Abstract

Digitalization and its associated technology are shaping the world economy and society. Data collection, data exchange, and connection throughout the wood supply chain have become increasingly important. There exist many technologies for the implementation of Industry 4.0 applications in forestry. For example, the integration of harvester production data throughout the wood supply chain seems to have strong optimization potential but it is faced with several challenges due to the high number of stakeholders involved. Therefore, the objective of this article is to analyze the legal, social, and economic conditions surrounding the integration of harvester production data integration in Germany. For analysis of the legal and economic conditions, a narrative literature analysis was performed with special consideration of the relevant German and European legal references. For determination of the social conditions, a qualitative content analysis of 27 expert interviews was performed. Results showed that legal ownership of harvester production data cannot be clearly defined in Germany, but there exist several protection rights against misuse, which can define an ownership-similar data sovereignty. Furthermore, harvester data use can be restricted in the case where personal data are traceable, based on European data protection law. From a social perspective, the stakeholders interviewed in the study had different opinions on data ownership. Stakeholders require specific criteria on the data (interfaces) and other factors for the acceptance of new structures to allow successful harvester data integration. From an economic perspective, harvester production data are tradeable through varying transaction forms but, generally, there is no accepted and valid formula in existence for calculating the value or price of harvester data. Therefore, the authors advise discussing these issues with key stakeholders to negotiate and agree on data ownership and use in order to find a suitable solution to realize optimization potentials in the German wood supply chain.

1. Introduction

The world economy and society are facing fundamental changes as digitalization is shaping many areas of our lives, and the systematic collection and analysis of data is becoming increasingly important [1]. These developments triggered changes in production processes, which led to the fourth Industrial Revolution, known as Industry 4.0 [2]. It focuses on cyber-physical systems, internet of things, internet of services, and the smart factory [3]. Information and communication technologies are a central element of this new Industry 4.0, which aims to connect and computerize traditional industries [1]. Moreover, its objective is to improve adaptability, resource efficiency, and integration of supply and demand processes between factories facing all challenges, opportunities, and drivers of Industry 4.0 technologies [4,5]. In Germany, the promotion and realization of the digitization’s potential is a declared goal of the federal government [1].

Digitalization has found its way into forest industry. It is propagated under the term “Forestry 4.0” [6]. In Forestry 4.0, applications are ranging from computerized support aids to electronic control, machine vision, and post-harvest management [7]. Its value lies in the connection of process steps along the wood supply chain with a close to unlimited information flow and allocation in an internet of trees and services, which can lead to changes and added value in harvest planning, harvest organization and control, operations, transport, logistics and timber sales. Within the internet of trees and services, a considerable amount of data from different sources is collected. In the last years, remote sensing data has been particularly analyzed, which is one basis for the concept of virtual forests [7].

However, there are also other data, such as forest machine data, which can be collected automatically. Modern harvesters are equipped with an on-board computer (OBC) that collects a large amount of information concerning machine parameters and the harvested timber in a standardized format according to the Standard for Forest Machine Data and Communication 2010 [8,9], which provides best technical prerequisites for data exchange and use. Additionally, in German forestry, the importance of highly mechanized harvesting systems has steadily increased. In 2018, 65 million m3 of timber were harvested in Germany. Almost 80% of the timber was spruce, fir, pine, and larch [10]. The main share of this timber was felled, processed, and forwarded by highly mechanized harvesting systems. References from the last two decades agree that about 50% of the timber is provided through highly mechanized systems in Germany and also Bavaria [11,12]. This reality increases the need for improved harvester data integration. Another point for using these data are the developing technologies that permit the real-time analysis of big data with the support of artificial intelligence. Predictive analytics such as regression and machine learning techniques (e.g., neural networks as the backbone of deep learning algorithms) offer new possibilities of gaining richer and more comprehensive insights into the company and getting an advantage over the competition [13] and seem to deliver promising results.

The German forestry sector is facing a variety of challenges which are mostly linked to the increasing demands on the forests. The conservation of vast forest areas as well as the careful and sustainable utilization of wood in connection with climate change are becoming essential. This is particularly the case for calamity situations, such as wind throws/breaks and bark beetle infestations, where it can be useful to provide information about harvested trees as quickly as possible to ensure the efficiency of the wood supply chain. Harvester production data could be an option to deliver first information about the harvested wood for further planning purposes.

Stakeholders of the wood supply chain, such as forest owner associations, forest management companies and their forest, contractors, and customers of the timber industry, have a strong interest in the use of these harvester data for logistic planning, economic benefits, and better customer orientation. In 2018, Labelle et al. stated that the integration of harvester production data such as tree species, assortments, amount of harvested timber or diameter and length information into the German wood supply chain is expected to lead to added value through a more consistent flow of information and optimized networking of the stakeholders involved [14]. The German cluster of forest and wood is comprised of diverse stakeholders and, thus, it represents a high mixture of processes and structures [15]. This complexity is one of the reasons for a lack of standardization of business processes and a shortage of predefined data interfaces for optimization. Comprehensive data integration involving all key stakeholders participating in the German wood supply chain is missing in many fields of forestry business, and the reasons for this are strongly discussed [16].

There are some studies that have analyzed the general challenges, opportunities, and drivers for the implementation of Industry 4.0 [4,5,17]. As there are already many technical possibilities of using IT in forestry, Müller et al. (2019) recommend, in their article, not only to look at the technical challenges but also analyze the socio-economic challenges, such as willingness for cooperation, changes in work environments, labor qualification, data autonomy, and added value distribution [7]. Rantala et al. (2020) also recommended analyzing the social and governance aspects of forest data [18].

Furthermore, the successful integration of harvester production data in the wood supply chain is tied to various requirements. Therefore, the main objective of this article is to present the requirements and conditions for the continuous use of harvester data throughout the German wood supply chain, in addition to the technical requirements. In detail, the objectives are to analyze (1) which legal basics determine continuous harvester data use, (2) what are the social challenges of harvester data integration, (3) what is the current economic situation of value creation of data and whether it is possible to trade harvester data.

2. Materials and Methods

Two different research approaches were chosen. To address objectives 1 and 3, a narrative literature research was performed and supplemented with expert recommendations, whereas objective 2 was achieved through a qualitative content analysis of 27 expert interviews.

2.1. Legal and Economic Literature Analysis

A three-step approach was used to gather the published findings related to harvester data integration in German wood supply chains.

- Step 1: Scientific databases

Within a legal context, the German Basic Law (GG), Civil Code (BGB), Criminal Code (StGB), Copyright Law (UrhG), Federal Data Protection Act (BDSG), Working Hours Act (ArbZG), Personnel Representation Act (BPersVG) and the Work Constitution Act (BetrVG) were reviewed. EU-General Data Protection Regulation (EU-GDPR) and supplementary court judgements or juridical deliberations were also examined. To avoid misinterpretations and the omission of relevant sections, secondary literature, interpretations from lawyers, and literature from practitioners were considered. Legal references were accessed through internal university databases (Göttinger Universitätskatalog and Elektronische Zeitschriftenbibliothek), as the issues of data use and exploitation are only slightly covered in articles in natural scientific databases. Since some suitable OECD articles were found via cross referencing, OECDiLibrary was used as an additional database.

- Step 2: Search terms

To find suitable legal references and to also achieve the economic goal of this article, the focus was first directed at German laws and articles, but a wider international perspective was also warranted. Time restriction was from 2000 to 2020 and articles written in German and English were considered. Search terms were entered in different combinations using the Boolean operators “AND” and “OR”. The following terms were used to generate results for the legal and economic results section:

- Legal articles:

- -

- “Data” AND (“ownership” OR “sovereignty” OR “power”) (German words used).

- -

- “Data” AND (“personal” OR “protection” OR “industry 4.0”) (German words used).

- Laws: “Law” AND (“Labor” OR “Civil” OR “Copyright” OR “Data protection” OR “Criminal” OR “Work Constitution” OR “Personnel Representation”) (German words used).

- Economic articles:

- -

- “Data” AND (“price” OR “value” OR “costs” OR “economy”)

- -

- “Data” AND (“platforms” OR “digital” OR “markets”)

- -

- “Data” AND (“digitization” OR “wood supply” OR “industry 4.0”)

References were further supplemented by cross referencing and expert recommendations.

- Step 3: Literature analysis

Article titles that seemed appropriate to answer the research questions were first selected for a closer look. After screening the abstracts, irrelevant articles were discarded. In the deeper analysis, topics were formed, e.g., “construction of ownership-similar rights on data” or “data tradability”. These topics were considered as the basis for the article structure. The legal analysis was aiming at identifying the owner of the harvester production data, whereas the economic analysis was set to explore the framework of tradability of harvester production data. However, the research object of this study was unexplored and therefore, results of literature analysis were then transferred to harvester production data.

2.2. Qualitative Content Analysis of Expert Interviews

To examine the stakeholders’ conditions and requirements for harvester data integration in the German wood supply chain, a two-step approach was chosen.

- Step 1: Preparation and conduction of interviews

A total of 27 exploratory expert interviews with all in all 30 experts were performed. The interviewees all have professional experience in forestry and were selected on the basis of expertise, their position in the companies interviewed, and also accessibility. The interviews were conducted between April 2018 and February 2019. The participation in the interviews was voluntary. The interviews were conducted with a semi-structured guideline and recorded by a voice recorder. Stakeholders of the wood supply chain of a federal German state forest management enterprise and a private forest owner association, such as employees, forest contractors and representatives of the timber industry in Bavaria were interviewed (Table 1). The recordings were then transcribed with the software “f4” by two research assistants according to the transcription rules and afterwards validated by the interviewer.

Table 1.

Interview material.

- Step 2: Interview analysis

To explore the stakeholders’ conditions on harvester data integration, an exploratory qualitative content analysis was performed. Firstly, the transcripts were anonymized and examined with the software MAXQDA 12 (version 12.3.5). Therefore, the technique of content structuring by deductive category application was applied. Basis for the derivation of structuring the material was the construction of a category system. This was formed out of the theoretical knowledge context as well as certain questions of the interview guideline.

Based on the interview guideline and the study objectives four main categories (challenges of data integration, characteristics of data (interfaces), definition of data ownership and the definition data value) were deductively built. Sub-categories were added inductively during analysis of interview content to assign the interviewees answers to specific topics. Statements referring to these topics were then paraphrased and presented in the results section.

2.3. Definition of Data, Ownership, Possession, and Ownership-Similar Data Sovereignty

A definition of the term “data” is, in general, not straightforward. The international standard ISO/IEC 2382-1:2015-05-00 defines data as “a reinterpretable representation of information in a formalized manner, suitable for communication, interpretation, or processing” [19]. The German and European laws relevant for this study, do not include a precise definition of harvester production data or in a broader sense, machine data. Section 202 a (2) of the German Criminal Code (StGB) only describes an attribute of data as the possibility to save it in an electronic, magnetic, or otherwise not directly predictable way [20]. However, personal data is defined in the Federal Data Protection Act (BDSG) (Section 46 No. 1) and the EU-General Data Protection Regulation (Section 4 No. 1) [21,22]. Throughout these attempts to define data, it became clear that the concept of information, created through the interpretation of data, is central [23]. Therefore, harvester production data is defined in this article in accordance with Section 46 No. 1 BDSG [21], 202 a StGB [20] and ISO/IEC 2382-1 [19] as “information about tree species, distribution of assortments, quality or diameter and length information and its associated position, represented on the OBC, based on StanForD 2010 (Standard for Forest Machine Data and Communication)”.

Based on German Civil Code (BGB), ownership is defined as the right to control an object from which others can be excluded, while possession is considered as the exercise of actual power over a physical object [24]. In the context of this paper, ownership-similar data sovereignty is understood as all legal possibilities to establish sovereignty over data and exclude others from using it.

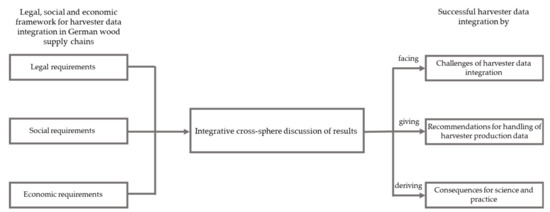

2.4. Scientific Research Approach

Due to the nature of this project, a mixture between the three spheres (legal, social, and economic) was warranted and addressed through a combination of literature review and qualitative content analysis (Figure 1). This two-fold research approach was necessary to fully understand the problems and challenges faced with harvester data integration in German wood supply chains. This is especially the case since the topic of harvester data integration remains scarcely reported in literature and, hence, required the input of key stakeholders.

Figure 1.

Integrative cross-sphere research approach.

3. Results

3.1. Legal Conditions for the Integration of Harvester Production Data in German Wood Supply Chains

- Data Ownership and Possession

The legal requirements for the integration of harvester production data in German wood supply chains are mostly related to the question of ownership, possession, and ownership-similar sovereignty of the data. Therefore, it is important to first know the difference between data ownership and possession.

As described above, Section 903 of German Civil Code (BGB) defines ownership as the right to control an object from which others can be excluded. An “object” in sense of the Civil Code includes only physical objects (Section 90 BGB). The binary codes on the harvester’s OBC do not initially represent such legal entities. It is possible to have ownership on the data carrier, which is the OBC on the forest machine or, specifically, the hard disc, because this is a physical object [24].

The German law differentiates between ownership and possession. The owner of an object does not always have to be the possessor, for example in rental agreements of forest machines. According to Section 854 (1) BGB, possession of an object is acquired through the attainment of actual power over it. Therefore, possession of data cannot be substantiated. Only actual power over the data carrier within the meaning of Section 854 (1) BGB does exist on the side of the contractor. Therefore, there is no ownership and no possession of harvester production data itself, but in the German law it is possible to construct ownership-similar rights [24].

- Construction of Ownership-Similar Data Sovereignty

In the context of this paper, “data sovereignty” is understood as all legal possibilities to establish sovereignty over data and exclude others from using it. One option is the construction of a data sovereignty similar to ownership as an “other right” according to Section 823 (1) BGB [24,25]. The infringement of these other rights may result in claims for damages and/or injunctive relief on the part of the entitled party. Whether this applies to “machine data”, such as harvester production data, is controversial [25].

Furthermore, data may be covered by the scope of protection of so-called “protective laws” within the meaning of Section 823 (2) BGB. A violation of such protective laws can lead to obligations to pay damages [24]. For example, in the German Criminal Code, the “spying out of data” (Section 202 a StGB) and the “modification of data” (Section 303 a StGB) are punishable, if it is under premeditation according to Section 15 StGB. Therefore, use and exploitation of data is not allowed for every stakeholder [20]. According to the judgement of the Higher Regional Court of Naumburg (OLG Naumburg), the one who produces the measuring data is the authorized party for data use [26]. Provided that the forest contractor is also the owner of the harvester, whose OBC performs the script act, he would be the “authorized party”.

An ownership-similar data sovereignty on harvester data could also be constructed to limited extent with German Copyright Law (UrhG). The production data collected by the harvester’s OBC is systematically stored and displayed in StanForD 2010 and could therefore be seen as a database according to Section 87 a (1) [27]. According to Section 87 b (1) UrhG alone, the producer of this database has the right to copy, spread, and publicly reproduce the database. The database producer is the one who made the investment according to Section 87 a (2) UrhG [27]. This means forest contractors, and not employed operators, can decide if they want to spread their harvester data because they hold the right of distribution according to Section 17 UrhG [27]. The protected subject is, therefore, the sum of collected information in the database, but not their structure [28].

In accordance with Section 4 No. 1 EU-General Data Protection Regulation (EU-GDPR), harvester data are personal if the machine data in combination with other data results in a personal reference [29] and this could, therefore, limit data use and access. For example, the “UserID” in StanForD 2010 links the machine information contained in the messages and assigns it to a personalized user account. It is also possible to link production data not only to machine operators but also to a specific forest owner [30].

However, in accordance with Sections 5 and 6 of EU-GDPR, the collection or processing of personal data in the Federal Data Protection Act is only permitted under certain conditions, like a need for official data processing or permission from the affected person (Section 22 BDSG) [21,22]. Basically, this is given by standardized employment contracts. Additionally, the employer must inform the employee about the legal basis on which this is conducted, according to Art. 13 EU-GDPR [22]. In the absence of permission or contractual regulations, the forest machine operator could formulate ownership-similar sovereign claims to data and thus prevent others from further processing (Sections 32–37 BDSG) [21].

The use of personal relatable harvester data for the collection of working and rest times can be permitted according to the German Working Hours Act (ArbZG) (Section 16 (2)) [31]. In addition, if a technical device, like a harvester’ s OBC, allows the time control of employees, the work and personnel councils are entitled to a right of co-determination in the “introduction and use of technical equipment designed to monitor the behaviour and performance of employees” (Section 87 (1) No. 6 BetrVG, Section 75 (3) No. 17 BPersVG) [32,33,34].

3.2. Social Conditions for the Integration of Harvester Production Data in German Wood Supply Chains

Overall, the interviewees´ conditions for successful harvester data integration into the German wood supply chain were quite diverse but remained primarily oriented towards operational interests of the interviewed stakeholders. Based on the interviews, social requirements that needed to be overcome can be grouped into four different categories, which are presented along with the main findings in Figure 2. Particular interests of the key stakeholders are presented in the Table A1.

Figure 2.

Overview of the interviewees’ conditions on harvester data integration (based on content analysis with MAXQDA v. 12.3.5).

- The first category describes common challenges of data integration, such as the technical prerequisites and the acceptance of restructurings depending on its knowledge, costs, extent, and duration. According to the interviewees’ statements, the resistance against standardized working processes mainly originated from the uncertainty about the purpose and use of new processes. Moreover, the legality of handling personally referenced production data needs to be clarified, and data security needs to be guaranteed.

- The second category relates to the characteristics of the data, namely the data interfaces, which need to be fulfilled for the stakeholders to be useful for them. For this aspect, interviewees mentioned that the data need to be standardized, understandable, structured, georeferenced, rapidly available, complete, and accurate. Interviewees also wanted to differentiate timber data according to assortments, diameter (top diameter, middle diameter), length, quality, and customer wishes. Concerning the data interfaces, the digital information flow needs to be continuous, and interfaces should be user-friendly, clearly arranged for planning of logistic processes, and show the processing status of the timber.

- The third category showed that the clear definition of ownership and possession of data is another requirement for successful integration of harvester production data into the wood supply chain. Besides the legal definition of ownership for harvester data, the different stakeholders do not differentiate between legal ownership, possession, and ownership-similar sovereignty definition. This is especially important when contractors or machine owners hand out the harvester data. In this instance, some contractors defined data ownership in terms of machine ownership, calculation basis, power or control over the data, and the scripture act, whereas certain employees of forest management companies defined data ownership because of the contract situation and forest ownership.

- The last category of social requirements is definition of the value of harvester data. The interviewees had only a few ideas of data value, but if so, it was quantified within the time required for the data processing effort, costs of technical investment, opportunity costs, operation optimization, and context dependency. No one had a fixed price for harvester data in mind. The missing idea of harvester data value arises because of unclearness of data value and the meaning for the wood supply chain. Some forest contractors would therefore pass the harvester data on for free. Moreover, doubts about a possible payment of harvester data were mentioned, as some interviewees feel that the willingness to pay the data provision is very low.

3.3. Economic Conditions for the Integration of Harvester Production Data in German Wood Supply Chains

As some forest contractors mentioned passing their harvester data onto a counterpart, but they have no clear idea about its value, the question arises whether harvester data are tradeable, how they can be traded, and for how much money.

- Tradability of Harvester Data

From the economic point of view, harvester data are tradeable because they fulfil the requirements of an economic asset in Germany. According to Schweitzer and Peitz (2017) they are reproducible at negligible costs, they cannot be “over-consumed”, and they are basically collective goods with exclusivity. However, it is important to note that the boundaries between good types can become blurred, and hybrid forms can emerge. In general, it is possible to deal with and sell data. If data may be personally referenceable, anonymization and pseudonymization can open up market access. Despite anonymity, if the sample size is too small, a data trade seems to be impossible. Further contextual information often leads to personal references [35].

- Trading Data

Through digitalization, a data economy has emerged [36], for which harvester data can possibly be seen as being a part of. This data economy concerns all aspects of analysis and economic use of data, including the complexity of new supply chains. Moreover, it is characterized by the availability of large amounts of data, their processing and storage, as well as the authorization for data trading [35] and fast data circulation [37]. The economic use of data primarily serves to optimize operational processes [35], and the use of harvester production data aims at optimization of the wood supply chain.

This optimization potential is already realized within data trading on secondary markets, where trading usually takes place as paid, licensed data access as companies do not want to give up competitive advantages and, therefore, conclude contracts bilaterally [35,38]. Therefore, harvester data could play a role in these secondary markets. A transaction begins with the collection and storage of the data. The second stage is organization, refinement, anonymization/pseudonymization, and disposal. For a possible trade with harvester data, different transaction forms can be considered [36], which are shown in Table 2.

Table 2.

Transaction forms suitable for harvester production data.

Possible market models for trading the data are data auctions, data broker, data cooperatives, and data dealer. The latter is mostly possible for harvester data. A data dealer, e.g., the contractor or machine owner, sells data from their own data portfolio [36].

- Price, Value, and Costs of Data

Several studies confirm that a general method for defining a value or a price for data does not exist, and that novel alternatives for measuring it need to be found [38,41,42]. In general, the value of the data seems to depend on the application idea and is a prognosis of the achievable price. The price is the actual achieved revenue. Should the economic value of the data be quantified, then added value for the com-plete supply chain is possible [35].

One possibility for monetary quantification of harvester production data could be the determination of the intrinsic data value resulting from accessibility, accuracy, completeness, and rarity. Furthermore, the value of data could be determined from the value for the current contracting business or the prompt achievement of business fig-ures. Moreover, it could be determined by the cost for data acquisition or the realizable selling price on the market [43]. Other approaches are the costs for data collection and the additional effort for the contractor for the system setting [39].

For harvester production data, Butterweck-Kruse (2017) calculated the value of the data firstly through additional costs for the forest machine equipment (e.g., for OBC technology, measuring equipment). The second aspect is additional personnel costs for setting up the OBC, calibration, documentation, and data control and trans-mission. Thirdly, additional administrative costs incurred by reading out and passing on the data to third parties influence the data value. The result is an additional cost of 1.00–2.00 €/m3 timber [39].

Since there are fewer approaches to determine the value of machine data, value determination approaches of personal data could conceivably be adapted and used for it. Table 3 shows some of these key approaches.

Table 3.

Data value calculation approaches.

4. Discussion

4.1. Challenges of Harvester Data Integration

4.1.1. Organizational and Personal

Data security can be granted through standardization and uniform system configurations [45]. Motivation of all stakeholders to participate in the data exchange is essential. This can be achieved by making them aware of the data integration process and rationalization potentials of harvester data integration for operational optimization. As costs are one of the key factors for investment decisions [46], financial willingness and acceptance of restructuring processes are essential. This could be addressed by transparency and increased value creation. The issue of technical understanding as a personal requirement would be weakened by the fact that younger generations as digital natives are more familiar with digitized applications. Trust in the harvester data can be enhanced by informed and regular calibration of the harvesting head and control logs, which also improves the accuracy of harvester data.

IT infrastructures and data interfaces need to be standardized (for example, StanForD2010 [30] and ELDAT [47]) and efficient. Efficient data interface means user-friendliness, which can be improved by a simple design as well as a fast data upload and fast data availability. However, since the German mobile network coverage is very poor in parts, especially in larger continuous forest areas [48], this remains a main problem. In this regard, Varghese and Tandur (2014) assume that latency, longevity, and reliability are the most important elements of Industry 4.0-related communication [5].

The interest of displaying the operation status probably originates out of the necessity for planning the logistic follow-up processes. Filtering the data by assortment and linking them to geo-information is another demand. Forest machine manufacturers already offer applications that meet these needs. However, the use of these tools requires modern OBCs, which could be a problem for some contractors because of older machines and financing issues. The weakness of these applications is that they are mainly targeted at forest contractors. If, for example, a forest owner association wants to use it for monitoring the harvesting progress and the harvester in question is registered in the system, they could see all work- and operator-related aspects, which lead to data protection issues.

4.1.2. Trading and Value

Finding a value or a price for harvester data is quite difficult. None of the interviewees had a clear idea of how to calculate the value of data. Furthermore, there is no published universal method for calculating the value of harvester data. Willingness to share data is increased when obtaining a financial counterpart, meaning a transparent financial compensation. It is important to show stakeholders that data use leads to increased value creation over the entire supply chain [35], efficiency, and cost optimization [38].

The calculation of harvester data by its intrinsic value [43] seems to be plausible but highly subjective. Using the costs for data acquisition [43] could be used to determine value of harvester data. The opportunity cost method also appears as an option. Value calculation approaches from personal data, such as the one from von Lewinski (2019), seem reasonable. In the case of harvester data, the information and data storage prices are somewhat variable but generally considered as negligible. In combination with other data, harvester data could be given more exclusivity and become meaningful to other companies in certain contexts [42].

Because the development of a generally accepted approach to measuring the value of data is not evident [42], a more pragmatic approach where there is financial renumeration for time spent handling the data appears to be more valid [39].

As quantification of data value is difficult and customers are generally not willing to pay for data, another transaction form, aside from economic value, could be of interest. For example, a social exchange could be feasible [36]. As an exchange for providing harvester data, forest contractors could receive supplementary information from the forest management company in form of improved map material, a digital work order, or more precise data on the harvesting area [49]. This could also increase the willingness of the forest contractors to share their data.

4.1.3. Ownership and Data Protection

As described above, no clear definition of harvester data ownership exists. This leads to confusion of the interviewees about the legal legitimacy of data use, which is shown by the different answers of who the owner is. For example, representatives of forest owner associations see themselves as the harvester data owner, but this is not in line with the scripture act [26]. This is one aspect that prevents the emergence of efficient data markets in the German forestry sector. Therefore, it would be helpful if the German legislative would pass laws for defining a clear data ownership. This was also postulated by the working group digital new start of the justice minister conference in Germany [50].

Another issue is the limitation of data use through data protection. This can be relevant when working behavior or work performance patterns of machine operators can be drawn and, thus, enabling the employer to monitor the employee. This could have a sensitive effect on employment relationships. Additionally, through data about harvest quantity and sorting, a financial overview of the forest owner could be possible. Anonymization and pseudonymization of the data or permission for collecting and distributing personal data from the machine driver would help to face this challenge. Hornung and Hoffmann (2018) warned about unauthorized use of data by third parties, which can provide information about a company’s production methods and amounts. This could lead to considerable financial damage to the concerned companies [51]. According to Schweitzer and Peitz (2017), sufficient data protection is granted by a technically secured data ownership and the introduction of standard contractual clauses for data use licenses [35].

4.2. Recommendations for Handling of Harvester Production Data

One possibility to promote data exchange and clarify use and exploitation rights is the use of General Terms and Conditions (GTC) as an addition to operation contracts, which are common in German industry [51]. However, if a forest management company contractually guarantee themselves the rights to the harvester production data, problems could occur if the forest contractor originally does not want to share the data. Contractors are often obligated to sign a GTC since it is a requirement for the operation contract in most cases. It is questionable if it is socially acceptable to demand harvester data from the contractor who is regularly doing the investments in technology, but to not honor this financially while the other parties draw benefits from the data. A financial surcharge on the timber harvesting services is therefore conceivable. For example, a flat-rate data provision fee could be achieved, through business associations, such as the German Forest Contractor Association [36].

An efficient alternative for handling harvester data usage and exploitation rights to non-personal data could be data platforms, as these can be organized in a flexible way under the umbrella of private law regulations in combination with liability and sanction rules. However, they have the weaknesses that sufficient credit worthiness of the platform stakeholder is necessary to make sanctions tangible and to ensure punishment of unauthorized data use. Furthermore, there would be legal and political steps and extensions of the antitrust exemptions needed to implement such a system [52]. Another approach of data exchange and use that will be examined in Germany is data cooperatives. They should allow efficient, secure, and trustworthy sharing of data between stakeholders [53]. The legal basis of cooperatives has the advantage that it is an established concept for the implementation of collaborative projects in which goals and interests of the members are jointly pursued [54]. In the context of harvester data exchange, knowledge commons with limited access to key stakeholders are also an option [55].

Another alternative could be an agreement of key interested parties on harvester data use similar to the private-law agreement of representatives of the forest industry, contractors and machine manufacturers in Finland. This recommendation took EU-GDPR and StanForD-2010 into account and consists out of common rules for data ownership, use, and processing of forest machine data. It aims for a classification into different data types and subsequently assigns use and exploitation rights of interested key parties [56].

For successful harvester data integration throughout the German wood supply chain, we recommend educating the stakeholders about data protection and the legal situation. It is essential to get key stakeholders talking to each other and to find a common solution, similar to the Finnish recommendation for handling of forest machine data. From our perspective, this makes the most sense, since laws are changing slowly and value calculation is difficult, and it is a process in which key interested stakeholders are involved.

4.3. Consequences for Science and Practice

Further research should be conducted to find methods for measuring and calculating the value of non-personal data. Furthermore, investigations should be carried out on possibilities for using harvester production data throughout the wood supply chain and its benefits, but also on methods for using harvester production data for science. Such an example would be to analyze stem curves to improve algorithms for predicting tree growth and understanding forest management measures on tree growth, wood quality, and bucking. More research could also be conducted when using harvester data in combination with other forest data. Therefore, more attention should be paid on possibilities exchanging forest data meeting the requirements of all stakeholders and the data protection. The creation of, for example, a central platform, similar to the one that exists for forest data in Finland or Sweden (Biometria), would be helpful.

5. Conclusions

The cross-sphere approach consisting of a narrative literature review and exploratory content analysis of expert interviews revealed the intense connection of the legal, social, and economic spheres. The discussion of challenges, recommendations for handling harvester data in Germany, as well as the consequences for science and practice could show that successful integration of harvester data in German wood supply chains is only possible if all conditions are considered. The approach provided interesting insights that could be important and potentially transferable on an international level.

Basically, since there exists no legal ownership or possession on harvester production data in Germany, but on the data carrier, the forest contractor has, in fact, the power over the harvester production data. If he is willing to share the data with others, the use of the data could be limited through data protection laws and protected against misuse. Moreover, other legal alternatives could be chosen, such as contractual regulations for data handling. The tradability for harvester production data is given, but no fixed value or price for the harvester data have yet been established. The discussed approaches for monetary quantification of harvester data have clear weaknesses in terms of objectivity and quantification of some variables. Therefore, pragmatic approaches are probably the most suitable at present to determine the harvester data value. This is also impacting the social requirements because the interviewees also had no idea of price and value. However, the willingness to share harvester data is increasing, particularly when it is associated with monetary value. To guarantee successful integration of harvester production data into the German wood supply chain, the authors suggest that key stakeholders of the wood supply chain (forest contractors, forest owners, state forest management enterprises, forest owner associations, and timber customers) should join and discuss the possibilities and economic benefits of data exchange. The key stakeholders should individually define their data use and exploitation interests and work out a recommendation on how harvester production data can be exchanged, similar to the example of the Finnish recommendation for principles relating to the ownership, use, and processing of forest machine data.

Author Contributions

The authors F.H. and J.K. equally contributed to this article. Conceptualization, methodology and interview conduction was done by J.K. Analysis of the interviews and literature research was performed by F.H. The manuscript was drafted and written by F.H. and J.K. E.R.L., D.J. and T.W. critically revised the article. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Bayerische Forstverwaltung (Bayerisches Staatsministerium für Ernährung, Landwirtschaft und Forsten) as part of the project A037 PVDat. The study was carried out with financial support from the Bayerische Forstverwaltung as part of the project A037 PVDat. We acknowledge support through the open access publication funds of the Göttingen University.

Institutional Review Board Statement

Ethical review and approval were waived for this study, due to no medical research was conducted. Furthermore, it is not common for expert interviews to apply for an ethical review.

Informed Consent Statement

Informed consent was obtained from all subjects involved in the study.

Data Availability Statement

To keep the interviewees anonymity, the interviews are not publicly accessible.

Acknowledgments

This study was carried out with financial support from the Bayerische Forstverwaltung as part of the project A037 PVDat. The authors would also like to acknowledge research assistants for transcription of the interviews, all interviewees for their thoughtful input and suggestions, as well as Michael Ottl for his advice concerning the legal section.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Appendix A

Table A1.

Key interests of stakeholders (based on analysis with MAXQDA v. 12.3.5).

Table A1.

Key interests of stakeholders (based on analysis with MAXQDA v. 12.3.5).

| Stakeholder | Key Interests |

|---|---|

| Contractors |

|

| Forest owner association |

|

| Forest management company |

|

| Customers (Timber industry) |

|

References

- Bundesministerium für Wirtschaft und Energie (BMWI). Industrie 4.0 und Die Digitale Wirtschaft. Impulse für Wachstum, Beschäftigung und Innovation. 2018. Available online: https://www.bmwi.de/Redaktion/DE/Publikationen/Industrie/industrie-4-0-und-digitale-wirtschaft.pdf?_blob=publicationFile&v=5 (accessed on 8 March 2019).

- Piccarozzi, M.; Aquilani, B.; Gatti, C. Industry 4.0 in Management Studies: A Systematic Literature Review. Sustainability 2018, 10, 3821. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What Drives the Implementation of Industry 4.0? The Role of Opportunities and Challenges in the Context of Sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Varghese, A.; Tandur, D. Wireless requirements and challenges in Industry 4.0. In Proceedings of the 2014 International Conference on Contemporary Computing and Informatics (IC3I), Mysore, India, 27–29 November 2014; pp. 634–638. Available online: https://ieeexplore.ieee.org/abstract/document/7019732 (accessed on 17 November 2020).

- FPInnovations: Forestry 4.0. Available online: https://web.fpinnovations.ca/ (accessed on 25 February 2019).

- Müller, F.; Jaeger, D.; Hanewinkel, M. Digitization in wood supply—A review on how Industry 4.0 will change the forest value chain. Comput. Electron. Agric. 2019, 162, 206–218. [Google Scholar] [CrossRef]

- Wodniok, J. StandForD und StanForD 2010. KWF, 2018. Available online: https://www.kwf-online.de/index.php/wissenstransfer/forst-holz-logistik/428-stanford-und-stanford-2010-informationenmationen (accessed on 2 May 2020).

- Kemmerer, J.; Labelle, E.R. Using harvester data from on-board computers: A review of key findings, opportunities and challenges. Eur. J. For. Res. 2020. [Google Scholar] [CrossRef]

- Statistisches Bundesamt (Destatis). Land- und Forstwirtschaft, Fischerei. Forstwirtschaftliche Bodennutzung -Holzeinschlagsstatistik-. Fachserie 3 Reihe 3.3.1. 2018. Available online: https://www.destatis.de/DE/Themen/Branchen-Unternehmen/Landwirtschaft-Forstwirtschaft-Fischerei/Wald-Holz/Publikationen/Downloads-Wald-und-Holz/holzeinschlag-2030331187004.pdf;jsessionid=6942FCB258A43686D49A6FAAEA04B63B.internet722?__blob=publicationFile (accessed on 26 February 2020).

- Kuratorium für Waldarbeit und Forsttechnik, e.V. (KWF). Lastenheft Harvestervermessung. KWF-Bericht Nr. 41/2010. Available online: https://www.landesforsten.de/wp-content/uploads/2018/06/lastenheft_harvestervermessung_nds.pdf (accessed on 23 November 2020).

- Bayerische Staatsforsten AöR. Maschinen. Available online: https://www.baysf.de/de/wald-bewirtschaften/holzernte/maschinen.html (accessed on 15 December 2020).

- Kavlakoglu, E. Machine Learning vs Deep Learning vs. Neural Networks: What’s the Difference? 2020. Available online: https://www.ibm.com/cloud/blog/ai-vs-machine-learning-vs-deep-learning-vs-neural-networks (accessed on 17 November 2020).

- Labelle, E.R.; Kemmerer, J.; Breinig, L. Nutzung der Daten von Harvester-Bordcomputern in forstlichen Wertschöpfungsketten: Möglichkeiten und Herausforderungen. In Proceedings of the InterForst, Munich, Germany, 18–22 July 2018; Available online: https://www.kwf-online.de/images/KWF/Veranstaltungen/Interforst2018/2_Labelle_4_Using_data_from_harvester_on_board_computers_in_forest_V05_deutsch.pdf (accessed on 3 March 2019).

- Landesbetrieb Wald und Holz Nordrhein-Westfalen. 2019. Available online: https://www.wald-und-holz.nrw.de/fileadmin/Presse/Dokumente/2019/20190528_Wald_und_Holz_Leistungsbericht_LuV.pdf (accessed on 15 December 2020).

- Nagel, M.; Ruminski, N. Go digital—Wald 4.0. In AFZ-Der Wald; Deutscher Landwirtschaftsverlag: Berlin, Germany, 2018; Volume 10, p. 34. [Google Scholar]

- Kiel, D.; Müller, J.M.; Arnold, C.; Voigt, K.-I. Sustainable industrial value creation: Benefits and challenges of Industry 4.0. Int. J. Innov. Manag. 2017, 21, 1740015. [Google Scholar] [CrossRef]

- Rantala, S.; Swallow, B.; Paloniemi, R.; Raitanen, E. Governance of forests and governance of forest information: Interlinkages in the age of open and digital data. For. Policy Econ. 2020, 113, 102123. [Google Scholar] [CrossRef]

- IEC International Electrotechnical Commission. ISO/IEC 2382-1:2015-05-00 Informationstechnik—Begriffe—Grundbegriffe. Ausgabedatum 2015-05-00. Original language: English. Available online: https://www.iso.org/obp/ui/#iso:std:iso-iec:2382:ed-1:v1:en (accessed on 21 October 2020).

- Strafgesetzbuch (Criminal Code) in the Version of the Announcement of 13 November 1998 (BGBI. I S 3322), Which Was Changed by Section 1 from the Law of 30 October 2017 (BGBI. I S. 3618) (StGB). Available online: https://www.gesetze-im-internet.de/stgb/ (accessed on 15 February 2020).

- Bundesdatenschutzgesetz (Federal Data Protection Act) of 30. June 2017 (BGBI I 2097) (BDSG). Available online: http://www.gesetze-im-internet.de/bdsg_2018/ (accessed on 15 February 2020).

- Regulation (EU) 679/2016 of the European Parliament and of the Council of 27 April 2016 on the protection of individuals with regard to the processing of personal data, on the free movement of such data and repealing Directive 95/46/EG (EU-GDPR). Available online: https://dsgvo-gesetz.de/ (accessed on 15 February 2020).

- Morik, K. Daten—Wem Gehören Sie, Wer Speichert Sie, Wer Darf Auf Sie Zugreifen? Ferdinand-Schöningh-Verlag: Paderborn, Germany, 2018; pp. 15–48. [Google Scholar]

- Bürgerliches Gesetzbuch (Civil Code) in the Version of 2 January 2002 (BGBI. I S. 42, 2909; 2003 I S. 738), Changed with Section 6 of the Law of 12 July 2018 (BGBI I S. 1151) (BGB). Available online: https://www.gesetze-im-internet.de/bgb/ (accessed on 15 February 2020).

- Riehm, T. Dateneigentum—Schutz nach allgemeinem Zivilrecht. In Rechtsfragen der Industrie 4.0, Datenhoheit—Verantwortlichkeit—Rechtliche Grenzen der Vernetzung; Gerrit Hornung, Der Elektronische Rechtsverkehr; Nomos: Baden-Baden, Germany, 2018; Volume 39, pp. 73–96. [Google Scholar]

- OLG Naumburg. Judgement of 27.08.2014—6 U 3/14. Available online: https://dejure.org/dienste/vernetzung/rechtsprechung?Gericht=OLG%20Naumburg&Datum=27.08.2014&Aktenzeichen=6%20U%203%2F14 (accessed on 14 December 2020).

- Urheberrechtsgesetz (Copyright Law) vom 9. September 1965 (BGBI. I S. 1273), Changed with 1 of the Law of 28 November 2018 (BGBI. I S. 2014 (UrhG). Available online: https://www.gesetze-im-internet.de/urhg/ (accessed on 14 December 2020).

- Keller-Stoltenhoff, Elisabeth Serie der IT-Recht-Kanzlei: Das Deutsche Urheberrecht Nach Seiner Novellierung aus IT-Rechtlicher Sicht (Teil 5: Schutz von Datenbanken). 2010. Available online: https://www.it-recht-kanzlei.de/schutz-von-Datenbanken.html (accessed on 21 October 2020).

- Lachenmann, M. 11 Datenschutz/2. Personenbezug bei Maschinendaten. Beitrag aus Deutsches Anwalt Office Premium. Haufe Recht-Rechtsportal für Anwälte und Juristen. Available online: https://www.haufe.de/recht/deutsches-anwalt-office-premium/11-datenschutz-2-personenbezug-bei-maschinendaten_idesk_PI17574_HI11616879.html (accessed on 8 March 2019).

- Skogforsk. StanForD 2010- Moderne Kommunikation mit Forstmaschinen. 2011. Available online: https://www.kwf-online.de/images/KWF/Wissen/HoDat/StanForD_2010-tysk-low.pdf (accessed on 7 December 2018).

- Arbeitszeitgesetz (Working Hours Act) vom 6. Juni 1994 (BGBI I S. 1170, 1171), Das Zuletzt Durch Artikel 12a des Gesetzes vom 11 November 2016 (BGBI. I S. 2500) Geändert Worden ist (ArbZG). Available online: https://www.gesetze-im-internet.de/arbzg/BJNR117100994.html (accessed on 9 April 2021).

- Betriebsverfassungsgesetz (Work Constitution Act) in der Fassung der Bekanntmachung vom 25 September 2001 (BGBI. I S. 2518), das zuletzt durch Artikel 4e des Gesetzes vom 18 Dezember 2018 (BGBI. I S. 2651) geändert worden ist (BetrVG). Available online: https://www.gesetze-im-internet.de/betrvg/ (accessed on 9 April 2021).

- Bundespersonalvertretungsgesetz (Personnel Representation Act) vom 15. März 1974 (BGBI. I S. 693), das Zuletzt Durch Artikel 7 des Gesetzes vom 17. Juli 2017 (BGBI. I S. 2581) Geändert Worden ist (BPersVG). Available online: https://www.gesetze-im-internet.de/bpersvg/ (accessed on 9 April 2021).

- Bundesarbeitsgericht. Urteil vom 06.12.1982—1 ABR 43/81. Available online: https://dejure.org/dienste/vernetzung/rechtsprechung?Gericht=BAG&Datum=06.12.1983&Aktenzeichen=1%20ABR%2043%2F81 (accessed on 9 April 2021).

- Schweitzer, H.; Peitz, M. Datenmärkte in der Digitalisierten Wirtschaft: Funktionsdefizite und Regelungsbedarf? Discussion Paper No. 17-043. Zentrum für Europäische Wirtschaftsforschung GmbH. Available online: http://ftp.zew.de/pub/zew-docs/dp/dp17043.pdf (accessed on 11 January 2019).

- Jentzsch, N. Datenhandel und Datenmonetarisierung. Ein Überblick. In Dateneigentum und Datenhandel, DatenDebatten Schriftenreihe der Stiftung Datenschutz; Erich-Schmidt-Verlag: Berlin, Germany, 2020; Volume 3, pp. 177–190. [Google Scholar]

- Lammi, M.; Pantzar, M. The data economy: How technological change has altered the role of the citizen-consumer. Technol. Soc. 2019, 59, 101157. [Google Scholar] [CrossRef]

- Breuer, M.; Greif, C.; Klekamp, J.; Lippert, S.; Meier, S.; Mies, S.; Rieber, D.; Schauf, T.; Stümpflen, V.; Vogelbacher, M.; et al. Data Economy. Datenwertschöpfung und Qualität von Daten. Bundesverband Digitale Wirtschaft (BVDW) e.V. Düsseldorf, Germany. 2018. Available online: https://www.bvdw.org/fileadmin/bvdw/upload/publikationen/data_economy/BVDW_Datenwertschoepfung_2018.pdf (accessed on 23 August 2020).

- Butterweck-Kruse, V. Datenschutz—Datenhoheit. In Neue Aufgaben für Forstunternehmer: Dienstleister für forstlichen Datentransfer? In Proceedings of the 4 KWF-Thementage, Paaren im Glien, Germany, 28 September 2017. [Google Scholar]

- Palmetshofer, W.; Semsrott, A.; Alberts, A. Der Wert persönlicher Daten. Ist Datenhandel der Bessere Datenschutz? Open Knowledge Foundation Deutschland e.V. Sachverständigenrat für Verbraucherfragen Beim Bundesministerium der Justiz und für Verbraucherschutz. 2017. Available online: https://www.svr-verbraucherfragen.de/wp-content/uploads/Open_Knowledge_Foundation_Studie.pdf (accessed on 19 October 2020).

- Nguyen, D.; Paczos, M. Measuring the economic value of data and cross-border data flows. A business perspective. OECD Digit. Econ. Pap. 2020, 297, 1–47. [Google Scholar]

- Lewinski, K.V. Wert von Personenbezogenen Daten. Dateneigentum und Datenhandel. DatenDebatten Bd. 3. Schriftenreihe der Stiftung Datenschutz; Erich-Schmidt-Verlag: Berlin, Germany, 2019. [Google Scholar]

- Rüdiger, A. Den Wert der Daten konkret erfassen. In VDI Nachrichten; VDI Verlag: Düsseldorf, Germany, 2016; p. 13. [Google Scholar]

- OECD. Exploring the economics of personal data: A survey of methodologies for measuring monetary value. Oecd Digit. Econ. Pap. 2013, 220, 1–39. [Google Scholar]

- Kappes, M. Eine praktische Einführung. In Netzwerk- und Datensicherheit; Springer: Wiesbaden, Germany, 2013. [Google Scholar]

- Wang, S.; Tian, Y.; Liu, X.; Foley, M. How Farmers Make Investment Decisions: Evidence from a Farmer Survey in China. Sustainability 2020, 12, 247. [Google Scholar] [CrossRef]

- Blattert, C.; Lemm, R.; Erhardt, I.; Seeling, U. Durch Standards die Interoperabilität von forstlichen Warenwirtschaftssystemen verbessern. Schweiz. Z. Für Forstwes. 2012, 163, 2. [Google Scholar] [CrossRef]

- Bundesnetzagentur—Breitbandmonitor- Funkloch-Karte. Available online: https://breitbandmessung.de/kartenansicht-funkloch (accessed on 23 November 2020).

- Kemmerer, J.; Labelle, E.R. Business process reengineering of a large-scale public forest enterprise through harvester data integration. Croat. J. For. Eng. 2021, 17. Under review. [Google Scholar]

- Arbeitsgruppe „Digitaler Neustart“ der Konferenz der Justizministerinnen und Justizminister der Länder. Bericht vom 15. Mai 2017 unter Mitwirkung der Länder Baden-Württemberg, Bayern, Berlin, Hamburg, Hessen, Niedersachsen, Nordrhein-Westfalen (Federführung), Rheinland-Pfalz, Saarland, Sachsen, Sachsen-Anhalt und Schleswig-Holstein. Available online: https://www.justiz.nrw.de/.../digitaler_neustart/...arbeitsgruppe/bericht_ag_dig_neustart.pdf (accessed on 18 October 2020).

- Hornung, G.; Hoffmann, K. Industrie 4.0 und das Recht. Drei zentrale Herausforderungen. In Rechtsfragen der Industrie 4.0. Datenhoheit-Verantwortlichkeit-Rechtliche Grenzen der Vernetzung; Gerrit Hornung: Der Elektronische Rechtsverkehr Bd. 39. Nomos: Baden-Baden, Germany, 2018; pp. 9–64. [Google Scholar]

- Spindler. Plattformen und Plattformregulierungen als Alternative zu Dateneigentumsrechten. In: Rechtsfragen der Industrie 4.0. Datenhoheit—Verantwortlichkeit—Rechtliche Grenzen der Vernetzung, pp. 151–174. Gerrit Hornung: Der Elektronische Rechtsverkehr Bd. 39, Nomos, Baden-Baden, Germany. Statistisches Bundesamt (Destatis) Land- und Forstwirtschaft, Fischerei. Fachserie 3 Reihe 3.3.1. Forstwirtschaftliche Bodennutzung. Holzeinschlagsstatistik 2018. Available online: https://www.destatis.de/DE/Themen/Branchen-Unternehmen/Landwirtschaft-Forstwirtschaft-Fischerei/Wald-Holz/Publikationen/Downloads-Wald-und-Holz/holzeinschlag-2030331187004.html (accessed on 18 December 2020).

- dpa Deutsche Presse-Agentur GmbH. 1,4 Millionen Euro für Pilotprojekt zu Datengenossenschaften. Available online: https://www.baden-wuerttemberg.de/de/service/presse/pressemitteilung/pid/14-millionen-euro-fuer-pilotprojekt-zu-datengenossenschaften/ (accessed on 15 December 2020).

- Weber, P.; Werling, M. Datengenossenschaften—Eine Chance für den Mittelstand. Baden-Württembergischer Genossenschaftsverband e.V. (bwgv). Mitgliederzeitschrift Geno Graph. Available online: https://www.wir-leben-genossenschaft.de/de/Datengenossenschaften-Eine-Chance-fuer-den-Mittelstand-8878.htm (accessed on 11 November 2020).

- Cox, J.C.; Swarthout, J.T. Creating and Maintaining a Knowledge Commons. Andrew Young School of Policy Studies Research Paper No. 06-38 2005. Available online: https://ssrn.com/abstract=895546 (accessed on 11 November 2020).

- Anonymous. Metsäkonetiedon Omistusta, Käyttöä ja Käsittelyä Koskevat Periaatteet -Suositus (Principles Relating to the Ownership, Use and Processing of Forest Machine Data—A Recommendation). Signed 16th October 2017 22p. Translated in English. 2017. (Internal document).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).