Abstract

Enterprise Resource Planning (ERP) plays a vital role in an organization’s growth and sustainability in the supply chain. ERP implementations have a mix of critical success factors (CSFs) that are very important. Hence, it is essential to study the CSFs, their mutual influence and their severity in terms of prioritization for the I4.0. The goal of the current study is to identify CSFs for ERP implementations, as well as their interdependence and ranking. The CSFs of ERP deployment were discovered by a thorough analysis of the literature and subsequent input from a group of subject matter experts. Using the interpretive structural modeling (ISM) method, the shortlisted CSFs were modeled, and after that, the matrice d’ impacts croises multiplication appliqué an classement (MICMAC) analysis was used to classify them. The interpretative ranking technique was used to carry out the subsequent prioritization and ranking (IRP). In the present research, the modeling of CSFs for successful ERP implementations was carried out to accomplish much-needed sustainability in the supply chain. The result revealed the three top-ranked CSFs for successful ERP implementations: “Top management support”, “Change management” and “Business process reengineering.” This research can help practicing managers prepare an ERP implementation plan to accomplish sustainability in SCM. Each CSF’s role can be studied in terms of the mutual relationships for its control. This research can also help in prioritizing strategies for optimizing the resources required for ERP implementations.

1. Introduction

Supply Chain 4.0, commonly referred to as “digital supply chain (DSC)”, was introduced along with Industry 4.0 (I4.0) for manufacturing. A digital transformation of supply chain management (SCM) is vital to I4.0. Enhanced ERP influences firm performance through green SCM, supplier integration and internal integration []. The effect of ERP was investigated and found to be positively associated with firm performance through information quality and supply chain integration []. An Indonesian study investigated the ERP benefits of practicing green SCM and found encouraging results in enhanced operational performance []. A study based on feedback from ERP experts of Taiwanese IT firms showed that ERP benefits SCM, which leads to SCM’s competitive advantages []. A Turkish study investigated the impact of ERP and SCM practices to reveal a positive influence on business performance [].

A packaged or customized software-based system known as an enterprise resource planning (ERP) system is used by an organization to manage the optimal use of resources (7M = men, machines, materials, methods, money, management and matrix) through the use of a total integrated information-processing system. For businesses in I4.0 to compete in a volatile and intensely competitive business climate, ERP systems have become essential []. Today, it has become the foundation of effective information management and the backbone of businesses. It also plays a vital role in an organization’s growth and sustainability []. In many cases, it is difficult for organizations to integrate various organizational functions in order for a correct decision to be taken. In such a situation, ERP can manage company-wide information systems that can facilitate sound decision making for organizational sustainability []. Eleven economic performance indicators, nine social performance indicators and twelve environmental performance indicators were identified by reviewing the literature on sustainability indicators for ERP adoption []. An ERP system’s selection and deployment are not only expensive but also difficult and time consuming, frequently going over budget while being installed []. The ERP selection and implementation process involves the careful study of business processes, ERP software availability and ERP software configurations to deliver the best employee training and customization. The basic difference between present and future ERP evolution is that sustainability is infused into it. Sustainable ERP (S-ERP) is a necessity today, as many organizations struggle to maintain much-needed sustainability to survive and compete in local and global markets. Due to automatically receiving data from the source, cloud computing and big data technologies greatly enhance ERP software capabilities []. The latest developments in the ERP domain are cloud S-ERP systems. Figure 1 shows the present and future ERP evolution.

Figure 1.

Present and future ERP evolution for I4.0.

Amending ERP should take care of imbibing new technologies, such as the Internet of Things (IoT), big data analytics (BDA), Artificial intelligence (AI), radio frequency identification (RFID)-based data and cloud computing (CC) []. ERP systems may be employed to accomplish many organizational activities. Various ERP applications may be found in organizational management, such as in business intelligence, commercial activities, etc. ERP can help streamline and automate a variety of business-related procedures. It can also share data and the best practices with the rest of the company to enable efficient decision making through real-time information access []. The ERP system was shown to considerably increase productivity, efficiency and service quality, as well as to reduce service costs and promote improved decision making []. ERP consists of various modules that can be used as a whole or that can be customized to suit particular organizational activities as well. The ERP system needs to be integrated properly into the user’s department or with suppliers to avoid silos. ERP systems used for business intelligence may cover order forecasting, such as in customer service management (CRM) and operational excellence. The ERP system used for commercial applications in an organization may help with production planning, sales, financial planning marketing, etc. The ERP system may also be used for the organizational management of human resource activities, corporate responsibility, vendor management, governance, etc. ERP can also be used in part in the form of modules. It may be further customized to serve customized activities such as life cycle assessment, corporate and product sustainability, and product management.

A case study based on qualitative methods was employed to investigate the CSFs of ERP implementation in two organizations in developing countries []. The scope of the study was limited to ‘medium-sized’ organizations. The review-based study involving qualitative and interpretive research methods was conducted to examine the criticality of CSFs []. The scope of the study was constrained by the limited empirical studies investigating and confirming the role and effect on performance outcomes. A qualitative comparative study was carried out to compare the CSFs for implementing enterprise portals for ERP implementations. The study was constrained due to the sample size []. A literature review process, along with analysis and synthesis, was carried out to identify the CSFs based on 37 case studies []. The study was limited to case studies only. A study on ERP upgrades was conducted, employing a literature review and qualitative interviews with chief executive officers []. The study used qualitative data to devise a framework to find CSFs []. A total ISM and MICMAC-based study was conducted to model the interrelationships of ERP []. A similar methodology was employed along with principal component analysis (PCA) for supply chain sustainability in the wood industry []. Considering the various approaches used in CSF identification and relationship modeling, a comprehensive method is warranted. Furthermore, ERP implementation projects have reported a high failure rate, jeopardizing organizations’ core activities, so there is a significant challenge in ERP implementation. Therefore, there is a need for more studies [].

The following research questions are addressed in the current study: (a) What are the key CSFs for successful ERP implementations for SCM sustainability? (b) How do the CSFs influence each other while contributing to ERP success? and (c) What are the rankings of these CSFs? The research is provided in various sections, as shown below: The literature review in Section 2 identifies the CSFs of ERP implementation. Additionally, it gives a brief overview of each CSF for ERP implementations. Section 3 discusses several ISM, MICMAC and IRP research approaches. Section 4 presents various findings from the application of research approaches to CSF identification and ERP deployment. A comprehensive discussion of the current research is provided in Section 5. Section 6 provides the results, limitations of the present study and recommendations for future research.

2. Literature Review

An ERP system that can capture data for sustainable SCM is needed. ERP systems are considered the backbone of I4.0 []. The ERP system is a well-established communication system for creating values for sustainable SCM []. A study leading to sustainable SCM through ERP was conducted using a model of sustainable computing []. An SEM model based on an empirical study confirmed the ERP benefits to firm competencies in supply chain management []. ERP adaptability towards imbibing several Wi-Fi-enabled technologies, such as BDA, AI, RFID, IoT, etc., for sustainability in automotive SCM was studied using an empirical analysis []. The identification of CSF for ERP selection and deployment has been thoroughly researched by numerous academics. Organizations need a sustainable ERP that can meet the present and future needs of organizational sustainability []. A case study was undertaken for the selection of ERP to meet the growing high-tech demands for its growth and sustainability []. An analysis of the sustainability metrics necessary for a sustainable ERP system was conducted []. A detailed examination of CSFs is required in light of the high failure rate of ERP deployment to achieve success []. A primary investigation into successful CSF deployments was conducted []. A relationship model among CSF in ERP implementations using the total ISM and MICMAC approaches was carried out [].

The study was carried out to compare the impact of CSFs on ERP implementation in developing countries with that of developed countries []. The study was undertaken to investigate CSFs across 10 different countries or regions []. Numerous studies identifying and researching CSFs for the deployment of ERP systems can be found in the literature. Table 1 includes a list of a few such studies.

Table 1.

ERP implementation in CSF-based studies.

It is evident from the review of the literature that ERP implementation has not been successfully implemented in many cases to accomplish sustainable SCM. According to [], 96.4% of ERP implementations have failed. Similarly, an ERP implementation failure rate of 70% was reported as not achieving its intended purpose []. Apart from many studies identifying the CSF of ERP implementations, there are several studies investigating various stages of ERP implementation. The ERP implementation process was categorized into six stages of implementation [,].

According to a thorough analysis of the literature on ERP implementation, CSFs are crucial to the success of ERP systems. It is important to comprehend how CSF organizations are related to one another; therefore, practicing managers of I4.0 can effectively assess them and put them into practice in their organizations. Thus, there is a need for the present research to bridge the gap that exists in the mutual relationship modeling of CSFs and their ranking.

3. Research Methodology

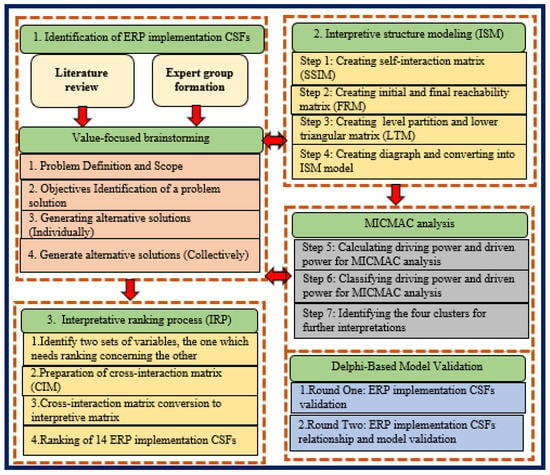

The three phases of the current research methodology are shown in Figure 2.

Figure 2.

Research methodology.

Each phase is further explained as follows:

Phase 1 discusses identifying the CSFs of ERP implementation for sustainable SCM. The CSFs of ERP deployment can be determined by performing a thorough analysis of the literature. The most relevant ERP CSFs are chosen from the databases of scientific research with the aid of an extensive literature analysis with targeted keywords. The collected literature on CSFs of ERP implementation through such a process may be further filtered using additional steps of segregation, shortlisting and grouping. The identified CSFs may be accepted or eliminated based on their significance, level of applicability to the case, academic or industry relevance, timeline, relevance to technology, general acceptability, etc. By utilizing an expert group, the essential CSF may be filtered using conventional brainstorming or value-focused brainstorming methodologies. Value-focused brainstorming can be used to generate higher-quality solution alternatives for difficult decision making [,]. The value-focused brainstorming process has four steps: (i) identifying the problem; (ii) identifying the goals for a solution to the problem; (iii) finding alternative solutions (individually); and (iv) identifying alternative solutions (collectively).

Phase 2 explains the modeling techniques of ISM and MICMAC that are used to evaluate the CSFs of ERP implementation. A structural self-interaction matrix (SSIM) can be produced using the ISM model, which also displays contextual linkages. It also aids with creating initial and final reachability and conical matrices. The matrix formation process ultimately leads to a digraph and an ISM model. The following steps make up the ISM and MICMAC methodologies: Step 1: Create an SSIM; Step 2: Create an initial and final reachability matrix; Step 3: Determine the level partition and the lower triangular matrix; Step 4: Prepare the digraph and convert it to an ISM model; Step 5: Prepare the MICMAC analysis by calculating driver-driven power; Step 6: Group driving power and dependability for the MICMAC analysis; and Step 7: Generate four groups for further inference. The SSIM may be created by considering the contextual relationship between two CSFs to identify their possible dependence on each other to develop meaningful dependency or independency. Let ‘p’ and ‘q’ be considered ERP CSFs. The relationship between these two ERP CSFs, ‘p’ and ‘q’, has the following rules: If CSF ‘p’ drives or influences CSF ‘q’, the relationship is denoted by ‘V’. If CSF ‘q’ drives or influences CSF ‘p’, ‘A’ is used. When CSF ‘p’ and CSF ‘q’ influence each other, ‘X’ is used, and if CSF ‘p’ and CSF ‘q’ do not influence each other, ‘O’ is used. The SSIM is produced by applying the ISM methodological steps to generate contextual relationships among CSFs. The SSIM is thus prepared based on the contextual relationships among CSFs suggested by the expert group. The initial reachability matrix (IRM) is further subjected to the use of binary digits ‘1′ and ‘0′ using the specified conditions. The various conditions for deciding to replace ‘V’, ‘A’, ‘X’ and ‘O’ with ‘1′ and ‘0′ are as follows: (i) if the SSIM’s (p, q) entry is ‘V’, the reachability matrix’s (p, q) entry becomes 1, and the (q, p) entry becomes 0; (ii) if the SSIM’s (p, q) entry is ‘A,’ the reachability matrix’s (p, q) entry becomes 0, and the (q, p) entry similarly becomes 1; (iii) if the SSIM’s (p, q) entry is ‘X’, the reachability matrix’s (p, q) entry similarly becomes 1, and the (q, p) entry similarly becomes 1; and (iv) if the SSIM’s (p, q) entry is ‘O’, the reachability matrix’s (p, q) entry similarly becomes 0, and the (q, p) entry similarly becomes 0.

The SSIM is converted into a reachability matrix using binary digits ‘0′ and ‘1′. The final reachability matrix also takes care of the prevailing transitivity. Transitivity may be explained as follows: if CSF ‘p’ > CSF ‘q’ and CSF ‘q’ > CSF ‘r’, then CSF ‘p’ > CSF ‘r’, wherein “>” provides a degree of influence. The reachability element and antecedent element for each CSF are accomplished through the final reachability matrix (FRM). It includes the CSF itself and another CSF that helps it. The antecedent elements have their elements as well as another enabler that influences them. The various elements of the iterative process are derived using the intersection between them. When the intersection satisfies these requirements, the identified CSF is placed at the top, and the enabler is excluded from further consideration for identifying the influence. The process is repeated until all CSFs are classified. Thus, using the FRM, the structural model is developed. Subsequently, a digraph may be formulated by ignoring the transitivity. A lower triangular matrix (LTM) may be used to obtain the digraph. The digraph shows a directed graph that provides a detailed understanding of each CSF.

The MICMAC diagram is prepared using the driving and dependent variables of each CSF. A systematic classification of CSFs can be obtained using this methodology. It provides a good method to further investigate the relative significance of each CSF of ERP implementation. MICMAC analysis categorizes the CSFs of ERP implementation into four groups: autonomous, dependent, linkage and independent. Furthermore, it provides an opportunity to carry out cluster analysis.

Phase 3 employs the interpretive ranking process (IRP) to rank the CSFs of ERP implementation []. IRP uses an interpretative matrix along with a paired comparison matrix. The chance of judgmental bias in decision making may exist, which poses difficulty with arriving at a fair decision in the presence of complicated hierarchies. Such judgmental bias may become involved in decision making while using the analytic hierarchy process (AHP). The use of IRP can eliminate such judgmental biases present in AHP. Furthermore, the IRP process also uses interpretive logic that provides dominance among the CSFs for its correct comparison. Furthermore, IRP does not demand dominant information while performing such a comparison. Thus, IRP provides a systematic ranking of the CSFs of ERP implementation based on their influence. The general IRP methodical steps are documented in the literature [,,,]. These steps are (i) determination of two sets of variables, one of which needs ranking in relation to the other. Here, the CSFs of ERP implementation are ranked; (ii) the creation of a cross-interaction matrix between ERP implementation CSFs and performance indicators; (iii) the conversion of the cross-interaction matrix to an interpretive matrix; (iv) the formation of a pairwise comparison based on the interpretive matrix to obtain the dominating interactions matrix; and (v) the ranking of ERP implementation CSFs and the subsequent exploration of dominance and rank.

4. Results

The following results are drawn from each phase:

4.1. Phase 1

Phase 1 helped with the identification of CSFs for ERP implementation. A systematic review employing the keywords “CSFs of ERP implementation”; “Enablers of ERP implementation”; “Factors for ERP implementation”; and “Drivers of ERP implementation” was carried out. The authors searched for and reviewed articles in several databases, including ScienceDirect, Web of Science and Scopus. Further filtering was performed on the ERP implementation CSFs that were collected. Fourteen of the most relevant CSFs for ERP implementation were identified. The CSFs were determined based on their importance, level of applicability to the case issue and influence over other CSFs of ERP deployment. An expert group of eleven decision makers, including four ERP consultants belonging to the information technology (IT) domain and seven academicians from the information systems group, was invited. In their respective fields, each expert had more than five years of working experience. All working professionals from the industry and academicians held a graduate degree in information systems or information technology. A brief group meeting was convened to outline the goals of the current study. All experts voluntarily decided to participate following a brief group meeting. Seven academicians and all four consultants volunteered to take part in the current study with the full freedom and flexibility to leave the study at short notice. This expert group’s development was consistent with prior research of a similar nature [,]. The relevant literature on the CSFs of ERP implementation was distributed among the expert group. Additionally, a briefing on the study’s objectives and prospective research methodologies was provided. Various methods of ‘identifying by literature review’, ‘evaluation by experts’ or ‘brainstorming’ for identifying the CSFs of ERP implementation were discussed. It was further agreed upon to shortlist the CSFs of ERP implementation using the value-focused brainstorming method [] by deploying an identified expert group.

Brainstorming techniques play a significant role in shortlisting CSFs from a pool of CSFs []. Thus, in the present study, value-focused brainstorming was deployed to identify the CSFs of ERP implementation. Two sessions of value-focused brainstorming were conducted over fifteen days. The first session was the introductory mock round, conducted following the ‘Dos’ and ‘Do nots’ for encouraging a creative environment and avoiding criticism. The seventeen CSFs of ERP implementation were reduced to fourteen based on their relevance at the end of the second session.

In the current study, the fourteen CSFs of ERP deployment were discussed for their applicability. The group of experts found that three CSFs of ERP implementation—enough resources, software development, and cultural change and political issues—were less important in this study. Thus, the present study identified fourteen CSFs for ERP implementation from consultation with the expert group. Table 2 shows various CSFs of ERP implementation.

Table 2.

CSFs of ERP implementation with brief descriptions and references.

4.2. Phase 2

Various matrices were created using methodologies such as ISM and MICMAC. Using the contextual relationship provided by the expert group, an SSIM was generated. The SSIM depicted in Table 3 was derived using the contextual interactions among CSFs of ERP implementation. The derived SSIM was built upon the previously mentioned rules. For example, ERP5, “Clear goals and objectives”, is compared with enabler ERP11, “Project team organization and competence”, for their contextual relationship. Since ERP5 influences ERP11, ‘V’ is used to represent the contextual relationship.

Table 3.

Structural self-interaction matrix (SSIM).

Similarly, other relationships may be repeated by ‘A’, ‘X’ and ‘O’ according to the rules discussed in the previous section. Following the rules, the comparison may be carried out for the remaining CSFs of ERP implementation. The transformation of ‘V’, ‘A’, ‘X’ and ‘O’ using the binary digits ‘1′ and ‘0′ is carried out according to the rules discussed in the methodology section. Thus, the initial reachability matrix (IRM) can be obtained, as shown in Table 4.

Table 4.

Initial reachability matrix.

The IRM can be transformed into the final reachability matrix (FRM) by considering transitivity. The row sum and column sum are determined as the driving power and dependence, respectively. Table 5 shows the final reachability matrix (FRM).

Table 5.

Final reachability matrix (FRM).

To obtain the level partition, the CSFs of ERP implementation were intersected. The CSF “Troubleshooting/crisis management (ERP14)” appeared in the first iteration of the level partition, hence taking first place at level I. The different level partitions that were made by using this method were put in the order of top to bottom for interpretive structural modeling (ISM). The process was followed repeatedly until the last level of participation was obtained. Table 6 shows that the I–VIII levels came from the level partitions that were found after several iterations.

Table 6.

All iterations of CSFs of ERP implementation for levels I-VIII.

By rearrangement following the level partition, the FRM can be changed into a lower triangular matrix (LTM). The result is the LTM. The LTM based on the level partitions is displayed in Table 7.

Table 7.

Lower triangular matrix (LTM).

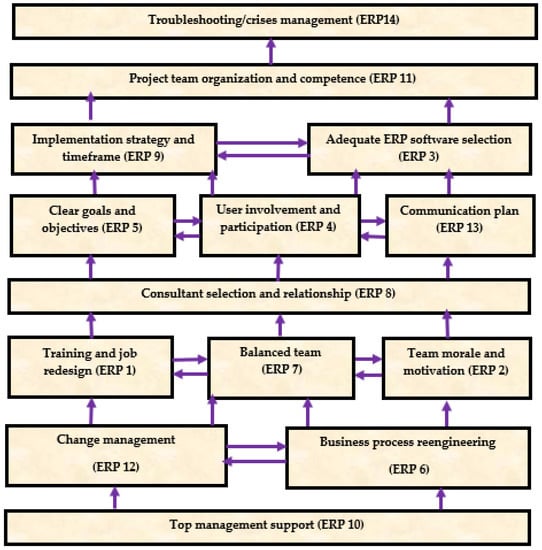

To create the digraph, all the CSFs for ERP deployment are grouped according to the level partition matrix. The ISM for the CSFs of ERP implementation is shown in Figure 3.

Figure 3.

ISM for CSFs of ERP implementation.

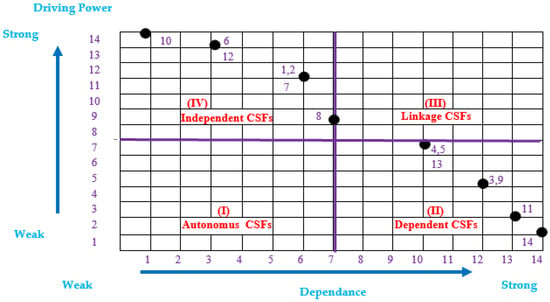

Each CSF of ERP implementation possesses the driving power and dependence, which can be used to draw the diagram. The influence and reliance of each CSF on ERP implementations are depicted in Figure 4. Through MICMAC analysis, it is possible to complete Groups I through IV. The CSFs of ERP implementation are “Training and job redesign (ERP1)”, “Team morale and motivation (ERP2)”, “Business process reengineering (ERP6)”, “Balanced team (ERP7)”, “Top management support (ERP10)” and “Change management (ERP12)”, which were discovered to have a strong driving force and less reliance, thus falling into the independent ERP CSF category. The CSFs of ERP implementation of “Adequate ERP software selection (ERP3)”, “Implementation strategy and timeframe (ERP9)”, “Project team organization and competence (ERP11)” and “Troubleshooting/crisis management (ERP14)” have a high degree of dependency and low driving power, forming a dependent group. The CSF of ERP implementation of “Consultant selection and relationship (ERP8)” is a border case for the independent and linkage types. The CSFs of ERP implementation “User involvement and participation (ERP4)”, “Clear goals and objectives (ERP5)” and “Communication plan (ERP13)” are on the border between the dependent and linkage types. Moreover, there is no CSF of ERP implementation that works on its own.

Figure 4.

Driving power and dependence diagram using MICMAC.

The ISM-based model and MICMAC analysis classification for identified CSFs of ERP implementation were validated through the Delphi technique []. Five experts, three from the IS and two from the IT domains, were identified. The identified Delphi members constituted the Delphi panel. There were no common members between the Delphi member panel and the expert group. All the Delphi participants received pertinent data on the CSFs of ERP implementation. The ISM model was provided for validation in the first round. The contextual relationship presented by the expert group of CSFs of ERP implementation was accepted by every participant in the Delphi panel. The identified CSFs of ERP implementation were therefore verified following the initial round. To confirm the contextual link, the driving and dependent powers of each CSF of the ERP implementation were examined. After the second round, the ISM model was put out for approval. The MICMAC analysis diagram was judged to have persuaded the Delphi panel, leading to the attainment of 100% agreement.

4.3. Phase 3

Six performance criteria [] were selected from the literature to carry out the interpretive ranking process (IRP) for the CSFs of ERP implementation. The selected performance criteria, (P1) to (P6), were “Service quality (P1), Cost and Productivity (P2), Lead Time (P3), Product Design (P4), Brand Value (P5) and Customer Satisfaction (P6)”. A binary value of ‘1′ or ‘0′ was used to indicate the existence or non-existence of the relationship between CSFs of ERP implementation and performance criteria. The relationship between the CSFs of ERP implementation and performance criteria indicates the cross-interaction matrix (CIM), which is shown in Table 8.

Table 8.

Cross-interaction matrix of CSFs of ERP implementation and performance criteria.

The CSFs of ERP implementation and performance criteria are contrasted using the contextual relationship from a cross-interpretive matrix. Table 9 displays the interpretive matrix, which demonstrates the relationship between the CSFs of ERP implementation and performance standards. The CSFs of the knowledge base matrix for the ERP deployment can be used to prepare the building of dominant and non-dominating CSFs.

Table 9.

Interpretive matrix.

The interpretive matrix is employed while comparing the CSFs of ERP implementation with the performance criteria. To prepare the knowledge base, the interpretive logic of the dominant interaction between “ERP1” and “ERP3” for the different performances, P1 through P6, is written down. Table 10 shows the knowledge bases for the CSFs of ERP implementation using interpretive logic.

Table 10.

Knowledge base of CSFs of ERP implementation using interpretive logic.

The matrix of dominant interactions is displayed in Table 11. All the dominating CSFs of ERP implementation are summarized in the dominating interaction matrix. Based on the dominating interaction matrix, dominance matrix as shown in Table 12 can be derived.

Table 11.

Dominating interaction matrix.

Table 12.

Dominance matrix.

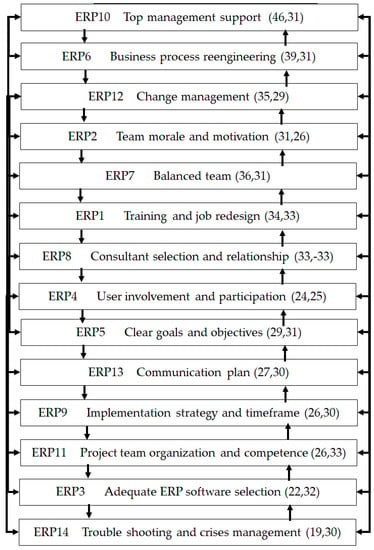

The impact of CSFs on ERP implementations can be understood using the diagram. Figure 5 shows an interpretive ranking model.

Figure 5.

Interpretive ranking process model.

5. Discussion

Sustainable supply chain management relies mainly on how sustainable production and consumption issues are resolved []. ERP plays a vital role in exchanging large amounts of digitized data at the fastest pace for sustainable SCM. The success and failure of ERP implementation have been the subject of several studies. The results can aid with the planning of strategies and resources, as well as with providing leadership to manage the ERP CSFs that were determined to be crucial for ERP success [].

Many organizations have attempted ERP implementation. However, numerous academics have advised caution and have advised for an in-depth analysis of the organization’s business processes before attempting ERP. Since the ERP system integrates various organizational activities relying on rapid interdepartmental communication, the ERP implementation process is also regarded as costly, cumbersome and complex, and it needs more resources than that which is estimated. ERP implementations depend heavily on the identification of CSFs and their relationships. The nature of CSFs may also be essential while implementing ERP during various stages of implementation.

The present research provides a systematic process of identifying CSFs for ERP implementation for sustainable SCM. It has been argued that CSFs are interrelated. If one CSF is changed, the other related CSF is also influenced through its direct or indirect connection with the CSF. It is also important to know if the effect of such CSFs is positive or negative, leading to a strong or weak performance. The identified CSFs may be evaluated based on their impact on organizational or operational factors. ERP’s success may depend on its classification as an organization or operation. The influence of CSFs may be regarded as significant for ERP implementation. Furthermore, CSFs may also be identified as dependent, critical and basic for understanding the nature of CSFs. The impact analysis of each CSF can provide more clarity and a proactive approach to attending to and controlling CSFs while implementing ERP.

The ISM methodology helps with identifying the direct and indirect relationships among CSFs []. The direct and indirect relationships help the manager understand the contextual relationship among CSFs. Practicing managers may employ experts’ decision-making qualities, simplifying the complex problem into a simple hierarchy-based problem. The ISM process offers more simplicity in decomposing a complex problem into an iterative-based solution []. The various CSFs of ERP have different contextual relationships, which are easily discovered through ISM.

The driving power and dependence of the CSFs of ERP implementation are provided by the MICMAC study. Additionally, it groups all the CSFs for ERP deployment into four categories or clusters, giving each CSF complete visibility. The transparency of each CSF’s contextual link and hierarchy position is made clear. This aids management with reviewing their plans and altering their course of action for implementing ERP. Four categories—autonomous, dependent, linking and independent enablers—are used to organize the fourteen CSFs for ERP implementation. Considering their driving power and dependence on the six CSFs, “Training and job redesign (ERP1)”, “Team morale and motivation (ERP2)”, “Business process reengineering (ERP6)”, “Balanced team (ERP7)”, “Top management resistance (ERP10)” and “Change management (ERP12)” are classified as dependent enablers. “Adequate ERP software selection (ERP3)”, “Implementation strategy and timeframe (ERP9)”, “Project team organization and competence (ERP11)” and “Troubleshooting/crisis management (ERP14)” are classified as dependent CSFs.

The success of ERP implementations for sustainable SCM is significantly influenced by teamwork between the ERP implementer and organizational team members. Communication plays a significant role within and outside the enterprise. The ERP team that is selected must have sound knowledge and experience to make the ERP implementations successful. There are geographic restrictions on the current investigation. The CSFs involve “employee attitude”, “employee motivation”, “skill and expertise” and “training and education”. The role played by CSFs varies from place to place. The lean implementation project is costly and time-consuming because identical CSFs in another region of the country present different difficulties.

6. Conclusions

ERP provides many strategic advantages, such as operational benefits, business process and management benefits, and strategic IT planning benefits, to enhance SCM sustainability through operational process integration, customer and relationship integration, and planning and control process integration []. The current study uses the ISM, MICMAC and IRP methodologies to investigate the CSFs of ERP deployment for sustainable SCM. ISM assists with categorizing the various CSFs of ERP implementation into four clusters, whereas MICMAC assists with measuring the influence of each CSF of ERP implementation on other CSFs of ERP implementation utilizing contextual linkages. Before the real ERP implementation, the results of both techniques can help working managers better understand the CSFs. Relation modeling reveals a considerable relationship between the CSFs of ERP implementation and relation modeling, which aids with planning and decision making. The results of this study are pertinent to the installation of ERP for its expansion and sustainability in SCM. Ranking the CSFs of ERP implementation provides an advantage to practicing managers for prioritizing strategies and decision making for sustainable SCM. The different industrial sectors can use the ISM, MICMAC and IRP methods to identify the relationship between CSFs, which is essential for successful ERP implementation for their strategic SCM. This work’s logical expansion might be to expand into other industries to identify common CSFs. Results from the exploratory analysis and structural equation modeling could be helpful to practicing managers.

Future studies related to ERP advancement and its readiness to suit various sectors of I4.0 can be undertaken. Empirical studies to investigate the effectiveness and robustness of the ERP implementation process can be investigated. Exploratory studies and structural equation modeling can be used to identify and study the contextual relationships of the CSFs of ERP implementation, and investigations of the organizational fit for ERP can be undertaken []. The successful integration between ERP and SCM can enhance SCM capabilities for sustainable SCM []. To defend against counterfeiting in the production process, ERP systems must be properly integrated with SCM systems [].

Funding

This research was funded by the Deanship of Scientific Research, King Khalid University, Kingdom of Saudi Arabia, and the grant number is RGP.1/373/43.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

I would like to express my gratitude to the Deanship of Scientific Research, King Khalid University, Kingdom of Saudi Arabia, for funding this work, as well as to my family, friends and colleagues for their constant inspiration and encouragement.

Conflicts of Interest

The author declares no conflict of interest.

References

- Tarigan, Z.J.H.; Siagian, H.; Jie, F. Impact of Enhanced Enterprise Resource Planning (ERP) on Firm Performance through Green Supply Chain Management. Sustainability 2021, 13, 4358. [Google Scholar] [CrossRef]

- Santoso, R.W.; Siagian, H.; Tarigan, Z.J.H.; Jie, F. Assessing the Benefit of Adopting ERP Technology and Practicing Green Supply Chain Management toward Operational Performance: An Evidence from Indonesia. Sustainability 2022, 14, 4944. [Google Scholar] [CrossRef]

- Su, Y.; Yang, C. A Structural Equation Model for Analyzing the Impact of ERP on SCM. Expert Syst. Appl. 2010, 37, 456–469. [Google Scholar] [CrossRef]

- Jayender, P.; Kundu, G.K. Intelligent ERP for SCM Agility and Graph Theory Technique for Adaptation in Automotive Industry in India. Int. J. Syst. Assur. Eng. Manag. 2021, 1–22. [Google Scholar] [CrossRef]

- Žabjek, D.; Kovačič, A.; Indihar Štemberger, M. The Influence of Business Process Management and Some Other CSFs on Successful ERP Implementation. Bus. Process Manag. J. 2009, 15, 588–608. [Google Scholar] [CrossRef]

- De Soete, W. Towards a Multidisciplinary Approach on Creating Value: Sustainability through the Supply Chain and ERP Systems. Systems 2016, 4, 16. [Google Scholar] [CrossRef]

- Chofreh, A.G.; Goni, F.A.; Shaharoun, A.M.; Ismail, S.; Klemeš, J.J. Sustainable Enterprise Resource Planning: Imperatives and Research Directions. J. Clean. Prod. 2014, 71, 139–147. [Google Scholar] [CrossRef]

- Hasan, M.S.; Ebrahim, Z.; Mahmood, W.H.W.; Ab Rahman, M.N. Sustainable-ERP System: A Preliminary Study on Sustainability Indicators. J. Adv. Manuf. Technol. 2017, 11, 61–74. [Google Scholar]

- Ahmad, M.M.; Pinedo Cuenca, R. Critical Success Factors for ERP Implementation in SMEs. Robot. Comput. Integr. Manuf. 2013, 29, 104–111. [Google Scholar] [CrossRef]

- Akyurt, İ.Z.; Kuvvetli, Y.; Deveci, M. Enterprise resource planning in the age of industry 4.0: A general overview. In Logistics 4.0; CRC Press: Boca Raton, FL, USA, 2020; pp. 178–185. [Google Scholar]

- Majstorovic, V.; Stojadinovic, S.; Lalic, B.; Marjanovic, U. ERP in Industry 4.0 Context. In Proceedings of the FIP WG 5.7 International Conference, APMS 2020, Novi Sad, Serbia, 30 August–3 September 2020; pp. 287–294. [Google Scholar] [CrossRef]

- Fui-Hoon Nah, F.; Lee-Shang Lau, J.; Kuang, J. Critical Factors for Successful Implementation of Enterprise Systems. Bus. Process Manag. J. 2001, 7, 285–296. [Google Scholar] [CrossRef]

- Ngai, E.W.T.; Law, C.C.H.; Wat, F.K.T. Examining the Critical Success Factors in the Adoption of Enterprise Resource Planning. Comput. Ind. 2008, 59, 548–564. [Google Scholar] [CrossRef]

- Al-Mashari, M.; Ghani, S.K.; Al-Rashid, W. A Study of the Critical Success Factors of ERP Implementation in Developing Countries. Int. J. Internet Enterp. Manag. 2006, 4, 68. [Google Scholar] [CrossRef]

- Ram, J.; Corkindale, D. How “Critical” Are the Critical Success Factors (CSFs)? Bus. Process Manag. J. 2014, 20, 151–174. [Google Scholar] [CrossRef]

- Remus, U. Critical Success Factors for Implementing Enterprise Portals. Bus. Process Manag. J. 2007, 13, 538–552. [Google Scholar] [CrossRef]

- Subba Rao, S. Enterprise Resource Planning: Business Needs and Technologies. Ind. Manag. Data Syst. 2000, 100, 81–88. [Google Scholar] [CrossRef]

- Barth, C.; Koch, S. Critical Success Factors in ERP Upgrade Projects. Ind. Manag. Data Syst. 2019, 119, 656–675. [Google Scholar] [CrossRef]

- Holland, C.R.; Light, B. A Critical Success Factors Model for ERP Implementation. IEEE Softw. 1999, 16, 30–36. [Google Scholar] [CrossRef]

- Nagpal, S.; Kumar, A.; Khatri, S.K. Relative Importance of CSF in ERP Implementation Strategy: A Multi-Participant AHP Approach. Int. J. Bus. Inf. Syst. 2018, 27, 105–122. [Google Scholar] [CrossRef]

- Paul, S.; Ali, S.M.; Hasan, M.A.; Paul, S.K.; Kabir, G. Critical Success Factors for Supply Chain Sustainability in the Wood Industry: An Integrated PCA-ISM Model. Sustainability 2022, 14, 1863. [Google Scholar] [CrossRef]

- Hong, K.-K.; Kim, Y.-G. The Critical Success Factors for ERP Implementation: An Organizational Fit Perspective. Inf. Manag. 2002, 40, 25–40. [Google Scholar] [CrossRef]

- Haddara, M.; Elragal, A. The Readiness of ERP Systems for the Factory of the Future. Procedia Comput. Sci. 2015, 64, 721–728. [Google Scholar] [CrossRef]

- Bhardwaj, B.R. Sustainable Supply Chain Management through Enterprise Resource Planning (ERP): A Model of Sustainable Computing. In Proceedings of the 2014 International Conference on Computing for Sustainable Global Development (INDIACom), New Delhi, India, 5–7 March 2014; pp. 166–171. [Google Scholar] [CrossRef]

- Frazee, K.; Khan, M.R. ERP Implementation for Corporate Growth and Sustainability. Int. J. Bus. Soc. Sci. 2012, 3. Available online: https://ijbssnet.com/journals/Vol_3_No_3_February_2012/8.pdf (accessed on 7 October 2022).

- Naveed, Q.N.; Islam, S.; Qureshi, M.R.N.M.; Aseere, A.M.; Rasheed, M.A.A.; Fatima, S. Evaluating and Ranking of Critical Success Factors of Cloud Enterprise Resource Planning Adoption Using MCDM Approach. IEEE Access 2021, 9, 156880–156893. [Google Scholar] [CrossRef]

- Asemi, A.; Jazi, M.D. A Comparative Study of Critical Success Factors (CSFs) in Implementation of ERP in Developed and Developing Countries. Int. J. Adv. Comput. Technol. 2010, 2, 99–110. [Google Scholar]

- Parr, A.; Shanks, G. A Model of ERP Project Implementation. J. Inf. Technol. 2000, 15, 289–303. [Google Scholar] [CrossRef]

- Somers, T.M.; Nelson, K. The Impact of Critical Success Factors across the Stages of Enterprise Resource Planning Implementations. In Proceedings of the 34th Annual Hawaii International Conference on System Sciences, Maui, HI, USA, 6 January 2001; p. 10. [Google Scholar] [CrossRef]

- Akkermans, H.; van Helden, K. Vicious and Virtuous Cycles in ERP Implementation: A Case Study of Interrelations between Critical Success Factors. Eur. J. Inf. Syst. 2002, 11, 35–46. [Google Scholar] [CrossRef]

- Finney, S.; Corbett, M. ERP Implementation: A Compilation and Analysis of Critical Success Factors. Bus. Process Manag. J. 2007, 13, 329–347. [Google Scholar] [CrossRef]

- Dawson, J.; Owens, J. Critical Success Factors in the Chartering Phase: A Case Study of an ERP Implementation. Int. J. Enterp. Inf. Syst. 2008, 4, 9–24. [Google Scholar] [CrossRef]

- Françoise, O.; Bourgault, M.; Pellerin, R. ERP Implementation through Critical Success Factors’ Management. Bus. Process Manag. J. 2009, 15, 371–394. [Google Scholar] [CrossRef]

- Nagpal, S.; Kumar, A.; Khatri, S.K. Modeling Interrelationships between CSF in ERP Implementations: Total ISM and MICMAC Approach. Int. J. Syst. Assur. Eng. Manag. 2017, 8, 782–798. [Google Scholar] [CrossRef]

- Kiran, T.S.; Reddy, A.V. Critical Success Factors of ERP Implementation in SMEs. J. Proj. Manag. 2019, 4, 267–280. [Google Scholar] [CrossRef]

- Al-Mashari, M. Constructs of Process Change Management in ERP Context: A Focus on SAP R/3. In Proceedings of the 2000 Americas Conference on Information Systems, AMCIS 2000, Long Beach, CA, USA, 10–13 August 2000; pp. 977–980. [Google Scholar]

- Sandoe, K.; Corbitt, G.; Boykin, R. Enterprise Integration; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Rajagopal, P. An Innovation—Diffusion View of Implementation of Enterprise Resource Planning (ERP) Systems and Development of a Research Model. Inf. Manag. 2002, 40, 87–114. [Google Scholar] [CrossRef]

- Keeney, R.L. Value-Focused Brainstorming. Decis. Anal. 2012, 9, 303–313. [Google Scholar] [CrossRef]

- Qureshi, M.R.N.M. Evaluating and Prioritizing the Enablers of Supply Chain Performance Management System (SCPMS) for Sustainability. Sustainability 2022, 14, 11296. [Google Scholar] [CrossRef]

- Sushil, D. Interpretive Ranking Process. Glob. J. Flex. Syst. Manag. 2009, 10, 1–10. [Google Scholar] [CrossRef]

- Thanki, S.J.; Thakkar, J. Interdependence Analysis of Lean-Green Implementation Challenges: A Case of Indian SMEs. J. Manuf. Technol. Manag. 2018, 29, 295–328. [Google Scholar] [CrossRef]

- Qureshi, K.M.; Mewada, B.G.; Alghamdi, S.Y.; Almakayeel, N.; Mansour, M.; Qureshi, M.R.N. Exploring the Lean Implementation Barriers in Small and Medium-Sized Enterprises Using Interpretive Structure Modeling and Interpretive Ranking Process. Appl. Syst. Innov. 2022, 5, 84. [Google Scholar] [CrossRef]

- Qureshi, K.M.; Mewada, B.G.; Alghamdi, S.Y.; Almakayeel, N.; Qureshi, M.R.N.; Mansour, M. Accomplishing Sustainability in Manufacturing System for Small and Medium-Sized Enterprises (SMEs) through Lean Implementation. Sustainability 2022, 14, 9732. [Google Scholar] [CrossRef]

- Haleem, A.; Sushil; Qadri, M.A.; Kumar, S. Analysis of Critical Success Factors of World-Class Manufacturing Practices: An Application of Interpretative Structural Modelling and Interpretative Ranking Process. Prod. Plan. Control 2012, 23, 722–734. [Google Scholar] [CrossRef]

- Tripathy, S.; Sahu, S.; Ray, P.K. Interpretive Structural Modelling for Critical Success Factors of R&D Performance in Indian Manufacturing Firms. J. Model. Manag. 2013, 8, 212–240. [Google Scholar] [CrossRef]

- Qureshi, M.N.; Kumar, P.; Kumar, D. Framework for benchmarking logistics performance using fuzzy AHP. Int. J. Bus. Perform. Supply Chain. Model. 2009, 1, 82–98. [Google Scholar] [CrossRef]

- Ince, H.; Imamoglu, S.Z.; Keskin, H.; Akgun, A.; Efe, M.N. The Impact of ERP Systems and Supply Chain Management Practices on Firm Performance: Case of Turkish Companies. Procedia Soc. Behav. Sci. 2013, 99, 1124–1133. [Google Scholar] [CrossRef]

- Thangaratinam, S.; Redman, C.W. The Delphi Technique. Obstet. Gynaecol. 2005, 7, 120–125. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of Sustainability in Supply Chain Management: A Literature Review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Qureshi, M.N.; Kumar, D.; Kumar, P. An Integrated Model to Identify and Classify the Key Criteria and Their Role in the Assessment of 3PL Services Providers. Asia Pacific J. Mark. Logist. 2008, 20, 227–249. [Google Scholar] [CrossRef]

- Qureshi, M.N.; Kumar, D.; Kumar, P. Modeling the Logistics Outsourcing Relationship Variables to Enhance Shippers’ Productivity and Competitiveness in Logistical Supply Chain. Int. J. Product. Perform. Manag. 2007, 56, 689–714. [Google Scholar] [CrossRef]

- Tarn, J.M.; Yen, D.C.; Beaumont, M. Exploring the Rationales for ERP and SCM Integration. Ind. Manag. Data Syst. 2002, 102, 26–34. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).