Abstract

This experimental research aimed to examine potential production and utilization of RDF derived from mixed municipal solid waste using bio-drying technology to be used as a substitute fuel for the traditional fuel currently used in cement plants in Jordan. The characteristics of RDF produced were identified and compared with limits and criteria set by some European countries. An economic model for RDF utilization in cement industry was created. The model proposes six different options resulting from adding RDF as a substitute fuel for the petcoke fuel currently used. A cost analysis for each option proposed was performed to estimate the economic and environmental savings of RDF utilization in cement industry. At the end of the bio-drying process, the mass of dried waste directed to the landfill was reduced by about 35%. In the case of the recovery of RDF materials from dried waste, the mass of waste to be landfilled was reduced by 69%. The bio-drying process allowed an increase in the heating value of waste (LHV) by 58% to reach 15.58 MJ/kg, as a result of the reduction of waste moisture. RDF produced had high calorific value, low water content, and satisfactory chlorine content. With regard to the concentration of the heavy metals, all of the RDF samples tested had lower concentrations than those values set by some European countries. The findings showed that adding 15% RDF as a substitute fuel, equaling 4.92 tons/h, to the fuel used in cement kilns will save 486 USD/h in petcoke costs, with 2.27 tons/h of CO2 being emitted into the atmosphere at a net saving of 389 USD/h.

1. Introduction

Solid waste management (SWM) and disposal is considered one of the main significant challenges facing urban communities around the world. The effective management of solid waste involves the application of several treatment approaches, technologies, and concepts to ensure the protection of public health and the environment. Over the past years, SWM has utilized many advanced technologies and strategies [1]. There is a wide range of alternative solid waste management options and strategies available for dealing with mixed solid waste to limit the residual amount left for disposal to the landfill [2].

As in many developing countries, municipal solid waste (MSW) is considered one of the major environmental problem in Jordan. Population growth in urban centers, lack of strategic planning, lack of proper disposal facilities, limited collection services, use of inappropriate technology, and inadequate financing are considered the main problems facing SWM [3].

In Jordan, there are several factors that contribute to making waste and waste management processes some of the most serious environmental problems, in line with population growth, current modern standards of living, rapid economic growth, the expansion of urbanization, the lack of suitable and well-designed sanitary landfills, and finally, political reasons, which include the huge influx of refugees caused by the conflicts in neighboring countries [4,5,6]. According to Jordan’s Ministry of Municipal Affairs, in terms of the generation and collection of MSW, about 2.7 million tons is generated by a population of 6.7 million [7], while in 2009 it was about 1.9 million tons for a population of 5.8 million [8]. However, the massive influx of refugees is the main reason for the remarkable increase in the recent generation rate with regard to MSW in Jordan. Therefore, waste and waste management have become some of the major challenges for the hosting regions [9,10,11,12]. In this context, it is worth mentioning that Jordan is not an oil producing country, with 96% of the energy supply in Jordan being imported [13,14,15,16,17].

Solid waste landfilling, composting, recycling, and incineration are usually used as solid waste disposal or treatment methods. Landfilling is the most commonly used waste disposal method worldwide, despite all the significant environmental, health, and economic impacts associated with this method. However, the landfilling of MSW is challenging in many areas, mainly because landfill space is becoming rare, and there is a growing public environmental awareness. Present solid waste management strategies therefore encourage material recycling, energy recovery and stabilization of solid waste before landfilling. Thus, combustion, biological processes (thermal energy production), Refused-Derived Fuel (RDF), organic fertilizer and stable products have attracted increased attention. Therefore, MSW could be a viable source of energy rather than being a source of pollution, if properly managed and utilized [10].

A good alternative to the region is the concept of waste to energy (WtE), through which the mixed solid waste is converted to RDF. This alternative mainly involves reducing the moisture content of the waste, which increases the calorific value of the product produced and reduces the production of leachate in the case of landfilling of the waste substances if no further stabilization of the organic material is applied. It also includes the possibility of altering waste into energy, recovering recyclable materials, and reducing pollutants emitted into the environment.

Due to a high proportion of organic waste (>50%), the MSW of several developing countries, such as Jordan, has a high moisture content, which reduces the recovery of materials and increases the operational cost of the combustion [18,19]. Some processes could be applied to mixed MSW to overcome these problems, and to improve the material and energy recovery from the waste stream. Composting and other bio-stabilization processes resulting in the degradation of easily degradable organic matter, while bio-drying processes dry the MSW while increasing the heating value by reducing their moisture content [18,20,21,22].

However, RDF is an alternative fuel produced from energy-rich MSW materials that are converted from landfills. It is a recovered solid fuel that can be used as an alternative for conventional fossil fuels in industrial sectors, for example in the cement manufacturing [1].

Cement manufacturing industry is considered one of the greatest energy consumers in the world. Moreover, it currently faces several economic and environmental challenges. Therefore, there is great potential for using solid waste as a substitute fuel in this sector. Cement subsector uses around 12%–15% of the total industrial energy worldwide [21] in order achieve a consumption level of 120 kWh/t of cement [23]. Regarding carbon dioxide (CO2) emissions, 5–7% of generated CO2 emissions are produced by the cement production industry globally [1]. However, several studies have shown that these figures have decreased by about 5% worldwide in recent years as a result of improved energy efficiency and the use of substitute fuels.

The typical method of municipal waste disposal in Jordan is landfilling, which is poorly operated and lacks most of the basic engineering and sanitary procedures for the collection and treatment of gas and leachate. This problem represents a significant risk to public health and environmental quality and requires national attention of the highest priority and urgency. Moreover, the massive influx of refugees, the increase of per capita solid waste generation rates, the lack of resources and proper infrastructure, the shortage of available landfill space and difficulties in constructing new landfills, the impact of solid waste landfilling on non-engineering landfills, gaps in existing relevant legislation, as well as the lack of appropriate solid waste collection and management practices are the main challenges that make this problem very complex for government bodies responsible for solid waste treatment and management.

Being faced by these challenges related to municipal solid waste management (MSWM), and with expectations of increasing urbanization and subsequent increase in generated waste, Jordan is looking for solutions to improve their MSWM and utilize the untapped resources in the waste streams. Simultaneously, expected higher fuel prices are pressing the cement industry to look for alternative fuels for clinker production. Since cement manufacturing requires extremely high temperatures, it consumes more energy than other industrial processes, which is why the cement industry is also responsible for a large part of Greenhouse Gas (GHG) emissions. The large energy requirements and fossil fuel usage also lead to high costs in the manufacturing process. Therefore, reducing the use of fossil fuels in an economically efficient way represents a challenge for the sector.

Experiences from European countries with well-established waste collection systems and high disposal costs show that the use of MSW to produce RDF in cement production can save companies large amounts of money and provide an alternative controlled disposal of waste. Using RDF as substitute fuel in the cement industry would significantly reduce the mass of waste to be landfilled, greenhouse gas (GHG) emissions, energy consumption, as well as raw material consumption [1,23].

In 2011, Europe produced 201 million tons of cement, which is equivalent to the investment of 33.2 million tons of raw materials. In addition, about 0.8 million tons of waste was used, thus saving 22.4% of energy consumption. Waste use in European cement plants has increased on a large scale in recent years. The European Union (EU) currently has 268 cement plants, and more than 64% of enterprises use waste materials as substitute fuels [23].

Germany is a representative example that supports the above scenario. Currently, a total of 6.15 million tons of high-calorific waste (i.e., calorific value > 11 MJ/kg) is obtainable in Germany. Part of this is produced by Mechanical Biological Treatment (MBT) facilities, while part of it concerns commercial waste. Approximately 1.9 million tons per year (mainly fractions with a heating value more than 14 MJ/kg) is used for combined combustion in cement kilns [24].

However the use of municipal solid waste for the production of RDF and its usage as an alternative fuel in cement kilns are still relatively new concepts and are largely untapped. Therefore, the aim of the present study was to investigate the potential for RDF production and utilization as an alternative fuel for the Jordanian cement industry by using the biodrying process. A further objective was to investigate both the economic feasibility of the production and utilization of RDF (for cement kilns) and the environmental impact in the context of Jordan’s integrated solid waste resource management plan. Significant environmental benefits would be achieved in this way, such as the savings of solid fuels, decreasing the dependency of import fuels, decreasing the CO2 emissions of the cement industry sector as well as the avoidance of landfilling, as many researches have exposed [1,4,21,22,23,24,25,26].

2. Materials and Methods

2.1. Study Area

The pilot project, with an annual capacity of 52 tonnes, was conducted in the Greater Amman Municipality (GAM), the city of Amman, Jordan. An established materials recovery facility (Tadweer Company) was selected to be a site of the research experiments. Tadweer Company is located opposite the Al-Ghabawi landfill site, around 40 km east of Amman, Jordan. The site is characterized by a continental climate, in that its climate is semi-arid, with hot dry summers and cool wet winters. This site is used as a recovery spot for recyclable materials, compost production, and energy retrieval from non-recyclable substances, such as RDF. It has been serving Amman city since 2003.

2.2. Input Materials (MSW)

In Amman, as in other Jordanian cities, municipalities are responsible on a daily basis for municipal cleaning, waste collection, and disposal of the generated mixed household waste. Given the geographical and population of the region, the city of Amman is divided into six (6) regions or areas for the collection of solid waste in an effective manner.

The wastes under consideration has the typical characteristics of most wastes in developing countries, such as high moisture content and a large organic fraction. Organics material represents the highest part of the waste stream, at about 60.2%. It contributes to high moisture and thus leads to a decrease in caloric value.

However, for the purpose of obtaining a representative sample of the waste generated by the city of Amman, the input raw waste materials were taken from the six regions of Amman over a period of six days from the Al-Ghabawi landfill.

For each district, according to the proportion of its participation in the total amount of municipal solid waste generated annually (in 2017), sub-samples were taken from different waste trucks to achieve a representative sample for each trial. A total amount of 50 tons of municipal waste was collected as a sample from the targeted regions and unloaded at the test site.

2.3. Methodology

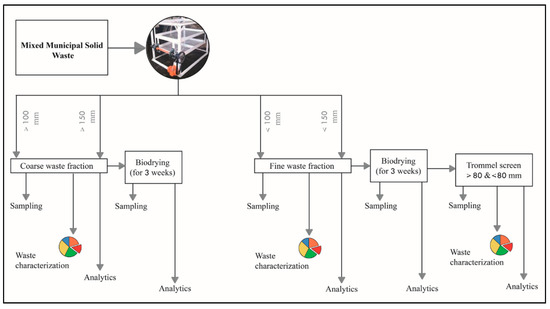

After delivery of fresh waste (about 50 tons of mixed MSW), a screening unit was used to categorize it according to size in the form of fractions of >100, >150, <100, <150, and <10 mm. The waste fractions <100 mm during trial 1 and the fractions <150 mm during trial 2 were subjected to a biodrying phase (the self-draining of waste) for a three week period. This enabled an effective screening of waste for separation of recyclable materials from those of high calorific value made up of components of fine organic fraction (see Figure 1).

Figure 1.

The adopted methodology.

2.4. Biodrying Concept

In the process bio-drying, the main drying mechanism is thermal evaporation. This process uses heat generated from the aerobic degradation of the organic waste fractions and is facilitated through a mechanically supplied airflow. The moisture content of the waste is reduced by two main processes: water evaporates from the waste surface into the surrounding air, and the evaporated water is then transported through the waste by the airflow and removed with the exhaust gasses. A limited amount of free water may leak through the waste and be collected at the bottom in the form of leachate. Efficient control of the operational parameters of aeration (e.g., air-flow rate and direction) and temperature can achieve a high bio-drying efficiency (66.7% of initial water removed) [2,21]. However, the concept of aerobic bio-drying is to drive evaporation with energy recovery from the degradation of organic matter. Consequently, the capacity for water removal is effected by the quantity of biodegraded organic materials.

Temperature is the main parameter for water evaporation and organic matter degradation during the bio-drying process. Waste aeration is important for bio-drying, as it offers a medium for mass and energy flow, enables the removal of moisture content, redistributes heat transfer, removes excess heat, can adjust the windrow temperature, and ensure O2 delivery for aerobic decomposition. The thermometer probe was set to maintain an average windrow temperature from 40 °C to 70 °C. The air supply was controlled through the turning schedule. Waste was turned daily by the loader machine in order to avoid poor air distribution and uneven composting of the organic waste in the windrow, and also to ensure a good structure in order to keep porosity during the composting period.

The generated dry materials was afterwards screened in order to separate the coarse fractions, characterized by high heating value, from the fine fractions (“biodried MSW fine fraction”, MSWFF), characterized by low heating values [26,27].

Two bio-drying trials were carried out over the same time period. Both trials were spread over nearly three months, and during this period municipal waste characterization, sampling, and physical and chemical analyses were carried out.

The technique of bio--drying, which was based on the principle of windrow composting technology, was conducted by turning the material in such a way that it allowed the aerobic decomposition of organic waste into odor-free and stable finished product (compost). Therefore, the prepared materials were well-mixed and aligned in two long windrow piles (2m high, 3m wide, and 25 m long) by an end-front loader, and turned periodically using the loader to ensure efficient mechanical turning and to keep adequate O2 levels for rapid decomposition. The bio-drying process of the windrows was monitored continuously. Typical operating parameters, temperature, and moisture content were monitored on a daily basis. A temperature thermometer probe was used to measure the temperature, and samples were taken weekly to examine the moisture content of the windrow piles. After 3 weeks, the process was finished, at which point the waste was dry. The waste, derived from trial 1 and trial 2, was separately screened at 80 mm using a drum screen (trommel screen). Accordingly, the split between >80 and <80 mm was determined on site. Afterwards, the total RDF was weighed using a weighbridge in the closed dumping site in order to estimate and calculate the mass balance. The schedule of the two trials is listed in Table 1 below. Sampling was conducted over the different phases of the process, as follows:

Table 1.

The schedule for both trials during the pilot project period.

- Sampling to characterize the received waste at the site;

- Sampling the dried waste during screening (at 80 mm) after 3 weeks (output);

- Sampling during the weekly turning of waste in order to monitor biological reactions.

All the samples proceeded three times through preparation and shredding stages at 20 mm to reduce their size before analysis. The main parameters were the dry matter content, ash content, chlorine content, heavy metals content, and calorific value.

2.5. Characterization of MSW

Waste Categories: Material classification was carried out on the basis of the “Methodology for the Analysis of Solid Waste” by the European Commission [28]. A screen unit with 100 mm and 150 mm measurements was used to screen the waste to fractions <100 mm and >100 mm for trial 1 and fractions <150 mm and >150 mm for trial 2, to record the size distribution of the waste.

The characterization method followed that described in the manual of the pilot project. A screening unit machine with 100 mm and 150 mm measurements was used for the first screening. The entire waste sample was screened. After separating the waste into the initial four categories (<100, >100, <150, and >150 mm), waste bigger 100 mm and 150 mm was then placed on a table and sorted. The sorting team consisted of five sorters with a team leader. Before the first screening step at 100 mm and 150 mm, plastic bags containing materials were opened to make the contents available for screening and sorting. In addition, large particles (e.g., large pieces of cardboard, plastic film, etc.), which could have disturbed the screening process and reduced the quality of the screening, were separated by hand and specified according to the defined sorting fractions. The sorted fractions were then weighed.

From the waste that was fed in the first screening steps at 100 mm and 150 mm, about 10% was separated as a sample for lab analysis. The screen overflow >100 mm and >150 mm was then sorted by hand into the sorting fractions defined in Table 2. The sorting fractions were then weighed.

Table 2.

Sorting fractions of waste samples (the manual of the pilot project).

According to the waste sorting guidelines, about 10% of the complete fine fraction material (<100 and <150 mm) was then manually sorted on a sorting table into up to 18 individual waste types. Sorting was performed until a fraction size of about 20 mm was obtained; smaller fractions were not feasible. However, the fine fractions <100 and <150 mm were weighed, and then a proportionate quantity of at least 40 liters (40 L) was taken for further investigation. The procedure to obtain this sample of 40 L was performed as follows: the material <100 and <150 mm, separately, were piled on an even surface into a cone. This cone was turned once into a new cone to further homogenize the material. The homogenized cone was flattened to a uniform truncated cone and divided into four equal sections. Each of the diagonally opposite portions was combined into a new subset. The entire process was repeated until the desired quantity of about 40 l was obtained.

As mentioned previously, waste was divided into 18 primary categories, as shown in Table 2. The last mentioned category is all waste material particles that passed through the smallest screen (e.g., parts smaller than 10 mm). For this work, two primary categories—plastics and metals—were subdivided. Then, secondary categories of plastics were chosen, namely plastic films and 3D plastic. Metals were subdivided into ferrous and non-ferrous (aluminium). However, the individual waste types were largely separated during sorting. Plastic bags were emptied to obtain their contents. Even though one plastic bag itself does not represent a large mass fraction, it can still alter the calorific value of a sample.

2.6. Sampling

Through the bio-drying process, the fresh waste samples were taken from each windrow for the fresh input of waste and during each turning of the windrows. Four 80-L buckets were filled from different places along the windrow; all of the samples went through shredding at 20 mm three times to reduce their size before analysis. The sampling procedure for input material and during the biodrying is illustrated in Figure 2. The main parameters are the dry matter content, the ash content, the chlorine content, heavy metals, and calorific value.

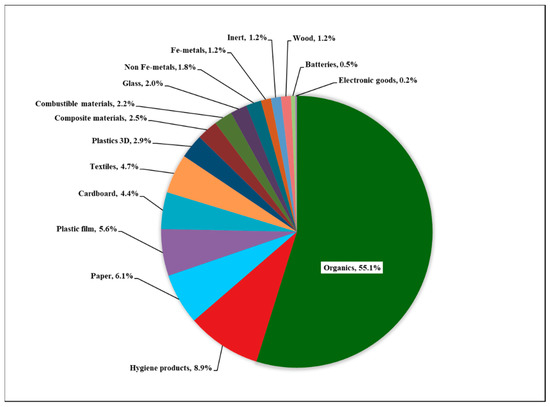

Figure 2.

Composition of municipal waste from Amman city. Average of total analysis during both trials.

After three weeks, the biodrying process was finished and the material was then dry. The waste was screened at 80 mm using the drum screen. Samples were taken from the total waste, the coarse fraction >80 mm (RDF), and the fine fraction <80 mm. During the screening and sampling processes, the split between >80 and <80 mm was determined.

Four RDF samples were sorted manually—two samples during trial 1 (the main input screened at 100 mm) and two samples during trial 2 (the main input screened at 150 mm).

Sampling for coarse fraction characterization and analysis was done by collecting at least 15 buckets of 80 L each during screening, parallel to the sampling at <80 mm for the determination of the screening split. 11 buckets were used for the waste characterization by hand sorting, Different components of the RDF were weighed, and the results are presented as percentages based on a weight/weight. The other four buckets were used for the lab samples, which went through various sample preparation processes, such as shredding and drying.

RDF is one of the combustible recycling waste fractions products made from mixed MSW. It can be utilized as an alternative fuel for steam and electricity production. For the production of RDF, the calorific value and chemical components, especially the existence of heavy metals and chloride, are usually taken into account to ensure the quality of RDF, in order to avoid environmental problems that may result from burning [29].

2.7. Chemical Analysis

As previously mentioned, one of the main objectives of this research is to determine the specific properties of RDF to be used in the cement industry in Jordan. Laboratory analyses of RDF samples were performed at Rostock University laboratories, Germany.

• Dry Matter (DM) Determination

Dry matter was analyzed by placing the prepared samples in a preheated furnace set at 105 °C for 24 h. The dry matter was measured three times per sample after reporting the wet and dry weights. Dry matter for each sample was then obtained through the following equation.

Dry Matter (W) % = (Dry sample weight/Wet sample weight) × 100%

• Ash Content Determination

Ash content of the prepared samples was measured three times per sample and the average was taken. However, the ash content of the original material (OS) and the total solids (TS) was analyzed by burning the samples, using a muffle oven heated up to 815 ± 10 °C for 6 h under strict time controlled conditions, sample mass, and equipment specifications. The ash content was identified by calculating the residual mass after heating, following the European standard (EN 15403).

• Calorific Value Determination

Calorimeters provide a simple means for measuring the heating values of fuels. There are two basic types of calorimeters that can be used to measure the heating value: a steady-flow calorimeter for gaseous fuels, and the bomb calorimeter (constant volume) for liquid and solid fuels. Moreover, the heating value is usually measured in units of energy per unit of weight: as kcal/kg and kJ/kg.

However, the heating value for the samples was calculated three times per sample and the average value was taken at the laboratories of Rostock University lab, Germany, using a bomb calorimeter and following the European Standards (DIN EN 51900-1 and 51900-2).

• Heavy Metal and Elemental Analysis

The elemental analysis (CHNOS) was carried out using an elemental analyzer. It is vital to determine the contents of S, C and N, especially when applying thermal treatments to the RDF. Furthermore, S, C, and N are considered the main causes of SO2, CO2, and NOx formation, which in lead to the formation of photochemical smog at the nearest atmospheric layer to the ground “troposphere” and the greenhouse effect.

Concentrations of metals, such as cadmium (Cd), arsenic (As), lead (Pb), chromium (Cr), mercury (Hg), nickel (Ni) and zinc (Zn), were measured by using the inductively coupled plasma mass spectrometry (ICP-OES) technique.

• Chlorine (Cl) Determination

Chlorine content was determined based on the European Standard (EN 15408). The determination of Cl was conducted through two steps. Firstly, the sample was oxidized by combustion in a bomb containing oxygen under pressure. Halogenated compounds were converted to chloride, which were absorbed or dissolved in an absorption solution. Secondly, the Cl was analyzed by ion chromatography, with the following specifications:

- Conductivity detector: Display range: 0.01–5000 µS/cm, operating temperature: 25–50 °C, temperature precision: ±0.01 °C,

- Pump: Dual piston, 0.001 to 10 mL/min in 0.001 mL steps for flow rate, flow reproductivity at 0.1%, maximum pressure 400 bar, pulsation rate less than ±0.5% at 2 mL/min.

- Ion Chromatography Heater: Temperature range ambient +5 °C to 70 °C (maximum 12 °C below ambient), ±0.01 °C temperature stability, Rheodyne valve polyetheretherketone (PEEK) flowpath.

- Solvent Degassers: 4 flow channels, 10 mL/min maximum flow rate.

2.8. Environmental and Economic Assessment

In order to investigate and identify key technical, economic and environmental challenges and considerations related to the production of RDF to be used as an alternative fuel in the selected cement industry (Manaseer Cement Factory) in Jordan, several structural and semi-structural interviews with all stakeholders were conducted to accomplish this research. Different institutes were visited to obtain all data required, such as the Ministry of Municipal Affairs (MoMA), the Ministry of Environment (MoEnv), Greater Amman Municipality (GAM), and Manaseer Cement Factory.

The technical requirements of cement factories, in order to use RDF as a substitute fuel in cement kilns, were identified through site visits, data gathering, and meetings with Manaseer Cement industry representatives. The topics of the interviews were as follows:

- Used energy source;

- The daily kiln production quantity;

- Total operating hours per year;

- Daily petcoke consumption (ton/day);

- Total energy consumption (kcal/kg.cl);

- Total energy consumption for clinker stage (kWh/t);

- Current energy cost per ton of used fuel or produced cement;

- Minimum calorific value needed in the manufacturing process;

- Composition, quantity, quality, and form “grain size” of RDF required in the manufacturing process.

As a result, an economical model was proposed. The model proposes six different options resulting from adding RDF as a substitute fuel for the fuel currently used at Manaseer Cement Factory. RDF fractions were added to the main fuel (petcoke) in total thermal input ratios of 5%, 10%, 15%, 20%, 25%, and 30%. The proposed options for this model were based on the literature, previous studies, publications, real data, requirements, and assumptions that were obtained from Manaseer Cement Factory. The model estimates RDF substitution amount, traditional fuel (petcoke) cost savings, CO2 emission savings, and the net savings when considering the energy losses for the whole system.

The RDF quantity needed to substitute 1 ton of petcoke was then estimated to finally calculate the traditional fuel (petcoke) cost savings. The amount of carbon dioxide (CO2) emissions savings were estimated on the assumption that seventy percent (70%) of one kilogram (1 kg) petcoke is emitted as CO2 [30], It is then converted into CO2 emissions cost savings as the emission of 1 kg CO2, which is estimated as 0.015 USD [31]. However, the net savings for all options were calculated according to the following formula:

Net Savings = ((Traditional Fuel Cost Savings + CO2 Emissions Cost Saving − RDF Production Cost) × (100 − Energy Loss))/100

3. Results and Discussion

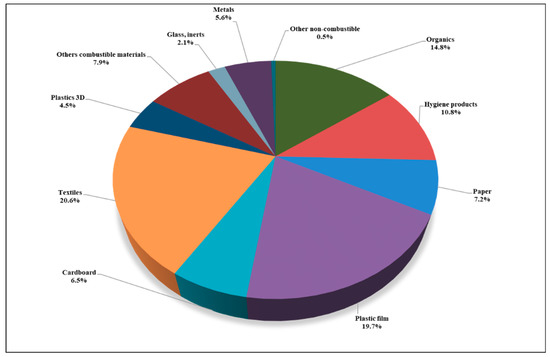

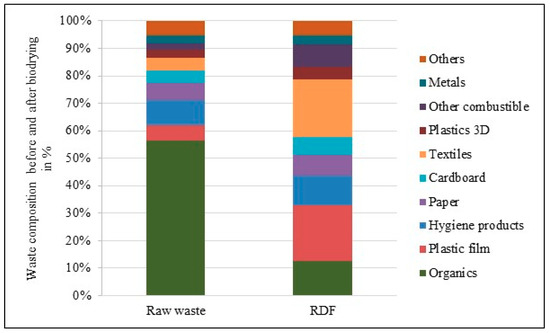

3.1. MSW Characterization

Waste characterization is based on the “Methodology for the Analysis of Solid Waste” of the European Commission [28]. Waste is divided into 18 primary categories. The composition of the total waste delivered shows that the fresh matter in the waste for both trials was strongly dominated by organics. The results of the analysis show that the overall waste composition consisted of four main parts, in the form of organic matter (55.1%), paper and cardboard (11%), plastics (9%), and hygiene products (8.9%). The remainder accounted for 14.9 % of the total and contained textiles (4.7%), metal (3%), glass (2%), composite materials (2.5%), and others. The average results of the fresh municipal solid waste characterization are summarized in Figure 2.

The waste of the area under consideration had the typical waste characteristics of most developing countries, in terms of the high water content and large organic fractions, both of which contribute to the production of leachat and landfill gasses, with the additional problem of the presence of an unpleasant odor.

3.2. Size Distribution of Fresh MSW

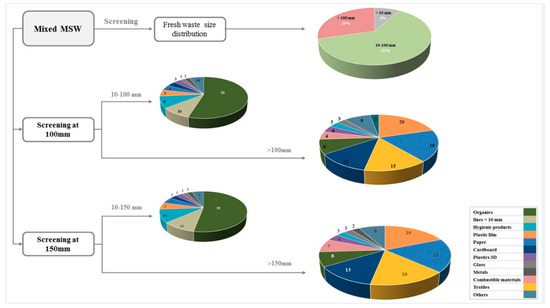

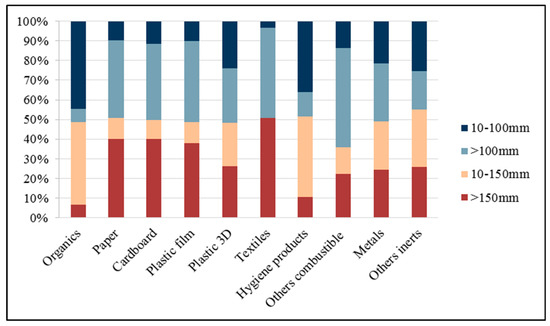

The screening of the waste received at the site revealed that most of the waste was 10–100 mm in size in trial 1 and 10–150 mm in size in trial 2 (see Figure 3). In terms of the size distribution of the solid waste, around 30% of the total solid waste screened could be recovered as large fraction waste (>100 and >150 mm), whereas 10% of the waste had sizes <10 mm.

Figure 3.

Size distribution and composition of fresh waste. Note: MSW = municipal solid waste.

From the sorting analysis it was assumed that about 80% of the fine fraction (<10 mm) was organic material. The additional classification of waste composition found that about 55.2% and 52.5% of the total organic materials were included in the waste fraction for 10–100 mm and 10–150 mm sizes, respectively (see Figure 4). For waste measuring 10–100 mm, the analysis results show that the overall solid waste composition consisted of two main parts: organic matter (55.2%) and combustible material (29.8%). The remainder accounted for 15% and contained inert materials. In terms of waste fractions measuring 10–150 mm in size, approximately 52.5% of the waste was organics, while combustible material accounted for around 30.2%. The small fractions were textiles (0.6%), metals (2.4%), and cardboard (3.1%).

Figure 4.

Size distribution of each waste component for the received waste (input).

The results revealed that 29.8% of waste measuring 10–100 mm and 30.2% of waste measuring 10–150 mm can be recovered as RDF. Moreover, for the large fraction waste >100 mm and >150 mm, the waste included 8.4% and 8.1% organics, and 79.9% and 76.5% combustible materials, respectively, which are considered RDF.

3.3. The Physical and Chemical Characteristics of MSW

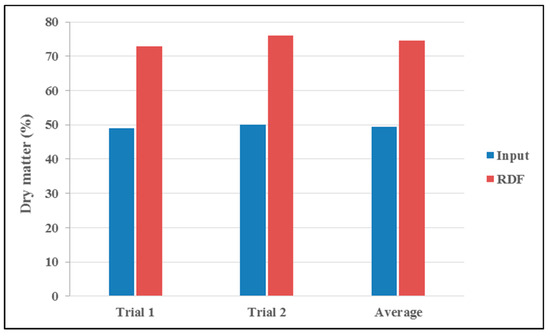

3.3.1. Dry Matter (DM)

Samples of unclassified waste were taken and dried for analysis of dry matter. The initial dry matter (DM) obtained from the input raw waste material was in the same range of 48%–49% for the two windrows formed during each session (see Table 3).

Table 3.

Dry matter results with regard to raw waste during the biodrying process.

The average DM during trial 1 was about 49%, while the average DM during trial 2 was 48%. Table 3 illustrates the results of the DM for the input material with regard to the biodrying process (over three weeks), before the screening at 80 mm to separate the fine and coarse fractions for RDF production.

This implies that the moisture content during both trials can support a biostabilization process. For this process to be successful the water content should be no less than 50%, while for thermal treatment, the moisture content of the waste should be less than 45% [32]. This means that the high water content of the waste produced in the research would reduce the effectiveness of its energy retrieval, as well as the feasibility of the mechanical separation of different fractions for valuable utilization.

3.3.2. Screening at 80 mm and Mass Balance

After three weeks of composting and drying, the waste can be efficiently screened into a coarse fraction with high calorific values, which can be used as a basis for the production of substitute fuel (e.g., for use in cement kilns or combustion facilities).

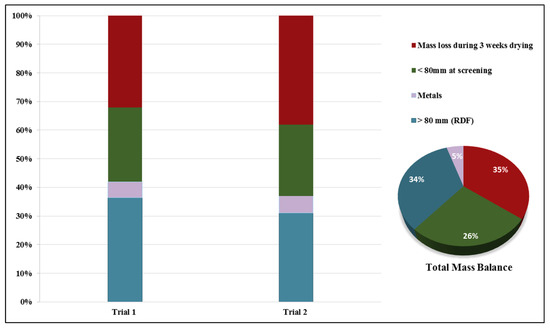

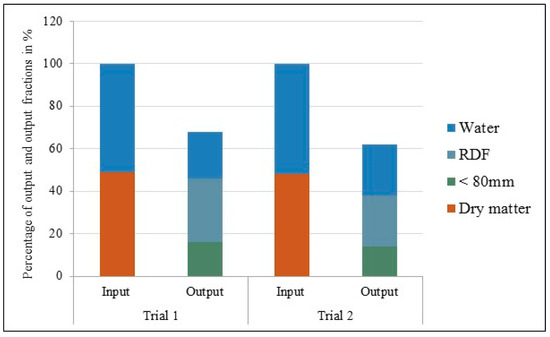

At the end of the bio-drying process (after 3 weeks), the waste mass was reduced on average by 35% when the dried waste was directed to the landfill without the material recovery (see Figure 5). In case of RDF utilization from the dried waste, the waste mass to be landfilled was reduced by 69%. Additionally, when dumping the dried waste in the landfill, leachate will not be generated if the landfill was properlycovered and protected from rainfall.

Figure 5.

The percentage of output fractions after screening at 80 mm for each trial and for the total. Note: RDF = refuse-derived fuel.

On average, for trials 1 and 2, biodrying removed 29% of water, and 7% of solid waste mass was lost from the input material weight. Overall, the weight of municipal solid waste decreased by 32% during trial 1 and 38% during trial 2. The efficiency of the biodrying process is apparent when considering the reduction in the mass of raw waste by the end of the 3 week biodrying period (see Figure 6). Up to 30% of water was removed by biodrying, and, on average, up to 35% of the input raw materials were converted into RDF.

Figure 6.

The mass balance after the biodrying process for both trials.

3.3.3. Characterization of the Coarse Fraction

An 80 mm drum screen was used to separate the coarse fraction >80 mm from the fine fraction <80 mm. Approximately 39% of the waste input material was found to be >80 mm. Material samples were taken from this, both for lab analysis and for waste characterization (by means of hand sorting). Sorting analysis of the coarse fraction at the end of the biodrying process was conducted for each trial during the pilot project.

The average characteristics of the coarse fraction for both trials are illustrated in Figure 7. On average, for both trials (see Figure 10), the major components of RDF were textiles (20.6%), plastic films (19.7%), hygiene products (10.8%), paper (7.7%), and cardboard (6.5%). Other combustible materials present included paper (15.4%), other plastics (4.5%), and organics (14.8%).

Figure 7.

Average total composition of coarse fraction characteristics.

The proportion of plastics, textiles, nappies, and paper or cardboard was seen to have increased compared to the fresh waste composition, as shown in Figure 8. There were still some organics in the coarse fraction, but this could be further reduced by optimization measures. Contaminants in the RDF consist of non-combustible materials, specifically metals (6.4%) and glass and inert materials (2.3%).

Figure 8.

The average characteristics of fresh waste (input) and the coarse fraction >80 mm after the end of the biodrying process (three weeks).

RDF offers several advantages as a fuel over raw MSW. The main advantages are: higher thermal values, which remain fairly constant; more uniformity of physical and chemical composition; ease of handling, transportation and storage; low pollutant emissions; less excess air requirements during combustion [33].

3.3.4. Chemical Properties of the RDF

The results of the basic chemical features of RDF are discussed in the current section. In addition to the heating value, other important fuel properties, such as moisture content/dry matter ratio, chlorine content, and ash content were measured (see Table 4).

Table 4.

The basic chemical features of RDF produced in the study.

DM showed great variability, ranging from 50% to 75%. Figure 9 presents the DM of the RDF produced in each trial compared with the DM of the input material for each trial. The climatic conditions were one of the main factors that probably have influenced the water content of the received MSW, and therefore of the RDF product. However, after 3 weeks of bio-drying process, the moisture content was still close to 25%. Obviously, the lower the water content, the greater the thermal energy content of the waste. This could be achieved by using bulking agents, such as pruning waste or sawdust. It is proven, through the findings of several studies, that adding bulking agents can significantly improve moisture reduction as well as increase calorific value and the performance of bio-drying process, in both the shredded and non-shredded form. Bulking agents could be preferable as they provide required porosity, which is important to reduce moisture content in the absence of leachate generation. Using bulking agents will regulate the primary moisture content of the waste, as well as enable air flow through the waste during the bio-drying process [34,35]. The reduction in moisture content is also significantly influenced by turning frequency. Moisture reduction increases as turning frequency increases. A high reduction in moisture content, therefore, could be achieved by increasing the turning frequency [36].

Figure 9.

The dry matter of the input waste and the RDF produced after the biodrying process.

The moisture content significantly lowered the fuel value. As the moisture increased, there was less combustible material per unit. In addition, a significant amount of high heat energy was used to heat and evaporate the water in the waste [33].

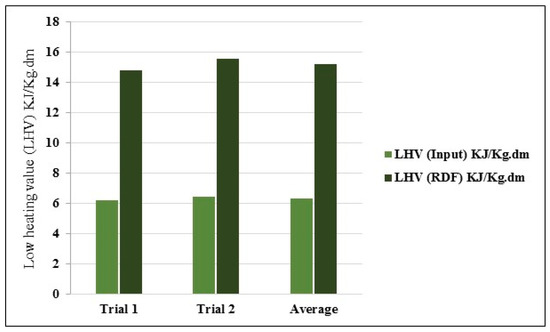

The bio-drying process allowed an increase in the waste heating value (LHV) of about 58% due to the reduction of waste moisture. The calorific value of fresh MSW ranged between 6.21 and 6.45 MJ/Kg. The calorific value of the RDF produced ranged from 14.83 to 15.58 MJ/kg, making it appropriate to be used use as a fuel (see Figure 10). Ash content of the RDF produced in Amman city was found to be in a low range of between 16% and 19%.

Figure 10.

Low heating value (LHV) of the input material and the RDF produced after the biodrying process.

Chlorine was also a restricting factor for the quality of RDF, not only for environmental reasons, but also for technical ones. The concertation of chlorine was in the range of 0.56–1.20% w/w, because of the existence of plastic material in the RDF production. This required more attention because it is considered a source of acidic contaminants and a vital reactive component in the creation of dioxins [35].

As Table 4 shows, the RDF samples showed concentrations of heavy metals. The values of the heavy metals could be explained by the large organic material content as well as by the fine particles in the RDF production, given that they may have high concentrations of heavy metals.

The advantage of RDF produced from municipal solid waste is that RDF has stable thermal and energy properties, with little pollutant content and with a good calorific value, meaning it can be utilized for energy production or for replacing conventional fuels. However, due to the high water content, low heating value, and high ash content of raw municipal solid waste, it is essential to separate the raw waste for the production of RDF.

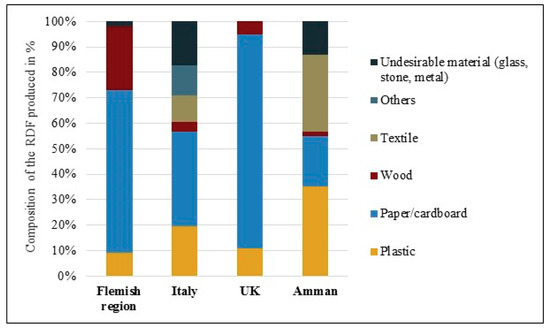

The significant characteristics of RDF as an alternative fuel can be summarized as: the heating value, moisture content, ash content as well as chlorine content. The values of these parameters will differ according to the properties of the raw waste and the processes applied to the production of RDF. The composition of the RDF produced in Amman city was compared with the typical composition of RDF produced from municipal solid waste generating in some European countries (Figure 11). The characteristics and results of the RDF produced in Amman city were obtained from unprocessed RDF, which means that samples were taken from the screened material at 80 mm, just after three weeks of bio-drying process.

Figure 11.

Composition of the RDF produced in Amman compared with the composition set by European countries.

A better quality RDF will be obtained after further shredding and screening or sorting. Despite this, the quality of the RDF produced did not vary from the quality of RDF obtained by some European countries.

RDF quality depends on its high calorific value and low concentration of toxic chemicals, particularly with regard to heavy metals and chlorine. Due to the different perspectives of RDF producers, RDF’s potential customers, and the authorities involved, the quality of the proposed RDF varies from one group or country to another [29].

Despite many European countries and establishments have already developed quality standards and criteria for the chemical properties of RDF, there is limited work on the actual measurements of chemical standards for RDF samples. This is especially true for data on heavy metal concentrations, which often refer to the specific components of municipal solid waste [37]. In Table 5 and Table 6, the results of RDF produced in the city of Amman are compared with obtainable data on the chemical properties of RDF stated by a number of European countries.

Table 5.

Chemical properties of the RDF produced in Amman compared with quality criteria established by several European countries [36].

Table 6.

Heavy metals content of the RDF produced in Amman compared with quality criteria set by European countries [36].

Obviously from the results obtained that the RDF produced in the city of Amman had high calorific value, low water content, and satisfactory chlorine content compared to the RDFs produced by some European countries (Table 5).

With regard to the concentration of the heavy metals, it is motivating to note that despite the RDF produced in the city of Amman showed various ranges of heavy metal concentrations in the samples tested, as shown in Table 6, in all cases, the heavy metal concentrations were lower than those values set by other countries.

3.4. Feasibility of RDF Utilization in Cement Industry

As reported through the previous experimental researches, adding 15% of RDF as additional fuel in cement production did not lead to any defects in terms of the quality of clinker and flue gas emission values. Overall, 840 kcal of energy is required to produce 1 kg of clinker. Previous studies have been reported that 6030.77 kg/h of petcoke equals 13,440 kg/h RDF [30,38].

Many researches have shown that different combinations of potential environmental benefits and effects are related to RDF production and use in cement plants. On the one hand, the production of RDF affects the environment through the consumption of energy and materials, while on the other hand, substituting conventional fossil fuels with RDF in industry sector facilities leads to energy recovery and reduced emissions [1]. In this light, the aim of this section was to assess the feasibility of producing RDF materials to be used as a substitute fuels in cement industry. This feasibility study included a study of the proportion of carbon dioxide (CO2) in greenhouse gas emissions, and the determination of energy demand by replacing petcoke with RDF.

In order to assess the economic benefits of RDF utilization, an economic model was proposed. The model proposes six distinct options resulting from adding RDF as a substitute for the fuel currently used in Jordanian cement factories, namely petcoke. The options for this model were based on the literature, previous studies, publications [30], real data, and the requirements and assumptions that have been obtained from Manaseer Cement Factory, Jordan.

Six distinct options were considered for the economic assessment of the addition of RDF to the main fuel (petcoke) at ratios of 5%, 10%, 15%, 20%, 25%, and 30%. The suggested options represent the results based on the following assumptions:

- Daily kiln production quantity is 4000 ton/day (24 h) [39].

- Number of total operating hours is 7200 h/year [39].

- Daily petcoke consumption is 381 ton/ day, which equals 15.9 Kg/hr [39].

- Total energy consumption is 715 kcal/kg.cl. [39].

- Total energy consumption for the clinker stage is 46 kWh/t. [39].

- The calorific value of petcoke equals 8000 kcal/kg [23].

- 1 ton of petcoke currently costs 150 USD [30].

- The production cost of 1 ton RDF is estimated to be 24.24 USD [30].

- The calorific value of RDF equal 3500–4000 kcal/kg [23].

- The calorific value of RDF produced in this research is 15.21 MJ/kg (3632 kcal/kg).

- 70% of 1 kg petcoke is released as CO2 [30].

- Emission cost of 1 ton CO2 is estimated to be 15 USD [31].

- The energy efficiency of the facility using RDF is estimated to be 97% [40].

Several studies have shown that if RDF is utilized as an alternative fuel in the cement industry, it should not exceed 15% of the original fuel, due to the effects it may have on the physical properties of the cement produced. Moreover, previous studies have shown that there are maximum net savings that can be obtained by adding RDF to conventional fuels, with a 15% replacement ratio and without any negative impact on the quality of the final cement product [30]. Therefore, the next section will explain the results of option 3 in detail. However, as shown in Table 7, in cases of adding 15% of RDF as a substitute fuel to the petcoke fuel currently used, the remaining 85% petcoke match to consumption of 12.66 tonnes/hour, which means that 3.24 tonnes/hour of petcoke energy consumption will be saved.

Table 7.

The economic model for the use and savings associated with RDF and petcoke.

The energy consumption of petcoke to produce 4000 ton/day is:

4000 ton/day × 1000 × 715 kcal/kg.cl. = 286 × 107 kcal/kg.cl.

Thus, when 15% RDF is used as a substitute fuel, the petcoke energy consumption saving is:

286 × 107 kcal/kg.cl. × 0.15 = 429 × 106 kcal/kg.cl.

The RDF amount to be substituted per hour to achieve the required energy of 429 × 106 kcal/kg.cl is:

429 × 106 kcal/kg.cl/3632 kcal/kg.cl./1000/24 h per day = 4.92 ton/h

The petcoke amount per hour in to achieve the required energy of 2431 × 106 kcal/kg.cl is:

2431 × 106 kcal/kg.cl./8000 kcal/kg.cl/1000/24 h per day = 12.66 ton/h.

The quantity of RDF needed to substitute 1 ton of petcoke is 4.92 ton/h/3.24 ton/h = 1.52 ton

When 15% RDF is used as a substitute fuel, the annual petcoke saving is:

3.24 tons/h × 24 h/day × 300 day/year = 23,328 ton/year

The cost of 1 ton petcoke to the cement plant is 150 USD on the basis of current market prices; thus, the annual income is:

23,328 ton/year × 150 USD/ton = 3,499,200 USD/year

Since RDF consumption is 4.92 tons/h, when 15% RDF is used as a substitute fuel, the annual consumption of RDF becomes:

4.92 tons/h × 24 h/day × 300 day/year = 35,424 tons/year.

The cost of 1 ton RDF to the cement plant is 24.24 USD on the basis of current market prices; thus, the annual cost is:

35,424 tons/year × 24.24 USD/ton = 858,677 USD/year.

In this state, the actual financial saving will be:

3,499,200 USD/year − 858,677 USD/year = 2,640,522 USD/year.

The above-mentioned calculation illustrates only the savings gained by RDF utilization in the cement kilns. Since RDF is acquired from waste, savings will also be achieved in waste collection, sorting, treatment and storage.

Carbon dioxide is a by-product of the chemical transformation (calcination) process used in clinker production, a component used in cement production. Through the cement production process, calcium carbonate (CaCO3) is heated in the cement kiln at a temperature of around 1300 °C to form lime (calcium oxide or CaO) and carbon dioxide. This process is defined as calcination. The process releases CO2 into the atmosphere. Lime interacts with several materials such as silica, aluminum and others to produce clinker. Small amounts of gypsum is then added to the clinker materials to produce Portland cement. Carbon dioxide emissions may also be released from cement kiln dust (CKD) that is not recovered in the manufacturing process [30].

Typically, cement kiln dust is collected and recycled and used again in the system. Any non-recycled CKD is deposited in landfills. Cement kiln dust is generated in every cement plant and its quantity depends on the operating efficiency of the plant. Mostly, the amount of CKD produced is estimated at 1.5–2% of clinker production weight [41].

However, Table 7 provides the net savings in the total operational costs and carbon dioxide emissions by adding RDF as a substitute fuel for the petcoke fuel currently used in cement industry. It is recognized that 70% of 1 kg petcoke is emitted as carbon dioxide, the cost of emissions of 1 tonne of CO2 is at 15 USD and the production cost of 1 tonne RDF is estimated to be 24.24 USD [31].

As the cost of 1 ton petcoke is 150 USD, and 15% RDF is used as a supplementary fuel, the cost savings obtained for petcoke are:

3.24 tons/h × 24 h/day × 300 day/year × 150 USD/ton = 3,499,200 USD/h

The annual CO2 emission savings in petcoke (amount) are:

3.24 tons/h × 0.70 × 24 × 300 = 16,330 tons/year

CO2 emission savings in petcoke (cost) re:

16,330 tons/ year × 15 USD/tons = 244,944 USD/year.

The efficiency loss is 20% × RDF% consumption × 100 = (0.20 × 0.15) × 100 = 3%.

Therefore, based on the abovementioned equations, the net cost saving is:

((petcoke saving + CO2 emission saving in petcoke − RDF production cost) × (100 − efficiency loss))/100

((3,499,200 USD/year + 244,944 USD/year − 858,677 USD/year) × (100 − 3))/100 = 2,798,902 USD/year.

From a net cost savings point of view, based on the above calculations, it is clearly shown that it is feasible to take the RDF value as 15%, with the remaining 85% as petcoke (option 3).

The option achieved 3,499,200 USD annual petcoke cost savings after adding 35,424 tons/year of RDF to the traditional fuel, while the current cost of using petcoke on an annual basis is about 17,172,000 USD.

The net cost savings calculations, which take CO2 cost savings and RDF cost and efficiency losses into account, show that the net annual savings are about 2,798,902 USD/year USD.

4. Conclusions

In this experimental research, using bio-drying technology, potential production and utilization of RDF derived from mixed municipal solid waste to be used as an alternative fuel for the cement industry in Jordan was investigated. The characteristics of RDF produced were identified and compared with limits and criteria set by some European countries. An economic model for RDF utilization in cement industry was created. The model proposes six different options resulting from adding RDF as a substitute fuel for the fuel currently used. A cost analysis was finally performed to estimate the economic and environmental savings of RDF utilization in cement industry.

At the end of the bio-drying process, the mass of dried waste directed to the landfill was reduced by about 35%. In the case of the recovery of RDF materials from dried waste, the mass of waste to be landfilled was reduced by 69%. The bio-drying process allowed an increase in the heating value of waste (LHV) by about 58% to reach 15.58 MJ/kg, as a result of the reduction of waste moisture. RDF produced had high calorific value, low water content, and satisfactory chlorine content. With regard to the concentration of the heavy metals, all of the RDF samples tested had lower concentrations than those values set by some European countries.

Furthermore, adding 15% RDF, which equals 35,424 tons/year < to the fuel used at cement kilns will save 23,328 ton/year in petcoke, 3,499,200 USD/year from petcoke costs, 16,330 tons/year of CO2 being emitted into the atmosphere, 244,944 USD/year from the decrease in CO2 emissions alone, and 2,798,902 USD/year as the net savings.

Overall, the results revealed that RDF has high credit to be a suitable waste treatment option and can be a strategic component of an integrated solid waste management system in Jordan.

Author Contributions

Conceptualization, S.H., M.I., A.N. and M.N.; Methodology, S.H., M.I. and A.N.; Project administration, S.H.; Resources, S.A.-Z.; Supervision, M.I., A.N. and M.N.; Writing—original draft, S.H. and S.A.-Z.; Writing—review & editing, S.H., M.S., M.I. and A.N.

Funding

This research received no specific grant from any funding agency.

Acknowledgments

The research experiments were carried out in an established materials recovery facility (Tadweer Company) located at the Al-Ghabawi landfill site around 40 km east of Amman, Jordan. The project was supported by the GIZ with cooperation with Tadweer Company, Greater Amman Municipality (GAM) and the University of Jordan (UJ) in terms of the provision of equipment, working staff and laboratories needed.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Reza, B.; Soltani, A.; Ruparathna, R.; Sadiq, R.; Hewage, K. Environmental and economic aspects of production and utilization of RDF as alternative fuel in cement plants: A case study of Metro Vancouver Waste Management. Resour. Conserv. Recycl. 2013, 81, 105–114. [Google Scholar] [CrossRef]

- Adani, F.; Baido, D.; Calcaterra, E.; Genevini, P. The influence of biomass temperature on biostabilization-biodrying of municipal solid waste. Bioresour. Technol. 2002, 83, 173–179. [Google Scholar] [CrossRef]

- Diaz, L.F.; Savage, G.M.; Eggerth, L.L. Overview of Solid Waste Management in Economically Developing Countries. In Proceedings of Organic Recovery and Biological Treatment, ORBIT 99, Part 3; Rhombos: Berlin, Germany, 1999; pp. 759–765. [Google Scholar]

- Nassour, A.; Al-Ahmad, M.; Elnaas, A.; Nelles, M. Practice of waste management in the Arab region. Contribution in: Kule-weidemeier, M.: (Editor), water-to-resources 2011-4. In Proceedings of the International Conference MBT and Sorting Systems, Hanover, Germany, 24–26 May 2011; pp. 81–91, ISBN 978-3-86955-747-2. [Google Scholar]

- Al-Awad, T.; Saidan, M.; Gareau, B. Halon management and ozone-depleting substances control in Jordan. Int. Environ. Agreem. 2018, 18, 391–408. [Google Scholar] [CrossRef]

- Alrabie, K.; Saidan, M. A preliminary solar-hydrogen system for Jordan: Impacts assessment and scenarios analysis. Int. J. Hydrogen Energy 2018, 43, 9211–9223. [Google Scholar] [CrossRef]

- MOMA. Ministry of Municipal Affairs Report; Ministry of Municipal Affairs: Amman, Jordan, 2014. [Google Scholar]

- MOMA. Ministry of Municipal Affairs Report; Ministry of Municipal Affairs: Amman, Jordan, 2009. [Google Scholar]

- Saidan, M.; Abu Drais, A.; Al-Manaseer, E. Solid waste composition analysis and recycling evaluation: Zaatari Syrian Refugees Camp, Jordan. Waste Manag. 2017, 61, 58–66. [Google Scholar] [CrossRef] [PubMed]

- Al-Hamamre, Z.; Saidan, M.; Hararah, M.; Rawajfeh, K.; Alkhasawneh, H.; Al Shannag, M. Wastes and biomass materials as sustainable-renewable energy resources for Jordan. Renew. Sustain. Energy Rev. 2017, 67, 295–314. [Google Scholar] [CrossRef]

- Saidan, M. Sustainable Energy Mix and Policy Framework for Jordan; Friedrich Ebert Stiftung: Amman, Jordan, 2012. [Google Scholar]

- Saidan, M. Baseline Carbon Emission Assessment in Water Utilities in Jordan Using ECAM Tool. J. Water Supply Res. Technol. AQUA 2019, 68, 460–473. [Google Scholar] [CrossRef]

- Saidan, M.; Al-Weshah, R.; Obada, I. Potential Rainwater Harvesting: Adaptation Measure for Urban Areas in Jordan. Am. Water Work. Assoc. 2015, 107, 594–602. [Google Scholar] [CrossRef]

- Saidan, M. Cross-Sectional Survey of Non-Hazardous Waste Composition and Quantities in Industrial Sector and Potential Recycling in Jordan. Environ. Nanotechnol. Monit. Manag. 2019, 12, 100227. [Google Scholar] [CrossRef]

- Al-Weshah, R.; Saidan, M.; Al-Omari, A. Environmental ethics as a tool for sustainable water resource management. Am. Water Work. Assoc. 2016, 108, 175–181. [Google Scholar] [CrossRef]

- Aboelnga, H.; Saidan, M.; Al-Weshah, R.; Sturm, M.; Ribbe, L.; Frechen, F.B. Component analysis for optimal leakage management in Madaba, Jordan. J. Water Supply Res. Technol. AQUA 2018, 67, 384–396. [Google Scholar] [CrossRef]

- Saidan, M.; Al-Yazjeen, H.; Abdalla, A.; Khasawneh, H.; Al-Naimat, H.; Al Alami, N.; Adawy, M.; Jaber, M.; Sowan, N. Assessment of on-site treatment process of institutional building’s wastewater. Processes 2018, 6, 26. [Google Scholar] [CrossRef]

- Bezama, A.; Aguayo, P.; Konrad, O.; Navia, R.; Lorber, K.E. Investigations on mechanical biological treatment of waste in South America: Towards more sustainable MSW management strategies. Waste Manag. 2007, 27, 228–237. [Google Scholar] [CrossRef] [PubMed]

- Hazra, T.; Goel, S. Solid waste management in Kolkata, India: Practices and challenges. Waste Manag. 2009, 29, 470–478. [Google Scholar] [CrossRef]

- Rada, E.C.; Istrate, I.A.; Ragazzi, M. Trends in the management of residual municipal solid waste. Environ. Technol. 2009, 30, 651–661. [Google Scholar] [CrossRef]

- Sugni, M.; Calcaterra, E.; Adani, F. Biostabilization-biodrying of municipal solid waste by inverting air-flow. Bioresour. Technol. 2005, 96, 1331–1337. [Google Scholar] [CrossRef]

- Zhang, D.Q.; He, P.J.; Shao, L.M.; Jin, T.F.; Han, J.Y. Biodrying of municipal solid waste with high water content by combined hydrolytic-aerobic technology. J. Environ. Sci. 2008, 20, 1534–1540. [Google Scholar] [CrossRef]

- Usón, A.A.; Lopez-Sabirón, A.M.; Ferreira, G.; Sastresa, E.L. Uses of alternative fuels and raw materials in the cement industry as sustainable waste management options. Renew. Sustain. Energy Rev. 2013, 23, 242–260. [Google Scholar] [CrossRef]

- Psomopoulos, C. Residue Derived Fuels as an Alternative Fuel for the Hellenic Power Generation Sector and their Potential for Emissions Reduction. AIMS Energy 2014, 2, 321–341. [Google Scholar] [CrossRef]

- Madlool, N.A.; Saidur, R.; Hossain, M.S.; Rahim, N.A. A critical review on energy use and savings in the cement industries. Renew. Sustain. Energy Rev. 2011, 15, 2042–2060. [Google Scholar] [CrossRef]

- Tambone, F.; Scaglia, B.; Scotti, S.; Adani, F. Effect of biodrying process on municipal solid waste properties. Waste Manag. 2011, 102, 7443–7450. [Google Scholar] [CrossRef] [PubMed]

- Velis, C.A.; Longhurst, P.J.; Drew, G.H.; Smith, R.; Pollard, S.J.T. Production and quality assurance of solid recovered fuels using mechanical-biological treatment (MBT) of waste: A comprehensive assessment. Crit. Rev. Environ. Sci. Technol. 2010, 40, 979–1105. [Google Scholar] [CrossRef]

- European Commission. Methodology for the Analysis of Solid Waste (SWA-Tool) User Version. In Project: SWA-Tool, Development of a Methodological Tool to Enhance the Precision & Comparability of Solid Waste Analysis Data; Coordinator: iC consulenten ZT GmbH, Austria; Solid Waste Analysis (SWA)-Tool Consortium, European Commission: Vienna, Austria, 2004. [Google Scholar]

- Rotter, V.S.; Kost, T.; Winkler, J.; Bilitewski, B. Material flow analysis of RDF-production process. Waste Manag. 2004, 24, 1005–1021. [Google Scholar] [CrossRef] [PubMed]

- Kara, M. Environmental and economic advantages associated with the use of rdf in cement kilns. Resour. Conserv. Recycl. 2012, 68, 21–28. [Google Scholar] [CrossRef]

- Lechtenberg, D. MVW Lechtenberg. Available online: http://www.lechtenberg-partner.de (accessed on 17 April 2018).

- Shukla, S.R. Manual on “Municipal Solid Waste Management”; Ministry of Urban Development Government of India: New Delhi, India, 2000.

- Caputo, A.C.; Pelagagge, P.M. RDF production plants: I Design and costs. Appl. Therm. Eng. 2002, 22, 423–437. [Google Scholar] [CrossRef]

- Rhyner, C.R.; Schwartz, L.J.; Wenger, R.B.; Kohrell, M.G. Waste Management and Resource Recovery; Lewis Publishers: Boca Raton, FL, USA, 1995. [Google Scholar]

- Watanabe, N.; Yamamoto, O.; Sakai, M.; Fukuyama, J. Combustible and incombustible speciation of Cl and S in various components of municipal solid waste. Waste Manag. 2004, 24, 623–632. [Google Scholar] [CrossRef]

- Gendebien, A.; Leavens, A.; Blackmore, K.; Godley, A.; Lewin, K.; Whiting, K.J. Refuse Derived Fuel, Current Practice and Perspectives Final Report; European Commission; Water Research Centre (WRc): Swindon, UK, 2003. [Google Scholar]

- Scoullos, M.; Siskos, P.; Zeri, C.; Skordilis, A.; Ziogas, C.H.; Sakellari, A.; Giannopoulou, K.; Tsiolis, P.; Mavroudeas, S.; Argyropoulos, I.; et al. Composition and chemical properties of RDF product at a MSW mechanical separation plant in Greece. In Proceedings of the Conference on Thermal Processing of MSW, National Technical University of Athens, Athens, Greece, 19–21 June 2009. [Google Scholar]

- Directive 2000/76/EC of the European Parliament and of the Council of 4 December 2000 on the incineration of waste. Off. J. Eur. Communities L 2000, 332, 91–111.

- Manaseer Cement Industry. Modern Cement and Mining Company, Jordan. Available online: http://www.mgc-cement.com (accessed on 23 August 2018).

- European Commission. Guidelines on the Interpretation of the R1 Efficiency Formula for Incineration Facilities Dedicated to the Processing of Municipal Solid Waste According to Annex II of Directive 2008/98/EC on Waste; EU Commission, Directorate-General for Environment: Brussels, Belgium, 2008. [Google Scholar]

- Direct Emissions from the Cement Sector. Climate Leaders Greenhouse Gas Inventory Protocol Core Module Guidance, Climate Leaders; Draft Comment; Environmental Protection Agency (EPA): Washington, DC, USA, 2003.

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).