Abstract

The paper presents an analysis of the low-cycle fatigue (LCF) properties of C45, X20Cr13, and 34CrNiMo6 steels subjected to various heat treatment processes. Strain-controlled LCF tests were carried out with a total cyclic strain amplitude equal to 0.5, 1 and 1.5%. Fatigue life, cyclic stress-strain behavior and hardness were analyzed. Qualitative and quantitative relationships between material LCF properties resulting from the heat treatment processes, were related to the indentation force P*, which was derived experimentally by applying an instrumented indentation procedure with the use of the Vickers indenter. The proposed parameter P* and its changes ΔP* seem to be promising for the identification of the structural stress parameter σ* that is necessary for deriving values of the fatigue strength coefficients σf’ corresponding to different tempering temperatures. The common feature of all steels analyzed in this paper is that the elastic parts of the strain-life characteristics remain parallel after being subjected to different tempering temperatures.

1. Introduction

Machine elements and structures are usually subjected to variable loads that may cause fatigue damage. The design of such mechanical parts consists in the preliminary assessment of fatigue life and requires the experimental representative fatigue data of particular materials [1,2]. Such material characteristics are valid for a given or supposed material state usually considered in the design [3,4]. In many cases, modern technology requires versatility in material features, which may be formed by different processing methods. In this way, many mechanical properties, such as yield and ultimate stress, hardness, elongation, fracture toughness, high-cycle fatigue characteristics etc., may be obtained by a properly applied technological process [5]. Many types of steels are suitable for heat treatment, which is generally understood as heating to the strictly defined temperature, quenching and tempering [6,7,8]. It is well known that such processes may significantly change all mechanical properties including fatigue strength [9,10]. However, there is a lack of information about the influence of the heat treatment process on qualitative and quantitative changes in the low-cycle fatigue (LCF) characteristics of steels, especially when the material is subjected to different tempering temperatures. From the point of view of the designer, the knowledge of how low-cycle fatigue characteristics change would be valuable. An example of an experimental program of low-cycle fatigue for various specimen geometries and loading conditions is described in [11].

Indentation methods have been used for many years to determine the mechanical properties, including fatigue behavior, of various materials. Attempts to find relationships between the hardness of materials and their mechanical properties are known in the literature, as hardness is a convenient and relatively easy parameter to measure. In paper [12], the authors searched for a relationship between material surface hardness and fatigue strength. The authors of paper [13] proved that changes in surface hardness obtained by using a pack-carburizing process showed that the changed fatigue behavior depended on the heat treatment and that it can improve fatigue life. In paper [14], the authors proposed a linear relationship between the fatigue limit and the Brinell Hardness for selected steels and aluminum alloys. However, in the available literature, there is a lack of works dealing with direct relationships between the quantities obtained in the instrumental indentation process and material properties in terms of LCF. Knowledge of such relationships would allow for an easier estimation of fatigue life based on relatively simple experimental tests.

The present paper deals with the influence of the heat treatment process on the strain-controlled low-cycle fatigue behavior of steels with different mechanical properties and chemical compositions. The assumption was made that the tempering temperature of the heat treatment process produces qualitative and quantitative changes in LCF material characteristics [15,16]. However, some more general conclusions arising from the fatigue behavior of steels in such conditions may be drawn after comparing the experimental results of more than one material. For this reason, three different steels, namely: C45, X20Cr13, and 34CrNiMo6 were chosen. On the other hand, it is convenient to have a tool for identifying material features corresponding to LCF properties after a heat treatment process. One approach, presented in [17], applied to X20Cr13 steel, seems to be very promising. It is based on Vickers probe together with the instrumented indentation procedure for a constant indentation depth h* = 4 μm. The method has appeared to be very effective in determining the magnitude of the equi-biaxial stresses at the surface layer of the X20Cr13 material and may be especially useful in identifying residual stresses. Constant indentation depth h* makes it possible to measure the strength of material, represented physically by external force P*, and maintaining similar penetration conditions while applying the probe to a given depth. The same measurement procedure, based on the P* force, has been applied to identify the strength of materials after various heat treatment processes.

The main objective of the present work was to experimentally determine the influence of the heat treatment process on LCF characteristics for C45, X20Cr13, and 34CrNiMo6 steels and to analyze the possible applicability of indentation force P* as a potential discriminant parameter of material features.

2. Materials, Specimens and Heat Treatment

Three steels, C45, X20Cr13, and 34CrNiMo6, suitable for quenching and tempering, were chosen. These steels of different mechanical properties and chemical compositions are commonly used in mechanical engineering. The mechanical properties of the selected steels are given in Table 1.

Table 1.

Mechanical properties of C45, X20Cr13, and 34CrNiMo6 steels [18].

Fatigue properties and failure mechanisms under different loading conditions are presented in [19,20,21,22,23].

Each material was delivered in the form of 16 mm-diameter cylindrical cold drawn bars. The chemical composition of all materials, determined using a Thermo ARL Quantris optical emission spectrometer (Thermo Fisher Scientific Inc., Waltham, MA, USA) and 10 mm-thick samples, are presented in Table 2.

Table 2.

Chemical composition of steels (wt.%).

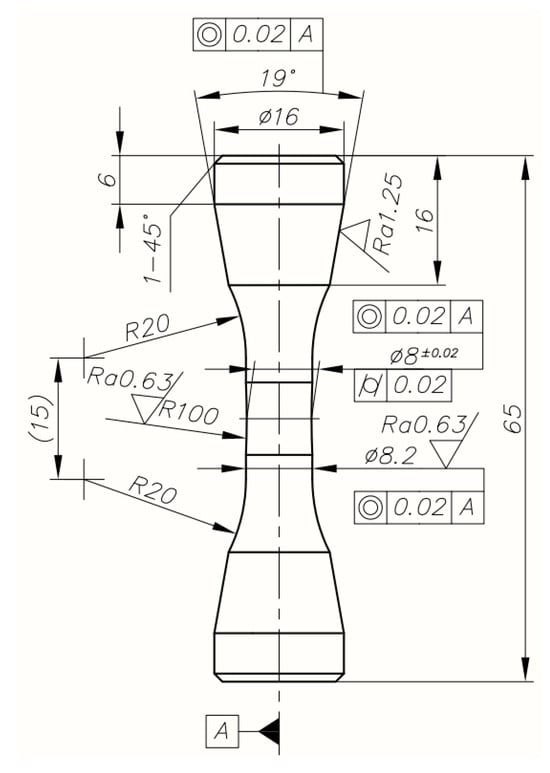

Geometrical details of the specimen are shown in Figure 1. Conical ends provided co-linear fixing, high rigidity and prevented the specimens from sliding in the jaws of the hydraulic machine when testing the very hard material. All specimens were placed in the testing machine using specially designed and fabricated mounting devices. A grinding allowance, left in the central part of all specimens, made it possible to prepare the surface properly for LCF testing.

Figure 1.

Geometrical details of specimens used in LCF tests.

Before performing the heat treatment processes on particular specimens, preliminary tests of all materials were carried out in order to relate material hardness to the tempering temperatures. Three different hardness levels were chosen. The procedure was carried out according to the information concerning quenching temperatures and liquids provided by the steel producers. The heat treatment parameters and hardness measurements obtained from the preliminary tests are shown in Table 3.

Table 3.

Heat treatment parameters and hardness obtained from preliminary Q and T tests.

The process was performed in a furnace with a protective atmosphere. Hardness measurements were made using Rockwell and Vickers’ methods on the end faces of the specimens.

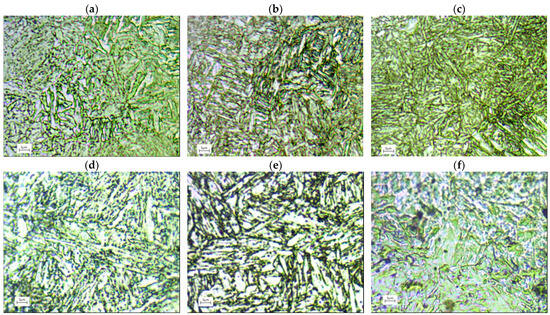

Figure 2a–c shows the microstructures of C45 steel samples quenched from 850 °C and (a) tempered at 620 °C, (b) at 520 °C and (c) at 620 °C. Details of the heat treatment are shown in Table 3. The annealing time before quenching was 45 min and the tempering time was 20 min. The microstructure of a sample after tempering consists mainly of martensite, pearlite, some ferrite and a mixture of ferrite and cementite with a dispersion that decreases with increasing temperatures. This results in a decrease in hardness and an increase in ductility of the material [24,25].

Figure 2.

Microstructure of different steel samples after heat treatment (a–c) C45; (d–f) X20Cr13; and (g–i) 34CrNiMo6 steel used in final experiments.

Figure 2d–f shows the microstructure of the martensitic X20Cr13 stainless steel consists of ferrite and spherical carbides in the annealed state. After heat treatment (austenitising at 1000 °C for 45 min and tempering at 700 °C, 620 °C and 550 °C for 20 min), low-carbon tempered martensite is the main phase in the microstructure [26,27].

34CrNiMo6 steel met the performance requirements after appropriate heat treatment consisting of quenching and tempering at high temperatures [28]. After oil quenching of the samples (heated at 850 °C for 45 min) and tempering at 700, 620 and 500 °C for 20 min by air cooling, the microstructure of the samples was mainly homogeneous tempered martensite (Figure 2g–i).

3. LCF Tests and Results

3.1. Experimental Procedure

All strain-controlled LCF tests were carried out at room temperature with a strain ratio of Rε = εmin/εmax = −1 and with a frequency of 0.2 Hz, using an Instron 8502 hydraulic machine (Instron, High Wycombe, UK) provided with an extensometer with a 12.5 mm gauge length. Three different values of total strain amplitude εa equal to 0.5%, 1.0% and 1.5% were chosen. Such values were considered as the most representative for analyzing LCF properties of the materials subjected to heat treatment due to the fact that both elastic and plastic strain amplitudes are of the same order. All tests were terminated when the force dropped to 50% of the force corresponding to 0.5 Nf [29].

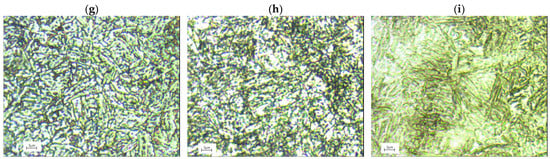

3.2. Cyclic Stress–Strain Behavior

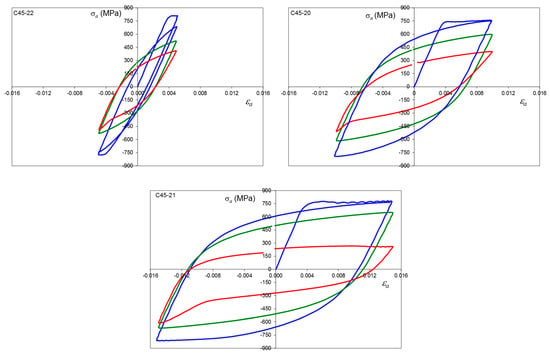

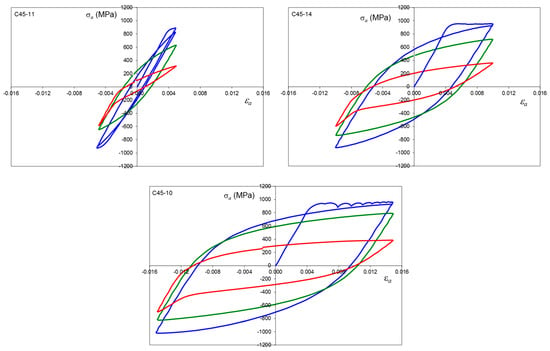

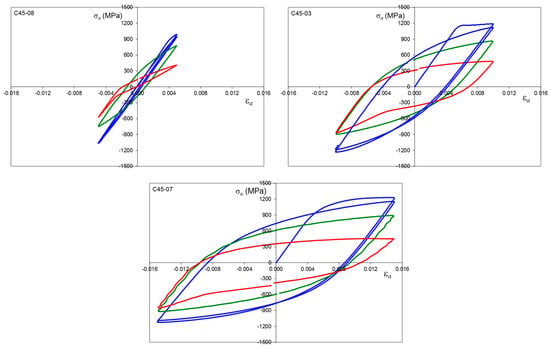

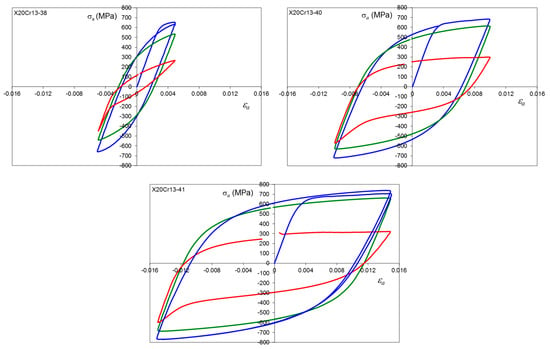

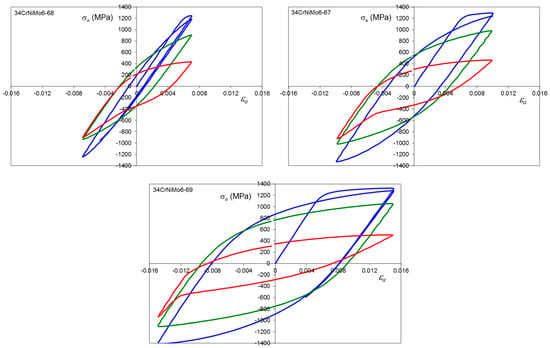

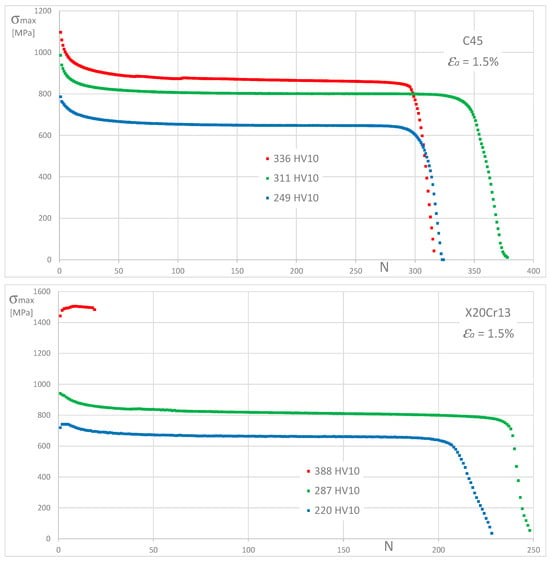

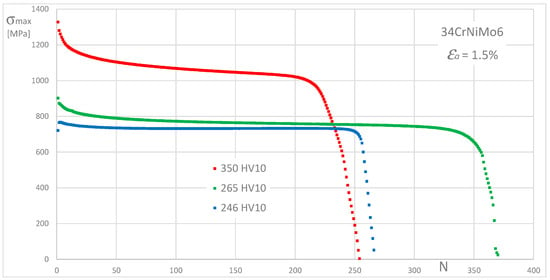

Hysteresis loops for the half-life cycle for all chosen strain amplitudes and materials subjected to heat treatment procedures were identified. Some examples of the experimental results for the strain amplitude εa = 1.5% are shown in Figure 3. Additionally, the particular data corresponding to all LCF tests are presented in Table 4, Table 5 and Table 6. All remaining experimental data, including first, half-life, and final hysteresis loops, for total strain amplitudes εa equal to 0.005, 0.010, and 0.015, are given in Appendix A. The maximum cyclic stress σmax history, representing the material degradation process during cyclic loading, is presented in Figure A10 for εa = 1.5%. The fracture surfaces of the fatigue-tested specimens, depending on their hardness and strain amplitudes, are shown in Table A1. It can be observed that the brittle fracture corresponds to lower strain amplitudes and higher hardness of the specimens. Because the tests were conducted in the elastic–plastic strain range, the fractures are dominated by plastic deformation.

Figure 3.

Stress–strain hysteresis loops for C45, X20Cr13, and 34CrNiMo6 steels, corresponding to 50% Nf, for εa = 1.5%.

Table 4.

LCF test results of C45 steel.

Table 5.

LCF test results of X20Cr13 steel.

Table 6.

LCF test results of 34CrNiMo6 steel.

3.3. Cyclic Stress–Strain Curves

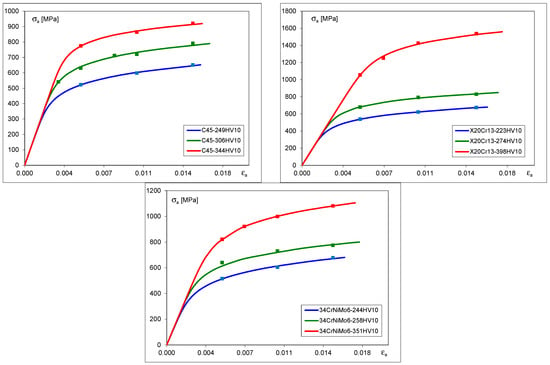

Graphical representations of the cyclic stress–strain characteristics obtained from the experimental results of stabilized hysteresis loops are shown in Figure 4.

Figure 4.

Cyclic stress–strain curves for C45, X20Cr13 and 34CrNiMo6 steels.

These curves were derived using the Ramberg–Osgood formula [30] given by Equation (1) by fitting experimentally obtained values of stress and strain ranges to the formula as follows:

Particular values of K′ and n′, corresponding to the Ramberg–Osgood equation for different hardness ranges of particular materials are presented in Table 7.

Table 7.

Strain-stress characteristic parameters obtained from LCF tests.

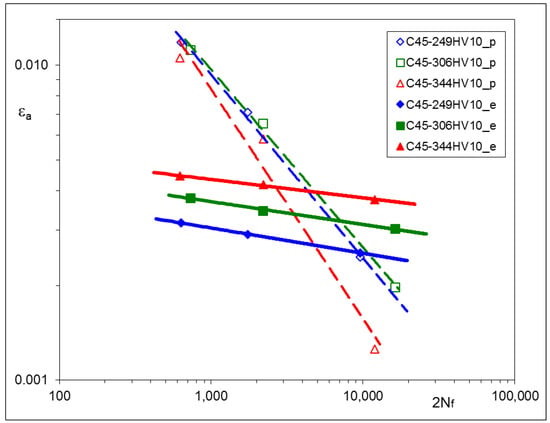

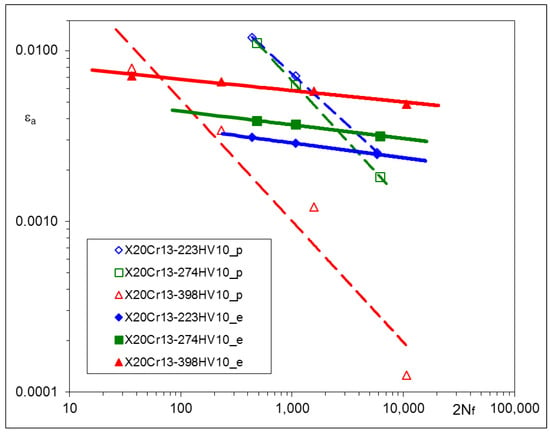

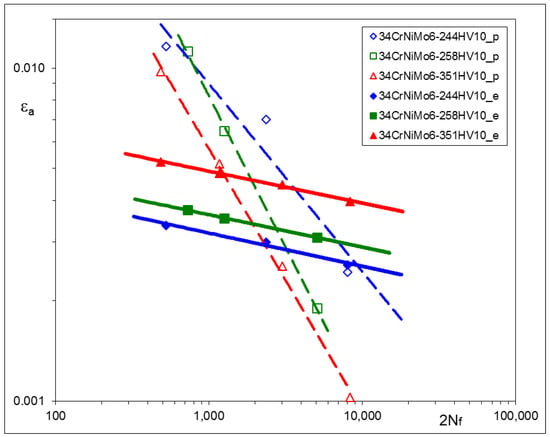

3.4. Strain–Life Characteristics

Other sets of experimental results, obtained from LCF tests, are represented by strain–life characteristics based on stabilized loops for 0.5 Nf and depicted for particular materials in Figure 5, Figure 6 and Figure 7. For convenience, corresponding pairs of elastic and plastic strain amplitudes are shown separately. In such a way, the mutual proportions between elastic and plastic parts of strain amplitudes are clearly seen, and the Manson–Coffin–Basquin Formula (2) may be applied as the mathematical representation of experimental results [31] as follows:

where E, σf′, εf′, b, c are material constants.

Figure 5.

Strain–life characteristic of C45 steel subjected to various Q and T processes.

Figure 6.

Strain–life characteristic of X20Cr13 steel subjected to various Q and T processes.

Figure 7.

Strain–life characteristic of 34CrNiMo6 steel subjected to various Q and T processes.

The values of the Manson–Coffin–Basquin parameters for all steels subjected to heat treatment are presented in Table 8.

Table 8.

Strain-life characteristic parameters obtained from LCF tests.

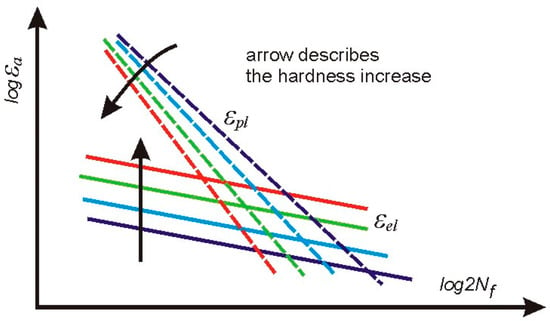

Particular values of b have been found as follows: –0.0706 ± 0.0111 for C45, –0.0818 ± 0.0043 for X20Cr13 and –0.0976 ± 0.0019 for 34CrNiMo6 steel. Plastic parts of the strain–life characteristics change their position and rotate. Such a qualitative feature is common for all steels being analyzed.

3.5. Conclusions Arising from LCF Tests

The experimental results of LCF tests have shown that material characteristics, represented by the Ramberg–Osgood and Manson–Coffin–Basquin equations, depend on the parameters of the tempering process. For all steels: C45, X20Cr13, and 34CrNiMo6, qualitative relationships between tempering temperatures and the material characteristics were very similar. Lower tempering temperature applied in the process resulted in higher values of the cyclic stress–strain branches and the elastic part of the strain–life characteristics. This observation is rather obvious and might be expected. However, the most interesting feature of all steels analyzed here is that elastic parts of the strain–life characteristics remain parallel after being subjected to different tempering temperatures, which means that the fatigue strength exponent b does not change and the fatigue strength coefficient σf’ should be modified. A similar phenomenon can be also observed in [32,33], as a result of plastically pre-strained and asymmetrically loaded steels.

Therefore for each material Equations (3) and (4) are proposed

where particular subscripts 1, 2, and 3 in Equation (3) correspond to different tempering temperatures.

b1 = b2 = b3 = b

The Equation (4) is similar to the Morrow fatigue formula, where the effect of mean stress on fatigue life is considered. In the present case the meaning of an additional term σ*, necessary for correcting the value of Basquin’s strength coefficient, was named as structural stress.

4. Determination of Characteristic force P* and Structural Stresses σ*

4.1. Material and Method

A method of determining surface stresses in X20Cr13 steel through the use of the Vickers indenter is presented in [17]. The method consists in applying the probe to reach a characteristic constant penetration depth h*. In this way, a characteristic stabilized force P* was obtained that depended on the equi-biaxial stress state of the material surface. It was shown that the relationship between the equi-biaxial stresses and the differences in indentation force ΔP* is linear.

The same approach has been used in the present study for analyzing material properties corresponding to the elastic part of fatigue characteristics, occurring in the Manson–Coffin–Basquin equation. The procedure used for determining the magnitude of the characteristic force P* is based on the indentation method, considering a constant indentation depth h* = 4 μm.

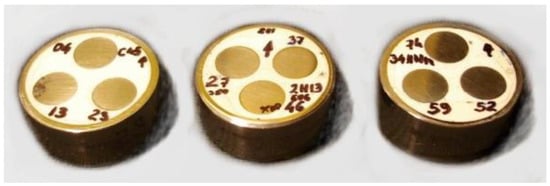

The specimens prepared for deriving the characteristic values P* were made from the same materials subjected to heat treatment, with carefully finished surfaces, as shown in Figure 8.

Figure 8.

Specimens prepared for deriving characteristic values of forces P* by means of indentation using Vickers probe.

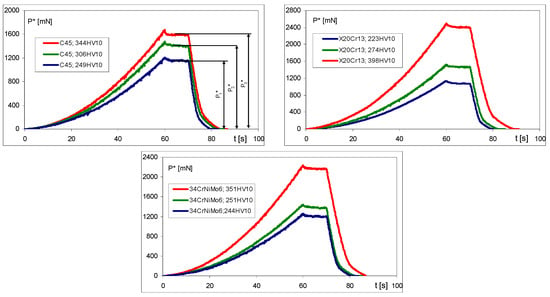

Indentation tests were performed several times for each specimen in order to obtain average P* values. Examples of the indentation histories are presented in Figure 9.

Figure 9.

Examples of indentation graphs for C45, X20Cr13, and 34CrNiMo6 steels.

4.2. Experimental Results

Average values of characteristic stabilized forces P* are summarized in Table 9.

Table 9.

Characteristic indentation force P* for various materials subjected to heat treatment.

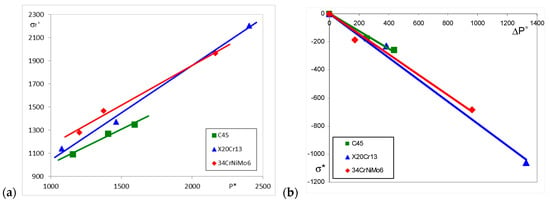

It can be seen that the particular values of the indentation force P* are different for each material and depend on the tempering temperature of the Q and T process. The relationships between the indentation force P* and the fatigue strength coefficient σf′ for particular steels and different tempering temperatures are depicted in Figure 10a.

Figure 10.

Relationship between the indentation force P* and the fatigue strength coefficient σf′ (a), and between the structural stress σ* and the increase in indentation force ΔP* due to the heat treatment (b).

For each material, particular ΔP*i values were obtained by equation (5), representing the increase of the characteristic indentation force with respect to the lowest P* value (corresponding to the highest tempering temperature), named as P*1 as follows:

Next, using Equation (6), the particular values of the structural stresses σ*, based on experimentally determined strength coefficients and indentation forces, were derived as follows:

The relationship between σ* and ΔP* for particular steels are given in Table 10 and shown in Figure 10b.

Table 10.

Relationship between the structural stress parameter σ* and range of indentation force ΔP* resulting from the heat treatment.

5. Discussion

The most important observation resulting from the experimental data is that elastic parts of strain–life relationships appeared for the elastic strain amplitudes, being parallel for each material. This means that the fatigue strength exponent b does not change during heat treatment and may be considered as a constant value for a given steel.

The LCF tests performed for three different steels suitable for heat treatment have shown the significant influence of the process parameters (tempering temperatures) on the hardness and cyclic stress–strain and strain–life characteristics. For all steels: C45, X20Cr13, and 34CrNiMo6, qualitative relationships between tempering temperatures and the material characteristics were very similar. Lower tempering temperatures applied in the process resulted in higher values of the cyclic stress–strain branches and the elastic part of strain–life characteristics.

For each type of steel, elastic parts of the strain–life characteristics remain parallel after being subjected to different heat treatment processes, which means that the fatigue strength exponent b does not change. Such a material behavior may be explained considering two phenomena related to the microstructural changes in volume and with changes in the microstructure due to the Q and T processes. The former may produce additional residual stresses and the latter may change local conditions where plastic deformations occur. It is interesting to note that, in the case of X20Cr13 steel, the coefficient values relating equi-biaxial stresses to the changes of indentation force ΔP* presented in [17] and the structural stress σ* vs. ΔP*, in the present work, are different. This means that in the second case, both effects occur simultaneously, resulting in increases in both the yield stresses and elastic parts of the strain–life fatigue characteristics.

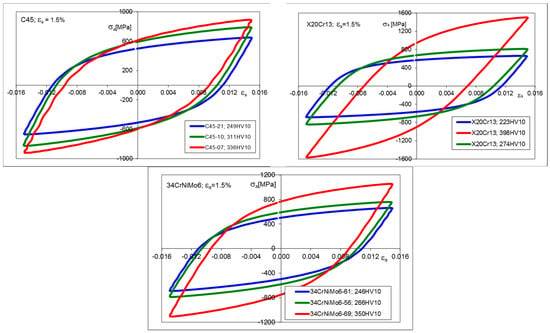

The plastic parts of the strain–life characteristics diminish and rotate (Figure 11), while the material hardness increases, which means that plastic strength exponent c changes due to the heat treatment. Unfortunately, the structural stress parameter σ* cannot be directly used in this case. However, the plastic part of the displacement amplitude εap, which applies in the Manson–Coffin–Basquin formula, can be derived from the Ramberg–Osgood equation, considering the known elastic strain component.

Figure 11.

General qualitative behavior of elastic and plastic parts of the strain–life characteristics found for all steels subjected to heat treatment.

Rotations of, and decreases in, the plastic components of the fatigue characteristics are more difficult to explain, considering their qualitative features. However, it can be observed that lower positions of the plastic strain amplitudes occur with accompanying higher stress amplitudes. This fact is omitted while analyzing the plastic strain amplitude vs. fatigue life. Therefore, additional experimental and analytical work was necessary in order to explain this phenomenon.

6. Conclusions

An analysis of experimental results yielded the conclusions that heat treatment processes have a significant influence on hardness, cyclic stress–strain and strain–life characteristics. With lower tempering temperatures, higher hardness and higher branches of the cyclic stress–strain characteristics were obtained. These results agree with some observations reported in the literature [34,35] dealing with changes in fatigue properties due to the high temperature produced during laser welding.

The characteristic parameter ∆P*, given by Equation (5), was introduced to show the analogy between the quantitative determination of stress values by the method described in [17] and the value of the hypothetical structural stress σ* occurring as a result of heat treatment. However, while in the first case, the stress σ* corresponded to the existing equi-biaxial stress, in the present situation, this allowed us to shift the elastic part of the strain–life characteristic, that is, to change the parameter σ’f to the proper value resulting from the experiment.

The proposed indentation force P* and its changes ΔP* seem to be promising in identifying the σ* parameter necessary for correcting values of the fatigue strength coefficients σf’ for various tempering temperatures. However, the constant indentation depth h* = 4 μm, assumed in the present study, was based on the previous results carried out for X20Cr13 steel that have been used in comparative studies. Future work may show that the h* value should be changed.

Author Contributions

Conceptualization, K.L.M.; methodology, B.H. and K.L.M.; validation, B.H. and K.L.M.; formal analysis, B.H. and K.L.M.; investigation, B.H.; resources, B.H. and K.L.M.; data curation, B.H.; writing—original draft preparation, B.H. and K.L.M.; writing—review and editing, B.H. and K.L.M.; visualization, B.H. and K.L.M.; supervision, K.L.M.; project administration, B.H.; funding acquisition, B.H. All authors have read and agreed to the published version of the manuscript.

Funding

Project financing was funded through the program of the Minister of Science and Higher Education of Poland named “Regional Initiative of Excellence” in 2019–2023, project number 011/RID/2018/19. The amount of financing was 12,000,000 PLN.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Krzysztof L. Molski was employed by the company SaMASZ Sp. z o.o. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Nomenclature

| E | Young’s modulus |

| HV | Vickers hardness |

| h* | constant penetration depth (4 μm) used to determine the characteristic force P* |

| K′, n′ | Ramberg–Osgood parameters |

| LCF | low-cycle fatigue |

| Nf | number of cycles to failure |

| Q and T | quenching and tempering |

| P* | characteristic stabilized force (mN) corresponding to a specified penetration depth h* |

| Rε | strain ratio |

| Δσ | stress range |

| Δε | strain range |

| Δεe | elastic strain range |

| Δεp | plastic strain range |

| εa | total strain amplitude |

| εf′, σf′, b, c | Manson–Coffin–Basquin parameters |

| εae | elastic strain amplitude |

| εap | plastic strain amplitude |

| σa | stress amplitude |

| σa50 | stress amplitude corresponding to 50% of fatigue life Nf |

| σ* | structural stress parameter (MPa) |

Appendix A

First, stabilized, and last, hysteresis loops corresponding to different strain amplitudes 0.005, 0.010, and 0.015 for C45, X20Cr13, and 34CrNiMo6 steels.

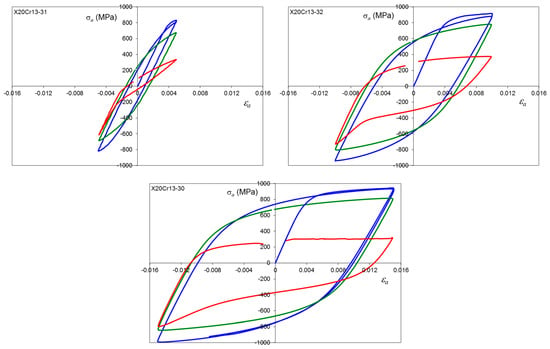

Figure A1.

Stress–strain hysteresis loops for C45, average hardness 249 HV10, εa = 0.5, 1.0 and 1.5%, where: first cycle (blue line), 0.5 Nf (green line) and final cycle (red line).

Figure A2.

Stress–strain hysteresis loops for C45, average hardness 306 HV10, εa = 0.5, 1.0 and 1.5%, where: first cycle (blue line), 0.5Nf (green line) and final cycle (red line).

Figure A3.

Stress–strain hysteresis loops for C45, average hardness 344 HV10, εa = 0.5, 1.0 and 1.5%, where: first cycle (blue line), 0.5Nf (green line) and final cycle (red line).

Figure A4.

Stress–strain hysteresis loops for X20Cr13 steel, average hardness 223 HV10, εa = 0.5, 1.0 and 1.5%, where: first cycle (blue line), 0.5Nf (green line) and final cycle (red line).

Figure A5.

Stress–strain hysteresis loops for X20Cr13 steel, average hardness 274 HV10, εa = 0.5, 1.0 and 1.5%, where: first cycle (blue line), 0.5Nf (green line) and final cycle (red line).

Figure A6.

Stress–strain hysteresis loops for X20Cr13 steel, average hardness 398 HV10, εa = 0.5, 1.0 and 1.5%, where: first cycle (blue line), 0.5Nf (green line) and final cycle (red line).

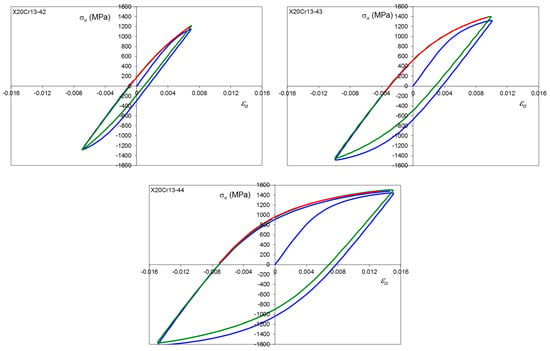

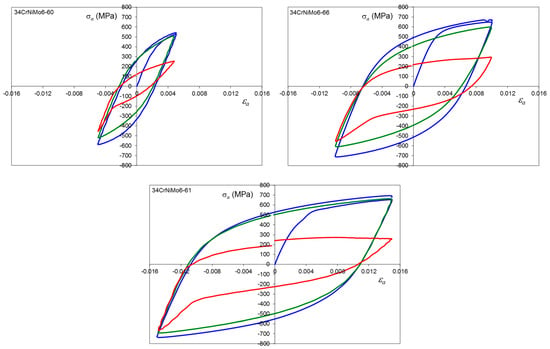

Figure A7.

Stress–strain hysteresis loops for 34CrNiMo6 steel, average hardness 244 HV10, εa = 0.5, 1.0 and 1.5%, where: first cycle (blue line), 0.5Nf (green line) and final cycle (red line).

Figure A8.

Stress–strain hysteresis loops for 34CrNiMo6 steel, average hardness 258 HV10, εa = 0.5, 1.0 and 1.5%, where: first cycle (blue line), 0.5Nf (green line) and final cycle (red line).

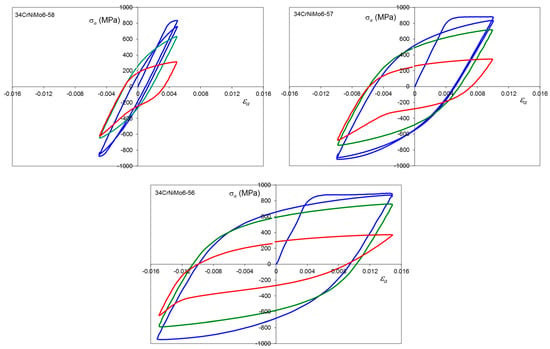

Figure A9.

Stress–strain hysteresis loops for 34CrNiMo6 steel, average hardness 351 HV10, εa = 0.5, 1.0 and 1.5%, where: first cycle (blue line), 0.5Nf (green line) and final cycle (red line).

Figure A10.

Maximum cyclic stress history for C45, X20Cr13, and 34CrNiMo6 steels, for εa = 1.5%.

The fracture surfaces of the fatigue-tested specimens depending on their hardness and strain amplitudes for C45, X20Cr13, and 34CrNiMo6 steels.

Table A1.

Fracture surfaces of fatigue-tested specimens for C45, X20Cr13, and 34CrNiMo6 steels, corresponding to Table 4, Table 5 and Table 6, number of specimens in column: (A) 08, 11, 22; (B) 03, 14, 20; (C) 07, 10, 21; (D) 45, 31, 38; (E) 43, 32, 40; (F) 44, 30, 41; (G) 70, 58, 60; (H) 67, 57, 66; (I) 69, 56, 61.

Table A1.

Fracture surfaces of fatigue-tested specimens for C45, X20Cr13, and 34CrNiMo6 steels, corresponding to Table 4, Table 5 and Table 6, number of specimens in column: (A) 08, 11, 22; (B) 03, 14, 20; (C) 07, 10, 21; (D) 45, 31, 38; (E) 43, 32, 40; (F) 44, 30, 41; (G) 70, 58, 60; (H) 67, 57, 66; (I) 69, 56, 61.

| C45 | X20Cr13 | 34CrNiMo6 | ||||||

| (A) | (B) | (C) | (D) | (E) | (F) | (G) | (H) | (I) |

|  |  |  |  |  |  |  |  |

|  |  |  |  |  |  |  |  |

|  |  |  |  |  |  |  |  |

References

- Hu, Y.; Shi, J.; Cao, X.; Zhi, J. Low Cycle Fatigue Life Assessment Based on the Accumulated Plastic Strain Energy Density. Materials 2021, 14, 2372. [Google Scholar] [CrossRef] [PubMed]

- Branco, R.; Costa, J.D.M.; Antunes, F.V.; PerdigĂŁo, S. Monotonic and Cyclic Behavior of DIN 34CrNiMo6 Tempered Alloy Steel. Metals 2016, 6, 98. [Google Scholar] [CrossRef]

- Jiang, K.; Li, W.; Chen, J.; Ma, L.; Zeng, W.; Yang, J. High Temperature Fatigue Behavior and Failure Mechanism of Ti-45Al-4Nb-1Mo-0.15B Alloy. Crystals 2022, 12, 1669. [Google Scholar] [CrossRef]

- Abarkan, I.; Khamlichi, A.; Shamass, R. A Numerical Analysis on the Cyclic Behavior of 316 FR Stainless Steel and Fatigue Life Prediction. Eng. Proc. 2021, 11, 28. [Google Scholar] [CrossRef]

- Yang, M.; Gao, C.; Pang, J.; Li, S.; Hu, D.; Li, X.; Zhang, Z. High-Cycle Fatigue Behavior and Fatigue Strength Prediction of Differently Heat-Treated 35CrMo Steels. Metals 2022, 12, 688. [Google Scholar] [CrossRef]

- Zhenming, L.; Qigui, W.; Alan, A.L.; Jichun, D.; Hui, Z.; Liming, P. Effect of heat treatment on strain-controlled fatigue behavior of cast Mg-Nd-Zn-Zr alloy. J. Mater. Sci. Technol. 2018, 34, 2091–2099. [Google Scholar] [CrossRef]

- Adamczyk-Cieślak, B.; Koralnik, M.; Kuziak, R.; Brynk, T.; Zygmunt, T.; Mizera, J. Low-cycle fatigue behaviour and microstructural evolution of pearlitic and bainitic steels. Mater. Sci. Eng. A 2019, 747, 144–153. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, T.; Liu, L. Low Cycle Fatigue Life Prediction Model of 800H Alloy Based on the Total Strain Energy Density Method. Materials 2019, 13, 76. [Google Scholar] [CrossRef] [PubMed]

- Droste, M.; Henkel, S.; Biermann, H.; Weidner, A. Influence of Plastic Strain Control on Martensite Evolution and Fatigue Life of Metastable Austenitic Stainless Steel. Metals 2022, 12, 1222. [Google Scholar] [CrossRef]

- Thomä, M.; Wagner, G. Effect of Quenching and Partitioning Heat Treatment on the Fatigue Behavior of 42SiCr Steel. Metals 2021, 11, 1699. [Google Scholar] [CrossRef]

- Fumfera, J.; Halama, R.; Prochazka, R.; Gal, P.; Španiel, M. Strain Range Dependent Cyclic Hardening of 08Ch18N10T Stainless Steel-Experiments and Simulations. Materials 2019, 12, 4243. [Google Scholar] [CrossRef] [PubMed]

- Celik, A.; Arslan, Y.; Yetim, A.F.; Efeoglu, I. Fatigue behaviour of duplex treated AISI 316L stainless steel. Met. Mater. 2007, 45, 35–40. [Google Scholar]

- Nasser, S.H.; Bader, Q.H. Surface hardening effect on the fatigue behavior of isotropic beam. Diagnostyka 2022, 23, 2022312. [Google Scholar] [CrossRef]

- Assi, A.D.; ALKalali, R.H.M. Fatigue Limit Prediction Based on Hardness for Both Steel and Aluminum Alloys. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021. [Google Scholar]

- Saygili, H.H.; Tugrul, H.O.; Kockar, B. Effect of Aging Heat Treatment on the High Cycle Fatigue Life of Ni50.3Ti29.7Hf20 High-Temperature Shape Memory Alloy. Shape Mem. Superelasticity 2019, 5, 32–41. [Google Scholar] [CrossRef]

- Xu, J.; Huang, Z.; Jiang, L. Effect of heat treatment on low cycle fatigue of IN718 superalloy at the elevated temperatures. Mater. Sci. Eng. A 2017, 690, 137–145. [Google Scholar] [CrossRef]

- Hościło, B.; Molski, K.L. Determination of Surface Stresses in X20Cr13 Steel by the Use of a Modified Hardness Measurement Procedure with Vickers Indenter. Materials 2020, 13, 4844. [Google Scholar] [CrossRef]

- Harvey, P.D. Engineering Properties of Steel; American Society for Metals: Detroit, MI, USA, 1992; p. 538. [Google Scholar]

- Leguinagoicoa, N.; Albizuri, J.; Larranaga, A. Fatigue improvement and residual stress relaxation of shot-peened alloy steel DIN 34CrNiMo6 under axial loading. Int. J. Fatigue 2022, 162, 107006. [Google Scholar] [CrossRef]

- Brancoa, R.; Costaa, J.D.; Bertob, F.; Kotousovc, A.; Antunesa, F.V. Fatigue crack initiation behaviour of notched 34CrNiMo6 steel bars under proportional bending-torsion loading. Int. J. Fatigue 2020, 130, 105268. [Google Scholar] [CrossRef]

- Branco, R.; Costa, J.D.; Antunes, F.V. Low-cycle fatigue behaviour of 34CrNiMo6 high strength steel. Theor. Appl. Fract. Mech. 2012, 58, 28–34. [Google Scholar] [CrossRef]

- Brnic, J.; Turkalj, G.; Canadija, M.; Lanc, D.; Krscanski, S. Martensitic stainless steel AISI 420—Mechanical properties, creep and fracture toughness. Mech. Time-Depend. Mater. 2011, 15, 341–352. [Google Scholar] [CrossRef]

- Teng, Z.; Wu, H.; Boller, C.; Starke, P. Thermography in high cycle fatigue short-term evaluation procedures applied to a medium carbon steel. Fatigue Fractture Eng. Mater. Struct. 2019, 43, 515–526. [Google Scholar] [CrossRef]

- Carvajala, L.; Artigasa, A.; Monsalvea, A.; Arévaloa, E. Monitoring Heat Treatments in Steels by a Non Destructive Ultrasonic Method. Mater. Res. 2016, 20, 347–352. [Google Scholar] [CrossRef]

- Xiao, J.; Zhao, Z.; Xie, X.; Liang, Z.; Liu, Z.; Liu, X.; Tang, R. Micromorphology, Microstructure, and Wear Behavior of AISI 1045 Steels Irregular Texture Fabricated by Ultrasonic Strengthening Grinding Process. Metals 2022, 12, 1027. [Google Scholar] [CrossRef]

- Sharifi, H.; Kheirollahi-Hosseinabadi, I.; Ghasemi, R. The Effect of Tempering Treatment on the Microstructure and Mechanical Properties of DIN 1.4021 Martensitic Stainless Steel. Int. J. ISSI 2015, 12, 9–15. [Google Scholar]

- Rosemann, P.; Muller, T.; Babutzka, M.; Heyn, A. Influence of microstructure and surface treatment on the corrosion resistance of martensitic stainless steels 1.4116, 1.4034, and 1.4021. Mater. Corros. 2015, 66, 45–53. [Google Scholar] [CrossRef]

- Liang, R.; Huang, C.; Hao, H.; Liu, F.; Liu, F.; Song, M.; Ke, L. Microstructure and mechanical properties of 34CrNiMo6 steel repaired by laser remelting. J. Mater. Res. Technol. 2020, 9, 13870–13878. [Google Scholar] [CrossRef]

- ASTM E606/E606M—12; Standard Practice for Strain Controlled Fatigue Testing. ASTM: West Conshohocken, PA, USA, 2012.

- Ramberg, W.; Osgood, W.R. Description of Stress–Strain Curves by Three Parameters; NASA: Washington, DC, USA, 1943. [Google Scholar]

- Coffin, L.F. A study of the effect of cyclic thermal stress on a ductile metal. Trans. ASME 1954, 76, 931–950. [Google Scholar]

- Zhang, J.; Li, W.; Dai, H.; Liu, N.; Lin, J. Study on the Elastic-Plastic Correlation of Low-Cycle Fatigue for Variable Asymmetric Loadings. Materials 2020, 13, 2451. [Google Scholar] [CrossRef]

- Prosgolitis, C.G.; Kermanidis, A.T.; Kamoutsi, H.; Haidemenopoulos, G.N. Low Cycle Fatigue Behavior of Plastically Pre-Strained HSLA S355MC and S460MC Steels. Materials 2022, 15, 7927. [Google Scholar] [CrossRef]

- Boroński, D. Cyclic material properties distribution in laser-welded joints. Int. J. Fatigue 2006, 28, 346–354. [Google Scholar] [CrossRef]

- Song, W.; Liu, X.; Berto, F.; Razavi, S.M.J. Low-Cycle Fatigue Behavior of 10CrNi3MoV High Strength Steel and Its Undermatched Welds. Materials 2018, 11, 661. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).