Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Two-Speed Transmission and 800 V Technology of the Porsche Taycan

Abstract

1. Introduction

1.1. Contributions

- Aerodynamic impact on driving dynamics.The vehicle under study includes active aerodynamic components that affect the driving resistance in respective driving situations and are controlled by the vehicle and driver inputs.

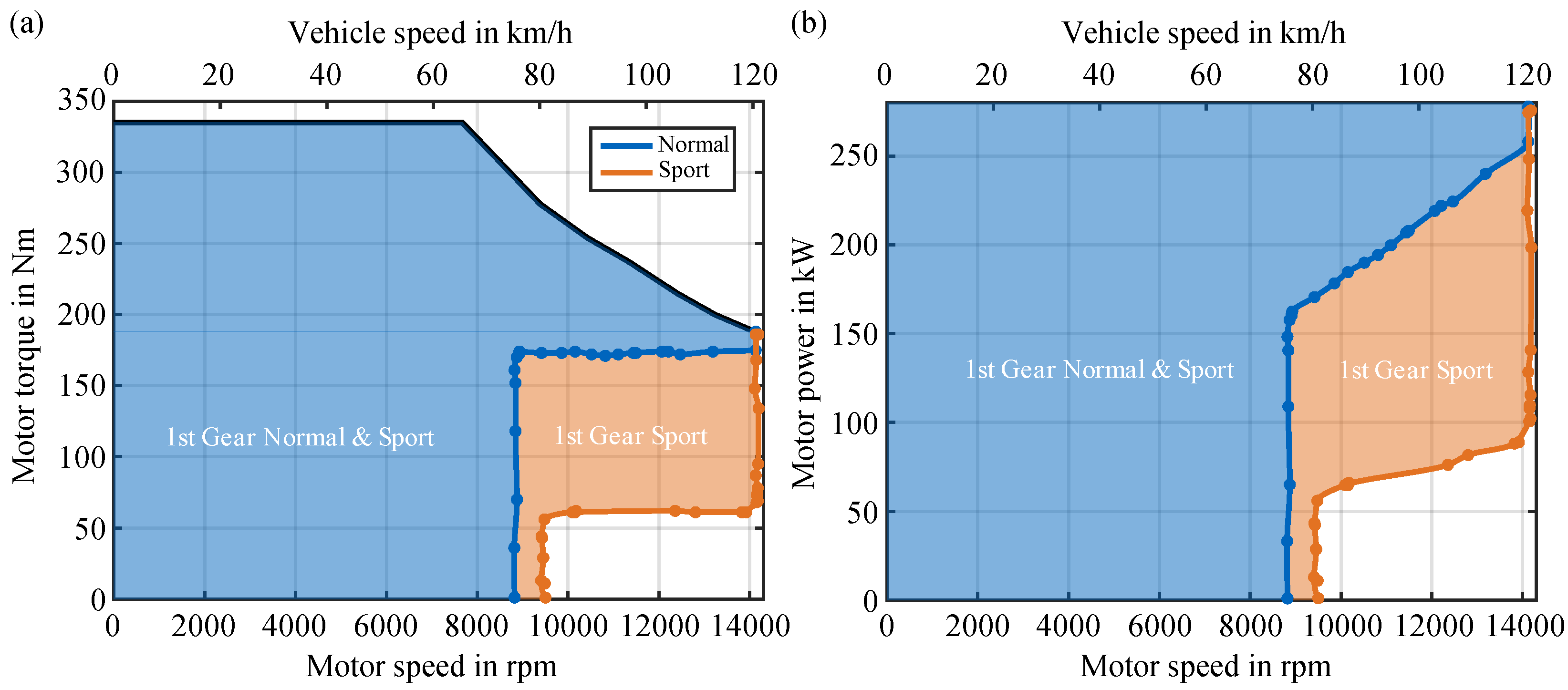

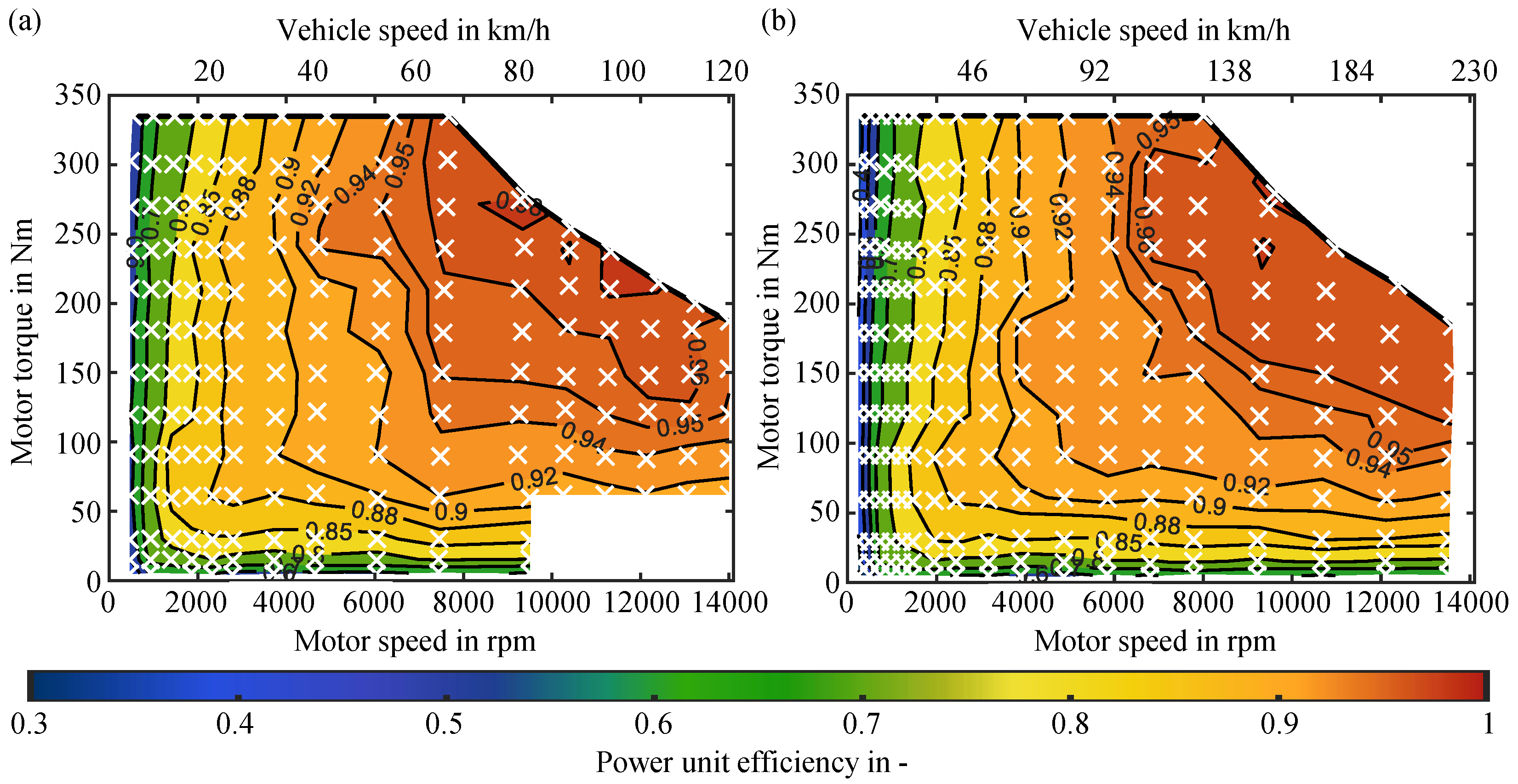

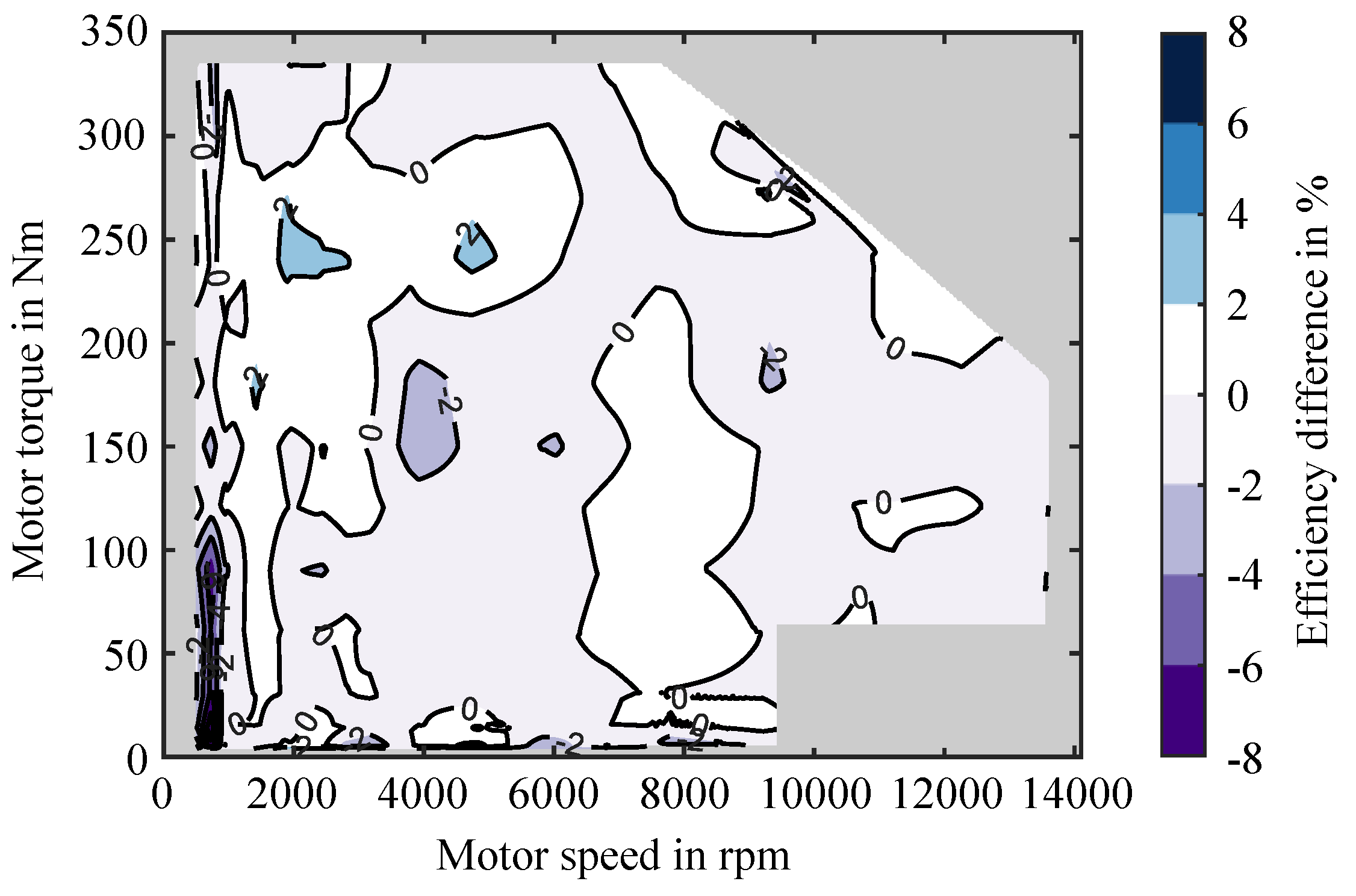

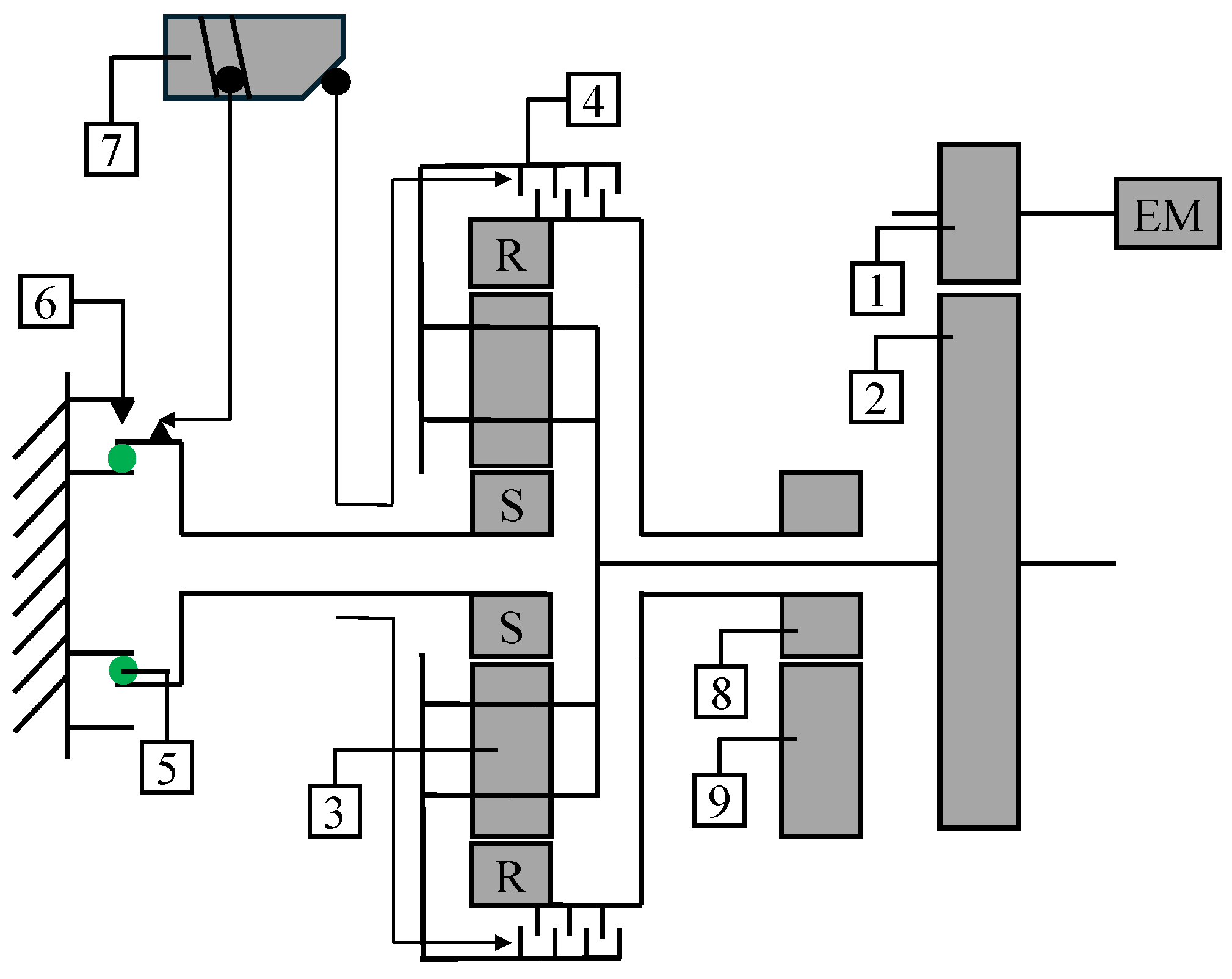

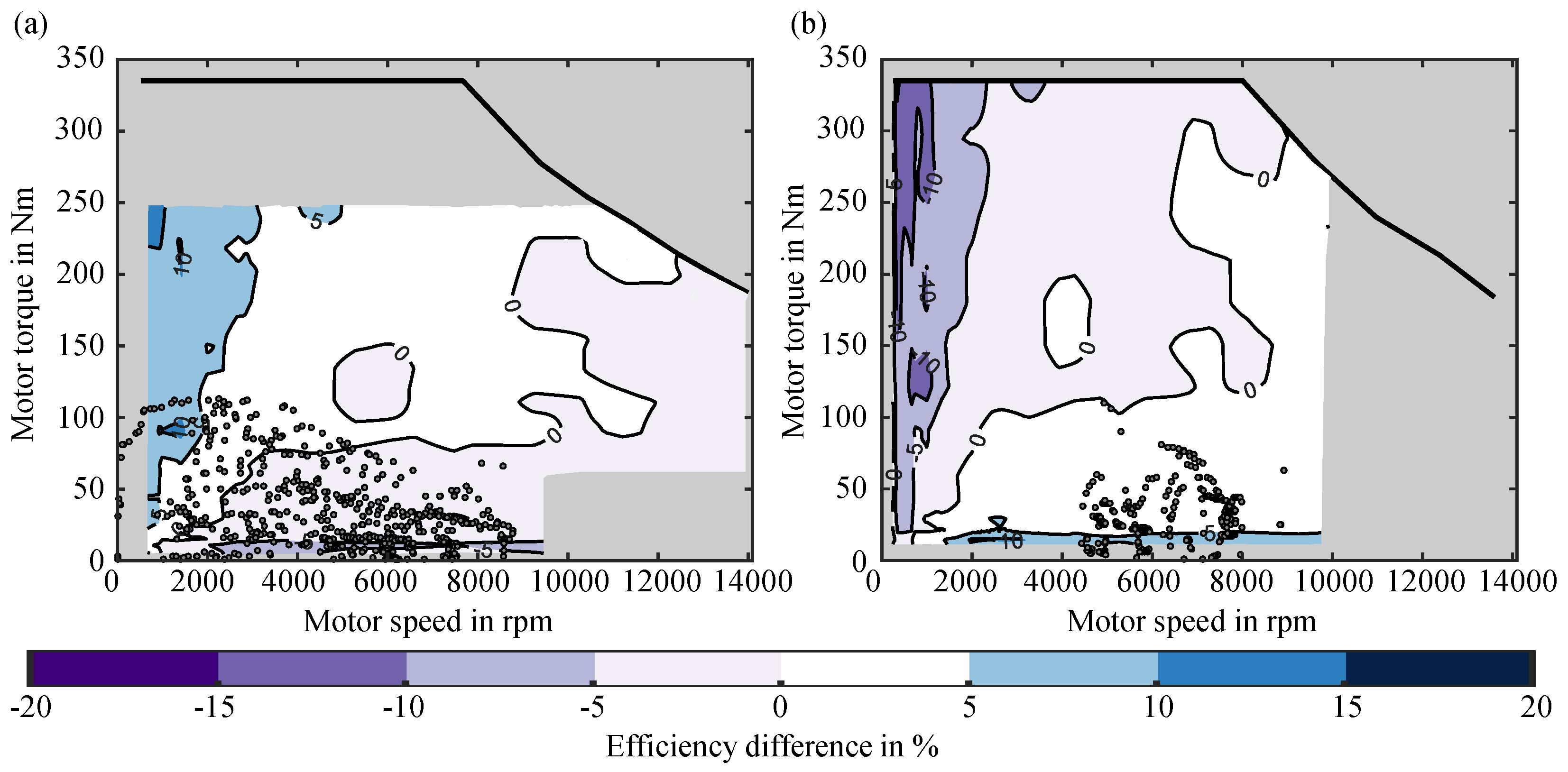

- Electric powertrain efficiency with two gears.The transmission’s two gears provide two different efficiency maps of the power unit, including the inverter, the electric machine, and the transmission. This requires a gear shift heuristic with a strategy that is affected by selectable driving modes.

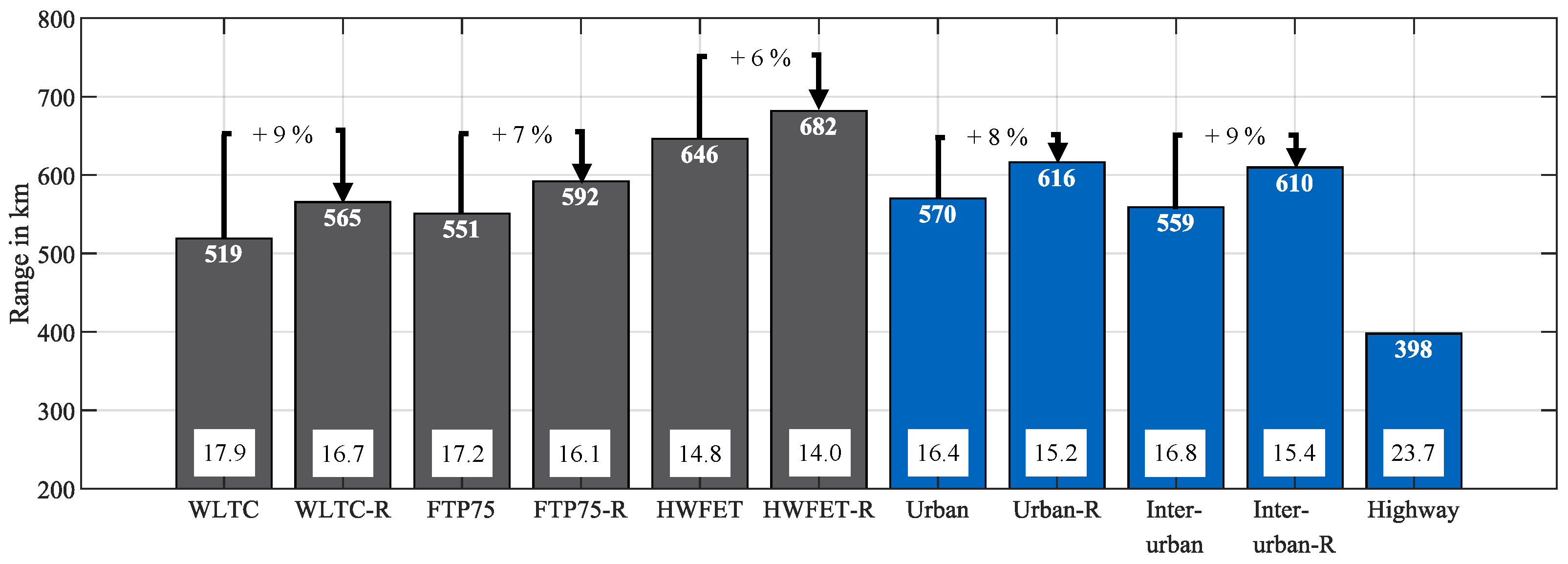

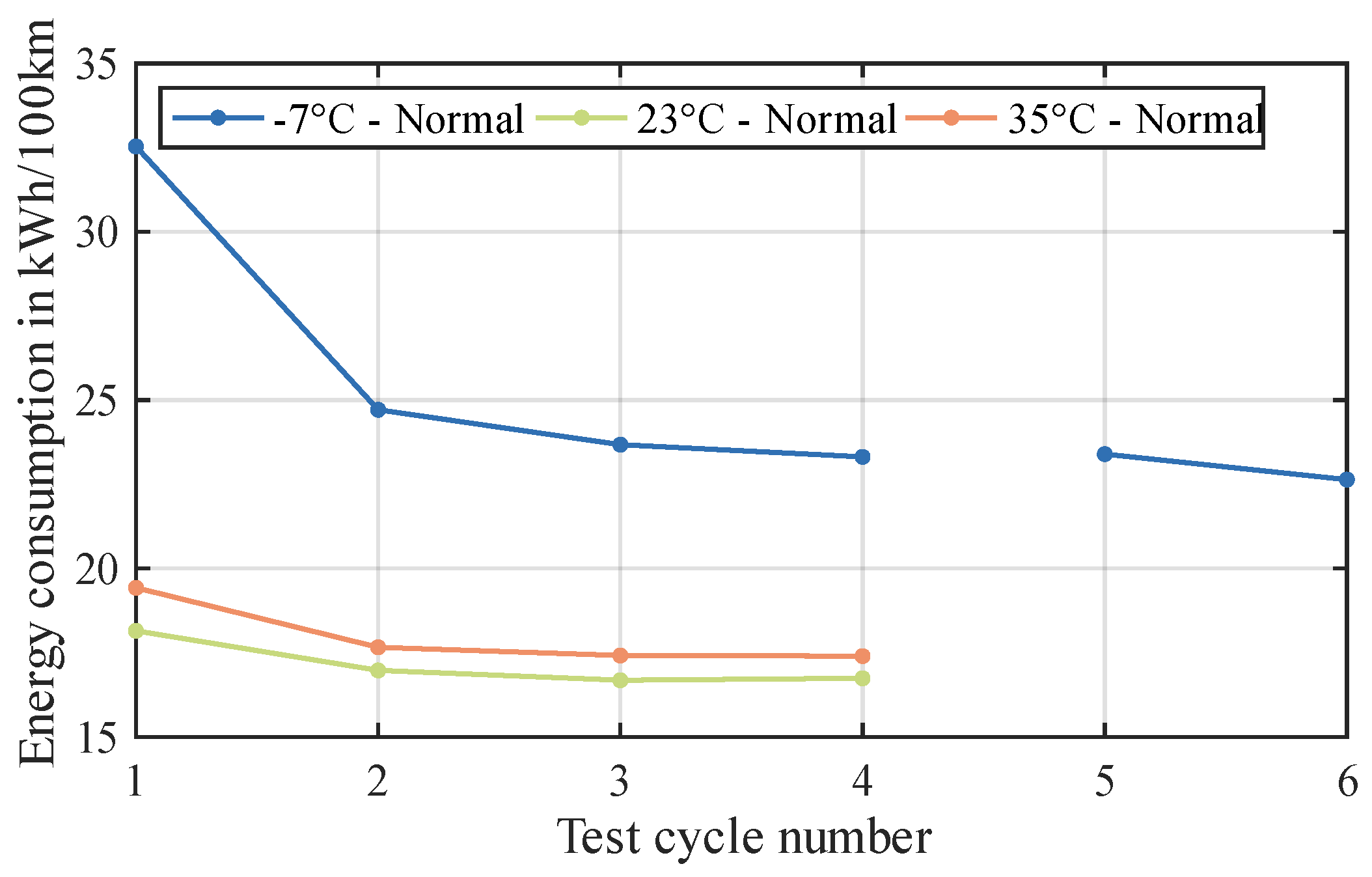

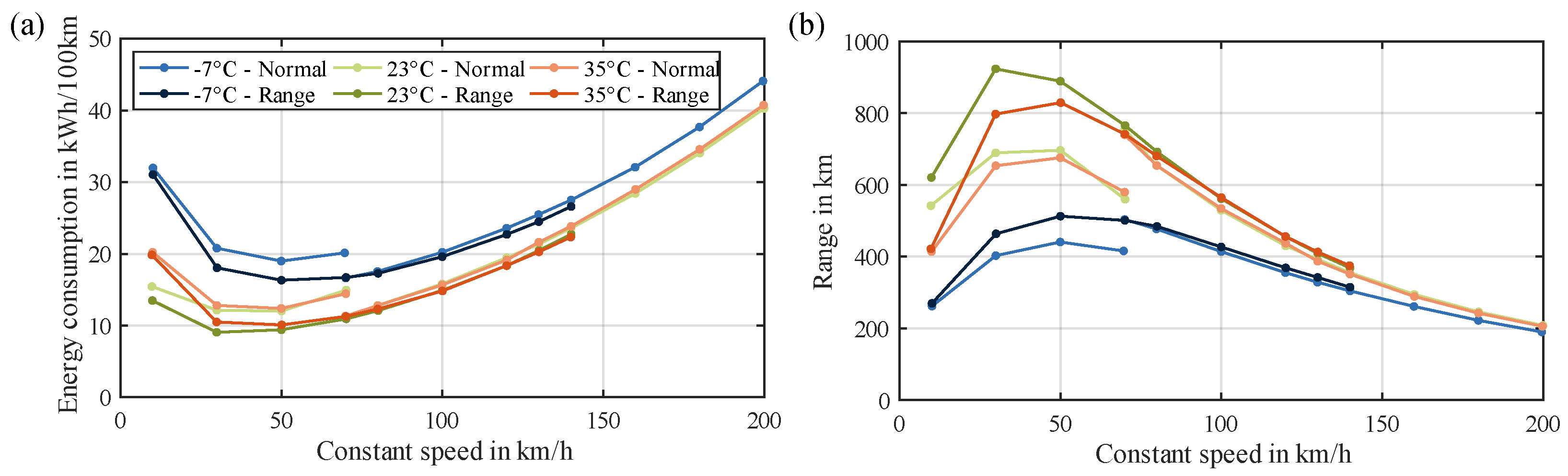

- Range across driving modes and ambient conditions.The electric range of the vehicle under study and its energy consumption are investigated in various conditions and different driving modes. Official test cycles and real-world driving scenarios are performed. To determine the influence of ambient temperature, the vehicle’s warm-up behavior and constant velocity characteristics are observed in a climate chamber.

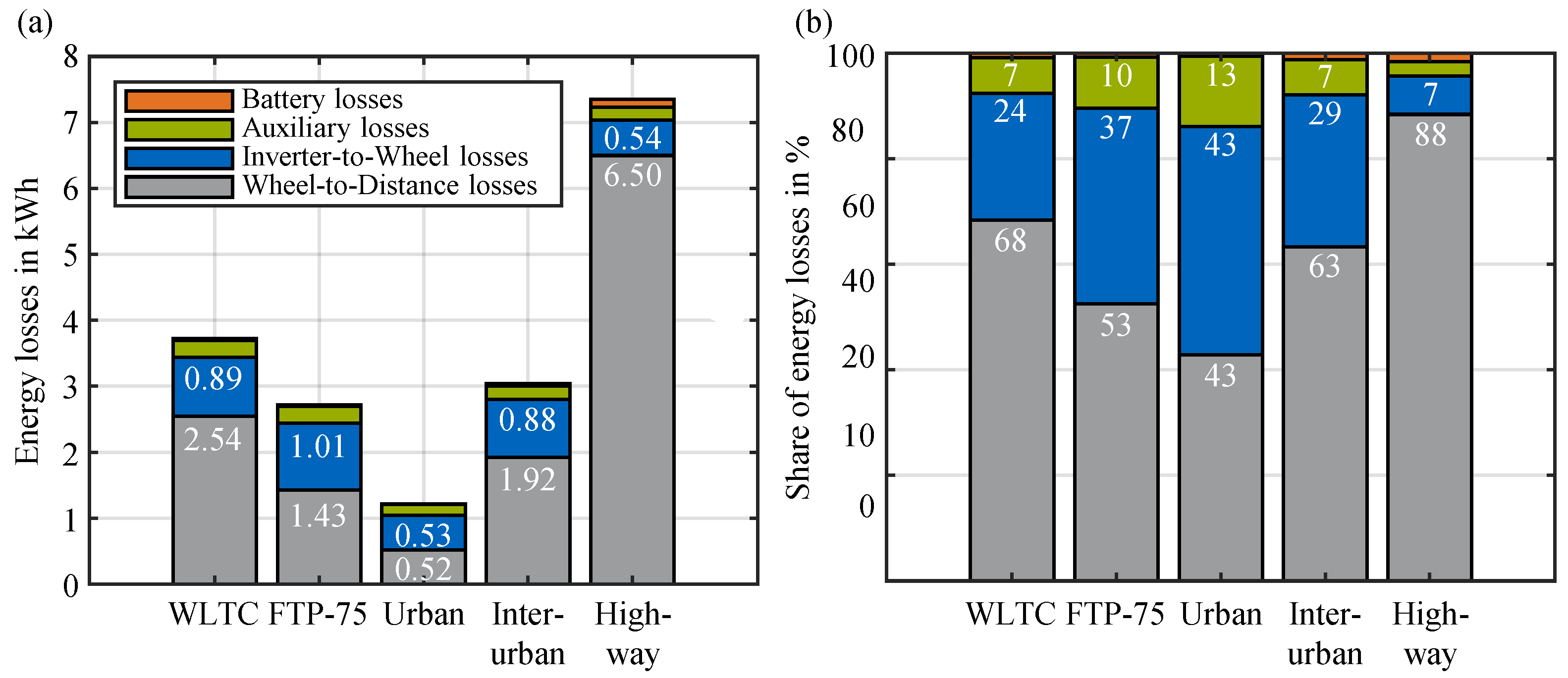

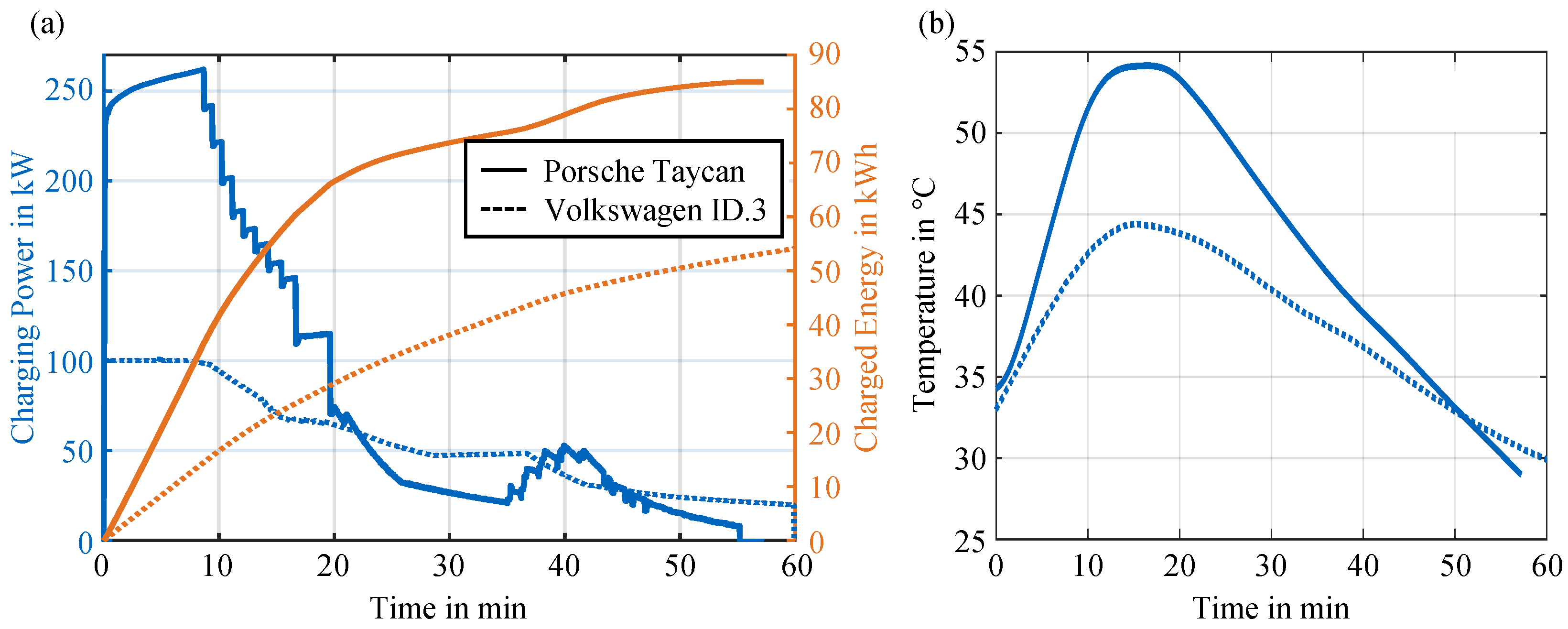

- Two-speed transmission and 800 V architecture.The technological advancements with the two-speed transmission and the 800 V battery system and their potential optimization in energy consumption are investigated. The two-speed transmission is compared to a single-speed transmission’s materials and components, followed by a powertrain efficiency analysis. The 800 V system’s impact on the charging and discharging processes is observed, and potential energy or time savings are discussed.

1.2. Layout

2. Vehicle Dynamics Investigation

2.1. Vehicle Under Study and Data Acquisition

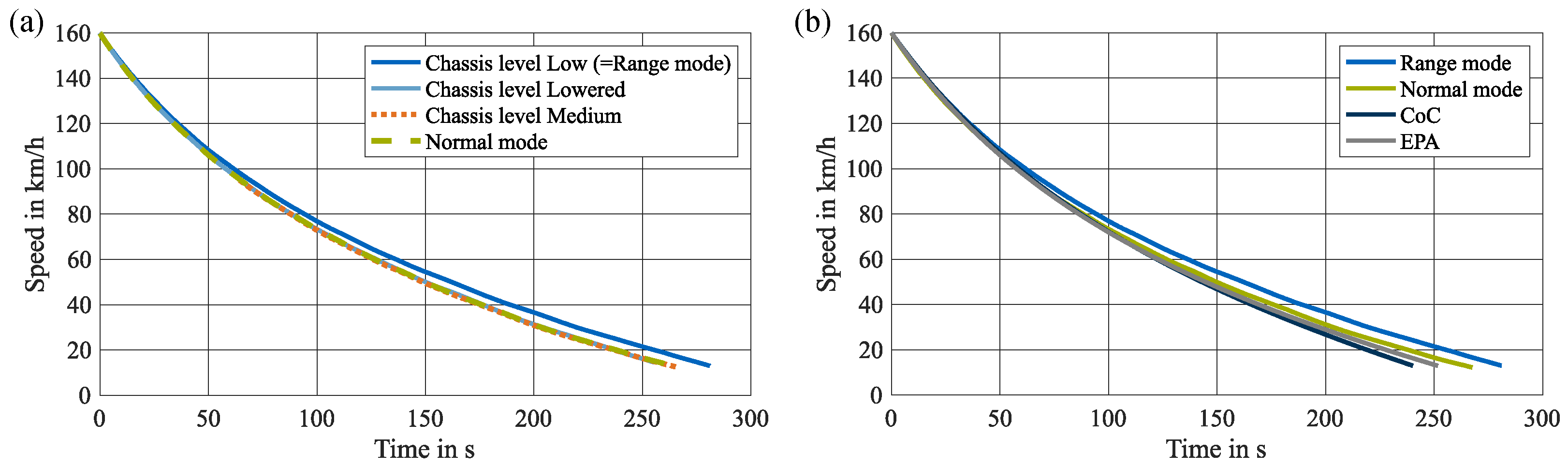

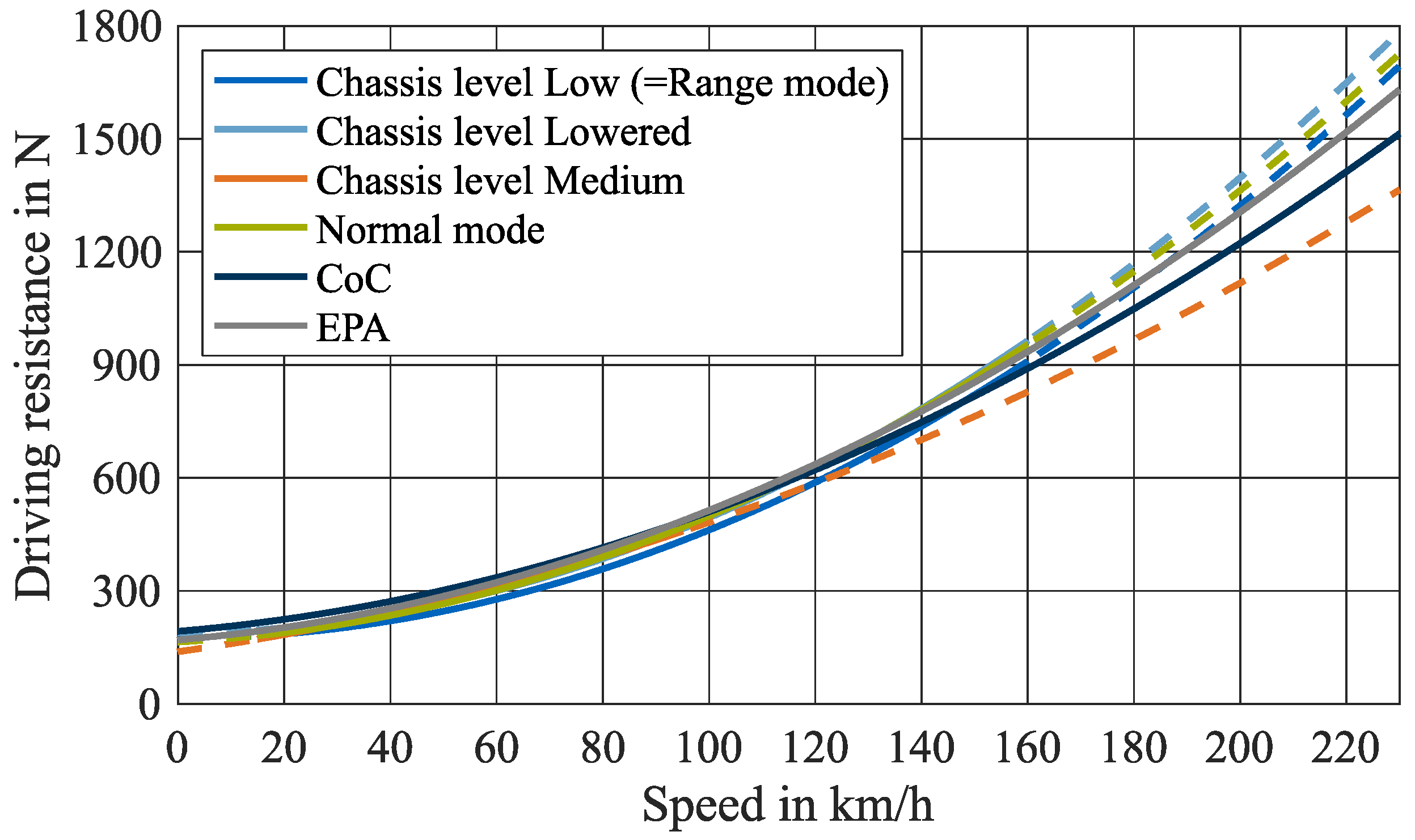

2.2. Vehicle Coast-Down Procedure and Driving Resistance Determination

2.3. Driving Dynamics Results

3. Electric Powertrain Analysis

3.1. Efficiency Analysis Procedure and Operation Strategy Investigation

3.2. Gear Shift Timing Heuristic

3.3. Power Unit Efficiency Results

4. Vehicle Concept Observation

4.1. Driving Resistance Simulation and Performance Validation

4.2. Real-World Range and Influencing Factors

4.3. Warm-Up Behavior and Constant Velocity Range at Different Temperature Levels

5. Technology Advancement Investigation

5.1. Two-Speed Transmission Investigation

5.1.1. Materials and Components Comparison

5.1.2. Influence on Power Unit Efficiency and Electric Range

5.2. 800 V Architecture Analysis

5.2.1. Efficiency Share Analysis

5.2.2. Fast Charging Optimization

6. Summary and Conclusions

- Aerodynamic impact on driving dynamics.The vehicle under study is equipped with active aerodynamic components that influence the vehicle dynamics and, thus, the driving resistances of the vehicle under study. With the chassis level as the main contributor to driving resistance changes, the chassis levels are essential in describing the current operating mode.

- Electric powertrain efficiency with two gears.Analyzing the vehicle’s electric powertrain characteristics, its gear shift strategy was identified with the APP, the vehicle speed, and the driving mode as the main influencing factors of the heuristic. This results in two respective efficiency maps of the power unit consisting of the inverter, electric machine, and the two-speed transmission. It is observed that the efficiencies vary by small margins based on the transmission characteristics.

- Range across driving modes and ambient conditions.The combination of driving resistances in the respective driving modes and the electric powertrain efficiency in two gears results in the vehicle concept behavior. The influence of these characteristics is shown through official and real-world test cycles. The Normal mode is compared to the Range mode, which achieves significantly greater electric ranges. The climate chamber tests prove that electric vehicles struggle in cold conditions and that vehicles work optimally in official test conditions.

- Two-speed transmission and 800 V architecture.The technological advancements of this vehicle prove optimization potentials, with the two-speed transmission neglectably increasing the vehicle’s overall mass and, therefore, not influencing the electric range. The 800 V system results show improved charging capabilities and lower internal battery losses during discharging. Considering higher cost and complexity, the advancements improve the vehicle’s overall efficiency characteristics.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A. Vehicle Specifications

| Domain | Attribute | Value | Unit |

|---|---|---|---|

| Vehicle | Range (WLTP) c | 484 | km |

| Max. speed c | 230 | km/h | |

| Mass c | 2205 | kg | |

| Actual mass c | 2282 | kg | |

| Test mass m | 2307 | kg | |

| Front tyres c | 245/45 R 20 103Y XL | - | |

| Rear tyres c | 245/45 R 20 103Y XL | - | |

| Wheel rim c | Taycan Turbo Aero wheel | - | |

| Tyre radius m | 346.8 | mm | |

| RLC- c | 192.4 | N | |

| RLC- c | 1.2 | N/(km/h) | |

| RLC- c | 0.01976 | N/(km/h)2 | |

| Air resis.- l | 0.22 | ||

| Frontal area-A l | 0.22 | ||

| Power unit | Max. power c | 280 | kW |

| 30 min power c | 120 | kW | |

| LC max. power l | 350 | kW | |

| Max. speed l | 14000 | 1/min | |

| LC max. torque c | 357 | Nm | |

| Drive type l | PSM | ||

| Inverter l | IGBT | ||

| Gear 1 ratio l | 15.56:1 | - | |

| Gear 2 ratio l | 8.16:1 | - | |

| Battery unit | Gross energy c | 93.4 | kWh |

| Net energy l | 83.7 | kWh | |

| Module number l | 33 | - | |

| Cell number l | 396 | - | |

| Cell l | LG Chem E66A | - | |

| Cell format l | Pouch | - | |

| Cell chemistry l | NMC721 | - | |

| Configuration l | 198s2p | - |

Appendix B. UDS IDs and Physical Interpretation

| Control Device Name | Control Device ID | Signal Name | Signal ID | Start-Bit | Bit-Length | Conversion | Unit |

|---|---|---|---|---|---|---|---|

| Power steering | 0x712 | Steering wheel angle | 0x1F0F | 40 | 24 | 1/2400+0 | ° |

| ABS control | 0x713 | Brake pedal activation | 0xFD11 | 24 | 8 | 1+0 | - |

| Accelerator pedal position | 0x2B2F | 24 | 8 | 10/25+0 | % | ||

| Gear selected | 0x2BB8 | 24 | 8 | 1+0 | - | ||

| Rear spoiler | 0x724 | Rear spoiler level | 0x0302 | 32 | 8 | 1+0 | - |

| Thermal management | 0x742 | HV heater current | 0x475F | 24 | 8 | 1/4+0 | A |

| Air intake level right | 0x5133 | 32 | 8 | 1/200+0 | - | ||

| Air intake level left | 0x5134 | 32 | 8 | 1/200+0 | - | ||

| Air conditioning | 0x746 | Outside temp | 0x2609 | 32 | 8 | 1/10+0 | °C |

| Interior temp | 0x2613 | 24 | 16 | 1/10+0 | °C | ||

| Rear motor | 0x7E0 | Gearbox speed output | 0x2C69 | 24 | 16 | 1+0 | rpm |

| Rear motor torque | 0x3E81 | 24 | 16 | 1/10+0 | Nm | ||

| Gearbox oil temp | 0x2C6E | 24 | 8 | 1–50 | °C | ||

| Gearbox speed input | 0x2C77 | 24 | 16 | 1+0 | rpm | ||

| HV battery | 0x7E5 | State of charge | 0x028C | 24 | 8 | 1+0 | % |

| HV pack voltage | 0x1801 | 24 | 16 | 1/10+0 | V | ||

| HV pack current | 0x1802 | 24 | 24 | 1/100–1500 | A | ||

| HV pack inlet temp | 0x181C | 24 | 8 | 1–50 | °C | ||

| HV pack outlet temp | 0x181D | 24 | 8 | 1–50 | °C | ||

| HV battery temp avg | 0x1E10 | 24 | 8 | 1–100 | °C | ||

| Rear inverter | 0x17FC007C | Rear stator temp | 0x3E94 | 24 | 16 | 1/64+0 | °C |

| Rear inverter temp | 0x3E95 | 24 | 16 | 1/64+0 | °C | ||

| Gear selected neutral | 0x3E9B | 24 | 8 | 1+0 | - | ||

| Chassis level | 0x17FC0080 | Chassis level | 0x2B94 | 24 | 8 | 1/32+0 | - |

| Body control | 0x17FC008B | Vehicle speed | 0x100E | 32 | 16 | 1/100+0 | km/h |

| DCDC converter | 0x17FC00B7 | HV dcdc power | 0x1303 | 24 | 8 | 100+0 | W |

| AC compressor power | 0x1304 | 24 | 8 | 100+0 | W | ||

| LV power | 0x1305 | 24 | 8 | 100+0 | W |

Appendix C. Test Duration Log

| Description | Time in h | Distance in km |

|---|---|---|

| Vehicle preparation | 100 | 516 |

| Reverse engineering and logger configuration | 40 | |

| Application and implementation pedal control | 60 | |

| Coast-down tests | 15 | 457 |

| Chassis level Medium and Lowered | 6 | |

| Chassis level Low | 9 | |

| Evaluation | 40 | |

| Gear shift timing | 27 | 248 |

| Upshift Normal mode | 12 | |

| Upshift Sport mode | 12 | |

| Downshift | 3 | |

| Evaluation | 15 | |

| Power unit efficiency | 35 | 625 |

| Efficiency map 1st gear | 18 | |

| Efficiency map 2nd gear | 17 | |

| Evaluation | 20 | |

| Official and real-driving driving cycles | 259 | 8,680 |

| Parameterization vehicle dynamometer | 20 | |

| Validation dynamometer setup | 6 | |

| Normal mode driving cycles | 111 | |

| Range mode driving cycles | 117 | |

| Individual driving cycle tests | 5 | |

| Evaluation | 120 | |

| Climate chamber tests | 14 | 874 |

| Warm-up profiles | 7 | |

| Constant velocity consumption | 7 | |

| Evaluation | 40 | |

| Charging measurements | 14 | - |

| AC Charging | 10 | |

| DC Charging | 4 | |

| Evaluation | 10 | |

| Total | 464 | 11,400 |

References

- European Union Council. Regulation (EU) 2021/1119 of the European Parliament and of the Council of 30 June 2021 Establishing the Framework for Achieving Climate Neutrality and Amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’). 2021. Available online: http://data.europa.eu/eli/reg/2021/1119/oj (accessed on 19 February 2025).

- European Union Council. Regulation (EU) 2019/631 of the European Parliament and of the Council of 17 April 2019 Setting CO2 Emission Performance Standards for New Passenger Cars and for New Light Commercial Vehicles, and Repealing REGULATIONS (EC) No 443/2009 and (EU) No 510/2011. 2019. Available online: https://eur-lex.europa.eu/eli/reg/2019/631/oj (accessed on 19 February 2025).

- Kampker, A. Elektromobilität: Grundlagen Einer Fortschrittstechnologie; Springer: Berlin/Heidelberg, Germany, 2024. [Google Scholar] [CrossRef]

- Fritz, A.; Verband der Automobilindustrie e.V. (VDA). E-Mobility Globally on the Rise. 2024. Available online: https://www.vda.de/en/topics/electromobility/market-developments-europe-international (accessed on 19 February 2025).

- Statista, Inc. Market Share of Electric Vehicles in Germany from 2014 to 2024. 2024. Available online: https://www.statista.com/statistics/1166826/electric-vehicles-market-share-germany/ (accessed on 19 February 2025).

- Nationale Plattform Zukunft der Mobilität. Customer Acceptance as the Key to the Market Ramp-Up of Electromobility. 2024. Available online: https://www.plattform-zukunft-mobilitaet.de/en/2download/customer-acceptance-as-the-key-to-the-market-ramp-up-of-electromobility-german-report/ (accessed on 20 February 2025).

- Rudschies, W.; Allgemeiner Deutscher Automobil-Club (ADAC) e.V. Fakten zur Elektromobilität: Das sind die Vor- und Nachteile. 2023. Available online: https://www.adac.de/rund-ums-fahrzeug/elektromobilitaet/elektroauto/elektroauto-pro-und-contra/ (accessed on 20 February 2025).

- Rosenberger, N.; Fundel, M.; Bogdan, S.; Köning, L.; Kragt, P.; Kühberger, M.; Lienkamp, M. Scientific benchmarking: Engineering quality evaluation of electric vehicle concepts. e-Prime-Adv. Electr. Eng. Electron. Energy 2024, 9, 100746. [Google Scholar] [CrossRef]

- Lienert, P. Reuters. Exclusive: Automakers to Double Spending on EVs, Batteries to $1.2 Trillion by 2030. 2022. Available online: https://www.reuters.com/technology/exclusive-automakers-double-spending-evs-batteries-12-trillion-by-2030-2022-10-21/ (accessed on 20 February 2025).

- Bank Vontobel Europe, AG. Der Markt für Elektrofahrzeuge Ist Hart Umkämpft. 2022. Available online: https://www.boerse.de/nachrichten/Der-Markt-fuer-Elektrofahrzeuge-ist-hart-umkaempft-Werbung/33467234 (accessed on 20 February 2025).

- Doppelbauer, M. Grundlagen der Elektromobilität: Technik, Praxis, Energie und Umwelt; Springer: Wiesbaden, Germany, 2020. [Google Scholar] [CrossRef]

- Rimac Automobili. Rimac Nevera. 2021. Available online: https://www.rimac-automobili.com/nevera/ (accessed on 20 February 2025).

- Jordan, M. MBpassion. Fahrwerk & Getriebe des G 580 mit EQ Technologie. 2024. Available online: https://mbpassion.de/2024/04/fahrwerk-getriebe-des-g-580-mit-eq-technologie/ (accessed on 20 February 2025).

- Porsche Newsroom. The Powertrain: Pure Performance. 2019. Available online: https://newsroom.porsche.com/en/products/taycan/powertrain-18555.html/ (accessed on 20 February 2025).

- Machado, F.A.; Kollmeyer, P.J.; Barroso, D.G.; Emadi, A. Multi-Speed Gearboxes for Battery Electric Vehicles: Current Status and Future Trends. IEEE Open J. Veh. Technol. 2021, 2, 419–435. [Google Scholar] [CrossRef]

- Störiko, A. HIGHEST–Innovations-und Gründungszentrum. Effizientere E-Autos dank Gangschaltung. 2024. Available online: https://highest-darmstadt.de/de/news/unkategorisiert/effizientere-e-autos-dank-gangschaltung/ (accessed on 20 February 2025).

- Laitinen, H.; Lajunen, A.; Tammi, K. Improving Electric Vehicle Energy Efficiency with Two-Speed Gearbox. In Proceedings of the 2017 IEEE Vehicle Power and Propulsion Conference (VPPC), Belfort, France, 11–14 October 2017; pp. 1–5. [Google Scholar] [CrossRef]

- Köllner, C. Etabliert sich die 800-V-Systemarchitektur im Massenmarkt? Springer, 2024. Available online: https://www.springerprofessional.de/elektrofahrzeuge/antriebsstrang/etabliert-sich-die-800-v-systemarchitektur-im-massenmarkt-/26653216/ (accessed on 20 February 2025).

- Greenhalgh, K. Transport Topics. Tesla Promises Semi Truck Production to Begin in Late 2025. 2024. Available online: https://www.ttnews.com/articles/tesla-semi-truck-2025/ (accessed on 20 February 2025).

- Blomgren, G.E. The Development and Future of Lithium Ion Batteries. J. Electrochem. Soc. 2017, 164, A5019–A5025. [Google Scholar] [CrossRef]

- Momen, F.; Rahman, K.; Son, Y. Electrical propulsion system design of Chevrolet Bolt battery electric vehicle. IEEE Trans. Ind. Appl. 2018, 55, 376–384. [Google Scholar] [CrossRef]

- Sarlioglu, B.; Morris, C.T.; Han, D.; Li, S. Benchmarking of electric and hybrid vehicle electric machines, power electronics, and batteries. In Proceedings of the 2015 Intl Aegean Conference on Electrical Machines & Power Electronics (ACEMP), 2015 Intl Conference on Optimization of Electrical & Electronic Equipment (OPTIM) & 2015 Intl Symposium on Advanced Electromechanical Motion Systems (ELECTROMOTION), Side, Turkey, 2–4 September 2015; pp. 519–526. [Google Scholar] [CrossRef]

- Kovachev, G.; Schröttner, H.; Gstrein, G.; Aiello, L.; Hanzu, I.; Wilkening, H.M.R.; Foitzik, A.; Wellm, M.; Sinz, W.; Ellersdorfer, C. Analytical Dissection of an Automotive Li-Ion Pouch Cell. Batteries 2019, 5, 67. [Google Scholar] [CrossRef]

- Löbberding, H.; Wessel, S.; Offermanns, C.; Kehrer, M.; Rother, J.; Heimes, H.; Kampker, A. From Cell to Battery System in BEVs: Analysis of System Packing Efficiency and Cell Types. World Electr. Veh. J. 2020, 11, 77. [Google Scholar] [CrossRef]

- Oh, G.; Leblanc, D.J.; Peng, H. Vehicle Energy Dataset (VED), A Large-Scale Dataset for Vehicle Energy Consumption Research. IEEE Trans. Intell. Transp. Syst. 2020, 23, 3302–3312. [Google Scholar] [CrossRef]

- Diez, J. Advanced Vehicle Testing and Evaluation, Final Technical Report Encompassing Project Activities from 1 October 2011 to 30 April 2018; Technical Report; Intertek Testing Services, NA, Inc.: Arlington Heights, IL, USA, 2018. [Google Scholar] [CrossRef]

- Wassiliadis, N.; Steinsträter, M.; Schreiber, M.; Rosner, P.; Nicoletti, L.; Schmid, F.; Ank, M.; Teichert, O.; Wildfeuer, L.; Schneider, J.; et al. Quantifying the state of the art of electric powertrains in battery electric vehicles: Range, efficiency, and lifetime from component to system level of the Volkswagen ID.3. eTransportation 2022, 12, 100167. [Google Scholar] [CrossRef]

- Rosenberger, N.; Rosner, P.; Bilfinger, P.; Schöberl, J.; Teichert, O.; Schneider, J.; Abo Gamra, K.; Allgäuer, C.; Dietermann, B.; Schreiber, M.; et al. Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Tesla Model 3 on the Vehicle Level. World Electr. Veh. J. 2024, 15, 268. [Google Scholar] [CrossRef]

- EV Database. Porsche Taycan. 2021. Available online: https://ev-database.org/car/1393/Porsche-Taycan (accessed on 11 February 2025).

- EV Database. Porsche Taycan 4S. 2020. Available online: https://ev-database.org/car/1237/Porsche-Taycan-4S (accessed on 11 February 2025).

- EV Database. Porsche Taycan GTS. 2022. Available online: https://ev-database.org/car/1560/Porsche-Taycan-GTS (accessed on 11 February 2025).

- EV Database. Porsche Taycan Turbo. 2020. Available online: https://ev-database.org/car/1229/Porsche-Taycan-Turbo (accessed on 11 February 2025).

- EV Database. Porsche Taycan Plus. 2021. Available online: https://ev-database.org/car/1394/Porsche-Taycan-Plus (accessed on 11 February 2025).

- EV Database. Porsche Taycan Sport Turismo. 2022. Available online: https://ev-database.org/car/1621/Porsche-Taycan-Sport-Turismo (accessed on 11 February 2025).

- EV Database. Porsche Taycan 4 Cross Turismo. 2021. Available online: https://ev-database.org/car/1186/Porsche-Taycan-4-Cross-Turismo (accessed on 11 February 2025).

- EV Database. Porsche Taycan Turbo GT. 2024. Available online: https://ev-database.org/car/2144/Porsche-Taycan-Turbo-GT (accessed on 11 February 2025).

- Porsche Newsroom. Technical Data: Taycan with Performance Battery/Taycan with Performance Battery Plus. 2022. Available online: https://press.cee.porsche.com/prod/presse_pag/PressResources.nsf/Content?ReadForm&languageversionid=1364534&hl=modelle-missione-concept (accessed on 11 February 2025).

- European Parliament. Regulation (EU) 2018/858 of the European Parliament and of the Council of 30 May 2018 on the Approval and Market Surveillance of Motor Vehicles and Their Trailers, and of Systems, Components and Separate Technical Units Intended for Such Vehicles, Amending Regulations (EC) No 715/2007 and (EC) No 595/2009 and Repealing Directive 2007/46/EC. 2018. Available online: https://eur-lex.europa.eu/eli/reg/2018/858/oj (accessed on 15 January 2025).

- Porsche Newsroom. Aerodynamics: The Best Value of All Current Porsche Models. 2022. Available online: https://newsroom.porsche.com/en_US/products/taycan/aerodynamics-18554.html (accessed on 11 February 2025).

- Porsche Newsroom. Greater Driving Precision, Driving Dynamics and Driving Comfort. 2022. Available online: https://newsroom.porsche.com/en/press-kits/taycan/Das-Fahrwerk.html (accessed on 11 February 2025).

- The European Comission. Commission Regulation (EU) 2017/1151 of 1 June 2017 Supplementing Regulation (EC) No 715/2007 of the European Parliament and of the Council on Type-Approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information, Amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No 1230/2012 and Repealing Commission Regulation (EC) No 692/2008. 2017. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02017R1151-20230901 (accessed on 7 December 2024).

- United Nations. Global Technical Regulation on Worldwide Harmonized Light Vehicles Test Procedure. Addendum 15: Global Technical Regulation No. 15 (ECE/TRAN/180/Add.15). 2014. Available online: https://unece.org/fileadmin/DAM/trans/main/wp29/wp29r-1998agr-rules/ECE-TRANS-180a15e.pdf (accessed on 4 January 2025).

- Merkle, L.; Pöthig, M.; Schmid, F. Estimate e-Golf Battery State Using Diagnostic Data and a Digital Twin. Batteries 2021, 7, 15. [Google Scholar] [CrossRef]

- Rosenberger, N.; Lienkamp, M. Vehicle Parameter and Electric Powertrain Efficiency Analysis Using Real-Driving Data. Int. J. Electr. Electron. Eng. Telecommun. 2024, 13, 494–502. [Google Scholar] [CrossRef]

- The European Comission. Comission Regulation (EU) 2018/1832. 2018. Available online: https://climate.ec.europa.eu/eu-action/transport-emissions/road-transport-reducing-co2-emissions-vehicles/co2-emission-performance-standards-cars-and-vans_en (accessed on 7 May 2023).

- Sarkan, B.; Skrucany, T.; Semanova, S.; Madlenak, R.; Kuranc, A.; Sejkorova, M.; Caban, J. Vehicle coast-down method as a tool for calculating total resistance for the purposes of type-approval fuel consumption. Sci. J. Silesian Univ. Technol. 2018, 98, 11. [Google Scholar] [CrossRef]

- Box, G.E.P.; Jenkins, G.M. Time Series Analysis: Forecasting and Control; Holden-Day: San Francisco, CA, USA, 1970. [Google Scholar]

- Alami, A.; Belmajdoub, F. Noise Reduction Techniques in Adas Sensor Data Management: Methods and Comparative Analysis. Int. J. Adv. Comput. Sci. Appl. 2024, 15, 679. [Google Scholar] [CrossRef]

- Rohde-Brandenburger, K. Verbrauch in Fahrzyklen und im Realverkehr. In Energiemanagement im Kraftfahrzeug: Optimierung von CO2-Emissionen und Verbrauch konventioneller und Elektrifizierter Automobile; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2014; pp. 243–306. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Data on Cars Used for Testing Fuel Economy-2021 Test Car List Data. 2022. Available online: https://www.epa.gov/compliance-and-fuel-economy-data/data-cars-used-testing-fuel-economy (accessed on 4 January 2025).

- Qi, H.; Chen, Y.; Zhang, N.; Zhang, B.; Wang, D.; Tan, B. Improvement of both handling stability and ride comfort of a vehicle via coupled hydraulically interconnected suspension and electronic controlled air spring. Proc. Inst. Mech. Eng. Part J. Automob. Eng. 2020, 234, 552–571. [Google Scholar] [CrossRef]

- Busch, R.; Beck, M. Elektrotechnik und Elektronik: Für Maschinenbauer und Verfahrenstechniker; Springer: Wiesbaden, Germany, 2024. [Google Scholar] [CrossRef]

- Tschöke, H.; Gutzmer, P.; Pfund, T. Elektrifizierung des Antriebsstrangs: Grundlagen-vom Mikro-Hybrid zum Vollelektrischen Antrieb; Springer: Wiesbaden, Germany, 2019. [Google Scholar] [CrossRef]

- Koch, A. Energieeffizientes Fahren und Optimale, Elektrische Antriebsstränge für Automatisierte Fahrzeuge. Ph.D. Thesis, Technical University of Munich, Munich, Germany, 2022. [Google Scholar]

- Binder, A. Elektrische Maschinen und Antriebe: Grundlagen, Betriebsverhalten; Springer: Wiesbaden, Germany, 2018. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. Fuel Economy and EV Range Testing. 2024. Available online: https://www.epa.gov/greenvehicles/fuel-economy-and-ev-range-testing (accessed on 4 January 2025).

- Liu, Y.; Wu, Z.X.; Zhou, H.; Zheng, H.; Yu, N.; An, X.P.; Li, J.Y.; Li, M.L. Development of China Light-Duty Vehicle Test Cycle. Int. J. Automot. Technol. 2020, 21, 1233–1246. [Google Scholar] [CrossRef]

- United States Environmental Protection Agency. EPA SC03 Supplemental Federal Test Procedure (SFTP) with Air Conditioning. 2024. Available online: https://www.epa.gov/emission-standards-reference-guide/epa-sc03-supplemental-federal-test-procedure-sftp-air (accessed on 4 January 2025).

- Allgemeiner Deutscher Automobil-Club (ADAC) e.V. Porsche Taycan 4S Performancebatterie Plus (01/20–02/24). 2020. Available online: https://www.adac.de/rund-ums-fahrzeug/autokatalog/marken-modelle/porsche/taycan/y1a/305473/#eco-test (accessed on 23 January 2025).

- Küçükay, F. Grundlagen der Fahrzeugtechnik: Antriebe, Getriebe, Energieverbrauch, Bremsen, Fahrdynamik, Fahrkomfort; Springer: Wiesbaden, Germany, 2020. [Google Scholar] [CrossRef]

- Lightshape GmbH & Co. KG. Porsche Mission E: 3D Animation/Product Vizualization/Realfilm. 2022. Available online: https://www.lightshape.net/en/projects/porsche-mission-e-drive-movie (accessed on 23 January 2025).

- Aghabali, I.; Bauman, J.; Kollmeyer, P.J.; Wang, Y.; Bilgin, B.; Emadi, A. 800-V Electric Vehicle Powertrains: Review and Analysis of Benefits, Challenges, and Future Trends. IEEE Trans. Transp. Electrif. 2021, 7, 927–948. [Google Scholar] [CrossRef]

- Snyder, J. autoblog. Here Are All the EVs with 800 V Charging Available in 2024. 2024. Available online: https://www.autoblog.com/news/800-volt-electric-vehicles-list (accessed on 23 January 2025).

- Specht, K.; Gall, M.; Scheidhammer, G. Von 400 auf 800 V–Auswirkungen auf das Hochvoltbordnetz. ATZ Elektron 2019, 14, 42–45. [Google Scholar] [CrossRef]

- Batemo. Batemo Cell Explorer–LG Chem E66A. 2022. Available online: https://www.batemo.com/products/batemo-cell-explorer/lg-chem-e66a/#get-model-popup (accessed on 24 February 2025).

| Medium | Lowered | Low |

|---|---|---|

| 100–80 km/h | 165–150 km/h | 165–145 km/h |

| 85–70 km/h | 155–135 km/h | 150–135 km/h |

| 75–60 km/h | 140–120 km/h | 140–125 km/h |

| 65–45 km/h | 120–105 km/h | 130–115 km/h |

| 50–30 km/h | 110–95 km/h | 120–105 km/h |

| 35–0 km/h | 100–85 km/h | 110–95 km/h |

| 85–65 km/h | 100–75 km/h | |

| 70–50 km/h | 90–75 km/h | |

| 55–30 km/h | 80–55 km/h | |

| 35–0 km/h | 60–45 km/h |

| Parameter (Unit) | (N) | (N/(km/h)) | (N/(km/h)2) |

|---|---|---|---|

| Low = Range | 173.9 | 0.005 | 0.02871 |

| Lowered | 188.7 | 0.064 | 0.02989 |

| Medium | 138.4 | 1.981 | 0.01456 |

| Normal | 164.3 | 0.698 | 0.02649 |

| CoC | 192.4 | 1.200 | 0.01976 |

| EPA | 169.7 | 1.200 | 0.02240 |

| Two-Speed Transmission | Single-Speed Transmission | ||

|---|---|---|---|

| Component Name | Mass in kg | Component Name | Mass in kg |

| Housing (3-piece) | 26.05 | Housing (2-piece) | 9.90 |

| Differential | 16.50 | Differential | 9.95 |

| Input shaft | 0.90 | Input shaft | 1.49 |

| Inner shaft | 3.80 | Intermediate shaft | 2.12 |

| Outer shaft | 1.70 | Output shaft | 1.05 |

| Ring gear | 2.50 | ||

| Planet carrier | 3.70 | ||

| Sun gear | 0.90 | ||

| Planet gears | 1.05 | ||

| Multi-plate clutch | 2.70 | ||

| Dog clutch | 2.20 | ||

| Total mass | 62.00 | Total mass | 24.51 |

| Test Cycle | Energy Consumption in kWh | Energy Consumption in kWh | ||||

|---|---|---|---|---|---|---|

| 1st Gear | Compromise Gear | Difference in % | 2nd Gear | Compromise Gear | Difference in % | |

| WLTC | 2.632 | 2.595 | −1.42 | 1.948 | 1.999 | +2.54 |

| FTP-75 | 2.966 | 2.932 | −1.17 | 0.6141 | 0.6353 | +3.35 |

| HWFET | 0.4871 | 0.4809 | −1.29 | 1.875 | 1.957 | +4.2 |

| Urban | 1.490 | 1.480 | −0.64 | 0 | 0 | - |

| Interurban | 2.357 | 2.3401 | −0.72 | 1.561 | 1.623 | +3.83 |

| Highway | 1.035 | 1.025 | −0.97 | 7.309 | 7.446 | +1.84 |

| Test Cycle | |||||

|---|---|---|---|---|---|

| WLTC-P | 0.03 (0.83) | 0.25 (6.89) | 0.89 (24.03) | 2.54 (68.35) | 3.72 |

| WLTC-VW | 0.06 (1.99) | 0.14 (4.41) | 0.67 (21.01) | 2.33 (72.59) | 3.20 |

| FTP-75-P | 0.02 (0.77) | 0.26 (9.61) | 1.01 (37.11) | 1.43 (52.51) | 2.72 |

| FTP-75-VW | 0.03 (1.64) | 0.15 (7.61) | 0.51 (25.91) | 1.29 (64.84) | 1.99 |

| Urban-P | 0.01 (0.56) | 0.16 (13.29) | 0.53 (43.33) | 0.52 (42.82) | 1.21 |

| Urban-VW | 0.01 (1.23) | 0.08 (10.57) | 0.25 (31.49) | 0.46 (56.71) | 0.80 |

| Interurban-P | 0.04 (1.20) | 0.20 (6.66) | 0.88 (28.85) | 1.92 (63.29) | 3.04 |

| Interurban-VW | 0.07 (2.73) | 0.11 (4.50) | 0.45 (18.55) | 1.78 (74.22) | 2.40 |

| Highway-P | 0.12 (1.61) | 0.20 (2.69) | 0.64 (7.29) | 5.40 (88.41) | 7.35 |

| Highway-VW | 0.29 (3.96) | 0.21 (2.86) | 0.86 (11.18) | 6.02 (82.01) | 7.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Published by MDPI on behalf of the World Electric Vehicle Association. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosenberger, N.; Wagner, N.; Fredl, A.; Riederle, L.; Lienkamp, M. Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Two-Speed Transmission and 800 V Technology of the Porsche Taycan. World Electr. Veh. J. 2025, 16, 296. https://doi.org/10.3390/wevj16060296

Rosenberger N, Wagner N, Fredl A, Riederle L, Lienkamp M. Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Two-Speed Transmission and 800 V Technology of the Porsche Taycan. World Electric Vehicle Journal. 2025; 16(6):296. https://doi.org/10.3390/wevj16060296

Chicago/Turabian StyleRosenberger, Nico, Nicolas Wagner, Alexander Fredl, Linus Riederle, and Markus Lienkamp. 2025. "Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Two-Speed Transmission and 800 V Technology of the Porsche Taycan" World Electric Vehicle Journal 16, no. 6: 296. https://doi.org/10.3390/wevj16060296

APA StyleRosenberger, N., Wagner, N., Fredl, A., Riederle, L., & Lienkamp, M. (2025). Quantifying the State of the Art of Electric Powertrains in Battery Electric Vehicles: Comprehensive Analysis of the Two-Speed Transmission and 800 V Technology of the Porsche Taycan. World Electric Vehicle Journal, 16(6), 296. https://doi.org/10.3390/wevj16060296