediction parameters of the neural network model and another two groups of simulation parameters of the spiral. The fertilizer discharging performances were manifested by the transient fertilizer discharge effect and the contact force of the fertilizer particles. Moreover, a quantitative analysis of the CV of the transient fertilizer discharge rate and fertilizer filling coefficient was performed.

4.4.1. Macroscopic and Mesoscopic Analyses of the Fertilizer Discharge Process

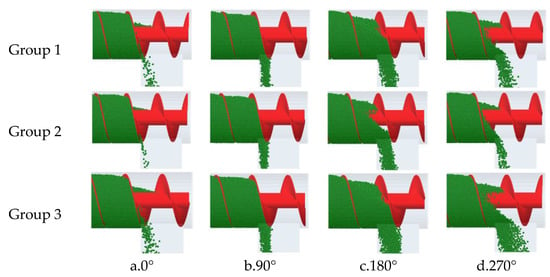

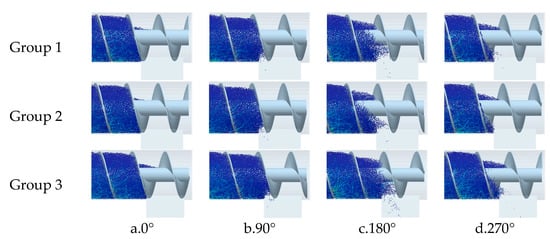

The periodic fluctuation of the fertilizer discharge quantity is one of the causes for the poor fertilizer discharge uniformity. The transient fertilizer discharge effect when the spiral fertilizer applicator is rotating by different phase angles is shown in Figure 6. Group 1 refers to the group of the optimized fertilizer discharge parameters. As can be observed from Figure 6, the fertilizer discharge quantity of Group 2 at the outlet presents obvious periodic fluctuation, which is mainly attributed to the continuous rotating of the spiral blade and the periodic changes of the opening between the spiral blade and the fertilizer outlet. Moreover, the transient fertilizer discharge of Group 1 was relatively uniform.

Figure 6.

Transient fertilizer discharge effect when spiral fertilizer applicator rotates for different phase angles. Notes: Numbers 1, 2, and 3 are the numbers of observation groups. Group 1: rotating speed of 47.6 rpm, blade diameter of 90 mm, pitch of 60 mm (optimal conditions); Group 2: rotating speed of 30 rpm, blade diameter of 95 mm, pitch of 60 mm; Group 3: rotating speed of 50 rpm, blade diameter of 100 mm, and pitch of 70 mm.

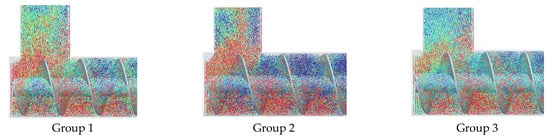

The contact force of fertilizer particles is the resultant force on fertilizer particles. The existence of an uneven distribution of the contact forces of fertilizer particles can easily lead to uneven distribution of the fertilizer filling coefficient and it is one of the causes of the poor fertilizer discharge uniformity []. The contact resultant force of the fertilizer particles when the simulation test reached stability is shown in Figure 7 (the arrow direction is the resultant direction; the dark blue contact force is 0 and the red contact force denotes the peak). The red contact force of Group 2 was distributed below the spiral and at the inlet. The red contact force of Group 3 was mainly distributed below the spiral and right wall of the inlet. The red contact force of Groups was distributed relatively uniformly. According to the comparison of three groups of the spiral parameters, the fertilizer particle stresses of Group 1 were relatively uniform.

Figure 7.

Contact forces of the fertilizer particles. Notes: Numbers 1, 2, and 3 are the numbers of observation groups. Group 1: rotating speed of 47.6 rpm, blade diameter of 90 mm, pitch of 60 mm (optimal conditions); Group 2: rotating speed of 30 rpm, blade diameter of 95 mm, pitch of 60 mm; Group 3: rotating speed of 50 rpm, blade diameter of 100 mm, pitch of 70 mm.

4.4.2. Macroscopic and Mesoscopic Analyses of the Fertilizer Discharging Performances during the Fertilizer Discharge Process

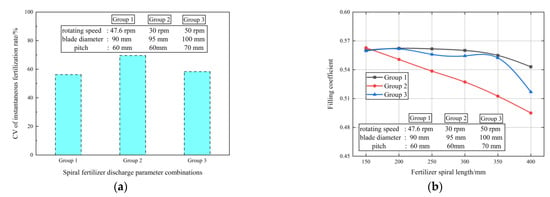

The periodic fluctuation of the transient fertilizer discharge quantity at the outlet can influence the fertilizer discharge uniformity. A quantitative analysis of the CV of the transient fertilizer discharge rate was carried out. As can be seen from Figure 8a, the CV of the transient fertilizer discharge rate of the Group 1 was the lowest (56.20%), followed by that of Group 3 (58.31%). The CV of the transient fertilizer discharge rate of Group was the highest, reaching 69.53%. The transient fertilizer discharge uniformity of Group 1 was better than for Group 2 and Group 3, respectively.

Figure 8.

Impact of the different spiral fertilizer discharge parameter combinations on fertilizer discharging performances. (a) Impact of the different spiral fertilizer discharge parameter combinations on the transient fertilizer discharge. (b) Impact of the different spiral fertilizer discharge parameter combinations on the filling coefficient.

The stability of the fertilizer filling coefficient influences the discharge uniformity. The fertilizer filling coefficient refers to the filling coefficients of fertilizers in different spiral sections, which is the volume ratio of the fertilizer particles per unit length and the spiral spatial volume of the fertilizer discharge at an equal length. As can be ascertained from Figure 8b, the filling coefficient of Group 2 decreased quickly, while those of Group 1 and Group 3 decreased slowly. The filling coefficient of Group 1 changed slightly and the fertilizer discharge was relatively uniform.

To summarize, it can be concluded from the macroscopic structure that the transient fertilizer discharge rate of Group 1 was relatively uniform. According to the microstructure, the contact force of fertilized particles in Group 1 is distributed relatively uniformly. From both the macroscopic and microscopic phenomena, it was demonstrated that the CV of fertilizer discharge uniformity was relatively small.

4.4.3. Fertilizer Discharge Process Discussion Based on Force Chains

Except for the above-mentioned reasons, there are interacting force chains among the fertilizer particles, which are one of the influencing factors of the fertilizer discharge uniformity (Figure 9). The variations of the different phase-angle force chains in different groups are displayed in Figure 9. As can be seen from Figure 9 (b1,b2,b3) and Figure 9 (c1,c2,c3), the fertilizer particles cannot be discharged in a timely way since they cannot break the force chain with their own gravity during the fertilizer discharge process, thus resulting in the uneven fertilizer discharge. Cui et al. [] pointed out that the force chain broken by external stresses failed on a large scale when the uniform distribution of force chains existed. Hence, when the force chains formed by contacts of fertilizer particles can be distributed uniformly, they can be broken in a timely way upon gravity and fertilizers can be discharged. Thereby, a uniform fertilizer discharge procedure can be realized.

Figure 9.

Variation of the force chains when spiral fertilizer applicator rotates by different phase angles. Notes: Numbers 1, 2, and 3 are the numbers of the observation groups. Group 1: rotating speed of 47.6 rpm, blade diameter of 90 mm, pitch of 60 mm (optimal conditions); Group 2: rotating speed of 30 rpm, blade diameter of 95 mm, pitch of 60 mm; Group 3: rotating speed of 50 rpm, blade diameter of 100 mm, pitch of 70 mm.

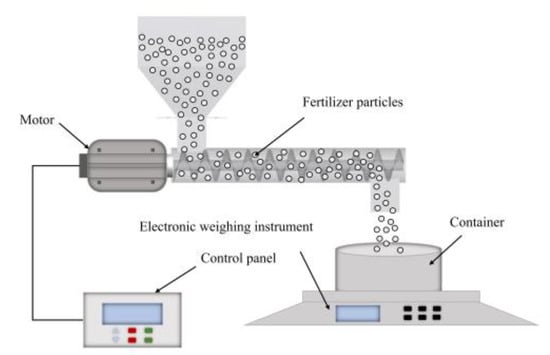

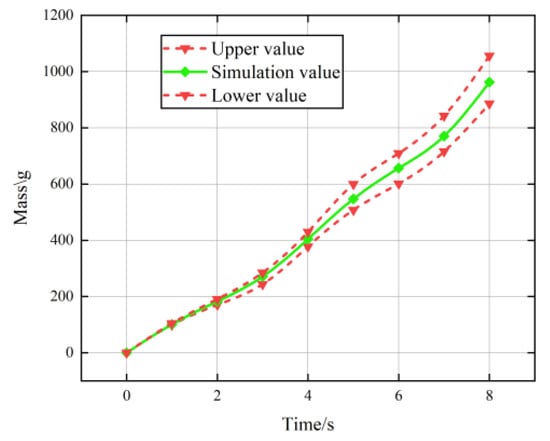

4.5. Bench Test

A bench test was carried out to verify the reliability of the simulation test by using the optimal fertilizer discharge parameters (rotating speed of 47.6 rpm, blade diameter of 90 mm, and pitch of 60 mm). The fertilizer particles are poured into the fertilizer tank and the motor is controlled through the control panel. The mass of fertilizer particles in the container is weighed, as show in Figure 10. A total of 10 tests were carried out to obtain statistics on the upper and the lower limits, as depicted by red dotted lines in Figure 11. The dotted lines represent the upper and lower limits of the multiple tests. If the simulation data (green solid line) are within the range of the dotted lines, the simulation data agree with the practical data. As can be seen from Figure 11, the green solid line was always kept within two green dotted lines, indicating that the simulation test data have a relatively high reliability.

Figure 10.

Experimental principles.

Figure 11.

Depiction of the verification results.

5. Conclusions

In this work, a spiral fertilizer discharge parameter dataset was built by using the BBD design. A prediction model was constructed by using the CV of fertilizer discharge uniformity as the response index and the standard least square method in JMP Pro 14.0. The parameter combinations were optimized and the fertilizer discharge effects under different parameter combinations were predicted. Moreover, the fertilizer discharge mechanism was explored through the EDEM simulation.

(1) The three-factor three-level BBD test of the spiral fertilizer applicator was implemented by choosing the rotating speed, blade diameter, and pitch. An ANN prediction model that used the CV of the fertilizer discharge uniformity as the index, rotating speed, blade diameter, and pitch as inputs was constructed. According to the acquired results, the determination coefficient and MRE of the model were 0.99 and 2.29%, respectively. In a word, this prediction model exhibited good prediction capability.

(2) The influence of the different fertilizer discharge parameter combinations on fertilizer discharging performances of the spiral fertilizer applicator was analyzed in this work. Furthermore, an EDEM simulation model was built and the fertilizer discharge mechanism was explored. (1) During the fertilizer discharge process, the fertilizer discharge uniformity was low due to the continuous rotation of the spiral blade and periodic changes of the opening between the spiral blade and fertilizer outlet. (2) During the fertilizer discharge, since interacting force chains among fertilizer particles were not broken in a timely way, poor fertilizer discharge uniformity was obtained.

(3) With comprehensive consideration of the fertilizer discharge efficiency and effect, as well as the CV of fertilizer discharge uniformity, the spiral parameters after the optimization by the neural network were as follows: rotating speed of 47.6 rpm, blade diameter of 90 mm, pitch of 60 mm, and CV of fertilizer discharge uniformity of 19.05%. Under these optimal parameters, the fertilizer discharge effect and the efficiency were relatively good.

Author Contributions

Resources, H.N.; data curation, H.Z.; writing—original draft preparation, M.Z. and Y.T.; writing—review and editing, Y.T. and H.L.; visualization, H.Z.; supervision, H.N.; project administration, H.N. and H.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This is research was financially supported by Xinjiang Construction Corps, grant number(2021AA005,2021AA0050302).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

This work was supported by financial scientific and technological projects of Xinjiang Construction Corps, grant number (2021AA005, 2021AA0050302). The authors are grateful to the anonymous reviewers for their comments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tang, H.; Wang, J.W.; Xu, C.S.; Zhou, W.Q.; Wang, J.F.; Wang, X. Research progress analysis on key technology of chemical fertilizer reduction and efficiency increase. Trans. Chin. Soc. Agric. Mach. 2019, 50, 1–19. [Google Scholar]

- Hu, H.; Li, H.W.; Wang, Q.J.; He, J.; Zhang, Y.F.; Chen, W.Z.; Wang, X.L. Design and experiment of targeted hole-pricking and deep-application fertilizer applicator between corn rows. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2016, 32, 26–35. [Google Scholar]

- Liu, X.D.; Ding, Y.C.; Shu, C.X.; Wang, K.Y.; Liu, W.P.; Wang, X.P. Mechanism analysis and test of disturbance and blockage prevention of screw cone centrifugal fertilizer apparatus. Trans. Chin. Soc. Agric. Mach. 2020, 51, 44–54. [Google Scholar]

- Kretz, D.; Callau-Monje, S.; Hitschler, M.; Hien, A.; Raedle, M.; Hesser, J. Discrete element method (DEM) simulation and validation of a screw feeder system. Powder Technol. 2015, 287, 131–138. [Google Scholar] [CrossRef]

- Van Liedekerke, P.; Tijskens, E.; Ramon, H. Discrete element simulations of the influence of fertilizer physical properties on the spread pattern from spinning disc spreaders. Biosyst. Eng. 2009, 102, 392–405. [Google Scholar] [CrossRef]

- Yu, S.H. Optimization design of performance parameters of vertical screw conveyor. Mach. Des. Manuf. 2015, 11, 215–218. [Google Scholar]

- Mondal, D.; Ghosh, N. Study on filling factor of short length screw conveyor with flood-feeding condition. Mater. Today Proc. 2018, 5, 1286–1291. [Google Scholar] [CrossRef]

- Minglani, D.; Sharma, A.; Pandey, H.; Dayal, R.; Joshi, J.B.; Subramaniam, S. A review of granular flow in screw feeders and conveyors. Powder Technol. 2020, 366, 369–381. [Google Scholar] [CrossRef]

- Zhang, Z.L.; Liu, Y.Q.; Zheng, B.; Li, R.Y.; Yu, H.L. Flow characteristics of particles in water-cooled screw conveyor. Chem. Ind. Eng. Prog. 2017, 36, 3217–3222. [Google Scholar]

- Xue, Z.; Zhao, L.; Wang, F.H.; Wang, S.; Wang, G.; Pan, R. Performance simulation test of the spiral fertilizer distributor based on discrete element method. J. Hunan Agric. Univ. (Nat. Sci.) 2019, 45, 548–553. [Google Scholar]

- Yang, Q.L.; Li, Z.H.; Li, H.W.; He, J.; Wang, Q.J.; Lu, C.Y. Numerical analysis of particle motion in pneumatic centralized fertilizer distribution device based on CFD-DEM. Trans. Chin. Soc. Agric. Mach. 2019, 50, 81–89. [Google Scholar]

- Liao, Y.T.; Gao, L.P.; Liao, Q.X.; Zhang, Q.S.; Liu, L.C.; Fu, Y.K. Design and test of side deep fertilizing device of combined precision rapeseed seeder. Trans. Chin. Soc. Agric. Mach. 2020, 51, 65–75. [Google Scholar]

- Qi, J.T.; Meng, H.W.; Kan, Z.; Li, C.S.; Li, Y.P. Analysis and test of feeding performance of dual-screw cow feeding device based on EDEM. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 65–71. [Google Scholar]

- Dun, G.Q.; Liu, W.H.; Wu, X.P.; Mao, N.; Ji, W.Y.; Ma, H.Y. Simulation optimization design and experiment of screw extrusion precision fertilizer ejector. J. Jilin Univ. (Eng. Technol. Ed.) 2021, 1–10. [Google Scholar]

- Khan, F.A.; Ghafoor, A.; Khan, M.A.; Chattha, M.U.; Kouhanestani, F.K. Parameter Optimization of Newly Developed Self-Propelled Variable Height Crop Sprayer Using Response Surface Methodology (RSM) Approach. Agriculture 2022, 12, 408. [Google Scholar] [CrossRef]

- Zheng, B.W.; Song, Z.H.; Mao, E.R.; Zhou, Q.; Luo, Z.H.; Deng, Z.C.; Shao, X.D.; Liu, Y.X. An ANN-PSO-Based Method for Optimizing Agricultural Tractors in Field Operation for Emission Reduction. Agriculture 2022, 12, 1332. [Google Scholar] [CrossRef]

- Bonini Neto, A.; Alves, D.A.; Minussi, C.R. Artificial Neural Networks: Multilayer Perceptron and Radial Basis to Obtain Post-Contingency Loading Margin in Electrical Power Systems. Energies 2022, 15, 7939. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Liu, G.; Hu, H.; Hang, J.Y.; Liu, Y.J. Influence of Control Sequence of Spiral Fluted Roller Fertilizer Distributer on Fertilization Performance. Trans. Chin. Soc. Agric. Mach. 2020, 51, 138–144. [Google Scholar]

- Xiao, W.L.; Liao, Y.T.; Shan, Y.Y.; Li, M.L.; Wang, L.; Liao, Q.X. Design and experiment of quad-screw double-row fertilizer apparatus for rape seeding machine. Trans. Chin. Soc. Agric. Mach. 2021, 52, 68–77. [Google Scholar]

- Yu, Y.W.; Saxen, H. Experimental and DEM study of segregation of ternary size particles in a blast furnace top bunker model. Chem. Eng. Sci. 2010, 65, 5237–5250. [Google Scholar] [CrossRef]

- Yang, W.W.; Fang, L.Y.; Luo, X.W.; Li, H.; Ye, Y.Q.; Liang, Z.H. Experimental study of the effects of discharge port parameters on the fertilizing performance for fertilizer distribution apparatus with screw. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2020, 36, 1–8. [Google Scholar]

- Liu, C.L.; Li, Y.N.; Song, J.N.; Ma, T.; Wang, M.M.; Wang, X.J.; Zhang, C. Performance analysis and experiment on fertilizer spreader with centrifugal swing disk based on EDEM. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2017, 33, 32–39. [Google Scholar]

- Zhu, Q.Z.; Wu, G.W.; Chen, L.P.; Zhao, C.J.; Meng, Z.J. Influences of structure parameters of straight flute wheel on fertilizing performance of fertilizer apparatus. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2018, 34, 12–20. [Google Scholar]

- Chen, Y.T.; Cheng, Z.; Qian, Y. Research on Wet Clutch Switching Quality in the Shifting Stage of an Agricultural Tractor Transmission System. Agriculture 2022, 12, 1174. [Google Scholar] [CrossRef]

- Cui, X.C.; Zhang, L.K.; Wang, J.X. Inversion of meso parameters and triaxial test simulation of the gravel materials for high rockfill dam. Trans. Chin. Soc. Agric. Eng. (Trans. CSAE) 2022, 38, 113–122. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).