Powertrain in Battery Electric Vehicles (BEVs): Comprehensive Review of Current Technologies and Future Trends Among Automakers

Abstract

1. Introduction

1.1. Review Methodology

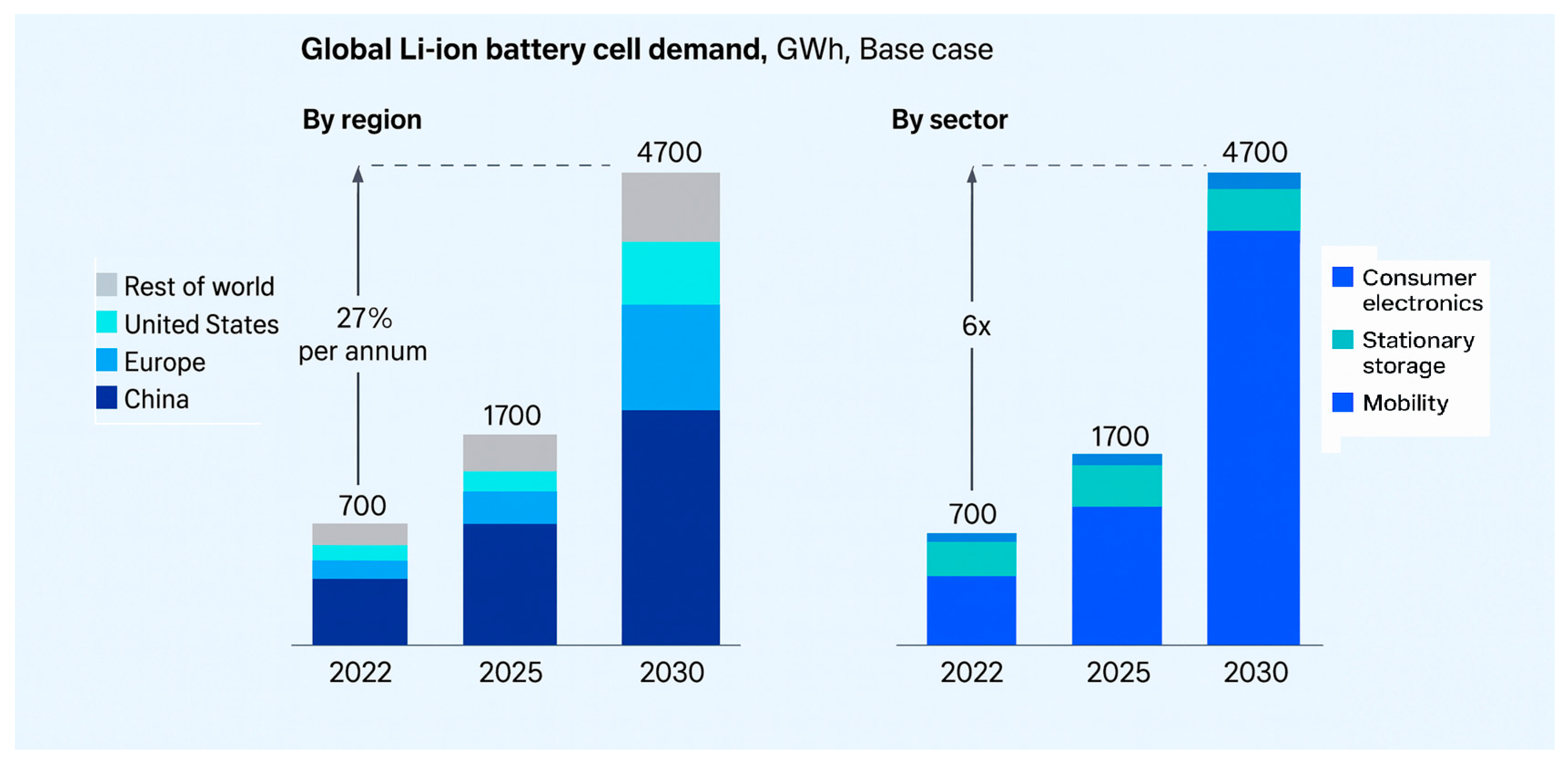

1.2. The Rise of Battery Electric Vehicles (BEVs)

1.3. Core Subsystems of BEV Powertrains

2. Battery Energy Storage Systems

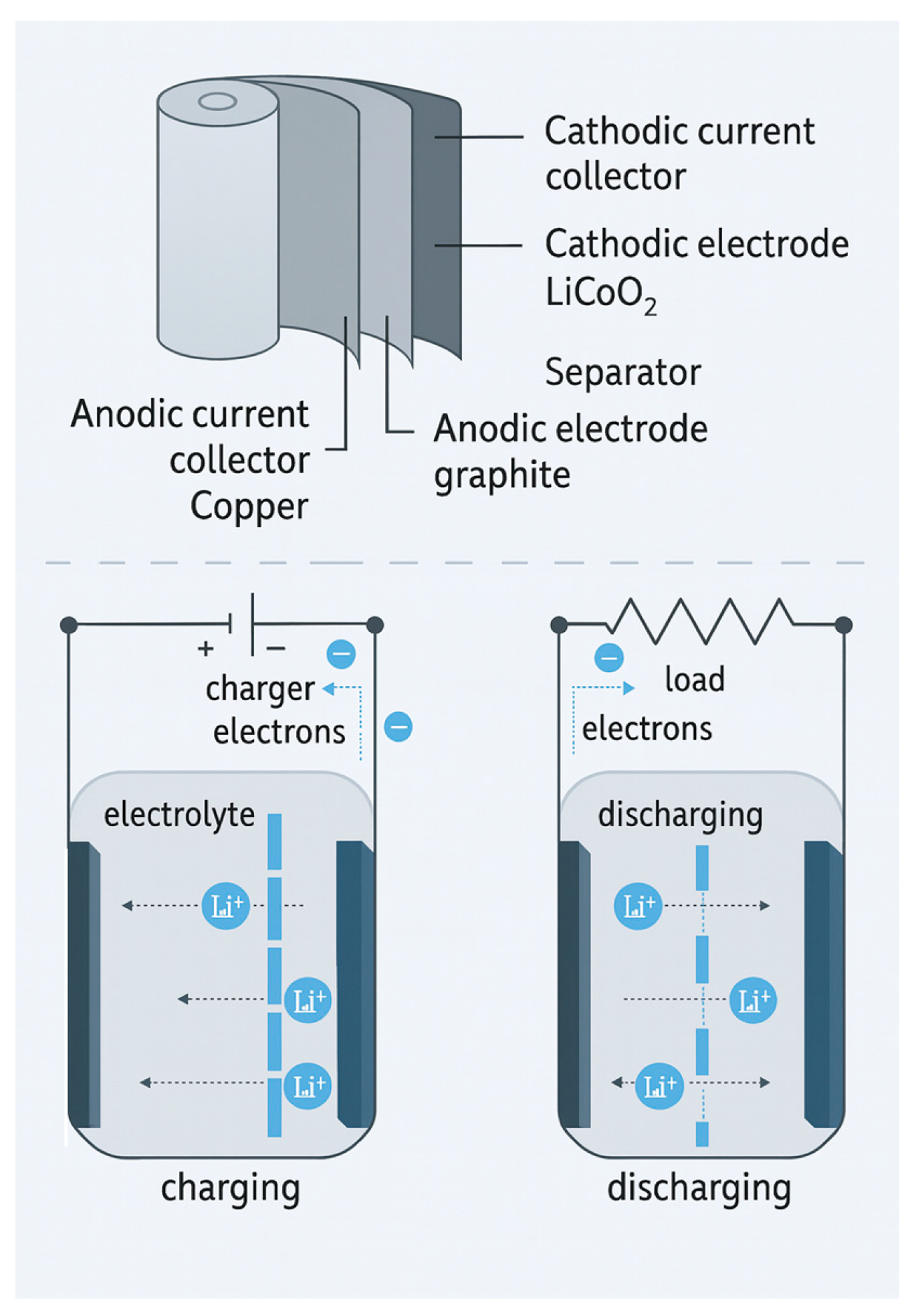

- Charging Process

- When the battery is connected to a charger, an external electric field forces lithium ions (Li+) to move from the cathode, see Equation (1). through the electrolyte and separator toward the anode (graphite). At the same time, electrons flow through the external circuit to the anode, balancing the charge. Lithium ions intercalate (embed) into the graphite layers of the anode, see Equation (2). Energy is stored in the battery in this process.

- Discharging Process

- When the battery powers a load, the lithium ions move from the anode back to the cathode via the electrolyte. Simultaneously, electrons flow through the external circuit, supplying power to the connected device. Lithium ions are deintercalated from graphite and return to the LiCoO2 structure, see Equation (1). This process releases the stored energy.

- Practical BEV chemistries and electrode utilization.

- In contemporary BEVs, cathodes are not LiCoO2 (LCO) but are dominated by layered Ni-Mn-Co oxides (NMC/NCA) and lithium iron phosphate (LFP), with shares varying by region and segment [38]. For layered oxides, pushing toward near-complete delithiation destabilizes the lattice (oxygen loss, surface reconstruction), so upper cut-off voltages and usable SoC windows are limited to preserve structure and cycle life [39,40,41]. On the anode side, BEV cells use graphite or graphite–SiOx blends operated within conservative SoC windows; complete delithiation is avoided because high/low-SoC extremes accelerate SEI growth and increase the risk of lithium plating during charging, especially at low temperatures or high C-rates [42,43]. Accordingly, BEV packs are designed and managed so that both electrodes operate within partial (de)lithiation windows enforced by the BMS.

2.1. Battery Cell Types and Arrangements in BEVs

2.1.1. Cylindrical Cells

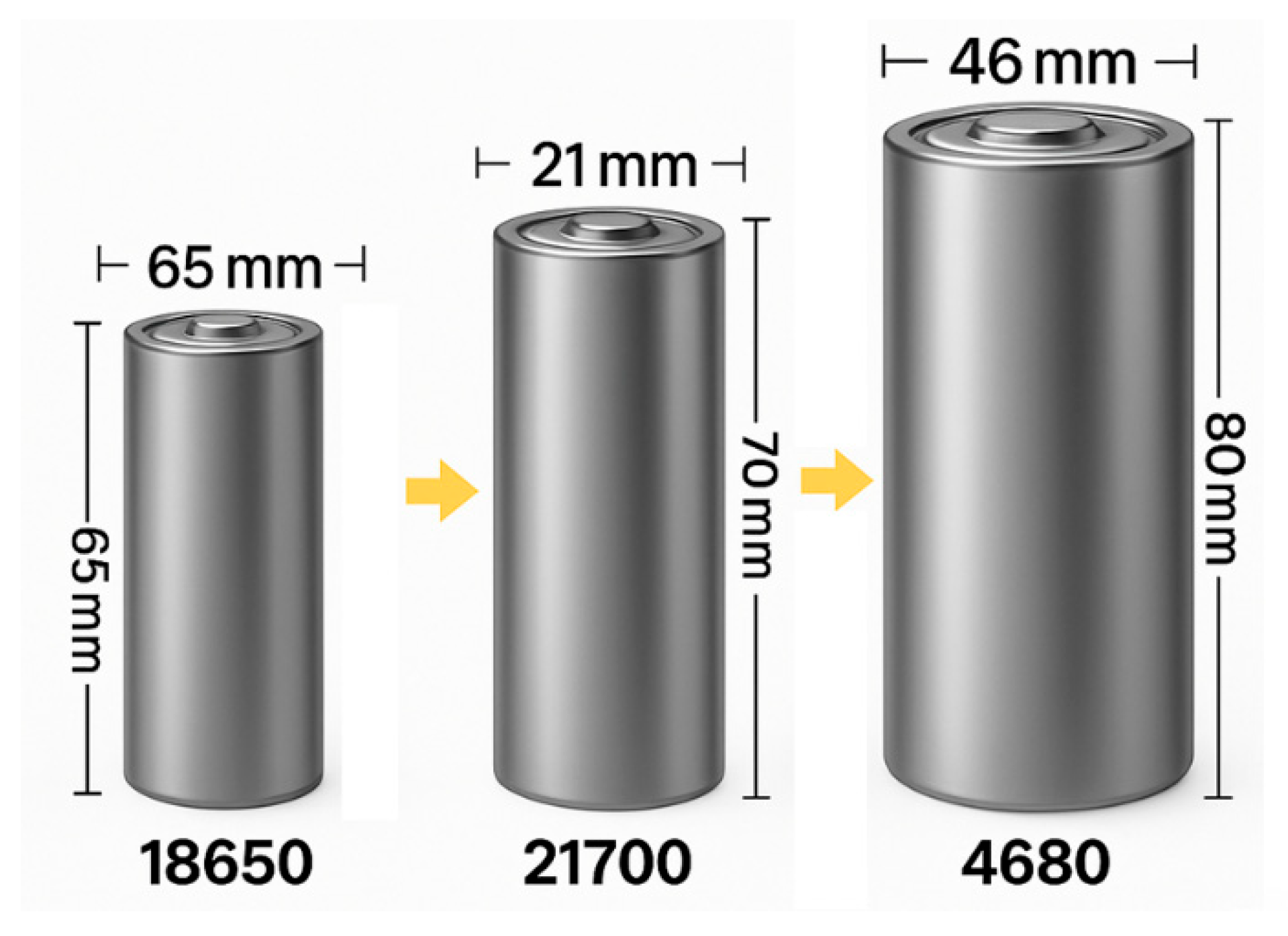

- 18650 Cells

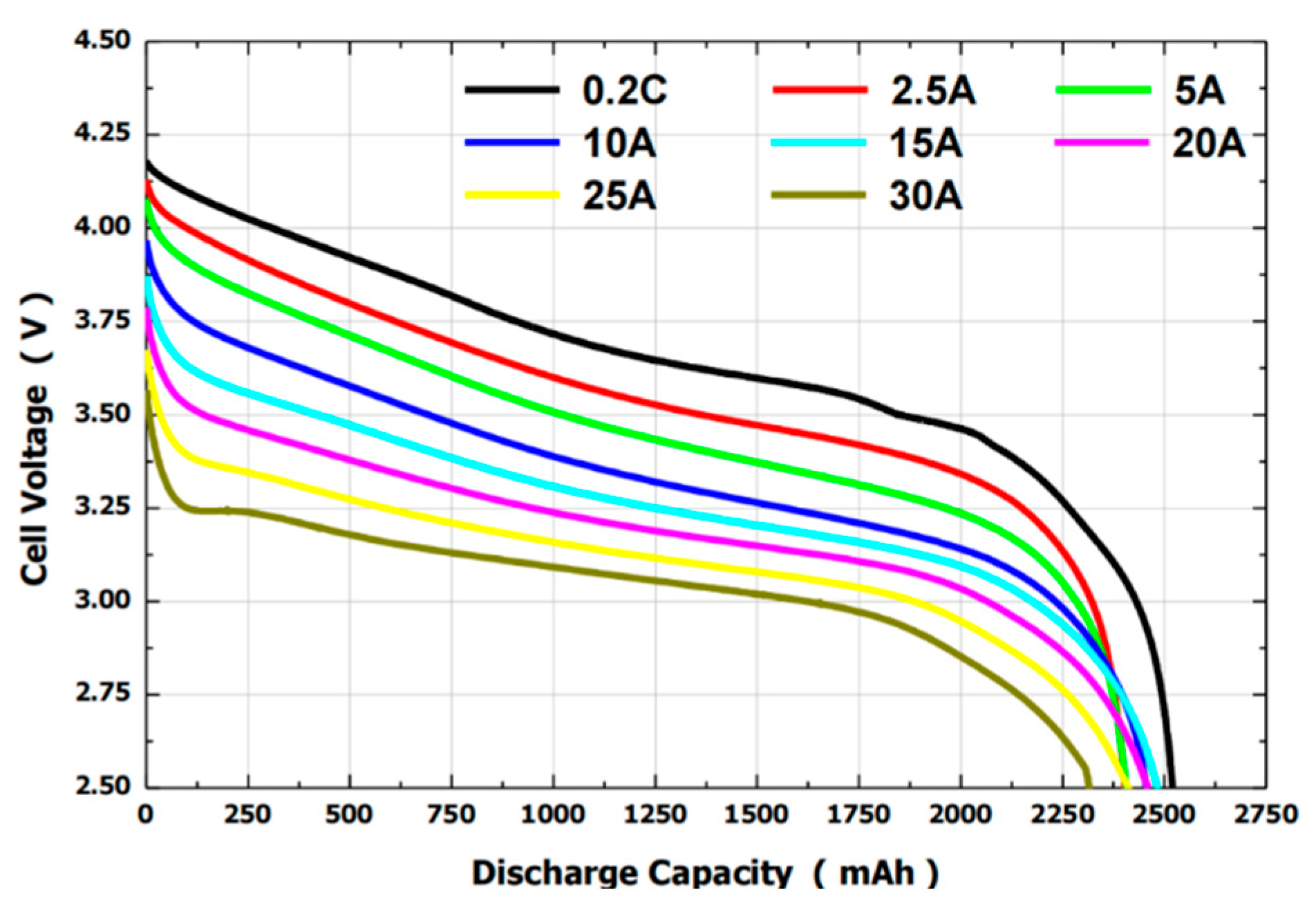

- 18650 Cell is 18 mm in diameter and 65 mm in length. Each cell typically weighs 45–48 g and can store up to 3000–3500 mAh (equivalent to 3.0–3.5 Ah) of charge [47]. Its nominal voltage is 3.7 V; this means that the 18650 contains roughly 11–13 Wh of energy [48]. Early EV models of 18650 cells have about 240–250 Wh/kg (Energy Density). This type of cylindrical cells pioneered Tesla EV models—the 2008 Tesla Roadster and Model S/X packs each contained thousands of 18650 cells [49]. The Model S 85 kWh battery pack contains about 7000 18650 cells arranged in parallel/series, and assembled into modules [50,51].The plots in Figure 8 show typical discharging characteristics of a 18650 lithium-ion cell at various constant currents. As discharge current increases from 0.2 to 30 A, voltage drops faster, and capacity decreases. Higher currents cause greater internal resistance effects, reducing the usable capacity and cell terminal voltage.Figure 8. Discharge Characteristics of 18650 Cylindrical Lithium-Ion Cells, Reprinted with permission from [48].Figure 8. Discharge Characteristics of 18650 Cylindrical Lithium-Ion Cells, Reprinted with permission from [48].

- 2170 (21700) Cell

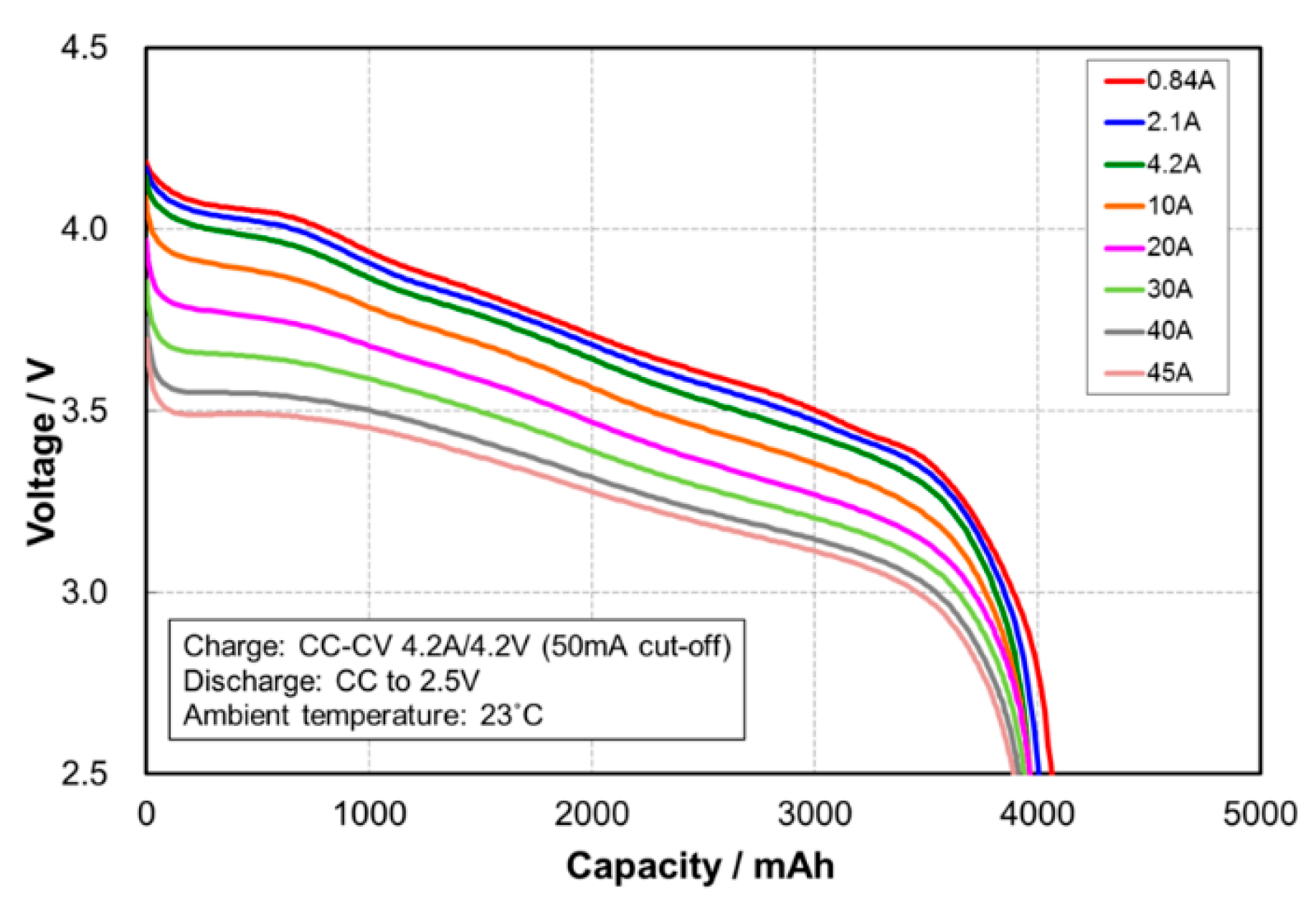

- The 2170 (21700) Cell has dimensions of 21 mm in diameter and 70 mm in length. Typical EV 2170 cell is around 4.5–5.0 Ah each, which is about (4800–5000 mAh) [49,52], with energy density of 260–300 Wh/kg [53]. Figure 9 is the discharge characteristic plot for 2170 lithium-ion cells for voltage versus capacity at different constant current rates (0.84 A to 45 A). Higher discharge rates lead to lower operating voltages and reduced usable capacity [52]. Each 2170 cell holds more energy than a 18650, so an EV pack can use fewer cells to achieve the same capacity.Figure 9. Discharge Characteristics of 2170 Cylindrical Lithium-Ion Cells, Lithium-Ion Cells, Reprinted with permission from [52].Figure 9. Discharge Characteristics of 2170 Cylindrical Lithium-Ion Cells, Lithium-Ion Cells, Reprinted with permission from [52].

- 4680 Cell

- The 4680 Cell has a 46 mm diameter and 80 mm length. This format was unveiled by Tesla at Battery Day 2020; it is larger in volume than that of the 2170 cell. Each 4680 cell can store up to 25 Ah of charge, equivalent to 96–99 Wh per cell, which is five times the energy capacity of 18650 Cells [54]. Tesla’s first 4680 cells were made of a high-nickel NCM811 cathode, achieving 272–296 Wh/kg [55].

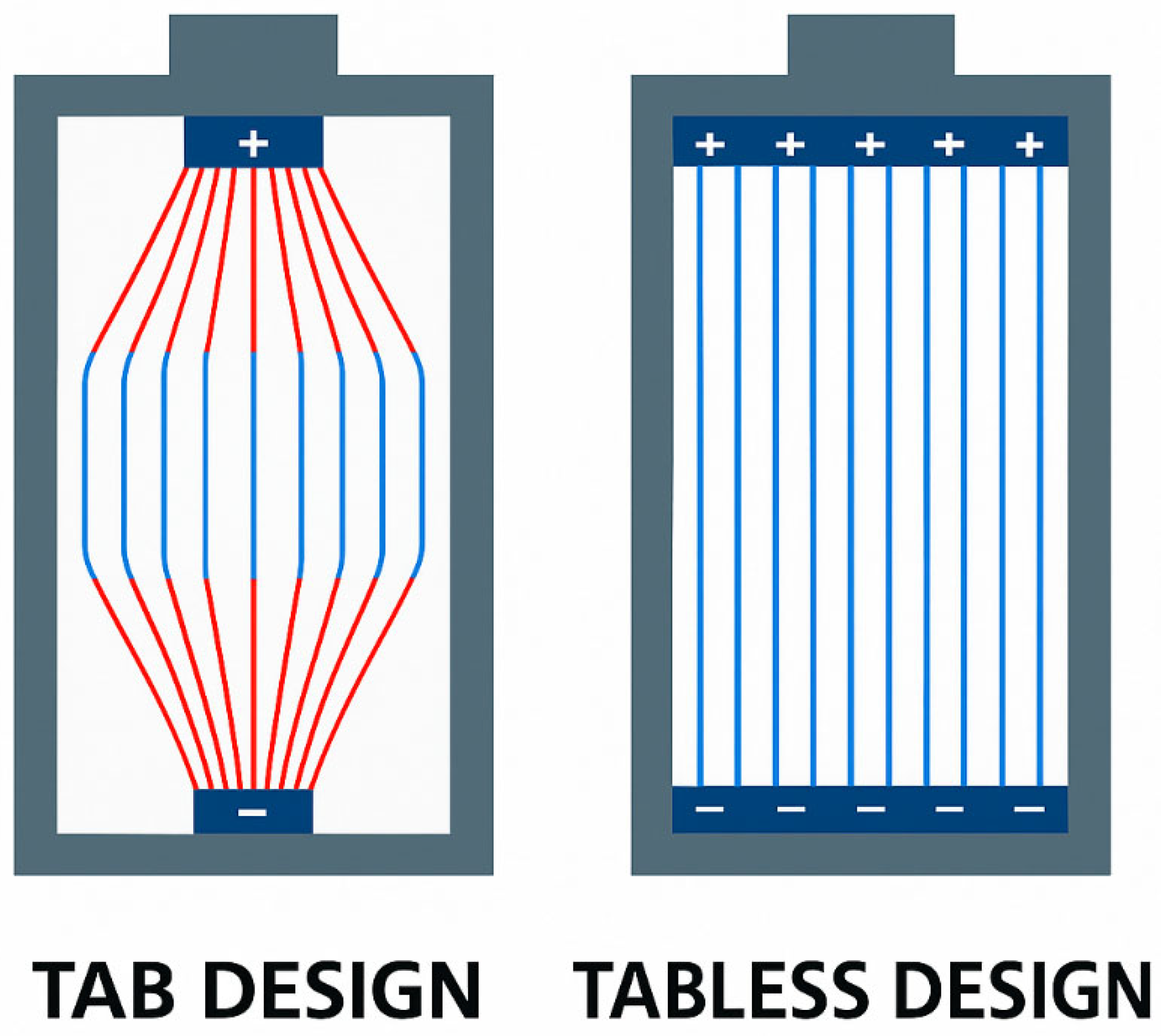

- Recent and Future Developments in Cylindrical Cell Technology

- Cylindrical cell batteries are undergoing transformations that will boost their performance and extend their range of applications. Tabless designs integrate continuous current collectors directly on the electrode, shortening current paths, improving electrical uniformity, enhancing thermal management, and boosting rate capability, energy efficiency, and power density [60]. Below are the recent trends in cylindrical cell developments.

- Cylindrical Cell Tabless and Advanced Internal Designs

- 2.

- Cylindrical Cell Structural Integration into Vehicles

- 3.

- Solid-State and New Chemistries in Cylindrical Format.

- 4.

- Cylindrical Cell Enhanced Thermal Management Techniques.

- Automakers and BEV Models Using Cylindrical Cells

- Advantages of Cylindrical Cells

- Disadvantages of Cylindrical Cells

2.1.2. Prismatic Cells

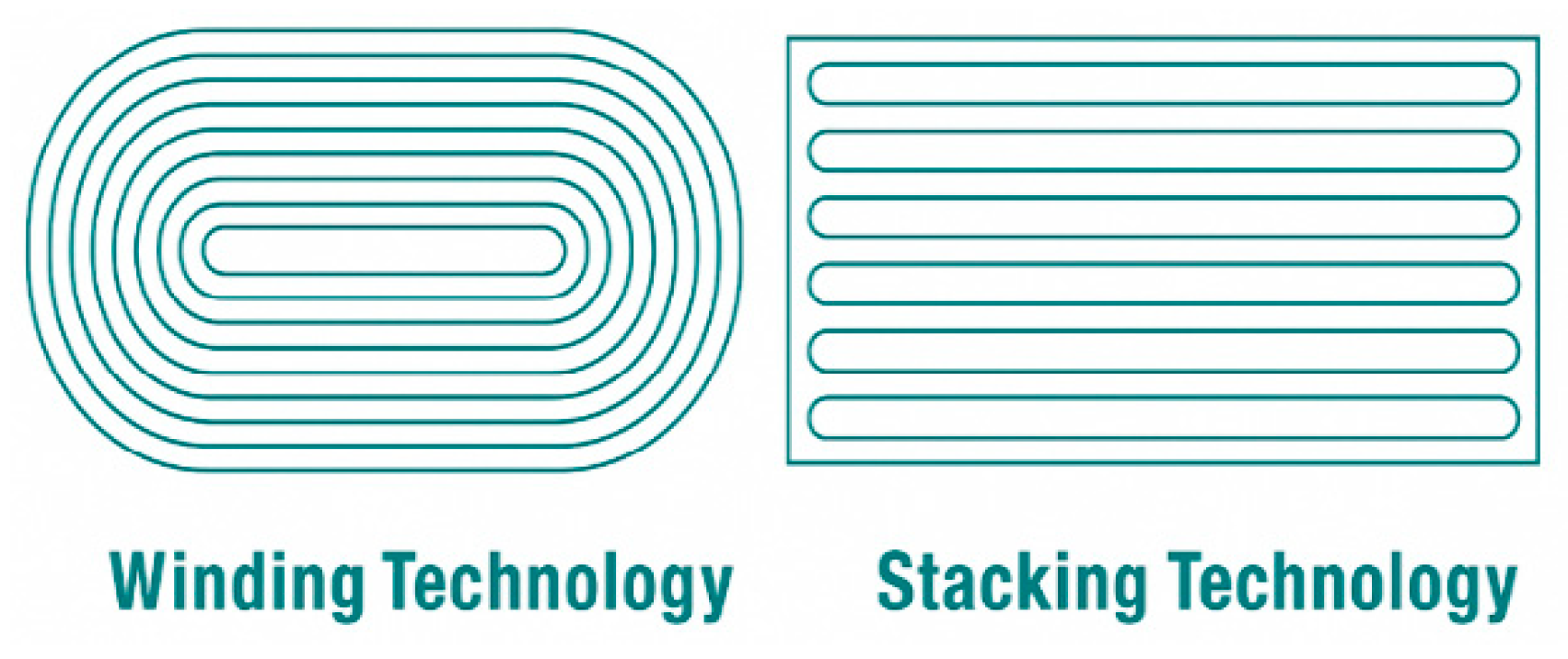

- Internal Design—Stacked vs. Wound Prismatic Cell

- Energy Density of Prismatic Cell

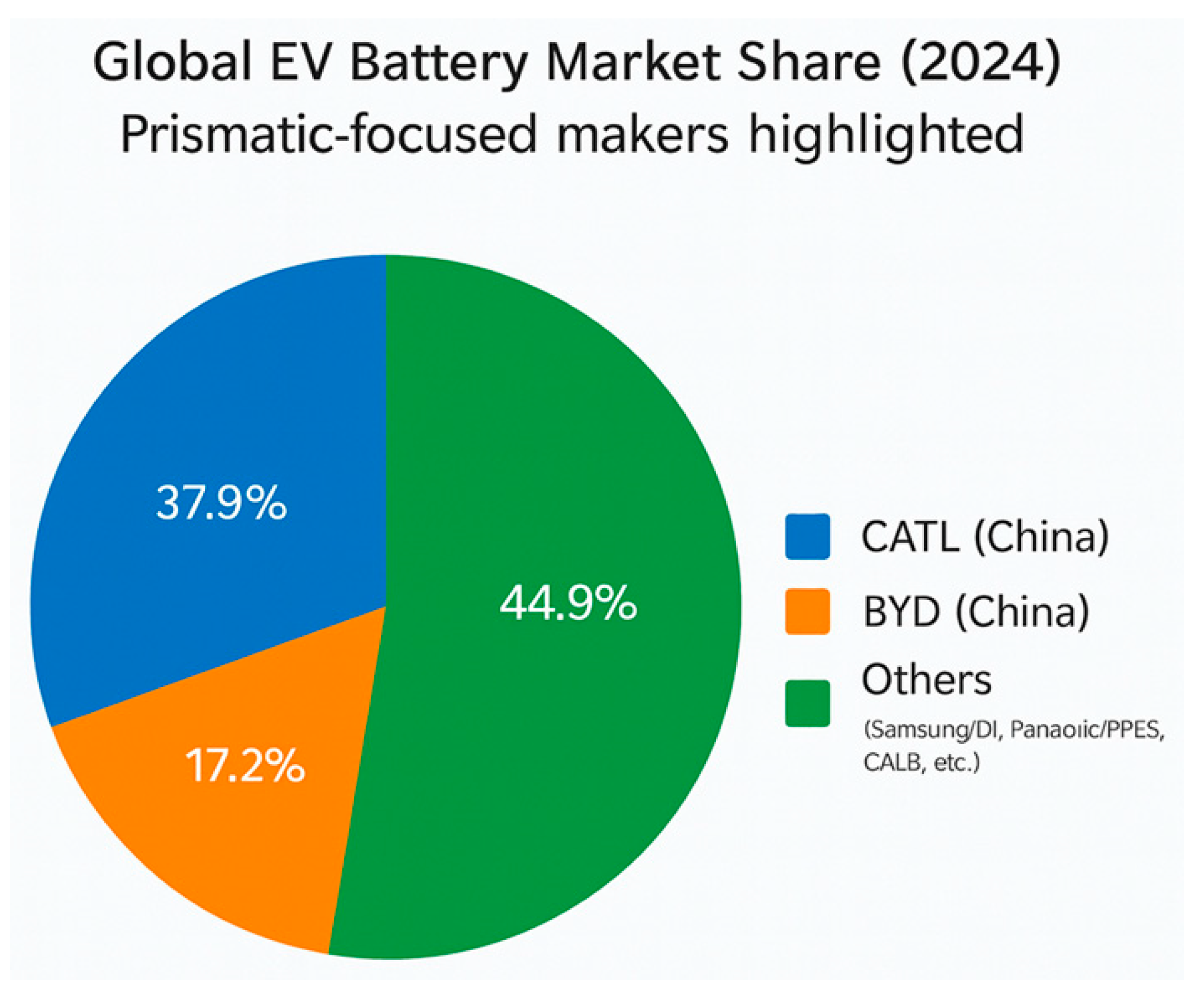

- Key Manufacturers of Prismatic Cells

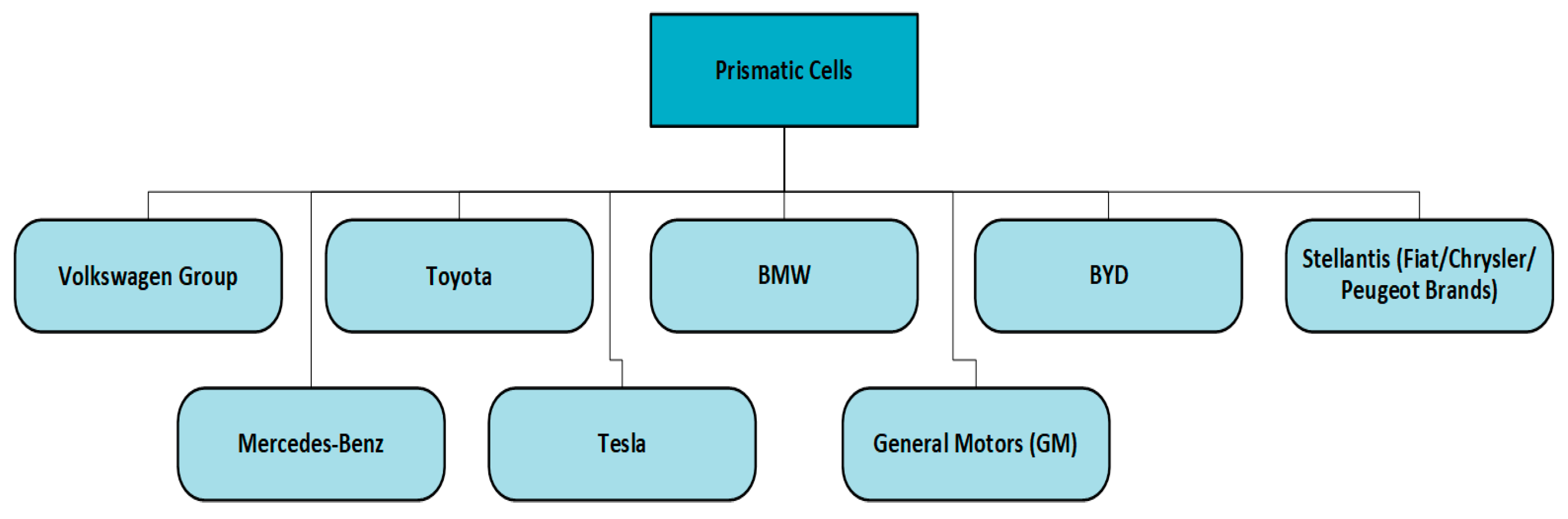

- Automakers and BEV Models Using Prismatic Cells

- Future Developments and Innovations in Prismatic Cell Technology

- Advantages/Disadvantages of Prismatic Cells

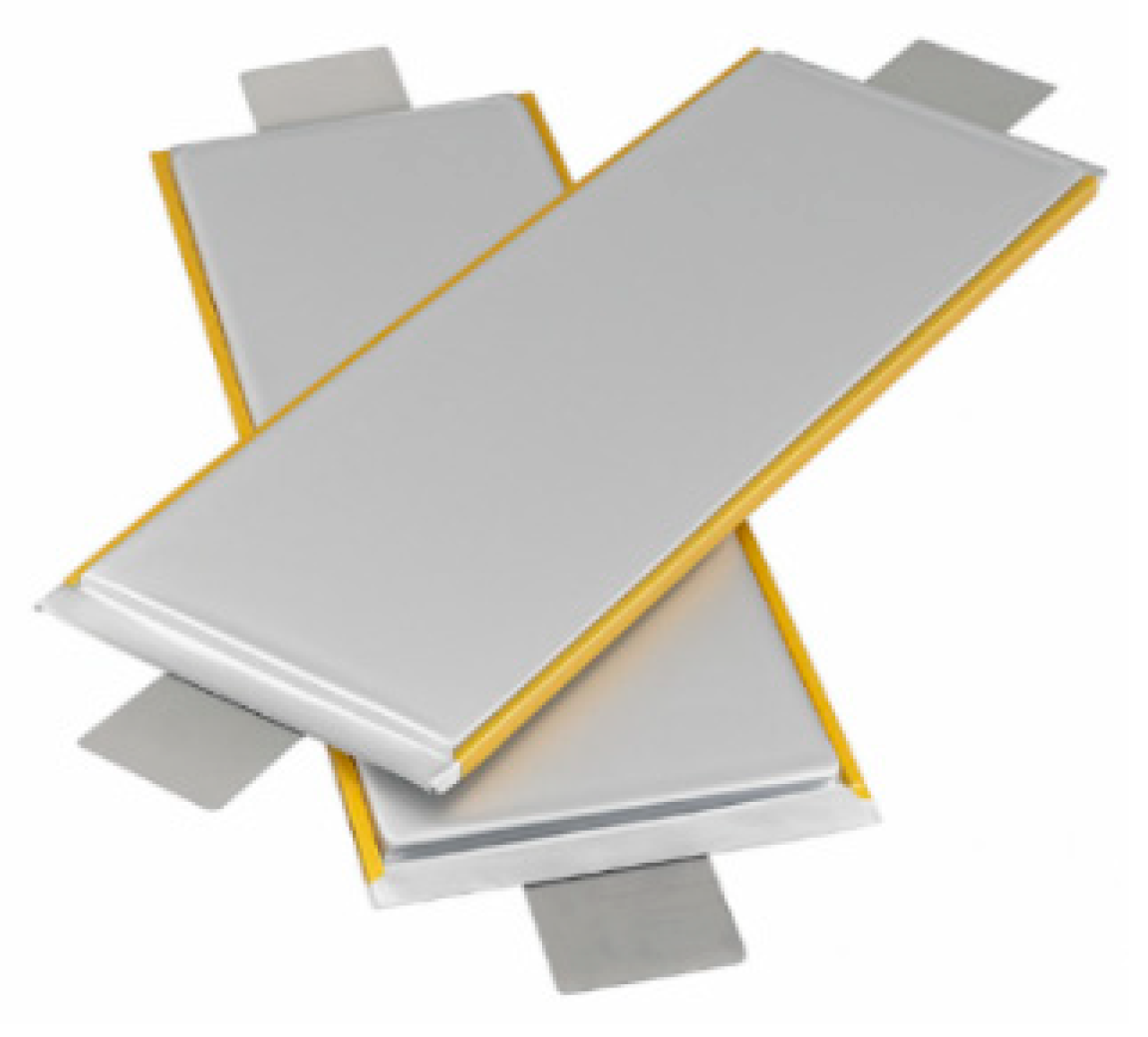

2.1.3. Pouch Cells

- Leading Pouch Cell Manufacturers and Technologies

- Automakers and EV Models Using Pouch Cells

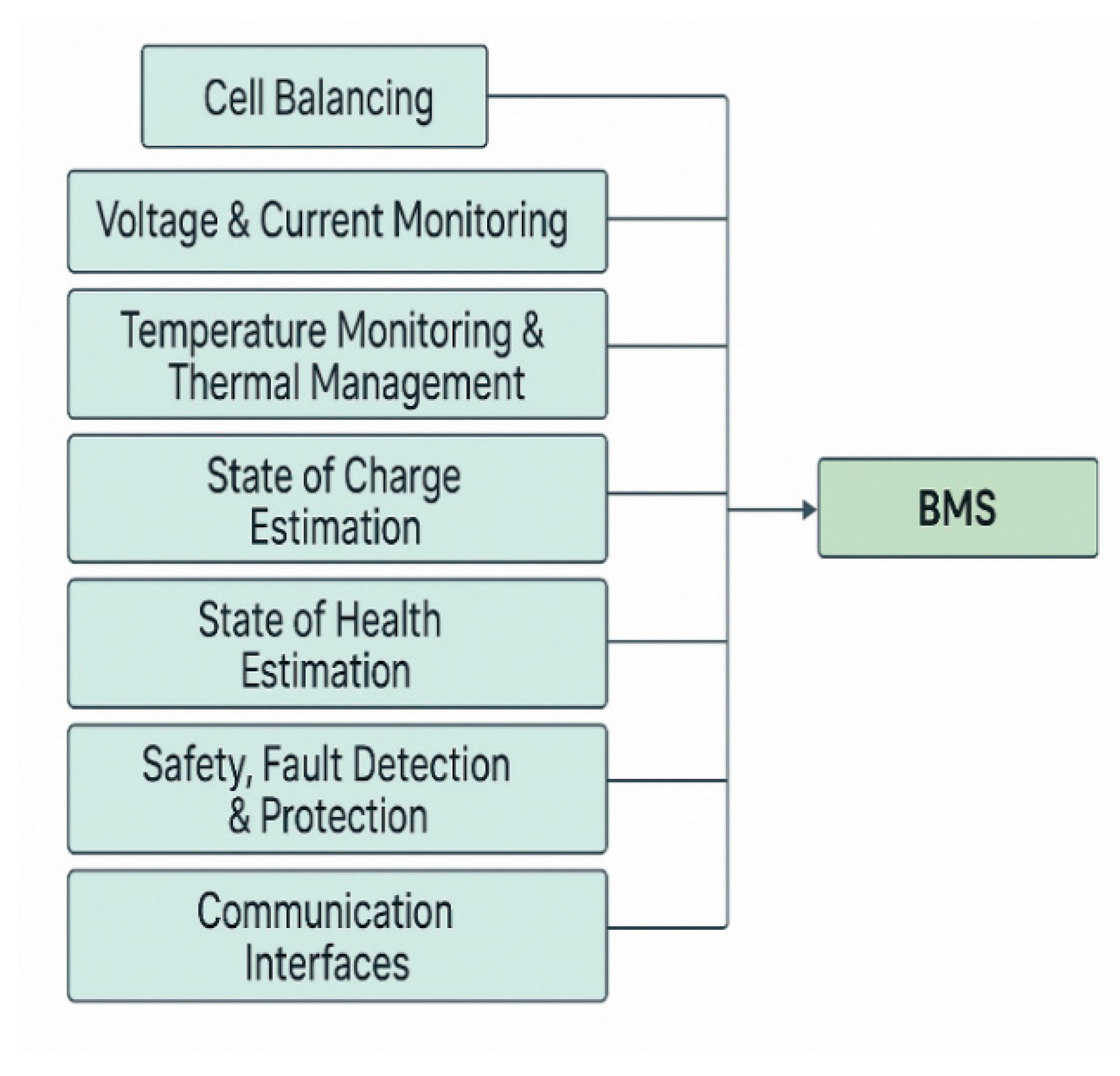

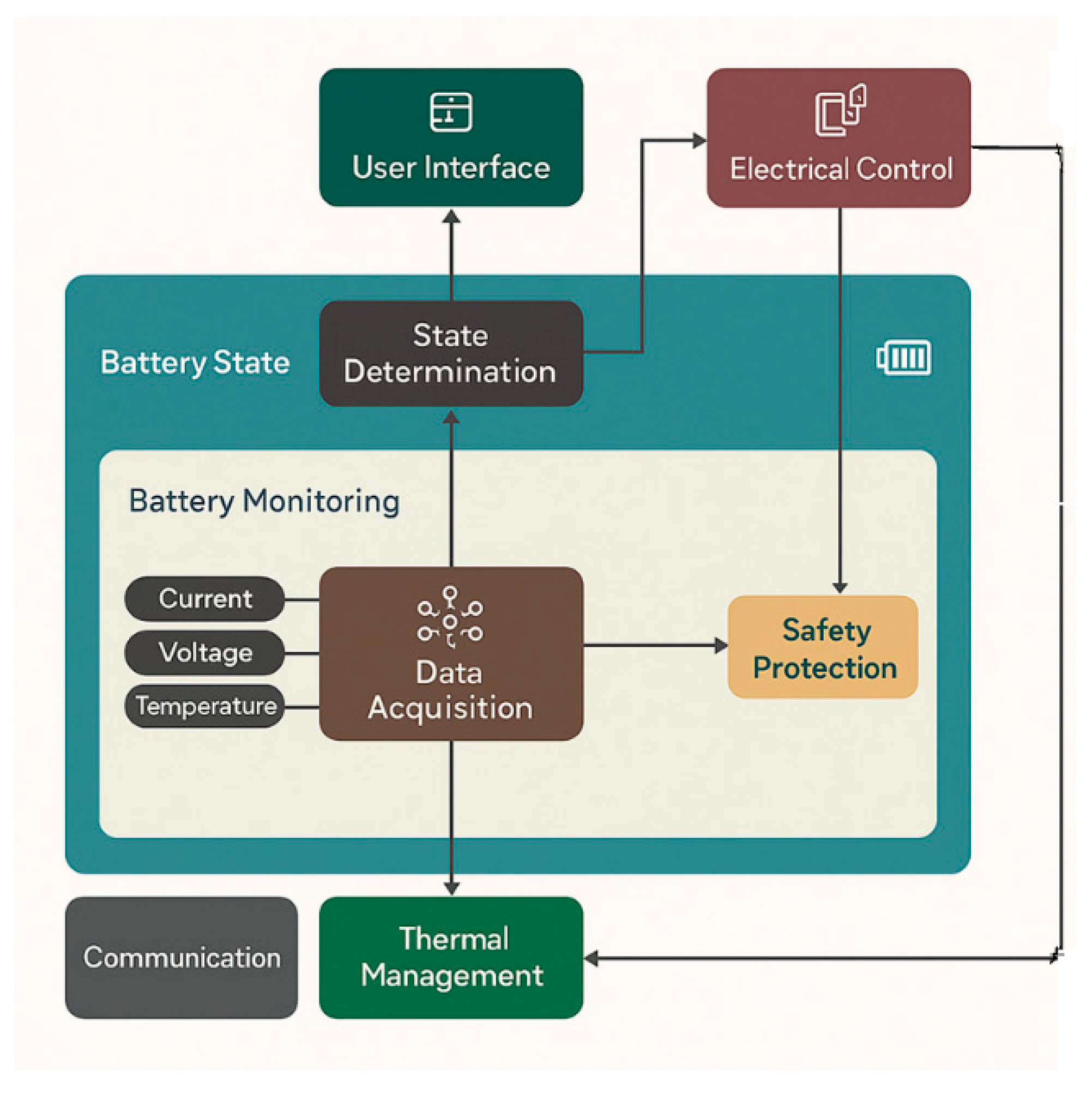

2.2. Battery Management System (BMS)

2.2.1. BMS Functions and Critical Roles

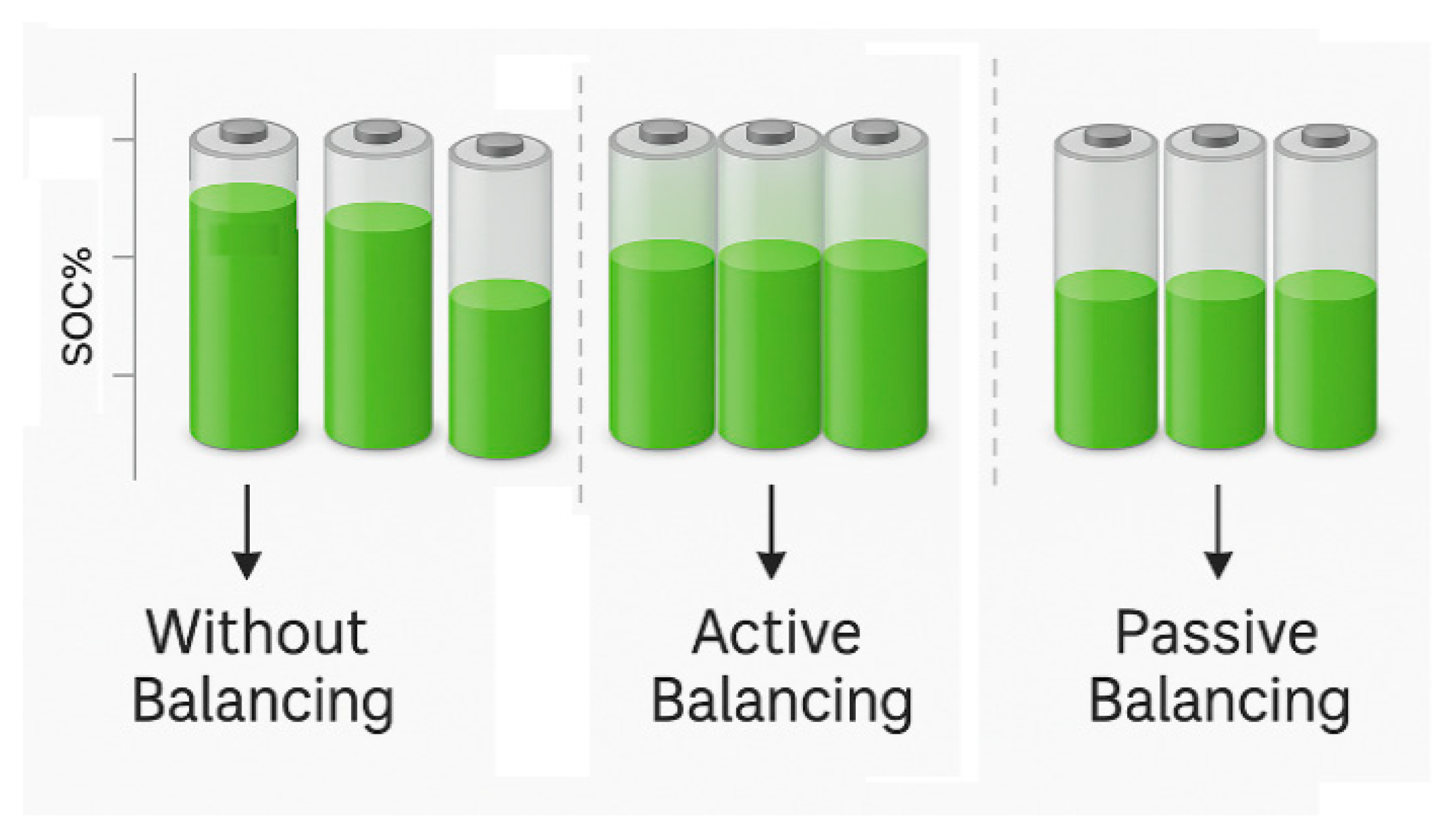

- In passive balancing, the BMS takes off excess energy from higher-charge cells as heat via resistors, allowing lower cells to catch up when charging. This method is simpler and used in many EVs, albeit with some energy loss as heat.

- In active balancing, the BMS redistributes energy from higher-charge cells to lower-charge ones (using capacitor or converter circuits), which is faster and more energy-efficient [143]. Figure 24 presents an explicit pictorial view of cell balancing in both active and passive modes. In active balancing, the charge is distributed equally among the cells, while in the passive mode, the cells take the level of the least charged cell. Active balancing can preserve more energy and potentially extend range, though it adds complexity.

- Tesla’s packs use passive balancing relying on the cells’ inherent consistency and thermal management, whereas the Nissan Leaf’s BMS employed active balancing to efficiently even out its fewer, larger cells. In both cases, balancing ensures no cell over-charges or over-discharges before the others, protecting overall pack health [144].

- Voltage and Current Monitoring

- The BMS measures the voltage of individual cells or groups of cells and keeps them within their safe voltage range (typically 3.0–4.2 V for Li-ion). The BMS prevents over-charge or over-discharge, which could damage the cells [142]. Monitoring current flow in and out of the pack allows tracking of charge/discharge rates and detecting abnormal spikes that may indicate faults. These real-time data are foundational for calculating state-of-charge (SOC) and state-of-health (SOH), ensuring each cell operates within specifications.

- Temperature Monitoring and Thermal Management

- Temperature sensors throughout the pack feed data to the BMS so it can maintain each of the cells in an optimal temperature range (often around 15–35 °C) [36,141]. Over-temperature conditions can lead to accelerated degradation or even thermal runaway, while low temperatures affect the pack’s performance. The BMS can activate cooling (e.g., pumps, fans) or heating systems to keep the battery within safe limits [108]. For example, if cells are getting too hot during fast charging or heavy use, the BMS will trigger cooling to prevent overheating. Thermal management is especially critical during fast charging when high current can rapidly heat the pack. Many EVs integrate BMS with a cooling loop or heat pump to enable features like battery pre-conditioning—warming up the battery before fast charging for optimal results [58,122].

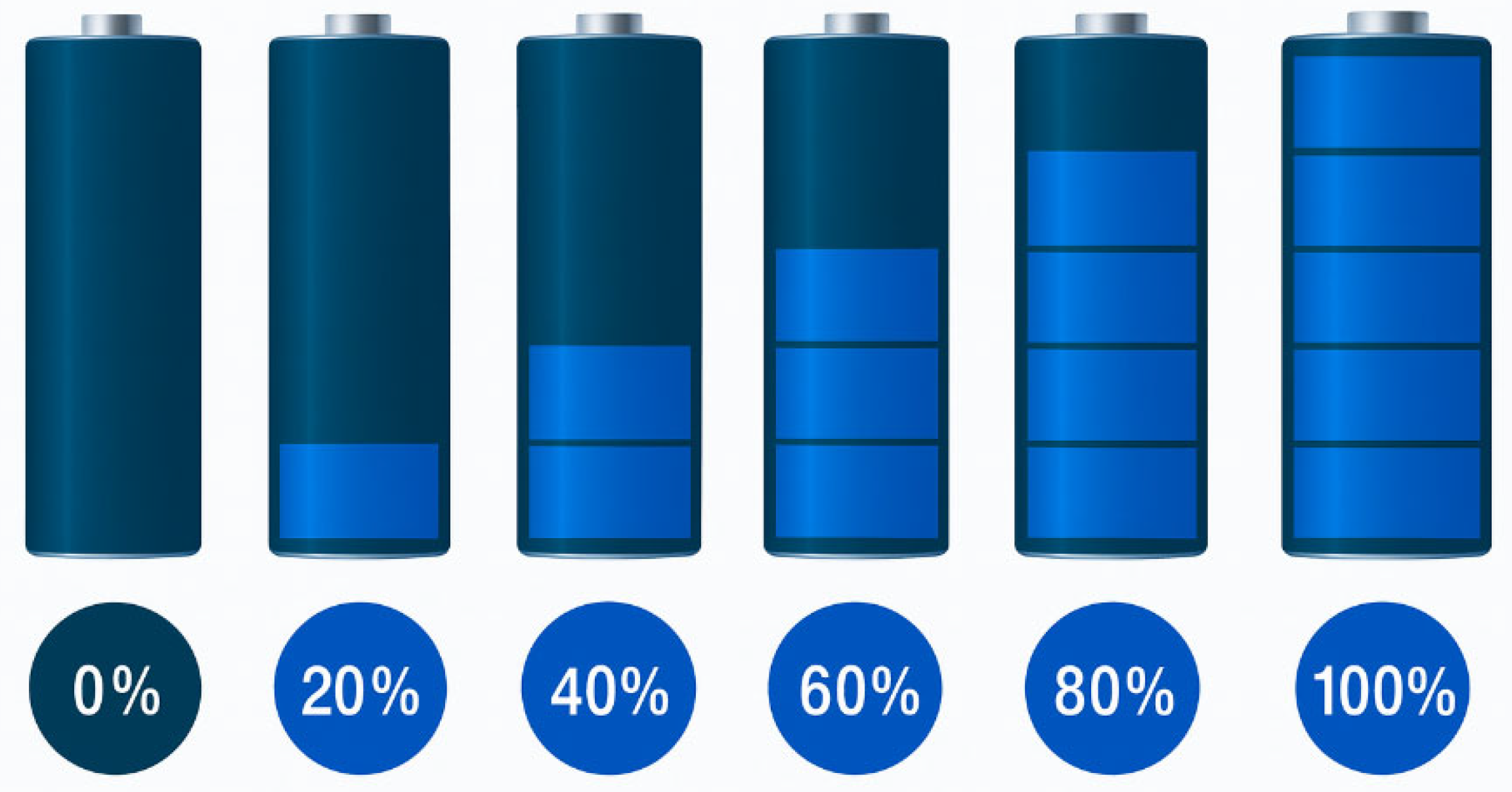

- Battery States Estimation

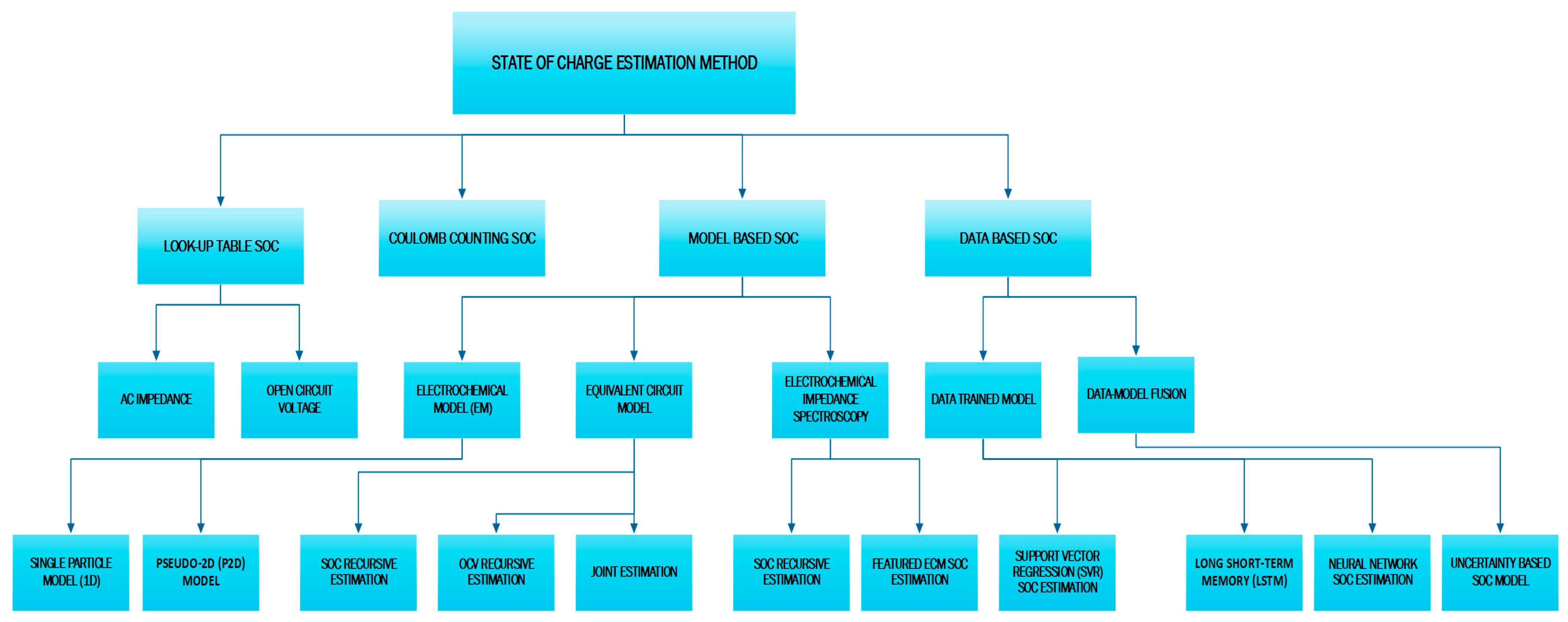

- State of Charge (SOC) Estimation

- 1.

- Look-Up Table SOC Methods

- 2.

- Coulomb Counting SOC.

- Also called the Ampere-Hour Counting method. Measures current over time to calculate charge in/out of the battery. SOC is computed as shown in Equation (4)where is the nominal capacity, (t) the current going in and out of the battery.

- 3.

- Model-Based SOC

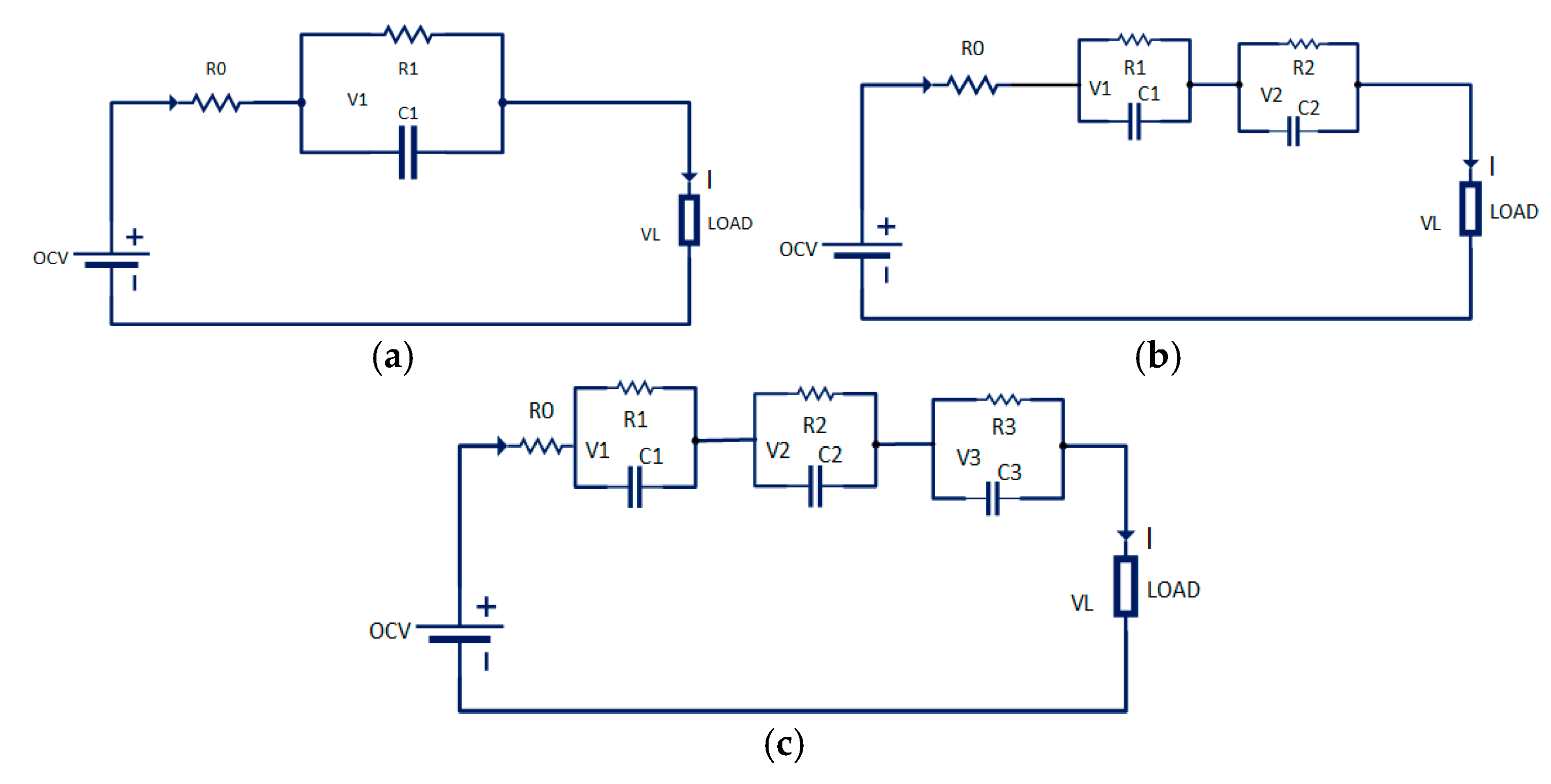

- These methods use mathematical models to simulate battery behavior and estimate SOC.Equivalent Circuit Model (ECM)—Models shown in Figure 27 the battery using resistors, capacitors, and voltage sources. Widely used due to simplicity and reasonable accuracy.Figure 27. (a) 1 RC, (b) 2 RC, and (c) 3RC Battery Equivalent Circuit Models. Figure 27 (a–c) Show Battery Equivalent circuit models (ECMs) that approximate battery behavior by resistor and capacitor combinations to capture its voltage dynamics.Figure 27. (a) 1 RC, (b) 2 RC, and (c) 3RC Battery Equivalent Circuit Models. Figure 27 (a–c) Show Battery Equivalent circuit models (ECMs) that approximate battery behavior by resistor and capacitor combinations to capture its voltage dynamics.

- (a)

- (b)

- (c)

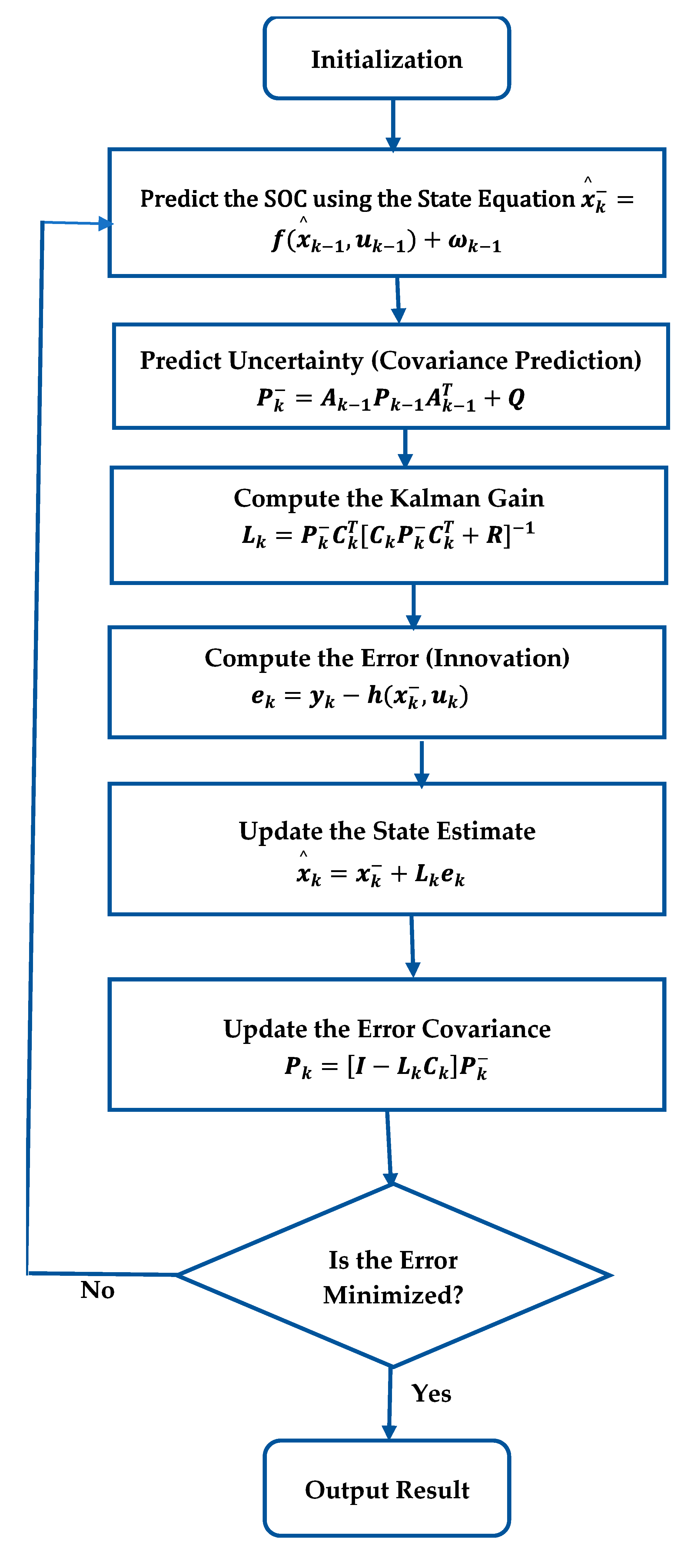

- Kalman Filtering Algorithm

- Kalman filtering is a widely used model-based algorithm for estimating the Battery State of Charge (SOC) based on equivalent circuit models (ECMs). It recursively updates SOC by combining model predictions with real-time voltage and current measurements, effectively correcting for noise and sensor errors. The Extended Kalman Filter (EKF) is commonly employed due to the nonlinear nature of ECMs. It linearizes the model around the current operating point, improving estimation accuracy. Kalman filtering enhances SOC tracking under dynamic conditions, compensates for uncertainties, and reduces drift associated with methods like Coulomb counting, making it suitable for real-time battery management systems.

- : Predicted error covariance

- : Jacobian matrix (linearized system matrix) from the previous step

- : Process noise covariance.

- : Error Covariance matrix at the previous step

- State Transition Model (Process Model).

- : Kalman Gain—decides how much to trust the new measurement

- : Output model (Jacobian of measurement function)

- : measurement noise covariance.

- For SOC estimation, if the prediction uncertainty is high and the measurement is reliable, the filter trusts the measurement more.

- This tells how off the predicted voltage is from the actual measured voltage.

- : The difference between the measured output and the expected measurement from the prediction

- : nonlinear output function (e.g., voltage output from ECM).

- SOC is updated and estimated by combining the predicted value and the scaled measurement error.

- 4.

- Data-Based SOC

- Data-driven approaches use machine learning and AI models trained on historical battery data. Data Trained Model uses historical data (voltage, current, temp) to train predictive models. Examples of the data trained models include Support Vector Regression (SVR), SOC Estimation, Long Short-Term Memory (LSTM), Neural Network SOC Estimation, etc. Another new data-based method is the Data-Model Fusion SOC Method, which combines physical models with data-driven insights for robust SOC estimation [9,145]

- State of Health (SOH) Estimation

- 1.

- Direct Measurement Methods

- Based on capacity measurement by discharging the battery under controlled conditions.

- 2.

- Model-based Methods

- These methods rely on mathematical battery models to estimate SOH.

- Equivalent Circuit Model (ECM): Here, changes in internal parameters like internal resistance and capacitance are analyzed to infer SOH.

- 3.

- Data-driven Methods (Machine Learning)

- This approach utilizes historical battery data to predict SOH, using Artificial Neural Networks (ANN), Support Vector Machines (SVM), Random Forest, and Gradient Boosting.

- Safety, Fault Detection and Protection

- Safety is paramount for EV batteries. The BMS serves as a guardian that can detect fault conditions and take action. It monitors for events such as over-voltage (OV), under-voltage (UV), over-current (OC), short circuits, and over- or under-temperature (OT/UT) situations [9]. If a parameter goes out of the safe range, the BMS will intervene—for example, by disconnecting the battery via contactors to prevent damage. It also enforces proper operation: preventing over-charge that could lead to cell venting or fire, and over-discharge that could permanently damage cells. Modern BMS units often implement redundant safety checks and are designed to meet automotive functional safety standards (like ISO 26262) at high ASIL levels to ensure reliability [147]. They may also include features like “fault codes” or diagnostics that can isolate which cell/module is failing.

- Communication Interfaces

- The BMS does not work in isolation; it communicates with other vehicle systems and external devices. Typically, a BMS connects to the vehicle’s control network (often via CAN bus, the Controller Area Network) to exchange data with the Vehicle Control Unit (VCU), charger, thermal system, and more [147]. Through this interface, the BMS can receive commands like the charge current limits from a charger and send out information like SOC, SOH, temperature, or fault alarms. Many EV BMS also support diagnostic connections and sometimes telemetry, for example, logging data to cloud systems or apps [147]. Additionally, some BMS have wireless or Bluetooth capabilities for certain uses (in smaller systems), though in automotive EVs, the primary interface is a wired bus for reliability [148]. As EVs adopt over-the-air (OTA) updates, the BMS firmware itself can be updated remotely to improve algorithms or address issues, which requires secure communication links [148,149]. In summary, robust communication allows the BMS to integrate into the EV’s ecosystem, coordinate charging, and even participate in energy management at a higher level, like vehicle-to-grid scenarios.

- Data Logging and Diagnostics

- Modern BMS units record a wealth of data on the battery’s usage—voltages, temperatures, charge cycles, etc. These data provide insight into battery health and can be used for diagnostics and analysis [150]. For example, if an EV experiences an unexpected range drop, service technicians can retrieve BMS logs to see if a particular cell block is weak or if the battery was exposed to extreme temperatures, etc. The BMS’s ongoing “learning” of the battery also allows it to refine its SOC/SOH calculations over time, improving accuracy as it gathers more real-world data. Some automakers implement cloud-connected BMS analytics (digital twin or “battery in the cloud” services) to analyze these data for predictive maintenance [151].

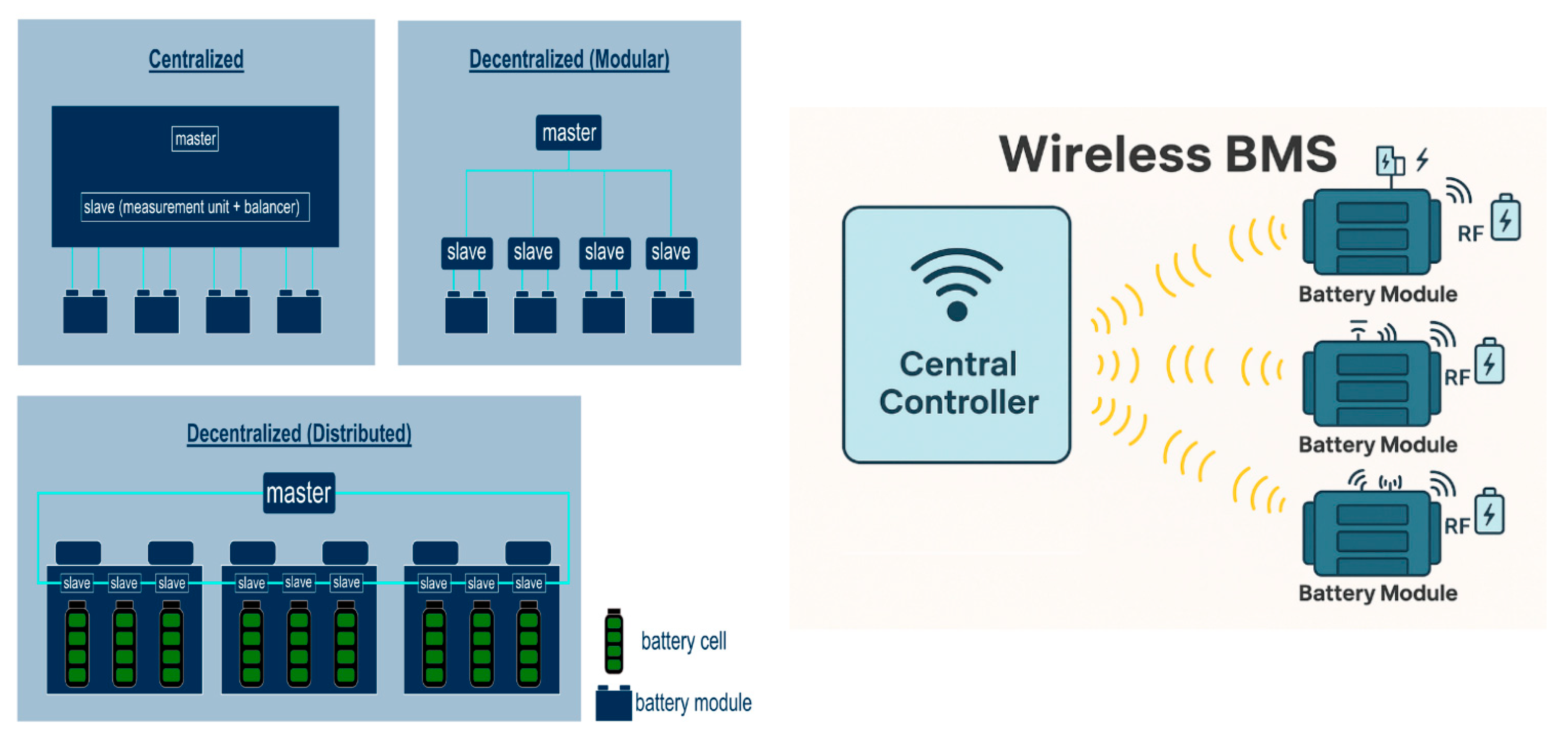

2.2.2. BMS Architecture Variations (Centralized, Modular, Distributed, Wireless)

- Centralized BMS

- In a centralized architecture, one controller (PCB/board) contains most of the BMS circuitry and directly monitors every cell in the battery pack. All voltage sensor wires from the cells and temperature sensors run to this central BMS unit. This architecture is straightforward: a single computer handles data collection, balancing, and protection for the entire pack. Typical calculation for centralized BMS is the following:

- Modular BMS

- Modular BMS splits the battery pack into modules, each with its own local BMS controller board, sometimes called a BMS “slave”, and one higher-level controller that coordinates them. For example, a pack might be divided into 8 modules; each module’s BMS monitors the cells in that module and handles balancing locally, while a central BMS unit (master) connects to each module’s BMS for overall coordination [149]. We can calculate the module voltage using the following expression.

- Module voltage:

- Advantages: Modular BMS design is the middle ground that improves scalability. Each module BMS handles a subset of cells, so adding more modules is straightforward for larger capacity or higher voltage packs. Fault tolerance is improved: if one module’s BMS has an issue, it might be isolated to that module rather than turning off the whole pack (depending on design) [147]. Also, modular BMS can simplify pack construction; battery modules can be built as self-contained units with BMS, which are then assembled into packs. This approach was used in the production of EVs: e.g., the Chevy Bolt EV’s pack (60 kWh) was built from multiple smart modules [132].

- Disadvantages: While modular topologies have simplified pack construction, they require more materials and wiring at the module level, additional controllers, sensors, and connectors. Cross-module synchronization and calibration increase software complexity; more connectors raise assembly time and potential failure points. Pack-level protection coordination (fuses/contactors) and inter-module communication bus loading must be carefully engineered to maintain deterministic fault response. For very small packs, the per-module electronics are a cost penalty versus a centralized design. Modular remains the dominant production choice for passenger-car/bus packs because it balances cost, serviceability, and scalability [153,154].

- Distributed BMS

- In a distributed BMS, rather than having a centralized control unit monitoring the entire battery pack, each cell or module has its own small BMS circuit—often called a BMS node or sensor node. These nodes independently measure parameters like voltage, temperature, and current, communicate with a central controller or among themselves using wired or wireless protocols [148,149]. Essentially, the monitoring, balancing, and even protection can be handled at the cell level, with a network of many small BMS nodes.

- Advantages: This offers maximum scalability and fault tolerance. The system can easily be expanded by adding more cells/nodes—the network self-configures for a larger pack. Fault tolerance is high: if one cell’s BMS node fails, it may affect only that cell and not incapacitate the whole pack. Redundancy and reliability are improved because the network can reroute or tolerate a lost node [154].

- Distributed BMS can also produce very accurate, synchronized monitoring data from all parts of the pack, useful for advanced control.

- Disadvantages: Placing controllers at the cell or sub-module level increases part count, standby power, and tight packaging near cells. Synchronized measurement and fail-safe networking across hundreds of nodes demand stringent electromagnetic compatibility. The added silicon increases heat and $/kWh. This method can only be applied in platforms requiring extreme redundancy; fully distributed BMS is rare in mass production due to cost, thermal/electromagnetic compatibility burden, and certification complexity [154].

- Wireless BMS

- Wireless BMS (wBMS) is an innovation that can be applied to either modular or distributed systems. In a wireless BMS, the communication between battery module/cell monitoring units and the central controller is done via wireless RF signals instead of a traditional wiring system [149,151]. Each cell module is equipped with a wireless transmitter and a small battery or power harvester to send its data. General Motors was the first to introduce wBMS in production EVs (Ultium platform) in collaboration with Analog Devices and Visteon [27]. Figure 29 is a clear illustration of the Wireless BMS architecture, showing how the central controller wirelessly communicates via RF signals with each battery module node.

- Advantages: The elimination of long wiring harnesses yields multiple benefits. GM cited up to 90% reduction in BMS wiring and 15% reduction in volume of the pack by removing bulky wire bundles [27]. It also simplifies manufacturing—no complex wire routing means modules can be freely placed and easily assembled or reconfigured. Wireless communication allows modularity: you can mix-and-match module arrangements without redesigning harnesses, which accelerates vehicle development.

- Another benefit is in maintenance and second-life: modules can be swapped or used outside the vehicle with their BMS nodes communicating wirelessly [148].

- Disadvantages: Although wBMS reduces harness mass and complexity, RF links must remain deterministic and robust inside a metal-rich, high voltage environment; packet loss, latency, coexistence, and cybersecurity impose stringent design and certification burdens. Powering each node introduces maintenance or reliability trade-offs. Early production exists on select platforms; broader adoption remains limited while automakers validate long-term reliability, safety, and total cost benefits versus proven wired modular systems [153,155]. Table 3 bellow shows the automakers and their models with different BMS features.

2.2.3. Future Trends in BMS Design

- AI-Based State Estimation and Management

- Future BMS will embed AI/ML models instead of static lookup tables, using patterns in voltage, current, temperature, and usage history to predict SOC and SOH with higher accuracy [9,146]. Edge-embedded learning enables dynamic optimization of charging protocols and thermal control, early anomaly detection like internal short circuit, and proactive maintenance alerts.

- Digital Twin Integration

- Cloud-connected BMS will mirror each battery via a real-time digital twin, using actual data and AI to simulate aging and performance [151]. Automakers can adjust charging profiles or thermal limits based on twin predictions, meet warranty regulations, and deliver over-the-air updates. Users gain “health forecasts,” enabling smarter usage and longer life.

- BMS for Solid-State and New Chemistries

- Next-generation BMS hardware and software will be chemistry-agnostic, adding new sensors (pressure, acoustic) and AI-driven algorithms to manage solid-state, lithium-sulfur, or sodium-ion cells. They will enforce tailored charge regimes, integrate tighter thermal control for cells, and employ redundant sensing to ensure safety across various chemistries on a common platform [156].

- Vehicle-to-Grid (V2G) and Energy Ecosystem Control

- Future BMS will interface directly with smart grids via ISO 15118-20 protocols [157], autonomously coordinating charge/discharge to provide frequency regulation, demand response, or user-defined V2G limits. Integrated scheduling will optimize cost and renewables availability, while robust cybersecurity prevents unauthorized grid commands, making each EV an active, secure node in the energy ecosystem [156].

- Enhanced Cybersecurity and Functional Safety

- With greater connectivity, BMS will adopt hardware security modules for encrypted communication and secure boot, comply with updated requirements, and feature redundant processors for fail-safe operation [151,156]. Real-time AI anomaly detection will become mandatory, isolating cell faults before thermal events, while secure over-the-air updates guard against malicious attacks throughout the battery’s life [149].

- Modular, Reusable BMS and Second-Life Integration

- BMS architecture will become highly modular and standardized, enabling seamless repurposing of retired EV packs for stationary storage. Each module will export “aging transfer” metadata to inform second-life controllers, while stackable BMS boards allow rapid scaling for diverse pack sizes. This design will maximize manufacturability, sustainability, and lifecycle value.

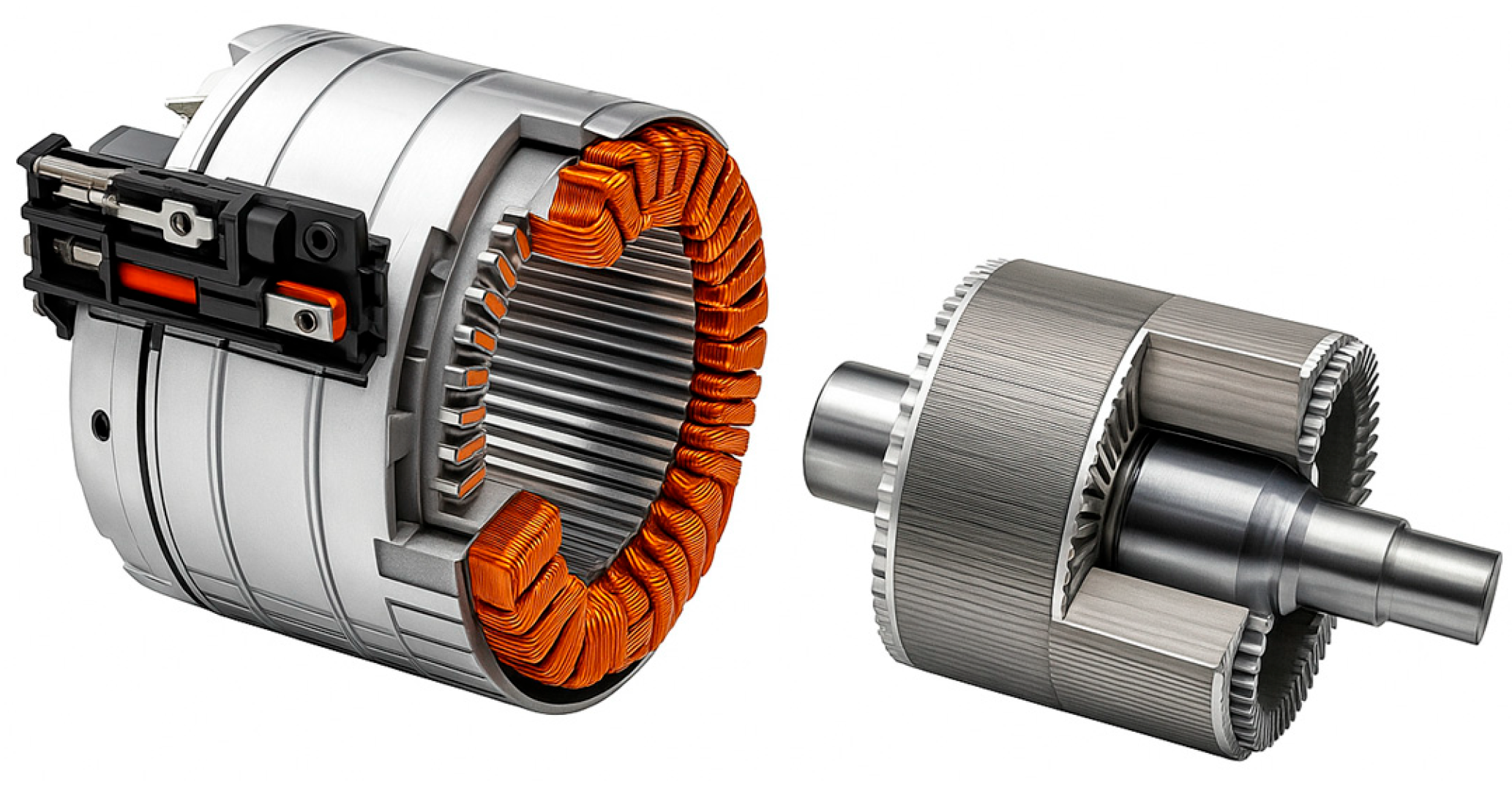

3. Electric Motor in BEV

3.1. Battery Electric Vehicle Motor Configurations

3.2. BEV Motor Types and Their Characteristics

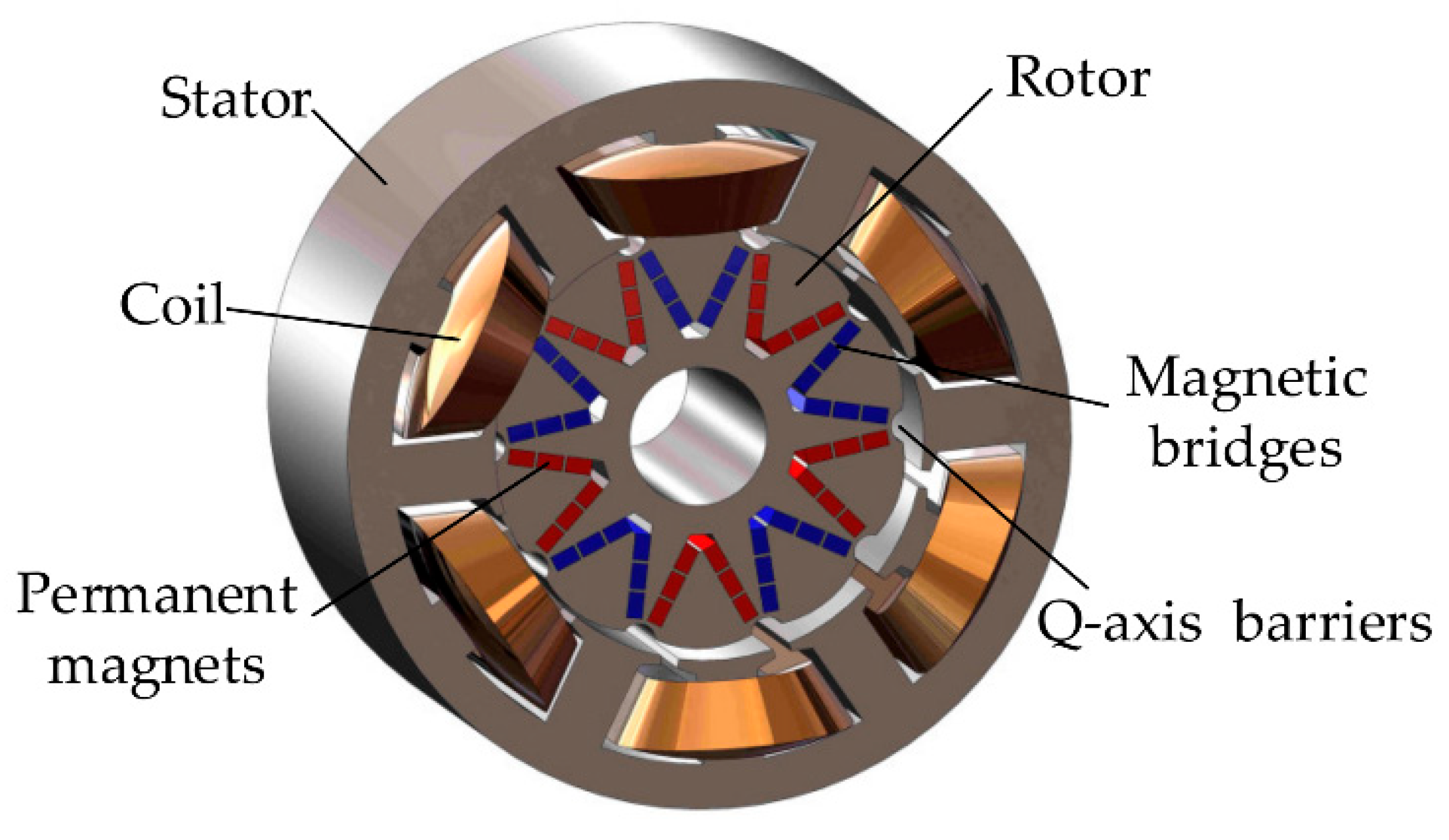

3.2.1. Permanent Magnet Synchronous Motors (PMSM)

- Advantages of PMSM

- PMSMs deliver excellent efficiency (up to 95%), resulting in superior BEV range. Their high torque and power density make them ideal for compact vehicles, while quick response and no slip enable precise control and effective regenerative braking. Lower rotor losses also reduce heat dissipation and therefore minimize cooling requirements.

- Disadvantages of PMSM:

- Use of Rare Earth Materials: Permanent magnet motors rely on rare-earth materials, which are costly. They are more expensive than other designs, risk partial demagnetization under fault or overheating, and experience drag losses when unpowered.

- BEVs that Use PMSM

- Permanent magnet motors are used by the majority of modern BEVs, especially when a single motor is employed for primary traction [158]. Their combination of efficiency and compact size makes them the default choice. For example, the Nissan Leaf, Chevy Bolt EV, Ford Mustang Mach-E, Jaguar I-Pace, Porsche Taycan, Audi e-tron GT, and Hyundai/Kia E-GMP models (Ioniq 5, Kia EV6, etc.) all use PMSMs for propulsion [25,123,168]. Tesla has also moved to PMSMs—the Model 3 uses an IPM synchronous motor. Tesla’s first use of magnets was after the Model S/X initially used induction machines [169]. Recently, industry-wide, there has been a clear trend toward PMSMs for new BEV models. Ford has also keyed in on using Permanent Magnet Motors after discovering that they are more efficient than the induction motors they used before [169]. Others who started on induction are moving to permanent magnets.

3.2.2. Induction Motors

- BEVs That Use Induction Motors

- Induction motors have been pivotal in BEVs, especially with Tesla’s early Roadster and Model S/Model X rear drives. Dual-motor AWD models like Tesla’s Model 3, Model Y, and Volkswagen’s ID.4/Audi Q4 e-tron use induction motors on the front axle for extra power or traction, combined with PMSMs at the rear. Mercedes-Benz EQC initially featured induction motors. Though PMSMs dominate new designs, induction motors remain important for their robustness and overload capability in multi-motor setups [172,173].

- Table 4 summarizes electric vehicle models across major automakers and their traction motor architecture used in each.

| Manufacturer and Model | Motor Type(s) | Notes |

|---|---|---|

| Tesla Model S (2012–2018) | AC Induction | Early Tesla strategy |

| Tesla Model 3/Y | PMSM + Induction (AWD) | PMSM primary, induction secondary |

| Tesla Model S Plaid (2021) | 3× PMSM | High-performance PM |

| GM EV1 (1996) | AC Induction | Early EV, industrial motor |

| Chevy Bolt EV (2017) | PMSM | Efficiency, range |

| GMC Hummer EV (2022) | 3× PMSM | Rare-earth minimized |

| Cadillac Lyriq (2023) | 1–2× PMSM | GM’s standard PM motors |

| Ford Mach-E (2021) | PMSM (RWD/AWD) | Efficiency-focused |

| Ford F-150 Lightning (2022) | 2× PMSM | Durability, torque |

| Nissan Leaf (2010) | PMSM | Compact, early mass EV |

| Nissan Ariya (2022) | 2× PMSM (AWD) | PM with inverter efficiency |

| BMW i3 (2013) | PMSM (reduced magnets) | Magnet-reduced design |

| BMW iX/i4 (2021) | EESM (no magnets) | Magnet-free innovation |

| Audi e-tron SUV (2019) | 2× AC Induction | Early non-PM, less efficient |

| Audi e-tron GT/Porsche Taycan (2021) | 2× PMSM | Performance-focused PM |

| VW ID.4 RWD (2020) | PMSM | Standard MEB motor |

| VW ID.4 AWD/Audi Q4 e-tron | PMSM + Induction | AWD efficiency |

| BYD Han EV (2020) | PMSM | Primary PM design |

| BYD Seal AWD (2022) | PMSM + Induction | Mixed-motor setup |

| Hyundai Ioniq 5/Kia EV6 (2021) | PMSM | Clutch-disconnect front |

| Rivian R1T Quad (2022) | 4× PMSM | Torque vectoring |

| Lucid Air (2022) | 2–3× PMSM | High-power density |

| NIO ET7 (2022) | PMSM + Induction | Performance-focused mix |

- Comparing PMSM Versus IM

3.2.3. Emerging and Future Motor Technologies in BEVs

- 1.

- Integration and Compact Efficiency:

- Automakers are increasingly integrating motors, inverters, and gearboxes into single compact units (e-axles) to improve efficiency, save space, and reduce overall vehicle weight.

- 2.

- Advanced Cooling Techniques:

- Innovative cooling solutions like oil spray, immersion, or shared thermal management are enabling motors to achieve higher continuous power ratings and improved durability.

- 3.

- Higher RPM Motors and Multi-Speed Transmissions:

- Next-generation EVs are adopting high-RPM motors and multi-speed transmissions to maximize power density and efficiency while optimizing performance across driving conditions.

- 4.

- New Materials and Manufacturing:

- Research is focused on new magnet chemistries, cobalt-free or cerium-based materials, and additive manufacturing to lower costs, improve thermal stability, and enable advanced motor designs.

- 5.

- AI in Motor Design and Control:

- AI and machine learning are increasingly used to optimize motor design, torque management, and real-time control for greater performance, efficiency, and material savings.

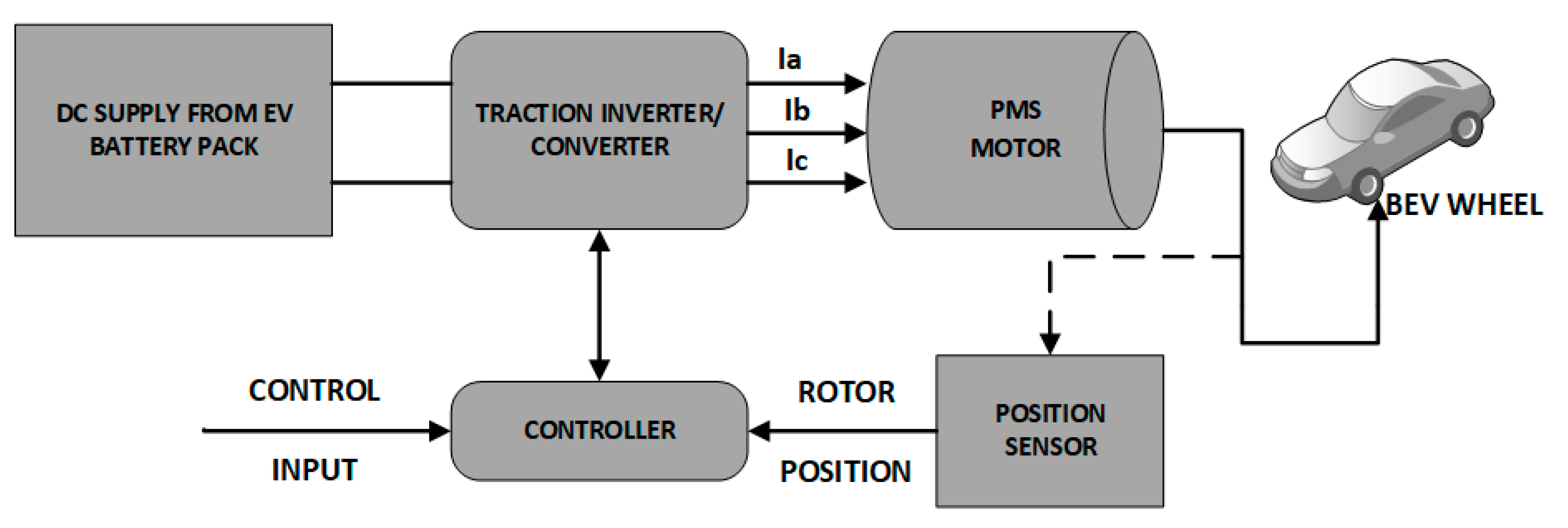

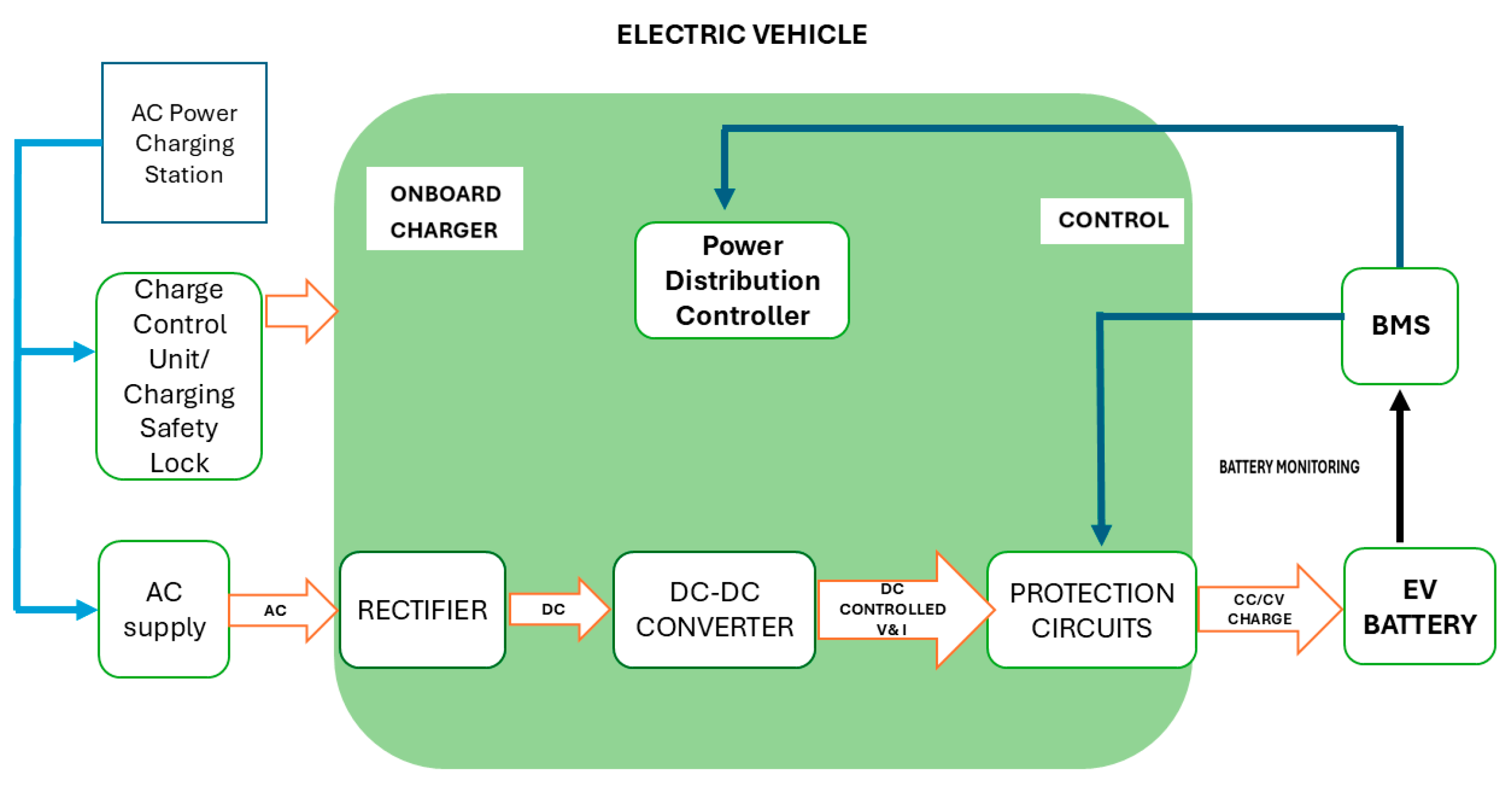

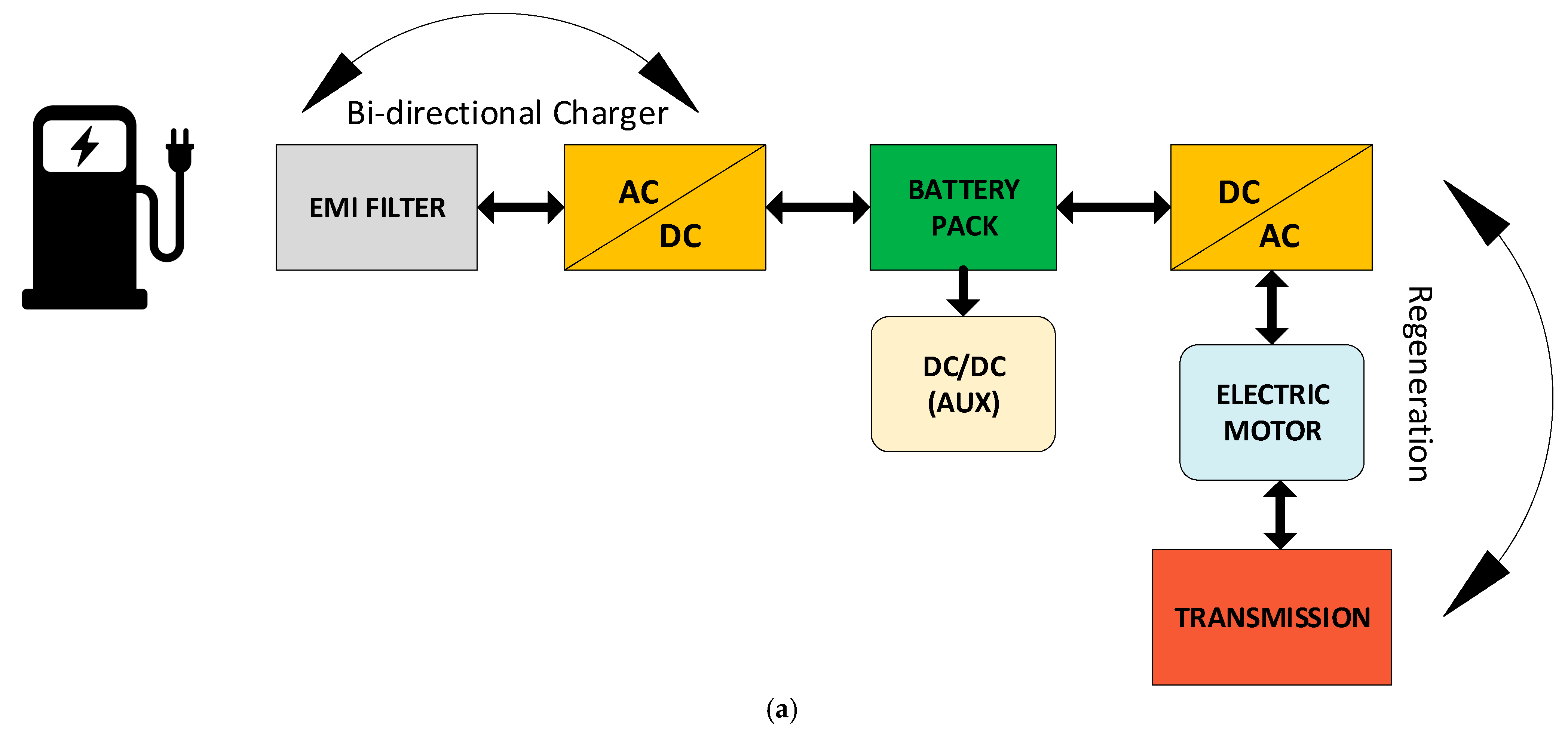

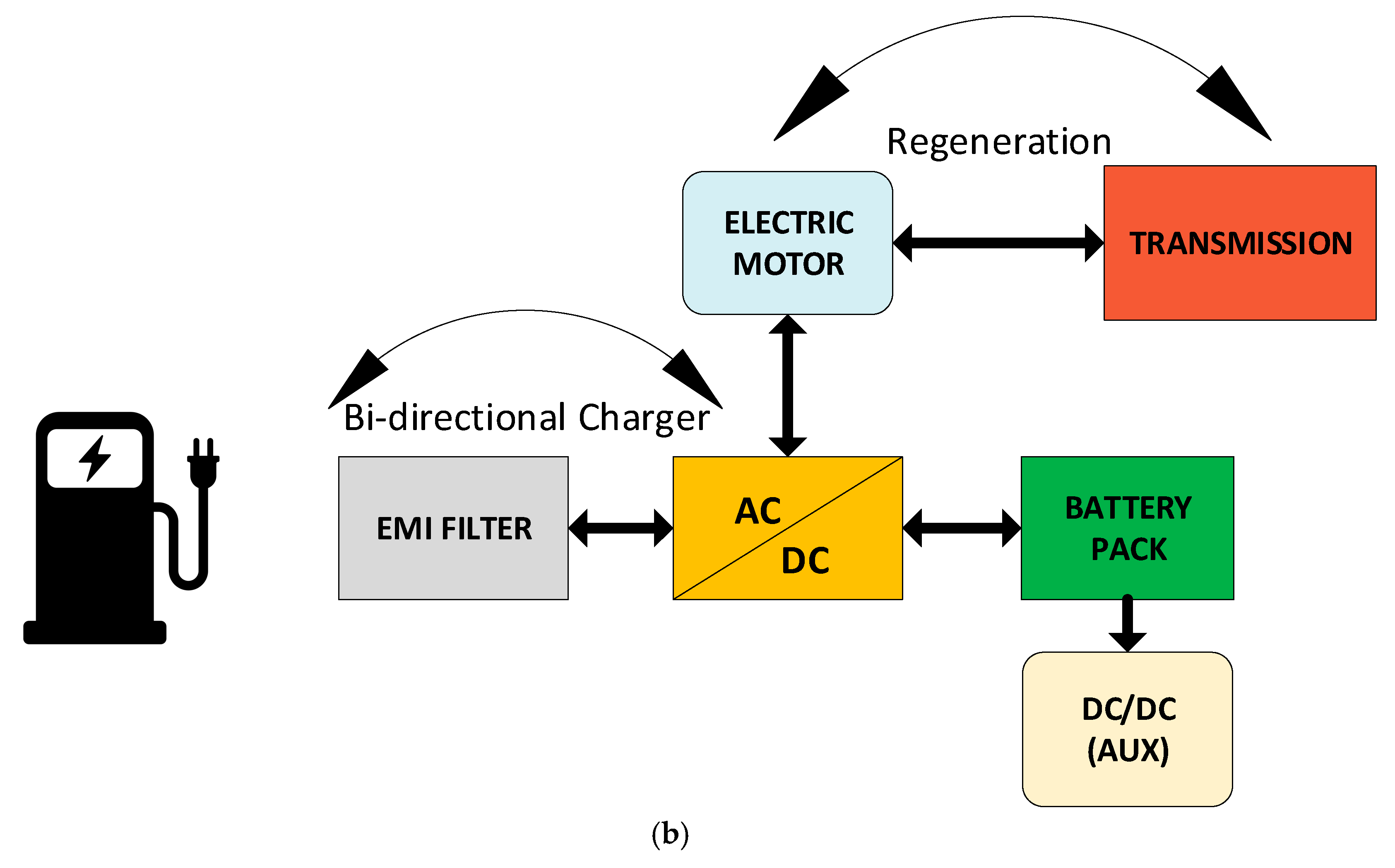

4. Power Electronics Converters in BEVs

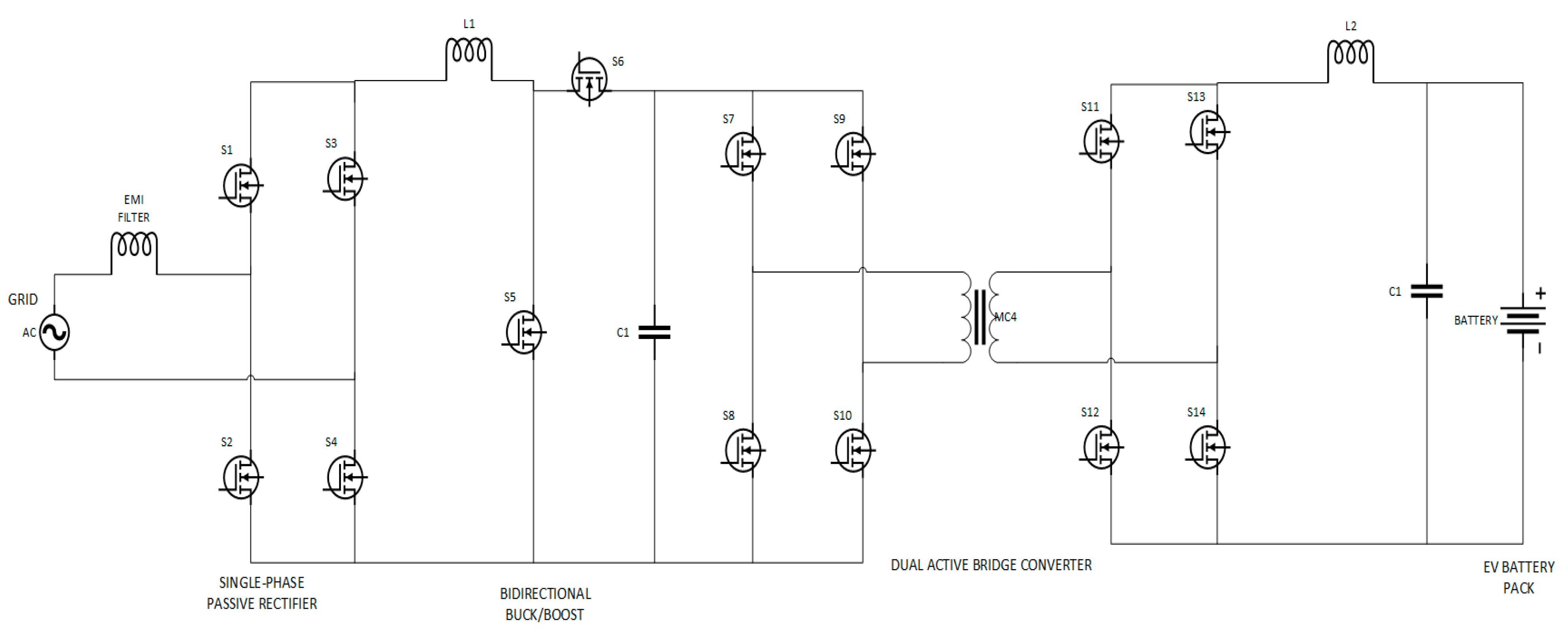

4.1. Onboard Charger

4.2. Traction Inverter (DC to AC)

4.3. HV-To-LV DC/DC Converters

4.4. High-Voltage Systems (400 V vs. 800 V)

4.5. Auxiliary Converters, Power Cabin Electronics, and Accessories

4.6. Future Trends in EV Power Electronics

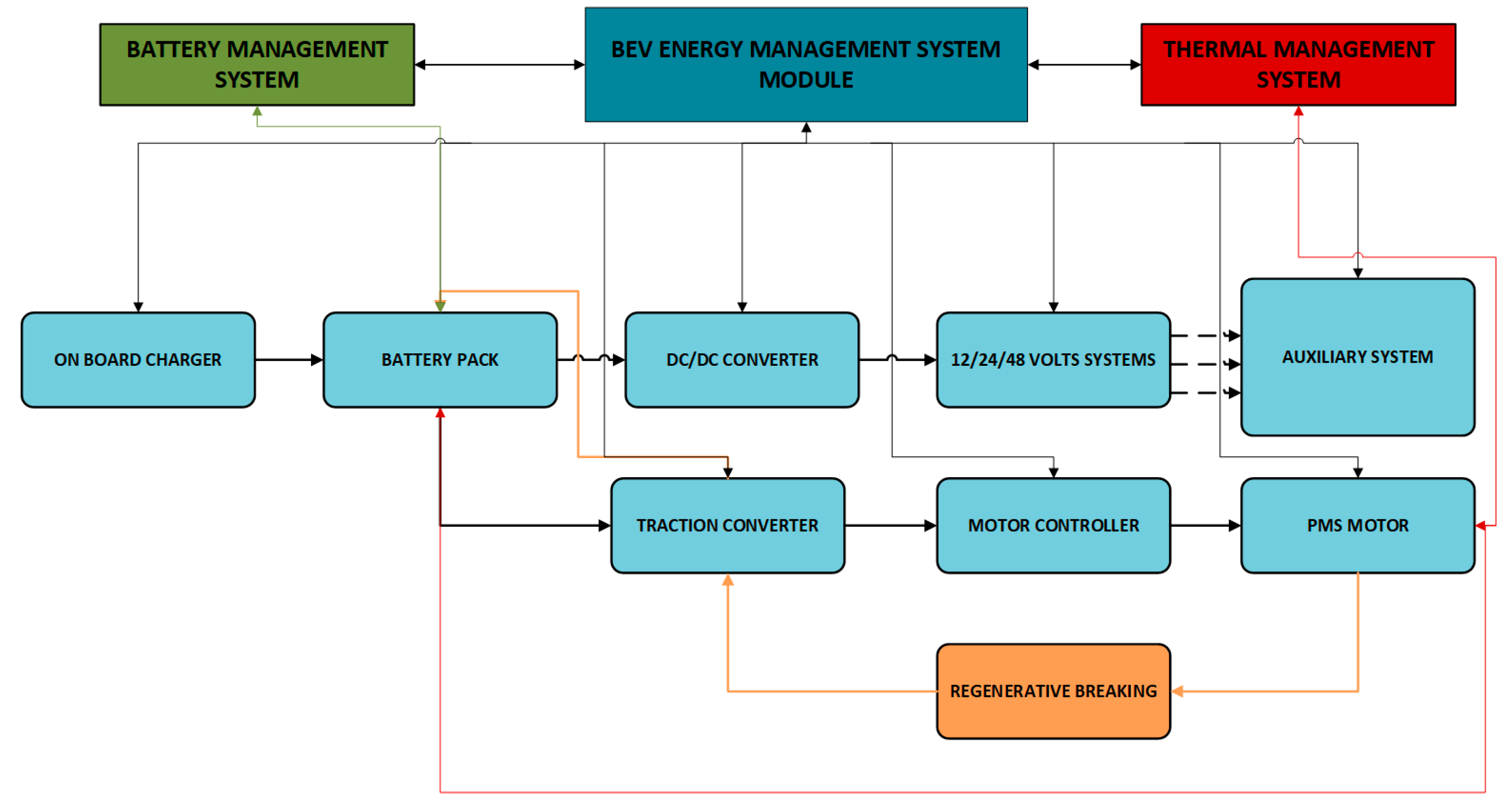

5. Energy Management Systems in BEVs

5.1. Key EMS Functions Include

5.2. Current Technology in BV Energy Management Systems (EMS)

5.3. Integration with Vehicle Systems

5.4. Future Trends in EMS

6. Charging Infrastructure for Battery Electric Vehicles (BEVS)

6.1. Connector Types and Standards

6.2. Charging Locations: Home, Workplace, and Public

6.2.1. Home Charging

6.2.2. Workplace Charging

6.2.3. Public Charging—Urban vs. Highway Corridors

6.2.4. Smart Charging, V2G, Plug-and-Charge, Mobile Charging and Battery Swapping

6.3. Future Trends in BEV Charging

7. Battery Electric Vehicle Future Trends and Findings

Main Findings

8. Research Gaps in Battery Electric Vehicles (BEVS) Powertrain

8.1. Research Gaps in Battery Packs and BMS

8.2. Research Gaps in Electric Propulsion Motors

8.3. Research Gaps in Power Electronic Converters

8.4. Research Gaps in Energy Management Systems (EMS)

8.5. Research Gaps in Charging Infrastructure

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The Evolution of the Prius | Toyota Motor Corporation Official Global Website. Available online: https://global.toyota/en/prius20th/evolution (accessed on 28 August 2025).

- Selvakumar, S.G. Electric and Hybrid Vehicles—A Comprehensive Overview. In Proceedings of the 2021 IEEE 2nd International Conference on Electrical Power and Energy Systems, ICEPES 2021, Bhopal, India, 10–11 December 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Shingo, K.; Kubo, K.; Katsu, T.; Hata, Y. Development of Electric Motors for the TOYOTA Hybrid Vehicle “PRIUS”. In Proceedings of the 17th International Electric Vehicle Symposium (EVS-17), Montreal, QC, Canada, 13–16 October 2000; Available online: https://attachments.priuschat.com/attachment-files/2018/01/138195_evs17priusmotorpaper_shingo.pdf (accessed on 20 May 2025).

- Ezugwu, E.O.; Okozi, S.O.; Hilary, O.S.; Godwin, E.G.; Nwibo, E.G.; Jack, K.E. Decentralized energy trading systems for microgrids using blockchain and smart contract technologies. J. Ghana Inst. Eng. (JGhIE) 2024, 24, 41–50. [Google Scholar] [CrossRef]

- Jack, K.E.; Kantiyok, R.Z.; Ezugwu, E.O.; Anunuso, J.C.; Chukwuemeka, O.; Nwibo, E.G. Development of a convolutional neural network model for solar panel fault detection with preventi—Ve maintenance reporting options. IET Conf. Proc. 2025, 2025, 314–319. [Google Scholar] [CrossRef]

- Muratori, M.; Alexander, M.; Arent, D.; Bazilian, M.; Cazzola, P.; Dede, E.M.; Farrell, J.; Gearhart, C.; Greene, D.; Jenn, A.; et al. The rise of electric vehicles-2020 status and future expectations. Prog. Energy 2021, 3, 022002. [Google Scholar] [CrossRef]

- Udendhran, R.; Mohan, T.R.; Babu, R.; Uthra, R.A.; Anupama, C.G.; Selvakumarasamy, S.; Dinesh, G.; Mukhopadhyay, M.; Saraswat, V.; Chakraborty, P. Transitioning to sustainable E-vehicle systems—Global perspectives on the challenges, policies, and opportunities. J. Hazard. Mater. Adv. 2025, 17, 100619. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook Special Report Batteries and Secure Energy Transitions. Available online: https://www.iea.org/reports/batteries-and-secure-energy-transitions (accessed on 30 May 2025).

- Ranjith Kumar, R.; Bharatiraja, C.; Udhayakumar, K.; Devakirubakaran, S.; Sekar, K.S.; Mihet-Popa, L. Advances in Batteries, Battery Modeling, Battery Management System, Battery Thermal Management, SOC, SOH, and Charge/Discharge Characteristics in EV Applications. IEEE Access 2023, 11, 105761–105809. [Google Scholar] [CrossRef]

- Boudmen, K.; El Ghazi, A.; Eddaoudi, Z.; Aarab, Z.; Rahmani, M.D. Electric vehicles, the future of transportation powered by machine learning: A brief review. Energy Inform. 2024, 7, 80. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Z.; Liu, Y.; Xu, Z.; Qu, X. A Review of Machine Learning Approaches for Electric Vehicle Energy Consumption Modelling in Urban Transportation. Renew. Energy 2024, 234, 121243. [Google Scholar] [CrossRef]

- Islam, S.; Ahsan, S.; Rahman, K.; Amintanvir, F. Advancements in Battery Technology for Electric Vehicles: A Comprehensive Analysis of Recent Developments. Available online: https://globalmainstreamjournal.com/index.php/IEET/article/view/63?utm_source=chatgpt.com (accessed on 12 May 2025).

- Chevrolet Will Reportedly Start Producing the Bolt EV in Late 2016 | Carscoops. Available online: https://www.carscoops.com/2015/02/chevrolet-will-reportedly-start/ (accessed on 22 August 2025).

- The New 2014 Mercedes-Benz B-Class Electric Drive. Available online: https://media.mbusa.com/releases/the-new-2014-mercedes-benz-b-class-electric-drive? (accessed on 22 August 2025).

- A Decade of Innovation—The LEAF’s Incredible Journey | Stories | Nissan Motor Corporation Global Website. Available online: https://www.nissan-global.com/EN/STORIES/RELEASES/nissan-leaf-10years/ (accessed on 22 August 2025).

- History of BYD Automobile Factory: A Journey of Innovation And Sustainability—Car Channel. Available online: https://canalcarro.net.br/en/history-of-byd-automobile-factory-a-journey-of-innovation-and-sustainability/ (accessed on 22 August 2025).

- 40 BYD e6-Based Electric Taxis Enter Service in Shenzhen City—Green Car Congress. Available online: https://www.greencarcongress.com/2010/05/byd-20100518.html (accessed on 22 August 2025).

- Thomas, V.J.; Maine, E. Market Entry Strategies for Electric Vehicle Start-Ups in the Automotive Industry-Lessons from Tesla Motors. J. Clean. Prod. 2019, 235, 653–663. [Google Scholar] [CrossRef]

- North America Climate Summit—NACS 2025—IETA. Available online: https://www.ieta.org/events/north-america-climate-summit-nacs-2025/ (accessed on 22 August 2025).

- Nissan’s Shocking Evolution: A Comprehensive History of Electric Cars from Nissan—Electric Car Wiki. Available online: https://electriccarwiki.com/nissan-electric-car-history/ (accessed on 29 June 2025).

- BMW’s Approach in the Electric Vehicle Industry. Available online: https://ev-global.org/blogs/articles/Article4_BMW_Performance (accessed on 30 June 2025).

- Ozcelik, N.G.; Sen, I.; Ergene, L.T. A Case Study: An Approach to Decrease Voltage Distortion and Enhance Field Weakening Capability in BMW i3 Traction Motor. IEEE Access 2024, 12, 145881–145892. [Google Scholar] [CrossRef]

- Fleischmann, J.; Hanicke, M.; Horetsky, E.; Ibrahim, D.; Jautelat, S.; Linder, M.; Schaufuss, P.; Torscht, L.; van de Rijt, A. Battery 2030: Resilient, Sustainable, and Circular. Available online: https://www.mckinsey.com/industries/automotive-and-assembly/our-insights/battery-2030-resilient-sustainable-and-circular (accessed on 3 June 2025).

- Alan, C. EV Buyers Guide—Complete Review; Electric Car Insider: San Diego, CA, USA, 2025; Available online: https://www.electric-car-insider.com/buyers-guides/ (accessed on 23 May 2025).

- Nissan LEAF Brochure | 2025 Nissan LEAF Electric Driving. Available online: https://www.nissanusa.com/interactivebrochures/electric-hybrid-cars/leaf/nissan-leaf/index.html (accessed on 26 May 2025).

- ID. Family | Volkswagen Newsroom. Available online: https://www.volkswagen-newsroom.com/en/id-family-5002 (accessed on 26 May 2025).

- General Motors Ultium Battery Technology | GM Authority. Available online: https://gmauthority.com/blog/gm/general-motors-technology/gm-electric-vehicle-technology/general-motors-ultium-battery-technology/ (accessed on 26 May 2025).

- Everything You Need to Know About GM’s Ultium EV Platform. Available online: https://www.slashgear.com/1476899/everything-to-know-about-gm-ultium-ev-platform/ (accessed on 26 May 2025).

- Home | Lucid Motors. Available online: https://lucidmotors.com/?utm_source=bing&utm_medium=paid_search&utm_campaign=bing_paid_search_en-us_acquisition_b_core-modified_phrase&platform=bing&locale=en-us&initiative_a=acquisition&targeting_a=b&targeting_b=core-mod&ref=bing&keyword=lucid%20vehicle&cmpid=Bing_Paid-Search_USA_EN_NAT_Acquisition_Brand_Core-Modified_Lucid_Phrase&agid=1361197936248620&adgroup=Vehicle&adid=85075277147689/&network=o/&msclkid=ce8b23fa150917bc41aa4bcc44126f25 (accessed on 26 May 2025).

- Rivian—Electric Adventure Vehicles. Available online: https://rivian.com/?utm_source=bing&utm_medium=cpc&utm_campaign=MB~RIVIAN_YR~25_MK~US_CN~COREPLUS_TG~PRO_FS~LOWER_OB~CNVDD_TC~BRAND_PB~MICROSOFT_ID~B0001YQO&adgroup_id=1235852150288874&utm_term=rivian%20incentives&network=o&gclid=&msclkid=678d3b1084141532efef5326d50fbe8f (accessed on 26 May 2025).

- BYD’s Battery Revolution—No Lithium, No Limits—Engineerine. Available online: https://engineerine.com/byd-blade-battery/ (accessed on 26 May 2025).

- Nio’s Firefly EV Debuts with Swappable Battery tech to Cut Costs and Range Anxiety. Available online: https://interestingengineering.com/transportation/firefly-nio-ev-swappable-battery-tech (accessed on 26 May 2025).

- Mali, A.; Shukla, A.; Husain, A.; Hole, K.; Edake, V. Design and Analysis of Powertrain for Electric Vehicle. Int. Res. J. Eng. Technol. (IRJET) 2021, 8, 1222–1242. Available online: https://www.irjet.net/archives/V8/i8/IRJET-V8I8171.pdf (accessed on 2 May 2025).

- Nyamathulla, S.; Dhanamjayulu, C. A review of battery energy storage systems and advanced battery management system for different applications: Challenges and recommendations. J. Energy Storage 2024, 86, 111179. [Google Scholar] [CrossRef]

- Wu, C.; Sehab, R.; Morel, C.; Akrad, A. Entropy-Based Diagnosis Method for Open-Circuit Fault of an Inverter Supplying Wound Rotor Synchronous Machine of Electric Vehicle Powertrain. In Proceedings of the 2023 IEEE 4th International Conference on Advanced Electrical and Energy Systems, AEES 2023, Shanghai, China, 1–3 December 2023. [Google Scholar] [CrossRef]

- Goel, V.; Chaturvedi, S.; Sharma, B. Design and Simulation of Battery Thermal Management System for Electric Vehicles. In Proceedings of the 2025 IEEE International Conference on Interdisciplinary Approaches in Technology and Management for Social Innovation, IATMSI 2025, Gwalior, India, 6–8 March 2025; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2025; pp. 1–4. [Google Scholar] [CrossRef]

- Ning, X.; Wang, Z.; Lin, Y.; Yin, Y.; Wang, J.; Hong, Y. Optimization of Regenerative Braking Control Strategy in Single-Pedal Mode Based on Electro-Mechanical Braking. IEEE Access 2024, 12, 170994–171014. [Google Scholar] [CrossRef]

- Greitemeier, T.; Kampker, A.; Tübke, J.; Lux, S. China’s hold on the lithium-ion battery supply chain: Prospects for competitive growth and sovereign control. J. Power Sources Adv. 2025, 32, 100173. [Google Scholar] [CrossRef]

- Darby, J.P.; Harper, A.F.; Nelson, J.R.; Morris, A.J. Structure prediction of stable sodium germanides at 0 and 10 GPa. Phys. Rev. Mater. 2024, 8, 105002. [Google Scholar] [CrossRef]

- Phelan, C.M.E.; Björklund, E.; Singh, J.; Fraser, M.; Didwal, P.N.; Rees, G.J.; Ruff, Z.; Ferrer, P.; Grinter, D.C.; Grey, C.P. Role of Salt Concentration in Stabilizing Charged Ni-Rich Cathode Interfaces in Li-Ion Batteries. Chem. Mater. 2024, 36, 3334–3344. [Google Scholar] [CrossRef]

- Banerjee, H.; Grey, C.P.; Morris, A.J. Stability and Redox Mechanisms of Ni-Rich NMC Cathodes: Insights from First-Principles Many-Body Calculations. Chem. Mater. 2024, 36, 6575–6587. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [Google Scholar] [CrossRef]

- Petzl, M.; Kasper, M.; Danzer, M.A. Lithium plating in a commercial lithium-ion battery—A low-temperature aging study. J. Power Sources 2015, 275, 799–807. [Google Scholar] [CrossRef]

- Full, J.; Wanner, J.; Kiemel, S.; Miehe, R.; Weeber, M.; Sauer, A. Comparing technical criteria of various lithium-ion battery cell formats for deriving respective market potentials. In Proceedings of the 2020 IEEE Electric Power and Energy Conference, EPEC 2020, Online/Virtual, Edmonton, AB, Canada, 9–10 November 2020; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Hossain, I.; Anonto, H.Z.; Omi, M.I.; Shufian, A.; Emon, M.H.; Basak, R. Advancing Battery Management Systems: A Hybrid Approach Combining Unscented Kalman Filter and Machine Learning for Accurate State of Charge Estimation. In Proceedings of the 2025 IEEE International Conference on Robotics, Electrical and Signal Processing Techniques, ICREST 2025, Dhaka, Bangladesh, 11–12 January 2025; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2025; pp. 515–519. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Al Mamun, A.; Ansari, S.; Miah, M.S.; Hasan, K.; Meraj, S.T.; Abdolrasol, M.G.M.; Rahman, T.; Maruf, H.; Sarker, M.R.; et al. Battery Management, Key Technologies, Methods, Issues, and Future Trends of Electric Vehicles: A Pathway toward Achieving Sustainable Development Goals. Batteries 2022, 8, 119. [Google Scholar] [CrossRef]

- 18650 Battery Size: Dimensions, Specifications, And Key Features Explained [Updated on 2025]. Available online: https://poweringautos.com/what-is-the-size-of-18650-battery/ (accessed on 27 May 2025).

- E-One Moli Energy Corp. (Molicel). MODEL INR-18650A—Lithium-Ion Rechargeable Battery: Product Data Sheet; E-One Moli Energy Corp.: Taipei, Taiwan; Available online: https://www.molicel.com/wp-content/uploads/DM_INR18650A-V4-80078.pdf (accessed on 27 May 2025).

- Engineering: Tesla Roadster (2008)—HandWiki. Available online: https://handwiki.org/wiki/Engineering:Tesla_Roadster_(2008) (accessed on 27 May 2025).

- Baker, D.R. Elon Musk: Tesla Was Founded on 2 False Ideas, and Survived Anyway; SFGATE (San Francisco Chronicle): San Francisco, CA, USA, 2016; Available online: https://www.sfgate.com/business/article/Elon-Musk-Tesla-was-founded-on-2-false-ideas-7955528.php (accessed on 15 May 2025).

- Garcia-Valle, R.; Lopes, J.A.P. (Eds.) Electric Vehicle Integration into Modern Power Networks; Springer: New York, NY, USA, 2013; pp. 1–325. [Google Scholar] [CrossRef]

- E-One Moli Energy Corp. (Molicel). INR-21700 P45B—Product Data Sheet (80109), ver. 1.2; E-One Moli Energy Corp.: Taipei, Taiwan; Available online: https://www.molicel.com/wp-content/uploads/INR21700P45B_1.2_Product-Data-Sheet-of-INR-21700-P45B-80109.pdf (accessed on 22 May 2025).

- Lim, K.C. Battery Management System for Electric Vehicles. Ph.D. Thesis, University of Wollongong, Wollongong, NSW, Australia, 2017. Available online: https://ro.uow.edu.au/articles/thesis/Battery_Management_System_for_Electric_Vehicles/27668715 (accessed on 23 May 2025).

- Sabarimuthu, M.; Radha, J.; Gomathy, S.; Eswaran, R.; Kaushik, A.U.; Koushika, S. Integrated Battery Management and Thermal Control System for Lithium-Ion Battery Pack in Electric Vehicle. In Proceedings of the 2nd International Conference on Self Sustainable Artificial Intelligence Systems, ICSSAS 2024—Proceedings, Erode, India, 23–25 October 2024; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024; pp. 1685–1690. [Google Scholar] [CrossRef]

- Ank, M.; Sommer, A.; Abo Gamra, K.; Schöberl, J.; Leeb, M.; Schachtl, J.; Streidel, N.; Stock, S.; Schreiber, M.; Bilfinger, P.; et al. Lithium-Ion Cells in Automotive Applications: Tesla 4680 Cylindrical Cell Teardown and Characterization. J. Electrochem. Soc. 2023, 170, 120536. [Google Scholar] [CrossRef]

- Tesla 4680 Cell—Battery Design. Available online: https://www.batterydesign.net/tesla-4680-cell/ (accessed on 27 May 2025).

- Tesla 4680 Cell Generation 2—Battery Design. Available online: https://www.batterydesign.net/tesla-4680-cell-generation-2/ (accessed on 27 May 2025).

- Gholap, A.; Parashar, V. Design of a Battery Thermal Management System for the Tesla 4680 Module. Int. J. Curr. Sci. 2023, 13, 699–727. Available online: https://rjpn.org/IJCSPUB/papers/IJCSP23A1089.pdf (accessed on 2 June 2025).

- Ahmad, T.; Mishra, A.; Ghosh, S.; Casari, C.S. Identifying Efficient Cooling Approach of Cylindrical Lithium-Ion Batteries. Energy Technol. 2021, 10, 2100888. [Google Scholar] [CrossRef]

- Eze, C.; Zhao, J.; Chung, D.; Fakhimi Bonab, M.; Chuang, A.; Burke, A.F.; Chen, G. Numerical heat generation analysis of the tabbed and novel tabless designs of cylindrical-type lithium-ion batteries. Appl. Therm. Eng. 2024, 246, 122879. [Google Scholar] [CrossRef]

- Pegel, H.; Grimm, A.; Frey, C.; Seefeldt, V.; Baazouzi, S.; Sauer, D.U. Manufacturing of tabless cylindrical lithium-ion cells: Quantifying the influence of cell dimensions and housing material via process-based cost modeling. J. Energy Storage 2024, 98, 112863. [Google Scholar] [CrossRef]

- CATL’s New LFP Battery: 620+ Miles of Range and Ultra-Fast Charging—UNDERCODE NEWS. Available online: https://undercodenews.com/catls-new-lfp-battery-620-miles-of-range-and-ultra-fast-charging/ (accessed on 31 May 2025).

- Baazouzi, S.; Feistel, N.; Wanner, J.; Landwehr, I.; Fill, A.; Birke, K.P. Design, Properties, and Manufacturing of Cylindrical Li-Ion Battery Cells—A Generic Overview. Batteries 2023, 9, 309. [Google Scholar] [CrossRef]

- Tesla’s 4680 Battery Cell—TESLA.ROCKS. Available online: https://tesla.rocks/2025/04/29/teslas-4680-battery-cell/ (accessed on 28 May 2025).

- Chen, S.; Zhang, G.; Wu, C.; Huang, W.; Xu, C.; Jin, C.; Wu, Y.; Jiang, Z.; Dai, H.; Feng, X.; et al. Multi-objective optimization design for a double-direction liquid heating system-based Cell-to-Chassis battery module. Int. J. Heat. Mass Transf. 2022, 183, 122184. [Google Scholar] [CrossRef]

- 2026 BMW i3 and BMW iX3: Our Best Look Yet. Available online: https://insideevs.com/news/753610/2026-bmw-i3-ix3-neue-klasse/ (accessed on 1 July 2025).

- Cell-to-Pack Batteries—E-Mobility Engineering. Available online: https://www.emobility-engineering.com/cell-to-pack-batteries/ (accessed on 22 June 2025).

- Puls, S.; Nazmutdinova, E.; Kalyk, F.; Woolley, H.M.; Thomsen, J.F.; Cheng, Z.; Fauchier-Magnan, A.; Gautam, A.; Gockeln, M.; Ham, S.-Y.; et al. Benchmarking the reproducibility of all-solid-state battery cell performance. Nat. Energy 2024, 9, 1310–1320. [Google Scholar] [CrossRef]

- Kravchyk, K.V.; Okur, F.; Kovalenko, M.V. Break-even analysis of all-solid-state batteries with Li-garnet solid electrolytes. ACS Energy Lett. 2021, 6, 2202–2207. [Google Scholar] [CrossRef]

- Kim, K.J.; Balaish, M.; Wadaguchi, M.; Kong, L.; Rupp, J.L.M. Solid-state Li–metal batteries: Challenges and horizons of oxide and sulfide solid electrolytes and their interfaces. Adv. Energy Mater. 2021, 11, 2002689. [Google Scholar] [CrossRef]

- Luo, Y.; Rao, Z.; Yang, X.; Wang, C.; Sun, X.; Li, X. Safety concerns in solid-state lithium batteries: From materials to devices. Energy Environ. Sci. 2024, 17, 7543–7565. [Google Scholar] [CrossRef]

- Naseer, M.N.; Serrano-Sevillano, J.; Fehse, M.; Bobrikov, I.; Saurel, D. Silicon anodes in lithium-ion batteries: A deep dive into research trends and global collaborations. J. Energy Storage 2025, 111, 115334. [Google Scholar] [CrossRef]

- Roe, C.; Feng, X.; White, G.; Li, R.; Wang, H.; Rui, X.; Li, C.; Zhang, F.; Null, V.; Parkes, M.; et al. Immersion cooling for lithium-ion batteries—A review. J. Power Sources 2022, 525, 231094. [Google Scholar] [CrossRef]

- Lucid Motors. Official Website; Lucid Group, Inc.: Newark, CA, USA, 2025; Available online: https://www.lucidmotors.com (accessed on 28 May 2025).

- Insights—Bloomberg NEF. Available online: https://about.bnef.com/insights/ (accessed on 28 May 2025).

- BYD Company Ltd. BYD SEAL Specification (EU—V4); BYD Company Ltd.: Shenzhen, China, 2023; Available online: https://www.byd.com/content/dam/byd-site/eu/product/seal/BYD%20SEAL%20V4.pdf (accessed on 2 June 2025).

- Mussa, A.S.; Lindbergh, G.; Klett, M.; Gudmundson, P.; Svens, P.; Lindström, R.W. Inhomogeneous active layer contact loss in a cycled prismatic lithium-ion cell caused by the jelly-roll curvature. J. Energy Storage 2018, 20, 213–217. [Google Scholar] [CrossRef]

- Li, X.; Zeng, T.; Qin, H.; Huo, R.; Liu, Y.; Wei, D.; Ding, X. Investigation of inhomogeneous degradation in large-format lithium-ion batteries. J. Energy Storage 2021, 42, 103113. [Google Scholar] [CrossRef]

- Winding vs. Stacking, Which Works Best for Lithium-Ion Batteries | Bonnen. Available online: https://www.bonnenbatteries.com/winding-vs-stacking-which-technology-works-best-for-lithium-ion-batteries/ (accessed on 29 May 2025).

- Type of Prismatic Cells—Winding and Z Stacking | Part 1 EVreporter. Available online: https://evreporter.com/type-of-prismatic-cells-winding-and-z-stacking-part-1/ (accessed on 29 May 2025).

- CATL Achieves 304 Wh/kg in New Battery Cells—Posts—🔋PushEVs. Available online: https://pushevs.com/2019/03/30/catl-achieves-304-wh-kg-in-new-battery-cells/#google_vignette (accessed on 1 July 2025).

- Guo, F.; Couto, L.D.; Trad, K.; Mulder, G.; Haghverdi, K.; Thenaisie, G. Optimizing Parameter Estimation for Electrochemical Battery Model: A Comparative Analysis of Operating Profiles on Computational Efficiency and Accuracy. arXiv 2025, arXiv:2503.00604. [Google Scholar] [CrossRef]

- Global EV battery Market Share in 2024: CATL 37.9%, BYD 17.2%—CnEVPost. Available online: https://cnevpost.com/2025/02/11/global-ev-battery-market-share-2024/ (accessed on 29 May 2025).

- CATL’s Expanding EV Battery Empire: Can It Overcome, U.S. Scrutiny? Available online: https://finance.yahoo.com/news/catls-expanding-ev-battery-empire-145800386.html (accessed on 29 May 2025).

- EV Battery Maker CATL Shares Surge in Hong Kong After $4.6 Billion IPO | AP News. Available online: https://apnews.com/article/catl-ev-batteries-listed-hong-kong-1e87c749f080779e70b4b00b3516a635 (accessed on 29 May 2025).

- SAMSUNG SDI Wins InterBattery Awards 2025 for Outstanding Innovation. Available online: https://news.samsungsdi.com/global/articleView?seq=234 (accessed on 30 May 2025).

- Samsung SDI Introduces Cylindrical NCA Cells with 91% Nickel. Available online: https://insideevs.com/news/513181/samsungsdi-cylindrical-nca-cells-91nickel/ (accessed on 30 May 2025).

- CALB Group Co., Ltd. Specialized in Lithium Batteries. Available online: http://en.calb-tech.com/ (accessed on 30 May 2025).

- Samsung Opts for Solid Prismatic Batteries—News About Energy Storage, Batteries, Climate Change and the Environment. Available online: https://blog.upsbatterycenter.com/samsung-opts-for-solid-prismatic-batteries/ (accessed on 30 May 2025).

- Report: Samsung SDI to Produce Unified Cells for VW Group. Available online: https://insideevs.com/news/525019/samsung-sdi-unified-cells-volkswagen/ (accessed on 31 May 2025).

- VW Breaks Ground on First Cell Plant, Shows Prismatic Unified Cell. Available online: https://insideevs.com/news/596993/volkswagen-salzgiga/ (accessed on 31 May 2025).

- How Do We Identify *Which* Battery Chemistry Our BZ4X Shipped with? | Toyota BZ Forum. Available online: https://www.bzforums.com/threads/how-do-we-identify-which-battery-chemistry-our-bz4x-shipped-with.990/ (accessed on 29 May 2025).

- BYD Blade—Battery Design. Available online: https://www.batterydesign.net/byd-blade/ (accessed on 30 May 2025).

- Tesla’s EV Battery Production and Global Gigafactory Network | Article | Automotive Manufacturing Solutions. Available online: https://www.automotivemanufacturingsolutions.com/ev-battery-production/teslas-ev-battery-production-and-global-gigafactory-network/45873.article (accessed on 28 May 2025).

- Tesla Switches Standard Range Vehicles to lfp Battery Chemistry. Available online: https://www.teslarati.com/tesla-switches-standard-range-vehicles-to-lfp-battery-chemistry/ (accessed on 31 May 2025).

- GM Unveils New Battery Cells for Affordable EV Trucks and SUVs. Available online: https://electrek.co/2025/05/13/gm-unveils-new-battery-cells-for-affordable-ev-trucks-suvs/ (accessed on 31 May 2025).

- Samsung SDI Finalizes Deal with GM to Build $3.5 bln Joint EV Battery Factory in US | Reuters. Available online: https://www.reuters.com/markets/deals/samsung-sdi-signs-deal-with-gm-its-joint-ev-battery-factory-us-2024-08-27/ (accessed on 31 May 2025).

- Samsung SDI and General Motors Finalize Agreement to Establish Battery Joint Venture in the US. Available online: https://samsungsdi.com/sdi-now/sdi-news/3942.html (accessed on 31 May 2025).

- Jeep Recall of Samsung SDI Prismatic Batteries | Rivian Forum—R1T R1S R2 R3 News, Specs, Models, RIVN Stock—Rivianforums.com. Available online: https://www.rivianforums.com/forum/threads/jeep-recall-of-samsung-sdi-prismatic-batteries.33694/ (accessed on 31 May 2025).

- CATL Launches 3rd Generation of Cell-to-Pack; 72% Volume Utilization Efficiency Up to 255 Wh/kg—Green Car Congress. Available online: https://www.greencarcongress.com/2022/06/20220624-qilin.html (accessed on 29 May 2025).

- Leapmotor Unveils CTC Technology That Does Not Use Separate Battery Pack—AutoTech News. Available online: https://autotech.news/leapmotor-unveils-ctc-technology-that-does-not-use-separate-battery-pack/ (accessed on 31 May 2025).

- PowerCo: VW Battery Production on Schedule—Electrive.com. Available online: https://www.electrive.com/2024/06/26/powerco-vw-battery-production-on-schedule/ (accessed on 31 May 2025).

- How Battery Cell Formats Will Change the Face of the EV Industry—The Armchair Trader. Available online: https://www.thearmchairtrader.com/ev-cells-battery-design-format/ (accessed on 31 May 2025).

- Stellantis and Factorial Energy Reach Key Milestone in Solid-State Battery Development | Stellantis. Available online: https://www.stellantis.com/en/news/press-releases/2025/april/stellantis-and-factorial-energy-reach-key-milestone-in-solid-state-battery-development (accessed on 31 May 2025).

- Khan, W.S.; Darwish, M. Advancing Electric Vehicle Technologies: A Comparative Analysis of Lithium-Ion and Emerging Solid-State Battery Systems. In Proceedings of the 2024 59th International Universities Power Engineering Conference, UPEC 2024, Cardiff, UK, 2–6 September 2024; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Machín, A.; Femia, N.; Gatta, F. Advancements and Challenges in Solid-State Battery Technology for Electric Vehicles. Batteries 2024, 10, 29. [Google Scholar] [CrossRef]

- Building the Best Solid State Battery | QuantumScape. Available online: https://www.quantumscape.com/ (accessed on 31 May 2025).

- Broatch, A.; Olmeda, P.; Margot, X.; Agizza, L. A Physical-Based Electro-Thermal Model for a Prismatic LFP Lithium-Ion Cell Thermal Analysis. Energies 2025, 18, 1281. [Google Scholar] [CrossRef]

- CATL’s New Sodium Battery to Challenge Lithium Dominance in EVs. Available online: https://interestingengineering.com/energy/catl-sodium-ev-battery-unveiled (accessed on 29 May 2025).

- Nguyen, T.D.; Deng, J.; Robert, B.; Chen, W.; Siegmund, T. Experimental investigation on cooling of prismatic battery cells through cell integrated features. Energy 2022, 244, 122580. [Google Scholar] [CrossRef]

- GM Says These EV Batteries Are “Critical” For Its Future. Available online: https://insideevs.com/news/759479/gm-lmr-prismatic-ev-battery-critical/ (accessed on 31 May 2025).

- [SDI Focus] Prismatic Battery: Achieving Both Safety and Performance. Available online: https://news.samsungsdi.com/global/articleView?seq=207 (accessed on 30 May 2025).

- Sevilgen, G.; Dursun, H.; Kılıç, M. Experimental and Numerical Investigations on the Thermal Performance of Three Different Cold Plates Designed for the Electrical Vehicle Battery Module. Sustainability 2023, 15, 14162. [Google Scholar] [CrossRef]

- Kim, Y.T.; Han, S.Y. Cooling channel designs of a prismatic battery pack for electric vehicle using the deep Q-network algorithm. Appl. Therm. Eng. 2023, 219, 119610. [Google Scholar] [CrossRef]

- Ahmadian-Elmi, M.; Zhao, P. Review of Thermal Management Strategies for Cylindrical Lithium-Ion Battery Packs. Batteries 2024, 10, 50. [Google Scholar] [CrossRef]

- Heimes, H.; Offermanns, C.; Frieges, M.; Ghandily, N.; Zamit, G.; Gorsch, J. Influence of cell dimensions and number of tabs on cylindrical lithium-ion cell sidewall and bottom cooling performance. In Proceedings of the 2023 22nd IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 30 May–2 June 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–7. [Google Scholar] [CrossRef]

- Prismatic Cells—Battery Design. Available online: https://www.batterydesign.net/battery-cell/formats/prismatic-cells/ (accessed on 1 June 2025).

- Billal Boumegouas, M.K.; Kouzi, K.; Trabelsi, M.; Bougrine, M.; Bendjedia, B.; Iqbal, A. Comparative Performance Analysis of 21700-Type Cylindrical and Pouch Nickel Manganese Cobalt Battery Cells for Electric Vehicle Applications. In Proceedings of the 2024 IEEE 21st International Power Electronics and Motion Control Conference (PEMC), Pilsen, Czech Republic, 30 September–3 October 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Dong, Y.; Hays, K.; Huang, B.; Zhang, W.; Venkatachalam, S.; Kumar, S.; Sinkula, M.; Lopez, H. Fast-Charge and Low-Cost Lithium-Ion Batteries for Electric Vehicles. DOE Vehicle Technologies Office Annual Merit Review (AMR) 2020—Project BAT247; Zenlabs Energy Inc.; U.S. Department of Energy: Washington, DC, USA, 2020. Available online: https://www.energy.gov/sites/prod/files/2020/05/f75/bat247_lopez_2020_p_5.11.20_725PM_LR.pdf (accessed on 3 June 2025).

- Schmidgruber, N.; Smith, A.; Löwe, R.; Schabel, S.; Fleischer, J. Investigation on Defects of Battery Pouch Cell Housing. In Proceedings of the 2024 1st International Conference on Production Technologies and Systems for E-Mobility, EPTS 2024, Bamberg, Germany, 5–6 June 2024; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Pouch Cell—Small but Not Trouble Free—Battery University. Available online: https://batteryuniversity.com/article/pouch-cell-small-but-not-trouble-free (accessed on 2 June 2025).

- Schuster, E.; Ziebert, C.; Melcher, A.; Rohde, M.; Seifert, H.J. Thermal behavior and electrochemical heat generation in a commercial 40 Ah lithium ion pouch cell. J. Power Sources 2015, 286, 580–589. [Google Scholar] [CrossRef]

- JAGUAR I-PACE: THE ART of ELECTRIC PERFORMANCE | Jaguar 2024 Media Newsroom. Available online: https://media.jaguar.com/2018/jaguar-i-pace-art-electric-performance (accessed on 2 June 2025).

- Hettesheimer, T.; Neef, C.; Rosellón Inclán, I.; Link, S.; Schmaltz, T.; Schuckert, F.; Stephan, A.; Stephan, M.; Thielmann, A.; Weymann, L.; et al. Lithium-Ion Battery Roadmap—Industrialization Perspectives toward 2030; Fraunhofer ISI: Karlsruhe, Germany, 2023; Available online: https://www.isi.fraunhofer.de/content/dam/isi/dokumente/cct/2023/Fraunhofer-ISI_LIB-Roadmap-2023.pdf (accessed on 2 June 2025).

- PowerCo Confirms Results: QuantumScape’s Solid-State Cell Passes First Endurance Test | Volkswagen Group. Available online: https://www.volkswagen-group.com/en/press-releases/powerco-confirms-results-quantumscapes-solid-state-cell-passes-first-endurance-test-18031 (accessed on 28 May 2025).

- Innovations for the Future: The Development of Safe Batteries for Electric Vehicles—Farasis Energy. Available online: https://www.farasis-energy.com/en/innovations-for-the-future-the-development-of-safe-batteries-for-electric-vehicles (accessed on 2 June 2025).

- Farasis Energy Reports 25% Energy Boost for EV Batteries with SCC55® | Group14. Available online: https://group14.technology/resources/press-releases/farasis-energy-reports-25-energy-boost-for-ev-batteries-with-scc55/ (accessed on 2 June 2025).

- Nissan’s Solid State Battery Should Arrive In 2028: “That’s Our Ambition”. Available online: https://insideevs.com/news/755673/nissan-solid-state-battery-plans/ (accessed on 31 May 2025).

- General Motors. Why LMR Batteries Will Change the Outlook for the EV Market; General Motors Co.: Detroit, MI, USA, 2025; Available online: https://news.gm.com/home.detail.html/Pages/topic/us/en/2025/may/0513-LMR-batteries-outlook-EV-market.html (accessed on 2 June 2025).

- Envision AESC. Battery Business Strategy; Presentation (PDF), Envision AESC: Kanagawa, Japan, 2 June 2022; Available online: https://cdnw8.eu-japan.eu/sites/default/files/imce/Envision%20AESC%202022.6.2%20V2.pdf (accessed on 4 June 2025).

- Nissan Leaf—Battery Design. Available online: https://www.batterydesign.net/nissan-leaf/ (accessed on 2 June 2025).

- Bolt Individual Cell Capacity Ratings… ChevyBolt.org Forum (Online). 2021. Available online: https://www.chevybolt.org/threads/bolt-individual-cell-capacity-ratings.39578/ (accessed on 2 June 2025).

- LG Energy to Supply Batteries for Ford’s Electric Commercial Vehicles—KED Global. Available online: https://www.kedglobal.com/batteries/newsView/ked202410150019 (accessed on 31 May 2025).

- Ford Reveals Its VW-Based EV Crossover for Europe, the Explorer. Available online: https://www.caranddriver.com/news/a43374939/ford-explorer-ev-europe-revealed/ (accessed on 31 May 2025).

- Ford F-150 Lightning FAQs and Battery Capacity Details. Ford Motor Company Support (Online). 2025. Available online: https://www.ford.com/support/how-tos/electric-vehicles/f-150-lightning/f-150-lightning-charging-frequently-asked-questions/ (accessed on 8 June 2025).

- Hyundai Motor Group and SK on to Establish EV Battery Cell Production Joint Venture in US. Available online: https://www.hyundai.com/worldwide/en/newsroom/detail/hyundai-motor-group-and-sk-on-to-establish-ev-battery-cell-production-joint-venture-in-us-0000000237 (accessed on 31 May 2025).

- Hyundai Motor Group and LG Energy Solution to Establish Battery Cell Manufacturing Joint Venture in the U.S. Available online: https://www.hyundai.news/eu/articles/press-releases/hmg-and-lg-energy-solution-establish-battery-cell-manufacturing-joint-venture.html (accessed on 9 June 2025).

- LG Energy Solution. LG Energy Solution and Hyundai Motor Group to Establish Battery Cell Manufacturing Joint Venture in the U.S.; LG Energy Solution: Seoul, Republic of Korea, 2023; Available online: https://www.prnewswire.com/news-releases/lg-energy-solution-and-hyundai-motor-group-to-establish-battery-cell-manufacturing-joint-venture-in-the-us-301835407.html (accessed on 30 May 2025).

- Audi E-Tron vs Jaguar I-PACE Battery Pack Comparison—Electric Revs. Available online: https://electricrevs.com/2018/04/21/audi-e-tron-vs-jaguar-i-pace-battery-pack-comparison (accessed on 9 June 2025).

- Bohn, G.; Taub, J.; Oeser, D.; Ziegler, A.; Gielinger, S. Fast and High Resolution Expansion Measurement at an Audi e-tron Battery Cell. In Proceedings of the 2022 IEEE Vehicle Power and Propulsion Conference, VPPC 2022, Merced, CA, USA, 1–4 November 2022; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Gharehghani, A.; Rabiei, M.; Mehranfar, S.; Saeedipour, S.; Mahmoudzadeh Andwari, A.; García, A.; Reche, C.M. Progress in battery thermal management systems technologies for electric vehicles. Renew. Sustain. Energy Rev. 2024, 202, 114654. [Google Scholar] [CrossRef]

- Bashir, H.; Yaqoob, A.; Kousar, F.; Khalid, W.; Akhtar, S.; Sultan, W. A Comprehensive Review of Li-ion Battery Cell Balancing Techniques & Implementation of Adaptive Passive Cell Balancing. In Proceedings of the 2022 International Conference on Electrical Engineering and Sustainable Technologies, ICEEST 2022, Lahore, Pakistan, 14–15 December 2022; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Paidi, R.; Gudey, S.K. Active and Passive Cell Balancing Techniques for Li-Ion Batteries used in EVs. In Proceedings of the 2022 IEEE International Power and Renewable Energy Conference, IPRECON 2022, Karunagappally, Kerala, India, 16–18 December 2022; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Pavan, M.V.S.V.R.; Shareef, I.; Sathish, D.V.S.; Sankar, J.P.S. Optimizing Battery Performance—Active and Passive Cell Balancing. In Proceedings of the 2024 Third International Conference on Intelligent Techniques in Control, Optimization and Signal Processing, INCOS 2024, Krishnankoil, Tamil Nadu, India, 14–16 March 2024; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Wang, C.; Yang, M.; Wang, X.; Xiong, Z.; Qian, F.; Deng, C.; Yu, C.; Zhang, Z.; Guo, X. A review of battery, S.O.;C estimation based on equivalent circuit models. J. Energy Storage 2025, 110, 115346. [Google Scholar] [CrossRef]

- Soyoye, B.D.; Bhattacharya, I.; Anthony Dhason, M.V.; Banik, T. State of Charge and State of Health Estimation in Electric Vehicles: Challenges, Approaches and Future Directions. Batteries 2025, 11, 32. [Google Scholar] [CrossRef]

- Marcos, D.; Garmendia, M.; Crego, J.; Cortajarena, J. Functional Safety BMS Design Methodology for Automotive Lithium-Based Batteries. Energies 2021, 14, 6942. [Google Scholar] [CrossRef]

- Cao, Z.; Gao, W.; Fu, Y.; Mi, C. Wireless Battery Management Systems: Innovations, Challenges, and Future Perspectives. Energies 2024, 17, 3277. [Google Scholar] [CrossRef]

- Samanta, A.; Williamson, S.S. A Survey of Wireless Battery Management System: Topology, Emerging Trends, and Challenges. Electronics 2021, 10, 2193. [Google Scholar] [CrossRef]

- Basic, F.; Seifert, C.; Steger, C.; Kofler, R. Secure Data Acquisition for Battery Management Systems. In Proceedings of the 26th Euromicro Conference on Digital System Design (DSD 2023), Durrës, Albania, 6–8 September 2023; IEEE: Piscataway, NJ, USA, 2024; pp. 553–560. [Google Scholar] [CrossRef]

- Njoku, J.N.; Nkoro, E.C.; Medina, R.M.; Nwakanma, C.I.; Lee, J.-M.; Kim, D.-S. Leveraging Digital Twin Technology for Battery Management: A Case Study Review. IEEE Access 2025, 13, 21382–21412. [Google Scholar] [CrossRef]

- Schärtel, L.; Reick, B.; Pfeil, M.; Stetter, R. Analysis and Synthesis of Architectures for Automotive Battery Management Systems. Appl. Sci. 2022, 12, 10756. [Google Scholar] [CrossRef]

- Gabbar, H.; Othman, A.; Abdussami, M. Review of Battery Management Systems (BMS) Development and Industrial Standards. Technologies 2021, 9, 28. [Google Scholar] [CrossRef]

- Kurkin, A.; Chivenkov, A.; Aleshin, D.; Trofimov, I.; Shalukho, A.; Vilkov, D. Battery Management System for Electric Vehicles: Comprehensive Review of Circuitry Configuration and Algorithms. World Electr. Veh. J. 2025, 16, 451. [Google Scholar] [CrossRef]

- Analog Devices; General Motors. Analog Devices Introduces the Automotive Industry’s First Wireless Battery Management System for EVs; GM to Use ADI’s wBMS Across Ultium; Analog Devices, Inc.: Wilmington, MA, USA, 2020; Available online: https://investor.analog.com/news-releases/news-release-details/analog-devices-introduces-automotive-industrys-first-wireless (accessed on 23 May 2025).

- Mulpuri, S.K.; Sah, B.; Kumar, P. An intelligent battery management system (BMS) with end-edge-cloud connectivity—A perspective. Sustain. Energy Fuels 2025, 9, 1142–1159. [Google Scholar] [CrossRef]

- ISO 15118-20; AFIR Update Spring 2025, Smart Charging. Pionix GmbH: Bad Schönborn, Germany, 2025. Available online: https://www.pionix.com/news/afir-regulation-update-spring-2025 (accessed on 10 June 2025).

- Mohana Devi, S.; Bagyaveereswaran, V. Electric Motor Systems: Relative Study on Diverse Motors in the Electric Vehicles. In Proceedings of the 2023 Innovations in Power and Advanced Computing Technologies, i-PACT 2023, Kuala Lumpur, Malaysia, 8–10 December 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Ntombela, M.; Musasa, K.; Moloi, K. Review of the Technology and Problems Faced by Electric Vehicles Drive Circuits. In Proceedings of the 2023 International Conference on Electrical, Computer and Energy Technologies, ICECET 2023, Cape Town, South Africa, 16–17 November 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Luong-Gia, H.; Nguyễn, B.-H.; Tran, L.H.; Ta, M.C.; Vo-Duy, T. Modeling and Control of Multi-phase Motor Fed by Multi-level Inverter for Electric Vehicles. In Proceedings of the 2024 IEEE Vehicle Power and Propulsion Conference, VPPC 2024, Washington, DC, USA, 7–10 October 2024; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024; pp. 1–6. [Google Scholar] [CrossRef]

- Comajuncosa, P.M.; Albiol, J. Affordable Battery Electric Vehicle Design Concept. Bachelor’s Thesis, Escola Universitària Politècnica de Manresa, Manresa, Spain, 2021. [Google Scholar]

- Development of Wheel Hub Motor Drive Application in Electric Vehicles | PURE. Available online: https://pure.sabanciuniv.edu/project/2248/development-wheel-hub-motor-drive-application-electric-vehicles (accessed on 17 June 2025).

- Wu, P.; Luo, R.; Yu, Z.; Hou, Z. Evaluation of the Unsprung Mass Effect on Ride Comfort of In-Wheel Motor Driving Vehicles. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2025, 239, 09544070241288615. [Google Scholar] [CrossRef]

- eAxles—E-Mobility Engineering. Available online: https://www.emobility-engineering.com/eaxle-transmission/ (accessed on 17 June 2025).

- Monadi, M.; Nabipour, M.; Akbari-Behbahani, F.; Pouresmaeil, E. Speed Control Techniques for Permanent Magnet Synchronous Motors in Electric Vehicle Applications Toward Sustainable Energy Mobility: A Review. IEEE Access 2024, 12, 119615–119632. [Google Scholar] [CrossRef]

- Prajapati, A.M. Advanced Control Strategies of PMSM for Battery Electric Vehicle Application: A Review. J. Electr. Syst. 2024, 20, 1139–1149. [Google Scholar] [CrossRef]

- Zhao, X.; Kou, B.; Huang, C.; Zhang, L. Optimization Design and Performance Analysis of a Reverse-Salient Permanent Magnet Synchronous Motor. Machines 2022, 10, 204. [Google Scholar] [CrossRef]

- 2016 Chevrolet Volt Dissected: Everything You Need to Know, Feature, Car and Driver. Available online: https://www.caranddriver.com/features/a15108381/2016-chevrolet-volt-dissected-everything-you-need-to-know-feature/ (accessed on 2 June 2025).

- Two Types of Tesla Model 3 Motors: Everything You Need to Know. Available online: https://lammotor.com/electric-motors-in-tesla/ (accessed on 14 June 2025).

- Hughes, A.; Drury, B. Electric Motors and Drives: Fundamentals, Types and Applications, 5th ed.; Elsevier/Newnes: Oxford, UK, 2019. [Google Scholar]

- Asynchronous Motor | Photo | Audi MediaCenter. Available online: https://www.audi-mediacenter.com/en/photos/detail/asynchronous-motor-70267 (accessed on 14 June 2025).

- Model Y RWD v Dual Motor Version... | Tesla Motors Club. Available online: https://teslamotorsclub.com/tmc/threads/model-y-rwd-v-dual-motor-version.300630/ (accessed on 14 June 2025).

- Check Out Tesla Model 3/Model Y’s Modular Electric Drive Units. Available online: https://insideevs.com/news/518692/tesla-model-3y-drive-units/ (accessed on 14 June 2025).

- Chao, C.-H. Tesla Model S Induction Motor Analysis. In Proceedings of the 2023 IEEE 3rd International Conference on Power, Electronics and Computer Applications, ICPECA 2023, Shenyang, China, 29–31 January 2023; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2023; pp. 1462–1464. [Google Scholar] [CrossRef]

- Müller, S.; Maier, D.; Parspour, N. Inductive Electrically Excited Synchronous Machine for Electrical Vehicles—Design, Optimization and Measurement. Energies 2023, 16, 1657. [Google Scholar] [CrossRef]

- Regen Braking: Pedal Versus Paddle? | Hyundai IONIQ Forum. Available online: https://www.ioniqforum.com/threads/regen-braking-pedal-versus-paddle.48831/ (accessed on 18 June 2025).

- Panpean, C.; Mangkala, N.; Santiprapan, P.; Homjan, J. Predictive Controller Based on Indirect Vector Control for Induction Motor in Electric Vehicle. In Proceedings of the 2024 27th International Conference on Electrical Machines and Systems, ICEMS 2024, Fukuoka, Japan, 26–29 November 2024; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024; pp. 1562–1567. [Google Scholar] [CrossRef]

- Gone Too Soon? Final Drive in the Pioneering Renault Zoe | Autocar. Available online: https://www.autocar.co.uk/car-news/new-cars/saying-goodbye-pioneering-renault-zoe (accessed on 26 August 2025).

- Maroti, P.K.; Padmanaban, S.; Bhaskar, M.S.; Ramachandaramurthy, V.K.; Blaabjerg, F. The state-of-the-art of power electronics converters configurations in electric vehicle technologies. Power Electron. Devices Compon. 2022, 1, 100001. [Google Scholar] [CrossRef]

- Brenna, M.; Foiadelli, F.; Leone, C.; Longo, M. Electric Vehicles Charging Technology Review and Optimal Size Estimation. J. Electr. Eng. Technol. 2020, 15, 2539–2552. [Google Scholar] [CrossRef]

- Khaligh, A.; D’Antonio, M. Global Trends in High-Power On-Board Chargers for Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 3306–3324. [Google Scholar] [CrossRef]

- Lenka, R.K.; Panda, A.K.; Dash, A.R.; Venkataramana, N.N.; Tiwary, N. Reactive Power Compensation using Vehicle-to-Grid enabled Bidirectional Off-Board EV Battery Charger. In Proceedings of the 2021 1st International Conference on Power Electronics and Energy, ICPEE 2021, Bhubaneswar, India, 2–3 January 2021; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Nguyen, H.V.; To, D.-D.; Lee, D.-C. Onboard Battery Chargers for Plug-in Electric Vehicles With Dual Functional Circuit for Low-Voltage Battery Charging and Active Power Decoupling. IEEE Access 2018, 6, 70212–70222. [Google Scholar] [CrossRef]

- Pan, L.; Zhang, C. A High Power Density Integrated Charger for Electric Vehicles with Active Ripple Compensation. Math. Probl. Eng. 2015, 2015, 1–18. [Google Scholar] [CrossRef]

- SiC Power for 800V EV Traction Inverter Platforms | Wolfspeed. Available online: https://www.wolfspeed.com/knowledge-center/article/add-miles-and-years-of-performance-to-your-next-800-v-ev-traction-inverter-platform/ (accessed on 17 June 2025).

- Qiu, G.; Khadkikar, V.; Zahawi, B. Capacitively Isolated Dual Active Bridge Converter for On-Board Charger Applications. IEEE Trans. Ind. Electron. 2025, 72, 5833–5845. [Google Scholar] [CrossRef]

- He, J.; Chen, Y.; Lin, J.; Chen, J.; Cheng, L.; Wang, Y. Review of Modeling, Modulation, and Control Strategies for the Dual-Active-Bridge DCDC Converter. Energies 2023, 16, 6646. [Google Scholar] [CrossRef]

- Gong, X. Design Priorities in EV Traction Inverter with Optimum Performance; Technical White Paper; Texas Instruments: Dallas, TX, USA, 2023; Available online: https://www.ti.com/lit/SPRAD58 (accessed on 30 May 2025).

- Sumathy, R.; Rajesh, V.; Reddy, V.A.; Vamsi Krishna, K.; Harikrishna, C.H.; Kumar Raju, M.M. Design and Implementation Of Traction Inverter and its Examination. In Proceedings of the 2024 5th International Conference on Recent Trends in Computer Science and Technology, ICRTCST 2024, Jamshedpur, India, 15–16 April 2024; Institute of Electrical and Electronics Engineers Inc.: Piscataway, NJ, USA, 2024; pp. 444–448. [Google Scholar] [CrossRef]

- Kotb, R.; Chakraborty, S.; Tran, D.-D.; Abramushkina, E.; El Baghdadi, M.; Hegazy, O. Power Electronics Converters for Electric Vehicle Auxiliaries: State of the Art and Future Trends. Energies 2023, 16, 1753. [Google Scholar] [CrossRef]

- Hyundai IONIQ 6 Delivers a New Electric Mobility Experience. Available online: https://www.hyundai.news/eu/models/electrified/ioniq-6/press-kit/hyundai-ioniq-6-delivers-a-new-electric-mobility-experience.html (accessed on 9 June 2025).

- Audi Q4 E-Tron Motor: Electrichasgoneaudi.net. Available online: https://electrichasgoneaudi.net/models/q4-e-tron/drivetrain/motor/ (accessed on 14 June 2025).

- Rathore, V.; Rajashekara, K.; Nayak, P.; Ray, A. A High-Gain Multilevel dc–dc Converter for Interfacing Electric Vehicle Battery and Inverter. IEEE Trans. Ind. Appl. 2022, 58, 6506–6518. [Google Scholar] [CrossRef]