Abstract

Additive manufacturing (AM) comes in various types of technologies and comparing it with traditional fabrication methods provides the possibility of producing complex geometric parts directly from Computer-Aided Designs (CAD). Despite answering challenges such as poor workability and the need for tooling, the anisotropy of AM constructions is the most serious issue encountered by their application in industry. In order to enhance the microstructure and functional behavior of additively fabricated samples, post-processing treatments have gained extensive attention. The aim of this research is to provide critical, comprehensive, and objective methods, parameters and results’ synthesis for post-processing treatments applied to AM builds obtained by 3D printing technologies. Different conditions for post-processing treatments adapted to AM processes were explored in this review, and demonstrated efficiency and quality enhancement of parts. Therefore, the collected results show that mechanical characteristics (stress state, bending stress, impact strength, hardness, fatigue) have undergone significant improvements for 3D composite polymers, copper-enhanced and aluminum-enhanced polymers, shape memory alloys, high-entropy alloys, and stainless steels. However, for obtaining a better mechanical performance, the research papers analyzed revealed the crucial role of related physical characteristics: crystallinity, viscosity, processability, dynamic stability, reactivity, heat deflection temperature, and microstructural structure.

1. Introduction

The technology of 3D printing has rapidly gained popularity over the past few years due to its versatility and ability to produce complex parts and structures. Applications of 3D printing include the manufacturing of various products such as medical devices, aerospace components, and consumer goods. Despite its benefits, there are certain limitations associated with 3D printing that include poor surface quality, dimensional inaccuracies, and low mechanical strength. These limitations highlight the need for post-processing treatments such as sanding, polishing, and heat treatment to enhance the properties and functionality of the 3D-printed parts.

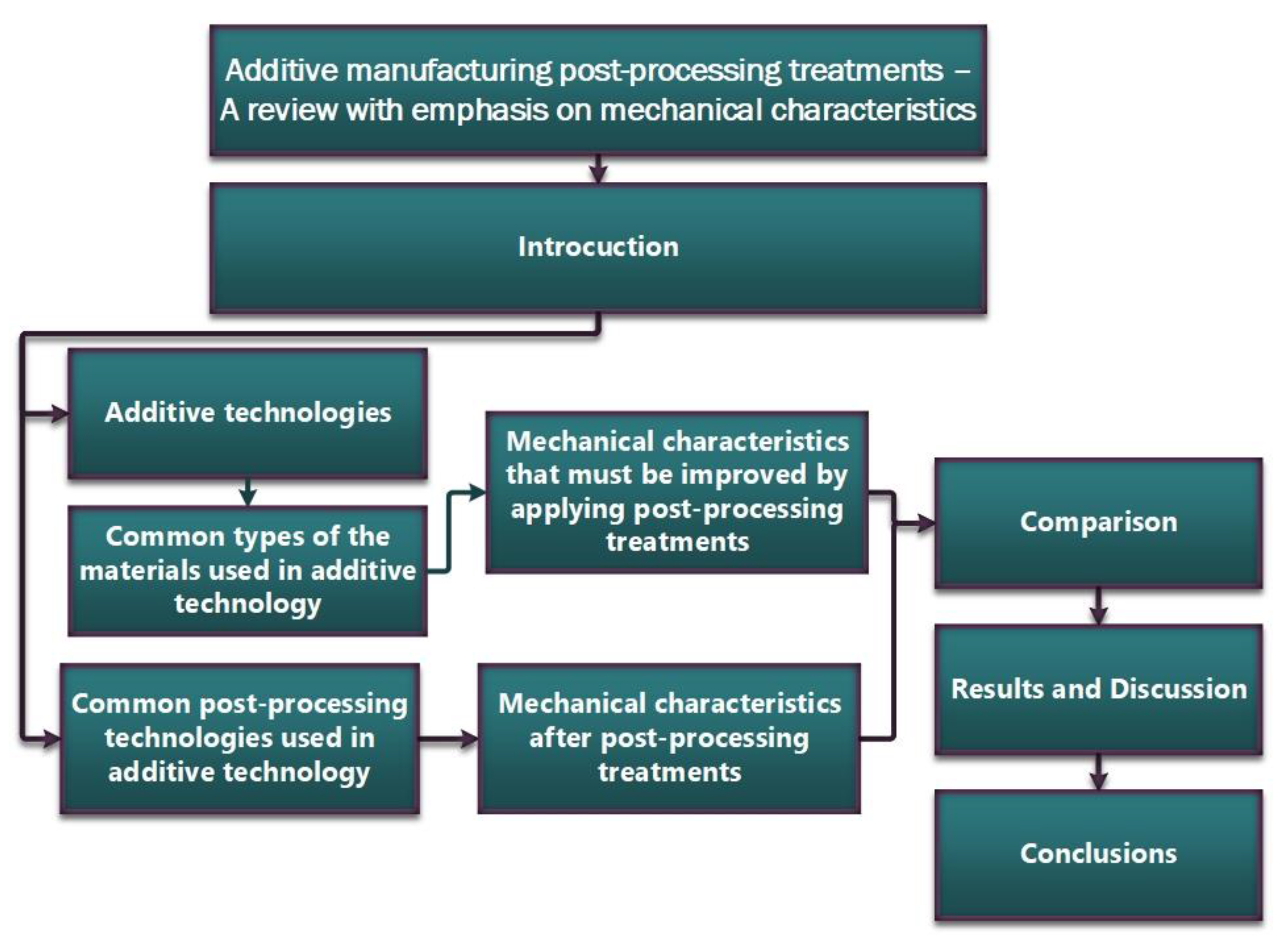

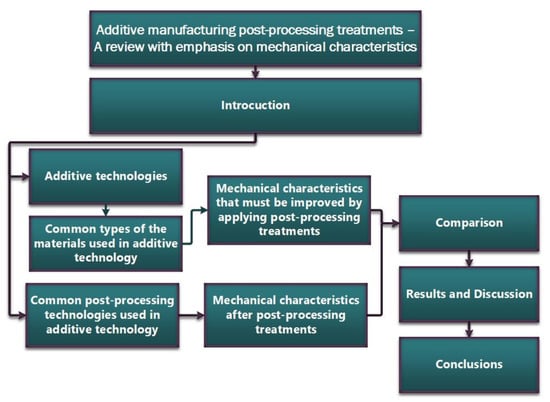

As can be seen in the graphical abstract (Figure 1), this review article aims to highlight the applications of post-processing of 3D-printed parts and their associated limitations, as well as the importance of these treatments to overcome these limitations and improve the quality and performance of the 3D-printed parts.

Figure 1.

Graphical abstract (Source: authors as the basis of article content).

Additive printing technology and its applications are vast, ranging from healthcare to aerospace. Some of the most significant applications of 3D printing technology are:

- Healthcare

Prosthetics, implants, and surgical instruments. In some cases, 3D printing has been used to produce patient-specific models for surgical planning, allowing for more accurate procedures.

- Aerospace

Light and complex parts for aircraft, such as engine components and wing structures. This technology has allowed for faster and more efficient production processes.

- Manufacturing

Prototyping and production of small batches of parts, such as in the automotive and electronics industries.

- Architecture and construction

Production of small-scale models of buildings, allowing architects and engineers to visualize designs and make modifications before construction begins.

- Education

Used in education to teach students about engineering, design, and manufacturing principles.

The 3D printing materials refer to the substances used in the creation of 3D-printed objects. They come in a variety of forms, including filaments, resins, and powders, and can be made from a range of materials, including plastic, metal, and ceramic.

Some popular 3D printing materials for the filaments include:

- PLA (Polylactic Acid)

Biodegradable and eco-friendly plastic commonly used for its ease of printing and low warping tendency. It is ideal for creating prototypes, toys, and figurines.

- ABS (Acrylonitrile Butadiene Styrene)

Strong, durable, and lightweight plastic that is often used in the creation of products such as phone cases and automotive parts.

- PETG (Glycol-Modified Polyethylene Terephthalate)

Flexible, food-safe plastic that is easy to print and resistant to impacts, chemicals, and UV light.

Resins are another popular 3D printing material. They are typically used with SLA (Stereolithography) and DLP (Digital Light Processing) printers and offer higher precision and accuracy than filaments. Some common resins include:

- UV resin

Fast-curing, high-resolution resin that is ideal for creating intricate and detailed models.

- Flexible resin

Bendable and soft resin that is suitable for creating flexible and soft-touch parts, such as phone cases.

- Castable resin

This resin can be melted and cast in metal to produce high-quality jewelry and other metal objects.

In addition, there are 3D printing powders, which include materials such as metal and ceramic. These materials are typically used with SLS (Selective Laser Sintering) printers and are best suited for creating complex and robust objects, such as aerospace parts and medical implants.

Popular 3D-printing metallic filament materials include:

- Titanium

This is one of the most commonly used metals for 3D printing. It has excellent strength, light weight, and high corrosion resistance.

- Stainless steel

Known for its durability, corrosion resistance, and high strength-to-weight ratio. Widely used in aeronautical and medical applications.

- Aluminum

Aluminum is light, strong, and has good thermal and electrical conductivity. It is commonly used in the aerospace, automotive, and consumer electronics industries.

- Inconel

Inconel is renowned for its high strength, excellent resistance to corrosion and oxidation, and high temperature resistance. The aerospace and power industries use it extensively.

- Cobalt Chromium

This metal is known for its excellent biocompatibility, high strength, and corrosion resistance and is used in the medical and dental industries.

- Copper

Known for its high thermal and electrical conductivity, this metal is commonly used in the electronics industry.

- Gold

Widely used in jewelry, this metal is highly prized for its unique aesthetic qualities.

- Nickel

It is known for having high strength, resisting corrosion, and withstanding high temperatures. It is widely used in the aerospace and energy industries.

- Bronze

Renowned for its durability, corrosion resistance, and unique appearance. It is often the material of choice for art and sculpture.

- Silver

Valued for its unique aesthetic qualities, this metal is often used in jewelry and decorative objects.

There are a wide range of 3D printing materials available, each with its own unique properties and capabilities. When choosing a material, it is important to consider the desired end-product, the printing method, and the desired level of precision and accuracy.

As stated in the previous paragraphs, the additive printing technology has revolutionized many industries, it is still in its early stages of development, and limitations such as surface finish, strength, accuracy, and cost mean that post-processing treatments are often necessary.

Heat treatment is a process commonly applied to 3D-printed parts to improve their mechanical properties. The process involves exposing the parts to high temperatures to cause a change in the microstructure of the material, resulting in a desired change in properties such as increased strength, improved dimensional stability, and reduced brittleness.

However, despite the many benefits of 3D printing, there are also limitations that prove the need for post-processing treatments. Some of the limitations include:

- Surface finish

The printed parts often have a rough and porous surface that requires post-processing treatments such as sanding, smoothing, and painting.

- Strength and durability

The 3D-printed parts are often weaker than conventionally manufactured parts and require additional post-processing treatments such as reinforcement and hardening.

- Accuracy

The additive printing technology is still developing, and the accuracy of printed parts can vary depending on the technology used. Post-processing treatments such as finishing and calibration are often necessary to achieve the desired level of accuracy.

- Costs

The technology can be expensive, and post-processing treatments can add to the overall cost of the process.

There are several types of heat treatment commonly applied to 3D-printed parts, including annealing, normalizing, hardening, and tempering. Annealing is a process of heating and cooling the parts to reduce internal stress and improve their toughness and ductility. Normalizing involves heating the parts to a temperature above the critical range and cooling them in still air to achieve a uniform grain structure. Hardening is a process of heating and rapidly cooling the parts to form a hard, strong, and brittle structure. Tempering is a process of reheating the hardened parts to a lower temperature to reduce their brittleness and improve toughness.

The choice of heat treatment depends on the material and the desired properties of the parts. For example, Acrylonitrile Butadiene Styrene (ABS) parts are typically annealed, while stainless steel parts are hardened and tempered. The process parameters, including the temperature, cooling rate, and the time at temperature, are critical to achieving the desired properties and must be carefully controlled.

The heat treatment is an important post-processing step in the manufacture of 3D-printed parts. It can significantly improve the mechanical properties of the parts, making them more suitable for a wide range of applications. However, it requires a careful control of the process parameters to achieve the desired results and must be tailored to the specific material and application requirements.

The parameters for heat treatment of 3D-printed parts include:

- Heat treatment temperature

This is a crucial factor for heat treatment, as it determines the microstructural changes that occur in the material of the 3D parts. The temperature must be carefully controlled to ensure that the desired properties are achieved.

- Duration of heat treatment

The time taken to heat treat the 3D parts is also important. The longer the 3D part is held at the desired temperature, the more time it has to reach equilibrium, and the greater the chances of the desired microstructural changes occurring.

- Atmosphere in the heat treatment furnace

The atmosphere surrounding the 3D part during heat treatment is also important. Controlled atmospheres can be used to prevent unwanted reactions during the heat treatment process.

- Cooling rate

The rate at which the 3D part is cooled after heat treatment also affects its properties.

- Equipment (furnace for heat treatment)

The furnace used for heat treatment can also affect the outcome. For example, the type of furnace used can impact the temperature uniformity, heating rate, and cooling rate of the 3D-printed parts.

- Post-processing operations

Any post-processing, such as machining, sanding, or polishing, should be performed after heat treatment to avoid affecting the desired properties.

The parameters for heat treatment of 3D-printed parts are crucial for achieving the desired properties in the final product. Careful consideration and control of temperature, time, atmosphere, cooling rate, equipment, and post-processing is essential for successful heat treatment.

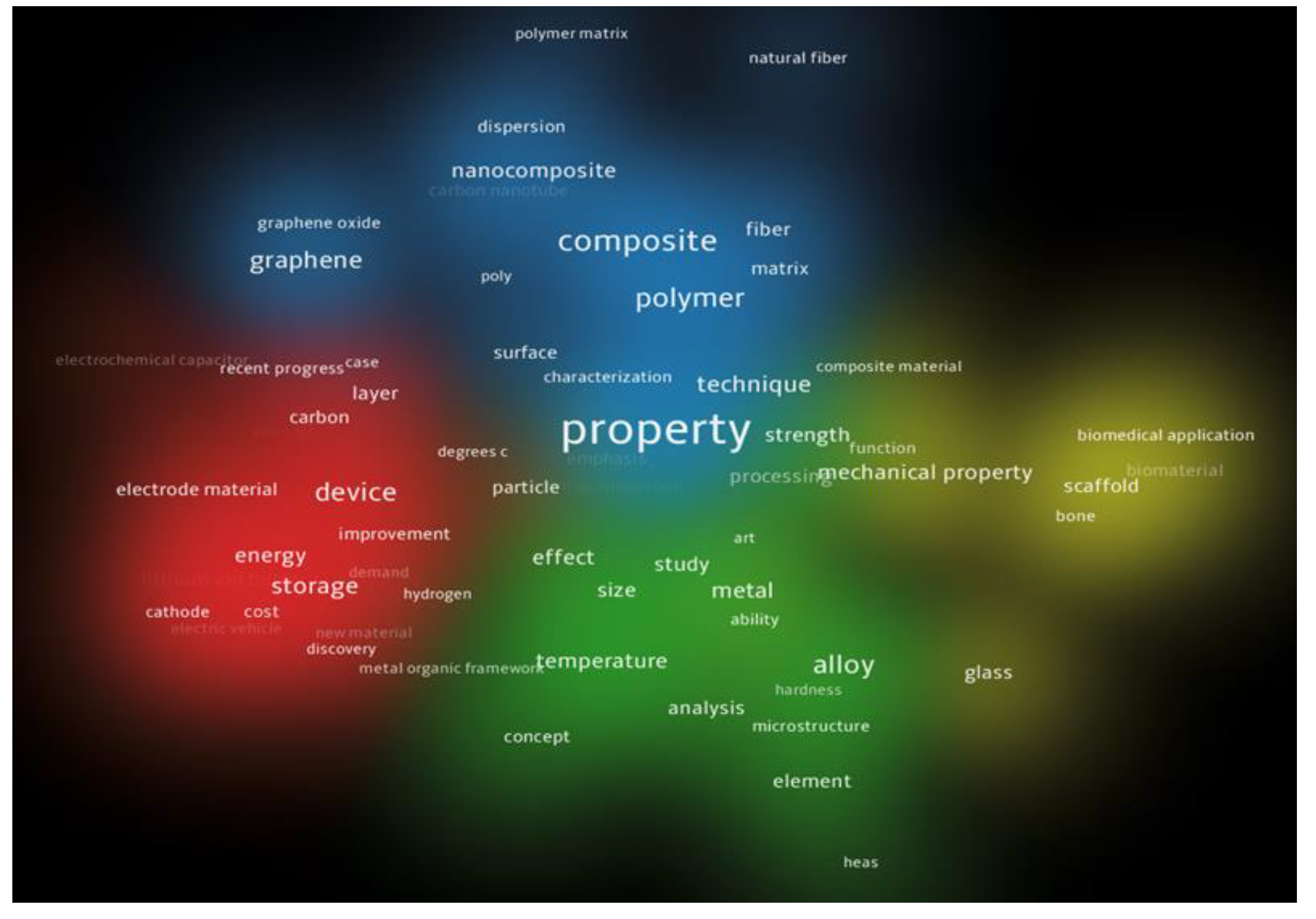

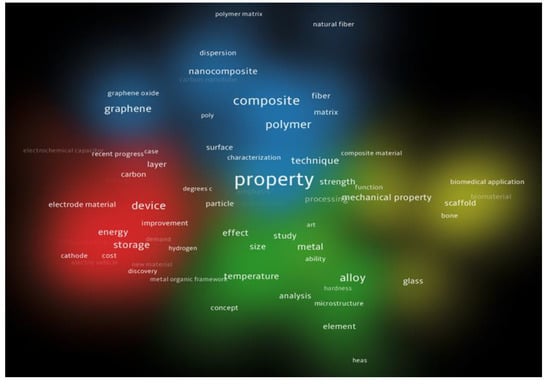

In order to analyze the most relevant concepts in the field of this review, a bibliometric analysis was used, using the academic platform Web of Science as the source of scientific articles analyzing 3D printing materials and post-processing treatments. Therefore, the content of 100 highly cited articles related to these topics on Web of Science were explored to highlight the structure of the scientific field, using content analysis that examined the most common words (3D printing technologies, materials, post-processing treatments, mechanical properties) and the relationship between these words. The empirical analysis showed that the most common words in the full content of the selected articles, apart from the keywords used, are presented in Figure 2, including “mechanical property” and “structure”.

Figure 2.

Common words in scientific publications (Source: authors based on articles analyzed).

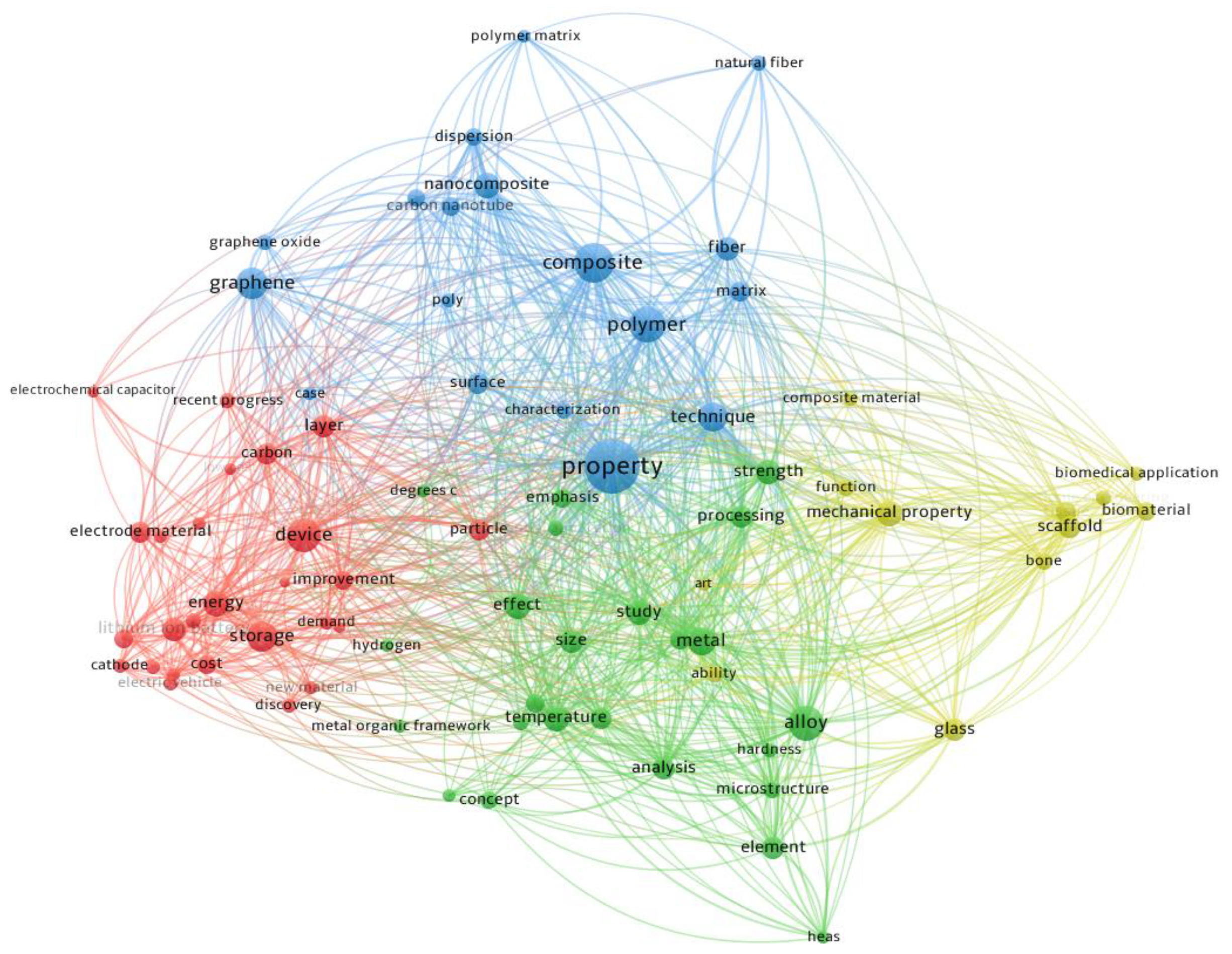

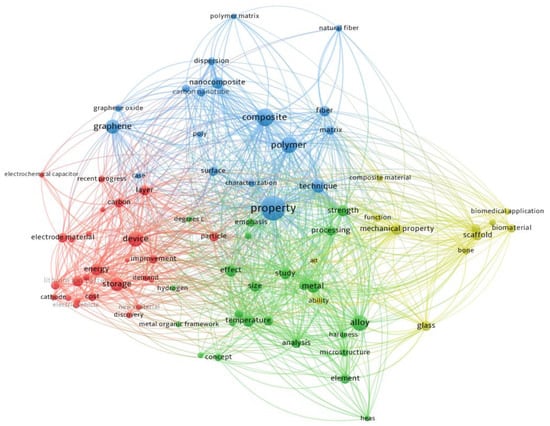

From the analysis of the clusters shown in Figure 2 and Figure 3, the nature of the materials and the different technologies used to make parts by additive technologies for various industries are closely related to the size of the mechanical characteristics needed to meet the demands of practical applications.

Figure 3.

Word network in renewable energy transition scientific publications’ content (Source: authors based on articles analyzed).

From the above, it can be seen that additive technology, also known as additive manufacturing, is a manufacturing process that uses a 3D model created with CAD technology to build a three-dimensional object from a variety of materials by depositing successive thin layers of material. A literature review of over 100 key papers in the field showed that this technology has revolutionized the way parts and components are produced in various industries, allowing the creation of more complex and precise parts than using traditional technologies. However, parts produced using additive technology can be susceptible to both internal stress parity and other technological problems that can affect their strength and durability. Therefore, heat treatments are often required to improve the properties of additive parts. These heat treatments can include various types of heat treatments and related technological operations. The following are the main advantages and disadvantages of using heat treatments for additive manufacturing parts.

It is also clear from the literature review that heat treatment of additive manufactured parts can provide a number of benefits, which are listed below:

- Improved mechanical properties of additive parts, including hardness and strength. Additive parts can have internal stresses and micro-cracks that can affect their strength and durability. Heat treatments can reduce these stresses and harden the material, improving part strength and durability;

- Elimination of internal stresses. The 3D printing process can create internal stresses in parts, and heat treatments can help eliminate these stresses, reducing the risk of parts breaking or cracking. The process can also reduce thermal distortion and shrinkage that occurs during the manufacturing process, improving the dimensional stability of parts;

- Improved geometric accuracy. Heat treatment can help reduce non-uniform deformation and shrinkage during the production process, which can improve the geometric accuracy of parts;

- Uniformity/homogeneity of part structure. The 3D printing process can produce parts with a porous structure, and heat treatments can help strengthen the structure by eliminating porosity and voids, thus increasing the homogeneity of the materials used in 3D printing, which can lead to better quality printed parts;

- Impurity removal. The 3D printing process can introduce impurities into the material used, and heat treatments can help remove these impurities;

- Improved adhesion between layers. Heat treatments can increase adhesion between layers of material, which can lead to better stability and strength of printed parts;

- Reduced brittleness. Some materials used in 3D printing can be brittle, and heat treatments can help reduce brittleness by improving hardness and strength;

- Improved ductility. Heat treatments can increase the ductility of some materials, resulting in a better ability to deform under stress;

- Increased corrosion resistance. Parts produced by additive technology can be more susceptible to corrosion than parts produced by other methods. Heat treatments can increase the corrosion resistance of materials, which can extend the life of printed parts;

- Improved surface finish. Heat treatments can also provide the appropriate surface roughness required for certain technical applications, improving the quality and appearance of parts;

- Improved ductility. Parts produced by additive technology can be more brittle than parts produced by other methods. Heat treatments can improve the ductility of the material, making it less susceptible to cracking or fracture;

- Increased thermal and electrical conductivity. Parts produced by additive technology may have lower thermal and/or electrical conductivity than parts produced by other methods. Heat treatments can increase the thermal and/or electrical conductivity of parts, improving their ability to transfer heat;

The following are some of the categories of reasons why problems/disadvantages may arise in the use of post-processing heat treatments:

- Part distortion. If inappropriate temperature regimes are used, they can lead to deformation of additive manufactured parts;

- Undesirable changes in mechanical properties. Additive technology is a manufacturing process that involves the variation of many specific factors that give parts certain mechanical properties. Heat treatments can affect these properties, often in unexpected ways, which can lead to reduced performance;

- Increased porosity. Post-treatment heat treatments can lead to increased porosity in additive manufactured parts, which can adversely affect both the strength and durability of the parts;

- Irregularities on part surfaces. Heat treatments applied to parts produced by additive technology can cause irregularities on the surface of the parts, which can affect their accuracy and quality;

- Increased production time. The length of heat-treatment cycles often involves additional heating, holding, and cooling time, which can significantly increase the production time of parts;

- Higher production costs. Due to the high consumption of equipment/tools, energy, consumables, and labor, heat treatment involves additional costs that can significantly increase the production cost of parts;

- Creation of critical situations in the production process. Heat treatments can be difficult to apply during the part production process, which can lead to complications and delays;

- Increased risk of damage. Both high temperatures and sudden temperature changes can cause damage to parts during heat treatment, resulting in rejection;

- Dimensional limitations. Due to the volume of the furnaces, part dimensions can be limited to small values, which can restrict design and manufacturing options;

- Inherent risks of failure in service. If not carried out correctly, heat treatments can cause parts to fail in service, which can be dangerous in critical applications;

In the next subsections, the materials used and the method of analysis used to carry out this review are presented in relation to the use of heat treatments on parts produced by technological processes specific to additive technologies.

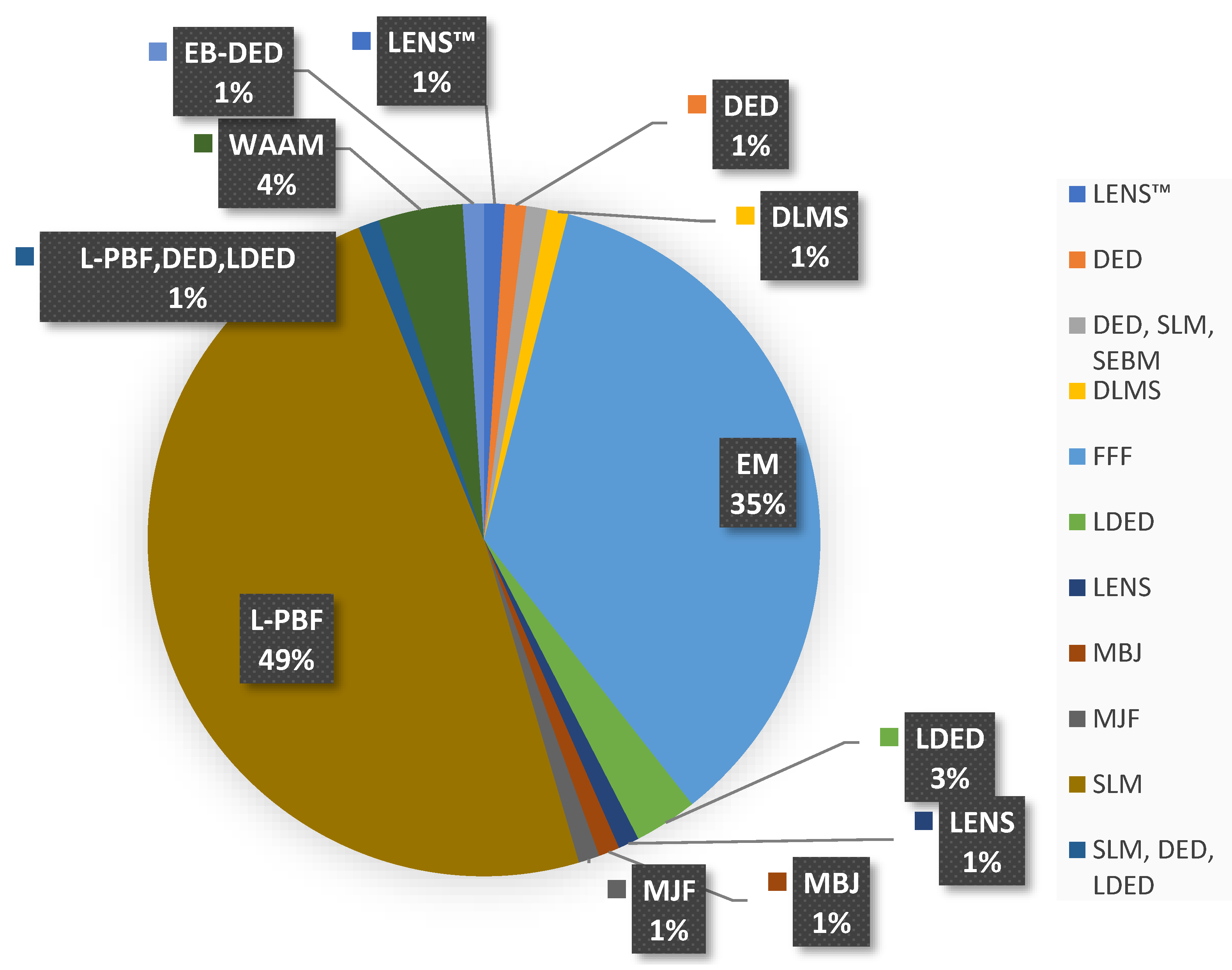

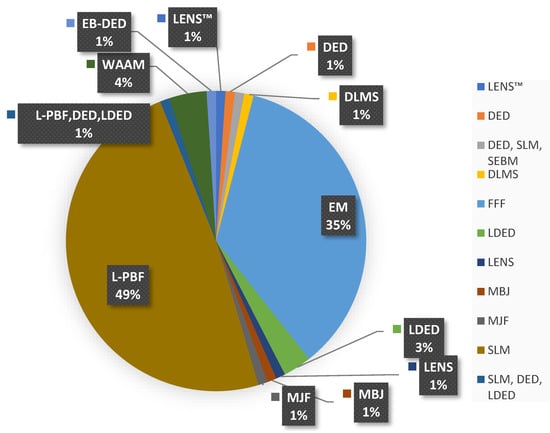

2. Studied Additive Technologies

The present study conducted a comprehensive analysis of several additive technologies and their respective variations. It is known that the diverse post-treatment procedures employed are inherently specific to the particular type of additive manufacturing process utilized. It is observable from the graphical data presented in Figure 4 that a substantial proportion of the post-treatment techniques employed in the analyzed literature are utilized for parts fabricated via Laser Beam Bed Fusion (L-PBF) and represents a significant percentage of 49% of the post-treatment techniques applied; in addition, parts generated through the technology material extrusion (ME) comprise 35% of the total. The remaining post-treatment methodologies are distributed across a range of additive manufacturing processes, including Laser Engineered Net Shaping™ (LENS™), Directed Energy Deposition (DED), Selective Electron Beam Melting (SEBM), Digital Light Processing Stereolithography (DLMS), Laser Direct Energy Deposition (LDED), Laser Powder Bed Fusion (L-PBF), Material Jetting (MBJ), Multi Jet Fusion (MJF), and Wire Arc Additive Manufacturing (WAAM), among others, in varying proportions, that are shown in Figure 4.

Figure 4.

Distribution of studied additive technologies.

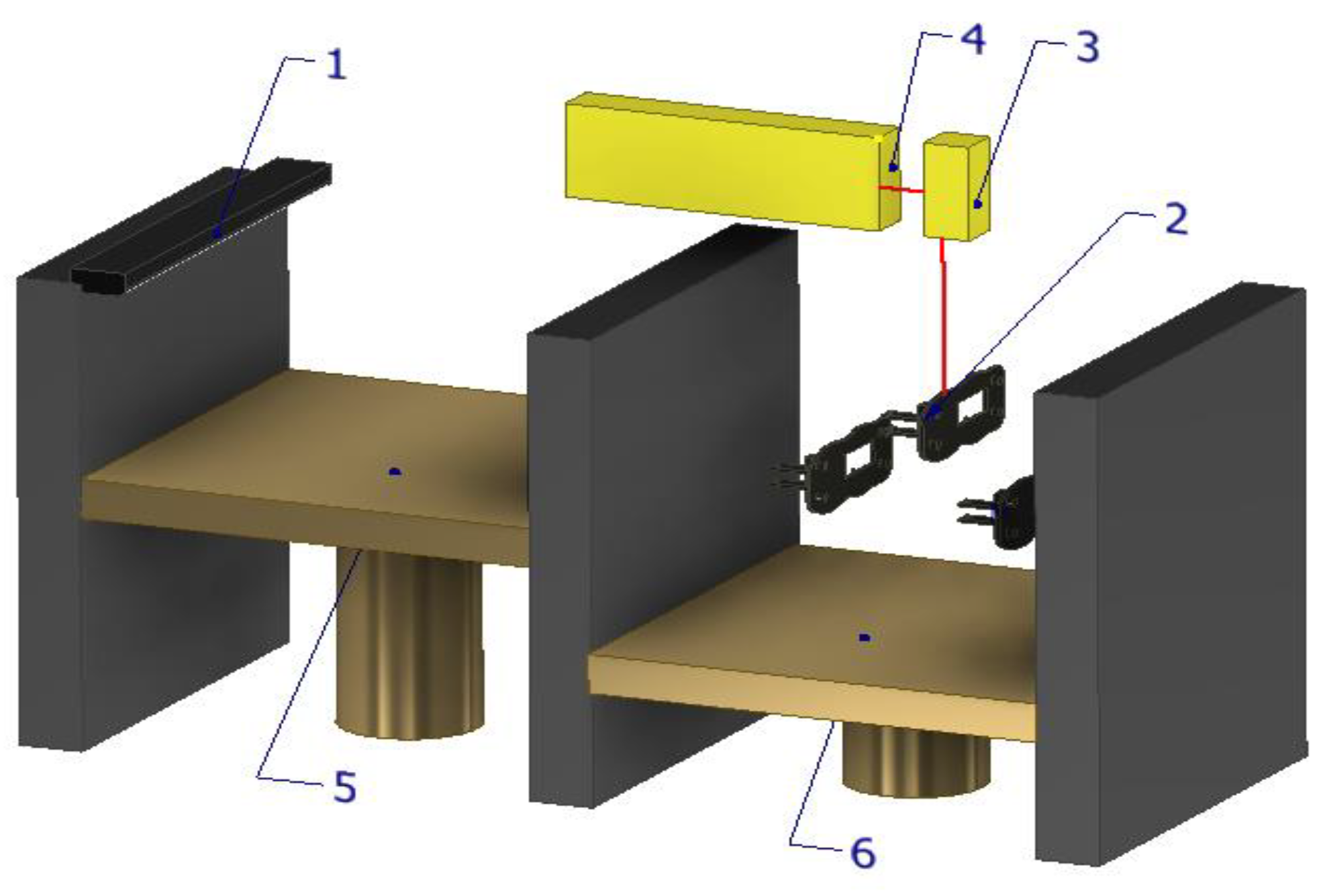

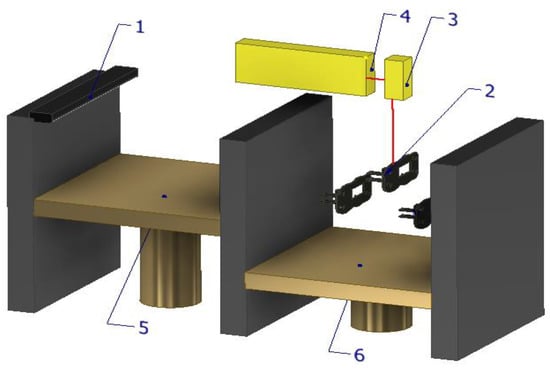

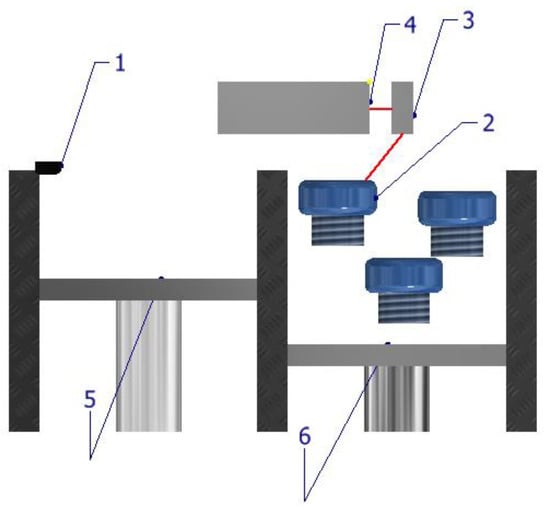

2.1. Laser Powder Bed Fusion (L-PBF)

Laser Powder Bed Fusion (L-PBF L-PBF [1] represents the most extensively utilized powder bed-based additive manufacturing (AM) technique. The L-PBF process employs a laser beam for melting and fusing metal powders together, with a thin layer of powder uniformly distributed over the substrate or a previously deposited layer (Figure 5). The laser beam selectively melts and fuses the powder particles in accordance with the computer-aided design (CAD) model. In order to fabricate parts with optimized microstructure and properties that are free of defects, the L-PBF technique necessitates the careful adjustment of several process parameters, including laser power, laser scanning speed, layer thickness, hatching distance, and scanning strategy. Typically, depending on the reactivity of the metallic powders employed, the L-PBF process is performed in a closed chamber that is filled with an inert atmosphere, such as argon or nitrogen. The principal motivation for applying post-treatments to L-PBF parts are presented as follows and the primary factors behind the implementation of post-processing techniques on L-PBF parts lies in the pursuit of enhanced material properties and improved functional performance of the fabricated components:

Figure 5.

Principal graphical scheme of L-PBF.

- Residual stress [2,3];

- Microstructure high porosity [4,5];

- Microstructure instability [5,6,7,8];

- Homogenization, microstructural refinement, and martensite-to-austenite reversion [9];

- Parts distortion [6];

- Heterogeneous microstructure [10];

- Coarse plate martensite with uneven distribution [11];

- Anisotropic microstructures [12];

- Low material density [13];

- Martensite matrix with trace amount of austenite phase [14,15];

- Enhance superelasticity of NiTi structures [16,17,18];

- Stress-induced cracks and residual porosity [19];

- Intermetallic precipitates [20];

- Internal defects, such as entrapped-gas-pores or lack-of-fusion [21];

- High nitrogen content [22];

- Porosity, grain morphology and precipitates [23,24].

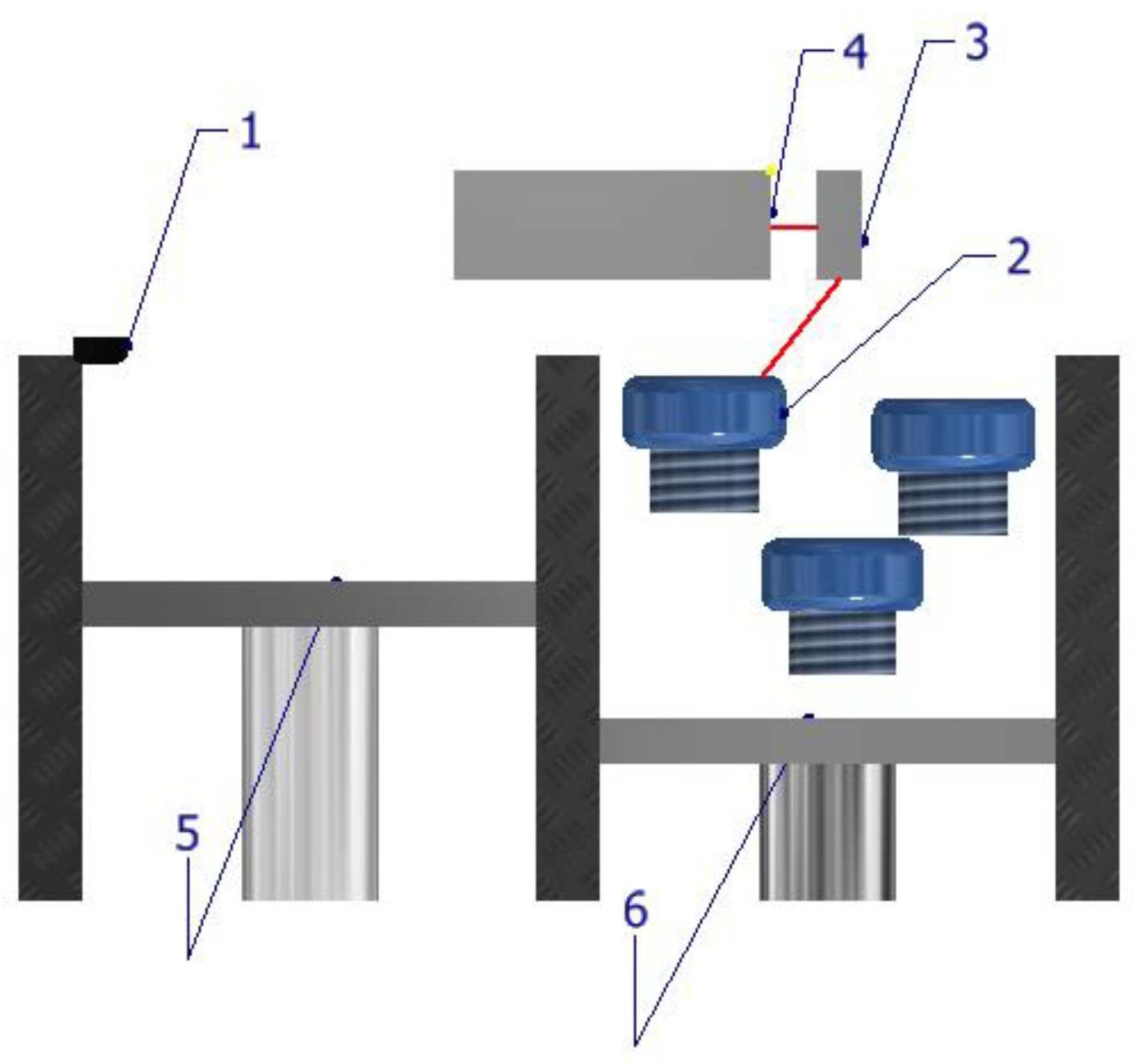

The principal scheme (Figure 5) of L-PBF involves several key components, including a build platform, a powder bed, a laser system, and a computer control system. The process begins with a thin layer of metal powder spread uniformly across the build platform. The material used in powder form is leveled using the leveling cylinder (1). The raw material powder acts as a support for the printed parts (2). A cross section of the part is melted by the laser, solidifying afterwards. The laser beam is focused by a laser generator system (4) and passes through a scanning mirror (3). A new layer of powder from the powder reservoir (5) is reapplied and then, the construction platform (6) lowers with a layer thickness. The process is repeated until a solid part is printed. The only difference between SLS and L-PBF is that L-PBF relies on the complete melting of metal powder particles. Laser beam bed fusion technology can be applied to any metal. Overall, the principal scheme of L-PBF involves the precise control of laser melting and powder deposition to create a solid metal part with high accuracy and dimensional integrity. The technique has numerous applications in industries such as aerospace, automotive, medical, and tooling.

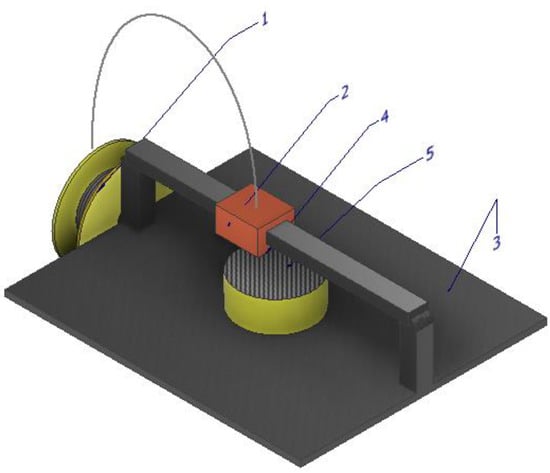

2.2. Material Extrusion (ME)

This is a type of 3D printing technology (named in this study according to the ISO/ASTM 52900:2015(E) standard) that uses a thermoplastic filament as the printing material. The process involves feeding a spool of the filament through a heated extruder, which melts the material and extrudes it through a small nozzle onto a build platform. The nozzle moves back and forth in the X and Y directions, while the build platform moves down in the Z direction, building up the object layer by layer.

ME is popular because it is a relatively low-cost and accessible 3D printing technology that can be used for a wide range of applications, including prototyping, tooling, and production parts. There is also a large variety of filaments available, including standard plastics such as PLA and ABS, as well as more advanced materials such as carbon fiber, nylon, and even metal-filled filaments.

However, ME parts can sometimes exhibit certain limitations, such as poor surface finish, low strength, and dimensional inaccuracies. Post-treatments can be applied to ME parts to address these limitations and enhance the overall performance and quality of the printed parts. Synthesized from relevant literature, various factors can drive the motivation for the application of post-treatments on ME such as:

- Stress relief, dimensional instability [25,26,27];

- Need for controllable crystallinity and deterioration phenomenon of polymer materials [28];

- Enhancing tensile properties [29,30,31,32,33,33,34,35];

- Improving composite flexural properties [36];

- Poor interfacial adhesion between the printed layers [37,38];

- Enhancing interlayer strength [39,40,41];

- Improving thermal conductivity [42,43];

- Increasing crystallinity [44,45,46,47,48,49,50];

- Increasing fracture toughness [51];

- Poor bead-to-bead interfacial bonding and relatively high void content [52,53];

- Reducing anisotropy [54];

- Behavior study of annealed defect parts [55];

- Eliminating the warpage of semi-crystalline polymer [56];

- Increasing the dynamic flexural properties [57];

- Poor interfacial bond formation [58].

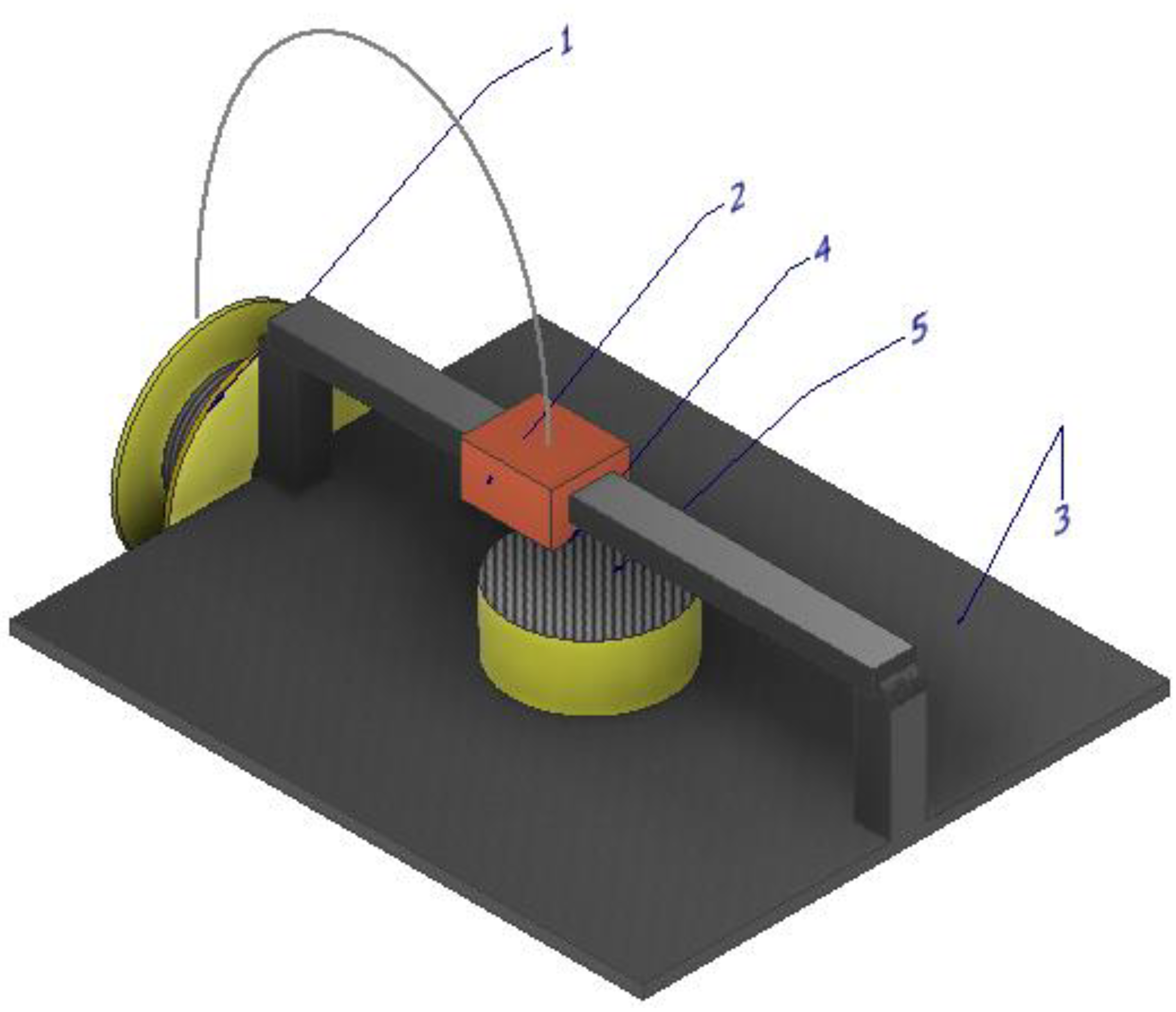

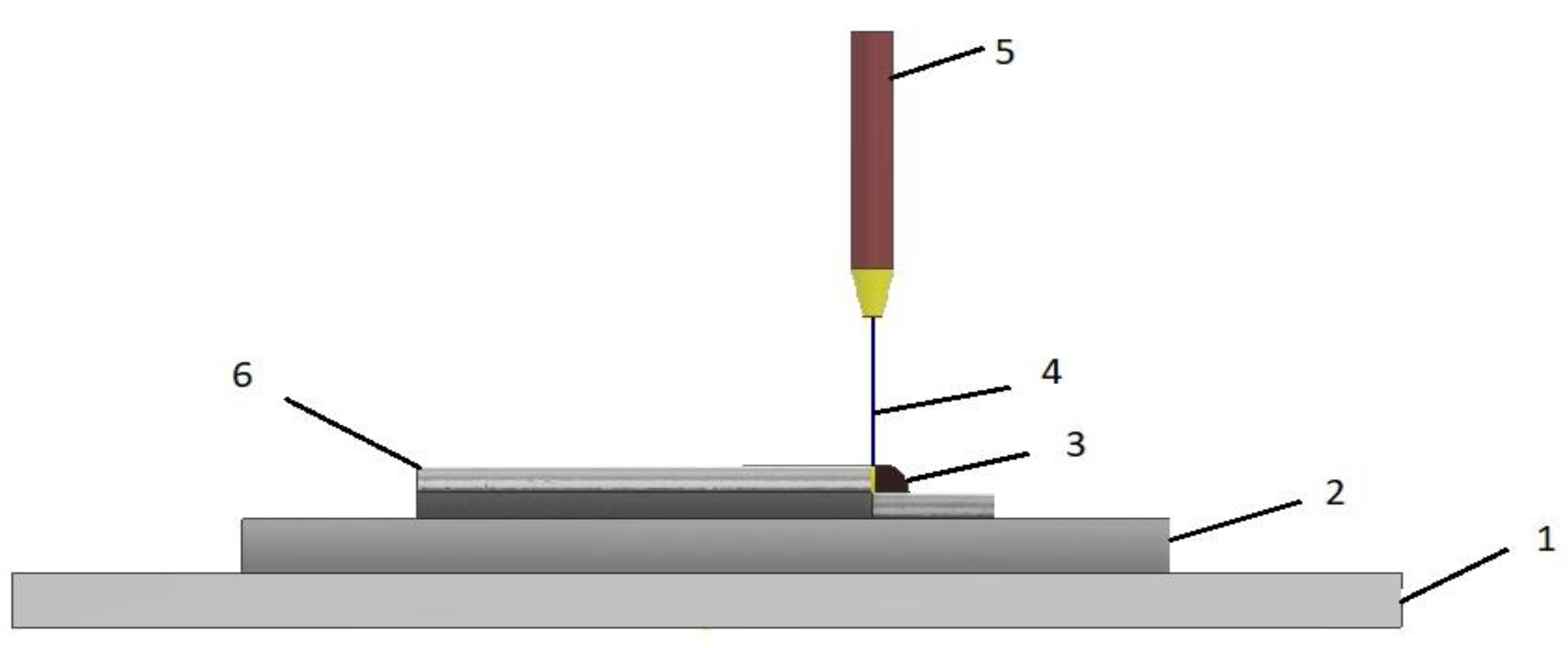

Components can be manufactured via the utilization of threads of solid state thermoplastic material. The process (Figure 6) entails winding the wire onto a filament roll (1) and feeding it into an extruder head (2), the initial layer of the part adheres to the build platform (3), and for parts containing console components, support structures made of either the same material or specially formulated materials that dissolve in water are required. The filament is subsequently propelled through a heated nozzle (4), where it is liquefied. The 3D printer facilitates the movement of the nozzle, which deposits the molten material in precise locations forming the part (5), following the predetermined path prescribed by the G-code.

Figure 6.

Principal graphical scheme of ME.

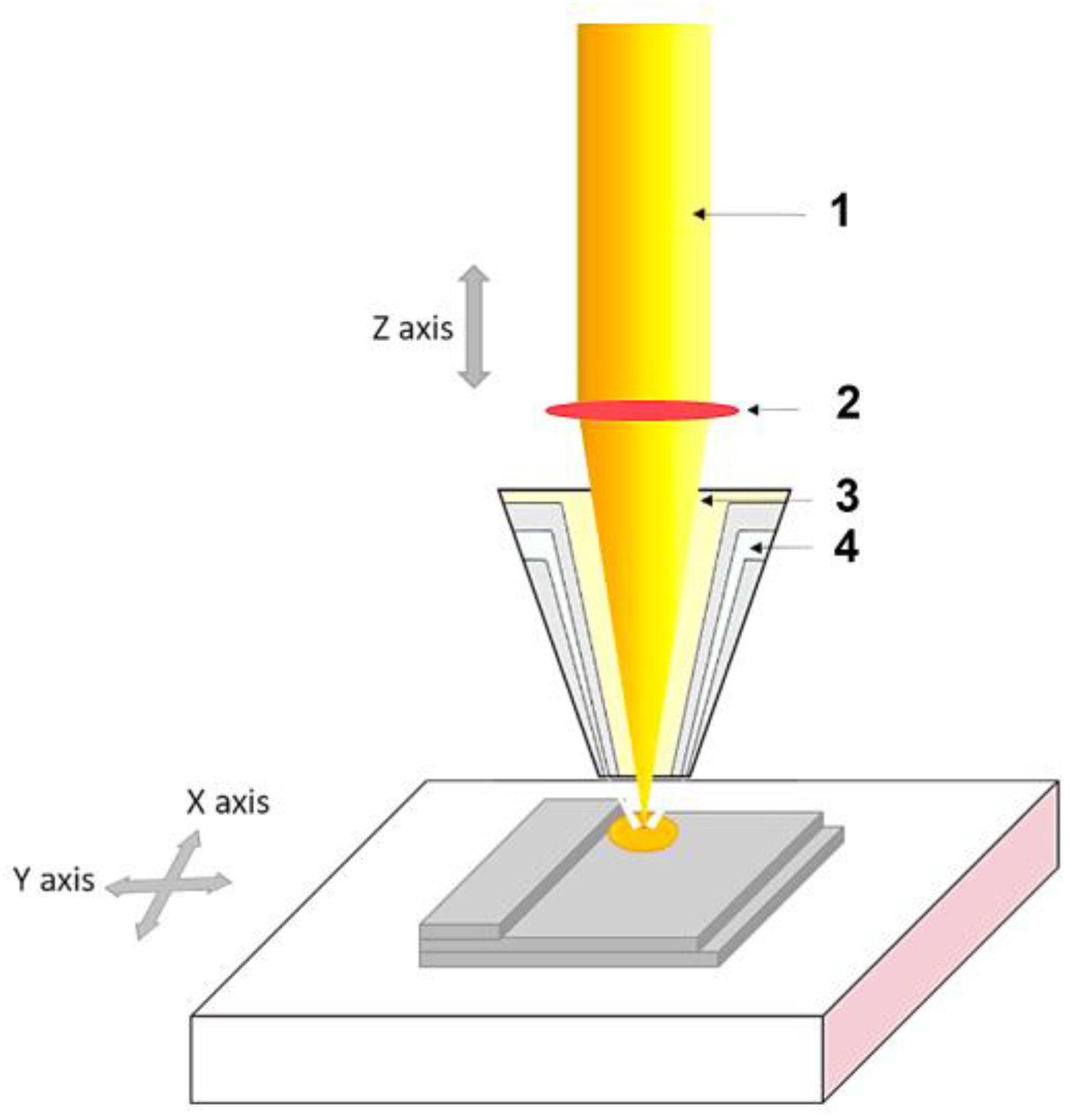

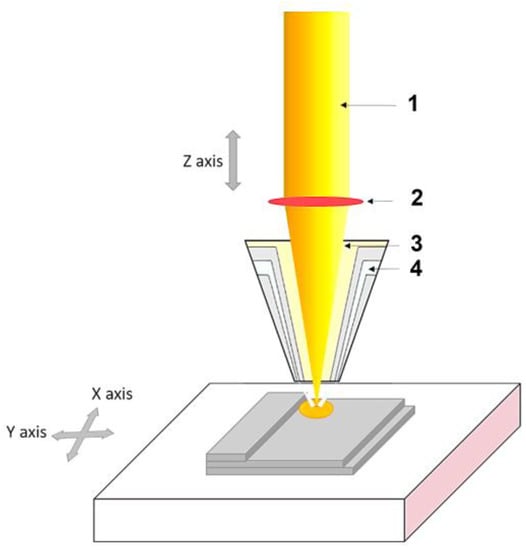

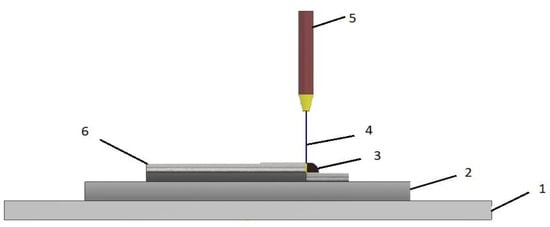

2.3. Laser Engineered Net Shaping (LENS)

Laser powder forming, known as laser engineered net shaping, is a state-of-the-art additive manufacturing technology utilized to produce metal parts directly from a computer-aided design (CAD) solid model. This innovative technique involves injecting metal powder into a molten pool formed by a concentrated, high-powered laser beam. Several proprietary techniques, such as direct metal deposition (DMD) and laser consolidation (LC), are similar to this approach. Unlike powder bed-based techniques such as laser beam bed fusion (L-PBF), laser powder forming enables the fabrication of significant-sized objects, sometimes surpassing several feet in length. Utilizing the trademarked Laser Engineered Net Shaping (LENS™) technique developed by Optomec Inc. in Albuquerque, NM, cylindrical equiatomic NiTi alloy samples were fabricated with diameters of 12 mm and lengths of 40 mm. The process involved using a Ytterbium-doped fiber laser with a 0.5 mm beam diameter to melt and deposit pre-alloyed NiTi powder with a nominal composition of 55.2 wt.% Ni and balance Ti, featuring trace amounts of O, N, and C with an average particle size between 50 and 150 mm. The powder feed rate was regulated at 4.36 g/min. Two sets of samples were produced using different laser power inputs (200 W and 400 W) and laser scan rates (10 mm/s and 20 mm/s), with each set’s laser energy density (E) calculated using the formula E = Pvd, where P is the laser power, v is the scan rate, and d is the laser beam diameter (0.5 mm). The deposited samples were then sliced into 10 mm-thick discs, annealed in a furnace with argon flowing at 500 °C and 1000 °C for 30 min, and cooled to room temperature in the furnace. The laser parameters and heat treatment schedules employed in this study are succinctly outlined [59].

Analyzing Figure 7, it can been seen that the process of laser welding with powder or wire involves generating a laser beam (1) using a laser generator, which is then focused through a lens (2) onto the work piece. To prevent contamination of the welding process, an inert gas (3) is provided to shield both the laser and the melt. At the point of focus, metal powder (4) or wire is introduced, causing the metal powder and workpiece to melt and subsequently build on the surface [60].

Figure 7.

Principal graphical scheme of LENS.

This incremental process allows for the step-by-step creation of a cross section of the detail, ultimately leading to the complete detail being produced. Additionally, this method can also be employed for repairing damaged or worn surfaces, a variation commonly referred to as laser welding with powder.

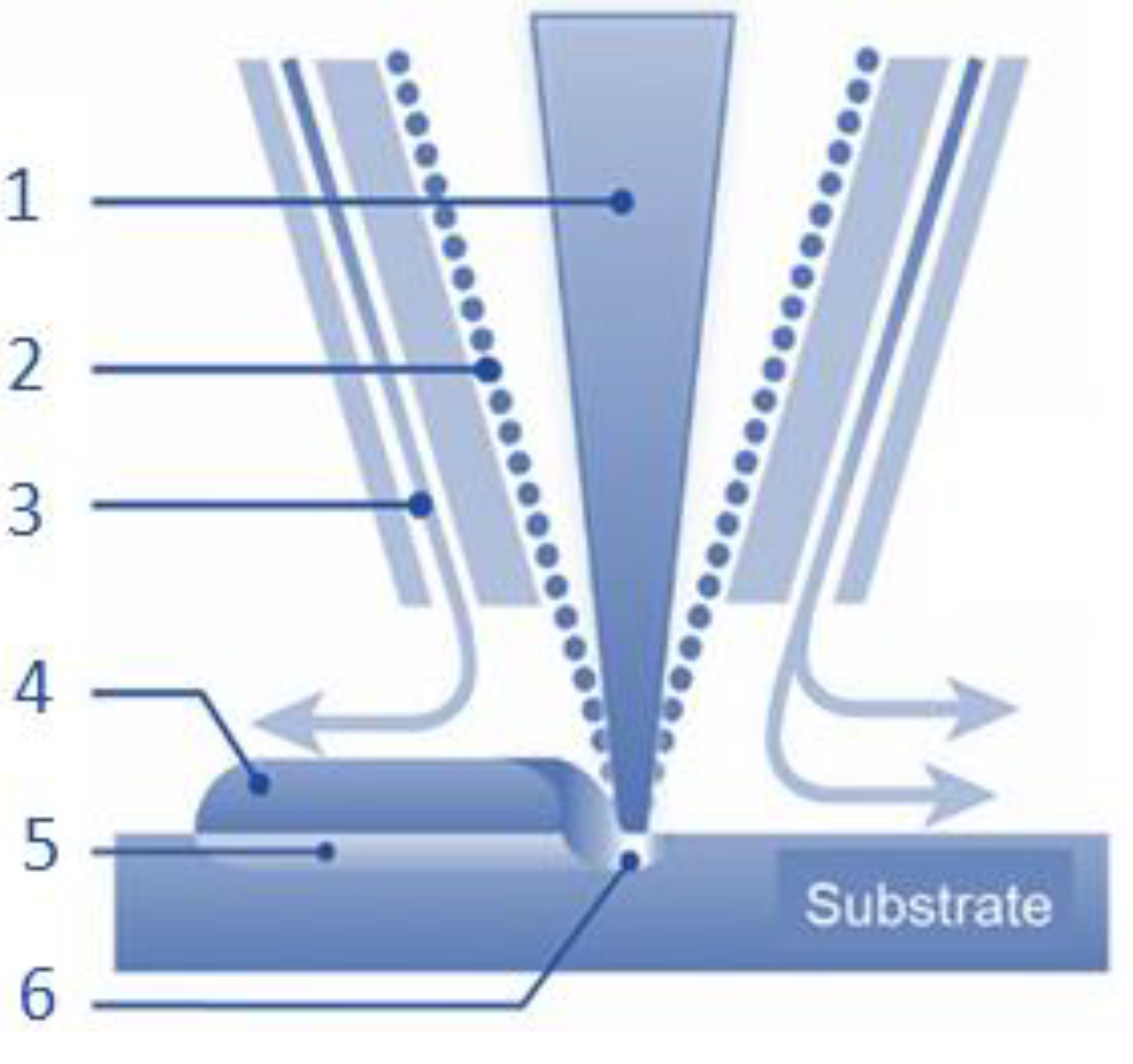

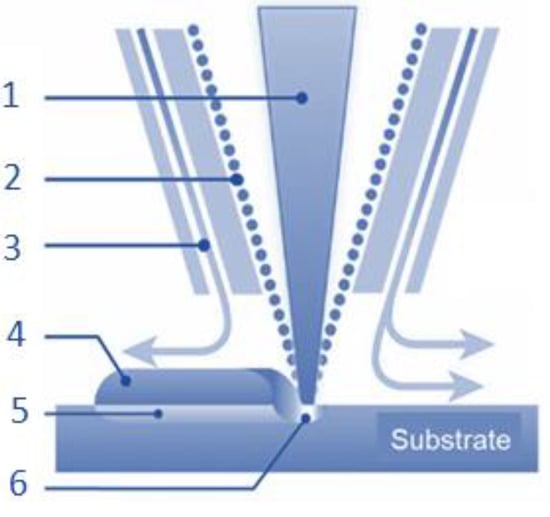

2.4. Directed Energy Deposition (DED)

Within the realm of additive manufacturing (AM), Directed Energy Deposition (DED) presents itself as an exceptionally promising technique in terms of build-up rate, capacity to create large components, and ability to repair pre-existing parts. DED processing is frequently employed in the fabrication of the Ti-6Al-4V alloy, which has become a well-established material in the overall AM market. In its as-built state, the tensile properties of Ti-6Al-4V alloy are generally superior to those of conventionally processed materials. However, this comes at the cost of reduced ductility, which remains a significant constraint regarding the alloy’s suitability for various applications [61].

This procedural approach of DED is succinctly conveyed through a schematic illustration in Figure 8. The DED process uses three common heat sources: electron beam, electric arc or plasma, and laser (1). In this process, the heat source is typically focused on the point of metal deposition within the feedstock. To guide the deposition process, G-Code is used to control the nozzle of the gun or tool, dictating the specific tool path to be taken around the object [62].

Figure 8.

Principal graphical scheme of DED.

The feed material (2) and heat source are carefully controlled to direct the melt pool along the tool path. The resulting weld pool is subsequently deposited in a precise manner to achieve the desired shape and structure of the object. The DED process is thus highly adaptable and allows for the production of complex geometries with greater control over material properties and structure. In a controlled environment, typically a vacuum or inert gas (3), the feedstock (4), which can be in the form of a metal wire or powder, is melted and deposited onto the object’s surface (5), as illustrated in Figure 8. As with other additive manufacturing methods, the Directed Energy Deposition (DED) process employs a feeder to channel feedstock through a heat source, thus creating a weld pool (6).

A standard Directed Energy Deposition (DED) apparatus comprises a nozzle that is affixed to a multi-axis arm. This arm controls the nozzle’s movements as it deposits molten material onto a targeted surface, where it subsequently solidifies. While this process shares similarities with material extrusion, the nozzle is capable of moving in multiple directions and is not restricted to a specific axis. The deposited material, whether in powder or wire form, can be melted via a laser or electron beam and can be applied from any angle by utilizing four and five axis machines. While DED technology can be used with materials such as ceramics or polymers, it is typically employed with metals.

In order to optimize the process parameters, two distinct laser powers (500 W and 1000 W) were modified in reference [63]. The orientation of the hatches was shifted by 90 degrees for each consecutive layer, and upon depositing a single layer, the laser head would move upwards from the substrate by a distance equivalent to the thickness of the layer. This mechanism would then repeat automatically until the intended build was fully realized.

2.5. Direct Metal Laser Sintering (DMLS)

Direct metal laser sintering (DMLS), an additive manufacturing (AM) process, has emerged as a popular technique for the fabrication of functional metallic objects directly from powders. However, a significant challenge facing the industrial application of DMLS is the limited range of materials that can be processed, while still maintaining surface roughness and mechanical properties that are at least comparable to those of wrought materials. To address this issue, the authors of [64] aimed to improve the physical and mechanical properties of components made of 17-4 stainless steel produced by DMLS through grain refinement induced by a shot-peening (SP) process. This process involves subjecting the outer surface layers to severe plastic deformation [64].

The DMLS process utilizes lasers to selectively melt and solidify powdered materials, primarily metals, into desired shapes. However, there are significant differences between DL-PBF and L-PBF techniques:

- ○

- Laser Scanning: In L-PBF, a laser scans the entire surface of the powder bed, melting and fusing the particles together to create a solid part. In contrast, DL-PBF uses a multi-fiber laser head with multiple beams to selectively melt and fuse the powder particles. This allows for greater control over the heat input and leads to a more uniform temperature distribution;

- ○

- Precision: Due to the use of multiple lasers in DL-PBF, the process is generally more precise than L-PBF. This is especially true for parts with fine features or high aspect ratios;

- ○

- Build Time: DL-PBF typically has a faster build time than L-PBF, as the multiple lasers can cover more surface area at once;

- ○

- Materials: L-PBF is generally more versatile in terms of the range of materials that can be processed, including some ceramics and plastics. DL-PBF, on the other hand, is primarily used for metal alloys;

- ○

- Cost: DL-PBF systems tend to be more expensive than L-PBF systems due to the use of multiple lasers and the associated equipment required to control them.

As can be seen in Figure 9, direct metal laser sintering (DMLS) is a type of additive manufacturing process that involves the sintering of powders and is limited to the fabrication of alloys, particularly titanium-based alloys [64]. Due to the high residual stress and potential distortion, DMLS often necessitates additional support structures during the production process. This technique has found numerous applications in various fields such as the jewelry and dental industries, as well as for the manufacturing of spare parts and prototypes. The material used in powder form is leveled with the coater arm (1). The raw material powder is scanned into printed parts (2). A cross section of the piece is sintered by laser, solidifying. Through a targeting mirror (3), the multi-fiber laser is focused by a laser generator system (4) and passes. The powder reservoir (5) feeds the system with a small amount of powder and then, the construction platform (6) lowers with a layer thickness and a new layer of powder is applied. The process is repeated until a solid part is printed.

Figure 9.

Principal graphical scheme of DMLS.

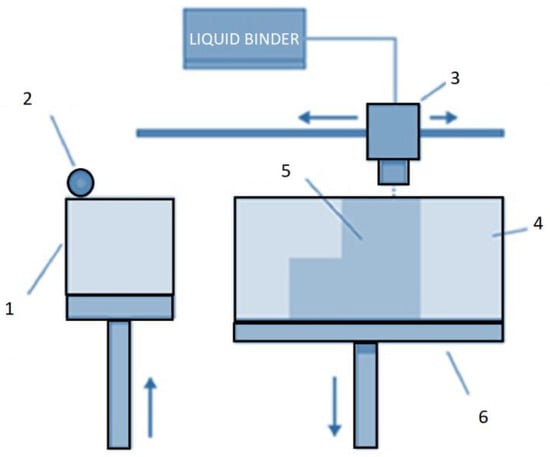

2.6. Metal Binder Jetting (MJB)

In the domain of additive manufacturing, metal binder jetting (MBJ) has emerged as a viable alternative to laser powder bed fusion (L-PBF) techniques, allowing for the production of intricate geometries at a faster rate and with lower manufacturing costs. MBJ is a two-step process that involves the printing of a green body followed by sintering. In the printing stage, MBJ utilizes a combination of powder bed process and jetting technique. The jetting nozzles distribute an agent, composed of binder and solvent, onto the build platform at the precise location of the part’s contour. This process is repeated layer by layer until the entire 3D contour is formed. The binder serves to bond the powder particles together, resulting in the formation of a green body. The green strength of the part is established through the curing treatment. The next step is to extract the green part from the loose powder in a process commonly referred to as “de-powdering” or “de-caking” [65]. The green parts undergo a debinding step to eliminate the binder, followed by a sintering step to compact the printed parts at high temperatures, during which they are heated in a high-temperature furnace, as part of the ultimate process sequence.

Currently, stainless steels X2CrNiMo17-12-2 (AISI 316L) and X5CrNiCuNb16-4 (AISI 630), also known as 17-4 PH, are predominantly utilized in the additive manufacturing of steel parts in the MBJ industry. 17-4 PH, a martensitic precipitation-hardening steel, is well-known for its exceptional properties including good corrosion resistance, machinability, and high strength, toughness, and hardness in heat-treated conditions. These properties make it ideal for use in various fields including automotive, aeronautical, maritime, and medical engineering. In fact, 17-4 PH is already a well-established steel for metal injection molding (MIM) processes. Upon precipitation heat treatment, the martensitic structure of this steel is formed with Cu-rich precipitates, as well as Cr-rich phase, Mn-, Ni-, and Si-rich phases [64].

However, the plastic material known as polyamide (PA-12) has found extensive use in various industries such as defense, automotive, and aerospace due to its exceptional properties such as impact strength, toughness, flexibility without breaking, and tensile strength. In addition to being popular for creating prototypes via 3D printing and injection molding, PA-12 has become a popular material for fabricating end-use parts and prototypes through AM fabrication. The utilization of PA-12 in the fabrication of samples has highlighted its mechanical properties, including the ability to print thin and flexible joints [66].

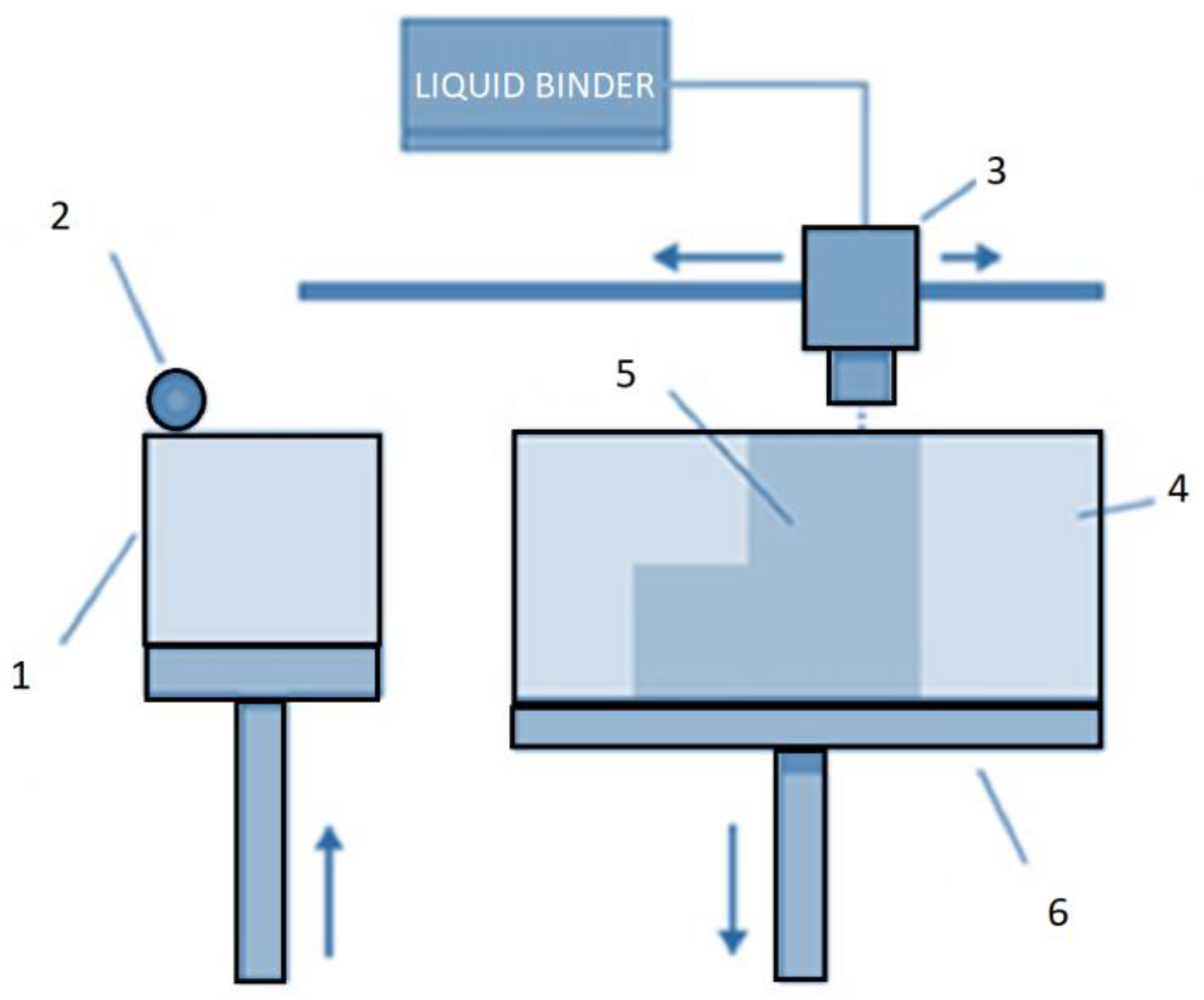

The process of metal binder jetting, graphically described in Figure 10, is a multi-step procedure that involves several intricate steps.

Figure 10.

Principal graphical scheme of MJB.

Initially, a layer of powder material is evenly dispersed from the new powder stock (1) utilizing a recoater (2). Following this, the print head (3) is employed to dispense the liquid binder adhesive selectively onto specific areas of the powder layer as required.

After the application of the binder, the build platform (6) is lowered by the thickness of the model’s layer, providing the foundation for the subsequent layer of the powder material. A fresh layer of powder is then uniformly spread over the previous layer, and the cycle of depositing binder, lowering the build platform, and adding a new layer of powder is repeated.

Throughout this iterative process, the powder is precisely deposited and bound in specific areas, forming the desired object (5) where the powder is bound to the liquid binder. Meanwhile, the unbound powder (4) is left intact, encircling the object in position. This methodology is then repeated until the entire object is fully formed, layer by layer, with the final result representing a three-dimensional solid object, precisely constructed with additive manufacturing technology.

2.7. Wire-Arc Additive Manufacturing (WAAM)

Wire-based additive manufacturing processes utilize heat sources, such as arc, electron beam, or laser beam, to melt feedstock wires and fabricate freeform 3D components in a layer-by-layer manner at high deposition rates. These processes offer the flexibility to produce large area parts using a wide range of metals or alloys, without the need for molds or dies that may introduce metal contamination and cost. Compared to conventionally cast parts of similar size, wire-based additive manufactured components exhibit refined microstructures with less micro segregation and smaller cell or dendrite spacing, owing to the small size of the liquid melt pool used in the process. In addition, wire-based additive manufacturing methods can be utilized for direct build-up, cladding, and hard facing of existing components, as well as for the repair and maintenance of castings and other metal parts. Moreover, wire-based additive manufacturing has the potential to generate semi-finished products, such as custom plates that can be formed into shape by conventional methods or custom forging blanks with unique shapes that enhance forging properties. However, the thermomechanical post-processing of wire-based additive manufactured parts remains to be thoroughly explored [67]. The gradual buildup of metal parts through the melting of metal wire using an electric arc as the heat source is the essence of WAAM. This method is highly advantageous for producing complex components on a large scale [68]. In WAAM, the heat input is carefully controlled, leading to faster solidification of the melted metal and consequent refinement of the grains. However, upon heat treatment of the alloy, the grains tend to coarsen, and in some cases, the presence of very large grains can be observed.

WAAM is an ideal method for fabricating medium to large-sized components due to its high deposition rates (typically ranging from 2 to 4 Kg/h), exceptional material utilization (>90%), impressive energy efficiency (ranging from 85% to 90%), and expandable working environment. According to research, utilizing the WAAM process can reduce production costs by 7% to 69% in contrast to conventional subtractive techniques such as machining [69].

In Figure 11, the principal scheme of the WAAM is presented. On a work flat (1), a substrate is positioned (2) to be the support to a 3D-printed component, an electric arc to melt and deposit in a melt pool (3) and the metal wire (4). The basic principle of WAAM involves melting the wire through the heat source, the torch (5), and using an electric arc and then depositing it layer by layer to create the desired object (6). This process is commonly used in the aerospace and automotive industries to create large, complex parts quickly and cost-effectively. The WAAM process can be used with a variety of materials, including aluminum, titanium, and steel, and is a promising technology for producing large-scale metal structures with high precision and quality. However, the porosity generated in the WAAM process was detrimental to the mechanical properties of the metal alloy, as noticed in the studied literature [70].

Figure 11.

Principal graphical scheme of WAAM.

Multidirectional forging and aging treatments are often utilized to adjust the microstructure and mechanical properties of an Al-Zn-Mg-Li alloy produced by wire arc additive manufacturing. This approach was adopted to improve the tensile strength and Young’s modulus of WAAM-produced parts tailored to the need of industries such as the military and aerospace [70].

3. Used 3D Printing Materials

3.1. Materials Studied and Their Specific Mechanical Behavior with Emphasis on Areas to Improve by Applying Post-Processing Treatments

The materials used for additive technology can be classified into several categories depending on the applications in which they are used, or the printing method used, see Table 1.

Table 1.

The materials used for additive technology.

Polymers: This category includes a wide range of materials, such as thermoplastics, thermosets, and elastomers. These materials are popular for their ease of use, low cost, and wide availability. Polymers used in 3D printing can be classified into several categories based on their chemical composition and properties. Here is a general classification of polymers used in 3D printing [25,26,46,58,66]:

Thermoplastics: These polymers become soft and moldable when heated and harden when cooled. They can be melted and solidified multiple times without significant degradation of their properties. Some examples of thermoplastics used in 3D printing include:

- PLA (polylactic acid)

- ABS (acrylonitrile-butadiene-styrene)

- PETG (polyethylene terephthalate glycol)

- Nylon (polyamide)

- PEEK (polyether ether ketone)

Elastomers: These polymers are highly elastic and can be stretched and deformed without permanent deformation. Some examples of elastomers used in 3D printing include:

- TPE (thermoplastic elastomer)

- TPU (thermoplastic polyurethane)

Other polymers: There are several other types of polymers used in 3D printing that do not fit neatly into the above categories, such as:

- PVA (polyvinyl alcohol) support material

- PC (polycarbonate)

- PEI (polyetherimide)

- PPS (polyphenylsulfone)

Metals: Metals are used in 3D printing to create high-strength, durable parts. Common metals used for 3D printing include stainless steel, titanium, aluminum, and copper.

Ceramics: Ceramic materials are used for applications that require high temperature resistance, chemical resistance, and wear resistance. Examples of ceramic 3D printing materials include zirconia, alumina, and silicon carbide.

Composites: Composites are made by combining two or more materials to create a new material with enhanced properties. Common composite materials used for 3D printing include carbon fiber, glass fiber, and Kevlar. These are polymers mixed with other materials, such as metals or ceramics, to achieve enhanced mechanical or thermal properties. Some examples of composite materials used in 3D printing include carbon fiber-reinforced polymer (CFRP), metal-filled polymers, ceramic-filled polymers.

Biomaterials: Biomaterials are used in 3D printing to create tissue and organ replacements. Examples of biomaterials used in 3D printing include collagen, chitosan, and alginate.

The mechanical properties of the materials used in additive technology vary greatly, the main characteristics being presented in Table 2.

Table 2.

Some mechanical characteristics of 3D materials used for additive technology.

Thermal treatments can be used to modify the properties of 3D-printed materials. Here are some examples of thermal treatments that can be used for different types of 3D printing materials:

Polymers: Many thermoplastic polymers used in 3D printing can be annealed, which involves heating the part to just below its melting temperature for a period of time and then slowly cooling it down. This can help to relieve internal stresses and improve the part’s dimensional stability and mechanical properties. Some polymers can also be post-cured, which involves heating the part to a higher temperature to complete the curing process and improve its strength and durability [38,42,43,52,71].

Metals: Metal 3D-printed parts can be heat-treated to improve their mechanical properties. For example, they can be annealed to relieve internal stresses and improve ductility, or they can be quenched and tempered to increase their hardness and strength.

Ceramics: Ceramic 3D-printed parts can be sintered, which involves heating the part to a high temperature to fuse the ceramic particles together and densify the part. This can significantly improve the part’s mechanical properties, such as strength and toughness.

Composites: Composite 3D-printed parts can be post-cured to improve their mechanical properties. The exact type of post-cure treatment will depend on the specific composite material used.

Biomaterials: Biomaterials used in 3D printing can be crosslinked, which involves heating the part to a specific temperature to form covalent bonds between the polymer chains. This can improve the part’s mechanical properties and biocompatibility.

In addition to these specific treatments, some 3D printing materials may also require pre-treatments, such as surface preparation or coating, to ensure optimal adhesion between layers and improve the final part’s properties.

3.2. General Characteristics of Polymers Materials Used in Additive Technologies

3.2.1. Polylactic Acid (PLA)

PLA is the most widespread material used in additive technologies and due to its ecological aspect, but it has poor mechanical characteristics and there is research to increase the tenacity of these types of materials. The main properties are briefly presented in Table 3 [27,29,32,39,52].

Table 3.

Some mechanical characteristics of PLA.

PLA is a biodegradable and compostable material made from renewable resources such as cornstarch or sugarcane. It is often considered a more eco-friendly alternative to other thermoplastics used in 3D printing.

PLA is a relatively easy material to print with, as it has a low melting temperature (around 180–220 °C) and does not require a heated bed for most prints. It also has a low tendency to warp, which can make it easier to achieve successful prints.

PLA has a relatively low tensile strength compared to other 3D printing materials, typically ranging from 25 to 70 MPa. However, it can be stiffened by increasing its density through annealing.

PLA can be printed with high detail and resolution, making it a popular choice for creating intricate models or prototypes. It is also available in a wide range of colors and finishes.

PLA is generally not recommended for high-temperature applications or load-bearing parts, as it can soften and deform at relatively low temperatures compared to other thermoplastics. It is also not recommended for parts that will be exposed to moisture, as it can degrade over time.

PLA is a popular choice for 3D printing hobbyists and educational settings due to its ease of use, low cost, and eco-friendly properties.

The main applications in which PLA 3D printing material can be used:

Prototyping and product development: PLA is often used for creating prototypes and models due to its ease of use and ability to produce high-detail prints;

Educational settings: PLA is a popular material for use in classrooms and educational settings due to its low cost, ease of use, and eco-friendly properties;

Decorative objects: PLA is available in a wide range of colors and finishes, making it a popular choice for creating decorative objects such as figurines, vases, and jewelry;

Toys and games: PLA is commonly used for creating toys and games due to its safety, durability, and ability to produce intricate designs;

Household items: PLA can be used to create household items such as phone cases, storage containers, and kitchen gadgets, as well as decorative objects such as picture frames and planters.

3.2.2. Acrylonitrile-Butadiene-Styrene (ABS)

Acrylonitrile-butadiene-styrene (ABS) is a thermoplastic commonly used in 3D printing. It is a popular material due to its combination of strength, rigidity, and impact resistance. ABS is also known for its ability to be easily processed, making it a good choice for manufacturing a variety of objects. In 3D printing, ABS is typically used for making functional and durable parts that require strength, such as automotive parts, toys, and electronic enclosures. Its good strength and heat resistance also make it a popular choice for parts that will be exposed to higher temperatures, such as parts for household appliances or electronics, the main properties are briefly presented in Table 4 [43,46,47,66,71].

Table 4.

Some mechanical characteristics of ABS.

PEEK is a high-performance thermoplastic polymer that is commonly used in various industries due to its unique combination of properties. It is known for its excellent mechanical, thermal, and chemical resistance properties, which make it a popular choice for applications that require high strength, durability, and resistance to harsh environments. Due to its unique combination of properties, PEEK is often used in demanding applications such as aerospace components, automotive parts, medical implants, and oil and gas industry components. In recent years, PEEK has also become increasingly popular in 3D printing due to its high strength, durability, and resistance to high temperatures, as well as its ability to be processed using a variety of 3D printing technologies, such as ME, SLS, and SLA. The mechanical properties of PEEK are presented in Table 5 [25,38,42,58].

Table 5.

Some mechanical characteristics of PEEK.

3.2.3. Nylon (Polyamide)

Nylon, also known as polyamide, is a synthetic polymer that is widely used in a variety of industrial applications, including 3D printing. It is a strong and durable material with good mechanical properties and excellent chemical resistance. Nylon is also known for its low friction coefficient and high melting point, which make it suitable for use in applications where high temperatures and wear resistance are important. In 3D printing, nylon is often used to produce functional parts and prototypes that require strength, durability, and flexibility. It is available in a variety of formulations, including nylon 6, nylon 66, and nylon 12, each with slightly different mechanical properties and characteristics presented in Table 6 [31,52].

Table 6.

Some mechanical characteristics PLA.

3.2.4. Polyethylene terephthalate glycol (PETG)

Polyethylene terephthalate glycol (PETG) is a thermoplastic polyester that is commonly used in 3D printing. It is a variation of polyethylene terephthalate (PET) that contains a glycol modifier, which improves its toughness and durability. PETG has become a popular 3D printing material due to its ease of use, low shrinkage, and high impact resistance. It also has a high level of transparency, making it ideal for printing clear or translucent parts. PETG is a food-safe material and is often used for creating food containers and packaging. It is also commonly used in medical and dental applications due to its biocompatibility and resistance to chemicals. The mechanical properties are presented in Table 7 [26,28,36,37].

Table 7.

Some mechanical characteristics of PETG.

3.2.5. Thermoplastic Elastomer (TPE)

Thermoplastic elastomers (TPEs) are a class of polymers that exhibit both thermoplastic and elastomeric properties. They are often used as a flexible or rubber-like material in 3D printing. TPEs are composed of a hard plastic phase and a soft rubber phase, which are chemically bonded together to create a material that can stretch and compress in the same way as rubber, but also melt and flow in the same way as plastic when heated. TPEs have several advantages as 3D printing materials, including: flexibility: TPEs are highly flexible and can be used to create parts that need to bend, twist, or stretch, such as gaskets, seals, and phone cases; softness: TPEs have a softer, more rubbery feel than traditional plastics, which can be useful for creating parts that need to be comfortable or non-slip, such as grips or handles; durability: TPEs are resistant to abrasion and tearing, and can withstand repeated flexing and stretching without breaking or degrading; ease of printing: TPEs are relatively easy to print compared to other flexible materials, and can be printed on many standard 3D printers with a direct drive extruder or a flexible filament feeder.

The mechanical characteristics of TPE can vary depending on the specific formulation and processing conditions, but some general properties include:

TPEs typically have a lower tensile strength than traditional plastics, but still have good strength and elasticity. The tensile strength can range from 5 MPa to 30 MPa, depending on the material composition and printing parameters.

TPEs have a high elongation at break, meaning they can stretch significantly before breaking. This property can be useful for creating parts that need to flex or bend repeatedly without breaking. The elongation at break can range from 100% to 1000% or more, depending on the material formulation.

TPEs have a range of hardness levels, typically measured on the Shore A or Shore D scales. The hardness can vary from very soft and flexible (Shore A 10–20) to more rigid and tough (Shore D 50–70). The choice of hardness will depend on the specific application and desired properties of the printed part.

TPEs have good tear resistance, meaning they can resist tearing or ripping under stress. This property can be useful for creating parts that need to withstand repeated bending or twisting, such as hinges or flexible joints.

TPEs can experience some permanent deformation or “set” when subjected to prolonged compression or stress. The amount of compression set can vary depending on the material’s formulation and processing conditions.

3.2.6. Thermoplastic Polyurethane (TPU)

Thermoplastic polyurethane (TPU) is a type of flexible, rubber-like plastic that is commonly used in 3D printing. It is a thermoplastic elastomer, meaning it can be melted and reformed multiple times without degrading its physical properties. TPU has a number of desirable mechanical characteristics for 3D printing, including:

TPU can stretch up to several times its original length before breaking, making it useful for creating parts that need to bend or flex repeatedly without breaking.

TPU is resistant to tearing or ripping, making it a good choice for parts that will be subjected to repeated stresses or impacts.

TPU can recover its original shape after being compressed or stretched, making it ideal for parts that will be subjected to repeated compression or tension.

TPU is resistant to a wide range of chemicals and oils, making it suitable for parts that will be used in harsh or demanding environments.

TPU has a soft, rubber-like texture that can provide a high level of grip and friction, making it useful for creating parts such as phone cases, handles, or grips.

3.2.7. Polyvinyl Alcohol (PVA) Support Material

Polyvinyl alcohol (PVA) is a water-soluble support material commonly used in 3D printing. It is often used in conjunction with other 3D printing materials, such as PLA, to provide support during the printing process. PVA is ideal for creating complex prints with overhangs, bridges, or intricate details that would be difficult to print without support. PVA has a number of desirable properties for use as a support material, including:

PVA dissolves in water, which makes it easy to remove from the finished print without damaging the surface of the main material.

PVA has low adhesion to most materials, which means it can be easily removed from the finished print without leaving any residue or damaging the surface.

PVA is stable and does not degrade over time, which means it can be stored for long periods of time without losing its effectiveness.

PVA can bond well to a variety of materials, making it a versatile support material for a wide range of 3D printing applications.

PVA is non-toxic and biodegradable, making it a safe and eco-friendly alternative to some other support materials.

3.2.8. Polycarbonate (PC)

Polycarbonate (PC) is a strong, durable, and versatile thermoplastic material used in a wide range of industries and applications, including 3D printing. Some of the main characteristics and properties of PC for 3D printing include:

PC is one of the strongest thermoplastics, with high tensile and impact strength, making it suitable for demanding applications that require durability and toughness.

PC has a high glass transition temperature (Tg) and can withstand high temperatures without deforming or melting, making it ideal for applications that require heat resistance.

PC is a transparent material that allows light to pass through, making it suitable for applications such as lenses, windows, and protective covers.

PC is resistant to many chemicals, including acids, bases, and oils, making it suitable for use in harsh environments.

PC has low thermal expansion and contraction, making it suitable for applications that require tight tolerances and precise dimensions.

PC can be easily machined, molded, and 3D printed, making it a versatile material for a wide range of manufacturing processes.

3.2.9. Polyetherimide (PEI)

Polyetherimide (PEI) is a high-performance engineering thermoplastic used in a variety of industries, including the aerospace, automotive, electronics, and medical industries. Some of the main characteristics and properties of PEI for 3D printing include:

PEI has excellent mechanical properties, with high tensile and flexural strength, stiffness, and impact resistance.

PEI has a high glass transition temperature (Tg) of around 217 °C, which makes it suitable for high-temperature applications that require thermal stability and resistance to creep and deformation.

PEI is resistant to a wide range of chemicals, including acids, bases, and hydrocarbons.

3.2.10. Polyphenylsulfone (PPS)

Polyphenylsulfone (PPS) is a high-performance thermoplastic that is known for its excellent thermal and chemical resistance. It is commonly used in the aerospace, automotive, and medical industries, as well as in electronic applications. Some of the main characteristics and properties of PPS for 3D printing include:

PPS has a glass transition temperature (Tg) of around 220 °C, which makes it suitable for high-temperature applications that require thermal stability and resistance to creep and deformation.

PPS is resistant to a wide range of chemicals, including acids, bases, and solvents.

PPS is an excellent electrical insulator, with a high dielectric strength and low dielectric constant and dissipation factor.

PPS has low thermal expansion and contraction, which results in excellent dimensional stability and tight tolerances.

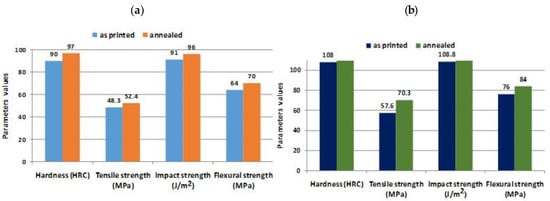

According to [71], annealing heat treatments can be applied to materials such as poly(lactic acid) (PLA), with a density of 1.24 g/cm3, melt flow index (MFI) = 6.0 g/10 min (210 °C/2.16 kg), produced by Nature Works, and copolymer ethylene vinyl acetate (EVA), trade name EVA HM728, with a density of 0.950 g/cm3, MFI = 6.0 g/10 min (190 °C/2.16 kg), and 28% vinyl acetate content (VA), supplied by Braskem. The tensile modulus, elastic modulus, flexural strength, impact strength of PLA, PLA/EVA blends, and annealed compounds are improved by applying a heat treatment.

Using a temperature for the thermal treatment of annealing [25] of between 75 °C and 125 °C, for materials such as PLA and ABS, demonstrates the fact that no significant increase is obtained in terms of tensile strength, so special importance must be given to the deformations that occur during the heating and cooling the samples subjected to heat treatment. According to [25], an increase in the hardness of the samples was observed mainly due to thermal treatment annealing which leads to the reduction in the level of residual stresses and to a better quality of the joint areas between the deposited layers.

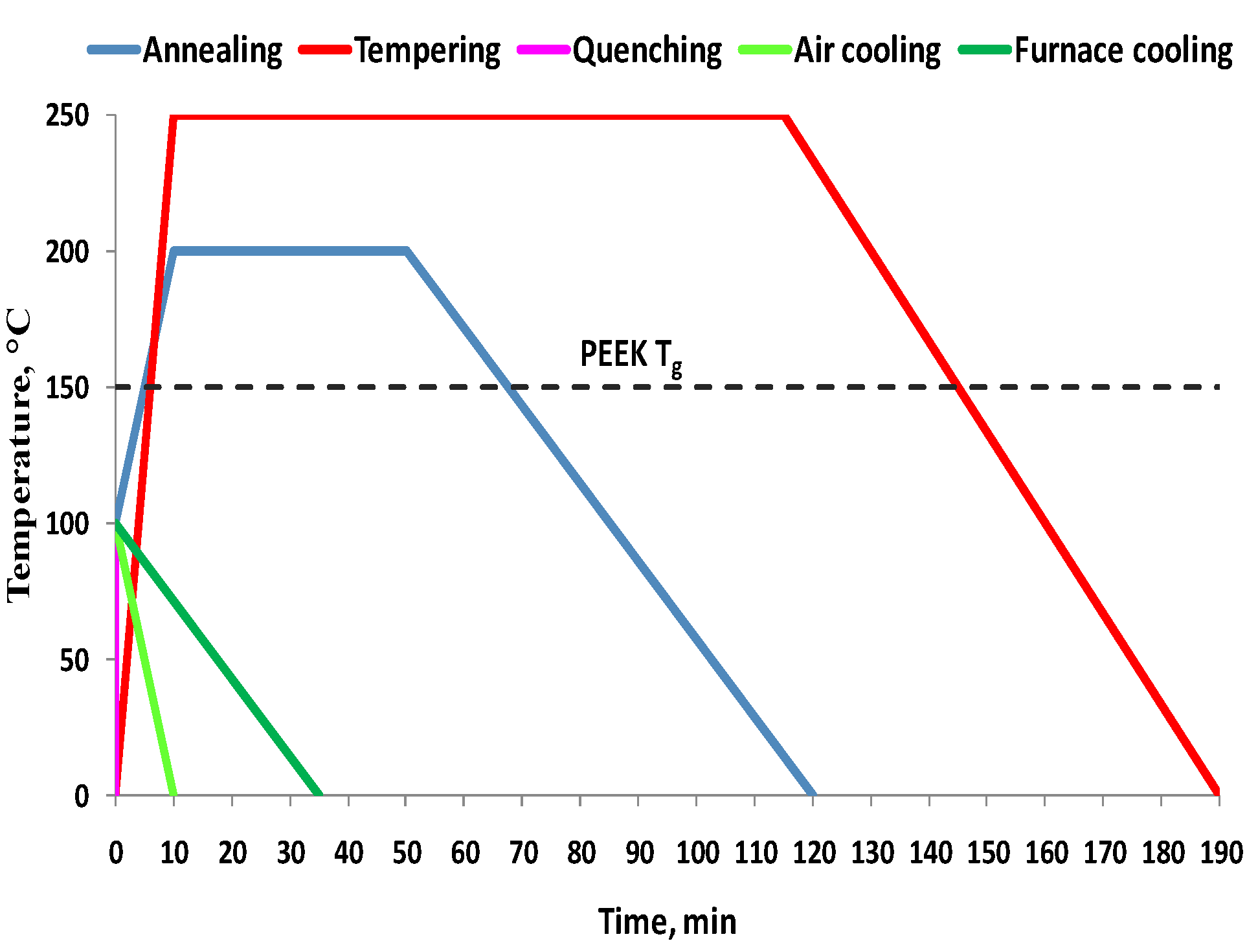

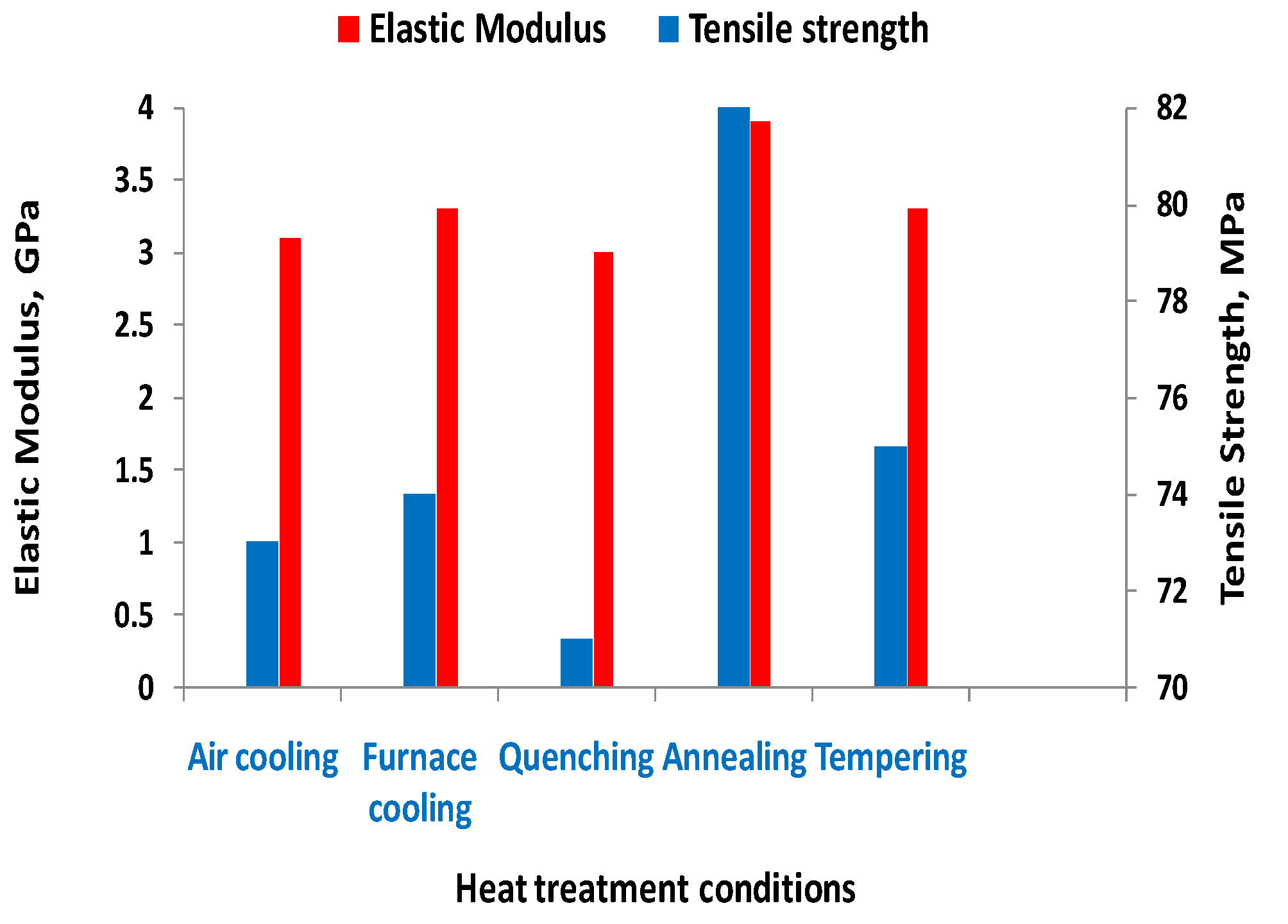

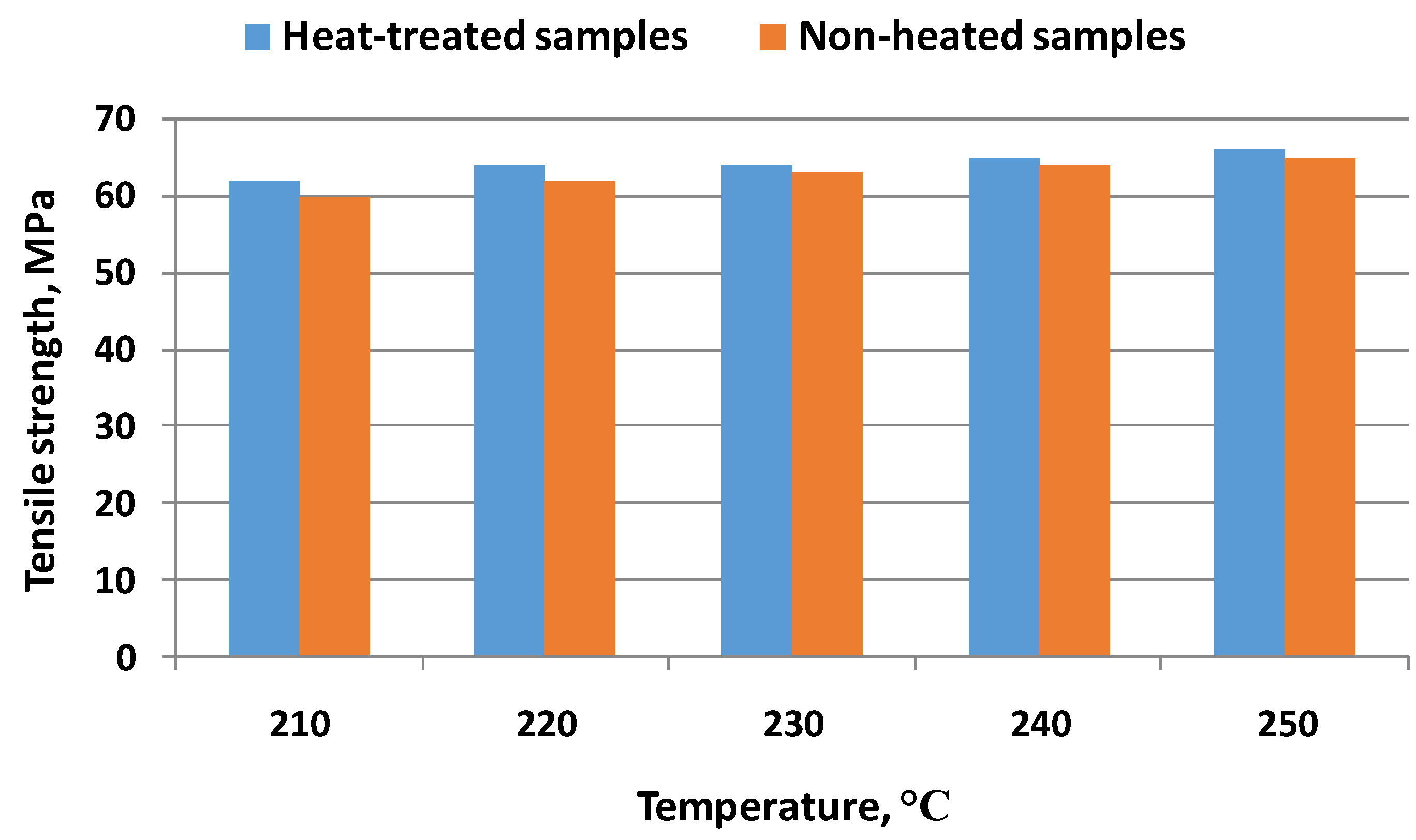

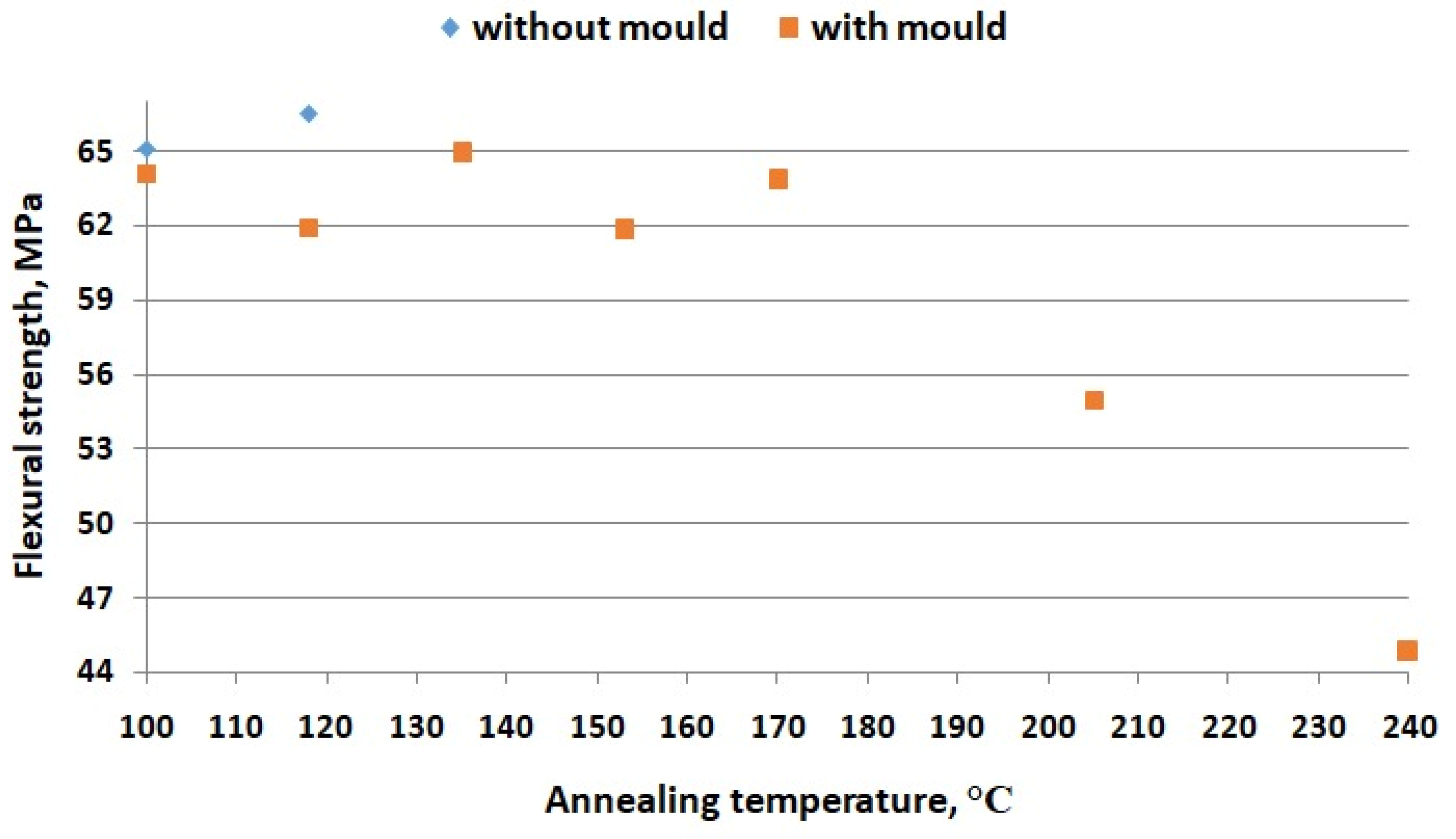

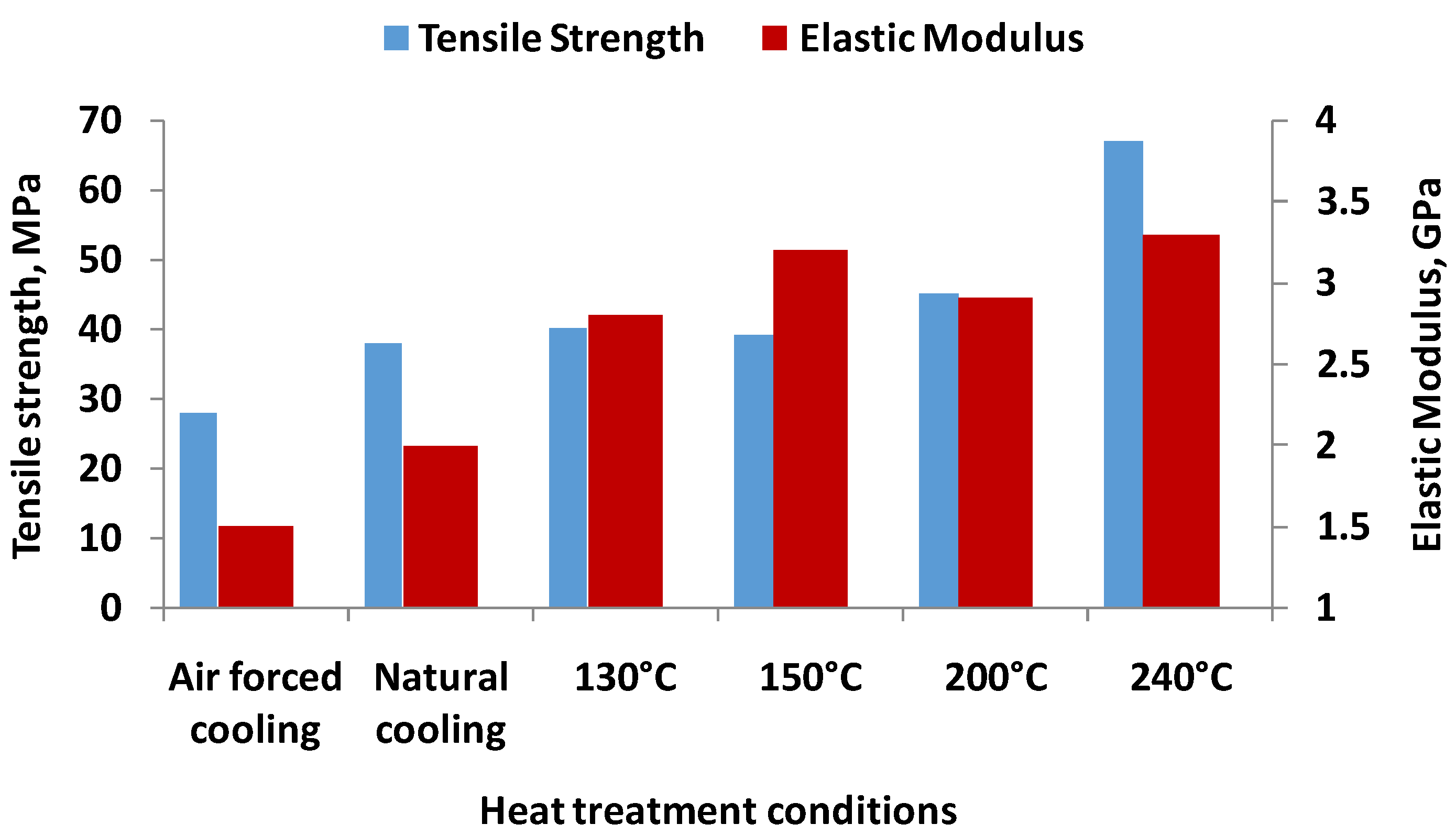

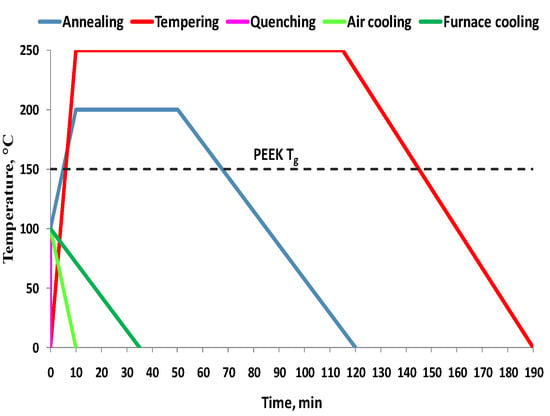

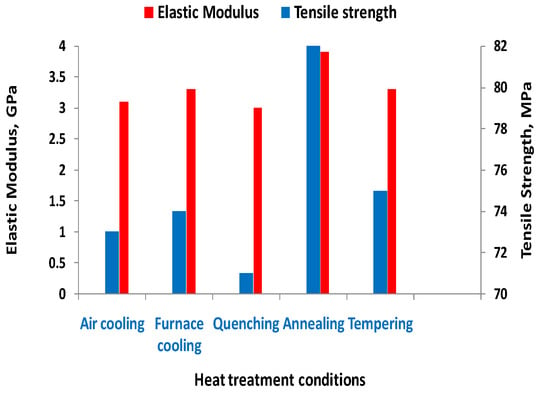

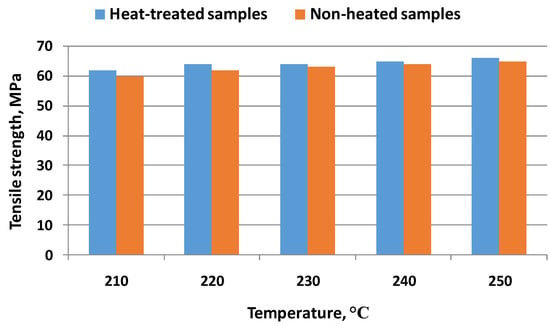

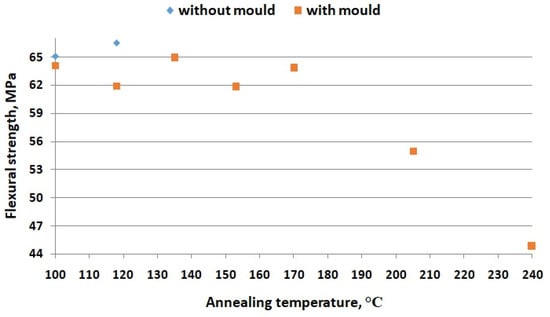

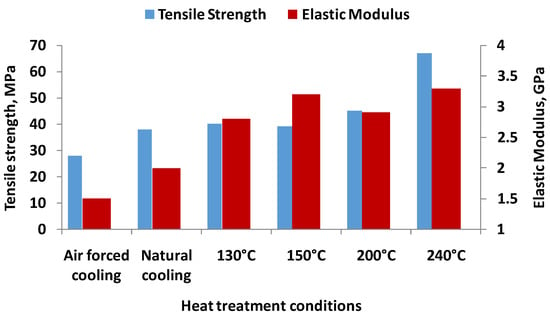

In [28], the printing parameters were considered as the main factors for the thermal treatment (ambient temperatures, nozzle temperatures, and cooling temperature). In Figure 12, the main thermal treatment schemes applied in the research are represented schematically. The authors of [28] analyzed the influence of several types of thermal treatments on the mechanical properties of PEEK, as shown in Figure 13.

Figure 12.

Heat treatments applied on 3D-printed specimens [28].

Figure 13.

The influence of the type of heat treatment [28].

A PLA-type material, printed in the following conditions value layer height 0.15 mm, infill 100%, print speed 75 mm/s, print-bed temperature 30 °C, production time 35 min, was subjected to an annealing heat treatment at 75 °C for 2 h [29]. The effects of applying this type of thermal treatment led to the improvement in the bonding between layers and the creation of a more homogeneous and consolidated material, leading to changes in mechanical properties.

Materials such as PLA/PLA-g-CNFs (Grade: Ingeo Biopolymer 4032D) were purchased from NatureWorks Inc. (Minnetonka, MN, USA). (3S)-cis-3,6-dimethyl-1,4-dioxane-2,5-dione (L-Lactide), tin (II) 2-ethylhexanoate (Sn(OCt)2), and organic solvents (i.e., toluene, acetone, methanol, and chloroform) were purchased from Sigma-Aldrich Inc. (St. Louis, MO, USA). CNFs were purchased from Daicel FineChem Co. (Tokyo, Japan) and were analyzed in [36]. In these pieces of research, the increase in creep resistance before and after annealing was analyzed, observing a slight increase.

Poly(ethylene terephthalate)-glycol (PETG) was used in [37] for evaluating the influence of thermal treatments on the mechanical characteristics. The printing parameters for the heat treatment are presented in Table 8.

Table 8.

Printing parameters for the heat treatment [37].

The researchers in [37] aimed to increase the mechanical characteristics, but with emphasis on the dimensional changes suffered by the samples during the thermal treatments.

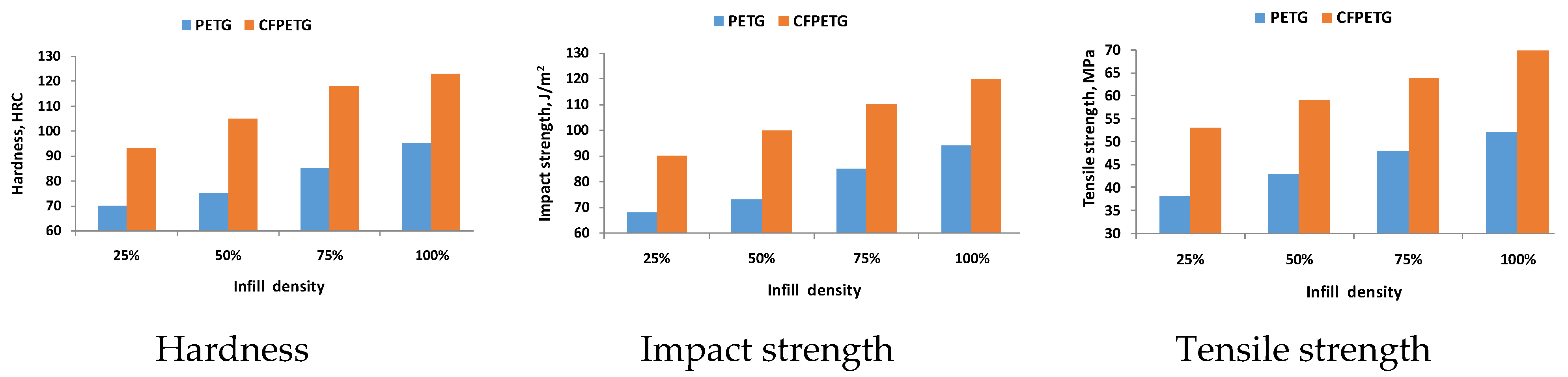

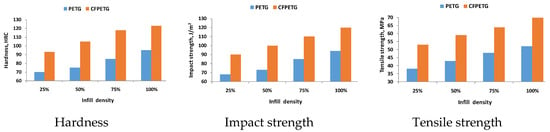

The use of materials such as polyethylene terephthalate glycol (PETG) and carbon fiber-reinforced polyethylene terephthalate glycol (CFPETG) composites, especially in the automobile industry, has become a reality nowadays. The effect of infill density such as 25%, 50%, 75%, and 100% and of thermal treatments was studied in [38] with the results showing changes in hardness (124HRC for 100% infill) and tensile strength as shown in Table 9.

Table 9.

Mechanical properties of PETG and CFPETG sample [38].

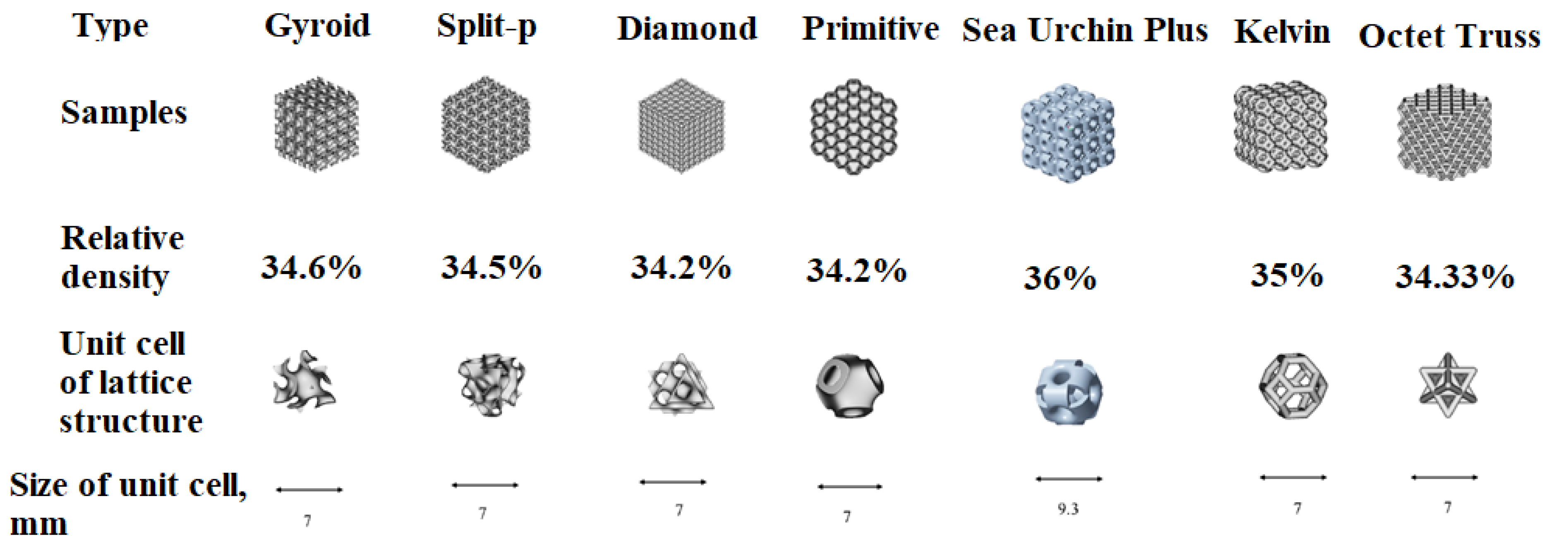

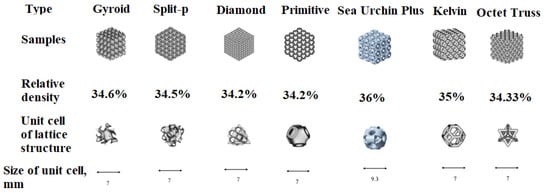

The evaluation of PA-12 material—density (g/cm3) 1.01; Young’s modulus (MPa) 1437; Poisson’s ratio 0.33; tensile strength (MPa) 27; ultimate tensile strength (MPa) 44—from the point of view of compression behavior was studied according to seven types of lattice structures (presented in Figure 14) which were fabricated by the additive manufacturing method [66]; the mechanical properties were evaluated and compared with annealed (at 110 °C and 130 °C).

Figure 14.

Lattice structures for 3D printing.

Materials such as MAX-G PETG filament from 3DXTECH; CARBONX CFR-PETG filament from 3DXTECH with 20% by weight fiber reinforcement; ECOMAX PLA filament from 3DXTECH; CARBONX CFR-PLA filament from 3DXTECH with 20% by weight fiber reinforcement were used to evaluate the mechanical characteristics [31]. The printing parameters used to make the samples are presented in Table 10.

Table 10.

The 3D printing parameters for MAX-G PETG, CARBONX CFR-PETG, ECOMAX PLA, CARBONX CFR-PLA [39].

The improvement of the mechanical properties can be obtained by combining the following parameters’ infill density, annealing, and layer thickness [31]. The printing parameters used in the analysis are presented in Table 11. The main conclusion is that an increase in tensile strength can be obtained but with a decrease in yield strength.

Table 11.

3D printing parameters [31].

Setting appropriate printing parameters (see Table 12) is very important for materials such as poly(lactic acid) (PLA, Ingeo™ 3D850), pellets containing 0.5% D-isomer, and poly (3-hydroxybutyrate) (PHB) pellets [42].

Table 12.

The 3D printing parameters for PLA Ingeo and PHB [42].

To identify the temperature of the heat treatment, a cold crystallization peak was used, so that temperatures of 80 °C and 100 °C were used, and holding times of 0.5 h, 1 h, and 2 h were chosen. Making a mixture of PLA and PHB [42] leads to an increase in mechanical characteristics, with possible subsequent heat treatments not leading to positive effects.

Research on materials such as unreinforced Fortron grade PPS, and three short CF-reinforced grades (filler content: 40 wt.%, 50 wt.%, and 60 wt.%) showed that increases in the modulus of elasticity are obtained at temperatures above the glass transition temperature [46]. The main settings taken into account when evaluating these materials are presented in Table 13.

Table 13.

Additive printing setting [46].

Considering the iso-static compaction (pressure of 0.55 MPa) of samples, studies regarding the influence of the heat treatment temperature (see Table 14) were carried out on an XSTRAND GF30-PA6 type material with a filament diameter of 1.75 mm (the filament is made of nylon matrix reinforced with 30% of glass fibers by weight) and a melting temperature of 206 °C [52]. The printing parameters were as follows: 30 mm/s speed, extruder temperature 250 °C and 90 °C for bed, flow rate 130%, 100% infill, layer thickness 0.2 mm, and nozzle diameter 0.4 mm [52]. Samples compacted at 0.55 MPa at 150 °C have increased in mechanical characteristics (elastic modulus and strength), samples compacted at 170 °C showed a decrease in strength and modulus.

Table 14.

Annealing treatment parameters [52].

A widely used polymer due to high performance engineering thermoplastics is polyaryletherketone polymer (PAEK). In [47], two materials were studied: Victrex PEEK 151 and Victrex AM 200 whose properties are shown in Table 15. The printing parameters and the temperatures used in the heat treatment for two materials are presented in Table 16.

Table 15.

Victrex PEEK 151 and Victrex AM 200 mechanical properties [47].

Table 16.

The printing parameters and the annealing temperatures [47].

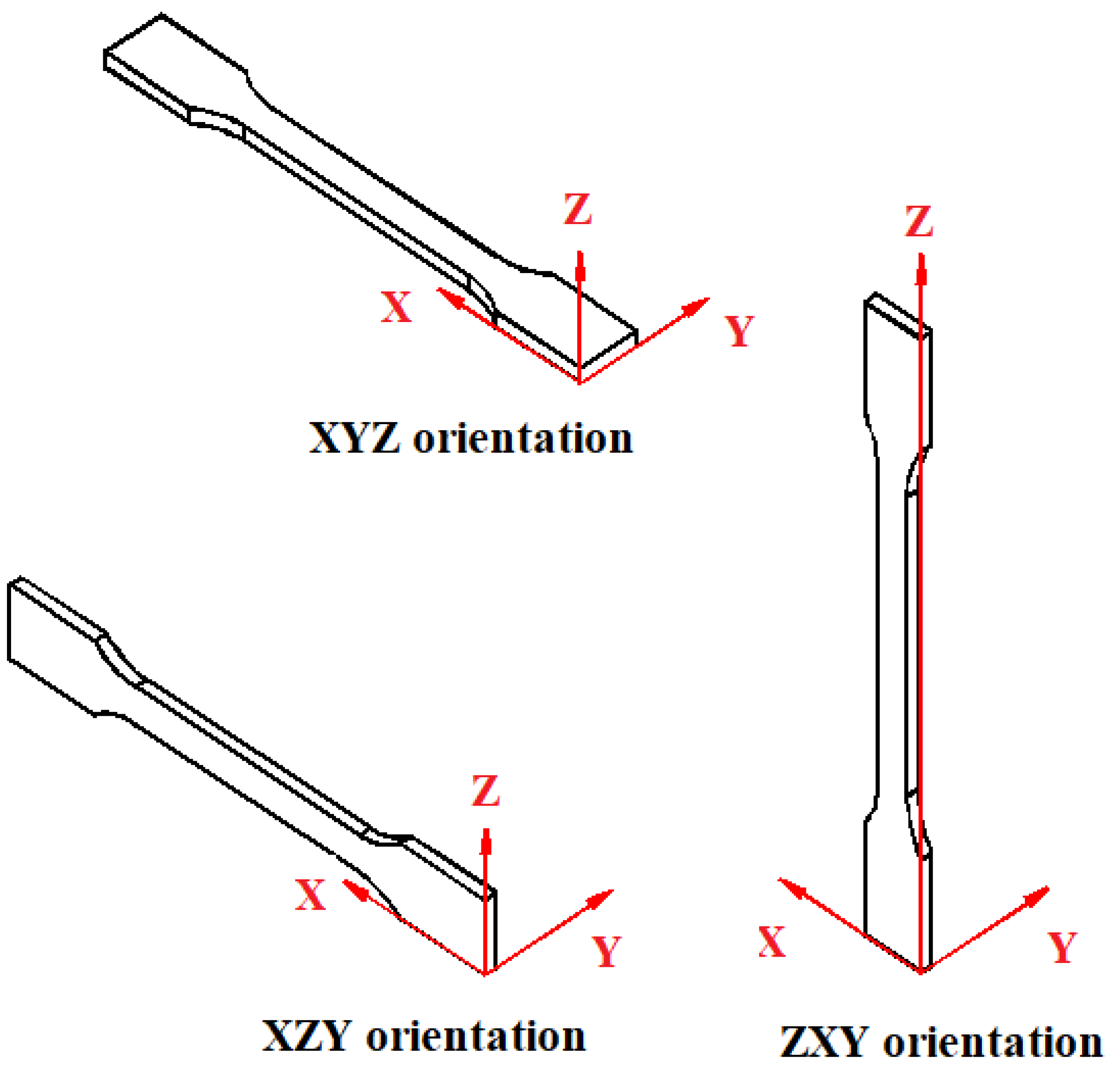

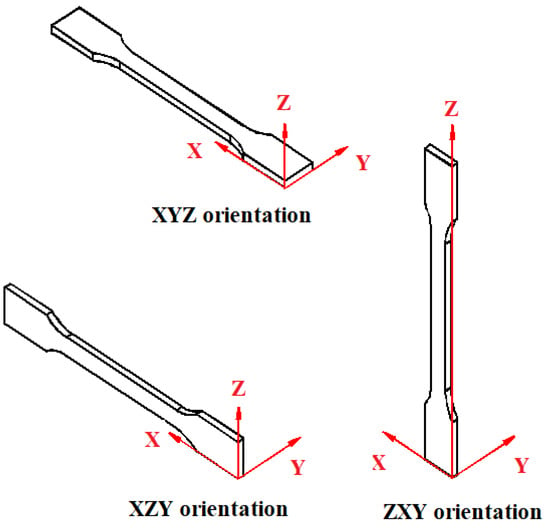

Effects of thermal annealing on materials such as Spectrum Premium PLA and Prusament PETG Orange were studied from the point of view of the printing orientation of the samples (see Figure 15) [32].

Figure 15.

Specimens’ printing orientations.

The tensile strength of specimens printed in XZY is almost egal to XYZ, the tensile modulus drops quite a lot (18%). Specimens printed in ZXY have an over 30% increase in tensile strength than the XYZ orientation and around 27% smaller than XZY. The tensile modulus of the specimens printed in ZXY is 15% smaller than specimens printed in XYZ but almost equal to the tensile modulus of specimens printed in XZY [32].

In order to evaluate the ability of 3D-printed high modules carbon fiber-reinforced composite specimens to increase the mechanical characteristics by applying different thermal treatments, the following materials were used [26], as shown in Table 17.

Table 17.

Mechanical properties for acrylonitrile butadiene styrene 9% concentration of carbon fibers (ABSCF)/polylactide with 9% concentration of carbon fibers (PLACF) [26].

A novelty is the analysis of a type of sandwich material consisting of ABSCF-PLACF-ABSCF and PLACF-ABSCF-PLACF. In order to distribute the temperature evenly and avoid possible deformations, a mixture of sodium chloride powder (table salt), potassium iodate 50 mg/kg, and E536 anti-caking agent is used in the oven chamber [26]. The glass transition temperature and the melting point of the sandwich specimen were considered as an average value of the two materials. Following the application of thermal treatments, significant increases were obtained at temperatures of 150 °C more for the simple material compared to the sandwich type material.

For the comparative analysis of two types of PA12 materials (FX256 and CF15), the second material is a short fiber reinforcement version of the first material and the analysis was carried out for the evaluation of mechanical performance subjected to thermal treatment [43]. The mechanical properties of the analyzed materials (FX256 and CF15) are briefly presented in Table 18, and the printing parameters are shown in Table 19.

Table 18.

FX256 and CF15 mechanical properties [43].

Table 19.

Printing parameters used [43].

Commercial materials of the type 2.85 mm White ABS (melting temperature range is 225–245 °C, Vicat softening temperature is 97 °C) and Pearl White PLA 3D (melting temperature range is 145–160 °C, transition temperature is 60 °C) are used for the study of post-process thermal effects [27]. The conditions for applying the heat treatment are: introduction into a mixture of dry alumina powder with an average grain size of 150 µm and covered by another powder layer of the same thickness; applying a pressure of 12 g/cm2 to avoid creep deformations [27]. The samples were used to analyze the influence of the heat treatment on the geometric dimensions and mechanical characteristics, the main conclusion being the fact that geometric variations are directly proportional to the annealing temperature, with a mention of the use of a ceramic powder mold which reduces these dimensional changes.

A superior material in terms of mechanical properties and with chemical and thermal resistance is considered to be polyetherimide (PEI/ULTEM 1010). The properties of the material and the parameters used to configure the printer are presented in Table 20.

Table 20.

Mechanical properties and printing parameters used [58].

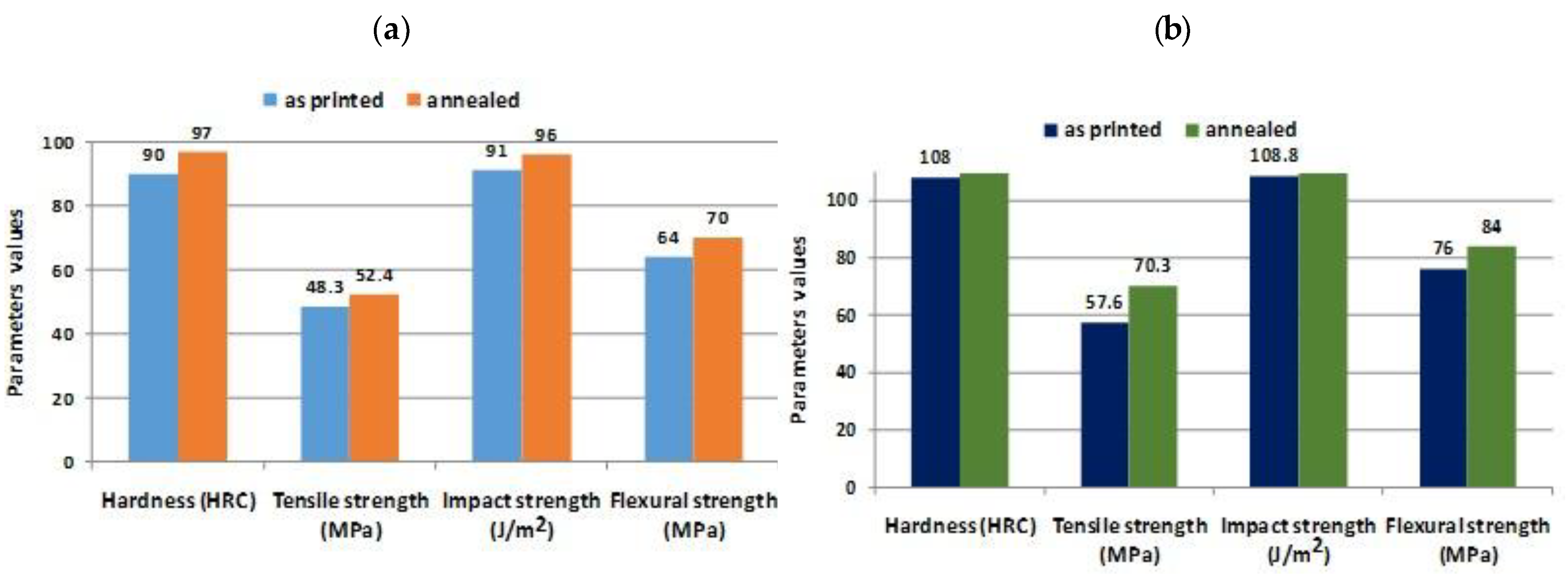

A heat treatment temperature value of 225 °C is considered optimal from the point of view of the increase obtained in the case of mechanical test results (tensile test, static bending test, hardness determination) [58].

3.3. General Characteristics of Metal Materials Used in Additive Technologies

The mechanical properties of metal materials used in additive manufacturing vary depending on the specific alloy and the printing process used (see Table 21). Some common mechanical properties that are important for metal materials used in additive manufacturing include tensile strength, yield strength, elongation, and hardness:

Table 21.

A short summary of different post-processing of the heat treatment impact on additive manufacturing: L-PBF (laser powder bed fusion); L-PBF (laser beam bed fusion); DMD (direct melting deposition); EBM (electronic beam melting); ME (fused deposition melting); DMLS (direct melting laser sintering); LMD (laser melting deposition); PBF (powder bed fusion), WAAM (Wire + arc additive manufacturing); and ME (material extrusion) [66].

Stainless Steel—A corrosion-resistant metal that has excellent strength and durability, making it ideal for applications in the medical and aerospace industries.

316 L Stainless Steel: This is the most commonly used stainless steel for 3D printing. It has good corrosion resistance, high strength, and is biocompatible, making it ideal for medical and dental applications.

17-4 PH Stainless Steel: This stainless steel has high strength and is corrosion-resistant, making it ideal for applications in aerospace, defense, and the oil and gas industries.

15-5 PH Stainless Steel: This stainless steel is similar to 17-4 PH, but with better corrosion resistance and improved toughness.

304 L Stainless Steel: This stainless steel is often used for applications requiring high corrosion resistance, such as in the food and beverage industry.

420 Stainless Steel: This stainless steel has high strength and is often used for applications requiring wear resistance, such as in the manufacture of surgical instruments.

Titanium—A lightweight, strong, and corrosion-resistant metal that is commonly used in the aerospace and medical industries for implants and other components.

Ti6Al4V (Grade 5): This is the most common titanium alloy used in 3D printing. It is a combination of titanium, aluminum, and vanadium and is known for its high strength, corrosion resistance, and biocompatibility.

Ti6Al4V ELI (Grade 23): This is a variant of Ti6Al4V that has lower oxygen and iron content, making it more biocompatible. It is often used in medical and dental implants.

TiAl6V4: This is a high-strength titanium alloy that is commonly used in aerospace applications. It has a higher strength-to-weight ratio than Ti6Al4V and is also resistant to fatigue and corrosion.

Ti6Al7Nb: This titanium alloy is used in medical implants and has excellent biocompatibility. It is also resistant to corrosion and wear.

Ti13Nb13Zr: This is a titanium alloy that is often used in dental implants. It has good biocompatibility and is resistant to corrosion and wear.

Inconel—A nickel-chromium alloy that has excellent high-temperature resistance and is often used in aerospace and industrial applications.

Inconel 625: This is the most commonly used Inconel alloy for 3D printing. It has high strength, excellent corrosion resistance, and is often used in aerospace, defense, and marine applications.

Inconel 718: This Inconel alloy has high strength, good corrosion resistance, and is often used in aerospace and gas turbine applications.

Inconel 939: This Inconel alloy has excellent high-temperature strength and is often used in gas turbine engine components.

Inconel 713C: This Inconel alloy has excellent high-temperature strength and is often used in gas turbine engine components.

Inconel 625LCF: This is a low-carbon version of Inconel 625 and has improved fatigue resistance.

Aluminum—A lightweight, strong, and corrosion-resistant metal that is used in the aerospace and automotive industries for producing lightweight parts.

AlSi10Mg: This aluminum–silicon–magnesium alloy is lightweight, strong, and has good corrosion resistance. It is often used in aerospace and automotive applications.

AlSi12: Another aluminum–silicon alloy, AlSi12 is known for its excellent fluidity and castability, making it a good choice for complex geometries.

Al6061: This alloy contains magnesium and silicon, and is known for its strength, corrosion resistance, and weldability. It is often used in structural applications.

Al7075: This aluminum–zinc–magnesium–copper alloy is known for its high strength-to-weight ratio and good fatigue resistance. It is commonly used in aerospace and automotive applications.

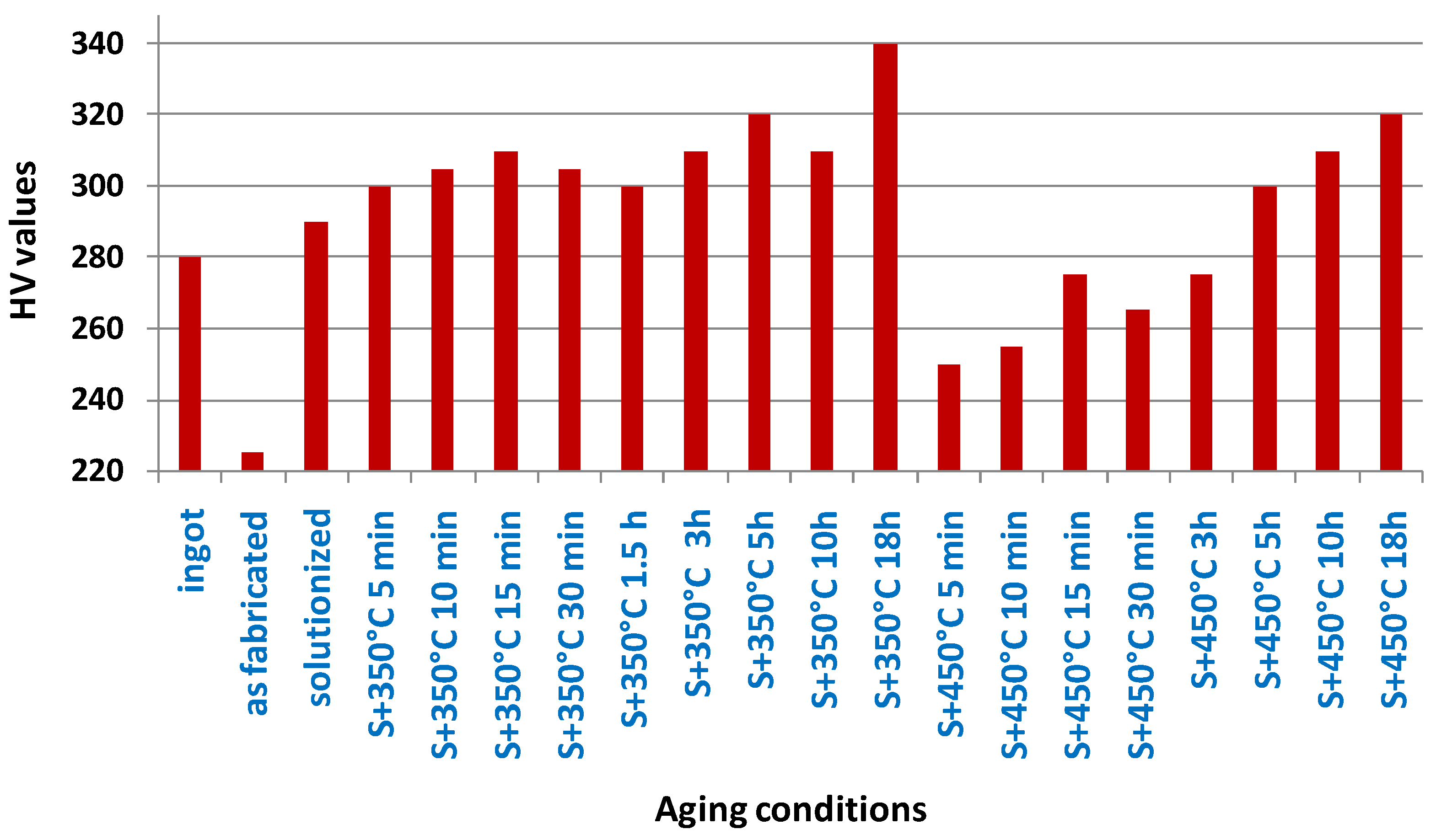

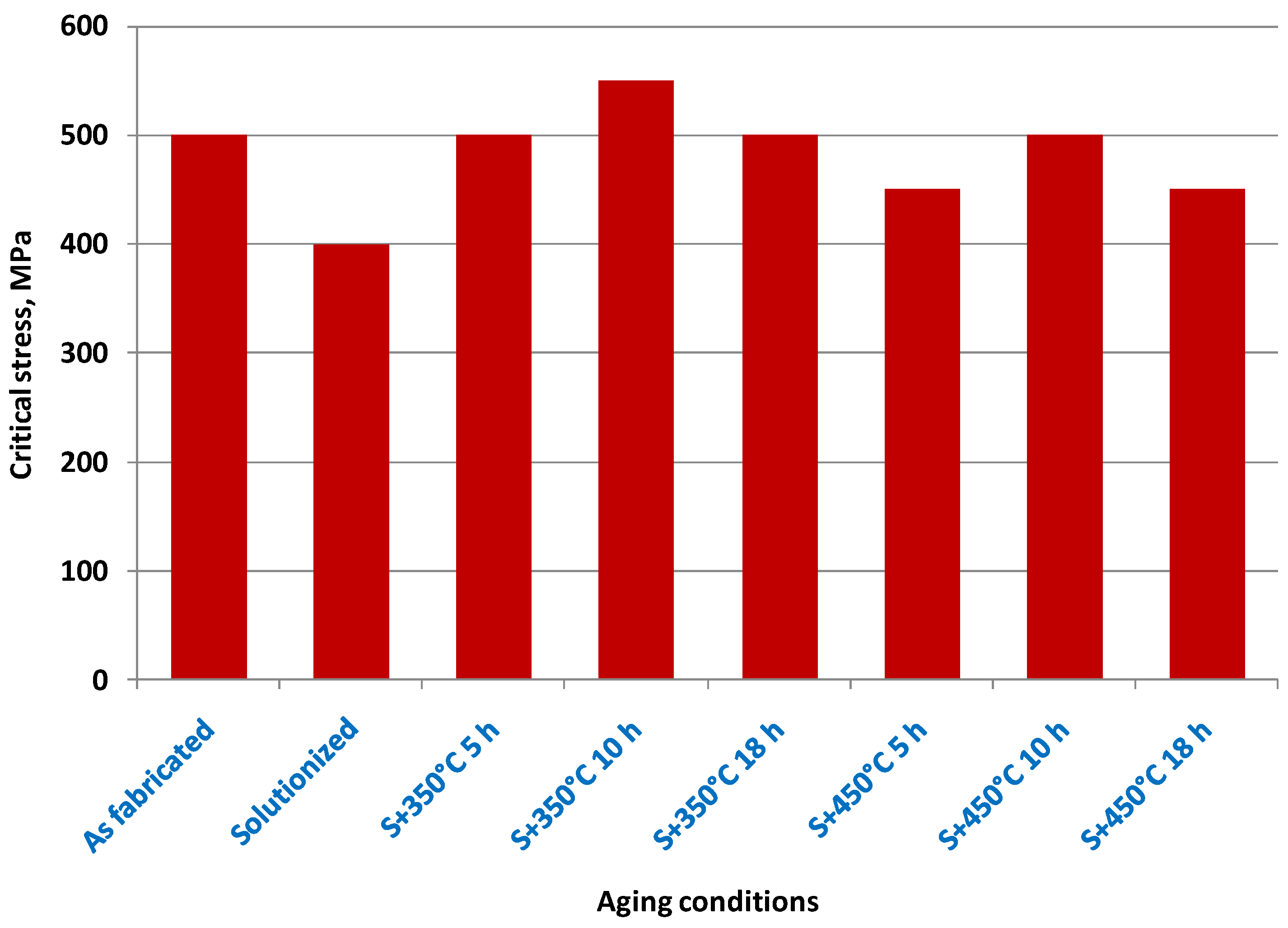

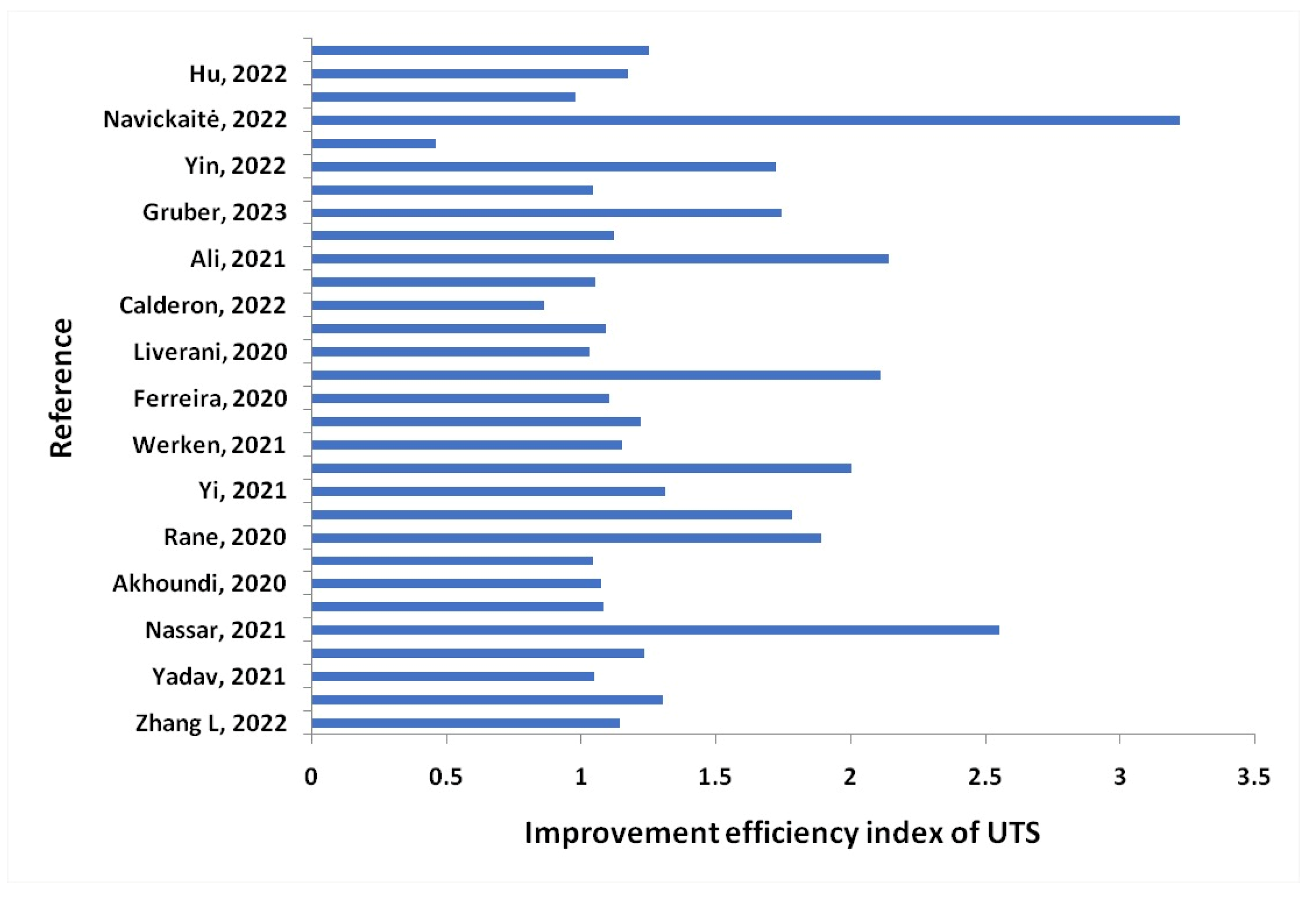

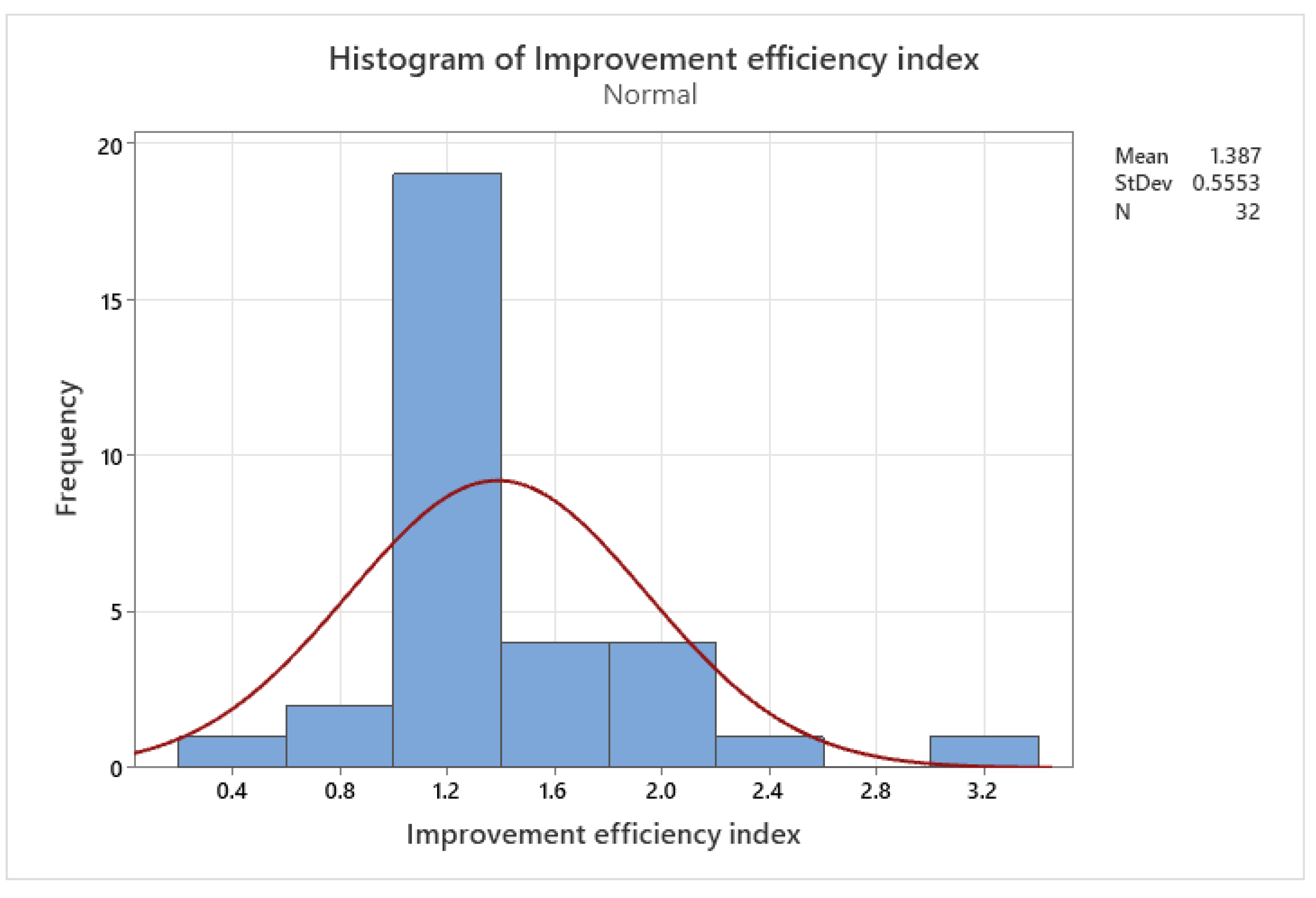

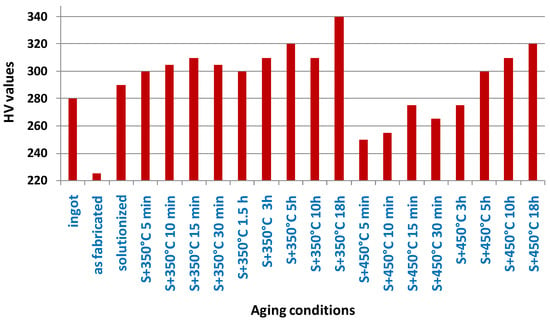

Al2024: This alloy contains copper and magnesium, and is known for its good machinability and high strength-to-weight ratio. It is often used in aerospace and structural applications.