Abstract

Bamboo is already a convenient construction resource, as it offers an efficient structural performance. As this plant has native varieties adapted to different climates and soils of Brazil, bamboo silviculture can be intensified to supply the national industry. Three bamboo species from Brazil (Dendrocalamus asper, Bambusa tuldoides, and Phyllostachys aurea) were analyzed for the flexural load capacity applied on the internal and external surfaces. Specimens were prepared without knots and with knots centered at the middle of each sample. In total, 240 samples were tested in terms of static bending and dynamic bending (impact). The results showed a higher flexural elasticity and a higher proportional limit strength of knotted P. aurea. The presence of knots provided higher values of ultimate strength in P. aurea, even reducing the bamboo flexibility. Also, P. aurea exhibited the best characteristic of flexural dynamic energy absorption among the three bamboo species under evaluation.

1. Introduction

Woody products are already being developed and highly industrialized to replace unsustainable solutions, since bioresources such as wood and bamboo have presented versatile uses oriented to boost the bioeconomic development of modern nations [1]. A greater need for the utilization of renewable materials to mitigate and reverse the intense exploitation of natural resources justifies the use of bioalternative solutions. In this context, bamboo has a visible potential to be utilized by industry, since it is a highly renewable bioresource marked by its rapid growth, global recurrence, and low cost [2].

Bamboo has a variety of uses, from medical applications to feeding activities and as material in large buildings and aeronautical technology, which evince its effective potential to replace both wood and other materials. Like wood, bamboo is the material of the future, because it is used in different products for construction, it becomes a good alternative to mitigate the impacts caused by industrialization, and it reduces the pressure on the ecosystems caused by the intense exploitation of natural resources [3,4,5].

Bamboo becomes a strong resource capable of generating work and income and, therefore, developing rural communities [6]. An important feature of bamboo is related to its excellent mechanical properties, as this biomaterial combines high values of tensile strength and good flexibility [7]. In structural performance, bamboo exceeds wood, steel, and concrete in different situations [8]. Its high tensile strength is supported by its high fiber content [9]. Bamboos are utilized in innovative processes to design and build modern structures and buildings since this bioresource offers high levels of sustainable performance and structural behavior [10].

In-depth research on bamboo materials has prioritized the use of laminas, slats, and strips. They are utilized in the manufacture of scrimber beams [11], glued-laminated panels [12,13,14], oriented-strand boards [15], walls and floors [16,17,18], ceilings and roofs [19], the reinforcement of concrete elements [20], the reinforcement of juvenile and low-density woods [21], particleboards from residues [22], and other engineered solutions [23,24]. In addition to the multiple examples mentioned above, bamboo slats may be glued to assemble curved elements for lightweight architectural works, one of the reasons why bamboo products are serviceable for construction. Despite its multiple uses and convenient features, bamboo is still contrastingly categorized as a lesser-known or lesser-used species [15]. There is a demand to evaluate culms from different perspectives, as mentioned by Elejoste et al. [25]. However, there is a lack of studies to support the use of laminas and slats, especially for the Brazilian bamboo species.

To contribute to the literature focused on the greater valorization of bamboo uses in massive forms, this study analyzed the static and dynamic bending properties of three bamboo species of the main genera naturally originating in Brazil: Bambusa tuldoides Munro, Dendrocalamus asper (Schult.) Backer, and Phyllostachys aurea Rivière & C. Rivière. Load capacity was applied to the external and internal culm surfaces (external surface and inner skin), and the influence of the knot presence in flexural strength was evaluated to measure its capacity and identify the behavior in these species native to Brazil.

2. Materials and Methods

2.1. Material and Sample Preparation

The three mentioned species of bamboo growing in the rural region of Uberaba City, Brazil, were used. Native to Brazil, these species were selected due to local availability and construction applicability in structural parts for housing, as confirmed by Souza [26].

Aiming to reduce the possibility of insect attacks, only those bamboo plants after the sprouting phase were selected due to lower vegetative activities. Hand tools and saws were utilized in the manual harvesting process. As the experiment only used culms collected directly from natural forests, it was not possible to identify the plantation age. It should be noted that all culms exceeded three years of age, as some conditions of a mature plant were visually and physiologically considered such as the absence of sprouts and protective sheaths in knots, colorations, and lichen stains, and the greater presence of developed branches. Two culms per species were cut 30 cm from the ground, with average heights exceeding 25 m. Initially, they were conditioned for ten days in a confined room with controlled temperature and moisture (24 °C and 40%).

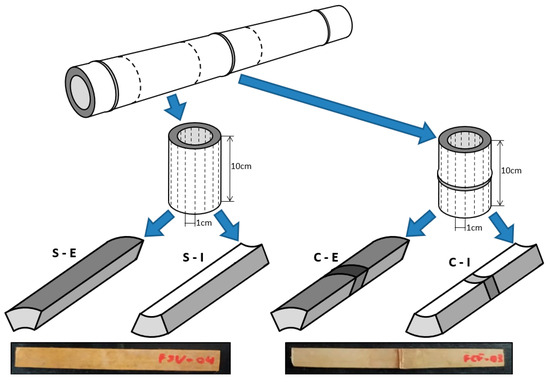

Three bamboo species were evaluated in terms of the flexural performance of “woody” slat-shaped elements, with and without knots. From culms, all specimens were processed according to ASTM D143 [27], which is a standard document that prescribes the standard test methods for small-sized wood. Material preparations and tests were performed at the Mechanical Testing Laboratory of the Federal University of Triângulo Mineiro, Brazil. For both properties under evaluation for flexural strength, the dimensions of each specimen were 10 cm × 1 cm × T, with “T” considered the natural thickness of the culm walls. Due to the diversified applications of bamboo, specimens can be used in different positions, and therefore they were tested in four types (Figure 1).

Figure 1.

Schematic description of specimens processed from culms: S-E: without knot and load applied to the outer external surface; S-I: without knot and load applied to the inner skin; C-E: with knot and load applied to the outer surface; C-I: with knot and load applied to the inner skin.

In total, 240 specimens were processed from bamboo culms, as demonstrated in Figure 1. This total number of specimens was determined as the sum of 80 individual slats produced with each bamboo species under evaluation. As a strategy to evaluate the flexural properties of each species, 40 specimens were allocated to the three-point bending test (static), and the remaining 40 were evaluated in the impact test (dynamic).

These 40 specimens were equally divided into knotted and knotless samples, of which 10 samples were tested with the load applied to external surfaces, and the other 30 individuals were evaluated considering the internal surfaces (inner skin).

Table 1 specifies the division of the experimental groups in use for bamboo species (Bambusa tuldoides, Dendrocalamus asper, and Phyllostachys aurea) according to features such as the presence of internodes, surface evaluation, and the type of mechanical property. Before testing evaluation, all machined specimens of the three species were conditioned and dried at 60 °C for 72 h for sample stabilization according to ASTM D143 [27].

Table 1.

Experimental groups per bamboo species.

2.2. Three-Point Bending Test

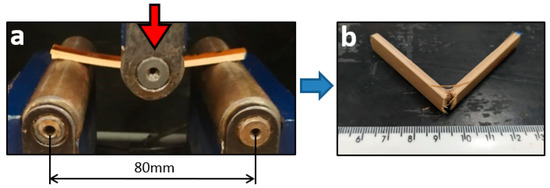

The static bending test consisted of a vertical load applied to the specimen, which was supported on two cylinders 80 mm apart (Figure 2a). With a 2 mm/min load application speed, the tests were carried out until the rupture of the samples (Figure 2b).

Figure 2.

Specimens: (a) centralized load on cylinders and (b) ruptured in static bending test.

From the three-point bending tests, the values of load (P, in Newton) and deflection (f, in millimeters) were obtained. According to Souza [28], it is possible to determine the flexural strength using Equation (1).

where σf is the flexural strength (megapascal), M is the bending moment (Newton·millimeter), c is the distance from the neutral line to the point of load application (millimeter), and I is the moment of inertia (double square millimeter).

For three-point loading, the bending moment was calculated using Equation (2).

where M is the bending moment (Newton·millimeter), F is the applied load (Newton), and L is the distance between supports (millimeter).

Using flexural strength values, stress–deflection diagrams were verified in the studied conditions for each specimen. The modulus of elasticity, limit of proportionality, and ultimate strength properties were obtained. The modulus of elasticity (E) is a mechanical measure of the material stiffness (intrinsic). Elastic deformation resulting from the load application will be lower when this modulus has a higher value, and consequently, the material will be stiffer [28]. For three-point bending, it was obtained using Equation (3).

where E is the modulus of elasticity (megapascal), P is the load (Newton), L is the distance between supports (millimeter), f is the deflection (millimeter), and I is the moment of inertia (double square millimeter).

The modulus of elasticity in a bending test was obtained for a single stress, which was determined at all points of the elastic phase. The final value was obtained from the average of all values found for each condition. The proportional limit, or elastic limit, is the imaginary point that divides the elastic region from the plastic region. This limit is the greatest stress the material can bear without any permanent deformation when the load is discharged. The maximum limit, or ultimate strength, is the point with the maximum stress that the material can bear throughout the test. This point is found in the plastic phase of the material, and its value, together with the deflection at this point, represents the plasticity of the material before rupture, indicating the maximum load that the material can resist.

2.3. Geometric Properties of Specimens

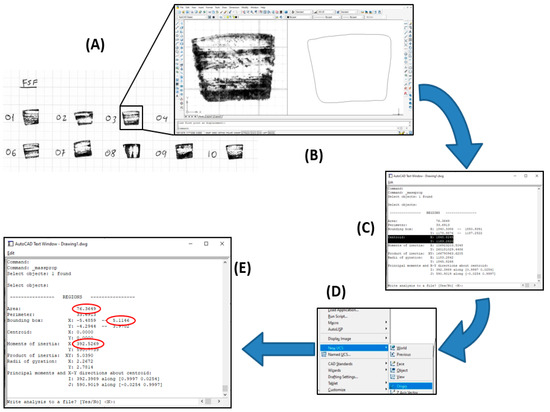

Data from the mechanical tests were represented by force (Newton), and therefore, it was necessary to obtain the geometric properties (moment of inertia, cross-sectional area, and distance from the neutral line) to calculate the stresses (megapascal) of each sample. Yet, Shimano [29] was used as a reference for this procedure.

Specimens were not sanded, nor was their cross-section standardized, as this analysis prioritized the fully integrated structure. Therefore, there were variations in some properties (the moment of inertia and the distance from the neutral line).

These geometric properties were determined from a stamping process of the cross-section of each specimen (240 samples) using graph paper (Figure 3A). The stamped images were digitized in TIFF format and sequentially loaded with AutoCAD® software (version 2022, Autodesk, Mill Valley, CA, USA) using the Raster Image command at 1:1 scale (Figure 3B). Still using AutoCAD®, the images were outlined using the Spline command, and then a region was created for each section with the Region command (Figure 3C). The center of the coordinate system was transferred in this program to the centroid of the section to determine the geometric properties (Figure 3D). Lastly, the final properties were obtained using the Mass Properties command (Figure 3E).

Figure 3.

Illustrative script to obtain geometric properties in the cross-section of each bamboo specimen with AutoCAD® software: (A) stamps marked on paper, (B) stamp digitization using the “Raster Image” command, (C) centroid identification using the “Region” command, (D) centroid transference using the “Origin” option in the “New UCS” command, and (E) the final properties displayed.

2.4. Impact Bending Test

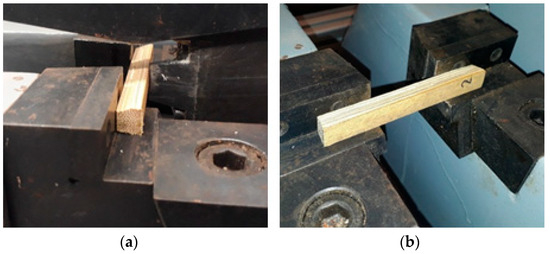

The dynamic bending test was used to evaluate the fracture behavior of the materials, and their impact tests were carried out according to ASTM D-2017 [30].

For the dynamic bending test, the impact test was carried out according to the technical prescriptions given in the abovementioned standard document [30]. This test is performed to determine the ability of any material to absorb energy before fracture when subjected to sudden stresses. Therefore, the results of this test can guide professionals as they can assist in the adequate selection of materials in order to ensure the safety and performance of structural parts and components for many uses.

In this work, this test was performed on a Charpy impact machine, EQIM-300 (EQUILAM®, Diadema, Brazil) at the same cited university. This machine had a pendulum of 150 Joules to evaluate bamboo samples (Figure 4a), as the distance between the supports was 80 mm (Figure 4b).

Figure 4.

Charpy impact machine: (a) intact specimen and (b) pendulum position.

The impact energy was measured with this machine since its mechanical property represents how much energy the tested material can absorb when it suffers a very fast impact (impact energy). The material is more tenacious when more energy is absorbed. The cross-sectional area of the specimens was also determined using the same method previously presented for the three-point bending test (Figure 3). Dividing the impact energy by the area, the impact resistance property was obtained (in Joules per area).

2.5. Data Analysis Procedure

The analysis of variance (ANOVA) was used to verify the real influence of isolated factors (species, presence of knots, and load position), as well as their interactions, on the values of mechanical properties under investigation in this study. The Anderson–Darling (AD) normality test and the multiple comparison (MC) test were applied to validate the ANOVA’s results.

Through the formulation of these tests, both at a 5% significance level, a p-value equal to or greater than 0.05 implies the normality and homogeneity of residue, which validates the results from the analysis of variance.

Additionally, Tukey’s test of contrast of means was used, also at a 5% significance level, to evaluate the hierarchy of significance of isolated factors. In the Tukey test, A denotes the group associated with the highest average value of a given property, B is the second highest average value, and so on. Equal letters imply distinct treatments and means that are statistically equivalent to each other.

Twelve different experimental conditions were studied in static bending and impact tests, based on a combination of factors, namely species (B. tuldoides, D. aspen, and P. aurea), the presence of knots (knot and knotless), and the position of the external surface in relation to the loading (external (external surface) and internal (skin)).

Ten samples were considered per property and for each of the experimental treatments outlined, which resulted in the production of 240 samples, with 120 samples used in the static bending tests and 120 used in the impact tests.

3. Results and Discussion

Descriptive statistics with the average property values and standard deviations and the results of Tukey’s test of contrast of means are presented in Table 2 and Table 3, respectively. In Table 3, the p-values of the Anderson–Darling test [0.115; 0.653] and the multiple comparison test [0.086; 0.821] regarding the homogeneity of the ANOVA residues were both higher than the level of significance adopted (5% significance), validating the use of ANOVA and Tukey’s tests. For the three levels studied in the static bending test, Phyllostachys aurea bamboo species showed the highest value, and the values of these properties were equivalent for the two other species, that is, Bambusa tuldoides and Dendrocalamus aspen.

Table 2.

Mechanical properties (average values ± standard deviations) of the three bamboos tested using the three-point bending test.

Table 3.

Results of Tukey’s test of contrast of means at 5% significance in the static bending test.

Also, the presence of knots was responsible for the increase in the values of the three properties—a fact that is justified by the increase (in the proximity of the knot) in the moment of inertia of the transversal section.

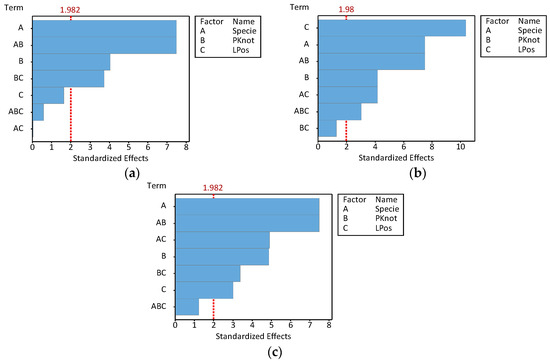

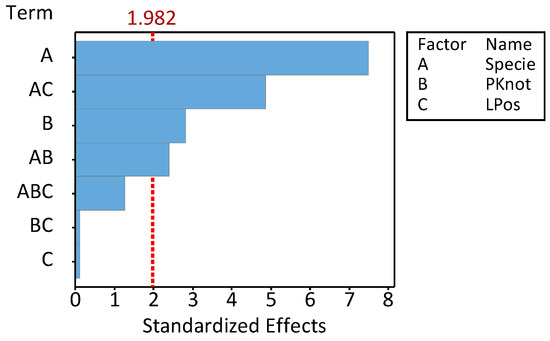

The external surface positioned in the tension region of the flexion test (internal surface—skin) resulted in the highest values of these three properties. In addition, Pareto’s graphs are presented for the static bending properties (Figure 5). These graphs allow for the visual identification of significance and the order of significance of the isolated factors and the effects of their interaction (×).

Figure 5.

Effects of the interaction on property values in static bending: (a) modulus of elasticity—E, (b) proportional limit stress—PLStress, and (c) ultimate stress—UStress.

For the modulus of elasticity (E), the significance of the interaction of Species × PKnot and PKnot × LPos was verified. Still, the significance of the interaction involving all three factors (Species × PKnot × LPos) was verified in the proportional limit stress. For ultimate stress (UStress), a significant interaction was observed between three conditions (Species × PKnot, Species × LPos, and PKnot × LPos). According to Christoforo et al. [31], even in cases where interactions are less significant than the effects of isolated factors, the discussion on the response variable should be based on interaction effects.

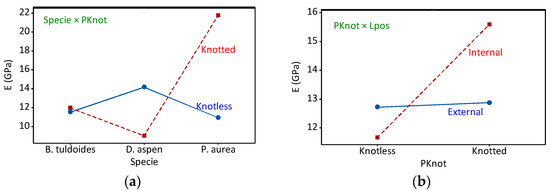

The graph images showing the interaction among the significant effects using ANOVA are presented for E, PLStress, and UStress (Figure 6, Figure 7 and Figure 8), respectively. For the modulus of elasticity, the combination of Phyllostachys aurea bamboo species with the presence of knots (Species × PKnot) resulted in the highest value of this property (Figure 6a). From the PKnot × LPos interaction (Figure 6b), bamboo samples composed of knots with the external surface under tensile—that is, internally positioned—resulted in the highest value of this property. The highest value of the modulus of elasticity was obtained with the combination of P. aurea species, the presence of knots, and the position of the external surface in the traction region (internal surface—skin).

Figure 6.

Graphs of interaction among the significant effects using ANOVA for modulus of elasticity (E) considering (a) species × PKnot and (b) PKnot × LPos.

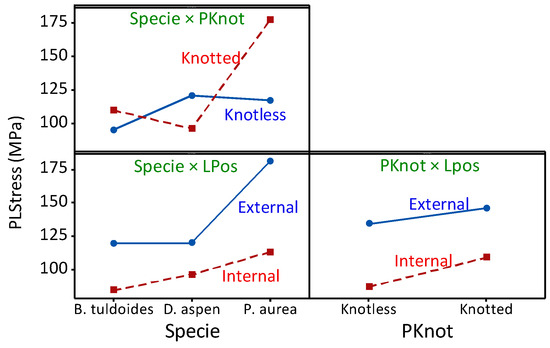

Figure 7.

Graphs of interaction among the significant effects using ANOVA for the proportional limit stress (PLStress) considering species × PKnot, species × LPos, and PKnot × LPos.

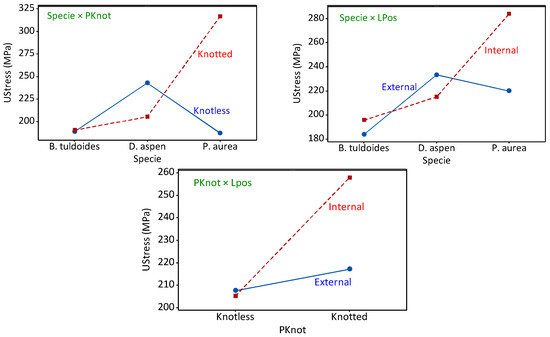

Figure 8.

Graphs of interaction among the significant effects with ANOVA for ultimate stress (UStress) considering Species × PKnot, Species × LPos, and PKnot × LPos.

For the proportional limit stress (Figure 7), P. aurea species, together with the presence of knots and the external surface fibers positioned in the compressed region, resulted in the best combination. As the hardness of bamboo’s external surface is notably higher than the hardness of its skin (internal part), and the compression stiffness is lower than the stress stiffness, the external surface position in the compressed region in the static bending test resulted in a significant increase in this property, as the inertia moment associated with knots also led to an increase in PLStress.

For the ultimate stress (UStress), Figure 8 illustrates that, as in the case with the modulus of elasticity, the combination of the species of P. aurea, the presence of knots, and the position of the external surface in the stress region resulted in the best performance. Descriptive statistics (average and standard deviation values) are shown in Table 4, and the results of Tukey’s test of contrast of means showing the values of impact energy by transversal section area (En/CSArea) are also presented. Still, it is worth highlighting the validation of ANOVA and the Tukey test results as the p-values from the Anderson–Darling test [0.098; 0.722] and the multiple comparison test [0.163; 0.447] were more than the significance level adopted (5%).

Table 4.

Average values ± standard deviations of energy impact per cross-section area for the three bamboo species.

As shown in Table 5, Dendrocalamus aspen exhibited the highest average value on the impact of energy by transversal section area, which differed from the results obtained for the properties determined in the static bending test, as in that test, the P. aurea species exhibited the best performance.

Table 5.

Results of Tukey’s test of contrast of means at 5% significance in the impact test.

Thus, the presence of knots was responsible for a reduction in the value of En/CSArea, whereas the external surface position was not significant. As the other factors were significant, it is possible that their interactions with the load position resulted in a significant influence on En/CSArea.

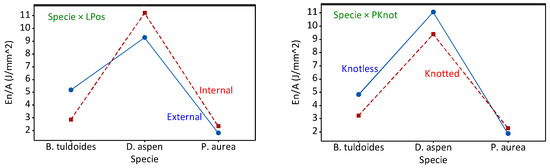

The results of the effects of interaction among factors on the values of the impact energy by the transversal section area are presented in Figure 9. For En/CSArea, the significant interaction effects were Species × LPos and Species × PKnot. These interactions are also illustrated (Figure 10).

Figure 9.

Effects of interaction among factors on the values of impact energy by transversal section area (En/CSArea).

Figure 10.

Graphs of interaction among the significant effects using ANOVA for the impact energy by transversal section area (En/CSArea) considering Species × LPos and Species × PKnot.

Considering the Species × LPos and Species × PKnot interactions, the bamboo samples of D. aspen species with the external surface positioned in the stress region (internal surface—skin) in the impact test and without the presence of knots resulted in the highest values for En/CSArea. Unlike static bending (slow loading; few inertia forces), in the impact test, the presence of knots, a region known for the concentration of tensions, significantly influenced the reduction in the samples’ ability to absorb energy.

In the static bending and impact tests, the cross-sectional areas of the samples in the different treatments naturally showed differences. The significance of the differences in the transversal area values for the species evaluated is presented in Table 6.

Table 6.

Results of Tukey’s test of contrast of means (5% significance) in the transversal section areas (CSArea) of the samples in static bending and impact tests.

As shown in Table 6, the results of ANOVA and Tukey’s test were verified as the p-values from the Anderson–Darling test [0.079; 0.522] and the multiple comparison test [0.127; 0.634] were both more than the significance level used (5%). In the static bending test, the bamboo species with the best performance was P. aurea. Considering the impact energy by the transversal section area, D. aspen bamboo showed a better performance. The material strength and modulus of elasticity do not change with an increase or reduction in the volume of a part, as they are intrinsic characteristics of the material; however, increases in its cross-section affect the increase in the value of the load causing failure and the energy required for the failure and fracture of the structural element. This expected behavior can be verified by the difference in the cross-sectional areas of the samples studied in static bending and impact tests (Table 6). The highest value of the modulus of elasticity was obtained with P. aurea, a species associated with the lowest average value of the cross-sectional area, which can confirm the independence of the mechanical properties in relation to the dimensions of the bamboo samples. The largest samples were associated with the D. aspen species, which notably showed the highest values of impact energy by transversal section area. This condition implies that if samples had statistically equivalent cross-sectional areas among the species, the species with the best performance in impact energy would be P. aurea.

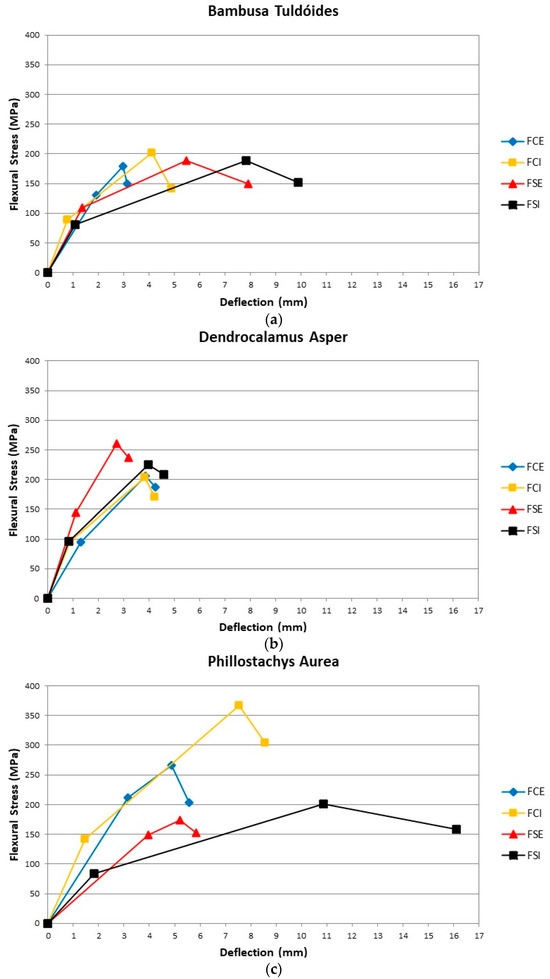

About the behaviors of bamboo species (Figure 11), it was possible to verify that P. aurea with the load applied to the inner skin (F-C-I and F-S-I) was more flexible than all groups, as it deformed much more before breaking. In this species, the load applied to the external surface (F-C-E and F-S-E) provided a higher proportional limit but with lower total flexibility. The presence of knots yielded higher values of ultimate strength (Table 3). D. asper provided more homogeneous results and it showed the least flexibility compared to the other two bamboo species (Figure 11). The presence of knots reduced the flexibility of B. tuldoides bamboo, but it presented a homogeneous proportional limit and ultimate strength. To plot the diagrams in Figure 11, strength values were recorded for every millimeter of displacement. Based on these discrete readings, straight-line functions were used in order to interpolate two associated quantities: flexural stress and deflection. The linear relationship between these quantities was thus established.

Figure 11.

Flexural stress–deflection diagrams for (a) B. tuldoides, (b) D. asper, and (c) P. aurea, in which groups are given by the following parameters: flexion (F), knotted (C), knotless (S), external surface (E), and internal surface (I).

The results of our observations serve as guidance for the determination of the most appropriate structural uses of bamboo based on the better positioning of pieces in terms of the orientation of their external surfaces in regions of greater mechanical stresses and reinforcements by glued laminae in engineered beams and floors. It should be noted that the external surface with bark offers a singular finish.

4. Conclusions

From the multiple observations of the average results of mechanical properties and the different statistical results analyzed, this study can conclude as follows:

- Phyllostachys aurea presented the best performance among other bamboo species in the static bending test.

- The presence of knots promoted an increase in the three properties evaluated in the static bending test.

- In stress, the external surface positioned (internal surface—skin) in the tensile region caused a visible significant increase in the three properties evaluated;

- The combination of P. aurea species with the presence of knots and the external surface positioned in the tensile region resulted in the best bending performance among the twelve configurations tested.

- Considering the relationship between tension and deformation in the bending test among the three species, P. aurea was more flexible (i.e., it had greater ductility). Ductility is a highly desirable behavior for materials for structural projects, as a structure built with fragile material can collapse without visible indications.

- In the impact test, P. aurea with the external surface in the tensile region and without the presence of knots was the best configuration in relation to the other eleven conditions.

- Considering bamboo orientation by the positioning of its external surface can offer better structural performance than the use of laminae in its inner surface.

- More species may be considered in future studies, together with the verification of the tested effects, as well as the influence on other different mechanical properties.

Author Contributions

Conceptualization and methodology, H.R.S. and M.M.S.; validation and formal analysis, H.R.S., A.C.B.M.A., M.M.S., J.C.-B. and A.L.C.; writing—original draft preparation, H.R.S., M.M.S., V.A.D.A., J.C.-B. and A.L.C.; writing—review and editing, all authors; visualization, all authors; supervision, M.M.S. and J.C.-B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- De Araujo, V.; Vasconcelos, J.; Lahr, F.; Christoforo, A. Timber forest products: A way to intensify global bioeconomy from bio-materials. Acta Fac. Xylologiae 2022, 64, 99–111. [Google Scholar] [CrossRef]

- Matsuoka, J.H. Avaliação da Eficiência do Ácido Pirolenhoso no Tratamento Preservativo de Taliscas de Bambu Gigante Contra a Deterioração por Fungos [Evaluation of Pyroligneous Acid Efficiency on Preservative Treatment of Giant Bamboo Strips Against Fungi]. Master’s Thesis, Agricultural Engineering Postgraduation Program, University of Campinas, Campinas, Brazil, 2011; pp. 1–164. [Google Scholar]

- Hidalgo-Lopez, O. Bamboo: The Gift of the Gods; Oscar Hidalgo-Lopez: Colombia, 2003; pp. 1–533. [Google Scholar]

- Cedeño Valdiviezo, A.; Irigoyen Castillo, J. El bambú en México [The bamboo in Mexico]. Arq.urb 2011, 6, 223–243. [Google Scholar]

- De Araujo, V.A.; Colauto, L.R.; Abel, L.G.C.; Rosário, F.S.; Vasconcelos, J.S.; Morales, E.A.M.; Cortez-Barbosa, J.; Gava, M.; Christoforo, A.L. Bamboo construction: Main building techniques and their resources, sustainability, history, uses, and classification. In Bamboo and Sustainable Construction, 1st ed.; Palombini, F.L., Nogueira, F.M., Eds.; Springer-Nature: Singapore, 2023; pp. 25–60. [Google Scholar]

- Clark, L.G.; Lodoño, X.; Ruiz-Sanchez, E. Bamboo taxonomy and habitat. In Bamboo: The Plant and Its Uses (Tropical Forestry 10), 1st ed.; Liese, W., Köhl, M., Eds.; Springer International: Cham, Switzerland, 2015; pp. 1–30. [Google Scholar]

- Barros, B.R. Bambu: Alternativa construtiva de baixo impacto ambiental [Bamboo: A low environmental impact construction alternative]. In I Anais da Conferência Latino-Americana de Construção Sustentável; ENTAC: São Paulo, Brazil, 2004. [Google Scholar]

- Ghavami, K.; Marinho, A.B. Determinação das Propriedades dos Bambus das Espécies: Mossô, Matake, Guadua Angustifolia, Guadua Tagoara e Dendrocalamus Giganteus para Utilização na Engenharia [Determination of Bamboo Species Properties: Mossô, Matake, Guadua Angustifolia, Guadua Tagoara, and Dendrocalamus Giganteus for the Utilization in Engineering]; RMNC Bambu 01/2001; Civil Engineering Department, Pontifical Catholic University of Rio de Janeiro: Rio de Janeiro, Brazil, 2001. [Google Scholar]

- Liese, W. The Anatomy of Bamboo Culms; International Network for Bamboo and Rattan: Beijing, China, 1998. [Google Scholar]

- Mimendi, L.; Lorenzo, R.; Li, H. An innovative digital workflow to design, build and manage bamboo structures. Sustain. Struct. 2022, 2, 1–17. [Google Scholar] [CrossRef]

- Huang, X.; Xie, J.; Qi, J.; De Hoop, C.; Xiao, H.; Chen, Y.; Li, F. Differences in physical-mechanical properties of bamboo scrimbers with response to bamboo maturing process. Eur. J. Wood Wood Prod. 2018, 76, 1137–1143. [Google Scholar] [CrossRef]

- Rivero, L.A.; Beraldo, A.L. Bambu Laminado Colado (BLC) [Glued laminated bamboo (GLB)]. Floresta e Ambiente 2003, 10, 36–46. Available online: www.floram.org/article/588e2205e710ab87018b45fc/pdf/floram-10-2-36.pdf (accessed on 2 March 2024).

- Munis, R.A.; Camargo, D.A.; De Almeida, A.C.; De Araujo, V.A.; Lima Junior, M.P.; Morales, E.A.M.; Simões, D.; Biazzon, J.C.; Matos, C.A.O.; Cortez-Barbosa, J. Parallel compression to grain and stiffness of cross laminated timber panels with bamboo reinforcement. BioResources 2018, 13, 3809–3816. [Google Scholar] [CrossRef]

- Barreto, M.I.M.; De Araujo, V.A.; Cortez-Barbosa, J.; Christoforo, A.L.; Moura, J.D.M. Structural performance analysis of cross-laminated timber-bamboo (CLTB). BioResources 2019, 14, 5045–5058. [Google Scholar] [CrossRef]

- Fatrawana, A.; Maulana, S.; Nawawi, D.S.; Sari, R.K.; Hidayat, W.; Park, S.W.; Febrianto, F.; Hwan Lee, S.; Kim, N.H. Changes in chemical components of steam-treated betung bamboo strands and their effects on the physical and mechanical properties of bamboo-oriented strand boards. Eur. J. Wood Wood Prod. 2019, 77, 731–739. [Google Scholar] [CrossRef]

- Berndsen, R.S. Caracterização Anatômica, Física e Mecânica de Lâminas de Bambu (Phyllostachys pubescens) [Anatomical, Physical, and Mechanical Characterization of Bamboo Laminae]. Master’s Thesis, Mechanical Engineering Postgraduation Program, Federal Technological University of Paraná, Curitiba, Brazil, 2008; pp. 1–113. [Google Scholar]

- Paes, J.B.; Oliveira, A.K.F.; Leal, A.F.; Nascimento, J.W.B. Caracterização e aspecto de um piso confeccionado com bambu (Dendrocalamus giganteus Munro) [Characterization and appearance of a floor constructed with bamboo (Dendrocalamus giganteus Munro)]. Ciência da Madeira 2010, 1, 52–67. [Google Scholar] [CrossRef]

- Cortez-Barbosa, J.; Silva, J.R.M.; Alvarenga, F.; Souza, A.J.D.; De Araujo, V.A.; Garcia, J.N. Simulation analysis of in-service bamboo and pine EGP composite flooring. Adv. Mat. Res. 2014, 1025–1026, 233–240. [Google Scholar] [CrossRef]

- Padovan, R.B. O Bambu na Arquitetura: Design de Conexões Estruturais [Bamboo in Architecture: Design of Structural Connections]. Master’s Thesis, Faculty of Architecture, Arts and Communication, São Paulo State University, Bauru, Brazil, 2010; pp. 1–181. [Google Scholar]

- Ghavami, K.; Marinho, A.B. Propriedades geométricas e mecânicas de colmos dos bambus para aplicação em construções [Geometrical and mechanical properties of bamboo culms for construction application]. Eng. Agrícola 2003, 23, 415–424. [Google Scholar]

- Muzel, S.D.; Gava, M.; Cortez-Barbosa, J.; Oliveira, K.A.; Morales, E.A.M.; De Araujo, V.A. MDP Panels manufactured with Hevea brasiliensis overlaid with bamboo foil of Phyllostachys edulis. Adv. Mat. Res. 2015, 1088, 686–689. [Google Scholar] [CrossRef]

- Zaia, U.J.; Cortez-Barbosa, J.; Morales, E.A.M.; Lahr, F.A.R.; Nascimento, M.F.; De Araujo, V.A. Production of particleboards with bamboo (Dendrocalamus asper) reinforcement. BioResources 2015, 10, 1424–1433. [Google Scholar] [CrossRef]

- De Almeida, A.C.; De Araujo, V.A.; Morales, E.A.M.; Gava, M.; Munis, R.A.; Garcia, J.N.; Cortez-Barbosa, J. Wood-bamboo particleboard: Mechanical properties. BioResources 2017, 12, 7784–7792. [Google Scholar] [CrossRef]

- Gauss, C.; De Araujo, V.; Gava, M.; Cortez-Barbosa, J.; Savastano, H., Jr. Bamboo particleboards: Recent developments. Pesqui. Agropecu. Trop. 2019, 49, e55081. [Google Scholar] [CrossRef]

- Elejoste, A.; Osa, J.L.; Arevalillo-Roman, A.; Eceiza, A.; Abascal, J.M.; Rico-Martinez, J.M.; Butron, A.; Peña-Rodriguez, C. Mechanical properties of three bamboo species: Effect of external climatic conditions and fungal infestation in laboratory conditions. Forests 2022, 13, 2084. [Google Scholar] [CrossRef]

- Souza, A.P.C.C. Bambu na habitação de interesse social no Brasil [Bamboo in the social interest habitation in Brazil]. Cadernos de Arquitetura e Urbanismo 2004, 11, 217–245. Available online: http://periodicos.pucminas.br/index.php/Arquiteturaeurbanismo/article/view/860/826 (accessed on 2 March 2024).

- ASTM D143; Standard Test Methods for Small Clear Specimens of Timber. ASTM Standards: West Conshohocken, PA, USA, 2014.

- Souza, S.A. Ensaios Mecânicos de Materiais Metálicos [Mechanical Testing of Metallic Materials]; Blucher: São Paulo, Brazil, 1982. [Google Scholar]

- Shimano, M.M. Histerese de Fêmures de Ratas Submetidos a Ensaio de Flexão, em Diferentes Faixas Etárias [Hysteresis of Fêmur of Rat Submitted in Bending Test, in Different Age Groups]. Master’s Thesis, Bioengineering Postgraduation Program, University of São Paulo, Ribeirão Preto, Brazil, 2001. [Google Scholar]

- ASTM D-2017; Standard Method for Accelerated Laboratory Test of Natural Decay Resistance for Woods. ASTM Standards: West Conshohocken, PA, USA, 2005.

- Christoforo, A.L.; Ferro, F.S.; Arroyo, F.N.; De Araujo, V.A.; Icimoto, F.H.; Santos, H.F.; Lahr, F.A.R. Chromated copper borate influence on physical and mechanical properties of oriented strand boards using Schizolobium amazonicum wood specie. Constr. Build. Mater. 2022, 356, 129237. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).