Sustainable Production Management Model for Small and Medium Enterprises in Some South-Central EU Countries

Abstract

1. Introduction

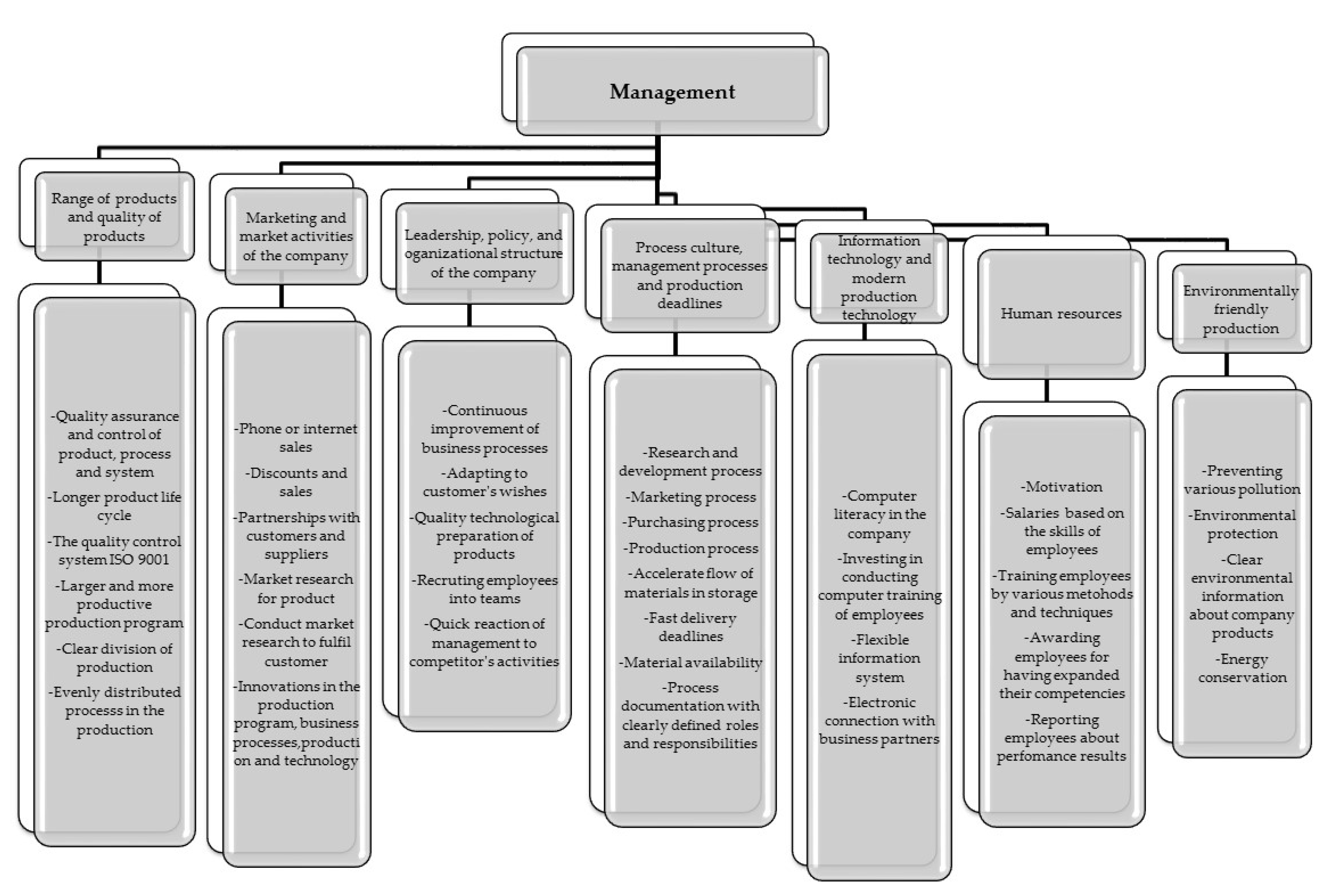

2. Materials and Methods

2.1. Survey

- LPOSC–Leadership, Policy, and Organizational Structure of the Company

- PCMPPD–Process Culture, Management Processes, and Production Deadlines

- RPQP–Range of Products and Quality of Products

- MMAC–Marketing and Market Activities of the Company

- HR–Human Resources

- ITMPT–Information Technology and Modern Production Technology

- EFP–Environmentally friendly production.

2.2. Analytic Hierarchy Process (AHP)

2.3. Simple Multi-Attribute Rating Technique Exploiting Ranks (SMARTER)

3. Results

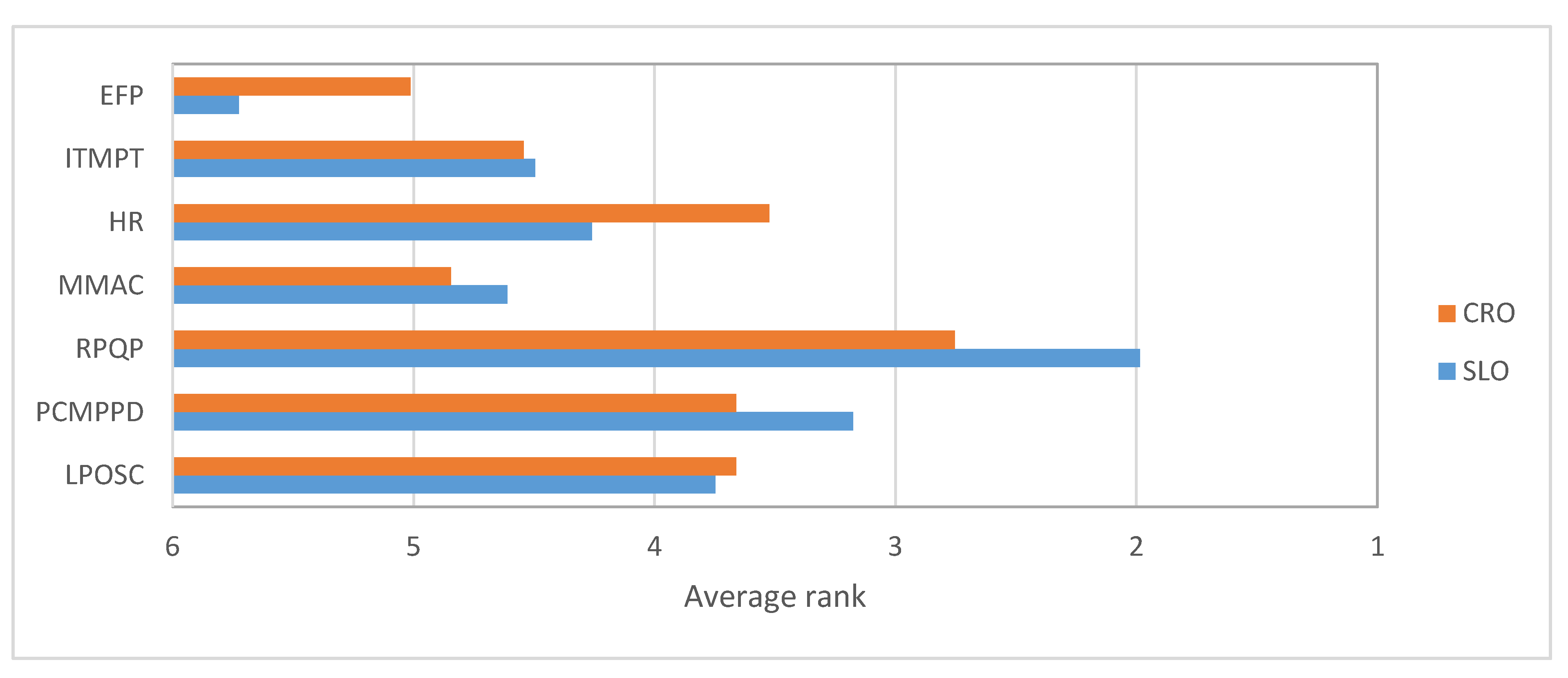

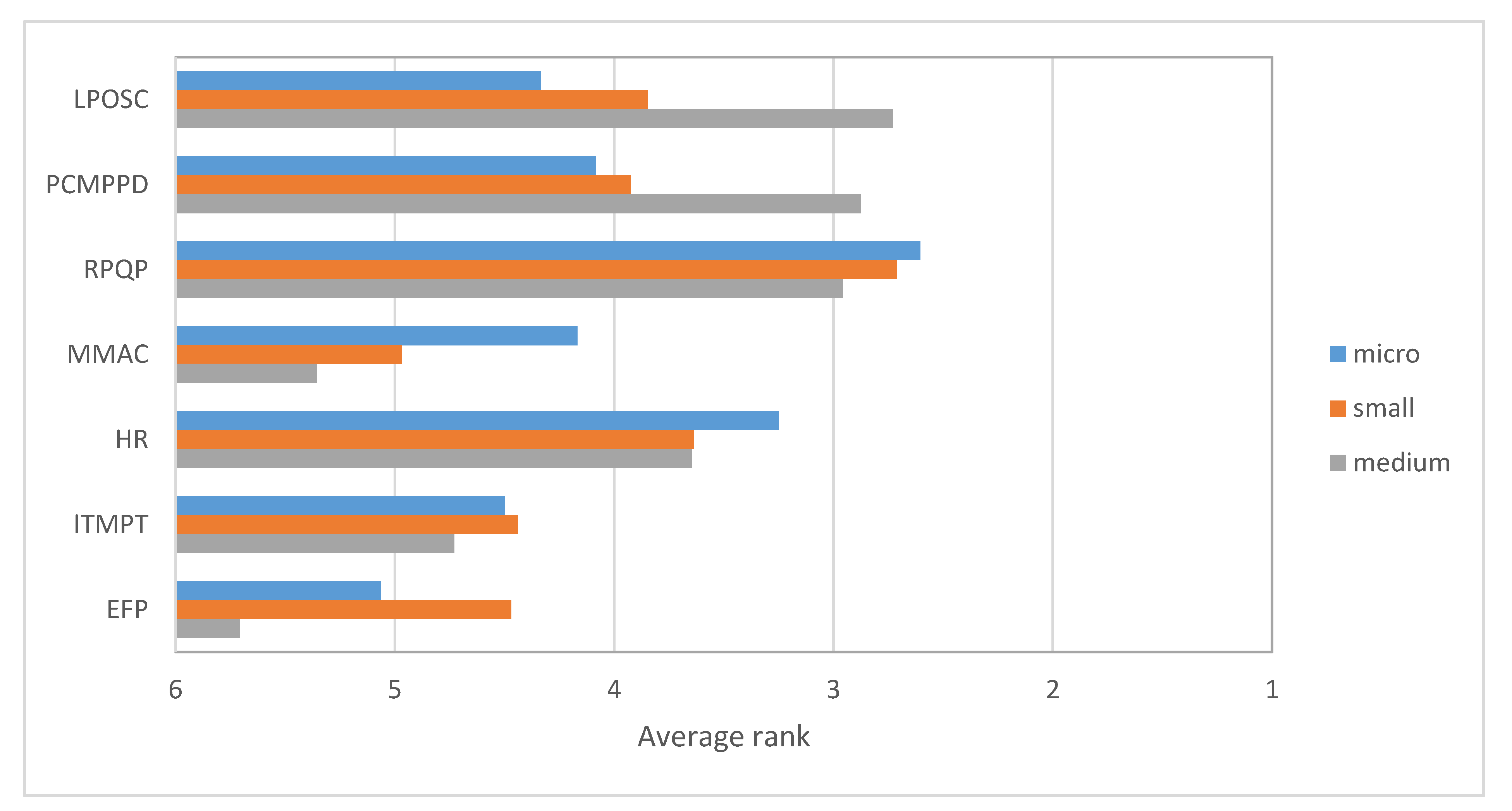

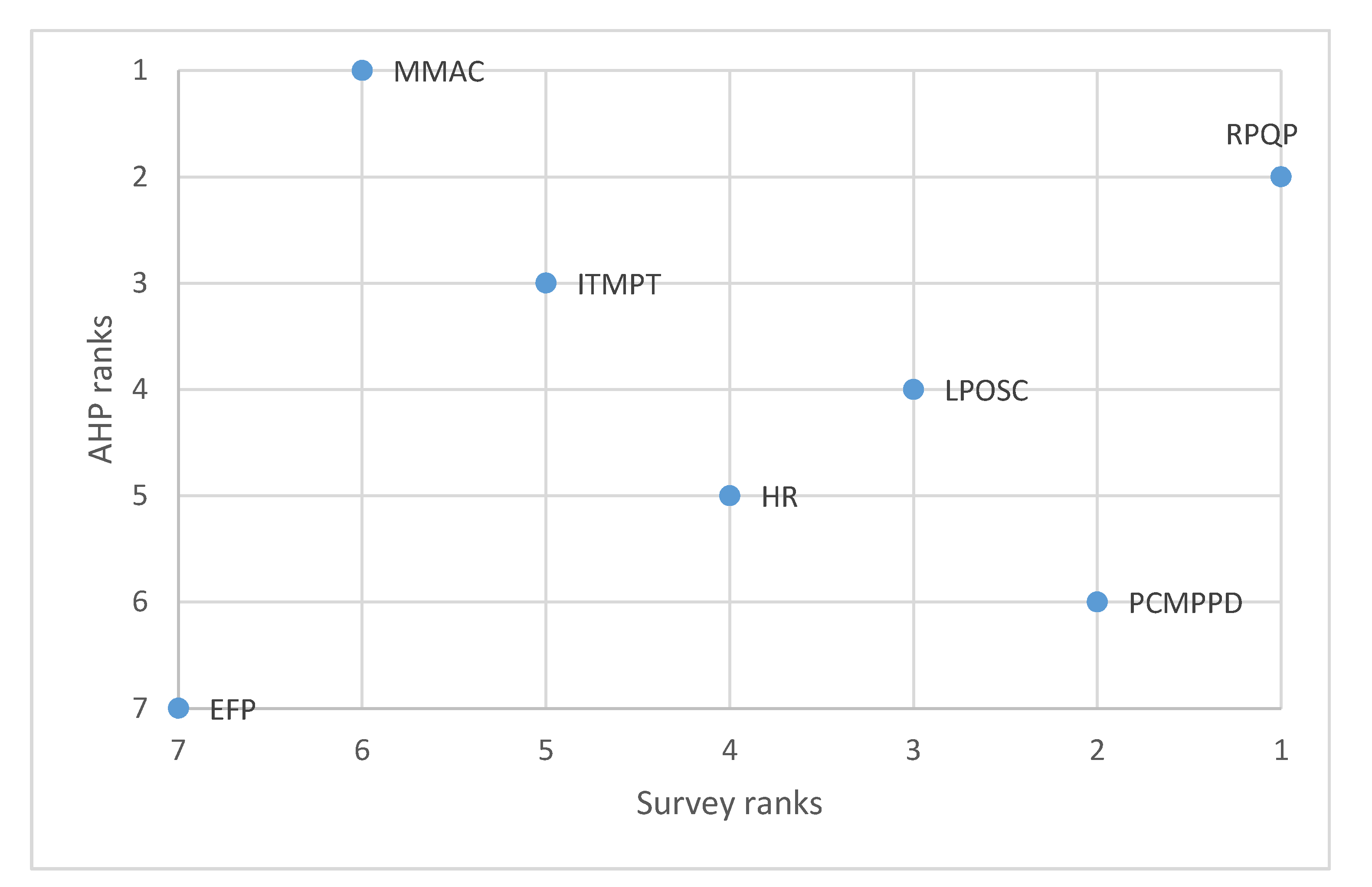

3.1. Results of the Ranking of Business and Production Management Paremeters in the Survey

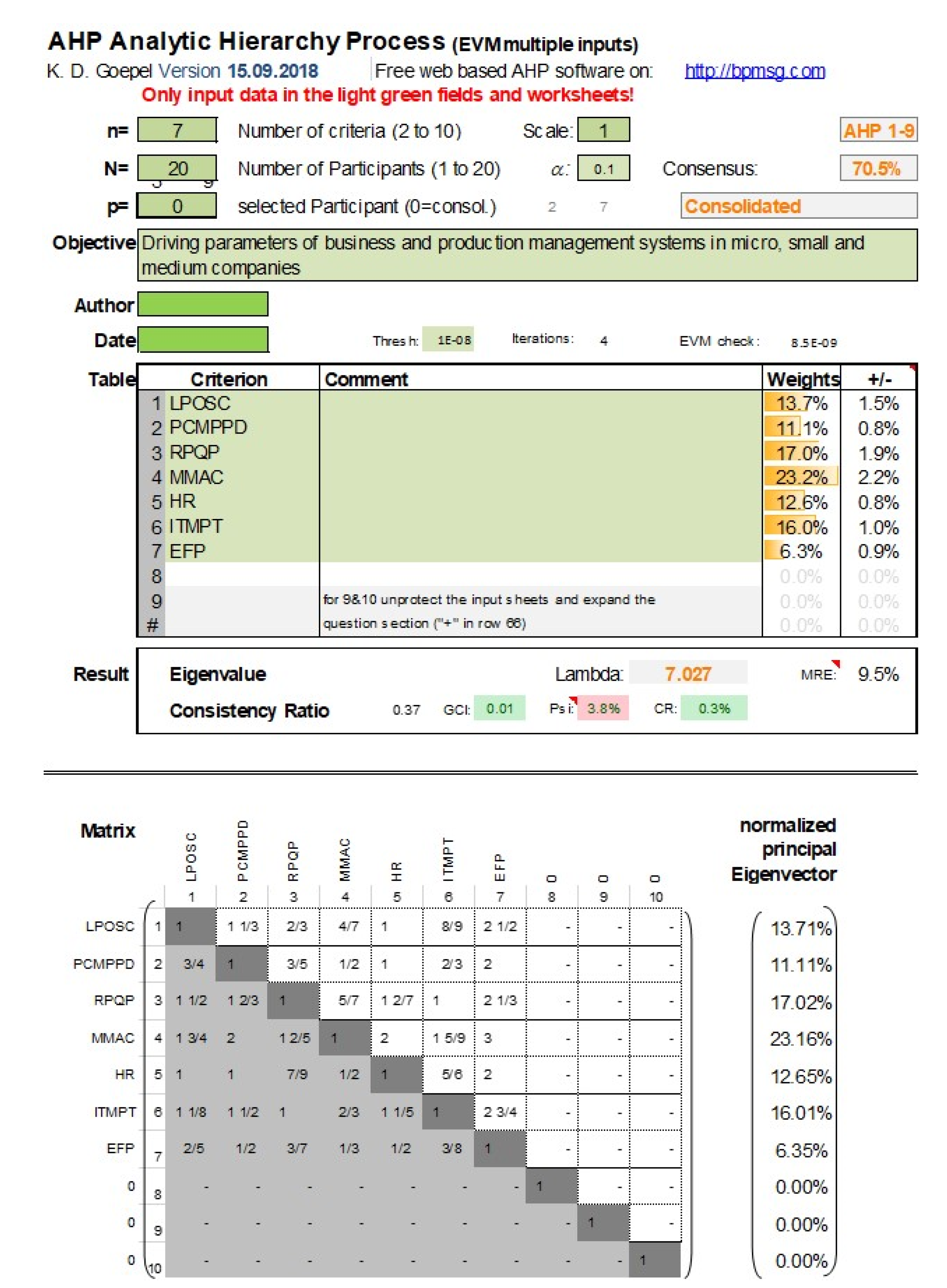

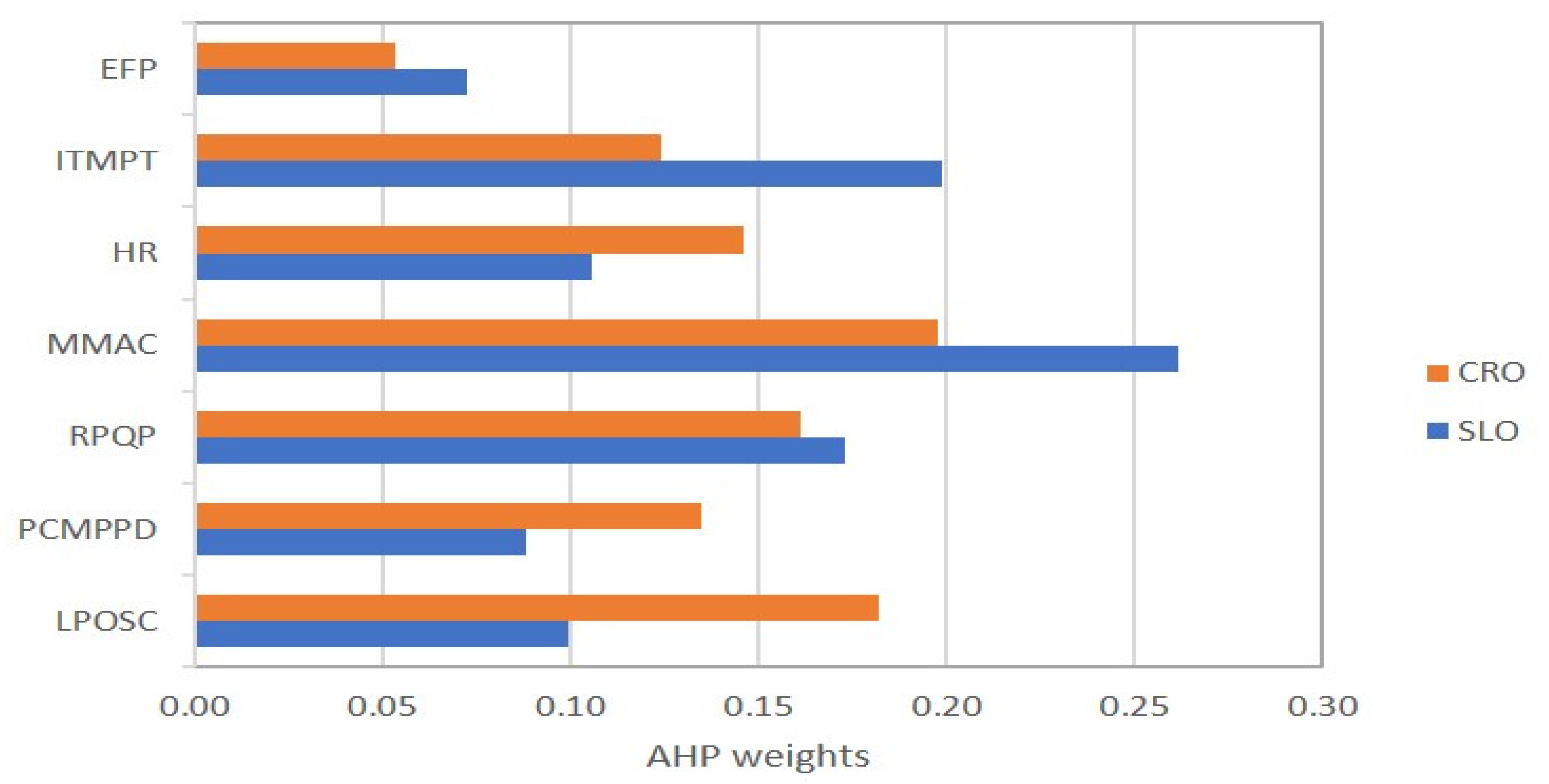

3.2. AHP Results

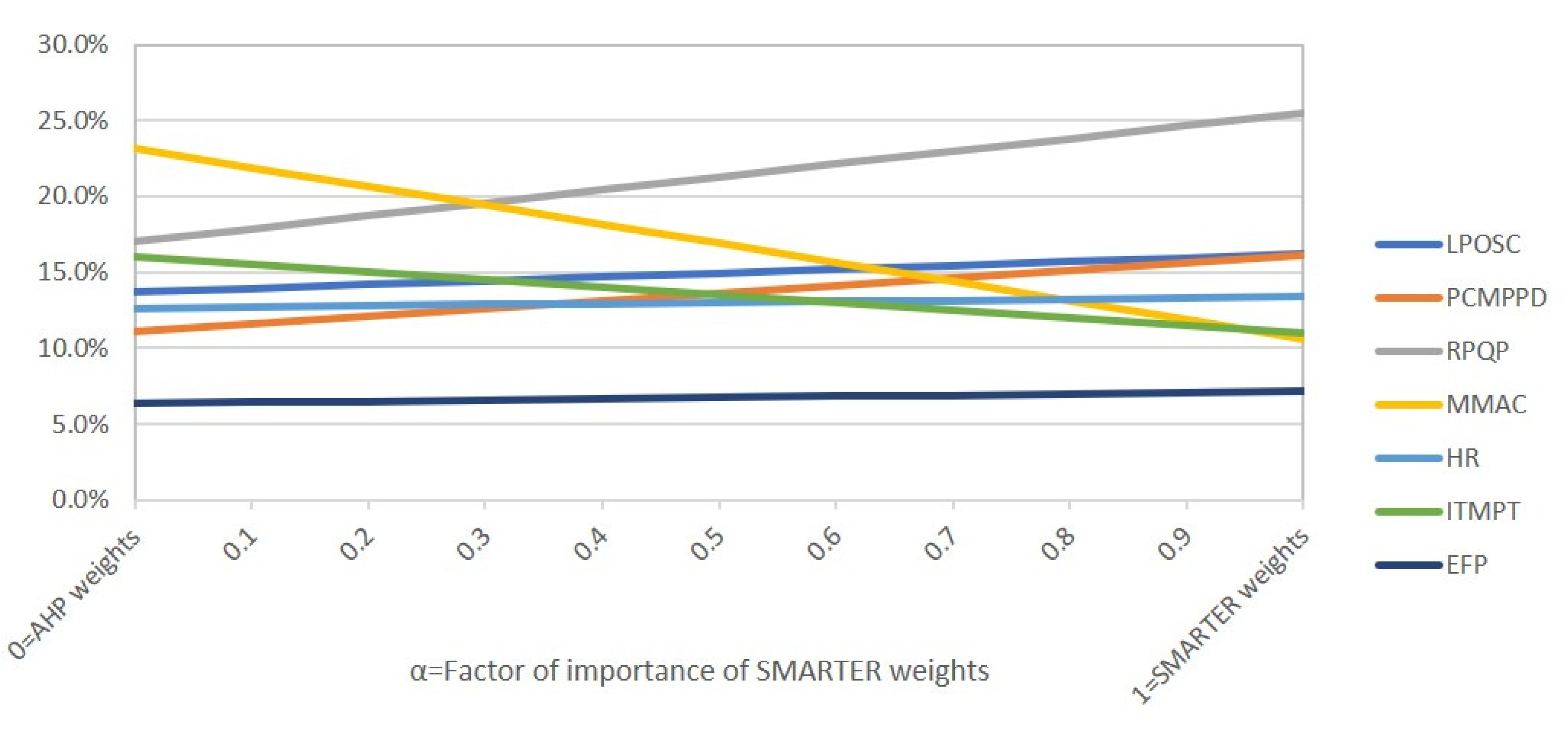

3.3. The Final Weights of Driving Parameters

4. Discussion

- Range of products and quality of products—RPQP

- Marketing and market activities of the company—MMAC

- Leadership, policy and organizational structure of the company—LPOSC

- Process culture, management processes and production deadlines—PCMPPD

- Information technology and modern production technology—ITMPT

- Human resources—HR

- Environmentally friendly production—EFP.

- Marketing and market activities of the company—MMAC

- Range of products and quality of products—RPQP

- Information technology and modern production technology—ITMPT

- Process culture, management processes and production deadlines—PCMPPD

- Human resources—HR

- Leadership, policy and organizational structure of the company—LPOSC

- Environmentally friendly production—EFP.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bistričić, A.; Agatić, A.; Trošić, N. The Importance of Small and Medium-Sized Enterprises in the Croatian Economy and in the European Union States Economies. Sci. J. Marit. Res. 2011, 25, 145–158. [Google Scholar]

- Bumgardner, M.; Buehlmann, U.; Schuler, A.; Crissey, J. Competitive Actions of Small Firms in a Declining Market. J. Small Bus. Manag. 2011, 49, 578–598. [Google Scholar] [CrossRef]

- Buehlmann, U.; Bumgardner, M.; Sperber, M. How Small Firms Contrast with Large Firms Regarding Perceptions, Practices and Needs in the U.S. Secondary Woodworking Industry. BioResources 2013, 8, 2669–2680. [Google Scholar] [CrossRef]

- European Commission. Annual Report on European SMEs 2018/2019; Research & Development and Innovation by SMEs. Available online: https://op.europa.eu/en/publication-detail/-/publication/ (accessed on 15 March 2021).

- European Commission. Unleashing the Full Potential of European SMEs. Available online: https://op.europa.eu/en/publication-detail/-/publication/ (accessed on 15 March 2021).

- European Commission. 2019 SBA Fact Sheet–Croatia. Available online: https://ec.europa.eu/growth/smes/sme-strategy/performance-review_en#sba-fact-sheets (accessed on 15 March 2021).

- European Commission. 2019 SBA Fact Sheet–Slovenia. Available online: https://ec.europa.eu/growth/smes/sme-strategy/performance-review_en#sba-fact-sheets (accessed on 15 March 2021).

- CEPOR SMEs and Entrepreneurship Policy Center. Small and Medium Enterprises Report Croatia–2019. Available online: http://www.cepor.hr/publikacijepolicy-dokumentiprezentacije/izvjesce-o-malim-i-srednjim-poduzecima/ (accessed on 15 March 2021).

- Croatian Bureau of Statistics. 2018 Statistical Yearbook of The Republic of Croatia; Section 17 Industry; Croatian Bureau of Statistics: Zagreb, Croatia, 2018; pp. 27–302.

- Kivijärvi, H.; Tuominen, M. A decision aid in strategic planning and analysis of a wood-processing company. Comput. Ind. Eng. 1996, 31, 467–470. [Google Scholar] [CrossRef]

- Dasmohapatra, S. Future marketing drivers for the forest products industry. BioResources 2009, 4, 1263–1266. [Google Scholar]

- Yoon, B.; Shin, J.; Lee, S. Open Innovation Projects in SMEs as an Engine for Sustainable Growth. Sustainability 2016, 8, 146. [Google Scholar] [CrossRef]

- Lyver, M.J.; Lu, T.J. Sustaining Innovation Performance in SMEs: Exploring the Roles of Strategic Entrepreneurship and IT Capabilities. Sustainability 2018, 10, 442. [Google Scholar] [CrossRef]

- Baković, T.; Ledić-Purić, D. Uloga inovacija u poslovanju malih i srednjih poduzeća [Role of innovations in business of small and medium enterprises]. Posl. Izvr. Zagreb 2011, 5, 27–42. [Google Scholar]

- Tsvetkova, D.; Bengtsson, E.; Durst, S. Maintaining Sustainable Practices in SMEs: Insight from Sweden. Sustainability 2020, 12, 10242. [Google Scholar] [CrossRef]

- Neira, C.O.; Lindman, M.T.; Fernández, M.J. Innovation and performance in SME furniture industries: An international comparative case study. Mark. Intell. Plan. 2009, 27, 216–232. [Google Scholar] [CrossRef]

- Nowduri, S. Management information systems research for small and medium enterprises: A sustainability perspective. Int. J. Softw. Eng. Appl. 2014, 8, 201–208. [Google Scholar]

- Ren, S.; Eisingerich, A.B.; Tsai, H.T. How do marketing, research, and development capabilities, and degree of internationalization synergistically affect the innovation performance of small and medium-sized enterprises (SMEs)? A panel data study of Chinese SMEs. Int. Bus. Rev. 2015, 24, 642–651. [Google Scholar] [CrossRef]

- Wu, N.; Hoque, K.; Bacon, N.; Bon Llusar, J.C. High-performance work systems and workplace performance in small, medium-sized, and large firms. Hum. Resour. Manag. J. 2015, 25, 408–423. [Google Scholar] [CrossRef]

- Nielsen, K.J.; Kines, P.; Pedersen, L.M.; Andersen, L.P.; Andersen, D.R. A multi-case study of the implementation of an integrated approach to safety in small enterprises. Saf. Sci. 2015, 71, 142–150. [Google Scholar] [CrossRef]

- Sedliaciková, M.; Vacek, V.; Sopkova, E. How Slovak small and medium enterprises perceive financial controlling. Procedia Econ. Financ. 2015, 26, 82–85. [Google Scholar] [CrossRef]

- Wielgórka, D. Environmental management in the aspect of sustainable development in micro, small, and medium-sized enterprises. Desalination Water Treat. 2015, 24, 982–992. [Google Scholar] [CrossRef]

- Gourinchas, P.O.; Kalemli-Özcan, S.; Penciakova, V.; Sander, N. Covid-19 and SME Failures. In International Monetary Fund; Working paper 27877; National Bureau of Economic Research: Cambridge, MA, USA, 2020; pp. 1–55. [Google Scholar] [CrossRef]

- Gregurec, I.; Tomičić Furjan, M.; Tomičić-Pupek, K. The Impact of Covid-19 on Sustainable Business Models in SME. Sustainability 2021, 13, 1098. [Google Scholar] [CrossRef]

- Crowling, M.; Brown, R.; Rocha, A. Did you Save Some Cash for a Rainy Covid-19 Day? The Crisis and SMEs. Int. Small Bus. J. Res. Entrep. 2020, 38, 593–604. [Google Scholar] [CrossRef]

- Paunescu, C.; Matyus, E. Resilience Measures to Dealing with the Covid-19 Pandemic. Evidence from Romanian Micro and Small Enterprises. Manag. Mark. Chall. Knowl. Soc. 2020, 15, 439–457. [Google Scholar] [CrossRef]

- Song, L.G.; Zhou, Y.K. The Covid-19 Pandemic and its Impact on the Global Economy: What Does it Take to Turn Crisis into Opportunity? China World Econ. 2020, 28, 1–25. [Google Scholar] [CrossRef]

- Basarac Sertić, M.; Pirc Barčić, A.; Klarić, K. Economic determinants and analysis of the European Union wood industry SMEs employment. BioResources 2018, 13, 522–534. [Google Scholar] [CrossRef]

- Sedliačiková, M.; Hajdúchová, I.; Krištofík, P.; Viszlai, I.; Gaff, M. Improving the performance of small and medium wood-processing enterprises. BioResources 2016, 11, 439–450. [Google Scholar] [CrossRef]

- Hitka, M.; Lorincová, S.; Pajtinková Bartáková, G.; Ližbetinová, L.; Štarchoň, P.; Li, C.; Zaborova, E.; Markova, T.; Schmidtová, J.; Mura, L. Strategic tool of human resource management for operation of SMEs in the wood-processing industry. BioResources 2018, 13, 2759–2774. [Google Scholar] [CrossRef]

- Dušak, M.; Jelačić, D.; Pirc Barčić, A.; Novakova, R. Improvements to the production management system of wood-processing in small and medium enterprises in southeast Europe. BioResources 2017, 12, 3303–3315. [Google Scholar] [CrossRef]

- Dillman, D.A. Mail and Internet Surveys—The Tailored Design Method; John Wiley & Sons, Inc.: New York, NY, USA, 2000. [Google Scholar]

- O’Connor, J.; Kozak, R.; Gaston, C.; Fell, D. Wood use in nonresidential buildings: Opportunities and barriers. For. Prod. J. 2004, 54, 19–28. [Google Scholar]

- Kendall, M.G.; Smith, B.B. The problem of m rankings. Ann. Math. Stat. 1939, 10, 275–287. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process; McGraw-Hill: New York, NY, USA, 1980; p. 278. [Google Scholar]

- Oblak, L.; Pirc Barčić, A.; Klarić, K.; Kitek Kuzman, M.; Grošelj, P. Evaluation of Factors in Buying Decision Process of Furniture Consumers by Applying AHP Method. Drv. Ind. 2017, 68, 37–43. [Google Scholar] [CrossRef]

- Camci, A.; Temur, G.T.; Beskese, A. CNC router selection for SMEs in woodwork manufacturing using hesitant fuzzy AHP method. J. Enterp. Inf. Manag. 2018, 31, 529–549. [Google Scholar] [CrossRef]

- Goyal, S.; Garg, D.; Luthra, S. Sustainable production and consumption: Analysing barriers and solutions for maintaining green tomorrow by using fuzzy-AHP–fuzzy-TOPSIS hybrid framework. Environ. Dev. Sustain. 2021, 23, 1–47. [Google Scholar]

- Karuppiah, K.; Sankaranarayanan, B.; Ali, S.M.; Paul, S.K. Key Challenges to Sustainable Humanitarian Supply Chains: Lessons from the COVID-19 Pandemic. Sustainability 2021, 13, 5850. [Google Scholar] [CrossRef]

- Saaty, T.L. Fundamentals of Decision Making and Priority Theory with the Analytic Hierarchy Process; RWS Publications: Pittsburgh, PA, USA, 2006; p. 478. [Google Scholar]

- Grošelj, P.; Zadnik Stirn, L. The environmental management problem of Pohorje, Slovenia: A new group approach within ANP–SWOT framework. J. Environ. Manag. 2015, 161, 106–112. [Google Scholar] [CrossRef]

- Akaa, O.U.; Abu, A.; Spearpoint, M.; Giovinazzi, S. A group-AHP decision analysis for the selection of applied fire protection to steel structures. Fire Saf. J. 2016, 86, 95–105. [Google Scholar] [CrossRef]

- Lee, A.H.I.; Chang, H.-J.; Lin, C.-Y. An evaluation model of buyer-supplier relationships in high-tech industry—The case of an electronic components manufacturer in Taiwan. Comput. Ind. Eng. 2009, 57, 1417–1430. [Google Scholar] [CrossRef]

- Goepel, K.D. Implementing the analytic hierarchy process as a standard method for multi-criteria decision making in corporate enterprises—A new AHP Excel template with multiple inputs. In Proceedings of the International Symposium on the Analytic Hierarchy Process; Creative Decisions Foundation Kuala Lumpur: Kuala Lumpur, Malaysia, 2013; p. 10. [Google Scholar]

- Barron, F.H.; Barrett, B.E. The efficacy of SMARTER—Simple multi-attribute rating technique extended to ranking. Acta Psychol. 1996, 93, 23–36. [Google Scholar] [CrossRef]

- Roszkowska, E. Rank Ordering Criteria Weighting Methods–a Comparative Overview. Optimum. Studia Ekon. 2013, 5, 14–33. [Google Scholar] [CrossRef]

- Danielson, M.; Ekenberg, L. Trade-Offs for Ordinal Ranking Methods in Multi-Criteria Decisions; Springer International Publishing: Cham, Switzerland, 2017; pp. 16–27. [Google Scholar]

- Sironen, S.; Mononen, L. Spatially Referenced Decision Analysis of Long-Term Forest Management Scenarios in Southwestern Finland. J. Environ. Assess. Policy Manag. 2018, 20, 1850009. [Google Scholar] [CrossRef]

- Makan, A.; Fadili, A. Sustainability assessment of large-scale composting technologies using PROMETHEE method. J. Clean. Prod. 2020, 261, 121244. [Google Scholar] [CrossRef]

- Sohn, J.; Bisquert, P.; Buche, P.; Hecham, A.; Kalbar, P.P.; Goldstein, B.; Birkved, M.; Olsen, S.I. Argumentation Corrected Context Weighting-Life Cycle Assessment: A Practical Method of Including Stakeholder Perspectives in Multi-Criteria Decision Support for LCA. Sustainability 2020, 12, 2170. [Google Scholar] [CrossRef]

- Ratten, V. Coronavirus (Covid-19) and Entrepreneurship: Changing Life and Work Landscape. J. Small Bus. Entrep. 2020, 32, 503–516. [Google Scholar] [CrossRef]

- Syriopoulos, K. The Impact of Covid-19 on Entrepreneurship and SMEs. J. Int. Acad. Case Stud. 2020, 26, 1–2. [Google Scholar]

- Seetharaman, P. Business models shifts: Impact of Covid-19. Int. J. Inf. Manag. 2020, 54, 102173. [Google Scholar] [CrossRef] [PubMed]

- Akpan, I.J.; Soopramanien, D.; Kwak, D.-H. Cutting-edge technologies for small business and innovation in the era of COVID-19 global health pandemic. J. Small Bus. Entrep. 2020, 1–11. [Google Scholar] [CrossRef]

- Dušak, M.; Jelačić, D. Production Management Model in Small and Medium Enterprises in Croatia. Drvna Ind. 2018, 69, 265–272. [Google Scholar] [CrossRef]

| Croatia | Slovenia | All | Croatia | Slovenia | aAll | ||

|---|---|---|---|---|---|---|---|

| Response share | 38.2% | 61.8% | 100.0% | Mostly computer aided technology | 23.5% | 11.5% | 16.0% |

| Less than 10 employees (micro) | 29.6% | 59.5% | 48.1% | Mostly classic technology | 22.2% | 19.1% | 20.3% |

| Less than 50 employees (small) | 40.7% | 32.1% | 35.4% | Mostly hand tools and machines | 9.9% | 11.5% | 10.8% |

| Less than 250 employees (medium) | 29.6% | 8.4% | 16.5% | A combination of all of the above | 44.4% | 58.0% | 52.8% |

| Individual production | 35.8% | 61.8% | 51.9% | Work for a known customer | 63.0% | 74.8% | 70.3% |

| Small series production | 39.5% | 27.5% | 32.1% | Work for an unknown customer (showrooms and retail stores) | 0.0% | 1.5% | 0.9% |

| Serial production | 24.7% | 10.7% | 16.0% | A combination of work for a known and an unknown customer | 37.0% | 23.7% | 28.8% |

| LPOSC | PCMPPD | RPQP | MMAC | HR | ITMPT | EFP | |

|---|---|---|---|---|---|---|---|

| Mean rank | 3.7 | 3.4 | 2.3 | 4.7 | 4.0 | 4.5 | 5.5 |

| Ranks | 3 | 2 | 1 | 6 | 4 | 5 | 7 |

| SMARTER weights | 0.162 | 0.161 | 0.255 | 0.106 | 0.134 | 0.110 | 0.072 |

| AHP weights | 0.137 | 0.111 | 0.170 | 0.232 | 0.126 | 0.160 | 0.063 |

| Ranks | 4 | 6 | 2 | 1 | 5 | 3 | 7 |

| Final weights | 0.150 | 0.136 | 0.213 | 0.169 | 0.130 | 0.135 | 0.068 |

| Ranks | 3 | 4 | 1 | 2 | 6 | 5 | 7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jelačić, D.; Pirc Barčić, A.; Oblak, L.; Motik, D.; Grošelj, P.; Jošt, M. Sustainable Production Management Model for Small and Medium Enterprises in Some South-Central EU Countries. Sustainability 2021, 13, 6220. https://doi.org/10.3390/su13116220

Jelačić D, Pirc Barčić A, Oblak L, Motik D, Grošelj P, Jošt M. Sustainable Production Management Model for Small and Medium Enterprises in Some South-Central EU Countries. Sustainability. 2021; 13(11):6220. https://doi.org/10.3390/su13116220

Chicago/Turabian StyleJelačić, Denis, Andreja Pirc Barčić, Leon Oblak, Darko Motik, Petra Grošelj, and Matej Jošt. 2021. "Sustainable Production Management Model for Small and Medium Enterprises in Some South-Central EU Countries" Sustainability 13, no. 11: 6220. https://doi.org/10.3390/su13116220

APA StyleJelačić, D., Pirc Barčić, A., Oblak, L., Motik, D., Grošelj, P., & Jošt, M. (2021). Sustainable Production Management Model for Small and Medium Enterprises in Some South-Central EU Countries. Sustainability, 13(11), 6220. https://doi.org/10.3390/su13116220