Abstract

Plastic waste (PW) constitutes a nuisance to our environment despite several efforts to reduce, reuse and recycle it. This study experimentally explores the possibility of storing plastic waste within a cement-stabilised soil that can be used as a road pavement layer material without adversely affecting the geotechnical characteristics of the stabilised soil. The soil is an A-2-6 soil, according to classification by the American Association of State Highway and Transportation Officials (AASHTO). Compaction characteristics, the California bearing ratio (CBR) and the unconfined compressive strength (UCS) of soil with 10% cement were determined for the 0, 2, 5, 10 and 15% addition of PW. The cementing of soil particles, which played a vital role in enhancing its strength on the addition of cement, may have been activated by the pozzolanic reaction between cement and soil particles. However, the addition of PW to this cement-stabilised mix led to a decrease in strength parameters at all variations. The soil with 10% cement and 2% PW yielded higher strength when compared to other mix ratios with PW and is suitable for use as a layer material in road pavement construction. As a sustainable strategy for PW management in developing nations, the usage of PW in cement-stabilised soil layer is recommended.

1. Introduction

The total weight of virgin plastics in circulation around the world keeps skyrocketing, irrespective of the efforts and campaigns that have been put in place to checkmate these wastes from causing environmental nuisance and hazards to marine life []. However, it is no news that the increasing volume of PW produced and discarded annually is mostly attributed to industrialisation and changes in human lifestyles. These wastes are produced by anthropogenic activities in huge proportions in product manufacturing, which poses a threat to the preservation and stability of our ecosystem []. Following the traditional “take–make–dispose” linear material-flow economic paradigm has contributed significantly to the rapid expansion in the use of plastic products and the generation of PW since the advancement of plastic (or synthetic fibre) in the 1950s. These benefits include an affordable price, resistance to heat and corrosion and its significant light weight []. Every year, a substantial quantity of PW enters the environment as a result of inappropriate disposal methods, raising several issues regarding its effects on ecosystem safety and natural resources []. The Organisation for Economic Co-operation and Development (OECD) conducted a survey on worldwide plastic production and consumption in 2022 []. This analysis predicts that in the absence of radical new regulations, the worldwide consumption of plastics would increase more quickly than that of most raw resources, from 460 million tonnes (Mt) in 2019 to 1231 Mt in 2060. Africa and Asia will see the quickest growth, despite the fact that in 2060, OECD countries will still produce 238 kg of plastic waste yearly per person on average, more than non-OECD nations (an average of 77 kg per year). The accumulation of plastic in lakes, rivers, and oceans is predicted to more than triple while plastic leakage into the environment is predicted to double to 44 Mt annually as plastic waste soars from 353 Mt in 2019 to 1014 Mt in 2060. Although leakage of microplastics or synthetic polymers with a diameter of less than 5 mm from objects such as industrial plastic pellets, textiles and tyre wear is alarming, the majority of pollution comes from larger debris termed as macroplastics. The projected increase in plastic consumption and waste will continue despite anticipated increases in the use of recycled plastic in the manufacture of new goods, technological innovations and regional economic changes that should result in an estimated 16% decrease in the amount of plastic required to generate 1 USD (US Dollar) of output production by 2060. Additionally, it is predicted that the percentage of effectively recycled plastic waste would increase to 17% in 2060 from 9% in 2019, while landfilling and incineration will progress to account for 50% and 20% of plastic waste, respectively. The amount of plastic in the world that bypasses waste management systems and instead ends up in unregulated dumpsites, is burned in open pits, or leaks into the ground or aquatic habitats is predicted to decrease from 22% to 15%.

Discharge of these PW can pose a serious hazard to health and the environment. It is anticipated that each year, 8 million tonnes or more of PW will enter the sea []. Then, via land-based means including ground water runoff, combined sewer spills, pollution, industrial effluents, dumping of solid wastes and landfills, these wastes enter water bodies []. As they move up the food chain from marine life to man through consumption of contaminated seafood, this contaminant enters tissues and skin []. Additionally, PW from landfill disposal can release harmful compounds into the soil, which may seep into nearby subsurface water sources and other water sources. This poses a serious health risk to humans and other organisms that consume water and crops [].

In large cities of developing nations such as Nigeria, plastic waste is frequently burned as an alternative to land filling. This process emits toxins such as ammonium, polyvinyl chloride, dioxins, furans and polychlorinated biphenyls (PCBs) that can pollute the environment []. These chemicals can worsen respiratory conditions, raise the risk of heart disease, harm the kidney, liver, neurological system, and skin, result in cancer and even cause death [].

Microplastics have even been suggested as a new global change factor []. Anthropogenic microplastic pollution builds up gradually in ecological systems, endangering the health and quality of the soil, for example by reducing aggregate stability and modifying bio-activity []. These microplastics typically operate as transport vectors for dangerous contaminants from the environment and have the ability to release chemicals into the atmosphere []. PW are also well recognised for blocking drainage when they build up with time, preventing storm water from flowing freely []. This is among the primary factors responsible for drainage blockage in developing countries as shown in Figure 1. The amount of PW generated yearly in big cities of developing countries such as Lagos, Nigeria continues to skyrocket, which ultimately affects the water-holding capacity of drains, river channels and reservoirs in these megacities as people dispose PW in these canals.

Figure 1.

Plastic waste blocking a drainage system in Lagos, Nigeria [].

The constant growth of PW in the environment has sparked concern. Thus, efforts and strategies have been employed over time to manage these wastes.

Recycling, also known as ‘renewing or reusing’, is among the most common strategies. Recycling is a waste management technique, where waste is gathered and turned into raw materials that may be utilised again to create other valuable items []. Gathering discarded plastics, grouping them, washing them to remove impurities, shredding and resizing them, identifying and segregating the various types of plastics, and compounding are all steps in the recycling process []. By minimising the quantity of carbon dioxide and other hazardous gases released into the atmosphere as a result of burning or incinerating these wastes, recycling serves to safeguard human life []. However, throughout the recycling process, some chemicals are released into the environment. When inhaled by creatures that reside close to the recycling zones, some of these chemicals (including volatile gases derived from plastic waste constituents and organic chains of monomer units that create plastic cycles of organic toxins and ashes) kill plant structures and have a negative impact on wildlife []. Plastics must be heated during the process in order to melt them, which results in the release of sulphur, carbon and other gases into the atmosphere. These gases can result in acid rain, the greenhouse effect and global warming; all of which have different negative environmental effects []. Additionally, this may cause health problems for people who enter the recycling zone for plastics. Wastes are separated for continuous recycling after the downcycling of plastics, which explains why the plastic is ultimately unsuitable for further recycling. As a result, they are viewed as a secondary use of leftover plastic waste and end up in landfills []. Incineration is another strategy that has been employed over the years []. Waste incineration is the process of burning wastes in the presence of oxygen, also referred to chemically as complete combustion, which results in the emission of water molecules and carbon dioxide into the environment. Waste incineration makes significant efforts towards reducing waste and generating electricity from waste, both of which are crucial for modern industrialisation []. Incineration as a chemical process offers benefits and drawbacks, as with all other biochemical or scientific operations. The incineration process has some limitations in comparison to other alternate waste management methods, such as costly setup. Waste incineration also emits waste ash that could be harmful to both people and the environment []. Landfilling is another commonly used method. After being used, plastics are disposed of in various trash cans and end up in landfills. Landfills are any locations or areas where all disposable plastic wastes are discarded after use before burying it beneath the surface of the earth []. During this landfill operation, every organic molecule goes through biodegradation and decomposition. Plastic bags and other lengthy polymer wastes might take ten to one hundred years to decompose in landfill processing []. Landfills are a tremendous source of energy because of the carbon dioxide and methane gas produced during the biodegradation process. Landfills preserve sanitation, keep cities tidy and distinguish hazardous waste from other waste types. Additionally, this is a cost-effective method of managing plastic waste. Although this method can be used to manage plastic waste, it has a number of disadvantages, including the fact that it causes climate change and ignites methane (a combustible gas). Additionally, it harms wildlife and taints soil and water []. The process of pyrolysis has also been employed as a management strategy for plastic wastes []. The conversion of gases and fatty oils into hydrocarbons and recovered crude petrochemicals is known as pyrolysis. With this, even unrefined petrochemicals can be recovered, and plastic waste can be used to create renewable energy []. By using catalytic methods of chemical processing or thermal reactions, the first derivative of petroleum refining cuts and petrochemicals are transformed to their monomers and other valuable elements, such as stabilisers and plasters []. Despite the potential for large upfront costs, this scientific approach to waste management is effective []. Microorganisms have also been employed to decompose wastes in a process referred to as bioremediation [,]. The biotechnology aspect of bioremediation can also be described as having primary principles of detoxification and decontamination by using microorganisms to biodegrade entirely natural materials that can be treated under the biological degradation of plants, fungi, bacteria and algae []. This process, however, requires huge investments in employing enzymes for the degradation of synthetic compounds.

Plastic wastes have also been employed as construction materials for sustainable development []. By utilising polyethylene terephthalate (PET), scrap plastic wastes (SPW) and foundry sand (FS), sustainable productive bricks were created []. Compressed earth bricks (CEB) were also produced using clayey sand and finely shred PET waste. During the CEB production process, soil and shreds of waste plastic were combined with a cementitious binder to increase the strength and durability []. Plastic bottles (PET) filled with either dry sand, wet sand, or air have been used as building materials, with cement mortar being employed as the binding agent. Low thermal conductivity was an outcome, resulting in solid masonry walls []. Taafe et al. [] also utilised PET bottles in the production of eco-bricks with high sound reduction index. Greenhouse walls were constructed from plastic bottles by Mokhtar et al. [] to cut down on CO2 emissions into the atmosphere. It has also been discovered that PET polymeric wastes increase the efficiency of unfired clay bricks [,]. When making interlocking bricks, clay and cement were swapped out for a binder made of polyethylene terephthalate (PET) and polyurethane (PU). These bricks were recommended for usage as a partition wall and were determined to be suitable as masonry bricks that do not support loads []. However, waste plastics such as polyethylene, high-density polymer (nylon 66) and polythene terephthalate, as well as red soil, crushed stone and river sand were used to make bricks in a range of formulations []. During the soundness test, no noise was heard and these bricks were strong and long-lasting. Results have shown that composite bricks made from fly ash and powdered polythene wastes are cost-effective and environmentally sustainable []. Blocks for pavers were also made using polythene bags and demolition debris rather than cement []. It was recommended that instead of cement, waste plastic bags may be melted down and used to make concrete blocks and bricks. Waste plastic may be transformed into construction materials such as bricks and concrete blocks due to its lightweight, great flexibility and capacity to be altered to meet particular technological requirements []. In addition to paver blocks and bricks, plastic wastes have been used in making different tiles [,]. This is already a common practice in certain regions of the world to improvise concrete for use in road construction. As a partial or complete alternative for aggregate, researchers have looked into various plastic admixtures [,,,,,].

PW outcomes of numerous research offer an encouraging implication to the opportunity for application of PW for stabilising or reinforcing of different soil [,,,,]. This employment disposes PW and reduces use of virgin materials []. When compared to chemically stabilised soils, plastic fibre proffers a more affordable option to soil stabilisation for pavement constructions and feasible for sustainable road construction. One benefit of plastic fibre stabilisation against stabilisation with chemicals is that PW stabilisation does not result in carbon dioxide emissions, but chemical stabilisation does []. Furthermore, the employment of PW was tagged an alternative innovative material compared to conventional materials in building masonry walls due to its good construction ability, low-cost, non-brittle characteristics and absorption of abrupt shock loads []. This alternative material also poses an eco-friendly way of replacing bitumen in flexible pavement construction geared towards cost reduction [] and the possible consequence of the elimination of many million metric tonnes of PW []. More so, its impact as a pavement construction material in underdeveloped and developing countries cannot be overemphasised as it improves the economy and environment []. Additionally, plastic material can be employed with fly ash and cement for rigid pavement construction. Even though the viability in concrete reduces as the percentage of plastic increases, this workability can be retained to a certain degree by increasing the water–cement (w/c) ratio [].

As evidenced in applications such as road and lightweight aggregates, paving techniques and soil stabilisation, polymer concrete, separation membranes or geogrid, asphalt binders and sheet piling, the potential for use of these PW is continually expanding []. Regardless of the efforts made to reduce PW, its constant and incremental emergence in recent years is still very alarming. As of 2022, the world will produce twice as much PW as it did two decades prior []. The majority of these wastes will be rid of by landfilling, burning, or even leaked into the environment. Although processes such as soil stabilisation have proved over the years to be advantageous in reducing PW from the ecosystem, its wide adoption has been limited. Rather than just stabilisation with conventional materials, attempts as to how these PW can be properly contained in a stabilised soil layer at a large magnitude should be examined. Thus, this study aims at exploring the possibilities of containing PW in cement-stabilised soil as a layer material for road pavement construction.

The use of cement as a binder dates back to the 1960s, when soil stabilisation technology was first developed. Because it can be used by itself to produce the necessary stabilising effect, it may be regarded as a primary stabilising agent or hydraulic adhesive []. When cement is introduced to the fine soil particles, various pozzolanic processes are involved, increasing soil strength. Cement stabilisation is quicker and independent of the soil properties []. Cement has calcium aluminates and calcium silicates, which hydrate to produce cementitious materials. Fast cement hydration results in quick strength gain in the stabilised soil []. Its adequate mechanical qualities and accessibility make it the material of choice for geotechnical engineering projects. As a result, it is utilised in a variety of stabilisation methods, including deep cement mixing and grouting []. The main benefits of using cement for stabilisation are that it is produced in accordance with strict ASTM standards, ensuring consistency of efficiency and durability; it is effective in soil stabilisation and has been used for more than 50 years on a diverse range of projects; it has a long track record of performance; it requires less volume increase than other materials; and it is widely available in bulk across nations []. Enhancement of soil with cement has yielded desirable results over the years in the field of construction. This material can be used alone to give desirable results for soil stabilisation. Cement generally enhances any type of soil, improving its California bearing ratio (CBR), thus making it stronger for use as a pavement layer material []. The durability obtained from soil–cement stabilisation has been known to be outstanding for years. Additionally, it helps pavement by evenly spreading the load, eliminating base rutting and lowering deflection as well as moisture issues []. The use of cement as a soil stabiliser for enhancing the engineering characteristics of soils for base and sub-base courses on highways and rail tracks at the best levels has been examined and proven []. Additionally, this stabilising material significantly decreases the coefficient of permeability of soil by filling up pore spaces within the fabric, making it less susceptible to the infiltration of water [].

Cement has also been used jointly with other additives to improve the geotechnical properties of soil for the intent of construction. Lime is most commonly utilised with cement for stabilisation. A cement and lime mix improves the strength characteristics (angle of resistance and cohesion) of all soil types, even those with low bearing capacity such as peat []. Researchers have employed other additives with cement for stabilisation so as to yield desirable results while minimising costs of excess cement usage. Through the reduction in soil plasticity and an increase in the California bearing ratio (CBR) for a pavement layer material, cement integrated with rice husk ash (RHA) has been used to enhance soil []. Cement and calcium carbide-stabilised laterite is recommended for use as base materials for constructing road pavements due to its high strength []. This is also a way of disposing calcium carbide waste. Further, the addition of fly ash to cement-stabilised clay strengthens the stabilising potential cement has on expansive clay []. Moreover, shear strength and axial strain are improved by the addition of cement with ethylene vinyl acetate (EVA) to soil []; and this has been advanced for improving subgrade materials. Another way of improving subgrade is seen in the use of cement and copper slag. The incorporation of these materials improves the strength of subgrade material used for road embankment construction []. Palm kernel shells have also been employed with soil–cement mix to create a material for construction use []. More so, studies have shown that a super-plasticiser mixed with cement improves the strength of soil compared to using cement alone []. Cement is also well known for use in the process of full-depth reclamation for pavement construction [,,]. Contaminated soils are also not left out, as cement has proved to be effective in improving these soil conditions [].

The wide range of cement usage in soil improvement cannot be elaborated enough, as it has proved to be effective in generating construction materials with high strength and durability. However, a significant gap exists in its combination with PW as a means of containing the growing circulation of plastic in the environment. Hence, the need for this study which is geared towards investigating the potentiality of incorporating PW in cement-stabilised pavement layers for the purpose of containing this waste material. Studies have shown that different diameters of pulverised waste plastic have been employed for use in soil stabilisation. These include plastic materials passing the following sieve sizes; 12 mm [], 10 mm [], 5 mm [], 4.75 mm [], 2 mm [] and 0.425 mm []. Nevertheless, this research is limited to the use of fine particles (0.075 mm diameter) for pulverised plastic in contrast to previous studies done. Studies have shown that cement is used frequently in combination with materials of fine particle size due to ease of binding, mixing and adequate cementation []. Additionally, the cement used in this case would principally function as a binder to contain these waste plastic materials in order to prevent the likelihood of microplastics leaching far beneath the soil and contaminating ground water, which can be hazardous to human health and pose a great threat to the ecosystem.

Terrestrial ecosystems can be directly affected by microplastics (primary microplastics) or indirectly (secondary microplastics) []. Primary microplastics are produced for a variety of uses and commodities, such as cosmetics, medical items, aqueous paints, coatings, adhesives and electronics. Through air deposition, a significant part of primary microplastics infiltrate terrestrial habitats []. In addition, the usage of sludge on agricultural fields and the dumping of waste materials in landfills all contribute to the primary build-up of microplastic in ecological systems []. When bigger plastics break down into tiny pieces as a result of ultraviolet (UV) radiation, wind, tillage, bio-activity, chemical and mechanical breakdown, secondary microplastics are formed []. Multiple sources, such as plastic mulches, greenhouse components, soil additives, irrigation water, municipal solid waste, climate invasions, inappropriate landfill disposal, and littering, all introduce secondary microplastics into terrestrial ecosystems [,,]. According to Zhang et al. [], there is a notable significant interface between the number of years of mulching and the formation of soil microplastic. Furthermore, microplastics can constitute atmospheric inputs to terrestrial ecosystems due to wind transmission over long distances from surfaces such as roadways and landfills [,]. Tillage, animal activity, such as earthworm ingestion and egestion, or water ingress brought on by digging are all methods by which plastic particles are assimilated into deep soil layers [,]. Microplastics can be broken down by microbial activity [], UV radiation [], physical abrasion [], thermal oxidation at high temperatures [] or by reaction with soil colloids []. Microplastics may age as a result of the cumulative effects of these conditions; nevertheless, each factor behaves differently depending on the season, the location and other circumstances. For example, light irradiation is important during the day but may have little impact at night []. Furthermore, the aging of microplastics may be affected more by temperature in desert regions in the summer than in polar regions in the winter []. Microplastics have physical and chemical properties that change with time, including colour, crystalline structure, chemical properties and surface characteristics []. A number of chemicals, including phthalates, stabilisers, pigments, oligomers and oxygenated compounds (such as phenolic acids, acetophenones, and carboxylated compounds), may permeate into the soil as microplastics deteriorate []. Microplastics may enter terrestrial food webs, be taken up by terrestrial plants and pollute groundwater as a result of biogenic transport in soil []. Furthermore, runoff of microplastics could result in the pollution of freshwater ecosystems by ground microplastics [,], which will then give rise to marine microplastic contamination [].

Mehra et al. [] suggested three main strategies for managing microplastics—namely (1) measures should be taken to reduce the use of needless single-use plastics, such as plastic shopping bags, straws, and water bottles; (2) governments should implement rigorous regulations to ensure the necessity of bolstering waste collection and recycling systems in order to stop these wastes from escaping into the environment and increase recycling rates; (3) new techniques for disassembling plastic into its component parts, which can then be reformed to generate new plastics or other materials, should be explored. However, these smaller units of plastic can also be contained in a composite system for construction such as soil–cement mixture, as in the case of this research; for the main purpose of mitigating the increasing rate of plastic pollution in the environment.

A high percentage of cement (10%) was chosen so as to yield stronger binding forces [,]. This high amount of cement boosts cementation within the soil–cement–PW mix which holds the plastic waste in place. A situation where the fine particles of the plastic wastes are not well bounded can pose an environmental issue as the seepage of microplastics into groundwater can contaminate ecological systems for a long time. Therefore, the percentage of cement utilised was explored to yield higher bonding of these waste plastics; holding them together and consequently preventing this discharge of microplastics. Cement content of less than 10% is typically recommended for soil–cement stabilisation. Therefore, the use of 10% cement will ensure that plastic waste is contained in a concrete matrix to prevent or minimise the migration of microplastics. It is due to these concepts that this research tends more towards providing a means of containment of plastic wastes rather than an outright stabilisation; taking the well-being of the environment as the key consideration. This technique of containment was also adopted by Genazzini et al. [], where masonry blocks were used to contain hospital waste ash. This was used to form a new cement–ash composite system for applications in building materials. Plastic waste in itself does not possess the same degree of stabilisation when used as a ‘stand-alone’ stabiliser compared to when it is used with conventional stabilisers, as this yields better results []. Treatment with conventional stabilisers (lime and cement) can impact brittleness in the soil over time, leading to the formation of cracks. This behaviour can be countered via the inclusion of plastics to the stabilised mix []. Generally, the cement addition to the pulverised plastic would help in improving the compressive strength and durability of the natural soil used for construction []. In summary, plastic waste does not possess any cementitious property. Consequently, the cement content of 10% in the soil–cement mixture will produce an effect that is similar to the soil–cement stabilisation with less than 10% cement content in the matrix. Cracking behaviour can be minimised by the inclusion of plastic waste to the stabilised mix.

An exploratory assessment of the effects of containing PW in cement-stabilised soil as a pavement layer material is presented in this paper. This work is distinctive since, as far as the authors are aware, no peer-reviewed paper in the open literature has discussed the use of cement-stabilised soil as a containment layer for PW in road pavements. It was hypothesised that applying PW in this fashion would considerably reduce the pollution from plastics in the environment, while providing a durable pavement layer.

2. Materials and Methods

2.1. Materials Preparation

Disturbed samples were procured at a 0.5 m depth from ground at Iju, Ota in Ogun State as shown in Figure 2. The area falls within latitude 6°40′50″ N and longitude 3°8′24″ E. The soil is brown in colour, with coarse, medium and fine components. Prior to being put into collection polythene bags and sacks, vegetative components were taken out of the samples. Exploratory geotechnical tests were used to identify the rudimental index qualities of the sample that was acquired.

Figure 2.

A map showing the location where the soil was obtained [].

Portland cement was purchased locally in Ogun State, Nigeria, for this investigation as shown in Figure 3. For the purpose of stabilising the soil containing PW and stopping microplastics from entering subsurface water, cement was added by weight to the samples at 10%. The cement in the soil–cement–PW mix functions as a binder which holds the finer particles of the plastic waste together. The cement bond in the mix serves as a form of containment for the plastic, which prevents it from leaching into groundwater.

Figure 3.

Portland cement utilised for this study.

Bottles made of polyethylene terephthalate (PET) were gathered at Covenant University in Ota, Ogun State, Nigeria. They were melted, solidified and allowed to cool before they were crushed and then passed through a 0.075 mm sieve. The corresponding particle size was then used for this study.

2.2. Methods

The geotechnical characteristics of the natural soil were explored in accordance with ASTM standards. The tests conducted include natural moisture content [], specific gravity [], sieve analysis [], Atterberg limits [], permeability [], compaction characteristics [], the California bearing ratio (CBR) [] and the unconfined compressive strength (UCS) []. The soil was stabilised with cement at 10%. The cement used has chemical properties as shown in Table 1. PW was then introduced to soil samples that had been combined with cement in a variety of weight-based amounts (2, 5, 10 and 15%). The mixing was done with respect to optimum moisture content. Afterwards, the strength parameters of the samples were determined. The tests employed for the purpose of this study were chosen because majority of the standards [,,] available in tropical African countries use these engineering parameters as benchmark for selecting materials for use as sub-grades, sub-bases and road bases []. The effects of adding PW to cement-stabilised soil as a way of containing these wastes within a road pavement layer were determined.

Table 1.

Chemical properties of cement used for this study [].

2.3. Geotechnical Properties of Natural Soil

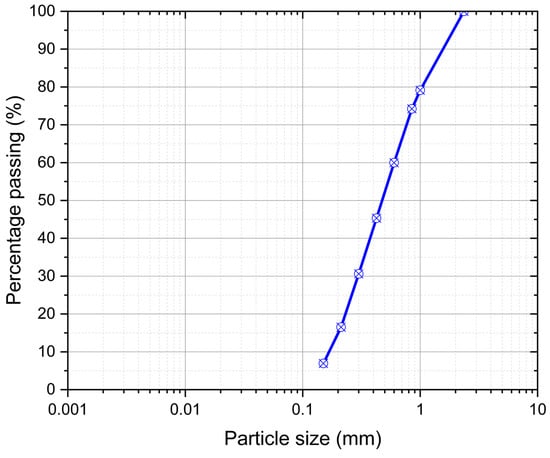

The summary of the geotechnical characteristics of the natural soil is shown in Table 2. The natural soil has a plasticity index of 16.11% and a specific gravity of 2.56. While the Unified Soil Classification System (USCS) describes the soil as well-graded sand (SW), the AASHTO classification system classifies the soil as A-2-6, which designates it as a granular material with 35% or less passing the 0.075 mm sieve. Particle size distribution for the natural soil is illustrated in Figure 4. The Atterberg limits test results shows that the soil particles have a medium plasticity. The optimum moisture content and the maximum dry unit weight of the soil were 19.56% and 17.0 kN/m3, respectively. The coefficient of permeability was 1.85 × 10−3 cm/s which means that it has medium permeability. A CBR of 1.7% was obtained, which is very poor []. Additionally, the UCS value of the natural soil was 133.0 kPa.

Table 2.

Geotechnical properties of the natural soil.

Figure 4.

Particle size distribution for the natural soil.

3. Results and Discussion

The strength parameters of the soil stabilised with 10% cement and modified with plastic waste at 0, 2, 5, 10 and 15% are summarised in Table 3.

Table 3.

Effects of PW on the strength parameters of cement-stabilised soil.

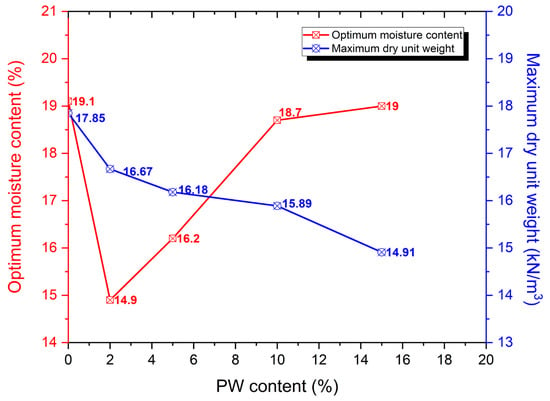

3.1. Compaction Characteristics

The maximum dry unit weight and OMC of the soil increased and decreased, respectively, upon the inclusion of 10% cement without PW. The maximum dry unit weight of the stabilised soil increased with the addition of cement because the specific gravity of cement was higher (3.15 in most cases) than that of natural soil (2.56). The rise in the maximum dry unit weight was also attributed to a decrease in the surface area of the clay fraction of the soil sample arising from the substitution of soil with the cement []. This increase generally signifies improvement in soil properties []. A corresponding decrease in OMC was also observed upon cement addition. This may be due to the reduction in porous voids filled by the cement. This condition results in the increase in dry density []. Additionally, the soil fabric’s ability to cement together its component parts improved. Due to this, the stabilised soil volume was reduced, which may also have caused its dry unit weight to increase []. A decrease in OMC was seen at 2% addition of PW. This might be due to the zero absorption capacity of the plastic for water []. Then, with the addition of plastic at 5, 10, and 15%, there was an increase that may be caused by an excess of water in the soil matrix that aided the exothermic reaction []. Yohanna et al. [] inferred that an increase in the OMC of a soil with plastic content can be as a result of the absorption of moisture by the plastic during the compaction process; thus, as the plastic content was increased, more water was needed to lubricate the soil surface which leads to an increase in OMC. A decrease in the maximum dry unit weight was then observed upon the addition of PW at 2, 5, 10 and 15%. The lightweight nature of plastic in comparison to soil weight can be responsible for this decline []. The increase in the plastic content in the soil led to the plastic occupying more spaces within the soil fabric that are supposed to be filled with soil in the matrix, therefore creating some voids in the mixture. This brought about a corresponding decrease in dry density []. The variation of OMC and the maximum dry unit weight with increasing PW content is illustrated in Figure 5.

Figure 5.

Variation of compaction characteristics for cement-stabilised soil with PW content.

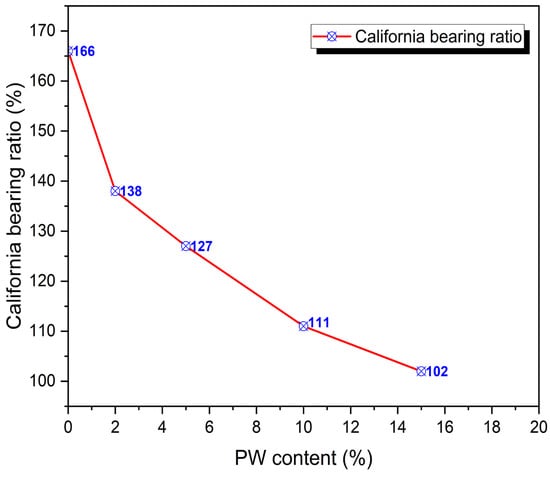

3.2. The California Bearing Ratio (CBR)

The CBR values for plunger penetration of 2.5 mm were used for analysis, with a higher value compared to the penetration at 5 mm. An increase in unsoaked CBR was observed upon the addition of cement. This increase is related to cementitious compounds that form in the soil that has been stabilised with cement, such as calcium silicate hydrates (C-S-H) and calcium aluminate hydrates (C-A-H) []. Gupta and Kumar [] inferred that chemical hydration during the reaction between cement and water gives rise to additional materials (C-S-H and C-A-H) that bound particles together and enhances strength. The development of these products occurs during the formulation of crystals after water and cement are mixed together to yield cementation. This process of cementation brings about high strength gain within the soil–cement mix []. This is an indicator for compacted soil strength and bearing capacity [], as cement treatment creates strong binding between soil particles, consequently increasing the CBR []. On the addition of PW at 2, 5, 10 and 15%, a decrease in CBR was observed as shown in Figure 6. This decline can be attributed to soil displacement induced by increase in the plastic content []. The Nigerian General Specification states that soil with a CBR value greater than or equal to (≥) 80 is suitable as a layer material to be used for subgrade, sub-base or base course. Taking this into account, the samples treated with PW can be employed as road pavement layer materials [].

Figure 6.

Variation of CBR for cement-stabilised soil with PW content.

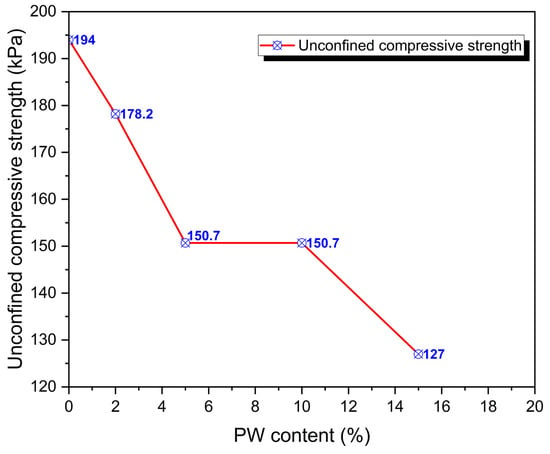

3.3. The Unconfined Compressive Strength (UCS)

This test was carried out on all variations of the samples on a 7-day curing period. Cement addition enhanced the compressive strength of the natural soil. This rise is the result of cation exchange and cement product synthesis caused by the reaction of cement with water upon hydration, binding the soil particles together []. Aparna et al. [] stated that cement addition to soil leads to the gradual formation of cementitious compounds via the reaction between the cement and some amounts of calcium hydroxide (CaOH) present in the soil. The agglomeration of large size particles within the soil fabric increases the compressive strength of the soil []. Upon the addition of PW at 2% to the soil–cement mix, it was observed that the UCS decreased. This is due to a reduction in the friction angle and maximum dry density. A further decrease in strength was noticed upon adding PW at 5%. The UCS value stayed constant up until 10%, which was then followed by a decrease upon the addition of PW at 15%. This behaviour is due to the increase in surface area of plastic, which easily gives rise to shear deformation of the soil []. The changes in values are shown in Figure 7. Furthermore, the presence of PW resulted in the production of weak shear planes that cause the soil to fail under strain [].

Figure 7.

Variation of UCS of cement-stabilised soil with PW content.

Generally, the improvement in strength characteristics upon the addition of cement is accredited to the reaction product in the mixture of soil and cement []. Wardani and Muntohar [] stated that the cement-stabilised soil will produce the main products of tricalcium silicate; and secondary products of calcium silicate hydrates (C-S-H) and calcium aluminate hydrates (C-A-H). These secondary products yield additional cementation agents to strengthen the soil–cement mix by increasing the bond between particles, while the primary products solidify into high-strength additives. Additionally, the inclusion of plastic materials to soil typically weakens soil matrix, especially beyond its optimal proportions []. This consequently leads to a decrease in soil strength characteristics. The results obtained suggest that the cement-stabilised sample with no amount of PW displayed the highest strength when compared to the cement-stabilised samples with PW. However, the soil with 10% cement and 2% PW has a higher strength when compared to all the soil–cement–PW mixtures; and does not adversely affect the geotechnical properties of the cement-stabilised mix.

The results in this study are similar to that obtained by Amena and Chakeri [], where the effect of lime and plastic strips on expansive soil strength properties was studied. It was inferred that adding lime alone to natural soil can enable the soil particles cement together and strengthen the soil. However, PW addition to the stabilised mix inevitably weakens it. This investigation also revealed that PW reduces the dry density of stabilised soils since it is lighter than soil relative to its weight. This trend was observed in the stabilisation of clay using plastic fibre and lime in subgrades []; and soil stabilisation with waste fibre and brick kiln dust []. Both studies attributed the reduction in the maximum dry unit weight and the strength of soil to the inclusion of PW within the stabilised soil fabric.

When the findings of the soil strength properties are compared to the Nigerian General Specification [], it is clear that the soil with 10% cement and 2% PW has the best strength when compared to the other mix ratios with plastic content, and is more appropriate for use as a material for road pavement layering as it does not adversely affect the geotechnical characteristics of the cement-stabilised soil. Although the cement-stabilised samples modified with PW at 2, 5, 10 and 15% PW meet the CBR requirement for subgrade, sub-base and base course materials, the sample with 10% cement and 2% PW is recommended, with the higher value for bearing capacity. In order to obtain the appropriate strength at a lower cost, additional studies can be performed to examine the inclusion of smaller amounts of cement with varied proportions of PW.

4. Conclusions

This research was directed towards providing experimental insight into the containment of PW in cement-stabilised soil for utilisation in road pavement construction. The findings can be summarised as follows:

- The Unified Soil Classification System (USCS) characterises the soil as well-graded sand (SW), while the AASHTO Classification System classifies it as belonging in group A-2-6.

- The maximum dry unit weight, CBR and UCS increased when cement was applied to natural soil. This is attributed to chemical hydration during the reaction between cement and water, which gives rise to additional materials (C-S-H and C-A-H) that bound particles together and enhance strength. The cementing of soil particles, which played a vital role in enhancing its strength on the addition of cement, may have been activated by the pozzolanic reaction between the cement and soil particles.

- PW addition to the cement-stabilised mix at 2, 5, 10, and 15% by weight brings about a reduction in soil strength as PW content increased. This is due to a reduction in the friction angle and maximum dry density. The increase in the plastic content in the soil easily gives rise to shear deformation, causing it to fail under strain.

- The results obtained suggest that the cement-stabilised sample with no amount of PW displayed the highest strength when compared to the cement-stabilised samples with PW. However, the soil with 10% cement and 2% PW has a higher strength when compared to all the soil–cement–PW mixtures; and does not adversely affect the geotechnical properties of the cement-stabilised mix.

- The various samples with PW are suitable for use as subgrade, sub-base and base course materials, as they meet the strength requirements based on the Nigerian General Specifications for CBR. However, the soil with 10% cement and 2% PW is recommended since it performed better than the other soil–cement–PW mixtures.

- PW should be added optimally to stabilised soils to prevent a significant loss in durability and strength.

These findings are especially significant since they show the potential to use cement-stabilised soil as a binder and containment for PW while also removing pollution from the environment as a result of the worrisome rise in PW pollution in our ecosystem. However, this study did not investigate the leaching of microplastics from the soil–cement–PW layer. Thus, it is recommended that future studies consider a leaching test to determine the amount of microplastics that would leach over the service life of the soil–cement–PW layer. Furthermore, the inclusion of lower amounts of cement with varied percentages of PW may be investigated in further research to obtain the appropriate strength at a lower cost. Additionally, further studies can be carried out to investigate how other cementitious materials can be used in containing PW that is circulating in the environment at an exponential rate.

Author Contributions

Conceptualisation, I.A.; methodology and software, I.A. and O.S.; resources and data curation, O.S., V.A. and P.E.; writing—original draft preparation, O.S., V.A. and P.E.; writing—review and editing, I.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to thank the Management of Covenant University and the Covenant University Centre for Research, Innovation and Discovery (CUCRID) for the platform made available for this research and also for publication support in terms of article processing charges. The authors also acknowledge the reviewers for their valuable comments.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Akinwumi, I.I.; Domo-Spiff, A.H.; Salami, A. Marine Plastic Pollution and Affordable Housing Challenge: Shredded Waste Plastic Stabilized Soil for Producing Compressed Earth Bricks. Case Stud. Constr. Mater. 2019, 11, e00241. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Adesina, A. Plastic Wastes to Construction Products: Status, Limitations and Future Perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Ki, D.; Kang, S.Y.; Ma, G.; Oh, H.J. Application of Waste Plastic Films in Road Infrastructure and Construction. Front. Sustain. 2021, 2, 756723. [Google Scholar] [CrossRef]

- Gambino, I.; Bagordo, F.; Grassi, T.; Panico, A.; De Donno, A. Occurrence of Microplastics in Tap and Bottled Water: Current Knowledge. Int. J. Environ. Res. Public Health. 2022, 19, 5283. [Google Scholar] [CrossRef]

- Organisation for Economic Co-operation and Development (OECD) Global Plastics Outlook Database: Policy Scenarios to 2060. Available online: https://www.oecd.org/newsroom/global-plastic-waste-set-to-almost-triple-by-2060.htm (accessed on 21 October 2022).

- Darshan, R.; Gururaja, S. Design and fabrication of crusher machine for plastic wastes. Int. J. Mech. Product. Eng. 2017, 5, 55–58. [Google Scholar]

- Blettler, E.; Abrial, F.; Sivri, N.; Espinola, L. Freshwater Plastic Pollution: Recognizing Research Biases and Identifying Knowledge Gaps. Water Res. 2018, 143, 416–424. [Google Scholar] [CrossRef]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; The World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Kehinde, O.; Ramonu, O.J.; Babaremu, K.O.; Justin, L.D. Plastic Wastes: Environmental Hazard and Instrument for Wealth Creation in Nigeria. Heliyon 2020, 6, e05131. [Google Scholar] [CrossRef]

- Alabi, O.A.; Ologbonjaye, I.A.; Awosolu, O.; Alalade, O.E. Public and environmental health effects of plastic wastes disposal: A review. J. Toxicol. Risk Assess. 2019, 5, 1–13. [Google Scholar]

- Department of Economic and Social Affairs (DESA). Sustainable Development Challenges, World Economic and Social Survey. E/2013/50/Rev. 1; United Nations: New York, NY, USA, 2013. [Google Scholar]

- Rillig, M.C.; Lehmann, A. Microplastic in terrestrial ecosystems. Science 2020, 368, 1430–1431. [Google Scholar] [CrossRef]

- Liang, Y.; Lehmann, A.; Yang, G.; Leifheit, E.F.; Rillig, M.C. Effects of Microplastic Fibers on Soil Aggregation and Enzyme Activities Are Organic Matter Dependent. Front. Environ. Sci. 2021, 9, 650155. [Google Scholar] [CrossRef]

- Issac, M.N.; Kandasubramanian, B. Effect of Microplastics in Water and Aquatic Systems. Environ. Sci. Pollut. Res. 2021, 28, 19544–19562. [Google Scholar] [CrossRef]

- Ogundairo, T.O.; Olukanni, D.O.; Akinwumi, I.I.; Adegoke, D.D. A Review on Plastic Waste as Sustainable Resource in Civil Engineering Applications. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1036, 012019. [Google Scholar] [CrossRef]

- Uwaegbulam, C.; Nwannekanma, B.; Gbonegun, V. Environment: Producers’ Responsibility and Plastic Pollution Crisis. Available online: https://guardian.ng/property/producers-responsibility-and-plastic-pollution-crisis/ (accessed on 21 October 2022).

- Evode, N.; Qamar, S.A.; Bilal, M.; Barceló, D.; Iqbal, H.M.N. Plastic Waste and Its Management Strategies for Environmental Sustainability. Case Stud. Chem. Environ. Eng. 2021, 4, 100142. [Google Scholar] [CrossRef]

- Szostak, E.; Duda, P.; Duda, A.; Gorska, N.; Fenicki, A.; Molski, P. Characteristics of plastic waste processing in the modern recycling plant operating in Poland. Energies 2021, 14, 35. [Google Scholar] [CrossRef]

- Vollmer, I.; Jenks, M.J.; Roelands, M.C.; White, R.J.; van Harmelen, T.; de Wild, P.; Weckhuysen, B.M. Beyond mechanical recycling: Giving new life to plastic waste. Angew. Chem. Int. Ed. 2020, 59, 15402–15423. [Google Scholar] [CrossRef]

- Shen, L.; Worrell, E. Plastic recycling. In Handbook of Recycling; Elsevier: Amsterdam, The Netherlands, 2014; pp. 179–190. [Google Scholar]

- Zheng, Y.; Yanful, E.K.; Bassi, A.S. A review of plastic waste biodegradation. Crit. Rev. Biotechnol. 2005, 25, 243–250. [Google Scholar] [CrossRef]

- De Weerdt, L.; Sasao, T.; Compernolle, T.; Van Passel, S.; De Jaeger, S. The effect of waste incineration taxation on industrial plastic waste generation: A panel analysis. Resour. Conserv. Recycl. 2020, 157, 104717. [Google Scholar] [CrossRef]

- Netzer, C.; Li, T.; Løvås, T. Surrogate reaction mechanism for waste incineration and pollutant formation. Energy Fuels 2021, 35, 7030–7049. [Google Scholar] [CrossRef]

- Thiounn, T.; Smith, R.C. Advances and approaches for chemical recycling of plastic waste. J. Polym. Sci. 2020, 58, 1347–1364. [Google Scholar] [CrossRef]

- Kedzierski, M.; Frère, D.; Le Maguer, G.; Bruzaud, S. Why Is There Plastic Packaging in the Natural Environment? Understanding the Roots of Our Individual Plastic Waste Management Behaviours. Sci. Total Environ. 2020, 740, 139985. [Google Scholar] [CrossRef]

- Sharuddin, S.D.A.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. A review on pyrolysis of plastic wastes. Energy Convers. Manag. 2016, 115, 308–326. [Google Scholar] [CrossRef]

- Shent, H.; Pugh, R.J.; Forssberg, E. A review of plastics waste recycling and the flotation of plastics. Resour. Conserv. Recycl. 1999, 25, 85–109. [Google Scholar] [CrossRef]

- Asgher, M.; Rani, A.; Khalid, N.; Qamar, S.A.; Bilal, M. Bioconversion of sugarcane molasses waste to high-value exopolysaccharides by engineered Bacillus licheniformis. Case Stud. Chem. Environ. Eng. 2021, 3, 100084. [Google Scholar] [CrossRef]

- Xu, S.; Yu, Z.; Zhou, Y.; Wang, F.; Yue, S.; Zhang, X. Insights into spatiotemporal distributions of trace elements in kelp (Saccharina japonica) and seawater of the western Yellow Sea, northern China. Sci. Total Environ. 2021, 774, 145544. [Google Scholar] [CrossRef]

- Asgher, M.; Qamar, S.A.; Bilal, M.; Iqbal, H.M.N. Bio-Based Active Food Packaging Materials: Sustainable Alternative to Conventional Petrochemical-Based Packaging Materials. Food Res. Int. 2020, 137, 109625. [Google Scholar] [CrossRef]

- Lamba, P.; Kaur, D.P.; Raj, S.; Sorout, J. Recycling/Reuse of Plastic Waste as Construction Material for Sustainable Development: A Review. Environ. Sci. Pollut. Res. 2021, 29, 86156–86179. [Google Scholar] [CrossRef] [PubMed]

- Aneke, F.I.; Shabangu, C. Green-efficient masonry bricks produced from scrap plastic waste and foundry sand. Case Stud. Constr. Mater. 2021, 14, e00515. [Google Scholar] [CrossRef]

- Mansour, A.M.H.; Ali, S.A. Reusing waste plastic bottles as an alternative sustainable building material. Energy Sustain. Dev. 2015, 24, 79–85. [Google Scholar] [CrossRef]

- Taafe, J.; O’Sullivan, S.; Rahman, M.E.; Pakrashi, V. Experimental characterization of Polyethylene Terephthalate (PET) bottle Ecobricks. Mater. Des. 2014, 60, 50–56. [Google Scholar] [CrossRef]

- Mokhtar, M.; Sahat, S.; Hamid, B.; Kaamin, M.; Kesot, M.J.; Wen, L.C.; Xin, L.Y.; Ling, N.P.; Jia Lei, V.S. Application of plastic bottle as a wall structure for green house. ARPN J. Eng. Appl. Sci. 2016, 11, 7617–7621. [Google Scholar]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Saadaoui, M.; Khaldoun, A. Thermal performance of unfired lightweight clay bricks with HDPE & PET waste plastics additives. J. Build. Eng. 2020, 30, 101251. [Google Scholar]

- Limami, H.; Manssouri, I.; Cherkaoui, K.; Khaldoun, A. Study of the suitability of unfred clay bricks with polymeric HDPE & PET wastes additives as a construction material. J. Build. Eng. 2020, 27, 100956. [Google Scholar]

- Alaloul, W.S.; John, V.O.; Musarat, M.A. Mechanical and thermal properties of interlocking bricks utilizing wasted polyethylene terephthalate. Int. J. Concr. Struct. Mater. 2020, 14, 24. [Google Scholar] [CrossRef]

- Kognole, R.; Shipkule, K.; Survase, K. Utilization of plastic waste for making plastic bricks. Int. J. Trend Sci. Res. Dev. 2019, 3, 878–880. [Google Scholar] [CrossRef]

- Sonone, P.; Devalkar, R. Green sustainable bricks made of fly ash and discarded polyethylene waste. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 6509–6516. [Google Scholar]

- Hemalatha, D. Reuse of waste plastics and demolition waste in the development of plastic paver block. J. Sci. Ind. Res. 2019, 78, 248–250. [Google Scholar]

- Abdel Tawab, O.F.; Amin, M.R.; Ibrahim, M.M.; Abdel Wahab, M.; Abd El Rahman, E.N. Recycling waste plastic bags as a replacement for cement in production of building bricks and concrete blocks. J. Waste Resour. Recycl. 2020, 1, 1–13. [Google Scholar]

- Seghiri, M.; Boutoutaou, D.; Kriker, A.; Hachani, M.I. The possibility of making a composite material from waste plastic. Energy Procedia 2017, 119, 163–169. [Google Scholar] [CrossRef]

- Behera, D. Experimental investigation on recycling of plastic wastes and broken glass in to construction material. Int. J. Creat. Res. Thoughts 2018, 6, 1659–1667. [Google Scholar]

- Hossain, M.; Bhowmik, P.; Shaad, K. Use of waste plastic aggregation in concrete as a constituent material. Progress. Agric. 2016, 27, 383–391. [Google Scholar] [CrossRef]

- Hameed, A.M.; Fatah Ahmed, B.A. Employment the plastic waste to produce the light weight concrete. Energy Procedia 2019, 157, 30–38. [Google Scholar] [CrossRef]

- Gavhane, A.; Sutar, D.; Soni, S.; Patil, P. Utilisation of E-plastic waste in concrete. Int. J. Eng. Res. Technol. 2016, 5, 594–601. [Google Scholar]

- Yang, S.; Yue, X.; Liu, X.; Tong, Y. Properties of self-compacting lightweight concrete containing recycled plastic particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Jain, A.; Siddique, S.; Gupta, T. Fresh, strength, durability and microstructural properties of shredded waste plastic concrete. Iran J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 455–465. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Dolati-Milehsara, S.; Lotfi-Omran, O.; Sadeghi-Nik, A. The Combined Effects of Waste Polyethylene Terephthalate (PET) Particles and Pozzolanic Materials on the Properties of Self-Compacting Concrete. J. Clean. Prod. 2016, 112, 2363–2373. [Google Scholar] [CrossRef]

- Salim, N.M.; AL-Soudany, K.Y.; Ahmed, A.A. The Impact of Using Recycled Plastic Fibres on the Geotechnical Properties of Soft Iraqi Soils. IOP Conf. Ser. Mater. Sci. Eng. 2018, 433, 012017. [Google Scholar] [CrossRef]

- Al-Neami, M.A.; Rahil, F.H.; Al-Ani, Y.H. Behavior of Cohesive Soil Reinforced by Polypropylene Fiber. Eng. Technol. J. 2020, 38, 801–812. [Google Scholar] [CrossRef]

- Jaber, N.H.; Radhi, M.S.; Alsaad, A.J. Ecological Applications of Polyethylene Terephthalate Plastic in Producing Modified Subbase Soil. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1067, 012006. [Google Scholar] [CrossRef]

- Fadhil, S.H.; Al-Soud, M.S.; Kudadad, R.M. Enhancing the Strength of Clay-Sand Mixture by Discrete Waste Plastic Strips. J. Appl. Sci. Eng. 2021, 24, 381–391. [Google Scholar]

- Hameed, A.; Shaban, A.M.; Almuhanna, R.R. Performance of Lime-Treated Sandy Soils after Sustainable Reinforcement Using Waste Plastic Fibre. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1067, 012047. [Google Scholar] [CrossRef]

- Radhi, M.S. Utilization of Waste Plastic in Geotechnical Engineering Applications in Iraq: A Review. J. Tech. 2021, 3, 9–14. [Google Scholar]

- Hassan, H.J.A.; Rasul, J.; Samin, M. Effects of Plastic Waste Materials on Geotechnical Properties of Clayey Soil. Transp. Infrastruct. Geotech. 2021, 8, 390–413. [Google Scholar] [CrossRef]

- Raut, A.; Patel, M.S.; Jadhwar, N.B.; Khan, U.; Dhengare, S.W. Investigating the Application of Waste Plastic Bottle as a Construction Material: A Review. J. Adv. Res. Mech. Civ. Eng. 2015, 2, 73–83. [Google Scholar] [CrossRef]

- Menaria, Y.; Sankhla, R. Use of Waste Plastic in Flexible Pavements-Green Roads. Open J. Civ. Eng. 2015, 5, 299–311. [Google Scholar] [CrossRef]

- Zulkafle, M.H.; Khalifa, N.A. A Review on the Use of Waste Plastic Material in Pavement. Recent Trends Civ. Eng. Built Environ. 2021, 2, 491–499. [Google Scholar]

- Hassan, K.E.; Elghali, L.; Soerby, C.R. Development of New Materials for Secondary and Recycled Aggregates in Highway Infrastructure; TRL Rep. 598; TRL Limited: Crowthorne, UK, 2004. [Google Scholar]

- Organisation for Economic Co-Operation and Development (OECD) Report on Plastic Pollution. Available online: https://www.oecd.org/newsroom/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.htm (accessed on 21 October 2022).

- Sukhmanjit, R. A review study on the soil stablization with cement and lime. Int. J. Lat. Res. Eng. Comput. 2017, 5, 33–37. [Google Scholar]

- Khan, K.A.; Nasir, H.; Alam, M.; Khan, S.W.; Ahmad, I. Performance of Subgrade Soil Blended with Cement and Ethylene Vinyl Acetate. Adv. Civ. Eng. 2020, 2020, 9831615. [Google Scholar] [CrossRef]

- Das, S.; Barua, A.; Chakraborty, S. Soil stabilization using cement as binder and nylon thread as reinforcement. Proc. Int. Conf. Plan. Archit. Civ. Eng. 2019, 2019, 1–5. [Google Scholar]

- Ghadir, P.; Ranjbar, N. Clayey soil stabilization using geopolymer and Portland cement. Constr. Build. Mater. 2018, 188, 361–371. [Google Scholar] [CrossRef]

- Solihu, H. Cement Soil Stabilization as an Improvement Technique for Rail Track Subgrade, and Highway Subbase and Base Courses: A Review. J. Civ. Environ. Eng. 2020, 10, 3. [Google Scholar] [CrossRef]

- Balkis, A.P.; Macid, S. Effect of Cement Amount on CBR Values of Different Soil. Eur. J. Sci. Technol. 2019, 16, 809–815. [Google Scholar] [CrossRef]

- Andavan, M.S.; Nagasai, P. Soil Stabilisation Using Cement. Ann. Romanian Soc. Cell Biol. 2021, 25, 1692–1701. [Google Scholar]

- Diana, W.; Hartono, E.; Muntohar, A.S. The Permeability of Portland Cement-Stabilized Clay Shale. IOP Conf. Ser. Mater. Sci. Eng. 2019, 650, 012027. [Google Scholar] [CrossRef]

- Zambri, N.; Ghazaly, Z. Peat Soil Stabilization Using Lime and Cement. E3S Web Conf. 2018, 34, 01034. [Google Scholar] [CrossRef]

- Basha, E.A.; Hashim, R.; Mahmud, H.B.; Muntohar, A.S. Stabilization of Residual Soil with Rice Husk Ash and Cement. Constr. Build. Mater. 2005, 19, 448–453. [Google Scholar] [CrossRef]

- Joel, M.; Edeh, E. Stabilization of Ikpayongo Laterite with Cement and Calcium Carbide Waste. Glob. J. Pure Appl. Sci. 2015, 20, 49–55. [Google Scholar] [CrossRef]

- Amu, O.O.; Fajobi, A.B.; Afekhuai, S.O. Stabilization potential of cement and fly ash mixture on expansive clay soil. J. Appl. Sci. 2005, 5, 1669–1673. [Google Scholar] [CrossRef][Green Version]

- Shahiri, J.; Ghasemi, M. Utilization of Soil Stabilization with Cement and Copper Slag as Subgrade Materials in Road Embankment Construction. Int. J. Transp. Eng. 2017, 5, 45–58. [Google Scholar]

- Arifin, Y.F.; Rahman, G. Stabilization of Soft Soil with Cement and Palm Kernel Shell Ash Admixture. MATEC Web Conf. 2019, 280, 04011. [Google Scholar] [CrossRef][Green Version]

- Ogirigbo, O.R.; Imafidon, D.; Ehiorobo, J.O. Chemical Stabilization of Deltaic Lateritic Soil Using Cement and Superplasticizer. NIPES J. Sci. Technol. Res. 2021, 3, 144–152. [Google Scholar]

- Gonzalo-Orden, H.; Linares-Unamunzaga, A.; Pérez-Acebo, H.; Díaz-Minguela, J. Advances in the Study of the Behavior of Full-Depth Reclamation (FDR) with Cement. Appl. Sci. 2019, 9, 3055. [Google Scholar] [CrossRef]

- Fedrigo, W.; Núñez, W.P.; Visser, A.T. A review of full-depth reclamation of pavements with Portland cement: Brazil and abroad. Constr. Build. Mater. 2020, 262, 120540. [Google Scholar] [CrossRef]

- Ghanizadeh, A.R.; Rahrovan, M. Full-Depth Reclamation Method for Rehabilitation of Streets Pavement in City of Sirjan: Mix Design and Bearing Capacity. J. Civ. Eng. Mater. App. 2020, 4, 1–14. [Google Scholar]

- Akinwumi, I.I.; Booth, C.A.; Diwa, D.; Mills, P. Cement Stabilisation of Crude-Oil-Contaminated Soil. Proc. Inst. Civ. Eng. Geotech. Eng. 2016, 169, 336–345. [Google Scholar] [CrossRef]

- Ahmadzai, M.; Sharma, A. Soil Stabilization with Brick Kiln Dust and Waste Fiber. Int. J. Innov. Res. Adv. Stud. 2019, 6, 31–35. [Google Scholar]

- Gowthami, D.; Sumathi, R. Expansive Soil Stabilization Using Plastic Fiber Waste Polypropylene. Int. J. Lat. Res. Eng. Technol. 2017, 3, 24–30. [Google Scholar]

- Harini, V.; Harsha, R.; Dhanalakshmi, S. Effect on Properties of Expansive Soil by Using LDPE Plastic Wastes. Int. J. Civ. Eng. 2018, 5, 13–16. [Google Scholar]

- Gangwar, P.; Tiwari, S. Stabilization of Soil with Waste Plastic Bottles. Mater. Today Proc. 2021, 47, 3802–3806. [Google Scholar] [CrossRef]

- Eltayeb, A.; Attom, M. The Use of Shredded Plastic Water Bottles in Soil Stabilization. Eurasia Proc. Sci. Technol. Eng. Math. 2021, 13, 37–44. [Google Scholar] [CrossRef]

- Rajesh, P.; Kalra, S.; Ramakrishna, G.; Naik, J.S.; Sankar, K.G. An Experimental Study on Soil Properties by Inducing Plastic Strips. Int. J. Mod. Trends Sci. Technol. 2021, 7, 131–137. [Google Scholar]

- Roy, A. Soil Stabilization using Rice Husk Ash and Cement. Int. J. Civ. Eng. Res. 2014, 5, 49–54. [Google Scholar]

- Waldman, W.R.; Rillig, M.C. Microplastic Research Should Embrace the Complexity of Secondary Particles. Environ. Sci. Technol. 2020, 54, 7751–7753. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, E.G.; Li, J.; Chen, Q.; Ma, L.; Zeng, E.Y.; Shi, H. A review of microplastics in table salt, drinking water, and air: Direct human exposure. Environ. Sci. Technol. 2020, 54, 3740–3751. [Google Scholar] [CrossRef] [PubMed]

- Karbalaei, S.; Hanachi, P.; Walker, T.R.; Cole, M. Occurrence, sources, human health impacts and mitigation of microplastic pollution. Environ. Sci. Pollut. Res. 2018, 25, 36046–36063. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Huang, X.; Xiang, L.; Wang, Y.; Li, Y.; Li, H.; Cai, Q. Source, migration and toxicology of microplastics in soil. Environ. Int. 2020, 137, 105263. [Google Scholar] [CrossRef] [PubMed]

- Blasing, M.; Amelung, W. Plastics in soil: Analytical methods and possible sources. Sci. Total Environ. 2018, 612, 422–435. [Google Scholar] [CrossRef]

- Bradney, L.; Wijesekara, H.; Palansooriya, K.N.; Obadamudalige, N.; Bolan, N.S.; Ok, Y.S.; Rinklebe, J.; Kim, K.H.; Kirkham, M.B. Particulate plastics as a vector for toxic trace-element uptake by aquatic and terrestrial organisms and human health risk. Environ. Int. 2019, 131, 104937. [Google Scholar] [CrossRef]

- Galafassi, S.; Nizzetto, L.; Volta, P. Plastic sources: A survey across scientific and grey literature for their inventory and relative contribution to microplastics pollution in natural environments, with an emphasis on surface water. Sci. Total Environ. 2019, 693, 133499. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, H.; Hu, W.; Qin, X.; Yan, C.; Wang, H. The status and distribution characteristics of residual mulching film in Xinjiang, China. J. Integr. Agric. 2016, 15, 2639–2646. [Google Scholar] [CrossRef]

- Rillig, M.C. Microplastic in terrestrial ecosystems and the soil? Environ. Sci. Technol. 2012, 46, 6453–6454. [Google Scholar] [CrossRef]

- Krueger, M.C.; Harms, H.; Schlosser, D. Prospects for microbiological solutions to environmental pollution with plastics. Appl. Microbiol. Biotechnol. 2015, 99, 8857–8874. [Google Scholar] [CrossRef] [PubMed]

- Sen, S.K.; Raut, S. Microbial degradation of low density polyethylene (LDPE): A review. J. Environ. Chem. Eng. 2015, 3, 462–473. [Google Scholar]

- Zhu, F.; Zhu, C.; Wang, C.; Gu, C. Occurrence and ecological impacts of microplastics in soil systems: A review. Bull. Environ. Contam. Toxicol. 2019, 102, 741–749. [Google Scholar] [PubMed]

- Benítez, A.; Sanchez, J.J.; Arnal, M.L.; Müller, A.J.; Rodríguez, O.; Morales, G. Abiotic degradation of LDPE and LLDPE formulated with a pro-oxidant additive. Polym. Degrad. Stabil. 2013, 98, 490–501. [Google Scholar] [CrossRef]

- Ren, Z.; Gui, X.; Xu, X.; Zhao, L.; Qiu, H.; Cao, X. Microplastics in the soil-groundwater environment: Aging, migration, and co-transport of contaminants–A critical review. J. Hazard. Mater. 2021, 419, 126455. [Google Scholar] [CrossRef]

- Liu, P.; Shi, Y.; Wu, X.; Wang, H.; Huang, H.; Guo, X.; Gao, S. Review of the artificially-accelerated aging technology and ecological risk of microplastics. Sci. Total Environ. 2021, 768, 144969. [Google Scholar] [CrossRef]

- Huerta Lwanga, E.; Gertsen, H.; Gooren, H.; Peters, P.; Salanki, T.; van der Ploeg, M.; Besseling, E.; Koelmans, A.A.; Geissen, V. Incorporation of microplastics from litter into burrows of Lumbricus terrestris. Environ. Pollut. 2017, 220, 523–531. [Google Scholar] [CrossRef]

- Ding, L.; Mao, R.; Guo, X.; Yang, X.; Zhang, Q.; Yang, C. Microplastics in surface waters and sediments of the Wei River, in the northwest of China. Sci. Total Environ. 2019, 667, 427–434. [Google Scholar] [CrossRef]

- Liu, F.; Olesen, K.B.; Borregaard, A.R.; Vollertsen, J. Microplastics in urban and highway stormwater retention ponds. Sci. Total Environ. 2019, 671, 992–1000. [Google Scholar] [CrossRef]

- Rocha-Santos, T.; Duarte, A.C. A critical overview of the analytical approaches to the occurrence, the fate and the behavior of microplastics in the environment. TrAC Trends Anal. Chem. 2015, 65, 47–53. [Google Scholar] [CrossRef]

- Mehra, S.; Sharma, K.; Sharma, G.; Singh, M.; Chadha, P. Sources, Fate, and Impact of Microplastics in Aquatic Environment. In Emerging Contaminants; Nuro, A., Ed.; IntechOpen: London, UK, 2021; ISBN 978-1-83962-418-6. [Google Scholar]

- Mamun, M.H.; Ovi, F.M.; Akhter, F.; Barua, S.; Ahmed, M.; Nipa, T.J. Improvement of Sub Base Soil Using Sand-Cement Stabilization. Am. J. Civ. Eng. 2016, 4, 241–246. [Google Scholar] [CrossRef][Green Version]

- Genazzini, C.; Giaccio, G.; Ronco, A.; Zerbino, R. Cement-Based Materials as Containment Systems for Ash from Hospital Waste Incineration. Waste Manag. 2005, 25, 649–654. [Google Scholar] [CrossRef] [PubMed]

- Prasad, R.R.; Venkateswararao, T.; Ram, D.A.S. Use of Lime and Waste Plastic Fibers for Subgrade Stabilization. Int. J. Eng. Adv. Technol. 2018, 8, 37–42. [Google Scholar]

- Google Maps. Available online: https://goo.gl/maps/kvzgJz86oASfNtGS9 (accessed on 21 October 2022).

- ASTM D2216; Standard Test Methods for Laboratory Determination of Water (Moisture) Content of Soil and Rock by Mass. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D854; Standard Test Method for Specific Gravity Test. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D4318; Standard Test Methods for Liquid Limit, Plastic Limit and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM D2434; Permeability of Granular Soils (Falling Head). ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM D698; Standard Test Method for Compaction Test. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM D1883; Standard Test Method for California Bearing Ratio (CBR) of Laboratory-Compacted Soils. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D293; Standard Test Method for Unconfined Compressive Strength (UCS). ASTM International: West Conshohocken, PA, USA, 2002.

- Nigerian General Specifications, Roads and Bridges; Federal Ministry of Works: Lagos, Nigeria, 1997.

- Structural Design of Flexible Pavements for Interurban and Rural Roads, TRH; Committee of Land Transport Officials, Ministry of Transport: Pretoria, South Africa, 1996.

- Overseas Road Note 31: A guide to the Structural Design of Bitumen-Surfaced Roads in Tropical and Sub-Tropical Countries; Transport Research Laboratory: Berkshire, UK, 1993.

- Akinwumi, I. Soil Modification by the Application of Steel Slag. Period. Polytech. Civ. Eng. 2014, 58, 371–377. [Google Scholar] [CrossRef]

- BS EN 197; Cement—Composition, Specifications and Conformity Criteria for Common Cements. BSI: Brussels, Belgium, 2011.

- Bowles, J.E. Engineering Properties of Soils and Their Measurement, 4th ed.; Mc Graw-Hill Publishing Company: New York, NY, USA, 1992; ISBN 978-00-7911-266-8. [Google Scholar]

- Kassa, R.B.; Workie, T.; Abdela, A.; Fekade, M.; Saleh, M.; Dejene, Y. Soil Stabilization Using Waste Plastic Materials. Open J. Civ. Eng. 2020, 10, 55–68. [Google Scholar] [CrossRef]

- Sharma, C.; Goel, A.; Tangri, A. Stabilization of Subgrade Soil by Using Alccofine and Waste Bottle Plastic Strips. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 2989–2995. [Google Scholar]

- Yohanna, P.; Badamasi, A.; Ishola, K.; Odoh, K.C.; Abdulkadir, M.N.; Fwangshak, G.M. A Comparative Study on the Effect of Sisal Fibre and Waste Plastic Strips in Structural Strength Improvement of Tropical Black Clay. J. Eng. Stud. Res. 2022, 28, 81–91. [Google Scholar]

- Amena, S.; Chakeri, D. A Study on the Effects of Plastic Waste Strips and Lime on Strength Characteristics of Expansive Soil. Adv. Civ. Eng. 2022, 2022, 1–6. [Google Scholar] [CrossRef]

- Prusinski, J.; Bhattacharja, S. Effectiveness of Portland cement and lime in stabilizing clay soils. Transp. Res. Rec. J. Transp. Res. Board 1999, 1652, 215–227. [Google Scholar] [CrossRef]

- Gupta, D.; Kumar, A. Strength Characterization of Cement Stabilized and Fiber Reinforced Clay–Pond Ash Mixes. Int. J. Geosynth. Ground Eng. 2016, 2, 32. [Google Scholar] [CrossRef]

- Firoozi, A.A.; Guney Olgun, C.; Firoozi, A.A.; Baghini, M.S. Fundamentals of Soil Stabilization. Int. J. Geo-Eng. 2017, 8, 26. [Google Scholar] [CrossRef]

- Truong, B.S.; Thi, N.N.; Thanh, N.D. An Experimental Study on Unconfined Compressive Strength of Soft Soil-Cement Mixtures with or without GGBFS in the Coastal Area of Vietnam. Adv. Civ. Eng. 2020, 2020, 1–12. [Google Scholar] [CrossRef]

- Hartono, E.; Prabandiyani Retno Wardani, S.; Setyo Muntohar, A. The Effect of Cement Stabilization on the Strength of the Bawen’s Siltstone. MATEC Web Conf. 2018, 195, 03012. [Google Scholar] [CrossRef][Green Version]

- Wardani, S.P.R.; Muntohar, A.S. Perbaikan Tanah, 1st ed.; LP3M: Yogyakarta, Indonesia, 2018; ISBN 978-602-7577-68-8. [Google Scholar]

- Niyomukiza, J.B.; Bitekateko, A.; Nsemerirwe, J.; Kawiso, B.; Kiwanuka, M. Investigating the Effect of PET Plastic Bottle Strips on the Strength and Compressibility Properties of Clayey Soil. IOP Conf. Ser. Earth Environ. Sci. 2021, 894, 012021. [Google Scholar] [CrossRef]

- Chauhan, M.; Kalra, S.; Singh, H. Stabilization of Clayey Soil Using Lime and Plastic Fiber in Sub Grades. Int. J. Innov. Technol. Explor. Eng. 2019, 8, 2118–2123. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).