Abstract

Electric vehicles (EVs) are gaining more and more traction as a viable option in the automotive sector. This mode of transportation is currently on track, according to current trends, to totally replace internal combustion engine (ICE) cars in the not-too-distant future. The economic system, the energy infrastructure, and the environment are just a few of the areas where electric vehicles could have a major impact. The transportation industry produces the second-most carbon dioxide gas from the combustion of fossil fuels, making it the second-highest contributor to global warming. A lot of people are looking to EVs, or electric vehicles, as a possible game-changing answer to this problem. Since an electric motor drives the electric vehicle’s propeller instead of an internal combustion engine, electric vehicles can reduce their carbon dioxide (CO2) emissions compared to traditional automobiles. If coupled with renewable energy sources, EVs might theoretically become emission-free automobiles. In this paper, we will examine the various EV drive circuit types, including their construction and the benefits and drawbacks of employing each. This article discusses the current state of battery technology with an emphasis on EV batteries. This article discusses the best electric motor for EVs in terms of efficiency, power density, fault tolerance, dependability, cost, and more. Next, we conduct in-depth research into the difficulties and potential rewards of EV adoption in the future. While improvements in areas like charging times and battery performance are encouraging, government regulation of EVs remains a big non-technical barrier.

1. Introduction

Battery electric vehicles (BEV), hybrid electric vehicles (HEV), plug-in hybrid electric vehicles (PHEV), and fuel cell electric vehicles (FCEV) are gaining popularity in the transportation sector. There is a growing consensus that these vehicles will replace conventional, internal combustion engine (ICE) vehicles in the near future. Each of the essential components of EC makes use of a range of technologies and, in the not-too-distant future, they will continue to do so [1,2]. EVs might significantly impact the environment and other businesses like the electrical system. Transportation emits the second-most greenhouse gases after agriculture because fossil fuels release carbon dioxide. Many people believe that electric vehicles, sometimes known as EVs, are an excellent solution to this problem [3]. Electric vehicles have the potential to produce fewer emissions of carbon dioxide due to the fact that, rather than having an internal combustion engine, an electric motor serves as the vehicle’s propeller. EVs, when combined with alternative forms of energy, have the potential to become emission-free automobiles. This article offers a summary of the numerous varieties of electric vehicle drive circuits, including the design of each type as well as the benefits and drawbacks associated with each [4]. In addition, information regarding the effectiveness, power density, fault tolerance, dependability, and cost of electric motors, as well as the electric motor that is the most effective when used in EVs, is provided. An in-depth discussion on future EV deployment obstacles and rewards follows. Charging time and battery performance are technological hurdles, but government regulation remains a major non-technical obstacle for EVs [5,6,7].

As a result of the widespread use of EVs, a number of studies have looked into the many types of EVs. Researchers Braun et al. examined the efficiency of electric vehicles by contrasting a BEV with an ICE passenger vehicle and driving them under a variety of scenarios [8,9]. In Erfurt, Germany researchers analyzed how different driving styles, as well as rush hour traffic, affect energy use [10]. Based on the findings, it was determined that the BEV is 69.2 percent more fuel efficient than conventional autos. This significant advantage is the result of the components of the BEV’s powertrain that are only activated when traction is necessary to be provided. They convert the kinetic energy created while braking into electrical energy, which is then used to charge the batteries regenerative braking [11,12]. As a result of these characteristics, the BEV is able to capitalize on the varying speeds of the vehicle.

After the development of the electric motor itself came the idea of employing electric motors to power the propulsion of vehicles. Between the years of 1897 and 1900, electric vehicles (EVs) outnumbered those driven by internal combustion engines (ICEs) and accounted for 28% of all automobiles [13]. In the years that followed, however, ICE models quickly matured and evolved thanks to extraordinarily low oil prices, while Evs faded into history. A glimmer of hope was provided by the EV1 prototype, which was initially released by General Motors in 1996 and almost instantly became incredibly popular [14]. Electric vehicles have also been produced by a number of other major automakers, including Ford, Toyota, and Honda, amongst others. The Toyota Prius was the world’s first mass-produced hybrid electric vehicle (HEV), and it made its debut in the Japanese market in 1997 [15,16,17,18]. In its first year of production, 18,000 of these vehicles were sold. Nearly none of these EVs are manufactured or sold today, with the notable exception of the Toyota Prius, which is still in production, albeit in an improved form. At the moment, the Nissan Leaf, the Chevrolet Volt, and the Tesla Model S are the most successful vehicles on the market.

This research investigates the most current developments in electric vehicle technology, focusing on such topics as the vehicles’ capabilities, the energy sources they draw from, and the prospects for EVs in the years to come. Because the technologies that are associated with electric vehicles and their energy system (production, storage, and use) are always developing, this study investigates the most recent electric vehicle technologies, including those that are connected to autonomous driving and battery storage [19]:

- The first part of this article covers electric vehicle batteries and motors. Moreover, information regarding electric vehicle kinds, battery capacities, and motor drives can be found in this area. A complete analysis of battery technology from lead-acid to LIB is also provided [20]. This section discusses battery technologies, especially electric vehicle batteries. The most prevalent electric motors in EVs and vehicles are presented. EV owners can use this information to select a motor that best suits their needs in terms of energy economy, power density, speed, dependability, size, and cost.

- The second section, which investigates the different configurations of electric vehicles, offers a summary of the numerous categories of electric vehicles, including BEVs, HEVs, and PHEVs. They incorporate the technology as well as the framework of electric automobiles [21].

- The third section makes projections about the future of transportation and discusses the challenges that will be faced by electric vehicles. These challenges include the need for improvements in battery performance, charging times, law and regulation, and an open market for power. By doing so, it is anticipated that updated EV technology will be made available. These challenges are necessary for obtaining a new point of view on EVs and the growing movement towards the future [22].

2. Batteries and Electric Motors

2.1. Battery Engineering

The battery is the primary source of energy for electric vehicles; other sources of energy include the energy produced by regenerative braking, the energy produced by fuels, and the energy produced by various power storages such as a super capacitor [23,24]. The battery features a versatile architecture that allows it to be assembled in either series, parallel, or series-parallel configurations, depending on the required amount of voltage and current. In addition, the battery incorporates the three standard forms of electric vehicle cells, which are cylindrical, pouch, and prismatic cells. While shopping for battery-powered equipment, be sure to give equal consideration to the product’s expected lifespan, power density, energy density, capacity, and state-of-charge (SOC). The most potent power sources for EVs are rechargeable batteries like lithium-ion [25]. The lithium-ion battery (LIB) was invented in 1970, the lead-acid battery in 1858, and the nickel-iron alkaline battery in 1908. Compared to the other two batteries, the LIB has a higher specific energy and energy density. Rechargeable batteries were developed as a result.

Lead-acid batteries have a specific gravimetric energy density of 30–50 Wh/kg, making them the least efficient. The lifespan of a lead-acid battery is 500–1000 cycles [26,27]. To cover 200 km, a lead-acid battery that weighs at least five hundred kilo-grams is needed to generate one kilo-watt-hour (kWh) of electricity. Lead-acid batteries are inexpensive (varying from USD 300 to USD 600 per kilowatt-hour) and recyclable, which is one of the most significant aspects of any battery technology. Low-performance, tiny vehicles can use lead-acid batteries. Since their invention, lead-acid batteries have been recycled. As a standard, this battery’s recycling rate is close to 100% in Western countries and elsewhere [28]. Lead-acid batteries use 85% of the world’s lead, and 60% of it is recycled. Lead-acid batteries are easily damaged; thus their components can fall out of their plastic containers with their acid. Ni-MH batteries outperform lead-acid batteries. This battery has a gravimetric energy density between 40 and 110 Wh/kg, far higher than lead-acid batteries. In the early 1990s, Ni-MH batteries were widely used in EVs (Prius) due to their environmental friendliness. The main drawbacks of this battery technology are its poor cold performance and memory effects. Another issue is the battery’s long recharge time and high self-discharge rate when idle. The battery’s poor charge and discharge efficiency is the biggest issue [29,30,31].

Ni-Cd batteries need high charge and discharge rates and are memory-prone. The substance is toxic and possesses 60–80 Wh/kg specific energy density. The recharging of nickel-hydrogen (Ni-H) batteries was studied by Chen and colleagues. It was difficult to develop a low-cost grid storage material with a longer battery cycle and calendar lifespan; the material needs more cycles. This paper proposes a 10,000-cycle manganese-hydrogen battery for grid energy storage. Mn2+/MnO2 redox cathodes and H+/H2 gas anodes comprise the battery [32,33]. The battery’s areal capacity loading was projected to improve tenfold to 35 mAh/cm2 by replacing the Mn2+/MnO2 redox with a nickel-based cathode. In place of an expensive platinum catalyst, a less expensive nickel-molybdenum-cobalt alloy was used to catalyze the evolution of hydrogen into oxygen in alkaline electrolytes for the anode. The Ni-H battery is recommended since it has a gravimetric energy density of 140 Wh/kg and can be recharged more than 1500 times. Both specifications are included in Table 1 [34].

The sodium-nickel chloride (Na-NiCL2) batteries, also known as the Zero Emissions Batteries Research Activity (ZEBRA) batteries, are regarded as safe and inexpensive. Additionally, they are able to have nearly all of their capacity depleted without having a negative impact on the amount of time they will last. In addition, the energy that is contained within the battery is at a value that is around 150 Wh/kg. Because a ZEBRA battery may operate at temperatures ranging from 245 to 350 degrees Celsius, the thermal management and safety challenges associated with this battery are under a significant amount of strain [35]. As a storage source, ZEBRA batteries are a good example. Due to the cell’s chemical reactions’ intrinsic safety, multiple tests, including immersion in 900 L of saltwater with a 5% salt content, seismic and vibratory testing, and a 30 min external fire expo-sure test that did not harm the modules or cells, showed that fire risk is low. Therefore, it is suitable for stationary energy storage. This technique is good for load leveling, voltage management, time shifting, and renewable energy power swing reduction due to its three-hour rate discharge length [36].

Lithium is the modern battery of choice. Powerful, compact, inexpensive, non-toxic, and fast-charging, these batteries are the future of energy storage. These batteries now have a specific energy capacity of between 118 and 250 Wh/kg, although advances in technology are increasing this number [37]. The high energy density of silicon nanoparticles (SiNPs) makes them a popular choice for use as the anode electrode in lithium-ion batteries. In terms of electrochemical potential and equivalent mass, lithium batteries are superior. They work well and last for a long time, but they cost over USD 70/kWh and can start fires and destroy property if they get too hot [38,39]. Significant polarization will occur even in high-performance lithium batteries due to mass transport restrictions in the electrolyte and the electrodes. Charging and discharging batteries each have their own unique effects on polarization due to their unique architectures and the dynamic and kinetic properties of the materials involved. In order to lessen the polarization of the solid-phase diffusion, Chen and colleagues at MIT scaled back the particle size of the active material. The concentration of the LIB might be drastically lowered if only half of the particles of the active ingredient were present. The disparity in Li-ion concentration was significantly larger when the particles of the active substance were doubled in size.

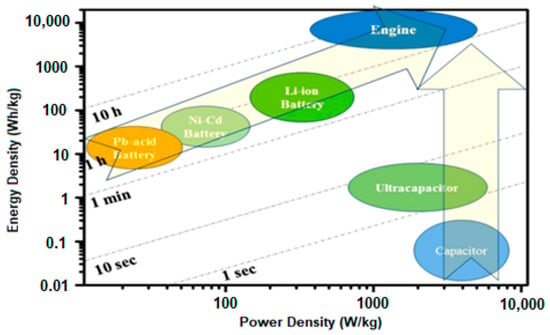

Several lithium-ion batteries (LIBs) have been made worldwide. LTO, LCO, LMO, NMC, and LFP are some of them (LFP). LIBs employ a different electrolyte than lithium-polymer batteries (Li-Po). The LIB, in contrast to the LB, possesses a higher energy density, a cheaper cost, and does not have a memory effect. LIBs are cheaper and memory-free [40,41,42]. In contrast, the Li-Po battery features a structure that is both flexible and adaptable, as well as a low profile and a reduced chance of electrolyte leakage; because doing so improves the efficiency of packaging, it is typically cut into multiple different sizes. On the other hand, Li-Po batteries have a lower energy density, a shorter lifespan, and a manufacturing cost that is significantly higher than average. The characteristics of electric vehicle batteries that are now in use are outlined in Table 1, which may be found here. Figure 1 also illustrates a correlation between the batteries’ specific power and specific energy levels.

Table 1.

A comparison of the energy storage capacities of the various batteries found in EVs.

Table 1.

A comparison of the energy storage capacities of the various batteries found in EVs.

| Specification | Lead-Acid Battery | Ni-MH Battery | Na-NiCl2 Battery | LIBs |

|---|---|---|---|---|

| Nominal voltage (V) | 2.00 | 1.20 | 2.40 | 3.60 |

| Energy efficiency (%) | >80 | 70 | 80 | >95 |

| Volumetric energy density (Wh/L) | 100 | 180–220 | 160 | 200–400 |

| Gravimetric energy density (Wh/kg) | 30–50 | 40–110 | 150 | 118–250 |

| Lifecycle | 500–1000 | <3000 | >1200 | 2000 |

| Cost (USD/kWh) | 100.00 | 853–1700 | 482–1000 | 700.00 |

| References | [43,44,45,46,47,48,49] | [50,51,52,53,54,55] | [56,57,58,59,60,61] | [62,63,64,65,66,67] |

Figure 1.

Graphs showing the power output versus the energy output of a given battery storage device [68].

2.2. Electric Motor Engineering

Due to its integral role, electric motors cannot be manufactured in the absence of electricity. An electric motor is a device used to transform electrical energy from its work form into its mechanical form and vice versa. High power and torque from an electric motor could be sent to the transmission or differential and then used for vehicle propulsion [69]. Electric vehicles (EVs) may not need transmissions since the electric motor might potentially supply instantaneous power and torque, unlike the internal combustion engine (ICE) [70]. Furthermore, electric motors are preferred over internal combustion engines because their energy conversion efficiency is substantially higher, ranging from 80% to 95%. Electric vehicles (EVs) can be propelled by a broad variety of electric motors:

- IM = Induction motor;

- PM-SM = Permanent magnet synchronous motor;

- PM-BLDC = Permanent magnet-brushless DC motor; and

- SRM = Switching reluctance motor.

Because of the high levels of efficiency and power density that they provide, IM and PM-SM motors are regarded as the most appealing possibilities for usage in EVs. This is due to the fact that they are the most common types of motors used in EVs. Electric motors are assessed and compared with regard to their installation space, power density, machine weight, dependability, efficiency, torque-speed relationship, overload capability, and cost before they are used in EVs [71,72].

IM is well-known for its effectiveness, starting torque, power, simplicity, inexpensiveness, roughness, and little amount of required maintenance. IMs can operate in any hazardous environment without speed limits. The IM’s complex control system struggles with power density [73]. Iron, copper, commutation, and stray losses in the magnetic circuit, windings, converter, and mechanical components affect this motor’s energy efficiency. IM motor losses were examined. In order to determine the effectiveness of an IM motor, they utilized a finite element research to map out the losses. According to the findings of the study, the motor’s efficiency map was decided by each loss map. To improve the performance of the IM motor, one researcher advises reducing the spins of the stators by one-half 2.25, and 3.7 kW IM motors were employed [74,75]. So, the new motor control is more efficient than the previous one, which led to an increase in motor performance. The 3.7 kW motor changed from having a power output of 78% to 85.39%, the 2.25 kW motor went from having an output of 83.23% to having an output of 86.22%, and the 3.7 kW motor went from having an output of 86.25% to having an output of 87.62% [76,76,77].

In addition to a constant high torque, PM-SM’s exceptional efficiency, high power density, and low energy consumption are all possible thanks to its implementation. By improving motor efficiency by 10%, PM-SM ensures consistent performance and electrical balance. The size of modern mechanical PM-SM packages has shrunk in comparison to their predecessors [78]. Due to the lack of brushes and coils, the PM-SM rotor operates at much lower temperatures. The PM-highly SM, with its conductive materials and high permeability permanent magnets, is ideal for electric and hybrid electric vehicles. This engine uses a permanent magnet, which increases the purchase price because PM materials are scarce and expensive. The problem of energy loss during the transformation from PM to SM has also not been overcome. Research indicates that a double Fourier integral can be used to measure fundamental and harmonic losses independently, allowing for the development of a novel global loss model of PM-SM. It was hoped that by reducing all forms of energy loss (i.e., fundamental iron loss, fundamental copper loss, harmonic iron loss, and harmonic copper loss), the performance of EVs may be enhanced. The least amount of energy was lost in 94% efficient systems [79].

Another form of motor, known as PM-BLDC, is one that is started by rectangular AC and features significant pulsing in its torque output. This motor might be able to deliver the highest torque in the constant-torque area because it keeps the flux angle between the stator and the rotor relatively close to 90 degrees [80]. Maintaining constant power can be accomplished through careful manipulation of the phase-advance angle. High power density, efficiency, and heat dissipation characterize the PM-BLDC motor, and these are this motor’s traits. The PM-BLDC motor’s initial cost is considerable due to the magnet in the rotor, and the device’s field-weakening capability is limited by the permanent magnetic field. This method was applied to the two motors that show the most promise for usage in hybrid electric vehicles (HEVs) by means of a sophisticated software application that simulates vehicles (IM and PM-BLDC) [81]. The fuel usage of each motor was 11.8 L per 100 km, the PMBLDC used 11.7 L, and the IM used 11.9 L. In addition, PM-BLDC had fewer overall pollutant emissions than IM did, which came up at 2.68 g/km compared to 2.72 g/km for IM. According to the findings, the PM-BLDC motor is more suitable for application in hybrid EVs than the IM motor is.

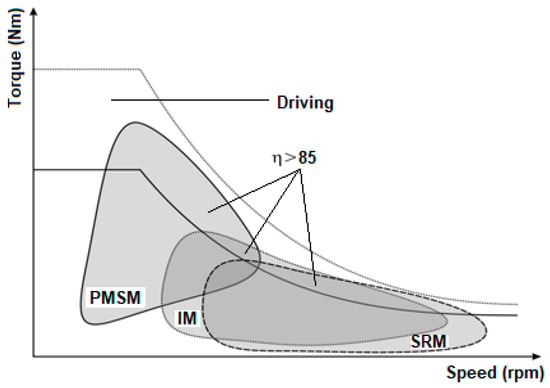

The SRM is the newest generation of electric vehicle motors. The alternative setups are more complicated than this one. The stator, which is stationary and opposite the rotor, is where the windings are situated. Without the need for a permanent magnet, SRM motors can be made at a lower cost [82]. Additionally, SRM is fault-tolerant, meaning that the failure of one phase will not influence the functioning of the others. Due to its low cost and durable architecture, SRM is viewed as a physically robust choice for electric vehicles and hybrid electric vehicles (HEVs), while needing to handle difficulties including acoustic noise, torque ripple, converter topology constraints, and electromagnetic interference (EMI). In a study published in reference [83], researchers evaluated the reliability of SRM 10/8 (SRM 5 phases) drives for EVs when subjected to open- and short-circuit failures. The SRM has amazing response to external stimuli and is built to endure harm. Top speeds, torque levels, and battery life were measured for SRM-driven electric vehicles. On average, SRM needed 1.23 s to catch up to the standard speed [84]. Torque never dropped below 485.3 Nm, even if SOC dropped by 0.04% 1.26 s into a 1-phase short circuit situation. Figure 2 shows the efficiency maps for the SRM motor, the IM motor, and the PM-SM motor, and Table 2 summarizes the benefits and drawbacks of electric motors ( +,++,+++ …etc., shows the difference between motor)

Table 2.

The electric motors utilized in EVs each have their own set of advantages and disadvantages.

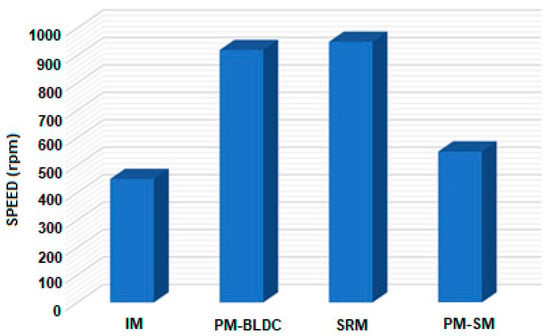

Figure 2 shows that every electric motor has a unique best efficiency area for both the driving and braking cycles. A study analyzed the different types of electric vehicle (EV) motors and drives in terms of their effectiveness, maximum speed, relative cost, and level of dependability (IM, PM-BLDC, PM-SM, and SRM). The PM-BLDC motor was the most efficient type of motor, while the SRM motor had the highest possible speed (Figure 3) [100]. Nonetheless, the brushless DC motor and the induction motor were the types of motors that were used the most frequently, and the induction motor was the type of motor that was the most cost-effective.

Figure 3.

Comparative analysis of the speeds of several motors [101].

Figure 2.

The effectiveness of electric motors and its components [100].

3. Configurations of EVs

The electric motor of an EV can be used alone or in conjunction with a conventional gas engine. Even though the most basic EV is powered by batteries, there are several variants that use other forms of energy to move the vehicle [102,103,104]. These vehicles are known as hybrid electric vehicles (HEVs). The Technical Committee 69 Electric Road Vehicles (ERV) of the International Electrical Technical Commission proposed adding vehicles with multiple energy sources, storage mechanisms, or converters to the definition of HEVs [105,106]. The Technical Committee 69 ERV of the International Electrical Technical Commission requested this recommendation in answer to a question it had posed. Many different types of hybrid electric vehicle combinations are now feasible thanks to this specification, which allows for the combination of internal combustion engines (ICE) and batteries, batteries and flywheels, batteries and capacitors, and batteries, etc. Consequently, both laypeople and experts have begun using the terms “hybrid electric vehicle” (HEV), “ultra-capacitor-assisted electric vehicle”, and “fuel cell electric vehicle” (FCEV) to refer to vehicles that combine the two power sources. These definitions have received widespread endorsement, allowing for the following classification of EVs in accordance with the standard [107,108,109]:

- Electric Battery Vehicle;

- Hybrid Electric Vehicle;

- Plug-in Hybrid Electric Vehicle.

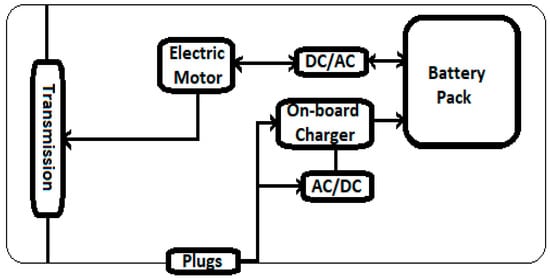

3.1. Batteries Electric Vehicles (BEVs)

A BEV’s range is directly related to the size of its battery, as the vehicle’s engine receives all of its energy from the battery (see Figure 4). Because it has no tailpipe or other means of exhaust, a BEV emits no carbon dioxide (CO2). A battery electric vehicle’s (BEV) range is between 100 and 250 km on a single charge, with energy consumption of 15 to 20 kWh per 100 km, depending on the model [110,111,112,113]. This range is subject to change based on the specifics of the vehicle. Battery electric vehicles with larger battery packs might have a range of 300 to 500 km. However, battery electric vehicles (BEVs) are significantly less advantageous than other types of EVs due to their significantly shorter driving range and significantly longer charging times. The easiest way to address this issue is to create and deploy an EMS designed specifically for BEVs [114,115].

Figure 4.

The structure of BEV circuit.

Three-wheel electric vehicles’ range was improved by one study’s method of regenerative braking, which surpassed that of full mechanical braking (19.2 km/kWh), as well as serial and parallel regenerative braking (19.3 and 19.5 km/kWh). When compared to the other three methods, this one is the best because it increases the range to 20 km/kWh. The efficiency gains from using this new braking technique could be as much as 4.16 km/kWh compared to the efficiency gain from using traditional mechanical braking. Several methods exist for increasing the range of battery electric vehicles (BEVs) [116,117,118,119]. It is possible that the extra weight and space requirements of a large battery pack make them impractical for usage in a given vehicle. This has a detrimental impact on the vehicle’s speed, gas mileage, and cost [120]. When carrying twice as much weight (300 kg) as when carrying half that weight (150 kg), the range of a three-wheeled electric vehicle with a 16 kWh lithium-ion battery pack (LIB) drops from 200 to 175 km, a 12.5% decrease.

Another way to expand the range of a battery electric vehicle (BEV) without increasing the capacity of the battery is to analyze the different driving behaviors. One possible application of this strategy while behind the wheel is to regulate the distribution of power and energy. In references [121,122], the need to increase the range of battery electric vehicles led to the creation of runtime power management. To reduce travel time and fuel consumption, an algorithm was devised [123,124]. Since this method is based on a multi-objective algorithm, it can achieve better outcomes than any of the other algorithms that have been considered. An ideal control strategy based on optimizing the velocity profile was proposed in order to lessen power usage in reference [125]. Thanks to its control of driving time and velocity, the proposed algorithm reduced energy usage by 8–10%. These references offer a practical solution to the issue of decreasing battery capacity while keeping energy use relatively low.

3.2. Hybrid Electric Vehicles (HEVs)

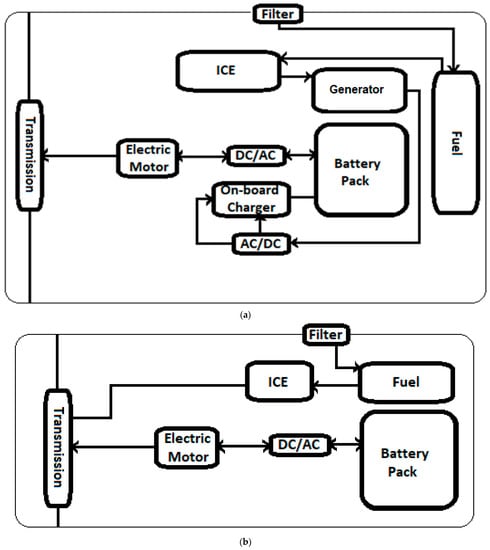

Hybrid electric vehicles (HEVs) employ multiple energy generation, storage, and conversion technologies [126]. Due to their short range, BEVs have seen an increase in competition from HEVs, which combine a conventional ICE with a battery system. As can be seen in Figure 5a, a series hybrid electric vehicle relies solely on an electric motor for propulsion. When it comes to powering the wheels, however, a parallel HEV uses both an ICE and an electric motor coupled to the gearbox (see Figure 5b). In order to determine the efficiency and consumption rates of parallel and series HEVs, numerous studies have been conducted. In references [127,128], for instance, researchers compared the fuel consumption of series and parallel HEV road sweeper trucks operating at the same speed and distance.

Figure 5.

(a) The structure of series HEV circuit and (b) the structure of parallel HEV circuit.

It was discovered that the series hybrid design uses less fuel (3.8 L/h) than the parallel hybrid design (6.2 L/h). The internal combustion engine (ICE) never slowed down or sped up when the vehicle was in series hybrid mode. However, when the vehicle was operating in parallel hybrid mode, the engine speed changed. Using a hybridization factor of 128 and 129, Li demonstrated that parallel HEV topologies are more energy-efficient than series HEV designs. Since parallel HEVs only need to carry out one set of conversions (from mechanical to electric to mechanical), they are assumed to have smaller power conversion losses than series HEVs. The transmission, engine, and braking system can take some of the load off with the help of the power splitting feature. Possible gains in fuel economy range from 0.3% to 37.7% [129,130]. In addition, compared to regular vehicles, parallel HEVs can improve fuel efficiency by as much as 68%. Regenerative braking, which involves the recovery of energy that would otherwise be squandered, contributed to this considerable increase in fuel efficiency. These research efforts paved the way for HEVs to become widely used vehicles. However, further adjustments to the drive train are required to increase the parallel HEVs’ energy efficiency [131].

Another type of HEV, mild hybrid electric vehicles (MHEVs), use a smaller electric motor and a battery with a lesser capacity (10–20 kW) than those found in full-on HEVs. While there is hardware parity between this EV and other HEVs, the control algorithms employed by the two classes of vehicles are rather distinct from one another [132,133,134]. It is anticipated that HEVs would face their greatest challenge in energy management through the integration and utilization of multiple energy sources. Energy consumption patterns during a driving cycle can be determined with the help of a thorough modeling system, test run data, and commercially viable simulator software. In addition, the test results are required to calculate the energy consumption.

3.3. Plug-In Hybrid Electric Vehicles (PHEVs)

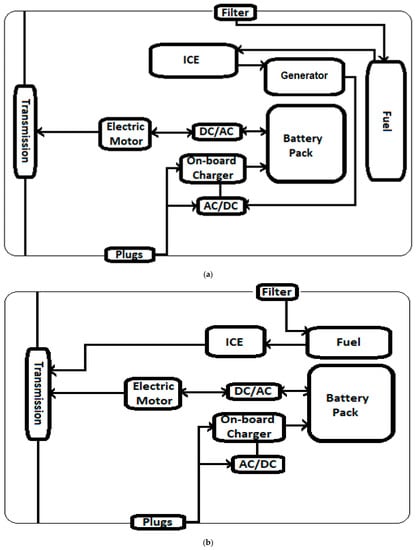

PHEVs were created so that the driving range of HEVs may be extended. Plug-in hybrid electric vehicles (PHEVs) are similar to HEVs in that they also consist of an ICE, an electric motor, a generator, and a battery. Instead of using regenerative braking, charging from the power grid can be used. BEV/HEV hybrids are PHEVs. Different plug-in hybrid electric vehicles (PHEVs) are depicted in Figure 6a,b. When it comes to charging the battery or providing propulsion (HEVs), hybrid electric vehicles utilize internal combustion engines in either a “series” or “parallel” configuration.

Figure 6.

(a) The structure of series PHEV circuit and (b) the structure of parallel PHEV circuit.

Unlike HEVs, the grid may provide charging for the batteries of PHEVs, which could allow for larger battery packs. Consequently, HEVs must always operate in charge sustenance mode (CS), which restricts the amount of energy that can be stored in the battery (state-of-charge). Plug-in hybrid electric vehicles (PHEVs) have the capability to switch between fully electric and mixed modes of operation while in charge depletion (CD) mode [135,136]. This gives PHEVs the advantage of using electric motors rather than internal combustion engines. An examination of the impact that the charge depletion mode has on the economy of parallel plug-in hybrid electric vehicles showed that the urban dynamometer driving schedule (UDDS) resulted in a 7.1% improvement in fuel economy for parallel PHEVs over 64 km, 6.3% improvement over 48 km, and 5.6% improvement over 32 km [137]. When the testing distance was expanded, it was discovered that the PHEV’s CD control mechanism became progressively effective.

The charging time of PHEVs becomes the primary concern, just as it does for BEVs, as battery capacity increases, requiring charging solutions to maintain vehicle functionality. It is preferable to have a fast charger with a high DC current capacity for charging a vehicle. Rapid DC charging methods, such as CHAdeMO (charge de mover) and Combo, may charge a vehicle up to as much as 80% capacity in 30 min [138]; however, this timeframe varies depending on the power transfer rate (6–200 kW). Vehicle-to-grid (V2G) technologies like CHAdeMO and Combo have a promising future. Both standards allow for fast charging. The V2G system was developed, installed, and extensively tested by researchers in reference [139]. To control the data and power transfer between the vehicle and the charger, the vehicle needed a fully functional CHAdeMO interface (VCI) on both the physical and protocol levels. The VCI was functioning well, and it met all of the standards for both the physical and the protocol [139].

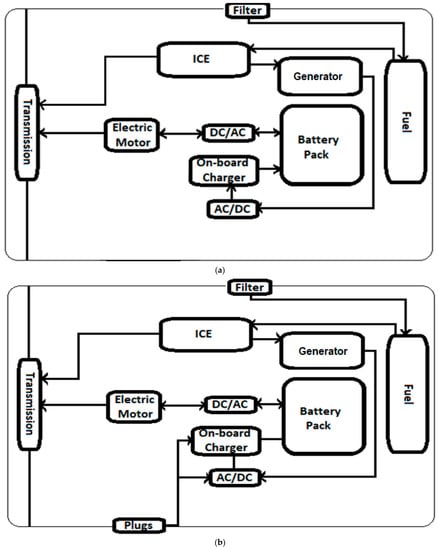

PHEVs are plagued with issues including power losses, stability systems, and durability, among other issues. Because of its increased level of dependability, the SCS approach, also known as the smart charging scheduling strategy, has the potential to alleviate these concerns. The ideal charging time for plug-in hybrid electric cars (PHEVs) was shown to be achieved through the coordination of many PHEVs within the context of a smart grid. The results demonstrated that it was reliable enough, with a standard deviation of values that was less than 1 (=0.8425) [140]. Figure 7 depicts the drivetrain that may be found in a series-parallel hybrid electric car, which is also commonly referred to as a plug-in hybrid electric vehicle. HEVs and PHEVs can operate in a series-parallel mode, which allows them to take advantage of the most beneficial aspects of both series and parallel operation. There are a number of advantages, including an increase in efficiency, an expansion in range, and a decrease in fuel costs. Research on the effectiveness of gasoline use in series-parallel plug-in hybrid electric vehicles was carried out by Zhao and Burke [141].

Figure 7.

Series-parallel hybrid electric vehicle circuit structure: (a) series-parallel HEV and (b) series-parallel PHEV.

According to the findings of their investigation, the fuel efficiency of a series-parallel PHEV using the UDDS (city driving) technique was 18.1 km per liter lower than that of a series shaft PHEV of the same sort, whose fuel economy was 20.4 km per liter. In contrast, the fuel economy of a series shaft PHEV was 20.4 km per liter. These data were gathered by doing head-to-head comparisons of both of the PHEV models while they were being driven under the same set of conditions. Using the HW-Interstate approach, which involves traveling on the highway at speeds of up to 77 miles per hour (120,7 km per hour), it was proved that a series-parallel PHEV is less efficient at utilizing fuel. According to the findings of another study [142], the utilization of the mixed power-split mode can greatly increase the energy efficiency of series-parallel plug-in hybrid electric vehicles (PHEVs). This served as a demonstration of the control approach for series-parallel plug-in hybrid electric vehicles’ two most important features—the allocation of energy and management of power in a drive system. A driving mechanism is what made this possible in the first place. The efficiency of the system increased by 27.50 percentage points, going from 19.3 to 24.6 km per liter. However, in contrast to other kinds of automobiles, this one is not only more expensive but also less convenient and less appealing [143].

Extended-range electric vehicle (EREVs) are an additional subcategory of plug-in hybrid electric vehicles (PHEVs). The electric motor always powers the wheels, unlike other plug-in hybrid electric vehicles (PHEVs), which use the gas-powered engine as a generator whenever the battery gets low or while the car is in motion. However, the gas-powered engine also serves as the vehicle’s primary propulsion system. The EREV is heavily in favor of conserving energy and materials [144]. Liu et al. found that, compared to HEVs, EREVs consume 14.68 percentage points fewer mineral resources and, compared to ICEVs, EREVs consume 34.72 percentage points fewer fossil fuels. The vehicle’s reduced mineral resource use is likely due to its smaller size and fewer components in general [145]. Savings on gasoline costs are substantial due to the fact that it is only used to run the generator. This generator is particularly efficient in terms of its use of fuel because it maintains a constant rotational speed and torque while charging the batteries. This is feasible due to the fact that the generator is the sole component required to provide power to the vehicle. The amount of fuel that is saved and the amount of energy that is saved can both be optimized through the adjustment of the generator’s speed and torque. EREVs are able to travel further than BEVs thanks to range extenders, but in order to compete with BEVs in terms of energy efficiency, EREVs need to be significantly smaller than BEVs [146].

4. Upcoming Opportunities and Challenges of EVs

EVs are considered the vehicles of the future for several reasons, including their expanding market share, their environmental friendliness, and their cutting-edge technology. The value of EV-related stocks rose from USD 3.7 million in 2019 to USD 13 million in 2020, and the International Energy Agency (IEA) predicts it will reach USD 130 million by 2030. Also, during the period under consideration, it is estimated that sales of EVs will rise by an average of 24. From 2019 to 2020, EV sales increased from 1.4 million to 4 million, and it is projected that by 2030, EV sales will have reached 21.5 million [147,148]. Notwithstanding the obvious benefits that EVs offer over traditional automobiles, this means of transportation must nevertheless overcome the five key challenges listed below:

- Charging times, technology for connecting vehicles to power grids, and fast charging;

- An increase in the efficiency of batteries;

- Public policy and regulatory frameworks; and

- A free and open market for power.

4.1. Charging Time, Technology for Connecting Vehicles to Power Grids, and Fast Charging

The wall-box was an integral part of the charging management system because it served as an additional semi-fast charger. Features such as real-time energy monitoring, charge scheduling, remote control (lock/unlock and output current), custom tariff configurations, consumption and cost data, and compatibility with iOS and Android system operations were all factory-installed [149,150,151]. These features allowed the wall-box to play a significant role in the management of chargers. It might make charging with a maximum capacity of 22 kW possible and assist consumers in controlling the amount of energy their EVs use. Researchers have developed a method of rapid recharging for battery-equipped EVs in order to alleviate the strain that the increased demand for EV charging is having on the power grid and to circumvent the exorbitant costs associated with charging during peak hours. The findings helped station builders and operators understand industry economics, requirements, operation, future demands, and maintenance approaches. While constructing charging stations, three more elements, including the dimensions of the station and its equipment, maintenance procedures, and operation strategies, should be taken into consideration [152,153].

As was discussed above, there can be unforeseen results from unmonitored EV charging. Power system facility overloading and increased power demand, both of which reduce the efficiency of energy transmission, are two examples of these unintended consequences. This is why “smart charging” or “intelligent charging schemes” have garnered so much interest in the academic world. Intelligent pricing methods’ aims can fluctuate [154,155]. Valley-filling charges are the result of some studies in the literature that aim to minimize system-related costs or charging costs in the electricity. In addition, some studies attempt to explicitly model the supply side, while others search for creative solutions to decrease the influence on the power system. Both of these approaches are taken by certain researchers. A well-tuned algorithm is required in order to efficiently schedule and make the most of the prospects given by the niche EV market. As more and more electric vehicles are wired into existing power grids, there is an increasing demand for research that can identify optimal solutions while taking into account a diverse set of restrictions. The goals of the electric vehicle (EV) system that has been deployed lead to the imposition of certain constraints, such as the limitation of charging costs, greenhouse gas emissions, or power system losses [156].

The authors of suggest a real-time solution to the issue of power losses in the smart grid, which, in addition to improving the voltage profile of the system, would address the issue of power losses. Studies on the behaviors of plug-in electric vehicle charging are now being conducted in order to have a better understanding of the influence that plug-in electric vehicles have on the electrical grid at various penetration levels and with both uncontrolled and regulated charging. This was the case regardless of the penetration rate. These changes can occur up to 0.83 p.u. (less than the 0.9 p.u. ceiling). However, coordinated charging approaches can enhance the voltage profile by up to 0.9 p.u. while simultaneously reducing it. In addition, Ferreira et al. [157,158] came up with the idea for a smart charging system. This system makes use of data mining techniques in order to optimize charging in line with usage history. Smartphones and other mobile devices can interact with the EV charging station and infrastructure via a suite of web-based applications. An electric vehicle’s battery life can be monitored by real-time information from a GPS-enabled mobile device. One major drawback of its architecture is the sluggishness of its communication pathways. Every step of the process might theoretically be handled by the machine itself in an ideal world.

4.2. An Increase in the Efficiency of Batteries

Electric vehicles may charge 80 percent of the way in just 15 min with the help of rapid charging. The feasibility of installing 450 kW of ultra-fast charging infrastructure for public buses was investigated. This allowed them to calculate the battery’s capacity. One terminal carrying a 450-kW charging station covered 100 separate routes ranging in length from 10 to 20 km. The bus covered 17.22 km and used 413.28 kWh of electricity in this case. The bus could be sustained on a single 450 kW charge, or 190.63 kWh, if the terminal had an ultra-fast charging station. Our analysis indicates that a reduction in battery capacity from 413.28 kWh to 222.64 kWh [159,160] is possible. Using an ultra-fast charging station in the terminal can help achieve this time saving.

Pulsed current is being considered to increase LIB battery performance. Huang et al. pulsed a LIB cell at 0.05 Hz to activate it. By changing duty cycles, C-rates, and ambient temperatures, the pulsed current’s influence on the battery charging may be determined. Pulsed current, when compared to steady current, increased charging capacity by 30.63 percent while simultaneously reducing the maximum temperature rise by 60.37 percent [161]. There is also the possibility of preheating the battery at a low temperature in order to improve its performance and reduce the risk of accidents involving the battery. An external pre-heating method was developed by Biao and colleagues. The battery’s electro thermal plate and a temperature field distribution are used in this procedure. The battery’s inside and outside case were different temperatures due to this method. The battery’s temperature was modest despite the case’s high temperature [162].

4.3. Public Policy and Regulatory Frameworks

EVs have emerged as a viable option in recent years and continue to garner significant interest. So, the diffusion of EVs is significantly dependent on governmental action, which is often justified primarily for the purpose of stimulating technological innovation features aimed at reducing negative externalities (such as emissions reduction). Meanwhile, the rate of adoption of EVs is largely dictated by the infrastructure support for EVs as well as the legislation surrounding EVs. The Asia-Pacific Economic Cooperation (APEC) examined electric vehicle (EV) policy, focusing on the charging network, boosting demand for these vehicles, industrialization, research, and development initiatives, and the incorporation of EVs into sustainable mobility plans [163]. This paper describes the APEC public policies to overcome barriers to electric vehicle adoption to improve policy instruments for new energy vehicles. The goal of this effort is to increase the efficacy of policy instruments for new energy vehicles. In a separate piece of research, researchers investigated and assessed two other forms of policy: the priority placed on purchase subsidies, and the expansion of charging infrastructure. These rules will have an effect on the rate of EV uptake and use in the future. So, the expansion of the market for EVs necessitates the creation of new charging infrastructure, technological advancements, and government restrictions [164]. Customers’ fears would be alleviated further if charging stations had adequate coverage and capabilities, and appropriate government laws may encourage the expansion of the electric EV sector.

4.4. A Free and Open Market for Power

The need for electricity to charge EVs is expected to rise in tandem with the growing popularity of EVs. In open electricity markets, where prices fluctuate daily, the power system of electric vehicle charging stations raises energy prices. When compared to the price of electricity during off-peak hours, the price of electricity during peak hours is typically three times higher. In order to solve this problem, it will be necessary to install charging stations for EVs that make use of a hybrid energy system. This type of system includes both conventional and renewable energy sources, such as photovoltaic panels and energy markets [165]. To prevent environmental contamination, renewable energy sources must be used, but they are scarce. To improve system performance, they are often employed alongside traditional components. The use of such a system presents a challenge due to the fact that achieving its optimal operation calls for a significant amount of research, which, in turn, brings down the price of charging an EV. EVs can have their charging and discharging processes made more efficient thanks to a market mechanism, that was devised in reference [166], based on the block chain technology. A multi-mode optimization method was proposed by these authors. This charging point is a hybrid of a traditional charging station and a photovoltaic system. Both components work together to provide power. The effectiveness of the strategy was demonstrated by the fact that initial costs were cut by more than fifty percent as a direct consequence of its implementation.

5. Concluding Remarks

EVs have the potential to not only become the future of transportation but also to save the globe from the oncoming calamities related to global warming. Conventional automobiles, which are wholly reliant on the ever-decreasing reserves of fossil fuels, have little chance of competing with these vehicles, which offer a workable alternative. In this article, the several types of EVs, their configurations, energy sources, motors, power conversion, and charging systems are dissected in great detail. The fundamental technologies of each segment, as well as the characteristics of those technologies, have been analyzed and outlined. The implications that EVs have on a variety of businesses have also been investigated, as have the tremendous prospects that EVs bring for promoting a cleaner and more efficient energy system by collaborating with smart grids and making it easier to include renewable sources. The shortcomings of currently available EVs have been outlined, as have some of the potential solutions for addressing those shortcomings. In addition to this, the many optimization approaches and control methods that are now in use have been presented. This study provides a condensed overview of the current electric vehicle market. Following an analysis of current tendencies and potential avenues for future growth is a discussion of the article’s conclusions, which serve to summarize the preceding material, paint an accurate picture of the sector in question, and highlight the research gaps that still need to be filled.

Funding

This research received no external funding and The APC was funded by Durban University of Technology.

Data Availability Statement

Available on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- May, G.; Davidson, A.; Monahov, B. Lead batteries for utility energy storage: A review. J. Energy Storage 2021, 15, 145–157. [Google Scholar] [CrossRef]

- Liang, Y.; Zhao, C.; Yuan, H.; Chen, Y.; Zhang, W.; Huang, J.; Yu, D.; Liu, Y.; Titirici, M.; Chueh, Y.; et al. A review of rechargeable batteries for portable electronic devices. InfoMat 2019, 1, 6–32. [Google Scholar] [CrossRef] [Green Version]

- Koehler, U. General Overview of Non-Lithium Battery Systems and Their Safety Issues; Elsevier B.V.: Amsterdam, The Netherlands, 2020; ISBN 9780444637772. [Google Scholar]

- Qazi, S. Fundamentals of Standalone Photovoltaic Systems; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780128030226. [Google Scholar]

- Chen, W.; Jin, Y.; Zhao, J.; Liu, N.; Cui, Y. Nickel-hydrogen batteries for large-scale energy storage. Proc. Natl. Acad. Sci. USA 2020, 115, 11694–11699. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, G.; Lu, X.; Kim, J.Y.; Meinhardt, K.D.; Chang, H.J.; Canfield, N.L.; Sprenkle, V.L. Advanced intermediate temperature sodium-nickel chloride batteries with ultra-high energy density. Nat. Commun. 2019, 7, 10683. [Google Scholar] [CrossRef]

- Benato, R.; Cosciani, N.; Crugnola, G.; Sessa, S.D.; Lodi, G.; Parmeggiani, C.; Todeschini, M. Sodium nickel chloride battery technology for large-scale stationary storage in the high voltage network. J. Power Sources 2020, 293, 127–136. [Google Scholar] [CrossRef]

- Juangsa, F.; Budiman, B.; Sambegoro, P.; Darmanto, P.; Nozaki, T. Synthesis of Nanostructured Silicon Nanoparticles for Anodes of Li-Ion Battery. In Proceedings of the International Conference on Electric Vehicular Technology (ICEVT), Bali, Indonesia, 18–21 November 2020. [Google Scholar]

- Schuster, S.; Brand, J.; Berg, P.; Gleissenberger, M.; Jossen, A. Lithium-ion cell to cell variation during battery electric vehicle operation. J. Power Sources 2019, 297, 242–251. [Google Scholar] [CrossRef]

- Amiribavandpour, P.; Shen, W.; Kapoor, A. An improved theoretical electrochemical thermal modeling of lithium-ion battery packs in electric vehicles. J. Power Sources 2020, 284, 328–338. [Google Scholar] [CrossRef]

- Rahardian, S.; Budiman, B.; Sambegoro, P.; Nurprasetio, I. Review of Solid-State Battery Technology Progress. In Proceedings of the International Conference on Electric Vehicular Technology (ICEVT), Bali, Indonesia, 18–21 November 2019. [Google Scholar]

- Tie, S.; Tan, C. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2020, 20, 82–102. [Google Scholar] [CrossRef]

- Rahman, M.; Wang, X.; Wen, C. A review of high energy density lithium-air battery technology. J. Appl. Electrochem. 2014, 44, 5–22. [Google Scholar] [CrossRef]

- Chang, C. Factors Affecting Capacity Design of Lithium-Ion. Batteries 2019, 5, 58. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Gene Liao, Y.; Lai, M.C. Lithium-ion polymer battery for 12-voltage applications: Experiment, modelling, and validation. Energies 2020, 13, 638. [Google Scholar] [CrossRef] [Green Version]

- Mongird, K.; Viswanathan, V.; Balducci, P.; Alam, J.; Fotedar, V.; Koritarov, V.; Hadjerioua, B. Energy Storage Technology and Cost Characterization Report|Department of Energy; Pacific Northwest National Lab. (PNNL): Richland, WA, USA, 2019. [Google Scholar]

- Canfield, H.J.; Sprenkle, N.L. Review of Battery Techonologies for Automotive Applications; ACEA: Brussels, Belgium, 2014. [Google Scholar]

- Sharma, A.; Sharma, S. Review of power electronics in vehicle-to-grid systems. J. Energy Storage 2019, 21, 337–361. [Google Scholar] [CrossRef]

- Zang, X.; Shen, C.; Sanghadasa, M.; Lin, L. High-Voltage Supercapacitors Based on Aqueous Electrolytes. ChemElectroChem 2019, 6, 976–988. [Google Scholar] [CrossRef]

- Afif, A.; Rahman, S.M.H.; Tasfiah Azad, A.; Zaini, J.; Islan, M.A.; Azad, A.K. Advanced materials and technologies for hybrid supercapacitors for energy storage—A review. J. Energy Storage 2019, 25, 100852. [Google Scholar] [CrossRef]

- Kate, R.S.; Khalate, S.A.; Deokate, R.J. Overview of nanostructured metal oxides and pure nickel oxide (NiO) electrodes for supercapacitors: A review. J. Alloys Compd. 2020, 734, 89–111. [Google Scholar] [CrossRef]

- Zhang, Q.; Deng, W.; Zhang, S.; Wu, J. A Rule Based Energy Management System of Experimental Battery/Supercapacitor Hybrid Energy Storage System for Electric Vehicles. J. Control Sci. Eng. 2018, 2018, 6828269. [Google Scholar] [CrossRef] [Green Version]

- Lü, X.; Qu, Y.; Wang, Y.; Qin, C.; Liu, G. A comprehensive review on hybrid power system for PEMFC-HEV: Issues and strategies. Energy Convers. Manag. 2020, 171, 1273–1291. [Google Scholar] [CrossRef]

- Li, T.; Liu, H.; Zhao, D.; Wang, L. Design and analysis of a fuel cell supercapacitor hybrid construction vehicle. Int. J. Hydrog. Energy 2018, 41, 12307–12319. [Google Scholar] [CrossRef]

- Balali, Y.; Stegen, S. Review of energy storage systems for vehicles based on technology, environmental impacts, and costs. Renew. Sustain. Energy Rev. 2021, 135, 110185. [Google Scholar] [CrossRef]

- Cheng, M.; Sun, L.; Buja, G.; Song, L. Advanced electrical machines and machine-based systems for electric and hybrid vehicles. Energies 2022, 8, 9541–9564. [Google Scholar] [CrossRef] [Green Version]

- Eldho Aliasand, A.; Josh, F.T. Selection of Motor foran Electric Vehicle: A Review. Mater. Today Proc. 2020, 24, 1804–1815. [Google Scholar] [CrossRef]

- López, I.; Ibarra, E.; Matallana, A.; Andreu, J.; Kortabarria, I. Next generation electric drives for HEV/EV propulsion systems: Technology, trends and challenges. Renew. Sustain. Energy Rev. 2019, 114, 109336. [Google Scholar] [CrossRef]

- Finken, T.; Felden, M.; Hameyer, K. Comparison and design of different electrical machine types regarding their applicability in hybrid electrical vehicles. In Proceedings of the 2021 18th International Conference on Electrical Machines, Vilamoura, Portugal, 6–9 September 2021; pp. 1–5. [Google Scholar]

- Bharadwaj, N.V.; Chandrasekhar, P.; Sivakumar, M. Induction motor design analysis for electric vehicle application. AIP Conf. Proc. 2020, 2269, 10–14. [Google Scholar]

- Mahmoudi, A.; Soong, W.L.; Pellegrino, G.; Armando, E. Efficiency maps of electrical machines. In Proceedings of the 2022 IEEE Energy Conversion Congress and Exposition (ECCE), Montreal, QC, Canada, 20–24 September 2022; pp. 2791–2799. [Google Scholar]

- Lumyong, P.; Sarikprueck, P. A Study on Induction Motor Efficiency Improvement for Implementing in Electric Vehicle. In Proceedings of the 2020 21st International Conference on Electrical Machines and Systems (ICEMS), Jeju, Republic of Korea, 7–10 October 2020; pp. 616–619. [Google Scholar]

- Loganayaki, A.; Bharani Kumar, R. Permanent Magnet Synchronous Motor for Electric Vehicle Applications. In Proceedings of the 2019 5th International Conference on Advanced Computing & Communication Systems (ICACCS), Coimbatore, India, 15–16 March 2019; pp. 1064–1069. [Google Scholar]

- Chiba, A.; Kiyota, K. Review of research and development of switched reluctance motor for hybrid electrical vehicle. In Proceedings of the 2022 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Turin, Italy, 26–27 March 2022; pp. 127–131. [Google Scholar]

- Guo, Q.; Zhang, C.; Li, L.; Zhang, J.; Wang, M. Maximum Efficiency Control of Permanent-Magnet Synchronous Machines for Electric Vehicles. Energy Proc. 2019, 105, 2267–2272. [Google Scholar] [CrossRef]

- Wang, W.; Fu, R.; Fan, Y. Electromagnetic Parameters Matching of Permanent Magnet Synchronous Motor for Hybrid Electric Vehicles. IFAC-PapersOnLine 2020, 51, 407–414. [Google Scholar] [CrossRef]

- Karki, A.; Phuyal, S.; Tuladhar, D.; Basnet, S.; Shrestha, B.P. Status of pure electric vehicle power train technology and future prospects. Appl. Syst. Innov. 2020, 3, 35. [Google Scholar] [CrossRef]

- Thakar, D.U.; Patel, R.A. Comparison of Advance and Conventional Motors for Electric Vehicle Application. In Proceedings of the 2019 3rd International Conference on Recent Developments in Control, Automation & Power Engineering (RDCAPE), Noida, India, 10–11 October 2019; pp. 137–142. [Google Scholar]

- Sharifan, S.; Ebrahimi, S.; Oraee, A.; Oraee, H. Performance comparison between brushless PM and induction motors for hybrid electric vehicle applications. In Proceedings of the 2022 International Aegean Conference on Electrical Machines & Power Electronics (ACEMP), Birmingham, UK, 29 June–1 July 2022. [Google Scholar]

- Sharifan, S.; Ebrahimi, S.; Oraee, A.; Oraee, H. In Proceedings of the 2022 International Conference on Optimization of Electrical & Electronic Equipment (OPTIM) & 2022 International Symposium on Advanced Electromechanical Motion Systems (ELECTROMOTION), Side, Turkey, 2–4 September 2022; pp. 719–724.

- Gan, C.; Wu, J.; Hu, Y.; Yang, S.; Cao, W.; Guerrero, J.M. New Integrated Multilevel Converter for Switched Reluctance Motor Drives in Plug-in Hybrid Electric Vehicles with Flexible Energy Conversion. IEEE Trans. Power Electron. 2019, 32, 3754–3766. [Google Scholar] [CrossRef] [Green Version]

- Kumar, R.; Saxena, R. Simulation and Analysis of Switched Reluctance Motor Drives for Electric Vehicle Applications using MATLAB. In Proceedings of the 2019 4th International Conference on Electrical, Electronics, Communication, Computer Technologies and Optimization Techniques (ICEECCOT), Mysuru, India, 13–14 December 2019; pp. 23–28. [Google Scholar]

- Chang, H.C.; Jheng, Y.M.; Kuo, C.C.; Hsueh, Y.M. Induction motors condition monitoring system with fault diagnosis using a hybrid approach. Energies 2019, 12, 1471. [Google Scholar] [CrossRef] [Green Version]

- Ganesan, S.; David, P.W.; Balachandran, P.K.; Samithas, D. Intelligent Starting Current-Based Fault Identification of an Induction Motor Operating under Various Power Quality Issues. Energies 2021, 14, 304. [Google Scholar] [CrossRef]

- Pindoriya, R.M.; Rajpurohit, B.S.; Kumar, R.; Srivastava, K.N. Comparative analysis of permanent magnet motors and switched reluctance motors capabilities for electric and hybrid electric vehicles. In Proceedings of the 2020 IEEMA Engineer Infinite Conference (eTechNxT), New Delhi, India, 13–14 March 2020; pp. 1–5. [Google Scholar]

- Rahman, M.S.; Lukman, G.F.; Hieu, P.T.; Jeong, K.-I.; Ahn, J.-W. Optimization and Characteristics Analysis of High Torque Density 12/8 Switched Reluctance Motor Using Metaheuristic Gray Wolf Optimization Algorithm. Energies 2021, 14, 2013. [Google Scholar] [CrossRef]

- Ronanki, D.; Kelkar, A.; Williamson, S.S. Extreme fast charging technology—Prospects to enhance sustainable electric transportation. Energies 2019, 12, 3721. [Google Scholar] [CrossRef] [Green Version]

- IEA. Global E V Outlook. Towards Cross-Modal Electrification; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Faizal, M.; Feng, S.; Zureel, M.; Sinidol, B.; Wong, D.; Jian, K. A review on challenges and opportunities of electric vehicles (evs). J. Mech. Eng. Res. Dev. JMERD 2019, 42, 130–137. [Google Scholar] [CrossRef]

- Suarez, C.; Martinez, W. Fast and Ultra-Fast Charging for Battery Electric Vehicles—A Review. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 569–575. [Google Scholar]

- Mansour, M.B.M.; Said, A.; Ahmed, N.E.; Sallam, S. Autonomous parallel car parking. In Proceedings of the 2020 Fourth World Conference on Smart Trends in Systems, Security and Sustainability (WorldS4), London, UK, 27–28 July 2020; pp. 392–397. [Google Scholar]

- Wang, Y.; Sun, W.; Lu, Y. Research on application in intelligent vehicle automatic control system. J. Phys. Conf. Ser. 2021, 1828, 012046. [Google Scholar] [CrossRef]

- Noh, B.; Park, H.; Yeo, H. Analyzing vehicle-pedestrian interactions: Combining data cube structure and predictive collision risk estimation mode. Accid. Anal. Prev. 2021, 152, 105970. [Google Scholar] [CrossRef]

- Elma, O.; Adham, M.I.; Gabbar, H.A. Effects of Ultra-Fast Charging System for Battery Size of Public Electric Bus. In Proceedings of the IEEE 8th International Conference on Smart Energy Grid Engineering (SEGE), Oshawa, ON, Canada, 12–14 August 2020. [Google Scholar]

- Brenna, M.; Foiadelli, F.; Leone, C.; Longo, M. Electric Vehicles Charging Technology Review and Optimal Size Estimation. J. Electr. Eng. Technol. 2020, 15, 2539–2552. [Google Scholar] [CrossRef]

- Sadeghian, O.; Oshnoei, A.; Mohammadi-ivatloo, B.; Vahidinasab, V.; Anvari-Moghaddam, A. A Comprehensive Review on EVs Smart Charging: Solutions, Strategies, Technologies, and Challenges. J. Energy Storage 2022, 54, 105241. [Google Scholar] [CrossRef]

- Kumar, S.; Usman, A.; Rajpurohit, B.S. Battery Charging Topology, Infrastructure, and Standards for Electric Vehicle Applications: A Comprehensive Review. IET Energy Syst. Integr. 2021, 3, 381–396. [Google Scholar] [CrossRef]

- Subramaniam, M.; Solomon, J.M.; Nadanakumar, V.; Anaimuthu, S.; Sathyamurthy, R. Experimental Investigation on Performance, Combustion and Emission Characteristics of DI Diesel Engine Using Algae as a Biodiesel. Energy Rep. 2020, 6, 1382–1392. [Google Scholar] [CrossRef]

- Abid, M.; Tabaa, M.; Chakir, A.; Hachimi, H. Routing and Charging of EVs: Literature Review. Energy Rep. 2022, 8, 556–578. [Google Scholar] [CrossRef]

- Ogunkunle, O.; Ahmed, N.A. A Review of Global Current Scenario of Biodiesel Adoption and Combustion in Vehicular Diesel Engines. Energy Rep. 2019, 5, 1560–1579. [Google Scholar] [CrossRef]

- Oladunni, O.J.; Mpofu, K.; Olanrewaju, O.A. Greenhouse Gas Emissions and Its Driving Forces in the Transport Sector of South Africa. Energy Rep. 2022, 8, 2052–2061. [Google Scholar] [CrossRef]

- Zuo, J.; Zhong, Y.; Yang, Y.; Fu, C.; He, X.; Bao, B.; Qian, F. Analysis of Carbon Emission, Carbon Displacement and Heterogeneity of Guangdong Power Industry. Energy Rep. 2022, 8, 438–450. [Google Scholar] [CrossRef]

- Matanov, N.; Zahov, A. Developments and Challenges for Electric Vehicle Charging Infrastructure. In Proceedings of the 2020 12th Electrical Engineering Faculty Conference (BulEF), Varna, Bulgaria, 9–12 September 2020. [Google Scholar]

- Weis, A.; Jaramillo, P.; Michalek, J. Estimating the Potential of Controlled Plug-in Hybrid Electric Vehicle Charging to Reduce Operational and Capacity Expansion Costs for Electric Power Systems with High Wind Penetration. Appl. Energy 2014, 115, 190–204. [Google Scholar] [CrossRef]

- Umoren, I.A.; Shakir, M.Z. Electric Vehicle as a Service (EVaaS): Applications, Challenges and Enablers. Energies 2022, 15, 7207. [Google Scholar] [CrossRef]

- He, T.; Lu, D.; Wu, M.; Yang, Q.; Li, T.; Liu, Q. Four-Quadrant Operations of Bidirectional Chargers for EVs in Smart Car Parks: G2v, V2g, and V4g. Energies 2021, 14, 181. [Google Scholar] [CrossRef]

- De Hoog, J.; Thomas, D.A.; Muenzel, V.; Jayasuriya, D.C.; Alpcan, T.; Brazil, M.; Mareels, I. Electric Vehicle Charging and Grid Constraints: Comparing Distributed and Centralized Approaches. In Proceedings of the 2013 IEEE Power & Energy Society General Meeting, Vancouver, BC, Canada, 21–25 July 2013. [Google Scholar]

- Zhang, Q.; Li, H.; Zhu, L.; Campana, P.; Lu, H.; Wallin, F.; Sun, Q. Factors Influencing the Economics of Public Charging Infrastructures for EV—A Review. Renew. Sustain. Energy Rev. 2018, 94, 500–509. [Google Scholar] [CrossRef]

- Nour, M.; Chaves-Ávila, J.P.; Magdy, G.; Sánchez-Miralles, Á. Review of Positive and Negative Impacts of EVs Charging on Electric Power Systems. Energies 2020, 13, 4675. [Google Scholar] [CrossRef]

- Rahman, I.; Vasant, P.M.; Singh, B.S.M.; Abdullah-Al-Wadud, M.; Adnan, N. Review of Recent Trends in Optimization Techniques for Plug-in Hybrid, and Electric Vehicle Charging Infrastructures. Renew. Sustain. Energy Rev. 2016, 58, 1039–1047. [Google Scholar] [CrossRef]

- Al-Ogaili, A.S.; Tengku Hashim, T.J.; Rahmat, N.A.; Ramasamy, A.K.; Marsadek, M.B.; Faisal, M.; Hannan, M.A. Review on Scheduling, Clustering, and Forecasting Strategies for Controlling Electric Vehicle Charging: Challenges and Recommendations. IEEE Access 2019, 7, 128353–128371. [Google Scholar] [CrossRef]

- Verma, A.; Singh, B. Multimode Operation of Solar PV Array, Grid, Battery and Diesel Generator Set Based EV Charging Station. IEEE Trans. Ind. Appl. 2020, 56, 5330–5339. [Google Scholar] [CrossRef]

- Chung, S.; Trescases, O. Hybrid Energy Storage System with Active Power-Mix Control in a Dual-Chemistry Battery Pack for Light EVs. IEEE Trans. Transp. Electrif. 2017, 3, 600–617. [Google Scholar] [CrossRef]

- Usman, A.; Kumar, P.; Divakar, B.P. Battery Charging and Discharging Kit with DAQ to Aid SOC Estimation. In Proceedings of the 2015 International Conference on Computation of Power, Energy, Information and Communication (ICCPEIC), Melmaruvathur, India, 22–23 April 2015. [Google Scholar]

- Saleem, Y.; Crespi, N.; Rehmani, M.H.; Copeland, R. Internet of Things-Aided Smart Grid: Technologies, Architectures, Applications, Prototypes, and Future Research Directions. IEEE Access 2019, 7, 62962–63003. [Google Scholar] [CrossRef]

- Wang, W.; Liu, L.; Liu, J.; Chen, Z. Energy management and optimization of vehicle-to-grid systems for wind power integration. CSEE J. Power Energy Syst. 2020, 7, 172–180. [Google Scholar]

- Ji, D.; Lv, M.; Yang, J.; Yi, W. Optimizing the locations and sizes of solar assisted electric vehicle charging stations in an urban area. IEEE Access 2020, 8, 112772–112782. [Google Scholar] [CrossRef]

- Amer, A.; Azab, A.; Azzouz, M.A.; Awad, A.S. A stochastic program for siting and sizing fast charging stations and small wind turbines in urban areas. IEEE Trans. Sustain. Energy 2021, 12, 1217–1228. [Google Scholar] [CrossRef]

- Shojaabadi, S.; Abapour, S.; Abapour, M.; Nahavandi, A. Simultaneous planning of plug-in hybrid electric vehicle charging stations and wind power generation in distribution networks considering uncertainties. Renew. Energy 2016, 99, 237–252. [Google Scholar] [CrossRef]

- Ahmad, A.; Khan, Z.A.; Saad Alam, M.; Khateeb, S. A review of the electric vehicle charging techniques, standards, progression and evolution of EV technologies in Germany. Smart Sci. 2018, 6, 36–53. [Google Scholar] [CrossRef]

- Singh, M.; Kumar, P.; Kar, I. A multi charging station for electric vehicles and its utilization for load management and the grid support. IEEE Trans. Smart Grid 2013, 4, 1026–1037. [Google Scholar] [CrossRef]

- Kiviluoma, J.; Meibom, P. Methodology for modelling plug-in electric vehicles in the power system and cost estimates for a system with either smart or dumb electric vehicles. Energy 2011, 36, 1758–1767. [Google Scholar] [CrossRef]

- Burger, S.; Chaves-Ávila, J.P.; Batlle, C.; Pérez-Arriaga, I.J. A Review of the Value of Aggregators in Electricity Systems. Renew. Sustain. Energy Rev. 2017, 77, 395–405. [Google Scholar] [CrossRef]

- Shinde, P.; Kouveliotis-Lysikatos, I.; Amelin, M.; Song, M. A Modified Progressive Hedging Approach for Multistage Intraday Trade of EV Aggregators. Electr. Power Syst. Res. 2022, 212, 108518. [Google Scholar] [CrossRef]

- Gkatzikis, L.; Koutsopoulos, I.; Salonidis, T. The Role of Aggregators in Smart Grid Demand Response Markets. IEEE J. Sel. Areas Commun. 2013, 31, 1247–1257. [Google Scholar] [CrossRef]

- Parvania, M.; Fotuhi-Firuzabad, M.; Shahidehpour, M. Optimal Demand Response Aggregation in Wholesale Electricity Markets. IEEE Trans. Smart Grid 2013, 4, 1957–1965. [Google Scholar] [CrossRef]

- Sadeghian, O.; Moradzadeh, A.; Mohammadi-Ivatloo, B.; Vahidinasab, V. Active Buildings Demand Response: Provision and Aggregation. In Active Building Energy Systems; Springer: Cham, Switzerland, 2022; pp. 355–380. [Google Scholar]

- Cao, Y.; Huang, L.; Li, Y.; Jermsittiparsert, K.; Ahmadi-Nezamabad, H.; Nojavan, S. Optimal scheduling of electric vehicles aggregator under market price uncertainty using robust optimization technique. Int. J. Electr. Power Energy Syst. 2020, 117, 105628. [Google Scholar] [CrossRef]

- Niringiyimana, E.; WanQuan, S.; Dushimimana, G. Feasibility Study of a Hybrid PV/Hydro System for Remote Area Electrification in Rwanda. J. Renew. Energy 2022, 2022, 4030369. [Google Scholar] [CrossRef]

- Sae J2293-2; Energy Transfer System for EVs—Part 2: Communication Requirements and Network Architecture. SAE International: Warrendale, PA, USA, 1997.

- Sae J1772; SAE Surface Vehicle Recommended Practice J1772, SAE Electric Vehicle Conductive Charge Coupler. SAE International: Warrendale, PA, USA, 2001.

- Salah, K.; Kama, N. Unification Requirements of Electric Vehicle Charging Infrastructure. Int. J. Power Electron. Drive Syst. 2016, 7, 246–253. [Google Scholar] [CrossRef]

- Sae J1773; SAE Electric Vehicle Inductively Coupled Charging. SAE International: Warrendale, PA, USA, 2014.

- Khaligh, A.; Li, Z. Battery, Ultracapacitor, Fuel Cell, and Hybrid Energy Storage Systems for Electric, Hybrid Electric, Fuel Cell, and Plug-in Hybrid EVs: State of the Art. IEEE Trans. Veh. Technol. 2010, 59, 2806–2814. [Google Scholar] [CrossRef]

- Jayasinghe, S.; Meegahapola, L.; Fernando, N.; Jin, Z.; Guerrero, J. Review of Ship Microgrids: System Architectures, Storage Technologies and Power Quality Aspects. Inventions 2017, 2, 4. [Google Scholar] [CrossRef] [Green Version]

- Rajabinezhad, M.; Firoozi, H.; Khajeh, H.; Laaksonen, H. Chapter 3—Electrical Energy Storage Devices for Active Buildings. In Active Building Energy Systems; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Acharige, S.S.; Haque, M.E.; Arif, M.T.; Hosseinzadeh, N. Review of Electric Vehicle Charging Technologies, Configurations, and Architectures. arXiv 2022, arXiv:2209.15242. [Google Scholar]

- Ali, A.; Shakoor, R.; Raheem, A.; Muqeet, H.A.; Awais, Q.; Khan, A.A.; Jamil, M. Latest energy storage trends in multi-energy standalone electric vehicle charging stations: A comprehensive study. Energies 2022, 15, 4727. [Google Scholar] [CrossRef]

- Habib, S.; Khan, M.M.; Abbas, F.; Sang, L.; Shahid, M.U.; Tang, H. A comprehensive study of implemented international standards, technical challenges, impacts and prospects for electric vehicles. IEEE Access 2018, 6, 13866–13890. [Google Scholar] [CrossRef]

- Ahmad, F.; Khalid, M.; Panigrahi, B.K. Development in energy storage system for electric transportation: A comprehensive review. J. Energy Storage 2021, 43, 103153. [Google Scholar] [CrossRef]

- Deb, N.; Singh, R.; Brooks, R.R.; Bai, K. A Review of Extremely Fast Charging Stations for Electric Vehicles. Energies 2021, 14, 7566. [Google Scholar] [CrossRef]

- Prasanna, U.R.; Singh, A.K.; Rajashekara, K. Novel Bidirectional Single-Phase Single-Stage Isolated AC-DC Converter with PFC for Charging of EVs. IEEE Trans. Transp. Electrif. 2017, 3, 536–544. [Google Scholar] [CrossRef]

- Kanamarlapudi, V.R.K.; Wang, B.; So, P.L.; Wang, Z. Analysis, Design, and Implementation of an APWM ZVZCS Full-Bridge DC-DC Converter for Battery Charging in EVs. IEEE Trans. Power Electron. 2017, 32, 6145–6160. [Google Scholar] [CrossRef]

- Mastoi, M.S.; Zhuang, S.; Munir, H.M.; Haris, M.; Hassan, M.; Usman, M.; Bukhari, S.S.; Ro, J.S. An in-depth analysis of electric vehicle charging station infrastructure, policy implications, and future trends. Energy Rep. 2022, 8, 11504–11529. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; d’Accadia, M.D.; Vicidomini, M. Smart Grid Energy District Based on the Integration of EVs and Combined Heat and Power Generation. Energy Convers. Manag. 2021, 234, 113932. [Google Scholar] [CrossRef]

- Das, H.S.; Rahman, M.M.; Li, S.; Tan, C.W. Electric vehicles standards, charging infrastructure, and impact on grid integration: A technological review. Renew. Sustain. Energy Rev. 2020, 120, 109618. [Google Scholar] [CrossRef]

- Sun, X.; Li, Z.; Wang, X.; Li, C. Technology development of electric vehicles: A review. Energies 2019, 13, 90. [Google Scholar] [CrossRef] [Green Version]

- Huda, M.; Tokimatsu, K.; Aziz, M. Techno economic analysis of vehicle to grid (V2G) integration as distributed energy resources in Indonesia power system. Energies 2020, 13, 1162. [Google Scholar] [CrossRef] [Green Version]

- Aziz, M.; Budiman, B.A. Extended utilization of electric vehicles in electrical grid services. In Proceedings of the 2019 4th International Conference on Electric Vehicular Technology (ICEVT), Bali, Indonesia, 2–5 October 2019; pp. 1–6. [Google Scholar]

- Kriukov, A.; Gavrilas, M. Energy/Cost efficiency study on V2G operating mode for EVs and PREVs. In Proceedings of the 2019 8th International Conference on Modern Power Systems (MPS), Cluj, Romania, 21–23 May 2019. [Google Scholar]

- Małek, A.; Caban, J.; Wojciechowski, Ł. Charging electric cars as a way to increase the use of energy produced from RES. Open Eng. 2020, 10, 98–104. [Google Scholar] [CrossRef] [Green Version]

- Aziz, M.; Oda, T.; Ito, M. Battery-assisted charging system for simultaneous charging of electric vehicles. Energy 2018, 100, 82–90. [Google Scholar] [CrossRef]

- Kurtz, J.; Bradley, T.; Winkler, E.; Gearhart, C. Predicting demand for hydrogen station fueling. Int. J. Hydrog. Energy 2020, 45, 32298–32310. [Google Scholar] [CrossRef]

- Wang, D.; Muratori, M.; Eichman, J.; Wei, M.; Saxena, S.; Zhang, C. Quantifying the flexibility of hydrogen production systems to support large-scale renewable energy integration. J. Power Sources 2020, 399, 383–391. [Google Scholar] [CrossRef]

- Huang, X.; Li, Y.; Meng, J.; Sui, X.; Teodorescu, R.; Stroe, I. The Effect of Pulsed Current on the Performance of Lithium-ion Batteries. In Proceedings of the 2020 IEEE Energy Conversion Congress and Exposition (ECCE), Detroit, MI, USA, 11–15 October 2020; pp. 5633–5640. [Google Scholar]

- Biao, J.; Fangfang, L.; Zhiwen, A.; Zhiqiang, X.; Bin, J. Thermal Simulation of Power Lithium-ion Battery under Low Temperature and Preheating Condition. In Proceedings of the 2020 5th International Conference on Smart Grid and Electrical Automation (ICSGEA), Zhangjiajie, China, 13–14 June 2020; pp. 51–54. [Google Scholar]

- Deng, J.; Bae, C.; Denlinger, A.; Miller, T. Electric Vehicles Batteries: Requirements and Challenges. Joule 2020, 4, 511–515. [Google Scholar] [CrossRef]

- König, A.; Nicoletti, L.; Schröder, D.; Wolff, S.; Waclaw, A.; Lienkamp, M. An overview of parameter and cost for battery electric vehicles. World Electr. Veh. J. 2021, 12, 21. [Google Scholar] [CrossRef]

- Hardman, S.; Chandan, A.; Tal, G.; Turrentine, T. The effectiveness of financial purchase incentives for battery electric vehicles—A review of the evidence. Renew. Sustain. Energy Rev. 2019, 80, 1100–1111. [Google Scholar] [CrossRef]

- Lévay, P.Z.; Drossinos, Y.; Thiel, C. The effect of fiscal incentives on market penetration of electric vehicles: A pairwise comparison of total cost of ownership. Energy Policy 2019, 105, 524–533. [Google Scholar] [CrossRef]

- Curtin, J.; McInerney, C.; Gallachóir, B.Ó. Financial incentives to mobilise local citizens as investors in low-carbon technologies: A systematic literature review. Renew. Sustain. Energy Rev. 2019, 75, 534–547. [Google Scholar] [CrossRef]

- Automotive Dialogue. The Impact of Government Policy on Promoting New Energy Vehicles (NEVs): The Evidence in APEC Economies; APEC: Singapore, 2019. [Google Scholar]

- Brückmann, G.; Bernauer, T. What drives public support for policies to enhance electric vehicle adoption? Environ. Res. Lett. 2020, 15, 094002. [Google Scholar] [CrossRef]

- Abuelrub, A.; Al Khalayleh, A.R.; Allabadi, A. Optimal operation of electric vehicle charging station in an open electricity market. Int. J. Smart Grid Clean Energy 2019, 8, 495–499. [Google Scholar] [CrossRef]

- Yan, Q.; Zhang, B.; Kezunovic, M. Optimized operational cost reduction for an EV charging station integrated with battery energy storage and PV generation. IEEE Trans. Smart Grid 2019, 10, 2096–2106. [Google Scholar] [CrossRef]

- Huang, Z.; Li, Z.; Lai, C.S.; Zhao, Z.; Wu, X.; Li, X.; Tong, N.; Lai, L.L. A novel power market mechanism based on blockchain for electric vehicle charging stations. Electron 2021, 10, 307. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Lai, C.M.; Teh, J. Application of particle swarm optimization to design control strategy parameters of parallel hybrid electric vehicle with fuel economy and low emission. In Proceedings of the 2020 International Symposium on Computer, Consumer and Control (IS3C), Taichung, Taiwan, 6–8 December 2020; pp. 342–345. [Google Scholar]

- Zhou, S.; Chen, Z.; Huang, D.; Lin, T. Model Prediction and Rule Based Energy Management Strategy for a Plug-in Hybrid Electric Vehicle with Hybrid Energy Storage System. IEEE Trans. Power Electron. 2021, 36, 5926–5940. [Google Scholar] [CrossRef]

- Lee, H.; Nakasaku, S.; Hirota, T.; Kamiya, Y.; Ihara, Y.; Yamaura, T. Analysis of Energy Consumption and Possibility of Further Reduction of a Fuel Cell Garbage Truck. In Proceedings of the 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2020. [Google Scholar]