Abstract

The paper provides a systematic review and analysis of the current literature on big data (BD) applications in the context of food supply chain management (FSCM) in order to categorize the state-of-the-art research trends exploring the adoption and implementation of big data analytics (BDA) across different segments of food supply chain (FSC). The use of BDA brings the digital transformation of FSCs closer providing sustainable implications and added value to their operation. Harnessing BD’s potential is becoming more and more relevant in addressing the constantly evolving complexities in food systems. However, the field of BD applications in the FSCM domain is severely fragmented and relatively “primitive”. The present research is one of the earliest attempts to recognize and present a comprehensive analysis for the BD applications across different segments of FSC proposing a conceptual framework that illustrates the role of BD in a data-driven FSCM environment. For the purposes of our research, we adopted the systematic literature review (SLR) method aiming at the identification of the dominant categories and themes within the research area. Based on the SLR findings, we propose a conceptual framework that captures the interconnection between FSC performance and BD applications by using the input-process-output (IPO) model within a data-driven FSCM context. The main research contribution lies on the thematic classification of relevant research, the conceptualization of this fragmented field, the development of a conceptual framework, and the presentation of a future research agenda pertaining to BD applications in a data-driven FSCM context.

1. Introduction

The recent emergence of advanced technologies has shifted the attention of practitioners and academia towards the deployment of the vast generated data as a crucial and efficient tool for addressing the modern food supply chain management (FSCM) challenges [1,2]. Data management has grown into an important asset in today’s food supply chains (FSCs) with the food and beverage (F&B) organizations concentrating more on capturing, processing, and analyzing valuable information deriving from multiple sources across their respective food systems [2,3]. Within this framework, the concept of big data (BD) has recently emerged referring essentially to huge amounts of data assets that are highly scattered and heterogenous in nature, represented by the features of velocity, variety, and volume [4,5]. Interestingly, the added value that could be achieved through the application of BD in FSCs is estimated between USD 120 and USD 150 billion on an annual basis [1]. This is a quite significant fact given that the growing rate of the globally generated data follows an exponential distribution [6].

Naturally, these data assets require proper management within the FSC framework in order to enable the F&B organizations to capitalize extensively on data-driven insights for the enhancement of the decision-making process in FSCM [4,7]. This process refers to the development and implementation of the data analytics capability (DAC) within food systems through resource management and effective collaboration among different organizational functions aiming at the facilitation of the data and information sharing process as well as the application of big data analytics (BDA) [8,9]. BDA could play a vital role in today’s FSCs by integrating vast data volumes deriving from both real-time market information and historical information fostering the identification of new opportunities and the improvement of food quality and safety across the different supply chain functions [1,2,10]. Thus, harnessing BD’s potential is becoming more and more relevant in addressing the constantly evolving complexities in these systems [1,2] providing the fertile ground for the exploration and the conceptualization of these advanced technologies within the FSCM context [11,12].

The present study is one of the earliest attempts to shed some light onto this area through the conduction of a systematic literature review (SLR) that aims at the identification and categorization of the dominant categories eventually proposing a conceptual framework that illustrates an operational approach to implement BD applications in a data-driven FSC. This process reflects the novelty of the current paper which consists of four thematic sections. Section 2 presents the SLR methodology that was adopted in order to ensure the credibility and the validity of the literature review findings. Section 3 presents the descriptive analysis of the SLR findings complemented by the qualitative thematic analysis based on the categorization of the current research trends. Section 4 proposes a conceptual framework of the data-driven FSCM from the BD perspective. Finally, Section 5 provides the concluding remarks and suggests a future research agenda.

2. Materials and Methods

As Frizzo-Barker et al. [11] and Zhong et al. [12] highlighted, the field of BD applications in FSCM domain is severely fragmented and relatively “primitive” since there is still insufficient literature evidence regarding the current research trends and perspectives on the ongoing FSC digital transformation through the utilization of such advanced technologies. In parallel, several studies emphasize on the need for bridging the gap between BD practical applications and the tackling of complex challenges in today’s food systems in order to theoretically conceptualize this research field and present value-adding managerial implications towards digital transformation within the FSCM framework [3,13,14,15]. This is further supported by the relevant studies of Ji et al. [2], Ahearn et al. [8], Kamble et al. [9], and Vlachopoulou et al. [16] who argue that the development of DAC and the capitalization on BDA within FSCs is crucial towards enhancing traceability and visibility aspects and facilitating the collaboration among different organizational units and functions. These recent technological advancements currently provide a great untapped opportunity for F&B organizations to leverage on practical and cost-efficient BDA applications setting the basis for the development of a data-driven FSC [17,18,19] that focuses on addressing today’s complex challenges which are directly connected to the enhancement of FSC performance and more particularly to the aspects of efficiency, quality, safety, and sustainability [20,21,22,23,24].

In response to the aforementioned research needs, the present research concentrates on the conduction of a SLR aiming at: (i) the presentation and the description of the dominant categories and themes within the research area, (ii) the proposal of a conceptual framework that captures the interconnection between FSC sustainability/performance and BD applications by using an input-process-output (IPO) model, and (iii) the identification of the research gaps in order to propose a future research agenda providing novel insights into the needs of practitioners and academia. The SLR was developed based on a broad range of published literature on BD applications within FSCM context from both academic and practitioner perspective. The adoption of this method exhibits certain strengths in relation to the identification and categorization of the current research trends facilitating the development of concrete propositions for future research [25,26,27]. The ultimate goal of the research lies in presenting a conceptual framework that suggests an operational approach to BD application in a data-driven FSC based on the SLR findings. In this context, the following research questions have been formulated:

- RQ1: How is the trend in BD applications within FSCM from 2010 and Onwards?

- RQ2: What are the current main study themes in this research area?

- RQ3: What are the current literature trends in BD applications within FSCM framework and how can they be categorized?

- RQ4: How can the dominant categories be organized and analyzed?

The applied SLR protocol was based on the following five (5) main phases [25,26]: (1) research scope mapping, (2) search strategy, (3) identification and selection of research papers, (4) data extraction and (5) data analysis and synthesis. The research scope was formulated at the intersection of the broad terms of “Food Supply Chain Management” and “Big Data”. The search string adopted in our analysis involves the following:

(“Food Supply Chain Management” OR “Food Supply Chain” OR “Food Value Chain” OR “Food Demand Chain” OR “Cold Chain” OR “Food Retail Chain”)

AND

(“Big Data” OR “Data Analytics” “Descriptive Analytics” OR “Predictive Analytics” OR “Prescriptive Analytics”)

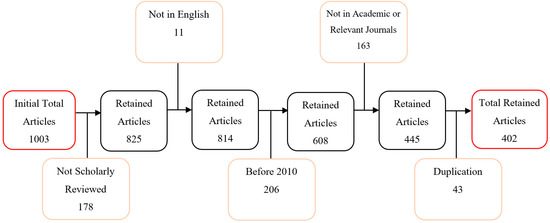

Based on the emerged search string, the search strategy was developed with a view to identifying the maximum number of qualified, relevant articles. In total, 1003 articles were identified and subject to the selection criteria. These articles were retrieved from Business Source Complete (EBSCO) (24 articles), Emerald Insight (153 articles), IEEE Xplore Digital Library (540 articles), and ScienceDirect (ELSEVIER) (286 articles). Subsequently, the exclusion and inclusion criteria were developed to justify the limitation of the retrieved articles. The total 1003 articles were filtered through the exclusion criteria resulting in the retainment of only full-text, scholarly-reviewed articles, published from 2010 and in English, and retrieved from academic journals that were solely related to the scope of the present research. Eventually, 402 articles fulfilled the criteria through the assessment stage (Figure 1).

Figure 1.

Process of selection against the exclusion criteria.

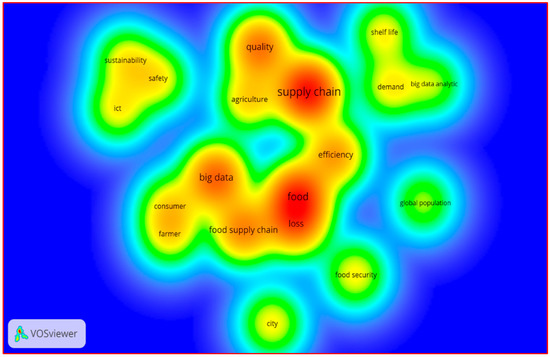

The final assessment process of the 402 retained articles was based on three (3) steps that focused on the thorough screening of the (1) title, (2) abstract, and (3) full-text. Eventually, a numerical evaluation of the articles was implemented following Boland et al.’s [25] guide. A numerical scoring system applied for the final assessment of each article incorporating four (4) criteria: (1) the depth of the literature review, (2) the methodology that was implemented, (3) the relevance and the potential contribution to this study, and (4) the journal ranking. The final and potentially the most critical process of the SLR methodology relied strongly on the comparison and the summarization of all the data that derived from the retained articles in order to capture and map the existing relevant literature [26]. For the purposes of our research, we adopted text analytics techniques based on Microsoft Research application programming interfaces (APIs) presenting a heatmap of keywords and identifying the frequency of their appearance within the 31 selected articles. VOSviewer software was utilized in order to record and analyze the keywords appearance. The binary counting method resulted in the red areas depicted in Figure 2, indicating the most frequently appeared keywords, such as “food”, “supply chain”, and “big data”. These highly frequent keywords formulated the main research focus of the current study. The orange-colored areas illustrate the slightly less frequent keywords in the heat map, such as “quality”, “loss”, and “food supply chain”.

Figure 2.

Heatmap of keywords frequency.

The numerical occurrences of the identified keywords are presented in Table 1 below based on the results produced by the previously described text analytics method.

Table 1.

Keywords occurrence.

These results could shed some light onto the current main study themes in this field providing the basis for addressing the formulated research questions. In this context, we proceeded into classifying the selected articles into clusters based on the most occurrent keywords of “quality”, “loss”, “agriculture”, “efficiency”, “sustainability”, and “city”.

3. Findings of Systematic Literature Review

As previously discussed, a total of 31 articles were selected as the core of the research area relating to BD applications in FSCM towards digital transformation. Throughout this section, the results that derived from the generic descriptive and content analysis are presented and systematically discussed. Each of the following subsections addresses a specific research question through the presentation of different charts and tables. The final subsection refers to the content analysis justifying the connection between the emerged insights and the proposed conceptual framework of a contemporary data-driven FSCM system.

3.1. RQ1: How Is the Trend in BD Applications within FSCM from 2010 and onwards?

All the selected articles were published from 2010 and onwards based on the inclusion criteria presented in the Materials and Methods section ensuring a state-of-the-art approach towards the identification of the research gaps in this particular scientific field capturing the increasing popularity of the digitalization phenomenon in FSCM.

Recently, in the wide-ranging research area of supply chain, the attention relating to the addressing of the “network design, risk management, inventory management, and retail” challenges has been shifted towards the application of BD and BDA [28]. In the context of FSCM, the attention towards BD and BDA was radically increased recently since these advanced technologies foster decision-making for perishable products through the analysis of vast amounts of data enabling the accurate and real-time depiction of the constantly changing market trends while facilitating the proper adjustment of inventory levels and distribution networks accordingly [12].

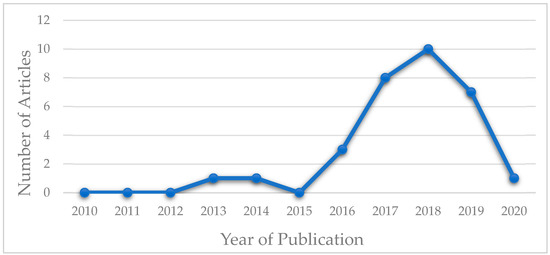

By analyzing the most recent studies, this review aims at validating the core sources. Figure 3 below illustrates the distribution of articles in relation to their publication year. The vast majority of the selected articles were published from 2016 to 2019 (approximately 90.32%) indicating a radical increase in this specific research area during the past recent years. By examining the general interest in literature on BD application in FSCM, one may anticipate that the number of publications is set to increase further in the future.

Figure 3.

Distribution of the selected articles by year of publication.

3.2. RQ2: What Are the Current Main Study Themes in This Research Area?

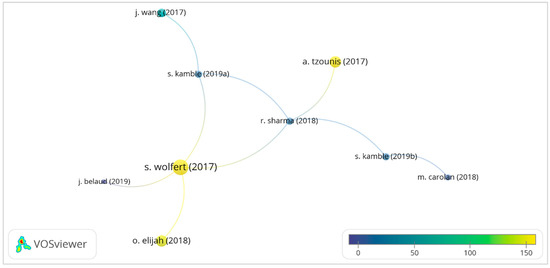

A network citation analysis was developed to present the links among the nodes on BD studies that are associated with the FSCM. This network presents the connections among the selected articles across the Microsoft Academic database based on the downloaded data from the respective API. This process eventually led to the depiction of the main study themes in the current literature.

The citation network analysis resulted into nine connections among the selected articles endorsing the authors’ argument in relation to the highly fragmented nature of the research area. This view is further supported by the current literature evidence provided by Frizzo-Barker et al. [11] and Zhong et al. [12] characterizing this area as a “primitive” and a highly fragmented domain. Interestingly, research efforts that are connected as illustrated in Figure 4 below, composed the citation network that is exclusively related to BD applications in agriculture supply chain. Carolan [6] also identified this phenomenon across literature arguing that there is a growing research trend in BD applications in agriculture which is omitted though the interrogation of their utilization in retail food systems especially through the ongoing FSC digital transformation that is driven by the ever-increasing production and collection of consumer data.

Figure 4.

Citation network analysis [6,9,10,15,29,30,31,32].

This process fostered the detection of the core papers which were more frequently cited in the aforementioned database as the citation bar score indicates. Based on the above, the article titled “Big Data in Smart Farming—A Review” by Wolfert et al. [10] was identified as the most frequently cited paper. The paper provides an interesting review on new technologies advancements within the context of agriculture focusing mainly on the application of BD in the entire agriculture supply chain providing insights concerning the future in smart farming and proposing research priorities.

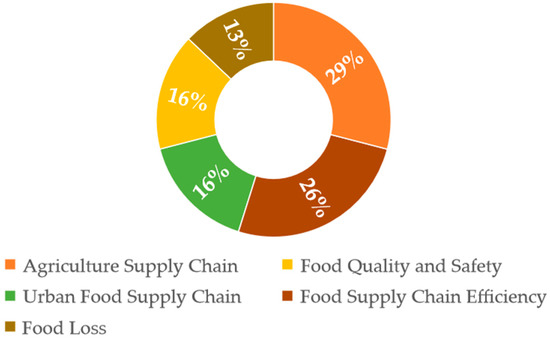

Following the citation network analysis, the study aimed at the classification of the current study themes in order to capture the present state of this field since the only connections that were identified were clearly associated with the cluster of BD application in agriculture supply chains. The categorization was based on five (5) main themes that were identified by the authors during the full-text screening process via information processing from each selected article concerning the keyword appearance frequency and their respective research objective(s). These five (5) distinct themes were determined by the insights, implications, and results that each article provided. Sequentially, the data was quantified, sorted, and classified based on the identified study themes. More specifically, 29% of the articles (9 papers) concentrated on the broad area of “Agriculture Supply Chain”, followed by a 26% (8 papers) that centered around the theme of “Food Supply Chain Efficiency” through the utilization of BD (Figure 5). Additionally, 16% (5 papers) of the selected articles studied the impact of BD on “Food Quality and Safety” within the FSC while another 16% (5 papers) focused on the “Urban Food Supply Chain”. Finally, the remaining 13% (4 papers) studied the methods of diminishing “Food Loss” within FSC through BD applications. Figure 5 illustrates the distribution of the selected articles across the different, emerging study themes.

Figure 5.

Study themes in the current literature.

The articles’ distribution across the different themes is fairly balanced further supporting the argument associated with the fragmentation of this field. However, these findings allowed the current study to analyze in depth the emerged themes consequently categorizing the current literature trends.

3.3. RQ3: What Are the Current Literature Trends in BD Applications within FSCM Framework and How Can They Be Categorized?

The five (5) study themes provided the basis for the categorization of the main literature trends.

3.3.1. Big Data Applications in Agriculture Supply Chain

The first category essentially derived from the citation network analysis which resulted in the identification of nine connections composing an exclusive cluster in relation to BD applications in the agriculture supply chain concentrating mainly on the issues of decision-making, sustainability analysis, and the adoption of tracking and tracing systems in smart agriculture.

3.3.2. Big Data Applications in Improving Food Supply Chain Efficiency

The second category analyzes the broad trend of improving FSC efficiency through the application of BD. This category engulfs articles that focus more on retail FSCs concentrating on the implementation of value-adding solutions through the utilization of BD in order to address FSCM challenges such as supply chain integration (SCI), demand forecasting, and efficient coordination of the distribution process in cold chains.

3.3.3. Big Data Applications in Managing Food Quality throughout the Food Supply Chain

The third category consists of articles that study the application of BD in the management of food quality and safety across the FSC network. The articles in this category emphasize the capitalization of the recent consumer trends towards food product quality and safety through the application of social media analytics and sensory data analytics.

3.3.4. Big Data Applications in Diminishing Food Loss throughout Food Supply Chain

The fourth category concentrates on the presentation of the current transition from conventional data to BD across retail FSCs and the effect of this transition on tackling food insecurity and consequently food loss across the entire supply chain network through the adoption of technological solutions such as the intelligent packaging systems.

3.3.5. Big Data Applications in Urban Food Supply Chain

Eventually, the fifth and final category is related to the urbanization concept and its impact on FSCM. The articles identify the new challenges deriving from the expansion of this concept across the world presenting solutions in relation to the enhancement of city logistics efficiency and the tackling of food security and food safety issues in smart cities of the future through the utilization of BD.

3.3.6. Classification of Current Literature Trends

Table 2 below depicts the allocation of every article across the distinguished categories presenting in brief the produced insights and the associated results. A more detailed discussion of the scope and content of the identified thematic/research categories is provided in Section 3.5.

Table 2.

Categorization of the current literature trends.

3.4. RQ4: How Can the Dominant Categories Be Organized and Analyzed?

The categorization process was based on the collection of homogenous information amongst the selected articles in order to develop the subclasses within every category. Through this process, the dominant categories have been organized aiming at the accurate and clear depiction of the current literature trends regarding the BD applications in the different FSC segments as presented in Figure 6 below.

Figure 6.

Organization of the current dominant categories in the literature.

3.5. Thematic Analysis

In this section, the thematic findings are further discussed in order to provide the theoretical background as the basis for the proposed conceptual framework.

3.5.1. Big Data Applications in Agriculture Supply Chain

The emergence of the advanced Internet of Things (IoT) technology has led agriculture activities to the implementation of more efficient and sustainable processes gradually transforming the traditional agriculture to precision agriculture (PA) [10,31,32]. PA is essentially the cornerstone for the development of smart agriculture (i.e., data-driven agriculture activities) and naturally the utilization of BDA in agriculture [10], since the central focus of this concept is focused upon the collection and the effective management of data in the context of decision-making [45]. In fact, the application of BDA fosters opportunities in agriculture supply chain especially, yet not solely in terms of process and results benchmarking, tracking and tracing of agricultural products within the entire supply chain, and eventually predictive modelling for the production and distribution of agriculture products [30,31]. As Wolfert et al. [10] argues, BDA are incorporated into the agricultural BD value chain which essentially refers to a system comprised of sequential activities that are interlinked with each other from data collection and storing to data transformation and utilization through data analytics eventually leading to data visualization and presentation to the agriculture value chain stakeholders.

Tracking and Tracing of Agriculture Products

Typically, in smart agriculture, data could be either recorded, enriched, enhanced, or in combination, as materials and information flow through the downstream supply chain by utilizing wireless sensor network (WSN) technology. The latter is based on interconnected sensor units that collect data from the environment and transmit digital signals through a radio frequency (RF) communication unit relating to storage, monitoring, and tracking of agriculture products throughout the IoT network [30,32]. Probably, the most common technology that fosters the capitalization on data collection within tracking and tracing networks is the radio frequency identification (RFID) which could also be considered as a wireless node application since it formulates the very fundamental example of interconnected “things” [30]. RFID tags incorporate electronic product code (EPC) data which are accessible through RFID readers providing information on item identification, inventory monitoring, quality tracking, and lifecycle evaluation of an agricultural product [30,32]. Essentially, RFID tags’ operation is linked to the enhancement of the barcodes permitting the tracking of agricultural products while fostering the information enrichment whenever RFID is recorded throughout the supply chain network [32]. The application of RFID technology within a WSN through BD utilization has been studied in automated irrigations systems that determined the optimized allocation of water [46]. Another interesting application of RFID within a WSN refers to the smart monitoring of the agriculture infrastructure through scalar sensor units that enable remote image capturing in order to evaluate agricultural production process and identify the appearance of pest problems or plant diseases in real-time [47].

Decision-Making in Agriculture Supply Chain

According to Wolfert et al. [10], the application of BD is expected to change the way in which agriculture supply chain operates through the incorporation of BDA and semi-active RFID and WSN technologies that may eventually trigger in-depth business process reengineering. Through a multiple case study analysis, Protopop and Shanoyan [4] argue that the most significant contribution of BDA in agriculture supply chains is potentially the predictability factor which facilitates decision-making from the management perspective. This is also supported by Wolfert et al. [10], Elijah et al. [30], and Sharma et al. [31] who highlight the utilization of BDA for forecasting volatile environmental changes and predicting upcoming diseases or natural disasters fostering eventually data-driven decision-making across the entire supply chain.

Sustainability in Agriculture Supply Chain

As the global population is still growing and the ever-evolving food consumption patterns are constantly changing, the pressure from various social groups, agriculture organizations, and policymakers to raise awareness towards food systems’ sustainability is gradually affecting the way agriculture supply chains operate in today’s business environment [5,8,9]. According to Nasrollahi et al. [48] the effective management of the sustainability aspect within the business context could be summarized as all the strategic decisions that aim at the minimization of the “environmental, economic, and social sustainable risks” while in parallel maximizing the corporate value. Interestingly, the same authors focused on investigating the drivers that positively affect the supply chain sustainability deducing that both non-coercive close collaboration with the suppliers and coercive environmental performance monitoring of the suppliers have the greatest impact on this aspect. In a similar logic, Singh et al. [5] conducted an agri-food supply chain case study presenting a novel methodological design for supplier selection by monitoring and scoring the environmental performance of each candidate supplier resulting in the development of a ranking system based on the application of prescriptive analytics through the implementation of fuzzy analytic hierarchy process (AHP) and decision-making trial and evaluation laboratory (DEMATEL) methods. Another example of BDA application is presented by Belaud et al. [29] aiming at the development of a decision support tool for the sustainability analysis of the by-product’s valorization process in a case study of a rice straw supply chain. The authors utilized BDA to analyze and process the vast amount of collected data that derived from the public web (i.e., weather data, raw material prices around the world, and other data that are linked to life-cycle assessment), corporate data, field data (i.e., data that are related to the biomass quality), technological data (i.e., the technologies that are utilized in the by-product valorization process), life-cycle assessment databases, and finally, scientific databases (i.e., scientific insights concerning the rice straw valorization processes). The results derived from the analysis of the aforementioned data sequentially led to the sustainability analysis by evaluating “environmental aspects and potential environmental impacts throughout the life cycle of a product or process”. Following this paradigm of BDA application and as Ahearn et al. [8] and Kamble et al. [9] argue, it is apparent that data-driven agriculture supply chains are expected to achieve higher sustainability goals in the near future through the design and facilitation of the DAC process providing abundant opportunities for enhanced information flows and efficient decision-making within the agriculture supply chain network. According to Safari et al. [49], this development over time is tied up to the standardization of the digital resource management process that could be incorporated in the maturity model (MM) of a supply chain which essentially represents different phases of either increasing quantitative, qualitative, or both, capability levels of an element as a means of performance evaluation through the capturing of its advances (i.e., maturing).

3.5.2. Big Data Applications to Improve Food Supply Chain Efficiency

In today’s global business environment, the capitalization on data has become a crucial part of the FSC efficiency with organizations constantly seeking new sources of information across their entire supply chain network from their multi-tier supply base to the end customer [1,2]. This is also emphasized by Abideen et al. [50] who argue that the application and integration of advanced technological solutions, such as BD in every stage of the food system, is directly linked to enhanced sustainability, traceability, and coordination among the participating actors. Within this framework, BDA play a vital role in improving supply chain efficiency by fostering the identification of new opportunities through the processing of vast data volumes that derive from both real-time market information and internal historical information [1,2,10].

Supply Chain Integration and Connectivity

As Dubey et al. [51] and Huo et al. [52] indicate, SCI could be distinguished into three dominating streams: (i) uncertainty management across the complex supply chain network (i.e., business environmental uncertainty, technological uncertainty, demand uncertainty); (ii) social capital aspect within the network, such as trust building, knowledge sharing, and commitment, in order to strengthen the inter-organizational relationships; and (iii) strategy formulation in accordance with the development of “higher-order supply chain capabilities” (i.e., the organization’s ability to identify opportunities and threats in the market and capitalize on them), such as IT capabilities. By concentrating on the third stream, Irfan and Wang [1], in their survey on the F&B industry of Pakistan, presented the significance of the data acquisition and assimilation across the entire supply chain as a higher-order capability that facilitates SCI. The authors introduced the data assimilation capability as a complementary element of flexible IT resources suggesting the utilization of BD in FSC channel integration as well as in demand forecasting and planning based on the notion that internal integration (II) essentially precedes external integration (EI). This concept is also supported by Engelseth et al. [3] through their case study in a complex banana supply chain implying that the capitalization on BD is based on accurate information flow and interconnections which are equally significant and related to both II and EI.

Advanced Demand Forecasting

According to Alfian et al. [33], consumer behavior is the cornerstone of many industries today including F&B since it is directly associated with the profitability. On this basis, the authors developed a digital signage-based online store (DSOS) system located in different public sites permitting the user to browse and purchase various products from various retail stores in order to obtain and analyze huge amount of purchasing and transaction data from customers in real time. Interestingly, out of fifteen (15) product categories, 53.33% were related to food products, indicating a strong tendency towards the application of BD in FSC. In the same context, Vallandingham et al. [7] presented the potential future utilization of BDA through their study on consumers’ trends and future applications of enabling technologies in grocery supply chains with emphasis on precise marketing and demand forecasting based on the combined analysis of historical, footfall (i.e., measurement metrics that are related to the customer movement), and market data. Another example of BD application in this particular area is presented by Ji et al. [2] who developed a BD “harvest model” aiming at more effective demand forecasting within the framework of a food product development/improvement process by translating market demand to collaborative FSC planning increasing the availability of products and eventually customer satisfaction.

Distribution Coordination in Cold Chains

The notion of a cold chain essentially refers to a supply chain that concentrates on perishable products which require proper protection from physical environmental conditions in order to avoid degradation and eventually devaluation [13,35,53,54]. The quality of the food products depends highly on the environmental conditions and the transfer time from either production, distribution, or both units, to the corresponding points of sale (POS) shifting the cold chain management’s attention to the distribution stage [35,53]. This is further supported by Chaudhuri et al.’s [13] study on BDA application within cold chains who argue that currently the required data sets for the effective coordination of the distribution process concentrate mainly on the temperature while tapping into enriched data that derive both from other environmental aspects (such as humidity and vibrations) and process-oriented aspects (such as picking rate, required transfer time from the production unit to the cooling unit, and overall transportation costs) to improve decision-making. Singh et al. [35] utilized BD instead of conventional data to reflect more accurately the geospatial aspects of the different locations within a cold chain network and realistically capture the distances amongst the nodes in order to address the issues of food product degradation throughout the distribution stage. Eventually, another interesting example is presented by Bogataj et al. [34] concentrating on real-time perishability control within the fruit and vegetables (F&V) category through the utilization of smart containers that embed sensory technologies permitting the dynamic tracking of food product quality status.

3.5.3. Big Data Applications in Managing Food Quality within Food Supply Chains

As previously discussed, in today’s world food quality is gradually becoming a more and more important aspect in consumers’ modern lifestyles since it is directly linked to the physical human health condition [13,35,41] shifting the attention of FSCM towards the enhancement of supply chain visibility and social responsibility aspects [17,36].

Social Media Analytics

In the era of social media, Singh et al. [36] studied the case of a beef supply chain based on social media data analytics obtained from Twitter in order to identify potential issues in this particular FSC from the consumers’ perspectives and accurately capture their opinions. The results of their study showed that consumers formulate negative sentiments through their Twitter accounts commenting on different quality aspects of the beef product leading to the accumulation of useful FSCM implications concerning production, packaging, and cold chain distribution. Similar to Singh et al.’s study [36], Soon and Saguy [37] presented the vast harnessing potential of social media analytics for FSCM through the accurate reflection of consumers’ opinion towards food quality and safety fostering the identification of degraded food products even prior to public health authorities.

Tracking and Sensory Data Analytics

The modern global FSCs endeavor to address sustainability issues as an attribute of their competitive advantage since the increasing wastage of vast food product quantities throughout their complex operations created a new challenge in relation to the development of the trust element amongst consumers through enhancement of transparency and traceability aspects [13,15,36]. According to Astill et al. [17], traceability in modern FSCs could be achieved through the utilization of data-obtaining sensory technologies which essentially refer to data colleting, processing, analyzing, and storing devices that are integrated into the different stages of the supply chain. In this very context, Li and Wang [15] developed a simulated dynamic pricing model which essentially permits the real-time adjustment of the selling price across the distribution network in accordance with the quality features of the food product, the prediction of its shelf-life duration (i.e., deterioration rate), and its time–temperature history (TTH) profile based on the analysis of BD generated and acquired through an imitated WSN. Maskey et al. [19] proceeded one step further by studying the transition from the conventional quality assessment system into a real-time accessible assessment system based on the TTH profiling of the food products through a BD processing server system.

3.5.4. Big Data Applications in Diminishing Food Loss throughout Food Supply Chain

The concept of “food loss” is usually accompanied by the term of “food waste” without however necessarily bearing the same meaning [38,40]. According to Irani et al. [38], food waste refers to the disposal of food products in the final stages of a FSC, while the food loss derives from the wastage of food products throughout the entire supply chain due to either the inappropriate manner of production, storage, distribution, or in combination. The ever-increasing complexity has created the demand for innovative advanced technological solutions regarding food security and food loss [13,35,41].

Tackling Food Insecurity: The Transition from Conventional Data to Big Data

Based on the current global food security tendency, Mc Carthy et al. [40] conducted a literature review of the applied tackling measures at FSCM level through BD applications within the current economic reality highlighting the transition from the traditional data to BD and presenting the future potential towards the enhancement of FSC transparency and real-time decision-making. On the other hand, Irani et al. [38] studied the food security problem by adopting a practical approach from the perspective of both FSCM experts and FSC stakeholders based on the dynamic simulation modelling technique of fuzzy cognitive map (FCM). The authors developed the FCM in order to simulate the manner in which common supply chain network interconnections impact food wastage throughout the FSC with emphasis on the necessity of transitioning to the acquisition of BD across the entire food system as a means of producing more accurate and real-time results.

Intelligent Packaging Systems

As Vanderroost et al. [41] indicate in their review, the so-called intelligent packaging systems will eventually become a part of the modern food safety management system within the F&B industry. In this context, Lang and Jedermann [39] focused beyond the primary food product packaging reviewing the literature evidence on the utilization of intelligent containers that permit the collection and the analysis of BD through an ever-expanding international sensor network across different container terminals.

3.5.5. Big Data Applications in Urban Food Supply Chain

The world population is estimated to exceed the threshold of 9 billion people by the 2050s [14] while at the same time the proportion of the people that will live in urban areas is expected to reach the 68% of the overall population [42]. In parallel, the FSC’s main functions are gradually expanding throughout the whole world encompassing more and more innovative and e-business solutions through the application of recent technological developments, such as BD, in order to address FSCM challenges relating to distribution, food security, and food safety issues in modern urban areas [14,43,44]. However, Carolan [6] argues that as the constantly increasing urban population encourages the wider utilization of the advanced technologies, the social aspect in BD applications should be closely examined both from the legislative and the FSCM perspectives distinguishing the borderline between consumers and citizens in relation to the “choice architecture” design and hence excluding the ethical point of view on this matter. This notion is further supported by Yang et al. [55] and Zhang [56] who emphasize the challenges that lurk in the path of the IoT deployment within a modern urban environment focusing on the data security and privacy aspects. Interestingly, Zhang [56] discusses these challenges from the BD perspective noting that data security challenges overcome the issues of personal privacy and require the development of legislative context as well as a supervision system for user information management given that this technology permits the prediction of an individual’s state or behavior. The author further suggests that apart from the privacy element, data security is also linked to the evaluation of BD credibility which provokes a challenge to the processing of information due to the data distortion during the reproduction and dissemination process.

Food Security and Food Safety in Smart Cities

The broad notion of smart city is linked to the implementation of IoT systems aiming at the enhancement of the standard of living in modern cities following the rapid growth of the urbanization trend globally [42,44]. In a paradigm of such a city, Zhang et al. [44] developed a modeled IoT system for FSCs which could efficiently and timeously detect potential foodborne diseases by encompassing both tracing and backtracking algorithms optimized for BD application to identify contamination sources and possible quality issues in the end products.

Data-Driven City Logistics

FSCs are gradually transforming from local to global networks encompassing more and more innovative solutions throughout their key processes in an effort to “shorten” and efficiently manage the ever-growing physical distances in end-to-end urban supply chains [14,43,44]. Taking into consideration the growing urban population and the increasing value of BD in the new global and data-driven FSCs, Gharehgozli et al. [14] focused mainly on discussing the digitalization of food product transportation. In the same context, Pan et al. [43] conducted an empirical study on the optimization of perishable food product transportation concentrating on the online home delivery service of grocery retail in an urban environment through the application of BD in the attended home delivery problem (AHDP) method.

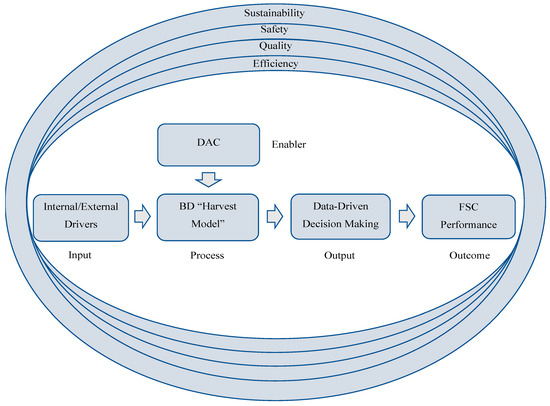

4. A Conceptual Framework for Data-Driven Food Supply Chain Management

In this section, we aim to capitalize on the findings derived from the SLR process in order to propose a conceptual framework illustrating the interconnection between FSC performance and BD applications. The latter is expressed through an input-process-output (IPO) model as schematically illustrated in Figure 7. In particular, the aim of the proposed framework is to depict a new model of an integrated FSCM from a BD perspective based on the four (4) FSC performance macro-areas: (1) efficiency, (2) quality, (3) safety, and (4) sustainability. These four (4) macro-areas emerged through the application of text analytics aimed at the identification of the most frequently appearing keywords amongst the selected articles while in parallel they are the focus of attention in a plethora of FSC performance studies [20,21,22,23,24].

Figure 7.

Conceptual framework of data-driven FSCM.

In the proposed conceptual framework, the aforementioned areas represent the pillars of a FSCM design that aims at the simultaneous and effective control of all the processes related to cost efficiency, food product quality and safety, and environmental sustainability across the whole FSC (i.e., “from farm to fork”) focusing on a more holistic view towards FSC performance which formulates the outer environment of this framework. Based on these four (4) pillars, an IPO model of a data-driven FSC was developed by incorporating five (5) distinct elements aiming at the improvement of the overall FSC performance. The first element refers to the drivers of FSC performance, which are essentially the factors that motivate the adoption of BD applications. These drivers have been divided into two distinguished groups in accordance with the SLR findings. The internal drivers which engulf organization-related supply chain management incentives concerning the commitment of the top-management in embracing and fostering policy changes at strategic and operational level by capitalizing on BD applications. In other words, these organizational factors include the various pressures from investors to improve food quality, food safety, and reduce the costs either through sustainable FSCs (e.g., enhanced waste management) [5,8,9,57] or through efficient FSCs (e.g., enhanced distribution coordination) by taking advantage of the recently developed technological advancements in the field of BD as highlighted by Chaudhuri et al. [13], Li and Wang [15], Singh et al. [35], and Badia-Melis et al. [53]. On the other hand, the external drivers are related to the pressure exerted from new legislative context towards sustainability, food quality, and food safety across FSCs [6,37]. Additionally, the societal driver led by the recent consumer trends towards food quality and food safety have affected marketing activities and hence the competitive landscape shifting the attention of the F&B organizations to the adaption of BD [13,15,36].

The second element refers to the development of the BD “harvest model” which is essentially related to the development of a process model that is designed to identify data sources and foster data collection, data transferring, and data harmonization [2]. These aspects provide the very basis for the data management which is the first step in a BD “harvest model”. According to Ji et al. [2] and Wolfert et al. [10], such models should involve the continuous enrichment of the obtained vast heterogenous data through the introduction of structured data (i.e., data deriving from in-house collectors and storing devices or from other open research platforms). The transformation process incorporates the mathematical modelling process through which crucial information is retrieved extending over the structural complexity of the acquired data sets. Eventually, the final stage of the BD “harvest model” will produce information deriving from BDA providing semantic relationships among the stored data. This process provides the basis for the capitalization on the three levels of BDA (i.e., descriptive, predictive, prescriptive) supporting data-driven decision-making on events that are associated with a wide range of issues on FSC performance.

The enabling factor for the development of a BD “harvest model” within FSCM context is solely related to the DAC of organization which currently appears to be significantly underdeveloped across the operating organizations within the F&B industry [9,17,19]. The enabler is presented as the third element in the IPO model referring essentially to a mediating factor on the relationship between the BD harvesting process and the data-driven decision-making. The emerged findings suggest that the development process of DAC depends heavily on the data integration across the entire food system since the characteristics of BD creates a challenge for the F&B organizations in relation to the capitalization on these technological advancements [2,8,9]. However, as these technologies continue to flourish the time is ripe for the development and the involvement of this particular capability in the data-driven FSCM model of the future.

Eventually, the fourth and fifth elements are closely connected, with the output of data-driven decision-making leading to the improvement of FSC performance as the final outcome of this model. As previously discussed, the harnessing of the BD potential requires the development of a “harvest model” in order to consistently produce the data for the utilization of BDA [2,9]. Leveraging on BDA provides the basis for data-driven decision-making within the given framework of FSC performance.

5. Conclusions and Future Research Agenda

There is a dramatic and dynamic increase of research papers in the field of BD applications within the FSCM context in recent years. However, the domain can be still characterized as “primitive” and highly fragmented with insufficient literature evidence to bridge the theory with the practice. The herewith presented research provided new insights pertaining to a comprehensive depiction of the current status quo of BD applications in FSCM presenting and discussing the dominant categories of the existing literature trends. The findings revealed different BD applications that are utilized in order to analyze and address the emerged challenges in five (5) categories: (1) agriculture supply chain, (2) improvement of food supply chain efficiency, (3) food quality management throughout the food supply chain, (4) food loss diminishment throughout food supply chain, and (5) urban food supply chain. However, the capitalization on these applications depends heavily on the harness potential of BD within a complete food system with the data acquisition procedure still posing a significant challenge for FSCM especially in the upstream operations stages indicating the underdevelopment of DAC in F&B organizations [2,9]. In the context of our research, we aimed at shedding some light onto the state-of-the-art literature evidence by synthesizing the SLR findings in order to conceptualize this area within business context and propose a framework to capture the operation of the data-driven FSCM from a BD perspective. These findings provided the background for an in-depth analysis of the emerged literature trend categories eventually leading to the identification of research gaps that are further discussed in what follows.

5.1. The Future Agriculture Supply Chain Model

Apart from the significant challenges concerning the development of data integration throughout FSC operations, there are certain implications deriving from the SLR findings that highlight the impact of BD on the future operation of agriculture supply chains networks. Kamble et al. [9] and Wolfert et al. [10] argue that there is an ongoing development of the food supply chain models transforming either first-tier suppliers into active “representatives” of the central FSC network actor through close collaboration and data integration, or alternatively farmers into direct distributors of their own products without the intervention of an intermediate member (i.e., short food supply chain model). These two models are met both in developing and developed countries with BD applications serving as the main catalyst for their development. Further investigation towards the role of BD in the formulation of the future FSC networks is required in order to produce generalized results and explore these two newly introduced models in-depth.

5.2. Development of Data Analytics Capability within Food Supply Chains

Even with the substantial increase of research papers in this highly fragmented area, the produced managerial implications in the field of FSCM are failing to address the practical requirements for harnessing the full potential of BD in FSCs. This issue was also addressed by Ji et al. [2], Ahearn et al. [8], and Kamble et al. [9] indicating that further research towards the development of DAC, the identification of the required IT infrastructure, and the fostering of analytical skillset within the FSC workforce is needed in order for the F&B organizations to tap into the exploding vast data within their respective food systems. This is also mentioned by Safari et al. [49] who consider technological capabilities as an assessment element in a MM of a supply chain emphasizing on the need to develop tools and guidelines in relation to the identification of the means and resources that are required to reach even higher maturity levels. Therefore, an investigation towards the required skills, human resources, and infrastructure for the development of DAC within the context of FSCM could shed some light into the future operation of FSCs and provide managerial and practical implications towards the capitalization on BD.

5.3. Food Quality and The Challenge of “Harvesting” Big Data within Food Supply Chains

The attention of FSCM is gradually shifting towards a customer-centric philosophy concentrating on the increased significance of food quality in relation to the development of the trust element from the consumer perspective [17,36]. The SLR findings revealed two (2) interdependent streams within data-driven FSCs aiming at building consumer trust: (1) social media analytics and (2) tracking and sensory data analytics. The majority of literature concentrates mainly on the second stream which essentially refers to the real-time monitoring of food products across end-to-end FSCs highlighting the significance of tapping into the potential of “harvesting” BD at the early stages of these food systems [2,9,13,34,35]. However, due to the complexity of this process, further investigation is required in order to examine the requirements, the barriers, and the challenges associated with the development of BD “harvest” models at the early stages of FSCs providing recommendations and managerial implications.

5.4. The Social Aspect of Big Data Utilization in Urban Food Supply Chains

The world population is estimated to exceed the threshold of 9 billion people by the 2050s [14]. At the same time, the proportion of people living in urban areas is expected to reach 68% of the overall population [42]. Carolan [6] argues that with 1.5 billion people worldwide currently participating in a “food retail loyalty program”, the social aspect in BD applications within FSCM framework should be further investigated both from the legislative and ethical context in order to encourage the wider utilization of BD and foster the more accurate capturing and personalization of the demand patterns in an urban environment. Furthermore, Zhang [56] argues that in the era of BD the challenges that are linked to data security and privacy should be further explored in relation to the citizens’ awareness and the deployment of private information security technologies in order to ensure the legitimate tracking and prediction of people’s behavior.

5.5. The Role of Big Data in the Future of Food Supply Chain Resilience and Responsiveness

The COVID-19 pandemic has undoubtedly brought on a new era on a global scale heavily hindering the operation of the FSC through the closure of food production/distribution facilities, appearance of great demand fluctuations, financial restrictions, and emergence of logistics-related obstacles [58]. As Abideen et al. [50] and Hobbs [58] argue, these disruptions have put to the test FSC resilience and responsiveness designating the weaknesses of the worldwide food systems. The authors further highlight the need for investigation of potential long-term changes that foster the development of shorter, more automated and digitalized, FSC models that would be able to withstand similar shocks in the future which could possibly lead to either shortages, food insecurity, or both. However, as the authors suggest, there is still insufficient evidence that could prove the greater resilience and responsiveness of the short digitalized FSCs in similar situations. Thus, the role of BD applications in the formulation of shorter more resilient and responsive FSC models needs to be examined and analyzed in depth.

Author Contributions

All authors have contributed equally. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Irfan, M.; Wang, M. Data-driven capabilities, supply chain integration and competitive performance. Br. Food J. 2019, 121, 2708–2729. [Google Scholar] [CrossRef]

- Ji, G.; Hu, L.; Tan, K.H. A study on decision-making of food supply chain based on big data. J. Syst. Sci. Syst. Eng. 2017, 26, 183–198. [Google Scholar] [CrossRef]

- Engelseth, P.; Molka-Danielsen, J.; White, B.E. On data and connectivity in complete supply chains. Bus. Process Manag. J. 2019, 25, 1145–1163. [Google Scholar] [CrossRef]

- Protopop, I.; Shanoyan, A. Big data and smallholder farmers: Big data applications in the agri-food supply chain in developing countries. Int. Food Agribus. Manag. Rev. 2016, 19, 173–190. [Google Scholar]

- Singh, A.; Kumari, S.; Malekpoor, H.; Mishra, N. Big data cloud computing framework for low carbon supplier selection in the beef supply chain. J. Clean. Prod. 2018, 202, 139–149. [Google Scholar] [CrossRef]

- Carolan, M. Big data and food retail: Nudging out citizens by creating dependent consumers. Geoforum 2018, 90, 142–150. [Google Scholar] [CrossRef]

- Vallandingham, L.R.; Yu, Q.; Sharma, N.; Strandhagen, J.W.; Strandhagen, J.O. Grocery retail supply chain planning and control: Impact of consumer trends and enabling technologies. IFAC-PapersOnLine 2018, 51, 612–617. [Google Scholar] [CrossRef]

- Ahearn, M.C.; Armbruster, W.; Young, R. Big data’s potential to improve food supply chain environmental sustainability and food safety. Int. Food Agribus. Manag. Rev. 2016, 19, 155–171. [Google Scholar]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Achieving sustainable performance in a data-driven agriculture supply chain: A review for research and applications. Int. J. Prod. Econ. 2020, 219, 179–194. [Google Scholar] [CrossRef]

- Wolfert, S.; Ge, L.; Verdouw, C.; Bogaardt, M.J. Big data in smart farming—A review. Agric. Syst. 2017, 153, 69–80. [Google Scholar] [CrossRef]

- Frizzo-Barker, J.; Chow-White, P.A.; Mozafari, M.; Ha, D. An empirical study of the rise of big data in business scholarship. Int. J. Inf. Manag. 2016, 36, 403–413. [Google Scholar] [CrossRef]

- Zhong, R.; Xu, X.; Wang, L. Food supply chain management: Systems, implementations, and future research. Ind. Manag. Data Syst. 2017, 117, 2085–2114. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Dukovska-Popovska, I.; Subramanian, N.; Chan, H.K.; Bai, R. Decision-making in cold chain logistics using data analytics: A literature review. Int. J. Logist. Manag. 2018, 29, 839–861. [Google Scholar] [CrossRef] [Green Version]

- Gharehgozli, A.; Iakovou, E.; Chang, Y.; Swaney, R. Trends in global E-food chain and implications for transport: Literature review and research directions. Res. Transp. Bus. Manag. 2017, 25, 2–14. [Google Scholar] [CrossRef]

- Li, D.; Wang, X. Dynamic supply chain decisions based on networked sensor data: An application in the chilled food retail chain. Int. J. Prod. Res. 2017, 55, 5127–5141. [Google Scholar] [CrossRef] [Green Version]

- Vlachopoulou, M.; Ziakis, C.; Vergidis, K.; Madas, M. Analyzing AgriFood-Tech e-Business Models. Sustainability 2021, 13, 5516. [Google Scholar] [CrossRef]

- Astill, J.; Dara, R.A.; Campbell, M.; Farber, J.M.; Fraser, E.D.; Sharif, S.; Yada, R.Y. Transparency in food supply chains: A review of enabling technology solutions. Trends Food Sci. Technol. 2019, 91, 240–247. [Google Scholar] [CrossRef]

- Kittichotsatsawat, Y.; Jangkrajarng, V.; Tippayawong, K.Y. Enhancing coffee supply chain towards sustainable growth with big data and modern agricultural technologies. Sustainability 2021, 13, 4593. [Google Scholar] [CrossRef]

- Maskey, B.B.; Sun, J.; Shrestha, K.; Kim, S.; Park, M.; Kim, Y.; Park, H.; Lee, S.; Han, Y.; Lee, J.; et al. A smart food label utilizing roll-to-roll gravure printed NFC antenna and thermistor to replace existing “use-by” date system. IEEE Sens. J. 2019, 20, 2106–2116. [Google Scholar] [CrossRef]

- Manzini, R.; Accorsi, R. The new conceptual framework for food supply chain assessment. J. Food Eng. 2013, 115, 251–263. [Google Scholar] [CrossRef]

- Krishnan, R.; Agarwal, R.; Bajada, C.; Arshinder, K. Redesigning a food supply chain for environmental sustainability—An analysis of resource use and recovery. J. Clean. Prod. 2020, 242, 118374. [Google Scholar] [CrossRef]

- Sharma, R.; Kamble, S.S.; Gunasekaran, A.; Kumar, V.; Kumar, A. A systematic literature review on machine learning applications for sustainable agriculture supply chain performance. Comput. Oper. Res. 2020, 119, 104926. [Google Scholar] [CrossRef]

- Sharma, J.; Tyagi, M.; Bhardwaj, A. Parametric review of food supply chain performance implications under different aspects. J. Adv. Manag. Res. 2020, 17, 421–453. [Google Scholar] [CrossRef]

- Sufiyan, M.; Haleem, A.; Khan, S.; Khan, M.I. Evaluating food supply chain performance using hybrid fuzzy MCDM technique. Sustain. Prod. Consum. 2019, 20, 40–57. [Google Scholar] [CrossRef]

- Boland, A.; Cherry, G.; Dickson, R. Doing a Systematic Review: A Student’s Guide, 2nd ed.; Sage: London, UK, 2017. [Google Scholar]

- Jesson, J.; Matheson, L.; Lacey, F.M. Doing Your Literature Review: Traditional and Systematic Techniques, 1st ed.; Sage: London, UK, 2011. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Rong, K.; Hu, G.; Lin, Y.; Shi, Y.; Guo, L. Understanding business ecosystem using a 6C framework in Internet-of-Things-based sectors. Int. J. Prod. Econ. 2015, 159, 41–55. [Google Scholar] [CrossRef] [Green Version]

- Belaud, J.P.; Prioux, N.; Vialle, C.; Sablayrolles, C. Big data for agri-food 4.0: Application to sustainability management for by-products supply chain. Comput. Ind. 2019, 111, 41–50. [Google Scholar] [CrossRef] [Green Version]

- Elijah, O.; Rahman, T.A.; Orikumhi, I.; Leow, C.Y.; Hindia, M.N. An overview of Internet of Things (IoT) and data analytics in agriculture: Benefits and challenges. IEEE Internet Things J. 2018, 5, 3758–3773. [Google Scholar] [CrossRef]

- Sharma, R.; Kamble, S.S.; Gunasekaran, A. Big GIS analytics framework for agriculture supply chains: A literature review identifying the current trends and future perspectives. Comput. Electron. Agric. 2018, 155, 103–120. [Google Scholar] [CrossRef]

- Tzounis, A.; Katsoulas, N.; Bartzanas, T.; Kittas, C. Internet of Things in agriculture, recent advances and future challenges. Biosyst. Eng. 2017, 164, 31–48. [Google Scholar] [CrossRef]

- Alfian, G.; Ijaz, M.F.; Syafrudin, M.; Syaekhoni, M.A.; Fitriyani, N.L.; Rhee, J. Customer behavior analysis using real-time data processing. Asia Pac. J. Mark. Logist. 2019, 31, 265–290. [Google Scholar] [CrossRef]

- Bogataj, D.; Bogataj, M.; Hudoklin, D. Mitigating risks of perishable products in the cyber-physical systems based on the extended MRP model. Int. J. Prod. Econ. 2017, 193, 51–62. [Google Scholar] [CrossRef]

- Singh, A.K.; Subramanian, N.; Pawar, K.S.; Bai, R. Cold chain configuration design: Location-allocation decision-making using coordination, value deterioration, and big data approximation. Ann. Oper. Res. 2018, 270, 433–457. [Google Scholar] [CrossRef]

- Singh, A.; Shukla, N.; Mishra, N. Social media data analytics to improve supply chain management in food industries. Transp. Res. Part E Logist. Transp. Rev. 2018, 114, 398–415. [Google Scholar] [CrossRef]

- Soon, J.M.; Saguy, I.S. Crowdsourcing: A new conceptual view for food safety and quality. Trends Food Sci. Technol. 2017, 66, 63–72. [Google Scholar] [CrossRef] [Green Version]

- Irani, Z.; Sharif, A.M.; Lee, H.; Aktas, E.; Topaloğlu, Z.; van’t Wout, T.; Huda, S. Managing food security through food waste and loss: Small data to big data. Comput. Oper. Res. 2018, 98, 367–383. [Google Scholar] [CrossRef]

- Lang, W.; Jedermann, R. What can MEMS do for logistics of food? intelligent container technologies: A review. IEEE Sens. J. 2016, 16, 6810–6818. [Google Scholar] [CrossRef]

- Mc Carthy, U.; Uysal, I.; Badia-Melis, R.; Mercier, S.; O’Donnell, C.; Ktenioudaki, A. Global food security–Issues, challenges and technological solutions. Trends Food Sci. Technol. 2018, 77, 11–20. [Google Scholar] [CrossRef]

- Vanderroost, M.; Ragaert, P.; Devlieghere, F.; De Meulenaer, B. Intelligent food packaging: The next generation. Trends Food Sci. Technol. 2014, 39, 47–62. [Google Scholar] [CrossRef]

- de Amorim, W.S.; Deggau, A.B.; do Livramento Gonçalves, G.; da Silva Neiva, S.; Prasath, A.R.; de Andrade, J.B.S.O. Urban challenges and opportunities to promote sustainable food security through smart cities and the 4th industrial revolution. Land Use Policy 2019, 87, 104065. [Google Scholar] [CrossRef]

- Pan, S.; Giannikas, V.; Han, Y.; Grover-Silva, E.; Qiao, B. Using customer- related data to enhance e-grocery home delivery. Ind. Manag. Data Syst. 2017, 117, 1917–1933. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Huang, T.; Zhu, Y.; Qiu, M. A case study of sensor data collection and analysis in smart city: Provenance in smart food supply chain. Int. J. Distrib. Sens. Netw. 2013, 9, 382132. [Google Scholar] [CrossRef]

- Pham, X.; Stack, M. How data analytics is transforming agriculture. Bus. Horiz. 2018, 61, 125–133. [Google Scholar] [CrossRef]

- Tongke, F. Smart agriculture based on cloud computing and IOT. J. Converg. Inf. Technol. 2013, 8, 210–216. [Google Scholar]

- Joshi, E.; Sasode, D.S.; Singh, N.; Chouhan, N. Wireless sensor network application for precision agriculture. Biot. Res. Today 2020, 2, 125–128. [Google Scholar]

- Nasrollahi, M.; Fathi, M.R.; Sanouni, H.R.; Sobhani, S.M.; Behrooz, A. Impact of coercive and non-coercive environmental supply chain sustainability drivers on supply chain performance: Mediation role of monitoring and collaboration. Int. J. Sustain. Eng. 2021, 14, 98–106. [Google Scholar] [CrossRef]

- Safari, H.; Etezadi, S.; Moradi-Moghadam, M.; Fathi, M.R. Maturity evaluation of supply chain procedures by combining SCOR and PST models. Int. J. Process Manag. Benchmarking 2021, 11, 707–724. [Google Scholar] [CrossRef]

- Abideen, A.Z.; Sundram, V.P.K.; Pyeman, J.; Othman, A.K.; Sorooshian, S. Food Supply Chain Transformation through Technology and Future Research Directions—A Systematic Review. Logistics 2021, 5, 83. [Google Scholar] [CrossRef]

- Dubey, R.; Altay, N.; Gunasekaran, A.; Blome, C.; Papadopoulos, T.; Childe, S.J. Supply chain agility, adaptability and alignment. Int. J. Oper. Prod. Manag. 2018, 38, 129–148. [Google Scholar] [CrossRef]

- Huo, B.; Zhao, X.; Zhou, H. The effects of competitive environment on supply chain information sharing and performance: An empirical study in China. Prod. Oper. Manag. 2014, 23, 552–569. [Google Scholar] [CrossRef]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Villalba, J.R. New trends in cold chain monitoring applications-A review. Food Control 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Mercier, S.; Marcos, B.; Uysal, I. Identification of the best temperature measurement position inside a food pallet for the prediction of its temperature distribution. Int. J. Refrig. 2017, 76, 147–159. [Google Scholar] [CrossRef]

- Yang, P.; Xiong, N.; Ren, J. Data security and privacy protection for cloud storage: A survey. IEEE Access 2020, 8, 131723–131740. [Google Scholar] [CrossRef]

- Zhang, D. Big data security and privacy protection. Adv. Comput. Sci. Res. 2018, 77, 275–278. [Google Scholar]

- Lazar, S.; Klimecka-Tatar, D.; Obrecht, M. Sustainability orientation and focus in logistics and supply chains. Sustainability 2021, 13, 3280. [Google Scholar] [CrossRef]

- Hobbs, J.E. Food supply chain resilience and the COVID-19 pandemic: What have we learned? Can. J. Agric. Econ. 2021, 69, 189–196. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).