Abstract

Although various types of management strategies have been proposed to improve construction productivity, they are seldom prioritized based on contribution. This study aims to bridge the knowledge gap to prioritize the critical management strategies that can help improve productivity in the construction industry. To achieve this goal, a comprehensive literature review was conducted first, to develop a conceptual framework of construction management strategies that are assumed to have positive relationships with productivity performance. A questionnaire was then developed and disseminated to 53 Singapore-based companies for data collection. The collected data were analyzed using partial least squares structural equation modelling. Results showed that “planning and communication” is the most critical management strategy category for productivity improvement, followed by “logistics,” “project strategic management”, “human resources”, and “on-site management.” This study contributes to the current body of knowledge by prioritizing critical management strategies that can help the construction industry improve productivity. Findings are likewise beneficial for the industry practitioners as well, as they can help deepen their understanding of the role played by these management strategies on increasing productivity and thereby formulate the best combinations for their own companies.

1. Introduction

The construction industry is widely reported to have a relatively low productivity level, especially when compared with other industrial sectors like mining, manufacturing, and oil and gas [1,2,3]. This is mainly because the construction industry is labor-intensive and is deeply affected by various internal and external factors including social culture, environmental and legal constraints, inappropriate management actions, extreme weather, excessive overtime, and transportation conditions [4,5,6].

Implementing management strategies at construction sites is highly necessary and important if companies intend to increase their projects’ productivity. In fact, the importance of management strategies in improving construction productivity has been strongly emphasized by many studies. For example, Adrian [7] stated that management strategies such as management skills training, improving worker motivation, and adopting new technology could improve productivity. For the same goal, Thomas and Horman [8] suggested full consideration of project variability, adopting a comprehensive and flexible labor strategy, and suitable work schedules. Dai et al. [9] focused on the influence of craft workers on productivity and emphasized retention of skilled craft workers, orderly construction site, and comprehensive communication as effective management strategies. Moreover, Nasir et al. [10] pointed out the importance of health and safety training, stable organizational structure, and detailed acquisition strategies in relation to productivity improvement.

Although numerous management strategies have been proposed to improve productivity, they were seldom prioritized, according to a systematic search of the productivity literature conducted by the research team. Therefore, the present study aims to fill this knowledge gap by addressing the following questions:

- What are the prevailing management strategies that can help improve the productivity of the construction industry?

- How can we prioritize those management strategies?

This study was conducted in the context of Singapore, where the low productivity of the construction industry has always been a major government concern. In 2012, the Deputy Prime Minister of Singapore, Mr. Tharman Shanmugaratnam, pointed out that Singapore’s construction productivity level is only over one-third that of Japan. To improve the situation, the government exerts considerable efforts. Since 2010, the Building Construction Authority (BCA) of Singapore has launched several initiatives, such as the Certified Construction Productivity Professional (CCPP) Scheme and Construction Productivity Capability Fund. The CCPP scheme requires each contractor to include a project productivity enhancement proposal in its bidding document, presenting its plan and strategies to be used for improving productivity in the project awarded. Such administrative actions taken by the government indicate that the contributions of management strategies on improving productivity are fully recognized in the construction industry of Singapore.

Although a large number of studies have been conducted in productivity, most of them focus on the evaluation of productivity. Few of them prioritize the various management strategies in sense of their contributions. Thus, this research can contribute to the current body of knowledge of productivity. In addition, this research is helpful to the industry as well, because it can deepen the practitioners’ understanding of management strategies and help them come up with strategies that are more effective for productivity improvement.

2. Literature Review

2.1. Management Strategies to Improve Productivity

A comprehensive literature review was first conducted to identify the prevailing management strategies adopted by the construction industry to improve productivity. The management strategies generated from the review can be grouped into five categories, namely, project strategic management, on-site management, planning and communication, logistics, and human resources.

Numerous studies recommended the adoption of project strategic management strategies. For example, Naoum [11] and Ying and Sen [12] suggested using advanced construction technologies such as prefabrication to improve productivity. Naoum [11] and El-Gohary and Aziz [13] encouraged using contractual methods such as design/build and design/build/operate/transfer and involving contractors in the design stage to increase the productivity of design and construction. Makulsawatudom and Emsley [14] and Abdul Kadir et al. [15] proposed that improving communication among stakeholders through weekly meetings is a good strategy. Furthermore, Alwi [16] recommended that project stakeholders should have regular meetings and maintain long-term relationships with manufacturers and suppliers to reduce issues in coordination or delivery.

On-site management was found to be critical for increasing productivity in construction projects. A research stream proposed dynamic site layout plans and installing machinery and equipment at suitable locations without affecting other site activities [13,14,17,18]. In addition, to ensure no debris on site, which may hinder work progress, Goodrum et al. [17] recommended scheduling housekeeping once a week.

Planning and communication were likewise observed as critical for productivity. Goodrum et al. [17] suggested that management could adopt organizational charts or command chains to ensure that information is correctly and timely delivered. Construction Industry Institute (CII) [19] indicated that two-way communication between process workers and field management enabled positive and negative feedback loops, which can tackle productivity issues in projects. In addition, CII [20] pointed out that team building facilitated the establishment of common goals among stakeholders, which could help achieve the desired project outcomes. Rojas and Aramvareekul [21] and Goodrum et al. [17] suggested integrating scheduling to update the project timetable and measure progress. Aziz and Hafez [22] summarized several strategies that could increase efficiency and productivity, such as involving a multidisciplinary team in concurrent engineering using a last planner system. A type of lean technique, this system stimulated workflow control through weekly work schedules and plans for the next two to six weeks. Integrating health and safety programs into project implementation was also suggested to reduce unforeseen time constraints. Moreover, Paez et al. [23] proposed that productivity could be improved by implementing concurrent engineering and parallel task implementation through multidisciplinary teams. Daily huddle meetings should be arranged to derive immediate actions and thereby improve productivity.

Improving logistics is also one of the management strategies that could increase productivity. Goodrum et al. [17] identified several best practices for increasing productivity, such as effective material management, machinery, and equipment logistics. Abdul Kadir et al. [15] and Goodrum et al. [17] suggested setting up a procurement team and developing procurement plans and procedures for materials, equipment, and tools. CII [20] proposed to conduct a prequalification to ensure that the best supplier of materials and equipment was shortlisted for a project. Goodrum et al. [17] suggested using tracking technology to track materials’ location for managing delivery. Goodrum et al. [17] and Rojas and Aramvareekul [21] also recommended that material quality checks should be performed prior to acceptance, to prevent rework due to poor material quality. Rivas et al. [24], Abdul Kadir et al. [15], and Makulsawatudom and Emsley [14] put forward that preventive maintenance should be implemented to minimize the shortage of tools and equipment due to malfunction, which can seriously lead to inefficiencies. Abdul Kadir et al. [15] and Diekmann and Heinz [25] suggested providing buffers for large inventories to provide flexibility for the construction process. Additionally, Abdul Kadir et al. [15] and Diekmann and Heinz [25] suggested using the lean just-in-time strategy for material handling.

Numerous studies showed that human resource management was vital to improve productivity in the labor-intensive construction industry. In terms of employment, Rojas and Aramvareekul [21], Makulsawatudom and Emsley [14], and Goodrum et al. [17] proposed skills assessment to screen employees and hiring highly skilled or experienced workers. El-Gohary and Aziz [13] and Ghoddousi et al. [26] proposed that training could increase labor productivity by ensuring the development of skills and knowledge of workers. Motivation could affect a person’s behavior, and thus Doloi [27] and Kazaz and Ulubeyli [28] encouraged using financial and non-financial incentive programs to boost worker motivation. Rojas and Aramvareekul [21] suggested that improving worker motivation served as an important opportunity for increasing productivity. Makulsawatudom and Emsley [14] recommended using charts, manuals, and guidelines to facilitate workers’ understanding of the work process.

Table 1 presents the project management strategy categories and the specific tactics summarized from the literature review.

Table 1.

Management strategy category and tactics to improve productivity.

Although a large number of management strategies have been proposed to improve productivity, the effectiveness of these strategies is seldom evaluated, and these strategies are rarely prioritized based on their real contributions. It makes the construction authorities and the industry practitioners unable to find out and to implement the management strategies that are most useful, helpful, and powerful for productivity enhancement. Thus, there is a gap both in the existing productivity research and in the needs of the practice, and the current study plans to bridge the gap.

2.2. Assessing Productivity

Productivity assessment is an essential activity for managing construction organizations, because it reveals the organizational efficiency. Productivity assessment mainly relies on productivity indicators. Through a systematic literature review, the prevailing productivity indicators adopted by the existing industry and governmental organizations were identified. A total of 33 indicators were found and grouped into four levels, namely, industry, company, project, and trade levels. Table 2 shows the indicators and their respective levels.

Table 2.

Productivity indicators.

At the industry level, the commonly used productivity indicators are total factor productivity, multi-factor productivity, square meter per man-day, a growth accounting approach, data envelopment analysis, output per worker, output per work hour, value added per worker, and value added per hour worked. The latter four indicators are also used to assess productivity at the company level. At the project level, the widely used indicators are square meter per dollar, square meter of built-up floor area per man-day, value added per worker, output per person-hour on key trades, constructability score, and buildable design score. Productivity indicators are used at the trade level and focus on specific tasks conducted by workers. These indicators include work-hours expended/quantity installed, formwork area per man-hour, amount of rebar/prefab mesh per man-hour, volume of concrete per man-hour, number of doors installed per man-hour, suspended ceiling per man-hour, and length of ducting per man-hour.

2.3. Research Hypothesis

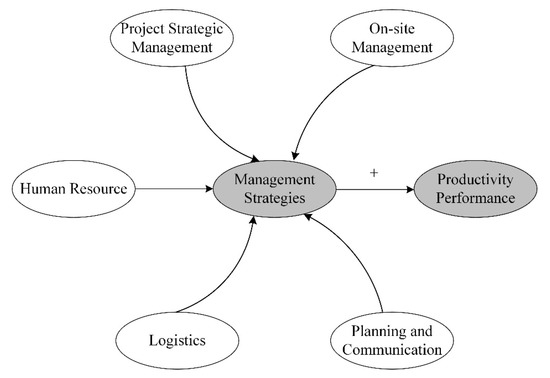

To identify the most critical management strategies that can help improve productivity, this study proposed a theoretical model that hypothesizes management strategies could result in growth of productivity performance. Figure 1 presents the model, where management strategies cover five aspects identified from the literature review, namely, project strategic management, on-site management, planning and communication, logistics, and human resources. Productivity performance covers productivity indicators at the industry, company, project, and trade levels.

Figure 1.

Hypothetical structural model. Notes: “+” represents management strategies could result in growth of productivity performance.

3. Methods

3.1. Research Methods

This study adopted five methods, namely, literature review, pilot interviews, questionnaire, structural equation modeling, and post-survey interviews.

A comprehensive literature review was conducted first to identify management strategies that could improve productivity, together with productivity indicators to assess productivity. To ensure a comprehensive review, the systematic search included government reports, web pages, journal articles, documents, and relevant books.

Conducting pilot interviews with experienced industry experts is a good strategy to verify the information obtained from the literature review. Thus, this study conducted pilot survey interviews to ensure that the identified management strategies and productivity indicators are applicable to the context of Singapore.

In construction engineering and management research, questionnaire survey is a widely used approach to obtain the opinions of industry professionals. Thus, this study used the questionnaire method to collect the perceptions of industry professionals on management strategies and productivity indicators. The questionnaire consisted of three sections, which can be seen in the Appendix A. First, the profiles of respondents were recorded, including designation, years of experience, and years of experience specific to assessing construction productivity. Second, respondents were required to rate the implementation level of various management strategies in their organizations using a five-point Likert scale (i.e., 1 = not implemented, 2 = implemented occasionally, 3 = implemented, 4 = implemented in most cases, and 5 = fully implemented). Third, respondents were asked to indicate their perceptions of organizational productivity performance under various productivity indicators using a five-point Likert scale (i.e., 1 = very poor, 2 = poor, 3 = moderate, 4 = good, and 5 = very good).

Structural equation modeling (SEM) is regarded as one of the most suitable methods for analyzing the causal relationships between multiple variables. Different from the first-generation regression models (e.g., stepwise multiple regression model), which can analyze only one layer of linkage between variables at a time, SEM can analyze the relationships among multiple variables simultaneously [41]. Considering the various types of management strategies identified in this study, SEM was adopted to test the hypothesis of this research, namely the implementation of management strategies could lead to growth of productivity performance. Williams et al. [42] mentioned that SEM has two forms, namely, partial least squares structural equation modeling (PLS-SEM) and covariance-based structural equation modeling (CB-SEM). Compared with CB-SEM, PLS-SEM has two major advantages, namely, its suitability for dealing with data collected from a questionnaire using a small sample size and better interpretability when dealing with highly skewed data [43,44]. Therefore, this study employed PLS-SEM.

Lastly, post-survey interviews were conducted with three experts in the local construction industry. The experts were provided with analysis results obtained from the questionnaire and requested to explain the results and propose recommendations to validate the survey findings and gather in-depth feedback. Table 3 highlights their profiles.

Table 3.

Profiles of post-interviewees.

3.2. Data Presentation

The sampling frame of the questionnaire covered 4168 contractors and licensed builders registered under the BCA Directory. Referring to a frequently used sample rate of 10% [45], 416 contractors were randomly selected from the BCA Directory as potential respondents of the questionnaire, which was distributed via email, phone calls, and in person. A total of 53 responses were received. The respondents had different types of designations, such as contractors, consultants, owners, and government agency personnel. Among the respondents, approximately 90% had at least five years of working experience in the construction industry and approximately 50% had at least five years of experience in assessing construction productivity. These proportions indicated that the questionnaire respondents were experienced in the field and that data collected were reliable. Table 4 presents the profiles of the survey respondents.

Table 4.

Profiles of survey respondents.

4. Results and Discussions

4.1. Model Test Results

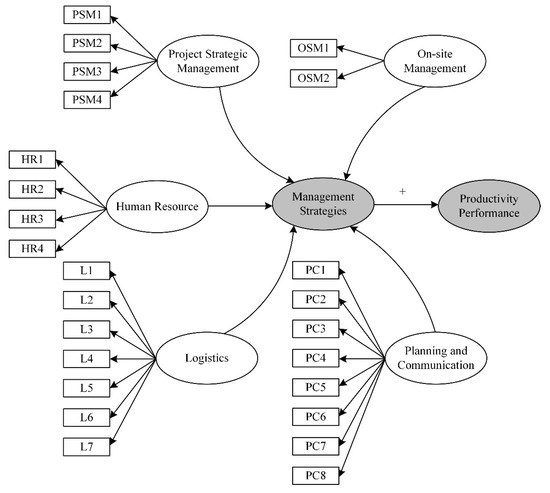

The hypothesized model was tested using the approach of PLS-SEM, which consists of two parts, namely, a structural model and measurement model. Figure 2 shows the hypothesized model, which consists of six measurement models and one structural model.

Figure 2.

Hypothesized model. Notes: “+” represents management strategies could result in growth of productivity performance.

Among the six measurement models, one measures the overall productivity performance of a given organization, and the others measure five categories of management strategies. The structural model measures the relationship between management strategies and productivity performance. Data collected from the questionnaire were input into SmartPLS to test the hypothesized model.

4.1.1. Measurement Model Evaluation

As recommended by Hair et al. [46], the measurement models are assessed with regard to their indicator reliability, internal consistency reliability, convergent validity, and discriminant validity. Table 5 presents the evaluation results of the measurement models. The factor loadings of all specific management strategies are larger than 0.4 with t-values greater than 2.58. This finding indicates that the indicator reliability of the measurement models is acceptable [46]. The composite reliability values of all management strategy categories are greater than 0.7, which indicates good reliability of internal consistency for all categories of management strategies. The average variance extracted (AVE) values in Table 5 are greater than 0.5, which implies a satisfactory level of convergent validity for all categories of management strategies. Table 6 shows the AVE of each management strategy category. The results are greater than the squared correlation of other categories of management strategies. Table 7 shows the cross loadings, which indicates that each management strategy has the highest loading on its corresponding category. These findings suggest that all categories of management strategies have high discriminant validity. Table 8 presents the evaluation results of the hierarchical model of management strategies, where the t-values of all paths are greater than 2.58. This finding suggests that the relationships among management strategies are significant at the 0.01 level. Moreover, the composite reliability values are greater than 0.7, which indicate good reliability of the hierarchical model of management strategies [47].

Table 5.

Measurement model.

Table 6.

Fornell–Larcker criterion.

Table 7.

Cross loadings.

Table 8.

Hierarchical model evaluation.

4.1.2. Structural Model Evaluation

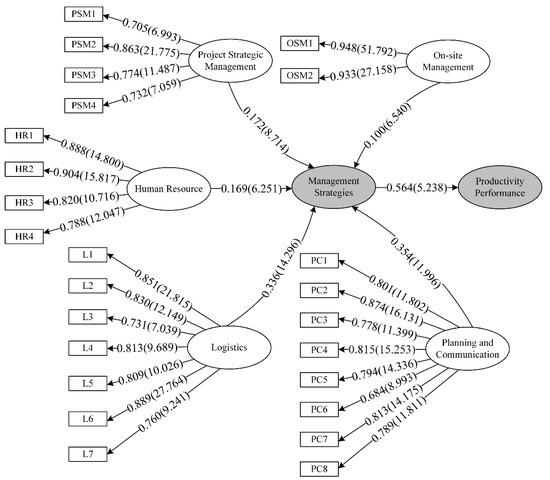

As for the structural model, the test results generated by the software SmartPLS show that the path coefficient between management strategies and productivity performance has a t-value of 5.238, which is higher than 2.58. The relationship between management strategies and productivity performance is therefore statistically significant at the 0.01 level. Such finding supports the hypothesis that management strategies can improve construction productivity. In addition, as shown in Table 8, “planning and communication” and “logistics” received higher path coefficients than the remaining three categories, suggesting they are more critical management strategies. Figure 3 shows the whole results of the proposed model tested by SmartPLS.

Figure 3.

Results of modelling.

4.2. Discussion

4.2.1. Planning and Communication

“Two-way communication between workers and supervisor” (PC2) received the highest factor loading (0.874) on planning and communication (PC). Two-way communication between workers and supervisors is critical for avoiding productivity problems caused by insufficient communication. By so doing, issues can be timely identified and corrected. CII [19] also supports this point. The organization recommends open communication between workers and supervisors, because the former are familiar with on-site activities and can thus quickly and accurately inform the latter about on-site productivity problems, such that the problems can be immediately addressed. Research by [48] shows that effective communication between supervisor and workers is very important for workgroup health and safety, and it is an effective way to improve construction performance.

“Integrated scheduling to measure project progress” (PC4) received the second highest factor loading. Scheduling is categorized as the most relevant determinant of labor productivity under the management system category [21]. Interviewees report that regular updating and tracking status enables the adjustment of intended productivity objectives back on track. Goodrum et al. [17] justifies this notion by identifying scheduling control as a best practice for avoiding negative effects on completion dates. In addition, interviewees also recommend using scheduling software, such as Microsoft Project, Primavera P6, and Building Information Modelling (BIM). These tools are effective in planning and controlling work progress to enable pro-active measures in a timely manner and mitigate delays.

“Daily huddle meetings to look for immediate actions” (PC7) ranked third in terms of factor loading. Interviewee C points out that daily site coordination meetings are necessary and effective due to the large number of workers and sub-contractors on site. Therefore, understanding work locations and issues faced by activities in these locations is important. This mechanism can stimulate effective follow-up of events and sharing of impediments. It should be noted that daily meetings should be quick by focusing on important questions only [49].

“Clear organizational structure to define line of authority and communication chain” (PC1) received the fourth highest loading. Lack of a proper organizational structure or chain of command can lead to poor exchange or distortion of information. Goodrum et al. [17] stated that the line of authority reduces the cycle time of information processing and exchange. Additionally, errors can occur in events where information is not conveyed to the appropriate agents, which disrupts workflow and reduces productivity. Hence, organizational structure needs to be clearly established to define the communication chain and person-in-charge and ensure that messages are correctly conveyed across departments.

“Concurrent engineering to involve a multidisciplinary team” (PC5) received the fifth highest loading. This is a lean construction technique that aims to improve construction productivity through parallel execution by multidisciplinary teams [22]. Concurrent engineering leverages on various methods, such as scheduling network analysis, overlapping or splitting activities, shrinking transfer time between activities, and algorithms [23]. Concurrent engineering can improve productivity through time savings and promoting a collaborative approach. For example, the practice of Design for Manufacture and Assembly (DfMA) integrates building materials, production and assembly technology, logistics and supply chain management, and concurrent engineering to involve a multidisciplinary team will help increase productivity.

“Integrate health and safety plan into project execution” (PC8) ranked sixth within the management category. Plan conditions and work environment in the construction industry embrace safety practices that limit scheduled work [22]. Interviewee C emphasized the importance of the health and safety plan to ensure that no such issues hamper work progress. A stop-work order can occur in the case of accidents on-site. If working conditions are deemed unsuitable, then construction productivity is significantly affected. Many studies have shown that the introduction of Sustainability and Occupational Health and Safety Management Systems (S_OHSMS) standards at the organizational level can increase productivity. The use of two management system standards have a positive effect on the reduction of risks and the improvement of productivity [50]. “Team building to enforce friendly relationships and common goals among co-workers” (PC3) received the seventh highest factor loading. Team building fosters shared goals, commitment, and accountability, which can all lead to high labor productivity [20]. Interviewee C also revealed that team building is enforced at the main contractor level and among his team to promote better relations. In addition, co-workers with healthier relationships in the workplace are increasingly motivated to generate useful output. However, team building is an extensive activity that involves numerous workers, because projects are typically large-scale. The study infers that this notion may be the reason why team building ranks low under this category despite its benefits.

“Last planner system for work flow control” (PC6) ranked eighth in the management category. As another lean construction technique proposed by Aziz and Hafez [22], the last planner system is a useful tool for management and process monitoring through a look-ahead, weekly work planning, and percentage of planned completed. The principle of “should–can–will–did” is applied to ensure that schedules are well defined and controlled, with tasks that are likely to be completed on time [22]. This view is further supported by interviewees who suggest a look-ahead of 3–4 months to ensure tasks are scheduled realistically for completion with necessary resources.

4.2.2. Logistics

“Buffer strategy for materials and labor in long-lead items” (L6) received the highest loading under this category. Interviewees explain this aspect as avoiding unforeseen delivery issues that can affect construction schedules. Labor and materials complement each other; therefore, work is futile if materials are not delivered to the site for the workers to install. This view is supported by Abdul Kadir et al. [15], who state that workers remain idle while waiting for materials. Therefore, long lead-time items should be identified early to ensure that delivery time does not affect the overall schedule. Interviewees from the pilot interviews also recognized the need to understand the necessary items and their respective lead times.

“Set up a procurement team and develop a procurement plan and procedures for materials, equipment, and tools” (L1) received the second highest loading. Unavailability of materials, tools, and equipment is notorious for its negative impact on work progress, which results in workers’ idling period and consequently major loss of productivity. Material shortage ranks the most critical factor in the loss of productivity [15]. Similarly, the lack of materials ranks first as a factor influencing productivity in Thailand [14]. Rojas and Aramvareekul [21] identify the 79% relative relevance of materials and equipment management problems as a driver of labor productivity. To address shortage problems, procurement procedures and plans are important in tracking prompt and correct delivery [17]. This view is further supported by interviewees’ opinions that optimizing and planning procurement in advance through a procurement team prevents disruption to the construction schedule and enables the meeting of productivity criteria.

“Implementing rigorous prequalification process for securing suppliers of equipment and material” (L2) ranked third in factor loading under the logistics category. A rigorous prequalification or screening process of suppliers avoids negotiating with those that fail to meet the requirements of quality materials or equipment [20]. Interviewee C confirms that the prequalification process effectively ensures the purchase of appropriate materials or equipment and is interrelated with PSM4 that considers a list of suppliers. By prequalifying suppliers that meet the imposed standards, poor quality or breakdown does not disrupt the projects; hence, avoiding a compromise in productivity.

“Careful inspection of materials before acceptance to ensure quality” (L4) attained the fourth highest loading. Inspection is carried out to ensure the quality of materials to eliminate faulty ones that can result in rework and affect productivity. This finding is supported by Rojas and Aramvareekul [21], who associate poor quality of materials with rework that can negatively impact construction productivity due to the required additional time and cost. Interviewees from the pilot interviews reveal that they conduct a spot checking of materials before acceptance to quickly examine their conditions.

“Develop preventive maintenance and inspection checklist for equipment and tools” (L5) received the fifth highest factor loading. Equipment and tool breakdown delay work progress, because activities cannot continue without proper equipment and tools. Abdul Kadir et al. [15] supported this finding, stating that equipment breakdown or improper maintenance results in major idling time. Likewise, Rivas et al. [24] related the decline in productivity to broken tools. With respect to breakdowns, preventive maintenance can minimize their impact on productivity through timely maintenance to ensure positive operating conditions [14]. The survey respondents of the present study also opine that developing a preventive maintenance and inspection checklist effectively ensures the good condition of equipment and tools, which thereby promotes productivity.

“Just-in-time strategy to ‘pull’ materials and equipment only when required” (L7) ranked sixth under the logistics category. This strategy adopts the concept of the lean manufacturing approach to deliver only as needed [20]. Abdul Kadir et al. [15] further support this strategy by pointing out the issue of lack of storage areas in construction sites across Singapore. In addition, for some projects that use prefabricated components, they are manufactured in a factory far away from the city center with sufficient operation and storage space. By incorporating just-in-time strategies into the delivery plan, it can save time and improve sustainable performance, which has a positive impact on both suppliers and contractors [51].

“Develop a material/equipment/tool status database to track information” (L3) is the seventh in factor loading. A database for tracking information is critical to sustain awareness of important deadlines. This strategy emphasizes the need to track information in an orderly manner to ensure such hiccups do not occur. Without materials, equipment, or tools, workers are unable to work and instead spend supposedly productive time waiting. Integrating the BIM model with real-time data streams from Internet of Things (IoT) sensors is a powerful example of status database and information tracking. In addition, BIM and IoT can also provide a variety of applications, such as real-time big data analytics and integration with other cutting-edge technologies, which can process logistics information in a timely manner and provide external feedback that can improve construction productivity [52].

4.2.3. Project Strategic Management

“Contractual methods that involve contractors at the design stage” (PSM2) received the highest factor loading under the project strategic management category. This strategy enables the negotiation between buildable design and better construction approach to improve productivity before execution. Particularly, contractual methods such as a design and build contract (D&B) facilitate project coordination and efficiency, which improves productivity compared with traditional forms of contracts with rigid contractors’ involvement in the design, such as design–bid–build. This finding is supported by Naoum [11], who argues that shifting from traditional to D&B contracts drives a collaborative approach. Furthermore, El-Gohary and Aziz [13] recommend adopting procurement methods that advocate the early involvement of contractors to improve the constructability level of a design. With a single point of responsibility, interviewee A agrees that such contractual arrangements are effective because they reduce wastage.

“Weekly meetings with project stakeholders to update on project progress” (PSM3) followed as the second highest factor loading. The main factors that affect productivity are associated with drawing issues or rework as a result of poor coordination, which pose delays to projects and are prevalent in many studies [15,40]. Regular meetings are held with the intention of resolving poor coordination problems among project stakeholders. Interviewee A opines that changes can be made promptly through meetings to avoid unproductive output, initiate good coordination, and eliminate any hindrance to work progress. The research [53] showed that contact with stakeholders seems to be very important to successful delivery of green building projects. Regular meetings every two weeks are most favored by respondents. Meeting with the customer once a month will lead to a longer time to solve the problem and affect the project schedule eventually.

“Long-term relationship with suppliers for trustworthy delivery and quality” (PSM4) ranked as the third factor loading in this category. Productivity can be negatively influenced due to late delivery and poor quality of materials. Alwi [16] recommends establishing long-term relationships with suppliers who can ensure prompt delivery and quality. The post-survey interviewees also recommend this strategy, citing that establishing long-term business relationships is effective, because suppliers become familiar with the needs of their regular clients.

“Adoption of advanced construction technologies” (PSM1) received the fourth highest loading under this category. Automation, semi-automation, and prefabrication are highly encouraged in recent years to enhance labor productivity [29]. A high level and overall growth of labor productivity are also observed when off-site production is adopted [11]. BCA’s massive efforts in pushing for technologically advanced construction further support the effectiveness of technologies in manpower and time savings of up to 50%. Although proven to be an effective strategy, such adoption ranked relatively low among other strategies. The reason for this finding may be the challenges faced by firms, specifically costs, to adopt advanced technologies. This aspect is supported by Ying and Sen [12]. That is, change happens in a drastic and fast-paced manner while the market is on the downturn, which renders adopting technologies difficult. Furthermore, interviewee C cites that adopting new technologies can be a challenge for small- and medium-sized enterprises due to increased costs. Nonetheless, advanced construction technologies can achieve a high level of productivity through labor and time savings, as revealed by the interviewees.

4.2.4. Human Resources

“Training for specific work activities to ensure workers are skilled in their work scope” (HR2) received the highest factor loading under the human resource category. Given the labor-intensive nature of construction, productivity is largely influenced by manpower-related factors such as experience and skills. This result is supported by the study of El-Gohary and Aziz [13], where “laborer experience and skills” rank first under the labor/human category for factors influencing construction labor productivity. Trained and experienced workers possess abilities that can lead to increased productivity and quality. Ghoddousi et al. [26] group skilled workers and training under “high effects” factors and cite that workers equipped with skills through training can raise labor productivity. Interviewee A believes that training is a must to avoid unnecessary production loss and wastage. Furthermore, interviewee C emphasizes that the scarcity of highly skilled manpower in the local construction industry leads to the necessity to provide training. In Singapore, most workers are foreigners with a few skills. Hence, training potential workers is crucial for familiarity with their job scope and to increase output. Training, as suggested by numerous studies, is also highly favored by survey respondents and interviewees for optimizing productivity in the context of Singapore.

“Assessment and interviews of employees to qualify hiring of competent staff” (HR1) received the second highest in factor loading. Experience and training are the top two drivers under the manpower category [21]. Typically, incompetency and unqualified employees or supervisors are the leading factors of productivity loss due to decreased or defective output. To address this problem, Makulsawatudom and Emsley [14] recommend selecting and interviewing employees. This solution is evidently effective according to the survey respondents and interviewees. Post-interviewees also mention that priority is given to qualified workers to avoid a long period of on-the-job training. Hence, this finding substantiates the effectiveness of pre-screening for experienced staff. Interviewee B further states that apart from hiring qualified staff, retaining staff with appropriate knowledge and skills is effective. This argument is supported by Goodrum et al. [17], who suggest the employment strategy of retaining productive employees.

“Financial and non-financial incentive programs to boost workers’ motivation” (HR3) received the third highest ranking under the category of human resources. A conducive work environment and incentivized employment contracts can increase employee output [27]. Workers receiving additional and attractive financial and non-financial benefits are expected to have increased motivation and consequently high productivity according to Kazaz and Ulubeyli [28]. Interviewee C supports this statement by sharing that, typically, financial incentives boost workers’ motivation to operate efficiently. BCA has launched several initiatives, such as the Productivity Innovation Project (PIP) and Construction Registration of Tradesmen (CoreTrade). The CoreTrade scheme provides a clear career progression path and gives workers due rewards and recognition, thereby retaining better and more experienced workers. Many companies also increase employee satisfaction with their jobs through transport and mobile phone allowances, overtime pay, appreciation, and job recognition.

“Easier means of communication with craft workers” (HR4) ranked fourth among the human resource strategies. This point is vital, as the local construction industry comprises a vast number of foreign workers. Lim and Alum [29] raise the issue of diversity of languages on site. Post-interviewees likewise agree that this is relevant to the local construction industry, because foreign workers on-site consist of many nationalities. Hence, a flexible means of communication is implemented at all times to ensure consistent understanding among workers, such as pictures and videos of the process for visualization. The research [54] showed that using VSM-based VR training, the productivity of the scaffolding erection process is increased by 12%, and the error rate is reduced.

4.2.5. On-Site Management

“Development of a dynamic site layout plan for the optimal location of work activities” (OSM1) received the highest factor loadings under the on-site management category. Planning, workflow, and site congestion or poor site layout frequently rank within the top 10 factors influencing construction productivity [14], according to El-Gohary and Aziz [13]. A dynamic site layout plan aims to optimize work activities and facilitates an efficient flow to reduce site congestion or accidents. Aligned to this finding, Gurmu et al. [18] suggest that a dynamic site layout can reduce site congestion, whereas Goodrum et al. [17] put forward a dynamic layout to facilitate efficient and safe workflow. Interviewee C reveals that a dynamic site layout plan is subject to site conditions and is necessary to prevent conflicts among work activities that can cause obstruction or double-handling. Therefore, a dynamic site layout plan is critical for every construction project to optimize productivity according to the survey respondents and interviewees.

“Weekly housekeeping to clear debris and hazard” (OSM2) follows as the second highest factor loading under the category of on-site management. Housekeeping is necessary to avoid obscuring workers’ access or safety issues in the work site. Materials and tools laying around the work site can result in safety issues that may lead to stop-work orders. Therefore, eliminating these problems through housekeeping promotes a safe and efficient work environment for operation without impeding productivity.

5. Conclusions

This study prioritized the critical management strategies that can help improve construction productivity by testing the hypothesis that prevailing management strategies are positively correlated with productivity performance in the current construction industry. The results show that “planning and communication” is the most critical management strategy category, followed by “logistics”, “project strategic management”, “human resources”, and “on-site management”. Results also show that a “two-way communication between workers and supervisors”, “buffer strategy for materials and labor in long-lead items”, “contractual methods that involves contractors at the design stage”, “training for specific work activities to ensure workers are skilled in their work scope”, and “development of a dynamic site layout plan for the optimal location of work activities” are the most critical strategies under each management strategy category.

Although the goals of this study are achieved, some limitations remain. First, although considerable efforts were made to ensure a large number of responses, the resultant sample size was still small. The number of 53 responses is statistically significant, but a larger sample size can ensure added reliability and accuracy to the analysis. Second, the number of respondents in the four target categories is uneven with few government agencies and owners, which may lead to biased results.

This study contributes to the current body of knowledge by revealing that critical management strategies can help the construction industry improve its productivity. The findings are likewise beneficial for industry practitioners to deepen their understanding of the role played by these management strategies on increasing productivity, and thereby formulate the best combinations for their companies. Developing a method to assess the implementation level of these management strategies in construction organizations and seeking possible improvement would be an interesting and necessary topic for future study.

Author Contributions

B.-G.H. contributed to this work by conceiving the study and interpreting the findings obtained by the PLS-SEM analysis. Y.-S.L. contributed to this work by developing the framework of management strategies and conducting data analysis. M.S. contributed to the research design and data analysis. J.-E.C. contributed to the literature review and data collection. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by National Natural Science Foundation of China (Grant No. 71901224) and Natural Science Foundation of Hunan Province, China (Grant No. 2020JJ5779).

Acknowledgments

Sincere thanks go to the industry experts who have participated in the survey carried out in this study.

Conflicts of Interest

The authors declare no interest of interest.

Appendix A. Main Survey Questionnaires

Respondents’ Profile:

Please indicate your designation by ticking √ below.

[ ] Consultant [ ] Contractor [ ] Owner [ ] Government Agencies [ ] Others (please specify:)

Please indicate your years of experience in the construction industry:

Please indicate your years of experience in assessing productivity in your organization:

Please indicate the years of experience of your company/organization in the construction industry:

Please indicate the years of experience in assessing productivity in your organization:

Appendix A.1. Management Strategies to Improve Construction Productivity

Please rate the level of implementation on the following strategies in the construction project you are currently working on by marking an X in the boxes below.

1: Not Implemented, 2: Implemented Occasionally, 3: Implemented Moderately, 4: Implemented in Most Cases, 5: Fully Implemented

Table A1.

List of Management Strategies to Improve Productivity.

Table A1.

List of Management Strategies to Improve Productivity.

| Categories | Strategies | Level of Implementation | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| Project Strategic Management | Adoption of advanced construction technologies, e.g., prefabrication, PPVC. | |||||

| Contractual methods that involves contractors at the design stage, e.g., Design and Build contract (D&B). | ||||||

| Weekly meetings with project stakeholders to update on project progress. | ||||||

| Long-term relationship with suppliers for trustworthy delivery and quality. | ||||||

| On-site Management | Development of a dynamic site layout plan for the optimal location of work activities. | |||||

| Weekly housekeeping to clear debris and hazard. | ||||||

| Planning and Communication | Clear organizational structure to define line of authority and communication chain. | |||||

| Two-way communication between workers and superiors. | ||||||

| Team building to enforce friendly relationships and common goals among co-workers. | ||||||

| Integrated scheduling to measure project progress. | ||||||

| Concurrent engineering to involve a multidisciplinary team. | ||||||

| Last planner system for work flow control. | ||||||

| Daily huddle meetings to look for immediate actions. | ||||||

| Integrate health and safety plan into project execution. | ||||||

| Logistics | Set up a procurement team and develop procurement plan and procedures for materials, equipment and tools. | |||||

| Prequalification process for securing suppliers of equipment and material. | ||||||

| Material/equipment/tool status database to track information | ||||||

| Inspection of materials before acceptance to ensure quality. | ||||||

| Preventive maintenance and inspection checklist for equipment and tools. | ||||||

| Buffer strategy for materials and labor in long-lead items. | ||||||

| Just-in-time strategy to ‘pull’ materials and equipment only when required. | ||||||

| Human Resources | Assessment and interviews of employees to qualify hiring of competent staff. | |||||

| Training for specific work activities to ensure workers are skilled in their work scope. | ||||||

| Financial and non-financial incentive programs to boost workers’ motivation. | ||||||

| Easier means of communication with craft workers (i.e., pictures for easy visualization). | ||||||

Appendix A.2. Construction Productivity Indicators

This section assesses the productivity performance of projects by indicators. You may encounter different outcomes when using different productivity indicators to measure the same project. Based on your experience in the past three to five years projects, please indicate your perception of the productivity performance under different productivity indicators by marking an X in the boxes below, using a scale of 1 to 5 for ALL the indicators:

Performance: 1- Very Poor, 2- Poor, 3- Moderate, 4- Good, 5- Very Good

Table A2.

Indicators to Assess Productivity.

Table A2.

Indicators to Assess Productivity.

| Levels | Indicators | Performance by Indicators | ||||

|---|---|---|---|---|---|---|

| 1- Very Poor | 2- Poor | 3- Moderate | 4- Good | 5- Very Good | ||

| Industry | Total Factor Productivity | |||||

| Multi-Factor Productivity | ||||||

| Output per worker | ||||||

| Output per work hour | ||||||

| Value-added per worker | ||||||

| Value-added per hour worked | ||||||

| Square metre per man day | ||||||

| Growth Accounting Approach | ||||||

| Data Envelopment Analysis | ||||||

| Company | Output per worker | |||||

| Output per work hour | ||||||

| Value-added per worker | ||||||

| Value-added per hour worked | ||||||

| Capital Productivity | ||||||

| Project | Square metre per dollar | |||||

| Square metre of built-up floor area per man-day | ||||||

| Value-added per worker | ||||||

| Output per person-hour on key trades | ||||||

| Constructability Score | ||||||

| Buildable Design Score | ||||||

| Trade | Work-Hours expended/Quantity Installed | |||||

| Formwork Area per manhour | ||||||

| Amount of rebar/prefab mesh per manhour | ||||||

| Volume of concrete per manhour | ||||||

| Area of Drywall per manhour | ||||||

| Painted Area per manhour | ||||||

| Number of doors installed per manhour | ||||||

| Wall tiled area per manhour | ||||||

| Floor tiled area per manhour | ||||||

| Suspended ceiling per manhour | ||||||

| Length of ducting per manhour | ||||||

| Length of electrical conduit per manhour | ||||||

| Length of water pipe per manhour | ||||||

References

- Yi, W.; Chan, A.P.C. Critical review of labor productivity research in construction journals. J. Manag. Eng. 2014, 30, 214–225. [Google Scholar] [CrossRef]

- Young, A.; Wilkie, J.; Ewing, R.; Rahman, J. International comparison of industry productivity. Econ. Round-up 2008, 3, 45–61. [Google Scholar]

- Barbosa, F.; Woetzel, J.; Mischke, J. Reinventing Construction: A Route of Higher Productivity; McKinsey Global Institute: New York, NY, USA, 2017. [Google Scholar]

- Caldas, C.H.; Kim, J.Y.; Haas, C.T.; Goodrum, P.M.; Zhang, D. Method to Assess the Level of Implementation of Productivity Practices on Industrial Projects. J. Constr. Eng. Manag. 2015, 141, 9. [Google Scholar] [CrossRef]

- Durdyev, S.; Ismail, S.; Kandymov, N. Structural Equation Model of the Factors Affecting Construction Labor Productivity. J. Constr. Eng. Manag. 2018, 144, 11. [Google Scholar] [CrossRef]

- Ghodrati, N.; Wing Yiu, T.; Wilkinson, S.; Shahbazpour, M. Role of Management Strategies in Improving Labor Productivity in General Construction Projects in New Zealand: Managerial Perspective. J. Manag. Eng. 2018, 34. [Google Scholar] [CrossRef]

- Adrian, J.J. Construction Productivity: Measurement and Improvement; Stipes Publishing: Champaign, IL, USA, 1995. [Google Scholar]

- Thomas, H.R.; Horman, M.J. Fundamental principles of workforce management. J. Constr. Eng. Manag. 2006, 132, 97–104. [Google Scholar] [CrossRef]

- Dai, J.K.; Goodrum, P.M.; Maloney, W.F. Construction Craft Workers’ Perceptions of the Factors Affecting Their Productivity. J. Constr. Eng. Manag. 2009, 135, 217–226. [Google Scholar] [CrossRef]

- Nasir, H.; Haas, C.T.; Caldas, C.H.; Goodrum, P.M. An integrated productivity-practices implementation index for planning the execution of infrastructure projects. J. Infrastruct. Syst. 2016, 22. [Google Scholar] [CrossRef]

- Naoum, S.G. Factors influencing labor productivity on construction sites: A state-of-the-art literature review and a survey. Int. J. Product. Perform. Manag. 2016, 65, 401–421. [Google Scholar] [CrossRef]

- Ying, W.S.; Sen, N.J. Construction industry faces tough times. In The Straits Times; Singapore Press Holdings Ltd. Co.: Singapore, 2017. [Google Scholar]

- El-Gohary, K.M.; Aziz, R.F. Factors Influencing Construction Labor Productivity in Egypt. J. Manag. Eng. 2014, 30, 1–9. [Google Scholar] [CrossRef]

- Makulsawatudom, A.; Emsley, M. Critical factors influencing construction productivity in Thailand. In Proceedings of the 10th International Symposium on Construction Innovation and Global Competitiveness, Cincinnati, OH, USA; 2003; pp. 1–10. [Google Scholar]

- Abdul Kadir, M.R.; Lee, W.P.; Jaafar, M.S.; Sapuan, S.M.; Ali, A.A.A. Factors affecting construction labour productivity for Malaysian residential projects. Struct. Surv. 2005, 23, 42–54. [Google Scholar] [CrossRef]

- Alwi, S. Factors influencing construction productivity in the Indonsesian context. In Proceedings of the 5th EASTS Conference, Fukuoka, Japan, 29 October 2003. [Google Scholar]

- Goodrum, P.M.; Shan, Y.; Haas, C.T.; Nasir, H.; Liu, J.; Caldas, C.H.; Kim, J.Y. Construction Productivity Research Program Phase V. In Research Report 252-11d; The University of Texas at Austin; Construction Industry Institute: Austin, TX, USA, 2014. [Google Scholar]

- Gurmu, A.T.; Aibinu, A.A.; Chan, T.K. A study of best management practices for enhancing productivity in building projects: Construction methods perspectives. Constr. Econ. Build. 2016, 16, 1–19. [Google Scholar] [CrossRef]

- Construction Industry Institute (CII). Craft Productivity Program Phase I. In Research Summary 252-1; The University of Texas at Austin: Austin, TX, USA, 2009. [Google Scholar]

- Construction Industry Institute (CII). Construction Industry Institute (CII). Construction Productivity Research Program Phase III. In Research Summary 252-1b; The University of Texas at Austin: Austin, TX, USA, 2011. [Google Scholar]

- Rojas, E.M.; Aramvareekul, P. Labor productivity drivers and opportunities in the construction industry. Int. J. Manag. Sci. Eng. Manag. 2003, 19, 78–82. [Google Scholar] [CrossRef]

- Aziz, R.F.; Hafez, S.M. Applying lean thinking in construction and performance improvement. Alex. Eng. J. 2013, 52, 679–695. [Google Scholar] [CrossRef]

- Paez, O.; Salem, S.; Solomon, J.; Genaidy, A. Moving from lean manufacturing to lean construction: Toward a common sociotechnological framework. Hum. Factors. Ergon. Manuf. 2005, 15, 233–245. [Google Scholar] [CrossRef]

- Rivas, R.A.; Borcherding, J.D.; Gonzlez, V.; Alarcn, L.F. Analysis of factors influencing productivity using craftsmen questionnaires: Case study in a Chilean construction company. J. Constr. Eng. Manag. 2011, 137, 312–320. [Google Scholar] [CrossRef]

- Diekmann, J.; Heinz, J. Determinants of jobsite productivity. Constr. Ind. Inst. Res. Rep. 2001. Available online: https://www.construction-institute.org/resources/knowledgebase/knowledge-areas/construction-execution/topics/rt-143/pubs/rr143-11 (accessed on 5 October 2020).

- Ghoddousi, P.; Poorafshar, O.; Chileshe, N.; Hosseini, M.R. Labour productivity in Iranian construction projects: Perceptions of chief executive officers. Int. J. Product. Perform. Manag. 2015, 64, 811–830. [Google Scholar] [CrossRef]

- Doloi, H. Twinning motivation, productivity and management strategy in construction projects. EMJ-Eng. Manag. J. 2007, 19, 30–40. [Google Scholar] [CrossRef]

- Kazaz, A.; Ulubeyli, S. Drivers of productivity among construction workers: A study in a developing country. Build. Environ. 2007, 42, 2132–2140. [Google Scholar] [CrossRef]

- Lim, E.C.; Alum, J. Construction productivity: Issues encountered by contractors in Singapore. Int. J. Proj. Manag. 1995, 13, 51–58. [Google Scholar] [CrossRef]

- Crawford, P.; Vogl, B. Measuring productivity in the construction industry. Build. Res. Informat. 2006, 34, 208–219. [Google Scholar] [CrossRef]

- Vogl, B.; Abdel-Wahab, M. Measuring the construction industry’s productivity performance: Critique of international productivity comparisons at industry level. J. Constr. Eng. Manag. 2015, 141. [Google Scholar] [CrossRef]

- OECD. Measuring Productivity. Organisation for Economic Co-operation and Development; OECD: Paris, 2001. [Google Scholar]

- SCAL. Construction Productivity in Singapore: Effective Measurement to Facilitate Improvement; The Singapore Contractors Association Ltd.: Singapore, 2016. [Google Scholar]

- Lowe, J.G. The measurement of productivity in the construction industry. Constr. Manag. Econ. 1987, 5, 101–113. [Google Scholar] [CrossRef]

- Dozzi, S.P.; Abourizk, S.M. Productivity in Construction; Institute for Research in Construction, National Research Council: Ottawa, ON, Canada, 1993. [Google Scholar]

- Shehata, M.E.; El-Gohary, K.M. Towards improving construction labor productivity and projects’ performance. Alex. Eng. J. 2011, 50, 321–330. [Google Scholar] [CrossRef]

- De Valence, G.; Abbott, M. Abbott, M. A review of the theory and measurement techniques of productivity in the construction industry. In Measuring Construction: Prices, Output and Productivity; Routledge: London, UK, 2015; pp. 205–221. [Google Scholar]

- Carson, C.; Abbott, M. A review of productivity analysis of the New Zealand construction industry. Australas. J. Constr. Econ. Build. 2012, 12, 1–15. [Google Scholar] [CrossRef]

- Li, Y.; Liu, C. Construction capital productivity measurement using a data envelopment analysis. Int. J. Constr. Manag. 2011, 11, 49–61. [Google Scholar] [CrossRef][Green Version]

- Building Construction Authority (BCA). Builders’ Guide on Measuring Productivity—A Guide to Help Builders Measure Productivity of Various Trades. 2012. Available online: https://www.bca.gov.sg/Productivity/others/builders_guide_productivity.pdf (accessed on 6 October 2020).

- Zhao, X.; Hwang, B.G.; Low, S.P. Critical success factors for enterprise risk management in Chinese construction companies. Constr. Manag. Econ. 2013, 31, 1199–1214. [Google Scholar] [CrossRef]

- Williams, L.J.; Vandenberg, R.J.; Edwards, J.R. Structural Equation Modeling in Management Research: A Guide for Improved Analysis. Acad. Manag. Ann. 2009, 3, 543–604. [Google Scholar] [CrossRef]

- Reinartz, W.; Haenlein, M.; Henseler, J. An empirical comparison of the efficacy of covariance-based and variance-based SEM. Int. J. Res. Mark. 2009, 26, 332–344. [Google Scholar] [CrossRef]

- Dijkstra, T.K. Latent Variables and Indices: Herman Wold’s Basic Design and Partial Least Squares. In Handbook of Partial Least Squares: Concepts, Methods and Applications; Esposito Vinzi, V., Chin, W.W., Henseler, J., Wang, H., Eds.; Springer: Heidelberg/Berlin, Germany, 2010; pp. 23–46. [Google Scholar]

- Sommer, A.; Steland, A. Multistage acceptance sampling under nonparametric dependent sampling designs. J. Stat. Plan. Inference 2019, 199, 89–113. [Google Scholar] [CrossRef]

- Hair, J.F.; Ringle, C.M.; Sarstedt, M. PLS-SEM: Indeed a silver bullet. J. Mark. Theory Pract. 2011, 19, 139–152. [Google Scholar] [CrossRef]

- Ling, F.Y.Y.; Ning, Y.; Ke, Y.; Kumaraswamy, M.M. Modeling relational transaction and relationship quality among team members in public projects in Hong Kong. Autom. Constr. 2013, 36, 16–24. [Google Scholar] [CrossRef]

- Lingard, H.; Zhang, R.P.; Oswald, D. Effect of leadership and communication practices on the safety climate and behaviour of construction workgroups. Eng. Constr. Archit. Manag. 2019, 26, 886–906. [Google Scholar] [CrossRef]

- Ludwig, R. Meetings Critical to Construction Project Success and Best Practices: A Case Study; California Polytechnic State University: San Luis Obispo, CA, USA, 2018; Available online: https://digitalcommons.calpoly.edu/cmsp/183 (accessed on 31 October 2020).

- Marhavilas, P.; Koulouriotis, D.; Nikolaou, I.; Tsotoulidou, S. International Occupational Health and Safety Management-Systems Standards as a Frame for the Sustainability: Mapping the Territory. Sustainability 2018, 10, 3663. [Google Scholar] [CrossRef]

- Kong, L.; Li, H.; Luo, H.; Ding, L.; Zhang, X. Sustainable performance of just-in-time (JIT) management in time-dependent batch delivery scheduling of precast construction. J. Clean. Prod. 2018, 193, 684–701. [Google Scholar] [CrossRef]

- Tang, S.; Shelden, D.R.; Eastman, C.M.; Pishdad-Bozorgi, P.; Gao, X. A review of building information modeling (BIM) and the internet of things (IoT) devices integration: Present status and future trends. Autom. Constr. 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Ferme, L.; Zuo, J.; Rameezdeen, R. Improving collaboration among stakeholders in green building projects: Role of early contractor involvement. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2018, 10, 04518020. [Google Scholar] [CrossRef]

- Wang, P.; Wu, P.; Chi, H.-L.; Li, X. Adopting lean thinking in virtual reality-based personalized operation training using value stream mapping. Autom. Constr. 2020, 119, 103355. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).