Abstract

The amount of steel waste produced is on the increase due to improvements in steel manufacturing industries. The increase in such wastes causes significant environmental problems and, furthermore, a large area is also required to store these waste products. Instead of disposing of these wastes, the reuse of them in different industries is an important success in terms of both reducing environmental pollution and providing low-cost products. From this motivation, the effect of lathe scrap fibers generated from Computer Numerical Control (CNC) lathe machine tools on concrete performance was investigated in this study. Pursuant to this aim and considering different fiber content, an experimental study was conducted on some test specimens. Workability and slump values of concrete produced with different lathe scrap fibers were determined, and these properties were compared with those of plain concrete. For the hardened concrete, 150 mm × 150 mm × 150 mm cubic specimens and cylindrical specimens with a diameter of 100 mm and a height of 200 mm were tested to identify compressive strength and splitting tensile strength of the concrete produced with different volume fracture of lathe waste scrap (0%, 1%, 2% and 3%). With the addition of the lathe scrap, the compressive and splitting tensile strength of fiber-reinforced concrete increases, but after a certain value of steel fiber content, there is a decrease in workability. Next, a three-point bending test was carried out on samples with dimensions of 100 × 100 × 400 mm and a span length of 300 mm to obtain the flexure behavior of different mixtures. It has been shown that the flexural strength of fiber-reinforced concrete increases with an increasing content of waste lathe. Furthermore, microstructural analysis was performed to observe the interaction between lathe scrap fiber and concrete. Good adhesion was observed between the steel fiber and cementitious concrete. According to the results obtained, waste lathe scrap fiber also worked as a good crack arrestor. Lastly, practical empirical equations were developed to calculate the compressive strength and splitting tensile strength of fiber-reinforced concrete produced with waste lathe scrap.

1. Introduction

Concrete is a composite material consisting of cement, aggregates, water and some additives, and it is widely employed as a building material in many structural applications. Due to some weak properties of conventional concrete, such as low ductility and low tensile strength, it is reinforced by making use of reinforcement bars and sometimes by using fibers or polymers [1,2,3,4,5,6,7,8,9,10,11,12,13]. Reinforcement bars improve the mechanical properties of the concrete; however, they may be insufficient in limiting crack widths. The use of fibers in concrete is the one of the most efficient ways to control crack width [14]. In addition to crack arrestment, fibers play an important role in preventing the above-mentioned disadvantages of concrete [15]. There are many fiber types to be used in concrete mixtures to enhance some properties such as ductility, crack resistance, tensile and flexural strength [16,17]. Steel, glass, polypropylene, polyvinyl alcohol and carbon are fiber types widely used in cement-based materials [2,18,19,20,21,22]. As an illustration, glass fibers are generally preferred for the roofs of the thin concrete shell structure and precast panels etc., while steel fibers are generally employed in floor slab, bridge deck and impact resistance structures. Furthermore, fibers such as steel and polyvinyl alcohol fiber have an important role at different levels in enhancing the toughness and strength of high-performance concrete [23]. Fibers such as waste polypropylene (PP) and metal are plentiful and inexpensive compared to conventional steel reinforcement [24]. Furthermore, instead of recycling steel scrap, produced in local lathes and workshops, and polypropylene waste, using them directly in the form of fibers may be more economical. El-Sayed [25], Sezhiyan and Rajkumar [26] and Vijayakumar et al. [27] and stated that the cost of waste lathe scraps collected from workshops and other steel industries is very low. The commonly used steel fibers may be either industrial steel fibers or waste fibers generated from various industries. Industrial steel fibers provide a positive effect to concrete by increasing its mechanical properties. However, industrial steel fibers are costly, and the use of such fibers causes fiber-reinforced concrete prices to increase [27]. Due to this reason, there is an increasing interest in employing reused or recycled waste fibers in concrete [28]. Furthermore, in addition to being eco-friendly, waste fibers show almost the same performance when compared to standard industrial fibers [29]. In some circumferences, combinations of industrial fibers and waste fibers (hybrid fibers) are used to obtain a better performance when compared to plain concrete. Recently, there is an increase in the amount of waste materials such as expired tyre and steel swarf generated from lathe and Computer Numerical Control (CNC) machines. These waste materials may be used as either fiber or for replacement of the natural aggregate in the concrete mixture. The use of recycled materials can contribute both to lessen land pollution and to produce environmentally friendly concrete [30]. In this study, the effect of steel waste generated from lathes and CNC machines on concrete properties have been explored. Steel swarf is a solid waste, and it generally occurs in steel manufacturing industries during the cutting, milling and turning processes. The high amount of steel swarf generated is an important issue since this material is difficult to recycle [31]. However, it was preferred as a replacement for aggregates in concrete [28,32,33,34]. In addition, steel swarf, which exhibits steel fiber properties, may be utilized as an alternative reinforcement in the concrete mixture. A study by conducted Abbas [16] demonstrated that lathe steel fibers may be used as a reinforcement, but workability of the fresh concrete including lathe waste fibers decreases as their amount increases in the mixture. Wang et al. [35] stated that the addition of a low amount of fiber provides little improvement in the mechanical behavior of concrete, but a high amount of fiber causes a decrease in workability. Vijayakumar [27] mentioned that lathe scrap used as a reinforcement increases the impact strength of reinforced concrete. According to the study [27], lathe scrap reinforced concrete exhibits better performance than normal unreinforced concrete. Thirumurugan and Sivaraja [36] explored the shear, impact and fracture strengths of concrete with steel lathe waste. Steel lathe waste has been shown to have a great effect in delaying crack propagation. Mansi et al. [37] studied the effect of different amount of steel lathe waste on concrete performance. According to their results [37], the addition of steel lathe waste improved the mechanical properties such as compression strength of concrete. However, there was a decrease in workability of the concrete with the increase of lathe steel waste. Bhavana and Rangarao [38] conducted an experimental study to investigate the influence of different amounts of steel scraps on conventional and self-compacting concretes. The deformational behavior of these types of concretes was compared by considering eight beam specimens. Akshaya et al. [39] investigated the flexural behavior of concrete produced by waste lathe fiber. It was shown that lathe fiber addition increases the flexural strength of the concrete and limits crack width. Vasudev and Vishnuram [40] carried out an experimental study to explore applicability of turn steel scraps as a fiber in M40 and M60 grade concretes. With the addition of lathe fiber, there was a 22% increase in the ultimate load capacity of the M40 grade concrete and a 17% increase in the ultimate load capacity of the M60 concrete. Gawatre et al. [41] studied effect of lathe scrap on the workability and compressive strength of M30 grade concrete. It was observed that the addition of lathe scrap fibers raises the compressive strength by up to 11%. There was a decrease in the workability of the concrete with the increase of fiber content. In the same manner, Nazir et al. [42] investigated the influence of straight lathe steel fiber on the workability and mechanical properties of M20 concrete. The use of lathe steel fiber increases compression strength by 15%, the split tensile strength by 30% and bending strength by 42%. Joy and Rajeev [43] stated that the low content of steel scrap fiber performed well in compressive strength and splitting tensile strength, but had little effect on flexural strength of M25 grade concrete.

Lathe waste sawdust is very valuable as a recycling material, and it is reusable after many industrial processes for different work sectors. In concrete production, adding the waste turning sawdust directly to the concrete without being subjected to a second industrial process increases the economic added value. It may require additional processing only for separation and sizing to additives in concrete. Therefore, since the addition of lathe sawdust to the concrete will improve the mechanical performance of the concrete, it will provide advantages such as using less steel in steel-reinforced concrete. The applicability of lathe scrap fibers obtained from lathe and CNC machines in civil engineering applications has been shown in the previous studies. However, there still remains a need to improve the structural performance of recycled steel fiber-reinforced concrete for various applications [44,45,46,47]. Based on this motivation, an experimental study was performed to determine an optimum amount of lathe scrap fibers for the concrete mixture. First, the effect of lathe waste on slump value and workability on the fresh state of concrete was investigated by considering different amounts of fibers. Next, the mechanical properties of fiber-reinforced concrete produced with different lathe scrap fibers contents were explored in the hardened state of concrete. For this purpose, compressive strength tests were conducted on cubic and cylindrical samples. Cylindrical samples were employed to find the splitting tensile strength. Furthermore, experimental tests were carried out on beam samples, which had dimensions of 100 × 100 × 400 mm and a span length of 300 mm. Load-displacement curves of test specimens were obtained for the bending behavior. An attempt was next made to optimize the most ideal fiber amount for fiber-reinforced concrete with lathe scrap steel fiber. Microstructural analysis was also performed to observe the interaction between lathe scrap fiber and concrete. Furthermore, practical empirical equations were developed for the compression strength and splitting tensile strength of the fiber-reinforced concrete.

2. Experimental Program

2.1. Materials and Mixture Proportions

In this study, the cement was selected as CEM I 32.5 Portland Cement. The chemical properties of this cement are given in Table 1. A maximum of 4 mm and 12 mm aggregate sizes were utilized for fine and coarse aggregates. The ratio of water to cement was selected as 0.60, while the ratio of cement to aggregate was selected as 0.22. The ratio of fine aggregate (0–4 mm) was around 48%, while the ratio of coarse aggregate (4–12 mm) was around 52%.

Table 1.

Chemical properties of PC.

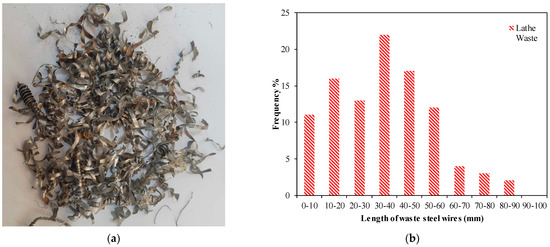

Lathe waste sawdust was utilized to investigate the influence of the fiber ratio on the mechanical properties in terms of compressive strength, split tensile strength and bending performance of concrete. The utilized steel wires are shown in Figure 1a. The shape of recycled steel wires obtained from the lathe machine were helical. The recycled steel wires were divided into small pieces before use. It was tried to obtain the same length and proportion in order to make a fair comparison. Figure 1b demonstrates the proportion of the lengths utilized of the lathe waste sawdust. The average length of lathe waste was 30–50 mm.

Figure 1.

Recycled steel wires obtained from Lathe machine. (a) Waste lathe used in the experiments. (b) Frequency of waste lathe.

2.2. Mix Procedure, Workability and Slump Test

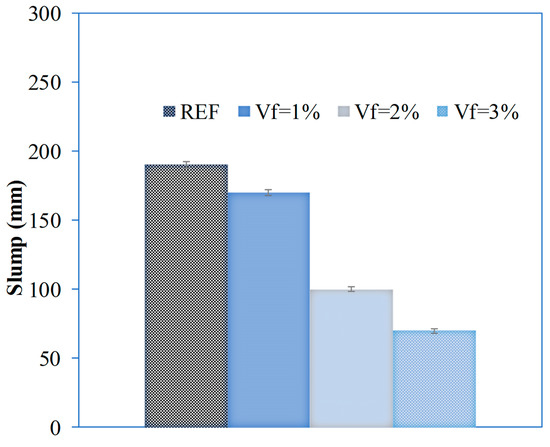

For the mix procedure, all aggregates, cement and water were initially mixed in the mixer. Afterwards, the sawdust was mixed into the concrete by slowly scattering it in order to ensure the homogeneous distribution of the turning sawdust in the concrete mixture and to prevent aggregation. Although the steel wires were slowly added to the mixture, aggregation was observed in the mixture with 3% lathe waste. Workability was significantly decreased after a 2% fiber content ratio. It was very difficult to work with the mixture with the 3% lathe (CNC) waste. Slump tests were also performed. The results of the slump tests are indicated in Figure 2. It is seen that slump values with steel lathe waste chips for all cases are lower than those of the reference specimen. Moreover, the slump value decreases as the fiber ratio increases. While the slump value of the reference sample was 19 cm, the slump value decreased to 17, 10 and 5 cm depending on the increasing fiber content.

Figure 2.

Slump test.

After mixing, the mixtures were poured into molds and vibrated for 30 s. The samples were kept at room temperature for 24 h after casting. The samples were then tested after curing for 28 days.

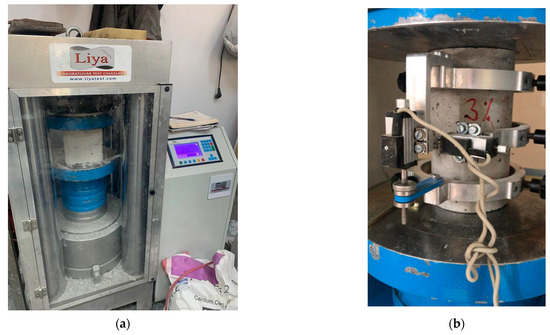

2.3. Test Procedure

Four types of tests were carried out to determine the mechanical properties of the concrete obtained with the addition of machine tool wastes. These tests are, respectively, the cubic compressive strength, cylindrical compressive strength, splitting tensile and bending tests. Some images of the tested samples are shown: Figure 3a shows the cubic compressive strength, Figure 3b shows the cylindrical compressive strength, Figure 3c shows the split tensile and Figure 3d shows the flexural tests. Three samples from each experimental group were tested, and the results were averaged.

Figure 3.

Mechanical test setupsL (a) compressive strength, (b) compressive strength, (c) splitting tensile test and (d) bending test.

Compressive strength performances were tested using 150 × 150 × 150 mm cube specimens and cylindrical specimens with a diameter of 100 mm and a height of 200 mm. While only compressive strength values were obtained with the cubic sample tests, compressive strength and stress curves were obtained with the cylindrical sample tests. Cubic samples were broken with an average loading speed of 6 kN/s until fracture, and cylindrical samples with a loading rate of 5 kN/s. Cylindrical test specimens were also used in splitting tensile tests. Bending tests were carried out with prisms of 100 × 100 × 400 mm in size, with an opening size of 300 mm and a loading speed of 0.5 mm/sn. As a result of the test, curves showing the bending behavior were obtained.

3. Experimental Results and Discussions

3.1. Compressive Strength

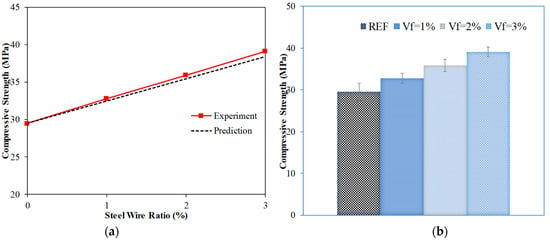

Figure 4 shows the test results of the compressive strength of 150 mm × 150 mm × 150 mm cubic specimens. The graph in Figure 4b shows, from left to right, the compressive strength results of the reference samples and concrete obtained by adding lathe steel waste. It is a positive indication that the samples containing waste material have superior compressive strength compared to the reference samples. The graph in Figure 4b clearly shows the increase in compressive strength as the ratio of turning waste in concrete increases.

Figure 4.

Results of compressive strength.

According to the compressive strength test results of the cubic samples, while the compressive strength of the reference sample was 29.5 MPa, it was around 32.8 MPa with 1% lathe waste chips, 35.9 MPa with 2% lathe waste chips, and 39.1 MPa with 3% lathe waste chips (Figure 4a). The compressive strength experimental strength test results are also estimated by using an analytical solution. According to the results obtained, there is a difference of about 1% between the experimental results and the estimated results. This shows that future studies can produce predictive results without experimenting but by employing the analytical solution. Yazıcı et al. [48] found that the strength of concrete increased between 4% and 19% in their study by adding three different fiber volumes of 0.5%, 1.0% and 1.5%, according to the concrete volume. In this study, it is seen that the compressive strength of concrete increases between 9% and 32% with lathe waste chips. Therefore, according to the study conducted by Yazıcı et al., it can be seen that waste turning sawdust provides better compressive strength [48]. The experimentally and analytically predicted compressive strength results are shown in Table 2.

Table 2.

Experimental and predicted compressive strength.

Compressive strength with recycled steel wires can be computed utilized the following proposed equations:

where is the compressive strength of plain concrete and is the compressive strength of concrete with lathe waste chips.

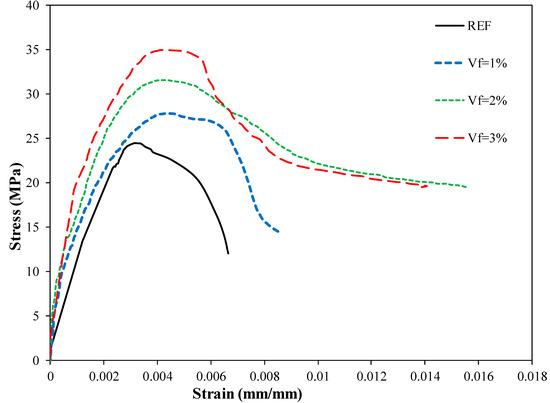

Figure 5 shows the compressive strength results of the cylindrical samples. The results show an increase in the elastic behavior capacity of the specimens as well as the maximum strength. As the waste volume ratio increased, the strength and ductility increased proportionally. Neves and Almeida [49] stated in their study that fiber additives increase the compressive strength of concrete up to 1.5%, but decrease the Young’s modulus slightly. However, it is understood from the graph that there is a very good increase in Young’s modulus with the addition of lathe waste chips. The results obtained in Shah and Rangan’s study indicated that lathe waste significantly improved the toughness and ductility of concrete in addition to increased final pressure [50]. In support of this, a study by Tscheg et al. [51] observed, in general, a much higher increase in load-displacement curves in steel fiber-reinforced concrete samples compared to synthetic macrofiber-reinforced concrete samples [51]. Lee [52], in his study with 0.25%, 0.375% and 0.50% fiber volume ratios, determined that as the fiber volume ratio in concrete increases, the energy absorption capacity increases [52]. It is also understood from the curves in Figure 5 that the energy absorption capacity continues at higher rates depending on the increasing fiber volume ratio.

Figure 5.

Compressive strength results of cylindrical samples.

3.2. Splitting Tensile Strength

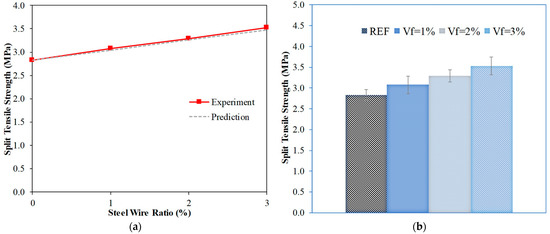

In order to understand the tensile strength of concrete, the split tensile strength test is performed. Figure 6 shows the splitting tensile strength result of concrete with lathe waste chips added. The results obtained were confirmed by an analytical solution. Figure 6a compares the experimental method results with analytical solution estimates. The overlap of the graph lines proves the accuracy of the experimental work. Figure 6b shows that the addition of lathe waste is effective in the split tensile strength test.

Figure 6.

Results of splitting tensile strength.

Table 3 shows the experimental and estimated split tensile strength results. The experimental result of the reference sample was 2.83 MPa, and the analytical solution result was 2.82 MPa. With 1% lathe waste chips additive, the experimental result was 3.08 MPa and the analytical solution was 3.04 MPa. With 2% contribution, the experimental result was 3.29 MPa and the analytical solution result was 3.26 MPa. With 3% contribution, the results were 3.53 MPa and 3.48 MPa in analytical solution. The results in the table show a proportional increase of 1.09% in strength as the lathe material additive ratio increases.

Table 3.

Experimental and predicted splitting tensile strength.

The splitting tensile strength with recycled steel wires can be computed utilized the following proposed equations:

where is the compressive strength of plain concrete and is the splitting tensile strength of concrete with lathe waste chips.

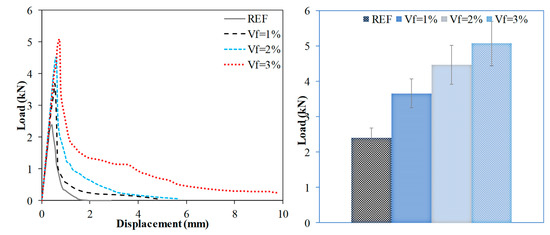

3.3. Flexural Performance

The effects of lathe waste chips addition on concrete flexural strength are shown in Figure 7. The results show that the flexural strength increases proportionally with the addition of high lathe waste chips. It is seen that the addition of lathe waste chips gives positive results in flexural strength compared to the reference sample, and when a 1% addition is made, it provides a flexural strength of 3.8 kN. For a 2% addition, the value was 4.5 kN. It provided a bending strength of 5 kN at the addition of 3%. While the displacement value of the reference sample was around 2 mm, the increase in fiber ratio with the addition of lathe waste chip is remarkable. In their research of synthetic fiber-reinforced concrete, Zhenng and Feldmen [53] observed an increase in post-crack energy absorption capacity and ductility, with a significant increase in both flexural fatigue strength and toughness limit due to the addition of synthetic fibers compared to plain concrete. However, fiber-reinforced concretes may also have disadvantages such as clumping. No such problem was encountered with the lathe waste chips additive. Xu et al. [54] revealed that the ultimate flexural strength of concrete obtained by adding straight, corrugated and hook-end steel fibers was improved by a maximum of 165.07% with the addition of the best hook-end fiber. It is also satisfactory that this result is obtained with lathe waste chips additive, which is not an industrial product and does not have a smooth geometry.

Figure 7.

Results of flexural strength.

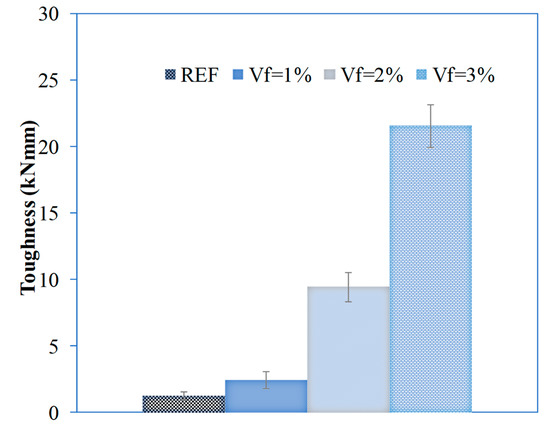

One of the most important results obtained from this study relates to the toughness of concrete. Figure 8 shows the toughness values. Generally, ductile materials have high toughness, while brittle materials have low toughness. According to the results obtained, it is seen that the addition of sawdust to the lathe waste chips provides very good toughness. While the toughness of the reference sample is close to 0, it is seen that the toughness is around 22 kN with the addition of 1.2 kN, 2% 10 kN and 3% lathe waste chips. Soluioti et al. [55], in their experimental study with steel fibers with different geometries, revealed that hook-end fibers provide better toughness in concrete than fibers with wavy geometry. Lathe waste chips geometry provided good toughness despite having wavy and irregular geometry. Yoo et al. [56] argued that spun fibers provide the highest flexural strength, but exhibit similar strength and weaker toughness to straight fibers at a Vf greater than or equal to 1.5%. They noted that at a Vf greater than or equal to 1.0%, lower flexural strength and toughness were observed in hook fiber samples compared to straight ones. As a result, the graph in Figure 8 shows that waste lathe chips are longer and their high addition to concrete significantly increases both strength and toughness.

Figure 8.

Effects of fiber volume fraction on toughness.

4. Damage Analysis

Considering the current research findings, it seems possible to improve some properties of lathe waste chips concrete. Compressive strength, bending strength and splitting tensile strength were obtained for concrete with different amounts of Lathe waste chips in the experimental studies. The volume ratio of the lathe waste chips was used as a variable parameter in the studies. Beams are mechanically accepted structural elements that transfer the loads of the usage area to the vertical carriers. For this reason, it is an important issue to carry out damage analysis, which takes into account the added fibers. Micro cracks were observed in the tensile region of the beam with lathe waste chips when the fracture strength was reached. The addition of lathe waste chips stabilized crack development until reaching the maximum load. When the initial tensile fracture developed in the reference samples, there was a sudden decrease in the load capacity. On the other hand, a slower decrease occurred in the samples with lathe waste chips. As seen in Figure 9, the crack formation moved towards the compression zone. Therefore, the stability of the beam section under the natural axis is effectively maintained by the fiber-bridging region, which is resistant to fiber rupture. Finally, the Lathe waste chips, which caused the beam sample to fail, were completely withdrawn. In all beam specimens, fracture was observed in the moment constant region of the beam. Lathe waste chips drawn on the cracked surface and tension fractures on the concrete matrix are shown in Figure 9.

Figure 9.

Damage analyses.

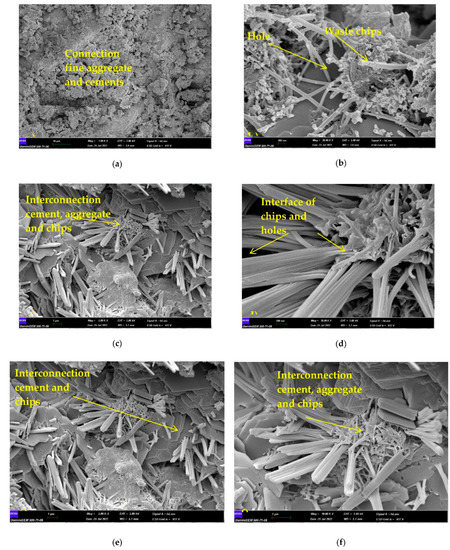

Scanning Electron Microscope (SEM) analysis was performed on sample pieces taken from lathe waste chips concrete samples. The main observed findings of the SEM analysis are shown in Figure 10. It should be noted that SEM analysis images of concrete samples obtained using lathe waste chips are shown at 500 times magnification. As shown in Figure 10a,b, a good bonding occurs with the addition of lathe waste chips in the microporous structure of the concrete. Furthermore, this bonding effect between concrete and fibers causes an increase in the elastic resistance capacity, ductility and toughness of concrete. The wavy nature of the lathe waste chips is also an important property resulting in good adhesion. Figure 10c,d shows that lathe chips bond well with cement and aggregate. Figure 10e,f shows the lathe waste chips’ interface and gap states.

Figure 10.

SEM photos.

5. Comparison with Existing Studies on Fiber-Reinforced Concrete Produced with Lathe Scrap Steel Fibers

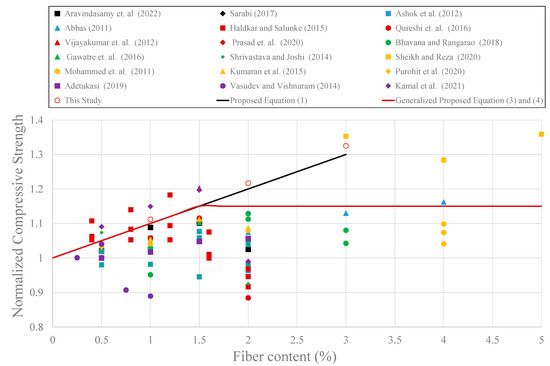

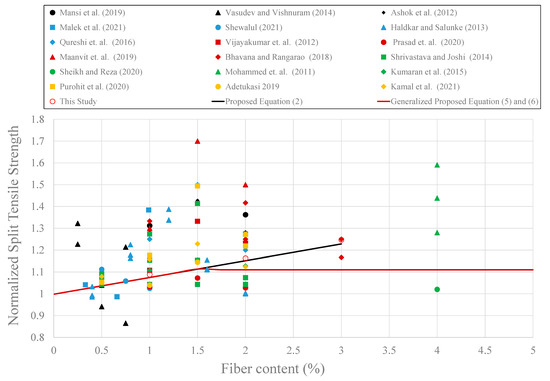

According to the results of existing research works, lathe waste steel fibers are applicable in order to improve concrete performance. The changes in compressive strength, flexural strength and split tensile strength have been reported considering different volume fractures of lathe scrap fibers. In this part of the study, values of compressive strength and split tensile strength for plain concrete and fiber-reinforced concrete produced with lathe scrap fiber were collected from these research publications [2,15,16,27,29,31,37,38,40,41,57,58,59,60,61,62,63,64,65,66,67,68,69]. Strength values of fiber-reinforced concrete were first normalized by plain concrete strengths. These normalized strength values were plotted in Figure 11 and Figure 12, respectively, as a function of the fiber content (%). In these plots, although there are some data below 1.0, both compressive and splitting tensile strength values of fiber-reinforced concretes were generally greater than 1.0. In some cases, although there was an improvement in the strength values up to a certain threshold value of the fiber dosage, further increasing the lathe scrap fiber addition causes either a small increase or a small decrease in the strength values. The maximum increase in compressive strength was observed in the study by Sheikh and Reza [66]. The use of 5.0% lathe scrap steel fiber resulted in a 36% increase in compression strength of the plain concrete specimens. On the other hand, the maximum decrease in compression strength occurred in the experimental study performed by Qureshi et al. [64]. The use of 2.0% lathe steel fiber causes a 12% reduction in the compressive strength. Considering the change in normalized splitting tensile strength, Maanvit et al. [59] showed a 70% increase in their studies, while Vasudev and Vishnuram [40] found a 13% decrease.

Figure 11.

Variation of the normalized compressive strength of the fiber-reinforced concrete produced with lathe scrap steel fibers [2,15,16,27,38,41,57,58,60,61,62,63,64,65,66,67,68,69].

Figure 12.

Variation of the splitting tensile strength of the fiber-reinforced concrete produced with lathe scrap steel fibers [2,15,16,27,31,37,38,40,41,57,58,59,60,61,62,63,64,66,67,68].

As shown in the experimental part of the study, there is a linear increase in the compression strength and splitting tensile strength. Thus, by applying curve fitting to the data obtained from experimental study conducted in the previous part of this study, empirical equations were derived for practical purposes. Considering these proposed equations and existing studies conducted by many researchers, generalized strength equations were developed as follows:

Use Equation (1) if Vf ≤ 1.5

Use Equation (2) if Vf ≤ 1.5

Compression strength and splitting tensile strength values of fiber-reinforced concrete produced with waste steel lathe fiber were expressed as a function of the compression strength of the plain concrete and volume fracture of the lathe steel fiber. These expressions can be easily used in design stages.

6. Conclusions and Summary

Waste materials are a subject of great concern in terms of both economic and environmental perspectives. Producing sustainable solutions to these problems is an issue that is gaining importance day by day. In this study, waste chips generated from lathe and CNC machines, one of the most abundant waste types, were considered and the effect of these waste materials on concrete performance was investigated. To pursuant this aim, the performance of concrete produced with waste chips was examined both in the fresh and hardened states. In the case of fresh concrete, the workability and slump properties of concrete produced with different amounts of lathe scrap fiber were identified. In the hardened concrete case, mechanical properties, such as compressive strength, splitting tensile strength and bending strength, were investigated. These properties were then compared with those of plain concrete. Furthermore, microstructural analysis was carried out to observe the interaction between lathe scrap fiber and concrete. The key findings drawn from this research are presented as follows:

- In the slump test, it was determined that as the amount of waste chips increased, the slump and workability decreased. The slump value decreased by 11% with 1% waste chip addition, 47% with 2% waste chip addition and 74% with 3% waste chip addition.

- According to the results of the compressive tests, the compression strength of plain concrete was measured as 29.5 MPa. The addition of 1%, 2% and 3% lathe waste chips increased the compression strength by 11%, 22% and 33%, respectively. Furthermore, it was observed that there is a proportional increase in the compressive strength according to the increase in the amount of lathe waste chips increase.

- According to the results of the split tensile strength test, the splitting tensile strength in the plain concrete was measured as 2.83 MPa. The split tensile strength in concrete increased with the increase in chip content. The splitting tensile strength in the concrete obtained with 1%, 2% and 3% chips additives increased by 9%, 16% and 25%, respectively, compared to plain concrete.

- By applying curve fitting to the data obtained test results, analytical equations were derived for both the compressive strength and split tensile strength. The difference between experimental and estimated values is about 1%.

- Considering these proposed expressions and existing studies conducted by many researchers, generalized strength equations were developed. Using these proposed equations, the compressive strength and splitting tensile strength of fiber-reinforced concrete produced with waste lathe scrap are calculated for practical purposes.

- The use of 2% lathe waste is recommended considering both workability and increases in the capacities. Using more than 2% lathe steel waste can cause workability problems.

- According to the results of microstructural analysis, good adhesion was observed between the waste steel lathe and cement-based concrete, and waste lathe scrap fiber plays an important role in limiting the crack width.

Author Contributions

Conceptualization, Y.O.Ö.; Methodology, Y.O.Ö.; Data curation, Ö.Z., and Y.O.Ö.; Investigation, A.İ.Ç., Y.O.Ö., Ö.Z. and N.Ö.; Writing-original draft preparation, A.İ.Ç., Y.O.Ö., Ö.Z and N.Ö. and Writing-review and editing, Y.O.Ö., Ö.Z. and B.A.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

There are no ethical issues with the publication of this manuscript.

Informed Consent Statement

Not applicable.

Data Availability Statement

All graphs and data obtained or generated during the investigation appear in the published article.

Conflicts of Interest

The authors declared no potential conflict of interest with respect to the research, authorship and/or publication of this article.

References

- Aksoylu, C.; Özkılıç, Y.O.; Arslan, M.H. Mechanical Steel Stitches: An Innovative Approach for Strengthening Shear Deficiency in Undamaged Reinforced Concrete Beams. Buildings, 2019; In press. [Google Scholar]

- Ashok, S.P.; Suman, S.; Chincholkar, N. Reuse of steel scarp from lathe machine as reinforced material to enhance properties of concrete. Glob. J. Eng. Appl. Sci 2012, 2, 164–167. [Google Scholar]

- Prakash, R.; Thenmozhi, R.; Raman, S.N.; Subramanian, C.J.S.C. Characterization of eco-friendly steel fiber-reinforced concrete containing waste coconut shell as coarse aggregates and fly ash as partial cement replacement. Struct. Concr. 2020, 21, 437–447. [Google Scholar] [CrossRef]

- Prakash, R.; Divyah, N.; Srividhya, S.; Avudaiappan, S.; Amran, M.; Naidu Raman, S.; Guindos, P.; Vatin, N.I.; Fediuk, R.J.M. Effect of steel fiber on the strength and flexural characteristics of coconut shell concrete partially blended with fly ash. Materials 2022, 15, 4272. [Google Scholar] [CrossRef]

- Lokman, G.; Madenci, E.; Özkılıç, Y.O. Çelik, Cam FRP ve hibrit donatılı betonarme kirişlerin eğilme performansının incelenmesi. Düzce Üniversitesi Bilim ve Teknoloji Dergisi 2020, 8, 1470–1483. [Google Scholar]

- Özkılıç, Y.O.; Yazman, Ş.; Aksoylu, C.; Arslan, M.H.; Gemi, L. Numerical investigation of the parameters influencing the behavior of dapped end prefabricated concrete purlins with and without CFRP strengthening. Constr. Build. Mater. 2021, 275, 122173. [Google Scholar] [CrossRef]

- Arslan, M.H.; Yazman, Ş.; Hamad, A.A.; Aksoylu, C.; Özkılıç, Y.O.; Gemi, L. Shear strengthening of reinforced concrete T-beams with anchored and non-anchored CFRP fabrics. Structures 2022, 39, 527–542. [Google Scholar] [CrossRef]

- Gemi, L.; Alsdudi, M.; Aksoylu, C.; Yazman, S.; Ozkilic, Y.O.; Arslan, M.H. Optimum amount of CFRP for strengthening shear deficient reinforced concrete beams. Steel Compos. Struct. 2022, 43, 735–757. [Google Scholar]

- Gemi, L.; Madenci, E.; Özkılıç, Y.O.; Yazman, Ş.; Safonov, A. Effect of Fiber Wrapping on Bending Behavior of Reinforced Concrete Filled Pultruded GFRP Composite Hybrid Beams. Polymers 2022, 14, 3740. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Aksoylu, C.; Yazman, Ş.; Gemi, L.; Arslan, M.H. Behavior of CFRP-strengthened RC beams with circular web openings in shear zones: Numerical study. Structures 2022, 41, 1369–1389. [Google Scholar] [CrossRef]

- Aksoylu, C.; Yazman, Ş.; Özkılıç, Y.O.; Gemi, L.; Arslan, M.H. Experimental analysis of reinforced concrete shear deficient beams with circular web openings strengthened by CFRP composite. Compos. Struct. 2020, 249, 112561. [Google Scholar] [CrossRef]

- Aksoylu, C.; Özkılıç, Y.O.; Yazman, Ş.; Gemi, L.; Arslan, M.H. Experimental and Numerical Investigation of Load Bearing Capacity of Thinned End Precast Purlin Beams and Solution Proposals. Tek. Dergi 2021, 32, 10823. [Google Scholar] [CrossRef]

- Gemi, L.; Madenci, E.; Özkılıç, Y.O. Experimental, analytical and numerical investigation of pultruded GFRP composite beams infilled with hybrid FRP reinforced concrete. Eng. Struct. 2021, 244, 112790. [Google Scholar] [CrossRef]

- Srividhya, S.; Vidjeapriya, R.; Neelamegam, M. Enhancing the performance of hyposludge concrete beams using basalt fiber and latex under cyclic loading. Comput. Concr. 2021, 28, 93–105. [Google Scholar]

- Adetukasi, A.O. Strength and deflection characteristics of concrete reinforced with steel swarf. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Wuhan, China, 10–12 October 2019; p. 012044. [Google Scholar]

- Abbas, A. Management of steel solid waste generated from lathes as fiber reinforced concrete. Eur. J. Sci. Res. 2011, 50, 481–485. [Google Scholar]

- Sharba, A.A.K.; Ibrahim, A.J. Evaluating the use of steel scrap, waste tiles, waste paving blocks and silica fume in flexural behavior of concrete. Innov. Infrastruct. Solut. 2020, 5, 94. [Google Scholar] [CrossRef]

- Balea, A.; Monte, M.C.; Blanco, A.; Negro, C. Recycled fibers for sustainable hybrid fiber cement based material: A review. Materials 2021, 14, 2408. [Google Scholar] [CrossRef]

- Merli, R.; Preziosi, M.; Acampora, A.; Lucchetti, M.C.; Petrucci, E. Recycled fibers in reinforced concrete: A systematic literature review. J. Clean. Prod. 2020, 248, 119207. [Google Scholar] [CrossRef]

- Altera, A.Z.; Bayraktar, O.Y.; Bodur, B.; Kaplan, G. Investigation of the Usage Areas of Different Fiber Reinforced Concrete. Kast. Univ. J. Eng. Sci. 2021, 7, 7–18. [Google Scholar]

- Yang, E.-H.; Wang, S.; Yang, Y.; Li, V.C. Fiber-bridging constitutive law of engineered cementitious composites. J. Adv. Concr. Technol. 2008, 6, 181–193. [Google Scholar] [CrossRef]

- Özkılıç, Y.O.; Aksoylu, C.; Arslan, M.H. Experimental and numerical investigations of steel fiber reinforced concrete dapped-end purlins. J. Build. Eng. 2021, 36, 102119. [Google Scholar] [CrossRef]

- Ju, Y.; Zhu, M.; Zhang, X.; Wang, D. Influence of steel fiber and polyvinyl alcohol fiber on properties of high performance concrete. Struct. Concr. 2022, 23, 1687–1703. [Google Scholar] [CrossRef]

- Manaswini, C.; Vasu, D. Fibre Reinforced Concrete from Industrial Waste-A Review. Int. J. Innov. Res. Sci. Eng. Technol. 2015, 4, 11751–11758. [Google Scholar]

- El-Sayed, T.A. Flexural behavior of RC beams containing recycled industrial wastes as steel fibers. Constr. Build. Mater. 2019, 212, 27–38. [Google Scholar] [CrossRef]

- Sezhiyan, T.; Rajkumar, R. Study on the Properties of High Strength Concrete Using Glass Powder and Lathe Scrap; Kongu Engineering College: Perundurai, India, 2014; Volume 3. [Google Scholar]

- Vijayakumar, G.; Senthilnathan, P.; Pandurangan, K.; Ramakrishna, G. Impact and energy absorption characteristics of lathe scrap reinforced concrete. Int. J. Struct. Civ. Eng. Res. 2012, 1, 1–6. [Google Scholar]

- GÜLmez, N. Reuse of Industrial Metal Wastes as Partial Replacement of Aggregates in Mortar Production. Dicle Üniversitesi Mühendislik Fakültesi Mühendislik Derg. 2021, 12, 875–880. [Google Scholar] [CrossRef]

- Meddah, M.S.; Bencheikh, M. Properties of concrete reinforced with different kinds of industrial waste fibre materials. Constr. Build. Mater. 2009, 23, 3196–3205. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Özkılıç, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Małek, M.; Kadela, M.; Terpiłowski, M.; Szewczyk, T.; Łasica, W.; Muzolf, P. Effect of metal lathe waste addition on the mechanical and thermal properties of concrete. Materials 2021, 14, 2760. [Google Scholar] [CrossRef]

- Shukla, A.K. Application of CNC waste with recycled aggregate in concrete mix. Int. J. Eng. Res. Appl. 2013, 3, 1026–1031. [Google Scholar]

- Prabu, M.; Vignesh, K.; Saii Prasanna, N.; Praveen, C.; Mohammed Nafeez, A. Experimental study on concrete in partial replacement of fine aggregate with lathe waste. Int. J. Sci. Eng. Res. 2020, 11, 68–72. [Google Scholar]

- Althoey, F.; Hosen, M.A. Physical and mechanical characteristics of sustainable concrete comprising industrial waste materials as a replacement of conventional aggregate. Sustainability 2021, 13, 4306. [Google Scholar] [CrossRef]

- Wang, X.; Fan, F.; Lai, J.; Xie, Y. Steel fiber reinforced concrete: A review of its material properties and usage in tunnel lining. Structures 2021, 34, 1080–1098. [Google Scholar] [CrossRef]

- Thirumurugan, A.; Sivaraja, M. Strength and fracture properties of hybrid fibre reinforced concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2015, 39, 93. [Google Scholar]

- Mansi, A.H.; Galal, O.H.; Lafi, M. The utilisation of lathe steel waste fibers to improve plain concrete. In Proceedings of the Ninth International Conference on Advances in Civil, Structural and Mechanical Engineering, Rome, Italy, 7–8 December 2019; pp. 7–8. [Google Scholar]

- Bhavana, A.; Rangarao, M.L.S. An Experimental Study on Structural Behavior of Lathe Waste in Conventional and Self-Compacting Concrete. Int. J. Eng. Technol. 2018, 7, 955–959. [Google Scholar]

- Akshaya, T.; Manikandan, G.; Esther Baby, J.; Jaambavi, I. Experimental study on bending behaviour of fibre reinforced concrete by using lathe waste fiber. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Shewalul, Y.W. Experimental study of the effect of waste steel scrap as reinforcing material on the mechanical properties of concrete. Case Stud. Constr. Mater. 2021, 14, e00490. [Google Scholar] [CrossRef]

- Gawatre, D.W.; Haldkar, P.; Nanaware, S.; Salunke, A.; Shaikh, M.; Patil, A. Study on addition of lathe scrap to improve the mechanical properties of concrete. Int. J. Innovat. Res. Sci. Eng. Technol. 2016, 5, 8573–8578. [Google Scholar]

- Nazir, L.; Sharma, P.; Kumar, M.; Mir, S.A. An Experimental Investigation Of Lathe Steel Fibres Reinforced With M20 Concrete. Int. J. Technol. Res. Eng. 2018, 5, 4264–4266. [Google Scholar]

- Joy, J.; Rajeev, R. Performance of Steel Scrap in Concrete. Int. J. Sci. Res. Dev. 2015, 2, 755–758. [Google Scholar]

- Liew, K.; Akbar, A.J.C.; Materials, B. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232. [Google Scholar] [CrossRef]

- Ahmad, I.; Qing, L.; Khan, S.; Cao, G.; Ijaz, N.; Mu, R.J.C.; Materials, B. Experimental investigations on fracture parameters of random and aligned steel fiber reinforced cementitious composites. Constr. Build. Mater. 2021, 284, 122680. [Google Scholar] [CrossRef]

- Junaid, M.F.; ur Rehman, Z.; Kuruc, M.; Medveď, I.; Bačinskas, D.; Čurpek, J.; Čekon, M.; Ijaz, N.; Ansari, W.S.J.C.; Materials, B. Lightweight concrete from a perspective of sustainable reuse of waste byproducts. Constr. Build. Mater. 2022, 319, 126061. [Google Scholar] [CrossRef]

- Salman, N.M.; Ma, G.; Ijaz, N.; Wang, L.J.C.; Materials, B. Importance and potential of cellulosic materials and derivatives in extrusion-based 3D concrete printing (3DCP): Prospects and challenges. Constr. Build. Mater. 2021, 291, 123281. [Google Scholar] [CrossRef]

- Yazıcı, Ş.; İnan, G.; Tabak, V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Constr. Build. Mater. 2007, 21, 1250–1253. [Google Scholar] [CrossRef]

- Neves, R.D.; Fernandes de Almeida, J.C.O. Compressive behaviour of steel fibre reinforced concrete. Struct. Concr. 2005, 6, 1–8. [Google Scholar] [CrossRef]

- Shah Surendra, P.; Rangan, B.V. Effects of Reinforcements on Ductility of Concrete. J. Struct. Div. 1970, 96, 1167–1184. [Google Scholar] [CrossRef]

- Tschegg, E.K.; Schneemayer, A.; Merta, I.; Rieder, K.A. Energy dissipation capacity of fibre reinforced concrete under biaxial tension–compression load. Part I: Test equipment and work of fracture. Cem. Concr. Compos. 2015, 62, 195–203. [Google Scholar] [CrossRef]

- Lee, J.-H. Influence of concrete strength combined with fiber content in the residual flexural strengths of fiber reinforced concrete. Compos. Struct. 2017, 168, 216–225. [Google Scholar] [CrossRef]

- Zheng, Z.; Feldman, D. Synthetic fibre-reinforced concrete. Prog. Polym. Sci. 1995, 20, 185–210. [Google Scholar] [CrossRef]

- Li, B.; Xu, L.; Shi, Y.; Chi, Y.; Liu, Q.; Li, C. Effects of fiber type, volume fraction and aspect ratio on the flexural and acoustic emission behaviors of steel fiber reinforced concrete. Constr. Build. Mater. 2018, 181, 474–486. [Google Scholar] [CrossRef]

- Soulioti, D.V.; Barkoula, N.M.; Paipetis, A.; Matikas, T.E. Effects of Fibre Geometry and Volume Fraction on the Flexural Behaviour of Steel-Fibre Reinforced Concrete. Strain 2011, 47, e535–e541. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Kim, S.; Park, G.-J.; Park, J.-J.; Kim, S.-W. Effects of fiber shape, aspect ratio, and volume fraction on flexural behavior of ultra-high-performance fiber-reinforced cement composites. Compos. Struct. 2017, 174, 375–388. [Google Scholar] [CrossRef]

- Vasudev, R.; Vishnuram, B.G. Experimental Studies of the Application of Turn Steel Scraps as Fibres in Concrete–A Rehabilitative Approach. Int. J. Eng. Technol. 2014, 6, 1885–1899. [Google Scholar]

- Haldkar, P.; Salunke, A. Analysis of Effect of Addition of Lathe Scrap on the Mechanical Properties of Concrete. Int. J. Sci. Res. 2016, 5, 2321–2325. [Google Scholar]

- Maanvit, P.S.; Prasad, B.P.; Vardhan, M.H.; Jagarapu, D.C.; Eluru, A. Experimental examination of fiber reinforced concrete incorporation with lathe steel scrap. IJITEE 2019, 9, 3729–3732. [Google Scholar] [CrossRef]

- Kumaran, M.; Nithi, M.; Reshma, K.R. Effect of lathe waste in concrete as reinforcement. Int. J. Res. Adv. Technol. 2015, 6, 78–83. [Google Scholar]

- Mohammed, H.J.; Abbas, A.H.; Husain, M.A. Using of Recycled Rubber Tires and Steel Lathes Waste as Fibbers to Reinforcing Concrete. Iraqi J. Civ. Eng. 2013, 9, 27–38. [Google Scholar] [CrossRef]

- Prasad, B.P.; Maanvit, P.S.; Jagarapu, D.C.K.; Eluru, A. Flexural behavior of fiber reinforced concrete incorporation with lathe steel scrap. Mater. Today Proc. 2020, 33, 196–200. [Google Scholar] [CrossRef]

- Purohit, R.; Dulawat, S.; Ahmad, E. To enhance mechanical properties of concrete by using lathe steel scarp as reinforced material. J. Eng. Sci. 2020, 11, 206–214. [Google Scholar]

- Qureshi, Z.N.; Raina, Y.M.; Rufaie, S.M.A. Strength characteristics analysis of concrete reinforced with lathe machine scrap. Int. J. Eng. Res. Gen. Sci. 2016, 4, 210–217. [Google Scholar]

- Sarabi, S.; Bakhshi, H.; Sarkardeh, H.; Nikoo, H.S. Thermal stress control using waste steel fibers in massive concretes. Eur. Phys. J. Plus 2017, 132, 1–8. [Google Scholar] [CrossRef]

- Sheikh, M.A.; Reza, M. Strengthening of concrete using lathe scrap waste. Int. Res. J. Eng. Technol. 2020, 7, 464–470. [Google Scholar]

- Shrivastava, P.; Joshi, D.Y. Reuse of lathe waste steel scrap in concrete pavements. Int. J. Eng. Res. Appl. 2014, 4, 45–54. [Google Scholar]

- Kamal, M.; Ahmad, F.; Khan, M.A.; Khan, D.; Afridi, M.; Habib, A. Microscopic and mechanical analysis of lathe waste steel fibers as fiber reinforcement in concrete. Glob. Sci. J. 2021, 9, 1319–1326. [Google Scholar]

- Aravindasamy, M.; Manikandan, M.; Somiyadevi, P. Studies on the Flexural Behavior of Concrete Beams with Lathe Waste in RC. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 1065–1070. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).