Abstract

The Intergovernmental Panel on Climate Change’s sixth assessment report (AR6) allocates 15% to 43% of global primary energy to biomass in 2050 across multiple mitigation scenarios. The report also emphasizes the importance of electrification. For increased reliance on electricity and on biomass, bioelectricity is expected to play a major role. It is therefore vital to know whether the energy generation potential of biomass electricity can support the removal of its environmental impact, particularly as generation at large scale is expected to rely almost solely on energy crops. This paper evaluates the potential of short-rotation woody crops in generating green electricity. This is performed using the “Green Energy Return on Investment (EROIg)” methodology, which indicates the net energy generated after investing in ecosystem maintenance energy (ESME). This study found that the EROIg of bioelectricity is marginally larger than unity when converted to its primary equivalent form (EROIg-PE). Three design options were proposed to improve bioenergy’s EROIg. Among these options, pelletizing wood chips has the largest advantage with an EROIg of 1.11 and an EROIg-PE of 3.17. We conclude with a discussion of the indirect advantages of growing energy crops, and discuss how this technique can be used alongside others to help generate cleaner energy.

1. Introduction

The IPCC’s latest AR6 report labelled current changes in the Earth’s climate as unprecedented in thousands and even hundreds of thousands of years [1]. In that report, the IPCC stressed the necessity of climate change mitigation via a reduction in Greenhouse Gas (GHG) emissions [1]. This can be achieved through measures like the large-scale deployment of low-emission sources of electricity. These include wind, solar, and biomass [2]. This report also highlights the importance of the electrification of end-uses of energy, a deep reduction in agricultural emissions, and carbon capture and storage [3]. Additionally, the sixth assessment report projects 15% to 43% (44 EJ/y—310 EJ/y) of global primary energy to be generated by biomass in 2050 across multiple GHG mitigation scenarios (Figure 2.15 in Chapter 2 of the IPCC Special Report on the impacts of global warming of 1.5 °C) [3]. Moreover, bioelectricity has been suggested in the literature as a low-carbon-emission renewable energy (RE) source. This source was labelled promising due to its universal availability and low storage cost [4]. With the threat of fossil fuel reserve depletion in the future, biomass for electricity can play a major role as the closest in nature and operation to the storable energy that humanity currently relies upon [2].

Many sources of biomass can be used to produce electricity. However, not all these sources are equally able to produce electricity at the utility scale required for global production. Consequently, the global technical potential for bioenergy is subject to much uncertainty [5]. This is especially true for sources of bioenergy that are not readily available on demand. For example, biogas sources provide less certainty in terms of large-scale electricity generation than other biomass options [6]. This is due to the level of processing required to achieve electricity production. Biogas can be more effective if used as a secondary system to an electricity generation plant [7], for example, the use of biogas as a co-firing fuel in industrial applications requiring thermal processing. Animal manure has low energy density, making it less efficient for electricity generation purposes. Microalgae production and cultivation processes are complex and are yet to reach the cost effectiveness level required for large-scale production [7]. Woody wastes from agriculture and construction are restricted by the production volumes and intervals of waste generation in those sectors. The use of biowaste as an energy source is excluded from the assessment as energy production is not the sole purpose of product use. Given these factors, these biomass types are less likely to be relied upon as the main sources for global scale production. As will be discussed below, short rotation crops (SRC), on the other hand, are suitable options for large-scale electricity generation. Among the sources of SRWC, because of their adaptability to high-density coppice management, willow species are particularly attractive.

Woody biomass, the largest overall source of bioelectricity globally [8,9], mainly consists of harvested natural materials and trees, energy crops, and short rotation crops, in addition to waste sources [8]. Growing trees and energy crops for bioelectricity takes up land that is necessary for other living organisms (habitat). Given this, a challenge to upscaling bioenergy is that ecosystem biodiversity faces an unprecedented crisis mainly driven by land use and biomass agriculture for different end-uses [10]. This is becoming so increasingly critical that the UN Biodiversity Conference of Parties COP15 declared that the world is losing biodiversity at an alarming rate [11]. That report included among its major goals the need to safeguard biodiversity. Land use for bioelectricity production and associated agricultural processes also intensifies major ecological challenges like the alterations of biogeochemical cycles of nitrogen and phosphorous [10]. Energy crops also compete with food production over global terrestrial productivity (or net primary production NPP) [12,13].

With the IPCC’s warning on climate change and COP15′s alarm on biodiversity loss, a clear indication is needed on whether the overall energy–environment potential of biomass electricity is positive. Assessing this requires the consideration of concepts such as the ecosystem maintenance mitigation measures proposed by both the IPCC’s AR6 (e.g., reduction of GHG emissions) and UN’s COP15 (e.g., the provision of biodiversity offsets and reforestation). By unifying these concepts, an energy generation system’s potential to produce “green energy” can be assessed. Green energy is defined [14] as energy generated while mitigating its resultant environmental impacts (e.g., from emissions and biodiversity loss). Net green energy is green energy produced after accounting for lifecycle energy inputs. The present study makes use of these concepts to evaluate the potential for net green energy production from biomass electricity. This is performed using the Green Energy Return on Investment method. Further, the viability of different design options applied to bioelectricity is assessed using the technology’s Green Energy Return on Investment.

The sources of bioelectricity chosen in this assessment are short-rotation woody crops (SRWC). Commercial scale biomass harvesting required for global scale production necessitates high production efficiency and harvest yield at a low energetic cost. This includes plantations resembling monoculture, of which SRWCs are typical. This reduces the chances for deployment of sustainable practices like the selective harvesting of native species being globally deployed for biomass electricity until further technological improvement. Perennial grasses have been suggested in the literature for conversions that operate at low temperatures [7,15]. Those, however, are not recommended for combustion-based energy generation that can convert and use existing power plants like coal plants.

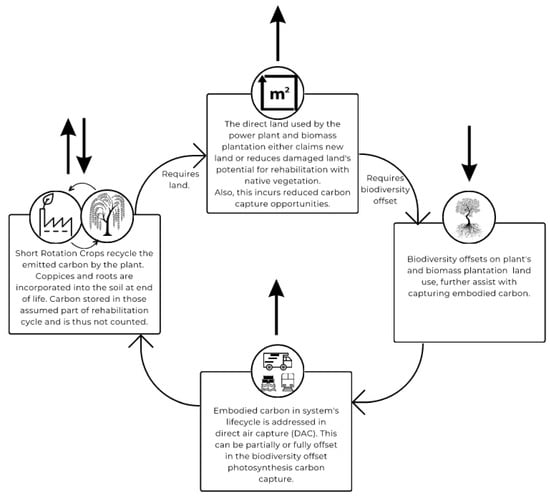

To assess the chosen SRWC, the approach taken makes use of the ecosystem maintenance energy (ESME) quantification method developed by Daaboul et al., (2022) [16]. The principle behind the method, outlined in Figure 1, is to estimate the energy required to remove the environmental impacts that result from energy generation (i.e., ESME). ESME is determined by linking the quantity of different environmental impact sources from lifecycle assessment (LCA) to what are termed “Impact Source Removal” (ISR) techniques. The energy required to remove the plant’s environmental impacts through the use of ISRs (e.g., removal of atmospheric CO2 by direct air capture technology) is included as an input cost in the plant’s energy accounting. Accounting for ESME and other energy inputs over the plant’s lifecycle allows the calculation of net green energy potential, and Green Energy Return on Investment (EROIg). EROIg is defined as lifecycle plant energy output divided by the sum of lifecycle ESME and operational input energy. As such, the EROIg calculated is a singular metric that embodies all environmental impacts and links these to the green energy generation potential. If the EROIg is >1, then green energy generation is viable using the assessed energy generation technique. Carbon capture by photosynthesis and biodiversity offsets have been shown to be of prime importance in improving EROIg [17].

Figure 1.

EROIg quantification methodology steps.

The paper is structured as follows. To provide context, the paper first reviews areas critical to the development of the ESME assessment of bioelectricity generation. A lifecycle assessment (LCA) of bioelectricity generation from SRWC is then performed. From this, an estimate of the energy required for maintenance of the ecosystem from the impacts of this technique (ESME) is provided, including biodiversity offsets. Biomass combustion power plants can normally operate on a mixed supply of wood and waste wood. The bioenergy plant assessed here was initially assumed to operate on 100% SRWC. The EROIg of bioelectricity is then computed. Three design options are proposed to evaluate the impact of different design and processing mechanisms on EROIg. We conclude that SRWC-sourced electricity production is only viable if the energy output delivered to society is in its primary energy form. This is when heat produced is included as an energy output such that the EROIg can be calculated as the primary energy equivalent form yielding EROIg-PE. The EROIg obtained is 0.58 for 1.0 kWh of bioelectricity produced and the EROIg-PE is 1.65. However, as the purpose of this assessment is to understand the EROIg of bioelectricity in future scenarios, converting EROIg to primary forms of energy is less meaningful (refer to part 3 of this paper). Further, we find that despite the added energy cost of pelletizing wood, the EROIg improves when wood pellets are used as feedstock due to reduced transportation and storage energy, and reduced environmental impacts. Electricity produced via willow wood pellets has an EROIg of 1.11 and an EROIg-PE of 3.17.

2. Literature Review

2.1. Literature Data on SRWC for Electricity

As stated above, the source of bioelectricity chosen in this assessment is short-rotation woody crops (SRWC). This section outlines the literature data on the characteristics of SRWC, particularly willow, in terms of growing, harvesting, replanting, and power plant scale. The data outlined in this section were relied upon in developing the LCA.

Species for woody biomass vary substantially from region to region. This variability depends on local climate suitability for species growth, regional elements including local forestry and landscaping practices [18], industrial operations, and government regulations promoting bioenergy. Woody crops cultivated specifically for bioelectricity and grown in coppice production systems are the largest wood feedstock sources of bioelectricity globally [19]. As a result of their adaptability to high-density coppice management, willow species are markedly attractive biomass sources [19]. Due to the popularity of willow plantation in the biomass industry, information on growing and harvesting willow is abundant in the literature.

The generation capacity of the power plant to be assessed is an important assessment parameter. Sizing a bioenergy generation plant is a complex exercise that requires an optimization study (refer to Section 2.4 for more details). This is primarily due to factors related to biomass supply. As this is not the main subject of this study, the bioenergy generation plant size was assumed to be 21 MW, expected to produce approximately 140 GWh/y. This is close in size to other biomass-burning plants around the world, such as the 22 MW Novo plant in Arizona USA that produced approximately 190 GWh/y in the year 2021 using forest-thinning wood residues [18].

2.2. Growing Bioenergy Plantations

Willow can be grown on marginal land not necessitating a high-quality soil which solves significant problems associated with degraded lands formerly used for mining [20]. However, the higher yield necessary for the large-scale production of willow at a short time scale requires better quality soil. The site preparation process in growing willow includes removing existing vegetation (e.g., mowing), the application of herbicides, tillage, and weed control for successful establishment of the crops, and avoiding the risk of weed competition [19]. The weed control process can be achieved by mechanical treatment (e.g., row crops) or cultural treatment (e.g., cover crops) [21].

Despite having up to three times less potential in boosting biomass production than its mechanical counterpart, cultural treatment (cover crops) reduces the processing, herbicides, and machinery involved in the weed control process [21]. Cover crops have proven to help establish economically viable quantities of willow SRC [21]. These can include species like Persian clover, white clover [21], oil radish, oilseed rape [22], and others.

Willows are mechanically planted as unrooted dormant cuttings using multiple-row mechanical planters. Planting density is approximately 18,000 stems/ha [23]. The annual fertilization and/or application of manure are required to grow biomass at a commercial scale. The willow harvesting rate is approximately 8 ha/day. It has been demonstrated in the literature that a significant increase in yield can be achieved with nitrogen fertilization [24]. Irrigation water demand can be estimated based on the water use efficiency (WUE). The WUE is the dry matter production per unit of water used. Depending on soil conditions and clay treatment [25], willow WUE has been estimated to vary between 1.4 g-dry/kg-water [25] and 6.3 g-dry/kg-water [26].

2.3. Harvesting, Storage, and Transport

Willow can be collected in the form of rods (or whips), chips, billets, or bales. Biomass quality is better when the fresh plants are chipped at the harvest site. Direct-chip harvesters are the most efficient harvesting systems, and so are widely used in bioenergy [27]. The fresh harvest, however, requires drying before storage as chip quality degrades if moisture is not removed directly after harvest. The drying process is designed to achieve a moisture content of around 30% [27]. Low-cost air drying can be performed at storage facilities with ventilated floors where heated air can circulate among chips to reduce moisture levels [28]. For storage and transport consideration, the optimal chip size is 5 × 5 × 5 cm. For lower transportation costs, chips are generally stored on site if space is available [23].

2.4. Replanting

After the final harvest, site preparation is necessary for replanting willow. To that end, the re-sprouting of stools is enabled at up to a 30–50 cm height, which allows for herbicide take-up. Herbicides are sprayed to kill the stool and left to set for a minimum of 2 weeks. This process is followed by either the mulching of sprouts for incorporation into soil or severing of the roots in-ground [23]. Before the production of willow (or alternative agriculture) is re-initiated, grass seeds are introduced into the soil and grown for a minimum of one year [28].

2.5. Scale

The scaling of bioenergy power plants requires an optimization study that considers the whole bioenergy production chain. This is because the optimal size of a power plant depends on multiple factors. Factors include biomass yield; transport within biomass growing sites, and between them and the generation destination; biomass storage and pre-processing strategies; generation plant capital cost per unit of production; irrigation infrastructure and pumping cost at a selected scale; and feedstock production and transport cost per unit of electricity produced [29]. Weight, quality, and hauling distances of the biomass are considered major factors in such an optimization exercise [30]. Moreover, the potential of biomass production depends on the territory, weather characteristics, and infrastructure features of every biomass production site. This is because these factors influence land productivity along with the logistics of the energy generation process, crop growing, and crop handling activities. Generic assumptions based on global averages and literature data were taken in this study as being representative of the general population of willow-based bioenergy to enable the computation of a non-site-specific EROIg of willow-based bioelectricity production.

3. Materials and Methods

3.1. Impact Source Removal for ESME and EROIg Computation

A critical component of EROIg assessment is lifecycle assessment (see Figure 1). Environmental impacts are determined by undertaking an LCA of the bioelectricity plant and generating its mid-point-level lifecycle impacts. As outlined below, this yields a physical quantity for each of the plant’s environmental impacts (Ii), e.g., lifecycle mass of CO2 emitted to the atmosphere. An Impact Source Removal (ISR) technique is allocated to every impact type based on its mid-point impact category determined by LCA (see Table A1). Direct Air Capture, for example, is the ISR method used to estimate the energy needed to remove CO2 from the atmosphere. ESME is quantified as the sum of energies needed to remove all life impacts through the operation of ISRs specific to each elementary lifecycle impact [16]. The energy required to operate an ISR (ei) is allocated per unit of gross energy produced (Egross). The ISRs and their corresponding impact sources used are adopted from Daaboul et al., (2023) [17].

What follows is a summary of the details of the ESME and EROIg assessment approach presented in Daaboul et al. [17]. The ESMEi for each ISR is calculated and summed as follows to give the total ESME:

ESME is then included as an energy cost in EROI to compute EROIg:

where is the net secondary energy output to society, and is the input of energy flow from other energy systems involved in the energy production lifecycle. Eout is Egross minus the self-use energy or energy used by the plant (Eself). Eself is assumed to be negligible; thus, for this plant it is assumed that Egross = Eout. For the energy system to have positive potential, the system is expected to have an EROIg > 1.

3.2. Primary Energy Equivalence

As this study seeks to answer questions on the future supply of electricity to meet 2050 targets and beyond, the EROI and EROIg methodology chosen are based on secondary energy carriers (direct equivalence 1:1 secondary to primary). This is consistent with an energy system that mostly relies on renewable energy [31]. Moreover, any primary-secondary quality adjustment that can be applied to the EROI would depend on the technology used for energy generation [31]. Thus, applying quality adjustments based on set-figures of primary–secondary conversion may render the results less certain if that adjustment factor used was not unified across the literature. As the purpose of the assessment is to understand the EROIg of future bioelectricity scenarios, converting EROIg to primary forms of energy is less significant. The computation of the primary form of energy is important when the target is to understand how much primary energy is being preserved for other uses [32]. For future scenarios of energy production, as projected by the IPCC, fossil fuels will no longer be expected to play a major role in producing energy if the increase in global temperature is to be controlled. The conversion to the primary equivalent here would therefore not be necessary.

Having said that, noting that many reported EROI figures in the literature adopt Raugei et al.’s (2012) [32] methodology in expressing Eout in the primary equivalent form, this work also computes the primary equivalent EROI and EROIg termed, respectively, EROIPE and EROIg-PE. We quote Raugei et al., (2012) [32]: “by expressing Eout-eq in terms of its ‘Primary Energy equivalent’ and calculating EROIPE accordingly, one is in fact calculating how much Primary Energy is virtually ‘returned’ to society (i.e., preserved for alternative uses) per unit of Primary Energy invested”. One use of this primary equivalent computation could be in the comparison of plants that produce electricity and make use of waste heat, such as a comparison of a renewable biomass combined heat and power plant to a natural gas combined heat and power plant. In calculating EROIg-PE in this work, it is assumed that all input biomass energy could be accessible in primary form.

3.3. Carbon Flows and Biodiversity Offset Used in ESME Computation

Factors related to land use play an important role in ESME accounting, particularly GHG estimation. Table 1 summarizes the different types of land use needed for ESME computation; these are presented as defined in Daaboul et al., (2023) [17]. Table A2 in Appendix A provides the quantification basis of land areas used in ESME computation.

Table 1.

Land use types in the ESME methodology—adapted from Daaboul et al., [17] with minor amendment.

The biodiversity offset land (LB) area requirement is based on the plant’s direct land (LD) and on the land use changes in the indirect land (LI)—refer to Table 1 for definitions.

where is the portion of land undergoing changes in the indirect land. Fbio is determined in accordance with Table 2 in Daaboul et al. [17].

Table 2.

ESME computation and EROIg results.

Carbon flows related to land use are shown in Figure 2. Combining CO2 capture from the biodiversity offset land with the reduced CO2 capture by the plant’s direct land gives the net GHG capture based on land use changes

Figure 2.

The major carbon flows assumed in this work.

For the direct emissions from the power plant, given by (kgCO2-eq/kWh), ESME is given by

where eGHG-d (kWh/kgCO2-eq) is the energy required to operate the direct GHG emission ISR (see Table 1). This may be operated at the power plant or located in the supply chain. DAC is assumed for the removal of all indirect emissions. DAC energy requirement is given by eGHG-e (kWh/kgCO2-eq). Indirect emissions are made up of those embodied in the plant and supply chain, IGHG-e (kgCO2-eq/kWh), and those resulting from land use change GHGΔL (kgCO2). Indirect GHG emissions ESME is calculated using

where

Total GHG emission ESME is given by summing direct () and indirect quantities:

ESMEGHG is required to be larger than or equal to zero. This is to avoid impact trading, and the excessive removal of impact in one category cannot justify reduced removal in another category.

Willows can be found in a variety of temperature zones, but they typically favour moderate climates [33]. Arid climates are not typically home to willows [33]. A lifecycle assessment (LCA) of willow species for electricity production is performed as it is representative of SRC. In the assessment, willow plantation is assumed to be grown in monoculture for ease of harvesting.

Equations (7)–(12) were applied for the estimation of carbon flows in this work (see Figure 2). An approximate value of 10% willow waste was taken into consideration in the lifecycle assessment following the assumptions made on harvest loss in the literature [34]. These residues are assumed to be non-useful in the combustion process due to their high moisture content and increased effort associated with collection for storage. The crop residues are associated with further GHG emissions due to their decomposition on site.

4. Calculation

4.1. The Lifecycle Assessment of SRWC

The ReCiPe Midpoint Europe impact assessment method and the Cumulative Energy Demand (CED) methods were used to generate the lifecycle impact in this study. As the study proposes methods for the generation to clean up its own emissions, major emissions are not expected to reside in the environment for longer than 20 years.

The general LCA process requirements, as listed in ISO 14040 [35], are the definition of a goal and scope of the study, the lifecycle inventory analysis, lifecycle impact assessment, and lifecycle interpretation. This is performed in this study as follows:

- Goal and scope: The goal of this lifecycle assessment is to understand the environmental impact of 1.0 kWh willow-sourced bioelectricity production. Bioelectricity is to be produced at a large scale. This is performed to guide sustainable energy planning. The functional unit is the production of 1.0 kWh produced electricity. Allocation is at the point of substitution where the allocation of valuable by-products and environmental burdens is performed via an expansion of processes towards the end product. The inventory is modelled for a “Global” geography.

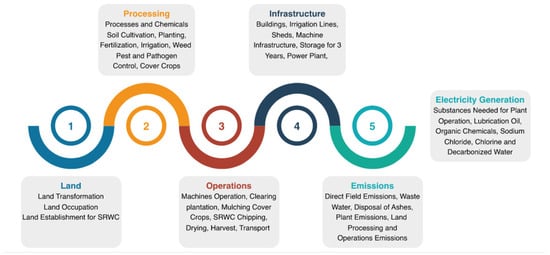

- Boundaries: The boundary of the assessment starts at the establishment and clearing of plantation, including mineral fertilizers and pesticides. This activity ends with electricity being produced (Figure 3). The assessment also includes all machine operations and corresponding machine infrastructure and sheds at the harvest sites. This adds the mulching of the cover crops (oil radish) and provision of willow wood chips at the farm gate. This dataset includes the infrastructure, the emissions to air, and the disposal of the ashes. Also included are substances needed for plant operation. Both short- and long-term storage were also included.

Figure 3. Assessment boundary.

Figure 3. Assessment boundary. - Inventory: The inventory is based on the EcoInvent library. Inventory includes soil cultivation, planting, fertilization, weed control, pest and pathogen control, harvest and chipping of willow stems, transport from field to farm (2 km), drying of wood chips under roof (air drying; no electricity input), and the clearing of the plantation via a rotary tiller including the growth of oil radish (not harvested). Further, direct field emissions are included. This assessment also includes all machine operations and corresponding machine infrastructure and sheds. For the energy plant, this dataset includes the infrastructure, the wood input, land impact, the emissions to air, and the disposal of ash. Also included are substances needed for plant operation: lubricating oil, organic chemicals, sodium chloride, chlorine, and decarbonized water.

- Impact assessment: The ReCiPe midpoint method is used to generate the impact of the functional unit on the environment. The Individualist (I) cultural perspective is chosen because this study assesses the removal of impacts within a 20-year time frame from plant establishment. This is based on the idea that the good and timely management of emissions and impacts will be able to prevent future harm.

- System description: The system used for electricity production has a lifetime of 20 years. This is based on up to seven three-year harvest cycles from SRC plantations [33]. The SRC is harvested from the fourth year after establishment. Infrastructure for the “under roof” air drying of willow wood chips, assuming a short-term storage time of 3 months [36] and 6.66 m3/tonne storage [28] space, is required for drying and 3-year long-term storage to ensure the continuity of large-scale supply over the harvest cycles.

- Power Plant: The power plant is assumed to use a co-generation plant structure. However, this structure is deployed solely for the production of electricity (the produced heat is assumed unused in the LCA). The plant operates on wood chips and has a capacity of 21 MW. The material quantities estimated to be used in plant manufacturing have been linearly scaled up from a 7 MW combined heat and power plant. Although the power plant may last longer than 20 years, the bioenergy plantation and corresponding site would need to be rehabilitated and relocated after 20 years with possible corresponding relocation of the power plant for an optimized cost of energy production. Power plant layout corresponds to a unit installed in 2014 in Switzerland, which is equipped with an electrostatic precipitator for particulate matter (PM) emission reduction and an SNCR (selective non-catalytic reduction) device for a reduction in NOx emissions. Electricity is produced with an organic Rankine cycle (ORC) steam generator with 35% electric efficiency. Wood chips are burned in a boiler at a temperature of 800–1300 °C under excess air conditions and turned into carbon dioxide and water. The wood chip lower heating value used is 18.9 MJ/kg dry mass; this is equivalent to approximately 12 MJ/kg at 30% moisture [28].

- Carbon Content: The computation of carbon flows in EcoInvent considers the total consumption of “Carbon dioxide, in air” by the biomass through photosynthesis. This is computed based on the stock of carbon (organic C-content) in harvested plants [37]. Reductions in the carbon stored in soils are included in the land transformation impacts computation. The release of carbon from the burning of biomass is included in the corresponding emissions of carbon dioxide, carbon monoxide, and methane [38]. See Figure 2 for more detail on system carbon flows.

4.2. Transport Assumptions Made for LCA Inputs

As the purpose of this assessment is to study future global-scale production, the SRWC biomass is expected to be transported between different locations to reach lands with low biomass potential or low seasonal availability. Transport distances are reported to largely affect the EROI and feasibility of bioelectricity generation [39]. Moreover, future scenario transport patterns are more likely to represent those of more commonly transported modes of solid fuels like coal [40]. The difference, however, is that the various forms of bioenergy plantation may be available in more locations than coal across the globe. Currently used sites for growing vegetation are chosen based on suitability for vegetation/biomass growth. Former agri-sites are considered in the literature as potential locations for bioenergy plantation. Therefore, future bioenergy vegetation production locations can also be like current agriculture production sites. Thus, transport can be estimated based on three factors: equivalence to coal transport, equivalence to agriculture vegetation transport, and reported viable biomass transport distances beyond which transport becomes unfeasible. Coal transport is currently reported at an average transport distance of approximately 1280 km by trains, 340 km by barges, and 60 km by trucks [41]. Fruit and vegetable transport distances are reported to vary between approx. 900 km and 9000 km depending on the produce and its global availability [42]. Feasible biomass transport distances were reported as follows: shipping > 800 km; rail 500 km [43]; and in-land trucks (lorry) between 80 km and 100 km [44]. As the different varieties of short-rotation crops can be grown across continents, transport within a continent can be assumed for biomass. Based on the above, the following is assumed to be representative of future international biomass transport: 80 km by trucks, 1000 km by barges, and 500 km by trains. Half the wood is assumed to be transported by land through trucks, trains, and barges in waterways and the other half through trains and trucks only.

Transported chips are assumed to have a moisture content of approximately 30%. Freshly harvested chips are assumed to have moisture content of more than 50%. The moisture content of willow crops at storage after air drying drops to approximately 30%.

4.3. Additional Amendment of the LCA Inventory

Further amendments to the lifecycle inventory include increased land occupation from the current annual default to the 12 ton/ha/yr figures reported in [19]. This is assuming that the SRC is cut back in the first year with the first full harvest 3 years after cut-back [28]. Harvest is then performed every third year from the first harvest date onwards [36]. The yield is the mean annual increment of the total above ground dry weight [19]. Also included are irrigation data reported in Martin and Stephens (2006) [25]. As the assessment is generic and modelled in LCA for a “Global” geometry, and as irrigation data are site specific, an average figure between the best- and worst-case scenarios was taken from Martin and Stephens (2006) [25] as representative of the global domain. Half the irrigation input was assumed to be reduced due to rain. Infrastructure was added for the irrigation component. Biodiversity offset is assumed at low land significance and low soil sealing from biodiversity offset requirements using the Bavarian method [45].

5. Results

EROIg of SRWC Electricity

Table 2 shows the EROI and EROIg results of willow-sourced bioelectricity, along with the midpoint level LCA indicators and corresponding ESMEi energy. If the ‘direct equivalent’ method to bioelectricity was adopted, allocating a 1:1 equivalence between electricity and primary energy, the resultant EROI = 1.54 and EROIg = 0.58. The primary equivalent (equivalence between thermal output and primary energy) EROIPE = 4.4 and primary equivalent EROIg-PE = 1.65.

Carbon emissions from electricity generation processes are expected to be captured at the stack. However, for this power plant, the amount of carbon captured by the plantation sites and biodiversity offset site offsets the entirety of the carbon generated via the operation of the plant. As discussed in Section 3.3, to avoid impact trading, the excessive removal of impact in one category cannot justify reduced removal in another category. Thus, when biodiversity offsets are implemented, further capturing of carbon at the stack of the energy plant does not improve EROIg. The LCA takes the captured CO2 by plantation through photosynthesis as the “input” and the carbon released by combustion as the “output” (part 4.1—carbon content) in carbon accounting. Thus, 80% of the net carbon flows do not come from the direct burning of the biomass. This makes bioelectricity a carbon-neutral electricity generation method when accompanied by the 0.25 m2/kWh/y biodiversity offsets (Figure 2). Low levels of biodiversity offsets are needed; this is due to low soil sealing and the use of lands with low significance for the growth of biomass (Table A1—Appendix A).

Among the largest contributors to ESME costs are the transport and storage stages of the wood chips. Because of the large storage space needed for continued large scale production, the 3-year rotational cycle has a big impact on the lifecycle performance of SRWC. Further, as demonstrated in Section 4, future large-scale biomass production for bioenergy generation is likely to be associated with long transport distances. If so, this will come at a considerable cost to EROI and EROIg.

For this plant, the largest elementary ESMEi energy consumption is associated with water use, terrestrial ecotoxicity, and land use. For water use, LCA results indicate that this is mostly due to willow irrigation and electricity production processes. For land use, this is mainly due to the quantity of land required in the biomass growing process. For the ecotoxicity impact, this is mainly due to transport, fertilization, and irrigation. This shows the multitude of impacts associated with bioelectricity production and their different origins. There are, however, other sources of biomass that may be less problematic in these aspects. As discussed in the introduction, although potentially more sustainable, they were not assessed here due to their current inability to produce energy at the scale necessary for global scale production.

6. Discussion

On-shore wind turbines and solar photovoltaic cells have been shown to achieve EROIg values of 17.19 and 3.59, respectively [17]. Although higher than bioenergy, these values still represent a decrease relative to EROI, with a 27% decrease for wind, 41% for solar, and, as shown here, 65% for bioenergy. Thus, depending on the renewable energy mix, a significant shortfall can be expected in net energy supply if energy is to be produced after accounting for its environmental impacts. Lifting the output to account for this shortfall will require either greater extraction of primary energy from the Earth’s ecosystem (and by virtue of this, greater payment of the associated ESME costs), or system improvements to reduce ESME costs. The second option is explored for bioenergy below by examining the sensitivity of EROIg to biomass type, storage/harvesting, and pelletizing/transport. The section ends with a discussion of the limitations of this work.

6.1. Design Option Results

Power plants may differ from the plant assessed here in, among other factors, supply chain, handling, and operation. For example, the largest bioenergy plant in the world, Alholmens Kraft, in Pietarsaari, Finland, is reported to use up to 15% waste wood and forest residues in its biomass feedstock mix. Another example is the pelletizing of wood for improved transport and storage prospects. The impacts on EROIg of representative differences are explored below, with the results summarized in Table 3.

Table 3.

EROI and EROIg results of SRWC under the original assumptions and the 3 design options proposed.

6.1.1. Waste Wood in the Mix

The scope of this work covers the EROIg of SRWC electricity generation when crops are purpose-grown to produce energy. In some cases, waste wood produced by other sectors like the construction and transport industries can be used to support energy generation. The embodied lifecycle impact and biodiversity offset cost and carbon capture advantage of those are allocated to the original use. The spared waste volume going to landfill is also allocated to the original use. This is performed to avoid the possibility of double counting. Assuming 20% of the burned wood originates from waste streams, the embodied impact of growing crops is reduced and so is the advantage of carbon reduction due to spared waste. Including 20% waste wood in the mix yields an increase in both EROI and EROIg by approximately 20% (Table 3). This improvement in EROIg is due to allocating the waste wood’s lifecycle impact to the original use. However, EROIg remains < 1.0 in its secondary form.

6.1.2. Storage Space for 1 Year with Staggered Rotational Harvesting

One way to reduce the impact of large storage space associated with a 3-year harvest cycle would be through staggered rotational harvesting at the plantation sites. In this instance, the site(s) is divided into three parts, each grown in a different year. This results in a harvest of the different parts every third year. The staggered production reduces the storage size by a factor of three. Another aspect of this case study is the increased transportation needed to achieve the annual rotations; this is true for both plantation site operations and feedstock transport to the power station. Transportation is a major contributor to the lifecycle environmental impact of SRWC; with this model, the associated transportation increases 3-fold. A staggered rotational harvesting increases the EROI by approximately 19% and EROIg by only 6%. EROIg remains < 1.0 in its secondary form. The 19% improvement in EROI is caused by the reduction in storage size by a factor of three. The EROIg, however, only improves by 6% and remains < 1.0 in its secondary form. This is due to the increased transportation needed to achieve the annual rotations. This difference in EROI and EROIg improvement demonstrates the variability of ESME costs for each application. Reducing storage space achieves a large reduction in GHG emissions and freshwater eutrophication impact and there is no major improvement in other impacts. The improvement in GHG emissions is masked by the amount of carbon captured by vegetation and therefore does not trigger a large improvement in EROIg. Additionally, other impacts appear to be compounded by the added transport associated with increased frequency in harvesting. This makes the improvement in EROIg lower than that in EROI.

6.1.3. Pelletized Wood for Reduced Volume in Transport and Storage

To reduce the impact of transportation and storage, transporting wood and plant materials at an alternative density can be performed [46]. For instance, wood pelletizing is proposed where biomass is compressed to crush its cellular structure and increase its density. This reduces both the storage space required and transport trips due to reduced volume and standardized product size. This process reduces storage volume by approximately 77% while adding material processing associated with the pelletizing process like heat-based drying or electricity-based compression [47]. The heating value of the pellets is larger than that of wood chips (LHV 15.68 MJ/kg) with a moisture content lower than 10% resulting in a reduced mass of wood being burned to produce an equivalent amount of energy. The number of transport trips is assumed to be reduced by 25% due to higher volumetric capacity [48]. Pelletizing wood increases the EROIg by 91% and only improves EROI by 8%. This results from the significant reduction in transport and storage accompanied with the additional processing of the chips to their pelletized form. Transport and storage are both associated with large ESME; a reduction in these items improved EROIg, but the processing energy associated with additional embodied energy resulted in less improvement in the EROI. Each kWh of electricity produced via pelletized wood is associated with an EROIg > 1.0. Transport and storage have large environmental impacts that extend beyond GHG emissions. By reducing these, major improvements were recorded in the levels of GHG emissions, ozone depletion, and freshwater and marine eutrophication. With an EROIg of 1.1, bioelectricity produced via pelletized wood is found to achieve less reduction in viability due to ESME inclusion (34.5% reduction) and thus better prospects in future energy generation.

6.2. Transportation Importance

Transportation energy costs can play a major role in EROI and EROIg performance. Part 2.4 of this work discusses the importance of the mode of transport chosen and transported distance and their impacts on the economic viability of the technology. Given the relatively low LHV of the biomass being transported, these factors ultimately place limits on how far the biomass can be moved while maintaining energetic viability. For example, among the modes of transport assessed in this study, the EcoInvent library reports the largest energy consumption per tkm to be associated with trucks, followed by barges (lower than truck by a factor exceeding two), followed by trains (lower than truck by a factor exceeding seven). The significant difference in energy consumption for the different modes is likely to influence where the power plant is located. Maximizing EROI and EROIg may require the power plant to be located near the plantations with the provision of easily accessible transmission lines. Another way to maximize EROI and EROIg could be by locating the plantation and power plant near rail lines (or water courses) capable of handling bulk transport such that transport by truck is minimized.

6.3. Limitations of This Study

As discussed in the introduction, other bioenergy sources can be used in electricity production, some with potentially lower environmental impacts and higher resulting EROIg. Examples include perennial grasses or co-product bioenergy sources, like waste or forest residues. With these, there exists a possibility of reducing the high ESME cost impacts, thus improving the viability of the system. This, however, was not quantified in this work. This study also did not include the consideration of biomass when it is produced as a co-product of ESME payment of other technologies. Examples include the rehabilitation lands [20] linked to ESME payments of other energy-producing technologies, and any biomass removed from the technology’s direct and indirect land or biodiversity offset lands. Depending on input costs (e.g., transport), co-firing with biomass produced in this way may lead to an improved EROIg for the linked technology. This is particularly true for technologies that rely heavily on mining, e.g., solar PV. These technologies can also use SRC in land rehabilitation programs for humus accumulation prior to the full re-establishment of land, and for seasonal back-up power production as part of a wider network. However, an accurate assessment of the benefits would require careful analysis to ensure that there is no double counting, particularly if the co-product biomass was to be used in, for example, natural gas power systems as a means to reduce their GHG emissions [49].

Finally, the use of biomass as an energy source has other beneficial returns not accounted for in this study. Examples include the possibility of the biomass providing nectar support for pollinators [7], the potential for erosion mitigation (when native species are used with mulching, reduced tillage etc…), and the ability of the biomass to help in increasing humus accumulation [7].

7. Conclusions

Due to biomass’s carbon recycling abilities and the possibility of its long-term storage, bioenergy is projected by many to play a significant role in transitioning away from fossil fuels. Wood is currently the most relied upon source of biomass globally [9] and will continue to be so based on IEA’s 2050 projections. Consequently, this work assessed the energetic and environmental viability of bioenergy from wood and SRWC sources, using the Green Energy Return on Investment method. This method quantifies the net energy generated to society after investing energy in ecosystem maintenance. Ecosystem services maintenance energy (ESME) is the removal of the various environmental emissions generated throughout the production lifecycle. Green energy requires full ESME payment.

For the biomass electricity system assessed here, the EROIg of 1.0 kWh produced bioenergy was found to be marginally larger than unity when converted to its primary equivalent form (EROIg-PE), which indicates that the technology is somewhat energetically viable if its production is green. Therefore, when biomass is used solely for energy, the energy’s use in the form of heat could be more viable than in the form of electricity. When expressed in this form, both electricity and heat are assumed to be available to society. This study has found the EROI to be 1.54 and EROIg to be 0.58. EROIg is 65% lower than EROI due to the inclusion of ESME. This highlights the large environmental impact associated with this technology, especially when compared to other technologies reported in the literature [17]. This also indicates the need to increase primary energy extraction by higher EROIg technologies to deliver the same amount of energy to end-users if bioenergy forms a significant part of a future green energy mix.

To improve the viability of the system, a number of options were assessed examining variations in the supply and handling of the SRWC. Including 20% waste wood in the energy mix improved the EROI and EROIg by approximately 21%. Implementing a staggered annual rotational harvesting only improved the EROIg by 7%. Pelletizing wood chips prior to storage and transport significantly improved the EROIg (91% improvement). Pelletizing wood is found to render the process energetically and environmentally viable even at a 1:1 secondary to primary energy equivalence. The resultant EROIg and EROIg-PE of electricity produced through pelletized willow are 1.11 and 3.17, respectively. This improvement is mainly due to the reduction in transport and storage and highlights the role of these in the technology’s viability.

Yet to be developed are methods that include, in the ESME assessment, other benefits associated with biomass production such as pollinator nectar support, carbon cycling and sequestration, and erosion mitigation. Moreover, yet to be examined is the potential for biomass produced as a co-product of land use in other energy technologies.

Author Contributions

Methodology, J.D., P.M. and D.H.; Formal analysis, J.D.; Investigation, J.D.; Writing—original draft, J.D.; Writing—review & editing, J.D., P.M. and D.H.; Supervision, P.M. and D.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Australian Government through the Research Training Program Scholarship.

Data Availability Statement

Data is contained within the article.

Acknowledgments

The first author acknowledges the support of the Australian Government through the Research Training Program Scholarship.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Measures required to control environmental impact. Adapted from Daaboul et al., (2023) [17] with minor amendment.

Table A1.

Measures required to control environmental impact. Adapted from Daaboul et al., (2023) [17] with minor amendment.

| Category |

Impact Type | Units | Impact Source Removal ISRi | Energy Equivalence ei |

|---|---|---|---|---|

| Atmosphere | Climate change IGHG-d | kg CO2-eq/kWh | Carbon Capture Direct Air Capture (DAC) and stack capture. | Embodied emissions 2.44 kWh/kg CO2-eq * Operational emissions 0.49 kWh/kg CO2-eq * |

| Stratospheric ozone depletion—ICFC | kg CFC11-eq/kWh | Replacement of refrigerants with R744 | 1163.9 kWh/kg ref | |

| Particulate matter formation—IPM | kg PM2.5-eq/kWh | Partially via the removal of SOx and NOx and partially via non-thermal plasma corona radical shower synthesis | 66.9 kWh/kg PM2.5 eq (50% captured by other processes) | |

| Loss of carbon capture opportunity IGHG-DL | m2/kWh | CO2 removal by DAC. Quantity of CO2 basis: 55 kgCO2/m2/y CO2 photosynthesis rate. | 2.44 kWh/kg CO2-eq | |

| CO2 capture by offset land—IGHG-B | m2/kWh | CO2 removal by DAC. Quantity of CO2 basis: 55 kgCO2/m2/y CO2 photosynthesis rate. | 2.44 kWh/kg CO2-eq | |

| Ozone formation human health —INOx-H | kg NOx-eq/kWh | De-nitrification | 8 kWh/kg NOx-eq | |

| Ozone formation, terrestrial ecosystem—INOx-T | kg NOx-eq/kWh | De-nitrification | 8 kWh/kg NOx-eq | |

| Aquatic Environment | Marine Eutrophication—IN | kg N-eq/kWh | Water treatment: Packed tower aeration | 0.10 kWh/kg N eq |

| Freshwater ecotoxicity—IDB-FE | kg 1,4-DB/kWh | Water treatment: Packed tower aeration | 1.67 kWh/kg DB eq | |

| Freshwater eutrophication—IP | kg P eq/kWh | Water treatment: Packed tower aeration | 3.33 kWh/kg P eq * | |

| Marine ecotoxicity IDB-ME | kg 1,4-DB/kWh | Water treatment: Packed tower aeration | 1.67 kWh/kg DB eq * | |

| Human toxicity—IDB-HE | kg 1,4-DB/kWh | Water treatment: Packed tower aeration | 1.67 kWh/kg DB eq * | |

| Terrestrial | Terrestrial ecotoxicity—IDB-TE | kg 1,4-DB/kWh | Water treatment: Packed tower aeration | 1.67 kWh/kg DB eq * |

| Terrestrial acidification—IDB-FE | kg SO2-eq/kWh | Non-thermal plasma corona radical shower synthesis of SO2 | 0.11 kWh/kg SO2 eq * | |

| Land | Ionizing radiation IBq | kBq Co-60-eq/kWh | Land preparation—deep borehole disposal | 3.56 × 10−1 kWh/kBq |

| Natural land transformation LR | m2 crop-eq/kWh refer to Table 3 | Land preparation for plantation or rehabilitation | 0.16 kWh/m2 * | |

| Biodiversity loss LB | m2/kWh | Land offset and preparation for plantation or rehabilitation. Bavarian metric with <50% soil sealing or >50% soil sealing. | 1 m2/m2 for <50% soil sealing 3 m2/m2 for >50% soil sealing | |

| Water use | Water depletion—IWD | m3/kWh | Desalination | 6 kWh/m3 * |

* Values adapted from Daaboul et al., (2023) [17].

Table A2.

Land areas and biodiversity offset quantification basis *.

Table A2.

Land areas and biodiversity offset quantification basis *.

| Factors Affecting Biodiversity Offset | Biodiversity Offset Factor—Fbio | |

|---|---|---|

| Over 50% Soil Sealing | Under 50% Soil Sealing | |

| Low Significance (I)—intensively used arable land, canalised water courses, biodiversity-poor agricultural or amenity landscapes, etc. | 0.3–0.6 | 0.2–0.5 |

| Medium Significance (II)—forest with non- native species, individual trees tree groups or hedges without high biodiversity, extensively used grassland, floodplain habitats, etc. | 0.1–1 | 0.5–0.8 (0.2 For intensively used grassland) |

| High Significance (III)—mature semi-natural forest with a high proportion of locally appropriate tree species, mature species-rich hedgerows, corpses and woodland edges, natural or near-natural freshwater landscapes, culturally significant landscapes, etc. | 1–3 (Or higher in exceptional cases) | 1–3 (Or higher in exceptional cases) |

* Adapted from Daaboul et al., (2023) [17] with minor amendment.

Table A3.

Calculation basis for land areas and CO2 capture by vegetation.

Table A3.

Calculation basis for land areas and CO2 capture by vegetation.

| Assumptions Made to Compute: | Calculation Basis |

|---|---|

| The direct land area affected by biomass plantation | Based on 1.2 kg/m2/y and 0.6 kg/kWh. This also assumes the same land is used over the years of operation of the plant. |

| Biodiversity offset land | Assumes low to medium significance land at <50% soil sealing. Fbio = 0.5. |

| Loss of opportunity in CO2 capture | 55 kgCO2/m2/y over 20 years. Applied to direct land. |

| CO2 capture by biodiversity offset. | 55 kgCO2/m2/y over 20 years. Applied to biodiversity offset land. |

References

- Pörtner, H.O.; Roberts, D.C.; Tignor, M.; Poloczanska, E.; Mintenbeck, K.; Alegría, A.; Rama, B. IPPC 2022: Climate Change 2022: Impacts, Adaptation and Vulnerability: Working Group II Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2022. [Google Scholar] [CrossRef]

- Antar, M.; Lyu, D.; Nazari, M.; Shah, A.; Zhou, X.; Smith, D.L. Biomass for a sustainable bioeconomy: An overview of world biomass production and utilization. Renew. Sustain. Energy Rev. 2021, 139, 110691. [Google Scholar] [CrossRef]

- Rogelj, J.; Shindell, D.; Jiang, K.; Fifita, S.; Forster, P.; Ginzburg, V.; Handa, C.; Kheshgi, H.; Kobayashi, S.; Kriegler, E.; et al. Mitigation pathways compatible with 1.5 C in the context of sustainable development. In Global Warming of 1.5 C; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2018; pp. 93–174. Available online: https://www.ipcc.ch/report/sr15/ (accessed on 15 May 2023).

- Bonechi, C.; Consumi, M.; Donati, A.; Leone, G.; Magnani, A.; Tamasi, G.; Rossi, C. Biomass: An overview. In Bioenergy Systems for the Future; Woodhead Publishing: Sawston, UK, 2017; pp. 3–42. [Google Scholar] [CrossRef]

- Moriarty, P.; Honnery, D. Can renewable energy power the future? Energy Policy 2016, 93, 3–7. [Google Scholar] [CrossRef]

- Havrysh, V.; Kalinichenko, A.; Mentel, G.; Olejarz, T. Commercial biogas plants: Lessons for Ukraine. Energies 2020, 13, 2668. [Google Scholar] [CrossRef]

- Von Cossel, M. Renewable Energy from Wildflowers—Perennial Wild Plant Mixtures as a Social-Ecologically Sustainable Biomass Supply System. Adv. Sustain. Syst. 2020, 4, 2000037. [Google Scholar] [CrossRef]

- Bajwa, D.S.; Peterson, T.; Sharma, N.; Shojaeiarani, J.; Bajwa, S.G. A review of densified solid biomass for energy production. Renew. Sustain. Energy Rev. 2018, 96, 296–305. [Google Scholar] [CrossRef]

- Bennett, P.; Buckley, P. IEA Bioenergy: EXCO; IEA: Paris, France, 2022. [Google Scholar]

- Erb, K.H.; Gingrich, S. Biomass—Critical limits to a vital resource. One Earth 2022, 5, 7–9. [Google Scholar] [CrossRef]

- UN COP15, 2022. CBD UN Biodiversity Conference COP15 (Fifteenth meeting of the Conference of the Parties (COP-15) to the Convention on Biological Diversity (CBD)), Official CBD Press Release, List of Targets. Available online: https://www.cbd.int/article/cop15-cbd-press-release-final-19dec2022 (accessed on 15 May 2023).

- Crutzen, P.J.; Brauch, H.G.; Paul, J. (Eds.) Crutzen: A Pioneer on Atmospheric Chemistry and Climate Change in the Anthropocene; Springer: Berlin/Heidelberg, Germany, 2016; Volume 50. [Google Scholar]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef] [PubMed]

- Moriarty, P.; Honnery, D. Ecosystem maintenance energy and the need for a green EROI. Energy Policy 2019, 131, 229–234. [Google Scholar] [CrossRef]

- Scordia, D.; Cosentino, S.L. Perennial energy grasses: Resilient crops in a changing European agriculture. Agriculture 2019, 9, 169. [Google Scholar] [CrossRef]

- Daaboul, J.; Moriarty, P.; Palmer, G.; Honnery, D. Making energy green–A method for quantifying the ecosystem maintenance energy and the green energy return on energy invested. J. Clean. Prod. 2022, 344, 131037. [Google Scholar] [CrossRef]

- Daaboul, J.; Moriarty, P.; Honnery, D. Net green energy potential of solar photovoltaic and wind energy generation systems. J. Clean. Prod. 2023, 415, 137806. [Google Scholar] [CrossRef]

- US EIA, U.S. Energy Information Administration. Form Eia-923 Detailed Data, December 2021. Available online: https://www.eia.gov/electricity/data/eia923/ (accessed on 30 July 2023).

- Wright, L.L.; Eaton, L.M.; Perlack, R.D.; Stokes, B.J. Woody Biomass; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Sonter, L.J.; Maron, M.; Bull, J.W.; Giljum, S.; Luckeneder, S.; Maus, V.; McDonald-Madden, E.; Northey, S.A.; Sánchez, L.E.; Valenta, R.; et al. How to fuel an energy transition with ecologically responsible mining. Proc. Natl. Acad. Sci. USA 2023, 120, e2307006120. [Google Scholar] [CrossRef] [PubMed]

- Albertsson, J.; Verwijst, T.; Rosenqvist, H.; Hansson, D.; Bertholdsson, N.O.; Åhman, I. Effects of mechanical weed control or cover crop on the growth and economic viability of two short-rotation willow cultivars. Biomass Bioenergy 2016, 91, 29. [Google Scholar] [CrossRef]

- Justes, E.; Mary, B.; Nicolardot, B. Comparing the effectiveness of radish cover crop, oilseed rape volunteers and oilseed rape residues incorporation for reducing nitrate leaching. Nutr. Cycl. Agroecosyst. 1999, 55, 207–220. [Google Scholar] [CrossRef]

- Dickmann, D.I.; Kuzovkina, J. Poplars and willows in the world. Chapter 2. Poplars and willows of the world, with enphasis on silviculturally important species. In International Commission on Poplars and Other Fast-Growing Trees Sustaining People and the Environment; FAO: Rome, Italy, 2008. [Google Scholar]

- Mola-Yudego, B.; Aronsson, P. Yield models for commercial willow biomass plantations in Sweden. Biomass Bioenergy 2008, 32, 829–837. [Google Scholar] [CrossRef]

- Martin, P.J.; Stephens, W. Willow growth in response to nutrients and moisture on a clay landfill cap soil. II: Water use. Bioresour. Technol. 2006, 97, 449–458. [Google Scholar] [CrossRef][Green Version]

- Lindroth, A.; Båth, A. Assessment of regional willow coppice yield in Sweden on basis of water availability. For. Ecol. Manag. 1999, 121, 57–65. [Google Scholar] [CrossRef]

- Hilton, B. Growing Short Rotation Coppice, Best Practice Guidelines; DEFRA Publication: Westminster, UK, 2002.

- Dawson, M. Short rotation coppice willow best practice guidelines. In IEA Bioenergy; Task 43: 2012:03; IEA: Paris, France, 2012. [Google Scholar]

- Jack, M.W. Scaling laws and technology development strategies for biorefineries and bioenergy plants. Bioresour. Technol. 2009, 100, 6324–6330. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Schuler, J.; Hartley, D.; Volk, T.; Eisenbies, M. Optimization of harvest and logistics for multiple lignocellulosic biomass feedstocks in the northeastern United States. Energy 2020, 197, 117260. [Google Scholar] [CrossRef]

- Fabre, A. Evolution of EROIs of electricity until 2050: Estimation and implications on prices. Ecol. Econ. 2019, 164, 106351. [Google Scholar] [CrossRef]

- Raugei, M.; Fullana-i-Palmer, P.; Fthenakis, V. The energy return on energy investment (EROI) of photovoltaics: Methodology and comparisons with fossil fuel life cycles. Energy Policy 2012, 45, 576–582. [Google Scholar] [CrossRef]

- Pennington, D. Bioenergy crops. In Bioenergy; Academic Press: Cambridge, MA, USA, 2020; pp. 133–155. [Google Scholar]

- Larsen, S.; Jaiswal, D.; Bentsen, N.S.; Wang, D.; Long, S.P. Comparing predicted yield and yield stability of willow and Miscanthus across Denmark. Glob. Change Biol. Bioenergy 2016, 8, 1061–1070. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization ISO: Brussels, Belgium, 2006.

- Livingstone, D.; Smyth, B.M.; Lyons, G.; Foley, A.M.; Murray, S.T.; Johnston, C. Life cycle assessment of a short-rotation coppice willow riparian buffer strip for farm nutrient mitigation and renewable energy production. Renew. Sustain. Energy Rev. 2022, 158, 112154. [Google Scholar] [CrossRef]

- Nemecek, T.; Schnetzer, J. Methods of assessment of direct field emissions for LCIs of agricultural production systems. In Agroscope Reckenholz-Tänikon Research Station ART; ETIP: Ettenhausen, Switzerland, 2011. [Google Scholar]

- Weidema, B.P.; Bauer, C.; Hischier, R.; Mutel, C.; Nemecek, T.; Reinhard, J.; Vadenbo, C.O.; Wernet, G. Overview and methodology. In Data Quality Guideline for the Ecoinvent Database Version 3; Ecoinvent Report 1(v3); The Ecoinvent Centre: St. Gallen, Switzerland, 2013. [Google Scholar]

- Yang, S.; Volk, T.A.; Fortier, M.O.P. Willow biomass crops are a carbon negative or low-carbon feedstock depending on prior land use and transportation distances to end users. Energies 2020, 13, 4251. [Google Scholar] [CrossRef]

- Lin, T.; Rodríguez, L.F.; Davis, S.; Khanna, M.; Shastri, Y.; Grift, T.; Long, S.; Ting, K.C. Biomass feedstock preprocessing and long-distance transportation logistics. Glob. Change Biol. Bioenergy 2016, 8, 160–170. [Google Scholar] [CrossRef]

- IEA ETSAP. Coal Mining and Logistics. IEA ETSAP—Technology Brief 2014, P07/08. Available online: https://iea-etsap.org/E-TechDS/PDF/P07-08_Coal%20M&L_KV_April2014_GSOK.pdf (accessed on 9 July 2023).

- Saunders, C.M.; Hayes, P. Air Freight Transport of Fresh Fruit and Vegetables; Lincoln University: Lincoln, PA, USA, 2007. [Google Scholar]

- Searcy, E.; Flynn, P.; Ghafoori, E.; Kumar, A. The relative cost of biomass energy transport. Appl. Biochem. Biotechnol. 2007, 137, 639–652. [Google Scholar]

- Woo, H.; Acuna, M.; Moroni, M.; Taskhiri, M.S.; Turner, P. Optimizing the location of biomass energy facilities by integrating Multi-Criteria Analysis (MCA) and Geographical Information Systems (GIS). Forests 2018, 9, 585. [Google Scholar] [CrossRef]

- Rayment, M.; Haines, R.; McNeil, D.; Conway, M.; Tucker, G.; Underwood, E. Study on specific design elements of biodiversity offsets: Biodiversity metrics and mechanisms for securing long term conservation benefits. In A Report to the European, Commission, DG Environment; European Commission (EC): Brussels, Belgium, 2014. [Google Scholar]

- Stelte, W.; Holm, J.K.; Sanadi, A.R.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U.B. Fuel pellets from biomass: The importance of the pelletizing pressure and its dependency on the processing conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Trømborg, E.; Ranta, T.; Schweinle, J.; Solberg, B.; Skjevrak, G.; Tiffany, D.G. Economic sustainability for wood pellets production–A comparative study between Finland, Germany, Norway, Sweden and the US. Biomass Bioenergy 2013, 57, 68–77. [Google Scholar] [CrossRef]

- Pokhrel, G.; Kizha, A.R.; Gardner, D.J. Transportation cost analysis on alternative wood feedstocks for manufacturing wood-plastic composites. Bioresources 2022, 17, 634. [Google Scholar] [CrossRef]

- Kazulis, V.; Vigants, H.; Veidenbergs, I.; Blumberga, D. Biomass and natural gas co-firing–evaluation of GHG emissions. Energy Procedia 2018, 147, 558–565. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).