Abstract

Industrialization is indispensable for socio-economic development but poses far-reaching implications for resources and the environment. Consequently, industrial symbiosis-based collaborations are gaining recognition as a viable strategy to manage resource consumption for mitigating environmental distress. However, these types of synergistic collaborations are more prevalent in developed regions and are linked to larger-sized industries. Admittedly, such collaborative partnerships are less focused in developing regions and small- to medium-size enterprises (SMEs). This calls for discovering the potentials for synergistic partnerships among the small and medium scaled industrial entities in developing economies. Therefore, the study was designed to identify, assess and explore the prospects of symbiotic collaborations among SMEs in Pakistan. Moreover, the inputs are equally relevant for developing and expanding such productive associations in developing regions. Data regarding inputs and outputs was collected from sixty-one (61) SMEs through field survey during the year 2019. It was processed and analyzed to uncover existing and potential synergies among SMEs. The significant findings transpired that the majority of collaborative linkages are bilateral and are driven to maximize economic gains. However, informal networks of recyclers and absence of a stringent regulatory regime are the ground realities in developing/transforming economies. These factors symptomatically interfere with the process of formal/informal exchanges between and among firms. Furthermore, it was observed that the lack of awareness and impulsiveness of SMEs, as well as the inconsistent supply of by-products, act as barriers for such partnerships in developing countries. It calls for proactive engagements and facilitations from the state institutions through policy instruments. The study addresses a broad audience including industrialists, investors, policy makers and researchers engaged in IS studies. Moreover, the inputs will provide impetus for stimulating eco-industrial progress in developing regions such as Pakistan.

1. Introduction

Industrialization and associated development have indelible imprints on socio-economic activities and resource use patterns in society. The pressures on resources and the quest for cost-effective production strategies have stimulated resource conservation and symbiotic collaborations among industries. As such, new approaches for catalyzing synergistic linkages between and among industries, employing Circular Economy (CE) principles, is gaining traction in industries which aim at resource and energy recovery through waste minimization while ensuring tangible economic benefits for the industry [1,2,3]. The conceptual paradigm places emphasis on the need that the economy should shift from a linear to a circular mode of production.

The CE-based initiatives envisage that industrial processes should ensure the utilization of waste in a similar way as natural systems function. The natural systems operate on the premise that output from one component serves as an input for the succeeding component (s). That is why the word “waste” is absent in the lexicon of nature. Similar is the case with industrial ecology and this begets CE-based initiatives as industrial symbiosis (IS) with its primary focus on sharing available resources [4,5] for monetary and environmental benefits [1,6]. The corollary effects of such collaborative engagements in the industrial sector contribute toward economic development without compromising the environment [7,8,9].

The term ‘industrial symbiosis’ started to gain recognition in the scientific literature at the onset of this century. Chertow [4] suggests that flexible and innovative strategies are helping to re-utilize discarded industrial material through IS. However, the density, type, and nature of industrial activities suggestively influence the inclinations toward IS [10]. Chertow [11] also elaborated on the conceptual contours of IS networks by postulating a “3–2 heuristic minimum criterion”. The elaboration argues that at least three different entities must collaborate in sharing two different resources to be termed IS, while the researchers Short et al. [12], Zhu et al. [13], and Yuan and Shi [14] suggest synergistic partnerships between different units of the same business entity are also the types of IS.

The IS-based linkages are compartmentalized into three major types based on the nature of the interactions: by-product exchanges, utility sharing, and collective procurement [4,15]. Consequently, researchers such as Zhu et al. [13], Yuan and Shi [14], Short et al. [12] and Walls and Paquin [16] have extended this concept, elaborating on the organizational contours of IS on the basis of the scale of linkages: intra-firm, inter-firm, and at the regional scale [17].

Similar to IS literature, Eco-Industrial Development (EID) based studies from Kalundborg (Denmark), Kwinana and Gladstone (Australia), Kawasaki (Japan), Guitang (China), Ulsan (Korea), and Guayama (USA) contend that these earlier models are realized due to self-organization as a result of collaborative efforts to maximize collective benefits. Researchers suggest that technological advancements and a desire for cleaner production stimulate such symbiotic collaborations [18] in large industries.

While many of the earlier examples stem from industrialized and developed economy settings, Shenoy [19] emphasized the role of development strategies in the context of developing economies. She argued that rapid industrialization and urbanization provide a breeding ground for by-product synergies in developing countries. However, at the same time, due to the involvement of informal sectors, grey markets and SMEs, most of the waste exchanges remain undocumented in the developing world. Such countries may need a bottom-up approach for industrial symbiosis, which can be facilitated through policies and regulations [19,20,21].

In developing economies, SMEs have been acknowledged to significantly contribute to socio-economic development [19,22]. However, the contribution of SMEs to progress in resource efficiency and cleaner production has been less acknowledged [23,24] due to a lack of awareness, a limited industrial base, and inconsistencies in policies [25]. Consequently, the inclinations for eco-industrial development are less observable among the developing economies as compared to developed regions. There is a need to identify, quantify, and facilitate such productive exchanges for robust industrial and economic growth [22]. However, the baseline information and assessments pertaining to existing resource synergies are the missing links in developing countries such as Pakistan.

The Rationale for Assessments in Pakistan

Manufacturing activities are gaining momentum in Pakistan [26]. SMEs constitute approximately 90% of all economic activities, providing job opportunities to 80% of the non-agricultural labor force and contribute to roughly 40% of the Gross Domestic Product (GDP) of Pakistan [27]. These SMEs are sparsely located and generally overlooked by regulatory control systems. Furthermore, there is a lack of reliable data about the type and amount of waste generated from these SMEs in Pakistan [28].

In light of these challenges, this study aims to assess the level to which SMEs in Pakistan are practicing IS, the challenges faced, and enabling factors for further IS development. Information collected provides empirical evidence for decision-makers, regional planners, and industries in order to promote circularity through exchange synergies and provide the IS literature with further examples from developing economies. This study is the first effort to uncover the existing industrial symbiosis network in Pakistan. For this purpose, a case study approach based on an industrial area located in Islamabad, concentrated with SMEs, was analyzed to identify existing as well as potential synergies. The study also identifies the barriers to prospective business partnerships and linkages in this region.

2. Materials and Methods

IS networks are commonly assessed from three perspectives namely: (i) identify cation, (ii) assessment, and (iii) implementation [29]. Yeo et al. [29], on the other hand, laid emphasis on a six-step framework for the purpose [29]. However, the present study relied on an exploratory mode for un-covering byproduct exchange synergies among industrial units in the study area. For the purpose of the study, the data was retrieved through field surveys and focus group discussions.

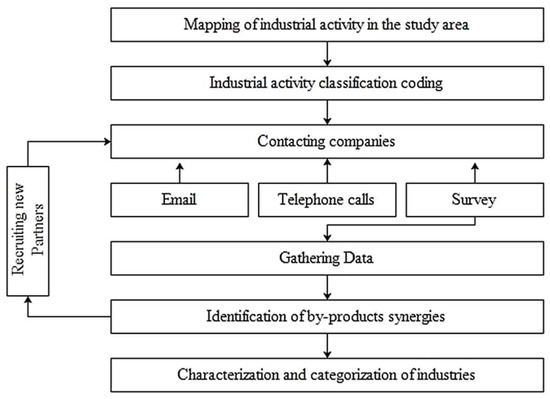

The assessment tool is composed of four primary steps: (1) a survey of the industrial area, (2) a classification of industrial activity, (3) data collection, and finally (4) an identification of synergies and potential barriers for industrial symbiosis. The adopted methodological framework is a pragmatic, reliable and robust approach for deciphering intricacies in industrial linkages [30,31,32]. It deftly contributed to a comprehension of the symbiotic connections among the industrial entities in the study area. The schematic representation (Figure 1) elucidates the methodological framework, while subsequent sections further elaborate on the methodological process followed in this study.

Figure 1.

Schematic representation of the methodological framework.

2.1. The Regional Context

The Industrial Estate of Islamabad (IEI) is located in the center of Islamabad, the capital of Pakistan. Islamabad has a population of over 2 million inhabitants, which is growing at the rate of 2.1% annually. Consequently, the area is witnessing a boom in the construction sector and serves as an important destination for tourism in the country. The industrial area was established in 1963 [33], and includes roughly 118 SMEs of diverse nature and sizes. The initial industrial survey was completed from August to December 2019. After the survey, ten (10) pharmaceutical industries were excluded from the survey as these units are in agreement with the National Cleaner Production Center for waste treatment.

Therefore, 108 SMEs were contacted for data collection, yet only 61 entities participated in the survey. The lack of awareness regarding the significance of scholastic initiatives are plausible explanations for reported inclinations [34,35]. However, the consultative meetings with regulatory bodies such as ICCI and Pak-EPA productively contributed towards data acquisition. The coordination with regulatory bodies encouraged the SMEs to participate in the survey. With respect to the nature of activities in the area, noticeable large-scale SMEs in this area are steel manufacturing units, pharmaceutical industries, and flour mills. In addition, there are smaller size units involved in marble and food processing. The largest-sized firms employ between 200-250 workers, while the smallest size SMEs employ roughly 10 to 15 employees. Most of the SMEs are members of the Islamabad Chamber of Commerce and Industries (ICCI) and are regulated by Pakistan Environmental Protection Agency (Pak-EPA) for their emission and effluents control [36].

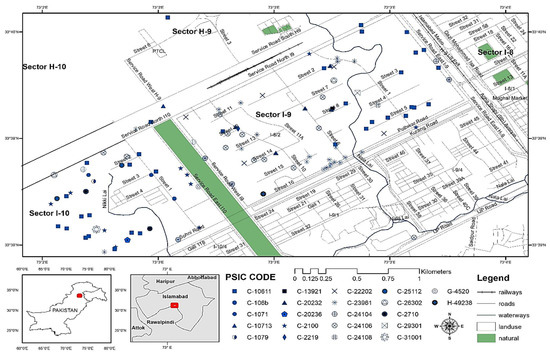

The industrial activities were classified in accordance with the Pakistan Standard Industrial Classification (For All Economic Activities) (PSIC) Code of 2010 (http://www.pbs.gov.pk/sites/default/files/other/PSIC_2010.pdf/, accessed on 16 September 2019), see Appendix A. For this purpose, the information regarding the industrial units located in the study area were retrieved from ICCI and Pak-EPA. The list was organized according to the PSIC classification scheme. The PSIC code-based mechanism is a set of internationally agreed classification rules based on economics and industrial activities [37,38]. It offers a robust framework for assessing and reporting industrial activities [10]. It is considered a suitable framework for such investigations in Pakistan [38]. The probe concluded that the classification of industrial activities is a challenging task in newly industrializing regions. Several field visits were conducted to the area, for verification of data and rapport building. During these initial survey visits, limited information pertaining to the nature of production, number of employees, contact details and certification status, along with geographical location was collected and compiled to make an inventory of the industrial activities. This information was then used for developing a map of the region using Geographic Information System (GIS) (ArcGIS software Version 10.3. Redlands, CA, USA: Environmental Systems Research Institute) for spatial/temporal assessments, see Figure 2. This approach for field investigation yielded the following advantages as it (1) enabled interaction with the respondents in an informal way; (2) provided an opportunity to scrutinize the contextual potentials and challenges for assessments; (3) collected insights from the stakeholders which helped to develop a conclusive survey booklet for data collection.

Figure 2.

The spatial distribution of industrial activities according to Pakistan Standard Industrial Classification (PSIC) code.

2.2. Data Collection

A three-tier approach was adopted for data collection using a questionnaire survey, see Appendix B. For the first level, prospective respondents were contacted through email (see Appendix C), to which only four firms responded. Therefore, in order to increase the availability of data, at the second level, calls by telephone were conducted to further encourage respondents to participate in this study. As a result, 44 firms agreed to participate. At the third level, those firms who were willing to participate in the study were provided a questionnaire. During these contacts, we found a further seventeen firms of similar nature, employing the principles of the ‘snowballing’ technique [39,40].

The questionnaire consisted of four sections that were designed to obtain (i) general information about the industry, (ii) input(s) used in the processing, (iii) output(s) of the firm, and (iv) to identify any synergies currently in place and potential barriers faced by the SMEs. The first part of the questionnaire was completed during the preliminary investigations (initial field visits), while the second and third parts provide a list of the options regarding the probable inputs and outputs related to industrial processing. The fourth section infers about the level of awareness regarding the IS in responding entities. The field survey was carried out during the year 2019. The respondents were production managers and/or quality control engineers working in these SMEs.

2.3. Data Analysis

The data collected through the questionnaire was compiled and tabulated using MS Excel (Microsoft Excel version 365, Microsoft Corporation, Redmond, WA, USA). Data was analyzed for each type of synergy which helped to develop an in-depth overview of the identified synergies.

2.3.1. Identification of Synergies

The synergistic collaborations in the industrial sector depend on the amount and nature of discarded material generated from industrial processes. For this purpose, the input-output matching technique was relied upon for identifying current synergies.

2.3.2. Identification of Potential Future Synergies

For the identification of potential future synergies in the industrial sector, a two-step strategy was adopted [39]. In the first step, items were selected from the questionnaire responses where inputs matched the output. Realizing that all of the identified synergies might not be feasible, in the second step, brainstorming sessions with stakeholders were conducted to decipher contextual potentials and possibilities for identified matching items. During brainstorming sessions, global databases such as the Hebei By-Product Synergy Project (https://marketplacehub.org/item/hebei-by-product-synergy-project/, accessed on 24 December 2020) were also consulted. During these brainstorming sessions stakeholders screened out all those synergies already in place or those feasible in the future. The brainstorming session also helped in compiling convergent and divergent views of the stakeholders regarding by-product exchange synergies in the study area. The findings are concluded in the form of drivers and barriers and are listed in Section 3 of this paper.

3. Results

The following sections uncover and outline the salient features of the industrial symbiosis network in Islamabad, Pakistan. These results were derived from a sizable proportion of SMEs (61) that participated in the survey.

3.1. Environmental Performance of Firms

The findings of the study suggest that the majority of SMEs (108) in the study area showed little or no concern for the environment. The findings show that out of the total participating units, only 8% have dedicated staff for waste management. Besides this, only 5% of the assessed firms are certified entities by International Standard Organization (ISO). (https://www.iso.org/publication/PUB100411.html, accessed on 23 February 2021). The accreditation infers the propensities for environmentally friendly productions ISO-2017 [41]. We deduced from the findings that proclivities for eco-industrial productions are not the priority of SMEs.

3.2. Identified Synergies

The inventory of identified synergies (see Appendix D) provides key features of by-product synergy collaborations identified in the study area. Many of the symbiotic partnerships identified are bilateral in nature. The synergistic collaborations were classified into five distinctive groups on the basis of the physical characteristics of the waste being exchanged. These included: (i) metal residues, (ii) food residues, (iii) plastics, (iv) mineral, and (v) others (acids, lubricants, wool, PVC resin, etc.); see also Appendix D.

3.2.1. The Spatial Orientations of Collaboration

The identified synergies were grouped in four categories from spatial perspectives, these included: (i) intra-firm exchanges, (ii) inter-firm exchanges within the industrial area, (iii) inter-firm exchanges outside industrial area, (iv) inter-firm exchange for co-product generation.

- Intra-firm exchanges: in these types of exchanges, waste generated from one process is utilized in another process within the firm boundary [39,42]. Table 1 conclusively elaborates on the intra-firm exchanges observed in the study area;

Table 1. Types of by-product exchange synergies.

Table 1. Types of by-product exchange synergies. - Inter-firm exchanges (within the industrial area): these types of partnerships evolved between traditionally separate industrial facilities located in the vicinity. These entities hold meetings, form associations, and team up resources for joint ventures. Table 1 sums up the nature of activities, by-products generated, and synergistic collaborations operative in the study area.

- Inter-firm exchanges (outside the industrial area): these types of exchanges reflect a peculiar type of interconnectedness in which the collaborations have also evolved with the partners located outside the study area. Table 1 sums up the details of the symbiotic linkages in which the industrial wastes are transported outside from the study area for subsequent utilization.

- Inter-firm exchanges for co-product generation: in this special type of engagement, the by-products generated at one facility are utilized at another processing unit by the same owner. Table 1 succinctly outlines the salient characteristics of the observed collaborations.

3.2.2. By-Product Synergies

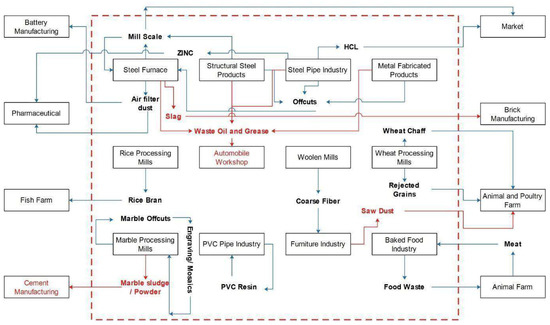

The inclinations for collaborative partnerships among selected industrial entities were assessed for insights. The discarded industrial wastes and their subsequent utilization were particularly focused. Figure 3 succinctly portrays the orientations of collaborations among the observed industries.

Figure 3.

By-product exchange synergies at IEI. (Black color: Existing synergies; Red Color: Potential Synergies).

- Marble offcuts: there are 21 marble processing units in the study area. The number of employees engaged in these units ranges from 6 to 20. Thus, these units are classified as small-scale industrial enterprises. During the processing, small irregular fragments of marble, referred to as offcuts, are produced [43]. The assessments found that approximately 5 to 8% of the total processed marble is discarded as offcuts. Hence, the study area’s processing units annually approximately produce between 1500 and 1800 tons of industrial waste as offcuts (Appendix D). The greater proportion of tiny offcuts are used for construction purposes as floor chips. While the offcuts of precious stones are reprocessed for decoration;

- Mill scale: mill scales or flakes contain a substantial amount of iron oxides. This is a by-product of steel making and processing. The processed mill scale has a variety of reported usages [44]. It is used as an industrial raw material in cement [45], iron and steel industries [46]. The findings infer that there is only one industrial facility in the study area which processes raw mill scale. Approximately 690 tons of mill scale is annually produced from this processing facility. The major share of processed mill scale is exported to China through vendors;

- Air filter dust (ADF): the particulate matter known as “Air Filter Dust” (ADF) is a by-product of steel furnaces. The dust contains a high concentration of components such as Zinc (Zn), Lead (Pb) and Iron (Fe). The retrieved material is consumed for manufacturing pigments, cells, and batteries. Besides this, it has a productive value for the pharmaceutical industry. The survey showed that the quantities of ADF produced in a unit differ from 0.5% to 0.8% of the total production. The variation in quantity and quality is dependent on raw material (scrap), the technology used for processing and, the quantum of steel produced. The estimates inferred that approximately 1550 tons of ADF is annually produced in the study area (Appendix D). The collected ADF is channelized through different conduits. One of the industrial units shifts it to the pharmaceutical industry where the Zn is extracted from the dust, while the others sell their produced materials to the battery or plastic manufacturing industry;

- Metal offcuts: the metal offcuts are small pieces of steel. The tiny fragments of iron are produced during the cutting of billets, iron rods, T-irons, and other metallic products. Approximately, between 10,000 and 15,000 tons of metal offcuts are annually produced in the study area. The offcuts are purchased by the scrap dealers. The dealers sell it to steel furnaces. These facilities re-utilize this material in the furnaces. There are only 04 industrial units equipped to consume this by-product;

- Zinc: zinc is used in the processing of galvanization in the steel pipe industry. During the associated procedures, a powdery substance mainly composed of Zinc is produced. That Zinc powder is recovered and sold to the pharmaceutical industry. Approximately, 4000 tons of zinc powder are annually retrieved and vented from the study area;

- Hydrochloric Acid: hydrochloric acid (HCl) is required for different processes in the iron and steel industry. It is a requirement of the galvanization process for producing iron pipes. The acid is recollected after procedures and impurities are removed/reduced from the waste. Subsequently, the by-product, the processed hydrochloric acid, is sold in the market;

- Wheat chaff and discarded grains: there are 36 wheat processing units in the study area that have large quantities of wheat chaff and discarded grains. Wheat chaff is the husk that covers the wheat grains. It is produced during the threshing and crushing processes. This by-product has beneficial nutrients. However, the product is indigestible for humans but useful as an animal feed, primarily as a supplement for livestock. As such, wheat chaff from these entities is sold to animal farms. Furthermore, a substantial proportion of rejected grains from these processing units are also sold to poultry farms as feed;

- Rice bran: there are two rice producers in the area. Pakistan is famous for its quality rice, but the crop is not cultivated in this region, although it is processed here. Rice processing is composed of de-husking and polishing. The procedures are required for producing value-added products such as silky and non-silky rice varieties. The by-products of two types, broken rice and rice bran, are produced due to processing. The broken rice is consumed as food while rice bran is used as feed for the fishery. Therefore, the production of broken rice and rice bran are important as co-products of the process. The unprocessed rice is brought to the processing units for required intermediary procedures before marketing. There is a rice-polishing/processing unit in the study area. The rice bran that is produced as a by-product constitutes between 8 and 10% of the total production. The by-product (rice bran) is sold to local fish farms and (broken rice) is marketed for domestic consumption;

- Polyvinyl Chloride Resin: there are five polyvinyl chloride (PVC) pipe manufacturing units in the study area. PVC resin is produced in these manufacturing facilities. A proportion of this scattered material is collected as industrial waste and re-utilized. Thus, the utilization of PVC resin is a productive contribution as it yields social, economic, and environmental benefits;

- Old wool: there are 2 small-scale woolen manufacturing units (less than 20 employees) in the study area. These industrial units operate in a batch-wise manner. The fine quality of fiber is used for knitwear production and coarse fiber (old wool) is rejected. It was found that 3% of the total processed wool is discarded. The rejected wool is subsequently sold to the furniture industry. The recipient industry utilizes wool as a filling material. A smaller share of the discarded wool is also purchased for quilt making;

- Food waste: food waste is a global concern. A substantial amount of food is discarded during food processing. The waste is utilized as animal feed [47]. There are two baking units in the study area. The food waste from these units is produced in the form of rejected baked items and ingredients. One of these baking units sells this waste to livestock keepers, while the other utilizes it in their subsidiary, the dairy farm.

3.3. Potential for Synergistic Collaborations in the Future

The assessments helped to identify and provide possibilities to employ the by-products to establish new symbiotic partnerships in the study area in the future. The following subsections provide details on the major industrial by-products that offer reliable avenues for industrial byproduct-based collaborations in this area. A depiction of the possibilities outlined below is also provided in Figure 3.

- Slag: slag is a glass-like by-product of the iron and steel industry [48,49]. It is mainly composed of metal oxides and silicon oxides [50]. The findings formulate that approximately 20,000 tons of slag of different varieties are annually produced in the study area. The production is being utilized for mining pit filling or leveling purposes. However, the slag has more promising utilization in the brick-making industry, see, for example, Refs. [51,52];

- Waste oil and grease: synthetic oil and grease are applied for machine lubrication [53]. The lubrication is profusely applied during rolling processes in the iron and steel industry. However, a smaller proportion of discarded oil and grease is recollected and processed for reuse, while the major share of wasted lubricants is washed away. This situation is a dangerous proposition for the contextual land resources and surface water bodies. The scenario suggests that this environmental challenge could be seen as an economic opportunity. It necessitates the in-situ collection of wasted lubricants. The collected waste after processing can be reused for cleaning and lubrication of auto-parts [54];

- Marble sludge: marble processing requires water during polishing and grinding [55,56]. Resultantly, a large amount of sludge is produced due to the mixing of marble dust with the water. At present, this sludge is being disposed of as industrial waste. The careless disposal in open land areas is a nuisance for aesthetics and a serious threat for soil and land resources. This waste could be channelized for productive use such as cement production. See, for example, the possibilities outlined in several studies [57,58];

- Sawdust: sawdust is a type of industrial waste in the timber and furniture industry. Due to rapid urbanization in this region [59], a sizable amount of sawdust is generated. At present, the sawdust is used as bedding material in poultry farms or utilized as a domestic fuel by the low-income groups of the population. However, a huge amount of sawdust is wasted. Therefore, integrated measures are needed to convert this potential resource for more productive outcomes such as energy generation and paper production, etc.

4. Discussion

The industrial productions are indispensable for poverty reduction and development [1]. However, unregulated industrial activities can cause resource depletion and environmental degradation. The aftermath of unplanned industrialization dilutes the fruits of this process itself [60]. This paradoxical situation calls for coordinated efforts and integrated measures for ensuring smart industrial production. It requires symbiotic linkages in industrial processes and among entities for resource conservation and pollution control. The observations rendered by Khan et al. [28] formulate that industrial symbiosis based collaborations are reducing pressures on resources and approximately saving between 10% and 20% energy demands in Pakistan. Consequently, it is curtailing emissions and yielding economic dividends for the industries. Therefore, the penchants for such initiatives are encouraging among the industrialized nations but far from satisfactory in developing countries [1,21]. Neves et al. [61] observed that developing countries such as India, Bangladesh and Egypt are new entrants in the tradition of synergy practices. Resultantly, their scholastic contributions based on case studies are modest as compared to industrialized/developed economies [62]. The late start of industrial activities, as well as the lack of capacity and awareness regarding contextual potential are considered to be major hindrances for smart industrial production in newly industrializing regions [19]. For the purpose of the study, the researchers such as Boom-Cárcamo and Peñabaena-Niebles [21] compared the characteristics of symbiotic linkages among industrial entities from developed and developing countries. The assessments construe that social, economic, environmental and political factors symptomatically determine the orientations toward such synergistic partnerships [21]. However, the resources and capacity building constraints hinder such initiatives in developing countries [21]. The highest number of publications concerning CE in China [61] vindicate that state patronage, regulatory supervision and institutional support energize such tendencies. Moreover, the concerns for environmental resilience, industrial diversity, geographic proximity, and the presence of facilitators also productively contribute towards industrial symbiosis. Therefore, integrated management of industrial activities based on contextual assessments is needed for EID in such regions.

The review of the contextual environment portrayed a less promising scenario for smart industrial collaborations in the study area. The rapid population and urban growth in Islamabad [34,59,63,64] are straining the natural and human resources [35,63,64,65,66]. Albeit, the reliance on IS-based strategies seems to be a pragmatic option for resource conservation, environmental protection and socio-economic development. Hence, the present study was designed to decipher the prospects for stimulating synergistic collaborations among the industries in Islamabad in order to identify and assess the prevalent and prospective collaborative linkages between and among industrial entities. These types of investigations are important for stimulating eco-industrial productions; see similar assertions by [4,18,67]. For this purpose, the criteria of geographical limits as proposed by Bain et al. [39], seems relevant for assessing resource exchanges. However, the implementation of this criterion was difficult in this study due to the overarching role of the middleman in industrial transactions in Pakistan. For the purpose of the study, the suggested benchmarks for classifying byproduct synergies were improvised to accommodate contextual requirements for realistic assessments [39].

It was observed that the study context is composed of a diverse mix of SMEs. These entities operate within a defined geographical area referred to as “Industrial Area of Islamabad”. These small-scale enterprises are members of ICCI. The Pak-EPA is mandated for effluents regulation and emission control. The findings affirmed that the available record pertaining to industrial units is not verifiable. Consequently, these regulatory organizations do not have an effective mechanism to regulate or monitor the activities of these SMEs. Besides that, these processing units keep on shifting their operations to other areas without an approved plan or strategy. Neves et al. [61] formulated that lack of knowledge about waste exchange mechanisms and uncertainty about quantum of waste flow serve as barriers for vibrant industrial symbiosis. Shenoy [19] also rendered similar observations based upon the conclusions drawn through SWOT analysis. The scholar deduced that a lack of awareness and outdated policies are major obstacles for eco-industrial developments in developing countries. While information is necessary for the identification, categorization and assessments pertaining to synergies, the availability and acquisition of statistical data is a real challenge in the undocumented economies [34,35]. The situation is further complicated as the majority of SMEs operate according to a batch-wise approach that produce a non-consistent amount of waste. Moreover, these small enterprises are more volatile. They start and halt processing for maximizing monetary benefits without a predefined strategy or schedule. Resultantly, these types of abnormalities in processing activities pose serious questions about the continuity and sufficiency of waste flows [61]. The lack of information, therefore, calls for preparing a periodic and inclusive inventory of industrial units, including the nature of processes, workforce records as well as amount and type of products and salvages. Besides this, the study conclusively enlists the knowledge gaps and highlight the prospects of future investigation in this domain. Thus, the empirical findings of this investigation can serve as baseline data for studying EID in Pakistan. Costa et al. [68], Gibbs and Deutz [69], and Tao et al. [70] suggest that assertions based on empirical findings are more relevant than laboratory-driven models for realistic policymaking and improving regulatory control.

The findings also show that most of the reported synergies and symbiotic collaborations are autogenously developed relationships. The observed linkages were materialized through bilateral negotiations rather than a systematic framework. Resultantly, the by-products, such as sludge from marble processing units and sawdust, are wasted and cause environmental pollution, despite the fact that the sludge can be a useful raw material for the cement industry [56,71] and sawdust can be utilized for biofuel and electricity generation, pulp and paper production, composting etc. [72,73,74]. However, the contextual settings, such as the diversities in industrial productions and geographical proximity, encourage resource synergies [4,75]. The focus on infrastructural developments, access to technology and associated awareness for smart industrial development due to CPEC are providing enabling environment for collaborative partnerships in this region [76]. Therefore, coordinated efforts are needed to identify and actualize such emerging opportunities.

For this purpose, consultative meetings with stakeholders were carried out based on the quantitative and qualitative assessments, identifying barriers and evaluating contextual potentials to enhance synergistic linkages among the industries of the study area. Therefore, the scholars such as Martin et al. [77] postulated that ‘synergy development workshops’ are effective tools for actualizing available synergy options. The cost-effective mechanism offers a reliable platform for improvising strategies to ensure synergistic collaborations in the industrial sector. The findings from “synergy workshops” inferred the following key enabling factors for promoting IS in the study area.

- Cost differences between virgin raw material and the material retrieved from industrial by-products;

- The supportive and catalytic role of autogenously evolved formal/informal networks;

- The presence of a non-stringent regulatory regime is also stimulating for waste utilization.

Furthermore, the following aspects were assessed as the chief barriers impeding industrial collaborations in the study area.

- The lack of knowledge and information about the contextual potentials is due to the non-availability of an organized mechanism and platform to facilitate such exchanges;

- The non-regulated supply of discarded materials is due to the fact that most of the SMEs operate in a batch-wise manner;

- The fluctuating prices of waste materials are due to the overarching role of the middleman;

- Little or no regulatory monitoring and fees and fines on industrial waste dumping make the synergy options less attractive in the absence of penalties, especially when the differences between the virgin material and by-products are not marked.

Therefore, integrated measures to facilitate IS mechanisms are obligatory for promoting eco-industrial development in the study area. The organized strategies/measures will contribute toward sustainable industrial growth, resilient socio-economic development, and a healthy environment in this region of Pakistan.

5. Conclusions

The economy in Pakistan is gradually transforming and shifting towards the manufacturing sector, rendering the role of SMEs very important. The SMEs in Pakistan are characteristically diverse and have limited resources. Therefore, these entities do not focus on improvising strategies to cultivate monetary benefits by complying with environmental regulations. Besides this, the required patronage for synergistic collaborations in the industrial sector is not vibrant in the country; considering this, it requires a transformed perspective regarding resources and waste. This objective could be achieved through industrial symbiosis or by-product synergy which is based on integrated management of industrial activities by assessing contextual potentials of collaboration among them. Therefore, an attempt has been made to identify existing and potential opportunities for industrial symbiosis among SMEs in Islamabad. The findings formulate that, although the stakeholders are not aware of the conceptual paradigm of industrial symbiosis, they are inclined towards collaborative partnerships primarily for maximizing the benefits. However, so far, only low-hanging fruits are being harnessed. The findings infer that loosely defined mechanisms between and among partners, an overarching role of the middleman in price control and a lack of information about the usefulness of by-products are the main barriers to synergistic partnerships. While the monetary gains and soft regulations were assessed as key enablers for symbiotic inclinations in this region, it is pertinent to mention that the research orientations towards IS are still in the embryonic stages in Pakistan. Therefore, the synchronization of efforts among policy makers, industrialists, academicians, and researchers are required for eco-industrial productions in such countries. It is anticipated that the current study will serve as a catalyst and precursor for similar research initiatives in Pakistan. The findings are also relevant for the resilience and development of industrial symbiosis-based networks in other developing countries. Thus, the findings of this study should serve as the baseline information for promoting eco-industrial development in this region. Future research on the quantification of waste materials being exchanged and discarded is needed.

Author Contributions

We declare that research conceptualization and methodology came from N.A. and M.A.M.; research supervision provided by Z.S. and M.I.K., validation by M.A.M.; data collection and analysis by S.A.B., M.Z.-u.-H. and S.A.; formal analysis, investigation, data curation, and original draft preparation, N.A. and S.A.B.; review and editing by A.M.; visualization by M.Z.-u.-H. All authors have read and agreed to the published version of the manuscript.

Funding

The research received no external funding.

Institutional Review Board Statement

This study was conducted in accordance with the Declaration of Helsinki and approved by the Institutional Ethical Review Committee of International Islamic University, Islamabad, Pakistan.

Informed Consent Statement

Informed consent was obtained from all respondents involved in the study.

Data Availability Statement

The data that support the finding of this study are available from the corresponding author on request.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

List of Industries contacted for the survey.

Table A1.

List of Industries contacted for the survey.

| Sr. No. | PSIC Code | Products | Name of Company | Latitude | Longitude | Website | Certification |

|---|---|---|---|---|---|---|---|

| 1 | C-25112 | Aluminum manufacturing | Pak Al-Tech Aluminum | 33°39′22.43″ N | 73°2′20.56″ E | - | - |

| 2 | G-4520 | Automobile Workshop | Auto Club (Workshop) | 33°39′16.37″ N | 73°2′40.46″ E | - | - |

| 3 | C-1071 | Bakery Products | Triways Food Industries | 33°39′19.66″ N | 73°2′28.20″ E | - | - |

| 4 | C-1071 | Baking Industry | Liaqat Karkhana (Tehzeeb Bakers) | 33°39′19.66″ N | 73°2′11.95″ E | - | - |

| 5 | C-26302 | Defence Electronics | RWR Pvt. Ltd. | 33°39′46.26″ N | 73°3′15.55″ E | - | - |

| 6 | C-26302 | Electronic assemblies for defence & telecommunication equipment | Zeeshan Electronics | 33°39′19.65″ N | 73°2′3.09″ E | http://www.zeeshanelectronics.com/ (accessed on 5 May 2022) | - |

| 7 | C-2219 | Cooling system Rubber parts | International Polymer Industries | 33°39′32.76″ N | 73°2′50.73″ E | http://www.ipitractorparts.com/ (accessed on 5 May 2022) | ISO 9001 |

| 8 | C-10611 | Flour and Processing Mills | Rizwan Flour Mills | - | - | - | - |

| 9 | C-10611 | Flour and Processing Mills | Akbar Flour & General Mills | 33°39′5.19″ N | 73°2′4.05″ E | - | - |

| 10 | C-10611 | Flour and Processing Mills | Mukhtar Flour & General Mills | 33°39′3.43″ N | 73°2′23.13″ E | - | - |

| 11 | C-10611 | Flour Mill | Al-Azeem Flour & General Mills | 33°39′7.97″ N | 73°2′10.14″ E | - | - |

| 12 | C-10611 | Flour Mill | Al-Faisal Flour & General Mills | 33°39′1.97″ N | 73°2′11.23″ E | - | - |

| 13 | C-10611 | Flour mill | New Al-Hilal Flour Mills Pvt. Ltd. | 33°39′35.80″ N | 73°3′29.51″ E | - | - |

| 14 | C-10611 | Flour Mill | New Arshad Flour Mills | 33°39′39.82″ N | 73°3′18.61″ E | - | - |

| 15 | C-10611 | Flour Mill | New Noor Flour & General Mills | 33°39′8.33″ N | 73°2′12.19″ E | - | - |

| 16 | C-10611 | Flour Mill | Rawal International Flour & General Mills Pvt. Ltd. | 33°39′34.58″ N | 73°2′28.13″ E | - | - |

| 17 | C-10611 | Flour Mill | Waqar Flour & General Mills Pvt. Ltd. | 33°39′32.68″ N | 73°3′23.89″ E | - | - |

| 18 | C-10611 | Flour Mill/Processing | Nafees Flour & General Mills | 33°39′49.88″ N | 73°3′42.61″ E | - | - |

| 19 | C-10611 | Flour Milling | Islamabad Sunny Flour Mills Pvt. Ltd. | 33°38′58.87″ N | 73°2′18.74″ E | http://www.sunnyflour.com/index.htm (accessed on 5 May 2022) | ISO 9001:2008, HACCP/ISO22000 |

| 20 | C-10611 | Flour Milling | Al-Sajjad Flour Mills | 33°39′54.91″ N | 73°3′38.83″ E | - | - |

| 21 | C-10611 | Flour Milling & Processing | Khawaja Bros Flour & General Mills (Pvt) Ltd. | 33°39′38.63″ N | 73°3′36.32″ E | - | - |

| 22 | C-10611 | Flour Milling & Processing | New Fine Flour & General Mills | 33°39′38.80″ N | 73°3′35.68″ E | - | - |

| 23 | C-10611 | Flour Milling & Processing | Noor Flour & General Mill | 33°39′23.06″ N | 73°2′11.56″ E | - | - |

| 24 | C-10611 | Flour Milling & Processing | Saeed Flour Mills | 33°39′28.30″ N | 73°3′15.92″ E | - | - |

| 25 | C-10611 | Flour Milling and processing | Al-Qaim Flour and General Mills | 33°39′2.43″ N | 73°2′11.99″ E | - | - |

| 26 | C-10611 | Flour Milling and processing | Bami Khan Flour and General Mills Pvt. Ltd. | 33°39′54.16″ N | 73°3′36.77″ E | - | - |

| 27 | C-10611 | Flour Milling and processing | Chaudhry Flour Mills Pvt. Ltd. | 33°39′34.61″ N | 73°3′25.41″ E | - | - |

| 28 | C-10611 | Flour Milling and processing | Esmail Flour Mills Pvt. Ltd. | 33°40′0.04″ N | 73°3′22.78″ E | - | - |

| 29 | C-10611 | Flour Milling and processing | Islamabad Flour and General Mills | 33°39′48.60″ N | 73°3′32.96″ E | - | - |

| 30 | C-10611 | Flour milling | Rehmat Flour & General Mills | 33°39′20.63″ N | 73°2′29.44″ E | - | - |

| 31 | C-10611 | Flour Milling/processing | United Flour Mills | 33°39′49.73″ N | 73°3′12.98″ E | - | - |

| 32 | C-10611 | Flour Mills | Al-Kausar Flour and General Mills | 33°39′31.95″ N | 73°2′46.79″ E | - | - |

| 33 | C-10611 | Flour Mills | Sihala Flour & General Mills Pvt. Ltd. | 33°39′59.90″ N | 73°3′34.43″ E | - | - |

| 34 | C-10611 | Flour Mills/Processing | Al-Imran Roller Flour Mills | 33°39′39.60″ N | 73°3′40.04″ E | - | - |

| 35 | C-10611 | Flour processing | Capital flour and General Mills | 33°39′3.24″ N | 73°2′25.33″ E | - | - |

| 36 | C-10611 | Flour Processing | Kashmir Flour and General Mills | 33°39′36.32″ N | 73°3′34.17″ E | - | - |

| 37 | C-10611 | Flour Processing | Mehboob Flour and General Mills | 33°40′4.02″ N | 73°2′32.51″ E | - | - |

| 38 | C-10611 | Flour Processing | Ismail Flour Mills Pvt. Limited | 33°40′1.91″ N | 73°3′22.59″ E | - | - |

| 39 | C-10611 | Flour Processing | Sarwar flour and Mills | 33°39′13.69″ N | 73°2′6.23″ E | - | - |

| 40 | C-10611 | Flour Processing | Hashim Sharif Flour Mills Pvt (Ltd) | 33°39′25.52″ N | 73°2′25.04″ E | - | - |

| 41 | C-10611 | Flour Processing | Gul Noor Flour & General Mills | 33°39′4.59″ N | 73°2′6.30″ E | - | - |

| 42 | C-10713 | Baked Products | United Biscuit Company | 33°39′39.12″ N | 73°2′31.36″ E | - | - |

| 43 | C-24108 | Steel Pipes | Victory Pipe Industries | 33°39′39.34″ N | 73°3′26.94″ E | - | - |

| 44 | C-2710 | Electric motors, thermostat, etc. | Tesla Industries | 33°39′15.01″ N | 73°2′11.32″ E | - | - |

| 45 | C-29301 | Manufacturing of auto parts, wheel hub | Rastgar Engineering Co., (PVT) Ltd. | 33°39′42.78″ N | 73°3′21.63″ E | http://www.rastgar.com/wheel-hubs/ (accessed on 5 May 2022) | ISO14001, OHSAS 18001, The Global Compact, Gender Equity |

| 46 | H-49238 | Transportation | Farazim Resource Pvt. Ltd. (KKC), Provides Transport | 33°39′14.31″ N | 73°2′57.24″ E | http://www.kkc.com.pk/index.php (accessed on 5 May 2022) | - |

| 47 | C-24108 | Steel Pipes | Shaheen Pipe Industries | 33°39′29.00″ N | 73°2′39.17″ E | - | - |

| 48 | C-23961 | Marble Processing | Swat Marbles | 33°39′24.68″ N | 73°3′18.48″ E | - | - |

| 49 | C-23961 | Marble Processing | Citi Marble Industries | 33°39′51.70″ N | 73°3′20.88″ E | - | - |

| 50 | C-23961 | Marble Processing | Arit Marbles chips and powder Factory | 33°39′32.58″ N | 73°2′24.25″ E | - | - |

| 51 | C-23961 | Marble Processing | Hassan Marbles | 33°39′26.11″ N | 73°3′22.83″ E | - | - |

| 52 | C-23961 | Marble Processing | Unique Marbles | 33°39′27.48″ N | 73°3′16.05″ E | - | - |

| 53 | C-23961 | Marble Processing | Crescent Marbles Granites | 33°39′52.52″ N | 73°3′16.41″ E | - | - |

| 54 | C-23961 | Marble Processing | Mughal Marbles and Granites | 33°39′23.27″ N | 73°3′15.70″ E | - | - |

| 55 | C-23961 | Marble Processing | International Granite Marbles | 33°39′22.84″ N | 73°3′14.81″ E | - | - |

| 56 | C-23961 | Marble Processing | Atlas Marble Industries | 33°39′22.17″ N | 73°3′14.56″ E | - | - |

| 57 | C-23961 | Marble Processing | National Marbles and Granite | 33°39′21.76″ N | 73°3′13.68″ E | - | - |

| 58 | C-23961 | Marble Processing | Saeed Marbles | 33°39′21.28″ N | 73°3′12.90″ E | - | - |

| 59 | C-23961 | Marble Processing | Daniyal Marbles | 33°39′23.99″ N | 73°3′14.42″ E | - | - |

| 60 | C-23961 | Marble Processing | Kashmir Marble Factory | 33°39′23.11″ N | 73°3′17.12″ E | - | - |

| 61 | C-23961 | Marble Processing | Star Marbles Industries | 33°39′38.12″ N | 73°2′45.72″ E | - | - |

| 62 | C-23961 | Marble Processing | Orient Marbles | 33°39′31.03″ N | 73°2′55.64″ E | - | - |

| 63 | C-23961 | Marble Processing | K-2 Marble Industries | - | - | ||

| 64 | C-23961 | Marble Processing | Irum Marble Industries | 33°39′24.79″ N | 73°3′9.22″ E | - | - |

| 65 | C-23961 | Marble Processing | Naseem Marble Industry | 33°38′58.03″ N | 73°2′16.12″ E | - | - |

| 66 | C-23961 | Marble Processing | New Bagh Marble Industry | - | - | ||

| 67 | C-23961 | Marble Processing | Amish Marble | - | - | ||

| 68 | C-23961 | marble processing | Kohsar Industries | 33°39′51.61″ N | 73°3′16.51″ E | - | - |

| 69 | C-2100 | Pharmaceutical | Wilson’s Pharmaceuticals | 33°39′33.14″ N | 73°3′36.82″ E | - | - |

| 70 | C-2100 | Pharmaceutical | Benson Pharmaceuticals | 33°39′4.14″ N | 73°2′16.12″ E | - | - |

| 71 | C-2100 | Pharmaceutical | Werrick Pharmaceuticals | 33°39′17.24″ N | 73°2′38.47″ E | - | - |

| 72 | C-2100 | Pharmaceutical | Werrick Health Care | 33°38′59.47″ N | 73°2′19.01″ E | - | - |

| 73 | C-2100 | Pharmaceutical | Attabak Pharmaceutical | 33°39′21.61″ N | 73°2′35.89″ E | - | - |

| 74 | C-2100 | Pharmaceutical Products | Leads Pharma | 33°39′11.62″ N | 73°2′2.22″ E | http://www.vetycare.com.pk/ (accessed on 5 May 2022) | - |

| 75 | C-2100 | Pharmaceutical Products | Maksons Pharmaceuticals | 33°39′14.74″ N | 73°2′7.32″ E | - | - |

| 76 | C-2100 | Pharmaceutical Products | Pearl Pharmaceuticals | 33°39′4.91″ N | 73°2′40.64″ E | http://www.pearl.com.pk/ (accessed on 5 May 2022) | ISO 9001:2008 |

| 77 | C-2100 | Pharmaceutical Products & machinery | Scotmann Pharmaceuticals | 33°39′19.78″ N | 73°2′37.56″ E | http://www.scotmann.com/index.html (accessed on 5 May 2022) | - |

| 78 | C-24108 | Steel pipes | Sachal pipes and pipe fittings | 33°39′21.24″ N | 73°2′10.63″ E | - | |

| 79 | C2100 | Flour Processing | Rehmania Flour Mills | 33°39′53.86″ N | 73°3′9.20″ E | - | |

| 80 | C-22202 | PVC Coated Wires | Dawn Electric Industries | 33°39′31.34″ N | 73°3′28.55″ E | - | |

| 81 | C-22202 | PVC Pipes | Pakistan PVC Ltd. | 33°39′35.96″ N | 73°2′37.22″ E | http://www.shavyl.com/ (accessed on 5 May 2022) | - |

| 82 | C-22202 | PVC Pipes | TF Pipes Ltd. | 33°39′42.06″ N | 73°2′57.03″ E | http://www.tfpipes.com/ (accessed on 5 May 2022) | - |

| 83 | C-22202 | PVC Pipes | Akbar & Zikria Pipes Pvt. Ltd. | 33°39′50.12″ N | 73°3′15.60″ E | - | - |

| 84 | C-22202 | PVC Pipes | Master Plus | 33°41′10.7628″ N | 73°1′45.1992″ E | - | - |

| 85 | C-24104 | Structural Steel products | Taibah Steel Re-Rolling Mills | 33°39′51.70″ N | 73°3′42.01″ E | - | - |

| 86 | C106b | Rice Polishing and finishing | Barkat Rice Mills | 33°39′13.03″ N | 73°2′34.21″ E | - | - |

| 87 | C20232 | Soap Manufacturing | Islamabad Soap & Chemical Industries | 33°39′38.12″ N | 73°3′14.89″ E | - | - |

| 88 | C20232 | Soap Manufacturing | Rose Enterprises Chemical Industry | 33°39′50.40″ N | 73°3′14.59″ E | - | - |

| 89 | C20232 | Soap Manufacturing | Mujahid Soap & Chemical Industries Pvt. Ltd. | 33°39′33.22″ N | 73°2′50.07″ E | - | - |

| 90 | C20232 | Soap Manufacturing | Sethi Soap Industries | 33°39′25.9″ N | 73°3′00.5″ E | - | - |

| 91 | C20232 | Soap Manufacturing | New Karachi Soap Industries | 33°39′38.44″ N | 73°3′8.07″ E | - | - |

| 92 | C-13921 | Spinning of woolen yarn, carpet yarn | Sarhad Woolen Mills (Pvt) Ltd. | 33°39′38.39″ N | 73°3′15.17″ E | - | - |

| 93 | C-24104 | Steel Furnace | Pak Iron & Steel Pvt Ltd. | 33°39′17.13″ N | 73°2′49.17″ E | - | - |

| 94 | C-24106 | Structural Steel products | Pak Iron & Steel Pvt Ltd. | 33°39′17.13″ N | 73°2′49.17″ E | - | - |

| 95 | C-24106 | Structural Steel Products | M. Muhammad Hussain & Sons Pvt. Ltd. | 33°39′2.07″ N | 73°3′36.32″ E | - | - |

| 96 | C-24106 | Structural Steel products | Islamabad Steel Re-rolling Mills | 33°39′31.03″ N | 73°2′51.80″ E | - | - |

| 97 | C-24104 | Steel Furnace | Karachi Steel & Re-rolling Mills | 33°39′1.45″ N | 73°2′35.22″ E | - | - |

| 98 | C-24106 | Structural Steel products | Karachi Steel & Re-rolling Mills | 33°39′1.45″ N | 73°2′35.22″ E | - | - |

| 99 | C-24106 | Structural Steel products | Zia Steel Re-rolling Mills | 33°39′24.86″ N | 73°2′21.87″ E | - | - |

| 100 | C-24106 | Structural Steel products | Capital Steel Industries | 33°39′41.58″ N | 73°3′12.63″ E | - | - |

| 101 | C-24106 | Structural Steel products | New Classic Steel Re-rolling Mills | 33°39′21.65″ N | 73°3′5.13″ E | SGI Group | - |

| 102 | C-25112 | Steel and Aluminim fabrication Works | Solajan | 33°39′13.08″ N | 73°2′3.77″ E | - | - |

| 103 | C-24106 | Structural Steel products | M.I.Z Re-rolling Steel Mills | 33°39′32.87″ N | 73°3′11.68″ E | - | - |

| 104 | C-24104 | Steel Furnace | Ittehad Steel Industries | 33°39′46.52″ N | 73°3′45.38″ E | - | - |

| 105 | C-24106 | Structural Steel products | Ittehad Steel Industries | 33°39′46.52″ N | 73°3′45.38″ E | - | - |

| 106 | C-24106 | Structural Steel products | H.S Steel Re-rolling Mills | 33°39′31.28″ N | 73°2′48.05″ E | - | - |

| 107 | C-24106 | Structural Steel products | Siddque Steel & Re-rolling Mills | 33°39′24.01″ N | 73°2′57.52″ E | SGI Group | - |

| 108 | C-24106 | Structural Steel products | Hassan Steel Re-Rolling mills | 33°39′36.75″ N | 73°2′46.06″ E | - | - |

| 109 | C-24106 | Structural Steel products | R.K. Steel | 33°39′27.37″ N | 73°2′47.50″ E | - | - |

| 110 | C-24104 | Steel Furnace | Fazal steel Pvt. Limited | 33°39′24.40″ N | 73°2′42.18″ E | - | - |

| 111 | C-24106 | Structural Steel products | Fazal steel Pvt. Limited | 33°39′24.40″ N | 73°2′42.18″ E | - | - |

| 112 | C-24106 | Structural Steel products | J.R. Steel Re-rolling Mills | 33°39′25.93″ N | 73°2′15.87″ E | - | - |

| 113 | C-24106 | Structural Steel products | Nomee Industries Steel Re-rolling Mills | 33°39′23.81″ N | 73°2′54.86″ E | - | - |

| 114 | C1079 | Tomato Ketchup | Kanas Pvt. Ltd. | 33°39′17.90″ N | 73°2′13.30″ E | - | - |

| 115 | C-20236 | Cosmetics and toiletries | Cosmo pro Pvt. Limited | 33°39′1.41″ N | 73°2′22.06″ E | - | - |

| 116 | C-25112 | Fabricated Metal Products | Sirius Drilling Gemstone | 33°39′4.56″ N | 73°2′27.84″ E | - | - |

| 117 | C-13921 | Wool caps | SB Traders | 33°39′4.58″ N | 73°2′27.84″ E | - | - |

| 118 | C-31001 | Sofa, beds, Chairs | Noor Timber Trading Co. | 33°39′4.37″ N | 73°2′14.05″ E | - | - |

Appendix B. Survey Booklet; Survey of Industrial Inputs and Outputs for Assessment of By-Product Exchange Potential in Industrial Area of Islamabad

Dear Respondent,

Thank you for taking time to complete this questionnaire. The purpose of this questionnaire is to gather information on potential utilization of industrial waste, instead of dumping it. Information gathered through this questionnaire will be utilized for Ph.D. Thesis on “Assessment of By-product Exchange Potential for Industrial Symbiosis in Islamabad’’. Industrial symbiosis is an emerging field of study which is defined as a relationship between two unrelated industries, where waste from one industry can be utilized as input for other industries. Worldwide companies are adopting to maximize their profits and as an alternative to dumping.

Researchers understand the need for confidentiality of this data. Data in raw form will only be disclosed to the researcher and supervisor. The questionnaire is divided into six parts. Please answer all questions. Please write N/A for questions not relevant to your industry).

Your contribution is highly appreciable for us. In case of any query please contact.

Appendix C. Template of Email

I am Nadia Akhtar, PhD Scholar at Department of Environmental Science International Islamic University. I am writing to you because we have received funding from the Higher Education Commission of Pakistan to work with businesses and institutions in I-9/I-10 Industrial Area of Islamabad to help them identify potential partnerships with other businesses and institutions for the reuse of currently unused by-products. These would include materials, water, and energy.

For example, you might have a by-product that somebody else could use, or you might be able to use something that somebody else is currently throwing in a landfill.

Businesses and other facilities in the region are also being contacted while some others have already agreed to participate in this project by providing us with information about their unused outputs and their inputs that could possibly come from somebody else. I am writing to find out whether you would be interested in participating also.

If you are interested in participating, we will send you a survey booklet to fill out. You would hang onto this survey booklet, and we would contact you in about a week to set up an appointment to come out to your office. We would meet with you to go over the survey and make sure we understand it before we take it away and try to match you up with other facilities. This wouldn’t take long, and there is no cost to you.

Would you be interested in participating? Please reply to this email with the name of the person to be contacted and his/her contact details.

Appendix D. Identified and Potential By-Product Exchange Synergies in the Study Area

| Synergy Characterization | By-Product Exchanged | Quantity Produced Annually | Symbiotic Partners | |

| Producer/s | Consumer/s | |||

| Metal | Offcuts/scrap metal | 10,000–15,000 tons | Structural steel manufacturers | Steel Furnaces |

| Steel Pipe Industry | ||||

| Mill Scale | 690 tons | Steel Furnaces | Offsite | |

| Structural steel manufacturers | Sold to vendors | |||

| Air Filter Dust | 1550 tons | Steel Furnaces | Battery manufacturing company, Pharmaceutical Company and plastic manufacturing | |

| Zinc | 4000 tons | Steel pipe industry | Pharmaceutical industry | |

| Slag * | 20,000 tons | Steel Furnace | Road filling (intra-firm) | |

| Minerals | Marble offcuts | 1500–1800 tons | Marble processing | Self (Co-product generation) |

| Marble Sludge * | Not-known | Marble Processing | Cement and brick making * | |

| Food Residues | Wheat Chaff/rejected grains | 5–8% of the total production | Wheat processing/Flour Mills | Poultry Farms |

| Rice bran | 8–10% of total production | Rice Mill | Fish Farms | |

| Baking industry | Variable | Leftovers/discarded food | Animal farms | |

| Plastics | PVC Resin | Variable | PVC Pipe Industry | PVC Pipe Industry (Intra-firm) |

| Others | Coarse/Old Wool | 3% of total production | Woolen Mill | Furniture Industry for filling + Quilt Making |

| HCl | Variable | Steel Pipe Industry | Sold to market | |

| Saw Dust * | Variable | Furniture industry | Bedding at poultry farms | |

| Waste Oil and Grease * | Variable | Structural Steel Industry | Auto-mobile Workshops * | |

| * Potential future synergies. | ||||

References

- Chiu, A.S.; Yong, G. On the industrial ecology potential in Asian developing countries. J. Clean. Prod. 2004, 12, 1037–1045. [Google Scholar] [CrossRef]

- Athanassiadis, A.; Christis, M.; Bouillard, P.; Vercalsteren, A.; Crawford, R.H.; Khan, A.Z. Comparing a territorial-based and a consumption-based approach to assess the local and global environmental performance of cities. J. Clean. Prod. 2018, 173, 112–123. [Google Scholar] [CrossRef]

- Oughton, C.; Kurup, B.; Anda, M.; Ho, G. Industrial Symbiosis to Circular Economy: What Does the Literature Reveal for a Successful Complex Industrial Area? Circ. Econ. Sustain. 2022, 1–28. [Google Scholar] [CrossRef]

- Chertow, M.R. “Uncovering” Industrial Symbiosis. J. Ind. Ecol. 2007, 11, 11–30. [Google Scholar] [CrossRef]

- Akhtar, N.; Saqib, Z.; Khan, M.; Martin, M.; Atif, S.; Zaman, M. A bibliometric analysis of contemporary research regarding industrial symbiosis: A path towards urban environmental resilience. Appl. Ecol. Env. Res. 2019, 17, 1159–1221. [Google Scholar] [CrossRef]

- Athanassiadis, A. Towards more comprehensive urban environmental assessments: Exploring the complex relationship between urban and metabolic profiles. Ph.D. Thesis, The University of Melbourn, Melbourn, Australia, 2016. [Google Scholar]

- Ehrenfeld, J.; Gertler, N. Industrial ecology in practice: The evolution of interdependence at Kalundborg. J. Ind. Ecol. 1997, 1, 67–79. [Google Scholar] [CrossRef] [Green Version]

- MacArthur, E. Towards the circular economy. J. Ind. Ecol. 2013, 2, 23–44. [Google Scholar]

- Berkel, R.V.; Fujita, T.; Hashimoto, S.; Fujii, M. Quantitative assessment of urban and industrial symbiosis in Kawasaki, Japan. Environ. Sci. Technol. 2009, 43, 1271–1281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ruiz-Puente, C.; Romero, E.; Evans, S. Industrial symbiosis opportunities for small and medium sized enterprises: Preliminary study in the Besaya Region. (Cantabria, Northern Spain). J. Clean. Prod. 2015, 87, 357–374. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial Symbiosis: Literature and Taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef] [Green Version]

- Short, S.W.; Bocken, N.M.P.; Barlow, C.Y.; Chertow, M.R. From Refining Sugar to Growing Tomatoes. J. Ind. Ecol. 2014, 18, 603–618. [Google Scholar] [CrossRef]

- Zhu, Q.; Lowe, E.A.; Wei, Y.a.; Barnes, D. Industrial symbiosis in China: A case study of the Guitang Group. J. Ind. Ecol. 2007, 11, 31–42. [Google Scholar] [CrossRef]

- Yuan, Z.; Shi, L. Improving enterprise competitive advantage with industrial symbiosis: Case study of a smeltery in China. J. Clean. Prod. 2009, 17, 1295–1302. [Google Scholar] [CrossRef]

- Van Beers, D. Capturing Regional Synergies in the Kwinana Industrial Area; Centre for Sustainable Resource Processing: Kensington, Australia, 2007. [Google Scholar]

- Walls, J.L.; Paquin, R.L. Organizational Perspectives of Industrial Symbiosis: A Review and Synthesis. Organ. Environ. 2015, 28, 32–53. [Google Scholar] [CrossRef]

- Lowe, E.A. Eco-Industrial Park Handbook for Asian Developing Countries. Report to Asian Development Bank; Indigo Department: Oakland, CA, USA, 2001. [Google Scholar]

- Bossilkov, A.; Van Berkel, R.; Corder, G. Regional Synergies for Sustainable Resource Processing: A Status Report; Centre for Sustainable Resource Processing: Kensington, Australia, 2005. [Google Scholar]

- Shenoy, M. Industrial Ecology in Developing Countries. In Taking Stock of Industrial Ecology; Clift, R., Druckman, A., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 229–245. [Google Scholar]

- Ashton, W.; Shenoy, M. Industrial ecology in India: Converging traditional practice and modern environmental protection. In International Perspectives on Industrial Ecology; Edward Elgar Publishing: Cheltenham, UK, 2015. [Google Scholar]

- Boom-Cárcamo, E.; Peñabaena-Niebles, R. Analysis of the Development of Industrial Symbiosis in Emerging and Frontier Market Countries: Barriers and Drivers. Sustainability 2022, 14, 4223. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Kumar, N.; Fine, C.; Olivetti, E. Industrial Symbiosis Among Small and Medium Scale Enterprises: Case of Muzaffarnagar, India. In REWAS 2016; Springer: Cham, Switzerland, 2016; pp. 173–177. [Google Scholar]

- Mir, D.F. Environmental behaviour in Chicago automotive repair micro-enterprises (MEPs). Bus. Strategy Environ. 2008, 17, 194–207. [Google Scholar] [CrossRef]

- Redmond, J.; Walker, E.A.; Parker, C.M.; Simpson, M. Australian SMEs waste to landfill. Australas. J. Environ. Manag. 2014, 21, 297–310. [Google Scholar] [CrossRef] [Green Version]

- Patricio, J.; Axelsson, L.; Blomé, S.; Rosado, L. Enabling industrial symbiosis collaborations between SMEs from a regional perspective. J. Clean. Prod. 2018, 202, 1120–1130. [Google Scholar] [CrossRef]

- Arshad, M.Z.; Khan, W.; Arshad, M.; Ali, M.; Shahdan, A.; Ishak, W. Importance and Challenges of SMEs: A Case of Pakistani SMEs. J. Res. Lepid. 2020, 51, 701–707. [Google Scholar] [CrossRef]

- Zafar, A.; Mustafa, S. SMEs and its role in economic and socio-economic development of Pakistan. Int. J. Acad. Res. Account. Financ. Manag. Sci. 2017, 6, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Khan, N.H.; Nafees, M.; Saeed, T.; Khan, A.; Bashir, A. Industrial Symbiosis and Industrial Waste Management in Wood-Based Industries. J. Ind. Pollut. Control. 2018, 34, 2152–2158. [Google Scholar]

- Yeo, Z.; Masi, D.; Low, J.S.C.; Ng, Y.T.; Tan, P.S.; Barnes, S. Tools for promoting industrial symbiosis: A systematic review. J. Ind. Ecol. 2019, 23, 1087–1108. [Google Scholar] [CrossRef] [Green Version]

- Rincón-Moreno, J.; Ormazabal, M.; Álvarez, M.J.; Jaca, C. Shortcomings of transforming a local circular economy system through industrial symbiosis: A case study in Spanish SMEs. Sustainability 2020, 12, 8423. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Industrial symbiosis in the Taranto industrial district: Current level, constraints and potential new synergies. J. Clean. Prod. 2016, 122, 133–143. [Google Scholar] [CrossRef]

- Harris, S. Industrial symbiosis in the Kwinana industrial area (Western Australia). Meas. Control 2007, 40, 239–244. [Google Scholar] [CrossRef]

- Malik, R.N.; Husain, S.Z.; Nazir, I. Heavy metal contamination and accumulation in soil and wild plant species from industrial area of Islamabad, Pakistan. Pak. J. Bot 2010, 42, 291–301. [Google Scholar]

- Atif Bokhari, S.; Saqib, Z.; Zaman-ul-Haq, M.; Akhtar, N.; Fatimah, H.; Atif, M.; Farooqi, S. Identification of key-trends and evaluation of contemporary research regarding urban ecosystem services: A path towards socio-ecological sustainability of urban areas. Appl. Ecol. Environ. Res. 2018, 16, 3545–3581. [Google Scholar] [CrossRef]

- Zaman-ul-Haq, M.; Saqib, Z.; Kanwal, A.; Naseer, S.; Shafiq, M.; Akhtar, N.; Bokhari, S.A.; Irshad, A.; Hamam, H. The Trajectories, Trends, and Opportunities for Assessing Urban Ecosystem Services: A Systematic Review of Geospatial Methods. Sustainability 2022, 14, 1471. [Google Scholar] [CrossRef]

- Khan, S.A.; Muhammad, S.; Nazir, S.; Shah, F.A. Heavy metals bounded to particulate matter in the residential and industrial sites of Islamabad, Pakistan: Implications for non-cancer and cancer risks. Environ. Technol. Innov. 2020, 19, 100822. [Google Scholar] [CrossRef]

- Kincaid, J.; Overcash, M. Industrial ecosystem development at the metropolitan level. J. Ind. Ecol. 2001, 5, 117–126. [Google Scholar] [CrossRef]

- GoP. Pakistan Standard Industrial Classification (All Economic Activities) PSIC Rev. 4. 2010. Available online: https://www.pbs.gov.pk/content/classifications (accessed on 16 September 2019).

- Bain, A.; Shenoy, M.; Ashton, W.; Chertow, M. Industrial symbiosis and waste recovery in an Indian industrial area. Resour. Conserv. Recycl. 2010, 54, 1278–1287. [Google Scholar] [CrossRef]

- Hein, A.M.; Jankovic, M.; Feng, W.; Farel, R.; Yune, J.H.; Yannou, B. Stakeholder power in industrial symbioses: A stakeholder value network approach. J. Clean. Prod. 2017, 148, 923–933. [Google Scholar] [CrossRef]

- IISO Standard No. 14001:2015; A Practical Guide for SMEs. International Standard Organization: Geneva, Switzerland. Available online: https://www.iso.org/publication/PUB100411.html (accessed on 31 May 2022).

- Fraccascia, L.; Magno, M.; Albino, V. Business models for industrial symbiosis: A guide for firms. Procedia Environ. Sci. Eng. Manag. 2016, 3, 83–93. [Google Scholar]

- Arens, M.; Worrell, E.; Eichhammer, W.; Hasanbeigi, A.; Zhang, Q. Pathways to a low-carbon iron and steel industry in the medium-term—the case of Germany. J. Clean. Prod. 2017, 163, 84–98. [Google Scholar] [CrossRef]

- Umadevi, T.; Sampath Kumar, M.; Mahapatra, P.; Mohan Babu, T.; Ranjan, M. Recycling of steel plant mill scale via iron ore pelletisation process. Ironmak. Steelmak. 2009, 36, 409–415. [Google Scholar] [CrossRef]

- Young, R.D.; Norris, D. Process for using mill scale in cement clinker production. U.S. Patent No. 6,709,510, 2004. [Google Scholar]

- Benchiheub, O.; Mechachti, S.; Serrai, S.; Khalifa, M. Elaboration of iron powder from mill scale. J. Mater. Environ. Sci. 2010, 1, 267–276. [Google Scholar]

- Griffin, M.; Sobal, J.; Lyson, T.A. An analysis of a community food waste stream. Agric. Hum. Values 2009, 26, 67–81. [Google Scholar] [CrossRef]

- Eloneva, S.; Puheloinen, E.-M.; Kanerva, J.; Ekroos, A.; Zevenhoven, R.; Fogelholm, C.-J. Co-utilisation of CO2 and steelmaking slags for production of pure CaCO3–legislative issues. J. Clean. Prod. 2010, 18, 1833–1839. [Google Scholar] [CrossRef]

- Bo, C.; Yang, J.-x.; Ouyang, Z.-y. Life cycle assessment of internal recycling options of steel slag in Chinese iron and steel industry. J. Iron Steel Res. Int. 2011, 18, 33–40. [Google Scholar]

- Shen, H.; Forssberg, E. An overview of recovery of metals from slags. Waste Manag. 2003, 23, 933–949. [Google Scholar] [CrossRef]

- Shih, P.-H.; Wu, Z.-Z.; Chiang, H.-L. Characteristics of bricks made from waste steel slag. Waste Manag. 2004, 24, 1043–1047. [Google Scholar] [CrossRef]

- Ahmad, S.I.; Rahman, M.S. Mechanical and Durability Properties of Induction-Furnace-Slag-Incorporated Recycled Aggregate Concrete. Adv. Civil. Eng. 2018, 2018, 3297342. [Google Scholar] [CrossRef] [Green Version]

- Olmez, G.M.; Dilek, F.B.; Karanfil, T.; Yetis, U. The environmental impacts of iron and steel industry: A life cycle assessment study. J. Clean. Prod. 2016, 130, 195–201. [Google Scholar] [CrossRef]

- Jönsson, J. Recycling of industrial lubricant oil: A screening LCA of Rocco oil cleaning system. Bachelor’s Thesis, Mid Sweden University, Ostersund, Sweden, 2016. [Google Scholar]

- Mashaly, A.O.; El-Kaliouby, B.A.; Shalaby, B.N.; El-Gohary, A.M.; Rashwan, M.A. Effects of marble sludge incorporation on the properties of cement composites and concrete paving blocks. J. Clean. Prod. 2016, 112, 731–741. [Google Scholar] [CrossRef]

- Arslan, E.I.; Aslan, S.; Ipek, U.; Altun, S.; Yazicioğlu, S. Physico-chemical treatment of marble processing wastewater and the recycling of its sludge. Waste Manag. Res. 2005, 23, 550–559. [Google Scholar] [CrossRef]

- Shah, W.; Mohammad, N.; Iqbal, M. Evaluation of marble slurry waste for preparation of commercial grade cement. J. Eng. Appl. Sci. 2015, 34, 28–37. [Google Scholar]

- Abdel-Gawwad, H.A.; Mohamed, S.A.; Mohammed, M.S. Recycling of slag and lead-bearing sludge in the cleaner production of alkali activated cement with high performance and microbial resistivity. J. Clean. Prod. 2019, 220, 568–580. [Google Scholar] [CrossRef]

- Atif Bokhari, S.; Saqib, Z.; Ali, A.; Zaman-ul-Haq, M. Perception of Residents about Urban Vegetation: A Comparative Study of Planned Versus Semi-Planned Cities of Islamabad and Rawalpindi, Pakistan. J. Ecosyst. Ecography 2018, 8, 251. [Google Scholar] [CrossRef]

- Singhal, S.; Kapur, A. Industrial estate planning and management in India—An integrated approach towards industrial ecology. J. Environ. Manag. 2002, 66, 19–29. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; G Azevedo, S.; Pimentel, C.; CO Matias, J. The potential of industrial symbiosis: Case analysis and main drivers and barriers to its implementation. Sustainability 2019, 11, 7095. [Google Scholar] [CrossRef] [Green Version]

- Ažman Momirski, L.; Mušič, B.; Cotič, B. Urban Strategies Enabling Industrial and Urban Symbiosis: The Case of Slovenia. Sustainability 2021, 13, 4616. [Google Scholar] [CrossRef]

- Ali, S.M.; Malik, R.N. Spatial distribution of metals in top soils of Islamabad City, Pakistan. Environ. Monit. Assess. 2011, 172, 1–16. [Google Scholar] [CrossRef]

- Khwaja, M.A. Environmental Challenges and Constraints to Policy Issues for Sustainable Industrial Development in Pakistan. Environ. Trade Gov. Sustain. Dev. 2012. Available online: https://sdpi.org/environmental-challenges-and-constraints-to-policy-issues-for-sustainable-industrial-development-in-pakistan-pb-31/publication_detail (accessed on 5 May 2022).

- Butt, M.J.; Waqas, A.; Iqbal, M.F.; Muhammad, G.; Lodhi, M. Assessment of urban sprawl of Islamabad metropolitan area using multi-sensor and multi-temporal satellite data. Arab. J. Sci. Eng. 2012, 37, 101–114. [Google Scholar] [CrossRef]

- Bokhari, S.A.; Saqib, Z.; Amir, S.; Naseer, S.; Shafiq, M.; Ali, A.; Zaman-ul-Haq, M.; Irshad, A.; Hamam, H. Assessing Land Cover Transformation for Urban Environmental Sustainability through Satellite Sensing. Sustainability 2022, 14, 2810. [Google Scholar] [CrossRef]

- Martin, M.; Eklund, M. Improving the environmental performance of biofuels with industrial symbiosis. Biomass Bioenergy 2011, 35, 1747–1755. [Google Scholar] [CrossRef]

- Costa, I.; Massard, G.; Agarwal, A. Waste management policies for industrial symbiosis development: Case studies in European countries. J. Clean. Prod. 2010, 18, 815–822. [Google Scholar] [CrossRef]

- Gibbs, D.; Deutz, P. Implementing industrial ecology? Planning for eco-industrial parks in the USA. Geoforum 2005, 36, 452–464. [Google Scholar] [CrossRef]

- Tao, Y.; Evans, S.; Wen, Z.; Ma, M. The influence of policy on industrial symbiosis from the Firm’s perspective: A framework. J. Clean. Prod. 2018, 213, 1172–1187. [Google Scholar] [CrossRef]

- El-Sayed, H.A.; Farag, A.B.; Kandeel, A.M.; Younes, A.A.; Yousef, M.M. Characteristics of the marble processing powder waste at Shaq El-Thoaban industrial area, Egypt, and its suitability for cement manufacture. HBRC J. 2018, 14, 171–179. [Google Scholar] [CrossRef] [Green Version]

- Wolf, A.; Petersson, K. Industrial symbiosis in the Swedish forest industry. Prog. Ind. Ecol. Int. J. 2007, 4, 348–362. [Google Scholar] [CrossRef] [Green Version]

- Albino, V.; Fraccascia, L. The Industrial Symbiosis approach: A classification of business models. Procedia Environ. Sci. Eng. Manag. 2015, 2, 217–223. [Google Scholar]

- Wahrlich, J.; Simioni, F.J. Industrial symbiosis in the forestry sector: A case study in southern Brazil. J. Ind. Ecol. 2019, 23, 1470–1482. [Google Scholar] [CrossRef]

- Jensen, P.D. The role of geospatial industrial diversity in the facilitation of regional industrial symbiosis. Resour. Conserv. Recycl. 2016, 107, 92–103. [Google Scholar] [CrossRef] [Green Version]

- Abid, M.; Ashfaq, A. CPEC: Challenges and opportunities for Pakistan. J. Pak. Vis. 2015, 16, 142–169. [Google Scholar]

- Martin, M.; Svensson, N.; Eklund, M.; Fonseca, J. Production synergies in the current biofuel industry: Opportunities for development. Biofuels 2012, 3, 545–554. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).