Abstract

In recent years, China’s electronics and communication equipment manufacturing (ECEM) industry has overgrown, and the government should assess the innovation performance of the industry for its sustainable development. However, most previous studies on the innovation efficiency of the ECEM industry have ignored the link and carry-over variables. This paper uses the number of patent applications as a link variable to consider the stage of innovation activities. It divides the innovation activities of the electronics industry into two stages: technology development and results in transformation. To consider the dynamics of innovation activities, this paper uses capital stock as a period carry-over variable and evaluates the change of innovation efficiency over time. In this paper, the DNSBM model is used to measure the innovation efficiency of the ECEM industry in 26 Chinese provinces from 2013–2019. This model includes both stage link variables and period carry-over variables, thus allowing for overall efficiency and stage efficiency and period efficiency. The results show that the overall innovation efficiency values in the Chinese ECEM industry are low, there are considerable differences between the two-stage efficiency values in the east, central and western regions, and the overall efficiency values show a slow upward trend.

1. Introduction

In recent years, with the development of globalization, China’s economy has made remarkable progress. China’s economy ranks second in the world. Still, the innovation level of China’s manufacturing industry is relatively backward, which is not conducive to the sustainable and healthy development of the economy [1]. To improve the innovation efficiency of China’s manufacturing industry, the government has also introduced a series of policies. Made in China 2025 points out that China should enhance the ability of independent innovation and realize the high-quality development of manufacturing industry, which should ensure both the speed of manufacturing development and the quality of development. The high quality development of manufacturing industry can not only promote the development of economy, but also promote the sustainable development of society.

As a representative of the advanced manufacturing industry, the ECEM industry has become an important symbol of the country’s informatization level [2]. In China’s economic development from factor-driven to innovation-driven, the innovation efficiency of this industry, as technology and knowledge-intensive sector, will affect the overall innovation capacity of the manufacturing industry, which will affect the development of China’s economy. However, this industry still has many problems: the issue of “large but not strong” remains prominent, with few independent, innovative products and technologies, and the core technology is restricted and heavily dependent on imports. Relevant data show that China’s ECEM industry has more than 60% foreign technology dependence. On the other hand, China’s ECEM industry is in the middle and low end of the industrial chain, and the products are mainly exported for processing. Engaging in simple work also means that compared with developed countries, the profits of Chinese electronics enterprises are lower. At the same time, along with the increase in China’s labor costs, the ECEM industry profits face shrinkage, seeking the road to industrial upgrading has also become one of the significant challenges facing the government and enterprises. To achieve sustainable development, promoting the industry’s innovation is necessary.

The innovation efficiency of the ECEM industry needs to be improved, so what do we need to do? Relevant studies have shown that scientific assessment of innovation efficiency is of great significance to the improvement of independent innovation capability [3,4,5]: a scientific assessment of innovation efficiency is helpful for policymakers to correctly understand the current level of innovation so that they can target policies based on innovation efficiency to promote the improvement of innovation capability. Therefore, the current innovation level should be reasonably evaluated first to encourage innovation development. Hence, it is crucial to select objective and fair indicators to assess the innovation efficiency of the ECEM industry.

There are two shortcomings in previous studies on innovation efficiency in the ECEM industry: researchers have mainly considered the innovation process as a whole, based on which an overall innovation efficiency value is obtained. However, according to the innovation value chain theory [6], the innovation process is a multi-stage process that includes idea generation and transformation. In the actual innovation process, innovation activities are formed by two stages: science and technology research and development and transformation of results. The science and technology research stage includes research and development activities mainly carried out by the cooperation of schools, enterprises, and R&D institutions. The transformation stage mainly refers to transforming scientific and technological achievements into economic benefits, and enterprises mainly do this stage. These two phases are not completely separated either. Intermediate products connect them. For example, for innovation activities in the ECEM industry, the output of the research phase of science and technology (e.g., the number of patent applications) can be used to input the transformation phase. Therefore, it is inappropriate to ignore intermediate products’ influence and analyze innovation efficiency by considering innovation activities as a black box. Another shortcoming is that most of the current studies on e-innovation efficiency have focused on static efficiency values at a specific time (e.g., 10 year). The efficiency values measured in this way are measured separately in each period. However, in actual innovation investment activities, innovation activities in one period are not entirely independent from the next period; there is an interdependence between innovation activities in adjacent periods [7]. Period carry-over variables connect this dependence. For innovation activities in the ECEM industry, capital is cumulative in nature. The capital stock of the previous year’s R&D phase can be the source of the next year’s R&D capital, which is a carry-over variable. Therefore, it is not appropriate to ignore the effect of capital stock to study the innovation efficiency of the ECEM industry.

Based on the above analysis, the main research question of this paper is: What is the overall innovation efficiency of the current Chinese ECEM industry after considering intermediate link variables and period carry-over variables? What is the innovation efficiency of each stage? How does the innovation efficiency change over time? To address these questions, this paper measures the overall innovation efficiency, the innovation efficiency of each stage, and the innovation efficiency of the period in the ECEM industry using the dynamic network SBM model to have a more accurate assessment of the innovation capability of the ECEM industry. The contribution of this study lies in the following aspects. First, this paper finds not only the overall efficiency, but also the divisional efficiency and period efficiency on this basis; second, previous studies mostly use the traditional DEA model and SBM model, this paper compares the efficiency gap between the DNSBM model and the SBM model and analyzes the reasons; third, no previous studies on the ECEM industry have used the DNSBM model, and previous studies often ignore the link and carry-over variables. In this paper, we consider both link and carry-over variables and calculate the efficiency loss values to provide a reference for measuring efficiency values. The rest of this paper is organized as follows. The second section presents the related literature review. The third section introduces the SBM model and the dynamic network SBM model. The fourth section presents the index selection, calculation results, and analysis results. Conclusions and recommendations are given in the Section 5.

2. Literature Review

2.1. The Measurement of Innovation Efficiency

Innovation efficiency is an essential indicator of innovation capability, which has attracted much attention from scholars in recent years [8,9]. Innovation efficiency refers explicitly to the relative ability of the evaluated unit to achieve innovation output with a given innovation input. By combing through the relevant literature, it can be found that the current research on innovation efficiency is mainly focused on two aspects: regional and high technology industries. Among them, the research on regional efficiency studies the level of efficiency among various regions explicitly, and on this basis, the reasons for the differences in efficiency values are studied [10].

In the studies of innovation efficiency of high-tech industries, it is easy to find that most of the existing studies focus on the innovation efficiency of high-tech industries as a whole, but few analyze the sub-industries. Li et al. [11] proposes a new framework based on the combination of the dynamic DEA to study the innovation efficiency of China’s high-tech industries, and the results show that the eastern region leads and the central and western regions are relatively lagging behind. In recent years, Haschka et al. used the Bayesian stochastic frontier approach to measure the innovation efficiency values of European high-tech industries [12]. Chen et al. [13] used the DEA method to measure the innovation efficiency of Chinese high-tech industries. The results showed that the innovation efficiency of high-tech industries was low. All of the above studies take high-tech industries as the research object, and the suggestions made are directed to high-tech industries as a whole. The high-tech industries include five industries: aerospace and aircraft manufacturing, the ECEM, electronic computer and office equipment manufacturing, pharmaceutical manufacturing, and medical equipment and instrumentation manufacturing. These industries develop at different rates and have other characteristics, so studying their innovation efficiency and taking targeted measures is necessary. Hong et al. [14] used the stochastic frontier model to analyze the impact of government grants on the innovation efficiency of high-tech industries. They found differences in the impact of government grants on their five different sub-industries. Wang et al. [15] constructed a two-stage DEA to study the innovation efficiency of high-tech industries and compared the efficiency of their sub-industries. The results showed that the difference in innovation efficiency of the five sub-industries was obvious. The ECEM industry occupies an important position in the high-tech industry: the primary business income and total profit in 2019 accounted for 63% and 50% of the corresponding indicators of the whole high-tech industry, respectively. Therefore, for the characteristics of the electronics industry, selecting a suitable index system to study its innovation efficiency can help improve the overall innovation capacity of the high-tech industry and thus promote the development of the economy.

In previous studies on innovation efficiency measurement, most scholars focused on high-tech industries as a whole, and fewer studies were conducted for the ECEM industry. Among the published studies on the innovation efficiency of the electronics industry, most of the findings indicate that the innovation efficiency of China’s ECEM industry is generally low, and the efficiency values vary significantly among regions. In addition, most of the past studies treat the innovation process of the electronics industry as a whole and measure its innovation efficiency from a static perspective. This is not in line with the stage and dynamic characteristics of innovation activities; therefore, it is necessary to select a suitable method to assess the innovation efficiency of the ECEM industry.

2.2. Research on Innovation Efficiency Methods

The main methods used to measure the efficiency of innovations containing multiple variables are Stochastic Frontier Analysis (SFA) and Data Envelopment Analysis (DEA) [16,17]. The SFA method is a parametric method that can only deal with multiple inputs and single outputs. It needs to set the production function in advance, and if it is not set correctly, it will lead to inaccurate calculation results [18]. On the other hand, the DEA method can simultaneously handle multiple inputs and outputs. It does not need to set the production function in advance and does not need to select the indicator weights subjectively, thus avoiding the influence of human factors on the results [19,20,21,22]. Given the above advantages of the DEA method and the fact that the index system containing multiple inputs and multiple outputs is selected in this paper, the DEA method is chosen to study the innovation efficiency of the ECEM industry.

Among the studies that have used the DEA approach to measure innovation efficiency, there are mainly divided into single-stage and multi-stage approaches. When using the single-stage system, early scholars considered the innovation process as a whole and used the traditional DEA method to measure innovation efficiency. The conventional DEA methods include the CCR (Charnes, Cooper, and Rhodes) model and the BCC (Banker, Charnes, and Cooper) model, radial models that consider the input-output variables equally proportional fail to take slack variables into account. In addition, ignoring the slack variables is not realistic and can cause bias in the measurement results, affecting the decision unit’s evaluation [23]. To solve this problem, Tone K [24] proposed a slack variable-based DEA model (SBM model), which considers the effects of input-output slack variables and is superior to the traditional DEA model. Then the SBM model was widely used to measure innovation efficiency. For example, Li and Zeng [25] used the SBM model and Tobit model to analyze the green innovation of 21 intensive pollution industries’ sub-sectors in China, and the results showed that there were significant disparities between industries and most of them did not reach DEA validity. Liu et al. [10] used the SBM model to measure the innovation efficiency of Chinese science and technology enterprises. They concluded that the overall innovation efficiency of enterprises was a low conclusion. The above case of considering the innovation process as a whole ignores the internal activities of the innovation system. In contrast, according to the innovation value chain theory proposed by Hansen and Birkinshaw [6], the innovation activities include two stages of science and technology R&D and result in transformation. Therefore, it is necessary to measure innovation efficiency in stages. This helps assess the innovation transformation capability at each stage so that targeted measures can be taken.

To measure the efficiency values of each stage, Färe and Grosskopf [26] proposed a network DEA model (NDEA) based on single-stage DEA by considering the link variables between stages in the computational equation. The NDEA model captures the efficiency values of the decision unit as a whole and the efficiency values of each stage. Based on this, Tone and Tsutsui [27] considered the slack values of inputs, outputs, and link variables, and they proposed a slacks-based measure called network SBM (NSBM). In this way, the efficiency values of each stage can be evaluated, but the different proportional changes of the variables are considered, which makes it more realistic.

In addition to this, for the evaluated unit to be developed in the long term, it is usually necessary to assess the innovation capacity of the evaluated unit over a certain period (e.g., 10 years), which necessitates the consideration of carry-over variables for adjacent periods [28]. To solve this problem and consider slack variables on this basis, Tone and Tsutsui constructed a slacks-based measure called dynamic SBM (DSBM) [29]. DSBM not only considers the dynamics of innovation activities but also slack variables, which makes it more realistic.

To consider both the efficiency values and the changes of efficiency values over time in both phases of innovation activities, Tone and Tsutsui [30] constructed a dynamic DEA model with a network structure model (DNSBM) by adding link variables and carry-over variables to the computational equation. Using the DNSBM model, the overall efficiency, divisional efficiency, and period efficiency can be obtained. The DNSBM model has been used for efficiency measurements in several fields, such as the efficiency of electric power systems, the efficiency of banks, China’s innovation during industry-university-research institute’s collaboration process [31,32,33].

2.3. Literature Review Summary

By combing through the existing literature, it can be seen that there is very little current literature that measures the efficiency of innovation in the ECEM industry. In addition, the articles that do measure it have two shortcomings: on the one hand, most of the current studies consider innovation activities as a whole [14,15,16], and few measure the research and development phases separately. Innovation is a continuous process, and some of the outputs of the R&D phase can be directly used as inputs in the transformation phase. Therefore, it is too idealistic to consider the innovation process as a “black box,” which is not in line with the actual situation. On the other hand, most of the current studies treat each year of innovation activity as a separate unit [17,18], without considering the period carry-over variables. Innovation activities are dynamic as they accumulate over time, and separating each year’s innovation activities from each other does not meet the requirements of sustainable capital development. Based on this, the DNSBM model is applied in this paper. Vertically, the innovation efficiency of the ECEM industry is measured in stages, and the innovation levels in the stages of research and development are assessed separately. On this basis, the country is divided into east, middle, and west regions, and the efficiency values of the two stages in each area are compared, respectively. Cross-sectionally, the dynamic changes of the innovation efficiency of the electronics industry in the country and the east, middle and west regions from 2013 to 2019 are evaluated. Finally, this paper makes relevant suggestions in the context of efficiency measurement.

3. Materials and Methods

3.1. Model

3.1.1. SBM Model

The SBM model treats the decision unit as a whole and does not consider either the internal network structure of the decision unit or the association between periods. The SBM model is non-radial and can deal directly with the slack in the input and output variables. The SBM model assumes that the system has n decision units, each with x inputs and y outputs. The objective function of the SBM model is shown in Equation (1), and the constraints are shown in Equation (2).

where is the target efficiency value, and are the input and output variables of decision unit k, respectively, m and q are the number of inputs and outputs, and are the corresponding slack values, and is the indicator weight. takes values in the range (0,1), and when = 1, it means the decision unit is in the production frontier plane, and when 0 ≤ ≤ 1, it means that the efficiency value needs to be improved.

3.1.2. DNSBM Model

According to the DNSBM model [30], the overall efficiency is:

The division efficiency is:

The period efficiency:

The DNSBM model assumes that there are n decision-making units (DMUj, j = 1, …, n) with K departments (k = 1, …, K), and innovation activities involve T periods (t = 1, …, T). The input-output variables satisfy the following equations:

The DNSBM model assumes that sectors are not independent of each other, and that there are four forms of link variables: free, fixed, as-input, and as-output. The link variables satisfy the following equations:

The DNSBM model assumes that activities in the preceding period have an impact on the later period, and there are also four forms of carry-over variables: good, bad, free, and fixed. The carry-over variables satisfy the following equations:

The optimal value of overall efficiency can be uniquely determined by Equation (3) and constraints (6)–(8). In the case of period efficiency and division efficiency, there are cases where the solutions are not unique. Next, based on finding , the efficiency value is obtained starting from the Tth period, and then in the reverse order of T−1, T−2, T−3, …, 3, 2, the previously found solutions and Equations (1)–(8) are used as constraints until the efficiency value at t = 2 is obtained. This paper summarizes symbolic notations and explanations in Table 1.

Table 1.

Symbolic notations and their explanations to be used in DNSBM model.

In addition to the ability to derive overall, division, and period efficiency values, the DNSBM model, as discussed earlier, has the advantage of being able to relate different sectors vertically through link variables and horizontally through carry-over variables to different periods. This means that a major advantage of the DNSBM model over past models (e.g., the SBM model) is that it can calculate efficiency loss values for both the link variables and the carry-over variables, providing a benchmark and direction for improving efficiency. This is one of the contributions of this paper: the ability to measure the efficiency loss values of the link and carry-over variables for the ECEM industry.

The efficiency loss of the link variables and the efficiency loss of the carry-over variables can be found by linear programming and are calculated as follows:

where and represent the current values of the link variables and carry-over variables, respectively, and and represent the target values of the link variables and carry-over variables, respectively. When the value of is both 0, it indicates that the link variable is fully valid, neither too much nor too short. When its value is not equal to 0, it indicates room for improvement. Specifically, when its value is greater than 0, it means that the link variable is excessive—namely, the connection among divisions is strong; when its value is less than 0, it means a weak connection. is the same as .

3.2. Indicators Selection

Our data include 26 regions, due to the serious lack of data in Tibet, Ningxia, Xinjiang, Qinghai, and Inner Mongolia, these five regions were excluded. In this paper, they are divided into east, middle, and west regions according to their geographical locations, as shown in Table 2.

Table 2.

Eastern, central and western regions within China.

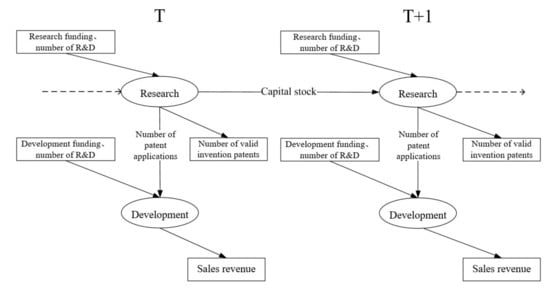

3.2.1. Input and Output Indicators of the Research Stage

In the new product research and development phase, we can learn from the valuable research results of related studies on the selection of indicators [2,15]. From the perspective of human and financial resources, the investment indicators select research funding and R&D personnel. Among them, the research funding is characterized by the indicator of internal expenditure of R&D expenses, and R&D personnel is characterized by the indicator of the full-time equivalent of R&D personnel. Since there is no full-time equivalent of R&D personnel in each of the two divisions in the statistical yearbook, we converted the full-time equivalent of R&D personnel to the two stages of new product development and achievement conversion according to a certain proportion. The output indicators in this stage should reflect the results of R&D [7]. We consider that patents are the primary manifestation of R&D results. They are the direct output of R&D activities and are widely used to measure innovation output. Therefore, this thesis chooses the number of patent applications and the number of valid invention patents as the output indicators.

3.2.2. Input and Output Indicators of the Development Stage

In the product transformation phase, in addition to human and financial resources, we also consider the number of patent applications, which is an output indicator of the new product research and development phase, can also be used as an input indicator for the product transformation phase [34], so the input variables include development funding, R&D number of personnel and patent applications. R&D personnel uses the index of the full-time equivalent of R&D personnel in the stage of product transformation. The output indicator at this stage is the final output indicator. The result of the commercialization stage is finally reflected in the sales of new products [2,15], so the output indicator is the sales revenue of new products.

3.2.3. The Link Variables

The link variables should have the nature of intermediate products, which should be one of the output indicators of the previous sector and one of the input indicators of the next sector. The number of patent applications has this nature [34,35]. The study shows that patents are closely related to innovation activities [36]. The use of patent indicators better reflects the originality of innovation activities in the research department than other indicators [37,38]. Patent applications mainly include the number of patent applications and the number of valid invention patents. The difference between the two is that the number of valid invention patents is the patents that have been granted. The number of valid invention patents is more subject to human interference and takes longer to be granted. Wang et al. [39] pointed out that even if a company’s patent application is not approved, it still reflects that the company is actively carrying out scientific and technological research and development work, which will positively impact its later work. The number of patent applications better reflects the contribution of the research sector to the development sector, as it takes into account the portion of patents that are not granted but still have a significant economic and social effect. The number of valid invention patents, on the other hand, focuses on the quality and results of innovation in the research sector and is more suitable for analysis of the direct output of the research sector. Given the above considerations, this paper selected the number of patent applications as the link variable, consistent with the variables selected in many existing studies [40,41,42,43].

3.2.4. The Carry-Over Variables

In the ECEM industry, a portion of the research funds invested in the first period is used to purchase instruments and equipment. The tools and equipment purchased are still available in later periods. We combine with the indicators selected in the relevant literature. This part of the research funding has a lagging and cumulative effect on the technological innovation efficiency of high-tech industries [29]. Therefore, we calculate the capital stock for the costs used to purchase apparatus and equipment and use the computed capital stock as the carry-over variable.

The above indicator system is shown in Table 3.

Table 3.

Indicator system of innovation efficiency evaluation.

The relationship of the input-output variables is shown in Figure 1.

Figure 1.

Structural diagram of the DNSBM model.

3.3. Sample Selection and Data Processing

The samples in this article are the ECEM industry of various provinces in China. All the data in this article come from the China High-tech Industry Statistical Yearbook and China Science and Technology Statistical Yearbook for 2014–2020. The individual missing data are supplemented by linear interpolation. In terms of data processing, considering the short R&D cycle of the electronics and communication equipment manufacturing industry and the rapid rate of renewal, it is assumed that there is no lag between the input items and the corresponding output items.

Regarding the deflation of R&D expenditures, to eliminate the impact of price changes, combined with relevant literature, there are research results [32], R&D internal expenditures, new product development expenditures, and new product sales revenue are, respectively, based on R&D expenditures price index and household consumption. The price index and the ex-factory price index of industrial producers are deflated. The capital stock is calculated using the perpetual inventory method [29]. The year involved in each indicator is 2013–2019, and each year’s data are converted using 2013 as the base period.

4. Analysis of Innovation Efficiency in the ECEM Industry

This paper uses MAXDEA software (8 ultra, Beijing Ruivomedi Software Co., Beijing, China) to calculate the panel data of the ECEM industry in China’s 26 provinces from 2013 to 2019. Then we obtained the overall efficiency, divisional efficiency, and period efficiency of the innovation activities of various provinces’ ECEM industries.

4.1. Analysis of Overall Efficiency

Through calculation, we can acquire the overall efficiency of each province. The calculation results of the DNSBM model and are shown in Table 4. In addition to calculating the efficiency value, the efficiency value is also sorted in Table 4.

Table 4.

Efficiency values of DNSBM model.

Regarding the innovation efficiency of China’s ECEM industry, by analyzing the efficiency values of the DNSBM model, we can see that Beijing and Guangdong are at the frontier of efficiency, and their efficiency values are both 1. Anhui, Shanghai, Jiangsu, Zhejiang, and Heilongjiang have relatively high innovation efficiency, their innovation efficiency values located between 0.9 and 1. Beijing, Guangdong, Shanghai, Jiangsu, and Zhejiang are at the forefront of China’s economic development. By observing the investment in R&D-related indicators over the years, it can be found that these provinces have a relatively significant investment based on their excellent geographical location and economic status. Therefore, their innovation efficiency is relatively high. Heilongjiang and Anhui have relatively weak industrial foundations and limited industrial development levels. However, the investment in R&D-related indicators has also increased year by year. Their resource utilization rates are also high, so their innovation efficiency is relatively high. The provinces with efficiency values between 0.78 and 0.9 are Tianjin, Jilin, Jiangxi, Shandong, Guangxi, Hainan, Sichuan, and Yunnan. The efficiency values of these provinces are higher than the average and lower than those with relatively higher efficiency values. The efficiency values of the remaining provinces are all lower than the average. Among them, the efficiency values of Hebei, Shanxi, Hunan, and Shaanxi are lower than 0.55. The overall efficiency of the ECEM industries in these provinces is low.

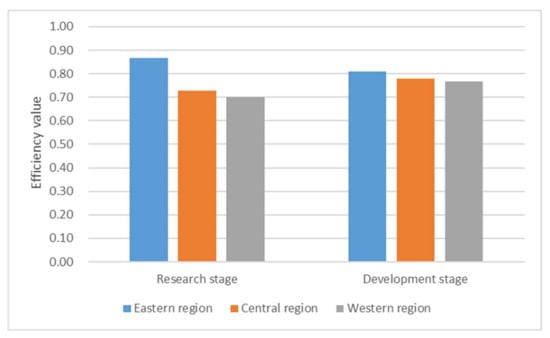

4.2. Analysis of Divisional Efficiency

To more intuitively compare the efficiency differences of each sector in the east, middle and west regions of mainland China, this paper divides each sector according to three major areas based on the measured efficiency averages of each province. It calculates the efficiency averages of each sector in each of the three major regions. This paper uses bar charts to compare the efficiency differences between the three major regions. The comparison result is shown in Figure 2. The figure shows that the Eastern region is the most efficient in the research and development divisions, followed by the central region, and the western region is the least efficient. This shows that the eastern region’s product development and product transformation efficiency is relatively the highest.

Figure 2.

Comparison of the efficiency values of the two sectors in the three regions.

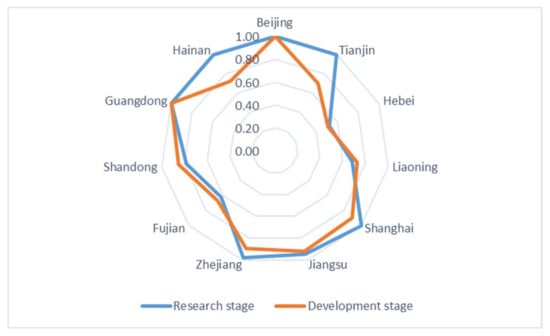

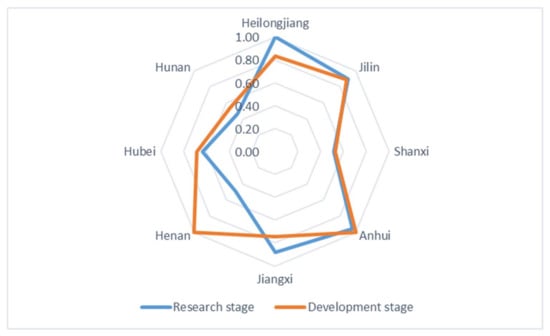

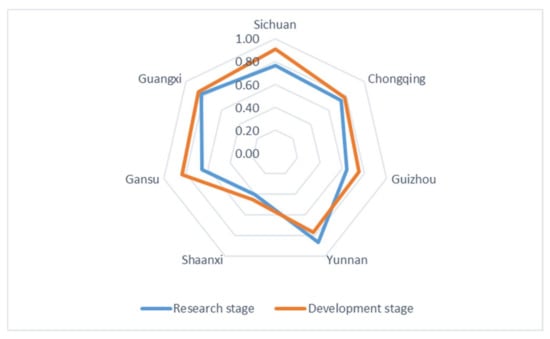

Figure 3, Figure 4 and Figure 5 describe the differences in the efficiency of research and development stages in different provinces under different regions. It can be seen from the figure that in the eastern region, the efficiencies of the two divisions in Beijing, Guangdong, Shanghai, Jiangsu, and Zhejiang are all equal to or close to 1. It shows that the ECEM industry in these provinces has sufficient inputs under the existing conditions. The output of scientific and technological achievements can be almost all converted into productivity. The innovation capacity of these provinces is good. The research efficiency of Hainan and Tianjin are both 1, which is significantly higher than the development efficiency. This shows that only part of the output of scientific and technological achievements in the ECEM industry is converted into productivity. Hebei, Liaoning, Shandong, and Fujian are all low in efficiency, indicating that their resource utilization and technological transformation capabilities are relatively low. In the central region, as shown in Figure 4, the efficiency of the development division in Anhui is 1. The efficiency of the research division is close to 1, so the innovation ability is good. While the efficiency of the development division in Henan province is 1, the efficiency of the research division is only 0.49, indicating that there is still much room for improvement in the efficiency of its product development. The efficiency of Jilin and Heilongjiang is relatively considerable, while that of Shanxi and Hubei is relatively low. In the western region, as shown in Figure 5, the efficiency of the two divisions in each province is generally low, and the difference is slight. However, it is not difficult to find that Yunnan province has the highest efficiency in the two divisions in the western region. Except for Yunnan province, the research efficiency of other provinces is higher than the corresponding development efficiency.

Figure 3.

The divisional efficiencies of the two stages in the Eastern region.

Figure 4.

The divisional efficiencies of the two stages in the Central region.

Figure 5.

The divisional efficiencies of the two stages in the Western region.

4.3. Analysis of Period Efficiency

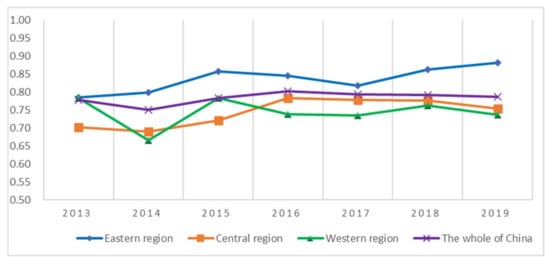

The period efficiency can reflect the change of efficiency value with the period, and the period efficiency calculated by using software in this paper is shown in Figure 6.

Figure 6.

The period efficiencies in 2013–2019 under different regions.

Figure 6 shows the changes in the period efficiency for the three major regions from 2013 to 2019. The trend of the folding line shows that in 2013–2014, the overall national efficiency values are on a downward trend. After 2014, the efficiency value of various regions across the country began to increase, inseparable from a series of related policies issued by China. In 2014 and 2015, China successively introduced the “Broadband China” particular action and “Made in China 2025”. The purpose is to improve informatization and promote the development of the country’s manufacturing industry as one of the five major industries in China’s high-tech industries. The electronics and communication equipment manufacturing industry has gradually improved its innovation efficiency under policies. Therefore, the innovation efficiency of the electronic and communication equipment manufacturing industry in all country regions improved substantially in 2014–2016. In recent years, the national innovation efficiency has stabilized. From the perspective of various regions, there are differences in the efficiency values of the eastern, central, and western regions. The innovation efficiency of the east region is higher than the national average, and the efficiency value is rising steadily. This is related to the superior geographical location and the denser industries in the high-tech zone. The innovation efficiency of the central and western regions is lower than the national average. There has been a steady or even a slight downward trend in recent years. This shows that although the state has introduced a series of supportive policies, the central and western regions have fewer innovation opportunities and resources than the eastern regions, so its innovation efficiency cannot increase substantially.

4.4. Comparison Analysis with SBM Model Efficiency Values

In contrast to the DNSBM model, the SBM model does not consider link and carry-over variables. However, in actual innovation activities, the link variables and carry-over variables is not perfect, and there will be underutilization. The number of patent applications and capital stock are also too much or too little in the innovation activities of the ECEM industry. Among innovation sectors, a high volume of patent applications in the research sector can lead to an underutilization of patents in the development sector, which is a waste of innovation results; conversely, if the volume of innovation output in the research sector does not meet the needs of the development sector, it can also affect the progress of the innovation process. The same is true for carry-over variables. During the innovation time period, the capital stock of the previous period, if properly invested, will neither cause a waste nor an oversupply of innovation assets. Both of these variables can lead to a loss of efficiency value in excess or deficiency, so ignoring the loss of efficiency in the number of patent applications and capital stock can lead to an overestimation of the overall efficiency value.

The DNSBM model can measure the efficiency loss values of link and carry-over variables by Equations (9) and (10) to determine the articulation of innovation activities between sectors and adjacent periods by analyzing efficiency loss of links and carry-overs.

This paper calculates the link efficiency loss from research to development stage by Equation (9) and calculates the carry-over efficiency loss from period T to T + 1 by Equation (10). The calculation results are shown in Table 5.

Table 5.

Average efficiencies loss of the link and carry-over variable.

Regarding the link efficiency loss, the study results show that the research sector and the development sector are closely related, with 19 out of 26 provinces having an efficiency loss value of 0, which proves that there is a positive relationship between the research and the development sector. In other words, the research results provided by the research sector are equal to the demand for research results from the development sector. The link efficiency loss in Tianjin, Liaoning, Shanghai, Anhui, Shandong, Guangxi, Hainan, and Shaanxi are all greater than 0, indicating that the research results provided by the research department exceed the demand for research results from the development department. Further, patent applications cannot be fully converted into new product sales revenue.

For the carry-over efficiency loss, Table 5 shows that 19 provinces have efficiency loss values greater than 0. This indicates that these provinces invest too much capital in the early period but do not use it efficiently in the later period. The accumulation of capital early exceeds the actual demand in the later period, which leads to the waste of capital. The other seven provinces have an efficiency loss value of 0, indicating that the capital accumulated in the first period can be well used in the later innovation activities.

From the above analysis, it can be seen that there is some room for improvement in the innovation efficiency of the Chinese ECEM industry. Specifically, the development sectors in Tianjin, Liaoning, Shanghai, Anhui, Shandong, Guangxi, and Hainan provinces underutilize research results; most provinces have excessive upfront capital investment, resulting in wasted resources. This leads to an overestimation of the efficiency of the decision unit when using models that do not consider link and carry-over variables (e.g., SBM models). To do a comparative analysis, this paper chooses the input-oriented linear programming, sets variable returns-to-scale, calculates the efficiency value of each DMU by the SBM model. Then we compare it with the efficiency value calculated by the DNSBM model. The calculation results of the DNSBM model and the SBM model are shown in Figure 7.

Figure 7.

Comparison chart of DNSBM model and SBM model efficiency.

By comparing the efficiency of the DNSBM model and the SBM model, we can see a distinct difference between the efficiency values of the two models regarding the innovation efficiency of the Chinese ECEM industry. It is evident from Figure 7 that the efficiency values calculated by the SBM model are overall higher than those calculated by the DNSBM model: the average efficiency of the former is 0.78, while the average efficiency of the latter is 0.84, which confirms the previous analysis of this paper. This is because the SBM model ignores the efficiencies loss of the link and carry-over variable and therefore overestimates the efficiency of each decision unit. As can be seen from Table 5, except for Beijing, Yunnan, and Shaanxi, where there is no efficiencies loss of both the link and carry-over variables, all other provinces have efficiencies loss, which leads to overestimating of their efficiency values. The DNSBM model, as an improved model of the SBM model, can acquire not only the overall efficiency but also the divisional efficiency and period efficiency. Therefore, the reasons for the low efficiency can be seen. DNSBM model provides a more realistic view of what is going on within the supply chain. More targeted suggestions and improvement programs can be put forward.

5. Conclusions and Implications

From the perspective of improving China’s innovation efficiency, this paper constructs a DNSBM model to measure the innovation efficiency of Chinese provinces and regions to achieve the sustainable development of innovation activities. Compared with previous studies, the DNSBM model used in this paper is more generalizable: it introduces the number of patent applications and capital stock as link and carry-over variables, both of which take into account the internal connectivity of innovation activities and the dynamics of sustainable innovation, providing a new perspective for evaluating innovation efficiency.

In terms of model application, this paper measures the innovation efficiency of China’s ECEM industry using the DNSBM model, yielding overall efficiency, divisional efficiency, and period efficiency. In terms of overall efficiency, the overall efficiency value of China’s ECEM industry is low; in terms of divisional efficiency, there are differences in innovation efficiency among the three regions. Whether it is the research stage or the development stage, the eastern region has the largest efficiency value, the central region is the second, and the western region is the smallest; from the perspective of period efficiency, the innovation efficiency of the eastern, central, and western regions differs over time: the eastern region shows a slow upward trend, the central region’s efficiency first rises and then slowly declines, and the western region’s innovation efficiency has a more zigzag trend over time, and a decreasing trend in recent years.

This paper puts forward the following policy recommendations based on the above analysis: 1. Promote technological innovation and encourage innovation-driven development. Innovation can drive economic development, and encouraging sustainable innovation is vital to achieving sustainable economic development. 2. Different policies should be designated for different regions. The eastern region should further exert its location and innovation advantages, strengthen exchanges and cooperation with the central and western regions, and actively drive and influence the innovation efficiency of the ECEM industry in the central and western regions under the premise of ensuring its innovation efficiency. The central and western regions should also take advantage of their resource endowments, combine their characteristics, grasp relevant national policies, and respond to the national call to proactively improve innovation efficiency. 3. China should further improve the innovation environment and guide the research and development sectors to interface effectively. The government should encourage the research sector to engage in research output actively and call on it to pay attention to the commercialization of research output. 4. Innovation actors should consider the sustainability of innovation activities and measure innovation capital investment from a long-term perspective. It should not only look at the immediate benefits without considering the future development of innovation.

However, this paper has some shortcomings, which are the focus of our future research. Firstly, the construction of an innovation indicator system is a complex task. Although the indicators selected in this paper are based on previous studies, human subjective factors also influence them. It is worth exploring other input-output indicators in future studies. Second, the research in this paper takes the Chinese ECEM industry as the research object, and the innovation efficiency of other industries can be studied in the future. The scope of the study can also be expanded in the future to compare the innovation efficiency of more countries.

Author Contributions

Conceptualization, J.L.; methodology, J.L. and R.Q.; formal analysis, J.L.; data curation, R.Q.; writing—original draft preparation, J.L.; writing—review and editing, J.L. and R.Q.; Funding acquisition, H.J.; visualization, R.Q.; supervision, H.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (Project no. 71801195).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to thank the editors and anonymous reviewers for their insightful comments and suggestions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Qu, Y.; Yu, Y.; Appolloni, A.; Li, M.; Liu, Y. Measuring Green Growth Efficiency for Chinese Manufacturing Industries. Sustainability 2017, 9, 637. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, J.F.; Pei, R.M.; Yi, B.W.; Yang, G.L. Assessing the technological innovation efficiency of China’s high-tech industries with a two-stage network DEA approach. Socio-Econ. Plan. Sci. 2020, 71, 100810. [Google Scholar] [CrossRef]

- Zhang, R.; Sun, K.; Delgado, M.S.; Kumbhakar, S.C. Productivity in China’s high technology industry: Regional heterogeneity and R&D. Technol. Forecast. Soc. Change 2012, 79, 127–141. [Google Scholar]

- Guo, X.; Deng, C.; Wang, D.; Du, X.; Li, J.; Wan, B. International Comparison of the Efficiency of Agricultural Science, Technology, and Innovation: A Case Study of G20 Countries. Sustainability 2021, 13, 2769. [Google Scholar] [CrossRef]

- Im, C.H.; Cho, K.T. Comparing and Identifying Influential Factors of Technological Innovation Efficiency in Manufacturing and Service Industries Using DEA: A Study of SMEs in South Korea. Sustainability 2021, 13, 12945. [Google Scholar] [CrossRef]

- Hansen, M.T.; Birkinshaw, J. The innovation value chain. Harv. Bus. Rev. 2007, 85, 121. [Google Scholar]

- An, Q.; Meng, F.; Xiong, B.; Wang, Z.; Chen, X. Assessing the relative efficiency of Chinese high-tech industries: A dynamic network data envelopment analysis approach. Ann. Oper. Res. 2020, 290, 707–729. [Google Scholar] [CrossRef]

- Luo, Q.; Miao, C.; Sun, L.; Meng, X.; Duan, M. Efficiency evaluation of green technology innovation of China’s strategic emerging industries: An empirical analysis based on Malmquist-data envelopment analysis index. J. Clean. Prod. 2019, 238, 117782. [Google Scholar] [CrossRef]

- Zhao, X.; Ding, X.; Li, L. Research on environmental regulation, technological innovation and green transformation of manufacturing industry in the Yangtze River Economic Belt. Sustainability 2021, 13, 10005. [Google Scholar] [CrossRef]

- Liu, L.; Hou, Y.; Zhan, X.; Wang, Z. Innovation efficiency of high-tech SMEs listed in China: Its measurement and antecedents. Discrete Dyn. Nat. Soc. 2020, 2020, 8821950. [Google Scholar] [CrossRef]

- Li, L.B.; Liu, B.L.; Liu, W.L.; Chiu, Y.H. Efficiency evaluation of the regional high-tech industry in China: A new framework based on meta-frontier dynamic DEA analysis. Socio-Econ. Plan. Sci. 2017, 60, 24–33. [Google Scholar] [CrossRef]

- Haschka, R.E.; Herwartz, H. Innovation efficiency in European high-tech industries: Evidence from a Bayesian stochastic frontier approach. Res. Policy 2020, 49, 104054. [Google Scholar] [CrossRef]

- Chen, H.; He, P.; Zhang, C.X.; Liu, Q. Efficiency of technological innovation in China’s high tech industry based on DEA method. J. Interdiscip. Math. 2017, 20, 1493–1496. [Google Scholar] [CrossRef]

- Hong, J.; Feng, B.; Wu, Y.; Wang, L. Do government grants promote innovation efficiency in Chinaa’s high-tech industries? Technovation 2016, 57, 4–13. [Google Scholar] [CrossRef]

- Wang, Q.; Hang, Y.; Sun, L.; Zhao, Z. Two-stage innovation efficiency of new energy enterprises in China: A non-radial DEA approach. Technol. Forecast. Soc. Change 2016, 112, 254–261. [Google Scholar] [CrossRef]

- Danna, S.; Yan, L. Analysis on Innovation Efficiency of China Meteorological Science and Technology and Its Influencing Factors. Am. J. Manag. Sci. Eng. 2019, 4, 32–38. [Google Scholar] [CrossRef][Green Version]

- Sun, H.; Edziah, B.K.; Sun, C.; Kporsu, A.K. Institutional quality, green innovation and energy efficiency. Energ. Policy 2019, 135, 111002. [Google Scholar] [CrossRef]

- El Mehdi, R.; Hafner, C.M. Erratum: Erratum to“Inference in stochastic frontier analysis with dependent error terms”. Math. Comput. Simulat. 2014, 105, 160. [Google Scholar] [CrossRef]

- Huang, F.; Du, Y.; Hu, D.; Zhang, B. Sustainable Performance Analysis of Power Supply Chain System from the Perspective of Technology and Management. Sustainability 2021, 13, 5972. [Google Scholar] [CrossRef]

- Krivonozhko, V.E.; Førsund, F.R.; Lychev, A.V. On comparison of different sets of units used for improving the frontier in DEA models. Ann. Oper. Res. 2017, 250, 5–20. [Google Scholar] [CrossRef]

- Wu, C.; Li, Y.; Liu, Q.; Wang, K. A stochastic DEA model considering undesirable outputs with weak disposability. Math. Comput. Model. 2013, 58, 980–989. [Google Scholar] [CrossRef]

- Wu, J.; Yu, Y.; Zhu, Q.; An, Q.; Liang, L. Closest target for the orientation-free context-dependent DEA under variable returns to scale. J. Oper. Res. Soc. 2018, 69, 1819–1833. [Google Scholar] [CrossRef]

- Zhang, N.; Choi, Y. Environmental energy efficiency of China’s regional economies: A non-oriented slacks-based measure analysis. Soc. Sci. J. 2013, 50, 225–234. [Google Scholar] [CrossRef]

- Tone, K. A slacks-based measure of efficiency in data envelopment analysis. Eur. J. Oper. Res. 2001, 130, 498–509. [Google Scholar] [CrossRef]

- Li, D.; Zeng, T. Are China’s intensive pollution industries greening? An analysis based on green innovation efficiency. J. Clean. Prod. 2020, 259, 120901. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Whittaker, G. Network DEA: Modeling Data Irregularities and Structural Complexities in Data Envelopment Analysis; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Tone, K.; Tsutsui, M. Network DEA: A slacks-based measure approach. Eur. J. Oper. Res. 2009, 197, 243–252. [Google Scholar] [CrossRef]

- Chen, K.; Kou, M.; Fu, X. Evaluation of multi-period regional R&D efficiency: An application of dynamic DEA to China’s regional R&D systems. Omega 2018, 74, 103–114. [Google Scholar]

- Tone, K.; Tsutsui, M. Dynamic DEA: A slacks-based measure approach. Omega 2010, 38, 145–156. [Google Scholar] [CrossRef]

- Tone, K.; Tsutsui, M. Dynamic DEA with network structure: A slacks-based measure approach. Omega 2014, 42, 124–131. [Google Scholar] [CrossRef]

- She, Z.Y.; Meng, G.; Xie, B.C.; O’Neill, E. The effectiveness of the unbundling reform in China’s power system from a dynamic efficiency perspective. Appl. Energ. 2020, 264, 114717. [Google Scholar] [CrossRef]

- Zha, Y.; Liang, N.; Wu, M.; Bian, Y. Efficiency evaluation of banks in China: A dynamic two-stage slacks-based measure approach. Omega 2016, 60, 60–72. [Google Scholar] [CrossRef]

- Bai, X.J.; Li, Z.Y.; Zeng, J. Performance evaluation of China’s innovation during the industry-university-research collaboration process—An analysis basis on the dynamic network slacks-based measurement model. Technol. Soc. 2020, 62, 101310. [Google Scholar] [CrossRef]

- Qian, L.; Xiao, R.Q.; Chen, Z.W. Environmental constraint, technology gap and the enterprises’ innovation efficiency: Empirical research on the provincial industrial enterprises in China. Stud. Sci. Sci. 2015, 33, 378–389. [Google Scholar]

- Guan, J.C.; Chen, K.H. Modeling the relative efficiency of national innovation systems. Res. Policy 2012, 41, 102–115. [Google Scholar] [CrossRef]

- Feldman, M.P.; Florida, R. The geographic sources of innovation: Technological infrastructure and product innovation in the United States. Ann. Assoc. Am. Geogr. 1994, 84, 210–229. [Google Scholar] [CrossRef]

- Bronzini, R.; Piselli, P. The impact of R&D subsidies onfirm innovation. Res. Policy 2016, 45, 442–457. [Google Scholar]

- Huang, E.Y.; Lin, S.C. How R&D management practice affects innovation performance: An investigation of the high-tech industry in Taiwan. Ind. Manag. Data Syst. 2006, 106, 966–996. [Google Scholar]

- Wang, X.; Liu, Y.; Chen, L. Innovation Efficiency Evaluation Based on a Two-Stage DEA Model with Shared-Input: A Case of Patent-Intensive Industry in China. IEEE T. Eng. Manag. 2021. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Z.; Zhu, Q. Performance evaluation of China’s high-tech innovation process: Analysis based on the innovation value chain. Technovation 2018, 74, 42–53. [Google Scholar] [CrossRef]

- Chen, K.; Guan, J. Measuring the efficiency of China’s regional innovation systems: Application of network data envelopment analysis (DEA). Reg. Stud. 2012, 46, 355–377. [Google Scholar] [CrossRef]

- Liu, Z.; Lyu, J. Measuring the innovation efficiency of the Chinese pharmaceutical industry based on a dynamic network DEA model. Appl. Econ. Lett. 2020, 27, 35–40. [Google Scholar] [CrossRef]

- Du, J.L.; Liu, Y.; Diao, W.X. Assessing regional differences in green innovation efficiency of industrial enterprises in China. Int. J. Environ. Res. Pub. Health 2019, 16, 940. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).