Abstract

This work presents the results of the homogenization of the color of sapwood and false heartwood Fagus sylvatica L. into a uniform color shade due to the influence of the temperature of saturated moist air and saturated water steam in individual steaming modes. The results of analyses of the influence of temperature within 24 h point out the different changes in the color of the sapwood and the wood of the false heartwood when the uniform color of the beech wood is achieved by the steaming process. By steaming beech wood with a false heartwood saturated with moist air at a temperature of tI = 95 °C during τ = 24 h, the color of the sapwood does not merge with the color of the wood of the false heartwood. The sapwood darkens and, on the other hand, the wood of the false heartwood slightly lightens, while the significant color contrast is removed, but the color homogenization in the individual zones does not occur. The unification of the colors in individual zones occurs during the steaming process at a temperature of saturated water steam tII ≈ 105 °C in 18 h, where the resulting brown color is identified in the color space CIE L*a*b* by the values of the lightness L* = 61.3 ± 2.2 and of the red color a* = 12.4 ± 1.3 and yellow color b* = 19.5 ± 1.4. The most pronounced homogenization of the color occurs through the steaming process at a temperature of saturated water steam tIII ≈ 120 °C, where the wood acquires a uniform dark brown–gray color in a time of τ ≈ 9 h steaming. The coordinates of the color-homogenized steamed beech wood are L* = 55.9 ± 1.9, a* = 12.3 ± 1.2, and b* = 19.6 ± 1.3. The unification of the colors by the steaming process is achieved by darkening both the sapwood and the wood of the false heartwood. In the overall color homogenization, the sapwood and the wood of the false heartwood do not participate equally in the steaming process. While the total color difference between the sapwood and a color homogenized state is quantified by the value ∆EtI* = 8, ∆EtIII* = 22.7, the total color difference in the wood with a false heartwood is only ∆EtI* = 1.9, ∆EtIII* = 11.8.

1. Introduction

Among the coreless woods with the possibility of forming a false heartwood during the growth of the tree is beech wood, which is included in the group of scattered-porous woods. The most common occurrence of brown–red wood, referred to as false heartwood, is in older trees. Air that penetrates into the trunk oxidizes the soluble carbohydrates and starches found in living or dead parenchymal cells, while the formation of polyphenolic compounds occurs, which penetrate into the neighboring tissue and color the wood [1,2,3,4,5,6,7].

The different shapes and positions of the wood of the false heartwood in the cross-section of the trunk led authors [8,9] to divide the false heartwoods in beech wood into the following types: Round, Mosaic, Star, and Flame (centric, eccentric).

The steaming of wood is a technological process in which wet wood is heated by the action of heat in the form of saturated moist air or saturated water steam and changes its physical, mechanical and chemical properties. While temporary physical-mechanical changes are used in the production of veneers, plywood, bent furniture, or pressed wood, permanent chemical changes manifested by, among other things, a change in color are used to modify the color of the wood into other shades. Recently, the attention of research in the field of thermal treatment of wood has focused on targeted changes in the color of the wood of individual trees to more or less distinct color shades, or wood imitations of domestic trees for exotic woods [10,11,12,13,14,15,16,17,18,19,20,21].

The color of beech sapwood and mature wood is light white–gray or pale-ochre to white–pink [2,21,22,23,24,25] and brown–red in the zone of false heartwood [2,24,26,27,28]. The author of [29] numerically documented the visual color differences between the color of sapwood and heartwood through the values of the coordinates of the color space CIE L*a*b* and the total color difference ∆E*. The color difference between sapwood and heartwood ∆E* = 14.1 is classified within the categorization of color differences in the category of significant color changes. The color differences of the wood of the false heartwood from the sapwood are in real practice the reason for the rejection of sawmill assortments with a share of wood of the false heartwood from the production of bent furniture, sports tools and parts for construction and carpentry products.

The aim of this work is based on experimental research aimed at analyzing the changes in the color of sapwood and the color of the heartwood in the color space CIE L*a*b during the process of wood color homogenization by evaporation of atmospheric saturated moist air with temperature tI = 95 ± 3 °C and saturated water steam with a temperature of tII = 105 ± 3 °C and with a temperature of tIII = 120 ± 3 °C to achieve homogenization of the color of the wood after the cross-section.

2. Materials and Methods

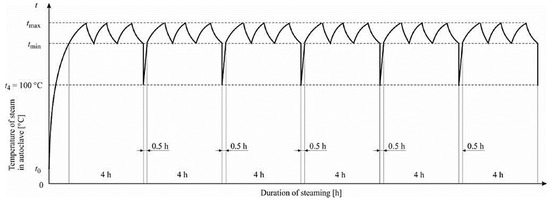

Test material in the form of blanks with dimensions of 32 × 50 × 800 mm were produced by longitudinal and transverse sawing from central lumber of thickness h = 32 mm with wood of false heartwood from Poľana (Slovakia). A total of 380 sapwood blanks and 380 false heartwood blanks were randomly selected. The blanks were divided into 19 groups so that each group contained 20 sapwood blanks and 20 false heartwood blanks. The cuttings of the first group in number were unsteamed. The other blanks were steamed with saturated moist air at a temperature of tI = 95 ± 3 °C, or with saturated steam in Mode II with a temperature of saturated water steam tII ≈ 105 ± 3 °C and Mode III with a temperature of saturated water steam tIII ≈ 120 ± 3 °C. Individual cages with steamed wood were removed from the steaming autoclave after steaming τ = 4 h, τ = 8 h, τ = 12 h, τ = 16 h, τ = 20 h and τ = 24 h. The steaming of the wood was carried out in a pressure autoclave APDZ 240 (Himmasch AD, Haskovo, Bulgaria) installed at Sundermann s.r.o. Banská Štiavnica (Slovakia). The steaming conditions of beech wood with a false heartwood with saturated water steam with marked time intervals of sampling during thermal treatment v are shown in the diagram in Figure 1.

Figure 1.

Diagram of wood color homogenization by steaming in a pressure autoclave.

The temperatures of the saturated moist air in Mode I, or of saturated water steam in Modes II and III, are shown in Table 1. Temperatures tmax and tmin are the temperature intervals in which heat is supplied to the autoclave in the form of saturated water steam to implement the technological process. Temperature t4 is the temperature of the saturated water steam in the autoclave to reduce the pressure in the autoclave to the limit of atmospheric pressure, which allows the safe opening of the pressure device and the selection of a group of steamed blanks in the specified steaming time.

Table 1.

Technological conditions for the homogenization of the color of beech wood in a pressure autoclave.

The unsteamed and steamed beech wood blanks were dried in a hot-air oven according to the [30] mode to a moisture content of 10 ± 2%, with an emphasis on preserving the wood color created by the steaming process. All the dried blanks, whether steamed or unsteamed, were machined on a FS 200 horizontal planer.

Color measurement was performed with a Color Reader CR-10 Plus colorimeter (Konica Minolta, Tokyo, Japan) with a reflection spectrum in the 400–700 nm range. A D65 light source was used and the diameter of the optical-sensing aperture was 8 mm. The color measurement was performed on the milled surfaces of each blank at three points, separately in each homogenization mode and time.

The results of the measured values, lightness L*, red color a*, yellow color b* on the coordinates of the color space CIE L*a*b*, are presented in the form of writing the average measured value and the standard deviation sx.

The color dispersion of the sapwood and wood colors of false heartwood in the color space CIE L*a*b* was determined through the standard deviations sL, sa, sb determined from the measured values of the coordinates of the color space according to the equation ΔEsx* in the form:

The differences between the average color values of the coordinates of the color space of the false heartwood L*hw, a*hw, b*hw and sapwood L*sw, a*sw, b*sw in the individual phases of the steaming process were evaluated through the color difference ΔE1* in the form:

The differences between the average color values of the unsteamed , , and steamed wood , , in the sapwood zone and the false heartwood zone were evaluated through the total color difference ΔE*:

3. Results and Discussion

The light white–gray color of the sapwood beech wood and the brown–red color of the wood of the false heartwood will change over the course of 24 h steaming with saturated moist air at a temperature of tI = 95 ± 3 °C, changing to a pale brown color. The color of sapwood beech wood and wood with a false heartwood changes over 24 h of steaming with saturated steam at temperatures tII = 105 ± 3 °C and tIII = 120 ± 3 °C, changing to brown–gray color shades. The colors of beech wood before steaming and after steaming are shown in Figure 2.

Figure 2.

Color of sapwood and heartwood before steaming and after 24 h during the steaming process in individual modes.

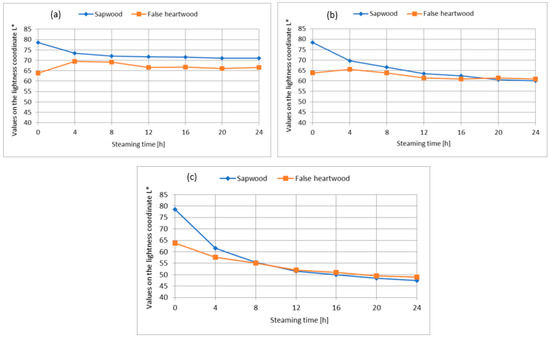

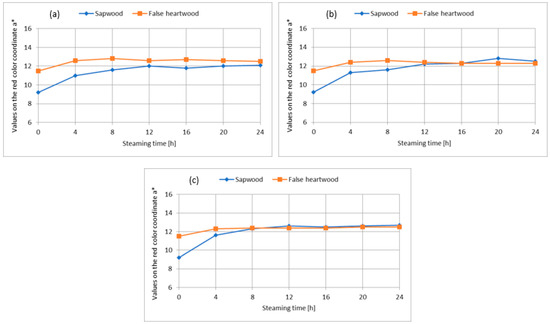

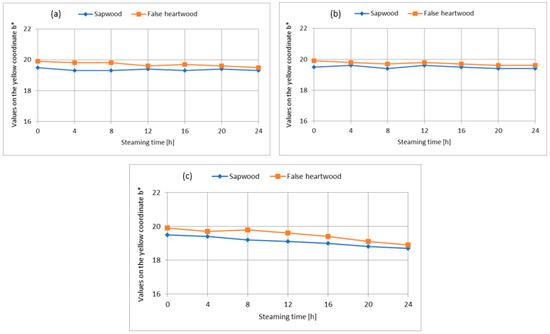

The course of the changes in the color of sapwood and false heartwood at individual coordinates of the color space depending on the steaming process with saturated moist air at a temperature of tI = 95 ± 3 °C and saturated water steam at temperature of tII = 105 ± 3 °C and temperature tIII = 120 ± 3 °C is shown in Figure 3, Figure 4 and Figure 5.

Figure 3.

(a) Course of changes on the coordinate L* during steaming with saturated moist air with temperature t = 95 °C; (b) Course of changes on the coordinate L* during steaming with saturated water steam at temperature t = 105 °C; (c) Course of changes on the coordinate L* during steaming with saturated water steam at temperature t = 120 °C.

Figure 4.

(a) Course of changes on the coordinate a* during steaming with saturated moist air with temperature t = 95 °C; (b) Course of changes on the coordinate a* during steaming with saturated water steam at temperature t = 105 °C; (c) Course of changes on the coordinate a* during steaming with saturated water steam at temperature t = 120 °C.

Figure 5.

(a) Course of changes on the coordinate b* during steaming with saturated moist air with temperature t = 95 °C; (b) Course of changes on the coordinate b* during steaming with saturated water steam at temperature t = 105 °C; (c) Course of changes on the coordinate b* during steaming with saturated water steam at temperature t = 120 °C.

From the changes in the color space, it follows that the biggest changes are in the lightness coordinate L*. At all the temperatures of the steaming process, the lightness of the sapwood decreased from the value L0* = 78.5 at the steaming temperature tI ≈ 90 °C to the value LI-24* ≈ 71.0 at the steaming temperature tII ≈ 105 °C to the value LII-24* = 60.5 and at the vaporization temperature tIII ≈ 120 °C to LIII-24* = 47.5. The darkening of the sapwood beech in the steaming process is caused by hemicellulose hydrolysis processes, their partial breakdown and an increase in the lignin content of the steamed wood [20,21,31,32].

The lightness of the wood of false heartwood L* varied in the opposite direction during steaming. While during the steaming of false core wood with saturated moist air at temperature tI ≈ 95 °C, the lightness of the wood increased from the value L0* = 63.8 to the value LI-24* = 65.5, the wood became lighter, so by steaming false heartwood beech with saturated water with steam at a temperature of tII ≈ 105 °C, the lightness value did not change, it oscillated around the value of L0* = 63.8 ± 2.6, and at a steaming temperature of tIII ≈ 120 °C, it decreased from the value of L0* = 63.8 to the value of LIII-24* = 49.0, which was manifested by the darkening of the wood.

The lightening of the wood of the false heartwood in the first τ = 12 h of steaming at temperature tI ≈ 95 °C points to the instability of the chromophore system of the wood of the false heartwood created by the enzymatic processes of peroxidase and polyphenoloxidase, which are responsible for the oxidation of phenolic compounds and the characteristic coloration of the wood of the false heartwood [15,33,34].

The changes in the red color coordinate a* during τ = 24 h of steaming of beech wood indicate certain differences in the color of the sapwood and the wood of the false heartwood. The sapwood, in the process of steaming at temperature tI ≈ 90 °C, recorded an increase in the values of the red color coordinate in the first τ = 12–16 h from the value a0* = 9.2 to the value a16* ≈ 12.1. During the steaming of beech sapwood at the steaming temperatures tII ≈ 105 °C and tIII ≈ 120 °C, the value of the red coordinate of the red color in the first hours of steaming increased by ∆a* ≈ 3.5, which was visually manifested by the reddening of the wood, and consequently, the value of the red color of the steamed wood did not change.

In terms of the coordinate of the red color a* of the false heartwood, the value increased from a0* = 11.5 to the value a8* = 12.4 in the first τ = 8 h of steaming. Subsequently, the values of the red color coordinate did not change, similarly to sapwood.

The values of the yellow coordinate b* did not change during the steaming of beech wood in the temperature interval t = 95–105 °C. For sapwood, the values of the yellow color coordinate oscillated around the value b* ≈ 19.5, and for the heartwood, around the value b* ≈ 19.9. The stated finding is similar to that reported by the authors of [15] in their work. At the steaming temperature tIII ≈ 120 °C, a slight decrease in the values by ∆b* ≈ 1.0 was recorded for both the steamed sapwood and steamed wood with false heartwood.

From the changes in the lightness coordinate L* and the chromatic coordinates of the red color a* and yellow color b* in Figure 3, Figure 4 and Figure 5, it follows that the uniform color of the steamed sapwood and wood of false heartwood is not the same, both from the aspect of the steaming time and the achievement of a uniform color. As the steaming temperature increases, the time required for color uniformity decreases. At the same time, the darkness of the brown or brown–gray color of the steamed beech wood, despite the shortened steaming time, increases.

Table 2 shows the technological parameters of the wood steaming process in which the unification of the color of the sapwood and the false heartwood occurs, such as the steaming temperature, minimum steaming time required to achieve unification of the colors of steamed beech wood, values of the coordinates of the color space CIE L*a*b*, differences between the color of sapwood and the color of false heartwood ∆E1*, and the dispersion of the color of sapwood and wood of false heartwood ∆Esx*.

Table 2.

Measured and calculated values of the color homogenization in the steaming process of sapwood and false heartwood beech.

The process of homogenizing the color of beech wood at the individual steaming temperatures is characterized by the following findings:

- (a)

- By steaming beech wood with saturated moist air with a temperature of tI = 95 °C, the unification of the color of the sapwood with the false heartwood does not occur within τ = 24 h. The sapwood darkens and takes on a pale brown color. The heartwood has lightened to a darker shade of pale brown than the sapwood. However, the significant color contrast between the sapwood zone and the heartwood zone, which is ∆E1* = 14.8 for unsteamed wood and reduced to ∆E1* = 5.5 for steamed wood at the steaming temperature tI = 95 °C, is removed. The mentioned changes occur in beech wood by a decrease in the values on the lightness coordinate by ∆L* = −7.5 and an increase in the values of the red color coordinate by ∆a* = +3.1. For wood with a false heartwood, the values increase, both for the lightness coordinate by ∆L* = +2.7 and for the red color coordinate by ∆a* = +1.0.

- (b)

- Through the process of steaming beech wood with saturated water steam at a temperature of tII ≈ 105 °C, the unification of the colors of sapwood and false heartwood occurs after 18 h of the technological process. The average values of the unified color of steamed sapwood and false heartwood in the color space are CIE L*a*b*: L* = 61.3 ± 2.2, a* = 12.4 ± 1.3 and b* = 19.5 ± 1.4. The mentioned uniform coloring of the steamed wood is achieved by the significant darkening of the sapwood and slight darkening of the wood of the false heartwood. The degree of darkening of steamed beech wood is quantified by the decrease in the values on the lightness coordinate by ∆L* = −17.0 and the increase in the values on the red color coordinate by ∆a* = +3.3, the slight darkening of the steamed wood of the false heartwood quantifies the decrease in the value of the lightness coordinate by ∆L* = −2.6 and the increase in the value of the red color official by ∆a* = +0.8.

The low color difference value ∆E1* = 0.4 expressing the difference between the color of steamed sapwood and the color of steamed false heartwood proves the elimination of the color differences between the colors of the steamed sapwood and steamed false heartwood.

The values of the color dispersion of steamed sapwood ΔEhwsx* = 2.6 and steamed wood of false heartwood ΔEhwsx* = 3.0 do not exclude the slight color variation of the wood of steamed blanks made from the zone of sapwood or the zone of false heartwood.

The color of the boundary line darkens under the stated steaming conditions, highlighting the interfaces between steamed sapwood and steamed false heartwood.

- (c)

- Unification of the colors of the sapwood with the wood of the false heartwood by the process of steaming with saturated water steam with temperatures tIII ≈ 120 °C to a dark brown–gray color occurs after 9 h of steaming. The average values of the dark brown–gray color of steamed beech wood in the color space are L* = 55.9 ± 1.9, a* = 12.3 ± 1.2, b* = 19.6 ± 1.3. The unification of the colors by the steaming process is achieved both by a decrease in the values of the coordinate of the lightness of the sapwood by ∆L* = −22.5 and of the false heartwood by ∆L* = −15.2, as well as by an increase in the values of the coordinate of the red color of the sapwood by ∆a* = +3.1 and wood with false heartwood by ∆a* = +0.9.

The high degree of agreement between the color of steamed sapwood and the color of steamed wood of a false heartwood is characterized by the color difference value ∆Ei* = 0.3.

A certain color diversity of the color-homogenized beech wood blanks is attributed to the dispersion of the colors of steamed sapwood ΔEhwsx* = 2.4 and steamed false heartwood ΔEhwsx* = 2.8.

The homogenized color of steamed beech wood at a temperature of tIII ≈ 120 °C is significantly darker compared to the homogenized color of steamed beech wood at a steaming temperature of tII ≈ 105 °C.

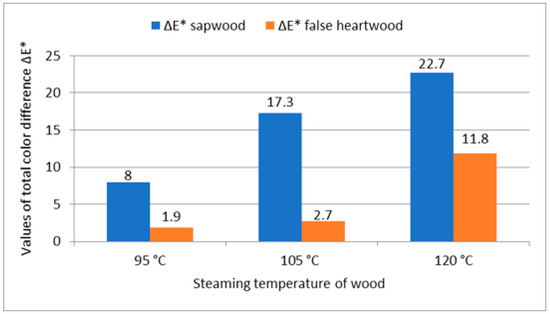

From the changes in the lightness coordinate L* and the coordinates of the red color a* and yellow color b* of the sapwood and wood of the false heartwood from the beginning of steaming to the time when color homogenization is achieved in Figure 3, Figure 4 and Figure 5, it seems that the sapwood and the false heartwood do not share equally in the unification of the colors of the sapwood and the false heartwood during the steaming process. This stated fact is clearly documented by the size of the changes in the color of the sapwood and the wood of the false heartwood, as expressed in the form of the total color difference ∆E* in Figure 6.

Figure 6.

Magnitudes of the changes in the color of sapwood wood and false heartwood wood by the steaming process after homogenization at individual temperatures.

The changes in the color of the false heartwood caused by the steaming process are at all the steaming temperatures significantly lower than the changes in the color of the steamed sapwood. The share of the color change of false heartwood wood by the steaming process at temperatures tI = 95 °C and tII = 105 °C is approximately six times lower and at the temperature tIII = 120 °C it is approximately two times lower than the color change achieved by the steaming process of beech sapwood.

4. Conclusions

The results of analyses of the influence of temperature within 24 h of the steaming process of beech sapwood and false heartwood show certain different changes in the color of the sapwood and false heartwood when the uniform color of beech wood is achieved by the steaming process.

By steaming beech wood with false heartwood saturated with moist air at a temperature of tI = 95 °C during τ = 24 h, the color of the sapwood does not unify with the color of the wood of the unsteamed false heartwood. The sapwood darkens and takes on a pale brown color. The heartwood lightens to a darker shade of pale brown than the sapwood. There is a significant color contrast between the color of the blanks from the white wood zone and the color of the blanks from the heartwood zone, which for unsteamed wood is ∆E1* = 14.8 and for steamed wood at the steaming temperature tI = 95 °C, is ∆E1* = 5.5.

The unification of the colors of the sapwood and the wood of the false heartwood in the process of steaming with saturated water steam with a temperature of tII ≈ 105 °C occurs at 18 h. The brown color created by the evaporation process is identified by the values of the lightness coordinate L* = 61.3 ± 2.2, the red color a* = 12.4 ± 1.3 and the yellow color b* = 19.5 ± 1.4. The mentioned uniform coloring of the steamed wood is achieved by the significant darkening of the sapwood and slight darkening of the wood of the false heartwood.

Sapwood and false heartwood steamed with saturated steam at a temperature of tIII ≈ 120 °C acquire a uniform dark brown–gray color in a time of τ ≈ 9 h steaming. The coordinates of the color homogenized steamed beech wood are L* = 55.9 ± 1.9, a* = 12.3 ± 1.2, b* = 19.6 ± 1.3. The unification of the colors through the steaming process is achieved by darkening the wood, both in the sapwood zone and in the false heartwood zone.

The unification of the colors by the steaming process is not evenly distributed in the individual modes between sapwood and heartwood. While the total color difference of sapwood to a color homogenized state is quantified by the value ∆E* = 8.0 at the steaming temperature of saturated moist air with a temperature of tI = 95 °C and at the steaming temperature of saturated water steam at the steaming temperature tIII = 120 °C by the value of ∆E* = 22.7, for wood with false heartwood at the steaming temperature tI = 95 °C, the total color difference is only ∆E* = 1.9, and at the steaming temperature tIII = 120 °C, ∆E* = 11.8.

Author Contributions

Conceptualization, L.D.; methodology, L.D., M.D.; software, M.D.; formal analysis, L.D., M.D.; resources, L.D., M.D.; data curation, L.D., M.D.; writing—original draft preparation, L.D.; writing—review and editing, L.D., M.D.; visualization, M.D.; project administration, L.D. All authors have read and agreed to the published version of the manuscript.

Funding

This experimental research was prepared within the grant project VEGA 1/0256/23 “Research on the sapwood and the false heartwood of Beech wood for the purpose of eliminating the differences in the color of the wood by steaming with saturated water steam”.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gorczynski, T. Comparative anatomical studies on common beech wood (Fagus sylvatica L.). Rocz. Demdr. Polsk. Tow. Bot. 1951, 7, 3–114. [Google Scholar]

- Nečesaný, V. Beech Heartwood, Structure, Origin and Development; Publishing House of the Slovak Academy of Sciences: Bratislava, Slovakia, 1959; 256p. [Google Scholar]

- Požgaj, A.; Chovanec, D.; Kurjatko, S.; Babiak, M. Structure and Properties of Wood; Príroda: Bratislava, Slovakia, 1997; 485p. [Google Scholar]

- Bauch, J.; Koch, G. Biologische und Chemische Untersuchungen über Holzverfarbungen der Rotbuche (Fagus sylvatica L.) und Möglichkeiten Vorbeugender Maßnahmen; Abschlussbericht; Bundesforschungsanstalt für Forst- und Holzwirtschaft, Universität Hamburg: Hamburg, Germany, 2001. [Google Scholar]

- Račko, V.; Čunderlik, I. Qualitative and quantitative evaluation of false heartwood in beech logs of various age and qualitative structure. Wood Res. 2006, 51, 1–10. [Google Scholar]

- Račko, V.; Čunderlík, I. Mature wood as a limiting factor in the formation of a false heartwood beech (Fagus sylvatica L.). Acta Fac. Xylologiae Zvolen 2010, 52, 15–24. [Google Scholar]

- Kúdela, J.; Čunderlík, I. Beech Wood Structure, Properties, Use; Technical University in Zvolen: Zvolen, Slovakia, 2012; 152p, ISBN 80-228-2318-0. [Google Scholar]

- Mahler, G.; Höwecke, B. Verkernungserscheinungen bei der Buche in Baden-Württemberg in Abhängigkeit von Alter, Standort und Durchmesser. Schweiz. Z. Forstwes. 1991, 142, 375–390. [Google Scholar]

- Trenčiansky, M.; Lieskovský, M.; Merganič, J.; Šulek, R. Analysis and evaluation of the impact of stand age on the occurrence and metamorphosis of red heartwood. iForest—Biogeosciences For. 2017, 10, 605–610. [Google Scholar] [CrossRef]

- Deliiski, N. The method extends the assessment of the degree of beech sawn timber during its drying process. In Current Problems and Perspectives of Beech Lumber Drying; ES-VŠLD: Zvolen, Slovakia, 1911; pp. 37–44. [Google Scholar]

- Trebula, P.; Klement, I. Drying and Hydrothermal Treatment of Wood; Technical University in Zvolen: Zvolen, Slovakia, 2005; 449p. [Google Scholar]

- Tolvaj, L.; Molnar, S. Colour homogenisation of hardwood species by steaming. Acta Silv. Lign. Hung. 2006, 2, 39–47. [Google Scholar] [CrossRef]

- Gonzalez-Pena, M.M.; Hale, M.D.C. Colour in thermally modified wood of beech, Norway spruce and Scots pine. Part 1: Colour evolution and colour changes. Holzforschung 2009, 63, 385–393. [Google Scholar] [CrossRef]

- Esteves, M.B.; Pereira, H.M. Wood Modification by heat treatment: A Review. BioResources 2009, 4, 370–404. [Google Scholar] [CrossRef]

- Tolvaj, L.; Nemeth, R.; Varga, D.; Molnar, S. Colour homogenisation of beech wood by steam treatment. Drewno 2009, 52, 5–17. [Google Scholar]

- Todorović, N.; Popović, Z.; Milić, G.; Popadić, R. Estimation of heat treated beechwood properties by color change. BioResources 2012, 7, 798–815. [Google Scholar]

- Dzurenda, L. Colouring of Beech Wood during Thermal Treatment using Saturated Water Steam. Acta Fac. Xylologiae Zvolen 2014, 56, 13–22. [Google Scholar]

- Milić, G.; Todorović, N.; Popadić, R. Influence of steaming on drying quality and colour of beech timber. Glas. Šumar. Fak. 2015, 112, 83–96. [Google Scholar] [CrossRef]

- Hadjiski, M.; Deliiski, N. Advanced Control of the Wood Thermal Treatment Processing. Cybern. Inf. Technol. Bulg. Acad. Sci. 2016, 16, 176–197. [Google Scholar] [CrossRef][Green Version]

- Geffert, A.; Vybohová, E.; Geffertová, J. Characterization of the changes of colour and some wood components on the surface of steamed beech wood. Acta Fac. Xylologiae Zvolen 2017, 59, 49–57. [Google Scholar]

- Dzurenda, L.; Dudiak, M. Cross-correlation of color and acidity of wet beech wood in the process of thermal treatment with saturated steam. Wood Res. 2021, 66, 105–116. [Google Scholar] [CrossRef]

- Čunderlík, I. Structure of Wood; Technical University in Zvolen: Zvolen, Slovakia, 2009; 135p. [Google Scholar]

- Drápela, J.; Humpolec, J.; Kamenický, J.; Konečný, L.; Pavlica, J.; Ráček, V.; Zapletal, J. Furniture Production—Technology; SNTL: Prague, Czech Republic, 1980; 485p. [Google Scholar]

- Makovíny, I. Useful Properties and Use of Different Types of Wood; Technical University in Zvolen: Zvolen, Slovakia, 2010; 104p. [Google Scholar]

- Meints, T.; Teischinger, A.; Stingl, R.; Hassmann, C. Wood colour of central European wood species: CIELAB characterisation and colour intensification. Eur. J. Wood Prod. 2017, 75, 499–509. [Google Scholar] [CrossRef]

- Molnár, S.; Németh, R.; Fehér, S.; Tolvaj, L.; Papp, G.; Varga, F. Technical and technological properties of Hungarian beech wood consider the red heart. Wood Res. 2001, 46, 21–30. [Google Scholar]

- Dzurenda, L.; Dudiak, M. Color diversity of beech wood with a false heartwood in the color space CIE L*a*b*. Wood Res. 2023, 68, 792–801. [Google Scholar] [CrossRef]

- Dzurenda, L.; Dudiak, M.; Kučerová, V. Differences in Some Physical and Chemical Properties of Beechwood with False Heartwood, Mature Wood and Sapwood. Forests 2023, 14, 1123. [Google Scholar] [CrossRef]

- Dzurenda, L. Natural Variability of the Color of Beech Wood in the Color Space CIE L*a*b*. Forests 2023, 14, 1103. [Google Scholar] [CrossRef]

- Dzurenda, L. Mode for hot air drying of steamed beech blanks while keeping the colors ac-quired in the steaming process. Acta Fac. Xylologiae Zvolen 2022, 64, 81–88. [Google Scholar]

- Bekhta, P.; Niemz, P. Effect of high temperature on color change, dimensional stability and mechanical properties of spruce wood. Holzforschung 2003, 57, 539–546. [Google Scholar] [CrossRef]

- Laskowska, A. The influence of ultraviolet radiation on the colour of thermo-mechanically modified beech and oak wood. Maderas Cienc. Tecnol. 2020, 22, 55–68. [Google Scholar] [CrossRef]

- Albert, L.; Hofmann, T.; Németh, Z.S.; Rétfalvi, T.; Koloszár, J.; Varga, S.Z.; Csepregi, I. Radial variation of total phenol content in beech (Fagus sylvatica L.) wood with and without red heartwood. Holz als Roh- und Werkst. 2003, 3, 227–230. [Google Scholar] [CrossRef]

- Hofmann, T.; Albert, L.; Rétfalvi, T.; Bányai, É.; Visiné Rajczi, E.; Börcsök, E.; Németh, Z.S. Quantitative TLC Analysis of (+)-Catechin and (-)-Epicatecin from Fagus sylvatica L. with and without Red Heartwood. J. Planar Chromatogr. 2004, 17, 350–354. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).