Effects of Co on Mechanical Properties and Precipitates in a Novel Secondary−Hardening Steel with Duplex Strengthening of M2C and β−NiAl

Abstract

1. Introduction

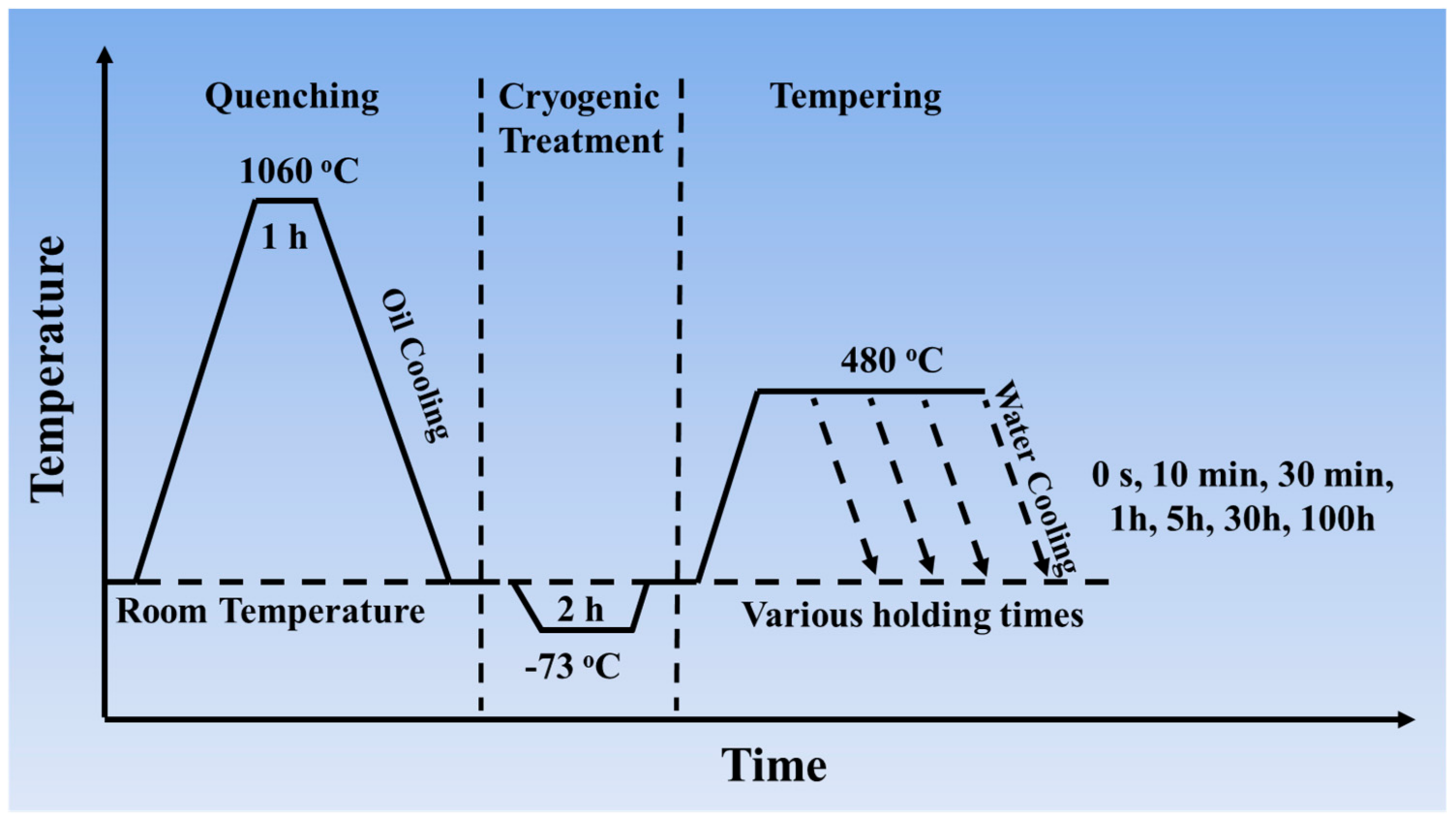

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

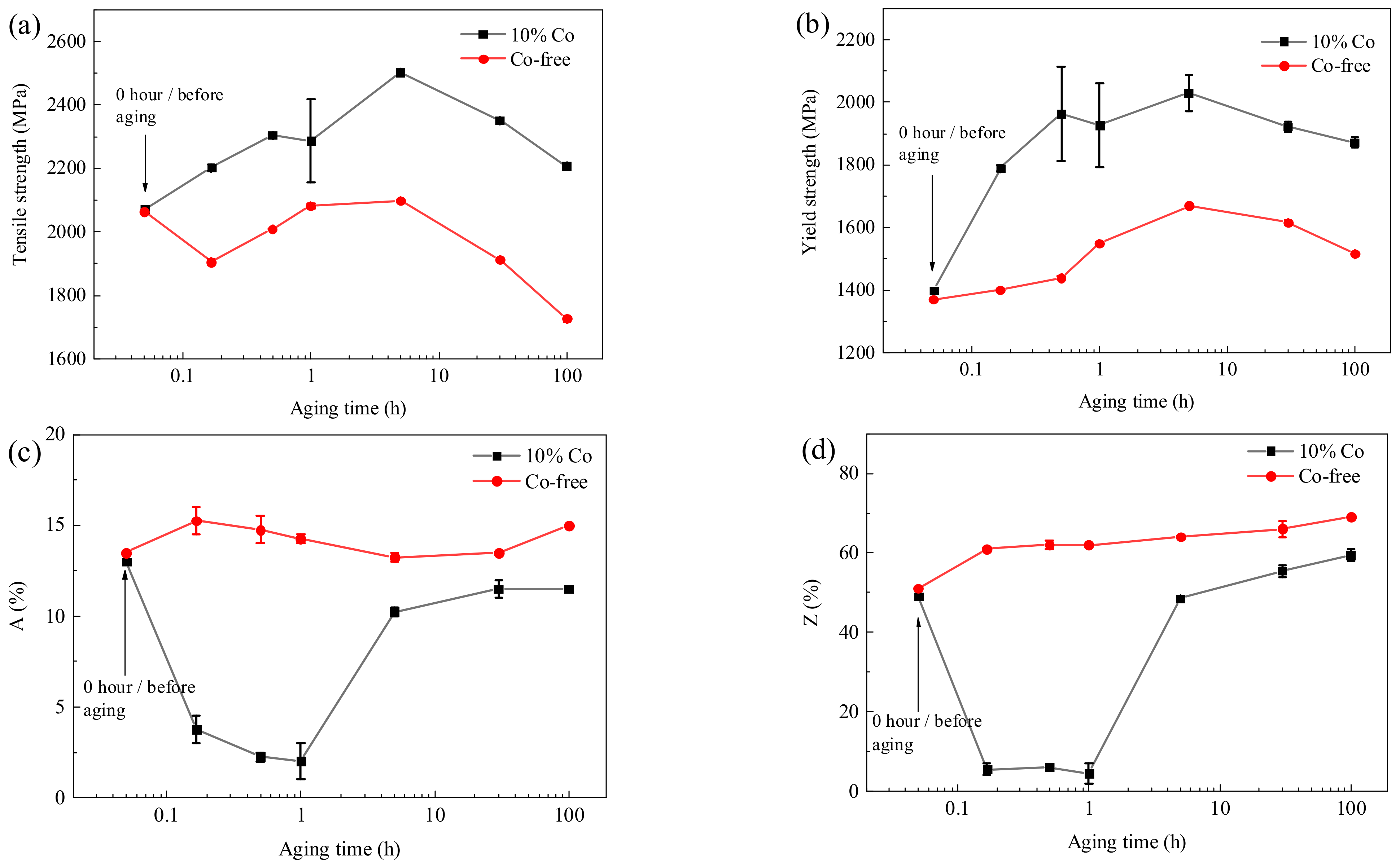

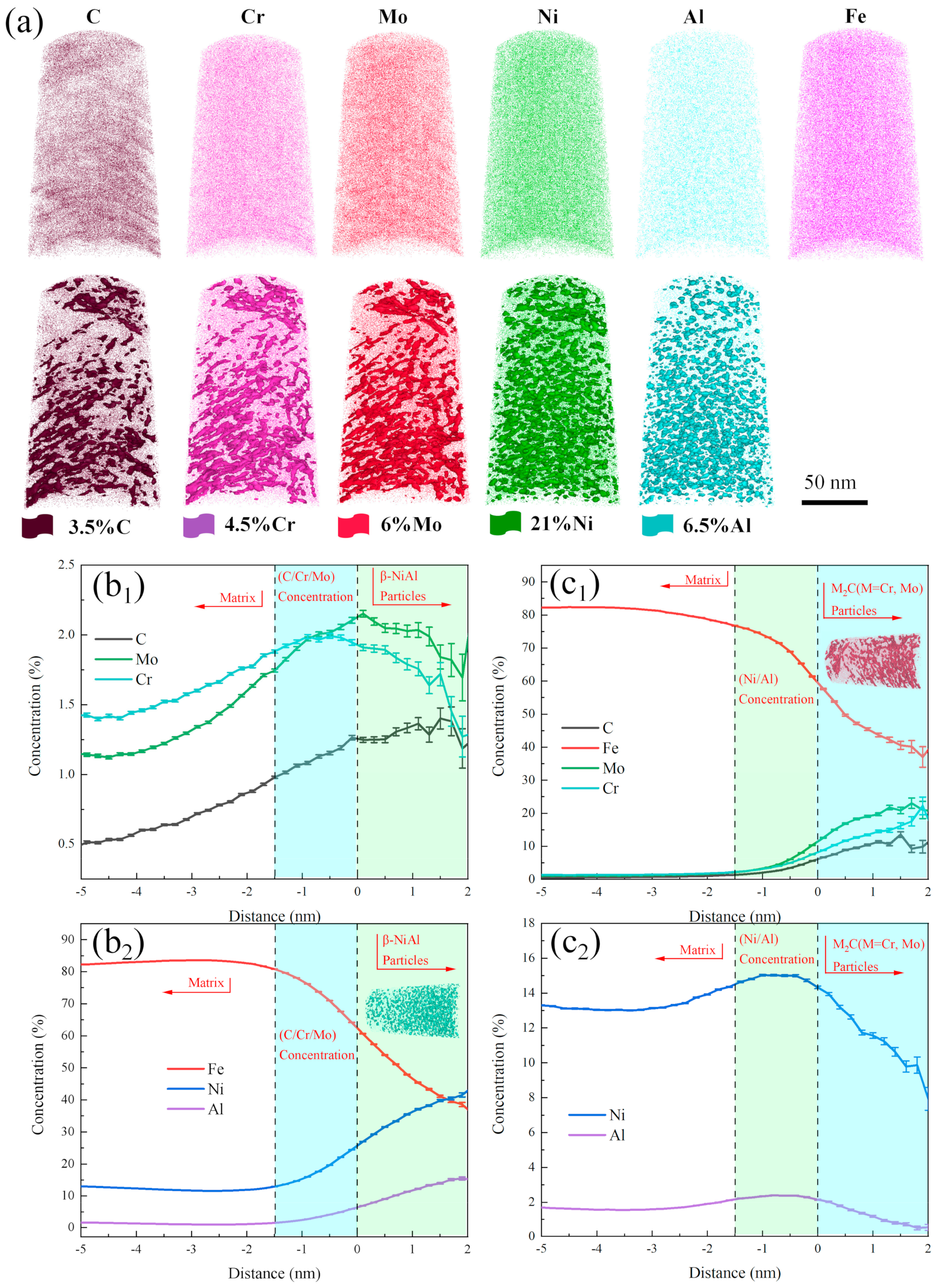

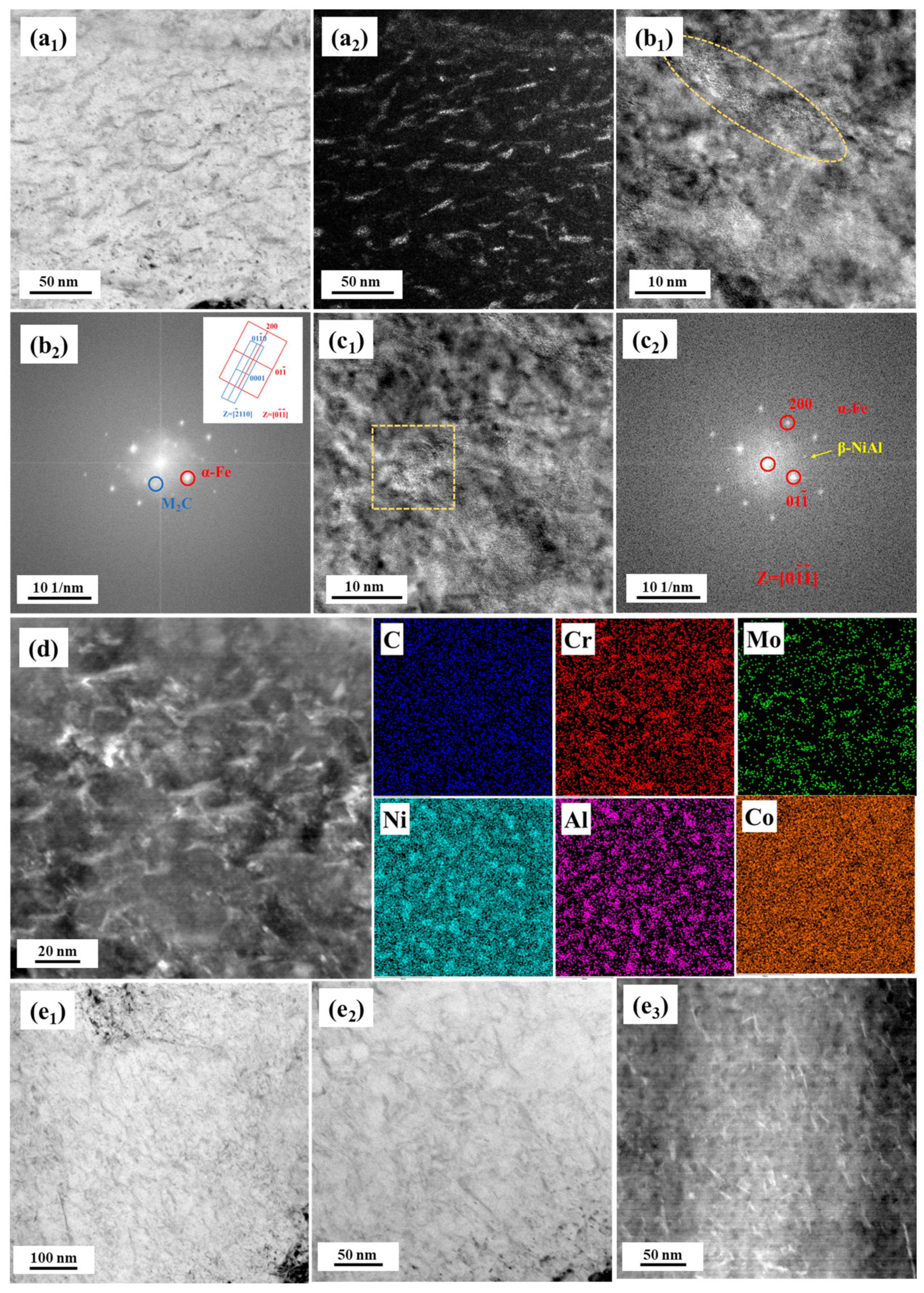

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.P.; Zhan, D.P.; Qi, X.W.; Jiang, Z.H. Austenite and precipitation in secondary−hardening ultra−high−strength stainless steel. Mater. Charact. 2018, 144, 393–399. [Google Scholar] [CrossRef]

- Hoshino, M.; Saitoh, N.; Muraoka, H.; Saeki, O. Development of super−9% Ni steel plates with superior low−temperature toughness for LNG storage tanks. Nippon Steel Tech. Rep. 2004, 90, 20–24. [Google Scholar]

- Li, J.H.; Zhan, D.P.; Jiang, Z.H.; Zhang, H.S.; Yang, Y.K.; Zhang, Y.P. Progress on improving strength−toughness of ultra−high strength martensitic steels for aerospace applications: A review. J. Mater. Res. Technol. JMRT 2023, 23, 172–190. [Google Scholar] [CrossRef]

- Liu, Y.G.; Liu, J.; Li, M.Q.; Lin, H. The study on kinetics of static recrystallization in the two−stage isothermal compression of 300 M steel. Comput. Mater. Sci. 2014, 84, 115–121. [Google Scholar] [CrossRef]

- Wang, C.C.; Zhang, C.; Yang, Z.G. Effects of Ni on austenite stability and fracture toughness in high Co−Ni secondary hardening steel. J. Iron Steel Res. Int. 2017, 24, 177–183. [Google Scholar] [CrossRef]

- Sun, Y.W.; Quan, J.; Salvador, H.; Lin, J.; Kozmel, T.; Mathaudhu, S. Ausforming and tempering of a novel ultra−high strength steel. Mater. Sci. Eng. A 2022, 838, 142750. [Google Scholar] [CrossRef]

- Niu, M.C.; Zhou, G.; Wang, W.; Shahzad, B.M.; Shan, Y.Y.; Yang, K. Precipitate evolution and strengthening behavior during aging process in a 2.5 GPa grade maraging steel. Acta Mater. 2019, 179, 296–307. [Google Scholar] [CrossRef]

- Zhang, H.L.; Ji, X.; Ma, D.P.; Tong, M.; Wang, T.J.; Xu, B.; Sun, M.Y.; Li, D.Z. Effect of aging temperature on the austenite reversion and mechanical properties of a Fe−10Cr−10Ni cryogenic maraging steel. J. Mater. Res. Technol−JMRT 2021, 11, 98–111. [Google Scholar] [CrossRef]

- Han, S.; Li, X.Y.; Liu, Y.; Geng, R.M.; Lei, S.M.; Li, Y.; Wang, C.X. Effect of aging treatment on the microstructure and properties of 2.2 GPa t ungsten−containing maraging steel. Materials 2023, 16, 4918. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.P.; Zhan, D.P.; Qi, Y.W.; Jiang, Z.H. Effect of tempering temperature on the microstructure and properties of ultrahigh strength stainless steel. J. Mater. Sci. Technol. 2019, 35, 1240–1249. [Google Scholar] [CrossRef]

- Manigandan, K.; Srivatsan, T.S.; Tammnana, D.; Poorganji, B.; Vasudevan, V.K. Influence of microstructure on stain−controlled fatigue and fracture behavior of ultra high strength alloy steel AerMet 100. Mater. Sci. Eng. A 2024, 601, 29–39. [Google Scholar] [CrossRef]

- Raghavan, A.; Machmeier, P. On the characteristics of M2C carbides in the peak hardening regime of AerMet 100 steel. Metall. Mater. Trans. A 1998, 29A, 903–905. [Google Scholar]

- Wen, X.R.; Zhang, J.W.; Sun, S.H.; Guo, H.; Guo, Q.Y.; Ding, R. Aging response of a Fe−Cr−Co−Ni secondary hardening steel: The significance of matrix ordering. Mater. Sci. Eng. A 2024, 890, 145923. [Google Scholar] [CrossRef]

- Shi, X.H.; Zeng, W.D.; Zhao, Q.Y.; Peng, W.W.; Kang, C. Study on the microstructure and mechanical properties of Aermet 100 steel at the tempering temperature around 482 °C. J. Alloy. Compd. 2016, 679, 184–190. [Google Scholar] [CrossRef]

- Garrison, W.M.; Rhoads, M.A. An evaluation of ultra−high strength steel strengthed by alloy carbide and intermetallic precipitates. Trans. Indian Inst. Met. 1996, 49, 151–162. [Google Scholar]

- Hamano, R. The effect of precipitation of coherent and incoherent precipitates on the ductility and toughness of high −strength steel. Metall. Trans. A 1993, 24, 127–139. [Google Scholar] [CrossRef]

- Delagnes, D.; Pettinari−Sturmel, F.; Mathon, M.H.; Danoix, R.; Bellot, C.; Lamesle, P.; Grellier, A. Cementite−free martensitic steels: A new route to develop high strength/high toughness grades by modifying the conventional precipitation sequence during tempering. Acta Mater. 2012, 60, 5877–5888. [Google Scholar] [CrossRef]

- Gao, Y.H.; Liu, S.Z.; Hu, X.B.; Ren, Q.Q.; Li, Y.; Dravid, V.P.; Wang, C.X. A novel low cost 2000 MPa grade ultra−high strength steel with balanced strength and toughness. Mater. Sci. Eng. A 2019, 759, 298–302. [Google Scholar] [CrossRef]

- Wang, C.X.; Gao, Y.H.; Li, Y.; Han, S.; Liu, S.Z.; Zhang, P.J. Effects of solid−solution temperature on microstructure and mechanical properties of a novel 2000 MPa grade ultra−high−strength steel. J. Iron Steel Res. Int. 2020, 27, 710–718. [Google Scholar] [CrossRef]

- Liu, T.Q.; Cao, Z.X.; Wang, H.; Wu, G.L.; Jin, J.J.; Cao, W.Q. A new 2.4 GPa extra−high strength steel with good ductility and high toughness designed by synergistic strengthening of nano−particles and high−density dislocations. Scr. Mater. 2020, 178, 285–289. [Google Scholar] [CrossRef]

- Zhu, H.F.; Xiong, Z.P.; Mao, J.W.; Cheng, X.W. Effect of aging temperature on the microstructural evolution and mehcnaical properties in M2C and NiAl co−precipitation secondary hardening ultrahigh−strength steel. J. Mater. Res. Techol. 2024, 30, 3522–3534. [Google Scholar] [CrossRef]

- Speich, G.R.; Dabkowski, D.S.; Porter, L.F. Strength and toughness of Fe−10Ni alloys containing C, Cr, Mo, and Co. Metall. Trans. 1973, 4, 303–315. [Google Scholar] [CrossRef]

- Heo, N.H.; Na, J.G. Effect of alloying elements on fracture behavior of Fe−18Ni−2Ti−(8Co) alloys. Met. Mater. 1997, 3, 125–129. [Google Scholar] [CrossRef]

- Won, Y.J.; Kwon, Y.J.; Moon, H.K.; Park, S.K.; Kwon, H.; Cho, K.S. Secondary hardening behavior in ausformed martensitic alloys with different Co content. Physica B−Condensed Matter 2018, 551, 16–20. [Google Scholar] [CrossRef]

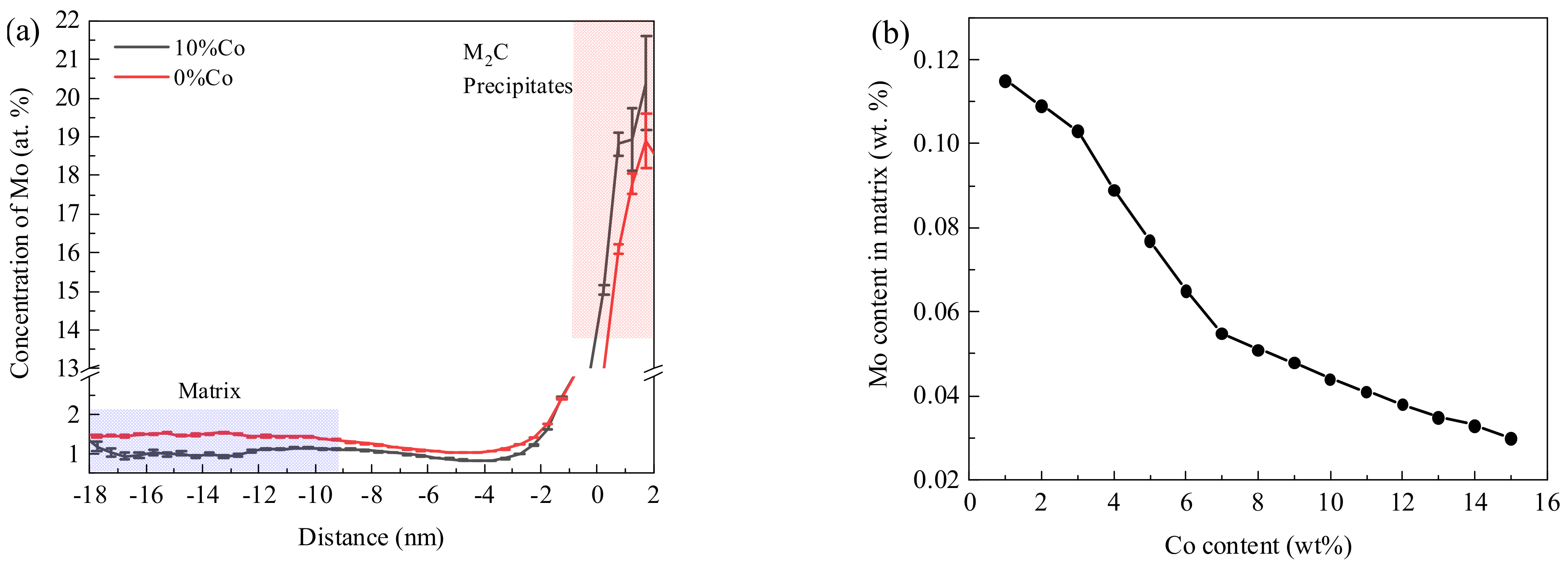

- Liu, Z.B.; Zhang, B.N.; Sha, G.; Jin, S.B.; Yang, Z.Y.; Liang, J.X.; Tian, Z.L. Effect of cobalt on precipitation in Fe−Cr−Co−Mo−Ni−C stainless steels. Mater. Lett. 2021, 289, 129439. [Google Scholar] [CrossRef]

- Wang, L.H.; Jiang, S.H.; Peng, B.; Bai, B.H.; Liu, X.C.; Li, C.R.; Liu, X.J.; Yuan, X.X.; Zhu, H.H.; Wu, Y.; et al. Ultrastrong steel strengthened by multiple shearable nanostrcutures. J. Mater. Res. Techol. 2023, 161, 245–257. [Google Scholar]

- Eriach, S.D.; Leitner, H.; Brichof, M.; Clemens, H.; Danoix, F.; Lemarchand, D.; Siller, I. Comparion of NiAl precipitation in a medium carbon secondary hardening steel and C−free PH13−8 maraging steel. Mater. Sci. Eng. A 2006, 429, 96–106. [Google Scholar] [CrossRef]

- Jakob, S.; Colliander, M.H.; Kawser, J.; Rashidi, S.; Ooi, S.W.; Thuvander, M. Concomitant precipitation of intermetallic β−NiAl and carbides in a precipitation hardened steel. Metall. Mater. Trans. A 2024, 55, 870–879. [Google Scholar] [CrossRef]

- Sun, L.; Simm, T.H.; Martin, T.L.; Mcadam, S.; Galvin, D.R.; Perkins, K.M.; Bagot, P.A.J.; Moody, M.P.; Ooi, S.W.; Hill, P.; et al. A novel ultra−high strength marging steel with balanced ductility and creep resistance achieved by nanoscale β−NiAl and laves phase precipitates. Acta Mater. 2018, 149, 285–301. [Google Scholar] [CrossRef]

- Garrison, W.M. A comparison of the effects of cobalt, silicon, nickel and aluminum on the tempering response of a medium chromium secondary hardening steel. ISIJ Int. 2006, 46, 782. [Google Scholar] [CrossRef][Green Version]

- Sha, W.; Cerezo, A.; Smith, G.D.W. Phase chemistry and precipitation reactions in maraging steels: Part Ⅰ. Introducation and study of Co−containing C−300 steel. Metall. Trans. A 1993, 24A, 1221–1232. [Google Scholar] [CrossRef]

| C | Cr | Mo | Ni | Co | Al | Fe |

|---|---|---|---|---|---|---|

| 0.28 | 1.5 | 2.5 | 14 | 10 | 1 | Bal. |

| Precipitates | Co Contents (wt. %) | ||

|---|---|---|---|

| 0%Co | 10%Co | ||

| M2C | Volume fraction (%) | 1.09 | 1.99 |

| Number density (/cm3) | 2.734 × 1017 | 5.596 × 1017 | |

| Average volume (nm3) | 40.09 | 35.80 | |

| Nominal radius (nm) | 2.12 | 2.04 | |

| β−NiAl | Volume fraction (%) | 2.55% | 2.49% |

| Number density (/cm3) | 1.085 × 1018 | 1.299 × 1018 | |

| Average volume (nm3) | 23.49 | 19.17 | |

| Nominal radius (nm) | 1.78 | 1.66 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Geng, R.; Han, S.; Pang, X.; Yuan, X.; Liu, Y.; Li, Y.; Wang, C. Effects of Co on Mechanical Properties and Precipitates in a Novel Secondary−Hardening Steel with Duplex Strengthening of M2C and β−NiAl. Materials 2024, 17, 3261. https://doi.org/10.3390/ma17133261

Geng R, Han S, Pang X, Yuan X, Liu Y, Li Y, Wang C. Effects of Co on Mechanical Properties and Precipitates in a Novel Secondary−Hardening Steel with Duplex Strengthening of M2C and β−NiAl. Materials. 2024; 17(13):3261. https://doi.org/10.3390/ma17133261

Chicago/Turabian StyleGeng, Ruming, Shun Han, Xuedong Pang, Xiaoyuan Yuan, Yue Liu, Yong Li, and Chunxu Wang. 2024. "Effects of Co on Mechanical Properties and Precipitates in a Novel Secondary−Hardening Steel with Duplex Strengthening of M2C and β−NiAl" Materials 17, no. 13: 3261. https://doi.org/10.3390/ma17133261

APA StyleGeng, R., Han, S., Pang, X., Yuan, X., Liu, Y., Li, Y., & Wang, C. (2024). Effects of Co on Mechanical Properties and Precipitates in a Novel Secondary−Hardening Steel with Duplex Strengthening of M2C and β−NiAl. Materials, 17(13), 3261. https://doi.org/10.3390/ma17133261