Abstract

Epoxy and unsaturated polyester resins are the most used thermosetting polymers. They are commonly used in electronics, construction, marine, automotive and aircraft industries. Moreover, reinforcing both epoxy and unsaturated polyester resins with carbon or glass fibre in a fabric form has enabled them to be used in high-performance applications. However, their organic nature as any other polymeric materials made them highly flammable materials. Enhancing the flame retardancy performance of thermosetting polymers and their composites can be improved by the addition of flame-retardant materials, but this comes at the expense of their mechanical properties. In this regard, a comprehensive review on the recent research articles that studied the flame retardancy of epoxy resin, unsaturated polyester resin and their composites were covered. Flame retardancy performance of different flame retardant/polymer systems was evaluated in terms of Flame Retardancy index (FRI) that was calculated based on the data extracted from the cone calorimeter test. Furthermore, flame retardant selection charts that relate between the flame retardancy level with mechanical properties in the aspects of tensile and flexural strength were presented. This review paper is also dedicated to providing the reader with a brief overview on the combustion mechanism of polymeric materials, their flammability behaviour and the commonly used flammability testing techniques and the mechanism of action of flame retardants.

1. Introduction

Polymeric materials are rapidly replacing metals and ceramic materials in various applications. This is attributed to the remarkable combination of properties like low weight, easy of fabrication and low processing temperature [1,2]. Use of polymers in the electric and electronics (E&E) industry is prominent such as in electronics housings, insulators and printed circuits [3], and similarly, in transportation industry [4,5], flexible solar cells [6] and synthetic fibres in textile industry [7,8].

Reinforcing polymers with continuous fibres like glass or carbon fibres opens a new field of applications in automotive, aerospace and construction buildings. In other words, fibre reinforcements have enabled polymeric materials to replace traditional materials like aluminium, steel and concrete that are used in high performance engineering structures [9]. High specific strength and stiffness, light weight and design flexibility are the key factors behind the continuous increase in using fibre reinforced polymer (FRP) composites [10,11]. In a commercial airplane 80–90% of the interior furnishings are manufactured from FRP [9]. Recently, FRP is used in construction and rehabilitation of metallic structures [10,12]. Constructing a FRP bridge typically reduces the weight by 75% compared to steel bridge and that is beneficial in case ground condition is poor [11].

Epoxy resin, phenolic resin, unsaturated polyester resin and vinylester resin are the most used thermosetting resins in FRP composites applications [13]. Amongst all thermosetting resins, Epoxy resins are the most widely used due to their higher mechanical properties, better adhesion to various substrates and lower shrinkage after curing compared to other resins [14]. However, longer curing time and higher cost for epoxy resin compared to polyester and vinyl ester resin hinders its use as a matrix material for automotive composites [15]. However, Epoxy composites are more appropriate for higher performance applications like aircrafts [16,17].

The ever-increasing demand for light structures and increasing fuel efficiency results in replacing more metallic parts with polymers and polymer composites. Despite the benefits of using polymeric materials, the risk of fire occurrence is increased [18,19]. The high flammability of polymers and polymer composites limits their applications and more stringent requirements should be passed for fire safety concerns [20,21]. In some studies, the reason behind the reduction in time to escape during airplane crashes, accompanied by fire, is attributed to the use of several tons of polymers in overhead bins, internal panels, seat fabric and cushions in aircraft’s passenger compartment [9,20]. Reducing the fire hazards accompanied by using polymeric materials can be achieved by incorporating flame retardants (FRs) [22]. The main applications that require flame retardants to be used in polymer composites are summarized in Table 1 [4,23,24,25].

Table 1.

Application of flame retardants.

The main functions of flame retardants are to reduce smoke and delay the time of flashover, subsequently provide sufficient time for people to escape [4]. Halogenated flame retardants were commonly used, but they were banned as they evolve toxic gases during combustion [27]. Recently halogenated FRs are replaced by phosphorus-based compounds, silicon-based compounds, borates and metal hydroxides. However, these non-halogenated flame retardants should be incorporated at high loading percentages to be effective and this in turn deteriorates the mechanical properties [16,28]. Moreover, the high loading percentages influence the resin processability. For example, the added particles increase the viscosity and the curing time for the resin and that leads to changing the processing conditions [27,29]. Thus, the challenge is to develop a flame-retardant system that enhances the fire performance of polymeric composites without deteriorating their mechanical properties.

Several review articles have analysed the different approaches that can be used to enhance the flame retardancy for polymeric materials and provide an overview of various types of flame retardant additives and their modes of action to inhibit the combustion cycle [3,23,26,30,31,32,33,34,35,36,37,38]. However, limited articles have worked on introducing quantified index to allow comparison of different flame retardant systems. Vahabi et al. [39] have proposed for a first time a universal dimensionless index known as flame retardancy index (FRI). This index helps the investigators to evaluate the performance of flame-retardant system. Vahabi et al. and Movahedifar et al. [39,40,41] have applied this index on a comprehensive set of data collected from literature to evaluate the fire performance of Polypropylene (PP), Poly (methyl methacrylate) (PMMA), Ethylene vinyl acetate (EVA), Poly (lactic acid) (PLA) and epoxy resin filled with different types of flame retardants. Moreover, literature lacks a simple selection tool that can be used to correlate between the effect of adding flame retardants on the flammability behaviour of polymeric materials and their effect on the mechanical, thermal and physical properties. Elsabbagh et al. [42] introduced a material selection chart that combines the flame retardancy performance represented by UL-94 test results with the tensile strength of natural fibre polymer composites treated with different flame retardants.

Based on the series of reliable data collected from the literature, this review concentrates on developing a variety of flame-retardant selection charts for the commonly used thermosetting polymers and their composites. These FR selection charts will relate different flame retardant test results with each other. Additionally, these charts will relate the flame retardancy performance with mechanical behaviour. These selection charts will pave a guiding tool that facilities the selection of the best FR system for different thermosetting matrix and their composites. This review is essentially divided into two sections: the first section briefly discusses the combustion mechanism, the flammability behaviour of polymers, laboratory fire testing and provides an overview of the flame retardancy mechanism and types of flame retardants. In the second section, articles on flame retardant epoxy resin and unsaturated polyester polymer matrices and their composites were reviewed and summarized in comprehensive master tables. These master tables include the type and content of flame retardant additive, cone calorimetry data including time to ignition (TTI), peak heat release rate (PHRR), total heat release (THR), calculated universal flame retardancy index (FRI) values and the available data for UL-94, limiting oxygen index (LOI) and mechanical properties represented by tensile strength and flexural strength are also included.

2. Combustion, Flammability and Flame Retardancy of Polymeric Materials

2.1. Combustion Mechanism

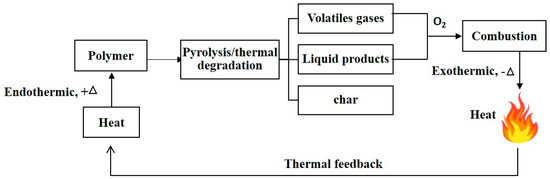

Understanding the combustion mechanism provides the basis of implementing an efficient flame retardant. The key contributors for the combustion process are fuel, oxygen, source of heat and chain reaction. Polymer combustion cycle starts by heating the flammable substrate till pyrolysis temperature. During pyrolysis, thermal degradation takes place and the material begins to depolymerize to unstable radicals and volatile gases. In the presence of enough oxygen and an ignition source, these volatile products act as fuel and combustion occurs. During combustion phase, toxic gases, smoke and heat are evolved. This released heat acts as a thermal feedback for further pyrolysis [13]. The combustion cycle is sustained by two main reactions, the endothermic reaction represented in thermal degradation and recycling the heat released during the exothermic reaction in the combustion phase [19,20]. Figure 1 represents a schematic diagram for the combustion process.

Figure 1.

Combustion process.

The structure of polymeric material, whether it is a single or double bond or aromatic structure determines the amount of energy required to break the bond and release volatile gases. The aromatic structure reduces fuel value as the chemical formula changes from C6 H12 to C6 H4 [18]. H, O and OH are the most important radicals evolved from hydrocarbon flamed and these radicals participate in combustion through the following reaction H + O2 → OH + O. This reaction generates more radicals that accelerate the burning behaviour of polymers [20].

It is worthy of note that thermosets behave differently from thermoplastics under fire. Thermoplastics undergo a reversible reaction as they melt when reheated and re-solidify when cooled. They soften when heated then flow under their own weight and drip. Dripping helps in removing heat and flame away from the bulk material. On the contrary, crosslinks in thermosets made them thermally decomposed, rather than melting [43]. Generally, thermosets are more heat-resistant compared to thermoplastics and most of them do not drip during combustion [24].

2.2. Flammability Behaviour of Polymers and Testing Techniques

The flammability behaviour of polymeric materials is described by several parameters such as flame spread rate, ease of ignition, time to ignition, ignition temperature, heat release rate, smoke production rate and ease of extinction [6]. There are small, medium and full-scale flammability tests applied in industrial and academic laboratories for testing manufactured products [25]. Toritzsch [24] covered the national and international fire testing regulations and procedures used for plastics and the fire regulations tests used in different applications such as building, transportation and electrical engineering. Herein, we briefly discussed the most used flammability tests on academic laboratory scale, the purpose of each test and the common test standards used for each one. These tests are underwriter laboratories test (UL-94), limiting oxygen index (LOI) and cone calorimeter. UL-94 is a rating test that measures the ignition resistance [36]. The sample is rated by V-0, V-1, V-2 or no rating after exposing it to a flame for 10 s then the flame is removed and after flame time (t1) is noted. The flame is applied again for another 10 s and after flame time (t2) is noted. The samples are rated according to the classified criteria shown in Table 2 [33].

Table 2.

UL-94 test criteria.

Limiting oxygen index is the minimum concentration of oxygen in a mixture of oxygen and nitrogen that is required to maintain combustion after ignition. It is expressed in volume percentage (vol%). The oxygen percentage is 21% in air that is why materials with LOI less than 21% are considered combustible material. On the other hand, materials with LOI greater than 21% are classified as self-extinguishing. ASTM D 2863 and ISO 4589 are the standards used for this test [44].

Cone calorimeter is a bench scale test that measures the fire reaction properties. These properties are time to ignition (TTI), heat release rate (HRR), peak heat release rate (PHRR), total heat release (THR) and smoke production rate (SPR) [23]. These measured parameters are essential to assess the fire hazards of a polymeric product in a full-scale fire. ASTM E 1354 and ISO 5660 are the commonly used standards for the cone calorimeter test [44].

2.3. Flame Retardant Mechanisms

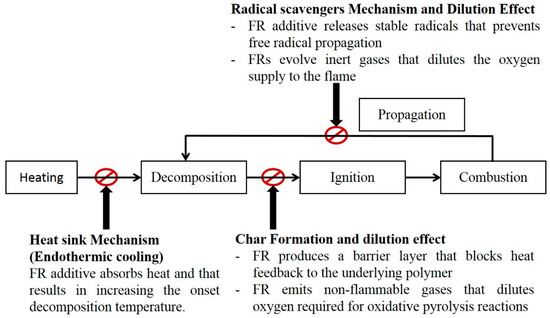

Combustion cycle can be divided into five stages. These stages are heating, decomposition, ignition, combustion and propagation [45]. Flame retardancy can be achieved by interrupting this cycle at any of these stages. There are three main ways to disrupt the combustion cycle. First, incorporation of additives that act as a heat sink and prevents the combustible material to reach pyrolysis temperature [30]. Second, addition of Flame Retardant (FR) compounds that produce non-flammable gases and form more char during pyrolysis. This char layer acts as an insulating layer that prevents oxygen and heat from interacting with the underlying material. The third method relies on interrupting the burning cycle during the combustion stage through adding FRs that release non-flammable gases and stable radicals that prevent progressive propagation of H· and O· free radicals and this leads to diluting the oxygen concentration in the flame zone [23,33]. Figure 2 shows the main FR mechanisms to interrupt the combustion cycle.

Figure 2.

The main flame retardant mechanisms.

Generally, flame retardants can be classified based on their mechanism of action, mode of action and the functional elements that built up FR [36]. Flame retardants commonly act either in the condensed phase (phase at which the thermal degradation occurs) or in the gas phase (phase at which combustion of volatile gases occurs) [46]. In both phases, the FRs can interfere and interrupt the combustion cycle either by physical or chemical mode [19,36]. The physical mode takes place either by dilution that is achieved by reducing the concentration of decomposition gases, cooling the polymer substrate that is occurred when FR endothermically degrades and releases inert gases such as water vapor and carbon dioxide or formation of protective layer [4,23]. On the other hand, chemical mode occurs either by a dehydration process accompanied by char formation or inhibiting the high energy radicals during combustion phase [47]. FRs can also be classified either as additive when FR compounds are directly incorporated to the polymer matrix or as reactive FR when FR functional groups are part of the molecular structure of polymers [16,33,48]. In case of direct incorporation of FR, FRs are as any filler materials, the particle size and mixing conditions (whether mechanical or ultrasonication, time of mixing and temperature) are very crucial factors that affect the dispersion distribution of fillers, consequently the properties of the final system. Flame retardants are based largely on seven elements: chlorine, bromine, phosphorus, antimony, boron, nitrogen and silicon [3]. Table 3, below, summarizes different examples for the most used flame retardants and their mechanism of action [30,31,32,33,49].

Table 3.

Examples of FRs and their mechanism of action.

3. Literature on Thermosetting Polymers and Their Composites Filled with FRs

The recent articles that have studied the effect of flame retardant additives on thermosets polymers and their composites have been discussed and analysed in this section. The data collected concentrate on analysing both the flammability test results and the mechanical test results for incorporating FRs into epoxy resin, unsaturated polyester resin matrix and their composites. Graphical charts are developed that can facilitate the comparison between the flammability test results obtained from literature. Moreover, flame retardant selection charts that correlate the flame retardancy performance with mechanical behaviour are also presented.

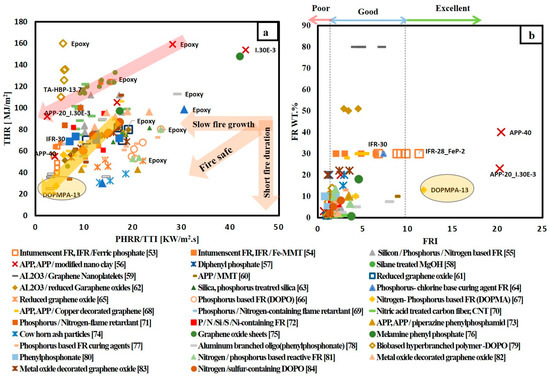

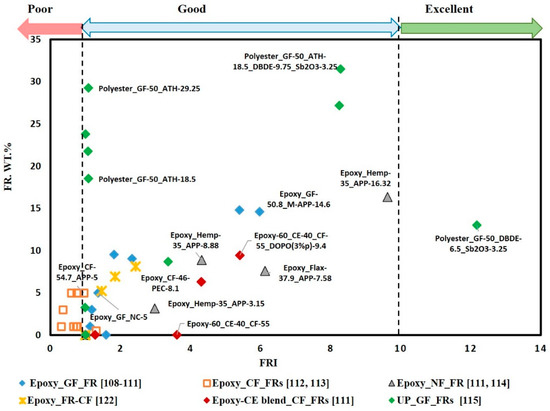

Cone calorimeter test is considered the best fire bench scale test that can simulate real state combustion of polymers. PHRR, THRR and TTI are the main results obtained from the cone calorimeter test. The hazard of fire can be evaluated by calculating the fire growth index (FGI), which is the ratio between PHRR divided by TTI and to obtain an overall fire performance of polymeric material a chart with THR (Y-axis) versus FGI (X-axis) is plotted. An increase in Y-axis value (THRR) indicates a fire of long duration. While, the increase in X-axis (FGI) value indicates a quick growth of fire [52]. The system with low THR and low FGI value gets a high safety rank. However, this plot is still a qualitative tool to evaluate the fire performance and a quantitative measure is needed. Vahabi et al. [39] have introduced a universal dimensionless index called Flame Retardancy Index (FRI), which is defined as the ratio between THR × PHRR/TTI of neat polymer and THR × PHRR/TTI of neat polymer filled with FR as shown in Equation (1).

According to the value of FRI, the FR polymer system can be ranked as poor, good and excellent. From Equation (1) it can be noted that FRI with a value of one is the low limit for flame retardancy performance, below which the incorporation of FR is not effective. FRI value below one is nominated as poor, while FRI value between 100 and 101 is ranked as good and a system with FRI above 101 is assigned as excellent.

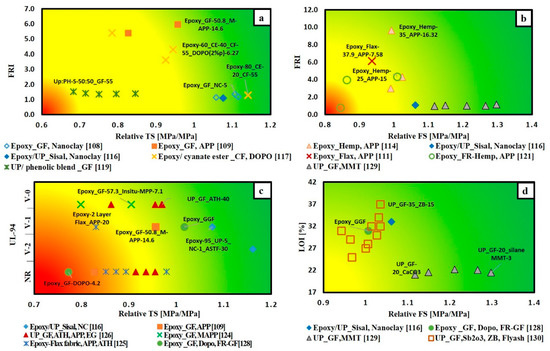

In this section, a comprehensive data on cone calorimetry measurements (PHRR, THR, TTI), LOI, UL-94 and mechanical measurements applied on FRs, incorporated with epoxy resin, unsaturated polyester resin and their composites, were collected and summarized in master tables. From these data, the flame retardancy performance for each FR-polymer/polymer composite system was qualitatively evaluated by plotting THR versus PHRR/TTI and quantitatively ranked by calculating FRI value. These different systems were categorized as Poor, Good and Excellent based on their location in a constructed chart that combines FR weight percentage and FRI value. Moreover, the flame retardancy performance was rechecked by UL-94 and LOI test results and a graphical correlation between these different performance measures (FRI versus LOI, UL-94 versus LOI) was plotted. Additionally, flame retardant (FR) selection charts that combine the effect of FR on the flame retardancy level (UL-94 and LOI)—as well as the mechanical properties (tensile strength (TS) and flexural strength (FS)) for different FR-polymer/polymer composite systems—were constructed.

3.1. Epoxy Resins Containing Flame Retardants

According to the literature, the effect of various flame retardants on the flame retardancy performance as well as the mechanical properties of epoxy resin have been studied. Table 4 summarizes the data extracted from the recent research articles. Some cells are left empty since these data were not available.

Table 4.

Cone colorimetry data (TTI, PHRR, THR), Calculated FRI value, LOI, UL-94, FS and TS for epoxy resin filled with a wide variety of FR. The designation in column two referred to FR type followed by wt.% of filler.

The data collected in Table 4 reveal that most of the recent articles concentrated on environmentally friendly FRs and mainly focused on incorporating phosphorus based FRs into epoxy resin. Knowing that the phosphorus-based FR is effective with polymers rich in oxygen [36]. In addition, the fact that the epoxy resin is composed of glycidyl group that contains oxygen. These two facts explain the researcher’s interest to study the effect of adding phosphorus-based FR to epoxy resin. Other non-phosphorus-based FR such as mineral hydroxide and inorganic additives (Al2O3, graphene, carbon nanotubes, nano clay) are also studied. Additionally, the synergism between phosphorus and non-phosphorus-based FR is included. Figure 3 gives a brief informative view of the effect of adding FRs on the flame retardancy performance of epoxy resin. The variations of THR values versus PHRR/TTI values for different FR/epoxy resin systems are presented in Figure 3a.

Figure 3.

(a) THR versus PHRR/TTI for different FR/epoxy resin systems; (b) FR wt.% versus flame retardancy index (FRI) for different FR/epoxy resin systems.

Figure 3a shows the three following observations:

- Adding various types of FR to epoxy resin reduced both THR and PHRR/TTI ratio. As we move towards the origin of the graph, the higher flame retardancy performance for FR/epoxy resin system is obtained. Incorporating 13 wt.% synthesized nitrogen-Phosphorus-based FR DOPMP to epoxy resin shows the best fire safe system. DOPMP can act in both gaseous and condensed phases to suppress fire. In the gaseous phase during combustion DOPMP releases P· and PO· that can interact with H· and OH· free radicals. In addition, nitrogen-containing non-flammable gases are evolved and these gases dilute the concentration of flammable gases. In the condensed phase, DOPMP is decomposed into polyphosphoric acid that interacts with epoxy resin and forms a compact char [67].

- The variation in flame retardancy levels for neat epoxy resin is noticed in Figure 3a due to the different sources of the collected data. This variation can be explained in terms of different molecular weight and viscosity for different grades of virgin epoxy resin.

- DOPMP is considered, on average, the best FR system, as it is the nearest point to the origin.

Calculating the FRI value to evaluate the flame retardancy performance is more representative. Referring to Equation (1), the calculated FRI value normalized the collected data by dividing the performance of each FR/epoxy resin system by the flame retardancy performance of neat epoxy resin. FR/epoxy resin systems were categorized based on FRI and FR content in the system, as shown in Figure 3b. It was observed that poor, good and excellent performance based on the calculated FRI values for different FR/epoxy resin systems were achieved. In addition, it can be noted that most of the FR systems are located in the Good performance zone.

There are two points that have an FRI value below one and this indicates that some FR additive cannot contribute to suppressing Fire. These systems contain reduced graphene oxide (RGO) and nano-silane treated magnesium hydroxide (n-S-MgOH). In the case of reduced graphene oxide, it was noted that 1 wt.% loading has decreased the flame retardancy of neat epoxy resin. The authors [61] enhanced the flame retardancy performance by functionalizing RGO with phosphorus, nitrogen and silicon elements. However, functionalizing RGO increased the FRI value slightly above 1. Increasing the RGO content to 3 wt.% resulted in increasing FRI to reach 1.8. Yuezhan et al. [62] also reported that modifying the RGO with a covalently grafting phosphorus element in the form of a polyphosphoramide oligomer (PDMPD) and incorporating it with 1 wt.% to epoxy resin increased FRI value to 1.4. Concerning (n-S-MgOH), it was noted that 1 wt.% loading was not enough to enhance flame retardancy performance, while adding 10 wt.% increased FRI value to 1.7 [54].

It can also be observed that 13 wt.% DOPMP is in the excellent zone and that this is consistent with Figure 3a, which shows the addition of 13 wt.% DOPMP has the best fire safe rank. However, there are three more points in the excellent zone: these systems contain IFR-27-FeP-2 [53], APP_40 and APP-20_Onium ion modified nanoclay-3 [56].

Lei et al. [53] studied the flame retardancy performance of adding ferric phosphate (FeP) together with intumescent flame retardants (IFRs) composed of ammonium polyphosphate and pentaerythritol on epoxy resin. It was concluded that FeP has a synergetic effect with IFR. IFR mainly acts in the condensed phase by releasing phosphorus compounds that react with carbon source and forms a protective carbonaceous layer [19]. The addition of FeP accelerates the rate of formation of this carbonaceous layer [53] and this in return results in increasing FRI value from 6.67 for IFR with 30 wt.% loading to 11.2 for IFR incorporated with 2 wt.% FeP.

The best system that has the highest FRI value around 20 was for APP with 40 wt.% weight content. However, the high loading content of APP results in increasing resin viscosity causing difficulties during processing and deteriorates the mechanical properties. In the light of the disadvantages accompanied by adding high amount of FRs, Reija et al. [56] have investigated the effect of adding nano-clay together with ammonium polyphosphate (APP) on enhancing the flame retardancy of epoxy resin. In their study, they succeeded in enhancing the flame retardancy performance by adding just 3 wt.% of Onium ion modified nano-clay together with 20 wt.% APP. Additionally, it can be observed from Figure 3b that the mixture of nano-clay and 20 wt.% APP can reach the same FRI value of around 20 as APP with 40 wt.% loading. The enhancement of flame retardancy performance by adding nano-clay was attributed to the formation of a protective layer by the migrating of nano-clay towards the surface during combustion [33]. However, adding nano-clay alone is not sufficient to enhance flame retardancy as can be seen in Figure 3a. 3 wt.% Onium ion modified nano-clay is located to the right of pure epoxy resin, which means it goes far away from the origin. In addition, this system has reduced FRI value to 0.6.

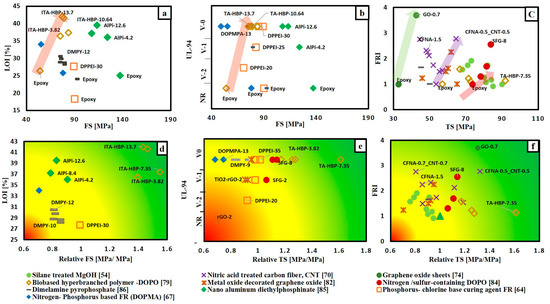

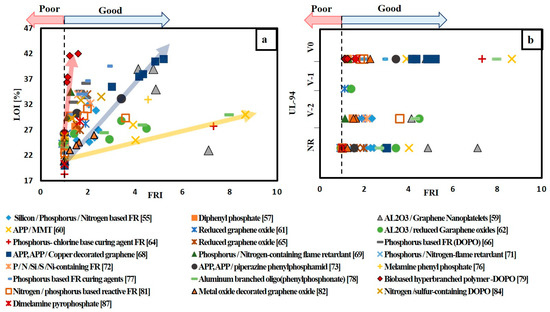

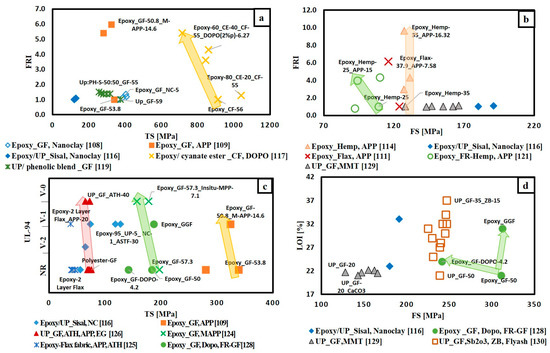

Based on the available data, different selection charts that relate flame retardancy performance with mechanical properties of FR/epoxy resin system are provided in Figure 4. Figure 4a,b relate UL-94 and LOI results with flexural strength, respectively, for different FR/epoxy resin systems. It can be noted that, although the addition of FRs of various FR/epoxy resin systems achieved V-0, the FS for these systems was reduced. However, the addition of biobased hyperbranched polymer containing DOPO (TA-HBP) [79] with different contents ranging from 3.8 to 13.7 wt.% shows enhancement in both flame retardancy performance and mechanical properties. This enhancement in both tensile and flexural strength was attributed to the partial engagement of the-NH-group (that is present in TA-HBP structure) with epoxy matrix during curing and that results in higher cross-linking density of epoxy resin. Thus, increasing crosslinks in epoxy matrix have enhanced the mechanical properties. Figure 4c shows that the addition of TA-HBP has increased FS, but FRI value is slightly above one. In addition, it can be noted that increasing wt.% content of nitrogen/sulphur-containing DOPO based oligomer (SFG) [84] from 2% to 8% has improved both flame retardancy performance and TS. The best condition was for SFG-8 that has reached V-0, FRI value of 2.55 and 13.7% increase in TS. Additionally, Figure 4a–c show that DPPEI-30 [64] which is a reactive curing agent has enhanced the flame retardancy performance in terms of LOI, UL-94 and FRI values without a significant change in both TS and FS. Moreover, Figure 4a–c show that DOPMA-13 [67] that has high FRI value around 11.76, LOI value of 34% and achieved V-0 in UL-94 test, has reduced both FS and TS by 29.4 and 25.6%, respectively.

Figure 4.

Selection chart of FR type regarding the desired flame retardance level and the mechanical property for epoxy resin. (a) LOI% versus FS; (b) UL-94 versus FS; (c) FRI versus TS; (d) LOI% versus relative FS; (e) UL-94 versus relative TS; (f) FRI versus relative TS.

Referring to Figure 4c, it can be depicted that the addition of graphene oxide (GO) [75] with 0.7 wt.% reached FRI value of 3.7 and increased TS by 23.9%. However, incorporating 2 wt.% of reduced graphene oxide achieved an FRI value of only 1.24 and TS was reduced by 29.6% [82]. Decorating reduced graphene oxide with Cu2O and adding 2 wt.% of this decorated GO to epoxy resin increased FRI value to 2.25 and slightly reduced the TS by 5% [82]. It can also be noted that the addition of 0.5 wt.% carbon fibre treated with nitric acid (CFNA) together with 0.5 wt.% carbon nanotube (CNT) has FRI value of 2.27 and increased TS by 20.5%. However, increasing the weight content of both CFNA and CNT to 1.5 wt.% kept the value of FRI around 2.77, but it reduced TS by 16.8%.

To summarize the previous discussion, the mechanical properties for each FR/polymer system were normalized and plotted versus the flame retardant properties to provide a simple chart that can evaluate the efficiency of different FR regardless the type of epoxy resin used. Therefore, relative tensile and flexural strength were calculated based on dividing the mechanical property of FR/polymer system by the mechanical property of neat polymer. The calculated value below one means that the mechanical strength has decreased.

The charts in Figure 4d–f were divided into three regions, according to the positions of points relative to the origin. The points in the red zone refer to low flame retardancy performance and low relative mechanical strength. Meanwhile, points located in the yellow zone represent good flame retardancy performance and relative mechanical strength below one. The best FR/polymer system goes to the points located in the green zone. The points in the green zone indicate that both the flame retardancy performance and relative strength are high. The points can be easily ranked relative to each other. It is observed that TA-HBP is in the green zone throughout Figure 4d–f. Moreover, Figure 4f shows that there are three more points in the green zone. These systems are SFG-8, GO-0.7, CF-0.5 (synergized with CNT-0.5) and DPPEI-30.

3.2. Unsaturated Polyester Containing Flame Retardants

According to the literature, various FRs have been used with unsaturated polyester resins. Table 5 summarizes PHRR, THR and TTI, FRI, LOI, UL-94, FS and TS results of various unsaturated polyester/FR systems.

Table 5.

Cone colorimetry data (TTI, PHRR, THR), calculated FRI value, LOI, UL-94, FS and TS for unsaturated polyester filled with a wide variety of FR. The designation in the second column refers to FR type followed by wt.% of filler.

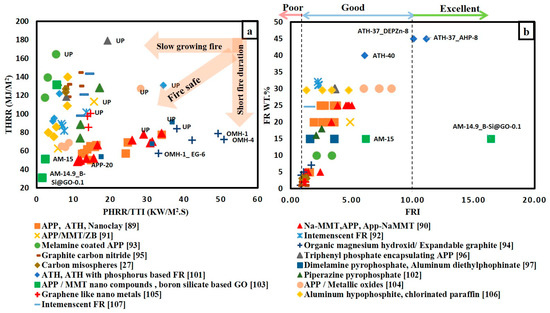

Comparing Table 5 with Table 4, it can be noted that various additive FRs have been used and there are no reactive FRs studied with unsaturated polyester. Some of the used flame retardants are more effective with epoxy resin than unsaturated polyester resin. For example, adding intumescent flame retardant (IFR) with 32 wt.% [92] to polyester has achieved FRI of value 2.3, while adding 30 wt.% IFR [53] to epoxy resin reached an FRI value of 6.69. Additionally, hybridizing IFR with montmorillonite reduced an FRI value of 4.48 for epoxy resin, while keeping an FRI value of 2.3 in the case of polyester resin. Moreover, hybridizing 20 wt.% APP with 3 wt.% nano-clay and adding it to epoxy resin [56] has achieved FRI value of 20.2, while adding 20 wt.% APP together with 5 wt.% Na modified nano-clay to unsaturated polyester resin [90] reached an FRI value of 5. However, hybridizing 14.9 wt.% APP with 0.1 wt.% boron silicate-based graphite oxide [104] raised the FRI value of unsaturated polyester resin to 16. Another example, the addition of 15 wt.% DMPY [98] to unsaturated polyester resin, has no rate in terms of UL-94 test. In contrast, adding 12 wt.% DMPY [87] to epoxy resin achieved V-0.

Figure 5a gives a bright view for the flame retardancy performance of various FR/unsaturated polyester system. Similar to Figure 4a, the addition of FRs reduced both the THR and PHRR/TTI ratio for polyester system. It was previously mentioned that FRI value is more representative in comparing the effect of different FRs on unsaturated polyester. Figure 5b illustrates the variation in FRI values for different FRs with different weight percentages. It is obvious that almost all points are in the good zone, except four points located in the poor zone and two points located in the excellent zone. The four points in the poor zone corresponded to organic magnesium hydroxide (OMH) with 1 and 4% loading content [95] and graphite carbon nitride (g-C3N4) [96] corresponded with loading content 1 and 2%. It can be concluded that low loading of inorganic compounds has an adverse effect on the flame retardancy performance. The best FR system goes to a mixture of 0.1 wt.% of boron silicate-based graphene oxide and 14.9 wt.% of APP/MMT nano-compound [104]. This system has achieved FRI value of 16.4. It is clearly noticed that hybridizing ammonium polyphosphate (APP) with low content of nano clay or carbon-based flame retardants as graphene oxide enhanced the flame retardancy of both epoxy and unsaturated polyester resins.

Figure 5.

(a) THRR versus PHRR/TTI for various FR/Unsaturated polyester resin; (b) flame retardancy index (FRI) for different FR/unsaturated polyester system with respect to weight content of FRs.

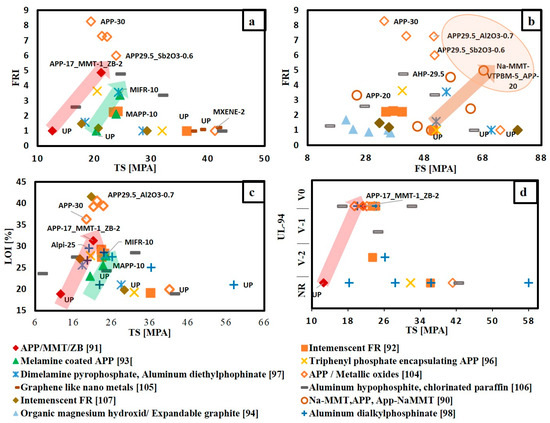

The material selection charts that correlate the flame retardancy performance with the mechanical properties for different FR/unsaturated polyester systems are shown in Figure 6 and Figure 7. The points are named according to the name of FR type and its content. These charts can be used as a simple tool to select the optimum FR that balances between flame retardancy performance and mechanical properties. Each flame retardant was evaluated according to its position relative to pure unsaturated polyester and relative to the other types of flame retardants.

Figure 6.

Selection chart of FR type regarding the desired flame retardance level and the mechanical property for unsaturated polyester resin. (a) FRI versus TS; (b) FRI versus FS; (c) LOI% versus TS; (d) UL-94 versus TS.

Figure 7.

Selection chart of FR type regarding the desired flame retardance level and the relative mechanical property for unsaturated polyester resin (a) FRI versus relative TS; (b) FRI versus relative FS; (c) LOI% versus relative TS; (d) UL-94 versus relative TS.

From Figure 6, it is obvious that the addition of various types of FRs has a negative effect on both tensile strength and flexural strength. However, as shown in Figure 6a,c,d, the addition of APP whether by hybridizing it with 2 wt.% zinc borate and 1 wt.% montmorillonite [91], or by coating it with melamine [93], enhanced both the flame retardancy and tensile strength. Moreover, Figure 6b shows that hybridizing 20 wt.% App with 5 wt.% organic modified montmorillonite [90] increased flexural strength and achieved an FRI value of 5. Figure 6a–c can be easily used to compare the effect of adding FRs on both mechanical and flame retardancy performance in terms of FRI, UL-94 and LOI with the non-flame retarded polymer.

Based on the charts in Figure 7, the points located in the green zone can be easily ranked relative to each other and the ranking can be as follows:

- APP 17 wt.% (synergized with nano-clay (1% MMT)-Mineral FR (2% ZB)) [91];

- APP 20 wt.% (synergized with organic modified nano-clay (5% MMT) [90];

- APP/MMT nano compounds 14.9 wt.% (synergized with 0.1% boron silicate-based GO) [103];

- Melamine coated APP 10 wt.% [93].

Moreover, it can also be observed throughout Figure 7a–c that the addition of APP alone at weight content of 30% [104] achieved an FRI value of 8 and LOI value of around 35. However, this high content of APP reduced both tensile and flexural strength by approximately 50%. Additionally, it can be noted that hybridizing APP with metal oxides at a low loading content of around 0.6% increased both tensile and flexural strength by 20%, compared with adding APP alone without influencing the flame retardancy performance. Figure 7c,d further show that increasing weight content of aluminium dialkylphosphinate (Alpi) from 5 to 25% can shift the Alpi/unsaturated polyester system from the red zone to the yellow zone, but this comes at the expense of the tensile strength. The unsaturated polyester has lost 70% of its tensile strength by the addition of 25 wt.% of Alpi [98].

Comparing Figure 7c with Figure 4d it can be observed that the addition of Alpi with 12.5 wt.% [85] reduced the flexural strength of epoxy resin by only 20%. Alternatively, the addition of just 5 wt.% Alpi to unsaturated polyester resin reduced the tensile strength by 40% and increasing the Alpi content to reach 15 wt.% reduced the tensile strength by 60%. Additionally, the incorporation of Alpi had a better effect on enhancing the flame retardancy performance of epoxy resin than unsaturated polyester resin. Adding 12.5 wt.% Alpi to epoxy resin has achieved LOI value of 39.5%, while the addition of 25 wt.% Alpi to unsaturated polyester has reached 29.5% in LOI test. The higher performance achieved by the addition of Alpi to epoxy resin can be attributed to using of nano sized Alpi [85]. It is worthy to note that the preparation of FR/polymer system may explain these different results. In Refs. [85,98], the authors mixed Alpi with epoxy and unsaturated polyester resins with a mechanical mixer followed by ultrasound sonication. However, the authors of [85] sonicated the mixture for 2 h at 30 °C, while the authors of [98] sonicated the FR/polymer mixture for 40 min. Increasing the time of sonication may result in better dispersion of FR particles, and consequently, better flame retardant and mechanical properties.

FRI can be used as a reliable measure in comparing the performance of different FR/polymer system. However, this is based on the data collected from cone calorimetry, which is an expensive test compared to UL-94 and LOI test. Therefore, correlating FRI with both UL-94 and LOI test results based on the data collected from the literature can guide researchers to select which FR/polymer system condition needs to be tested using a cone calorimeter. Figure 8 and Figure 9 illustrate the flame retardancy performance in terms of FRI versus UL-94 and FRI versus LOI for FR/epoxy resin and FR/unsaturated polyester resin systems, respectively. From Figure 8a and Figure 9a, it can be depicted that, whatever the FR/polymer system, there is a direct correlation between FRI and LOI values. This finding is in agreement with previous reviews [39,40,41]. However, in the case of UL-94 results, there is no specific correlation between FRI and UL-94 results, as it can be seen in Figure 8b and Figure 9b. Moreover, it can be noted that some systems did not pass UL-94 test but achieved FRI greater than 1.

Figure 8.

(a) FRI versus LOI for different FR/epoxy resin systems; (b) FRI versus UL-94 for different FR/epoxy resin systems.

Figure 9.

(a) FRI versus LOI for various FR/unsaturated polyester system; (b) FRI versus UL-94 for various FR/unsaturated polyester resin.

3.3. Fabric Composites Filled with FR Additives

Reviewing the effect of incorporating FRs into thermosetting composites is as important as reviewing the effect of FRs on the matrix only, since, for high performance applications carbon and glass fibre-fabric are commonly used as reinforcements for epoxy and unsaturated polyester resins. Moreover, as the awareness of environmental issues has increased, the number of studies investigating the possibility of replacing synthetic fibres with natural fibres in different applications have also increased. In this regard, this paper attempts to summarize and discuss the effect of adding FRs to fibre-fabric reinforced epoxy and unsaturated polyester composites.

Unfortunately, the number of research papers that studied the FR effects on thermosetting polymer composites is limited, especially for natural fibre reinforced thermosets. Table 6 gives the FR used with different fibre-fabric composites. The extracted cone calorimetry data, UL-94 and LOI results, as well as tensile and flexural strength results are also presented in Table 6. It can be noted that some composites provided in Table 6 are based on resin blends reinforced with different types of fibres. Blending of different types of resins is used as one of the techniques to reduce the flammability of polymeric materials.

Table 6.

Cone colorimetry data (TTI, PHRR, THR), Calculated FRI value, LOI, UL-94, FS and TS for Fabric composites filled with a wide variety of FRs. The designation in the second column refers to the type of matrix followed by fabric type and its wt.% content finally FR type and its wt.% content for example M_F-30_FR1-2_FR2-5 this means matrix M reinforced with 30 wt.% of Fabric F and incorporated by 2 wt.% of flame retardant type FR1 and 5 wt.% of flame retardant type FR2.

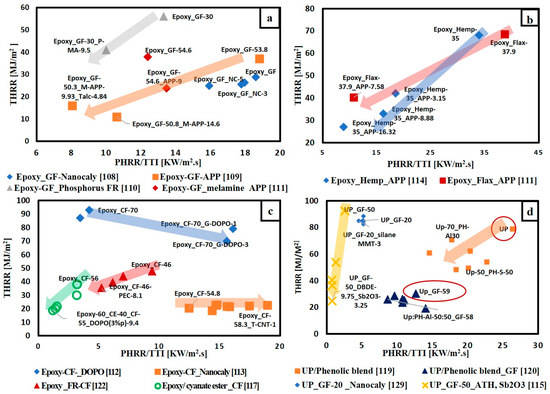

To give a bright view of FR effect on flame retardancy performance of thermosetting polymer composites, the extracted data are classified according to the type of matrix, whether epoxy resin or unsaturated polyester resin and according to the type of fibre-fabric reinforcement whether glass fibre, carbon fibre or natural fibre. Figure 10 illustrates the variation of THRR with respect to PHRR/TTI for different FRs added to glass fibre-fabric epoxy composites (Figure 10a), carbon fibre-fabric epoxy composites (Figure 10c), natural fibre-fabric epoxy composites (Figure 10b) and glass fibre-fabric unsaturated polyester composites (Figure 10d). It is observed that ammonium polyphosphate (APP) is the most used FR in all types of composites. The direction of arrows in Figure 10a,b,d reveals that the addition of flame retardants enhanced the flame retardancy performance of glass and natural fibres reinforced epoxy composites as well as glass fibre reinforced unsaturated polyester composites. However, Figure 10c shows that the arrows for both Epoxy_ CF-DOPO [112] and Epoxy-CF_ Nano clay [113] systems go towards the right side (away from the origin), while the other two systems (Epoxy-FR-CF [122] and Epoxy/Cyanate ester-CF [117]) arrows’ go towards the origin. This can be attributed to the different techniques and types of FRs used in enhancing the flame retardancy. In the articles [112,113], the authors mixed the FRs with epoxy resin first, then the mixture was added to the carbon fibre. Carbon-based materials in the form of graphene grafted by DOPO(G-DOPO) [112] and carbon nanotubes [113] were used as FRs. These carbon materials the reduced time to ignition of composites. The ignition properties of polymers are affected by absorption coefficient and thermal inertia, which is the product of thermal conductivity, density and specific heat capacity [131]. It is to be noted that thermal inertia and the absorption coefficient have a contradictory effect on TTI. Time to ignition can be delayed by increasing thermal inertia and decreasing the absorption coefficient [132]. The addition of carbon materials is supposed to increase both the thermal conductivity and absorption coefficient of the composites. Regarding the ignition time, the increase in absorption coefficient induced by carbon fillers is more significant than the increase in thermal conductivity [131]. Furthermore, it can be noted that in case of adding G-DOPO to carbon/epoxy composites there is a reduction in THRR and this is due the sheet structure of G-DOPO that restrains the escape of volatile gas. Consequently, the transfer of heat to the internal matrix was hindered [112].

Figure 10.

THRR versus PHRR/TTI for different composites (a) FR/epoxy reinforced glass fabric; (b) FR/epoxy reinforced natural fibre-fabrics; (c) FR/epoxy reinforced carbon fibre-fabrics; (d) FR/unsaturated polyester reinforced glass fibre-fabric.

On the other hand, Shi et al. [122] used another technique: instead of adding FRs to the matrix, they coated the carbon fabric with a bio-based polyelectrolyte complexes (PEC) composed of chitosan (CH) and ammonium polyphosphate (APP) that acts as a flame retardant material. This PEC coat decomposed at low temperature, producing phosphorus-rich condensed char and non-flammable gases that act as a shielding layer, hindering the transfer of heat and oxygen to the unburned material. Another well-known technique that can be used to reduce the flammability of polymeric materials is the blending of different types of resins. However, only very limited research [117,119,133] has used this method with polymer composites. Martins et al. [117] studied the effect of blending epoxy resin with different ratios of cyanate ester and the addition of DOPO to these blends on the flame retardancy of carbon fabric epoxy composites. They concluded that blending has a positive effect in enhancing the flame retardancy of the composites. This is attributed to the presence of the high content of triazine structure that is responsible for the high glass transition temperature of cyanate ester (Tg about 400 °C) [134]. Additionally, cyanate ester has a condensed cross-linked structure, and this leads to high charring during combustion [134]. Figure 10c shows that blending 40 wt.% cyanate ester with epoxy resin and adding 9.4 wt.% of DOPO to carbon fibre composites has the lowest PHRR/TTI and THRR. Another work conducted by Kandola et al. [119] also used the blending method in enhancing the flame retardancy of unsaturated polyester reinforced with glass fabric. In their study they blended unsaturated polyester with different grades of phenolic resin. Phenolic resins are known by their high fire resistance properties. However, their brittleness limits their use in structural applications. Therefore, blending can achieve a balance between FR and mechanical properties. Figure 10d illustrates that blending 50 wt.% of phenolic resin has the best FR properties.

According to the literature, some articles have studied the effect of adding FRs of the same type and weight content on both matrix resin alone and matrix reinforced fabric composites. Thus, it was interesting to compare the obtained results by plotting THRR versus PHRR/TTI for different FR/matrix and FR/composite systems. Two points can be observed from Figure 11: First, all composite systems, whatever the kind of fabric, whether synthetic fibre-fabric or natural fibre-fabric, have lower THRR and PHRR/TTI than the matrix. Reinforcing polymeric materials with synthetic fibres such as glass and carbon fibre helps in resisting fire, as fibres displace a certain weight fraction of polymer matrix results in reducing the flammable material content. Additionally, the fibres act as an insulating layer that slows down the heat penetration to the underneath composite material [135]. Furthermore, they act as a physical barrier to volatile gases [49]. Moreover, the high thermal stability of both glass and carbon fibres made them not directly contribute to increasing the heat released [51]. Consequently, the heat released per unit volume of the composite reduces with its increasing thickness [136,137]. Comparing the fire temperature range (500–1100 °C) with the softening temperature of glass fibre (about 850 °C), it can be noted that glass fibre has high fire resistance [137]. Thus, reinforcing polymeric materials with glass fibre has a significant effect on enhancing flame retardancy.

Figure 11.

THRR versus PHRR/TTI for FR/matrix and FR/composite.

Regarding natural fibres, their ability to char during combustion allows the formation of a charring layer that isolates the underlying polymer from the evolved heat [49]. The second point to be noted is that the addition of FRs has a more significant effect on enhancing the flame retardancy of non-reinforced polymers than composites. This behaviour was discussed by Todly et al. [138]; they suggested that the fabric reinforcements hinder the activity of the FRs of forming a well-developed charring layer.

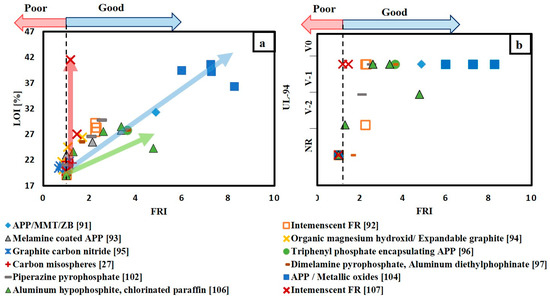

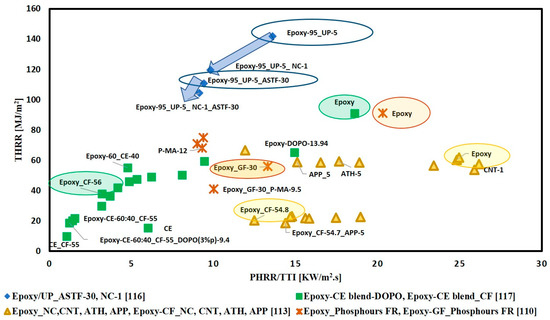

To compare the influence of adding FRs to fibre-fabric composites, regardless of the type of matrix resin or reinforcement, FRI versus FR wt.% was plotted for different FR/composite systems, as shown in Figure 12. It can be noted that almost all points are in the good zone, except that few points are located in the poor zone and one point is located in the excellent zone. The points that are located in the poor zone correspond to graphene grafted by DOPO(G-DOPO) [112] and carbon nanotubes [113] that are added to carbon fibre reinforced epoxy resin with a low loading content of below 5%. Alternatively, the point located in the excellent zone corresponds to bromine-based FR synergized with antimony trioxide that is added to glass fibre reinforced unsaturated polyester composite [115].

Figure 12.

Flame retardancy index (FRI) for different FR/composite systems with respect to weight content of FR.

Figure 13 and Figure 14 illustrate a number of material selection charts for different FR/composite systems. Figure 13a–d clearly shows that the addition of various FRs enhanced flame retardancy without a significant compromise in the mechanical properties. This indicates that the fibre-fabric reinforcement is the governing factor to determine the tensile and flexural strength of the composites. Figure 13d shows that flame retardancy performance (in terms of LOI) and mechanical properties (in terms of FS) for the glass fabric reinforced epoxy composite was enhanced by coating glass fabric with DOPO, instead of mixing FR with epoxy resin [128].

Figure 13.

Selection charts of FR type regarding the desired flame retardance level and the mechanical property for epoxy and unsaturated polyester composites (a) FRI versus TS; (b) FRI versus FS; (c) UL-94 versus TS; (d) LOI versus FS.

Figure 14.

Selection charts of FR type regarding the desired flame retardance level and the mechanical property for epoxy and unsaturated polyester composites (a) FRI versus relative TS; (b) FRI versus relative FS; (c) UL-94 versus relative TS; (d) LOI versus relative FS.

4. Conclusions and Future Perspectives

A survey of different FRs used with epoxy, unsaturated polyester and their composites was carried out. The effect of FRs on both flame retardancy performance and mechanical properties were considered. The universal flame retardancy index (FRI) was calculated based on the data extracted from the cone calorimetry test and this index was used to evaluate the efficiency of flame retardant performance. The main outcome of this paper is the construction of different material selection charts that combine the effect of certain FR on the flame retardancy performance in terms of FRI, LOI or UL-94, as well as mechanical properties in terms of TS, FS, relative TS and relative FS. These charts facilitate the ranking of different FRs and help in selecting the optimum systems that balance between both flame retardant and mechanical properties. Herein, the key findings of this review paper include the following:

- Phosphorus-based FRs proved their capability to enhance the flame retardancy of both epoxy and unsaturated polyester even at low loading below 10 wt.%. APP is the most effective phosphorus-based FR used. However, in order to achieve high FRI, APP should be loaded within the range 15–40 wt.% and this comes on the expense of mechanical properties. Therefore, synergizing APP with other additives or decorating APP with other FR compounds can reduce the required content of APP.

- Synergizing 20 wt.% APP with 3 wt.% of nano-clay achieved an FRI value of 20, which is the same value of loading 40 wt.% APP to epoxy resin. In addition, hybridizing 14.9% nano APP/MMT compound with 0.1 wt.% boron silicate graphene oxide achieved an FRI value of 16 for unsaturated polyester resin. Generally, the combination of different FRs is a good strategy to enhance flame retardant properties.

- Carbon-based fillers succeeded in acting as an FR at low loading percentage varied from 0.5 to 2 wt.%. However, they can just achieve FRI values between 1 and 2.5. The maximum attained FRI value of 3.7 was for the addition of 0.7 wt.% graphene oxide to epoxy. In addition to the flame retardant effect of carbon-based fillers, they can act as reinforcements. The addition of GO and carbon nanotubes to epoxy resin enhanced both FRI and tensile strength for epoxy resin.

- It can be concluded from the constructed selection charts that the mechanical properties are significantly affected by the type of FR used and its loading content. Generally, the addition of FRs reduced the mechanical properties. However, some systems enhanced both the flame retardancy performance and mechanical properties. With respect to the unsaturated polyester resin, hybridizing 20 wt.% APP with 5 wt.% nano-clay reached an FRI value of 5 and increased flexural strength by 40%. In addition, hybridizing 17 wt.% APP with 1 wt.% MMT and 2 wt.% zinc borates achieved V-0 in UL-94, an FRI value of 5 and increased tensile strength by 70%. On the other hand, increasing the APP content to 30 wt.% reduced both TS and FS by 50%. Regarding epoxy resin, the systems that enhanced both mechanical and flame retardant properties correspond to 0.7 wt.% GO (FRI value of 3.7 and relative TS value of 1.35), 8 wt.% nitrogen/sulphur-containing DOPO (FRI value of 2.5 and relative TS value of 1.2) and 7.35 wt.% biobased hyperbranched polymer-DOPO (FRI value of 1.2 and relative TS value 1.6)

- Reinforcing both epoxy and unsaturated polyester resins with carbon and glass fibre-fabric reduced the flammability behaviour of pristine resin. However, the addition of FRs to composite materials is not as effective as incorporating them with pure polymer. The presence of inert fabrics hinders the activity of FRs of forming a well-developed charring layer. The blending of different resins and coating of fabrics with FRs, instead of mixing them with the matrix, is a solution to enhance the flame retardant properties of the composites. The blending of epoxy resin with cyanate ester enhanced the flame retardancy performance of carbon fibre-fabric composites. Furthermore, the blending of unsaturated polyester with phenolic resin enhanced the flame retardancy performance of glass fibre-fabric composites.

- From the reviewed literature, it can be noted that there has not been enough research performed on studying the effect of FRs on flame retardant properties, as well as mechanical properties of epoxy resin, unsaturated polyester resin and their composites. Moreover, only very few articles have studied the effect of FRs on other properties, such as thermal conductivity, optical, sound absorption and rheological properties such as viscosity and curing behaviour. Studying the effect of FRs on different properties other than flame retardancy is necessary in order to meet the end needs of the final product. In addition, properties such as viscosity and the curing behaviour of polymers can guide the manufacturer to select the appropriate processing technique.

- It is recommended that future research focuses on the following points:

- Studying the effect of FRs on other properties, besides flame retardancy, such as mechanical, physical, optical and thermal conductivity.

- The idea of material selection chart should be extended to correlate properties (such as physical, optical and sound absorption), other than mechanical with flame retardant properties for different types of polymers and polymer composites. These charts will provide a quick selection tool for the production sector to select the needed FR/polymer materials that can meet the end needs of the final product.

- Combining data from future studies together with the data collected in this review and other reviews [39,40,41] will provide a large database and open the avenue to develop numerical models that can evaluate different aspects of flame-retarded polymers.

- From the environmental perspective, research should concentrate on using biobased FRs to overcome the negative impacts of FRs on human health and the environment. Moreover, use of the life cycle assessment (LCA) tool should be considered to study the impact of flame retardant polymeric products on the environment.

Author Contributions

Conceptualization, N.R., M.T. and A.E.; methodology, N.R.; validation, N.R. and A.E.; formal analysis, N.R., A.D.L.R. and A.E.; resources, N.R., A.D.L.R. and A.E.; writing—original draft preparation, N.R.; writing, review and editing, A.D.L.R. and A.E.; visualization, M.T. and A.E. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, [A.E.], upon reasonable request.

Acknowledgments

Thanks are due to the whole supervising team for the continuous plenary discussions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Glodek, T.E.; Boyd, S.E.; Mcaninch, I.M.; Lascala, J.J. Properties and Performance of Fire Resistant Eco-Composites Using Polyhedral Oligomeric Silsesquioxane (POSS) Fire Retardants. Compos. Sci. Technol. 2008, 68, 2994–3001. [Google Scholar] [CrossRef]

- Shan, G.; Jin, W.; Chen, H.; Zhao, M.; Surampalli, R.; Ramakrishnan, A.; Zhang, T.; Tyagi, R.D. Flame-Retardant Polymer Nanocomposites and Their Heat-Release Rates. J. Hazard. Toxic Radioact. Waste 2015, 19, 04015006. [Google Scholar] [CrossRef]

- Morgan, A.B. The Future of Flame Retardant Polymers—Unmet Needs and Likely New Approaches. Polym. Rev. 2019, 59, 25–54. [Google Scholar] [CrossRef]

- Morgan, A.B.; Gilman, J.W. An Overview of Flame Retardancy of Polymeric Materials: Application, Technology, and Future Directions. Fire Mater. 2013, 37, 259–279. [Google Scholar] [CrossRef]

- Velencoso, M.M.; Battig, A.; Markwart, J.C.; Schartel, B.; Wurm, F.R. Molecular Firefighting—How Modern Phosphorus Chemistry Can Help Solve the Challenge of Flame Retardancy. Angew. Chem. Int. Ed. 2018, 57, 10450–10467. [Google Scholar] [CrossRef] [PubMed]

- Grand, A.F.; Wilkie, C.A. Fire Retardancy of Polymeric Materials; CRC Press: Boca Raton, FL, USA, 2000; ISBN 0-8247-8879-6. [Google Scholar]

- Ebewele, R.O. Polymer Science and Technology, 1st ed.; CRC Press: Boca Raton, FL, USA, 2000; ISBN 0-0849-8939-9. [Google Scholar]

- Rivero, P.J.; Urrutia, A.; Goicoechea, J.; Arregui, F.J. Nanomaterials for Functional Functional Textiles and Fibers. Nanoscale Res. Lett. 2015, 10, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Uddin, F. Flame-Retardant Fibrous Materials in an Aircraft. J. Ind. Text. 2016, 45, 1128–1169. [Google Scholar] [CrossRef]

- Masuelli, M.A. Fiber Reinforced Polymers—The Technology Applied for Concrete Repair; InTech: Rijeka, Croatia, 2013; ISBN 978-953-51-0938-9. [Google Scholar]

- Smits, J. Fiber-Reinforced Polymer Bridge Design in the Netherlands: Architectural Challenges toward Innovative, Sustainable, and Durable Bridges. Engineering 2016, 2, 518–527. [Google Scholar] [CrossRef]

- Karbhari, V.M. Rehabilitation of Mettalic Civil Infrastructure Using Fiber-Reinforced Polymer (FRP) Composites; Woodhead Publishing: Cambridge, UK, 2014; ISBN 978-0-85709-665-4. [Google Scholar]

- Charles, A.; Wilkie, A.B.M. Fire Retardancy of Polymeric Materials, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2000; ISBN 978-1-4200-8399-6. [Google Scholar]

- Guo, W.; Zhao, Y.; Wang, X.; Cai, W.; Wang, J.; Song, L.; Hu, Y. Multifunctional Epoxy Composites with Highly Flame Retardant and Effective Electromagnetic Interference Shielding Performances. Compos. Part B Eng. 2020, 192, 107990. [Google Scholar] [CrossRef]

- Robinson, P.; Greenhalgh, E.; Pinho, S. Failure Mechanisms in Polymer Matrix Composites Criteria, Testing and Industrial Applications; Woodhead Publishing Limited: Cambridge, UK, 2012; ISBN 978-0-85709-532-9. [Google Scholar]

- Liu, Q.; Wang, D.; Li, Z.; Li, Z.; Peng, X.; Liu, C. Recent Developments in the Flame-Retardant System of Epoxy Resin. Materials 2020, 13, 2145. [Google Scholar] [CrossRef]

- Chan, K.; Quang, D.; Demir, B.; Yang, D.; Mayes, E.L.H.; Mouritz, A.P.; Ang, A.S.M.; Fox, B.; Lin, H.; Jia, B.; et al. Graphene Oxide Thin Film Structural Dielectric Capacitors for Aviation Static Electricity Harvesting and Storage. Compos. Part B 2020, 201, 108375. [Google Scholar] [CrossRef]

- Holder, K.M.; Smith, R.J.; Grunlan, J.C. A Review of Flame Retardant Nanocoatings Prepared Using Layer-by-Layer Assembly of Polyelectrolytes. J. Mater. Sci. 2017, 52, 12923–12959. [Google Scholar] [CrossRef]

- Lazar, S.T.; Kolibaba, T.J.; Grunlan, J.C. Flame-Retardant Surface Treatments. Nat. Rev. Mater. 2020, 5, 259–275. [Google Scholar] [CrossRef]

- Zhang, H. Fire-Safe Polymers and Polymer Composites; Report No. DOT/FAA/AR-04/11; US Department of Transport: Washington, DC, USA, 2004.

- Wang, D.-Y. Novel Fire Retardant Polymers and Composite Materials; Woodhead Publishing: Duxford, UK, 2017; ISBN 978-0-08-100163-9. [Google Scholar]

- Davis, R.; Zammarano, M.; Marsh, N.; Donnelly, P.; Mcqueen, S.; Raghunathan, A. Workshop Report: Research Roadmap for Reducing the Fire Hazard of Materials in the Future; NIST: Gaithersburg, MD, USA, 2018. [Google Scholar] [CrossRef]

- Ahmed, L.; Zhang, B.; Hatanaka, L.C.; Mannan, M.S. Application of Polymer Nanocomposites in the Flame Retardancy Study. J. Loss Prev. Process Ind. 2018, 55, 381–391. [Google Scholar] [CrossRef]

- Troitzsch, J. Plastics Flammability Handbook, 3rd ed.; Hanser Publishers: Munich, Germany, 2004; ISBN 978-3-446-21308-1. [Google Scholar]

- Saba, N.; Jawaid, M.; Paridah, M.T.; Al-othman, O.Y. A Review on Flammability of Epoxy Polymer, Cellulosic and Non-Cellulosic Fiber Reinforced Epoxy Composites. Polym. Adv. Technol. 2016, 27, 577–590. [Google Scholar] [CrossRef]

- Kim, N.K.; Dutta, S.; Bhattacharyya, D. A Review of Flammability of Natural Fibre Reinforced Polymeric Composites. Compos. Sci. Technol. 2018, 162, 64–78. [Google Scholar] [CrossRef]

- Chen, Z.; Yu, Y.; Zhang, Q.; Chen, Z.; Chen, T.; Jiang, J. Preparation of Phosphorylated Chitosan-Coated Carbon Microspheres as Flame Retardant and Its Application in Unsaturated Polyester Resin. Polym. Adv. Technol. 2019, 30, 1933–1942. [Google Scholar] [CrossRef]

- Özmen, F.K.; Üreyen, M.E.; Koparal, A.S. Cleaner Production of Flame-Retardant-Glass Reinforced Epoxy Resin Composite for Aviation and Reducing Smoke Toxicity. J. Clean. Prod. 2020, 276, 124065. [Google Scholar] [CrossRef]

- Pereira, C.M.C. Flame Retardancy of Thermoset Polymers Based on Nanoparticles and Carbon Nanotubes. Solid State Phenom. 2009, 151, 79–87. [Google Scholar] [CrossRef]

- Bar, M.; Alagirusamy, R.; Das, A. Flame Retardant Polymer Composites. Fibers Polym. 2015, 16, 705–717. [Google Scholar] [CrossRef]

- Ur, A.; Shah, R.; Prabhakar, M.N.; Song, J. Current Advances in the Fire Retardancy of Natural Fiber and Bio-Based Composites—A Review. Int. J. Precis. Eng. Manuf. Technol. 2017, 4, 247–262. [Google Scholar] [CrossRef]

- Rakotomalala, M.; Wagner, S.; Dö, M. Recent Developments in Halogen Free Flame Retardants for Epoxy Resins for Electrical and Electronic Applications. Materials 2010, 3, 4300–4327. [Google Scholar] [CrossRef] [PubMed]

- Laoutid, F.; Bonnaud, L.; Alexandre, M.; Lopez-cuesta, J.; Dubois, P. New Prospects in Flame Retardant Polymer Materials: From Fundamentals to Nanocomposites. Mater. Sci. Eng. R 2009, 63, 100–125. [Google Scholar] [CrossRef]

- Wang, X.; Naderi, E.; Wan, J.; Wang, D. Carbon-Family Materials for Flame Retardant Polymeric Materials. Prog. Polym. Sci. 2017, 69, 22–46. [Google Scholar] [CrossRef]

- Nikolaeva, M.; Kärki, T. A Review of Fire Retardant Processes and Chemistry, with Discussion of the Case of Wood-Plastic Composites. Balitic For 2011, 17, 314–326. [Google Scholar]

- Salmeia, K.A.; Gaan, S.; Malucelli, G. Recent Advances for Flame Retardancy of Textiles Based on Phosphorus Chemistry. Polymers 2016, 8, 319. [Google Scholar] [CrossRef]

- Sag, J.; Goedderz, D.; Kukla, P.; Greiner, L.; Schönberger, F.; Döring, M. Phosphorus-Containing Flame Retardants from Biobased Chemicals and Their Application in Polyesters and Epoxy Resins. Molecules 2019, 24, 3746. [Google Scholar] [CrossRef]

- Wang, X.; Guo, W.; Cai, W.; Wang, J.; Song, L.; Hu, Y. Recent Advances in Construction of Hybrid Nano-Structures for Flame Retardant Polymers Application. Appl. Mater. Today 2020, 20, 100762. [Google Scholar] [CrossRef]

- Vahabi, H.; Kandola, B.K.; Saeb, M.R. Flame Retardancy Index for Thermoplastic Composites. Polymers 2019, 11, 407. [Google Scholar] [CrossRef] [PubMed]

- Movahedifar, E.; Vahabi, H.; Saeb, M.R.; Thomas, S. Flame Retardant Epoxy Composites on the Road of Innovation: An Analysis with Flame Retardancy. Molecules 2019, 24, 3964. [Google Scholar] [CrossRef]

- Seidi, F.; Movahedifar, E.; Naderi, G.; Akbari, V.; Ducos, F. Flame Retardant Polypropylenes: A Review. Polymers 2020, 12, 1701. [Google Scholar] [CrossRef]

- Elsabbagh, A.; Attia, T.; Ramzy, A.; Steuernagel, L.; Ziegmann, G. Towards Selection Chart of Flame Retardants for Natural Fibre Reinforced Polypropylene Composites. Compos. Part B 2018, 141, 1–8. [Google Scholar] [CrossRef]

- Chai, M. Flammability Performance of Bio-Derived Composite Materials for Aircraft Interiors. Ph.D. Thesis, The University of Auckland, Auckland, New Zealand, 2014. [Google Scholar]

- Mngomezulu, M.E.; John, M.J.; Jacobs, V.; Luyt, A.S. Review on Flammability of Biofibres and Biocomposites. Carbohydr. Polym. 2014, 111, 149–182. [Google Scholar] [CrossRef] [PubMed]

- Babu, K.; Rendén, G.; Mensah, R.A.; Kim, N.K.; Jiang, L.; Xu, Q.; Restás, Á.; Neisiany, R.E.; Hedenqvist, M.S.; Försth, M.; et al. A Review on the Flammability Properties of Carbon-Based Polymeric Composites: State-of-the-Art and Future Trends. Polymers 2020, 12, 1518. [Google Scholar] [CrossRef] [PubMed]

- Sonnier, R.; Taguet, A.; Ferry, L.; Lopez-Cuesta, J.M. Towards Bio-Based Flame Retardant Polymers; Springer International Publishing: New York, NY, USA, 2018; ISBN 978-3-319-67082-9. [Google Scholar]

- Zhang, S.; Horrocks, A.R. A Review of Flame Retardant Polypropylene Fibres. Prog. Polym. Sci. 2003, 28, 1517–1538. [Google Scholar] [CrossRef]

- Kilinc, F.S. Handbook of Fire Resistant Textiles; Woodhead Publishing Limited: Philadelphia, PA, USA, 2013; ISBN 978-0-85709-123-9. [Google Scholar]

- Sienkiewicz, A.; Czub, P. Flame Retardancy of Biobased Composites—Research Development. Materials 2020, 13, 5253. [Google Scholar] [CrossRef]

- Yasin, S.; Behary, N.; Curti, M.; Rovero, G. Global Consumption of Flame Retardants and Related Environmental Concerns: A Study on Possible Mechanical Recycling of Flame Retardant Textiles. Fibers 2016, 4, 16. [Google Scholar] [CrossRef]

- Sohail, Y.; Parag, B.; Nemeshwaree, B.; Giorgio, R. Optimizing Organophosphorus Fire Resistant Finish for Cotton Fabric Using Box-Behnken Design. Int. J. Environ. Res. 2016, 10, 313–320. [Google Scholar] [CrossRef]

- Manfredi, L.B.; Rodrı, E.S. Thermal Degradation and Fire Resistance of Unsaturated Polyester, Modified Acrylic Resins and Their Composites with Natural Fibres. Polym. Degrad. Stab. 2006, 91, 255–261. [Google Scholar] [CrossRef]

- Liu, L.; Chen, X.; Jiao, C. Influence of Ferric Phosphate on Smoke Suppression Properties and Combustion Behavior of Intumescent Flame Retardant Epoxy Composites. Iran. Polym. J. 2015, 24, 337–347. [Google Scholar] [CrossRef]

- Chen, X.; Liu, L.; Zhuo, J.; Jiao, C. Influence of Organic-Modified Iron–Montmorillonite on Smoke-Suppression Properties and Combustion Behavior of Intumescent Flame-Retardant Epoxy Composites. High Perform. Polym. 2015, 27, 233–246. [Google Scholar] [CrossRef]

- Zhang, W.; He, X.; Song, T.; Jiao, Q.; Yang, R. The Influence of the Phosphorus-Based Flame Retardant on the Flame Retardancy of the Epoxy Resins. Polym. Degrad. Stab. 2014, 109, 209–217. [Google Scholar] [CrossRef]

- Suihkonen, R.; Nevalainen, K.; Vuorinen, J. The Effect of Ammonium Polyphosphate and Nanoclay on the Rheological, Thermal, and Flame Retardant Properties of Epoxy. Annu. Trans. Nord. Rheol. Soc. 2009, 17, 263–268. [Google Scholar]

- Zhao, W.; Liu, J.; Zhang, Y.; Ban, D. Simple Green Synthesis of Solid Polymeric Bisphenol A Bis(Diphenyl Phosphate) and Its Flame Retardancy in Epoxy Resins. R. Soc. Chem. Adv. 2015, 5, 80415–80423. [Google Scholar] [CrossRef]

- Suihkonen, R.; Nevalainen, K. Performance of Epoxy Filled with Nano- and Micro-Sized Magnesium Hydroxide. J. Mater. Sci. 2012, 47, 1480–1488. [Google Scholar] [CrossRef]

- Guan, F.; Gui, C.; Zhang, H.; Jiang, Z.; Jiang, Y.; Yu, Z. Enhanced Thermal Conductivity and Satisfactory Flame Retardancy of Epoxy Alumina Composites by Combination with Graphene Nanoplatelets and Magnesium Hydroxide. Compos. Part B 2016, 98, 134–140. [Google Scholar] [CrossRef]

- He, X.; Zhang, W.; Yi, D. Flame Retardancy of Ammonium Polyphosphate–Montmorillonite Nanocompounds on Epoxy Resin. J. Fire Sci. 2016, 34, 212–225. [Google Scholar] [CrossRef]

- Feng, Y.; He, C.; Wen, Y.; Ye, Y.; Zhou, X.; Xie, X. Improving Thermal and Flame Retardant Properties of Epoxy Resin by Functionalized Graphene Containing Phosphorous, Nitrogen and Silicon Elements. Compos. Part A 2017, 103, 74–83. [Google Scholar] [CrossRef]

- Feng, Y.; Hu, J.; Xue, Y.; He, C.; Zhou, X.; Xie, X.; Ye, Y.; Mai, Y. Simultaneous Improvement in the Flame Resistance and Thermal Conductivity of Epoxy/Al2O3 Composites by Incorporating Polymeric Flame Retardant-Functionalized Graphene. J. Mater. Chem. A 2017, 5, 13544–13556. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, D. The Influence of Mesoporous Silica Modified with Phosphorus and Nitrogen—Containing Hyperbranched Molecules on Thermal Stability, Combustion Behavior, and Toxic Volatiles of Epoxy Resin. Polym. Adv. Technol. 2017, 29, 372–383. [Google Scholar] [CrossRef]

- Shao, Z.; Zhang, M.; Li, Y.; Han, Y.; Ren, L.; Deng, C. A Novel Multi-Functional Polymeric Curing Agent: Synthesis, Characterization, and Its Epoxy Resin with Simultaneous Excellent Fl Ame Retardance and Transparency. Chem. Eng. J. 2018, 345, 471–482. [Google Scholar] [CrossRef]

- Guo, W.; Wang, X. Polyaniline-Coupled Graphene/Nickel Hydroxide Nanohybrids as Flame Retardant and Smoke Suppressant for Epoxy Composites. Polym. Adv. Technol. 2019, 30, 1959–1967. [Google Scholar] [CrossRef]

- Yang, S.; Hu, Y.; Zhang, Q. Synthesis of a Phosphorus–Nitrogen-Containing Flame Retardant and Its Application in Epoxy Resin. High Perform. Polym. 2018, 32, 186–196. [Google Scholar] [CrossRef]

- Chen, R.; Hu, K.; Tang, H.; Wang, J.; Zhu, F.; Zhou, H. A Novel Flame Retardant Derived from DOPO and Piperazine and Its Application in Epoxy Resin: Flame Retardance, Thermal Stability and Pyrolysis Behavior. Polym. Degrad. Stab. 2019, 166, 334–343. [Google Scholar] [CrossRef]

- Ye, T.; Liao, S.; Zhang, Y.; Chen, M.; Xiao, Y.; Liu, X. Cu(0) and Cu(II) Decorated Graphene Hybrid on Improving Fireproof Efficiency of Intumescent Flame-Retardant Epoxy Resins. Compos. Part B 2019, 175, 107189. [Google Scholar] [CrossRef]

- Hu, X.; Yang, H.; Jiang, Y.; He, H.; Liu, H.; Huang, H. Facile Synthesis of a Novel Transparent Hyperbranched Phosphorous/Nitrogen-Containing Flame Retardant and Its Application in Reducing the Fire Hazard of Epoxy Resin. J. Hazard. Mater. 2019, 379, 120793. [Google Scholar] [CrossRef]

- Chai, G.; Zhu, G.; Gao, Y.; Zhou, J.; Gao, S. Flame Retardancy of Carbon Nanotubes Reinforced Carbon Fiber/Epoxy Resin Composites. Appl. Sci. 2019, 9, 3275. [Google Scholar] [CrossRef]

- Wang, P.; Chen, L.; Xiao, H. Flame Retardant Effect and Mechanism of a Novel DOPO Based Tetrazole Derivative on Epoxy Resin. J. Anal. Appl. Pyrolysis 2019, 139, 104–113. [Google Scholar] [CrossRef]

- Zhao, B.; Liu, P.; Xiong, K.; Liu, H.; Zhao, P.; Liu, Y. Impacts of Multi-Element Flame Retardants on Flame Retardancy, Thermal Stability, and Pyrolysis Behavior of Epoxy Resin. Polym. Degrad. Stab. 2019, 167, 217–227. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, L.; Dong, L. Influence of a Novel P/N-Containing Oligomer on Flame Retardancy and Thermal Degradation of Intumescent Flame-Retardant Epoxy Resin. Polym. Degrad. Stab. 2019, 162, 129–137. [Google Scholar] [CrossRef]

- Ezeh, E.M.; Onukwuli, O.D.; Odera, R.S. Novel Flame-Retarded Polyester Composites Using Cow Horn Ash Particles. Int. J. Adv. Manuf. Technol. 2019, 103, 1701–1707. [Google Scholar] [CrossRef]

- Qu, L.; Sui, Y.; Zhang, C.; Li, P.; Dai, X.; Xu, B. POSS-Functionalized Graphene Oxide Hybrids with Improved Dispersive and Smoke-Suppressive Properties for Epoxy Flame-Retardant Application. Eur. Polym. J. 2019, 122, 109383. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, L.; Lin, X.; Dong, L. Synthesis of a Novel Phosphorus-Nitrogen Phosphorus-Nitrogen Flame Retardant and Its Application in Epoxy Resin. Polym. Degrad. Stab. 2019, 169, 108981. [Google Scholar] [CrossRef]

- Huo, S.; Liu, Z.; Li, C.; Wang, X.; Cai, H.; Wang, J. Synthesis of a Phosphaphenanthrene/Benzimidazole-Based Curing Agent and Its Application in Flame-Retardant Epoxy Resin. Polym. Degrad. Stab. 2019, 163, 100–109. [Google Scholar] [CrossRef]

- Yuan, Y.; Shi, Y.; Yu, B.; Zhan, J.; Zhang, Y.; Song, L.; Ma, C.; Hu, Y. Facile Synthesis of Aluminum Branched Oligo (Phenylphosphonate) Submicro- Particles with Enhanced Flame Retardance and Smoke Toxicity Suppression for Epoxy Resin Composites. J. Hazard. Mater. 2020, 381, 121233. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Mi, X.; Chen, S.; Xu, Z.; Zhang, D.; Miao, M.; Wang, J. A Bio-Based Hyperbranched Flame Retardant for Epoxy Resins. Chem. Eng. J. 2020, 381, 122719. [Google Scholar] [CrossRef]

- Fang, F.; Huo, S.; Shen, H.; Ran, S.; Wang, H.; Song, P. A Bio-Based Ionic Complex with Different Oxidation States of Phosphorus for Reducing Flammability and Smoke Release of Epoxy Resins. Compos. Commun. 2020, 17, 104–108. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, J.; Yang, S.; Zhang, Q.; Hu, Y.; Ding, G. Aminobenzothiazole-Substituted Cyclotriphosphazene Derivative as Reactive Flame Retardant for Epoxy Resin. React. Funct. Polym. 2020, 146, 104412. [Google Scholar] [CrossRef]

- Kalali, E.N.; Guo, W.; Wang, X.; Xing, W.; Song, L.; Hu, Y. Effect of Metal-Based Nanoparticles Decorated Graphene Hybrids on Flammability of Epoxy Nanocomposites. Compos. Part A 2020, 129, 105694. [Google Scholar] [CrossRef]

- Feng, Y.; Han, G.; Wang, B.; Zhou, X.; Ma, J.; Ye, Y. Multiple Synergistic Effects of Graphene-Based Hybrid and Hexagonal Born Nitride in Enhancing Thermal Conductivity and Flame Retardancy of Epoxy. Chem. Eng. J. 2020, 379, 122402. [Google Scholar] [CrossRef]

- Wang, P.; Chen, L.; Xiao, H.; Zhan, T. Nitrogen/Sulfur-Containing DOPO Based Oligomer for Highly Efficient Flame-Retardant Epoxy Resin. Polym. Degrad. Stab. 2020, 171, 109023. [Google Scholar] [CrossRef]

- Gu, L.; Qiu, J.; Sakai, E. Thermal Stability and Fire Behavior of Aluminum Diethylphosphinate-Epoxy Resin Nanocomposites. J. Mater. Sci. Mater. Electron. 2017, 28, 18–27. [Google Scholar] [CrossRef]

- Liu, L.; Xu, Y.; Xu, M.; Li, Z.; Hu, Y.; Li, B. Economical and Facile Synthesis of a Highly Efficient Flame Retardant for Simultaneous Improvement of Fire Retardancy, Smoke Suppression and Moisture Resistance of Epoxy Resins. Compos. Part B 2019, 167, 422–433. [Google Scholar] [CrossRef]

- Sudhakara, P.; Kannan, P.; Obireddy, K.; Varada Rajulu, A. Organophosphorus and DGEBA Resins Containing Clay Nanocomposites: Flame Retardant, Thermal, and Mechanical Properties. J. Mater. Sci. 2011, 46, 2778–2788. [Google Scholar] [CrossRef]

- Zhan, Z.; Zhang, Y.; Zhang, Y. Improving the Flame Retardancy and Electrical Conductivity of Epoxy Resin Composites by Multifunctional Phosphorus-Containing Polyaniline. Mater. Lett. 2020, 261, 127092. [Google Scholar] [CrossRef]

- Kandola, B.K.; Horrocks, A.R.; Nazare, S. Flame-Retardant Unsaturated Polyester Resin Incorporating Nanoclays. Polym. Adv. Technol. 2006, 17, 294–303. [Google Scholar] [CrossRef]

- Kandola, B.K.; Nazaré, S.; Horrocks, A.R.; Myler, P. Effect of Layered Silicate Nanocomposites on Burning Behavior of Conventionally Flame- Retarded Unsaturated Polyesters. In Fire and Polymers IV; Charles, A., Wilkie, G.L.N., Eds.; American Chemical Society: Washington, DC, USA, 2005; pp. 155–171. [Google Scholar] [CrossRef]

- Jiang, M.; Zhang, Y.; Yu, Y.; Zhang, Q.; Huang, B.; Chen, Z.; Chen, T.; Jiang, J. Flame Retardancy of Unsaturated Polyester Composites with Modified Ammonium Polyphosphate, Montmorillonite, and Zinc Borate. J. Appl. Polym. Sci. 2019, 136, 47180. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, Q.; Yu, Y.; Chen, T.; Jiang, J. Modified Montmorillonite Combined with Intumescent Flame Retardants on the Flame Retardancy and Thermal Stability Properties of Unsaturated Polyester Resins. Polym. Adv. Technol. 2019, 30, 998–1009. [Google Scholar] [CrossRef]

- Gao, M.; Wang, Y.; Chen, X.; Wang, H. A Mussel-Inspired Intumescent Flame-Retardant Unsaturated Polyester Resin System. J. Therm. Anal. Calorim. 2019, 138, 1097–1106. [Google Scholar] [CrossRef]

- He, J.; Zeng, W.; Shi, M.; Lv, X.; Fan, H.; Lei, Z. Influence of Expandable Graphite on Flame Retardancy and Thermal Stability Property of Unsaturated Polyester Resins/Organic Magnesium Hydroxide Composites. J. Appl. Polym. Sci. 2020, 137, 47881. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, T.; Yu, Y.; Zhang, Q.; Chen, Z.; Jiang, J. Metal-Organic Framework MIL-53 (Fe)@C/Graphite Carbon Nitride Hybrids with Enhanced Thermal Stability, Flame Retardancy, and Smoke Suppression for Unsaturated Polyester Resin. Polym. Adv. Technol. 2019, 30, 2458–2467. [Google Scholar] [CrossRef]

- Chen, Z.; Jiang, M.; Chen, Z.; Chen, T.; Yu, Y.; Jiang, J. Preparation and Characterization of a Microencapsulated Flame Retardant and Its Flame-Retardant Mechanism in Unsaturated Polyester Resins. Powder Technol. 2019, 354, 71–81. [Google Scholar] [CrossRef]

- Liu, L.; Xu, Y.; Xu, M.; He, Y.; Li, S.; Li, B. An Efficient Synergistic System for Simultaneously Enhancing the Fire Retardancy, Moisture Resistance and Electrical Insulation Performance of Unsaturated Polyester Resins. Mater. Des. 2020, 187, 108302. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Yang, Y.; Cai, X. The Investigation of Flammability, Thermal Stability, Heat Resistance and Mechanical Properties of Unsaturated Polyester Resin Using AlPi as Flame Retardant. J. Therm. Anal. Calorim. 2015, 122, 1331–1339. [Google Scholar] [CrossRef]