Abstract

Load safety is a critical component of successful logistic operations. Different influencing factors can affect the necessity of intensive load securing methods. The most dominant factor is the friction characteristics of the intended cargo. A cargo with special requirements on load safety is debarked roundwood. Due to modern forestry challenges, larger amounts of debarked roundwood assortments are now being produced within German forest operations. To assess the influence of debarking onto the static and sliding frictions of Norway spruce, pulling tests were performed and compared to barked assortments. Results showed that a significant difference in both static and sliding frictions exists between barked and debarked assortments within the first seven days after harvesting. However, this significant difference became less prominent after the logs continued to dry out and no difference was detected after 21 days. Over the monitored period, debarked assortments presented a 40%–45% faster drying rate than barked assortments. This resulted in a calculated 11%–28% additional transportable net load (m3) of debarked roundwood assortments for long trailer systems. Hence, debarked roundwood can be treated similarly to barked roundwood if stored long enough prior to road transportation, while having the potential of increased savings within the wood logistic chain.

1. Introduction

Over the past 25 years, the transport capacity in Germany has increased by ~90%, while the amount of accidents caused by freight traffic with fatal or severe injuries decreased simultaneously by 58% (fatal) and 45% severe injuries [1]. However, the latest official statistics state that 179 accidents with personal damage and 360 accidents with serious material damage, caused by insufficient cargo safety and loose parts, occurred on German roads in 2016. The frequency of unreported cases is suspected to be even higher [2]. Those accidents and the fact that 3.6 billion tons of cargo was transported on German roads in 2016, highlight the importance of conscientious cargo security [2]. This applies especially for cargo that is not usually transported in closed container units or trailers, which is the case for roundwood assortments.

During 2016, over 52 million m3 of wood were harvested in German forests and were subsequently transported on public roads towards the intended processing facility or to loading sites for bi-modal transportation via ships or trains [3,4]. Transporting this significant volume of wood with open-type truck and trailer combinations poses potential threats to all road users if the cargo is not safely secured. No official statistics of accidents concerning timber trucks are published for Germany, but occasional accident reports are appearing in the news. In February 2017, local media reported an incident of a timber truck that lost its complete load of roundwood assortments over a 200 m road length near Arendsee (Saxony-Anhalt) and was fleeing the scene afterwards [5]. In another accident in October 2017 near Munich (Bavaria), a timber truck lost parts of the load and damaged six cars in succession, while injuring four persons [6].

The topic of general load safety for frequently transported goods has been investigated in depth and remains a critical component in reducing injuries and accidents [7,8,9]. This development is propelled by the fact that legal maximum loading mass on trucks are further increasing [10]. In combination with a highly competitive surrounding, regulations and controls of overloads are therefore being adapted to address load safety [4,11].

A prominent factor to describe cargo characteristics on load safety is friction, more specifically the static and sliding frictions of objects. While friction factors between wood and other materials such as metal and stone have been investigated [12,13], limited research has been published concerning timber truck load safety, and in particular when considering cargo security when transporting debarked roundwood assortments. Furthermore, different standards concerning the best practice on load security exist throughout Europe. The highest standards for load security are found in Germany and the Nordic countries and are being effectively controlled by law systems [4]. This high safety threshold triggered some concerns and reservations towards transporting the increasing assortment “debarked roundwood” in Germany.

The current increase of debarked assortments is caused by the expanding threat of spruce bark beetle (Ips typographus L.) infestations throughout central European forests and a newly tested harvesting system that includes debarking ability as part of the harvester-based wood procurement [14,15,16,17]. Within the “Debarking Heads” research project, conventionally used harvester heads were modified to add debarking capability as part of the harvesting operations. Therefore, concerns regarding load security of debarked roundwood were communicated on multiple occasions and a comprehensive investigation was carried out to clarify differences in load security between debarked and bark roundwood assortments.

More specifically, the study aimed to quantify differences in static and sliding frictions within four treatments: (i) bark roundwood, (ii) debarked roundwood, (iii) mixed assortments, and (iv) debarked roundwood exposed to simulated consecutive heavy rainfall (watered). It was also of special interest to understand how the frictions fluctuated over time and if this had a significant influence on the differences between treatments. Particular attention was therefore given to drying rate, mass of logs, and whether the presence of water on the debarked log surface had a significant influence. Finally, suggestions on how to handle debarked roundwood compared to barked roundwood were developed to increase load safety within future transport operations.

2. Materials and Methods

2.1. Test Setup

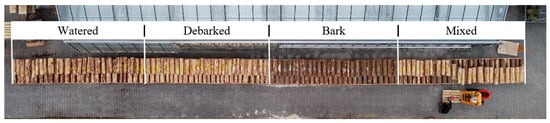

To evaluate differences in friction characteristics, 63 freshly harvested logs (lengths of 4.1 m and 5.1 m) of Norway Spruce (Picea abies L. H. Karst) were cut in the Talhauser Forst located in Freising, Germany and transported to a test site less than 3 km away. At the test site, logs were unloaded on a paved surface and then cross-cut into 1.5 m sections for the support layer and into 1.0 m sections for the actual test logs. This resulted in 104 logs of 1.5 m and 100 logs of 1.0 m. Support logs were bucked into 1.5 m lengths to ensure a continuous contact with the 1.0 m test log throughout the 0.5 m pulling distance. The 100 test logs were then subdivided into the four treatments: (i) bark roundwood (bark), (ii) debarked roundwood (debarked), (iii) mixed assortments (mixture of debarked and bark sections within a single log), and (iv) debarked roundwood exposed to simulated consecutive heavy rainfall (Figure 1).

Figure 1.

Top view of the test setup containing 100 test logs (1.0 m in length) lying on a row of support logs (1.5 m in length), divided into four treatments.

Based on the intended treatment, test logs and associated support logs were debarked with the use of hand-tools. Debarking was performed just prior to the first test run to maintain the surface moisture and sap layer as fresh as possible. Afterwards, consecutive support logs were spaced by 10 cm and fixed in position using planks and screws to ensure that no logs in the support layer would move during the pulling tests and also to avoid side friction from two adjacent test logs. During the test sessions, every test log had surface contact with only the two support logs forming the support layer. If side friction through neighboring logs was noticed prior to the pulling phase, those interfering logs were removed for the duration of the pulling cycle. In the end, a two-layered test setup was created, in which a lose test log of 1.0 m laid upon two support logs of 1.5 m length. Between the debarked and watered treatments, extra spacing was permitted to minimize the influence of the watering process on the debarked treatment. An open-eye hook was fastened on the front face of each test log to ease the attachment of the cable to the log (Figure 2).

Figure 2.

(A) Front display of the test setup and (B) open-eye hooks used for coupling to the measuring unit.

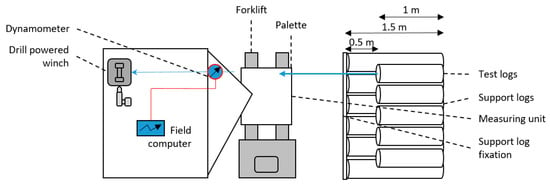

The measuring unit consisted of a drill-powered winch (max. 2650 N pulling force), a pushing/pulling force dynamometer (max. 1000 N, 0.5 N accuracy, 6–1600 Hz sampling rate, ±0.5% accuracy) and a field computer for recording and direct data storage. The winch was attached to a palette using a 5 mm diameter steel bolt and was supported by an electric forklift (Figure 3). The moving and leveling abilities of the forklift were used to ensure the pulling and measuring unit was in proper orientation with the test log, both on the vertical and horizontal profiles, thus providing a straight vector. The mass of the forklift (840 kg including battery) further ensured that the measuring unit remained static during the pulling phase.

Figure 3.

Schematic display of the test setup.

To simulate heavy rainfall of the watered assortment, debarked logs were watered before every trial with 25 l/m2 in accordance with the definition for heavy rain of the German Meteorological Service (DWD). This was done by using a hose, nozzle, and water supply of known volume from the nearby green house. Data recorded by a weather station located within 100 m from the test site was used to monitor weather conditions. The data was provided by the Bavarian State Institute of Forestry (LWF).

2.2. Test Measurements

Friction development was monitored in twelve tests performed over seven days with one test run occurring in the morning and the other at noontime. An additional control test was carried out after 21 days, to monitor longer-term effects on the static and sliding frictions, thus providing a total of 13 test sessions. Moreover, drying rate of logs through mass reduction was monitored as well as solar radiation intensity, air humidity and air temperature. Tests were performed at the start of the vegetation season at the end of April as it is expected that most of the debarked roundwood is supposed to be harvested and debarked within the start of the spruce bark beetle season.

The measuring methods were based on the VDI (Verein Deutscher Ingenieure) guideline VDI 2700 Part 14 of 2014, in accordance with the guideline VDI 1000 [18]. The VDI 2700 Part 14 describes a test procedure for determining the coefficients of friction (and coefficients of sliding friction in particular), which are required for the calculation of frictional forces and for the selection of load-securing measures in accordance with the series of guidelines VDI 2700 [18]. However, due to particulars of the test requirements, the measurement procedure had to be modified to ensure a high comparability between the four tested treatments (bark, debarked, mixed, and watered). Within a test session, each log was pulled horizontally three consecutive times (according to the VDI guideline) for a 10 s duration. A pulling speed of 100 cm per minute was used, thus equaling a 10-fold increase in pulling speed as compared to the speed described in the VDI guideline (10 cm per minute). This decision was made to increase the number of repetitions and provide a longer pulling length under observation. Therefore, the influence of appearing distortion factors (branch knobs and contamination by gravel and soil particles) on the sliding friction was considerably lowered. After each ten-second pull, the measurement acquisition stopped, the tension was zeroed, and a new measurement started. The chosen 50 cm pulling space (length difference between support and test logs) was sufficient to perform three consecutive pulls without repositioning the log at the starting position. The gathered static and sliding frictions of the three consecutive pulls were later averaged providing one static and one sliding friction per log and test session. To limit friction variations during the pre-load (tension building process), a threshold of 10 kg was defined in the measuring software and acted as a data acquisition starting point. Prior to every test session, the pulling force dynamometer was calibrated and zeroed.

To adequately capture the effects on the static and sliding frictions, measurements were performed at 200 Hz (50 Hz required according to VDI guideline). At this recording frequency, 2000 discrete pulling forces were detected and recorded within the 10-s pulling period. In total, 7.8 million discrete pulling forces were recorded throughout the 13 test sessions. The pulling force dynamometer recorded the forces with a resolution of 0.5 N to a maximum of 1000 N with a tolerance of 0.1%. The detected pulling forces were directly recorded by the field computer and every pulling cycle (creating 2000 discrete readings) was exported and saved as a CSV file.

The mass of each log was determined before the first test session (day 1), after the twelfth test session (day 7), and after the thirteenth test session (day 21) to correlate the required pulling forces to the mass of each log and to monitor drying effects of the different assortments. This task was done by suspending each log individually with the forklift and using the pulling force dynamometer to record the mass to the nearest 0.05 kg. Four additional logs (two debarked and two with bark) were placed beside the test logs and used to gather solid wood discs to measure the current moisture content after every test session. To measure the moisture content of the solid wood discs, the mass was determined before and after mass stability was achieved through the drying process in the oven. The moisture content was used to calculate a dynamic drying rate between the total measurements of the log weight.

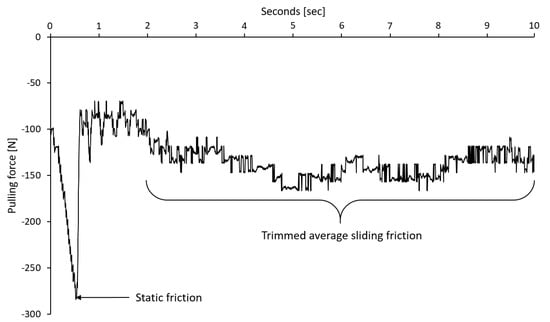

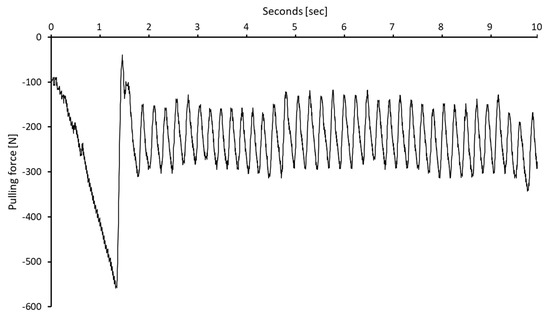

2.3. Data Evaluation

To minimize human related failures within the data importing, merging and calculation processes, all steps towards the final database were realized by Visual Basic macros within Microsoft Excel. After automatically uploading all CSV files into the database, the static friction was determined by taking the highest pulling force within the first two seconds of a test session, by searching the first 400 pulling force recordings. This time window was selected for every test to ensure comparable time frames for the identification of the static friction. The exact time depended on different variables and tension building processes within the pulling setup. The remaining eight seconds (1600 pulling force readings) were utilized to calculate the average sliding (Figure 4). To automatically erase the strongest outliers, a trimmed average sliding friction was calculated with the factor 0.2. This factor was chosen to erase most of the extreme events caused by branches or log shape related influencing factors. The calculated static and sliding frictions of the three consecutive pulling repetitions were then merged by calculating the average static and average sliding friction for every log per test session. IBM SPSS Statistics Version 24 (SPSS) was used to perform the statistical tests and evaluations. Kolmogorov–Smirnov (KS) tests were performed to verify the data for normal distribution. To test for significant differences parametric test (ANOVA with Tamhane/Tukey post hoc p = 0.05) were performed.

Figure 4.

Example of a typical pulling force measurement curve in function of time.

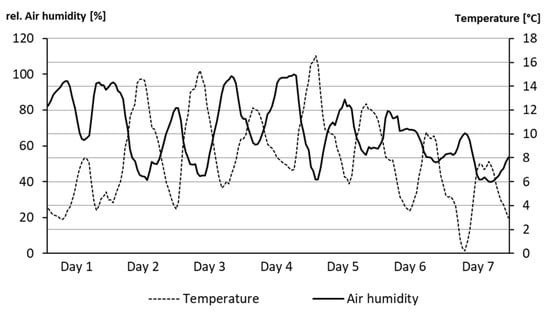

2.4. Weather Data

Due to the size of the test setup including 100 individual test logs, the test was performed outdoors. To retrace potential significant deviations of the measured frictions linked to weather factors, such as rain, solar radiation, wind, and humidity, weather data were recorded and provided by the nearby weather station. Air temperature varied between 0 to 16.2 °C with relative air humidity ranging from 40% and 100% (Figure 5). During the recorded test week, two light rain events (night of day 4 and during day 6) were detected and amounts reported did not exceed 0.2 l/m2.

Figure 5.

Display of the air temperature (°C) and relative humidity (%) during the test week (LWF).

3. Results

3.1. Mass Loss of Test Logs after 7 and 21 Days

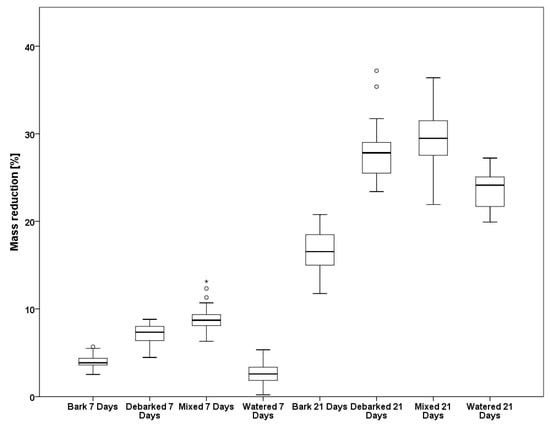

The investigation of the mass loss revealed considerable differences between treatments. Within the first seven days, logs of the bark treatment showed a 4% average reduction in mass compared to the initial mass. However, with an average mass loss of 2.7%, the debarked logs of the watered treatment dried noticeably slower compared to the debarked logs of the debarked treatment (7.2% mass loss within seven days) and mixed treatment (9% mass loss within seven days). This difference was less dominant after 21 days, as the logs were not watered throughout the additional two-week period. This resulted in a mass loss of 27.8% for logs within the debarked treatment, 29.3% for logs within the mixed treatment, and 23.5% for logs of the watered treatment (Figure 6). Therefore, all treatments that involved debarking showed a significantly higher drying rate as compared to the bark treatment, which had an average mass loss of 16.7% over the 21-day monitored period. Comparing drying rates between bark and debarked treatments, debarked logs dried 40 to 45% faster compared to logs with bark.

Figure 6.

Mass reduction (%) of test logs within the four treatments after 7 and 21 days.

3.2. Correlation between Pulling Force and Log Mass

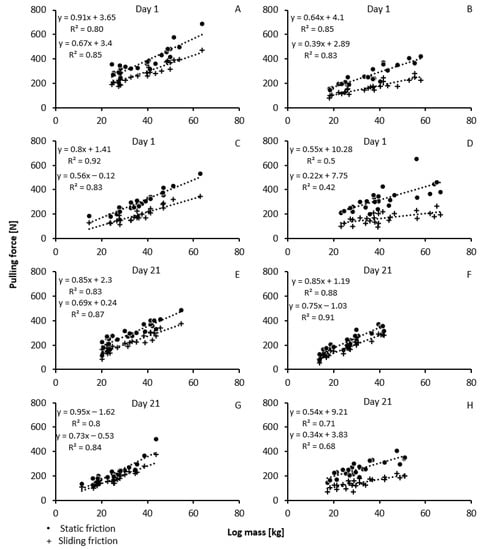

The potential influence of log mass on both static and sliding frictions was expected to be a predominant factor within the pulling tests. Therefore, the data of the first (day 1) and control (day 21) test sessions was searched for linear correlations between log mass and associated friction measurements (Figure 7). To ease interpretation, pulling force was multiplied by −1 from this point forward to convert the results into the positive display range. The investigations of the data revealed a strong linear correlation between log mass and static and sliding frictions for the bark (R2 = 0.80 and 0.85), the debarked (R2 = 0.83 and 0.85), and the mixed (R2 = 0.83 and 0.92) treatments. However, for the watered treatment, the trend appeared to be considerably weaker with R2 of 0.50 and 0.42 on day 1 and R2 of 0.71 and 0.68 on day 21. This increase within the calculated R2 towards day 21 was also observed within the other treatments, with one exception for the static friction of the mixed treatment. Further investigations of the correlation coefficient proved a strong positive correlation between the static/sliding frictions and the log mass for bark, debarked, and mixed treatments that differs between 0.81 and 0.96 (average 0.91) over all test sessions. The correlation coefficient of the watered treatment differed between 0.68 and 0.87 (average 0.80) indicating the presence of an additional influencing factor.

Figure 7.

Correlation between pulling force (N) and mass of log (kg) for the first test session (day 1) for: (A) bark treatment, (B) debarked treatment, (C) mixed treatment, and (D) watered treatment. Correlation between pulling force and mass of log for the last test session (day 21) for (E) bark treatment, (F) debarked treatment, (G) mixed treatment, and (H) watered treatment.

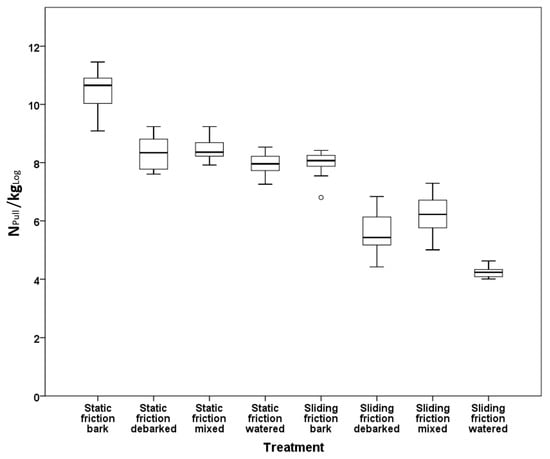

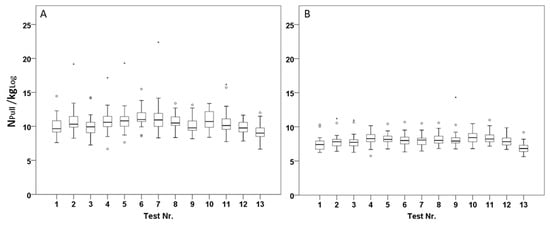

3.3. Static and Sliding Frictions Overview

After a strong correlation was detected between the required pulling force (N) and log mass (kg) (Figure 7), pulling force was calculated per kilogram log mass, to eliminate log mass-related deviations. When all test session results were grouped, the data showed significant differences between treatments. For both static (10.52 N) and sliding frictions (7.99 N), logs of the bark treatment showed significantly higher average frictions per kilogram log mass when compared to the other treatments including debarking (see Table 1 and Table 2). The average static friction of the debarked (8.31 N), mixed (8.44 N), and watered (8.09 N) treatments performed similarly showing no significant differences between treatments (Figure 8). Surprisingly, the average sliding friction of the bark treatment (7.99 N) showed also no significant difference in the required pulling force per kilogram log mass compared to the average static frictions of treatments with debarking. Considering the overall average sliding friction, the debarked (5.60 N) and mixed (6.20 N) treatments performed on par with no significant difference (see Table 1 and Table 2). The lowest overall sliding friction was measured for the watered treatment with a required pulling force of 4.32 N per kilogram wood mass, and is therefore 46% lower compared to the average sliding friction of the bark treatment and 23% lower compared to the debarked treatment.

Table 1.

Average static frictions in NPull/kgLog of test sessions 1, 12, and 13 as well as minimum, maximum, and overall average.

Table 2.

Average sliding frictions in NPull/kgLog of test sessions 1, 12, and 13 as well as minimum, maximum, and overall average.

Figure 8.

Boxplots showing the overview of the average static and sliding frictions in NPull/kgLog of the four different treatments based on the 13 carried out test sessions.

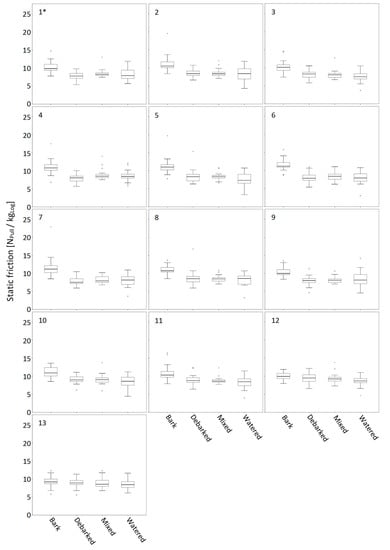

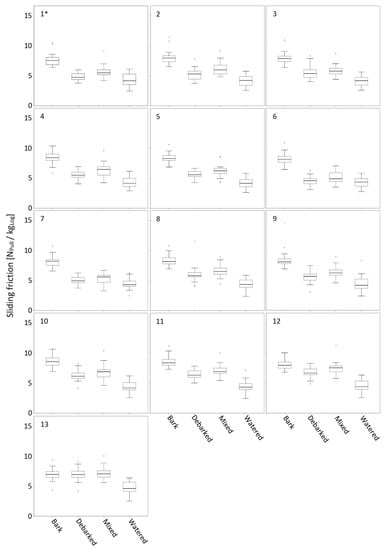

3.4. Development of Static and Sliding Frictions Single Test Wise Comparison

By calculating average static and sliding frictions over the complete test period, variations between the treatments and test sequences might be masked (Figure 8). Therefore, both static and sliding frictions were investigated separately for every test session and then compared among treatments. When focusing on static friction, no major differences developed within the seven-day monitoring period between the investigated treatments. One-way ANOVA and post hoc tests revealed no significant differences for the static friction between treatments that involved debarking (debarked, mixed, and watered). Average static friction of the bark treatment was significant higher throughout the first eleven tests, while the significant difference tended to decline towards test Nr. 12 (Figure 9). Within the twelfth test session occurring on day 7 however, no significant difference between the static friction of the treatments bark, debarked, and mixed was detected. However, a significant difference between the treatment bark and watered remained. This trend continued within the control test (Nr. 13) on day 21 illustrating no significant difference within all four tested treatments concerning the static friction. The tests also revealed that average static friction of all treatments increased within the 12 test sessions and then declined after 21 days (Table 1).

Figure 9.

Development of static friction (NPull/kgLog) for each treatment throughout the 13 test sessions (* test number).

Investigations of significant differences between sliding frictions of the tested treatments, showed a higher variance of differences compared to the static friction (Figure 9). Six out of 13 test sessions showed significant differences between all four tested treatments (test sessions 1, 2, 4, 5, 9, and 11). Within all other test sessions carried out in the first seven days, significant differences were present between the treatments bark and watered (Figure 10). No significant difference was detected between debarked and mixed, however, compared to bark and watered treatments significant differences were still present. Nevertheless, for the control test session of day 21, no significant difference was present between the treatments bark, debarked and mixed. Only the watered treatment performed on a significantly lower level when compared to the other treatments. In accordance to the static friction investigations, sliding friction increased over the test week but was lower for the measurements on day 21 (Test 13). In exception, the debarked treatment was presenting the highest measured average sliding friction within the test Nr. 13 (Table 2).

Figure 10.

Development of sliding friction (NPull/kgLog) for each treatment throughout the 13 test sessions (* test number).

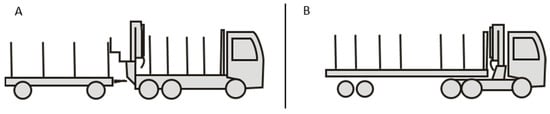

3.5. Influence of Debarking Treatment on Load Volume and Mass

To evaluate the influence of debarking on roundwood logistics, a calculation was performed to display the changes within load properties and management. Therefore, differences occurring by changing load volume and mass were calculated in an example considering the most commonly used truck and trailer systems for shortwood transportation within Germany (Figure 11). The transportation systems are either (A) a combined truck with loading space, self-loading crane and in attachment a simple trailer with comparable loading capacity or (B) a truck with self-loading crane and long trailer [19]. The technical machine characteristics and lorry dimensions are further displayed in Table 3.

Figure 11.

Schematic display of (A) self-loading combined truck with short wood trailer providing a lorry length of 2 × 5.1 m and lorry width of 2.27 m and (B) self-loading truck with long trailer and a lorry length of 13 m and lorry width of 2.4 m (adapted from [20]).

Table 3.

Machine-related characteristics and dimensions considered within the loading and mass capacity calculations.

For the calculation of the maximum loading capacity, the maximum loading height of 2.4 m was used (Table 3). To consider the rather poor stacking ability of round logs and to address the free space (air voids) between single logs, a correction factor of 0.6 that is commonly utilized to calculate the stack volume was employed [21]. The legal maximum total mass of 44 tons for (A) combined truck and trailer system and 40 tons for (B) conventional truck and trailer system were considered as overall thresholds, referring to the German Schedule of Fines and Penalties [22]. Wood density (kg/m3) for bark and debarked wood was calculated from the log mass measured in the study (Figure 6). An average wood density of 807 kg/m3 (day 1), 775 kg/m3 (day 7), and 673 kg/m3 (day 21) was calculated for spruce roundwood of the bark treatment. For debarked spruce roundwood an average wood density of 779 kg/m3 (day 1), 724 kg/m3 (day 7) and 564 kg/m3 (day 21) was calculated.

Results showed that a crucial overloading (>44 tons) of the first investigated truck and trailer system (A) was impossible when loading Norway spruce shortwood. The highest calculated total mass of the fully loaded combined truck and trailer system accounted to 36.4 tons when loaded with barked roundwood assortments and 35.9 tons for debarked assortments, when considering the legal loading, technical conditions, and density of the logs used in the study. For the truck in system (A), load capacity of 6.1 tons turned out to be the limiting factor. When ignoring the legal load capacity of 6.1 tons and calculating with the maximum load volume capacity of 16.7 m3 for the truck lorry, total mass of the fully loaded truck and trailer system never exceeded the 44 tons legal threshold for all calculated scenarios. For the trailer, the load volume capacity of 16.7 m3 worked as limiting factor at all time. The presence of both limiting factors (mass and volume) resulted in a 1.1% additional m3 of transported debarked wood and cargo mass reduction of 2.3% per load on day 1, when compared to a full load of barked roundwood. This effect increased on day 2, resulting in a 2.2% increase in the volume of debarked roundwood transported and 4.4% lower cargo mass, thus culminating in an increase of 6.8% in transported debarked roundwood and a 10.5% reduction in cargo mass (Table 4).

Table 4.

Calculated differences between debarked and bark assortments concerning additional load and total mass of the loaded truck and trailer combination, after different drying periods.

Within the second calculated truck and trailer transport system (B), load capacity functioned as the limiting factor for days 1 and 7. This implied that overloading (>40 tons) can occur when loading Norway spruce at the wood density measured in this study. The mass reduction through roundwood debarking resulted in a higher additional volume loading capacity of debarked roundwood when compared to a full load of barked roundwood. A potential additional net load of 3.4%, 7%, and 11% was calculated for days 1, 7, and 21 (Table 4), respectively. For the comparison of potential load mass and volume, both factors limit the additional cargo, resulting in an additional load mass reduction of 6.9% due to the limit of loadable debarking roundwood volume.

4. Discussion

4.1. Study Design and Measurement System

Overall, the study design operated as expected but some modifications to the VDI guideline were required to ensure good practicability. Specifically, the pulling speed was increased to be able to perform the intended amount of measurements per test session and day. Hence, the pulling length and resolution of the measurements were also increased to accommodate the faster pulling speed and to assure that local distortion factors such as branches or poor shape structure did not influence the full pulling attempt. It was initially planned to pull the logs three times over the full length of 50 cm and reposition the log after each pull. However, after preliminary testing, this method was abandoned because of possible wear-off on the outside surface of the logs over repeated measurements. Instead, it was decided to pull the log for 10 s (equaling to a horizontal distance of 16.7 cm) with 200 Hz producing 2000 single measurements per pulling attempt for three consecutive pulls, before repositioning the logs for the next test session. These settings proved to be beneficial as small disturbances were recorded with a higher resolution and tension problems within the pulling and measurement setup were not problematic within the data evaluation. The wear-off, especially on the bark treatment, did not show any negative influence. As presented in Figure 12, both static and sliding frictions increased over the test sessions instead of decreasing if surface wear-off would be a dominant factor. The decline for the last three test sessions might be explained through mass loss as also the mixed treatments showed no trend of influencing wear-off towards the later tests (Nr. 11, 12, and 13).

Figure 12.

Development of (A) static and (B) sliding frictions (NPull/kgLog) within the bark treatment displayed over all test sessions.

The measuring unit was solid and adequate for the mass of logs used and pulling forces measured. With its 860 kg, the electric forklift did not move laterally even during high pulling forces up to 1177 N. However, the interface between the palette and the winch, secured through a 5 mm diameter bolt, did show minor tension disturbances through bending processes during high pulling forces. Further studies could use a hydraulic cylinder system to apply a smoother pulling force, as used within a study setup in New Zealand in 2004 [23]. However, a hydraulic cylinder system would require a stronger fixation point and because of its weight it is rather complicated to move, and was therefore not ideal for our research.

A further deviation factor besides the tension within the measurement setup was expected to be the weather. Because of the extent of the test setup, logs had to be placed outdoors. This exposed the logs to differing weather conditions, such as temperature, air humidity, wind, and solar radiation. As those factors appeared to be similar for all tested treatments, deviations caused by weather did not show major distortions but also could not be completely eliminated. Therefore, it seems suitable to perform such measurements under controlled conditions within a building or test hall. As water proved to have a considerable influence on the sliding friction by lowering the adhesion (Figure 8), it would have been interesting to investigate the influence of water and rain on the bark treatment as well. For future studies, the mixed treatment could therefore be replaced by a watered bark treatment to improve the comparability and further investigate the influence of water on the static and sliding frictions of bark logs.

The test setup was designed to assure the highest comparability between the four treatments and to answer the question how debarked roundwood needs to be treated for load safety when compared to bark roundwood. This approach makes use of the drivers’ experience of load safety for bark roundwood and the ability of transferring this knowledge onto debarked operations. To monitor the basic static and sliding frictions, all influencing factors, e.g., mass, diameter, log length, and surface contact would need to be investigated by testing different logs with varying log characteristics.

4.2. Static and Sliding Frictions

The investigation of the mass development presented a 45% higher drying rate for the debarked treatment as compared to the bark treatment. In comparison, the mixed treatment presented an even higher mass loss over the testing period. This can be explained by the fact that the measured logs were also debarked and placed on bark support logs. Therefore, the drying procedure was identical to the debarked treatment, but were further placed in a less wind protected area and having a lower influence on the surrounding moisture content as the support logs were covered with bark and hence released less moisture into the air. Furthermore, the debarked treatment was located next to the watered treatment and an influence from the water application could not be completely excluded. The watering of the watered treatment also revealed another effect. Due to the sap remnants, the surface of the debarked logs started to become sticky and slippery at the same time resulting in a rather high static friction with a low sliding friction. This effect is called the “stick and slide effect”, whereas no smooth pull of the logs was possible (Figure 13). This made a reliable calculation of the sliding friction rather difficult. The influence of the water also resulted within a weaker correlation coefficient between the log mass and the pulling force (Figure 7). After 21 days, the effect of the water was not as dominant as compared to day 7. This can be explained by not watering the logs throughout the additional 14 days between the last two test sessions. Hereby, logs were able to perform on par with the debarked and mixed treatments. However, the negative influence was still detectable within the drying rate compared to the debarked and mixed treatments (Figure 6 and Figure 7).

Figure 13.

Example of a typical pulling force measuring curve of the watered treatment, with stick and slide effect.

In total, the sliding friction was 24% lower for the bark treatment and 33% lower for the debarked treatment as compared to the static friction. Average values of 8.3 N/kg for the static and 5.6 N/kg for the sliding frictions are comparable to results obtained in New Zealand in 2004 [23]. Within the study [23], the friction and load characteristics of completely debarked loads regarding the restrain type, tension method on different tilt angles, and break tests were investigated. Further comparable pulling tests were carried out to assess the static and sliding frictions. All tests were performed using loaded trailers or stanchions. As no considerable differences within the frictions between both studies appear, results within our study once more indicate a strong suitability to draw direct conclusions for German load safety. However, for load safety, the lower sliding friction needs to be considered. It cannot be assured that a higher static friction is not denied by vibrations or road surface roughness that is distributed into the loaded assortments. Therefore, the sliding friction becomes the important value for load safety. Based on the compared results of the different treatments, it can be stated that for load safety, the debarked logs have to dry for a certain period of time before they should be transported. For this study, a full week with cold and windy weather appeared to be sufficient and after 21 days no significant differences were present compared to bark logs. However, the weather dependency of the drying rate makes it impossible to provide a fix drying time before debarked logs can be handled similarly to bark logs. Due to the stick and slide effect that reduces sliding friction, rain can have a negative influence on load safety as well. Therefore, additional features to secure the load should be considered when transporting wet debarked roundwood. Nevertheless, it needs to be stated that for the utmost of incidents with lost loads on the road as mentioned within the introduction, load security was usually not the cause of the incident unlike overloading, tiredness, mechanical failures or traffic.

4.3. Load Mass and Volume

Investigations on the combined truck and trailer system (Figure 11A) showed that the limiting factor concerning the trailer appeared to be the load capacity (volume) instead of the load mass for both debarked and bark roundwood. Therefore, at day 1 the trailer could have been loaded with 23.7 m3 (bark) and 24.5 m3 (debarked) spruce roundwood but was limited to 16.7 m3 of loading capacity. The additional loaded m3 roundwood originated from the characteristics of the truck capacity (A). The truck is theoretically also limited to a loading capacity of 16.7 m3 but the threshold was the 6.1 tons of legal load mass. Therefore, debarking has an influence on both total load mass and total load volume, as the mass of the wood is reduced by a faster drying rate, a higher share of additional m3 of wood can be hauled by the truck itself. At the same time, the mass of the load on the trailer decreases with every drying day. Based on that higher drying rate, the total mass and therefore the wear-off (brakes, tires, bearings, transmission, compressed air system, chassis, etc.), fuel consumption and handling, uphill drive, and ground pressure per load could be improved. In addition, the impact onto the loading crane and hydraulic system is also expected to be lower, therefore contributing to a decreased wear-off. This effect might be even higher, as the correction factor of 0.6 is usually used for calculations without bark. A different correction factor for bark wood loads could hence result in a further decreased net load. However, as those factors are highly influenced by physical factors such as stem diameter and curviness, a fixed value was chosen to assure comparability within the hypothetical load calculation.

The second truck and trailer system (Figure 11B) offered a larger potential loading volume. Therefore, the mass of the logs became significantly important for the calculation of the possible total hauled m3 roundwood per single load. The higher drying rate of debarked roundwood was beneficial by allowing up to 11% additional m3 loaded wood when compared to a full load of barked wood. For day 21, the log mass decreased to an extent such that for a full load, volume became the limiting factor. However, 11% additional load could be hauled if logs are debarked and stored within the forest for a longer period of time, thus reducing the load mass by an additional 6.9%. When considering the necessity to transport the wood out of the forest within the first seven days to prevent the potential threat of the stored logs as spruce bark beetle breading habitat within the forest stand and therefore calculating with the log mass of the bark treatment on day 7, this effect would even raise to 28% additional load. The debarking of logs therefore offers a great potential for both forest health and lower transport costs for future operations as up to 30% of the transport costs are related to fuel costs [24]. Therefore, it is assumed that fuel consumption l/m3 would benefit greatly of in-stand debarking.

An additional benefit of a potential higher load volume capacity is linked to the fact that overall transport capacity of the logistic sector in Germany cannot fulfill the actual demand. This is particularly the case for the forest sector [24]. A higher load capacity per truck could therefore help distributing the time pressure within the wood logistic chain while reducing the dormant threat of a crucial overloading [25].

5. Conclusions

The focus of this study was to assess the difference between bark and debarked roundwood assortments according the static and sliding frictions, and to suggest improvements concerning load safety. In comparison, both static and sliding frictions proved to be higher favoring bark logs. Conversely, the drying rate over the monitoring period was up to 45% higher for debarked assortments. As log mass proved to be the dominating factor influencing the required pulling force, significant differences between bark and debarked logs decreased within 7 days and were not detectable after 21 days. This leads to the assumption that debarked logs could indeed pose a higher threat on load safety if the material is transported directly after harvesting and debarking. However, when considering the drying rate depending on exposition, wind, air humidity, etc., debarked logs monitored in this study could be handled similarly to bark logs, when stored over a sufficient period of time greater than seven days. This time can vary greatly depending on the above-listed predominant surrounding factors.

Simulated rainfall had a negative influence on the sliding friction even after a long drying period. Therefore, additional load safety precautions (lashing straps or chains) should be considered when transporting debarked roundwood in wet weather conditions. It is also important to mention that good practice guidelines on load security (orienting large diameters towards the driving direction, contact with at least two stanchions on both sides, sufficient lashing straps, and no overloading) remain essential to safely transport bark or debarked roundwood.

The increased drying rate and associated mass reduction through debarking resulted in either a lighter total loading mass or a higher net load volume, both potentially reducing the wear-off and fuel consumption per transported m3 wood. This effect shows the potential of reducing the carbon footprint of wood products even further in future, supporting the efforts towards a sustainable resource supply of forest products.

Author Contributions

Conceptualization, all authors; methodology, J.B.H; writing—original draft preparation, J.B.H. and E.R.L.; writing—review and editing, all authors; supervision, E.R.L.; funding acquisition, S.W.

Funding

This research was funded by the German Federal Ministry of Food and Agriculture (FKZ 22012214).

Acknowledgments

We would like to thank Alois Reichenberger for his help with the preparation, execution and recording of the test measurements. Further, we want to thank Anton Brumer, Christian Genser, and Tilman Zepf for their assistance with the test setup and wood acquisition. Finally, we want to thank Lothar Zimmermann (LWF) for providing the weather data.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bundesverband Güterkraftverkehr Logistik und Entsorgung (BGL) e.V. (2019). Available online: https://www.bgl-ev.de/web/mensch_umwelt_verkehr/verkehrssicherheit/verkehrssicherheit2.htm (accessed on 13 June 2019).

- DEKRA Automobil GmbH. Dekra Verkehrssicherheits Report 2018—Güterverkehr; ETM Corporate Publishing: Stuttgart, Germany, 2018; 76p. [Google Scholar]

- Statista Forst- und Holzwirtschaft. 161p. Available online: https://de.statista.com/statistik/daten/studie/152173/umfrage/entwicklung-des-holzeinschlags-seit-dem-jahr-1998/ (accessed on 8 February 2019).

- Jagelcak, J.; Gnap, J. Different measures for load securing create barriers in international road freight transport. Arch. Transp. Syst. Telemat. 2011, 4, 10–17. [Google Scholar]

- Strauß, M. Unfall: Holz-Lkw verliert Ladung. Volksstimme. Available online: https://www.volksstimme.de/lokal/salzwedel/unfall-holz-lkw-verliert-ladung (accessed on 8 July 2019).

- Abendzeitung. Holz-Lkw kippt auf A92 um—Lange Staus. Abendzeitung München. Available online: https://www.abendzeitung-muenchen.de/inhalt.zwischen-erding-und-freising-lkw-unfall-auf-a92-behinderungen-bis-zum-mittag.88436ae0-9739-4713-8f6f-404916abfc44.html (accessed on 8 July 2019).

- Monaco, K.; Williams, E. Assessing the determinants of safety in the trucking industry. J. Transp. Stat. 2000, 3, 69–80. [Google Scholar]

- Quinlan, M. Report of Inquiry into Safety in the Long Haul Trucking Industry; Motor Accidents Authority of New South Wales: Sydney, Australia, 2001; ISBN 1876958065. [Google Scholar]

- Singh, S.P.; Antle, J.; Singh, J.; Topper, E.; Grewal, G. Load Securement and Packaging Methods to Reduce Risk of Damage and Personal Injury for Cargo Freight in Truck, Container and Intermodal Shipments. J. Appl. Packag. Res. 2014, 6, 6. [Google Scholar] [CrossRef]

- McKinnon, A.C. The economic and environmental benefits of increasing maximum truck weight: The British experience. Transp. Res. Part D Transp. Environ. 2005, 10, 77–95. [Google Scholar] [CrossRef]

- Jacob, B.; Feypell-de La Beaumelle, V. Improving truck safety: Potential of weigh-in-motion technology. IATSS Res. 2010, 34, 9–15. [Google Scholar] [CrossRef]

- Zhang, P.; Nagae, T.; McCormick, J.; Ikenaga, M.; Katsuo, M.; Nakashima, M. Friction-based sliding between steel and steel, steel and concrete, and wood and stone. In Proceedings of the 14th World Conference on Earthquake Engineering, Beijing, China, 12–17 October 2008. [Google Scholar]

- Koubek, R.; Dedicova, K. Friction of Wood on Steel. Master’s Thesis, Linnaeus University, Växjö, Sweden, 2014. Available online: http://www.diva-portal.org/smash/record.jsf?dswid=6017&pid=diva2%3A729796&c=8&searchType=SIMPLE&language=en&query=Friction+of+Wood+on+Steel&af=%5B%5D&aq=%5B%5B%5D%5D&aq2=%5B%5B%5D%5D&aqe=%5B%5D&noOfRows=50&sortOrder=author_sort_asc&sortOrder2=title_sort_asc&onlyFullText=false&sf=all (accessed on 26 June 2019).

- Carroll, A.; Forster, B.; Hurling, R.; Nageleisen, L.M.; Ravn, H.P.; Weed, A.; Schroeder, M.; Grégoire, J.; Marini, L.; Økland, B.; et al. Climate drivers of bark beetle outbreak dynamics in Norway spruce forests. Ecography 2017, 40, 1426–1435. [Google Scholar]

- De Groot, M.; Diaci, J.; Ogris, N. Forest management history is an important factor in bark beetle outbreaks: Lessons for the future. For. Ecol. Manag. 2019, 433, 467–474. [Google Scholar] [CrossRef]

- Hinze, J.; John, R.; Delb, H. Spreading Dynamics of the European Spruce Bark Beetle in the Black Forest National Park; FVA Annual Report; Forest Research Institute: Freiburg, Germany, 2017; pp. 28–29. [Google Scholar]

- Abschlussbericht. Nährstoffentzüge bei Holzernte minimieren durch die Nutzung von entrindenden Harvesterfällköpfen (Debarking Head); Bundesministerium für Ernährung und Landwirtschaft: Bonn, German, 2018; 100p. [Google Scholar]

- Verein Deutscher Ingenieure e.V. Securing of loads on road vehicles—Determination of coefficients of friction. VDI 2700, Part 14; Beuth Verlag: Berlin, Germany, 2011; 20p. [Google Scholar]

- Korten, S.; Eberhardinger, A. Entwicklungen Für den Rundolztransport. Logistik—Holz Kommt in Fahrt, LWF Aktuell 2008; Bavarian State Institute of Forestry: Freising, Germany, 2008; Volume 65, pp. 16–18. ISSN 1435–4098. [Google Scholar]

- Erler, J.; Dög, M. Funktiogramme für Holzernteverfahren. Forsttechnische Informationen KWF 2009, 61, 14–17. [Google Scholar]

- Reisinger, K.; Höldrich, A.; Kuptz, D.; Hartmann, H. Poster: Umrechnungsfaktoren verschiedener Raummaße für Scheitholz. Technologie- und Förderzentrum im Kompetenzzentrum für Nachwachsende Rohstoffe. Available online: www. tfz.bayern.de (accessed on 8 July 2019).

- German Federal Ministry of Transport and Digital Infrastructure. Schedule of Fines and Penalties. Available online: https://www.bussgeldkatalog.org/zuladung-lkw (accessed on 8 July 2019).

- Baas, P.H.; Mueller, T.H.; Milliken, P. Load Security Testing of Logs A Summary Report for the Log Transport Safety Council; Transport Engineering Research New Zealand Limited: Manukau City, New Zealand, 2004. [Google Scholar]

- Korten, S.; Eberhardinger, A. Mehr Effizienz im Rundholztransport. LWF Aktuell 2008; Bavarian State Institute of Forestry: Freising, Germany, 2008; Volume 65, pp. 12–13. ISSN 1435–4098. [Google Scholar]

- Koirala, A.; Kizha, A.R.; Roth, B.E. Perceiving Major Problems in Forest Products Transportation by Trucks and Trailers: A Cross-sectional Survey. Eur. J. For. Eng. 2017, 3, 23–34. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).