Pd-Catalyzed Cyclocarbonylation of Allylic Alcohol under Benign Conditions with Ionic Liquid as Stabilizer

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals

2.2. Cyclocarbonylation Reactions

2.3. Product Analysis

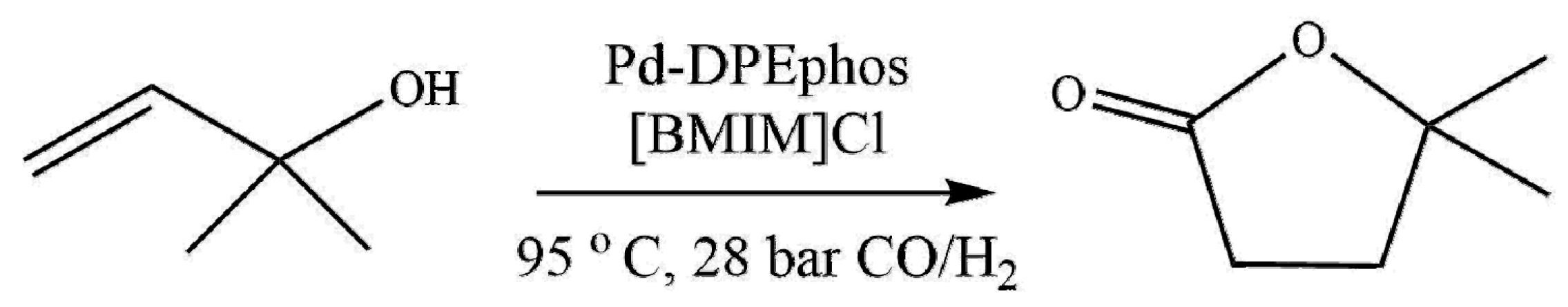

3. Results and Discussion

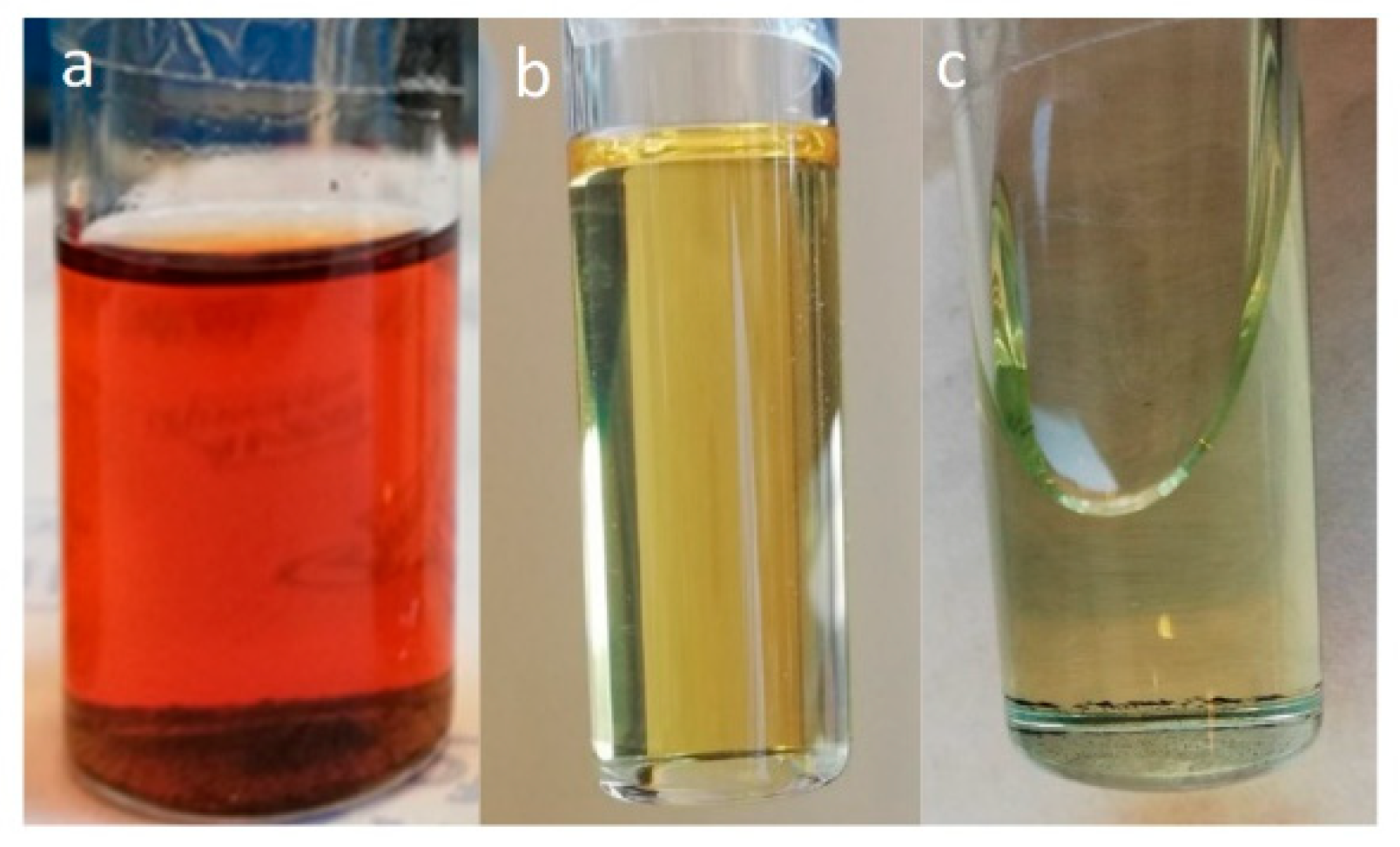

3.1. Effect of IL and Ligand Content

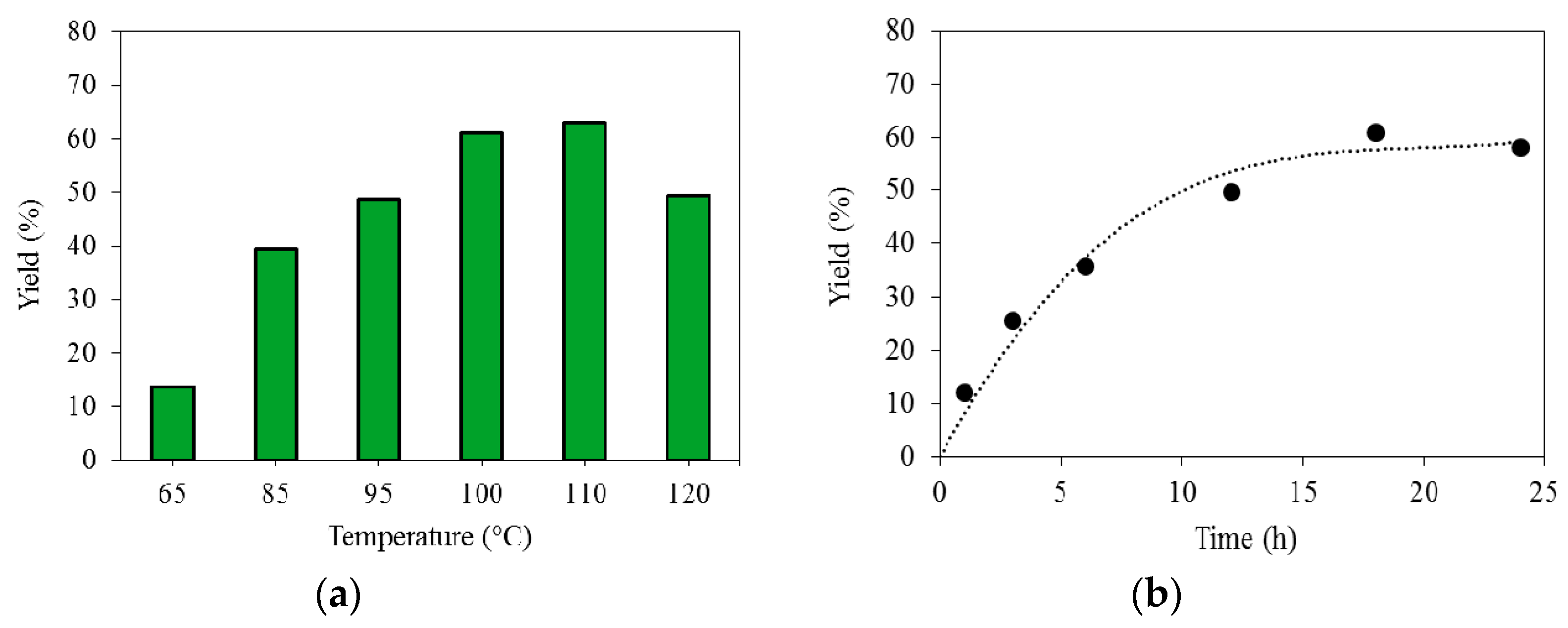

3.2. Effect of Reaction Temperature and Time

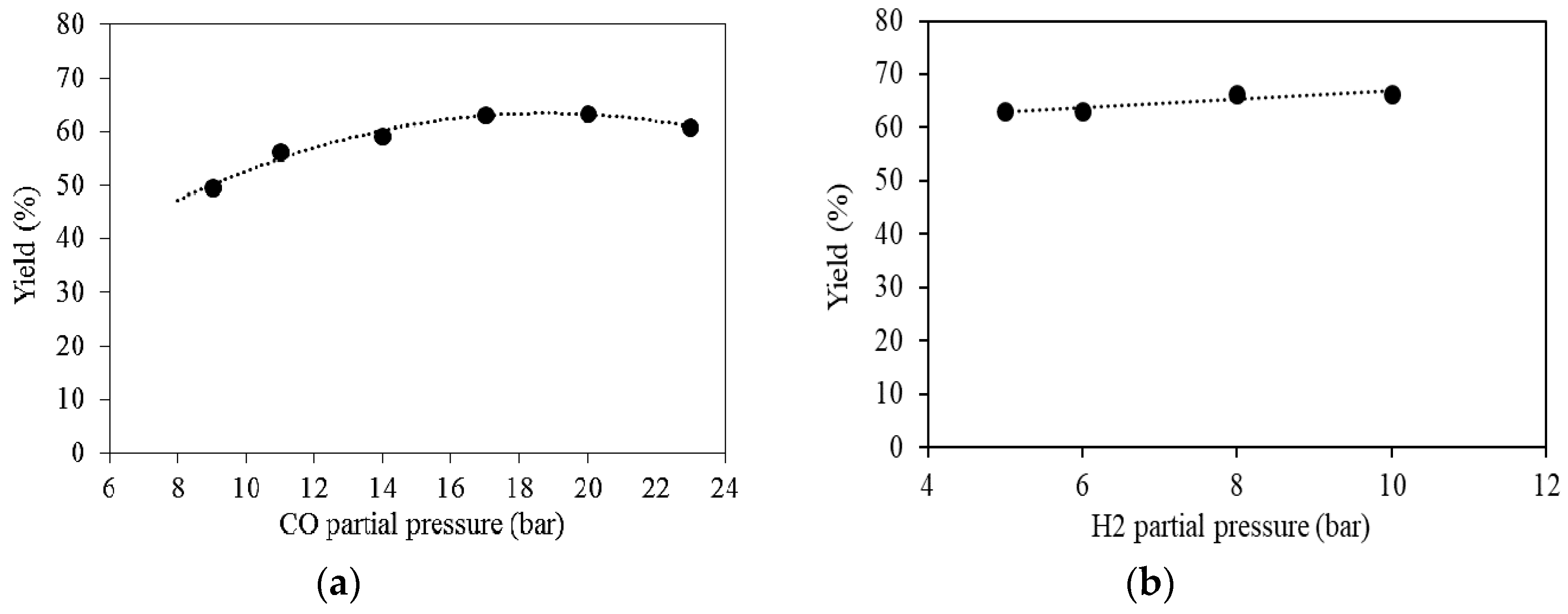

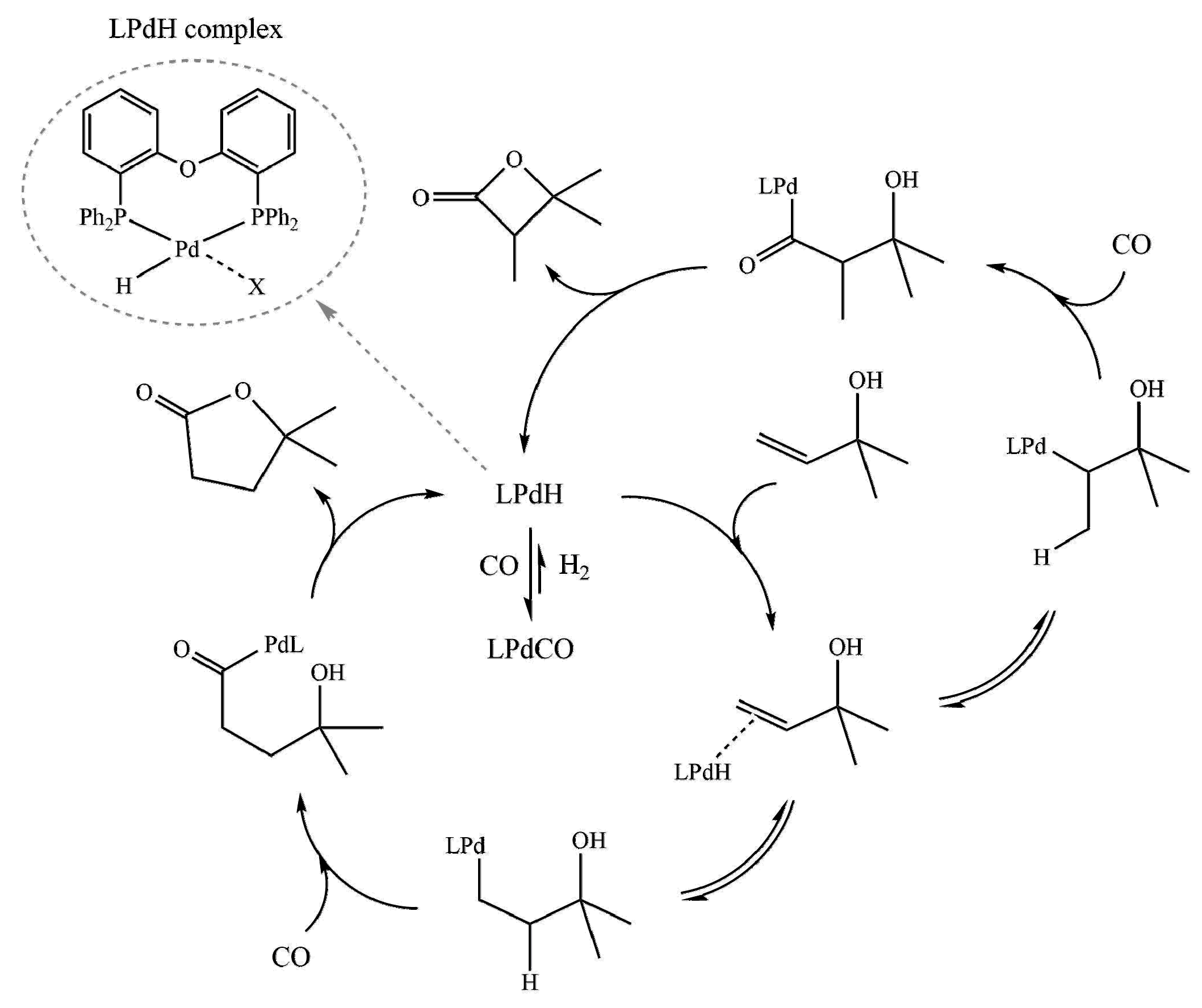

3.3. Effect of Gas Composition

3.4. Effect of Substrate Concentration

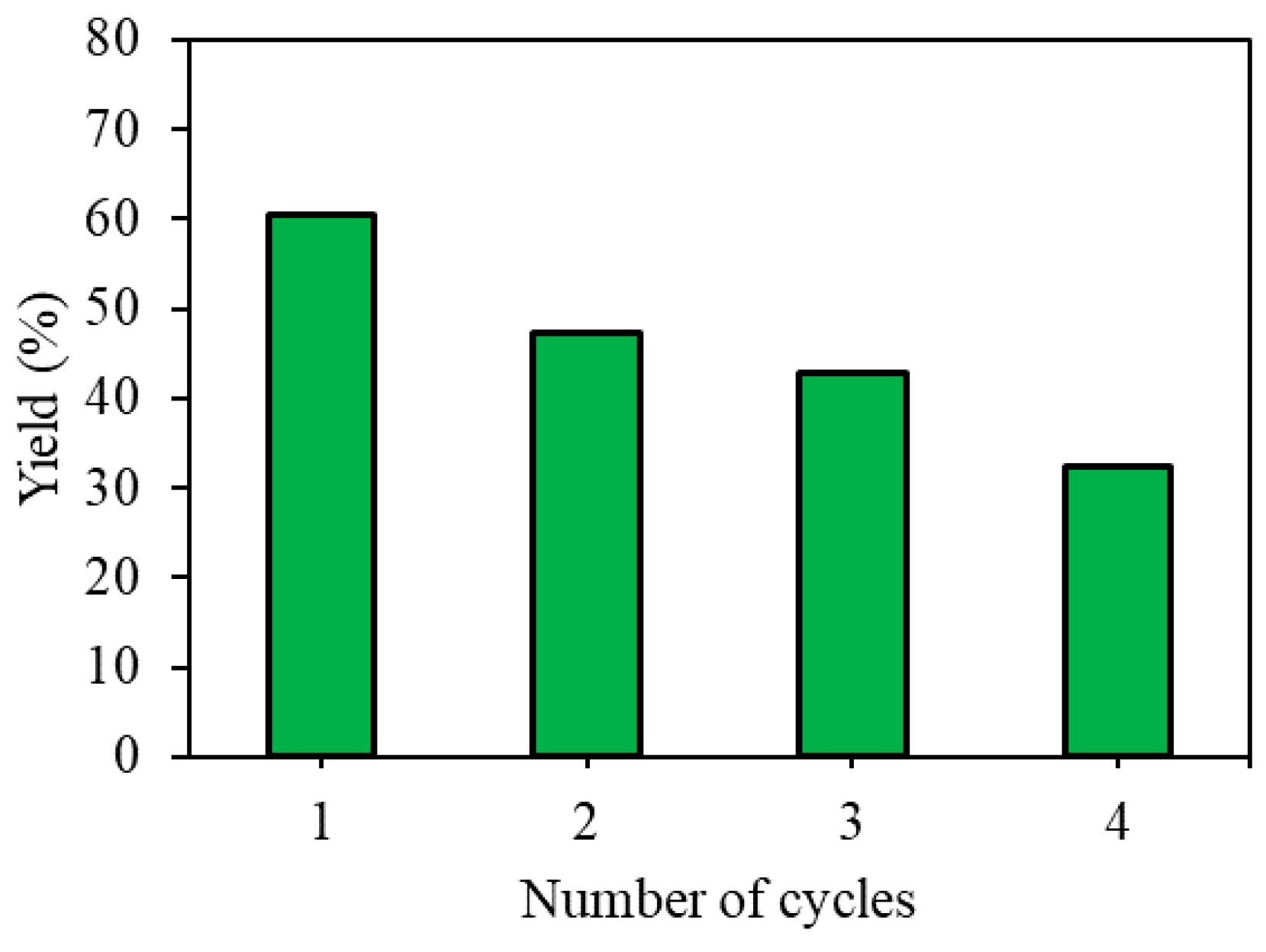

3.5. Reuse of the Catalytic System

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- El Ali, B.; Alper, H. Lactonization of Unsaturated Alcohols Catalyzed by Palladium Complexes under Neutral Conditions. J. Org. Chem. 1991, 56, 5357–5360. [Google Scholar] [CrossRef]

- Tamaru, Y.; Hojo, M.; Yoshida, Z.I. Palladium (II)-Catalyzed Carbonylation of 3-Buten-1-ols and 3-Butyn-1-ols: An Efficient Synthesis of γ-Butyrolactones. J. Org. Chem. 1991, 56, 1099–1105. [Google Scholar] [CrossRef]

- Matsushita, K.; Komori, T.; Oi, S.; Inoue, Y. Carbonylation of Tertiary Propargylic Alcohols Catalyzed by a Cationic Palladium (II) Complex: Synthesis of 2(5H)-Furanones. Tetrahedron Lett. 1994, 35, 5889–5890. [Google Scholar] [CrossRef]

- Yu, W.Y.; Bensimon, C.; Alper, H. A Novel Palladium-Catalyzed Asymmetric Cyclocarbonylation of Allylic Alcohols to γ-Butyrolactones. Chem. Eur. J. 1997, 3, 417–423. [Google Scholar] [CrossRef]

- El Ali, B.; Okuro, K.; Vasapollo, G.; Alper, H. Regioselective Palladium (II)-Catalyzed Synthesis of Five-or Seven-Membered Ring Lactones and Five-, Six-or Seven-Membered Ring Lactams by Cyclocarbonylation Methodology. J. Am. Chem. Soc. 1996, 118, 4264–4270. [Google Scholar] [CrossRef]

- Falbe, J. Carbon Monoxide in Organic Synthesis; Springer: New York, NY, USA; Heidelberg/Berlin, Germany, 1970. [Google Scholar]

- Galli, C.; Illuminati, G.; Mandolini, L. Tamborra, Ring-Closure Reactions. 7. Kinetics and Activation Parameters of Lactone Formation in the Range of 3- to 23-Membered Rings. J. Am. Chem. Soc. 1977, 99, 2591–2597. [Google Scholar] [CrossRef]

- Gabriele, B.; Salerno, G.; Pascali, F.D.; Costa, M.; Chiusoli, G.P. Stereoselective synthesis of (Z)-α-(alkoxycarbonyl)methylene β-and γ-lactones by palladium-catalysed oxidative carbonylation of alkynols. J. Chem. Soc., Perkin Trans. 1997, 1, 147–154. [Google Scholar] [CrossRef]

- Getzler, Y.D.Y.L.; Mahadevan, V.; Lobkovsky, E.B.; Coates, G.W. Synthesis of β-Lactones: A Highly Active and Selective Catalyst for Epoxide Carbonylation. J. Am. Chem. Soc. 2002, 124, 1174–1175. [Google Scholar] [CrossRef]

- Kramer, J.W.; Lobkovsky, E.B.; Coates, G.W. Practical β-Lactone Synthesis: Epoxide Carbonylation at 1 atm. Org. Lett. 2006, 8, 3710–3712. [Google Scholar] [CrossRef]

- Peng, J.B.; Wu, F.P.; Wu, X.F. First-Row Transition-Metal-Catalyzed Carbonylative Transformations of Carbon Electrophiles. Chem. Rev. 2019, 119, 2090–2127. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Y.; Wu, X.F. Non-noble metal-catalysed carbonylative transformations. Chem. Soc. Rev. 2018, 47, 172–194. [Google Scholar] [CrossRef] [PubMed]

- Gadge, S.T.; Bhanage, B.M. Recent developments in palladium catalysed carbonylation reactions. RSC Adv. 2014, 4, 10367–10389. [Google Scholar] [CrossRef]

- Mancuso, R.; Ca’, N.D.; Veltri, L.; Ziccarelli, I.; Gabriele, B. PdI2-Based Catalysis for Carbonylation Reactions: A Personal Account. Catalysts 2019, 9, 610. [Google Scholar] [CrossRef]

- Prakasham, A.P.; Ghosh, P. Nickel N-heterocyclic carbene complexes and their utility in homogeneous catalysis. Inorg. Chim. Acta 2015, 431, 61–100. [Google Scholar] [CrossRef]

- Kalck, P.; Urrutigoïty, M. Recent improvements in the alkoxycarbonylation reaction catalyzed by transition metal complexes. Inorg. Chim. Acta 2015, 431, 110–121. [Google Scholar] [CrossRef]

- Brunner, M.; Alper, H. The First Stereoselective Palladium-Catalyzed Cyclocarbonylation of β,γ-Substituted Allylic Alcohols. J. Org. Chem. 1997, 62, 7565–7568. [Google Scholar] [CrossRef]

- Alamgholiloo, H.; Rostamnia, S.; Hassankhani, A.; Liu, X.; Eftekhari, A.; Hasanzadeh, A.; Zhang, K.; Karimi-Maleh, H.; Khaksar, S.; Varma, R.S.; et al. Formation and stabilization of colloidal ultra-small palladium nanoparticles on diamine-modified Cr-MIL-101: Synergic boost to hydrogen production from formic acid. J. Colloid. Interf. Sci. 2020, 567, 126–135. [Google Scholar] [CrossRef]

- Haumann, M.; Riisager, A. Hydroformylation in Room Temperature Ionic Liquids (RTILs): Catalyst and Process Developments. Chem. Rev. 2008, 108, 1474–1497. [Google Scholar] [CrossRef]

- Chauvin, Y.; Mussmann, L.; Oliver, H. A Novel Class of Versatile Solvents for Two-Phase Catalysis: Hydrogenation, Isomerization, and Hydroformylation of Alkenes Catalyzed by Rhodium Complexes in Liquid 1,3-Dialkylimidazolium Salts. Angew. Chem. Int. Ed. 1996, 34, 2698–2700. [Google Scholar] [CrossRef]

- Swatloski, R.P.; Holbrey, J.D.; Rogers, R.D. Ionic liquids are not always green: Hydrolysis of 1-butyl-3-methylimidazolium hexafluorophosphate. Green Chem. 2003, 5, 361–363. [Google Scholar] [CrossRef]

- Garcia-Suarez, E.J.; Khokarale, S.G.; Van Buu, O.N.; Fehrmann, R.; Riisager, A. Pd-catalyzed ethylene methoxycarbonylation with Brønsted acid ionic liquids as promoter and phase-separable reaction media. Green Chem. 2014, 16, 161–166. [Google Scholar] [CrossRef]

- Khokarale, S.G.; Garcia-Suarez, E.J.; Fehrmann, R.; Riisager, A. Highly Selective Continuous Gas-Phase Methoxycarbonylation of Ethylene with Supported Ionic Liquid Phase (SILP) Catalysts. ChemCatChem 2017, 9, 1824–1829. [Google Scholar] [CrossRef]

- Scammells, P.J.; Scott, J.L.; Singer, R.D. Ionic Liquids: The Neglected Issues. Aust. J. Chem. 2005, 58, 155–169. [Google Scholar] [CrossRef]

- Holbrey, J.D.; Seddon, K.R. Ionic Liquids. Clean Prod. Proc. 1999, 1, 223–236. [Google Scholar] [CrossRef]

- Welton, T. Room-Temperature Ionic Liquids. Solvents for Synthesis and Catalysis. Chem. Rev. 1999, 99, 2071–2083. [Google Scholar] [CrossRef] [PubMed]

- Dupont, J.; Consorti, C.S.; Spencer, J. Room Temperature Molten Salts: Neoteric “Green” Solvents for Chemical Reactions and Processes. J. Braz. Chem. Soc. 2000, 11, 337–344. [Google Scholar] [CrossRef]

- Wasserscheid, P.; Keim, W. Ionic Liquids-New “Solutions” for Transition Metal Catalysis. Angew. Chem. Int. Ed. 2000, 39, 3772–3789. [Google Scholar] [CrossRef]

- Tzschucke, C.C.; Markert, C.; Bannwarth, W.; Roller, S.; Hebel, A.; Haag, R. Modern Separation Techniques for the Efficient Workup in Organic Synthesis. Angew. Chem. Int. Ed. 2002, 41, 3964–4000. [Google Scholar] [CrossRef]

- Baerns, M.; Claus, P. Chemical Reaction Engineering Aspects of Homogeneously Catalyzed Processes. In Applied Homogeneous Catalysis with Organometallic Compounds: A Comprehensive Handbook in Four Volumes, 3rd ed.; Cornils, B., Herrmann, W.A., Beller, M., Paciello, R., Eds.; Wiley-VCH: Weinheim, Germany, 2018. [Google Scholar]

- Ye, F.; Alper, H. Recyclable Selective Palladium-Catalyzed Synthesis of Five-, Six-or Seven-Membered Ring Lactones and Lactams by Cyclocarbonylation in Ionic Liquids. Adv. Synth. Catal. 2006, 348, 1855–1861. [Google Scholar] [CrossRef]

- Eastham, G.R. Studies on the Palladium Catalysed Methoxycarbonylation of Ethene. Ph.D. Thesis, Durham University, Durham, UK, 1998. [Google Scholar]

| Entry | 2-methyl-3-buten-2-ol (mmol) | Conversion (%) | Yield of Lactone (%) | Selectivity (%) |

|---|---|---|---|---|

| 1 | 0.43 | 98.1 | 69.7 | 71.0 |

| 2 | 0.46 | 96.8 | 63.5 | 65.6 |

| 3 | 0.48 | 91.4 | 60.0 | 65.6 |

| 4 | 0.52 | 88.8 | 58.1 | 65.4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nemati, N.; Eslamloueyan, R.; Modvig, A.; Riisager, A. Pd-Catalyzed Cyclocarbonylation of Allylic Alcohol under Benign Conditions with Ionic Liquid as Stabilizer. Materials 2020, 13, 2093. https://doi.org/10.3390/ma13092093

Nemati N, Eslamloueyan R, Modvig A, Riisager A. Pd-Catalyzed Cyclocarbonylation of Allylic Alcohol under Benign Conditions with Ionic Liquid as Stabilizer. Materials. 2020; 13(9):2093. https://doi.org/10.3390/ma13092093

Chicago/Turabian StyleNemati, Nasrin, Reza Eslamloueyan, Amalie Modvig, and Anders Riisager. 2020. "Pd-Catalyzed Cyclocarbonylation of Allylic Alcohol under Benign Conditions with Ionic Liquid as Stabilizer" Materials 13, no. 9: 2093. https://doi.org/10.3390/ma13092093

APA StyleNemati, N., Eslamloueyan, R., Modvig, A., & Riisager, A. (2020). Pd-Catalyzed Cyclocarbonylation of Allylic Alcohol under Benign Conditions with Ionic Liquid as Stabilizer. Materials, 13(9), 2093. https://doi.org/10.3390/ma13092093