Coercivity Mechanism and Magnetization Reversal in Anisotropic Ce-(Y)-Pr-Fe-B Films

Abstract

:1. Introduction

2. Materials and Methods

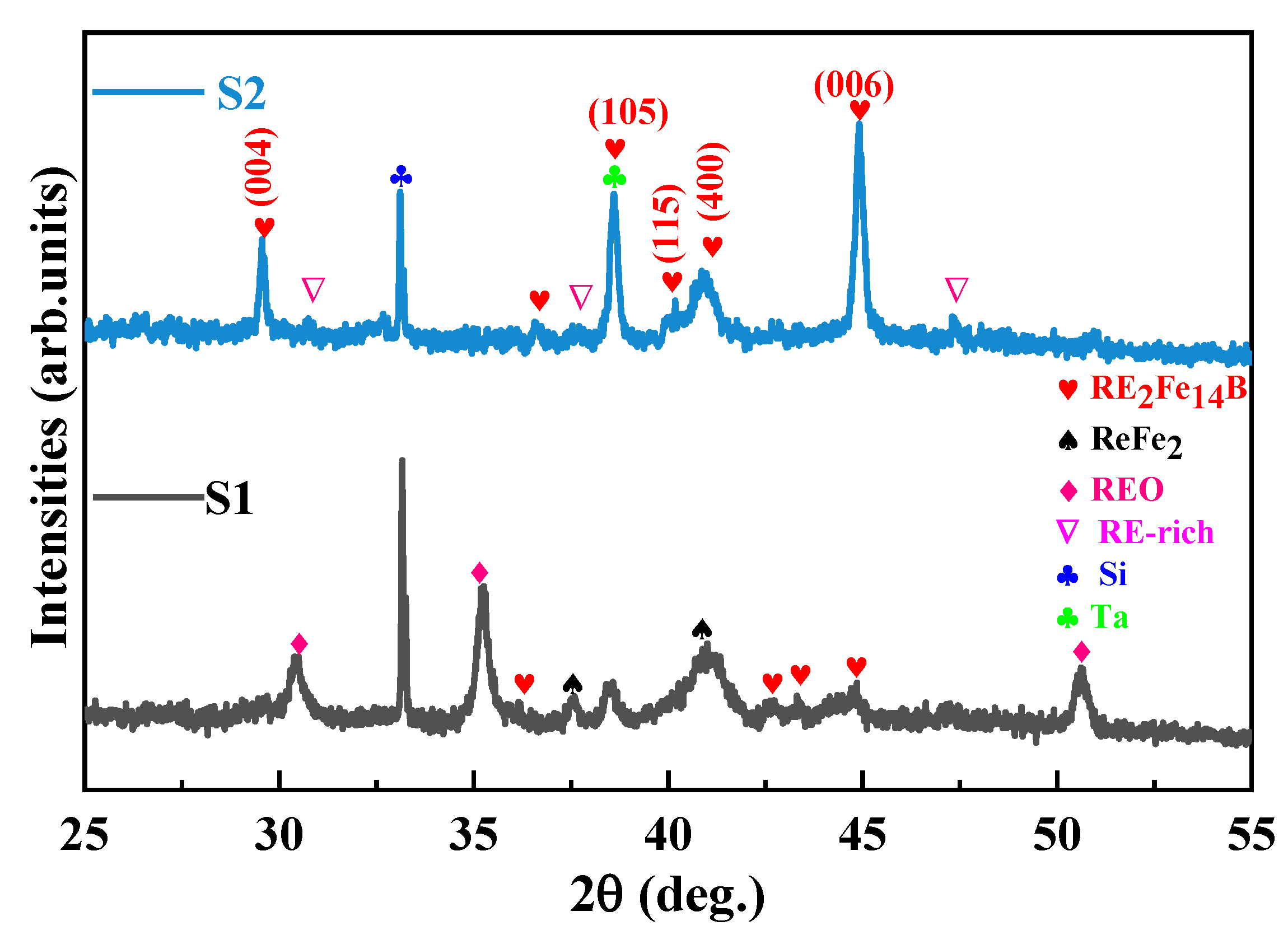

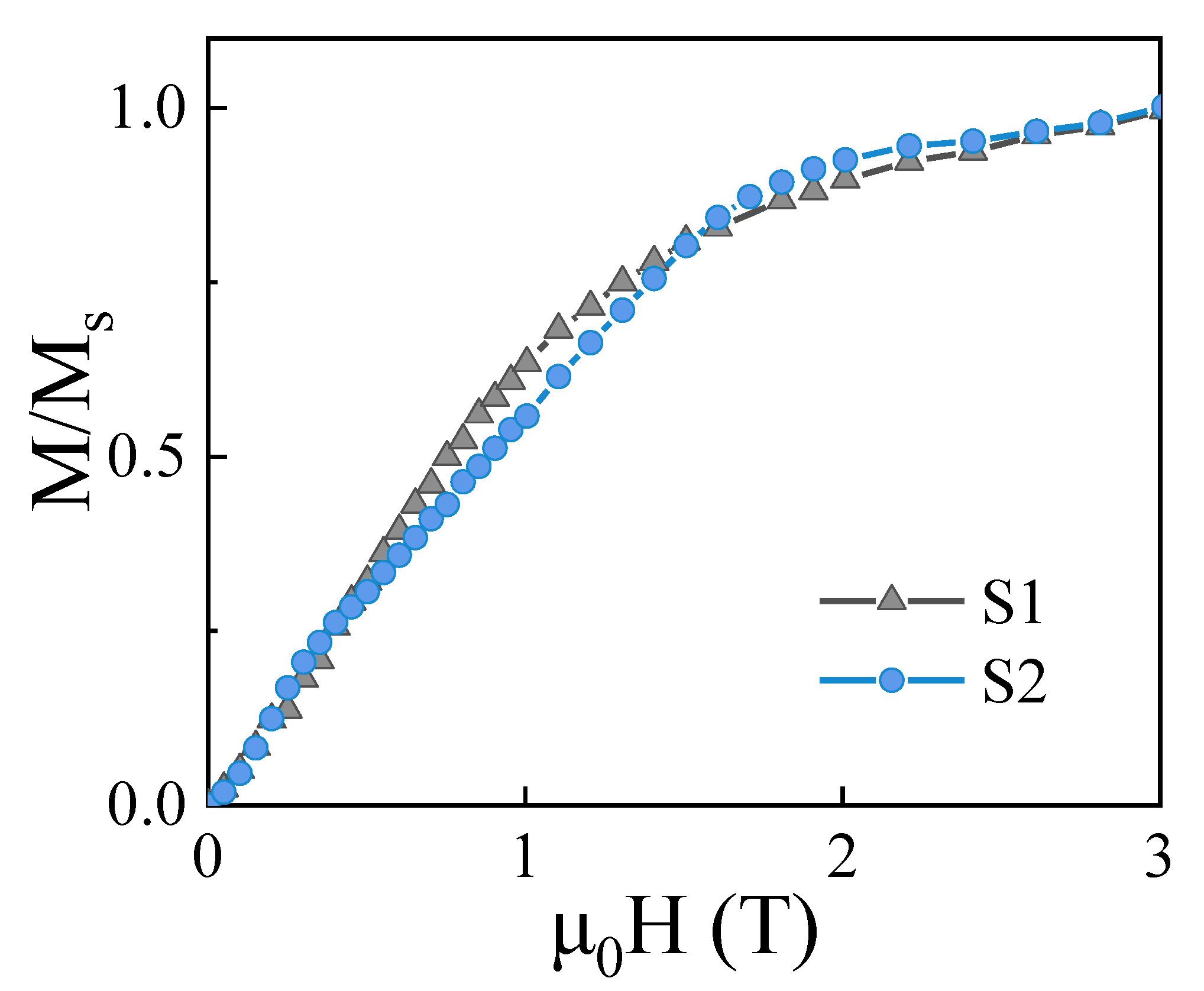

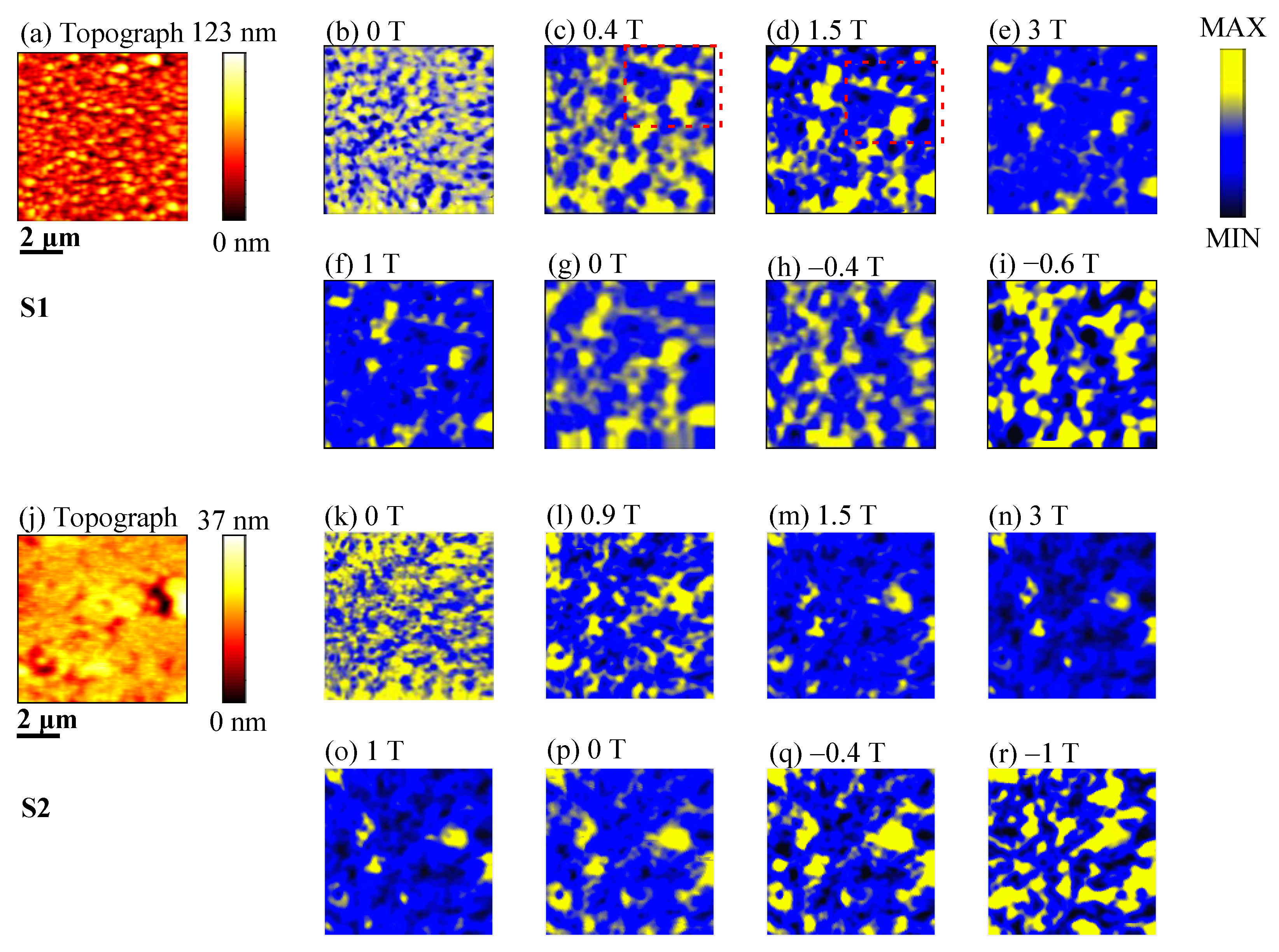

3. Results and Discussion

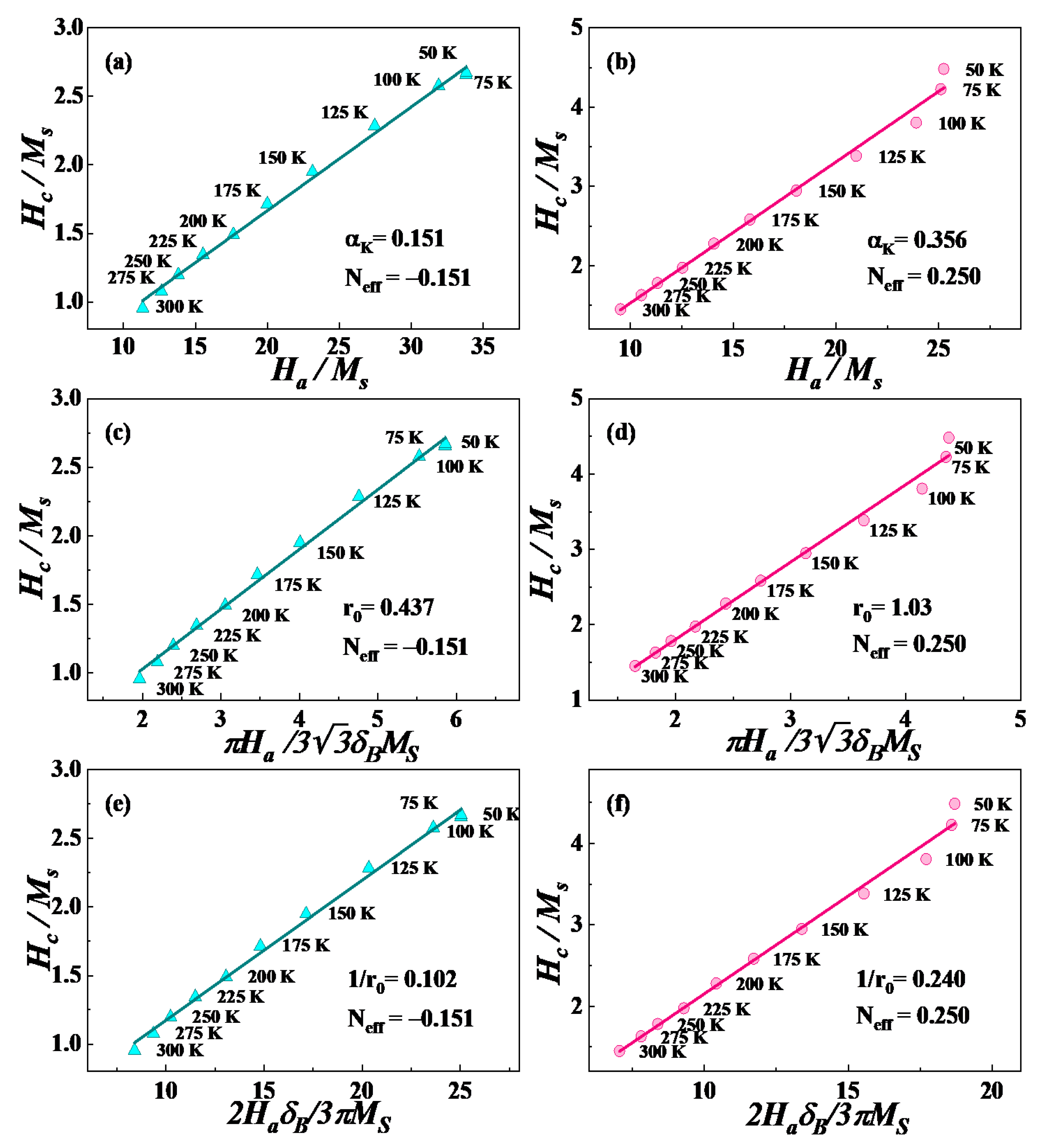

- (1)

- If the magnetization reversal process is uniform, in other words, it is controlled by the uniform reversal of the magnetic moment, then, a linear relationship between and exists within the entire temperature range.

- (2)

- Considering that the magnetic particles are strongly coupled and the anisotropy axis is not strictly along the c-axis, one reversed magnetic moment would lead to the joint reversal of the surrounding magnetic moments. In this case, it is necessary to consider the influence of the existence of strong misorientation grains on coercivity, and

- (a)

- In the case of thin inhomogeneities (), the coercivity field satisfies the following relation:

- (b)

- On the contrary, if the domain wall is pinned by extended planar defects (), the coercivity field satisfies the following expression:

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sagawa, M.; Fujimura, S.; Togawa, N.; Yamamoto, H.; Matsuura, Y. New material for permanent magnets on a base of Nd and Fe (invited). J. Appl. Phys. 1984, 55, 2083–2087. [Google Scholar] [CrossRef]

- Sugimoto, S. Current status and recent topics of rare-earth permanent magnets. J. Phys. D Appl. Phys. 2011, 44, 064001. [Google Scholar] [CrossRef]

- Rodewald, W.; Wall, B.; Katter, M.; Uestuener, K. Top Nd-Fe-B magnets with greater than 56 MGOe energy density and 9.8 kOe coercivity. IEEE Trans. Magn. 2002, 38, 2955–2957. [Google Scholar] [CrossRef]

- Buschow, K.H.J. Intermetallic compounds of rare-earth and 3d transition metals. Reports Prog. Phys. 1977, 40, 1179–1256. [Google Scholar] [CrossRef]

- Eggert, R.G. Minerals go critical. Nat. Chem. 2011, 3, 688–691. [Google Scholar] [CrossRef] [PubMed]

- Massari, S.; Ruberti, M. Rare earth elements as critical raw materials: Focus on international markets and future strategies. Resour. Policy 2013, 38, 36–43. [Google Scholar] [CrossRef]

- Pathak, A.K.; Khan, M.; Gschneidner, K.A.; McCallum, R.W.; Zhou, L.; Sun, K.; Dennis, K.W.; Zhou, C.; Pinkerton, F.E.; Kramer, M.J.; et al. Cerium: An unlikely replacement of dysprosium in high performance Nd-Fe-B permanent magnets. Adv. Mater. 2015, 27, 2663–2667. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Li, W.; Wang, J.; Zheng, L.; Li, Y.; Zhang, K.; Feng, H.; Liu, T. Influence of Ce content on the rectangularity of demagnetization curves and magnetic properties of Re-Fe-B magnets sintered by double main phase alloy method. IEEE Trans. Magn. 2014, 50, 5–8. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, T.; Yan, M.; Jin, J.; Wu, B.; Peng, B.; Liu, Y.; Yue, M.; Liu, C. Post-sinter annealing influences on coercivity of multi-main-phase Nd-Ce-Fe-B magnets. Acta Mater. 2018, 146, 97–105. [Google Scholar] [CrossRef]

- Hirosawa, S.; Matsuura, Y.; Yamamoto, H.; Fujimura, S.; Sagawa, M.; Yamauchi, H. Magnetization and magnetic anisotropy of R2Fe14B measured on single crystals. J. Appl. Phys. 1986, 59, 873–879. [Google Scholar] [CrossRef]

- Niu, E.; Chen, Z.A.; Chen, G.A.; Zhao, Y.G.; Zhang, J.; Rao, X.L.; Hu, B.P.; Wang, Z.X. Achievement of high coercivity in sintered R-Fe-B magnets based on misch-metal by dual alloy method. J. Appl. Phys. 2014, 115, 113912. [Google Scholar] [CrossRef]

- Eriksson, O.; Nordström, L.; Brooks, M.S.S.; Johansson, B. 4f-band magnetism in CeFe2. Phys. Rev. Lett. 1988, 60, 2523. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, T.; Jin, J.; Li, J.; Wu, C.; Shen, B.; Yan, M. Effects of REFe2 on microstructure and magnetic properties of Nd-Ce-Fe-B sintered magnets. Acta Mater. 2017, 128, 22–30. [Google Scholar] [CrossRef]

- Ding, G.; Liao, S.; Di, J.; Zheng, B.; Guo, S.; Chen, R.; Yan, A. Microstructure of core-shell NdY-Fe-B sintered magnets with a high coercivity and excellent thermal stability. Acta Mater. 2020, 194, 547–557. [Google Scholar] [CrossRef]

- Liu, X.B.; Altounian, Z.; Huang, M.; Zhang, Q.; Liu, J.P. The partitioning of la and y in Nd-Fe-B magnets: A first-principles study. J. Alloys Compd. 2013, 549, 366–369. [Google Scholar] [CrossRef]

- Fan, X.; Ding, G.; Chen, K.; Guo, S.; You, C.; Chen, R.; Lee, D.; Yan, A. Whole process metallurgical behavior of the high-abundance rare-earth elements LRE (La, Ce and Y) and the magnetic performance of Nd0.75LRE0.25-Fe-B sintered magnets. Acta Mater. 2018, 154, 343–354. [Google Scholar]

- Jiang, Q.; Song, J.; Huang, Q.; Rehman, S.U.; He, L.; Zeng, Q.; Zhong, Z. Enhanced magnetic properties and improved corrosion performance of nanocrystalline Pr-Nd-Y-Fe-B spark plasma sintered magnets. J. Mater. Sci. Technol. 2020, 58, 138–144. [Google Scholar] [CrossRef]

- Filipecka, K.; Pawlik, P.; Filipecki, J. The effect of annealing on magnetic properties, phase structure and evolution of free volumes in Pr-Fe-B-W metallic glasses. J. Alloys Compd. 2017, 694, 228–234. [Google Scholar] [CrossRef]

- Pei, K.; Zhang, X.; Lin, M.; Yan, A. Effects of Ce-substitution on magnetic properties and microstructure of Nd-Pr-Fe-B melt-spun powders. J. Magn. Magn. Mater. 2016, 398, 96–100. [Google Scholar] [CrossRef]

- Zhang, H.; Li, B.; Wang, J.; Zhang, J. Demagnetization behaviour in exchange-coupled Pr 10 Fe 85 B 5 ribbons. J. Phys. D Appl. Phys. 2000, 33, 3022. [Google Scholar] [CrossRef]

- Zhang, H.W.; Rong, C.B.; Zhang, J.; Zhang, S.Y.; Shen, B.G. Coercivity of isotropic nanocrystalline Pr12Fe82B6 ribbons. Phys. Rev. B 2002, 66, 184436. [Google Scholar] [CrossRef]

- Chen, S.L.; Liu, W.; Zhang, Z.D. Coercivity mechanism of anisotropic Pr2Fe14B thin films with perpendicular texture. Phys. Rev. B 2005, 72, 224419. [Google Scholar] [CrossRef]

- Tang, X.; Lai, J.; Sepehri-Amin, H.; Ohkubo, T.; Hono, K. (Pr0.75Ce0.25)-Fe-B hot-deformed magnets for cryogenic applications. Scr. Mater. 2021, 194, 113648. [Google Scholar] [CrossRef]

- Gong, W.J.; Wang, X.; Liu, W.; Guo, S.; Wang, Z.H.; Cui, W.B.; Zhu, Y.L.; Zhang, Y.Q.; Zhang, Z.D. Enhancing the perpendicular anisotropy of NdDyFeB films by Dy diffusion process. J. Appl. Phys. 2012, 111, 2010–2013. [Google Scholar] [CrossRef]

- Hubert, A.; Schafer, R. Magnetic Domains: The Analysis of Magnetic Microstructures; Springer: Berlin/Heidelberg, Germany, 1998. [Google Scholar]

- Kronmüller, H.; Durst, K.D.; Sagawa, M. Analysis of the magnetic hardening mechanism in RE-FeB permanent magnets. J. Magn. Magn. Mater. 1988, 74, 291–302. [Google Scholar] [CrossRef]

- Kou, X.C.; Kronmüller, H.; Givord, D.; Rossignol, M.F. Coercivity mechanism of sintered Pr17Fe75B8 and Pr17Fe53B30 permanent magnets. Phys. Rev. B 1994, 50, 3849–3860. [Google Scholar] [CrossRef]

- Kronmüller, H.; Schrefl, T. Interactive and cooperative magnetization processes in hard magnetic materials. J. Magn. Magn. Mater. 1994, 129, 66–78. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, X.T.; Liu, W.; Ma, J.; Liu, L.; Song, Y.H.; Deng, W.Y.; Qi, L.J.; Zhao, X.G.; Zhang, Z.D. Coercivity mechanism and effect of Dy element in anisotropic LaPrFeB multilayers with Dy diffusion. J. Appl. Phys. 2020, 128, 043903. [Google Scholar] [CrossRef]

- Goll, D.; Seeger, M.; Kronmüller, H. Magnetic and micro structural properties of nanocrystalline exchange coupled PrFeB permanent magnets. J. Magn. Magn. Mater. 1998, 185, 49–60. [Google Scholar] [CrossRef]

- Kronmüller, H. Theory of Nucleation Fields in Inhomogeneous Ferromagnets. Phys. Status Solidi 1987, 144, 385–396. [Google Scholar] [CrossRef]

- Pike, C.R.; Ross, C.A.; Scalettar, R.T.; Zimanyi, G. First-order reversal curve diagram analysis of a perpendicular nickel nanopillar array. Phys. Rev. B 2005, 71, 134407. [Google Scholar] [CrossRef] [Green Version]

- Pike, R. First-order reversal-curve diagrams and reversible magnetization. Phys. Rev. B 2003, 68, 104424. [Google Scholar] [CrossRef] [Green Version]

- Davies, J.E.; Hellwig, O.; Fullerton, E.E.; Denbeaux, G.; Kortright, J.B.; Liu, K. Magnetization reversal of Co/Pt multilayers: Microscopic origin of high-field magnetic irreversibility. Phys. Rev. B 2004, 70, 224434. [Google Scholar] [CrossRef] [Green Version]

- Roy, D.; Sreenivasulu, K.V.; Anil Kumar, P.S. Investigation on non-exchange spring behaviour and exchange spring behaviour: A first order reversal curve analysis. Appl. Phys. Lett. 2013, 103, 222406. [Google Scholar] [CrossRef] [Green Version]

- Gilbert, D.A.; Zimanyi, G.T.; Dumas, R.K.; Winklhofer, M.; Gomez, A.; Eibagi, N.; Vicent, J.L.; Liu, K. Quantitative decoding of interactions in tunable nanomagnet arrays using first order reversal curves. Sci. Rep. 2014, 4, 4204. [Google Scholar] [CrossRef] [PubMed]

- Winklhofer, M.; Dumas, R.K.; Liu, K. Identifying reversible and irreversible magnetization changes in prototype patterned media using first- and second-order reversal curves. J. Appl. Phys. 2008, 103, 07C518. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.Y.; Wang, L.W.; Chen, P.A.; Lin, H.J.; Lai, C.H.; Tseng, Y.C. Sharp variation in coercivity and magnetic interactions in patterned CoxNi1-x nanoarrays. J. Appl. Phys. 2013, 114, 036902. [Google Scholar] [CrossRef] [Green Version]

- Dai, Z.M.; Liu, W.; Zhao, X.T.; Han, Z.; Kim, D.; Choi, C.J.; Zhang, Z.D. Magnetic interactions in anisotropic Nd-Dy-Fe-Co-B/α-Fe multilayer magnets. J. Appl. Phys. 2016, 120, 163906. [Google Scholar] [CrossRef]

- Béron, F.; Clime, L.; Ciureanu, M.; Ménard, D.; Cochrane, R.W.; Yelon, A. Reversible and quasireversible information in first-order reversal curve diagrams. J. Appl. Phys. 2007, 101, 09J107. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Zhao, X.; Liu, W.; Li, Y.; Liu, L.; Song, Y.; Xie, Y.; Zhao, X.; Zhang, Z. Coercivity Mechanism and Magnetization Reversal in Anisotropic Ce-(Y)-Pr-Fe-B Films. Materials 2021, 14, 4680. https://doi.org/10.3390/ma14164680

Ma J, Zhao X, Liu W, Li Y, Liu L, Song Y, Xie Y, Zhao X, Zhang Z. Coercivity Mechanism and Magnetization Reversal in Anisotropic Ce-(Y)-Pr-Fe-B Films. Materials. 2021; 14(16):4680. https://doi.org/10.3390/ma14164680

Chicago/Turabian StyleMa, Jun, Xiaotian Zhao, Wei Liu, Yang Li, Long Liu, Yuhang Song, Yuanhua Xie, Xinguo Zhao, and Zhidong Zhang. 2021. "Coercivity Mechanism and Magnetization Reversal in Anisotropic Ce-(Y)-Pr-Fe-B Films" Materials 14, no. 16: 4680. https://doi.org/10.3390/ma14164680

APA StyleMa, J., Zhao, X., Liu, W., Li, Y., Liu, L., Song, Y., Xie, Y., Zhao, X., & Zhang, Z. (2021). Coercivity Mechanism and Magnetization Reversal in Anisotropic Ce-(Y)-Pr-Fe-B Films. Materials, 14(16), 4680. https://doi.org/10.3390/ma14164680