Abstract

The ongoing search for biodegradable and biocompatible microneedles (MNs) that are strong enough to penetrate skin barriers, easy to prepare, and can be translated for clinical use continues. As such, this review paper is focused upon discussing the key points (e.g., choice polymeric MNs) for the translation of MNs from laboratory to clinical practice. The review reveals that polymers are most appropriately used for dissolvable and swellable MNs due to their wide range of tunable properties and that natural polymers are an ideal material choice as they structurally mimic native cellular environments. It has also been concluded that natural and synthetic polymer combinations are useful as polymers usually lack mechanical strength, stability, or other desired properties for the fabrication and insertion of MNs. This review evaluates fabrication methods and materials choice, disease and health conditions, clinical challenges, and the future of MNs in public healthcare services, focusing on literature from the last decade.

1. Introduction

Following the approval of the first transdermal patch for scopolamine administration by the FDA in 1979, as an alternative to oral administration of medications and hypodermic injections, the distribution of transdermal pharmaceuticals has gained considerable interest [1]. This is due to the numerous benefits, including improved dose reliability and control, enhanced patient engagement, and reduced clinical side effects [2]. Currently, there are numerous transdermal gels, ointments, and patches that can be applied to the skin [3]. The anatomical site chosen for these applications depends on the drug used and the rate of drug diffusion at the site of application [4]. For example, when the Alza Corporation introduced the first testosterone patch for men with hypogonadism, it was designed specifically to be worn on the scrotal tissue for its high permeability [5], while fentanyl patches were first designed for application on the upper thigh for pain management [6].

The transdermal drug delivery (TDD) systems such as the above have a range of constraints in their applications [3]. In particular, they are unable to deliver certain drugs across the skin at the desired therapeutic rates because of the poor permeability of the stratum corneum (SC) to these drugs [7,8]. The skin barrier only allows lipophilic and low molecular weight compounds (<600 Da) to pass through [9]. Therefore, many attempts at improving drug permeability by physical and chemical approaches have been investigated previously. Chemically, the use of chemical penetration enhancers has been shown to improve lipophilicity and, therefore, the bioavailability of the drug. However, there are problems of skin irritation and loss of dose associated with them [10]. Alternative methods such as iontophoresis [11], sonophoresis [12], and electroporation [13] can physically disturb the SC of skin, reducing its resistance to drug permeability. However, these methods are costly and require a difficult set of guidelines for effective drug delivery, which make them less user-friendly. To this end, microneedles (MNs) promise to be a more cost-effective and patient-friendly TDD system for the delivery of a host of drugs. MNs can pierce the SC and create transient microchannels that actively disperse foreign molecules through the blood [14]. Without disturbing the nerves of the underlying dermis and destroying blood vessels, MNs may also be optimized to enter the specified depths in the skin [15]. Thus, MN therapy allows for a minimally invasive molecule delivery into the skin, unlike the traditional methods for transdermal delivery of pharmaceuticals [16].

MNs can be produced from a range of materials such as metals, silicon, carbohydrates, and polymers [17,18,19,20]. Microneedles fabricated from biodegradable and biocompatible materials such as polymers present major benefits i.e., low cost, non-toxicity, and a range of physicochemical and mechanical properties. The biodegradable and biocompatible nature of a polymer-based MN (also called polymeric microneedles) is important as the MNs penetrate biological barriers and are exposed to bodily fluids and tissue. In this context, the nontoxic nature of MNs should comply with the United Nations’ Sustainable Development Goal 3—good health and well-being [21].

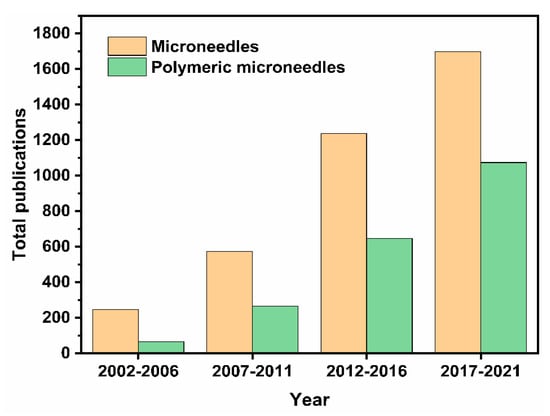

In the last two decades, MNs have become an increasingly popular study topic. This was evidenced in our analysis, which demonstrated that the number of publications obtained using the database Scopus with the search term ‘‘microneedle’’ has increased steadily. Figure 1 shows the number of these publications across different time periods in the last 20 years. This suggests a progression, and it can only be assumed that MN will continue as a technology in the future. The advanced search with term “microneedle” and “polymer” gave us the total number of publications that are related to polymeric MNs for that period. Figure 1 shows that the interest in polymeric MNs within the realm of MN drug delivery is increasing. For example, during 2017–2021, ~65% of the publications related to polymeric MNs. With the amount of research into TDD in conjunction with polymeric MN use continually growing, the potential of polymeric MNs is expected to increase.

Figure 1.

Bar charts displaying the total number of publications on MNs, and the number of MN publications related to polymeric MNs over the 5-year intervals. Information accessed on 26 June 2021 at www.scopus.com.

However, several challenges must be addressed for these MNs to find widespread medical applications. Challenges include skin irritation, microbial contamination, lack of mechanical strength of biomaterials, the quantity of drug loading, and the delivery of macromolecules with high hydrophilicity [22]. There is also a need to form an optimized compromise between painlessness and penetration [23]. Thus, without the formation of accurate mathematical models for the release of specific drugs, the viability in the performances of different MNs for treating different diseases is difficult to ascertain. Researchers have now performed modeling and simulation studies on polymeric MNs to optimize drug delivery [24]. At the same time, it has been argued that modeling has the potential to reduce the financial and time cost of MN manufacturing [21].

With the ongoing MNs’ progress toward commercialization, there is a greater need to address the issues surrounding their translation from the laboratory to the end-user. In addressing this point, this review aims to discuss the latest trends, progresses, and challenges of polymeric MNs specifically, e.g., key marketed products, drug delivery mechanisms, polymer kinetics, fabrication techniques, materials used and classifications, MNs evaluation techniques, preclinical and clinical trials, and others. Various drugs administered using MNs for different diseases and ailments along with MN compositions are also discussed briefly to motivate the review topics further. At the end of the review, we conclude that for a successful translation of MNs, one needs to consider all these aspects successfully.

2. Polymeric Microneedles

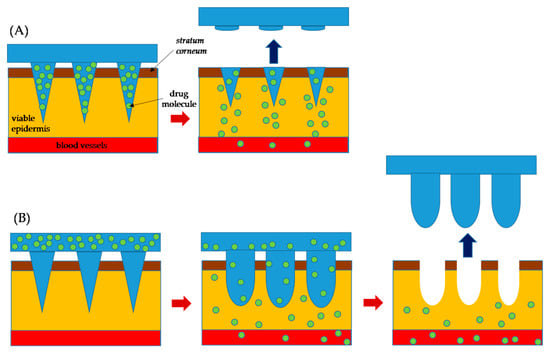

Polymeric MNs have been shown to be a strong technology to provide chemical molecules with clinical effectiveness and large complex biotherapeutic systems [25]. The polymeric MNs have also opened up a whole new horizon by offering many advantageous features as contrasted with silicone, metal, and other MNs [26]. They possess both the biodegradable and biocompatible properties and other benefits such as low cost, a wide selection of physicochemical and mechanical properties, and decreased risk of material build-up in the skin [27]. Polymeric MNs can be further separated into two categories of dissolving MNs and swellable microneedles. In the case of dissolving MNs, the drug is loaded inside the microneedle domain. Dissolving MNs absorb the skin water and completely dissolve in the skin which results in the release of the drug from the needle into the skin (Figure 2A). Swellable MNs have a reservoir attached at the base which contains drug in a lyophilized form (Figure 2B). Swellable MNs absorb local moisture within the skin, opening the polymeric matrix, and allowing the drug to diffuse from the reservoir into the skin. The swelled polymer matrix remains attached to the MN base throughout the delivery process, in which there is no polymer dissolution in the skin. We use the words “swellable” and “hydrogel forming” interchangeably as most of the swellable MNs are prepared using hydrogels. As the needle arrays either dissolve or soften, disposal of the medical waste can be executed safely without risk of stick injuries or contamination. Polymeric MNs are ideal for preserving the bioactivity of thermally unstable drugs such as protein vaccines and enzymes while at the same time minimizing the associated costs for cold storage [28]. There is a wide range of polymers with different swelling, degradation properties, and responsiveness to physical and biological stimuli. MNs made from these polymers allow control of the physicochemical properties and pharmacokinetics of drug molecules and performance in the skin for various biomedical applications [29].

Figure 2.

A schematic diagram for the mechanism of drug delivery: (A) dissolving MNs and (B) swellable MNs. The MN completely dissolve in skin in the case of (A), while there is no polymer dissolution in skin for the case of (B).

3. Material Choice and Drug Release Kinetics of Polymeric Microneedles

The choice of material for MN preparation and drug release kinetics has key roles in translating polymeric MNs to commercial applications for the treatment of human diseases. Becton Dickinson (BD), United States of America (USA), Georgia Institute of Technology, USA, and Alza Company, USA, led studies on the development of MNs for medication administration in the 1990s. Metal or silicone was initially used as the raw material to produce MNs [30]. Nevertheless, researchers began using other materials that were biologically viable, lighter, and more renewable [31]. Biodegradable polymer MNs were developed in 2003 for the biodegradability method used in TDDs [32]. A list of the polymers for MN with competitive features is included in Table 1.

Due to its cost, consistency, biodegradability, hygienic application, swelling, and dissolving capability, polymers are favored [33]. Polymers are primarily used in dissolving and swellable MN arrays [34]. The in vivo breakdown creates nontoxic subproducts in biodegradable MNs. This decreases the chance of infection in the body [35]. The polymeric MNs can be classified based on compositions, construction, in vivo efficiency, and ingredients [36]. The use of biodegradable polymers is important for the management and analysis of the continuous release profile of the products in terms of the rates of decline [37]. Common components that are widely used in dissolving polymeric MNs included sodium hyaluronate, which is naturally found in the skin, sodium carboxy-methynyl cellular, poly(vinylpyrrolidone) (PVP), carboxymethyl cellulose (CMC), hydroxypropyl methylcellulose (HPMC), sodium alginate, as well as other components [38,39]. Furthermore, bio-responsive polymers such as hyaluronic acid (HA), polyvinyl alcohol (PVA), and alginate, cross-linking methacrylate are also used [40]. Biocompatible, non-immunogenic, mechanically complex materials should be perfect for polymeric MN materials [41]. A list of the polymers for MNs with competitive advantages are included in Table 1 and Table 2.

Each polymer used within an MN is characterized by its potential for strength, penetration, and continuous release of drugs [42]. MN penetration through the skin is the greatest obstacle for polymer MNs [43]. In contrast to non-dissolving materials such as silicon or copper, the mechanical strength of water-soluble polymers is often lower, and drug encapsulation may further weaken the strength of MNs [44]. Flash modulus and polymer MN fractures are important for mechanical resistance, as the insertion capability of the polymer-based MN is reflected here [27]. Researches can also combine the mechanical power of two or more polymers and additional materials [45]. Furthermore, during polymer selection, the target tissue for the MN must be called transdermal or non-transdermal [46,47]. Aimed at soft tissues that cannot withstand pressure from the high-strength MN implant, careful balancing of strength and versatility must be considered [48]. Environmental moisture is also an important consideration, as greater moisture levels decrease the resistance of the MNs by the polymer and humidity [49].

Moreover, the active ingredient loaded into the polymeric MNs may improve mechanical strength [50]. The mechanical strength of the MNs can be decreased if the drug dispersed in the base plate of the MN arrays, which were shown by cracking the base plate after mechanical assessment, is placed in the MN not only to overcome the mechanical strength problem but also to decrease drug wastage [51]. The substance used for producing MNs is the most important design element, as it determines the strength of the mechanism and the release effect of MN drugs [52]. The substrate density, MN height, diameter width, and base of the MN are other factors to be considered [43]. However, manufacturing is constrained by the time-consuming steps typically needed, for example, master preparation, mold creation, and plasticization of thermoplastic polymers above their transition temperature. Therefore, thermal-free products cannot be used, and thus polymer MNs are usually manufactured with the aid of shaping techniques [53]. Researchers tackle the problem of thermal-friendly medicines by pouring the medication and polymer solutions into the mold under vacuum or heat [54]. In Table 1 it has been shown that the favorable materials and their benefits after using them to develop MN. It has been shown that the challenges that must be overcome for developing a good quality MN.

Table 1.

General properties of typical polymers used in the preparation of MNs.

Table 1.

General properties of typical polymers used in the preparation of MNs.

| Material * | Benefits | Limitations | Fabrication Technique | Reference |

|---|---|---|---|---|

| PVA | Low material cost Different grades and molecular weight (MW) available Composites provide good plasticity and dissolvability Nontoxic Can be used to prepare dissolving as well as swellable MNs | Cross-linkers used such as glutaraldehyde or formaldehyde may reduce biocompatibility Absorbs water quickly | Molding Fused deposition modeling (FDM) | [55,56] |

| PLGA | Offer excellent applicability Used in preparing dissolving MNs | High material cost | Molding Micro milling Hot embossing | [57,58] |

| HA | Offers rapid dissolution Used in preparing dissolving MNs as well as glucose-responsive MNs | Can cause skin irritation | Micro molding | [59] |

| Gantrez® | Copolymer of methyl vinyl ether and maleic anhydride Excellent swellable capacity Mostly used for preparing swellable MNs | High material cost | Micro molding | [36] |

| PCL | Exceptional thermal stability Easily processed High permeability | Slow degradation | Micro molding Hot embossing 3D printing | [60,61] |

| PEGDA | Easily customized to include biological molecules | High material cost | Photolithography | [62] |

| PGA | Fast degradation High tensile strength Excellent fiber-forming ability Excellent mechanical properties | High material cost | Injection molding Lithography Fused deposition modeling (FDM) | [61,63,64] |

| PLA | Easily processed Adjustable degradation rates Excellent physical and mechanical properties Mainly used in solid and coated MN fabrication | High material cost Slow degradation | Molding, FDM | [65,66,67] |

| PVP | Different grades and MW available Composites provide good plasticity and dissolvability Low cost | Difficulty scaling up the process efficiently | Molding Photopolymerization | [63,68] |

* Reference: HA: hyaluronic acid; PEEK: polyether ether ketone; PEG: polyethylene glycol; PEGDA: poly (ethylene glycol) diacrylate; PGA: polyglycolide; PLGA: poly (lactic-co-glycolic acid); PMVE/MA: polymethyl vinyl ether-alt-maleic anhydride; PVA: polyvinyl alcohol; PVP: polyvinylpyrrolidone.

Table 2.

Various polymers and fabrication techniques for dissolving and swellable MNs.

Table 2.

Various polymers and fabrication techniques for dissolving and swellable MNs.

| Type of Polymeric MN | MN Construction Polymers | Fabrication Techniques |

|---|---|---|

| Dissolving MNs | Chitosan [69]; Carboxymethyl cellulose, CMC [70]; Dextran [71]; Dextrin [72,73]; Hyaluronan, HA [74]; Polyvinyl alcohol, PVA [34] Polyvinylpyrrolidone, PVP [75] Sugars [76] | Micro molding [54]. Drawing lithography [70]; Continuous liquid interface production, CLIP [77]; 3D Printing [2,78]; Injection molding [79]; Hot embossing [80,81]; Photolithography and etching [82]; |

| Swelling MNs | Hyaluronan, HA [83]; (Hydroxyethyl) methacrylate, HEMA [84]; Polyvinyl alcohol, PVA [55]; Poly(styrene)-block-poly (acrylic acid), PS-b-PAA [85] | Crosslinking via: Lyophilization [55]; Heating [84]; UV exposure [86]; |

Polymer Dissolution Kinetics

Kinetics can be defined as the study of the rate of change of concentration. Dissolution is described as the process of a substance moving from a solid state to forming an aqueous solution. Hence, dissolution kinetics is the study of the rate of change of concentration due to a substance dissolving [87]. Therefore, research into dissolution kinetics is a vital part of modeling dissolving MNs. The dissolution of the polymer that forms the dissolving MNs can be prompted by several stimuli [88]. In this section, we briefly discuss the key parameters, namely, temperature, ultraviolet, pH, and moisture responsive polymers that affect the performances of dissolving MNs.

Photothermal Responsive. Photothermal responsive polymers are polymers that melt in the presence of photons of a specific range of wavelengths due to the absorption converting light energy into thermal energy [87]. Chen et al. [60] produced polycaprolactone MNs with silica-coated lanthanum hexaboride (LaB6@SiO2) nanostructures incorporated. The purpose of the LaB6@SiO2 was to absorb near-infrared ray (NIR) wavelengths. Therefore, when exposed to NIR, the structure heated, causing the MN to melt at 50 °C. This approach allows for the release of active pharmaceutical ingredients upon demand using externally applied NIR [89].

pH-Responsive. pH-responsive polymers are polymers that allow for the transfer of a substance as a direct result of acidic or alkaline conditions. Ke et al. [90] developed hollow MN arrays containing microspheres, which encapsulated two model drugs and sodium bicarbonate. The microspheres had a thin poly(d,l-lactic-co-glycolic acid) (PLGA) external membrane, which protons could diffuse through. Thus, when the hollow MN array delivered the microspheres into the skin, which is naturally acidic, the protons reacted with the sodium bicarbonate within the microspheres. This formed CO2, which generated pressure within the microsphere. The pressure increased until the microsphere membrane ruptured, releasing the encapsulated drugs [90]. Ullah et al. [91] implemented the foundations of the microsphere technology into a polymeric MN array. Ullah et al. [91] created a MN array containing pores of sodium bicarbonate mixed with the drug. The MN array had a thin PLGA external membrane that protons could diffuse through. Therefore, when introduced to the acidic environment of the skin, the pressure was generated inside the pore. When the pressure was large enough, the membrane ruptured, releasing the encapsulated drug [91].

Moisture Responsive. Moisture responsive polymers are polymers that undergo dissolution due to hydrolysis. Moisture responsive dissolving MNs can either be designed for an instant release or a controlled release system [92]. Commonly, water-soluble polysaccharides are used as the construction polymer for instant release systems. Examples used in instant release systems include polyvinyl alcohol (PVA), polyvinylpyrrolidone (PVP), hyaluronan (HA), dextran, and carboxymethyl cellulose (CMC). However, polysaccharides are also used in dissolving MNs for the controlled release of a drug due to their biocompatibility and stability [87]. Koh et al. [93] developed a method of delivering basic mRNA using a polyvinylpyrrolidone dissolving MN patch (RNA patch). The RNA patch was shown to completely preserve the physical and functional integrity of the encapsulated mRNA for at least two weeks. The kinetics of the RNA patch were comparable with subcutaneous injections and could be increased with longer MN lengths. The use of moisture responsive polyvinylpyrrolidone in a dissolving MN array showed potential for the safe and efficient delivery of mRNA-based therapeutics [93].

4. Modeling and Optimization for Designing Polymeric MNs

MNs are ultra-small and minimally invasive drug-delivery devices requiring regulated, precise, and repeatable injections into human skin [1]. During injection into the skin of the hard SC layer, complex injection methods are pursued because of the high flexibility and elasticity of the skin [94]. Lutton et al. [95] proposed three basic requirements in considering universal acceptance criteria for MNs: (1) they must pierce the skin, (2) they must penetrate and remain in the skin to dissolve or interact in the skin while delivering the therapeutic agent, and (3) they must act within the specified timeframe and must be able to dissolve or else be removed [95].

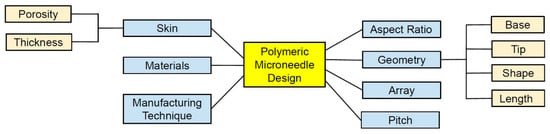

There are different parameters which shape the design and effectiveness of MN devices, as shown in Figure 3. Therefore, to successfully insert MN devices with various materials, geometric characteristics, and array size, the effect of MN design on the skin needed to be established [14]. The selection of materials capable of controlling the release and drug stability during manufacturing are central to the design strategy are the key for safe and efficacious MNs [66,96,97]. The materials (e.g., silicon, polymer, metals, or carbohydrates), arrangement on the substrate (e.g., radial, triangular, square, or hexagonal), and the geometry (i.e., base diameter, tip diameter, base-to-tip ratio, and center-to-center spacing) of the MNs can affect the penetration depth [36,82]. Controlling the length, sharpness, arrangement, and puncture rate of the MNs is important to meet the criteria set by the FDA for an MN system as a medical device [98]. Geometries of the MN, such as shapes, aspect ratios, and tip radius, affect the skin insertion capability of polymeric MNs [99]. For example, pyramidal shapes exhibited better mechanical strength than those with conical shapes due to their larger cross-sectional area with the same base width [2,100]. Also, the mechanical strength of pyramidal-shaped MNs can be further improved by increasing the base width and decreasing the aspect ratio [40]. Shorting the tip length and widening the base width increased the failure force [101]. Chen et al. [102] showed that the smallest aspect ratio exhibited the highest mechanical strength and the deepest insertion depth in the pyramidal MNs. The mechanical strength for MNs with the same aspect ratio but different dimensions does not vary significantly [102]. These results support that both shapes and aspect ratios are crucial variables for the mechanical properties of MN. It should be noted that widening the bases for decreasing the aspect ratio would increase the difficulties in achieving efficient skin insertion [40]. For better penetration, increasing the sharpness of the tip increases the penetration depth considering sufficient mechanical strength is present [103,104]. Insertion force for MN decreases by increasing the insertion speed, whereas increasing center-to-center interspacing of MN tips decreases the insertion force [104,105]. Overall, polymeric MNs with a pyramidal shape, smaller aspect ratio, and sharper tips exhibit good skin insertion [40].

Figure 3.

Several parameters affecting the design and performance of polymeric MNs.

4.1. Role of Skin on MN Insertion Behavior and Drug Delivery

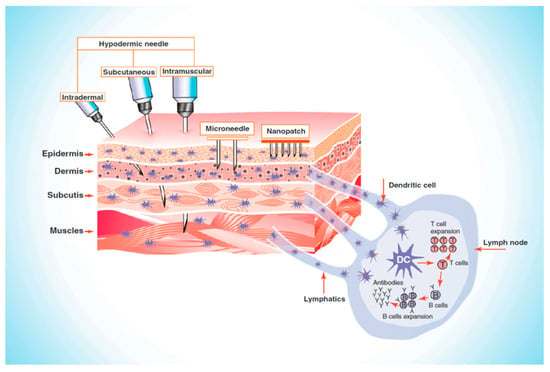

Numerous factors, including age, gender, ethnicity, anatomical area, and hormonal balance affect the thickness of the skin [106]. MN patches pierce the SC, thus bypassing the barrier layer and delivering 100% of the loaded drug without pain [107]. Then, the drug is directly delivered into the upper dermis layer, which distributes into the systemic circulation, and on reaching the site of action, produces a pharmacological response [9,108,109]. Most MNs are 150–1500 μm long and 50–250 μm wide, with 1–25 μm tip thickness. The MN length of up to 1500 μm is sufficient to release the drug into the epidermis since the epidermis is up to 1500 μm thick [110]. MNs larger than 1500 μm in length can go deep into the dermis, damage the nerves, and therefore cause pain [110,111]. Laurent et al. [112] found that regardless of gender (205 women and 137 men), age (18–70 years), and ethnicity (Asian, Caucasian, and African American), the mean skin thickness of the suprascapular, deltoid, and waist ranges from 1.55 to 2.54 mm and the suitable MN length for intradermal vaccine delivery is 1.5 mm [112]. As presented in Figure 4 [113], MNs only penetrate the epidermis to deliver the drug where hypodermic needles need to reach up to the muscle level for drug delivery.

Figure 4.

Illustrating the comparative penetration of hypodermic needle and microneedles (MNs), Reproduced with permission from [113], Elsevier, 2011.

Longer MNs can penetrate deeper and create longer micro-holes in the skin. As a result, more drugs can effectively move across the stratum corneum (SC), increasing drug permeability through the pathways created by the MNs [36,48,114]. Increasing the MNs height can promote the vertical and hardly affect the horizontal drug diffusion. The dosage of drug administered can be controlled by adjusting the height of MNs for skin pretreatment, and thus more drug distribution occurs in the skin [24,48]. Higher density MN patches can induce higher drug diffusion horizontally as higher densities of the MNs create more micro-holes and distribute more drugs through the micro-holes into the skin. Therefore, increasing MN density is an effective way to increase drug penetration for large scales of skin pretreatment with MNs [115,116].

To visualize and evaluate intradermal penetration depth, there are techniques such as histological sectioning, confocal microscopy, fluorescence microscopy, optical coherence tomography (OCT), X-ray computed tomography (micro-CT), and high-speed X-ray imaging [7,117,118,119,120,121].

4.2. Mathematical Modeling of Polymeric MNs

The mathematical models, in general, have been used mostly to verify the performance of the designed MNs [122]. The main objectives of mathematical modeling are to obtain the required design parameters to optimize the MN [123,124]. The establishment of a mathematical model that simulates the physical mechanisms occurring during transdermal drug delivery is essential for the medical industry as the development of such a model will enable key parameters that are difficult to measure be quantified. The most notable parameters include the rate of swelling and dissolution, insertion forces, drug release profiles, and MN efficiency (the percentage of drug released to drug initially encapsulated) [24,125,126,127,128].

When focusing on the skin, the major barrier-to-mass transfer within the skin is the SC. However, when modeling the MN-skin system, the full epidermis should be considered [129]. Andrews et al. [130] provided evidence for this statement as they showed the removal of the SC significantly increased the permeability of the drug. Also, the removal of the full epidermis increased drug permeability by another one to two orders of magnitude. The base membrane and tight junctions should also be considered when modeling as they may also provide resistance to mass transfer [130]. For an effective diffusion study of therapeutics using MN, the skin-related parameters (e.g., porosity, thickness, Young’s modulus, etc.) are needed to be included [127].

When modeling polymeric MNs, there are several factors associated solely with the MN that needs to be considered. The main consideration for the MN is the hydrolysis reaction occurring between the steric bonds of the polymer. The reaction results in a reduction of the molecular weight and describe the degradation of the MN array [21]. The geometry of the MN also needs to be considered [82]. However, as Sandrakov et al. [131] proved that conical MNs are the most optimal, it is logical to start with conical geometry as a standard when modeling. The length of the MNs, both tip and base diameter of the MNs, center-to-center spacing between two MNs, numbers of MNs in the array, and the distribution of the MNs in an array (square, diamond, triangle, rectangle, or exceptional design), etc. are responsible factors for MN performance [24,128]. The insertion force is further related to the MN tip angle and radius of the tip’s curvature [24,126]. Various mechanical parameters of MN, including Poisson’s ratio, Young’s modulus, ultimate tensile strength, etc. are used for evaluating insertion studies of MNs [132].

The other key component of modeling is the selection of physics that allows for the evaluation of drug-release profiles. The governing equation for the mass transfer of the drug is Fick’s law [12]. Once the physics has been selected and the parameters have all been defined, the model can be simulated on computational software. The most common software packages used are MATLAB® and COMSOL Multiphysics® [133,134]. The water absorption rate should also be considered while modeling the dissolving and swellable MNs [135]. Gomaa et al. [122] demonstrated that molecular weight is one of the significant factors that affect the molecular diffusion rate in the skin in general, and MN pierced skin.

Zhang et al. [136] developed a mathematical model to quantitatively predict the transient behavior of the drug delivery using solid polymeric MNs. To achieve this, Zhang et al. [136] applied mixture theory where the skin (biological tissue) was treated as a multi-phase fluid-saturated porous medium, using conservation equations to characterize the mathematical behavior of the tissue. The model [136] also included drug absorption by blood capillaries and tissue cells, modeled as a moving interface along the flowing pathway. The mathematical model was used to help solve problems with drug absorption within the blood capillaries and tissue cells. The Zhang et al. [136] model allowed for a greater understanding of the mechanics behind drug delivery from MNs. However, interest has moved away from solid MNs, and the focus is upon dissolving MNs.

Kim et al. [22] developed a mathematical model which predicts the quantity of drugs delivered via the dissolution of dissolving MNs. The initiative part of their model was the inclusion of a biological membrane. The model used governing equations and numerical solutions to estimate fentanyl concentrations within different layers of the skin and simulated the dissolution of the dissolving MNs. The model agreed with predictions created from dimensionless parameters. The predictions included the pitch of the dissolving MNs being inversely proportional to the fentanyl delivered and the insignificance of elimination kinetics to the dissolution of the dissolving MNs. The model also had an optimization algorithm applied to recover parameters that represented the experimentally obtained data most accurately. Kim et al. [22] concluded that the algorithm applied may provide a useful tool to characterize the drug delivery regimen by dissolving MNs.

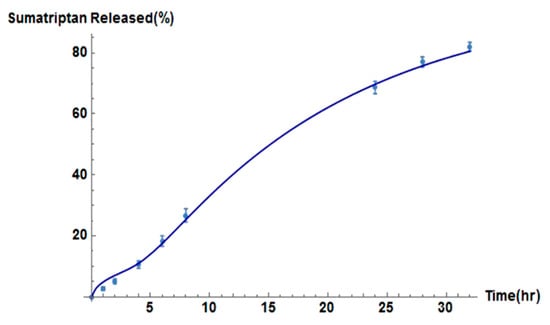

Recent research has focused on the advancement of dissolving MN technology to increase the therapeutic effects of drug molecules, which requires a further understanding of the transport mechanisms within the skin. Ronnander et al. [32] developed their model to assist researchers when evaluating the administration of sumatriptan with a limited dataset. The model simulates the dissolution of pyramidal-shaped dissolving MNs and the diffusion of sumatriptan using governing equations, as shown in Figure 5 [32]. The results obtained by Ronnander et al. [32], shown in Figure 5, suggest that the mathematical model developed agrees with the experimental data. Conclusions drawn by Ronnander et al. [32] included reducing pitch width significantly, which increased sumatriptan diffusion within the skin, coinciding with the findings of Kim et al. [22]. The PVP polymer concentrations also had a significant effect upon dissolution, and drug loading had a lesser effect upon dissolution [32].

Figure 5.

Relationship between sumatriptan released and time by the model (solid line) and in vitro (solid dots) for dissolving MN formulations, reproduced with permission from [32], Elsevier, 2020.

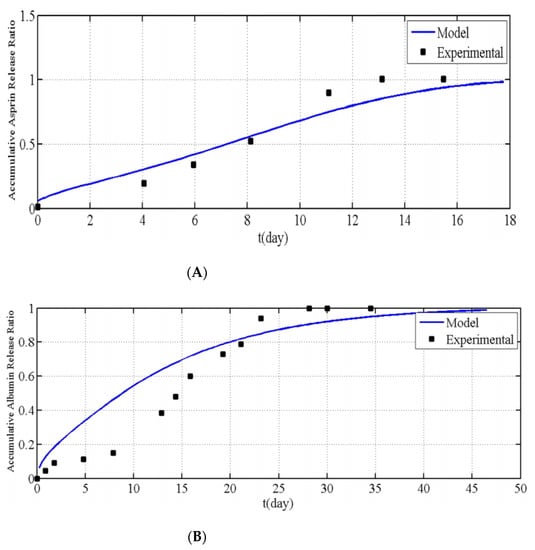

Chavoshi et al. [21] developed their mathematical model using the same methodology as Ronnander et al. [32]. However, Chavoshi et al. [21] considered autocatalytic effects on their polymeric dissolution to predict drug release profiles. The drug release profiles obtained for aspirin and albumin are shown in Figure 6. From Figure 6, it is apparent that the model produced by Chavoshi et al. [21] does not match the experimental values as accurately as the model developed by Ronnander et al. [32]. Chavoshi et al. [21] concluded that the differences between experimental and model values arose from errors within the estimation of some parameters of the model. The need for estimation is due to the difficulty in finding the parameters in the exact same utilized conditions.

Figure 6.

Relationship between the accumulative (A) aspirin and (B) albumin release ratio vs. time for modelling results and experiments, as reported by Chavoshi et al., reproduced with permission from [21], Springer Nature, 2019.

5. Polymeric Microneedle Manufacturing Techniques

The drug is normally embedded inside the needle through polymeric MNs, but swellable MNs may also distribute the medication from an external reservoir [137]. The drug is subsequently combined with a solvent to create a drug-containing solution. The composition of a solvent with a selected polymer forms a solvent for a polymer substance [80]. MNs may be made using a wide range of methods using a polymer-drug solution [32]. The choice of the construction technique of the polymer and the MN is dependent on the specifications of the MN patches needed [8]. A list of the building polymers and processing methods used in both dissolving MNs and swellable MNs is given in Table 3, in Section 8. The advancement of science and technology has aided the development of more versatile MN fabrication techniques in the past few decades [88,138].

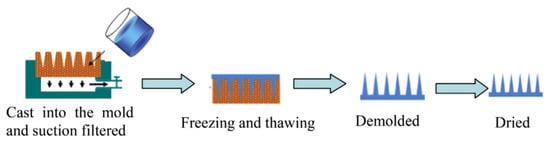

Micro molding is the preferred method for the preparation of polymeric MNs due to high reproducibility, convenience for scalable production, and cost-effectiveness [139]. This is because certain medications and vaccinations are thermolabile, and micro forming allows for the preparation of needles in mild conditions [51]. Usually, hot embossing methods, investment molding, and injection molding are used to fabricate degradable and insoluble MNs, but due to relatively high processing temperatures, the drug activity may be easily affected [140,141,142,143,144,145]. The casting method is currently the most used method to prepare dissolvable polymer MNs due to the advantages of low processing temperature, convenient fabrication process, and insignificant impact on drug activity [145,146]. Involved heat or UV irradiation in the micro molding method might reduce the activity of sensitive drugs [147]. Apart from the micro molding method, drawing lithography, droplet-born air blowing, electro-drawing, and 3D printing can achieve rapid (usually within 10 min) MN preparation as these do not require the use of a mold [70,77,148,149]. In Figure 7 [150], the basic steps for micro molding have been illustrated.

Figure 7.

Polymeric MNs manufacturing using micro molding method, reproduced with permission from [150], Elsevier, 2016.

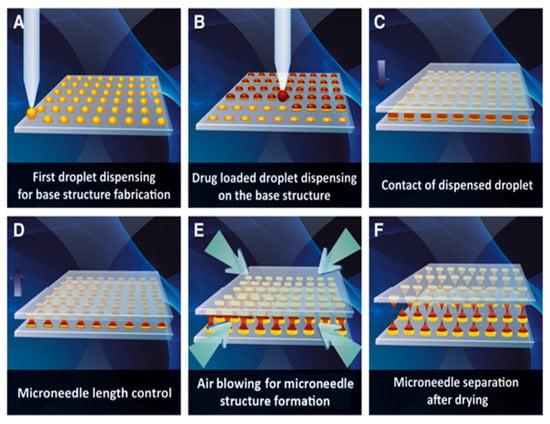

Droplet-born air blowing (DAB) is a novel technique of fabrication where the droplet of a polymer is shaped into the MN through air blowing [70], as shown in Figure 8. The direct application of the air is for the solidification of the polymer droplet that helps in the formation of the shape of the MN [151]. This DAB technology allows the fabrication under conditions without the need for UV irradiation or high heat [152]. It requires a temperature of 4–25 °C and a brief period (≤10 min) [153]. The number of drugs can be controlled by regulating the pressure and time with the help of the droplet dispenser [154]. As a result, loading the drug in the MN is possible without drug loss, which facilitates the maintenance of the activity of the biological drugs [155].

Figure 8.

Schematic illustration of dissolving microneedle fabrication via droplet-born air blowing method. (A) Biopolymer dispensing on the flat surface for base structure fabrication. (B) Dispensing of drug-containing droplet over the base structure. (C) Contact of dispensed droplet by downward movement of upperplate. (D) Control of microneedle length. (E) Air blowing-mediated solidification of droplet to shape microneedle structure. (F) Separation of two plates producing dissolving microneedle arrays on upper and lower plates. Droplet-born air blowing (DAB) technology for fabricating polymeric MNs, reproduced with permission from [70], Elsevier, 2013.

Drawing lithography involves creating microstructures that are three-dimensional from two-dimensional (2D) materials [156]. The drawing lithography method can not only fabricate MNs with a high aspect ratio but also eliminates the need for molds and UV light irradiation, thereby avoiding the use of toxic photo-initiators in comparison with conventional micro molding [157]. However, in comparison to micro molding, the drawing lithography method exhibits much worse reproducibility [149]. Electro-drawing has emerged as an alternative fast and mild temperature strategy to the conventional use of stamp-based techniques for the fabrication of biodegradable polymer MNs [158].

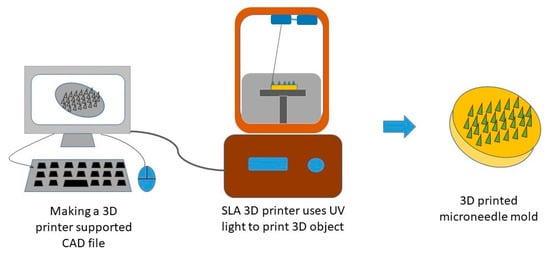

Most importantly, the mentioned conventional MN fabrication techniques can only fabricate MNs on a flat substrate surface; consequently, it is difficult to fabricate uneven or curved skin surfaces due to its decreased penetration efficiency and drug delivery amount [159]. The reason for the popularity of 3D printing technology has been attributed to the tunability and versatility that facilitates the personalized fabrication of physical models of the desired geometric shape with computer-aided design and computer-aided manufacturing [160,161,162]. This prototyping technology is based on layer-by-layer printing and superposition that provides high accuracy along with good reproducibility [163,164]. The most current and commonly utilized manufacturing technologies of 3D printing include inkjet printing, photopolymerization-based technique, and fused deposition modeling (FDM) for fabricating polymeric MNs [160,162,164,165,166,167]. Figure 9 [162] shows the steps for fabricating MN devices using 3D printing technology. Inkjet printing allows the selective deposition of droplets of the drug onto the MN surface with the help of thermal or piezoelectric-driven printing heads [168,169], and digital light processing (DLP), stereolithography (SLA), and two-photon polymerization (2PP) are the commonly used photo-polymerization-based techniques to fabricate polymeric MNs [170,171,172,173].

Figure 9.

Illustration of the process involved in 3D printing of polymeric MNs. Adapted from [162], Springer Nature, 2019.

6. Characterization Techniques for Polymeric MNs

A drug can be loaded in suspension or dispersion form or encapsulated into MNs [174]. The medication may also be coated or sprayed as a patch with a silicone solution [175]. For a drug-loaded MN, various physicochemical characterizations, including the grade of particle size, Poly dispersion index, viscosity, and zeta potential may be measured according to the type of formulation used in MNs [176]. An MN patch is complete after preprocessing for the release of drugs, adhesion, and permeation checks [177]. Dynamic light dispersion, X-ray dispersion, and transmission electron microscopy technologies allow for the characterization of MN size, inner structure, and crystallinity [178]. Drug dispersion stability and MNs can be tested at a different temperature, pH, and physiological stimulation in vivo [179]. Additional testing is conducted on engineered MNs, such as solubility experiments, pharmaceuticals content, in vitro release, and biocompatibility analyses [180].

Morphological Evaluation. Scanning electron microscopic (SEM) studies of MN patches are the most common techniques to understand MN morphology [181,182]. Previous research has used SEM studies to examine MN size, shape, height, base, pitch, and other physical attributes [36,183]. For SEM analysis, coating the MNs with a gold solution is used for capturing a clear image using a low voltage (1.0 kV) to avoid any electrical charges on the MNs surface [2,184]. The images of coated MNs are captured digitally from a fixed working distance using different magnifications (e.g., 30, 80, 110, or 120×) [2,164]. A closer look at the MN patches reveals high-resolution architecture with fine and sharp tips [181,183,184,185,186].

Dimensional Evaluation. Different techniques have been used for the measurements of MN geometry and for calculating the MN tip radius, length, and height [187]. Optical or electrical microscopy is the most common technique [188]. An optical scanning microscope is used to visualize the array and tips of the MNs, which capture digital images to show an entire array of uniformly distributed MNs with the same height and sharp tips [181,182]. A better image of the MN is produced using 3D image analysis, which helps to control quality [137], and for this purpose, scanning electron microscopic (SEM) and laser microscope confocal microscopy have also been used [164,189]. The SEM creates a sample image by using an electron-focused beam that interacts with the atoms of the sample when scanning and provides information on the topography and structure of samples [190]. Conversely, a confocal laser microscope produces images that are high in resolution [191]. Confocal microscopy studies are performed for producing fluorescent imaging of the MNs aimed at characterizing the compartmental structure of MNs using different chromophores in the sample [181,182,184].

Mechanical Testing. An MN should be sharp and thin enough to reach the skin quickly and firmly enough not to rupture within the skin [192]. The force at which the MN loses its structural integrity and insertion force are two essential considerations for the secure and effective construction of the MNs [193,194]. The Instron 5848 Micro Tester has been used to determine the mechanical properties of the MNs [195]. For this purpose, MNs are placed directly on a loading cell for an axial fracture test, using an axial force [196]. A block of aluminum is used for the transverse fracture test [197] and with ethyl cyanoacrylate super-glue gel, the back layer of the MNs are then fastened [198]. For transverse forces on the MN, a metal sonde with a 1 cm blunt can be used. To measure bend, the MN array is contained above the loading cell, using two aluminum blocks [199] and the sample then adds strength to the middle of the backplate [200].

In vitro and In vivo Studies. For the in vitro study, diffusion cells have been used to determine drug permeation across the skin [201]. The skin of the porcine ear was used primarily in the experiment between the recipient and the donor compartment [202]. Here, a typical set of permeation profiles for MN-treated and untreated skin were compared [203]. For the in vivo study, hairless rats were used [166]. The effective technique used for anesthetizing the animal and then measuring the trans epidermal water loss (TEWL) before and after MN insertion is one of the key parameters to be considered [204].

Content Uniformity Studies. According to FDA guidelines, the drug contents of the MNs need to be evaluated accurately [98]. For example, content uniformity is critical for solid MN systems; however, achieving a uniform coating on MNs is challenging [106,138]. Coating uniformity, including the homogeneity of drugs and the smoothness of the coating on coated MNs, have previously been qualitatively evaluated using scanning electron microscopy (SEM) and polarized microscopy [205,206,207].

Stability Evaluation. The stability of MNs depends on the stability of the polymers and drugs individually [35,208]. To evaluate the storage stability of MN arrays, the MN arrays, or their base-plates (with no MN) were exposed to different relative humidity and store in a temperature-controlled environment for a specific time [56,209]. Durability, deformation, and suction prevention are important considerations for MNs, whereas particle size, crystallinity, and polymorphism need to be considered for drugs coated on or dissolved in MNs [208]. The stability of the vaccine is of immense importance because of the limitation for refrigeration [210,211,212,213]. Several MN systems contain a solid form of vaccines that can potentially overcome the stability issue [214,215]. The addition of a stabilizer can improve the thermostability of the vaccine, and the appropriateness of the stabilizer depends on the nature of the vaccine [216]. The trivalent subunit influenza vaccine in a dissolving MN patch, for example, was stable at 25 °C for more than 1 year and at 60 °C during freeze-thaw cycles and electron beam irradiation for more than 6 months [205].

Chemical Stability. Differential scanning calorimetry (DSC) has been used to observe the enthalpy-related changes in the constituent materials of MNs by increasing the temperature. The constituent materials were heated to 300 °C at a rate of 10 °C min−1 using DSC that was calibrated previously with standard materials [44,217]. Thermogravimetric analysis (TGA) was used to record the samples’ weight loss on increasing temperature. To evaluate the physical and chemical stability of the materials, the desired samples were heated from 25 °C to 350 °C at a rate of 10 °C min−1, and the weight loss was recorded during this time. Fourier transform infra-red (FTIR) spectroscopic analysis was used to record the vibrational changes of different functional groups present in the samples in following interactions with light over a specific wavelength range (400–4000 cm−1) [44].

7. Pharmacokinetic and Drug Release Behavior from Polymeric MNs

Polymeric MN technology has been successfully used to improve drug penetration through the skin layer [218]. This has been shown in in vitro skin models with increased absorption of larger molecules such as calcein [219]. Polymeric MNs encompass the functions of a transdermal patch and hypodermic needle, aiming to achieve their benefits and remove each of their drawbacks [29].

Animal Models. Most pharmacological studies are conducted through in vivo animal models [46,50,220,221,222,223]. The animal fur was removed from the anesthetized animal, and the MN patch was subsequently applied to the underlying skin. Next, the blood was collected for the detection of different biomarkers [50,223,224,225], and a punch biopsy was performed on the dorsal skin of the mouse post-treatment [226]. Hematoxylin-eosin stain can be performed to observe epidermal status, while improvements in the bundle of collagen and elastic fibers were prepared with trichrome stain of Masson and blue Victoria stain, respectively [227]. The immunohistochemical components were evaluated using UltraVision LP Large Volume Detector Systems HRP Polymer Package (Thermo Fisher Scientific, Waltham, MA, USA) to determine the regulatory effects of UV and micronodular RF applications on the collagen in the extracellular matrix [228]. However, the structure and pharmacological response in an animal model differs from humans [50,106]. The pharmacological and pharmacokinetic analyses aid in optimizing the design of MNs and drug delivery for better therapeutic effect [44,200,220,224].

Porcine Skin Cargo Delivery Tests. The amount of drug delivered from the MNs to the skin was assessed using Franz diffusion cells with abdominal porcine skin [44,153,200,223]. Collected Skin samples were then placed in a phosphate-buffered saline (PBS) (pH 7.4) system for 1 h, and the prepared MN patch is inserted into abdominal porcine skin (1000 μm thick) for 30 s to determine the diffusion rates and effectiveness into porcine skin [153,164,229]. Methylene blue was applied to the needles to test the delivery of cargo covered on polymeric MNs [230]. The pierced skin and MN patch were then mounted onto the donor compartment of a Franz diffusion cell and maintain a temperature of 37 °C [223]. To determine drug concentrations, sample fractions were taken at set intervals, and atomic absorption spectroscopy used for quantitative analysis of drugs [164].

Skin Recovery Process and Irritation. When an MN device is implanted and removed from the skin following treatment, it leaves behind micron-size pants [231]. The skin needs time to recover its barrier properties [232]. If the skin is sensitive, it can lead to mild to medium inflammation or allergies, redness, pain, swelling, and itching may cause discomfort for the patient [233]. Although the pores formed by microns in comparison to the hypodermic needle are small, microbial penetration is also less serious [153], and the pores will take time to rescreen [234]. These pores must be immediately resealed the active drugs, or contamination will occur [235]. An electrical impedance measurement can be studied for the resealing of pores [236]. Depending on the skin’s occlusion and the geometry of the needle, it can take 2–40 h to recover [237]. TEWL and the shading of tissues can also be used for pores [238]. The MNs do not contact the pain receptors deep inside the dermis, causing less pain than the needle of a hypoderm [239]. The pain severity is influenced by the MN numbers on a patch, the MN duration, and the tip angle or needle shape [6]. The length and number of the MNs on the spot are smaller than the discomfort involved with the procedure [240,241].

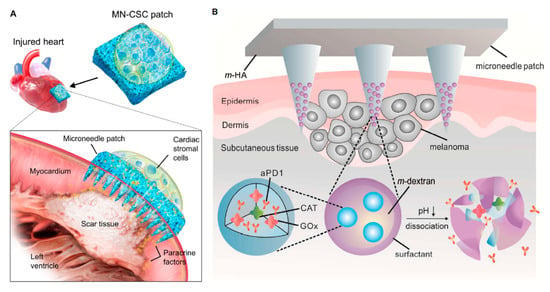

8. Key Human Diseases Studied by Polymeric MNs

Polymeric MNs have been studied for the treatment of various diseases such as cancer, HIV, diabetes, etc. They have also been used for vaccination and immunization. A successful translation of MN technology requires careful consideration for the targeted disease. To motivate this point, we discuss some key diseases targeted for polymeric MNs application in this section. Furthermore, Table 3 summarizes different drug molecules administered through polymeric MNs.

Diabetes. Diabetes mellitus is a common metabolic disorder that involves hyperglycemia or an excess of glucose in the bloodstream due to insulin deficiency or abnormality in the use of insulin [242]. Early work on insulin delivery was performed by administering insulin using nanovesicles combined with iontophoresis. The transdermal administration through porcine skin was aided by a solid stainless-steel MN array that perforated the skin, creating microchannels. The nanovesicles combined with iontophoresis and MNs had a penetration rate of insulin 713.3 times higher than passive diffusion [243]. Darvishha and Amiri [244] reported the viability of swellable MNs for the purpose of delivering high molecular weight molecules, such as insulin. Darvishha and Amiri [244] describe how the MNs swell and dissolve when they are inserted into the skin, allowing diffusion of the drug from the MN into the skin. The authors also state that swellable MNs provide a transdermal route of delivery with a prominent level of control on the release of compounds from the MNs [244]. Vora et al. [245] discussed the potential of dissolving MNs manufactured from the carbohydrate biopolymer pullulan to deliver low and high molecular weight drugs. Vora et al. [245] determined that the pullulan dissolving MNs were able to penetrate porcine skin and successfully deliver the insulin encapsulated within the MNs. With the stability of the insulin encapsulated confirmed by circular dichroism, pullulan dissolving MNs were shown to provide a viable route of insulin delivery [245]. Research performed by Yu et al. [86] is of significant interest as well. Yu et al. [86] validated a glucose-responsive polymeric MN in the form of a “smart insulin patch” that controls blood glucose levels by altering the insulin released in accordance with the quantity of glucose within the blood. This alteration is due to function of dissolution kinetics of blood glucose [86,246].

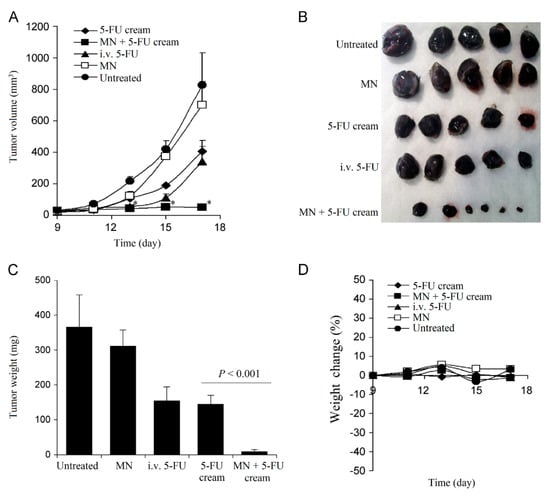

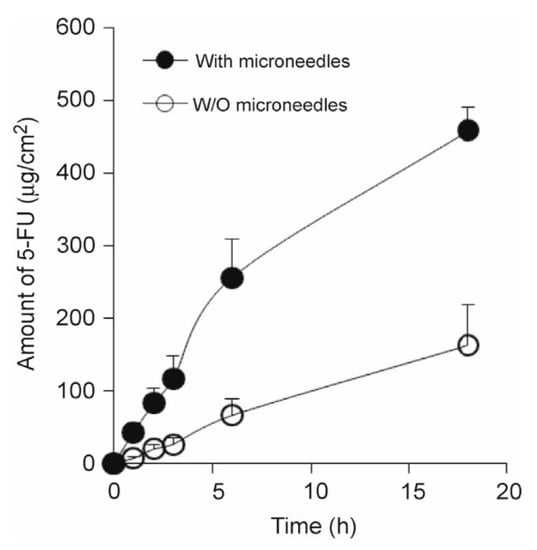

Basal Cell Carcinoma. Skin cancer is a worldwide threat [247]. Basal cell carcinoma (BCC) is a type of melanoma skin cancer caused by exposure to UV light from the sun or, more recently, sunbeds [248]. It can be found on the most exposed areas to the sun, such as the face, head, neck, and ears. Although it is not a hereditary disease, the people most susceptible to BCC are fair-skinned or those who have prolonged exposure to the sun [249]. Superficial BCC is a locally destructive skin tumor on the epidermis that can leave red scaly marks on the skin while other types can result in the formation of lumps [250]. If left untreated, BCC can lead to the development of skin ulcers that can be painful and itchy [251]. Although BCC is curable, the longer it is neglected, the more complex the treatment becomes [252]. Therapeutic techniques to treat BCC such as curettage, cautery, cryotherapy [253] exist, including the topical use of creams such as imiquimod (IMQ) and 5-fluorouracil (5-FU) as a noninvasive approach [254]. MNs have been introduced to improve the skin’s permeability of molecules as delivery efficiency is not optimized by the sole use of such creams [46]. Most of the drug remains in the formulation and is not delivered [255]. In an experiment conducted by Naguib et al. [256], it was found that the flux of 5-FU through the skin was increased by up to 4.5-fold when the skin was pretreated with the Dermaroller® MN (500 µm in length, 50 µm in base diameter). Figure 10A,B [256] show the decreased visibly in size and Figure 10C,D [256] show the decreased weight of the tumor after MN treatment. B16-F10 murine melanoma cells (100,000 cells per mouse) in 100 µL DMEM were injected subcutaneously in the lower dorsal skin of anesthetized mice. To investigate the effect of MNs on the skin’s permeability and antitumor activity of topical 5-FU, the mice were randomly grouped: (1) mice treated with 5% 5-FU once a day for 8 consecutive days; (2) MN + cream group where mice were pretreated with MNs prior to application of the cream; (3) I.V. 5-FU the positive control group where mice were injected with 5-FU in sterile PBS intravenously via tail vein on days 9 and 15 of the experiment; (4) the negative control groups where tumor-bearing mice were left untreated; or (5) treated with MN only. Figure 11 illustrates the diffusion of aqueous 5-FU solution through the skin treated or not treated with MNs over time. Without MNs, the relationship between the amount of 5-FU diffused is almost linear; however, when treated with MNs, it is evident that the amount diffused in each time increased resulting in a steeper gradient. The use of statistical analysis on experimental data led to the conclusion that MNs can significantly (p < 0.05 two-tailed test) improve the in vitro skin permeability and in vivo anti-tumor activity of topical 5-FU [256].

Figure 10.

(A) The growth curves of B16-F10 tumors in mice. The asterisks (*) in (A) indicates that the values of the 5-FU cream group and the MN + 5-FU cream group are different on day 13, 15, and 17 (P < 0.05). (B) Digital photographs of tumors at the end of the study. (C) The weights of tumors at the end of the study. (D) The changes in the body weight of B16-F10 mice, reproduced with permission from [256], Elsevier, 2013.

Figure 11.

The amount of 5-FU in an aqueous solution diffused through full-thickness mouse skin treated (●) or not treated (◌) with MNs as a function of time, reproduced with permission from [256], Elsevier, 2013.

HIV and Vaccination (Immunobiological Administration). In 2018, it was estimated that over 37.9 million people across the world had human immunodeficiency virus (HIV) [257]. HIV attacks the CD8+T cells of the body’s immune system, making it more difficult for the body to fight infectious diseases [258]. As a result, people with HIV become more susceptible to unintentional weight loss, chronic diarrhea, recurrent infections, and serious life-threatening illnesses, such as AIDS [259]. Vaccines can deliver protective antibody responses against HIV. Hence, the safe and effective delivery of HIV vaccines is imminent to minimize the impact of infection [260]. The skin has a high density of antigen cells in the epidermis and dermis, thus vaccines are typically administered through injections either intramuscular or subcutaneously, which have demonstrated effective systemic immunization [259]. However, exploration of the possible benefits of solid dosage forms over liquid dosage forms has led to the introduction of vaccine delivery via MNs [258]. Overall, solid dosage forms provide a higher level of immunogenicity, resulting in a dose-sparing effect and making vaccines more cost-effective [261]. With hollow polymeric MNs, the dose can be minimized, as seen with the rabies and anthrax vaccines [262,263]. The use of MNs also omits the use of cold-chain storage used for conventional vaccines due to better thermostability [28]. In addition, MNs are not limited in their applications for the delivery of different vaccinations. Coated MNs have been effectively tested to deliver Bacillus Calmette-Guerin (BCG) to guinea pigs for tuberculosis, resulting in a 1.3-fold higher IFN- γ in the lungs compared to a hypodermic needle [264].

Contraception—Transdermal Patches. While the introduction of the contraceptive pill in 1974 to the National Health Service (NHS), United Kingdom (UK) was pivotal to women’s health, the current state of reproductive and sexual health in the UK highlights the inconsistencies in contraception and effectiveness [265]. Although this cannot be determined solely by one factor, it does perpetuate the need for contraceptive innovation. One way to approach this is via transdermal delivery of contraceptives via penetration through the skin for systemic delivery [266]. The major concern with transdermal delivery is penetration affecting the pharmacokinetics of absorption; thus, the efficacy is influenced. Researchers are currently investigating MN skin patches for long-acting contraceptive delivery. Mofidfar et al. [80] aimed to create a self-administering long-acting contraceptive MN patch applied once a month for 5 s. The use of an effortless MN patch may combat several issues with the orally-administered contraceptive pill. The forgetfulness and, therefore, ineffectiveness may potentially be minimized; patients only must remember to apply it once per month. The increased level of estrogen exposure and reduced variability in plasma concentration of the pill minimizes typical side effects such as diarrhea, nausea, and vomiting. The patch also creates a hormone gradient, allowing a controlled and constant release rate [80,81]. Current patches are more than 99% effective (when used correctly) against pregnancies but do not protect against STIs such as less effective barrier devices in the same way as condoms. The number of drugs that can be integrated into an MN patch is limited and this technology is yet to be tested in humans as far as the authors are aware [267].

Dermatological Conditions and Cosmetics. The advances in the transdermal application of MNs to systemically deliver drugs through the skin have provoked the use of MNs for the treatment of dermatological conditions and nonmedical cosmetic therapeutics [268]. The application of MNs to treat acne, atrophic scars, actinic keratosis, hyperhidrosis, melasma, skin rejuvenation, alopecia, and more severe dermatological diseases can potentially be revolutionary in this field [269]. Dermatological conditions are proven to cause low self-esteem in individuals, leading to psychological problems [270]. In a recent study, MNs were combined with phototherapy to transmit light deeper into the skin, improving the use of phototherapy as a cosmetic and medical tool. The combination significantly increased the light transmissivity by 160%. For phototherapy with MNs, the light is internally reflected and then refracted at the tip of the MNs, mimicking optical fibers [271]. Such treatment can be used to treat psoriasis, a chronic papulosquamous disease estimated to affect 3% of the world’s population, according to the International Federation of Psoriasis Association [272]. It primarily affects the skin as well as nails, joints, and tendons. Acanthosis, increased thickness of the dermal layer, and hyperkeratosis of the SC are responsible for the scaly appearance and may cause the skin to be inflamed, bleed, crack, itch or shed scales. This is most found in areas such as the elbow, knee, and scalp [273]. There are a variety of treatment options for psoriasis, which are suppressive but of which none are curative [274]. Methotrexate is a drug that is typically administered orally or parenterally to help treat psoriasis. However, the side effects of systemic exposure to methotrexate include nausea, vomiting, and anemia [275]. Alternatively, Vemulapalli et al. [105] investigated the transdermal delivery of methotrexate utilizing MNs and iontophoresis. The solid maltose MN used to deliver Methotrexate with an applied voltage caused a 25-fold improvement of delivery into the skin in vivo [105]. Anti-TNF-α antibody therapy was employed to reduce the epidermal inflammation in psoriatic lesions. When anti-TNF-α was applied to a psoriatic mouse, the critical biomarkers of psoriasis inflammation were drastically reduced [276]. This suggests that with further research, the future application of MNs to treat psoriasis and other dermatological conditions of this nature can be widely improved. To demonstrate further the effect of combining MNs with techniques to treat dermatological conditions, Konicke and Olasz [277] investigated the use of a commercial Dermapen® and topical bleomycin to treat plantar warts. Plantar warts are viral proliferations caused by human papillomavirus (HPV) infection [278]. Current practices involve the physical destruction of the infected cells via cryotherapy. The limitations of such treatments are the intense pain associated and the recurrence of warts [279]. This clinical study concluded that with the use of MNs and bleomycin, all patients were completely cured with minimal pain [280]. The cosmetic field is the most progressive in the day-to-day physical application of MNs [268]. MNs have surpassed trial phases and are now available in clinical practices [281]. It is more advantageous than other techniques such as dermabrasion, laser treatment, or chemical peeling as there is less damage to the epidermis [282]. It is a quick and safe procedure resulting in skin rejuvenation due to the induced production of collagen. Collagen regenerates the skin to look smoother and healthier [283]. This is particularly appreciated for aging skin because, with time, the skin becomes dehydrated, elasticity decreases, and it is continually thinning [271]. Hyaluronic acid MNs have been statistically proven (p < 0.05) to improve wrinkles and skin hydration. This is attributed to its high-water binding and uptake capacity, biocompatibility, and biodegradable properties, making it suitable for anti-wrinkle treatment [284]. The delivery of other cosmetic ingredients such as ascorbic acid, retinoic acid, and adenosine has also been investigated [9]. Adenosine-loaded dissolvable MNs show better efficacy and skin improvements than topical adenosine cream. Despite the dosage of the MNs being 140 times less (10.72 µg) than the cream (1400 µg), this underlines the significance of the SC as a chemical and physical barrier [271].

Table 3.

Examples of polymeric MNs used in TDD.

Table 3.

Examples of polymeric MNs used in TDD.

| Drug/Molecule Loading (Targeted Disease) | Polymeric Material * | In Vivo/In Vitro Analysis | Type of MN | Advantages/Key Results | References |

|---|---|---|---|---|---|

| Etonogestrel (Contraceptive hormone) | PVA, HPMC | Female Sprague-Dawley rats, (200 ± 20 g) | Dissolving | Sustained release for around 1 week Fabrication process was optimized to increase drug loading without compromising the mechanical strength of the MN | [285] |

| Levonorgestrel (Contraceptive hormone) | PLGA, PLA | Adult female Sprague-Dawley rats, (200 ± 12g) | Dissolving | Air bubble between MN and patch backing for easy removal Sustained-release was achieved, maintaining concentration above the human therapeutic level for 1 month | [80] |

| Bleomycin (Treatment of warts) | PLA | Porcine skin, (2.3318 ± 0.22 mm thick) | Coated | The MN had high mechanical strength and was able to transport 80% of bleomycin in 15 min Can be used at different anatomical sites | [286] |

| Poly hexamethylene biguanide (PHMB) (Ocular diseases) | PLGA | Eight-week-old female mice | Dissolving | Patch was applied to the cornea Sustained drug release was achieved for 9 days when applied to the cornea | [140] |

| Bevacizumab (Cancer) | PVA (MW: 9–10 kDa) | Female Sprague-Dawley rat | Swellable, dissolving | Successful in diffusing high molecular weight drug Bevacizumab (MW: 149 kDA) Targeted delivery of chemotherapeutic agents to the lymphatic system was achieved Comparable study performed on dissolving and swellable MN | [287] |

| Esketamine (Treatment-resistant depression) | PMVE/MA + PEG (Gantrez®) | Female Sprague-Dawley rats | Swellable | No polymer degradation in skin Parafilm M used as a substitute model for the MN insertion study Sustained delivery of Esketamine was achieved for >24 h. | [219] |

| Amyloid β peptide (Aβ) (Alzheimer’s disease) | MicroHyala (containing Hyaluronic acid) | APPPS1 mice (genetic background; C57BL/6) | Dissolving | Approved polymeric MN for wrinkle treatment 100% delivery of encapsulated Aβ with efficient immune response. | [288] |

| Rapamycin (Skin tumors and vascular anomalies) | PVP (MW: 10 kDa) | Female BALB/c mice | Dissolving | Improved delivery of poorly water-dissolvable rapamycin 80% of the drugs into the skin in 10 min. | [220] |

| Tetanus toxoid (Immunization) | PVA (MW: 160 kDa), PVP (MW: 30 kDa) | Swiss-Albino mouse | Dissolving | Complete dissolution within 1 h of insertion. | [190] |

| Doxorubicin (Cancer) | GelMA | Mouse cadaver skin | Dissolving | Possibility of tunable drug release by adjusting the crosslinking density of GelMA MN swells initially followed by enzymatic degradation Ability to administer macromolecules (e.g., protein, nucleic acid) | [289] |

| Penta gastrin, Sincalide (Therapeutic peptides) | PVP (MW: 40 kDa) | Freshly excised skin (porcine ear) | Dissolving | Capable of delivering several types of peptides Release rate varies with peptide’s physical and chemical properties Looked into the effect of MW on delivery of peptide. | [290] |

| Dihydroergotamine mesylate (Migraine) | PVA (MW: 6 kDa), PVP (MW: 10 kDa), | Male Sprague–Dawley rats (500–550 g) | Dissolving | The delivery was in line with the subcutaneous administration with high relative bioavailability (97%). | [291] |

| Ovalbumin (Vaccination) | PMVE/MA-PEG (Gantrez®) | BALB/c mice | Swellable | Highlighted the importance of MN design and composition on the immune response to vaccine antigens | [292] |

| Doxorubicin HCl and docetaxel (Cancer) | PVA (MW: 160 kDa), PVP (MW: 40 kDa) | Excised mouse skin | Dissolving | MNs dissolved within 1 h of insertion in excised skin Co-delivery of doxorubicin and docetaxel | [63] |

| Amlodipine (Hypertension) | PEEK LT-3 grade | Pig ears skin | Coated | FDA approved polymer Effects of various MN geometry parameters on the degree of drug permeability enhancement were studied | [293] |

| Tranexamic acid (Melasma) | PVP (MW: 40 kDa) | Anesthetized Albino rat | Dissolving | All loaded drugs were released within 7 h of insertion Simulation studies were performed to understand the drug delivery mechanism using COMSOL software | [294] |

| Gentamicin (Neonatal sepsis) | PVA (MW: 9–10 kDa), PVP (MW: 360 kDa), PEG (0.4 kDa) | Female Sprague-Dawley rats (208.65 ± 21.48 g) | Dissolving | Three different doses of Gentamicin were successfully delivered into the skin with a delivery time ranging from 1 to 6 h | [153] |

* Reference: GelMA: gelatin meth acryloyl; HA: hyaluronic acid; HPMC: hydroxypropyl methylcellulose; PEEK: polyether ether ketone; PEG: polyethylene glycol; PLGA: poly (lactic-co-glycolic acid); PMVE/MA: polymethyl vinyl ether-alt-maleic anhydride; PVA: polyvinyl alcohol; PVP: polyvinylpyrrolidone.

9. Polymeric MN Based Devices and Preclinical and Clinical Trials

By the year 2025, the market for TDD is estimated to be worth approximately $95.57 billion [295]. Consequently, many preclinical and clinical trials have been conducted that involve polymeric MN devices. In the fabrication of an MN master template, it is required to have thousands of USD and the access and arrangement of facilities such as a clean room and photo-etching equipment for the implementation of techniques such as deep-reactive ion-etching, laser-etching, and anisotropic wet etching [296,297]. Hurdles are encountered along the way of clinical translation of this device [298]. The current production methods are often limiting as these methods employ batch production processes [297,299]. The biggest obstacle is in developing processes that allow for robust, efficient, and high throughput production in an industrial setting [31]. The usage of 3D printing technology for fabricating MNs can overcome the existing disadvantages of conventional techniques and can provide high precision, rapid fabrication, reduced processing steps, and freedom to print a wide range of shapes [160,161,162,166].

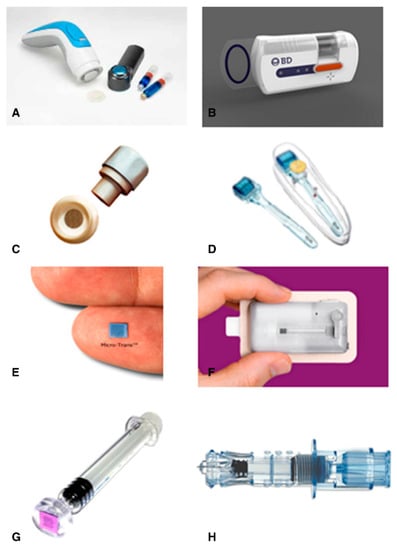

MNs have important advantages relative to traditional transdermal pads, particularly in the delivery of biopharmaceuticals [300]. Thus, in the last decade, economic activity in this field has grown considerably [301]. Several MN-based drugs are currently being produced by various firms, including Zosano Pharma (USA), 3M (USA), Sanofi Pasteur MSD (USA), Becton-Dickinson (BD) Technologies (USA), Valeritas (USA), Nano pass Technologies (Israel), MN Therapy System (USA), and Rodan+ Fields (USA). Remarkably, no drug delivery product based on the MN array is yet commercialized [297]. Micro-injection systems are also a type of MN-based device being developed. There exists Micronjet® (no-pass) and Soluvia® (BD), but they are not genuine MN arrays and are instead small hollow needles that can be used to insert a traditional syringe barrel with effective ID. These devices work in the same manner as traditional syringes. MicronJet®, a hollow MN device for intradermal injection, was developed by Nano pass Technology. The device consists of four hollow silicon needles smaller than 500 μm, which are attached to a plastic device that can be connected to any regular syringe. This method was used to vaccinate influenza with the immunogenicity of at least 20% of the traditional vaccine dosage. In 2010, the FDA approval was granted to Micronjet® [302,303]. The Micro structured Transdermal System®, which consists of coated MN arrays, was developed by 3M, which allows quicker delivery of medicines and vaccines. This machine demonstrated quick distribution, with a manageable administration for up to 90 min [304,305,306]. BD Technologies has produced a new type of machine, the Microinfusor. This machine is automatic and hands-free for delivery in a few seconds to several minutes of a large variety of pharmaceuticals to the subcutaneous tissue. The hollow MN device can be used to supply extremely viscous biotech medicines with a capacity of 0.2 to 15 mL [307,308,309,310]. Preclinical experiments found the delivery of the influenza vaccine with the same potency as a traditional intramuscular injection [146,222,235]. The Swiss business DE biotech has taken a similar approach. They also developed an injector system with one or more MNs called DebioJectTM silicon. It can be used to inject in under 2 s up to 100 μL and in less than 5 s up to 500 μL [311,312]. Sanofi Pasteur MSD Limited has already developed an intradermal influenza vaccine micro-injection system. This pioneering machine is called Intanza® and uses the BD technologies Soluvia® injector. This device includes a hypodermic needle 1.5 mm long attached to a syringe injector [214,305]. Soluvia® and MicronJet® are currently the only therapeutic-based MN-basic devices on the market. This injector is currently sold globally under the names IDflu® and Fluzone Intradermal® in addition to Intanza® [313,314,315]. In the last few years, MN rollers have become available on the market [316,317,318]. The FDA has authorized the MTS RollerTM for cosmetics. Clinical trials have shown, in enhancing collagen and elastin development and eradicating wrinkles, that this type of device is more successful than other traditional ablative and Non-ablative therapies [268,319,320,321]. Two types of MN-based systems were developed by Valeritas. The first one was Micro-TransTM Array Patch, a system for painless delivery to dermatics. The second was the h-PatchTM, a tool for controlled subcutaneous drug delivery [322,323]. Alza Macroflux® has been designed with coated titanium micro-projections as an optimized delivery of biopharmaceuticals. In this system, the skin penetration depth can be reproductively regulated due to the integration of an applicator device system. Moreover, the ovalbumin delivery system has been successfully tested [324]. Rodan+Fields Dermatologists produced a cosmetic MN product available on the market. It is a dissolving MN series of hydrolyzed hyaluronic acid for cosmetic use [325]. Furthermore, MN analysis was extended, and a more diverse and extensive MN product was created. Few currently available MN products are presented in Figure 12 [326].

Figure 12.

Current MN devices. (A) Micro structured Transdermal System, (B) Microinfusor, (C) Macroflux®, (D) MTS Roller™, (E) Micro-trans™, (F) h-patch™, (G) MicronJet, (H) Intanza®, reproduced with permission from [326], Elsevier, 2014.

Although polymeric MNs are biocompatible, when the accumulation of polymers occurs in our bodies through repeated application of the MN arrays, hepatic impairment, immunological reaction, and build-up of polymers in the dermal tissue are probable health implications with the use of this device [327]. One of the major challenges associated with the use of polymeric MNs is the penetration of MNs through the skin layer [328]. Thus, the insertion ability of the MN should not involve any bending or breakage [329]. To combat this challenge, a mixture of two or more polymers is used such that the mechanical strength and structural integrity are not compromised. It is important to strike the proper balance of flexibility and strength when targeting soft tissues that may not withstand the pressure of high-strength MN insertion [330].

To develop polymeric MNs, environmental factors need to be taken into consideration as well. The polymers used in MN fabrication can be hygroscopic [88]. This hygroscopic nature causes the arrays of MNs to absorb water from the production facility. The presence of moisture exerts a negative impact on the structural integrity and strength of the finished product. Eventually, the performance of the final MN product is also hampered [331]. Therefore, initiatives must be undertaken in the MN production facilities and methods necessary for the successful fabrication of MN arrays [332]. As the technology of MN-based products is quite innovative in terms of application in the clinical setting, sufficient standards are not available in the pharmacopeia in this regard [19]. There exists the need for the maintenance of environmental conditions for standardization and regulation regarding sterility, safety, durability, application, and disposal of MNs that will help in the commercialization of polymeric MNs in the pharmaceutical sector [106].

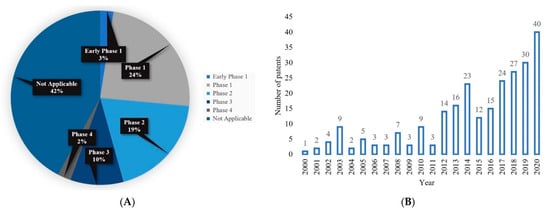

There are several clinical trials related to MN technology available on the ClinicalTrials.gov database. Data from 116 clinical trials are available on the database, using the keyword “microneedle”. The selected number of clinical trial studies in this review was 76 based on the “complete” status (information accessed on 21 February 2021 at www.clinicaltrials.gov). Depending on the availability of data, an overview of the percent of MNs in the clinical stage state and selected clinical trials are listed in Figure 13A and Table 4, respectively. Initially, a total of 260 issued US patents were found from the United States Patent and Trademark Office database (Information accessed on 21 February 2021 at http://patft.uspto.gov/netahtml/PTO/search-bool.html) using the term “microneedle” and field “Title”. From there, specific to each year, 2000–2020 were searched and is presented in Figure 13B. A total of 252 issued patents were the sum from 2000 to 2020. Table 5 lists the US patents relevant to the polymeric MN system.

Figure 13.

(A) Comparative percentage of completed MN clinical trials on ClinicalTrials.gov database. In total, 76 clinical trials data were found in distinct phases from the database. Information accessed on 21 February 2021 at www.clinicaltrials.gov, and (B) the number of issued US Patents for MN per year from 2000 to 2020. A total of 252 MN patents are available on the database. Information accessed on 21 February 2021 at http://patft.uspto.gov/.

Table 4.

List of completed clinical trials in MN technology. Information collected from the ClinicalTrials.gov database (Information accessed on 21 February 2021 at www.clinicaltrials.gov).

Table 5.

List of US patents related to polymeric MN technology. Information collected from the United State Patent and Trademark Office database (Information accessed on 21 February 2021 at http://patft.uspto.gov/netahtml/PTO/search-bool.html).

10. Regulatory Issues with Polymeric Microneedles