Further Increasing the Accuracy of Characterization of a Thin Dielectric or Semiconductor Film on a Substrate from Its Interference Transmittance Spectrum

Abstract

:1. Introduction

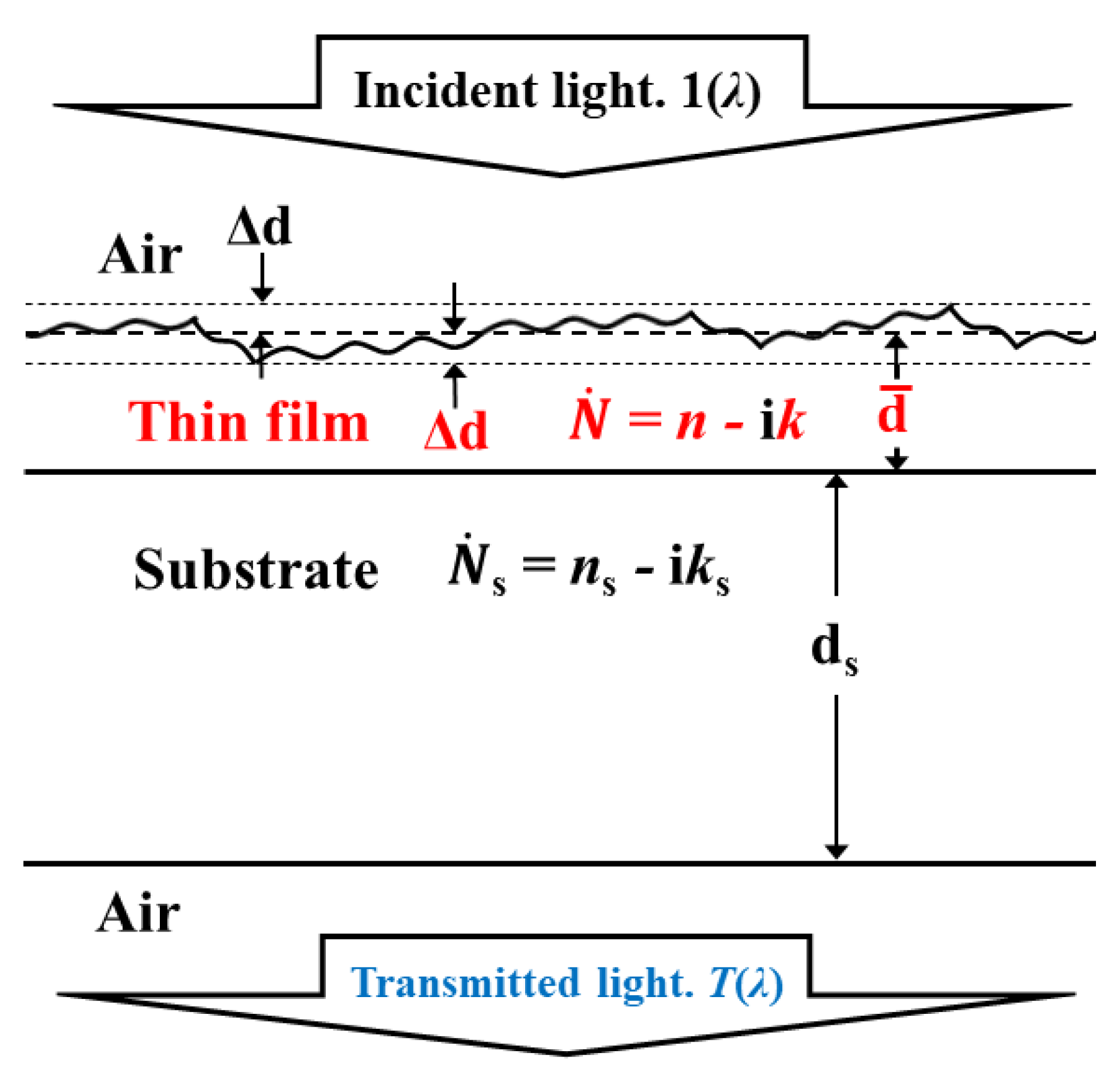

2. Materials and Methods

2.1. Preparation of the Specimens and Measuring the Transmittance Spectra T(λ)

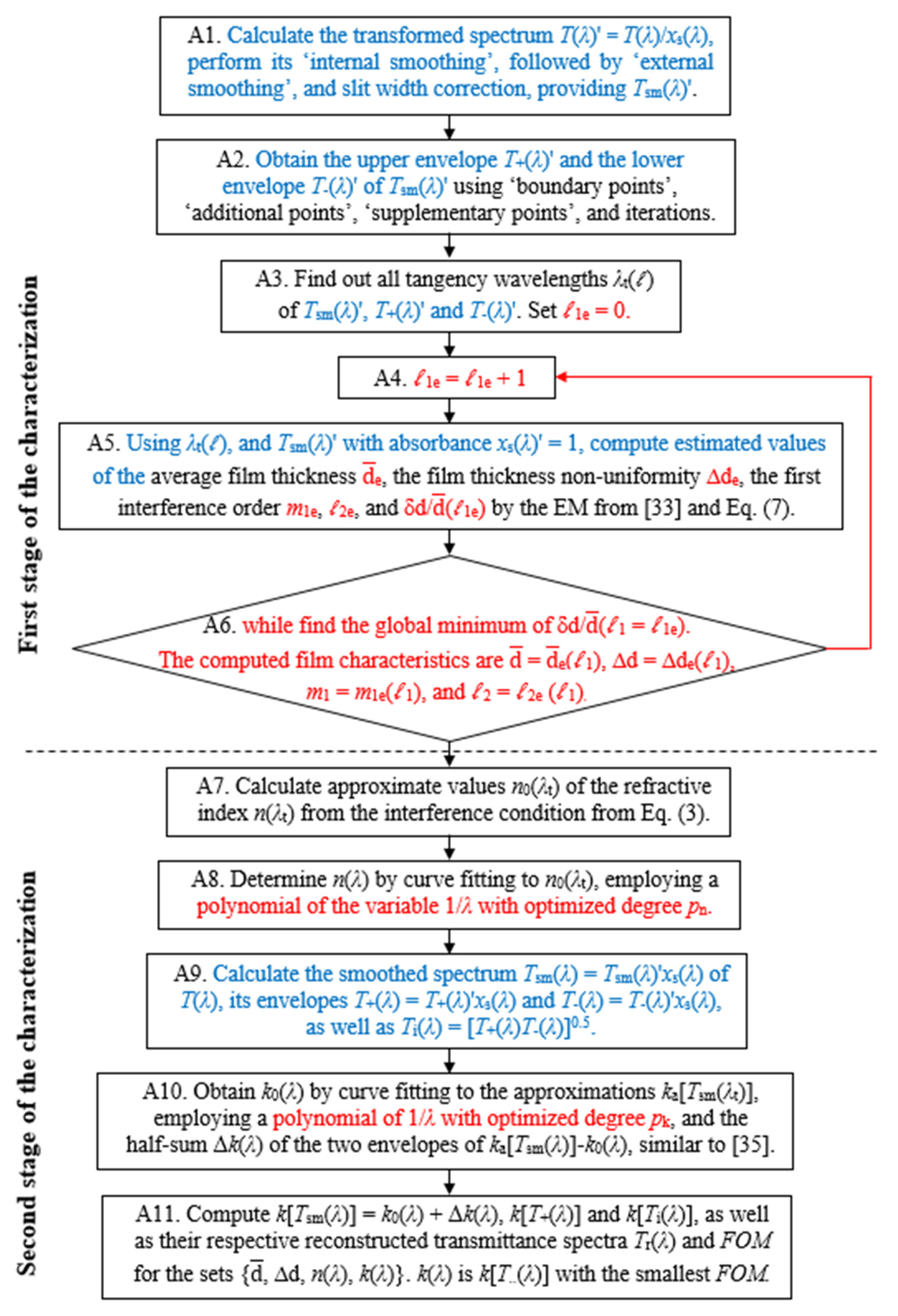

2.2. Details Regarding the Performed Accurate Thin Film Characterizations by EM for T(λ)

2.3. Algorithm for Accurate Thin-Film Characterization by EM for T(λ) Accounting for the Three Investigated Issues

2.4. Determination of Model Based Thin-Film Parameters Using Data from EM Characterization

3. Results

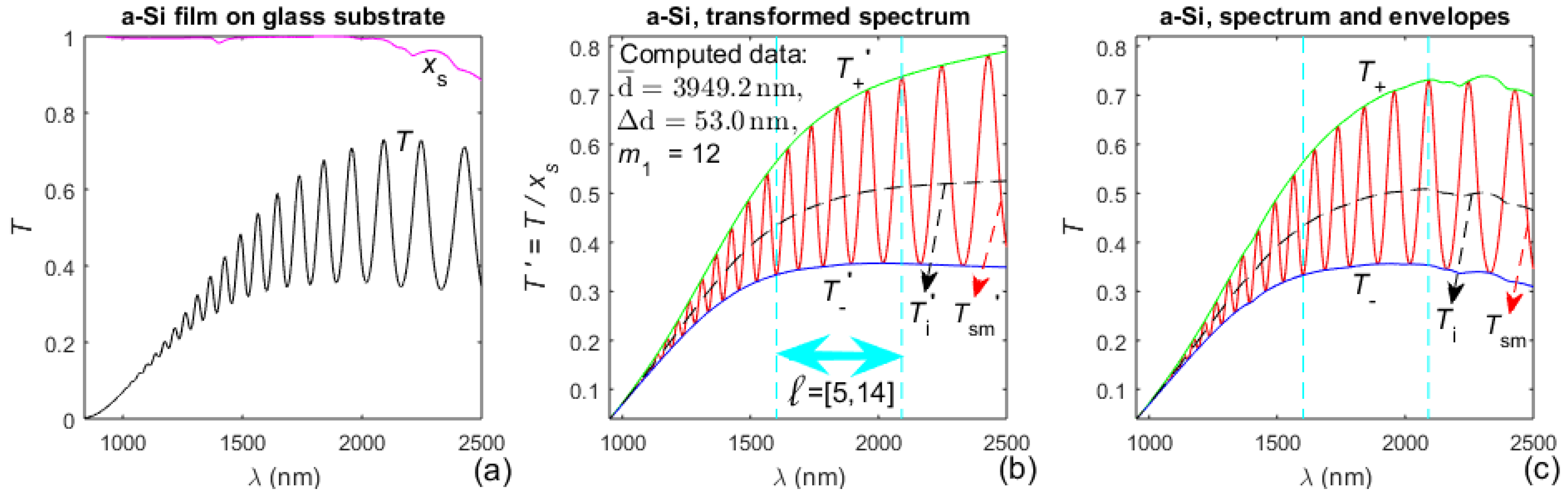

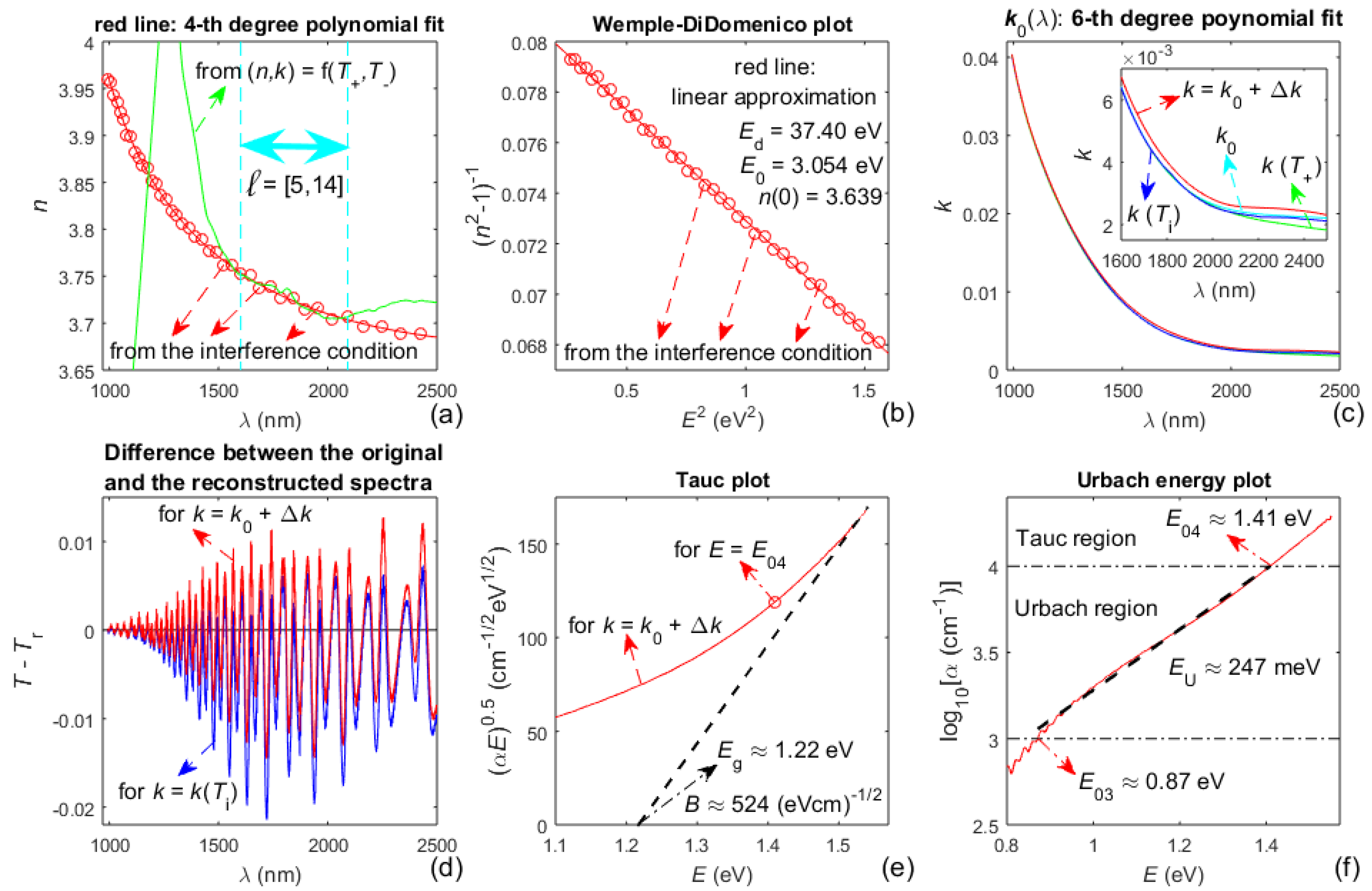

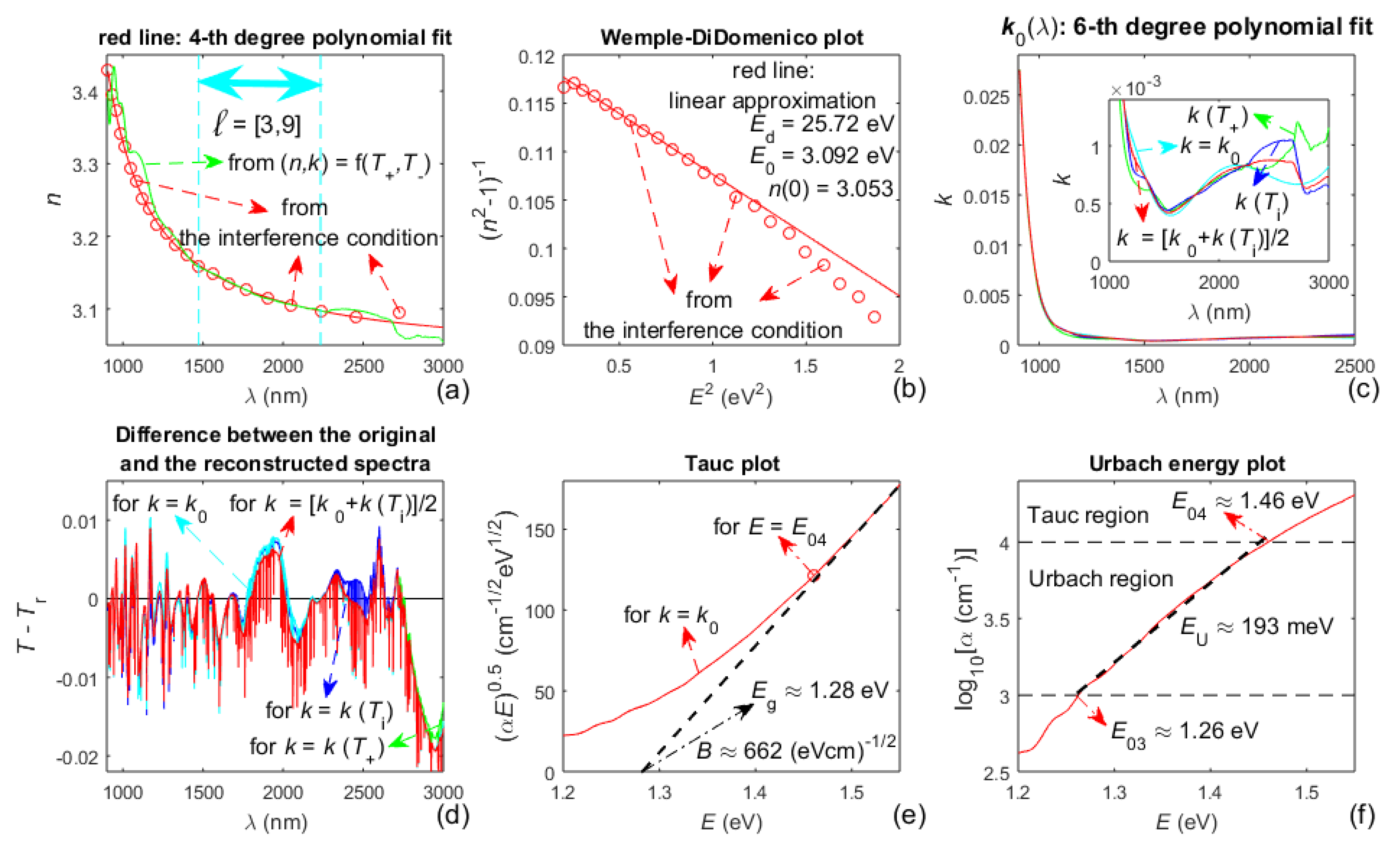

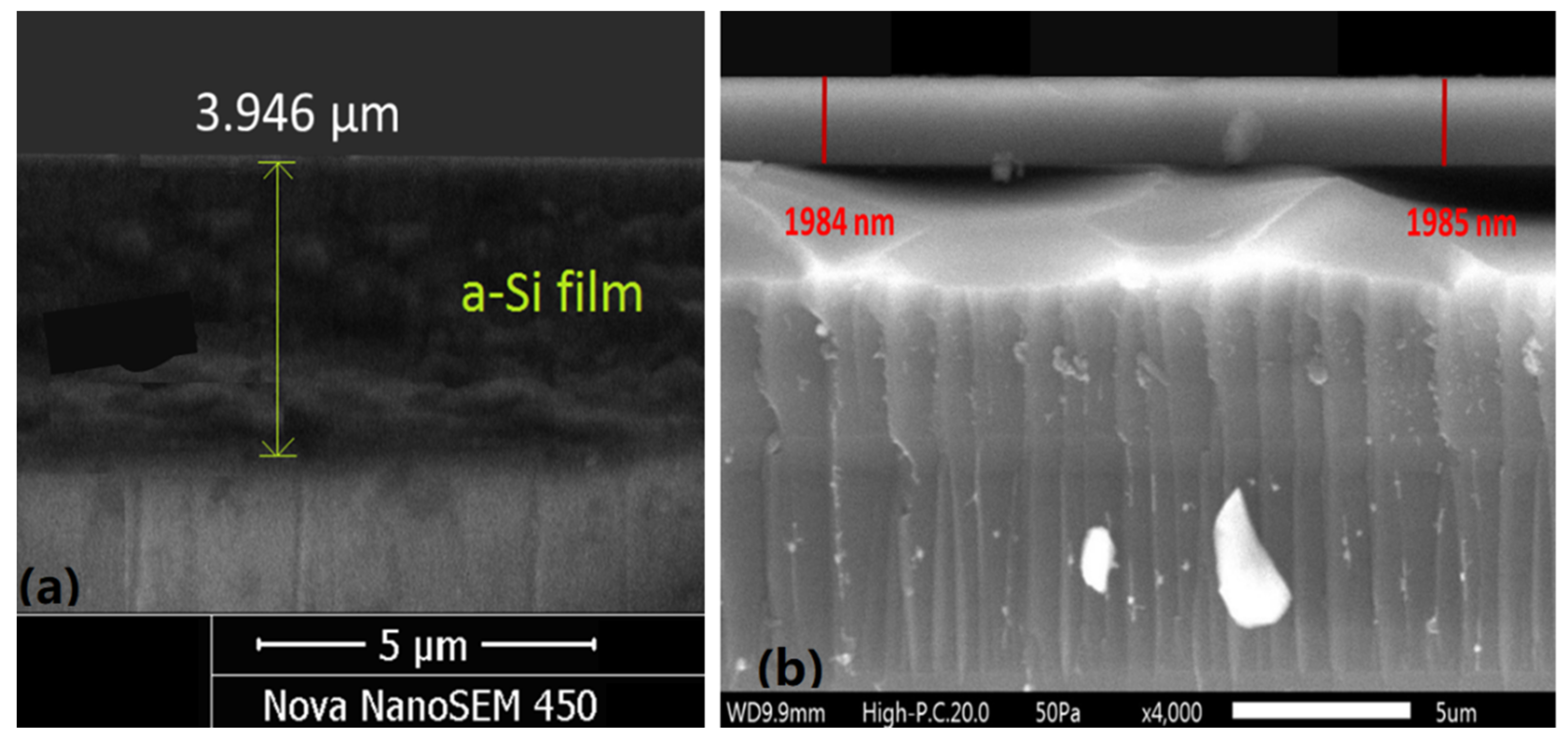

3.1. Characterization of the a-Si Film

3.2. Characterization of the a-As98Te2 Film

4. Discussion

5. Conclusions

- 1.

- Firstly, it is demonstrated that the dual transformation, based on the product T(λ)xs(λ), increases the accuracy of the envelopes T+(λ) and T−(λ) that are used in the computation of the average film thickness and the film thickness non-uniformity ∆d, when the substrate is non-transparent. In practice, this approach resolves the problem of computing accurate envelopes of the interference spectrum T(λ) of a thin film on a non-transparent substrate.

- 2.

- Secondly, how to select an interval ℓ = [ℓ 1, ℓ 2] (representing the used λt) over which the first stage of the characterization is performed most accurately, is shown. The increased accuracy of the computation of and ∆d of the studied a-Si and a-As98Te2 films indicates that employing this novel concept can increase the accuracy of the characterization of every thin dielectric or semiconductor film on a substrate, based on the EM for T(λ).

- 3.

- Thirdly, the regression of n(λ) and k0(λ), by a polynomial of the optimized degree of 1/λ, is consistent with the Cauchy’s dispersion formula for materials with normal dispersion. Moreover, using only such regression eliminates the inconvenience of attempting another regression function.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Poortmans, J.; Arkhipov, V. Thin Film Solar Cells: Fabrication, Characterization and Applications, 1st ed.; Wiley: Hoboken, NJ, USA, 2009; pp. 41–55. [Google Scholar]

- Stenzel, O. Optical Coatings: Material Aspects in Theory and Practice, 1st ed.; Springer: Heidelberg, Germany, 2016; pp. 35–51. [Google Scholar]

- The Role of Thin Film in Optical Field. Available online: https://www.alcatechnology.com/en/blog/the-role-of-thin-film-in-optical-field/ (accessed on 16 June 2021).

- Tamang, A.; Hongsingthong, A.; Sichanugrist, P.; Jovanov, V.; Gebrewold, H.T. On the potential of light trapping in multiscale textured thin film solar cells. Sol. Energy Mater. Sol. Cells 2016, 144, 300–308. [Google Scholar] [CrossRef]

- Islam, K.; Chowthury, F.; Alnuaimi, A.; Nayfeh, A. ~10% increase in short-current density using 100nm plasmonic Au nanoparticles on thin film n-i-p a-Si:H solar cells. In Proceedings of the IEEE Conference on Photovoltaic Specialists (PVSC 40), Denver, CO, USA, 1–13 June 2014; pp. 3071–3075. [Google Scholar]

- Diallo, A.K.; Ly, A.H.B.; Ndiaye, D.; Kobor, D.; Pasquinelli, M.; Diallo, A.K. Influence of temperature and pentacene thickness on the electrical parameters in top gate organic thin film transistor. AMPC 2017, 7, 85–98. [Google Scholar] [CrossRef] [Green Version]

- Jhu, J.C.; Chang, T.C.; Chang, K.C.; Yang, C.Y.; Chou, W.C.; Chou, C.H.; Chung, W.C. Investigation of hydration reaction-induced protons transport in etching-stop a-InGaZnO thin-film transistors. IEEE Electron. Device Lett. 2015, 36, 1050–1052. [Google Scholar] [CrossRef]

- Ta’eed, V.G.; Baker, N.J.; Fu, L.; Finsterbusch, K.; Lamont, M.R.E.; Moss, D.J.; Nguyen, H.C.; Eggleton, B.J.; Choi, D.Y.; Madden, S.; et al. Ultrafast all-optical chalcogenide glass photonic circuits. Opt. Express 2007, 15, 9205–9221. [Google Scholar] [CrossRef]

- Song, S.; Carlie, N.; Boudies, J.; Petit, L.; Richardson, K.; Arnold, C.B. Spin coating of Ge23Sb7S70 chalcogenide glass thin films. J. Non-Cryst. Solids 2009, 355, 2272–2278. [Google Scholar] [CrossRef]

- Waldman, D.A.; Li, H.Y.S.; Cetin, E.A. Holographic recording properties in thick films of ULSH-500 photopolymer. In Proceedings of the Diffractive and Holographic Device Technologies and Applications V (Proc. SPIE 3291), San Jose, CA, USA, 28–29 January 1998; pp. 89–98. [Google Scholar]

- Navarro-Fuster, V.; Ortuno, M.; Gallego, S.; Márquez, A.; Beléndez, A.; Pascual, I. Biophotopol’s energetic sensitivity improved in 300 μm layer by tuning the recording wavelength. Opt. Mater. 2016, 52, 111–115. [Google Scholar] [CrossRef] [Green Version]

- Dudney, N.J.; Jang, Y.I. Analysis of thin-film lithium batteries with cathodes of 50 nm to 4 μm thick LiCoO2. J. Power Sources 2003, 119, 300–304. [Google Scholar] [CrossRef]

- Huang, X.D.; Zhang, F.; Gana, X.F.; Huanga, Q.A.; Yang, J.Z.; Laic, P.T.; Tang, W.M. Electrochemical characteristics of amorphous silicon carbide film as a lithium-ion battery anode. RSC Adv. 2018, 8, 5189–5196. [Google Scholar] [CrossRef] [Green Version]

- Soriaga, M.P.; Stickney, J.; Bottomley, L.A.; Kim, Y.G. Thin Films: Preparation, Characterization, Applications, 1st ed.; Springer: Boston, MA, USA, 2002; pp. 37–45. [Google Scholar]

- Hilfiker, J.N.; Singh, N.; Tiwald, T.; Convey, D.; Smith, S.M.; Bakerb, J.H.; Tompkins, H.G. Survey of methods to characterize thin absorbing films with Spectroscopic Ellipsometry. Thin Solid Film. 2008, 516, 7979–7989. [Google Scholar] [CrossRef]

- Poelman, D.; Smet, P.J. Methods for the determination of the optical constants of thin films from single transmission measurements: A critical review. J. Phys. D 2003, 36, 1850–1857. [Google Scholar] [CrossRef]

- Stenzel, O. The Physics of Thin Film Optical Spectra, 1st ed.; Springer: Heidelberg, Germany, 2016; pp. 79–81. [Google Scholar]

- Shaaban, E.R.; Afify, N.; El-Taher, A. Effect of film thickness on microstructure parameters and optical constants of CdTe thin films. J. Alloys Compd. 2009, 482, 400–404. [Google Scholar] [CrossRef]

- Kaflé, B.P. Chemical Analysis and Material Characterization by Spectrophotometry, 1st ed.; Kindle: Seattle, DC, USA, 2019; pp. 72–75. [Google Scholar]

- Tompkins, H.G.; Hilfiker, J.N. Spectroscopic Ellipsometry: Practical Application to Thin Film Characterization, 1st ed.; Momentum Press: New York, NY, USA, 2015; pp. 84–88. [Google Scholar]

- Stenzel, O.; Ohlídal, M. Optical Characterization of Thin Solid Films, 1st ed.; Springer: Heidelberg, Germany, 2016; pp. 93–99. [Google Scholar]

- Swanepoel, R. Determining refractive index and thickness of thin films from wavelength measurements only. J. Opt. Soc. Am. A 1985, 2, 1339–1343. [Google Scholar] [CrossRef]

- Gao, L.; Lemarchand, F.; Lequime, M. Refractive index determination of SiO2 layer in the UV/Vis/NIR range: Spectrophotometric reverse engineering on single and bi-layer designs. J. Europ. Opt. Soc. Rap. Public. 2013, 8, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Frey, H.; Khan, H.R. Handbook of Thin Film Technology, 1st ed.; Springer: Berlin, Germany, 2015; pp. 24–41. [Google Scholar]

- Yen, S.T.; Chung, P.K. Extraction of optical constants from maxima of fringing reflectance spectra. Appl. Opt. 2015, 54, 663–668. [Google Scholar] [CrossRef]

- Ohlídal, I.; Vohánka, J.; Buršíková, V.; Franta, D.; Čermák, M. Spectroscopic ellipsometry of inhomogeneous thin films exhibiting thickness non-uniformity and transition layers. Opt. Express 2020, 28, 160–174. [Google Scholar] [CrossRef]

- Vohánka, J.; Franta, D.; Čermák, M.; Homola, V.; Buršíková, V.; Ohlídal, I. Ellipsometric characterization of highly non-uniform thin films with the shape of thickness non-uniformity modeled by polynomials. Opt. Express 2020, 28, 5492–5506. [Google Scholar] [CrossRef] [PubMed]

- Surface Roughness Parameters. Available online: https://www.keyence.eu/ss/products/microscope/roughness/line/tab02_a.jsp/ (accessed on 16 June 2021).

- Thin-Film Interference. Available online: https://en.wikipedia.org/wiki/Thin-film_interference/ (accessed on 16 June 2021).

- Thin-Film Interference. Available online: https://www.britannica.com/science/light/Thin-film-interference (accessed on 16 June 2021).

- Tompkins, H.; Irene, E.A. Handbook of Ellipsometry, 1st ed.; William Andrew Publishing: Norwich, CT, USA, 2006; pp. 102–143. [Google Scholar]

- Ogieglo, W.; Wormeester, H.; Eichhorn, K.J.; Wessling, M.; Benes, N.E. In situ ellipsometry studies on swelling of thin polymer films. Prog. Polym. Sci. 2015, 42, 42–78. [Google Scholar] [CrossRef]

- Mieghem, P.V. Theory of band tails in heavily doped semiconductors. Rev. Mod. Phys. 1992, 64, 755–793. [Google Scholar] [CrossRef]

- Fedyanin, D.Y.; Arsenin, A.V. Surface plasmon polariton amplification in metal-semiconductor structures. Opt. Express 2011, 19, 12524–12531. [Google Scholar] [CrossRef]

- Cisowski, J.; Jarzabek, B.; Jurusik, J.; Domanski, M. Direct determination of the refraction index normal dispersion for thin films of 3, 4, 9, 10-perylene tetracarboxylic dianhydride (PTCDA). Opt. Appl. 2012, 42, 181–192. [Google Scholar]

- Grassi, A.P.; Tremmel, A.J.; Koch, A.W.; El-Khozondar, H.J. On-line thickness measurement for two-layer systems on polymer electronic devices. Sensors 2013, 13, 15747–15757. [Google Scholar] [CrossRef] [Green Version]

- Brinza, M.; Emelianova, E.V.; Adriaenssens, G.Y. Nonexponential distributions of tail states in hydrogenated amorphous silicon. Phys. Rev. B 2005, 71, 115209. [Google Scholar] [CrossRef]

- Swanepoel, R. Determination of the thickness and optical constants of amorphous silicon. J. Phys. E 1983, 16, 1214–1222. [Google Scholar] [CrossRef]

- Google Scholar. Available online: https://scholar.google.com/scholar?cites=9869860102796010609&as_sdt=2005&sciodt=0,5&hl=bg (accessed on 1 August 2021).

- Minkov, D.A. DSc Thesis: Characterization of Thin Films and Surface Cracks by Electromagnetic Methods and Technologies; Technical University: Sofia, Bulgaria, 2018; pp. 114–119. [Google Scholar]

- Swanepoel, R. Determination of surface roughness and optical constants of inhomogeneous amorphous silicon films. J. Phys. E Sci. Instrum. 1984, 17, 896–903. [Google Scholar] [CrossRef]

- Leal, J.M.G.; Alcon, R.P.; Angel, J.A.; Minkov, D.A.; Marquez, E. Influence of substrate absorption on the optical and geometrical characterization of thin dielectric films. Appl. Opt. 2002, 41, 7300–7308. [Google Scholar] [CrossRef] [PubMed]

- Minkov, D.A.; Gavrilov, G.M.; Angelov, G.V.; Moreno, G.M.D.; Vazquez, C.G.; Ruano, S.M.F.; Marquez, E. Optimisation of the envelope method for characterisation of optical thin film on substrate specimens from their normal incidence transmittance spectrum. Thin Solid Film. 2018, 645, 370–378. [Google Scholar] [CrossRef]

- Minkov, D.A.; Angelov, G.V.; Nestorov, R.N.; Marquez, E.; Blanco, E.; Ruiz-Perez, J.J. Comparative study of the accuracy of characterization of thin films a-Si on glass substrates from their interference normal incidence transmittance spectrum by the Tauc-Lorentz-Urbach, the Cody-Lorentz-Urbach, the optimized envelopes and the optimized graphical methods. Mater. Res. Express 2019, 6, 036410. [Google Scholar]

- Minkov, D.A.; Angelov, G.V.; Nestorov, R.N.; Marquez, E. Perfecting the dispersion model free characterization of a thin film on a substrate specimen from its normal incidence interference transmittance spectrum. Thin Solid Film. 2020, 706, 137984. [Google Scholar] [CrossRef]

- Precision Cover Glasses and Microscope Slides. Available online: https://www.thorlabs.de/newgrouppage9.cfm?objectgroup_id=9704/ (accessed on 16 June 2021).

- Minkov, D.A.; Angelov, G.; Nestorov, R.; Nezhdanov, A.; Usanov, D.; Kudryashov, M.; Mashin, A. Optical characterization of AsxTe100-x Films Grown by Plasma Deposition Based on the Advanced Optimizing Envelope Method. Materials 2020, 13, 2981. [Google Scholar] [CrossRef] [PubMed]

- Cauchy and Related Empirical Dispersion Formulae for Transparent Materials, Technical Note. Spectroscopic Ellipsometry TN14. Available online: https://www.horiba.com/fileadmin/uploads/Scientific/Downloads/OpticalSchool_CN/TN/ellipsometer/Cauchy_and_related_empirical_dispersion_Formulae_for_Transparent_Materials.pdf (accessed on 6 June 2020).

- Smith, D.Y.; Inokuti, M.; Karstens, W.A. generalized Cauchy dispersion formula and the refractivity of elemental semiconductors. J. Phys. Condens. Matter. 2001, 13, 3883–3893. [Google Scholar] [CrossRef]

- Márquez, E.; Saugar, E.; Díaz, J.M.; Vázquez, C.G.; Ruano, S.M.F.; Blanco, E.; Ruiz-Pérez, J.J.; Minkov, D.A. The influence of Ar pressure on the structure and optical properties of non-hydrogenated a-Si thin films grown by rf magnetron sputtering onto room temperature glass substrates. J. Non-Cryst. Solids 2019, 517, 32–43. [Google Scholar] [CrossRef]

- Mochalov, L.; Nezhdanov, A.; Kudryashov, M.; Loghunov, A.; Strikovskiy, A.; Gushchin, M.; Chidichomo, G.; DeFilipo, G.A.; Mashin, A. Influence of plasma-enhanced chemical vapor deposition parameters on characteristics of As–Te chalcogenide films. Plasma Chem. Plasma Process. 2017, 37, 1417–1429. [Google Scholar] [CrossRef]

- Mochalov, L.; Dorosz, D.; Nezhdanov, A.; Kudryashov, M.; Zelentsov, S.; Usanov, D.; Logunov, A.; Mashin, A.; Gogova, D. Investigation of the composition-structure-property relationship of AsxTe100−x films prepared by plasma deposition. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2018, 191, 211–216. [Google Scholar] [CrossRef]

- Bartz, A.E. Basic Statistical Concepts, 4th ed.; Prentice-Hall Inc.: Upper Saddle River, NJ, USA, 1999; pp. 43–47. [Google Scholar]

- Nestorov, R.N. Selection of error metric for accurate characterization of a thin dielectric or semiconductor film on glass substrate by the optimizing envelope method. Int. J. Adv. Res. Sci. Eng. Technol. 2020, 7, 1–11. [Google Scholar]

- Wemple, S.H. Refractive-index behavior of amorphous semiconductors and glasses. Phys. Rev. B 1973, 7, 3767–3777. [Google Scholar] [CrossRef]

- Amorphous Silicon. Available online: https://en.wikipedia.org/wiki/Amorphous_silicon/ (accessed on 18 June 2021).

- Tylor, P.C. Nuclear Quadrupole resonance in amorphous semiconductors. Z. Naturforsch. 1996, 51, 603–610. [Google Scholar] [CrossRef]

- Knief, S.; von Niessen, W. Disorder, defects, and optical absorption in a-Si and a-Si:H. Phys. Rev. B 1999, 59, 12940–12946. [Google Scholar] [CrossRef]

- Pan, Y.; Inam, F.; Zhang, M.; Drabold, D.A. Atomistic origin of Urbach tails in amorphous silicon. Phys. Rev. Lett. 2008, 100, 206403. [Google Scholar] [CrossRef] [Green Version]

- Zaynobidinov, S.; Ikramov, R.G.; Jalalov, R.M. Urbach energy and the tails of the density of states in amorphous semiconductors. J. Appl. Spectrosc. 2011, 78, 223–227. [Google Scholar] [CrossRef]

- Guerrero, E.; Strubbe, D.A. Computational generation of voids in a-Si and a-Si:H by cavitation at low density. Phys. Rev. Mater. 2020, 4, 025601. [Google Scholar] [CrossRef] [Green Version]

- Bruggeman, D.A.G. Berechnung verschiedener physikalischer konstanten von heterogenen substanzen i. dielektrizitätskonstanten und leitfähigkeiten der mischkörper aus isotropen substanzen. Ann. Phys. 1935, 416, 636–664. [Google Scholar] [CrossRef]

- Chen, H.; Shen, W.Z. Perspectives in the characteristics and applications of Tauc-Lorentz dielectric function model. Eur. Phys. J. B 2005, 43, 503–507. [Google Scholar] [CrossRef]

- Passive Optical Properties of Glass. Available online: https://www.lehigh.edu/imi/teched/GlassProp/Slides/GlassProp_Lecture16_Lucas.pdf (accessed on 25 June 2021).

| a-Si, First-Stage Characterization | from Ref. [45] | ||||||

|---|---|---|---|---|---|---|---|

| ℓe = [ℓ 1e, ℓ 2e] | [1,18] | [2,18] | [3,26] | [4,26] | [5,14] | [6,26] | [1,16] |

| δ(ℓ 1e) (%) | 0.143 | 0.146 | 0.165 | 0.168 | 0.0901 | 0.170 | 0.245 |

| computed film characteristics | for ℓ = [5,14] = 3949.2 nm, Δd = 53.0 nm, m1 = 12 | = 3929.9 nm, Δd = 53.5 nm, m1 = 12 | |||||

| a-Si, Second-Stage Characterizations | |||||

|---|---|---|---|---|---|

| FOM | for k = k0 | for k = k0 + Δk | for k(T+) | for k(Ti) | for [k0 + Δk + k(Ti)]/2 |

| From ref. [45] | 7.36 × 10−3 | 5.71 × 10−3 | 7.78 × 10−3 | - | - |

| this study | 6.65 × 10−3 | 5.19 × 10−3 | 7.41 × 10−3 | 6.91 × 10−3 | 5.80 × 10−3 |

| a-As98Te2, First-Stage Characterization | From Ref. [47] | ||||||

|---|---|---|---|---|---|---|---|

| ℓe = [ℓ 1e, ℓ 2e] | [1,19] | [2,9] | [3,9] | [4,9] | [5,9] | [6,9] | [2,12] |

| δ(ℓ 1e) (%) | 0.308 | 0.0857 | 0.0426 | 0.0455 | 0.0491 | 0.0497 | 0.133 |

| computed film characteristics | for ℓ = [3,9]: = 1983.2 nm, Δd = 23.9 nm, m1 = 4.5 | = 1983.8 nm, Δd = 22.7 nm, m1 = 4.5 | |||||

| a-As98Te2, Second-Stage Characterizations | |||||

|---|---|---|---|---|---|

| FOM | for k = k0 | for k = k0 + Δk | for k(T+) | for k(Ti) | for [k0 + k(Ti)]/2 |

| from [47] | 4.36 × 10−3 | 4.26 × 10−3 | 3.96 × 10−3 | 3.74 × 10−3 | - |

| this study | 3.89 × 10−3 | 3.89 × 10−3 | 4.38 × 10−3 | 3.87 × 10−3 | 3.64 × 10−3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minkov, D.; Marquez, E.; Angelov, G.; Gavrilov, G.; Ruano, S.; Saugar, E. Further Increasing the Accuracy of Characterization of a Thin Dielectric or Semiconductor Film on a Substrate from Its Interference Transmittance Spectrum. Materials 2021, 14, 4681. https://doi.org/10.3390/ma14164681

Minkov D, Marquez E, Angelov G, Gavrilov G, Ruano S, Saugar E. Further Increasing the Accuracy of Characterization of a Thin Dielectric or Semiconductor Film on a Substrate from Its Interference Transmittance Spectrum. Materials. 2021; 14(16):4681. https://doi.org/10.3390/ma14164681

Chicago/Turabian StyleMinkov, Dorian, Emilio Marquez, George Angelov, Gavril Gavrilov, Susana Ruano, and Elias Saugar. 2021. "Further Increasing the Accuracy of Characterization of a Thin Dielectric or Semiconductor Film on a Substrate from Its Interference Transmittance Spectrum" Materials 14, no. 16: 4681. https://doi.org/10.3390/ma14164681

APA StyleMinkov, D., Marquez, E., Angelov, G., Gavrilov, G., Ruano, S., & Saugar, E. (2021). Further Increasing the Accuracy of Characterization of a Thin Dielectric or Semiconductor Film on a Substrate from Its Interference Transmittance Spectrum. Materials, 14(16), 4681. https://doi.org/10.3390/ma14164681