Abstract

Given the construction challenges and the impacts of industrial waste generation and the implications of using chemical adhesives, this study aims to evaluate epoxy as an alternative resin, whose application in the production of wood particleboards is still underexplored. In this regard, its results were compared with those of widely used adhesives, such as urea-formaldehyde (UF). Pine wood particles were used, and epoxy resin was applied as a binder in 5%, 10%, and 15% proportions. Panels were manufactured under pressing parameters of 5 N/mm2 for 10 min at 110 °C. Physical and mechanical properties of panels were evaluated using Brazilian, European, and American standards. The results showed that epoxy resin is potentially convenient for the particleboard industry, as the 15% trait panels met the P4 class criteria in the Brazilian and European standards and D-2 for the American code, and the 10% trait panels achieved the M-3i class for the American document. Although 5% adhesive was insufficient to envelop wood particles, these traits with greater percentages reached high enveloping ratings in the scanning electron microscopy (SEM) test, making epoxy resin viable for the panel industry as a potential alternative to formaldehyde-based adhesives.

1. Introduction

Wood-based particleboards have gained prominence in the industry due to their relatively low cost and ease of production, being widely used in applications such as furniture, construction, and packaging. Global production of these materials reached 102 million cubic meters in 2020, reflecting the growing demand for their favorable mechanical and physical properties, as reported by the Food and Agriculture Organization [1]. With increasing environmental awareness and the pursuit of wood products free of harmful volatile organic compounds (VOCs) such as formaldehyde, new approaches have been explored to optimize particleboard production using more sustainable adhesives [2,3].

In 2023, the global particleboard market was USD 23 billion, with a projected growth to USD 31.3 billion by 2032, with a 3.4% compound annual growth rate. This growth underscores the urgent need to develop alternative materials that combine superior performance with a lower environmental impact [4].

Particleboards are manufactured using urea-formaldehyde (UF)-based resins, widely utilized due to their commercial availability and lower costs. However, these adhesives have considerable limitations, such as low moisture resistance and limited durability, making them suitable only for indoor applications [5,6]. Furthermore, conventional adhesives like phenol-based compounds are often associated with the emission of formaldehyde and other VOCs, raising significant health and environmental concerns, thus elevating worries about the safety and environmental impact of these materials [7]. Given these risks, several international regulations, including those from the European Chemicals Agency (ECHA), are intensifying efforts to reduce the consumption of formaldehyde-based adhesives to mitigate the negative effects on human health and the environment [8], including respiratory diseases and cancer. This growing concern has driven the industry to seek alternatives that offer greater safety and sustainability and performance benefits, promoting solutions that meet the most stringent standards and the expectations for environmentally responsible materials [9].

In this context, epoxy resin, known for its excellent properties, becomes an efficient alternative to traditional adhesives due to its market growth and broad application across multiple sectors [10]. According to projections, the market value of epoxy resin, which was USD 10.5 billion in 2020, is expected to double by 2031 [11]. The growth of the epoxy resin market is not limited to established industries but is also expanding rapidly in regions such as Asia, particularly China, India, and Taiwan, where the development of the steel, petrochemical, and automotive industries significantly drive the demand for epoxy coatings. Government incentives and the availability of skilled and affordable labor create a favorable environment for the expansion of epoxy production and usage. Countries such as Taiwan and Indonesia, with a focus on the shipbuilding and automotive industries, also show robust growth in epoxy usage, reinforcing its importance in the global markets. At the same time, the demand for sustainable buildings in North America has driven the epoxy coatings’ usage, valued for their durability, moisture resistance, and lower environmental impact [12]. These factors make epoxy resin a strategic and promising option as an alternative adhesive, aligned with sustainability needs and market demands, though its uses remain underexplored [13]. Epoxy does not require heat for curing and, despite the lack of studies on volatile emissions with this adhesive, it is important to mention that there is no formaldehyde release, contributing to safety in the panel industry.

This study aims to evaluate the epoxy resin usage in wood particleboard production, proposing it as an alternative to traditional formaldehyde-based adhesives that aligns with global market demands for more sustainable materials. This research seeks to determine the physical and mechanical properties of the prototypes, analyzing the influences of the percentage of adhesive through scanning electron microscopy (SEM) and statistical assessment. This study also evaluates the feasibility, from codes, of epoxy resin for manufacturing more environmentally friendly panels.

2. Materials and Methods

2.1. Proposed Traits

Three traits were established with different mixtures for panel production, where the adhesive proportions were adjusted to 5, 10, and 15% (relative to the dry mass of pinewood), as considered by Herradon et al. [13]. A 500 kg/m3 nominal density for the panels was adopted regarding mass calculations of particles and resin, with approximate values adopted by Gilio et al. [14] and Cazella et al. [3]. Although this value may be considered low for the target density, the choice is justified by the need to adjust the final density due to the high density of the epoxy adhesive. The produced dimensions were 350 × 350 × 20 mm, adjusted to the size of the press plates, totaling 1225 g as the total mass for each panel. The proposals are detailed in Table 1.

Table 1.

Proposed traits.

2.2. Materials

Pinewood residues, generated during industrial processing with surface planers, were sourced from Brazilian sawmills (LMS 400, Rocco, Limeira, Brazil). In the laboratory, these residues were ground in a knife mill (Model 500, Metalúrgica Trapp, Jaragúa do Sul, Brazil) equipped with a 12 mm screen to reduce and classify size, following the methodology used by Campos et al. [2], producing particles with sizes ranging from 1 to 6 mm (Figure 1a,b).

Figure 1.

Laboratory processes: (a) pine shavings; (b) wooden particle processing using knife mill; and (c) epoxy resin and hardener.

The adhesive used was Epoxy Resin 2004, a two-component resin consisting of Resin 2004 (1120 kg/m3 density and viscosity from 600 to 900 cPs) and Hardener 3154 (1005 kg/m3 density and 200 cPs max viscosity) (Figure 1c). According to the manufacturer, the resin is composed of epichlorohydrin and bisphenol-A, while the hardener is based on modified polyamine. Its use is prescribed in a ratio of 2 parts resin to 1 part hardener, with respective densities of 1120 kg/m3 and 1005 kg/m3.

2.3. Evaluation of Materials and Compositions

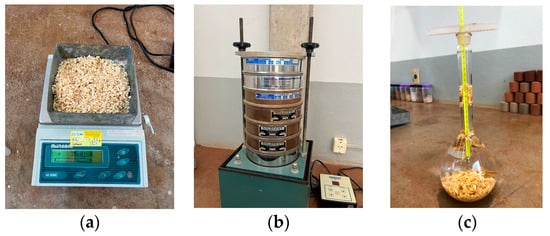

To characterize the granulometric wood composition, an adaptation of the standard code ABNT NM 248 [15] was performed, as described by Herradon et al. [13] and Souza et al. [16]. The procedure consisted of testing a 35 g sample in a set of sieves with mesh sizes of 6.30, 4.76, 2.38, 1.19, 0.595, and 0.297 mm (Figure 2).

Figure 2.

Laboratory processes: (a) weighing of pinewood used for the granulometric test; (b) granulometric test of the particles; and (c) determination of specific mass of pinewood particles.

To determine the specific mass of pinewood particles, two standards were used: ABNT NBR 6458 [17] and ABNT NBR 6457 [18], employing the volumetric flask method (Figure 2c). The test was conducted using a pycnometer No. 2, with a 500 mL volume, a mercury thermometer calibrated to a precision of 0.1 °C and capable of measuring within a range of −10 °C to 100 °C, and a high-precision analytical balance. Considering that conifer wood, e.g., pine, usually exhibits a comparatively lower specific density than water, absolute alcohol (with a 99.3% concentration and a 789 kg/m3 specific mass) was utilized as an alternative to water, as recommended by Cazella et al. [3] and Bispo et al. [19].

2.4. Panel Production

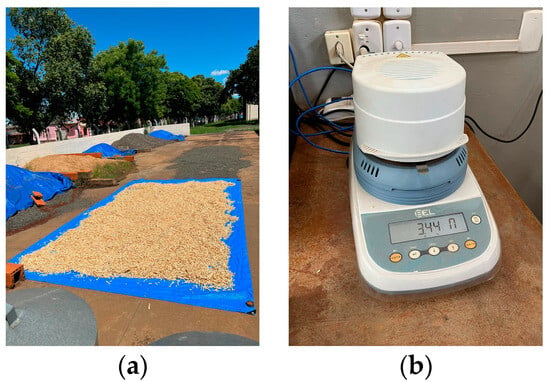

A moisture analyzer (Model i-Thermo G, BEL, Monza, Italy) was used to calculate the moisture content of the particles, which were initially exposed to open air until reaching a moisture level below 5% (Figure 3).

Figure 3.

Laboratory processes: (a) air-dried particles; and (b) moisture content test of the particles.

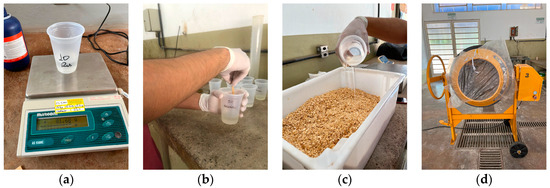

Epoxy resin was weighed according to the manufacturer’s recommendations, using a 2:1 ratio (resin/hardener) in proportion to the dry mass of the particles (Table 1). Prior to application, the manufacturer recommends an initial manual mixing of the components for 5 min to improve adhesion. After mixing, the resin was manually applied to the pinewood particles, which were then placed in a mechanical rotative mixer (Model 120L cv, CSM, Jaragúa do Sul, Brazil) for final homogenization with the epoxy resin. The entire process is illustrated in Figure 4.

Figure 4.

Laboratory processes: (a) resin weighing; (b) resin homogenization with the hardener; (c) resin application to the particles; (d) particle homogenization in a mechanical rotative mixer.

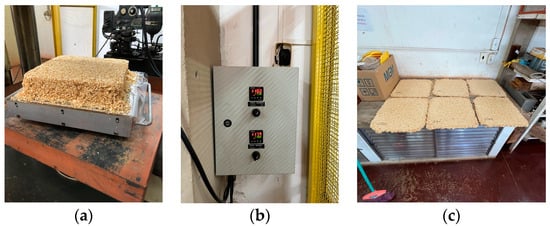

After homogenizing the wooden particles with the resin, they were prepared for cold pre-pressing in a 350 × 350 × 20 mm wooden form. Subsequently, the particles were subjected to a press with a 110 °C temperature and a 5 N/mm2 pressure as described by Herradon et al. [13]. The total pressing time was 10 min, with a 30 s pause after the first 5 min to prevent gas concentration and bubble formation inside the panel [2,19]. After pressing, the panels were left to stabilize at room temperature for over 7 days, according to the resin manufacturer’s specifications, to ensure complete adhesive curing, with a relative humidity at 65 ± 2% (Figure 5).

Figure 5.

Laboratory processes: (a) particles before pressing; (b) temperature control; and (c) panels after pressing.

2.5. Performance Tests

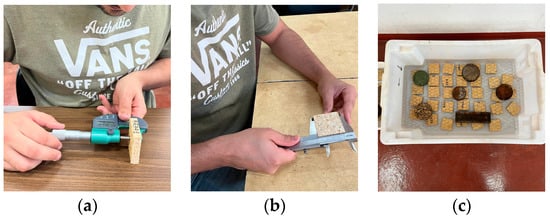

According to the ABNT NBR 14810-2 [20] standard, 10 specimens were used for each test. After the adhesive had fully cured, the produced panels were cut into 50 × 50 × 20 mm samples, totaling 40 specimens for each mixture, in order to evaluate their physical properties, such as density, moisture content, water absorption, and swelling after 24 h. Figure 6 illustrates the preparation of the specimens for the physical tests.

Figure 6.

Laboratory processes related to specimens: (a) dimensioning with a digital caliper; (b) measurement with a caliper; and (c) samples submerged in deionized water.

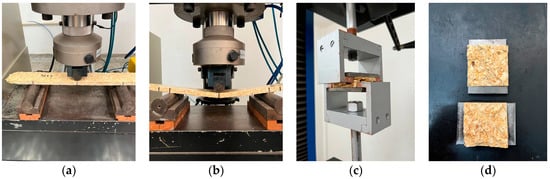

For the analysis of mechanical properties, they were conducted using a universal testing machine (GR048, EMIC, São José dos Pinhais, Brazil), the modulus of rupture (MOR) and modulus of elasticity (MOE) tests were conducted using specimens with a 50 mm width and a 350 mm length, with thicknesses from 10 to 16 mm. For the perpendicular tensile (PT) tests, the specimens had dimensions of 50 × 50 mm. Figure 7 illustrates the preparation of the specimens for the mechanical tests. Regarding panel performance, they were classified according to ABNT NBR 14810-2 [20], ANSI A208.1 [21], and EN 312 [22].

Figure 7.

Panel evaluation: (a) static bending test; (b) specimen after the static bending; (c) perpendicular tensile test; and (d) specimen after the perpendicular tensile test.

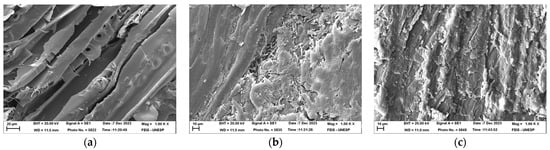

2.6. Scanning Electron Microscopy

Scanning electron microscopy (SEM) aims to analyze the interaction between epoxy and the wood particles, observing the adhesive’s behavior under pressing temperature and pressure, as well as studying the particle encapsulation with increasing adhesive content. The samples, prepared from the rupture region of the specimens (1 × 1 × 0.4 cm), were mounted on Stub holders with carbon tape, coated with gold (Quarum Q150TE), and analyzed using SEM (ZEISS EVO LS15 with EDS from OXFORD Instruments, model INCAx-act, Oberkochen, Germany).

The interaction between the panel’s components was analyzed through visual examinations, where voids and surface roughness were assessed based on the addition of adhesive. Regarding the voids, it was observed that the wood particle fibers exhibit a certain degree of spacing, whereas the roughness demonstrates the filling or encapsulation of the particles. The colors in the microscopic images indicate that lighter shades correspond to a greater degree of encapsulation, while darker tones signify voids or low filling levels.

2.7. Statistical Analysis

A statistical evaluation of the results was carried out using the Tukey mean comparison test with a 5% significance level, alongside the Anderson–Darling normality test (also at 5% significance) to confirm the validity of the analysis of variance (ANOVA, 5% significance). This procedure aimed to assess the impact of incorporating epoxy resin (5%, 10%, and 15%) on the physical and mechanical properties of the produced panels.

In the Tukey test, the designation “A” corresponds to the mixture with the highest mean value, “B” indicates the second highest, and so forth. Identical letters signify mixtures with statistically similar mean outcomes. It is noteworthy that, for these analyses and the computation of descriptive statistics, ten experimental data points were collected for each property across the different mixture types.

3. Results and Discussion

The results were initially presented based on the statistical analysis, highlighting whether the increase in adhesive quantity produced significant results according to its incorporation. Subsequently, the physical and mechanical properties were analyzed and compared with the literature to determine if epoxy is superior to conventional resins. Finally, a verification of compliance with the minimum requirements established by the standards was conducted.

3.1. Statistical Analysis of Results

Table 2 presents the statistical values for each percentage of epoxy resin. It is possible to observe that, for the density test (D), the adhesive had an influence (A) starting from 10% incorporation, maintaining the same statistical mean (A) for 15% incorporation. As for the water absorption (WA) and thickness swelling (TS) tests, the amount of incorporated adhesive influenced the results, with statistically different values for each mixture, suggesting that the increase positively contributes to better resistance. The results obtained for the moisture content (MC) test showed that the epoxy adhesive had statistically different means starting from 15% incorporation, which represents better values for the test conducted.

Table 2.

Tukey test results for mean value contrast across all studied properties.

In the mechanical tests, the increase in adhesive percentage had a positive effect on the performance of each mixture, resulting in statistically distinct means as the adhesive percentage was increased.

3.2. Granulometry of Mixtures

Pinewood particles were predominantly retained in sieve No. 8 (66.52%) and sieve No. 16 (24.56%), with openings of 2.38 mm and 1.19 mm, respectively, indicating greater efficiency in the grinding process for these dimensions (Table 3). Sieve No. 4, with an opening of 4.76 mm, retained 6.59% of the material. Summing the results of sieves No. 4, 8, and 16, a total of 97.67% of the 35 g tested mass was obtained. This particle size range, from 4.76 mm to 1.19 mm, demonstrates a good distribution, with only a small fraction of smaller particles, presenting a fineness modulus of 3.81. This distribution favors better adhesive bonding, as the efficiency of its application increases when the proportion of fine particles is reduced [23]. Sieve No. 50 and the bottom sieve did not retain any mass, having no impact on the granulometric composition of the mixtures. Similar results were found by Cazella et al. [3] when using the same species of pinewood.

Table 3.

Granulometry compositions and fineness module (FM).

For the specific mass results through testing, the value was 570 kg/m3. The value found for pine particles is similar to that specified by the ABNT NBR 7190 [24] standard, which establishes approximately 560 kg/m3 as the apparent specific mass of pine particles.

3.3. Physical Properties

The physical results obtained through the tests are summarized in Table 4.

Table 4.

Physical results.

The ABNT NBR 14810-2 [20] code establishes that low-density panels must have a density below 551 kg/m3, medium-density panels around 551 and 750 kg/m3, and high-density panels above 750 kg/m3. However, the density measurements achieved here exceeded these guidelines, even with a nominal density of 0.5 g/cm3, due to the use of epoxy resin, which has a high specific mass (1.12 g/cm3 for the resin and 1.005 g/cm3 for the hardener).

In a study led by Herradon et al. [13], pressing pinewood panels with 10% and 15% epoxy at a pressure of 4 N/mm2 resulted in 800 and 850 kg/m3. This shows that the pressing pressure and the use of epoxy resin significantly contribute to the increase in density.

Thickness swelling and water absorption results indicated that increasing the percentage of epoxy resin significantly improved performance in both tests. However, the increase in resin did not have a significant impact on moisture content. These results are superior to those found by Sozim et al. [25] who produced pinewood particleboards bonded with 10% urea-formaldehyde, 3.92 N/mm2, and 160 °C, achieving values of 90.02% and 31.47% for absorption and swelling, respectively. Similarly, Carvalho et al. [26] obtained absorption and swelling results inferior to those of 10% and 15% epoxy resin, although their panels were produced with a pressure of 3 N/mm2, 10% urea-formaldehyde, and a temperature of 180 °C.

The significant reduction in water absorption and swelling at higher epoxy resin contents (10% and 15%) demonstrates not only the technical feasibility but also the potential for advancing composite material science. This improvement provides a pathway for manufacturing panels suitable for humid environments, broadening the scope of applications compared to conventional adhesives.

While the performance of epoxy resin in this study is superior under controlled laboratory conditions, future studies should investigate its long-term durability under varying environmental conditions, such as extreme temperatures or prolonged exposure to moisture. Such studies would provide deeper insights into the viability of replacing formaldehyde-based adhesives at an industrial scale.

3.4. Mechanical Properties

Table 5 presents the mechanical properties results of the panels obtained through testing. It is observed that as the epoxy resin content increased, better results were obtained for all tests. This occurs because, by increasing the percentage of adhesives, a larger surface area of the particles adheres to the adhesive, thus providing better performance. The increase in the mechanical strength of the panels from 5% to 10% epoxy resin usage was 82.45%, 97.85%, and 236.67% for MOR, MOE, and PT, respectively.

Table 5.

Mechanical results.

The progressive increase in MOR and MOE values with higher epoxy contents (10% and 15%) reflects a significant improvement in mechanical bonding. This suggests that epoxy resin facilitates superior load distribution among wood particles, a phenomenon corroborated by Herradon et al. [13], who highlighted the critical role of pressure in enhancing resin performance. These findings provide a deeper understanding of the interaction between resin content and mechanical strength, which is pivotal for designing optimized composite materials.

The results demonstrate the potential of epoxy resin to meet industrial demands for stronger and more durable wood panels. When compared to 10% urea-formaldehyde adhesives, as observed by Sozim et al. [25] and Carvalho et al. [26], epoxy resin offers a viable alternative, particularly in applications requiring high mechanical performance (MOR and MOE). However, the higher perpendicular tensile (PT) values in previous studies highlight a limitation that warrants further optimization of the epoxy formulation. This finding is relevant to the industry, as Lee et al. [27] reported that resin costs can account for up to 30% of the production cost of panels. This cost percentage represents a significant challenge for industrial scalability, particularly in markets where cost-efficiency is a priority. Nonetheless, the superior mechanical properties achieved with higher epoxy resin contents suggest potential for value-added applications where performance outweighs raw material costs.

3.5. Scanning Electron Microscope Images

The micrographs through SEM allowed the analysis of the interaction between the wood particles and the epoxy resin following the rupture of the specimens during mechanical testing. Figure 8 illustrates a progressive filling of particles voids with increasing adhesive content, which accounts for the observed rise in panel density. This filling is essential, as a high number of voids facilitates water percolation, reducing the panel’s resistance to moisture, swelling, and absorption, as demonstrated by the physical results.

Figure 8.

(a) Surface of the specimen from the 5EP mixture. (b) Surface of the specimen from the 10EP mixture. (c) Surface of the specimen from the 15EP mixture.

In the 5EP mixture, the system was more prone to water percolation due to the lower encapsulation of the wood particles. In the 10EP and 15EP mixtures, this percolation was reduced, which is attributed to better coating of the particles by the adhesive. Although epoxy is water-resistant, the wood particles are hydrophilic, and the lack of proper encapsulation increases water absorption, resulting in higher swelling and absorption values in panels with lower adhesive content, negatively impacting their physical properties. The images confirm that increasing the adhesive content provided a more uniform coating between the particles, improving bonding and, consequently, the mechanical properties. In panels with 5% epoxy, there were still voids without proper resin interaction, weakening these areas. In contrast, panels with 10% and 15% epoxy showed superior coverage, with better mechanical results due to the larger adhesive area between the particles.

3.6. Classifications According to Standard Codes

Table 6 shows the requirements of the ABNT NBR 14810 [20], ANSI A208.1 [21], and EN 312 [22] standards, along with the panel classifications.

Table 6.

Panel classification according to the standard codes.

The panel with 10% epoxy resin achieved the M-3i classification according to the ANSI A208.1 [21] standard, while the panel with 15% resin obtained classifications across all evaluated standards. On the other hand, the panel with 5% epoxy resin did not achieve classification in any of the standards, primarily due to the low values obtained in the perpendicular tensile (PT) and thickness swelling (TS).

4. Conclusions

From the results obtained, the conclusions are as follows:

- Based on the tests conducted, it was confirmed that particleboards using epoxy resin can replace urea-formaldehyde and other adhesives, offering superior performance in some cases, such as physical and mechanical tests. Additionally, epoxy has the advantage of being less harmful to the environment and human health, making it a more sustainable option;

- The statistical analysis demonstrated that the epoxy resin content significantly influences all evaluated physical and mechanical properties;

- The scanning electron microscopy (SEM) analysis confirmed that the addition of 5% epoxy resin is not sufficient to adequately fill the voids in the panel or to provide good encapsulation of the particles, compromising protection against moisture. Panels with 10% and 15% present better resin encapsulation of the particles, which is sufficient to provide better protection in physical and mechanical tests;

- Panels met the parameters of both Brazilian and international standard codes for furniture applications under conditions of humid and not severe conditions.

The search for more sustainable materials for particleboard production represents an important step toward a more ecological future. To better understand the potential of epoxy resin, further research is needed to investigate its properties under different parameters, such as variations in temperature, pressure, and time. Additionally, it is essential to conduct studies exploring the application of epoxy-based panels in environments where urea-formaldehyde panels are already widely used.

Author Contributions

A.J.S.J.: Writing—review and editing, Writing—original draft, Resources, Project administration, Methodology, Investigation, Funding acquisition, Formal analysis, Data curation, Conceptualization. M.P.H.: Writing—review and editing, Visualization, Methodology, Validation, Investigation, Formal analysis, Data curation. M.V.d.S.: Writing—review and editing, Visualization, Validation, Investigation, Formal analysis, Data curation. S.A.M.d.S.: Writing—original draft, Visualization, Validation, Supervision, Resources, Project administration, Methodology, Funding acquisition, Formal analysis, Conceptualization. V.A.D.A.: Writing—review and editing, Writing—original draft, Visualization, Validation, Supervision, Formal analysis. D.H.d.A.: Writing—original draft, Methodology, Investigation, Formal analysis, Data curation. H.F.d.S.: Writing—original draft, Methodology, Investigation, Formal analysis, Data curation. A.L.C.: Writing—review and editing, Visualization, Validation, Supervision, Software, Investigation, Formal analysis. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Código de Financiamento 001.

Data Availability Statement

No data are shared, as most data were presented in the result sections.

Acknowledgments

The authors gratefully acknowledge the financial support from the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Funding Code 001, and the institutional support provided by the MAC Group (Alternative Materials for Construction), headquartered at the Ilha Solteira campus of São Paulo State University (UNESP).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- FAO. Global Production of Wood-Based Panels: Trends and Statistics; Food and Agriculture Organization of the United Nations: Rome, Italy, 2021; Available online: https://www.fao.org/faostat/en/#home (accessed on 11 November 2024).

- Campos, P.H.S.; Santos Junior, A.J.; de Souza, M.V.; Herradon, M.P.; Libera, V.B.L.; Dezen, L.E.; da Silva, É.V.; Silva, A.G.B.P.; Rodrigues, F.R.; Bispo, R.A.; et al. Evaluation and production of high-strength wood composite panels with polyethylene terephthalate (PET). BioResources 2023, 18, 8528–8535. [Google Scholar] [CrossRef]

- da Silva Cazella, P.H.; de Souza, M.V.; Rodrigues, F.R.; da Silva, S.A.M.; Bispo, R.A.; Araujo, V.A.; de Christoforo, A.L. Polyethylene terephthalate (PET) as a recycled raw material for particleboards produced from pinus wood and biopolymer resin. J. Clean. Prod. 2024, 447, 141460. [Google Scholar] [CrossRef]

- IMARC Group. Particleboard Market: Global Industry Trends, Share, Size, Growth, Opportunity, and Forecast 2023–2032; IMARC Group: New York, NY, USA, 2023; Available online: https://www.imarcgroup.com/particle-board-market (accessed on 11 November 2024).

- Mansouri, H.R.; Pizzi, A.; Leban, J.M. Improved water resistance of UF adhesives for plywood by small pMDI additions. Holz Als Roh-Und Werkst. 2006, 64, 218–220. [Google Scholar] [CrossRef]

- Guru, M.; Tekeli, S.; Bilici, İ. Manufacturing of urea–formaldehyde-based composite particleboard from almond shell. Mater. Des. 2006, 27, 1148–1151. [Google Scholar] [CrossRef]

- Salim, R.M.; Asik, J.; Sarjadi, M.S. Properties of Bark Particleboard Bonded with Demethylated Lignin Adhesives Derived from Leucaena leucocephala Bark. J. Renew. Mater. 2024, 12, 737–769. [Google Scholar] [CrossRef]

- Klein, C.; Nielsen, G.; Johanson, G.; Bolt, H.; Papameletiou, D.; European Commission: Directorate-General for Employment, Social Affairs and Inclusion. SCOEL/REC/125 formaldehyde–Recommendation from the Scientific Committee on Occupational Exposure Limits, Publications Office. 2016. Available online: https://data.europa.eu/doi/10.2767/399843 (accessed on 11 November 2024).

- Dorn, L.; Thirion, A.; Ghorbani, M.; Olaechea, L.M.; Mayer, I. Exploring fully biobased adhesives: Sustainable kraft lignin and 5-HMF adhesive for particleboards. Polymers 2023, 15, 2668. [Google Scholar] [CrossRef]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. Journal of Industrial and Engineering Chemistry. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Transparency Market Research. Epoxy Resins Market-Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2020–2031. Transparency Market Research. 2022. Available online: https://www.transparencymarketresearch.com/epoxy-resins-market.html (accessed on 12 November 2024).

- Zion Market Research. Epoxy Coatings Market: Global Industry Perspective, Comprehensive Analysis, and Forecast, 2018–2025. Zion Market Research. 2019. Available online: https://www.zionmarketresearch.com/report/epoxy-coatings-market (accessed on 12 November 2024).

- Herradon, M.P.; Santos Junior, A.J.; de Carvalho, F.A.; de Souza, M.V.; da Silva Cazella, P.H.; Rodrigues, F.R.; Bispo, R.A.; da Silva, S.A.M.; Christoforo, A.L. Produção e avaliação de painéis de partículas com resíduo de Pinus oocarpa aglutinadas com dois tipos de resinas. Cad. Pedagógico 2023, 20, 889–902. [Google Scholar] [CrossRef]

- Gilio, C.G.; Andraus Bispo, R.; Ferreira Trevisan, M.; Reis Rodrigues, F.; Frutuoso, C.; Junior, A.; Mello Da Silva, S.A. Produção de painéis aglomerados empregando seringueira, teca e poliuretano derivado de óleo de mamona. Rev. Principia 2021, 57, 86–97. [Google Scholar] [CrossRef]

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT. NBR NM 248: Agregados: Determinação da Composição Granulométrica; ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT: Rio de Janeiro, Brazil, 2003. [Google Scholar]

- Souza, M.V.; da Silva, S.A.M.; Cazella, P.H.S.; Rodrigues, F.R.; Bonfim, K.S.; Sanches, A.O.; de Araujo, V.A.; dos Santos, H.F.; Pinto, E.M.; Christoforo, A.L.; et al. Particleboards manufactured from Tectona grandis wood waste with homogeneous and three-layer heterogeneous compositions for commercial purposes. BioResources 2022, 17, 5011–5020. [Google Scholar] [CrossRef]

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT. NBR 6458: Grãos de Pedregulho Retidos na Peneira de Abertura 4,8 mm: Determinação da Massa Específica, da Massa Específica Aparente e da Absorção de Água; ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT. NBR 6457: Amostras de Solo—Preparação Para Ensaios de Compactação e Ensaios de Caracterização; ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT: Rio de Janeiro, Brazil, 2024. [Google Scholar]

- Bispo, R.A.; Trevisan, M.F.; da Silva, S.A.M.; Aquino, V.B.M.; Saraiva, R.L.P.; Arroyo, F.N.; Molina, J.C.; Chahud, E.; Branco, L.A.M.N.; Panzera, T.H.; et al. Production and evaluation of particleboards made of coconut fibers, pine, and eucalyptus using bicomponente polyurethane-castor oil resin. Bio Resour. 2022, 3944–3951. [Google Scholar] [CrossRef]

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT. NBR 14810-2: Painéis de Partículas de Média Densidade: Parte 2: Requisitos e Métodos de Ensaio; ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- American National Standards Institute–ANSI. A208.1: Particleboards; ANSI: Gaithersburg, MD, USA, 2016. [Google Scholar]

- European Comitee for Standardization. Particleboard: Specifications. EN 312; CEN: Brussels, Belgium, 2003; Available online: https://www.en-standard.eu/ (accessed on 12 November 2024).

- Iwakiri, S.; Trianoski, R. Painéis de Madeira Reconstituída, 2nd ed.; Fundação de Pesquisas Florestais do Paraná: Curitiba, Brasil, 2020; Available online: https://fupef.org.br/ (accessed on 12 November 2024).

- ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT. NBR. 7190: Projeto de Estruturas de Madeira; ASSOCIAÇÃO BRASILEIRA DE NORMAS TÉCNICAS–ABNT: Rio de Janeiro, Brazil, 2022. [Google Scholar]

- Sozim, P.C.L.; Napoli, L.M.; Ferro, F.S.; Mustefaga, E.C.; Hillig, É. Propriedades de painéis aglomerados produzidos com madeiras de Ligustrum lucidum e Pinus taeda. Pesquisa Florestal Brasileira 2019, 39, 1–8. [Google Scholar] [CrossRef]

- Carvalho, A.G.; Carlos, R.; Lelis, C.; Miguel Do Nascimento, A. Evaluation of adhesives based on tannins from pinus caribaea var. bahamensis and acacia mearnsii in the manufacture of particleboard. Ciência Florest. 2014, 2, 479–489. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pedzik, M.; Rogozinski, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from agricultural biomass and recycled wood waste: A review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).