Mechanical, Transportation, and Microstructural Characteristics and Application of High-Porosity Coal Mine Solid Waste Filling Materials: A Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

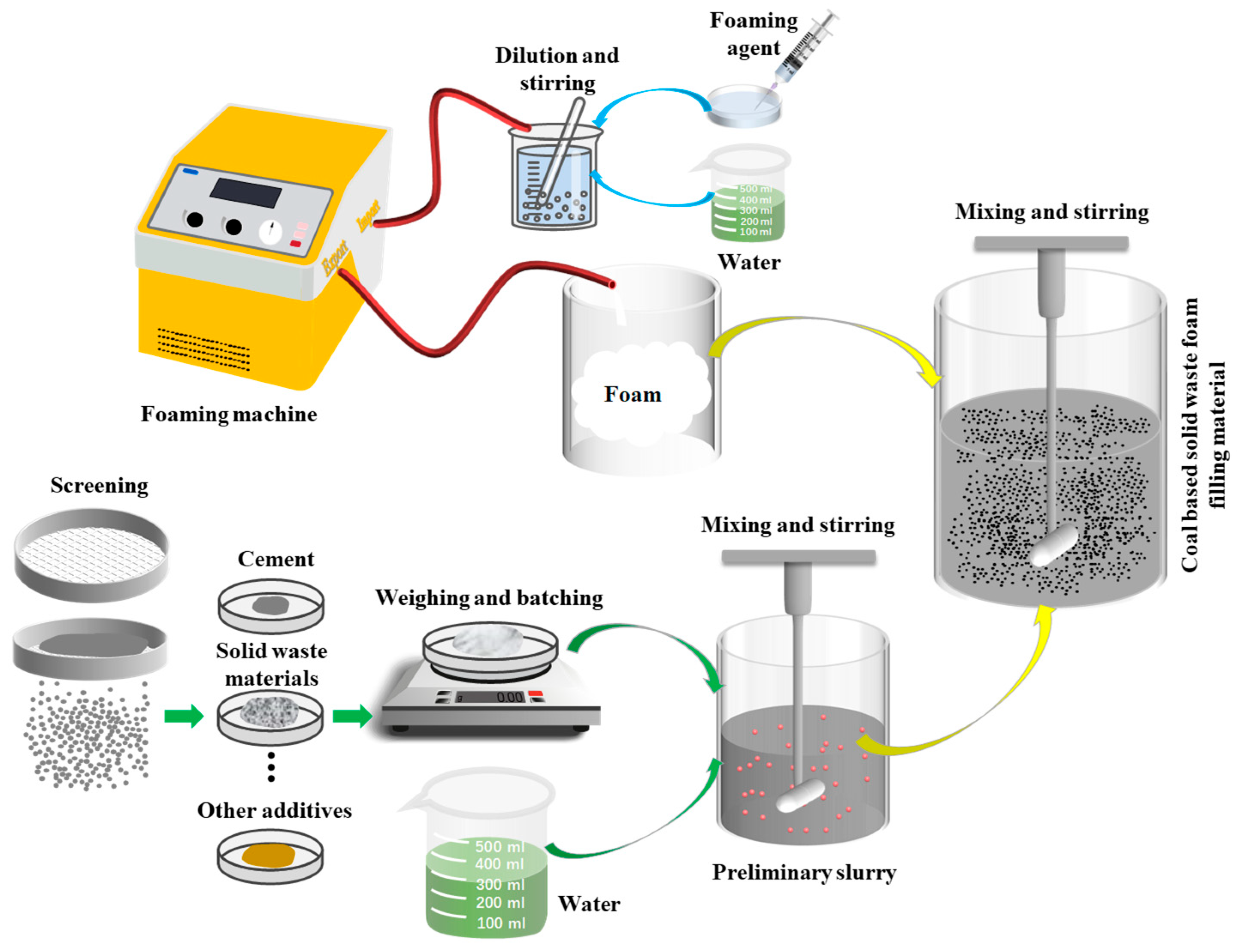

2.2. Preparation Method of Foam Filling Material

2.3. Optimal Dilution Ratio of Foaming Agent

2.4. Optimal Selection of Foam Stabilizer Dosage

2.5. Material Performance Testing Method

3. Characterization of Cement Foam Filling Materials

3.1. Mechanical and Transportation Properties Test

- (1)

- Water–cement ratios

- (2)

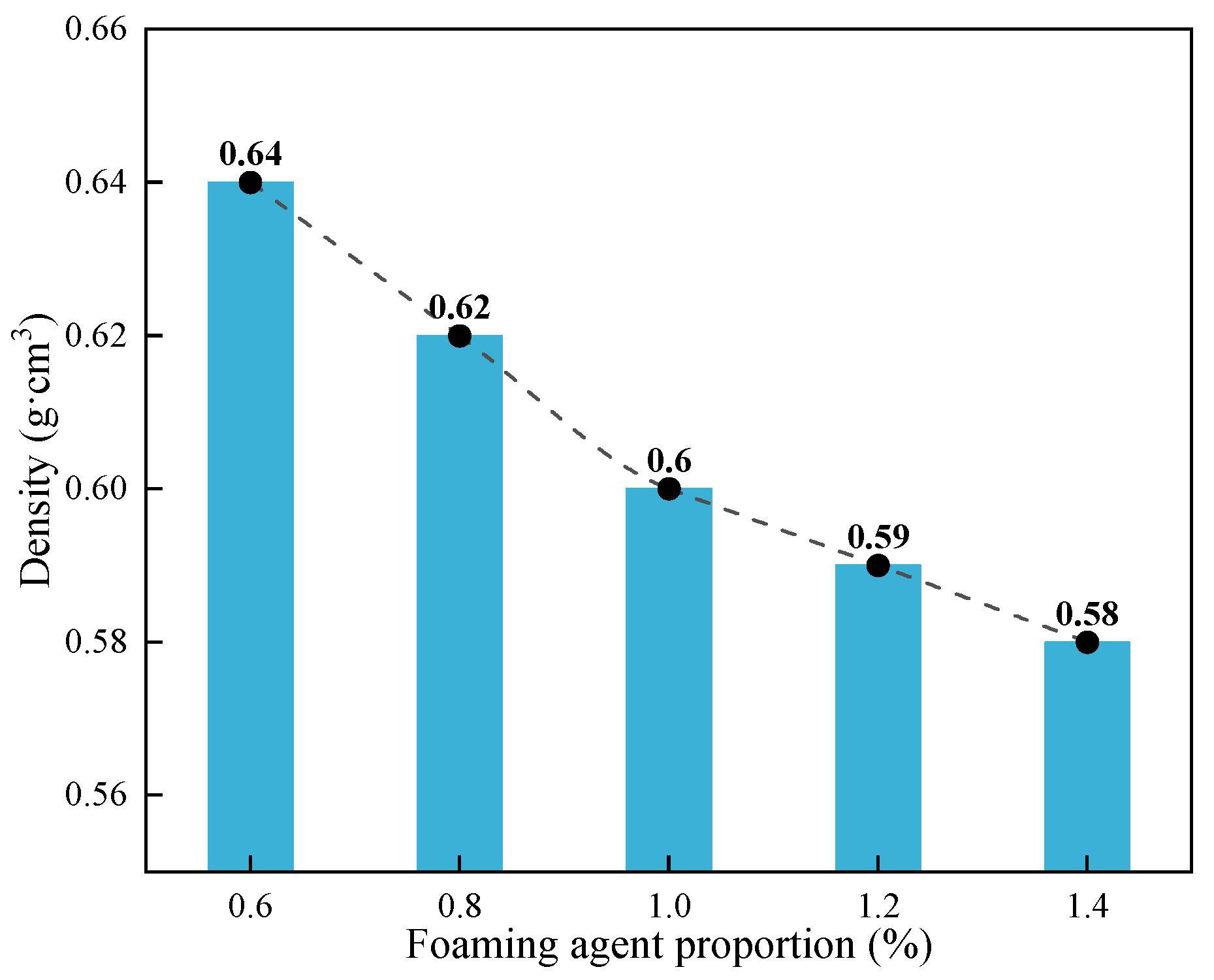

- Foaming agent proportion

- (a)

- When the water–cement ratio is constant, the performance test results of cement foam filling materials prepared with different foaming agent contents show that the initial setting time is positively related to the foaming agent content, while the slump is negatively related. The main reason is that with the increase in foaming agent content and surfactant concentration, the cell volume increases rapidly, while the fluidity of the foam is poor. With the increase in foam, the fluidity of the slurry will gradually decrease.

- (b)

- From the perspective of physical and mechanical properties, when the dosage of foaming agent is too high, the expansion ratio also increases, increasing the porosity of the cement slurry in the free state, relaxation of the structure, and a decrease in strength. As the curing period increases, the UCS of the specimen gradually increases. With the increase in foaming agent concentration, the UCS of the specimen continuously decreases. When the foaming agent dosage is 0.8% and the curing period is 28 days, the UCS reaches 2.08 MPa. When the foaming agent dosage is 1% and the curing period is 28 days, the UCS reaches 1.93 MPa. At a foaming agent dosage of 1.2% and a curing period of 28 days, the UCS reaches 1.86 MPa. Macroscopically, it manifests as an increase in the specimen’s size and quantity of holes.

- (3)

- Gypsum proportion

- (a)

- With the increase in gypsum content, the UCS of the samples first increases and then decreases. At a curing time of 28 days and a gypsum content of 7%, the UCS of each group of samples reaches the maximum value of 2.52 MPa. When the gypsum content increases from 4% to 7%, the UCS increases by 18%, 5%, and 3% at 14, 21, and 28 days, respectively. When the gypsum content exceeds 7%, the sample’s UCS drops with the increased gypsum content.

- (b)

- The main function of gypsum in Portland cement is to inhibit the rapid hydration reaction of calcium aluminate in cement, adjust the setting time, and an appropriate amount of gypsum can also improve the long-term strength of cement. The material’s initial setting time and slump increase with increased gypsum content. This is because gypsum can improve the workability of cement slurry, increase the fluidity of slurry, and also react with calcium aluminate in cement to generate calcium aluminate sulfate, which can inhibit the rapid hydration reaction of calcium aluminate and prolong the setting time of cement.

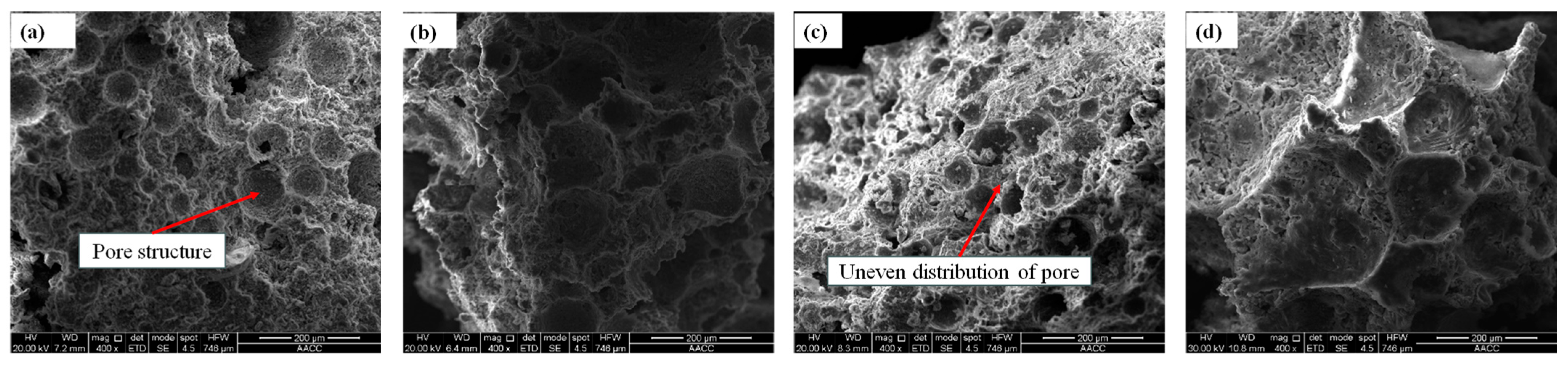

3.2. Microstructural Examinations

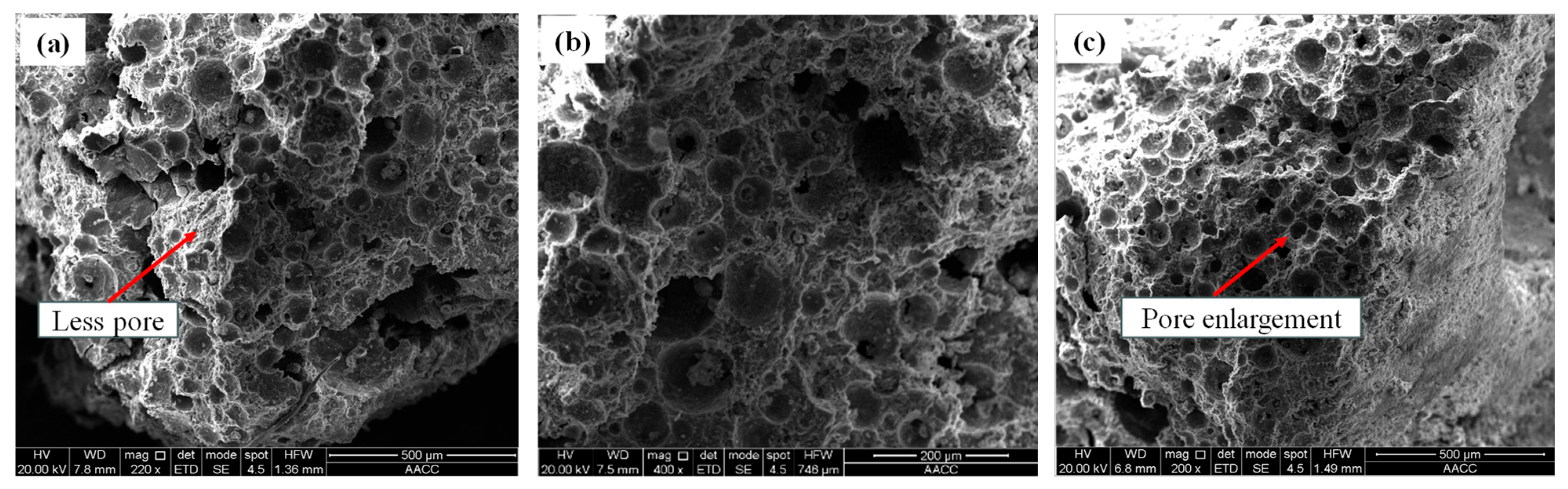

- (a)

- The cement foam filling materials prepared with different water–cement ratios can be seen in the electron microscope test, where no matter how much the water–cement ratio is, the main failure is the periodic fluctuation of roughness. When the stress wave acts on the crack tip during the failure process, the stress field at the crack tip periodically changes so that the crack front deviates from the crack’s main plane, leaving wavy patterns on the fracture surface. Cracks do not propagate in a continuously accelerating manner but in a fast–slow–fast–slow alternating manner. The fracture surface of specimens with a smaller water–cement ratio is relatively flat and smooth compared to specimens with a larger water–cement ratio, without obvious plastic deformation marks, and is more prone to brittle fracture. The larger the water–cement ratio, the more tensile textures and extension areas on the fracture surface of the specimen, indicating that the material experienced more plastic deformation during the fracture process, mainly due to the different forms of failure.

- (b)

- The cement foam filling materials prepared with different foaming agent contents can be seen in the electron microscope test that the size and shape of the microparticles of the debris structure on the surface of the specimens prepared with three foaming agent contents are irregular, the particles are arranged in a disorderly manner, the structure between particles is loose, and there are a large number of evenly distributed holes of different sizes. The appearance of microcracks and holes also accompanies the structural plane. As the concentration of foaming agent increases, the size and number of bubbles also increase, which leads to an increase in the internal pores and cracks of the specimen, directly affecting the strength and stability of the material. However, these bubble holes also affect the specimen’s volume expansion and density reduction. Adding a foaming agent to the same mass of dry material can expand the volume several times, but at the cost of losing its strength.

- (c)

- The cement foam filling materials prepared with different gypsum content can see in the electron microscope test that the addition of gypsum promotes the uniform nucleation of pores, which makes the pore structure more closed, low connectivity, and less ellipsoidal pores, indicating that the pore structure is relatively regular, the pore wall is relatively smooth, and the fracture crack propagation is moderate. The selected gypsum dosage is in the low dosage range (0~10%). If the gypsum dosage is too high, it will cause an imbalance in the reaction rate of the foaming agent, and the pores may merge to form irregular bubbles, while microcracks appear on the pore walls. However, when the content is too low (<5%), the micro morphology of gypsum is not much different from that of ordinary cement-based foam filling materials due to too little gypsum content, and some cracks and irregular bubbles appear.

4. Characterization of Fly Ash Foam Filling Materials

4.1. Mechanical and Transportation Properties Test

- (a)

- With the addition of fly ash, when the fly ash content is less than 40%, due to its spherical particles and microaggregate effect, spherical particles can reduce friction between particles, and fine particles can fill the gaps between cement particles, releasing more free water. However, when the fly ash content is greater than 40%, the active SiO2 and Al2O3 in the fly ash react with cement hydration products, which increases the viscosity of the slurry and may slightly reduce its flowability. At the same time, it can also lead to a decrease in the proportion of cement and a weakening of its bonding properties, thereby reducing the material’s mechanical strength. From the perspective of foaming, fly ash can enhance the stability of bubbles, preventing cracking and merging. The synergistic effect of fly ash and foaming agent helps to distribute bubbles evenly. The water demand for fly ash is relatively low, which can increase free water and improve fluidity under the same water–cement ratio.

- (b)

- The fly ash foam filling material’s strength decreases with the increase in fly ash proportion. Still, its strength is higher than that of cement foam filling material with the same proportion. The experimental results show that the UCS gradually decreases with the increase in fly ash content, and fly ash significantly impacts the material’s strength. However, with the gradual increase in fly ash content, this effect gradually weakens, especially when the fly ash content exceeds 60%, and the decrease in strength slows down significantly.

4.2. Microstructural Examinations

- (a)

- In the SEM test of foam filling materials prepared with different fly ash contents, it can be seen that no matter how much the content is, the main failure is the periodic fluctuation of roughness. However, when the content is 10% or 20%, the fracture surface is smoother and sharper than that of the high-content specimen. However, when the content of fly ash increases to 30% or more, the fracture surface is more of a periodic fluctuation of roughness, which indicates that the failure mode is more brittle failure. The strength is larger, which is consistent with the law of UCS measured in the test.

- (b)

- The pore shape of the fly ash foam filling material is a regular circle, but the pore distribution is uneven. With the increase in fly ash content, the distribution of pores inside the fly ash foam filling material is more uniform, and the shape is regular. This is because when fly ash is added to the slurry, a better morphological effect is formed between the particles inside the slurry.

5. Characterization of Gangue Foam Filling Materials

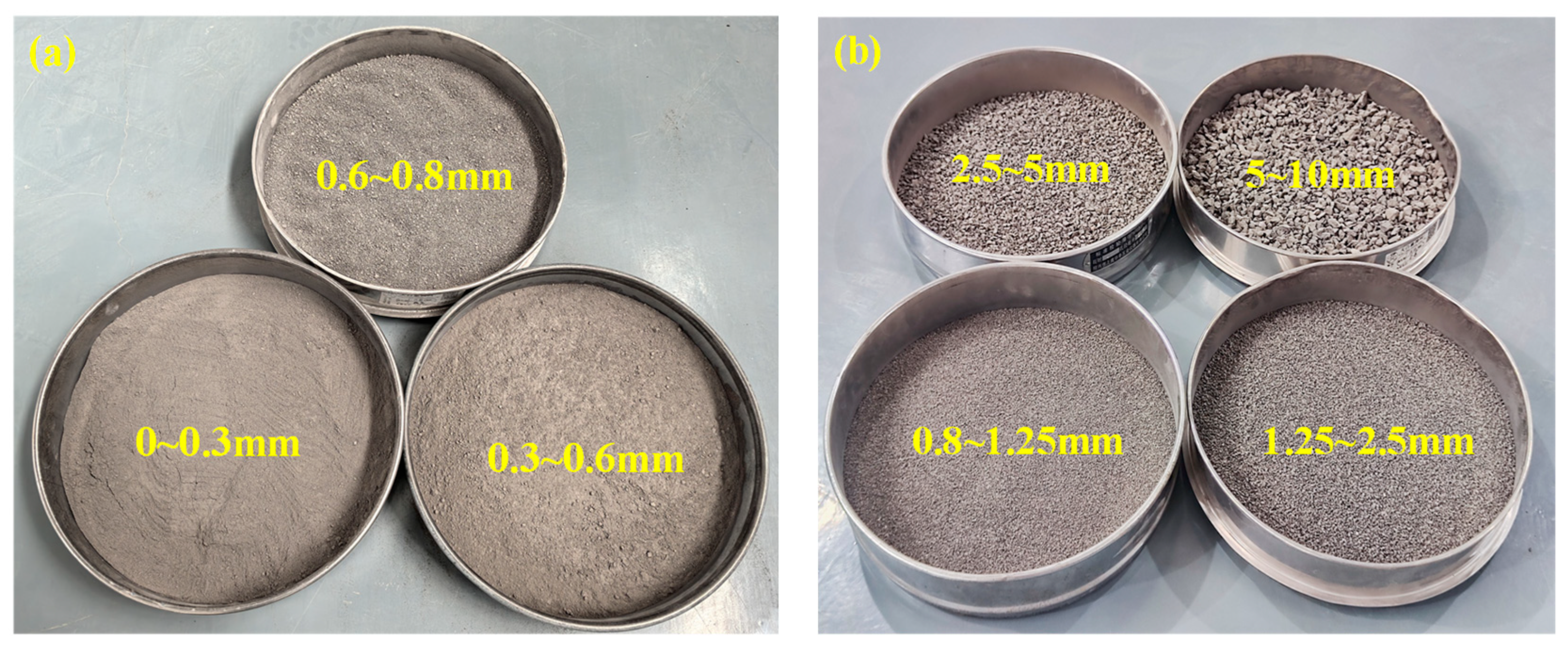

5.1. Mechanical and Transportation Properties Test

- (a)

- With the increase in gangue content and curing period, the moisture in the sample gradually decreases, and its quality and density decrease. With the increase in gangue particle size and content, the slump of foam materials shows a downward trend, and the gangue content has a greater impact on the slump. This is because gangue particles are rougher and have lower fluidity than cement, gypsum, and other materials. From a macro perspective, large particle size gangue should be considered solid particles mixed in the slurry, not fluid. The increase in gangue particle size will amplify the defects in the materials’ flowability, resulting in an increase in gangue particle size and a decrease in slump.

- (b)

- The strength of gangue foam filling material is lower than that of cement foam filling material under the same ratio. This is because the incorporation of gangue makes the originally uniformly mixed cement foam material become a heterogeneous cement, and the contact boundary with foam is prone to producing large bubbles, resulting in large holes after the specimen is dried and molded. Due to the high strength of gangue itself, when disturbed by external forces, it is easy to form a weak structural plane around the gangue particle size, which will form a macro fracture surface if more structural planes are connected.

- (c)

- The higher the content and particle size of gangue, the lower its strength, and it may even have no strength or be unable to demold. However, its UCS increases with the increase in the curing period. At a curing period of 28 days and a content of 10~40%, the UCS of different gangue particle sizes during the process of increasing from small to large are 1.23~2.31 MPa, 1.18~2.12 MPa, 1.15~1.66 MPa, 1.06~1.57 MPa, 0.88~1.47 MPa, 0.8~1.23 MPa, and 0.5~0.81 MPa.

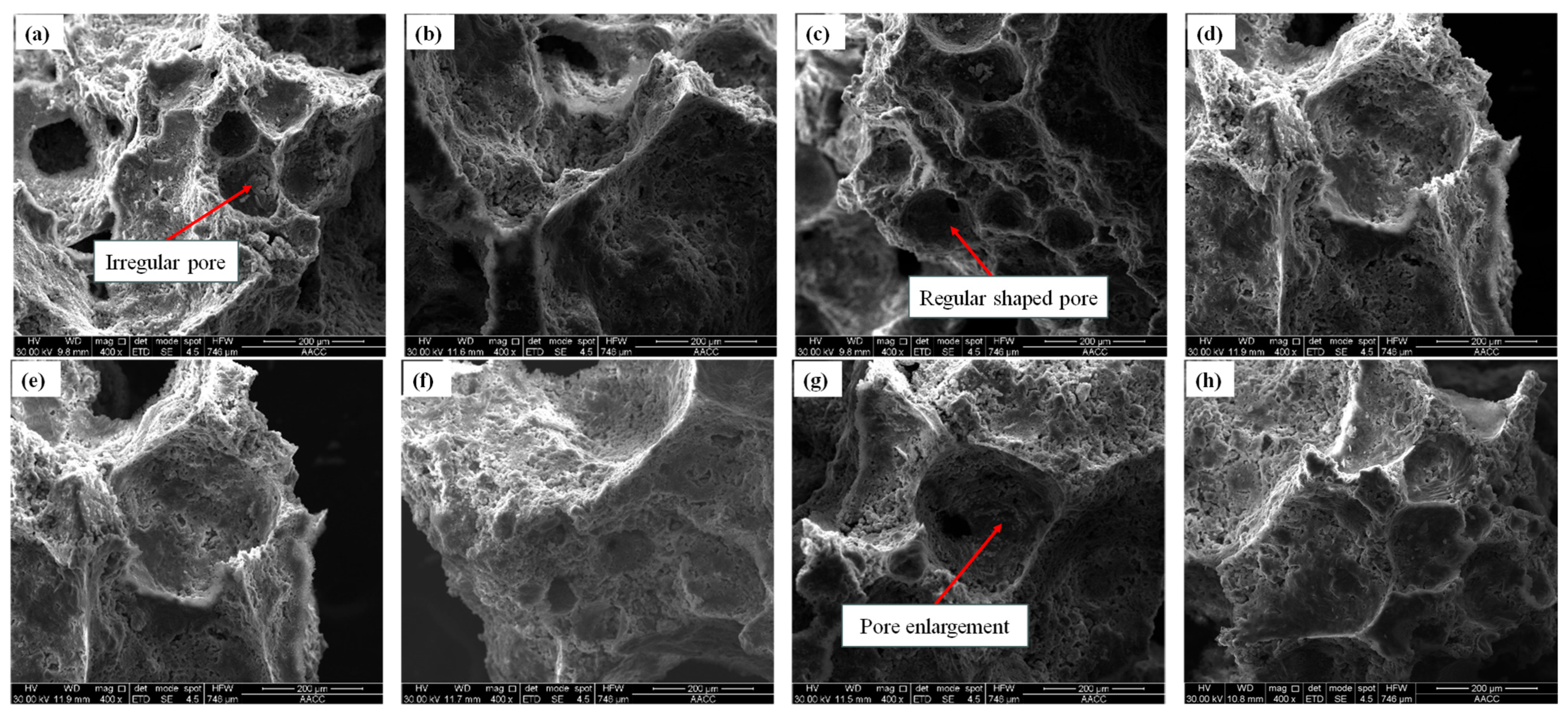

5.2. Microstructural Examinations

- (a)

- The fracture surface of gangue foam filling material prepared with different gangue content is coarser than that of cement foam filling material in the SEM test. There are many free particles on the surface of gangue foam material, and the strength of gangue particles is large, which will cut the surrounding cement foam material structure, making it easier for the specimen to break from the inside, which is also the reason for the reduction in mechanical properties of the material after adding gangue.

- (b)

- From the perspective of material morphology, the smaller the gangue particle size, the more complete and clear the pore structure under electron microscopy imaging. When the amount of gangue is small, the pore shape is regular and circular, but the pore distribution is not uniform. As the particle size and dosage of gangue increase, the pore shapes inside cement-based foam materials become irregular and diverse, and many pore structures are even damaged to varying degrees. This is because when a large amount of gangue is added to the slurry, the particles inside the slurry are more likely to cause the pores to rupture during mixing and stirring.

6. Discussion

7. Conclusions

- (1)

- The effects of water–cement ratio, foaming agent dilution ratio, foaming agent content, foam stabilizing agent content, and gypsum content on cement foam filling materials’ mechanics, transportation characteristics, and microstructure were studied. The dominant ratio of the comprehensive performance of cement-based foam filling material is determined as follows: the dilution concentration of foaming agent is 20 times, the content of foam stabilizer is 1%, the water–cement ratio is 0.5, the content of foaming agent is 1%, and the content of gypsum is 7%. At this time, the expansion ratio of the material is about three times, the UCS is 1.72~2.25 MPa, the initial setting time is 65~169 min, and the slump is 240~285 mm.

- (2)

- The test results of fly ash foam filling material show that with the increase in fly ash content, the mechanical strength and transportation characteristics of the prepared fly ash foam filling material are reduced. The fracture surface of the foam hole under the electron microscope image is gradually rougher with the increase in the proportion of fly ash. The pore shape of the fly ash foam filling material is a regular circle, but the pore distribution is uneven. With the increase in fly ash content, the pore distribution inside the fly ash foam filling material is more uniform, and the shape is regular. The fly ash content is generally controlled within 30%, which has good mechanical properties. The material expansion ratio is about three times, the UCS is 0.9~2.13 MPa, and the slump is 265~272 mm.

- (3)

- The test results of gangue foam filling material show that gangue foam filling material’s mechanical strength and transportation characteristics decrease with gangue content and particle size. The smaller the particle size of coal gangue, the more complete and clear the pore structure under electron microscopy imaging. When the amount of coal gangue is small, the pore shape is regular and circular, but the pore distribution is uneven. With the increase in coal gangue particle size and dosage, the pore shape inside the cement-based foam material becomes irregular and diversified, and even many pore structures are damaged to varying degrees. When the content of gangue is less than 30% and the particle size of gangue is less than 0.6 mm, it has good mechanical properties. At this time, the expansion ratio of the material is about three times, the UCS is 0.5~2.31 MPa, and the slump is 251~273 mm.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Xie, H.P.; Wu, L.X.; Zheng, D.Z. Prediction on the energy consumption and coal demand of China in 2025. J. China Coal. Soc. 2019, 44, 1949–1960. [Google Scholar]

- Chen, F.; Yu, H.C.; Bian, Z.F.; Yin, D.Y. How to handle the crisis of coal industry in China under the vision of carbon neutrality. J. China Coal. Soc. 2021, 46, 1808–1820. [Google Scholar]

- Zhong, G.L.; Deng, X.W.; Fang, C.J.; Zhang, Y.; Chen, Y.L. The status quo and development trend of coal gangue resource utilization. J. China Coal. Soc. 2025, 1–18. [Google Scholar]

- Zhang, X.; Feng, X.P.; Wang, Z.P.; Jian, J.C.; Chen, S.; Luo, W.; Zhang, C. Experimental study on the physico-mechanical properties and microstructure of foam concrete mixed with coal gangue. Constr. Build. Mater. 2022, 359, 129428. [Google Scholar] [CrossRef]

- Wang, G.F.; Xu, Y.X.; Ren, H.W. Intelligent and ecological coal mining as well as clean utilization technology in China: Review and prospects. Int. J. Min. Sci. Technol. 2019, 29, 161–169. [Google Scholar] [CrossRef]

- Zhang, J.X.; Jv, F.; Li, M.; Ma, D. Research progress of strata control theory and method in deep backfilling mining. Bull. Natl. Nat. Sci. Found. China 2024, 38, 1043–1051. [Google Scholar]

- Ma, L.Q.; Wang, S.K.; Yu, Y.H.; Du, H.L. Technology and practice of continuous mining and back filling with wall system for water conservation. J. Min. Saf. Eng. 2021, 38, 902–910+987. [Google Scholar]

- Zhang, Y.; Cao, S.G.; Zhang, N.; Zhao, C.Z. The application of short-wall block backfill mining to preserve surface water resources in northwest China. J. Clean. Prod. 2020, 261, 121232. [Google Scholar] [CrossRef]

- Xuan, D.Y.; Xu, J.L. Longwall surface subsidence control by technology of isolated overburden grout injection. Int. J. Min. Sci. Technol. 2017, 27, 813–818. [Google Scholar] [CrossRef]

- Guo, L.Z.; Zhou, M.; Wang, X.Y.; Li, C.; Jia, H.Q. Preparation of coal gangue-slag-fly ash geopolymer grouting materials. Constr. Build. Mater. 2022, 328, 126997. [Google Scholar] [CrossRef]

- Xu, Y.J.; Ma, L.Q. Characteristics of overburden migration under continuous extraction and continuous backfill mining method with CO2 mineralized filling materials. J. Clean. Prod. 2024, 440, 140920. [Google Scholar] [CrossRef]

- Zhang, L.M.; Lai, X.P.; Pan, J.L.; Shan, P.F.; Zhang, Y.; Zhang, Y.; Xu, H.C.; Cai, M.F.; Xu, X. Experimental investigation on the mixture optimization and failure mechanism of cemented backfill with coal gangue and fly ash. Powder. Technol. 2024, 440, 119751. [Google Scholar] [CrossRef]

- Sun, K.; Zhang, J.X.; He, M.C.; Li, M.; Wang, C.J.; Feng, W.C.; Li, F.M. Mechanical properties and damage evolution characteristics based on the acoustic emission of gangue and high-water-content materials based cemented paste backfill. Constr. Build. Mater. 2023, 395, 132324. [Google Scholar] [CrossRef]

- Tran, N.P.; Nguyen, T.N.; Ngo, T.D.; Le, P.K.; Le, T.A. Strategic progress in foam stabilisation towards high-performance foam concrete for building sustainability: A state-of-the-art review. J. Clean. Prod. 2022, 375, 133939. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, W.Y. China’s energy transition pathway in a carbon neutral vision. Engineering 2022, 14, 64–76. [Google Scholar] [CrossRef]

- Pan, Z.H.; Li, H.Z.; Liu, W.Q. Preparation and characterization of super low density foamed concrete from Portland cement and admixtures. Constr. Build. Mater. 2014, 72, 256–261. [Google Scholar] [CrossRef]

- Liu, X.M.; Wang, L.Y.; Li, S.L.; Wang, J.P. Study on high-efficiency complexed foaming agent for lightweight foamed concrete. Adv. Mater. Res. 2011, 250–253, 569–672. [Google Scholar] [CrossRef]

- Nazari, A.; Riahi, S. Improvement compressive strength of concrete in different curing media by Al2O3 nanoparticles. Mater. Sci. Eng. A 2011, 528, 1183–1191. [Google Scholar] [CrossRef]

- She, W.; Du, Y.; Miao, C.W.; Liu, J.P.; Zhao, G.T.; Jiang, J.Y.; Zhang, Y.S. Application of organic and nanoparticle-modified foams in foamed concrete: Reinforcement and stabilization mechanisms. Cem. Concr. Res. 2018, 106, 12–22. [Google Scholar] [CrossRef]

- Wan, K.T.; Zhu, H.G.; Yuen, T.Y.P.; Chen, B.M.; Hu, C.L.; Leung, C.K.Y.; Kuang, J.S. Development of low drying shrinkage foamed concrete and hygro-mechanical finite element model for prefabricated building fascade applications. Constr. Build. Mater. 2018, 165, 939–957. [Google Scholar] [CrossRef]

- Sun, Q.; Zhang, J.X.; Li, M.; Zhou, N. Experimental evaluation of physical, mechanical, and permeability parameters of key aquiclude strata in a typical mining area of China. J. Clean. Prod. 2020, 267, 122109. [Google Scholar] [CrossRef]

- Sun, Q.; Zhao, R.; Zhou, N.; Gao, J.L.; Yuan, H. Performance of coal based solid waste foam filling material and control of surrounding rock of abandoned roadways. Coal Sci. Technol. 2025, 53, 327–342. [Google Scholar]

- Wang, X.F.; Cao, W.H.; Zhang, D.S.; Yang, H.; Chang, Z.C.; Cai, W.Y. Mechanism study on influence of particle size and content of gangue on strength of high-sand and high-foam cement-based filling material. J. Min. Saf. Eng. 2020, 37, 376–384. [Google Scholar]

- Zhang, J.; Li, Y.L.; Hang, Z.B.; Feng, T.G.; Yang, H. Research on the development of green foaming fluid and the improvement in the performance of foamed cement. Constr. Build. Mater. 2024, 411, 134722. [Google Scholar] [CrossRef]

- Song, Q.; Xu, S.P.; Zou, Y.J.; Niu, D.T.; Zhao, H.Y.; Xia, J.L.; Bao, J.W.; Xue, S.B.; Tang, X.B. Enhancing the performance of multiple solid wastes foam concrete by foam stabilizer synergistic application and quantitative evaluation. Constr. Build. Mater. 2025, 489, 142298. [Google Scholar] [CrossRef]

- Shi, X.S.; Zhang, Y.H.; Hu, H.X.; Arachchi, E.N.; Cen, X.Q.; Li, W.R.; Wang, Q.Y. Role of red mud as a foam stabilizer in geopolymer foam concrete: Enhancing stability, rheology, and mechanical performance. J. Build. Eng. 2025, 105, 112446. [Google Scholar] [CrossRef]

- Wang, F.T.; Li, K.Q.; Liu, Y. Optimal water-cement ratio of cement-stabilized soil. Constr. Build. Mater. 2022, 320, 126211. [Google Scholar] [CrossRef]

| Chemical Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | Others |

|---|---|---|---|---|---|---|---|---|

| Fly ash, wt% | 50.6 | 27.1 | 7.1 | 2.8 | 1.3 | 0.8 | 0.2 | 10.1 |

| Coal gangue, wt% | 63.42 | 17.32 | 2.62 | 2.14 | 1.62 | 0.6 | 0.11 | 12.17 |

| Chemical Composition | CaO | SiO2 | Fe2O3 | Al2O3 | MgO | SO3 | Others |

|---|---|---|---|---|---|---|---|

| wt% | 36.50 | 6.63 | 1.69 | 1.02 | 2.08 | 51.08 | 1.0 |

| Index | Calcium Content/% | Free Acid/% | Loss on Drying/% | Melting Point/℃ | Fineness Through 325 Mesh/% |

|---|---|---|---|---|---|

| First-level indicator | 6.5 ± 0.5 | ≤0.5 | ≤3.0 | 140 ± 5 | ≥99 |

| Proportion/% | No | L/mm | W/mm | H/mm | M0/g | ρ0/(g·cm−3) |

|---|---|---|---|---|---|---|

| 0.6 | 1-1 | 71.5 | 70.8 | 71.4 | 232 | 0.64 |

| 1-2 | 71.5 | 70.1 | 70.0 | 224 | 0.64 | |

| 1-3 | 71.4 | 70.4 | 70.9 | 227 | 0.64 | |

| Average | 0.64 | |||||

| 0.8 | 1-1 | 70.8 | 70.2 | 70.4 | 218 | 0.62 |

| 1-2 | 70.4 | 70.6 | 70.5 | 217 | 0.62 | |

| 1-3 | 70.5 | 70.0 | 70.2 | 217 | 0.63 | |

| Average | 0.62 | |||||

| 1 | 1-1 | 70.5 | 69.7 | 70.4 | 210 | 0.61 |

| 1-2 | 70.2 | 69.3 | 70.0 | 202 | 0.59 | |

| 1-3 | 70.4 | 69.9 | 70.1 | 209 | 0.61 | |

| Average | 0.60 | |||||

| 1.2 | 1-1 | 70.9 | 70.3 | 70.7 | 209 | 0.59 |

| 1-2 | 70.0 | 70.2 | 70.0 | 203 | 0.59 | |

| 1-3 | 70.3 | 70.0 | 70.6 | 207 | 0.60 | |

| Average | 0.59 | |||||

| 1.4 | 1-1 | 71.3 | 69.4 | 71.0 | 205 | 0.58 |

| 1-2 | 71.2 | 71.0 | 70.5 | 210 | 0.59 | |

| 1-3 | 71.0 | 70.2 | 70.7 | 206 | 0.58 | |

| Average | 0.58 | |||||

| W/C Ratio | Set Time/min | Slump/mm | UCS/MPa | Density/g·cm−3 | |||

|---|---|---|---|---|---|---|---|

| 7 d | 14 d | 21 d | 28 d | ||||

| 0.40 | 65 | 240 | 1.94 | 2.06 | 2.13 | 2.25 | 0.73 |

| 0.45 | 73 | 254 | 1.75 | 1.91 | 2.01 | 2.06 | 0.61 |

| 0.50 | 101 | 265 | 1.66 | 1.81 | 1.92 | 1.98 | 0.61 |

| 0.55 | 138 | 272 | 1.48 | 1.54 | 1.71 | 1.79 | 0.58 |

| 0.60 | 169 | 285 | 1.37 | 1.41 | 1.62 | 1.72 | 0.55 |

| Foaming Agent Proportion/% | Set Time/min | Slump/mm | UCS /MPa | Density/g·cm−3 | |||

|---|---|---|---|---|---|---|---|

| 7 d | 14 d | 21 d | 28 d | ||||

| 0.8 | 97 | 270 | 1.77 | 1.81 | 1.92 | 2.08 | 0.68 |

| 1.0 | 112 | 266 | 1.61 | 1.73 | 1.87 | 1.93 | 0.59 |

| 1.2 | 124 | 263 | 1.47 | 1.60 | 1.71 | 1.86 | 0.55 |

| Gypsum Proportion/% | Set Time/min | Slump/mm | UCS/MPa | Density/g·cm−3 | |||

|---|---|---|---|---|---|---|---|

| 7 d | 14 d | 21 d | 28 d | ||||

| 4 | 101 | 256 | 1.77 | 1.90 | 2.03 | 2.20 | 0.61 |

| 5 | 112 | 258 | 1.83 | 2.05 | 2.14 | 2.26 | 0.61 |

| 6 | 119 | 259 | 1.88 | 2.23 | 2.39 | 2.41 | 0.60 |

| 7 | 125 | 260 | 1.97 | 2.33 | 2.45 | 2.52 | 0.61 |

| 8 | 137 | 263 | 1.94 | 2.20 | 2.38 | 2.44 | 0.61 |

| 9 | 146 | 265 | 1.94 | 2.16 | 2.32 | 2.37 | 0.60 |

| Cement/kg | Fly Ash /kg | Slump/mm | UCS /MPa | Density/g·cm−3 | |||

|---|---|---|---|---|---|---|---|

| 7 d | 14 d | 21 d | 28 d | ||||

| 9 | 1 | 265 | 1.72 | 1.92 | 2.06 | 2.13 | 0.62 |

| 8 | 2 | 268 | 1.54 | 1.71 | 1.88 | 1.95 | 0.62 |

| 7 | 3 | 270 | 1.25 | 1.51 | 1.69 | 1.86 | 0.62 |

| 6 | 4 | 272 | 1.02 | 1.18 | 1.32 | 1.50 | 0.61 |

| 5 | 5 | 271 | 0.91 | 1.06 | 1.23 | 1.37 | 0.60 |

| 4 | 6 | 270 | 0.79 | 0.88 | 1.03 | 1.13 | 0.60 |

| 3 | 7 | 269 | 0.66 | 0.72 | 0.87 | 0.97 | 0.60 |

| 2 | 8 | 269 | 0.64 | 0.73 | 0.79 | 0.90 | 0.59 |

| Gangue Particle Size/mm | Cement/kg | Gangue/kg | Slump/mm | UCS/MPa | Density/g·cm−3 | |||

|---|---|---|---|---|---|---|---|---|

| 7 d | 14 d | 21 d | 28 d | |||||

| 0~0.3 | 9 | 1 | 273 | 1.73 | 1.93 | 2.08 | 2.31 | 0.66 |

| 8 | 2 | 271 | 1.39 | 1.59 | 1.74 | 1.89 | 0.65 | |

| 7 | 3 | 270 | 1.04 | 1.28 | 1.36 | 1.53 | 0.64 | |

| 6 | 4 | 267 | 0.90 | 1.15 | 1.17 | 1.23 | 0.63 | |

| 0.3~0.6 | 9 | 1 | 272 | 1.53 | 1.89 | 1.95 | 2.12 | 0.66 |

| 8 | 2 | 270 | 1.26 | 1.56 | 1.60 | 1.78 | 0.64 | |

| 7 | 3 | 266 | 1.01 | 1.20 | 1.40 | 1.45 | 0.63 | |

| 6 | 4 | 263 | 0.77 | 0.85 | 1.04 | 1.18 | 0.63 | |

| 0.6~0.8 | 9 | 1 | 270 | 1.27 | 1.53 | 1.56 | 1.66 | 0.65 |

| 8 | 2 | 268 | 0.98 | 1.38 | 1.47 | 1.54 | 0.65 | |

| 7 | 3 | 265 | 0.77 | 1.23 | 1.30 | 1.35 | 0.63 | |

| 6 | 4 | 261 | 0.66 | 0.87 | 1.03 | 1.15 | 0.65 | |

| 0.8~1.25 | 9 | 1 | 268 | 1.01 | 1.15 | 1.53 | 1.57 | 0.64 |

| 8 | 2 | 265 | 0.83 | 1.04 | 1.19 | 1.28 | 0.63 | |

| 7 | 3 | 263 | 0.68 | 0.97 | 1.06 | 1.14 | 0.64 | |

| 6 | 4 | 260 | 0.54 | 0.77 | 0.98 | 1.06 | 0.63 | |

| 1.25~2.5 | 9 | 1 | 265 | 0.88 | 1.17 | 1.42 | 1.47 | 0.65 |

| 8 | 2 | 264 | 0.63 | 0.81 | 0.93 | 1.18 | 0.65 | |

| 7 | 3 | 262 | 0.53 | 0.72 | 0.82 | 1.01 | 0.63 | |

| 6 | 4 | 258 | 0.49 | 0.59 | 0.70 | 0.88 | 0.62 | |

| 2.5~5 | 9 | 1 | 264 | 0.80 | 1.01 | 1.17 | 1.23 | 0.62 |

| 8 | 2 | 261 | 0.58 | 0.78 | 0.85 | 1.07 | 0.64 | |

| 7 | 3 | 257 | 0.50 | 0.66 | 0.75 | 0.92 | 0.63 | |

| 6 | 4 | 254 | 0.43 | 0.55 | 0.67 | 0.80 | 0.63 | |

| 5~10 | 9 | 1 | 262 | 0.64 | 0.66 | 0.70 | 0.81 | 0.61 |

| 8 | 2 | 257 | 0.45 | 0.56 | 0.58 | 0.64 | 0.59 | |

| 7 | 3 | 254 | 0.34 | 0.44 | 0.54 | 0.56 | 0.60 | |

| 6 | 4 | 251 | 0.29 | 0.32 | 0.43 | 0.50 | 0.59 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, Q.; Nie, H.; Han, Y.; Zhao, R. Mechanical, Transportation, and Microstructural Characteristics and Application of High-Porosity Coal Mine Solid Waste Filling Materials: A Case Study. Materials 2025, 18, 5098. https://doi.org/10.3390/ma18225098

Sun Q, Nie H, Han Y, Zhao R. Mechanical, Transportation, and Microstructural Characteristics and Application of High-Porosity Coal Mine Solid Waste Filling Materials: A Case Study. Materials. 2025; 18(22):5098. https://doi.org/10.3390/ma18225098

Chicago/Turabian StyleSun, Qiang, Hongzhen Nie, Yong Han, and Rui Zhao. 2025. "Mechanical, Transportation, and Microstructural Characteristics and Application of High-Porosity Coal Mine Solid Waste Filling Materials: A Case Study" Materials 18, no. 22: 5098. https://doi.org/10.3390/ma18225098

APA StyleSun, Q., Nie, H., Han, Y., & Zhao, R. (2025). Mechanical, Transportation, and Microstructural Characteristics and Application of High-Porosity Coal Mine Solid Waste Filling Materials: A Case Study. Materials, 18(22), 5098. https://doi.org/10.3390/ma18225098