Abstract

The energy sources required for general development and maintenance cause environmental pollution due to the carbon emissions released into the atmosphere. For these reasons, countries have turned to renewable energy sources. Energy production methods also cause serious problems in terms of the health and safety of employees. This study aimed to create an occupational health and safety performance model in geothermal energy fields, which generate renewable energy sources, using multi-criteria decision-making methods. A two-stage model was created for OHS performance index measurement. In the first stage, a literature screening was performed, risk analysis criteria were examined, and performance measurement criteria were determined with geophysical engineers and OHS experts. Seven main criteria and forty-seven subcriteria were set. An analytical hierarchy process method (AHP) and a fuzzy analytical hierarchy process (F-AHP) using the main criteria and subcriteria were determined. In the second stage, exposure rates were obtained using the Promethee method in three geothermal wells. The risks in these three wells are listed according to their importance. A performance model was created. The Results section includes conclusions and suggestions. This study, by creating an OHS performance model, can be used by managers and OHS professionals working in geothermal energy production fields to solve problems.

1. Introduction

Global energy requirements have dramatically escalated due to increasing urbanization and population. This energy has great potential in terms of supporting economic growth, particularly in developing countries [1]. In recent centuries, fossil fuel waste has increased greenhouse gas emissions, which is the cause of concerns regarding global warming, climate change, and a loss of biodiversity. As a result, sustainable energy has been the center of attention owing to its positive contribution to climate change and economic growth. Establishing more environmentalist, sustainable, and renewable energy systems is needed to diminish global environmental threats [2].

Today, the renewable energy share is below 15%. Renewable energy continued to grow annually by about 0.9% between 2009 and 2019. Renewable power generation is expected to increase from 21% in 2021 up to 44% in 2050. The contribution of hydropower is expected to remain largely unchanged until 2050, and other renewable sources of power generation, such as geothermal and biomass, are expected to collectively constitute less than 3% of total generated energy. In addition, new studies are continuously carried out with the aim of developing more efficient and green energy sources. For example, the development of solar panels that work at night is studied in the fields of infrared technology, biomass energy, hydrogen energy, and wave/ocean energy. The direct usage of geothermal energy for thermal implementations has been quite intensified geographically, and it constitutes three-fourths of the energy consumed in countries such as China, Turkey, Iceland, and Japan. The direct use of geothermal energy resources has recently grown by approximately 8%, and it is the primary driving force of heating. The amount of geothermal energy power generated globally, based on data from late 2018, is 14.9 GWe. The top five countries generating electricity from geothermal energy are the USA, the Philippines, Indonesia, Turkey, and New Zealand. Non-electrical use has surpassed 70,000 MWt, with the United States, China, Sweden, Belarus, and Norway leading the globe in direct use applications [3].

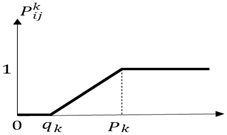

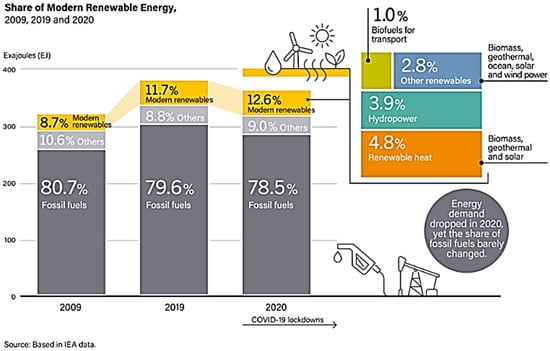

As indicated in Figure 1, the generation of renewable energy, which was 8.7% in 2009, reached 11.7% in 2019. Despite the negative impact of the COVID-19 pandemic, the generation of renewable energy has risen to 12.6%. Due to this rate of increase, a “zero emission” objective for 2050 has been imposed by the Paris Treaty, signed by 135 countries.

Figure 1.

Distribution of renewable energy usage between 2009 and 2020 [3].

Even though renewable and clean energy is considered positive, geothermal energy may cause environmental and socio-economic problems that can impact the ecological balance. Its greatest disadvantage is that it involves the use of hazardous chemicals. Although it does not emit greenhouse gases like fossil fuels do, hydrogen sulfur stored under the earth’s crust as well as carbon dioxide, ammoniac, methane, and boron may emerge at low rates. Naturally, these rates are higher in places near geothermal drilling. To provide sustainable geothermal energy, water needs to be pumped. Heat is measured in underground reservoirs. Since water is circulated in power plants and sent back again, a decrease in water quality may occur. Furthermore, it is also likely that geothermal drilling is associated with earthquake risks due to the creation of wells that are drilled in search of springs or produce water. Drilling into the crust while pumping hot water out of the ground may harm tectonic structures and cause earthquake risks [4].

Geothermal energy is generated by hot water and steam in underground reservoirs, being pumped out of the ground through drilled wells, using moving turbines that work via electric generators [1]. For this process, a vast area is needed for the establishment of drilling machines. When designing wells to be drilled by a drilling machine, reservoir depth, production pipe diameter, reservoir fluid type and features, and geologic and tectonic structures are of great importance. In geothermal drilling, the depth of the geothermal reservoir and the well diameter need to be chosen based on the capacity of the machine and pump. Wells that do not exceed 2000 m are considered shallow, and those above that depth are considered deep [5].

Drilling is a complex and expensive operation. To drill a geothermal well in an area, first, geological studies, geochemical analyses, and research via more than one geophysical method must be conducted. The drilling area must be designated as the most appropriate spot based on geological sections acquired from geological studies in the area. By laying a concrete foundation where the drilling machine will be placed, the stability of the drilling machine is ensured. As the depth of the well increases, risks increase too, in terms of drilling equipment and well security. Well diameter is important for that reason. When the diameter of the well is large, the success rate of well tests increases. Mud ponds need to be prepared, and mud quality must be determined; the well is observed through constant measurements of viscosity and temperature. In the wells at the production phase, pressure tests (decrease and increase), fluid production tests, water/steam ratio measurements and static and dynamic temperature tests are conducted [6].

Because of the constant shifting pattern from the time of construction to deconstruction, it is also known that the number and variety of occupational hazards that employees face are too high, and many involve various tasks and duties. Employees are exposed to various hazards that can cause many different accidents, such as cuts, falls, sprains, strains, and contact with hazardous chemicals. It is known these accidents may cause death and injuries, which would decrease the productivity of drilling operations.

Proactively predetermining all risks that might be posed in drilling operations is necessary for the sake of employees and for the continuity of drilling. Planning geothermal activities properly, using appropriate techniques, and taking necessary precautions not only reduce costs but also reduce environmental harm and unexpected accidents. Therefore, to determine criteria involved in this complex structure, and to measure and increase performance, fuzzy multi-criteria decision making is used, as the most appropriate method.

When the phases of pumping geothermal energy out of the ground are examined, occupational health and safety elements are seen to be involved in every step of the project, including worksite construction, artesian well production, and gas extraction and usage. Hence, 242 studies have been examined. Some of the studies carried out in Table 1 via multi-criteria decision-making (MCDM) methods in the field of OHS, particularly on risk analysis, are as follows:

Table 1.

Summary chart of literature review.

Even though there are a high number of studies in the field of risk assessment and performance measurement by multi-criteria decision-making methods in the literature, there are scarcely any studies in the field of occupational health and safety, especially on geothermal drilling areas. Moreover, there is no study on weighting occupational health and safety or risk assessment performances or making performance comparisons in geothermal drilling areas via multi-criteria decision-making methods. In this study, occupational health and safety performance factors in geothermal wells examined in the literature were studied by means of multi-criteria decision-making methods for the first time. This study integrated a model with results involving studies in the literature that measure OHS performance in drilling areas. Occupational health and safety vulnerability in drilling areas were determined, and a method providing performance development is provided.

2. Materials and Methods

The data received from the geothermal drilling area contain numerous criteria, so it was decided that multi-criteria decision-making methodologies would be used. Seven main criteria and forty-seven subcriteria obtained from the statistical study were weighted by the AHP method, one of the multi-criteria decision-making methodologies. The same process was performed using the F-AHP method. Criteria are listed in a table according to the order of importance.

Finally, the calculated weighting was evaluated by the Promethee method, and the OHS model was created and interpreted for geothermal wells.

2.1. Analytical Hierarchy Process

The analytical hierarchy process (AHP), suggested by Myers and Alpert in 1968 and developed as a model by Professor Thomas Lorie Saaty in 1977, is used to reach solutions to decision-making problems [35]. The AHP is a method that does not compel one to use a method for decision making; rather, it provides an opportunity to learn one’s own decision-making mechanisms and thus ensures that better decisions are made [36]. The AHP is an approach wherein the knowledge, experience, thoughts, and intuitions of individuals are combined in a logical framework [37]. Hence, the AHP is a mathematical method that takes the priorities of groups and individuals into consideration in decision making and evaluates qualitative and quantitative variables. This makes the AHP more substantial than other decision-making methods [38].

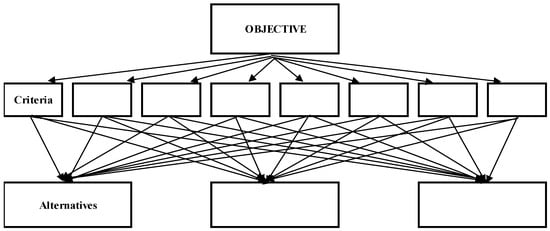

In the implementation phase of the AHP, first, the problem must be defined clearly and the objective in the problem must be determined. Starting with the objective, the main criteria, the subcriteria, and the lowest-level alternatives are established in a certain hierarchical structure. A hierarchical structure related to criteria and alternatives is constituted in accordance with the research topic, similar to the structure shown in Figure 2. The numbers of subfactors under each factor at the same level must be close to each other [39].

Figure 2.

General structure of the AHP hierarchy.

To determine the significance level in the relations between criteria and alternatives, pairwise comparisons between alternatives and criteria are made by decision makers. A square matrix in the dimension of a comparison matrix (n × n) is shown in Equation (1) below.

A: alternatives, a: binary comparison result, n: number of factors.

While making comparisons and forming matrices, the pairwise comparison scale shown in Table 2 is used.

To normalize each column in the pairwise comparison matrix, columns are added, and by dividing the matrix elements by the related column sum, a normalized matrix is formed. In the next step, by calculating the line sum of the normalized matrix formed for each alternative or criterion, a priority vector matrix is formed. Priority values determined for each criterion or alternative in the priority matrix formed via the priority vector are multiplied by column elements of the pairwise comparison matrix belonging to that particular criterion or alternative, and a weighted total matrix is obtained. The line value sum of the weighted total matrix is divided by the line values of the priority vector matrix, and the arithmetic mean of matrix elements formed in the (nx1) dimension is calculated, so the priority values of the criteria or alternatives are acquired. Priority values are calculated via the formula in Equation (2) [40].

W: relative level importance of i alternative to j criteria, n: number of factors, comparative importance of i alternative and j criterion.

In the final step, to determine whether pairwise comparisons of decision criteria and decision options of the decider are consistent, a consistency ratio is calculated. A low consistency ratio indicates that the decisions of the decider in the pairwise comparisons are consistent; a high ratio means that they are inconsistent. In the AHP method, a consistency value of up to 0.1 can be accepted. If this ratio is higher than 0.1, it is necessary for the decider to review his/her decisions in the pairwise comparisons again and repeat the steps [41]. While calculating the consistency index, the first CI value is determined [42].

2.2. Fuzzy Analytical Hierarchy Process

Even though the AHP method considers the information of experts, it cannot completely reflect uncertainties or fuzziness. Therefore, by combining fuzzy logic with the AHP, Fuzzy AHP (F-AHP) is formed. Unlike the AHP, where net values are used, comparison ratios in F-AHP are given in the range of a certain value [43]. The first study on Fuzzy AHP was conducted in 1983 by van Laarhoven and Pedrycz, who compared fuzzy ratios using triangle fuzzy numbers [44]. Buckley (1985) created a model using trapezoid fuzzy numbers [45]. In Buckley’s approach, the weightiness of measures is acquired, the performance of alternatives is designated, and the geometrical mean method in the fuzzy area is used. Considering this method, while the comparison matrix is being formed, as in the traditional AHP method, a part of the diagonal matrix is filled in, and the reverse of the assessment for the other part of the diagonal is conducted [46].

Fuzzy Logic: Mathematical interpretations of the real world are now more complex and therefore can be more widely applied. Rather than precise (crip) values of binary logic, looser, non-strict evaluations can take place. Fuzzy set theory is suggested to improve overly simplified models and thus analyze the complex systems of the real world [47]. The term “fuzzy” is used for situations where movement or observation sets do not have well-defined boundaries.

Hierarchical structures regarding criteria and alternatives are constituted in accordance with the research topic. Subfactor numbers under each factor at the same level must be close to each other [39].

After the step of constituting a hierarchy, criteria, subcriteria, and alternatives are evaluated via pairwise comparisons using linguistic terms. In Equation (3), a pairwise comparison matrix belonging to the expert is given [48].

A: result of matrix, a: fuzzy numbers

An indication of this equation via fuzzy numbers is given in Equation (4) [49].

A: result of matrix, (l, m, u): fuzzy numbers, n: number of factors.

Examples of linguistic scales used for qualitative evaluation in the literature are shown in Table 3.

After obtaining value judgments, a consensus matrix is acquired by taking expert weights into consideration. When there is more than one decider in an evaluation, a consensus matrix is obtained using Equation (5).

K: indicates the number of deciders, : fuzzy numbers.

To calculate the consistency of expert opinions, the consistency of comparison matrices needs to be calculated. Through the defuzzification of matrix elements in a fuzzy decision matrix, a pairwise comparison matrix is obtained. After sustaining the consistency of the pairwise comparison matrix, the step of weight calculation can follow. Fuzzy geometrical mean values for each line of each decision matrix are calculated [50].

2.3. The Promethee Method

The PROMETHEE method is a method of listing alternatives, which can be perceived and used easily by a decider. Six different functions can be used to evaluate criteria. Based on the nature of criteria, which one will be used is determined by the decider. Function types vary depending on the problem [51].

This method was developed by J. P. Brans in 1982, and first implementations were conducted in the same year. After two years, B. Mareschal and J. P. Brans improved the method, and, in their article published in 1985, put the program into its final form. In 1988, these authors proposed GAIA, a visual interaction module. Thanks to GAIA, it was possible to create detailed images regarding the results of problems solved via the PROMETHEE method [52]. The PROMETHEE method is widely and successfully used mostly because of its mathematical characteristics and practical usage [53].

Table 2.

Pairwise comparison scale [54].

Table 2.

Pairwise comparison scale [54].

| Intensity of Importance | Definitions | Explanation |

|---|---|---|

| 1 | Equally importance | Two activities contribute equally to the abjective |

| 3 | Modarate importance | Experience and judgement slightly favour one activity over another |

| 5 | Strong importance | Experience and judgement strongly favour one activity over another |

| 7 | Very strong or demonstrated importance | An activity is favour very strongly over another; its dominance demostrated in practice |

| 9 | Expreme importance | The evidance favouring one activity over another is of the highest possible order of affirmation |

| 2, 4, 6, 8 | For compromise between the above values | Sometimes one needsto interpolate a compromise justment numerically because there is no good word to |

Table 3.

The linguistic scale used for pairwise comparison [49].

Table 3.

The linguistic scale used for pairwise comparison [49].

| Saaty’s Relative Importance | Linguistic terms | Fuzzy Score |

|---|---|---|

| Cij = 1 | Equally important | (1,1,1) |

| Cij = 2 | Intermittent value between two adjesent scale | (1,2,3) |

| Cij = 3 | Weekly important | (2,3,4) |

| Cij = 4 | Intermittent value between two adjesent scale | (3,4,5) |

| Cij = 5 | Fairly important | (4,5,6) |

| Cij = 6 | Intermittent value between two adjesent scale | (5,6,7) |

| Cij = 7 | Strongly important | (6,7,8) |

| Cij = 8 | Intermittent value between two adjesent scale | (7,8,9) |

| Cij = 9 | Absolutaly important | (8,9,9) |

A data matrix is formed based on designated alternatives, criteria, criteria weights, and values acquired by alternatives regarding the related criteria. The data matrix on alternatives A = (a, b, c,…), evaluated by w = (w1, w2,…,wk) weights and criteria c = (f1, f2,…,fk), is formed, as shown in Table 4 [54].

Table 4.

Data matrix [53].

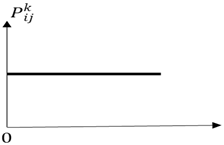

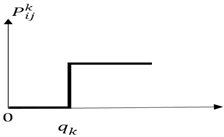

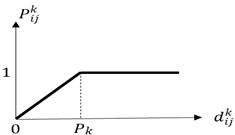

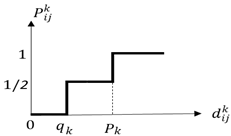

A choice function for the criteria is defined. Choice functions are determined in accordance with the nature of the criteria and the fundamental features of the alternatives. Six different choice functions used in the method are shown in Table 5 [55].

Table 5.

PROMETHEE choice functions [52].

Based on these choice functions, common choice functions are determined for alternative pairs [52].

P (a, b): preference function, f: alternatives.

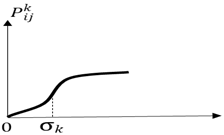

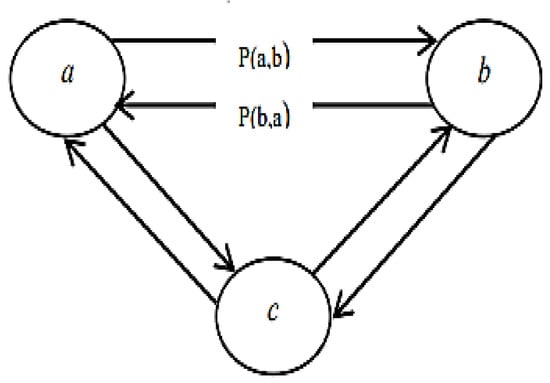

A schematic indication of common choice functions determined for alternatives is given in Figure 3. In the pairwise comparison of decision points, whether an evaluation factor has a maximization or minimization aspect is considered [52].

Figure 3.

Schematic indication of common choice functions [56].

Based on the common choice functions, choice indices are determined for each alternative pair. The choice index of alternatives a and b evaluated by criterion c with a weight of (i = 1, 2, …, k) is calculated by Equation (7) [54].

π: preference index, w: weight, i: criteria, P (a, b): preference function, and k: number of criteria.

Positive (+) and negative (−) superiority values are calculated by Equations (8) and (9) [54].

: superiority π: preference index, m: number of alternatives.

Partial priorities for alternatives are determined via Promethee 1. Partial priorities ensure the determination of the preference status of alternatives, the determination of alternatives that are no different from each other, and the determination of alternatives that are incomparable with each other.

There are three conditions in defining partial priorities for alternatives a and b [54].

If any of the conditions below are met, alternative a is preferred to alternative b and calculated by Equations (10)–(12) [54].

: superiority, or alternatives

If the condition given below is met, alternative a and b are no different and are calculated by Equation (13) [54].

: superiority, or alternatives

If any of the conditions below are met, alternative a cannot be compared with alternative b, and they are, respectively, calculated by Equations (14) and (15) [54].

: superiority, or alternatives

Whole priorities are calculated for each alternative. The total order is designated and calculated by Equation (16) [54].

: superiority, or alternatives

Based on the whole priority value calculated for alternatives a and b, the following decisions are made [54].

If , alternative a is superior, If , alternative a and b are no different.

: superiority,oralternatives

While sorting, a sequence starting from the alternative with a high index value to the alternative with a low index value is carried out. When index values are equal, there is no difference between/among alternatives [53].

3. Results

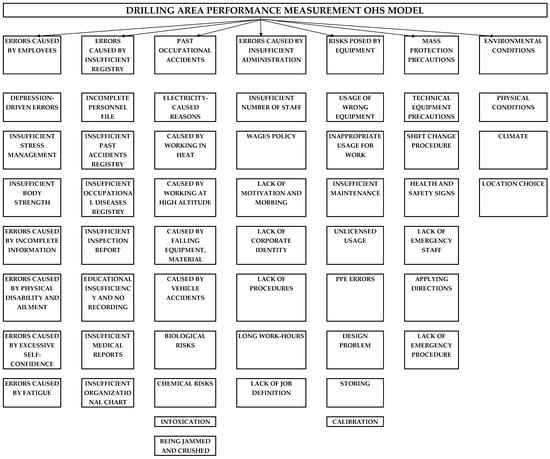

Proposal of Drilling Area Performance Measurement OHS Model

Taking the increase in renewable energy into consideration, an annotated chart and a hierarchic structure of criteria formed for drilling areas in the model proposed are given below. The main objective of the proposed index model is to find each determined criterion’s importance weight in the OHS performance. The process of defining the weight importance of criteria and subcriteria in the model proposed is as follows:

Step 1: To establish a decision-making team, criteria and subcriteria were determined by considering insufficiencies and basic concepts through a detailed literature review regarding the sector. The criteria determined and their definitions are shown in Table 6.

Table 6.

The criteria and descriptions of the performance index.

Step 2: A hierarchic building model is formed in Figure 4. In the hierarchical building model, the main criteria are shown at the highest level, and the subcriteria are shown at lower levels. Alternatives are not defined in the model because importance weights of drilling area alternatives for which criteria are determined will be designated by the Promethee method.

Figure 4.

The geothermal drilling hierarchical building model.

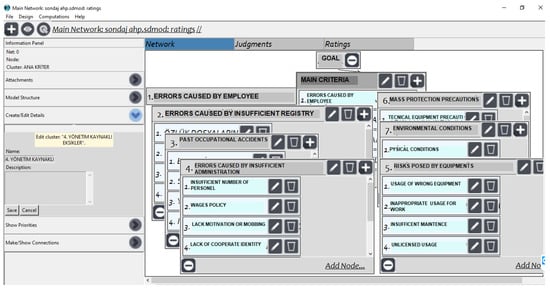

Step 3: The model formed was transformed into super-decision package software used for the AHP method. After providing relationship establishment among criteria in the program, pairwise comparison questionnaires on the designated criteria using a 1–9 Saaty scale were completed by eight engineers, three of whom were also occupational safety experts; they were asked to evaluate criteria related to drilling areas. While data were being input into the program, the geometrical mean of points obtained from experts was calculated.

Figure 5.

Model screenshot for hierarchical structure.

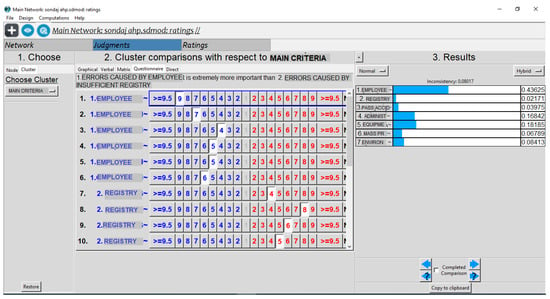

Figure 6.

Model screenshot for criteria weighting.

Step 4: After completing pairwise comparison questionnaires, the importance weight for each criterion was obtained. The consistency ratio was checked at each step. If it was higher than 0.10, the pairwise comparison conducted was revised and revaluated. Program screenshots for the consistency ratio is shown in Figure 7.

Figure 7.

Screenshot of the pairwise comparison survey.

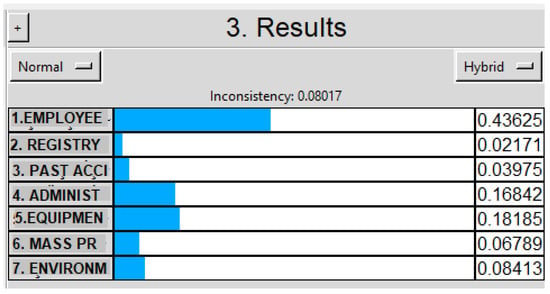

Step 5: The results of the evaluations yielded the importance weight of each designated criterion according to their OHS performance. Data belonging to the results are interpreted in Section 4.

Step 6: In the final step, the Visual Promethee program was used. Alternatives were requested from drilling supervisors of three geothermal drilling areas for which performance measurements were conducted. Taking criteria at the lowest level of each branch hierarchically into consideration, 47 subcriteria were input into the program, and the V-type was considered suitable as a choice function. Together with program outcomes, drilling area alternatives of those criteria were evaluated. Information regarding the results is explained in Section 4.

4. Discussion

Studies on multi-criteria decision-making methodologies and occupational health and safety in different sectors were examined. These studies have been examined and a framework for OHS performance modeling in geothermal energy fields has been established. The methodology and process of the four studies presented below were used.

Multi-criteria decision-making methods are the closest implementations to the ideal truth in answering multivariate questions. Through examining mostly studies conducted in the mining sector while designating multi-criteria decision-making methodologies, determining the required criteria for the designation of the most appropriate location in the mining fields and the mining method and also weighting the determined criteria have guided this article. In this way, the problems experienced in our country and other countries regarding occupational health and safety, especially in geothermal drilling fields, were compared and the criteria used in the study were reviewed [56]. Regarding the methods used, the AHP, F-AHP and PROMETHEE far outnumber the rest. Furthermore, through examining economic, environmental, and social dimensions of renewable energy in some OECD countries, the future significance of the sector was studied. In determining the locations of potential geothermal sources correctly, we also discussed which of the multi-criteria decision-making methodologies were used and why, and this contributed to our study [1,40]. Moreover, multi-criteria decision-making methods were used in order to study spatial distribution and spatial relationship among open geoscience data sets on a regional scale. It was observed that the AHP has been used for a long while as an essential method and is preferred since accurate results can be easily acquired thanks to programs such as Super Decision. Other methodologies used were F-AHP, PROMETHEE, Electre, TOPSIS, Fry Analysis, Data Envelopment and Weights of Evidence [39].

In the first step, the geometrical mean values of points obtained from all experts for each criterion were calculated via the AHP and F-AHP, and entry to the Super Decision program was carried out for the AHP. Fuzzy AHP calculations were conducted on Excel via Buckley F-AHP. Inconsistency ratios were checked. In the next step, the importance weight of each sub-criteria for OHS performance was acquired (Table 7).

Table 7.

According to the AHP method weights of the lower criteria of the geothermal drilling OHS performance index.

When Table 7 is examined, if the sequence is examined based on the weighting made by the AHP method, “Errors Caused By Fatigue” (0.170) is the first problem, while the F-AHP is in second place, “Errors Caused By Fatigue” (0.075). “Errors Caused By Incomplete Information” (0.088) and “Wage Policy” (0.066) rank second and third, while the F-AHP study does not appear in the first six weighting categories. “Errors Caused By Excessive Self-Confidence” (0.061) is in sixth place in the study with F-AHP. The “Lack Of Emergency Procedure” (0.046) ranks fifth and is not included in the F-AHP ranking. “Physical Conditions” (0.045) is in sixth place, and the F-AHP ranking (0.086) takes first place.

In the F-AHP methodology weighting study, “Lack Of Procedures” (0.067) takes third place, “Shift Change Procedure” (0.065) takes fourth place, and “Errors Caused By Physical Disability Additionally, Ailment” (0.060) takes fifth place. These three categories do not rank in the first six items in the AHP study.

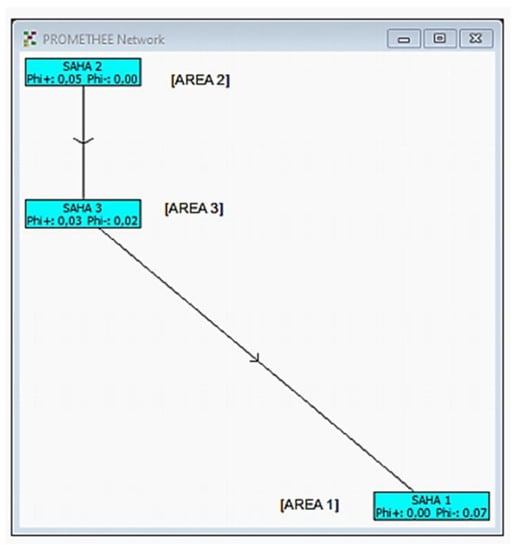

At the second step, for all criteria designated, geometrical mean values of scores obtained from all experts are calculated and put into the Visual Promethee program, and performance index results are obtained. Based on these results, partial sorting/sequencing is determined via PROMETHEE I. In the step with pairwise comparisons of positive and negative superiority values regarding decision points, three situations are likely to occur: the superiority of one decision point over another, a lack of difference between decision points, and incomparable decision points. In accordance with the criteria weights shown in Figure 8, there is a sequence from best to worst. According to PROMETHEE I, out of the three drilling areas, AREA 2 ranks first in terms of OHS criteria performance, followed by AREA 3 and AREA 1 in second and third, respectively.

Figure 8.

Sorted results calculated with PROMETHEE I.

5. Conclusions

Occupational accidents not only cause death and injuries. Invisible expenses are involved, including: labor loss, expertise loss together with experienced employees, compensations, various penalties, and insurance payouts. Hence, preventing accidents in every line of work requires research. It is economically and socially important to prevent accidents that might occur in the geothermal drilling of wells, which is one of the clean energy branches in the energy sector and is gradually gaining importance. Thus, it is necessary to conduct accurate analyses, use management systems, become knowledgeable about legislation, estimate risks beforehand, and understand how to work with equipment properly. It is important to apply occupational safety procedures according to standards such as OSHA and ISO45001. This paper covers and evaluates criteria and performance index proposals designated as a result of different studies on occupational health and safety in geothermal drilling areas. Table 7 shows that the weighting results of the AHP and fuzzy AHP subcriteria are similar. Errors caused by employees are frequent and include: fatigue, stress, a lack of physical strength, a lack of information, excessive self-confidence, wage policies, and an insufficient number of staff. The last two indirectly depend on the human factor. Following those, it is striking that errors caused by administration and insufficient mass protection precautions are also frequent. This emphasizes the importance of the spiritual, mental, and physical well-being of employees. It is clear that, along with being physically suitable for the work, the spiritual health of an employee is critical. In addition, occupational accidents in the past, the misuse of equipment and work machines, incorrect definitions of general protection measures, environmental conditions, location selection, PPE errors, vehicle accidents, chemical risk factors, and physical risk factors should also be considered in terms of occupational health and safety. In fact, there are human-induced risk factors influencing these factors. Mass protection precautions to be taken by administration and procedures to be implemented need to be studied further. Drilling works are continuous from beginning to end. It is important to financially satisfy working staff who are far from their homes and engaging in physically demanding work for long periods of time, to encourage them to pay attention to working hours, and to satisfy them spiritually by taking stress, depression, and fatigue criteria into consideration. In this regard, supportive actions from the Ministry of Energy and the Ministry of Labor and Social Security can be increased.

While we only expected this work to serve as a basis for the preparation of a risk assessment suitable for the sector, this study is considered to be significant not only for drilling areas through its OHS performance index model proposal, which provides an evaluation of performance measurement, but also in other sectors as well in terms of solving and clarifying obscurities and answering questions.

To conclude, drilling operations involve many complex elements, and elements originating from the work of human beings are also complex and important for drilling areas. Through a consideration of employee-based occupational health and security systems in economic, social, and ecologic dimensions, problems regarding health and sustainability can be overcome.

Author Contributions

Ş.K.T.: Conceptualization, methodology, software, validation, formal analysis, investigation, resources, data curation, writing—original draft preparation, and writing—review. I.E.: review and editing, supervision. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Ethics Committee or Institutional Review Board approval not be required for this manuscript, because we did not conduct surveys, experiments, etc. in obtaining data We used only occupational health and safety criteria data that was prepared by the us for Geothermal Drilling Areas. I would like to inform you that, in our study, multi-criteria decision-making methods were implemented with the opinions and assistance of only 8 experts in the Geothermal Drilling Areas of Turkey, no survey-like studies or tests have been conducted with any employee or official; all of the remaining calculations and analysis have been made by the authors. In our study we only used data belonging to the Geothermal Drilling Areas of Turkey, it does not belong anywhere else.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of the data, in the writing of the manuscript; or in the decision to publish the results.

Abbreviations

| AHP | assessment of the proportion effect |

| F-AHP | fuzzy analytical hierarchy process |

| MCDM | multi-criteria decision-making |

| OHS | occupational health and safety |

| GRA | gray relational analysis |

| ANP | analytic network process |

| GAIA | a preference ranking organization method |

| TFN | triangular fuzzy numbers |

References

- Kara, S.E.; Ibrahim, M.D.; Daneshvar, S. Dual Efficiency and Productivity Analysis of Renewable Energy Alternatives of OECD Countries. Sustainability 2021, 13, 13. [Google Scholar]

- Sher, F.; Curnick, O.; Azizan, M.T. Sustainable Conversion of Renewable Energy Sources. Sustainability 2021, 13, 2940. [Google Scholar] [CrossRef]

- REN21. Renewables 2022 Global Status Report; REN21: Paris, France, 2022. [Google Scholar]

- Ellsworth, W.L.; Giardini, D.; Townend, J.; Ge, S.; Shimamoto, T. Triggering of the Pohang, Korea, Earthquake (Mw 5.5) by enhanced geothermal system stimulation. Seismol. Res. Lett. 2019, 90, 1844–1858. [Google Scholar] [CrossRef]

- Toka, B. Derin Jeotermal Sondajlarda Kuyu Tasarimi Ve Sondaj Makineleri İçin Takim Dizisi Seçimi; MTA Sondaj Dairesi: Ankara, Turkey, 2011. [Google Scholar]

- Türkiye Jeotermal Enerji Potansiyeli Ve Arama Çalişmalari. Available online: https://www.mta.gov.tr/v3.0/arastirmalar/jeotermal-enerji-arastirmalari (accessed on 21 August 2022).

- Law, W.K.; Chan, A.H.S.; Pun, K.F. Prioritising the safety management elements: A hierarchical analysis for manufacturing enterprises. Indust. Manag. Data Syst. 2006, 106, 778–792. [Google Scholar] [CrossRef]

- Chang, J.I.; Liang, C. Performance evaluation of process safety management systems of paint manufacturing facilities. J. Loss Prev. Process Indust. 2009, 22, 398–402. [Google Scholar] [CrossRef]

- Grassia, A.; Gamberinia, R.; Morab, C.; Riminia, B. A fuzzy multi-attribute model for risk evaluation in workplaces. Saf. Science. 2009, 47, 707–716. [Google Scholar] [CrossRef]

- Hua, H.; Hsu, C.; Kuo, T.; Wu, W. Risk evaluation of green components to hazardous substance using FMEA and FAHP. Expert Syst. Appl. 2009, 36, 7142–7147. [Google Scholar] [CrossRef]

- Beriha, G.S.; Patnaik, B.; Mahapatra, S.S.; Sreekumar. Occupational health and safety management using grey relational analysis: An Indian perspective. Int. J. Indian Cult. Bus. Manag. 2011, 4, 298–324. [Google Scholar] [CrossRef]

- Janackovic, G.L.; Savic, S.M.; Stankovic, M.S. Selection and ranking of occupational safety indicators based on fuzzy AHP: A case study in road construction companies: Case study. S. Afr. J. Ind. Eng. 2013, 24, 175–189. [Google Scholar] [CrossRef]

- Mahdevari, S.; Shahriar, K.; Esfahanipour, A. Human health and safety risks management in underground coal mines using fuzzy TOPSIS. Sci. Total Environ. 2014, 488–489, 85–99. [Google Scholar] [CrossRef]

- Kısa, Y. Döküm Atölyelerindeki İş Sağliği Ve Güvenliği Koşullarinin Çok Ölçütlü Karar Verme Yöntemleriyle Değerlendirilmesi; T.C. Çalişma Ve Sosyal Güvenlik Bakanliği İş Sağliği Ve Güvenliği Genel Müdürlüğü: Ankara, Türkiye, 2014. [Google Scholar]

- Özdemir, B. Tekstil Atölyelerinde İş Sağliği Ve Güvenliği Koşullarinin Çok Ölçütlü Karar Verme Yöntemiyle Değerlendirilmesi; T.C. Çalişma Ve Sosyal Güvenlik Bakanliği İş Sağliği Ve Güvenliği Genel Müdürlüğü: Ankara, Türkiye, 2014. [Google Scholar]

- Podgórski, D. Measuring operational performance of OSH management system—A demonstration of AHP-based selection of leading key performance indicators. Safety Sci. 2015, 73, 146–166. [Google Scholar] [CrossRef]

- Guneri, A.F.; Gul, M.; Ozgurler, S. A fuzzy AHP methodology for selection of risk assessment methods in occupational safety. Indersci. Online 2015, 18, 319–335. [Google Scholar] [CrossRef]

- Djapan, M.J.; Tadic, D.P.; Macuzic, I.D.; Dragojovic, P.D. A new fuzzy model for determining risk level on the workplaces in manufacturing small and medium enterprises. Sage J. 2015, 229, 5. [Google Scholar] [CrossRef]

- Vahdani, B.; Salimi, M.; Charkhchian, M. A new FMEA method by integrating fuzzy belief structure and TOPSIS to improve risk evaluation process. Int. J. Adv. Manuf. Technol. 2015, 77, 357–368. [Google Scholar] [CrossRef]

- Liu, H.; You, J.; You, X.; Shan, M. A novel approach for failure mode and effects analysis using combination weighting and fuzzy VIKOR method. Appl. Soft Comput. 2015, 28, 578–588. [Google Scholar] [CrossRef]

- Khalil, N.; Kamaruzzaman, S.N.; Baharum, M.R. Ranking the indicators of building performance and the users’ risk via Analytical Hierarchy Process (AHP): Case of Malaysia. Ecol. Indicators 2016, 71, 567–576. [Google Scholar] [CrossRef]

- Delice, E.K.; Zegerek, S. Ranking Occupational Risk Levels of Emergency Departments Using a New Fuzzy MCDM Model: A Case Study In Turkey. Appl. Math. Inf. Sci. 2016, 10, 2345–2356. [Google Scholar] [CrossRef]

- Yerlikaya, M.A.; Efe, B.; Efe, Ö.F. İş Güvenliğinde Bulanık Promethee Yöntemiyle Hata Türleri ve Etkilerinin Analizi: Bir İnşaat Firmasında Uygulama. Gümüşhane Üniversitesi Fen Bilim. Dergisi. 2016, 6, 126–137. [Google Scholar] [CrossRef][Green Version]

- Şenol, M.B.; Yılmaz, B. İş Sağliği Ve Güvenliği Risk Değerlendirme Süreci İçin Bulanik Çok Kriterli Bir Model Ve Uygulamasi. Gazi Üniversitesi Mühendislik Mimar. Fakültesi Dergisi. 2017, 32, 1. [Google Scholar]

- Raviv, G.; Shapira, A.; Fishbain, B. AHP-based analysis of the risk potential of safety incidents: Case study of cranes in the construction industry. Saf. Sci. 2017, 91, 298–309. [Google Scholar] [CrossRef]

- Gul, M.; Ak, M.F.; Guneri, A.F. Occupational health and safety risk assessment in hospitals: A case study using two-stage fuzzy multi-criteria approach. Hum. Ecol. Risk Assess. Int. J. 2017, 23, 187–202. [Google Scholar] [CrossRef]

- İnan, U.H.; Gül, S.; Yılmaz, H. A multiple attribute decision model to compare the firms’ occupational health and safety management perspectives. Saf. Sci. 2017, 91, 221–231. [Google Scholar] [CrossRef]

- Kokangül, A.; Polat, U.; Dağsuyu, C. A new approximation for risk assessment using the AHP and Fine Kinney methodologies. Saf. Sci. 2017, 91, 24–32. [Google Scholar] [CrossRef]

- Öztürk, Z.K.; Toptanci, Ş. An Integrated MCDM Model for Occupational Safety Specialist Selection. İşletme Araştırmaları Dergisi. 2017, 9, 419–435. [Google Scholar]

- Efe, B.; Efe, Ö.F.; Kurt, M. An Integrated Intuitionistic Fuzzy Set And Mathematical Programming Approach For An Occupational Health And Safety Policy. Gazi Univ. J. Sci. 2017, 30, 73–95. [Google Scholar]

- Liu, H.; Wang, L.; You, X.; Wu, S. Failure mode and effect analysis with extended grey relational analysis method in cloud setting. Total Qual. Manag. Bus. Excell. 2017, 30, 745–767. [Google Scholar] [CrossRef]

- Ediz, A.; Yıldızbaşı, A.; Baytemur, E. İş Sağlığı Ve Güvenliği Yönetim Sistemi Performans Göstergelerinin AHP Ile Değerlendirilmesi. J. Acad. Soc. Sci. Stud. 2017, 62, 275–294. [Google Scholar]

- Janackovic, G.; Stojiljkovic, E.; Grozdanovic, M. Selection of key indicators for the improvement of occupational safety system in electricity distribution companies. Saf. Sci. 2020, 125, 103654. [Google Scholar] [CrossRef]

- Ilbahar, E.; Karaşan, A.; Cebi, S.; Kahraman, C. A novel approach to risk assessment for occupational health and safety using Pythagorean fuzzy AHP & fuzzy inference system. Saf. Sci. 2018, 103, 124–136. [Google Scholar]

- Islam, R.; Saaty, T.L. The analytic hierarchy process in the transportation sector. Lect. Notes Econ. Math. Syst. 2010, 634, 79–91. [Google Scholar]

- Saaty, T.L.; Vargas, L.G. Uncertainty and rank order in the analytic hierarchy process. Eur. J. Oper. Res. 1987, 32, 107–117. [Google Scholar] [CrossRef]

- Chin, K.S.; Chiu, S.; Rao Tummala, V.M. An evaluation of success factors using the AHP to implement ISO 14001-based EMS. Int. J. Qual. Reliab. Manag. 1999, 16, 341–361. [Google Scholar] [CrossRef]

- Min, H. Location analysis of international consolidation terminals using the analytic hierarchy process-ProQuest. J. Bus. Logist. 1994, 15, 25. [Google Scholar]

- Moghaddam, M.K.; Samadzadegan, F.; Noorollahi, Y.; Sharifi, M.A.; Itoi, R. Spatial analysis and multi-criteria decision making for regional-scale geothermal favorability map. Geothermics 2014, 50, 189–201. [Google Scholar] [CrossRef]

- Meng, F.; Liang, X.; Xiao, C.; Wang, G. Geothermal resource potential assessment utilizing GIS-based multi criteria decision analysis method. Geothermics 2021, 89, 101969. [Google Scholar] [CrossRef]

- Saaty, T.L. Highlights and critical points in the theory and application of the Analytic Hierarchy Process. Eur. J. Oper. Res. 1994, 74, 426–447. [Google Scholar] [CrossRef]

- Janjic, A.; Savic, S.; Janackovic, G.; Stankovic, M.; Velimirovic, L. Multi-Criteria Assessment of the Smart Grid Efficiency Using the Fuzzy Analytic Hierarchy Process. Facta Univ.-Ser. Electron. Energetics 2016, 29, 631–646. [Google Scholar] [CrossRef]

- Ertuğrul, İ. Electre ve Bulanık AHP Yöntemleri ile Bir İşletme İçin Bilgisayar Seçimi. Dokuz Eylül Üniversitesi İktisadi İdari Bilim. Fakültesi Derg. 2010, 25, 23–45. [Google Scholar]

- van Laarhoven, P.J.M.; Pedrycz, W. A fuzzy extension of Saaty’s priority theory. Fuzzy Sets Syst. 1983, 11, 229–241. [Google Scholar] [CrossRef]

- Chang, D.Y. Applications of the extent analysis method on fuzzy AHP. Eur. J. Oper. Res. 1996, 95, 649–655. [Google Scholar] [CrossRef]

- Buckley, J.J. Fuzzy hierarchical analysis. Fuzzy Sets Syst. 1985, 17, 233–247. [Google Scholar] [CrossRef]

- Paksoy, T.; Atak, M. Etkileşimli bulanık çok amaçlı doğrusal programlama ile bütünleşik üretim planlama: Hidrolik pompa imalatçısı firma örnek olayı. Gazi Üniversitesi Fen Bilim. Enstitüsü Derg. 2002, 15, 457–466. [Google Scholar]

- Mukherjee, K.; Sarkar, B.; Bhattacharyya, A. Supplier selection by F-compromise method: A case study of cement industry of NE India. Int. J. Comput. Syst. Eng. 2014, 17, 162–174. [Google Scholar] [CrossRef]

- Onay, A.; Karamaşa, Ç.; Saraç, B. Application of Fuzzy AHP in Selection of Accounting Elective Courses in Undergraduate and Graduate Level. J. Account. Financ. Audit. Stud. 2016, 2, 20–42. [Google Scholar]

- Göksu, A. Bulanik Analitik Hiyerarşik Proses Ve Üniversite Tercih Siralamasinda Uygulanmasi. Süleyman Demirel Üniversitesi İktisadi Ve İdari Bilim. Fakültesi Derg. 2008, 13, 1–26. [Google Scholar]

- Brans, J.-P.; Vincke, P. A Preference Ranking Organisation Method. Manag. Sci. 1985, 31, 647–656. [Google Scholar] [CrossRef]

- Brans, J.-P.; Mareschal, B. The PROMETHEE Methods for MCDM; the PROMCALC, GAIA and BANKADVISER Software. In Readings in Multiple Criteria Decision Aid; Springer: Berlin/Heidelberg, Germany, 1990; pp. 216–252. [Google Scholar]

- Korkusuz, A.Y.; İnan, U.H.; Özdemir, Y.; Başlıgil, H. Occupational health and safety performance measurement in healthcare sector using integrated multi criteria decision making methods. J. Fac. Eng. Archit. Gazi Univ. 2020, 35, 81–96. [Google Scholar]

- Nebati, E.E.; Ekmekçi, İ. Alışveriş Merkezleri İçin Yeşil Bina Performans Ölçüm Model Önerisi (Proposal of Green Building Performance Measurement Model for Shopping Malls). Gazi Mühendislik Bilim. Derg. 2018, 4, 241–255. [Google Scholar]

- Brans, J.-P.; De Smet, Y. PROMETHEE methods. In Multiple Criteria Decision Analysis; International Series in Operations Research and Management Science; Springer: New York, NY, USA, 2016; Volume 233, pp. 187–219. [Google Scholar]

- Bogdanovic, D.; Nikolic, D.; Ivana, I. Mining method selection by integrated AHP and PROMETHEE method. An. Acad. Bras. Cienc. 2012, 84, 219–233. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).