Abstract

Rare metals (RMs) are becoming increasingly important in high-tech industries associated with the Fourth Industrial Revolution, such as the electric vehicle (EV) and 3D printer industries. As the growth of these industries accelerates in the near future, manufacturers will also face greater RM supply risks. For this reason, many countries are putting considerable effort into securing the RM supply. For example, countries including Japan, Korea, and the USA have adopted two major policies: the stockpile system and Extended Producer Responsibility (EPR). Therefore, it is necessary for the manufacturers with RMs to establish a suitable supply chain plan that reflects this situation. In this study, the RM classification matrix is created based on the stockpile and recycling level in Korea. Accordingly, three different types of supply chain are designed in order to develop the closed-loop supply chain (CLSC) planning model of RM, and the CLSC planning models of RM are validated through experimental analysis. The results show that the stockpiling and the EPR recycling obligation increase the amount of recycled flow and reduce the total cost of the part manufacturing, which means that these two factors are significant for obtaining sustainability of the RMs’ CLSC. In addition, the government needs to set an appropriate sharing cost for promoting the manufacturer’s recycling. Also, from the manufacturer’s perspective, it is better to increase the return rate by making a contract with the collectors to guarantee the collection of used products.

1. Introduction

Rare metals (RMs) are a class of metals with extremely small reserves globally. One of their material characteristics, which makes them so significant in various industries, is that even a small amount of these metals improves the performance and quality of various products [1]. Therefore, in spite of their scarcity, many industries require them in the production process and the future demand for RMs is consequently predicted to increase. However, RM exist in very few countries, and this regional ubiquity causes manufacturers to depend heavily on those countries. Due to the scarcity and regional ubiquity of RM, governments and manufacturers are attempting to lower supply uncertainty.

Recently, keywords like low-carbon green growth and the Fourth Industrial Revolution have emerged in the global market. Naturally, the growth rate for high-tech industries related to those keywords, such as the electric vehicle (EV), self-driving car, and Internet of Things (IoT) device (mobile, sensor, etc.) industries, has increased. Demands for RMs have also been continuously increasing due to these being the most significant raw materials for those industries. For the Republic of Korea especially, rapidly increasing RM demands are predicted due to efforts towards competitiveness reinforcement of major industries (semiconductor, display, etc.) and securement of new industries (batteries for EVs, lightweight materials and alloys, IoT devices, etc.) [2].

However, issues arise with these aims as high geographical ubiquity causes monopolistic production of RMs by certain countries. China owns more than 35% of the world’s measured RM reserves and is responsible for more than 90% of world’s yearly RM production. The risk of constrained supply and rising prices for RMs has increased as domestic demand for RMs in China has grown, leading the country to strategically control the export quota and production capacity of the RMs [3,4].

Some countries, including Japan, Korea, and the USA, have adopted two major policies to lower RM supply uncertainty. One is to operate an RM stockpile system at the national level, and the other is to impose more legal responsibility on producers to recycle waste. First, the RM stockpile system aims to relieve the fluctuation in RM prices. With the RM stockpile system, some RMs are stored in the government’s repository when the market price is stable. Later, if the market price increases rapidly, the stored RMs are sold to manufacturers at a lower price. Second, Extended Producer Responsibility (EPR) requires producers to accept a duty to recycle RMs, and pay recycling charges when this duty is not fulfilled. The purpose of this policy is to encourage eco-friendly production as well as sustainable manufacturing by minimizing the impact of supply uncertainty and raising the circulation ratio [5].

Therefore, for producers using RMs as the raw materials for their products, it is necessary to consider all the conditions mentioned above when developing supply chain planning. To achieve this, the current supply chains must be analyzed and represented precisely in a diagram. For example, the government (Public Procurement Service and Korea Resources Corporation) can be an alternative supply route for producers using the stockpiled RMs, and this route can be open or closed depending on the external environment in terms of price fluctuations or market demand. Additionally, different supply chain structures are formed for producers who do not meet their recycling duty, or producers who cannot recycle.

The RM’s supply chain represents a closed-loop supply chain (CLSC) in the environment described above. In fact, for obtaining sustainability of the supply chain considering various realistic environments, many studies have been studied to design CLSC framework and develop an optimization model based on that framework [6,7,8]. However, the existing studies related to RMs only analyzed the supply risk of RMs or impact of price variation using qualitative approaches, and there have been no studies about CLSC of RMs considering all the conditions mentioned above. In other words, they do not provide quantitative solutions to manufacturers to prepare for supply risks. Therefore, manufacturers using RMs need a quantitative model for CLSC management to help them derive their CLSC planning.

This study delivers some contributions. First of all, we analyze that the structure of the RMs’ supply chain differs depending on whether each RM is stockpile or not and on the recycling level. Based on the results, the RM classification matrix is created based on the stockpile and recycling level of RMs in Korea. It would be valuable to identify that the impacts of the two elements make the form of the RMs’ supply chain different. The second contribution of this study is to design three different types of CLSC of RMs and to develop a CLSC planning model of RMs in order to minimize the manufacturer’s total cost considering the factors of the cost of purchase, inventory, scrap collection, recycling duty fulfillment, and recycling charges, according to the market demand and price. Finally, this study investigates the influence of proportion between sharing cost and recycling cost, changes in return rate, changes in recycling obligation rate on the optimal solution. As a result, this study suggests some managerial insights that the government and manufacturer will be able to enhance the sustainability of the CLSC of RMs, which will be useful to support decision making of RMs’ CLSC members.

Additionally, the EV industry is chosen as an example for experimental analysis. Many kinds of RMs are needed in the EV production process, especially lithium, nickel, magnesium. According to the classification matrix derived from this study, these three RMs belong to different types. Therefore, considering the EV industry, which manufactures the end product using all of these RM types, it will be possible to analyze how different types of CLSC of RMs affect a whole industry dynamically. On the other hand, the EV industry is growing fast as the sales volume increases by double over two recent years along with the market share of the automobile, which leads to an increase in demand for RMs [9,10].

The research procedure is presented as follows: In Section 2, the literature regarding RMs and CLSC management are reviewed. This chapter clarifies the differences between our research and existing studies. In Section 3, the supply chain for each segment of RMs in Korea is analyzed. Based on this, the integrated CLSC of RMs and the CLSC planning model are presented in Section 4. Section 5 presents experimental examples and sensitivity analysis using one representative metal from each RM type. In conclusion, the suggested CLSC planning model is verified, and useful insights are discussed.

2. Literature Review

2.1. Rare Metals Management and Recycling

Studies on RM management include research on how to respond to supply risks caused by a monopoly environment, and research which analyzes the material flow or availability of RMs. In addition, there are some studies which consider recycling a sustainable solution in order to overcome the supply risks and the scarcity of RMs [4,11,12,13,14].

Alonso et al. [15] pointed out that the availability of RMs has been at risk previously due to monopolistic supply conditions, unsustainable mining practices, and an increase in RM demands. Consequently, they created potential future demand scenarios and estimated the future RM supply availability. Sprecher et al. [16] analyzed the 2010 rare earth crisis and argued that the significant increase in demand for, and the large variance in the price of, neodymium showed that the RM supply chain lacked resilience. They used material flow analysis (MFA) along with the resilience theory to show that the supply chain’s resilience is composed of resistance, rapidity, and flexibility. Golev et al. [17] indicated that the unique properties of RMs resulted from the domination of RM production by only a few countries, which raised the concerns of countries without RMs regarding securing a supply. Therefore, the authors overviewed current RM supply chains for countries without RMs. They also addressed the constraints, opportunities, and challenges of producing and recycling RMs. Dutta et al. [18] emphasized the importance of RMs as a valuable resource for renewable energy and electronic devices. They also pointed out that the global demand for RMs is increasing, and that a stable RM supply chain will be required in the long term. To secure steady RM supplies in a monopoly environment, the authors addressed the problems of RM mining with the aim of minimizing the amount of RM required in relevant industries. Rollat et al. [19] forecasted that, for the next decade, RMs have significant recycling potential and will play an important role in a low-carbon energy transition in Europe. Different scenarios for material flow and the assumptions of RM recycling were considered. The major trends affecting the RM industry along the value chain in Europe included extraction, separation, fabrication, manufacture, use, and recycling.

To overcome the difficulties in supplying RMs and achieve sustainability in the supply chain, one effective method is to recycle them domestically. Meyer and Bras [11] addressed the reasons to recycle RMs and investigated the possibilities and difficulties of recycling RMs on an industrial scale. The results showed that large-scale recycling lines were required for economic benefits to be realized. Rademaker et al. [20] evaluated the historical annual flows of neodymium and dysprosium and estimated their future flows. This study indicated that the demand for recycling RMs will increase sharply in the long term, and RM industries must develop recycling technology and infrastructure. In addition, EPR and waste electrical and electronic equipment (WEEE) can be considered other effective ways to achieve supply chain sustainability. Several studies analyzed the impact of these policy regulations on producers’ performance in managing the supply chain [21,22,23,24].

Most of the previous papers, however, analyzed the supply risk of RMs and the resulting impact of price variation using a qualitative approach. Therefore, it is essential to develop a quantitative method, such as supply chain planning, which helps with the decision-making processes of manufacturers of RMs.

2.2. Closed-Loop Supply Chain (CLSC) Management

The closed-loop supply chain (CLSC) is a supply chain with a reverse flow, such as the recycling process utilized when considering sustainability in supply chain management. Research on CLSC management aims to understand various constraints in different industries, design a CLSC, develop an optimization model, and analyze the impact of recycling on the performance of each supply chain member.

Olugu et al. [25] identified CLSC management as an efficient, effective, and economical method for manufacturing companies working towards sustainability. They also pointed out the importance of the performance evaluation system for successful CLSC management in the automotive industry. The study developed the fuzzy rule-based system using Visual Basic.Net, and the performance of the system was evaluated using a case study of a company from the automotive industry. Özceylan et al. [26] pointed out the worldwide concerns for the environment, which is raising the motivation of manufacturers to implement recycling strategies. For example, automotive manufacturers in Turkey are obligated to take back end-of-life vehicles (ELVs) and recycle the used parts back into the industry. The authors developed a linear programming model including both forward and reverse supply chains and presented several scenarios to show the performance of the proposed model. Chuang et al. [27] proposed the CLSC model considering a short life-cycle demand for a high-tech product. This study found the optimal production quantities and profits under three different reverse channel alternatives and compared the impacts of each reverse channel alternative choice for manufacturers. Heydari et al. [28] focused on a two-echelon reverse supply chain network to increase the usage of sustainable products by offering benefits. Then, a CLSC model was developed considering the quantity discounts and increasing fee contracts. They analyzed the impact on the supply chain when the government donated different incentives to supply chain members. Amin et al. [29] proposed a CLSC network for a tire remanufacturing industry. An actual network in Canada was considered for applications of the optimization model. They calculated the net present value considering different uncertainties over multiple periods. Then, the discount cash flow was considered to compare the profitability of the model. Kim et al. [30] analyzed the two types of CLSC in the photovoltaic (PV) system industry. Based on an actual case analysis, the authors classified the CLSC of PV manufacturers with an internal and external recycling system. From the experimental analysis, the results showed that it is inefficient for the manufacturer of the c-Si module, one of the first-generation PV systems, to maintain an internal recycling system since the material prices are low. However, for CdTe, one of the second-generation PV systems, it is more efficient to have an internal recycling system rather than join the external recycling association due to the value of the materials. Huang et al. [31] investigated the uncertainty factors for the collection strategies of a remanufacturing closed-loop supply chain. A stochastic collection model was developed and the feedback control strategies were derived considering the stochastic disturbance. Then, a contract was proposed to coordinate the decentralized closed-loop supply chain. The results showed the impact on each members in the supply chain according to the intensity of stochastic disturbance. Also, Turki et al. [32] created a discrete flow model to describe the realistic system of a manufacturing/remanufacturing transport warehouse closed-loop supply chain. The model consists of two machines for manufacturing and remanufacturing, manufacturing stock, purchasing warehouse, transport vehicle and recovery inventory. The objective of this study is to evaluate the optimal capacities of the decision variables including manufacturing stock, purchasing warehouse and the vehicle, and the optimal value of returned used end-of-life products. In addition, several studies designed the CLSC of battery manufacturers and analyzed economic performance and the optimal use and waste of recycled products [33,34].

CLSC management is applied to many industries to help managers and scholars understand how the recycling system affects the entire supply chain and each supply chain member. Considering the growing importance of RMs in large industries such as the automobile industry, it is necessary to analyze RMs with a view to CLSC management. Therefore, this paper designs the CLSC of RMs and develops a CLSC planning model considering the actual government policies in Korea. In particular, this study focused on how the optimal solution of CLSC planning is influenced by policies, including the recycling responsibility of the part manufacturer and the stockpile system of the government.

3. Closed-Loop Supply Chain of Rare Metals

Korea is making efforts to grow major industries (semiconductor, display, automobile) and foster new growth-engine industries such as batteries for EV, lightweight materials and alloys, IoT devices, and solar cells, which result in rapid increase of demand and import of RMs. On the other hand, low self-sufficiency rate and recycling rate, as well as poor domestic reserve amount and production conditions of RMs cause a low resource circulation rate for RMs [1]. Thus, efficient CLSC design and operation are essential to prepare for the supply uncertainty of RMs.

Before designing the CLSC of RMs for Korea, this chapter analyzes the supply chains using RMs such as ore, ingots, catalysts, and so forth. The basic members of the supply chain include the raw material supplier, pre-manufacturing processor, part manufacturer, end product manufacturer, collector, and customer. The supply chain may include other supply chain members, such as the government and the recyclers, depending on the stockpile policy of the government and the recycling level of the RMs.

When a manufacturer who uses an RM as their raw material establishes the supply chain plan, one of the most important steps is to choose the proper supply routes with regard to the future supply risk and the fluctuation of the material price. The manufacturer may consider options including supply from overseas, the government’s procurement agency, and recycling companies. In Korea, an overseas supplier is regarded as a fixed supply source since most RMs are purchased from abroad due to low self-sufficiency. On the other hand, the government and recyclers are considered temporary supply sources since their supplying abilities are influenced by external environments such as government policy and recycling technologies. Therefore, the details of the mechanism of the two temporary supply routes need to be analyzed further to figure out how they are implemented into the CLSC of RMs.

3.1. Temporary and Conditional RM Supply Method

• Supply method based on the government’s stockpile

In Korea, two government agencies, the Public Procurement Service and Korea Resource Corporation, strategically designate some of the obtained metals as stockpile metals either because currently there is high demand or because a rapid demand increase is predicted. The stockpile systems are further classified into the direct stockpile and the request stockpile. In the case of the direct stockpile, RMs are stocked when the price is stable, and then released when the market price rises to a certain level. The request stockpile is the method used to stock and sell according to requests from a large number of manufacturers. Manufacturers should consider the raw material supply and demand, expected consumption, and environmental changes occurring in the company. Based on these factors, they can decide to request the government agencies to allow access to the raw material stockpile. Therefore, the structure of the supply chain differs depending on whether each metal is determined as a stockpile metal or not.

• Supply method based on recycling

In addition to the government’s participation in the supply chain, recycling RMs also affects the structure of the supply chain. While Korea is famous for its high-technology industries, the technology level of recycling RMs is quite low and the ratio of recycled RMs is low compared to the level of demand [1]. Although most of the RM scraps are exported to be recycled, some of the scraps, including Mg, In, and Ni, are recycled domestically. The properties of recycled metals are the same as those of natural metals in the manufacturing process, and they are cheaper than purchasing from an overseas supplier. For the manufacturers, therefore, this supply route can be more cost-efficient than other routes if the RM is recyclable.

If an RM is designated as a target material by EPR, the manufacturer can fulfill the recycling duty by either recycling the related objects or paying the sharing cost to the recycling cooperative. If the manufacturer decides to use both methods, the recycling charges are deducted from the sharing cost of the recycling cooperative. Some manufacturers let the recycling cooperative fulfill the recycling duty and pay the sharing cost instead of recycling the scraps. This paper considers both the recycler and the recycling cooperative in the CLSC planning model of RMs. However, although handing over the scraps to the recycling cooperative fulfills the EPR obligation, some problems arise when those RMs are not circulated in the CLSC of RMs after the scraps are sent. Therefore, in this research, the recycling cooperative is included in the supply chain diagram, but it is not considered a supplier type.

• RM Classification Matrix Diagram

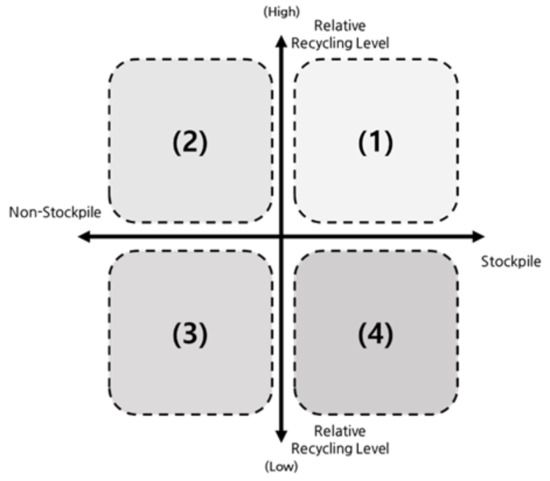

As mentioned above, the CLSC of RMs in Korea differs depending on two elements: stockpiles and recycling. This differentiates a traditional supply chain from the CLSC of RMs. Therefore, this study creates the RM classification matrix to classify the RMs as shown in Figure 1. In the matrix that we have defined, the third quadrant includes metals that are not stockpiled by the government and have a very low recycling level. The supply chain structure of these metal types is similar to the traditional forward supply chain, and for some of the third quadrant RMs recycling is less economically beneficial. Thus, in this study, the third quadrant was excluded from the supply chain design. As a result, the remaining quadrants are called Type A (first quadrant), Type B (second quadrant), and Type C (fourth quadrant), respectively.

Figure 1.

Rare metal (RM) classification matrix diagram.

3.2. Closed-Loop Supply Chain by RM Type

In this section, we design three CLSCs considering the characteristics of each RM type defined above.

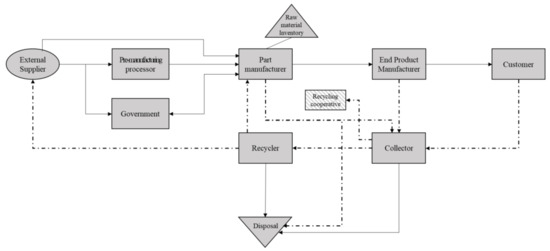

• Closed-Loop Supply Chain of Type A RMs

Type A RMs are the government stockpile metals, and they have a relatively high recycling level. In other words, the Korean government strategically stockpiles these metals since they are in high demand currently and demand is predicted to increase in future. Type A RMs in Korea include manganese, indium, nickel, tin, cobalt, tungsten, gallium, and more. As described in Figure 2, an external supplier, a pre-manufacturing processor, the government, and the recycler are the members of the CLSC of Type A RMs. The part manufacturer using Type A RMs can choose to purchase the raw materials from four different types of suppliers, and they have to decide when and how much of the RMs to order from which supplier. The recycling cooperative is also included in the supply chain if the manufacturing parts are in the EPR obligation items.

Figure 2.

Closed-loop supply chain of Type A RMs.

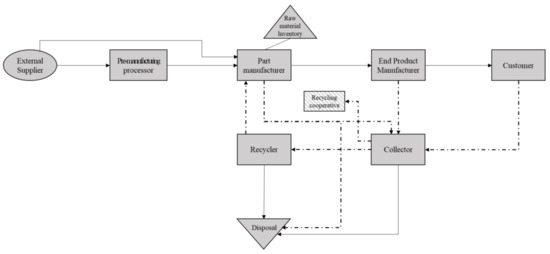

• Closed-Loop Supply Chain of Type B RMs

Type B RMs have a relatively high recycling level, but not as high as that of the government stockpile metals. Type B RMs in Korea include silver, gold, magnesium, and more. As shown in Figure 3, an external supplier, pre-manufacturing processor, and recycler are included in the CLSC of Type B RMs. The part manufacturer using Type B RMs has three options for purchasing the raw materials. Unlike the part manufacturer in the CLSC of Type A RMs, who has two cheaper purchase options (recycler and government) besides the external supplier or pre-manufacturing processor, the part manufacturer in the CLSC of Type B RMs is only able to purchase raw materials at a low price from the recycler. This provides the basis for analyzing the effects of the government stockpile by comparing the Type B RM supply chain with Type A and Type C RM supply chains, in which the government participates. Also, it is possible to verify the effectiveness of the stockpile system by analyzing the difference in the total cost to the part manufacturer when the government decides to stockpile the Type B RMs in the future. In this case, as for the Type A RMs, the recycling cooperative is included in the CLSC of Type B RMs when manufacturing parts are in the EPR obligation items.

Figure 3.

Closed-loop supply chain of Type B RMs.

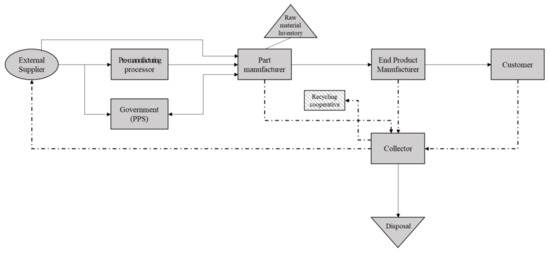

• Closed-Loop Supply Chain of Type C RMs

Type C RMs are government stockpile metals; however, they have a low recycling level. Type C RMs in Korea include lithium, vanadium, molybdenum, barium, titanium, most of the rare earth element (REE), and more. The future value of these metals is increasing, so the government has strategically designated them as stockpile metals to reduce the quantity of Type C RMs scraps being exported, which will consequently increase the domestic flow in the supply chain. Figure 4 shows that the CLSC for the Type C RMs includes the external supplier, pre-manufacturing processor, and government. In other words, a part manufacturer using the Type C RMs has three purchasing options. However, since the Type C RMs are not recycled domestically, directly consigning to the recycler is not possible. Therefore, this study develops a CLSC of Type C RMs in which most of the scraps collected are discarded or exported overseas.

Figure 4.

Closed-loop supply chain of Type C RMs.

4. Mathematical Modeling

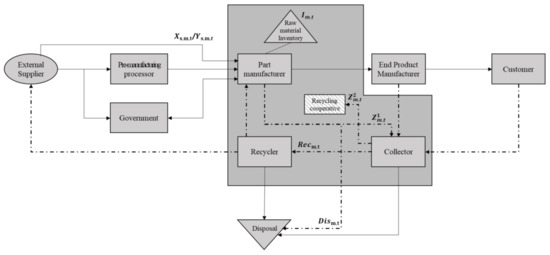

In this section, we develop a mixed integer linear programming model for CLSC planning of the three types of RMs mentioned in the previous section. This model aims to minimize the total cost to part manufacturers using RMs. Figure 5 shows the decision variables used in the CLSC planning model for RMs. The part manufacturer procures the raw materials through a total of five types of suppliers. The supplier type(s), the indices, the parameters, and the variables used in the model are as follows:

Figure 5.

Decision variables in the integrated closed-loop supply chain (CLSC) planning model of RMs.

The decision variables in the mathematical model are the amount of RM supplied from each supplier, the inventory level of the RM, the amount of RM sent for collection and disposal, the amount of RM recycled, the number of RMs sent to the recycling cooperative from the collector, and whether the part manufacturer purchased the RM from each supplier.

• Assumptions

The basic assumptions used in this model are as follows:

- (1)

- Part manufacturers considered in this study produce parts using many types of RMs in the RM classification matrix. When they need to collect and recycle, they form a contract with dedicated agencies. This study assumed that the consignment agencies accept the decision making of the part manufacturers completely.

- (2)

- The bill of materials (BOM) coefficients required to calculate the demand for RMs and the end product demands during the entire planning horizon are known.

- (3)

- The inventory and the backorder of the parts are not considered since part manufacturers produce the exact amount for the demand of each time period (t).

- (4)

- The production yield and return rate of EOL product are also known, and the part production yield and recycling rate is dependent on which RM is used.

- (5)

- There is a collecting capacity of the consignment collectors, and the inspection rate is known. Additionally, the amount of recycled RMs that can be purchased after one period from a recycler is known.

- (6)

- With regard to the stockpile system, it is assumed that the direct stockpile is based on the past market price and the request stockpile is based on future demand. Activating purchase availability from the government is determined based on the market price and demand, and the stockpile amount that can be purchased after one period from the government is known.

- (7)

- The amount of scrap disposed of by the collector or recycler, or exported overseas, is not considered.

- (8)

- The lead time is not considered in all manufacturing processes.

• Objective function

The objective of the CLSC planning model is to minimize the total cost to the part manufacturer. The part manufacturer purchases the RMs to meet the end product demand, and there are different fixed order costs depending on which supplier type they select. In addition, the total cost they have to pay includes the holding cost, collecting cost, recycling cost, and disposal cost. Furthermore, when producing parts are subject to the EPR recycling obligation, recycling charges and the cost of sending scrap to the recycling cooperative in order to fulfill this duty are included, and payback from fulfilled recycling is deducted from the total cost. The objective function can be expressed as follows:

Minimize Total Cost (TC):

Expressions such as , , are used to simplify the objective function and are calculated as follows:

Equation (2) represents the non-fulfilled quantity of the EPR obligation for the part manufacturer using metal m in time period t, and Equation (3) shows the recycling charges that must be paid for a non-fulfilled duty. Equation (4) shows the payback from the recycled amount regardless of the amount of non-fulfilled duty.

• Constraints

Equation (5) is the balance constraint that the inventory in period (t) must be equal to the value of subtracting the amount delivered from the value of adding the inventory in period (t − 1) and the purchased amount in period (t). Equation (3) shows that the total amount of materials recycled and disposed at period (t) must be smaller than or equal to the sum of that from manufacturing scrap and that from the product recycling processes, and Equation (7) sets the upper limit for the RM purchasing amount from the recycler. Binary variable rm is used to model that the non-recycled RM cannot be purchased from the recycler. Similarly, Equations (8)–(11) set the upper limit for the amount purchased from each supplier type. Binary variable sm, used in Equations (10) and (11), represents whether the government stockpiles the RM. Equation (12) is the activation constraint for purchasing the directly stockpiled metal, and the metal can be purchased from the government during period t when the average price of the global market for the three previous periods passes the fixed standard price. When period t is one or two, the previous period price is used due to the lack of data. Equation (13) is based on the market demand as a constraint for the release of the request stockpile. Equation (14) is the upper and lower limit of the part manufacturer’s inventory, and Equation (15) limits the collecting capacity of the consignment collectors. Equation (16) represents that the sum of the recycled amount and scrap amount delivered to the recycling cooperative does not exceed the amount collected by the collector and inspected. Finally, Equation (17) states that all variables used in this model must be non-negative.

5. Experimental Analysis and Results

5.1. Experimental Design

The global EV industry has been growing at a rapid pace in recent years [35], and many types of RMs are used in various parts of EVs and are therefore needed in the production process. Typical examples of parts requiring RMs are secondary batteries (lithium, cobalt, nickel, and manganese), permanent magnets (REE), and lightweight materials for the car body such as titanium and magnesium [2]. In Korea, although the cumulative sales volume of EVs is small, the market size has been growing for the past five years due to technology development and policy support. Such an increase in the demand for EVs will lead to an increase in the recycling potential of parts such as secondary batteries and the car body. In this study, it is assumed that there is parts manufacturer who produce secondary batteries and lightweight material for the car body in Korea, and we designed the experiment to apply the developed CLSC planning model of RMs. It is intended to then implement the CLSC planning model of RMs to manufacturers who need to consume many types of RMs, and to analyze the results.

First, a representative metal for each type in the RM classification matrix, used by the EV part manufacturer as the raw material, is chosen (see Table 1). The binary value of each RM type is used to represent the availability of the supply route (government or recycler) and the EPR recycling duty of the part. In addition, it is assumed that the upper and lower market prices over the past one year for each type of RM are gathered and that the market price follows a uniform distribution [36].

Table 1.

Basic information on RM type in the experimental analysis.

The planning horizon is for 10 periods. Lastly, for the EV demands used in this model, linearly increasing demand for the next 10 years is predicted by using the average increase rate of the real EV demands for the most recent six years in Korea (see Table 2).

Table 2.

EV demand (in units).

5.2. Results

We analyzed the results by changing sm, rm, and rdm to observe the effects of stockpiling, recycling, and recycling duty. Starting with Case 1 (base case), followed by Case 2 for analyzing the impact of the stockpile, Case 3 for analyzing the impact of recycling, and finally Case 4 for all RM stockpiling, recycling and imposed recycling obligations are analyzed.

• Case 1

The base case result from the CLSC planning model of RMs is shown below in Table 3. For Type C (lithium), the amount of recycled RM does not exist since the recycling rate is zero. However, the manufacturer has to pay recycling charges due to EPR recycling obligations. For the stockpile metals (Type A and Type C), an advantage of securing the metals at a low price from the government exists. Thus, they use government supplies to cope with increasing demand and price fluctuations, and the inventory ratio to demand remains relatively higher than other types of RMs. In addition, Type B (magnesium) RM is recyclable, but recycling charges do not need to be paid since a recycling obligation does not exist. Therefore, most of the scraps are sent to the collector and the part manufacturer does not actively participate in the recycling process themselves. However, some recycling action is found at the end of the planning horizon where demand is high. Type A (nickel) is recycled as much as possible. Nevertheless, the recycling duty ratio in the basic parameter is too high, so the part manufacturer has to pay the recycling charges for the non-fulfilled quantity of the EPR recycling obligation. This applies to all the metals, not just nickel, and it means that too high of a recycling obligation level can hinder the desired outcome. Also, from a policy perspective, it is important to set the appropriate recycling duty ratio considering the recycling ratio of each RM. This is analyzed in more detail using the sensitivity analysis below.

Table 3.

Results of Case 1.

• Case 2

In Case 2, sm is adjusted to analyze the effects of the stockpile. For every type of RM, the total cost with the stockpile is less than the total cost without the stockpile (see Table 4). Specifically, nearly $4 million of total cost can be reduced if 10% of the annual demand of Type B (magnesium), a non-stockpile metal, is stockpiled and sold. Thus, increasing the government’s stockpile and sales amount, and flexibility in adjusting the release standard price according to price fluctuations, can improve the economic performance of the part manufacturer using RMs. Therefore, as many types of RMs as possible should be designated as stockpiles, and the release standard price and stockpile targets should be quantified and managed by the government according to the importance of each RM.

Table 4.

Results of Case 2.

• Case 3

In this case, the effects of recycling are analyzed by adjusting the rm for each metal. When a Type C metal (lithium), which is processed only up to the point of collecting, is recycled, the total cost and recycling charges are reduced (see Table 5). However, even if the rm of Type C is set to 1 the recycling duty is fulfilled by sending the scraps to the recycling cooperative, instead of sending them to the recycler, because of the low recycling rate. The recycled proportion also increases drastically by 17.15%, contrary to in Case 1 where collected scraps are thrown out. In other words, if investments related the recycling technology for Type C metals occur, purchasing stability can be obtained by sending the increased amount of scraps to the recycler and recycling cooperative. This can enhance the sustainability of the CLSC of RMs.

Table 5.

Results of Case 3.

• Case 4

Lastly, the effect of imposing the recycling duty is analyzed by adjusting rdm. Type B (magnesium), which had no recycling duty until this case, is affected by this. As a result, although the total cost of about $0.4 million has increased, the recycling quantity (2755–9250 tons) and the payback resulting from fulfilling the recycling duty have surged (see Table 6). In other words, the reverse flow quantity for recycling increases rapidly when a recycling duty for the part and product is assigned. However, an excessive recycling duty increases the recycling charges, and generates the negative effect of lowering the part manufacturer’s willingness to recycle. Therefore, an annual recycling duty target needs to be set carefully. In conclusion, for the government to improve the sustainability of the CLSC of RMs, imposing a differentiated recycling duty for each part and product, taking into consideration the recycling technology level for each type of RM, is necessary.

Table 6.

Results of Case 4.

5.3. Sensitivity Analysis

5.3.1. Impact of Proportion between Sharing Cost and Recycling Cost

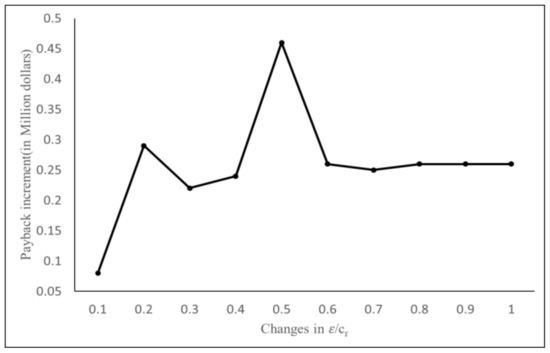

During the recycling process, the manufacturing scrap and EOL product returns are sent to the consignment collector. Next, the collected scraps can be sent to the recycling cooperative for indirect recycling (paying ) or sent to the recycler for direct recycling (paying ). In this section, the ratio ( fixed) is increased from 10% to 100% to show how this ratio affects the payback increment. Figure 6 shows that a part manufacturer with an EPR obligation wants to increase payback and reduce recycling charges as the ratio increases. As a result, the amount of recycled metals and payback increase until the ratio becomes 0.5, but the amount of recycled metals does not increase any further when the ratio exceeds 0.5. The subsequent payback increment is due to increasing the size of the sharing cost () per unit of part recycling.

Figure 6.

Payback increment according to .

In conclusion, the results suggest that setting the appropriate sharing cost for recycling, considering the recycling costs () of each part, is one of the most important factors in promoting the manufacturer’s recycling behavior.

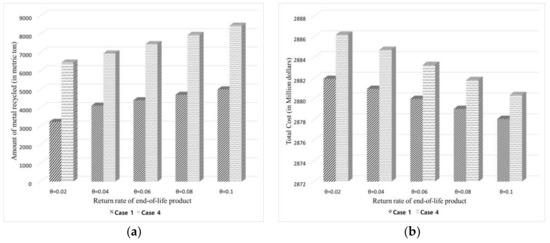

5.3.2. Impact of Changes in Return Rate

The collected amount of EOL products from customers at each period is decided by the return rate (θ). These EOL products are disassembled into parts and recycled after inspection by the collector. Thus, the return rate can be an important factor for achieving an optimal solution that includes the recycling plan of the part manufacturer. In this section, Figure 7a,b shows the changes in total cost and amount of recycled RMs with different return rates in Case 1 and Case 4. When the return rate is increased from 2% to 10%, the total amount of recycled RMs increases from 3241 tons to 5003 tons in Case 1, and from 6456 tons to 8455 tons in Case 4. Additionally, the total cost is reduced by about four million dollars in Case 1 and about six million dollars in Case 4. That is, for equivalent changes in the return rate, Case 4 shows better results in the increase in the amount of recycled RMs and in cost reduction compared to Case 1. To sum up, the part manufacturer in the CLSC of RMs can increase the amount of recycled RMs and reduce the total cost since the more the return rate increases, the more the collected amount of disassembled parts increases.

Figure 7.

Results with different return rates. (a) Total amount of recycled RMs (in metric tons); (b) Total cost (in millions of dollars).

The experiment results show that, from a national perspective, it is better to extend the EPR recycling obligation and stockpile range. Although the total cost to the part manufacturer increases, the reverse flow quantity of the CLSC of RMs increases, so more positive outcomes result from this expansion. Furthermore, these results can be utilized from the manufacturer’s perspective. The sustainability of the CLSC of RMs can be increased by lowering the total cost through a fixed contract for collecting, which is signed to make the return rate of the EOL product higher. For example, a part manufacturer can sign up to a used product collecting contract with local collectors to increase the return rate by more than 10% over the long term. This enables them to achieve a greater cost reduction and increase in their recycling amount. This tendency will be heightened even further in the situation with an uptrend of the minimum stockpile levels according to the demand increase for each metal, development of recycling technology, the upsurge in EV demand, and so forth.

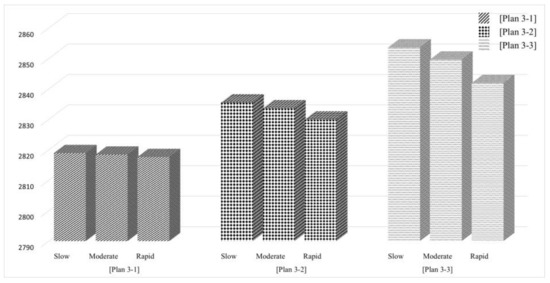

5.3.3. Impact of Changes in Recycling Obligation Rate on Total Cost

Experiments up until now have proceeded with a target of reaching a 90% recycling rate in the long term. However, the recycling charges show that this target is excessive when the current recycling level of RMs is considered. In this section, therefore, the final recycling duty target is set at 10%, 30%, and 50% in the long term, and the pace to reach the target is divided into slow, moderate, and rapid cases. Table 7 shows the recycling duty target for every five years starting from the beginning of the planning horizon. The annual target rate is calculated using an equation for annual recycling duty rates addressed in the Act on the Promotion of Saving and Recycling of Resources (enforcement ordinance 22) in the Ministry of Environment of Korea [37].

Table 7.

Plan for Sensitivity Analysis.

Figure 8 presents the total cost of each plan. This result allows the government to consider all factors in an effective way when imposing a recycling duty on the industry. Regardless of the final recycling duty target, the obligation for a rapid pace of change at the beginning of the planning horizon is set lower than the obligation for a moderate and slow pace. This reduces the total cost for the part manufacturer by reducing the recycling charges and sharing cost. First, the government needs to figure out the recycling capacity of the part manufacturers and the recycling technology level for each RM, and set an appropriate final recycling duty target. After that, a recycling duty target plan with a rapid pace needs to be designed. This improves the sustainability of the CLSC of RMs by reducing the total cost and increasing the amount of recycled RMs.

Figure 8.

Total cost changes in other duty ratio cases (in millions of dollars).

The experimental analysis of this study, as well as the CLSC model itself, can be useful for both recycling policy-makers and for manufacturers related to RMs. From the perspective of policy-makers, our study enables them to evaluate the effectiveness of the policies, such as imposing sharing cost and EPR recycling obligation on manufacturers, in advance. The approach, therefore, helps the policy-makers establish a better policy with the greater recycling motivation of supply chain members. Also, this study is valuable for the manufacturers who try to find an optimal CLSC plan to minimize the total cost in a CLSC of RMs. It also enables them to analyze the impact of return rate on economic performance and sustainability improvement. The manufacturers can organize a local community with their supply chain members by making a contract to guarantee the collection of used part/product they manufactured. The collection community may lead to the increase in the amount of reverse flow in CLSC, which results in the motivation for decision makers to invest on recycling technology.

6. Conclusions

As high-tech industry growth accelerates in the near future, manufacturers using RMs will face greater supply risks resulting from their ubiquity and scarcity. To overcome this, the Korean government has adopted major two policies: the stockpile system and EPR. To derive a supply chain plan for manufacturers using RMs, this study considered the situations mentioned above. First, the RM classification matrix for categorizing was developed by taking into consideration the stockpile and recycling level. Next, three different types of supply chain diagrams corresponding to each segment of the matrix were designed. Based on this, the CLSC planning model of RMs was developed to minimize the total cost. The mathematical model determined the optimal solution including the amount purchased, inventory, scrap collection, recycling duty fulfillment, and recycling charges. In addition, based on the example of the EV industry, this study carried out experimental analysis and sensitivity analysis using the CLSC planning model of RMs, and useful insights have been drawn.

The results showed that stockpiling of the RMs reduces the total cost to the part manufacturer regardless of the RM type. Additionally, it was confirmed that the reverse flow quantity of scrap was increased when the part and product were recyclable, and the sustainability of the CLSC of RMs could then be increased. When a recycling duty was imposed, the results showed that the scrap was sent to the recycler, not the recycling cooperative, in order to secure a stable supply route from the recycler and to obtain the payback reward.

In summary, this study was able to derive the strategy for the government and manufacturer to improve the sustainability of the CLSC of RMs. First, the government must expand the stockpile system for as many types of RMs as possible. Then, it must set and manage the quantified release standard and stockpile targets based on the importance of each RM. Next, manufacturers should continue to invest in the recycling technology of Type C RMs. As a result of investment, the amount of recyclable RMs can be increased, thereby securing purchasing stability from the recycler. Lastly, when the government extends the coverage of the EPR recycling obligation to more products, they must impose the appropriate recycling duty, differentiated for each product, by reflecting the recycling technology level for each type of RM.

Through sensitivity analysis we were able to draw some meaningful insights. First, this study found that setting the appropriate sharing cost when considering the recycling cost is an important factor in promoting the manufacturer’s recycling. Additionally, it was confirmed that a high return rate positively affects the amount of recycled RMs and the total cost reduction for the part manufacturer. Thus, the manufacturer must raise the return rate in the long term by making a contract with a number of collectors to guarantee the collection of used products. Furthermore, the EPR recycling obligation plan established by the government was a light burden on manufacturers at the beginning of the planning horizon. After that, designing the plan to rapidly increase the burden was a way to reduce the total cost and increase the total amount of recycled RMs in the CLSC of RMs. It is also necessary to consider ways to provide different incentives by dividing the achievement level of recycling obligations by segment.

Despite these implications, this study has some limitations. Firstly, a few simplified assumptions used in this study make the CLSC planning model impractical. For example, supply uncertainty is not fully taken into consideration because it does not limit the purchase limit from the external supplier with the largest proportion of purchases. In addition, it is a limitation to assume that EV demand is deterministic. Secondly, some parameters in the experimental analysis were set randomly. In particular, the government’s stockpile limit and the release standard price on the CLSC of RMs is very important. However, in this study, due to the difficulty of collecting real data, the stockpile limit of each RM and release standard price were arbitrarily set.

In future research it will be necessary to overcome these limitations. First, when purchasing RMs from an external supplier, the export quota of some countries will have an effect. Therefore, purchase constraints from external suppliers should be stricter. Additionally, the parameter values, including the stockpile level and release standard of each RM, end product demand, and some cost terms, have to be examined using more reasonable methods. Lastly, in order to examine the effect of price volatility of RMs on CLSC planning, a scenario-based analysis needs to be performed in future.

Acknowledgments

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2012R1A1A2009054).

Author Contributions

Dongmin Son wrote the manuscript and participated in all phases. Songi Kim especially participated in analyzing the supply chain of rare metal. Hyungbin Park investigated the data for the experiments. Bongju Jeong conceived the theme of this study, guided the whole research process, and responded to the reviewers. All authors have read and approved the final manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

Indices

| Index for supplier type | s = 1 for External supplier | |

| s = 2 for Pre-manufacturing processor | ||

| s = 3 for Recycler | ||

| s = 4 for Government (direct stockpile) | ||

| s = 5 for Government (request stockpile) | ||

| Index for metal | m = 1, 2, …, M | |

| Index for time period | t = 1, 2, …, T |

Decision Variables

| Amount of metal m supplied from supplier type s in time period t | |

| Binary variable for whether to purchase metal m from the supplier type s in time period t () | |

| Inventory level of metal m for part manufacturer in time period t | |

| Amount of metal m sent to consignment collector from part manufacturer in time period t | |

| Amount of metal m sent to a recycling cooperative from consignment collector in time period t | |

| Amount of metal m scrap sent for disposing from part manufacturer in time period t | |

| Amount of metal m scrap sent for recycling from consignment collector in time period t |

Parameters

| Product demand at time period | |

| Bill-of-Material (BOM) coefficient of metal m to produce a unit of product | |

| Part production yield using metal m | |

| End product production yield | |

| Return rate of end-of-life (EOL) product | |

| Inspection rate of collected goods | |

| Recycling rate of metal m at time period t | |

| Recycling duty ratio of part manufacturer at time period t | |

| Maximum purchase limit ratio of recycled metal for maintaining quality | |

| Maximum purchase limit of metal m from government at time period t in response to price/demand | |

| Maximum recycling capacity of metal m at time period t | |

| Price of metal m purchased from supplier s at time period t | |

| Government release standard price of metal m | |

| Government release standard demand at the manufacturer’s request | |

| Recycling cost estimation index at time period t | |

| Nonfulfillment penalty ratio of recycling duty at time period t | |

| Inventory lower bound of metal m at time period t | |

| Inventory upper bound of metal m at time period t | |

| Collecting capacity of metal m | |

| Sharing cost for recycling unit part | |

| Fixed ordering cost of metal m from supplier s | |

| Collecting cost of a unit scrap of metal m | |

| Recycling cost of a unit scrap of metal m | |

| Disposal cost of a unit scrap of metal m | |

| Inventory cost on a unit of metal m for part manufacturer | |

| Binary value of whether metal m has stockpile | |

| Binary value of whether metal m is recycled | |

| Binary value of whether metal m is subject to recycling duty | |

| Big M |

References

- Chung, W.; Part, J.M.; Yoo, H.S. The Research on the Development and Recycling of Critical Materials for Green Growth; Korea Energy Economics Institute (KEEI): Ulsan, Korea, 2011. [Google Scholar]

- Kim, K.H. High-Tech Industry Vitamins, Trade Trends and Implications for Rare Metals; Institute for International Trade (IIT): Seoul, Korea, 2018. [Google Scholar]

- Jewell, S.A.; Kim, S.M. Mineral Commodity Summaries 2015; US Geological Survey: Reston, VA, USA, 2015. [Google Scholar]

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Yang, Y.; Walton, A.; Buchert, M. Recycling of rare earths: A critical review. J. Clean. Prod. 2013, 51, 1–22. [Google Scholar] [CrossRef]

- Itoh, H. The recent trend of e-waste recycling and rare metal recovery in Japan. WIT Trans. Ecol. Environ. 2014, 180, 3–14. [Google Scholar]

- Turki, S.; Rezg, N. Unreliable manufacturing supply chain optimisation based on an infinitesimal perturbation analysis. Int. J. Syst. Sci. Oper. Logist. 2016, 25–44. [Google Scholar] [CrossRef]

- Soleimani, H.; Govindan, K.; Saghafi, H.; Jafari, H. Fuzzy multi-objective sustainable and green closed-loop supply chain network design. Comput. Ind. Eng. 2017, 109, 191–203. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; Zanoni, S. Carbon emissions and energy effect on a two-level manufacturer retailer closed loop supply chain model with remanufacturing subject to different coordination mechanisms. Int. J. Prod. Econ. 2017, 183, 394–408. [Google Scholar] [CrossRef]

- KPMG. KPMG’s Global Automotive Executive Survey. 2017. Available online: https://assets.kpmg.com/content/dam/kpmg/xx/pdf/2017/01/global-automotive-executive-survey-2017.pdf (accessed on 27 March 2018).

- Naceur, K.B.; Gagné, J.F. Global EV Outlook 2017; International Energy Agency (IEA): Paris, France, 2016. [Google Scholar]

- Meyer, L.; Bras, B. Rare earth metal recycling. In Proceedings of the IEEE International Symposium on Sustainable Systems and Technology, Chicago, IL, USA, 16–18 May 2011. [Google Scholar]

- Lee, J.C. Development of Technology for the Recycling of Urban Ore; KIGAM (GP2009-011-2009 (1)); Ministry of Knowledge and Economy: Sejong, Korea, 2009.

- Ayres, R.U.; Méndez, G.V.; Peiró, L.T. Recycling rare metals. In Handbook of Recycling; Elsevier: New York, NY, USA, 2014; pp. 27–38. [Google Scholar]

- Grandell, L.; Höök, M. Assessing rare metal availability challenges for solar energy technologies. Sustainability 2015, 7, 11818–11837. [Google Scholar] [CrossRef]

- Alonso, E.; Sherman, A.M.; Wallington, T.J.; Everson, M.P.; Field, F.R.; Roth, R.; Kirchain, R.E. Evaluating rare earth element availability: A case with revolutionary demand from clean technologies. Environ. Sci. Technol. 2012, 46, 3406–3414. [Google Scholar] [CrossRef] [PubMed]

- Sprecher, B.; Daigo, I.; Murakami, S.; Kleijn, R.; Vos, M.; Kramer, G.J. Framework for resilience in material supply chains, with a case study from the 2010 rare earth crisis. Environ. Sci. Technol. 2015, 49, 6740–6750. [Google Scholar] [CrossRef] [PubMed]

- Golev, A.; Scott, M.; Erskine, P.D.; Ali, S.H.; Ballantyne, G.R. Rare earths supply chains: Current status, constraints and opportunities. Resour. Policy 2014, 41, 52–59. [Google Scholar] [CrossRef]

- Dutta, T.; Kim, K.H.; Uchimiya, M.; Kwon, E.E.; Jeon, B.H.; Deep, A.; Yun, S.T. Global demand for rare earth resources and strategies for green mining. Environ. Res. 2016, 150, 182–190. [Google Scholar] [CrossRef] [PubMed]

- Rollat, A.; Guyonnet, D.; Planchon, M.; Tuduri, J. Prospective analysis of the flows of certain rare earths in Europe at the 2020 horizon. Waste Manag. 2016, 49, 427–436. [Google Scholar] [CrossRef] [PubMed]

- Rademaker, J.H.; Kleijn, R.; Yang, Y. Recycling as a strategy against rare earth element criticality: A systemic evaluation of the potential yield of NdFeB magnet recycling. Environ. Sci. Technol. 2013, 47, 10129–10136. [Google Scholar] [CrossRef] [PubMed]

- Spicer, A.J.; Johnson, M.R. Third-party demanufacturing as a solution for extended producer responsibility. J. Clean. Prod. 2004, 12, 37–45. [Google Scholar] [CrossRef]

- Subramanian, R.; Gupta, S.; Talbot, B. Product design and supply chain coordination under extended producer responsibility. Prod. Oper. Manag. 2009, 18, 259–277. [Google Scholar] [CrossRef]

- Koh, S.C.L.; Gunasekaran, A.; Tseng, C.S. Cross-tier ripple and indirect effects of directives WEEE and RoHS on greening a supply chain. Int. J. Prod. Econ. 2012, 140, 305–317. [Google Scholar] [CrossRef]

- Tsai, W.H.; Hung, S.J. Treatment and recycling system optimisation with activity-based costing in WEEE reverse logistics management: An environmental supply chain perspective. Int. J. Prod. Res. 2009, 47, 5391–5420. [Google Scholar] [CrossRef]

- Olugu, E.U.; Wong, K.Y. An expert fuzzy rule-based system for closed-loop supply chain performance assessment in the automotive industry. Expert Syst. Appl. 2012, 39, 375–384. [Google Scholar] [CrossRef]

- Özceylan, E.; Demirel, N.; Çetinkaya, C.; Demirel, E. A closed-loop supply chain network design for automotive industry in Turkey. Comput. Ind. Eng. 2017, 113, 727–745. [Google Scholar] [CrossRef]

- Chuang, C.H.; Wang, C.X.; Zhao, Y. Closed-loop supply chain models for a high-tech product under alternative reverse channel and collection cost structures. Int. J. Prod. Econ. 2014, 156, 108–123. [Google Scholar] [CrossRef]

- Heydari, J.; Govindan, K.; Jafari, A. Reverse and closed loop supply chain coordination by considering government role. Transp. Res. Part D Transp. Environ. 2017, 52, 379–398. [Google Scholar] [CrossRef]

- Amin, S.H.; Zhang, G.; Akhtar, P. Effects of uncertainty on a tire closed-loop supply chain network. Expert Syst. Appl. 2017, 73, 82–91. [Google Scholar] [CrossRef]

- Kim, S.; Jeong, B. Closed-loop supply chain planning model for a photovoltaic system manufacturer with internal and external recycling. Sustainability 2016, 8, 596. [Google Scholar] [CrossRef]

- Huang, Z.; Nie, J.; Tsai, S.B. Dynamic collection strategy and coordination of a remanufacturing closed-loop supply chain under uncertainty. Sustainability 2017, 9, 683. [Google Scholar] [CrossRef]

- Turki, S.; Didukh, S.; Sauvey, C.; Rezg, N. Optimization and analysis of a manufacturing remanufacturing-transport-warehousing system within a closed-loop supply chain. Sustainability 2017, 9, 561. [Google Scholar] [CrossRef]

- Sasikumar, P.; Haq, A.N. Integration of closed loop distribution supply chain network and 3PRLP selection for the case of battery recycling. Int. J. Prod. Res. 2011, 49, 3363–3385. [Google Scholar] [CrossRef]

- Kannan, G.; Sasikumar, P.; Devika, K. A genetic algorithm approach for solving a closed loop supply chain model: A case of battery recycling. Appl. Math. Model. 2010, 34, 655–670. [Google Scholar] [CrossRef]

- Finance, B.N.E. Electric Vehicle Outlook 2017; Bloomberg: New York, NY, USA, 2017. [Google Scholar]

- InvestmentMine. 2017. Available online: http://www.infomine.com/investment/ (accessed on 25 February 2018).

- The National Assembly of the Republic of Korea. Act on the Promotion of Saving and Recycling of Resources; Ministry of Environment: Sejong-si, Korea, 2013.

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).