Abstract

Industrial wastes are often used as aggregate in concrete production to promote a more sustainable construction and to reduce production costs. This article presents the results of an experimental campaign on the influence of replacing natural aggregate with several construction and demolition wastes (C&DW) as recycled aggregate, as well as the use of fly ash and slag, wastes produced in Gas Incinerator Combined Cycle (GICC) thermal power plants, in the mix design of non-structural concrete. Different percentages of natural aggregates were substituted with recycled aggregates either coming from construction and demolition wastes, or from the coarse fraction of the slags from thermic plants in the manufacture of concrete. The mechanical properties, capillary water absorption, density, carbonation, chloride ingress and sulphate resistance have been tested. The results show a decrease in properties when C&DW are used. Fine fraction of slag and fly ash has an important advantage, and can even improve the long term properties of concrete prepared with natural aggregates. Coarse fraction of slag as a recycled aggregate generally improves most of the properties of manufactured concretes.

1. Introduction

The construction industry is one of the most polluting nowadays, not only because of the gases produce during the manufacture of cement, but also because of the high amount of natural stone that is necessary for the manufacture of concrete. Recycling and reusing seem to be more and more essential in our society. In recent years, the Spanish construction industry has generated huge amounts of Construction and Demolition Waste (C&DW) that is mainly stored up in dumps. The directive 2008/98/CE of the European Parliament [1] states the necessity of reducing the consumption of natural resources and the need for recycling. The aim of reusing/recycling at least a 70% of the C&DW generated by 2020 has been established, according to the report of the European Commission [2]. In Spain, only about 7.5% of the C&DW generated is used [3]. There is a clear requirement to improve the recycling percentage to reach rates similar to those of other European countries, such as Holland, Belgium, or Denmark, where about 80% of waste is reused [3].

Recycled aggregates are mainly obtained after C&DW processing. Depending on their origin, recycled aggregates can be classified as Asphalt, Ceramic, Concrete, or Recycled Mixed Aggregate (RMA). The RMA is about 80% of the C&DW [4], and includes a great variety of materials, such as those just mentioned, as well as minor proportions of plaster, glass, plastic, etc. With the objective of promoting recycling and reusing, the Spanish Standard for concrete [4] allows to use recycled aggregates for the preparation of concrete, both for structural and non-structural purposes. In the case of structural concrete, the Spanish standard only allows to use recycled aggregate originating from concrete. This limit does not permit the massive use of C&DW. However, the use of any type of recycled aggregates is permitted for non-structural concrete

The aggregate that facilitates most the recycling of construction wastes is RMA, because it does not need classification prior to use. The bibliography shows that this aggregate is mainly used in non-structural elements [5,6,7]. Some attempts have been made to use recycled mixed aggregates in structural concrete, and the conclusion has been that they do not fulfill the requirements of Spanish standards [8]. As a general fact, it can be said that the use of a certain percentage of recycled mixed aggregate causes a decrease of the compressive and flexural strengths of concrete samples, and increases their porosity and water absorption [6,7,9,10].

The deficiency of properties, both from the point of view of the resistance, or from the point of view of the durability, could be improved by using active additions in the cement used in the concrete. Active additions are very commonly mixed with cement, and improve the service properties of cement-based materials (concretes and mortars) in many ways. Some of the additions are included in commercial cements, such as fly ash, or steel slag cements, and these cements have better mechanical strength and durability than ordinary Portland cement, in spite of the environment where they are used [11,12,13,14]. In recent years, some new additions to cement have been tested, and good results have been observed [15,16]. Among these new additions, the slag or bottom ash produced in the Gas Incinerator Combined Cycle (GICC) thermal power plants can be included. GICC thermal power plants are increasing their importance in Spain, because they produce less CO2, as is reflected in the report published by the Spanish government [17]. These plants use both gas and municipal solid waste to produce energy. The increase of production in 2017 can be estimated to be around a 28%, according to the same report. However, even if it is true that the emissions of CO2 are lower, this type of plants produce wastes, and in a circular economy, waste production should tend to 0 [18]. The slag produced has been proven to be efficient in terms of mechanical strength in the long term (90 days), and it is very sensitive to the fineness of the powder [19]; the reactivity of this material has been shown when it has been mixed with cement [19]. However, most of the literature refers to bottom ash produced in incinerators of municipal solid wastes (MSW), where most authors report the presence of metals, and state that this is a problem when this ash is mixed with cement [20,21,22]. There is also work where this type of waste has been used as fine recycled aggregate in mortars [23]. This study showed that the slag coming from thermal power plants, when it is used as partial replacement of the fine fraction of the aggregates (up to 40%), exhibits reactivity with cement, increasing the compressive strength of mortars. The authors have not found any paper where this type of waste is used as recycled coarse aggregate in concrete, but the results of the fine fraction are promising. In addition, efforts should be made to try to establish limits on the use of the coarse fraction, because it will make the production of concrete much more sustainable, as the biggest volume in concrete is occupied by coarse aggregates.

Several additions have been used together with C&DW as recycled aggregates, mainly with concrete recycled aggregates. Most of the results conclude that the combination of recycled concrete aggregate and fly ash [24,25] is not very beneficial for the mechanical resistance of concrete. A previous work limits the percentage of fly ash to 10% [25]. Other authors justify the use up to 30% of fly ash with recycled aggregate because the materials do not show a loss of flexural strength [26]. Some other works show a gain in the mechanical strength of concrete in the very long term (400 days) [27]. Commercial cements with blast furnace slag have also been used. The slag cement helps to minimize the loss of resistance due to use of recycled aggregates [28]. In a previous work, some authors also tried to use silica-fume as an addition to cement, but the result was not satisfactory [10]. Bottom and fly ash from GICC thermal power plants, due to their reactivity, could be used as active additions to improve the behavior of concrete when construction and demolition wastes are included as the recycled aggregate. No reference has been found regarding this possible use of such additions. To that purpose, several C&DW materials were used in this work, and the additions were included only for the worst possible scenario.

One aim of this work is related with the possibility of using wastes from GICC thermal power plants. Both fly ash and slag generated in GICC thermal power plants will be used as additions to cement to improve the properties of concrete prepared using C&DW. Several types of recycled aggregate will be used. On the other hand, the fine and coarse fractions of the slag can be used as another possible recycled aggregate. Both objectives share the promotion of sustainability in the construction industry by the reduction of raw materials and the reuse of waste that would otherwise be treated and landfilled, in a situation where there is a tendency to increase the production of this type of waste. This will help our society to fulfill the objective of zero waste and achieve more sustainable production of construction materials.

2. Materials and Methods

2.1. Sample Preparation and Curing

The concretes were prepared to study the effect of the substitution of natural aggregates by different types of recycled aggregates. They were produced based on a medium strength (around 20 MPa) and a soft consistence (around 8–9 cm in the slump cone test, according to the standard UNE-EN 12350-2 [29]).

The cement used in different concretes was a CEM II A-L 42.5R, which fulfilled the requirements of the Spanish standard [30]. The major properties of the cement are given in Table 1.

Table 1.

Physical and chemical properties of cement used.

A concrete with 100% natural aggregates was prepared as a reference to study the influence of the recycled aggregates and the slag coming from GICC thermal power plant on the materials properties of non-structural concrete elements.

Recycled aggregates from different sources have been used. They were incorporated into concrete in different percentages, between 15% and 30%. Concretes were prepared under laboratory conditions.

Two different additions from GICC thermal power plant were used. One of them was fly ash, with an 84.6% of amorphous phase, and the other was slag, with an 83.4% of amorphous phase. The chemical composition of each addition is summarized in Table 2. The main components of slag are silica and alumina, i.e., very similar to other slags from GICC plants analyzed earlier [31,32,33]. Both additions were sieved to ensure a maximum particle size of 0.063 mm, like cement particles.

Table 2.

Chemical composition of GICC fly ash and slag.

To obtain the desired slump of the concretes, a modified lignosulphonate based plasticiser additive (Sikament 175) was used. The total water was adjusted, taking into account the water absorption of the different aggregates for ensuring the same effective water for cement hydration.

The different types of aggregate have been described in the following subsection, for the sake of simplicity. The mix proportions used, in kg/m3 of concrete, are shown on Table 3.

Table 3.

Mix proportions of different prepared concretes.

The nomenclature that will be used from now on is as follows: “Control” means 100% natural aggregates. The concretes prepared with different recycled used aggregates: “C” is for the concrete, “M” for the ceramic recycled aggregate, “R” for the recycled mixed aggregate (abbreviated as RMA), followed by “A” or “B”, depending on the type of RMA used, and “G” for the case that slag coming from GICC has been used as the recycled aggregate. The number following the acronym stands for the percentage (in volume) of total recycled aggregate used. In the case of using RB, the two additions coming from the GICC thermal power plant, i.e., the fly ash and the fine fraction of the slag, were used,. It is very well known that this type of addition helps to improve the properties of concrete [3,4]. It is also well known that the recycled aggregates, especially the recycled mixed aggregates, worsen the properties of concrete [7], so the use of active additions can be useful to promote the use of both types of wastes without causing any quality problems.

2.2. Aggregates

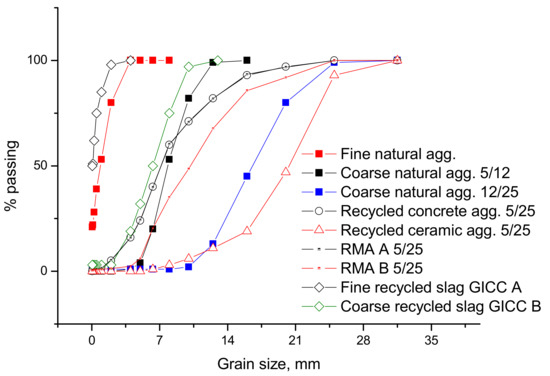

Both natural and recycled aggregates have been used in this study. Natural aggregates were crushed limestone; their properties are shown in Table 4, and the grading curves are presented in Figure 1.

Table 4.

Properties of natural aggregate.

Figure 1.

Grading curves of recycled and natural aggregates.

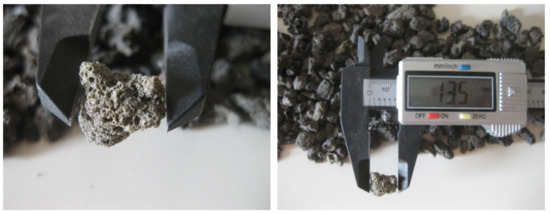

To promote a more sustainable construction, several recycled aggregates have been used. Some of those are C&DW, while others are the coarse fraction of the slag generated in the same GICC thermal power plant considered under this study. The physical properties of the recycled aggregates used are shown in Table 5. The C&DW materials used were composed of concrete aggregate (CA), a second one totally formed by ceramic pieces, or from masonry (MA), and two RMAs that include different types of C&DW. The first two have been studied in greater depth, but to obtain those recycled aggregates, a huge effort of classification and selection must be made on the C&DW. The composition of C&DW was 99% of concrete for concrete aggregate, and 100% of masonry wastes for the ceramic aggregate. The composition of RMA is shown in Table 6, determined according to the standard UNE EN 933-11 [34]. The chemical composition of the slag is given on Table 2; the changes only apply to the grain size of the particles. An image of the coarse fraction of the slag is shown in Figure 2, where the porous structure presented by the slag can be seen.

Table 5.

Physical properties of the recycled aggregates.

Table 6.

Composition of recycled aggregates as per UNE EN 933-11.

Figure 2.

Coarse fraction of the slag produced in the GICC thermal plant and used as recycled aggregate.

2.3. Methods

The effect of replacing a percentage of natural aggregate by different types of recycled aggregate was studied. In addition to the slump cone test (UNE-EN 12350-2 [29]) that guaranteed a similar consistency (7–9 cm) for all the samples, the mechanical properties and durability of the concretes prepared in laboratory have been tested. For each test and age, triplicate samples were used. The results presented are the average value of the obtained results.

The compressive strength of concrete was tested according to the standard UNE-EN 12390-3 [35] at 28, 90, and 180 days. For the samples that included GICC slag as aggregate, the mechanical strength was also tested after 360 days. Concrete density was determined according to the standard UNE-EN 12390-7 [36].

The durability of the concretes was tested by different methods. The capillary water absorption of the concretes at 90 days was determined following the recommendations of the standard UNE 83982 [37]. The carbonation resistance of concrete after 56 and 90 days (accelerated method) was determined according to the standard UNE 83993-2. At a given age, the samples for this test, which were prismatic with the dimensions 100 mm × 100 mm × 400 mm, were prepared by homogenizing the moisture content. They were stored in a climate chamber under the following conditions: 3% CO2, 21 ± 2 °C, and 60 ± 10% moisture content. With a 3% CO2 air concentration, the obtained hydrated cement reaction products are the same as in a regular atmosphere with a 0.03% CO2 content. At each age, a test piece portion of approximately 50 mm was broken to determine carbonation depth using the phenolphthalein method. The resistance to chloride ingress in concrete was determined using the standard AASHTO T259 [38]. According to this standard, the samples with dimensions 100 mm × 100 mm × 400 mm are placed inside a curing chamber for 76 days, and in a drying chamber for 90 days. Side faces are protected with an impermeable material to create a watertight area where a dissolution with 3% sodium chloride is introduced. The amount of dissolution was controlled to ensure a minimum thickness of the dissolution layer of 15 mm. At the testing age, a slice was cut off the sample and sprayed with silver nitrate to determine the penetration depth of the chlorides. Even though this method does not allow the calculation of any diffusion coefficient, it is very useful for the direct comparison of different types of concrete with respect to their resistance to chloride ingress. Finally, the resistance to sulphate attack was determined at 90 days according to the method proposed by Pico Cortés [39]. The samples were oven dried at 90 °C until reaching a constant mass. After that, they were submitted to 7 cycles of sulphate attack, 48 h each. In each cycle, the samples were kept immersed in a Na2SO4 solution with a concentration 80 g/L for 24 h. After that, the samples were oven dried for 8 h at 105 °C and then cooled to 20 °C over 16 h. The residual compressive strength was measured for the samples tested. For each concrete, triplicate samples were tested.

3. Results and Discussion

3.1. Compressive Strength

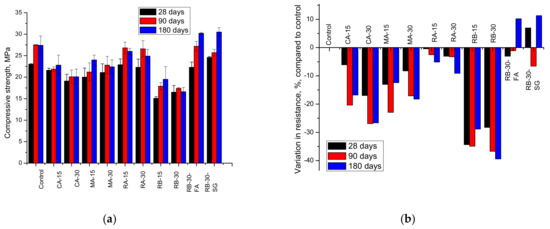

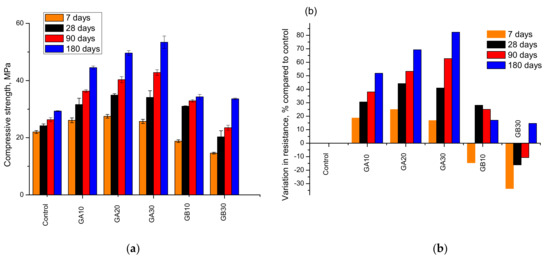

The compressive strength of the concretes was measured following the standard UNE-EN 12390-3, at 28, 90, and 180 days. Since there are two different control concretes (see Table 3), the results are presented in two sets: The results of the concretes including recycled aggregate coming from C&DW are shown in Figure 3, while the results for the concretes that include GICC slag as recycled aggregate are shown in Figure 4.

Figure 3.

(a) Compressive strength of the concretes with C&DW as recycled aggregates, as compared to control; (b) variation in resistance respect to the average value of the control concrete.

Figure 4.

(a) Compressive strength of the concretes with GICC slag as recycled aggregates, as compared to control. (b) Variation in compressive strength with respect to the reference concrete (average value).

The compression test results of the concretes including C&DW reveal that there is a decrease in the compressive strength with the increased percentage of recycled aggregate. It was noticed that the composition of the recycled aggregates influence the compressive strength of concrete; this is in agreement with previous papers [7,40,41,42]. For example, in [11] the recycled aggregate was composed of 74.3% unbound aggregate, 11.8% coming from concrete, and 5.6% of ceramic origin, and it produced a loss of more than 30% of compressive strength for 100% recycled coarse aggregate. In [41], the researchers used an aggregate from recycled concrete; they stated that it could be used replacing up to a 50% of natural aggregate to ensure the properties of low-resistance concrete. In [43], the composition of the aggregate mainly consists of recycled concrete (45.6%), unbound aggregates (28.1%), and asphalt (19.3%). The researchers established that a 50% of the natural coarse aggregate could be replaced by the recycled mixed aggregate in housing construction. However, it should be noted that the behavior of the concrete produced would depend on the type of aggregate used [10]. In the case of using recycled mixed aggregate, the behavior of the concrete, as has already been described in the literature, strongly depends on the type and amount of the aggregate [7,43,44,45]. RMA-A with an 86.4% of unbound aggregates shows a behavior very similar to the control. This recycled aggregate is very similar to that used in [11], and the results here obtained confirm that the presence of unbound aggregates in the recycled mixed aggregates produced give results very similar to the control concrete when the replacement amount is around 25–30%. On the other hand, the concretes containing a significant percentage of recycled concrete, ceramics, and other types of aggregates (CA, MA, and RMA-B) show a loss of compressive strength between 6 and 40%. The biggest loss of strength is shown by RMA-B at 180 days, when a 30% of the natural aggregates are replaced by RMA-B. The inferior behavior of this RMA could be due to the presence of floating particles and asphalt (sourced from recycled or reclaimed asphalt pavement). It has been proved that the paste-aggregate ITZ (interfacial transition zone) has a bigger porosity, and if the recycled aggregate contains floating particles and asphalt particles, the ITZ is wider; these could be the main factors that cause the decrease the resistance of concrete [46]. In [43] the authors obtained slightly better results, possibly due to the lower presence of floating particles, or to the coarser dimension of asphalt particles.

Some aggregate types show an improvement between 90 and 180 days. This happens for concrete, ceramic (masonry), and recycled mixed aggregates Type B. This aggregate (RMA-B) showed the highest water absorption (see Table 6) and there could be a self-curing effect, due to the release of water absorbed initially by the aggregates, helping the hydration of unreacted cement [47,48]. This fact had already been observed in [7] and attributed to the self-curing effect. In the cases where the substitution of natural aggregate by recycled was of 15%, this effect could partially compensate for the negative effect that the use of recycled aggregates produces. When the substitution is of a 30%, this self-curing is not able to compensate for the loss of mechanical strength. Also, recycled mixed aggregate Type A, which only showed a water absorption of 2.9% (the lowest value), does not show this effect.

The use of fly ash and the fines (diameter <0.063 mm) of the GICC thermal power plant slag shows a delayed beneficial effect on the compressive strength of the concretes prepared with mixed recycled aggregate B. The concretes prepared with this aggregate type showed the worst behaviour among all the C&DW materials. The loss of compressive strength was about 40% at 180 days; however, the use of the additions makes them gain more than 10%. This beneficial effect had already been reported [19], but in this case, it is important to highlight that these wastes can make recycled mixed aggregate suitable for use in concrete. Without these additions, recycled mixed aggregate would seriously affect the quality of concrete prepared using 30% of this aggregate. The combined use makes concrete have the same behaviour or better than a recycled aggregate whose main component is the unbound aggregate. It has to be remembered here that the authors had already tried to improve the resistance of concrete with silica fume and the results were not as promising as the results presented here [10]. The results of this study are in agreement with the ones shown in [19], even though here, the behaviour of the slag is better, and in that case the researchers were just testing the way to improve the resistance of standard concretes, while here the additions counteract the negative effect of using a bad quality recycled aggregate in concrete. In that case, the researchers determined that the optimum amount of addition is between 9% and 23% of the mass of the total binder.

The compressive strength results of the concretes with both the coarse (GB) and fine (GA) fractions of the slag as recycled aggregates are shown in Figure 4a. The concretes with the fine fraction of slag show higher resistance than the control concrete. The fine fraction of the recycled aggregate usually gives divergent results and the presence of fine particles is generally pernicious for the resistance of concrete. In this study, the results are very positive for the compressive strength, and the effect of a high percentage of fines present in the recycled sand is very positive. The findings are in agreement with the effect produced by the slag as an addition in the case of using recycled mixed aggregate Type B and already reported in literature [28]. It is also in agreement with the results that said that the fineness of the aggregate was crucial for the obtained results [23]. The presence of the coarse fraction (GB) causes a slight decrease in the compressive strength when it is used to replace natural aggregate, especially for the substitution percentage of 30% at initial ages. Possibly due to the reactivity shown by the material, especially when particles are very fine, the resistance of the concrete increases, and after 180 days, and it becomes higher than the resistance of the reference concrete. This finding indicates that the slag obtained from the GICC thermal plants could be used as coarse aggregates in concrete elements. However, the fact that the resistance does not increase significantly for the case of using 10% recycled slag as coarse aggregate might mean that this beneficial effect is limited. More research is required to determine the optimum amount of slag, as well as the effects in the longer term. Based on the level where this research has reached, it is possible to say that this waste in the coarse fraction can also be used for replacing aggregates in concrete. It is true that, to the authors’ knowledge, there are no references regarding the use of GICC slag as aggregate; however, some efforts have been made on the use of the wastes generated in the incineration plant of MSW. The case of using MSW usually presents problems concerning metals, and when they are used as aggregates they can produce lixiviation of toxic substances, as is explained in a recent paper [49]. Most efforts are focused on the environmental safety of the possible use of the wastes. The case of the GICC slag used in this study does not present this issue, because no metal is included in the composition, and it would be possible to use them as aggregates with no problem. This finding has important implications from the point of view of the sustainability, because it allows the use of a waste, and shows that the waste can be used without wasting energy for grinding it. It facilitates the possibilities of using the waste, and makes the concrete production much more sustainable, without being forced to consume energy for the activation of the waste.

3.2. Density

The results obtained for the density of concretes at 90 days are shown on Table 7, divided into the two series of concrete prepared. The value of the density and the variation with respect to the control concrete are shown.

Table 7.

Density of the two series of concrete prepared and variations with respect to the control concrete.

As it was understood from the literature already published on this field [7,50], the density of concrete decreases with the higher percentage of natural aggregate substitution with recycled aggregate, M, C, RA, RB, and G due to the higher porosity of the recycled aggregates compared to the natural ones.

The maximum decrease in density is 10.6% for the RB-30 concrete and 12.9% for the GB30 concrete; these findings are in agreement with the compressive strength results presented in previous section. Regarding the use of C&DW, the highest capillary water absorption was shown by ceramic recycled aggregates (M); however, the highest decrease in the porosity was for the case of recycled mixed aggregate Type B, possibly due to the presence of asphalt particles, that will cause a decrease of the density of the samples. As it was said the presence of these particles creates a wider ITZ [46], that is the less dense part of concrete. The result of the high porosity of this concrete seems to support the idea proposed by Brand et al. [46] that suggested the presence of an ITZ with higher porosity. This result is in agreement with previous results [7,42] where it was shown an almost linear decrease of density with the increased percentage of recycled aggregates.

The behaviour of the ceramic aggregates (M) is quite surprising. They exhibited the highest value of water absorption among the aggregates coming from C&DW, more than double water absorption of the rest of the aggregates, but they did not show a large density decrease in concrete compared to the control concrete. This result agrees with the compressive strength of the concrete samples, where the ceramic (M) recycled aggregate did not show a large decrease as compared with other aggregate types. This finding suggests the possibility that cement hydration products penetrate the pores of the recycled ceramic aggregate, making the concrete more resistant with higher density.

The positive effects of recycled mixed aggregate Type B on the mechanical properties of concrete, together with the addition of fly ash and slag coming from GICC plant, are also shown here. The concretes containing addition exhibited an increase in resistance as compared to the control concrete at 180 days. This result is in agreement with previous results, where even though the porosity of concrete was higher, the samples acquired the same resistance due to the products of the reaction of the active additions present in cement [14]. No reference has been found regarding the effect of GICC slag on the density of concrete.

The water absorption for GB recycled aggregate (the coarse fraction of the GICC slag) was higher than for GA (fine fraction), and this result agrees with the density results of the corresponding concretes. However, both concrete types Ga and GB exhibited a increase in the value of compressive resistance compared to control, at least at 90 days. This result confirms the reactivity of slag, both in the fine or coarse fraction, with the cement hydration products. Both aggregates and the concrete samples prepared with them have lower density, but they show compressive strength values higher than the reference sample. This apparent discrepancy in the results can be justified if the aggregates react with cement hydration products, and as a consequence the ITZ is no longer as weak as it usually is due to the chemical bonds produced during reaction. Another paper showed a loss of density using a slag obtained from a standard thermal power plant as fine recycled aggregate [23]. The different nature shown by the aggregates justifies the results here obtained.

3.3. Capillary Water Absorption

One of the main parameters related to the durability of concrete is capillary water absorption due to its relationship with the porosity and tortuosity in concrete as well as the velocity of ingress of aggressive substances into concrete [51,52]. The capillary suction coefficient, K, is linked with the velocity of water penetration into concrete. The results for the capillary suction coefficient measured at 90 days are presented in Table 8.

Table 8.

Capillary suction coefficient (K) for the two series of concrete prepared and variations with respect to the control concrete.

As can be seen for the concretes prepared with C&DW, there is an important increase in the velocity of ingress of water in concrete samples. The value obtained for concrete recycled aggregate is quite surprising; it shows the highest increase in this parameter. This result was not expected because many works claim that there is no important change in the properties of concrete when the percentage of aggregate is lower than 20% [6], and this is the reason why this percentage is allowed by Spanish standards even in the case of structural elements [4]. This could be due to the presence of pores from previous concrete that will absorb water as well. The water absorption data for the recycled aggregates of this study could confirm this fact. It could also be due to the low resistance of the concretes prepared for this study. However, a more in-depth study would be required. The aggregates coming from ceramics show smaller increases in the capillary suction coefficient, which reaffirms the previously established hypothesis. If, as it was hypothesised, the paste closes the pores of the ceramic recycled aggregate, the aggregate would not absorb water, and consequently, the velocity of ingress would decrease. The efficiency of the GICC wastes as additions is again confirmed by these results, and in agreement with the behaviour of active additions regarding the capillary suction of mortars [53]. The slag even makes the value of K decrease, and the use of fly ash almost keeps the value of the capillary coefficient constant. The better behaviour of slag had already been observed in commercial cements [14,53].

Regarding the results about the use of slag as recycled aggregate in concrete, as it can be seen in Table 7, this waste makes the value of the capillary suction coefficient decrease in a very significant way. This result is also in agreement with the theory of the reaction of aggregates inside concrete that increases resistance with decreased porosity and capillary water absorption. The decrease in the capillary suction coefficient could also justify an increase in the tortuosity of pore structure due to the reactivity of the aggregate [52]. Only using 30% coarse slag increased the coefficient, which is in agreement with the results observed for the rest of the parameters studied; the concrete with 30% coarse slag showed a decrease of resistance with a lower porosity at 90 days, as compared to the control concrete. The use of slag as recycled fine aggregate also makes capillary suction coefficient decrease substantially. It also increases the sustainability of the materials that include this waste, due to an increased service life with less maintenance.

3.4. Resistance to Carbonation

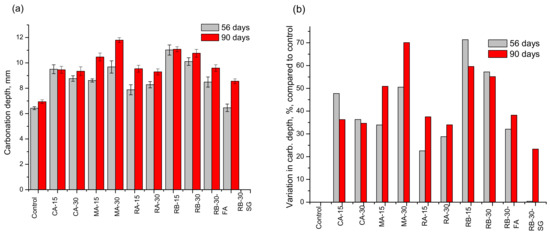

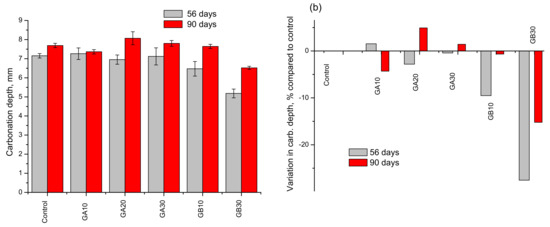

The results for the carbonation depth at 56 and 90 days, as well as its variation with respect the control samples, are shown in Figure 5 and Figure 6.

Figure 5.

(a) Carbonation depth of the concretes with C&DW as recycled aggregates, as compared to the control concrete; (b) variation in resistance with respect to the control concrete (mean value).

Figure 6.

(a) Carbonation depth of the concretes with GICC slag as recycled aggregates, as compared to the control concrete; (b) variation in resistance with respect to the average value of the control concrete.

The results for the concretes with C&DW show an increase in the carbonation depth in comparison to the control concrete. The best behaviour is exhibited by the recycled mixed aggregates Type A (with a large amount of unbound aggregates). These aggregates also were the ones that produced a minor decrease in compressive strength. It means that there is a good bond among cement mortar and coarse aggregate, like the control concrete. That could be the reason of this similar behaviour in terms of carbonation. The highest increase in terms of carbonation depth occurred for the ceramic aggregates. The ceramic pieces have no portlandite, so the carbonation depth can progress faster, since there is no reaction between this type of aggregates and carbon dioxide [54,55]. This is a general result in the short term [54,55], even though in the long term the carbonation depth values of some concretes are similar to those of the reference concrete [55]. The presence of additions coming from the fine fraction of the wastes of the GICC thermal plant does not improve the resistance to carbonation. This result confirms the reaction of the active additions, that consume portlandite and make the carbonation progress faster [56]. This a general result for cements with addition. The case of the use of slag from GICC thermal plant is more representative of this pozzolanic reaction, because it gives a very good result at 56 days, but the carbonation depth increases at 90 days, possibly due to the reaction of the addition with portlandite. In this case, the possible refinement of the pore network due to the reactions with the addition does not compensate the lack of porltlandite, and the carbonation front advances faster. The result is in agreement with the activity shown by the addition that improved substantially the compressive strength of the concrete. Most commonly used additions usually show a better behaviour as compared to Portland cement [57], but some other additions show the same behaviour, as found in this work [58].

In the case of using GICC slag as coarse recycled aggregate, the results are similar to those obtained for the rest of recycled aggregates and are in agreement with the results presented previously. The increase in the compressive strength together with the evolution of the density and the decrease of the water suction coefficient suggests that the aggregates and the cement hydration products react, and consequently a decrease of the portlandite occurs. The obtained results are in agreement with the results regarding the use of slag as active addition, better results for 56 days than for 90 days, except in the case of using a 10% slag as fine recycled aggregate, where the large amount of fines combined with the small amount of recycled aggregates could improve the porosity and compensate the decrease of portlandite.

3.5. Resistance to Chloride Ingress

The results obtained from the chloride ingress test (AASHTO T-259) for different concretes have been presented in Table 9.

Table 9.

Chloride penetration depth of the two series of concretes prepared and variations with respect to the control concrete.

There is a noticeable difference in chloride penetration depth between the two series of concrete prepared. On the one hand, the concretes with C&DW exhibit an increase in the value of the penetration depth of chlorides into the prepared samples. This increase is proportional to the density and capillary suction coefficient. The best behaviour is shown by the recycled mixed aggregate Type A with a large amount of unbound aggregates. The worst result is presented by the ceramic aggregates. These aggregates did not show the lowest density, neither had the highest capillary suction coefficient. This difference to the general rule may come from the composition of the ceramic aggregate. It has no phase that could chemically bind chlorides forming Friedel’s salt or a similar compound. The rest of the aggregates have mortar remnants that can contribute to the binding of chlorides, reducing their ingress. In the literature, some researchers reported that the use of recycled aggregates do not have any influence on the chloride ingress in concrete [59] while others reported a decrease of around 40% in the resistance to chloride ions, due to the presence of recycled aggregates (both fine and coarse fraction) [60]. The use of additions, as it has already been shown, increases the resistance to chloride ingress, not only because of the decrease of the porosity and pore dimensions, but also because of the chemical binding ability provided by the additions [13,52,61].

The beneficial effect of the use of active additions is what presented by the slag used as recycled aggregate. In every case, the penetration of chlorides decreases, and the effect is higher when the percentage of recycled aggregate increases. The concrete samples have a higher porosity, and if there was no effect of retention of chlorides due to the use of the slag waste as recycled aggregate, the chloride ion would penetrate deeper and faster. This effect is very common when cements with slag [53] are used. Here it is proved that the use of slag from the bottom of the GICC thermal power plant as recycled aggregate, under the studied conditions, provides excellent behaviour with respect to the durability of concrete regarding the chloride ingress.

3.6. Resistance to Shulphate Attack

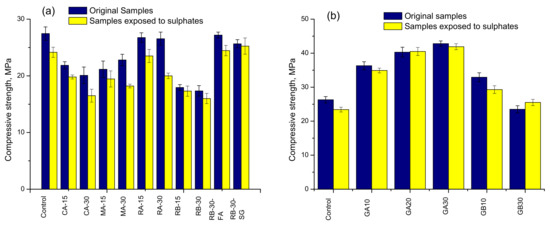

The results of the residual compressive strength after sulphate attack, simulated according to the standard ASTM C1012 [62], are shown in Figure 7.

Figure 7.

(a) Residual compressive strength of samples after exposure to sulphates, as compared to samples with no exposure for samples prepared with C&DW. (b) Residual compressive strength of samples after exposure to sulphates, as compared to samples with no exposure for samples prepared with slag from the GICC thermal power plant.

As can be seen, the general behaviour is a loss of compressive strength due to the sulphate attack for the samples prepared with C&DW; there is a decrease in the mechanical strength. The use of the additions helps to keep the strength values very similar to those of the control material. As was shown in [63], the samples subject to frezze-thaw cycles and sulphate attack are more influenced by the presence of active additions than the recycled aggregates, fact which is in agreement with the results presented in this paper.

In the case of using slag as recycled aggregates, the reactivity of the slag improves the results of the residual compressive strength, improving always the value of the control concrete. This result confirms the viability of using slag from GICC thermal power plant as aggregates in concrete subject to the main attacks commonly suffered by concrete.

4. Conclusions

According to the results presented and the discussion made in this study, the following conclusions can be drawn:

- The use of C&DW as recycled aggregate in concrete implies a loss of compressive strength. This loss is mainly due to the nature and composition of C&DW. The worst results were shown by mixed recycled aggregate Type B (RB) that contained floating particles and asphalt particles. However, the use of the fly ash and the fine fraction (Ø < 0.063 mm) of the slag, which were obtained from the GICC thermal power plant, improved substantially the mechanical properties of the concretes prepared with this recycled aggregate, providing better long-term properties than the concrete with 100% natural aggregates.

- The results of using both the fine and coarse fractions of the slag generated in the GICC thermal power plant as recycled aggregate exhibit excellent behaviour, especially the fine fraction, possibly due to the high percentage of fines (Ø < 0.063 mm). This finding indicates that the slag seems to react with either water or cement hydration products.

- The density of concrete decreases with the use of C&DW as recycled aggregates but it does not change much when slag is used as recycled aggregate, except for the case of 30% replacement of coarse aggregates by slag. The use of the wastes generated in the GICC thermal power plant together with C&DW gives very good density results, which are in agreement with the results of mechanical strength.

- The capillary water absorption of concrete decreases when slag from GICC thermal power plant is used, either as an addition to the cement or as recycled aggregate, probably due to the reactivity of this substance and the refinement of the pore network.

- The resistance to carbonation does not improve when using C&DW as recycled aggregates, not even with additions. In the case of using slag as the coarse fraction of the aggregates, the carbonation depth could be slightly reduced, possibly due to the more refined pore network. The resistance to chloride ingress improves substantially when using the wastes from GICC thermal power plant, either as an addition or as recycled aggregates. The resistance to sulphates is not clearly influenced by the use of any type of recycled aggregate. The influence of the additions to cement is more than that of the type of aggregate.

- It can be stated that under the studied conditions it is possible to use both types of recycled aggregate in a safe way from the mechanical behaviour and durability points of view. It is possible to combine C&DW (even in the worst-case) with the wastes from GICC thermal power plant obtaining materials that can be used without any problem, thus contributing to the sustainability of the construction industry.

Author Contributions

C.R., I.M. and F.B. did the experiments, C.R. and I.S. wrote the paper, and it was supervised by M.C. and C.P., with important contributions to the results analysis. The experimental design was done in a collaborative way among all authors.

Funding

This research received no external funding.

Acknowledgments

The authors wish to thank the laboratory technician Manuel Iniesta Castillo from CTCON, for his altruistic collaboration in the testing phase.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Parliament. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain directives. Off. J. Eur. Union 2008, 51, 312–330. [Google Scholar]

- European Comission. Service Contract on Management of Construction and Demolition Waste—Sr1 Final; IEEP; 2008 Arcadis; BIO Intelligence Service: Paris, France, 2008.

- Mália, M.; de Brito, J.; Pinheiro, M.D.; Bravo, M. Construction and demolition waste indicators. Waste Manag. Res. 2013, 31, 241–255. [Google Scholar] [CrossRef] [PubMed]

- Comissión Permanente del Hormigón. Comission for Instrucción de hormigón Estructural EHE-08 (Structural Concrete Instruction, EHE-08); Spanish Ministry of Public Works: Madrid, Spain, 2008.

- Poon, C.S.; Chan, D. Paving blocks made with recycled concrete aggregate and crushed clay brick. Constr. Build. Mater. 2006, 20, 569–577. [Google Scholar] [CrossRef]

- Mas, B.; Cladera, A.; del Olmo, T.; Pitarch, F. Influence of the amount of mixed recycled aggregates on the properties of concrete for non-structural use. Constr. Build. Mater. 2012, 27, 612–622. [Google Scholar] [CrossRef]

- Rodríguez, C.; Parra, C.; Casado, G.; Miñano, I.; Albaladejo, F.; Benito, F.; Sánchez, I. The incorporation of construction and demolition wastes as recycled mixed aggregates in non-structural concrete precast pieces. J. Clean. Prod. 2016, 127, 152–161. [Google Scholar] [CrossRef]

- Martín-Morales, M.; Zamorano, M.; Ruiz-Moyano, A.; Valverde-Espinosa, I. Characterization of recycled aggregates construction and demolition waste for concrete production following the Spanish Structural Concrete Code EHE-08. Constr. Build. Mater. 2011, 25, 742–748. [Google Scholar] [CrossRef]

- Lovato, P.S.; Possan, E.; Molin, D.C.C.D.; Masuero, Â.B.; Ribeiro, J.L.D. Modeling of mechanical properties and durability of recycled aggregate concretes. Constr. Build. Mater. 2012, 26, 437–447. [Google Scholar] [CrossRef]

- Rodríguez, C.; Miñano, I.; Aguilar, M.Á.; Ortega, J.M.; Parra, C.; Sánchez, I. Properties of concrete paving blocks and hollow tiles with recycled aggregate from construction and demolition wastes. Materials 2017, 10, 1374. [Google Scholar] [CrossRef] [PubMed]

- Bijen, J. Benefits of slag and fly ash. Constr. Build. Mater. 1996, 10, 309–314. [Google Scholar] [CrossRef]

- Sánchez, I.; López, M.P.; Climent, M.A. Effect of fly ash on chloride transport through concrete: Study by impedance spectroscopy. In 12th International Congress on the Chemistry of Cement; Beaudoin, J.J., Makar, J.M., Raki, L., Eds.; National Research Council of Canada: Montreal, QC, Canada, 2007. [Google Scholar]

- Ortega, J.M.; Sanchez, I.; Anton, C.; de Vera, G.; Climent, M.A. Influence of environment on durability of fly ash cement mortars. ACI Mater. J. Mater. J. 2012, 109, 647–656. [Google Scholar]

- Ortega, J.M.; Tremiño, R.M.; Sánchez, I.; Climent, M.Á. Effects of environment in the microstructure and properties of sustainable mortars with fly ash and slag after a 5-year exposure period. Sustainability 2018, 10. [Google Scholar] [CrossRef]

- Payá, J.; Monzó, J.; Borrachero, M.V.; Peris-Mora, E.; Ordóñez, L.M. Studies on crystalline rice husk ashes and the activation of their pozzolanic properties. Waste Manag. Ser. 2000, 1, 493–503. [Google Scholar] [CrossRef]

- Baeza, F.; Payá, J.; Galao, O.; Saval, J.M.; Garcés, P. Blending of industrial waste from different sources as partial substitution of Portland cement in pastes and mortars. Constr. Build. Mater. 2014, 66, 645–653. [Google Scholar] [CrossRef]

- Goverment of Spain. Aplicación de la Ley 1/2005. Análisis global y sectorial. Año 2017; Spanish Ministry of Ecology: Madrid, Spain, 2017.

- Lobato Gago, I. Economía Circular; Spanish Ministry of Ecology: Madrid, Spain, 2017; p. 7202. ISSN 978848326.

- Oruji, S.; Brake, N.A.; Nalluri, L.; Guduru, R.K. Strength activity and microstructure of blended ultra-fine coal bottom ash-cement mortar. Constr. Build. Mater. 2017, 153, 317–326. [Google Scholar] [CrossRef]

- Pera, J.; Coutaz, L.; Ambroise, J.; Chababbet, M. Use of incinerator bottom ash in concrete. Cem. Concr. Res. 1997, 27, 1–5. [Google Scholar] [CrossRef]

- Pan, J.R.; Huang, C.; Kuo, J.-J.; Lin, S.-H. Recycling MSWI bottom and fly ash as raw materials for Portland cement. Waste Manag. 2008, 28, 1113–1118. [Google Scholar] [CrossRef] [PubMed]

- Bertolini, L.; Carsana, M.; Cassago, D.; Quadrio Curzio, A.; Collepardi, M. MSWI ashes as mineral additions in concrete. Cem. Concr. Res. 2004, 34, 1899–1906. [Google Scholar] [CrossRef]

- Hashemi, S.S.G.; Mahmud, H.B.; Djobo, J.N.Y.; Tan, C.G.; Ang, B.C.; Ranjbar, N. Microstructural characterization and mechanical properties of bottom ash mortar. J. Clean. Prod. 2018, 170, 797–804. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Rohman, R.K.; Aji, S. Effect of fly ash on compressive strength of concrete containing recycled coarse aggregate. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2018; Volume 2014, p. 020097. [Google Scholar]

- Sunayana, S.; Barai, S.V. Flexural performance and tension-stiffening evaluation of reinforced concrete beam incorporating recycled aggregate and fly ash. Constr. Build. Mater. 2018, 174, 210–223. [Google Scholar] [CrossRef]

- Anastasiou, E.; Georgiadis Filikas, K.; Stefanidou, M. Utilization of fine recycled aggregates in concrete with fly ash and steel slag. Constr. Build. Mater. 2014, 50, 154–161. [Google Scholar] [CrossRef]

- Etxeberria, M.; Gonzalez-Corominas, A.; Pardo, P. Influence of seawater and blast furnace cement employment on recycled aggregate concretes’ properties. Constr. Build. Mater. 2016, 115, 496–505. [Google Scholar] [CrossRef]

- AENOR UNE-EN 12350-2:2009 Ensayos de Hormigón Fresco Parte 2: Ensayo de Asentamiento (Testing Fresh Concrete—Part 2: Slump-Test); AENOR: Madrid, Spain, 2009.

- AENOR UNE-EN 196-1:2005 Métodos de Ensayo de Cementos. Parte 1: Determinación de Resistencias Mecánicas; AENOR: Madrid, Spain, 2005.

- Acosta, A.; Aineto, M.; Iglesias, I.; Romero, M.; Rincón, J.M. Physico-chemical characterization of slag waste coming from GICC thermal power plant. Mater. Lett. 2001, 50, 246–250. [Google Scholar] [CrossRef]

- Rosales, J.; Cabrera, M.; Beltrán, M.G.; López, M.; Agrela, F. Effects of treatments on biomass bottom ash applied to the manufacture of cement mortars. J. Clean. Prod. 2017, 154, 424–435. [Google Scholar] [CrossRef]

- Sanjuan, M.A.; Menendez, E.; Argiz, C. Evaluación de un nuevo constituyente del cemento portland: ceniza de fondo molida. Dyna Ing. E Ind. 2018, 94, 192–196. [Google Scholar] [CrossRef]

- AENOR UNE EN 933-11, Tests for Geometrical Properties of Aggregates–Part 11: Classification Test for the Constituents of Coarse Recycled Aggregate; AENOR: Madrid, Spain, 2009.

- AENOR UNE-EN 12390-3:2009. Ensayos de Hormigón Endurecido. Parte 3: Determinación de la Resistencia a Compresión de Probetas; AENOR: Madrid, Spain, 2009.

- AENOR UNE-EN 12390-7:2001 Ensayos de Hormigón Endurecido Parte 7: Densidad del Hormigón Endurecido (Testing Hardened Concrete–Part 7: Density of Hardened Concrete); AENOR: Madrid, Spain, 2001.

- AENOR UNE 83982:2008 Durabilidad del Hormigón. Métodos de Ensayo. Determinación de la Absorción de Agua por Capilaridad del Hormigón Endurecido; Método Fagerlund; AENOR: Madrid, Spain, 2008.

- AASHTO Resistance of Concrete to Chloride Ion Penetration; American Association of State Highway and Transportation Officials: Washington, WA, USA, 2009; pp. 24–26.

- Pico Cortés, C.M. Propuesta de Concreto con Agregado fino de Escoria de Cubilote como Aporte al Estudio de la Durabilidad y Propiedades Acústicas; Universidad Industrial de Santander: Bucaramanga, Colombia, 2012. [Google Scholar]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Seara-Paz, S.; González-Fonteboa, B.; Martínez-Abella, F.; González-Taboada, I. Time-dependent behaviour of structural concrete made with recycled coarse aggregates. Creep and shrinkage. Constr. Build. Mater. 2016, 122, 95–109. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; de Rojas, M.I.S.; Frías, M. Influence of mixed recycled aggregate on the physical—mechanical properties of recycled concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Guzman, A. De Estudio de las propiedades fundamentales de elementos prefabricados de hormigón no estructurales, con incorporación de áridos reciclados en su fracción gruesa y fina. (Study of the Main Properties of Non-Structural Concrete Precast Pieces Prepared with Fine and Coarse recycled aggregates); Final Master Work; Polythechnic University of Madrid: Madrid, Spain, 2010. [Google Scholar]

- Kou, S.; Poon, C.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Brand, A.S.; Roesler, J.R. Bonding in cementitious materials with asphalt-coated particles: Part I—The interfacial transition zone. Constr. Build. Mater. 2017, 130, 171–181. [Google Scholar] [CrossRef]

- Dhir, R.K.; Hewlett, P.C.; Dyer, T.D. Mechanisms of water retention in cement pastes containing a self-curing agent. Mag. Concr. Res. 1998, 50, 85–90. [Google Scholar] [CrossRef]

- El-Dieb, A.S. Self-curing concrete: Water retention, hydration and moisture transport. Constr. Build. Mater. 2007, 21, 1282–1287. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Lynn, C.J.; Dhir, R.K. Environmental impacts of the use of bottom ashes from municipal solid waste incineration: A review. Resour. Conserv. Recycl. 2019, 140, 23–35. [Google Scholar] [CrossRef]

- Jankovic, K.; Nikolic, D.; Bojovic, D. Concrete paving blocks and flags made with crushed brick as aggregate. Constr. Build. Mater. 2012, 28, 659–663. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V. Water vapour sorption experiments on hardened cementitious materials. Cem. Concr. Res. 2007, 37, 414–437. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Durability related transport properties of OPC and slag cement mortars hardened under different environmental conditions. Constr. Build. Mater. 2012, 27, 176–183. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Influencia de diferentes condiciones de curado en la estructura porosa y en las propiedades a edades tempranas de morteros que contienen ceniza volante y escoria de alto horno. Mater. Constr. 2012, 63, 219–234. [Google Scholar] [CrossRef]

- Vieira, T.; Alves, A.; de Brito, J.; Correia, J.R.; Silva, R.V. Durability-related performance of concrete containing fine recycled aggregates from crushed bricks and sanitary ware. Mater. Des. 2016, 90, 767–776. [Google Scholar] [CrossRef]

- De Oliveira Andrade, J.J.; Possan, E.; Squiavon, J.Z.; Ortolan, T.L.P. Evaluation of mechanical properties and carbonation of mortars produced with construction and demolition waste. Constr. Build. Mater. 2018, 161, 70–83. [Google Scholar] [CrossRef]

- Nadesan, M.S.; Dinakar, P. Influence of type of binder on high-performance sintered fly ash lightweight aggregate concrete. Constr. Build. Mater. 2018, 176, 665–675. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- Zornoza, E.; Payá, J.; Monzó, J.; Borrachero, M.V.; Garcés, P. The carbonation of OPC mortars partially substituted with spent fluid catalytic catalyst (FC3R) and its influence on their mechanical properties. Constr. Build. Mater. 2009, 23, 1323–1328. [Google Scholar] [CrossRef]

- Etxeberria, M.; Gonzalez-Corominas, A. The assessment of ceramic and mixed recycled aggregates for high strength and low shrinkage concretes. Mater. Struct. Constr. 2018, 51, 1–21. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Durability performance of high-performance concrete made with recycled aggregates, fly ash and densified silica fume. Cem. Concr. Compos. 2018, 93, 63–74. [Google Scholar] [CrossRef]

- Ortega, J.M.; Albaladejo, A.; Pastor, J.L.; Sánchez, I.; Climent, M.A. Influence of using slag cement on the microstructure and durability related properties of cement grouts for micropiles. Constr. Build. Mater. 2013, 38, 84–93. [Google Scholar] [CrossRef]

- ASTM C1012/C1012M-15 Standard Test Method for Length Change of Hydraulic-Cement Mortars Exposed to a Sulfate Solution. ASTM International: West Conshohocken, PA, USA, 2015; Volume 11, pp. 5–9. [CrossRef]

- Li, Y.; Wang, R.; Li, S.; Zhao, Y.; Qin, Y. Resistance of recycled aggregate concrete containing low- and high-volume fly ash against the combined action of freeze–thaw cycles and sulfate attack. Constr. Build. Mater. 2018, 166, 23–34. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).