The Critical Raw Materials in Cutting Tools for Machining Applications: A Review

Abstract

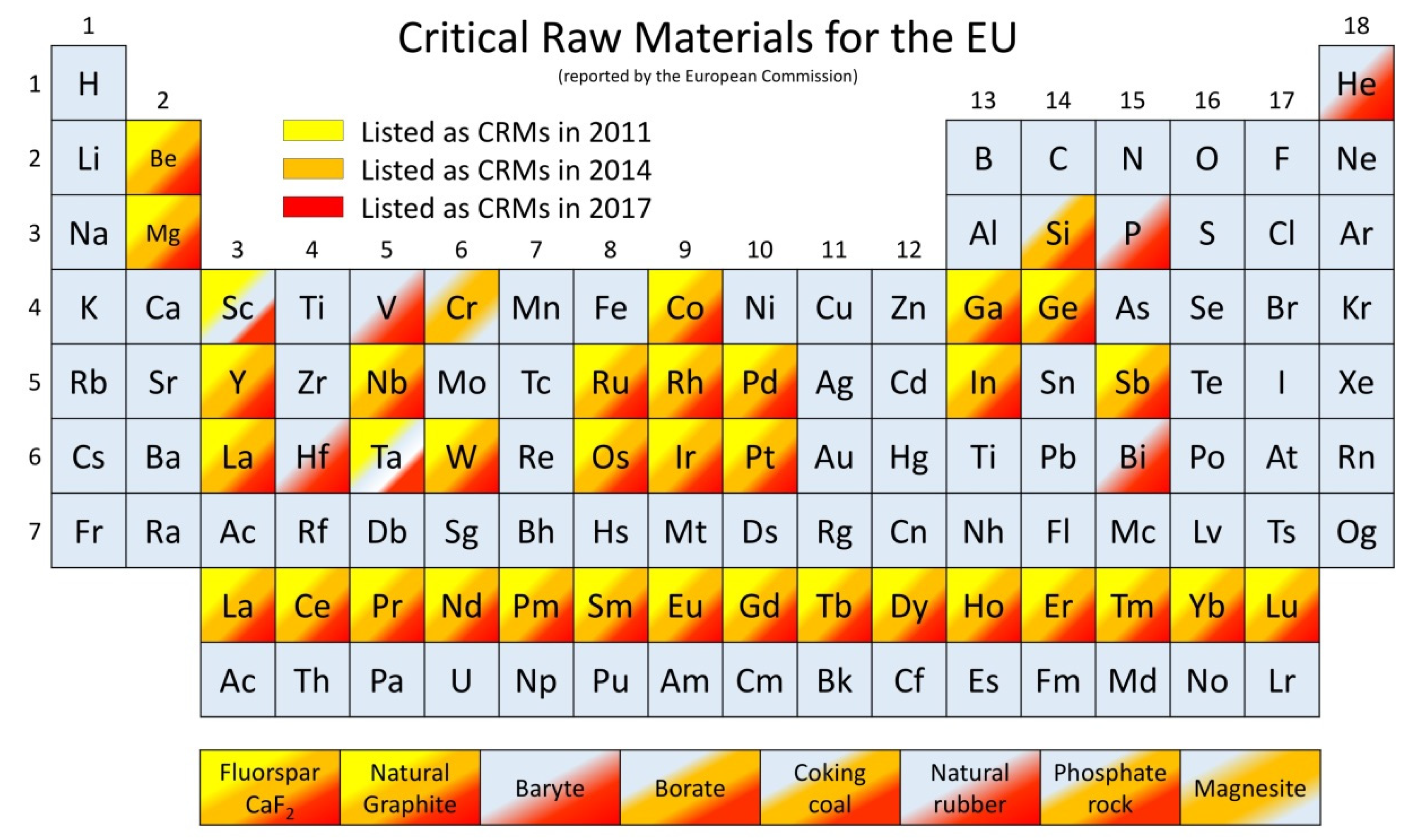

1. Introduction

- Increase the life of the tools by enhanced material removal techniques including laser assistance, cryogenic assistance, vibration assistance and use of protective coatings;

- Develop and synthesise newer materials that can adequately partially or totally replace the CRMs used in the tools;

- Rigorously involve modelling and simulation in the tool design and deploy digital twins to make improved predictions in the present era of digital manufacturing;

- Improve the recycling of worn-out tools.

2. Attempts to Expand the Life of Tungsten Carbide (WC)–Co Based Tools

2.1. WC–Co Based Materials

2.2. Advanced Machining Techniques

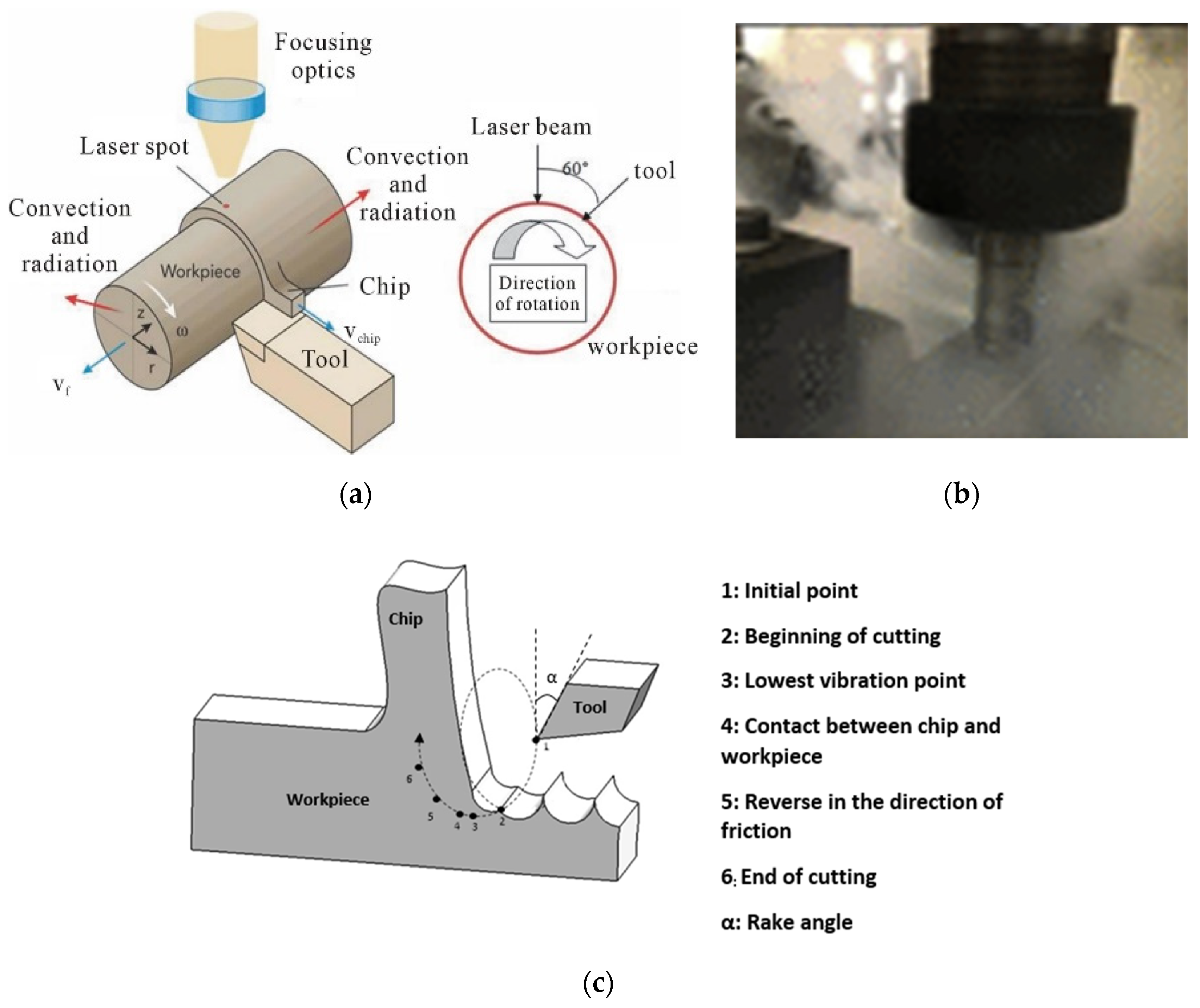

2.2.1. Machining by Laser Assistance (Thermal-Assisted Machining)

2.2.2. Cryogenic Machining

- Cryogenic treatment induces a structural variation with the formation of carbides of the eta phase and the redistribution or densification of Co, which increases its hardness;

- The micro-hardness of the treated tools is greater than that of untreated tools;

- The cryogenic treatment of tungsten carbide inserts increases the tool’s lifetime during the processing of austenitic AISI 316 steel;

- Wear patterns are smoother and more regular;

- Cryogenic treatment increases chipping resistance;

- The radius of the chip coil as well as the thickness of the chip itself is smaller after processing with cryogenically treated inserts or in cryo-processing conditions.

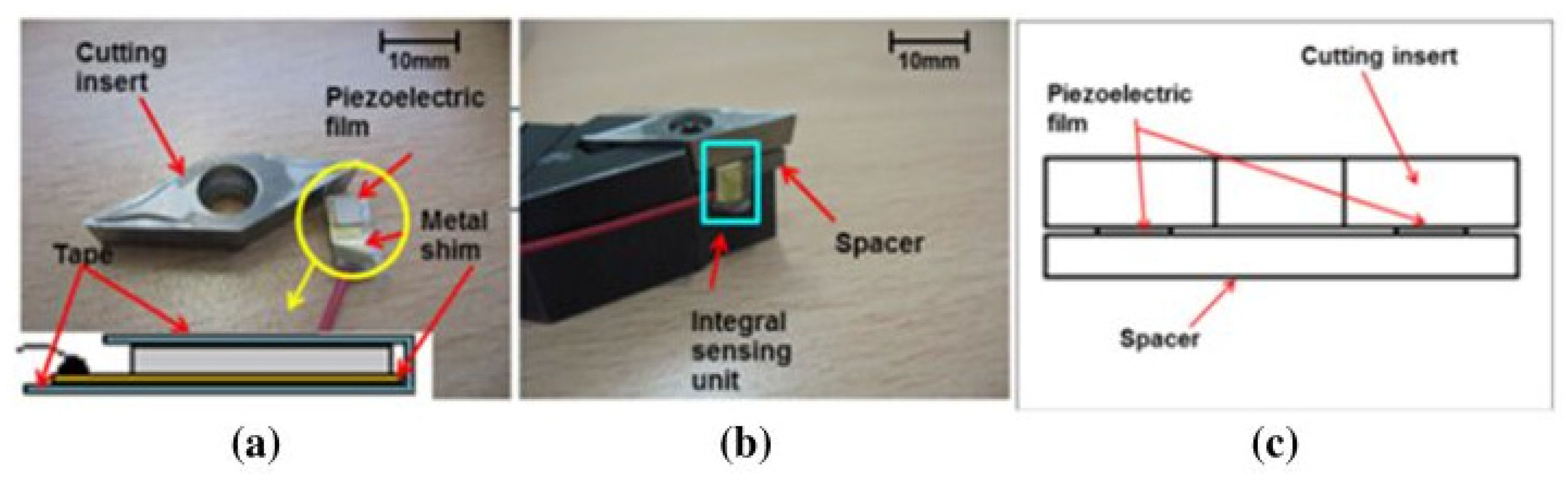

2.2.3. Vibration-Assisted Machining

- (i)

- uniaxial tool movement (1D VAM), where the tool vibrates in a plane parallel to the surface of the workpiece; and

- (ii)

- elliptical tool movement [68] (EVAM) where the tool vibrates with an elliptical motion. Both methods can be both resonance-based and non-resonance-based.

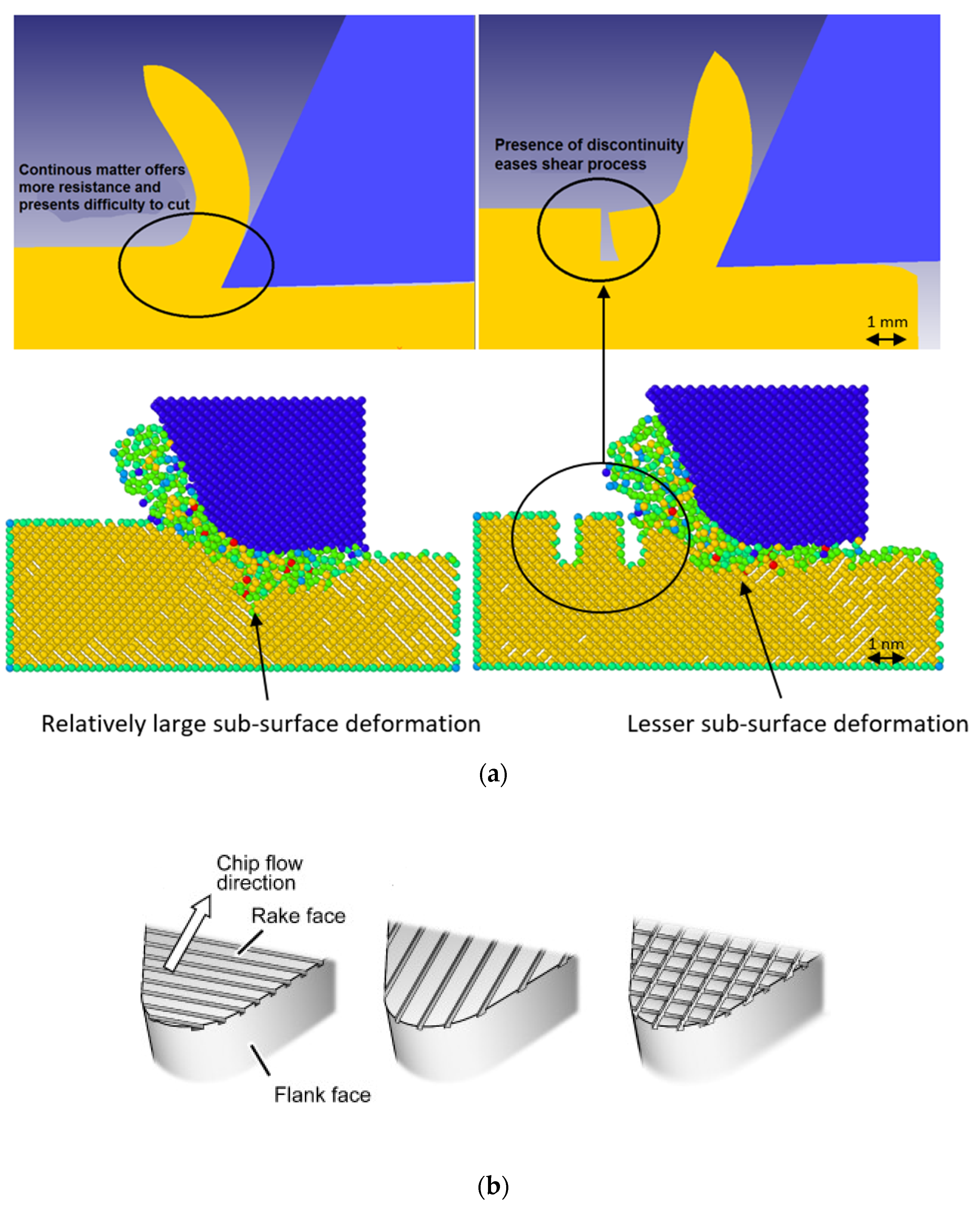

2.2.4. Surface Defect Machining

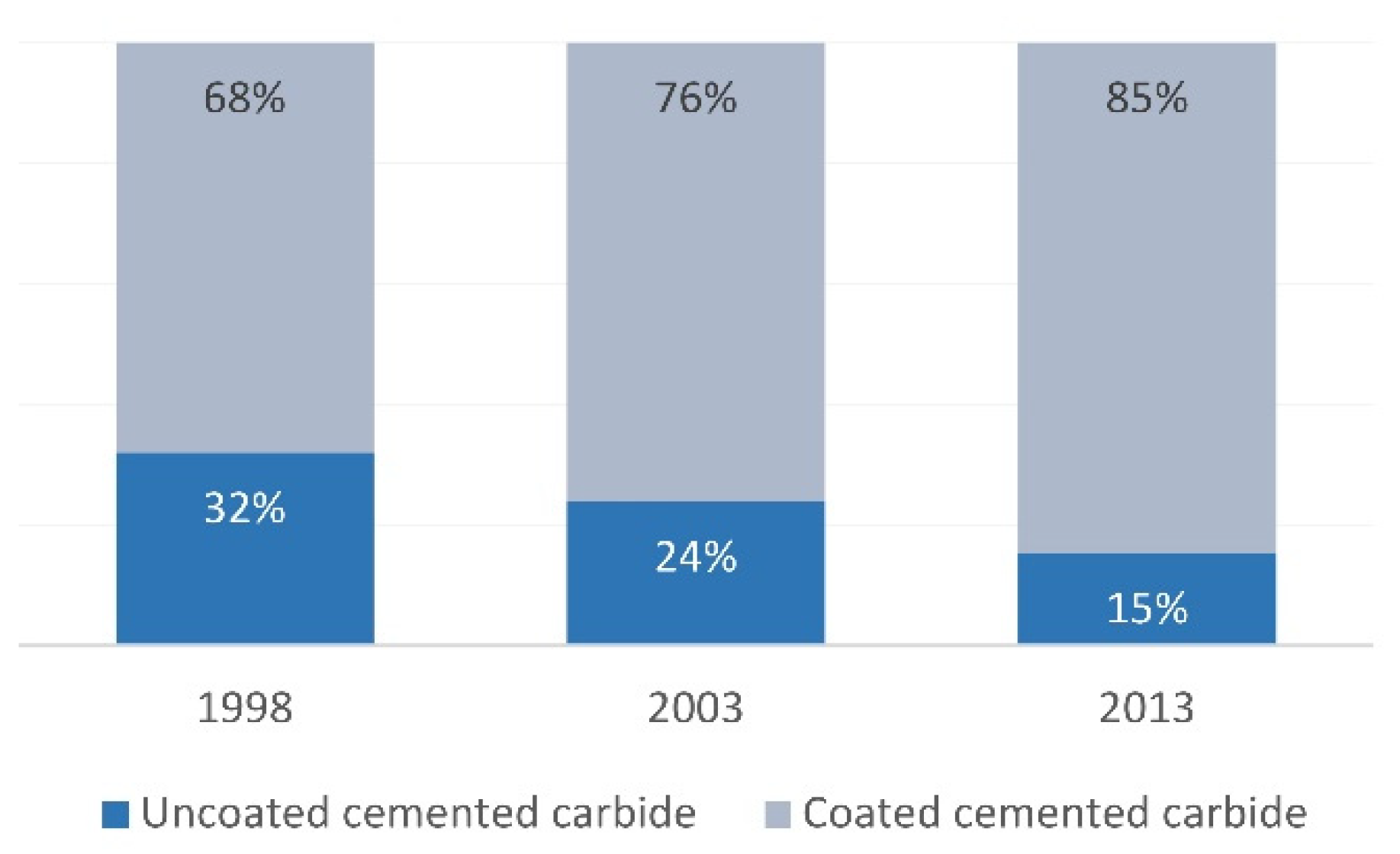

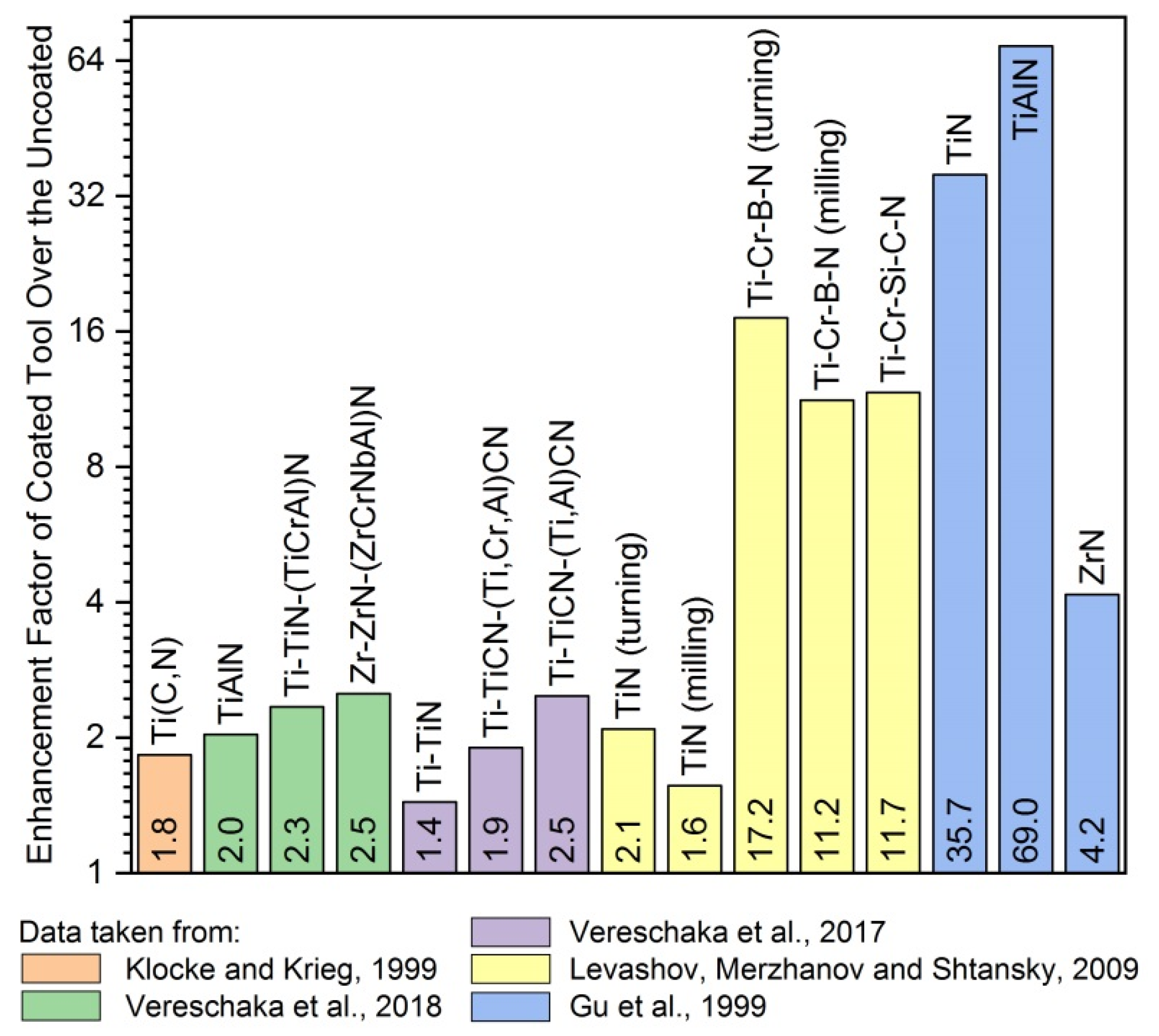

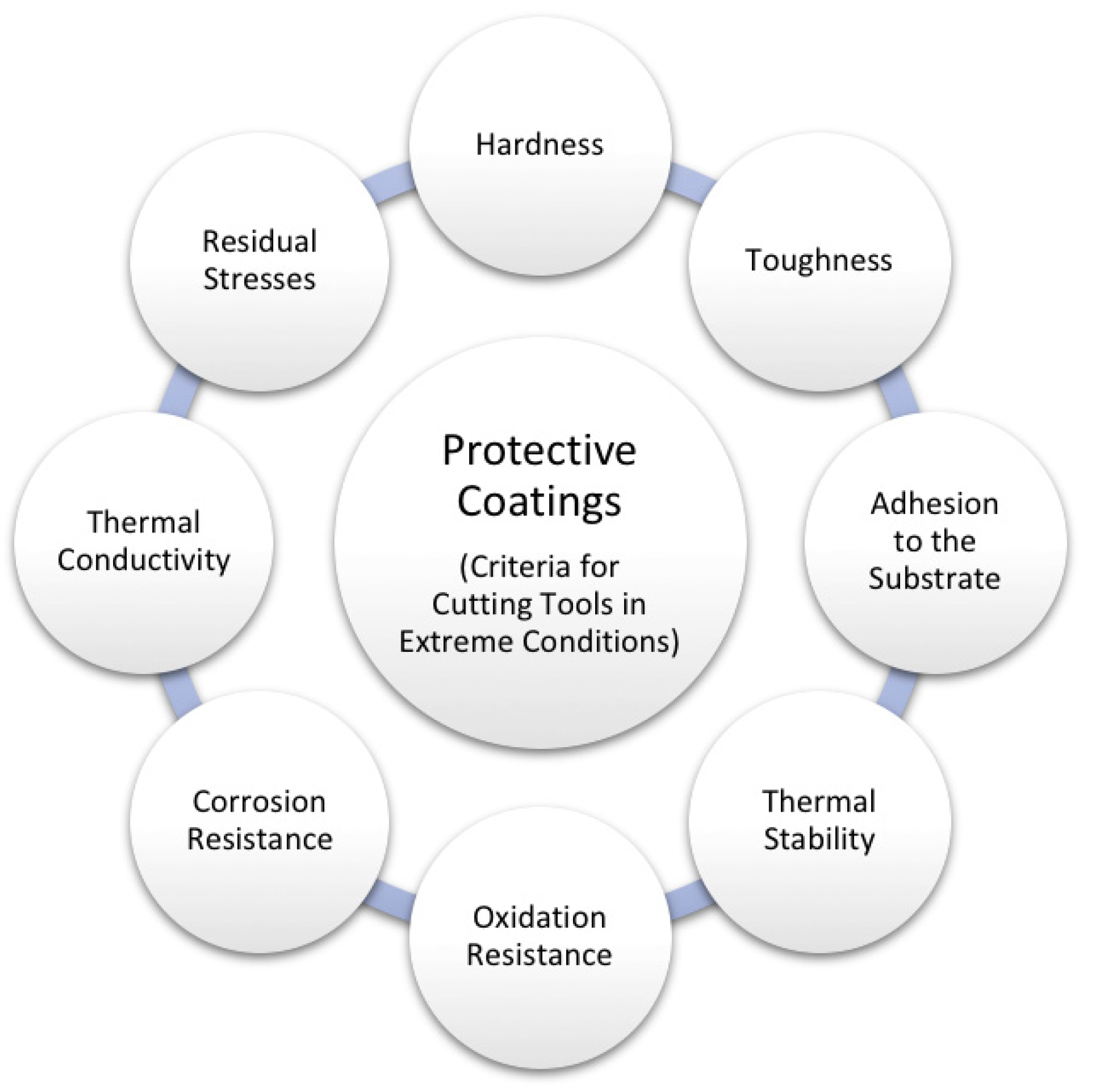

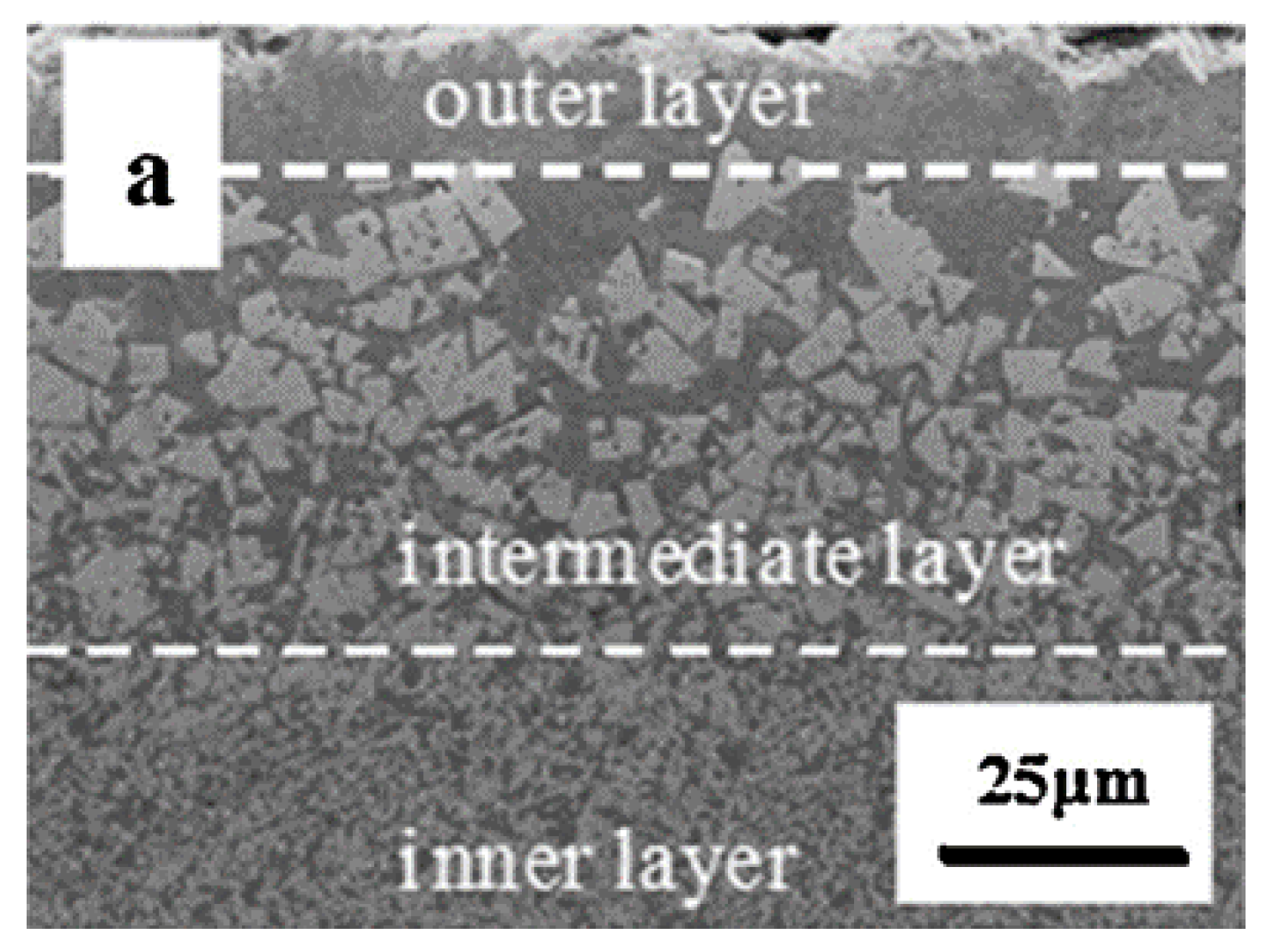

2.3. Protective Coatings

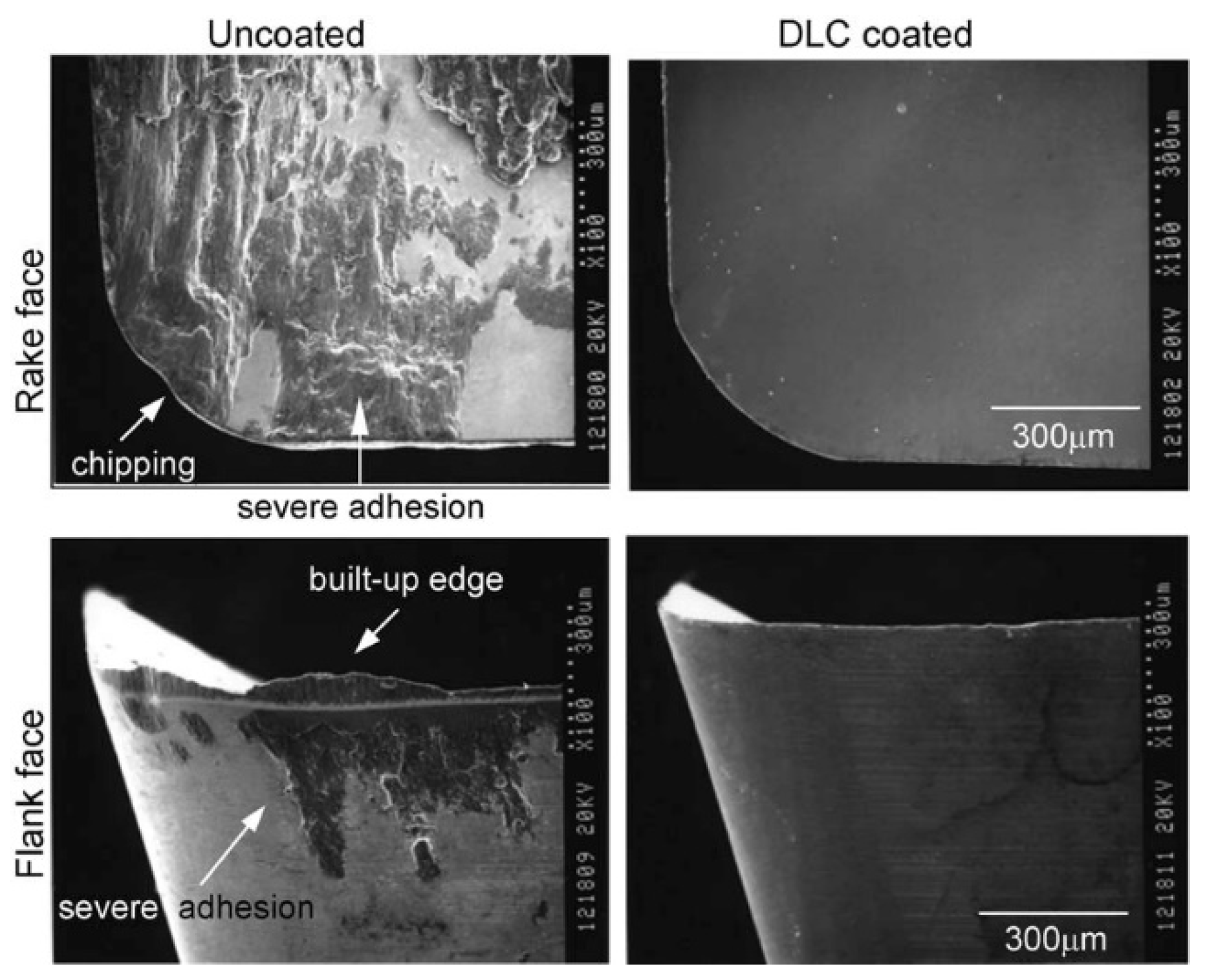

2.3.1. Diamond and Diamond-Like Carbon (DLC) Coatings

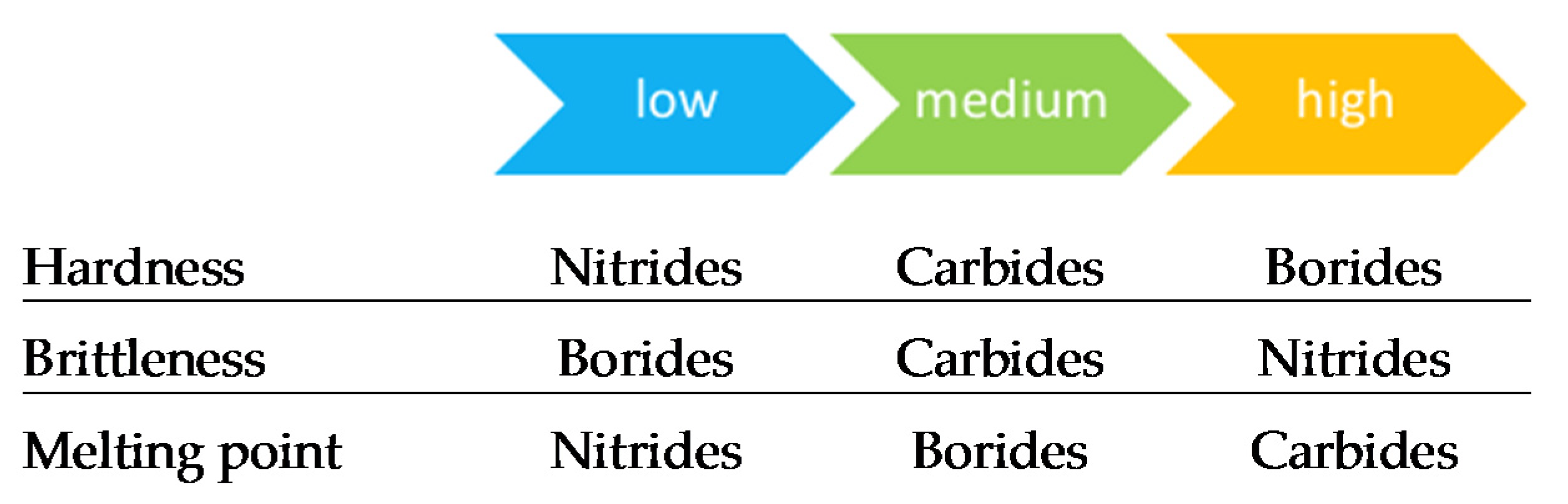

2.3.2. Transition Metal Compounds

2.3.3. Multi-Elemental Compounds and High-Entropy Alloy Protective Coatings

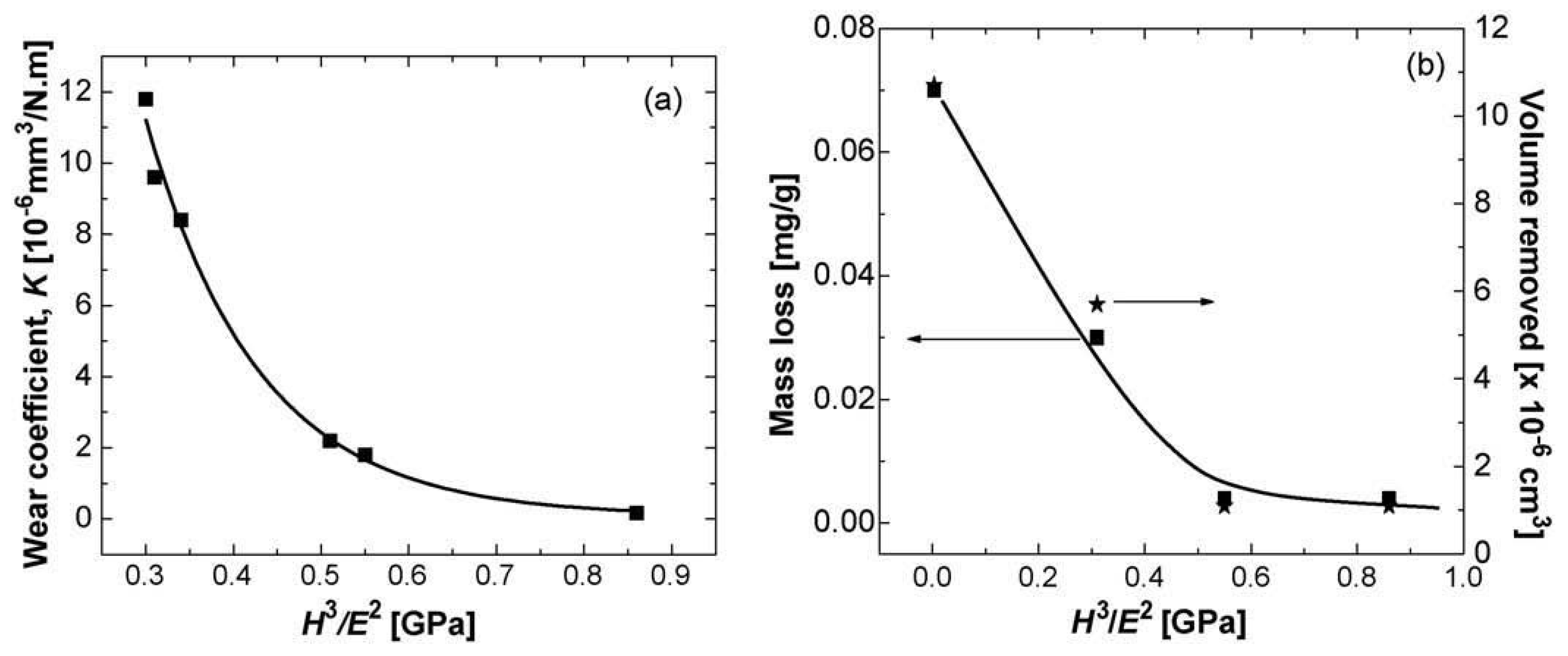

2.3.4. Nanocomposite Super-Hard Coatings

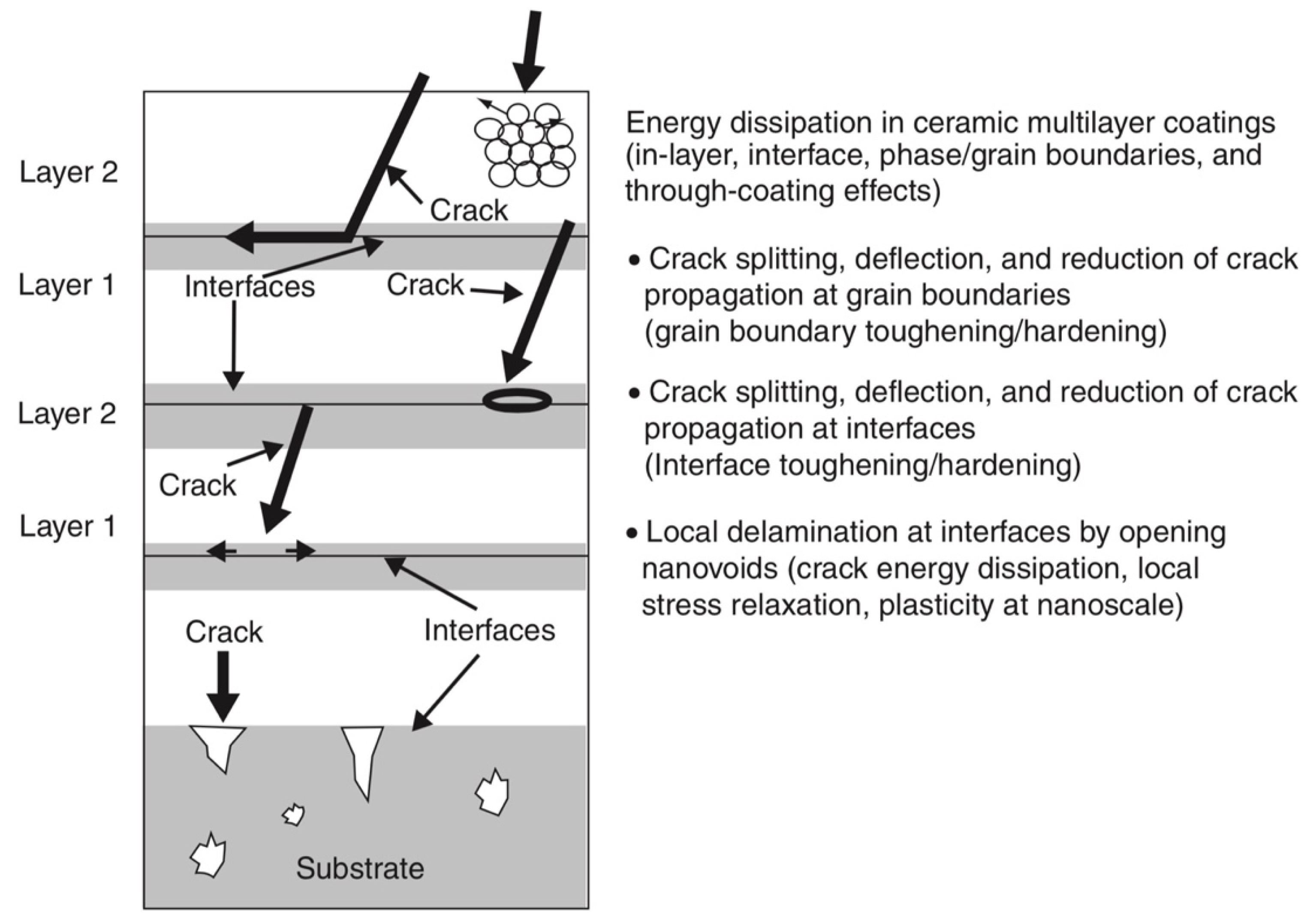

2.3.5. Multi-Layered and Graded Coatings

2.3.6. Thermal Barrier Coatings

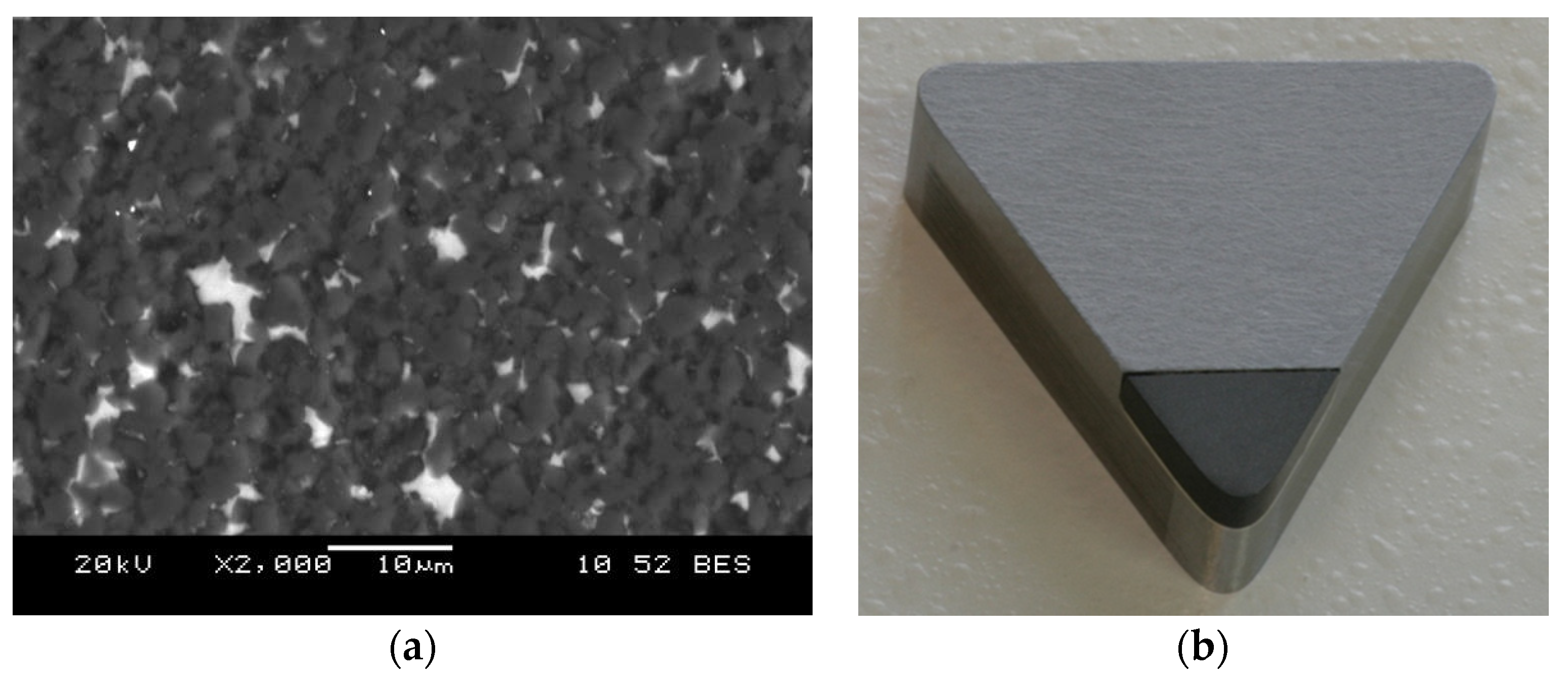

3. New Materials for Tools

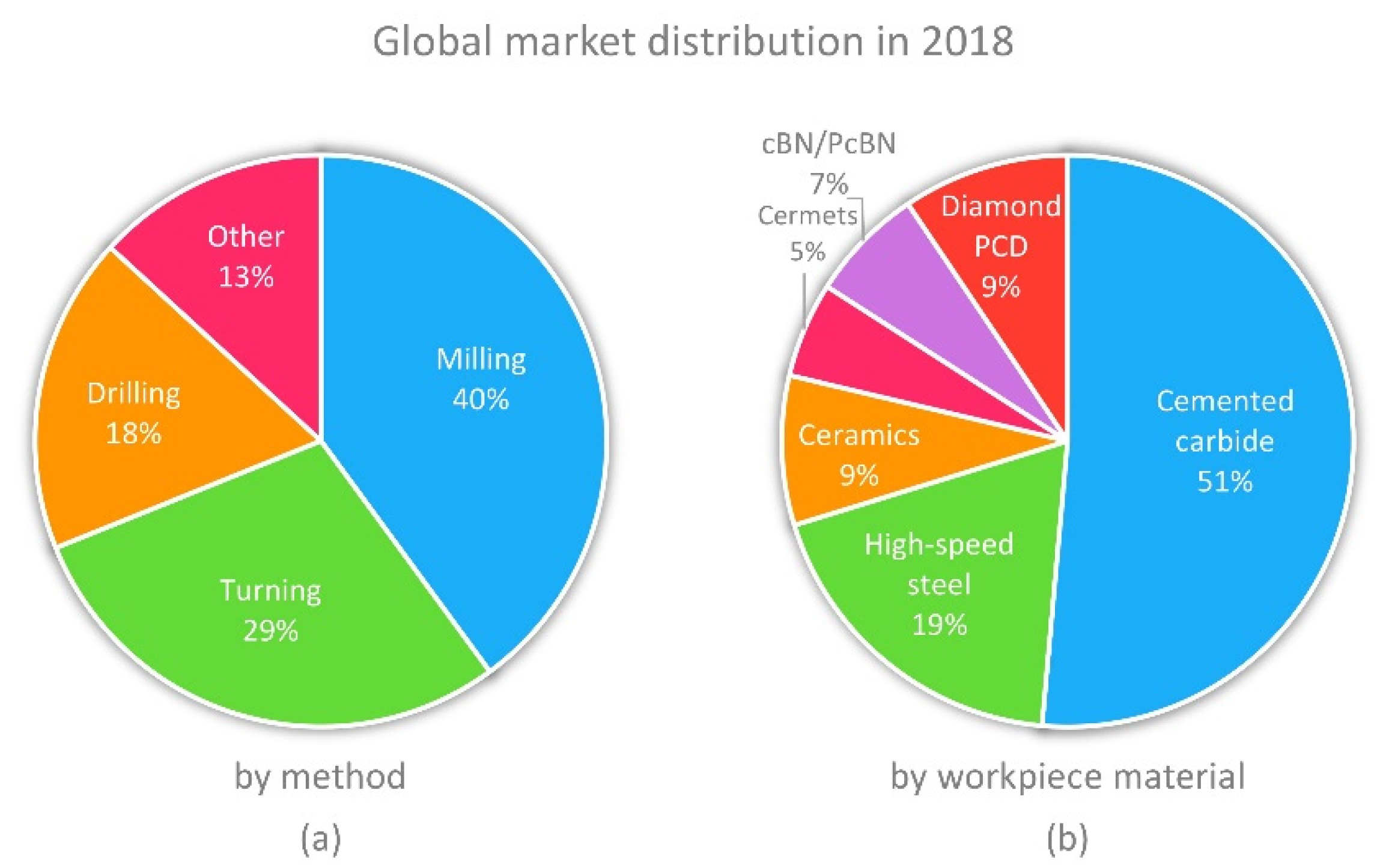

3.1. Basic Groups of Tool Materials Intended for Cutting

- Oxide ceramics are based on aluminium oxide (Al2O3). This material is chemically very stable, but lacks thermal shock resistance. Due to the low price and resistance to abrasion at high temperatures, it is used in the medium-fine machining of cast irons with a Brinell Hardness below HB235, carbon steels with a Rockwell Hardness the C scale lower than HRC38, as well as alloy steels. Most often, pure Al2O3 is used for machining parts made of grey cast iron for the automotive industry.

- Mixed ceramics Al2O3 with the addition of ZrO2, TiC, TiN, or TaC, NbC, Mo2C, Cr3C2: the most popular method of strengthening Al2O3 is the introduction of ZrO2. The polymorphic ZrO2 transformation occurs at 1150 °C and results in an increase in the volume of the zirconium-containing phase. The change in the volume of the ZrO2 phase generates in the Al2O3 matrix the stresses which are able to absorb the energy of the cracks. Mixed ceramics are particle-reinforced through the addition of cubic carbides or carbonitrides. These additives improve the toughness and thermal conductivity of the material. The materials are used to anneal iron alloys with a hardness of 55–65 HRC, including cast irons, brittle materials such as composites on metal matrix-reinforced ceramics or intermetallic materials and high-density alloys based on tungsten. These materials can also be used in continuous and intermittent processing and milling and turning as well as roughing and fine machining conditions.

- Whisker-reinforced ceramics use silicon carbide whiskers (SiCw or Si3N4w) or single-leaf monocrystals, most commonly SiC. The critical stress intensity factor KIc for such materials is from 8 to 10 MPa m1/2, and the bending strength is in the range of 600–900 MPa. These materials are used for machining with low cutting speeds of nickel alloys, hardened steels, non-metallic fragile materials and high hardness cast irons [214].

- Nitride ceramics: Si3N4 with additives to facilitate sintering, and SiAlON. Si3N4 elongated crystals form a self-reinforced material with high toughness. Silicon nitride grades are successful in grey cast iron machining, but their lack of chemical stability limits their use in other workpiece materials. Materials based on silicon nitride have a toughness similar to hard metals and the temperature resistance characteristic of oxides. This extends the scope of their applications and allows them to be used, for example, for the roughing and semi-finishing of cast iron castings with turning and milling as well as in the machining of special alloys with high nickel content. SiAlON grades combine the strength of a self-reinforced silicon nitride network with enhanced chemical stability. They are ideal for machining heat-resistant super alloys (HRSA).

- Superhard materials: diamond and regular boron nitride. These materials are designed for machining difficult-to-cut materials. The most commonly used are polycrystalline sintered materials. Diamond is used for non-ferrous metals, and regular boron nitride is used for hardened steels.

3.2. New Considerations for Cutting Tool Materials

3.3. New Solutions for Tool Materials

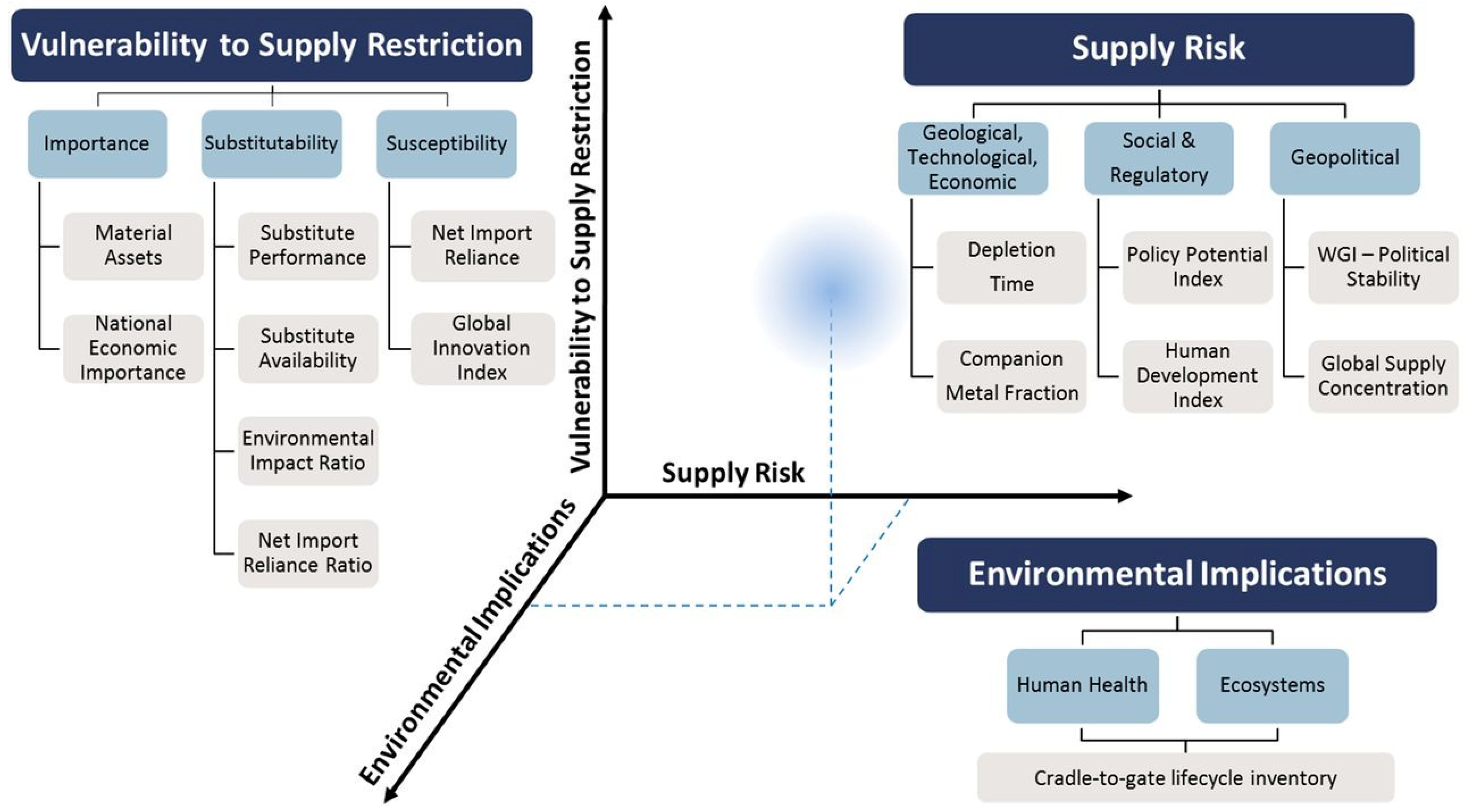

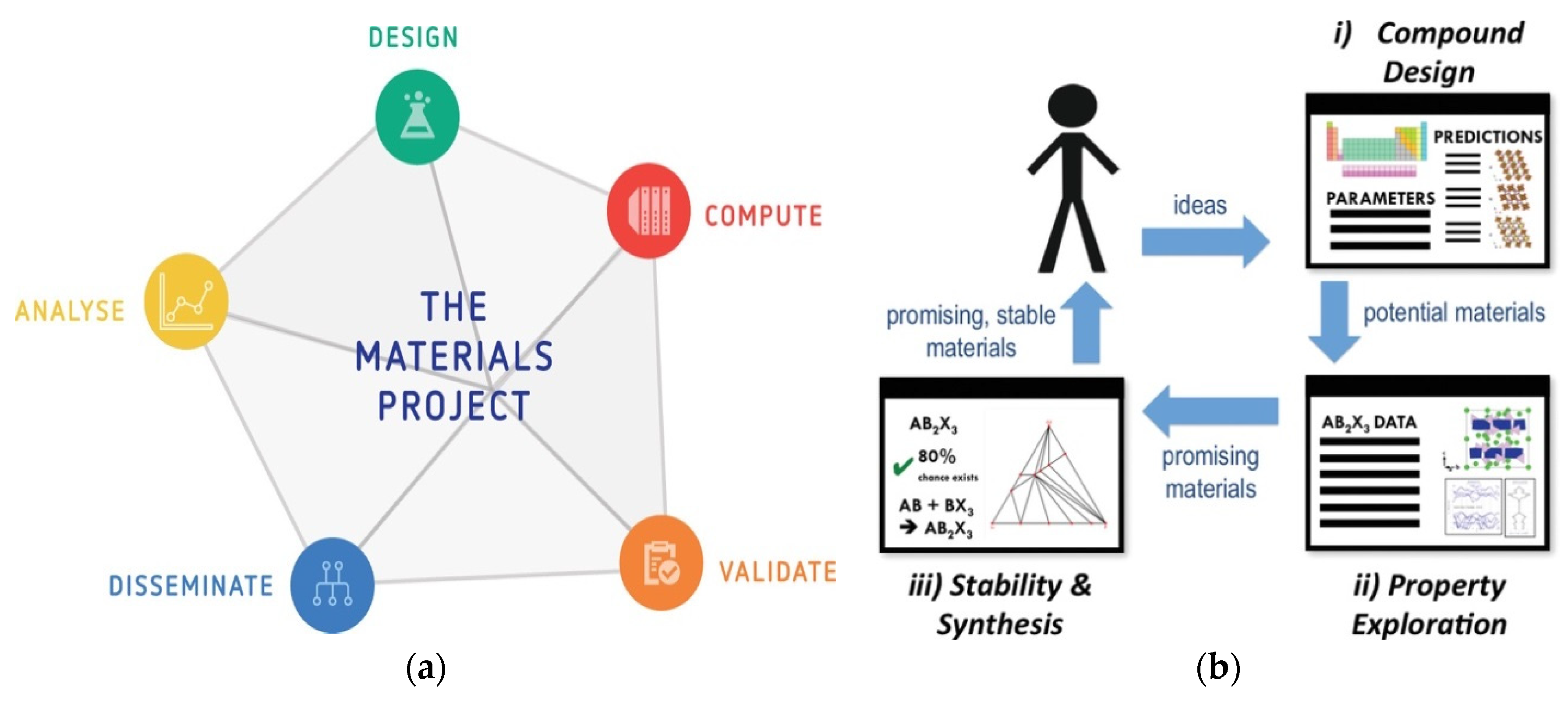

4. Modelling and Simulation

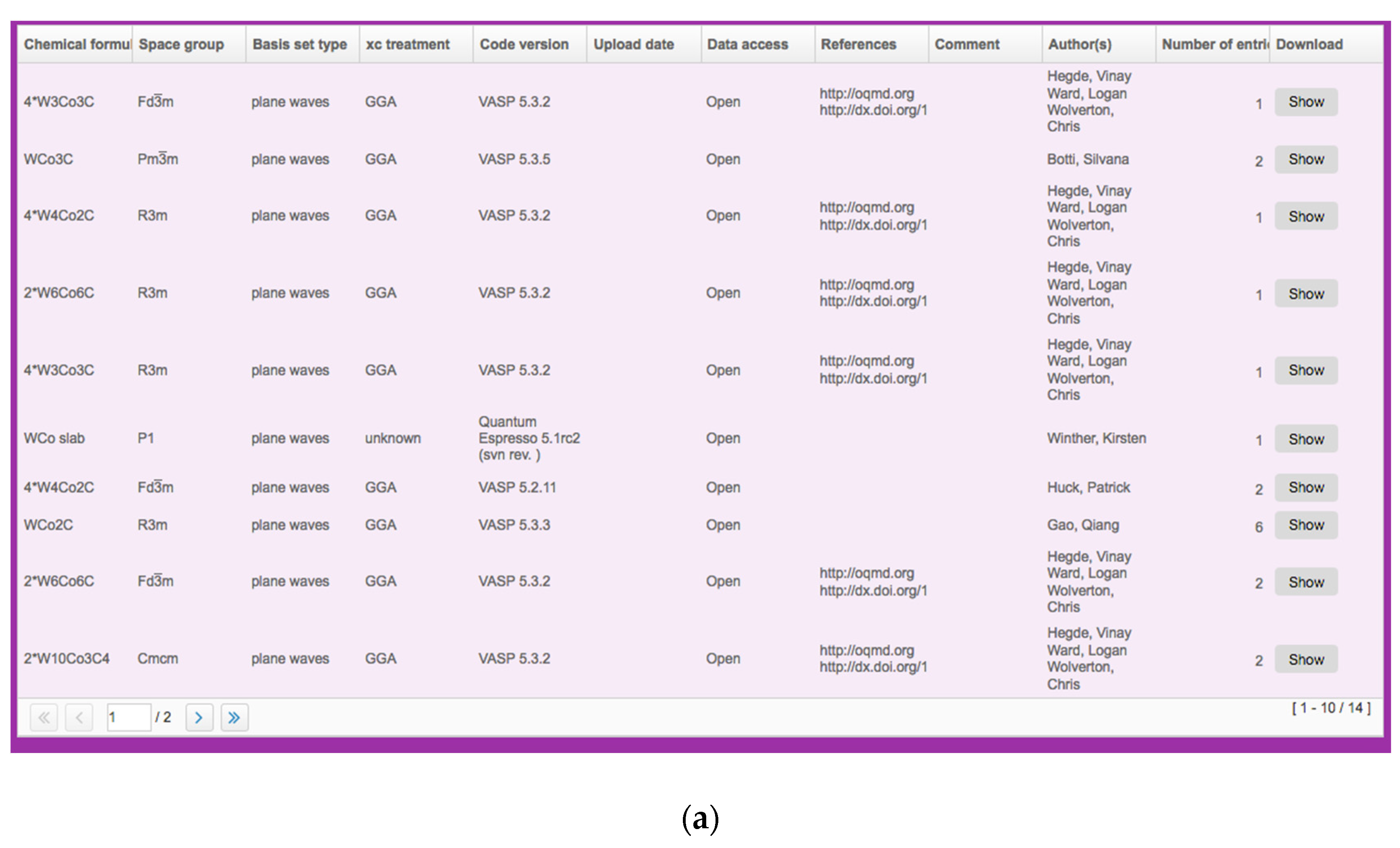

4.1. Data Mining

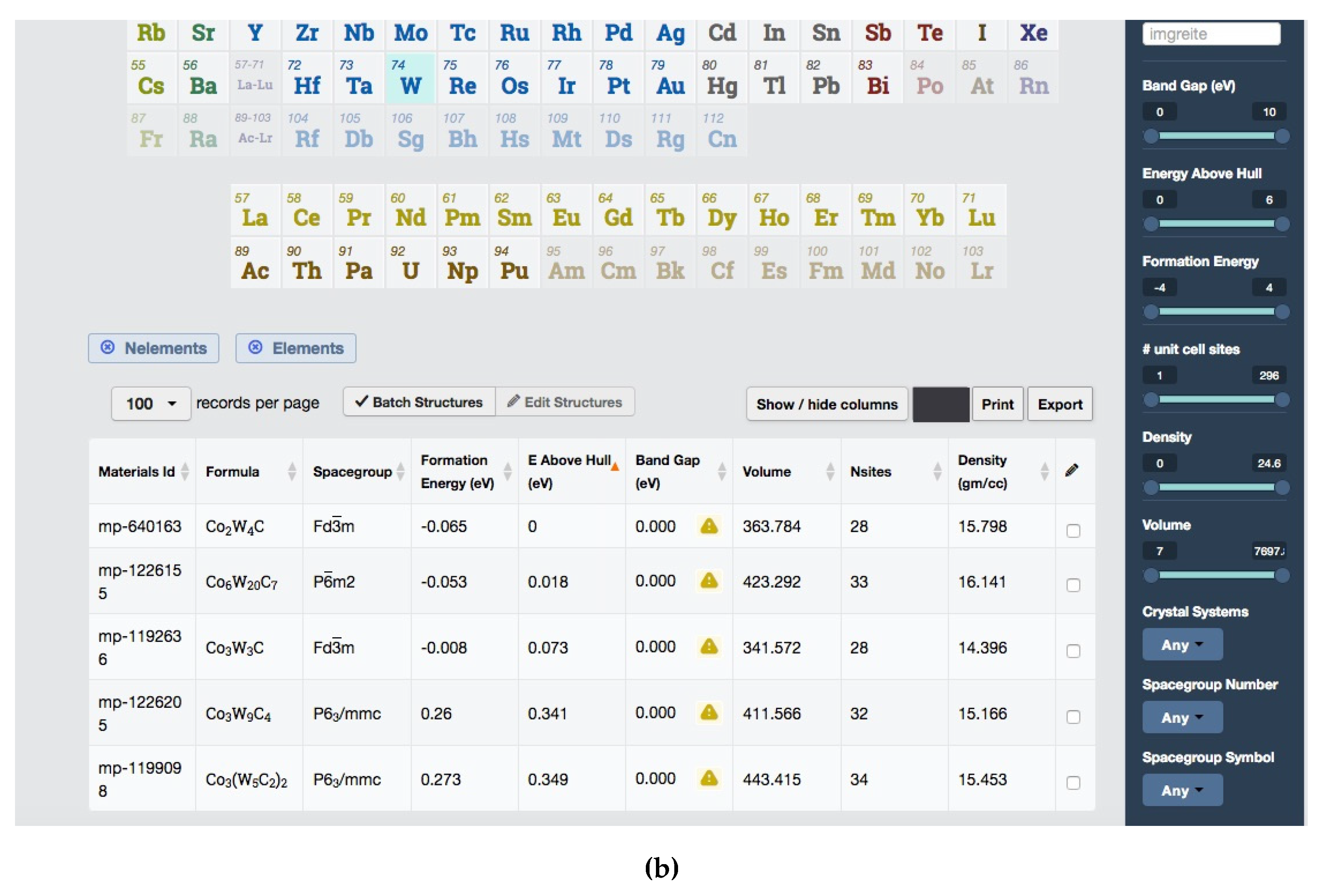

4.2. Computational Screening

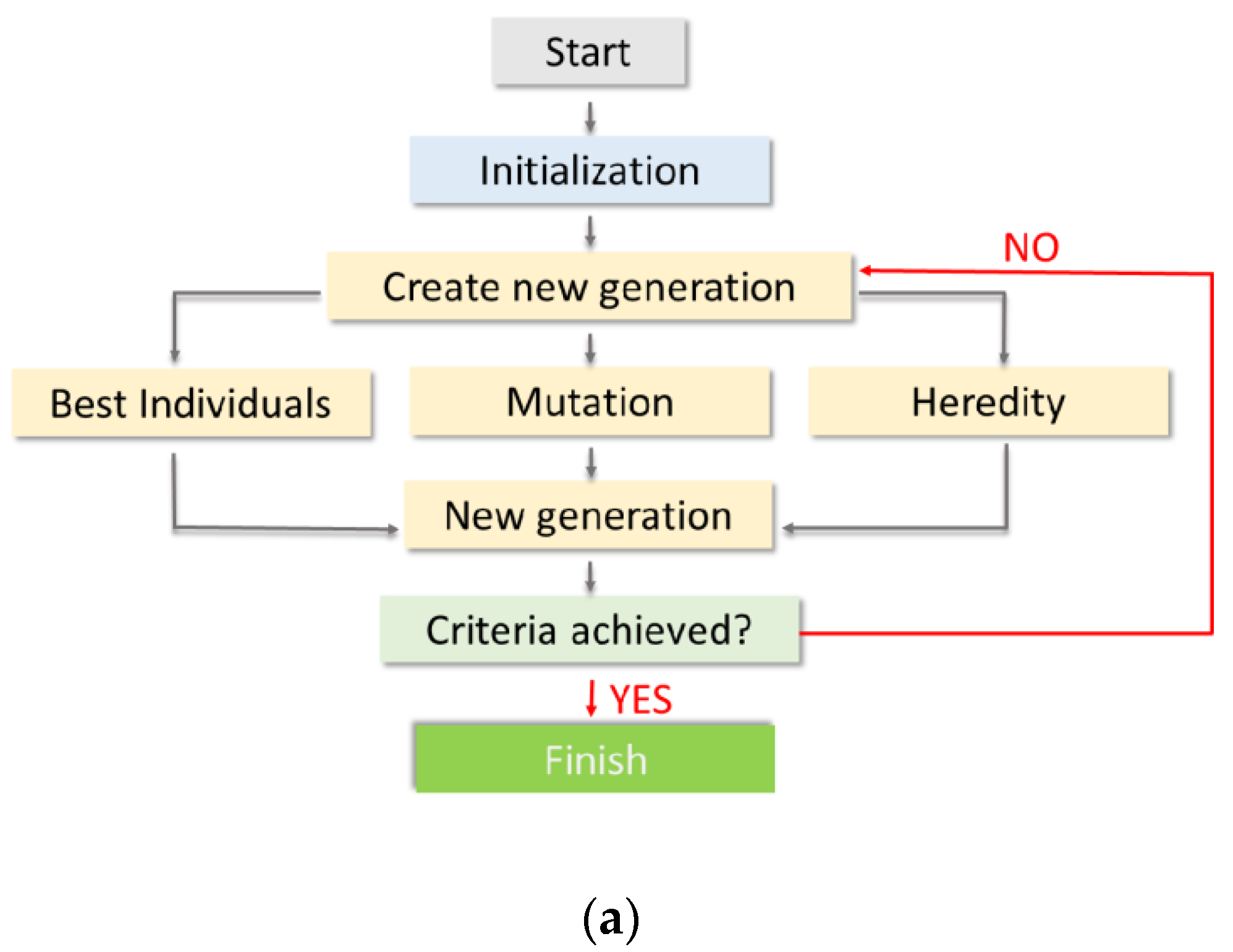

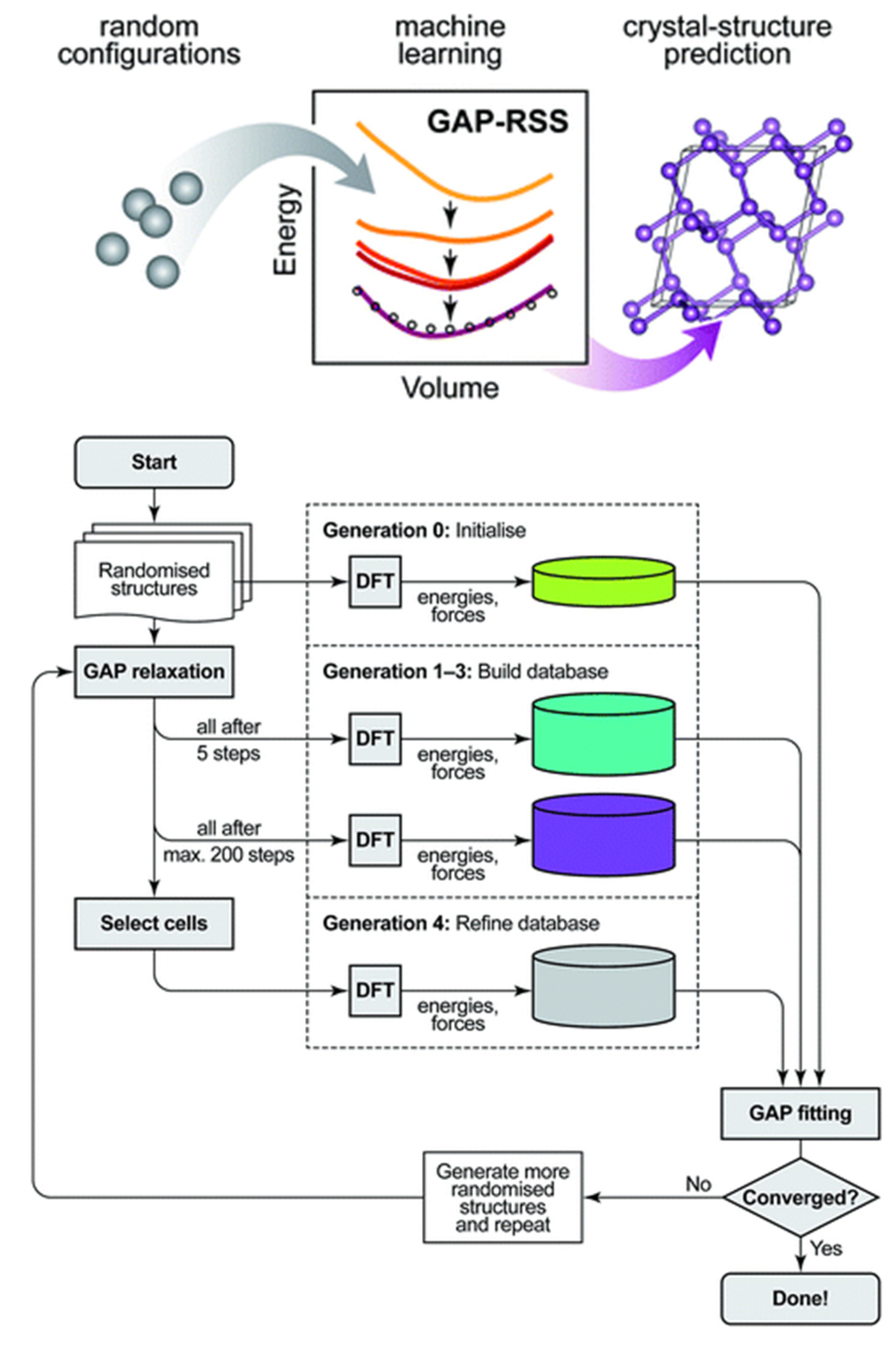

4.3. Machine Learning

4.4. Summary

5. Recycling

6. Conclusions

- The development of new cemented carbides based on environmentally harmless binders is a current research area. The substitution of cobalt in the cemented carbides is one of the research trends in the area of the environmental sustainability of industrial production and recycling processes.

- Different alternatives to the typical tungsten carbide material have been examined as constituents for the machining tools, such as ceramic materials, diamond-based systems, intermetallic systems and high entropy alloys, together with their related effective production techniques.

- We presented advanced machining techniques such as methods aided by laser, cryogenic temperatures, vibrations and surface defects with the aim of extending the tool life-span and thus reducing the amounts of CRMs used in the tools.

- We reviewed protecting coatings, which enable an increase in tool lifetimes under different machining situations.

- Additive manufacturing technologies along with the extensive use of advanced cost-effective fast-track computational methodologies facilitate the development of new materials by opening new ways of designing tools without or with only the partial use of CRMs with efficient strategies for the easy recycling of raw materials.

- Novel methodologies of tools manufacturing with geometric structures and challenging sub-structures and the potential to produce under-functionally different structures and optional materials with graded properties (e.g., the 4D-printing approach) provide a reasonable approach for decreasing the amounts of CRMs in tools.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Grilli, M.; Bellezze, T.; Gamsjäger, E.; Rinaldi, A.; Novak, P.; Balos, S.; Piticescu, R.; Ruello, M. Solutions for Critical Raw Materials under Extreme Conditions: A Review. Materials 2017, 10, 285. [Google Scholar] [CrossRef] [PubMed]

- Commission of the European Communities. The Raw Materials Initiative: Meeting Our Critical Needs for Growth and Jobs in Europe, Brussels. 2008. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52008DC0699 (accessed on 17 March 2020).

- Singla, A.K.; Singh, J.; Sharma, V.S. Processing of materials at cryogenic temperature and its implications in manufacturing: A review. Mater. Manuf. Process. 2018, 33, 1603–1640. [Google Scholar] [CrossRef]

- European Commission. DG Enterprise and Industry, Critical Raw Materials for the EU: Report of the Ad-hoc Working Group on Defining Critical Raw Materials; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- European Commission. Report on Critical Raw Materials for the EU: Report of the Ad hoc Working Group on Defining Critical Raw Materials; European Commission: Brussels, Belgium, May 2014. [Google Scholar]

- Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions, COM(2017) 490 Final. Available online: https://eur-lex.europa.eu/legal-content/en/ALL/?uri=CELEX:52017DC0490 (accessed on 17 March 2020).

- Bobzin, K. High-performance coatings for cutting tools. Cirp J. Manuf. Sci. Technol. 2017, 18, 1–9. [Google Scholar] [CrossRef]

- Byrne, G.; Ahearne, E.; Cotterell, M.; Mullany, B.; O’Donnell, G.E.; Sammler, F. High Performance Cutting (HPC) in the New Era of Digital Manufactoring–A Roadmap. Procedia Cirp 2016, 46, 1–6. [Google Scholar] [CrossRef]

- Vanegas, P.; Durana, G.; Zubia, J.; De Ocariz, I.S. Advanced monitoring systems for smart tooling in aeronautical Industry 4.0. In Proceedings of the 14th Quantitative InfraRed Thermography Conference, Berlin, Germany, 25–29 June 2018. [Google Scholar] [CrossRef]

- Cheng, K.; Chao, Z.; Wang, C.; Rakowski, R. Bateman Smart Cutting tools and smart machining: Development approaches and their implementation and application perspectives. Chin. J. Mech. Eng. 2017, 30. [Google Scholar] [CrossRef]

- Paulsen, T.; Pecat, O.; Brinksmeier, E. Influence of different machining conditions on the subsurface properties of drilled TiAl6V4. Procedia Cirp 2016, 46, 472–475. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Meng, X.; Xie, Y. A Review on High Entropy Alloys Coatings: Fabrication Processes and Property Assessment. Adv. Eng. Mater. 2019, 21, 1900343. [Google Scholar] [CrossRef]

- Kurlov, S.A.; Gusev, A.I. Tungsten Carbides: Structure, Properties and Application in Hardmetals; Springer Series in Materials Science 184; Springer: Cham, Switzerland, 2013. [Google Scholar] [CrossRef]

- Mills, B. Recent Developments in Cutting Tool Materials. J. Mater. Process. Technol. 1996, 56, 16–23. [Google Scholar] [CrossRef]

- Agte, C.; Kohlermann, R. Hilfsmetallarme Hartmetallegierungen. Die Tech. 1957, 10, 686–689. [Google Scholar]

- Richter, V. Hard sintered materials made of nano-sized powders. Annu. Rep. Fraunhofer IKTS 1995, 44–45. [Google Scholar]

- Li, S.K.; Li, J.Q.; Li, Y.; Liu, F.S.; Ao, W.Q. Dense pure binderless WC bulk material prepared by spark plasma sintering. Mater. Sci. Technol. 2015, 31, 1749–1756. [Google Scholar] [CrossRef]

- Gubernat, A.; Rutkowski, P.; Grabowski, G.; Zientara, D. Hot pressing of tungsten carbide with and without sintering additives. Int. J. Refract. Met. Hard Mater. 2014, 43, 193–199. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, J.; Shen, X.; Huang, Z.; Yan, K.; Xing, J.; Gao, Y.; Jian, Y.; Yang, H.; Liat, B. A Review on Binderless Tungsten Carbide: Development and Application. Nano-Micro Lett. 2019, 12, 13. [Google Scholar] [CrossRef]

- Gurland, J. A study of the effect of carbon content on the structure and properties of sintered WC–Co alloys. Trans. AIME 1954, 200, 285–290. [Google Scholar]

- Gubedrechtrnat, L. Stobierski, Fractography of dense metal-like carbides sintered with carbon. Key Eng. Mater. 2009, 409, 287–290. [Google Scholar] [CrossRef]

- Fox, R.T.; Nilsson, R. Binderless tungsten carbide carbon control with pressureless sintering. Int. J. Refract. Met. Hard Mater. 2018, 76, 82–89. [Google Scholar] [CrossRef]

- Kim, H.C.; Shon, I.J.; Garay, J.E.; Munir, Z.A. Consolidation and properties of binderless sub-micron tungsten carbide by field-activated sintering. Int. J. Refract. Met. Hard Mater. 2004, 22, 257–264. [Google Scholar] [CrossRef]

- Szutkowska, M.; Boniecki, M.; Cygan, S.; Kalinka, A.; Grilli, M.L.; Balos, S. Fracture behaviour of WC-Co partially substituted by titanium carbide. Iop Conf. Ser. Mater. Sci. Eng. 2018, 329. [Google Scholar] [CrossRef]

- Tai, W.P.; Watanabe, T. Fabrication and Mechanical Properties of Al2O3-WC-Co Composites by Vacuum Hot Pressing. J. Am. Ceram. Soc. 1998, 81, 1673–1676. [Google Scholar] [CrossRef]

- Basu, B.; Lee, J.H.; Kim, D.Y. Development of WC–ZrO2 Nanocomposites by Spark Plasma Sintering. Am. Ceram. Soc. 2004, 87, 317–319. [Google Scholar] [CrossRef]

- Uvarova, I.; Babutina, T.; Konchakovskay, I.; Timofeeva, I.; Petuchov, A. Nanostructure Composition of Diamond-WC-Co. In Advanced Science and Technology of Sintering; Stojanović, B.D., Skorokhod, V.V., Nikolić, M.V., Eds.; Springer: Berlin/Heidelberg, Germany, 1999. [Google Scholar]

- Martínez, V.; Echeberria, J. Hot isostatic pressing of cubic boron nitride-tungsten carbide/cobalt (cBN-WC/Co) composites: Effect of cBN particle size and some processing parameters on their microstructure and properties. J. Am. Ceram Soc. 2007, 90, 415–424. [Google Scholar] [CrossRef]

- Rong, H.Y.; Pen, Z.J.; Ren, X.Y.; Wang, C.B.; Fu, Z.Q.; Qi, L.H.; Miao, H.Z. Microstructure and mechanical properties of ultrafine WC-Ni-VC-TaC-cBN cemented carbides fabricated by spark plasma sintering. Int. J. Refract. Met. Hard. Mater. 2011, 29, 733–738. [Google Scholar] [CrossRef]

- Rosinski, M.; Michalski, A. WCCo/cBN composites produced by pulse plasma sintering method. J. Mater. Sci. 2012, 47, 7064–7071. [Google Scholar] [CrossRef]

- Mao, C.; Ren, Y.; Gan, H.; Zhang, M.; Zhang, J.; Tang, K. Microstructure and mechanical properties of cBN-WC-Co composites used for cutting tools. Int. J. Adv. Manuf. Technol. 2015, 76, 2043–2049. [Google Scholar] [CrossRef]

- Bengisu, M.; Inal, O.T. Whisker toughening of ceramics, toughening mechanisms, fabrication, and composite properties. Annu. Rev. Mater. Sci. 1994, 24, 83–124. [Google Scholar] [CrossRef]

- Chao, Y.J.; Liu, J. Study of WC ceramic tool material by SiC whisker toughening. Rare Met. Cem. Carbides 2005, 33, 13–16. [Google Scholar]

- Chen, K.; Xiao, W.; Li, Z.; Wu, J.; Hong, K.; Ruan, X. Effect of Graphene and Carbon Nanotubes on the Thermal Conductivity of WC–Co Cemented Carbide. Met. Open Access Metall. J. 2019, 9, 377. [Google Scholar] [CrossRef]

- Díaz-Álvarez, J.; Criado, V.; Miguélez, H.; Cantero, J. PCBN Performance in High Speed Finishing Turning of Inconel 718. Metals 2018, 8, 582. [Google Scholar] [CrossRef]

- Fortunato, A.; Valli, G.; Liverani, E.; Ascari, A. Additive Manufacturing of WC-Co Cutting Tools for Gear Production. Lasers Manuf. Mater. Process. 2019, 6, 247–262. [Google Scholar] [CrossRef]

- Goel, S.; Luo, X.; Agrawal, A.; Reuben, R.L. Diamond machining of silicon: A review of advances in molecular dynamics simulation. Int. J. Mach. Tools Manuf. 2015, 88, 131–164. [Google Scholar] [CrossRef]

- Komanduri, R.; Lee, M.; Flom, D.G.; Thompson, R.A.; Jones, M.G.; Douglas, R.J. General Electric Co, 1982. Pulse laser pretreated machining. U.S. Patent 4,356,376, 26 October 2020. [Google Scholar]

- Wu, J.F.; Guu, Y.B. Laser assisted machining method and device. Google Patents US20040104207A1, 21 Feburary 2006. [Google Scholar]

- Patten, J. Micro Laser Assisted Machining. Google Patents US8933366B2, 13 January 2015. [Google Scholar]

- Shin, Y.C. Laser Assisted Machining Process with Distributed Lasers. Google Patents US8698041B2, 15 April 2014. [Google Scholar]

- Shin, Y.C. Machining apparatus and process. Google Patents US20110048183A1, 3 March 2011. [Google Scholar]

- Dahotre, N.B.; Santhanakrishnan, S. Laser-assisted machining (lam) of hard tissues and bones. Google Patents US9387041B2, 12 July 2016. [Google Scholar]

- Santner, J.S.; Sciammarella, F.M.; Kyselica, S. Laser assisted machining system for ceramics and hard materials. Google Patents US20130134141A1, 30 May 2013. [Google Scholar]

- Abdulghani, O.; Sobih, M.; Youssef, A.; El-Batahgy, A.M. Modeling and Simulation of Laser Assisted Turning of Hard Steels. Modeling Numer. Simul. Mater. Sci. 2013, 3, 106–113. [Google Scholar] [CrossRef]

- Razavykia, A.; Delprete, C.; Baldissera, P. Correlation between Microstructural Alteration, Mechanical Properties and Manufacturability after Cryogenic Treatment: A Review. Materials 2019, 12, 3302. [Google Scholar] [CrossRef] [PubMed]

- Varghese, V.; Akhil, K.; Ramesh, M.R.; Chakradhar, D. Investigation on the performance of AlCrN and AlTiN coated cemented carbide inserts during end milling of maraging steel under dry, wet and cryogenic environments. J. Manuf. Process. 2019, 43, 136–144. [Google Scholar] [CrossRef]

- Goel, S.; Martinez, F.D.; Chavoshi, S.Z.; Khatri, N.; Giusca, C. Molecular dynamics simulation of the elliptical vibration-assisted machining of pure iron. J. Micromanuf. 2018, 1, 6–19. [Google Scholar] [CrossRef]

- Shokrani, A.; Dhokia, V.; Munos-Escalona, P.; Newmann, S.T. State-of-art cryogenic machining and processing. Int. J. Comput. Integr. Manuf. 2013, 26, 616–648. [Google Scholar] [CrossRef]

- Rakesh, S.; Nirmal, K. Cryogenic Treatment of Tool Materials: A Review. Mater. Manuf. Process. 2010, 25, 1077–1100. [Google Scholar] [CrossRef]

- Yildiz, Y.; Nalbant, M. A review of cryogenic cooling in machining processes. Int. J. Mach. Tools Manuf. 2008, 48, 947–964. [Google Scholar] [CrossRef]

- Gill, S.S.; Singh, R.; Singh, H.; Singh, J. Investigation on wear behavior of cryogenically treated TiAlN coated tungsten carbide inserts in turning. Int. J. Mach. Tools Manuf. 2011, 51, 25–33. [Google Scholar] [CrossRef]

- Seah, K.H.W.; Rahaman, M.; Yong, K.H. Performance evaluation of cryogenically treated tungsten carbide cutting tool inserts Proceeding of the Institution of Mechanical Engineers-Part B. J. Eng. Manuf. 2003, 217, 29–43. [Google Scholar] [CrossRef]

- Yong, A.Y.L.; Seah, K.H.W.M. Rahman Performance of cryogenically treated tungsten carbide tools in milling operations. Int. J. Adv. Manuf. Technol. 2006, 32, 638–643. [Google Scholar] [CrossRef]

- Sreeramareddy, T.V.; Sornakumar, T.; VenkataramaReddy, M.; Venkatram, R. Machining of C45 steel with deep cryogenic treated tungsten carbide cutting tool inserts. Int. J. Refract. Met. Hard Mater. 2009, 27, 181–185. [Google Scholar] [CrossRef]

- Stewart, H.A. Cryogenic treatment of tungsten carbide reduces tool wear when machining medium density fiberboard. For. Prod. J. 2004, 54, 53–56. [Google Scholar]

- Bryson, W.E. Cryogenics; Carl Hanser Verlag GmbH & Co.: Cincinnati, OH, USA, 1999; pp. 81–107. ISBN 978-1569902745. [Google Scholar]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Influence of different post treatments on tungsten carbide-cobalt inserts. Mater. Lett. 2008, 62, 4403–4406. [Google Scholar] [CrossRef]

- Sert, A.; Celik, O.N. Characterization of the mechanism of cryogenic treatment on the microstructural changes in tungsten carbide cutting tools. Mater. Charact. 2019, 150, 1–7. [Google Scholar] [CrossRef]

- Reddy, T.V.S.; Ajaykumar, B.S.; Reddy, M.V.; Venkataram, R. Machining performance of low temperature treated P-30 tungsten carbide cutting tool inserts. Cryogenic 2008, 48, 458–461. [Google Scholar]

- Vadivel, K.; Rudramoorthy, R. Performance analysis of cryogenically treated coated carbide inserts. Int. J. Adv. Manuf. Technol. 2009, 42, 222–232. [Google Scholar] [CrossRef]

- Swamini, A.; Chopra, V.; Sargade, G. Metallurgy behind the Cryogenic Treatment of Cutting Tools: An Overview. Mater. Today Proceed. 2015, 2, 1814–1824. [Google Scholar] [CrossRef]

- Ahmed, M.I.; Ismail, A.F.; Abakr, Y.A.; Amin, A.K.M.N. Effectiveness of cryogenic machining with modified tool holder. J. Mater. Process. Technol. 2007, 185, 91–96. [Google Scholar] [CrossRef]

- Dhananchezian, M. Study the machinability characteristics of Nicked based Hastelloy C-276 under cryogenic cooling. Measurement 2019, 136, 694–702. [Google Scholar] [CrossRef]

- VakkasYıldırım, Ç. Experimental comparison of the performance of nanofluids, cryogenic and hybrid cooling in turning of Inconel 625. Tribol. Int. 2019, 137, 366–378. [Google Scholar]

- Biswal, B.; Sarkar, B.; Mahanta, P. (Eds.) Characteristics During Hard Turning of Alloy Steel with Untreated and Cryotreated Cermet Inserts. In Advances in Mechanical Engineering; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2018. [Google Scholar]

- Sui, H.; Zhang, X.; Zhang, D.; Jiang, X.; Wu, R. Feasibility study of high-speed ultrasonic vibration cutting titanium alloy. J. Mater. Process. Technol. 2017, 247, 111–120. [Google Scholar] [CrossRef]

- Bulla, B.; Kloche, F.; Dambon, O.; Hunter, M. Ultrasonic Assisted Diamond turning of hardned steel for mould manufacturing. Key Eng. Mater. 2012, 516, 437–442. [Google Scholar] [CrossRef]

- Muhammad, R.; Hussain, M.S.; Maurotto, A.; Siemers, C.; Roy, A.; Silberschmidt, V.V. Analysis of a free machining α+ β titanium alloy using conventional and ultrasonically assisted turning. J. Mater. Process. Technol. 2014, 214, 906–915. [Google Scholar] [CrossRef]

- Ultrasonically Assisted Machining of Titanium Alloys. Available online: https://hdl.handle.net/2134/15909 (accessed on 17 March 2020).

- Joshi, S.; Tewari, A.; Joshi, S.S. Microstructural characterization of chip segmentation under different machining environments in orthogonal machining of Ti6Al4V. J. Eng. Mater. Technol. 2015, 137, 011005. [Google Scholar] [CrossRef]

- Maurotto, A.; Muhammad, R.; Roy, A. Comparing machinability of Ti-15-3-3-3 and Ni-625 alloys in UAT. Procedia Cirp 2012, 1, 330–335. [Google Scholar] [CrossRef]

- Nath, C.; Rahman, M.; Andrew, S. A study on ultrasonic vibration cutting of low alloy steel. J. Mater. Process. Technol. 2007, 192, 159–165. [Google Scholar] [CrossRef]

- Tutunea-Fatan, O.R.; Fakhri, M.A.; Bordatchev, E.V. Porosity and cutting forces: From macroscale to microscale machining correlations. Proceedings of the Institution of Mechanical Engineers. Part B J. Eng. Manuf. 2011, 225, 619–630. [Google Scholar] [CrossRef]

- Pulse Laser Pretreated Machining. US Patent No. 4356376 against Application No. 263235. Available online: https://patents.google.com/patent/US4356376A/en (accessed on 18 March 2020).

- Goel, S.; Rashid, W.B.; Luo, X.; Agrawal, A.; Jain, V. A theoretical assessment of surface defect machining and hot machining of nanocrystalline silicon carbide. J. Manuf. Sci.Eng. 2014, 136, 021015. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Glabe, R. Advances in Precision Machining of Steel. Cirp Ann. Manuf. Tecnol. 2001, 50, 385–388. [Google Scholar] [CrossRef]

- Kawasegi, N.; Sugimori, H.; Morimoto, H.; Morita, N.; Hori, I. Development of cutting tools with microscale and nanoscale textures to improve frictional behavior. Precis. Eng. 2009, 33, 248–254. [Google Scholar] [CrossRef]

- Evans, C.; Bryan, J.B. Cryogenic Diamond Turning of Stainless Steel. Cirp Ann. Manuf. Technol. 1991, 40, 571–575. [Google Scholar] [CrossRef]

- Chang, W.; Sun, J.; Luo, X.; Ritchie, J.M.; Mack, C. Investigation of microstructured milling tool for deferring tool wear. Wear 2011, 271, 2433–2437. [Google Scholar] [CrossRef]

- Kazuhiro, F.; Hideo, Y.; Naomichi, F.; Yutaka, Y.; Takashi, T.; Ryutaro, H.; Akitake, M.; Toshiro, H. Development of ultra-fine-grain binderless cBN tool for precision cutting of ferrous materials. J. Mater. Process. Technol. 2009, 209, 5646–5652. [Google Scholar] [CrossRef]

- Fang, F.Z.; Chen, Y.H.; Zhang, X.D.; Hu, X.T.; Zhang, G.X. Nanometric cutting of single crystal silicon surfaces modified by ion implantation. Cirp Ann. Manuf. Technol. 2011, 60, 527–530. [Google Scholar] [CrossRef]

- To, S.; Wang, H.; Jelenković, E.V. Enhancement of the machinability of silicon by hydrogen ion implantation for ultra-precision micro-cutting. Int. J. Mach. Tools Manuf. 2013, 74, 50–55. [Google Scholar] [CrossRef]

- Muhammad, R.; Maurotto, A.; Demiral, M.; Roy, A.; Silberschmidt, V.V. Thermally enhanced ultrasonically assisted machining of Ti alloy. Cirp J. Manuf. Sci. Technol. 2014, 7, 159–167. [Google Scholar] [CrossRef]

- Patil, S.; Joshi, S.; Tewari, A.; Joshi, S.S. Modelling and simulation of effect of ultrasonic vibrations on machining of Ti6Al4V. Ultrasonics 2014, 54, 694–705. [Google Scholar] [CrossRef]

- Muhammad, R.; Mistry, A.; Khan, W.S.; Ahmed, N.; Roy, A.; Silberschmidt, V.V. Analysis of tool wear in ultrasonically assisted turning of Iranica. B Transac. Engg. 2016, 23, 1800–1810. [Google Scholar] [CrossRef]

- Yan, J.; Zhang, Z.; Kuriyagawa, T. Effect of Nanoparticle Lubrication in Diamond Turning of Reaction-Bonded SiC. Int. J. Autom. Technol. 2011, 5, 307–312. [Google Scholar] [CrossRef]

- Inada, A.; Min, S.; Ohmori, H. Micro cutting of ferrous materials using diamond tool under ionized coolant with carbon particles. Cirp Ann. Manuf. Technol. 2011, 60, 97–100. [Google Scholar] [CrossRef]

- Zareena, A.R.; Veldhuis, S.C. Tool wear mechanisms and tool life enhancement in ultra-precision machining of titanium. J. Mater. Process. Technol. 2012, 212, 560–570. [Google Scholar] [CrossRef]

- Rashid, W.B.; Goel, S. Advances in the surface defect machining (SDM) of hard steels. J. Manuf. Process. 2016, 23, 37–46. [Google Scholar] [CrossRef]

- Rashid, W.B.; Goel, S.; Luo, X.; Ritchie, J.M. An experimental investigation for the improvement of attainable surface roughness during hard turning process. Proceedings of the Institution of Mechanical Engineers. Part B J. Eng. Manuf. 2013, 227, 338–342. [Google Scholar] [CrossRef]

- Rashid, W.B.; Goel, S.; Luo, X.; Ritchie, J.M. The development of a surface defect machining method for hard turning processes. Wear 2013, 302, 1124–1135. [Google Scholar] [CrossRef]

- Tamerabeta, Y.; Briouaa, M.; Tamerabeta, M.; Khoualdia, S. Experimental Investigation on Tool Wear Behavior and Cutting Temperature during Dry Machining of Carbon Steel SAE 1030 Using KC810 and KC910 Coated Inserts. Tribol. Ind. 2018, 40, 52–65. [Google Scholar] [CrossRef]

- Klocke, F.; Krieg, T. Coated Tools for Metal Cutting–Features and Applications. Cirp Ann. 1999, 48, 515–525. [Google Scholar] [CrossRef]

- Vereschaka, A.; Kataeva, E.; Sitnikov, N.; Aksenenko, A.; Oganyan, G.; Sotova, C. Influence of Thickness of Multilayered Nano-Structured Coatings Ti-TiN-(TiCrAl)N and Zr-ZrN-(ZrCrNbAl)N on Tool Life of Metal Cutting Tools at Various Cutting Speeds. Coatings 2018, 8, 44. [Google Scholar] [CrossRef]

- Levashov, E.A.; Merzhanov, A.G.; Shtanskv, D.V. Advanced technologies, materials and coatings developed in scientific-educational center of SHS. Galvanotechnik 2009, 100, 2102–2114. [Google Scholar]

- Gu, J.; Barber, G.; Tung, S.; Gu, R.-J. Tool life and wear mechanism of uncoated and coated milling inserts. Wear 1999, 225–229, 273–284. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Sitnikov, N.N.; Oganyan, G.V.; Batako, A. Working efficiency of cutting tools with multilayer nano-structured Ti-TiCN-(Ti,Al)CN and Ti-TiCN-(Ti,Al,Cr)CN coatings: Analysis of cutting properties, wear mechanism and diffusion processes. Surf. Coat. Technol. 2017, 332, 198–213. [Google Scholar] [CrossRef]

- Veprek, S. Recent search for new superhard materials: Go nano! J. Vac. Sci. Technol. A Vac. Surf. Film 2013, 31, 050822. [Google Scholar] [CrossRef]

- Roy, M. Protective Hard Coatings for Tribological Applications. In Materials Under Extreme Condition; Elsevier: Amsterdam, The Netherlands, 2017; pp. 259–292. [Google Scholar]

- Polini, R.; Barletta, M.; Rubino, G.; Vesco, S. Recent Advances in the Deposition of Diamond Coatings on Co-Cemented Tungsten Carbides. Adv. Mater. Sci. Eng. 2012, 2012, 1–14. [Google Scholar] [CrossRef]

- Kuo, C.; Wang, C.; Ko, S. Wear behaviour of CVD diamond-coated tools in the drilling of woven CFRP composites. Wear 2018, 398–399, 1–12. [Google Scholar] [CrossRef]

- Ramasubramanian, K.; Arunachalam, N.; Rao, M.S.R. Wear performance of nano-engineered boron doped graded layer CVD diamond coated cutting tool for machining of Al-SiC MMC. Wear 2019, 426–427, 1536–1547. [Google Scholar] [CrossRef]

- Poulon-Quintin, A.; Faure, C.; Teulé-Gay, L.; Manaud, J.P. A multilayer innovative solution to improve the adhesion of nanocrystalline diamond coatings. Appl. Surf. Sci. 2015, 331, 27–34. [Google Scholar] [CrossRef]

- Linnik, S.A.; Gaydaychuk, A.V.; Okhotnikov, V.V. Improvement to the adhesion of polycrystalline diamond films on WC-Co cemented carbides through ion etching of loosely bound growth centers. Surf. Coat. Technol. 2018, 334, 227–232. [Google Scholar] [CrossRef]

- Ye, F.; Li, Y.; Sun, X.; Yang, Q.; Kim, C.-Y.; Odeshi, A.G. CVD diamond coating on WC-Co substrate with Al-based interlayer. Surf. Coat. Technol. 2016, 308, 121–127. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, S.; Jiang, C.; Handschuh-Wang, S.; Chen, G.; Zhou, X.; Tang, Y. TiB2 barrier interlayer approach for HFCVD diamond deposition onto cemented carbide tools. Diam. Relat. Mater. 2018, 83, 126–133. [Google Scholar] [CrossRef]

- Chandran, M.; Sammler, F.; Uhlmann, E.; Akhvlediani, R.; Hoffman, A. Wear performance of diamond coated WC-Co tools with a CrN interlayer. Diam. Relat. Mater. 2017, 73, 47–55. [Google Scholar] [CrossRef]

- An Mahmud, K.A.H.; Kalam, M.A.; Masjuki, H.H.; Mobarak, H.M.; Zulkifli, N.W.M. An updated overview of diamond-like carbon coating in tribology. Crit. Rev. Solid State Mater. Sci. 2015, 40, 90–118. [Google Scholar] [CrossRef]

- Fukui, H.; Okida, J.; Omori, N.; Moriguchi, H.; Tsuda, K. Cutting performance of DLC coated tools in dry machining aluminum alloys. Surf. Coat. Technol. 2004, 187, 70–76. [Google Scholar] [CrossRef]

- Erdemir, A.; Donnet, C. Tribology of diamond-like carbon films: Recent progress and future prospects. J. Phys. D. Appl. Phys. 2006, 39, R311–R327. [Google Scholar] [CrossRef]

- Huang, L.; Yuan, J.; Li, C.; Hong, D. Microstructure, tribological and cutting performance of Ti-DLC/α-C:H multilayer film on cemented carbide. Surf. Coat. Technol. 2018, 353, 163–170. [Google Scholar] [CrossRef]

- Liu, Y.; Meletis, E.I. Evidence of graphitization of diamond-like carbon films during sliding wear. J. Mater. Sci. 1997, 32, 3491–3495. [Google Scholar] [CrossRef]

- Chen, J.G. Carbide and Nitride Overlayers on Early Transition Metal Surfaces: Preparation, Characterization, and Reactivities. Chem. Rev. 1996, 96, 1477–1498. [Google Scholar] [CrossRef]

- Han, Y.; Dai, Y.; Shu, D.; Wang, J.; Sun, B. Electronic and bonding properties of TiB2. J. Alloy. Compd. 2007, 438, 327–331. [Google Scholar] [CrossRef]

- Rasaki, S.A.; Zhang, B.; Anbalgam, K.; Thomas, T.; Yang, M. Synthesis and application of nano-structured metal nitrides and carbides: A review. Prog. Solid State Chem. 2018, 50, 1–15. [Google Scholar] [CrossRef]

- Holleck, H. Material selection for hard coatings. J. Vac. Sci. Technol. A Vacuum Surfaces Film 1986, 4, 2661–2669. [Google Scholar] [CrossRef]

- Grilli, M.L.; Valerini, D.; Piticescu, R.R.; Bellezze, T.; Yilmaz, M.; Rinaldi, A.; Cuesta-López, S.; Rizzo, A. Possible alternatives to critical elements in coatings for extreme applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 329, 012005. [Google Scholar] [CrossRef]

- Mayrhofer, P.H.; Rachbauer, R.; Holec, D.; Rovere, F.; Schneider, J.M. Protective Transition Metal Nitride Coatings. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; pp. 355–388. [Google Scholar] [CrossRef]

- Kalss, W.; Reiter, A.; Derflinger, V.; Gey, C.; Endrino, J.L. Modern coatings in high performance cutting applications. Int. J. Refract. Met. Hard Mater. 2006, 24, 399–404. [Google Scholar] [CrossRef]

- Fernandes, F.; Danek, M.; Polcar, T.; Cavaleiro, A. Tribological and cutting performance of TiAlCrN films with different Cr contents deposited with multilayered structure. Tribol. Int. 2018, 119, 345–353. [Google Scholar] [CrossRef]

- Danek, M.; Fernandes, F.; Cavaleiro, A.; Polcar, T. Influence of Cr additions on the structure and oxidation resistance of multilayered TiAlCrN films. Surf. Coat. Technol. 2017, 313, 158–167. [Google Scholar] [CrossRef]

- Mi, P.; He, J.; Qin, Y.; Chen, K. Nanostructure reactive plasma sprayed TiCN coating. Surf. Coat. Technol. 2017, 309, 1–5. [Google Scholar] [CrossRef]

- Kumar, T.S.; Jebaraj, A.V.; Sivakumar, K.; Shankar, E.; Tamiloli, N. Characterization of ticn coating synthesized by the plasma enhanced physical vapour deposition process on a cemented carbide tool. Surf. Rev. Lett. 2018, 25, 1950028. [Google Scholar] [CrossRef]

- Patscheider, J. Nanocomposite Hard Coatings for Wear Protection. MRS Bull. 2003, 8, 180–183. [Google Scholar] [CrossRef]

- Beake, B.D.; Vishnyakov, V.M.; Valizadeh, R.; Colligon, J.S. Influence of mechanical properties on the nanoscratch behaviour of hard nanocomposite TiN/Si3N4coatings on Si. J. Phys. D: Appl. Phys. 2006, 39, 1392–1397. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Smyrnova, K.; Bondar, O. Nanocomposite Multilayer Binary Nitride Coatings Based on Transition and Refractory Metals. Struct. Prop. Coat. 2019, 9, 155. [Google Scholar] [CrossRef]

- Yeh, J.-W. Recent progress in high-entropy alloys. Ann. Chim. Sci. Des Matériaux. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Yeh, J.-W.; Lin, S.-J. Breakthrough applications of high-entropy materials. J. Mater. Res. 2018, 33, 3129–3137. [Google Scholar] [CrossRef]

- Yip, S. The strongest size. Nature 1998, 391, 532–533. [Google Scholar] [CrossRef]

- Martinu, L.; Zabeida, O.; Klemberg-Sapieha, J.E. Plasma Enhanced Chemical Vapor Deposition of Functional Coatings. Handb. Depos. Technol. Film. Coat. 2010, 392–465. [Google Scholar] [CrossRef]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Uhlmann, E.; Fuentes, J.A.O.; Gerstenberger, R.; Frank, H. nc-AlTiN/a-Si3N4 and nc-AlCrN/a-Si3N4 nanocomposite coatings as protection layer for PCBN tools in hard machining. Surf. Coat. Technol. 2013, 237, 142–148. [Google Scholar] [CrossRef]

- Ma, Q.; Li, L.; Xu, Y.; Gu, J.; Wang, L.; Xu, Y. Effect of bias voltage on TiAlSiN nanocomposite coatings deposited by HiPIMS. Appl. Surf. Sci. 2017, 392, 826–833. [Google Scholar] [CrossRef]

- Settineri, L.; Faga, M.G. Laboratory tests for performance evaluation of nanocomposite coatings for cutting tools. Wear 2006, 260, 326–332. [Google Scholar] [CrossRef]

- Abadias, G.; Daniliuk, A.Y.; Solodukhin, I.A.; Uglov, V.V.; Zlotsky, S.V. Thermal Stability of TiZrAlN and TiZrSiN Films Formed by Reactive Magnetron Sputtering, Inorg. Mater. Appl. Res. 2018, 9, 418–426. [Google Scholar] [CrossRef]

- Musil, J.; Novák, P.; Čerstvý, R.; Soukup, Z. Tribological and mechanical properties of nanocrystalline-TiC/a-C nanocomposite thin films. J. Vac. Sci. Technol. A Vacuum Surfaces Film 2010, 28, 244–249. [Google Scholar] [CrossRef]

- El Mel, A.A.; Gautron, E.; Christien, F.; Angleraud, B.; Granier, A.; Souček, P.; Vašina, P.; Buršíková, V.; Takashima, M.; Ohtake, N.; et al. Titanium carbide/carbon nanocomposite hard coatings: A comparative study between various chemical analysis tools. Surf. Coat. Technol. 2014, 246, 41–46. [Google Scholar] [CrossRef]

- Qiu, L.; Du, Y.; Wang, S.; Li, K.; Yin, L.; Wu, L.; Zhong, Z.; Albir, L. Mechanical properties and oxidation resistance of chemically vapor deposited TiSiN nanocomposite coating with thermodynamically designed compositions. Int. J. Refract. Met. Hard Mater. 2019, 80, 30–39. [Google Scholar] [CrossRef]

- Schwaller, P.; Haug, F.-J.; Michler, J.; Patscheider, J. Nanocomposite Hard Coatings: Deposition Issues and Validation of their Mechanical Properties. Adv. Eng. Mater. 2005, 7, 318–322. [Google Scholar] [CrossRef]

- Mahato, P.; Nyati, G.; Singh, R.J.; Mishra, S.K. Nanocomposite TiSiBC Hard Coatings with High Resistance to Wear, Fracture and Scratching. J. Mater. Eng. Perform. 2016, 25, 3774–3782. [Google Scholar] [CrossRef]

- Verma, D.; Banerjee, D.; Mishra, S.K. Effect of Silicon Content on the Microstructure and Mechanical Properties of Ti-Si-B-C Nanocomposite Hard Coatings. Met. Mater. Trans. A 2019, 50, 894–904. [Google Scholar] [CrossRef]

- Mahato, P.; Singh, R.J.; Mishra, S.K. Nanocomposite Ti–Si–B–C hard coatings deposited by magnetron sputtering: Oxidation and mechanical behaviour with temperature and duration of oxidation. Surf. Coat. Technol. 2016, 288, 230–240. [Google Scholar] [CrossRef]

- Mahato, P.; Singh, R.J.; Pathak, L.C.; Mishra, S.K. Effect of nitrogen on mechanical, oxidation and structural behaviour of Ti-Si-B-C-N nanocomposite hard coatings deposited by DC sputtering. Surf. Interface Anal. 2016, 48, 1080–1089. [Google Scholar] [CrossRef]

- Yi, J.; Chen, S.; Chen, K.; Xu, Y.; Chen, Q.; Zhu, C.; Liu, L. Effects of Ni content on microstructure, mechanical properties and Inconel 718 cutting performance of AlTiN-Ni nanocomposite coatings. Ceram. Int. 2019, 45, 474–480. [Google Scholar] [CrossRef]

- Saladukhin, I.A.; Abadias, G.; Uglov, V.V.; Zlotski, S.V.; Michel, A.; Van Vuuren, A.J. Thermal stability and oxidation resistance of ZrSiN nanocomposite and ZrN/SiNx multilayered coatings: A comparative study. Surf. Coat. Technol. 2017, 332, 428–439. [Google Scholar] [CrossRef]

- Anwar, S.; Islam, A.; Bajpai, S.; Anwar, S. Structural and mechanical studies of W2N embedded Si3N4 nanocomposite hard coating prepared by reactive magnetron sputtering. Surf. Coat. Technol. 2017, 311, 268–273. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Postol’nyi, B.A.; Kravchenko, Y.A.; Shipilenko, A.P.; Sobol’, O.V.; Beresnev, V.M.; Kuz’menko, A.P. Structure and properties of (Zr-Ti-Cr-Nb)N multielement superhard coatings. J. Superhard Mater. 2015, 37, 101–111. [Google Scholar] [CrossRef]

- Bondar, O.V.; Postolnyi, B.O.; Kravchenko, Y.A.; Shypylenko, A.P.; Sobol, O.V.; Beresnev, V.M.; Kuzmenko, A.P.; Zukowski, P. Fabrication and Research of Superhard (Zr-Ti-Cr-Nb)N Coatings. Acta Phys. Pol. A 2015, 128, 867–871. [Google Scholar] [CrossRef]

- Gleich, S.; Breitbach, B.; Peter, N.J.; Soler, R.; Bolvardi, H.; Schneider, J.M.; Dehm, G.; Scheu, C. Thermal stability of nanocomposite Mo2BC hard coatings deposited by magnetron sputtering. Surf. Coat. Technol. 2018, 349, 378–383. [Google Scholar] [CrossRef]

- Kawasaki, M.; Nose, M.; Onishi, I.; Shiojiri, M. Structural Investigation of AlN/SiOx Nanocomposite Hard Coatings Fabricated by Differential Pumping Cosputtering. Microsc. Microanal. 2016, 22, 673–678. [Google Scholar] [CrossRef] [PubMed]

- Veprek, S.; Zhang, R.F.; Veprek-Heijman, M.G.J.; Sheng, S.H.; Argon, A.S. Superhard nanocomposites: Origin of hardness enhancement, properties and applications. Surf. Coat. Technol. 2010, 204, 1898–1906. [Google Scholar] [CrossRef]

- Veprek, S.; Veprek-Heijman, M.G.J. Limits to the preparation of superhard nanocomposites: Impurities, deposition and annealing temperature. Thin Solid Film. 2012, 522, 274–282. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Bagdasaryan, A.A.; Pshyk, A.; Dyadyura, K. Adaptive multicomponent nanocomposite coatings in surface engineering. Phys. Uspekhi. 2017, 60, 586–607. [Google Scholar] [CrossRef]

- Pogrebnyak, A.D.; Shpak, A.P.; Azarenkov, N.A.; Beresnev, V.M. Structures and properties of hard and superhard nanocomposite coatings. Phys. Uspekhi 2009, 52, 29–54. [Google Scholar] [CrossRef]

- Kumar, C.S.; Patel, S.K. Application of surface modification techniques during hard turning: Present work and future prospects. Int. J. Refract. Met. Hard Mater. 2018, 76, 112–127. [Google Scholar] [CrossRef]

- Ziebert, C.; Stüber, M.; Leiste, H.; Ulrich, S.; Holleck, H. Nanoscale PVD Multilayer Coatings. In Encyclopedia Material Science Technology; Elsevier: Amsterdam, The Netherlands, 2011; pp. 1–8. [Google Scholar] [CrossRef]

- Inspektor, A.; Salvador, P.A. Architecture of PVD coatings for metalcutting applications: A review. Surf. Coat. Technol. 2014, 257, 138–153. [Google Scholar] [CrossRef]

- Khadem, M.; Penkov, O.V.; Yang, H.-K.; Kim, D.-E. Tribology of multilayer coatings for wear reduction: A review. Friction 2017, 5, 248–262. [Google Scholar] [CrossRef]

- Wang, J.; Yazdi, M.A.P.; Lomello, F.; Billard, A.; Kovács, A.; Schuster, F.; Guet, C.; White, T.J.; Sanchette, F.; Dong, Z. Influence of microstructures on mechanical properties and tribology behaviors of TiN/Ti X Al 1−X N multilayer coatings. Surf. Coat. Technol. 2017, 320, 441–446. [Google Scholar] [CrossRef]

- Andersen, K.N.; Bienk, E.J.; Schweitz, K.O.; Reitz, H.; Chevallier, J.; Kringhøj, P.; Bøttiger, J. Deposition, microstructure and mechanical and tribological properties of magnetron sputtered TiN/TiAlN multilayers. Surf. Coat. Technol. 2000, 123, 219–226. [Google Scholar] [CrossRef]

- Contreras, E.; Bejarano, G.; Gómez, M. Synthesis and microstructural characterization of nanoscale multilayer TiAlN/TaN coatings deposited by DC magnetron sputtering. Int. J. Adv. Manuf. Technol. 2019, 101, 663–673. [Google Scholar] [CrossRef]

- Pshyk, A.V.; Kravchenko, Y.; Coy, E.; Kempiński, M.; Iatsunskyi, I.; Załęski, K.; Pogrebnjak, A.D.; Jurga, S. Microstructure, phase composition and mechanical properties of novel nanocomposite (TiAlSiY)N and nano-scale (TiAlSiY)N/MoN multifunctional heterostructures. Surf. Coat. Technol. 2018, 350, 376–390. [Google Scholar] [CrossRef]

- Illana, A.; Almandoz, E.; Fuentes, G.G.; Pérez, F.J.; Mato, S. Comparative study of CrAlSiN monolayer and CrN/AlSiN superlattice multilayer coatings: Behavior at high temperature in steam atmosphere. J. Alloy. Compd. 2019, 778, 652–661. [Google Scholar] [CrossRef]

- Seidl, W.M.; Bartosik, M.; Kolozsvári, S.; Bolvardi, H.; Mayrhofer, P.H. Mechanical properties and oxidation resistance of Al-Cr-N/Ti-Al-Ta-N multilayer coatings. Surf. Coat. Technol. 2018, 347, 427–433. [Google Scholar] [CrossRef]

- Braic, M.; Balaceanu, M.; Parau, A.C.; Dinu, M.; Vladescu, A. Investigation of multilayered TiSiC/NiC protective coatings. Vacuum 2015, 120, 60–66. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Bondar, O.V.; Abadias, G.; Eyidi, D.; Beresnev, V.M.; Sobol, O.V.; Postolnyi, B.O.; Zukowski, P. Investigation of Nanoscale TiN/MoN Multilayered Systems, Fabricated Using Arc Evaporation. Acta Phys. Pol. A 2015, 128, 836–841. [Google Scholar] [CrossRef]

- Postolnyi, B.O.; Konarski, P.; Komarov, F.F.; Sobol, O.V.; Kyrychenko, O.V.; Shevchuk, D.S. Study of elemental and structural phase composition of multilayer nanostructured TiN/MoN coatings, their physical and mechanical properties. J. Nano- Electron. Phys. 2014, 6, 04016. [Google Scholar]

- Buchinger, J.; Koutná, N.; Chen, Z.; Zhang, Z.; Mayrhofer, P.H.; Holec, D.; Bartosik, M. Toughness enhancement in TiN/WN superlattice thin films. Acta Mater. 2019, 172, 18–29. [Google Scholar] [CrossRef]

- Pogrebnjak, A.; Ivashchenko, V.; Bondar, O.; Beresnev, V.; Sobol, O.; Załęski, K.; Jurga, S.; Coy, E.; Konarski, P.; Postolnyi, B. Multilayered vacuum-arc nanocomposite TiN/ZrN coatings before and after annealing: Structure, properties, first-principles calculations. Mater. Charact. 2017, 134, 55–63. [Google Scholar] [CrossRef]

- Major, L.; Major, R.; Kot, M.; Lackner, J.M.; Major, B. Ex situ and in situ nanoscale wear mechanisms characterization of Zr/Zr x N tribological coatings. Wear 2018, 404–405, 82–91. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Kravchenko, Y.O.; Bondar, O.V.; Zhollybekov, B.; Kupchishin, A.I. Kupchishin, Structural Features and Tribological Properties of Multilayer Coatings Based on Refractory Metals. Prot. Met. Phys. Chem. Surf. 2018, 54, 240–258. [Google Scholar] [CrossRef]

- Postolnyi, B.; Bondar, O.; Opielak, M.; Rogalski, P.; Araújo, J.P. Structural analysis of multilayer metal nitride films CrN/MoN using electron backscatter diffraction (EBSD). In Proceedings of the SPIE 10010, Advanced Topics in Optoelectronics, Microelectronics, and Nanotechnologies VIII, 100100E, Constanta, Romania, 14 December 2016. [Google Scholar] [CrossRef]

- Pogrebnjak, A.D.; Beresnev, V.M.; Bondar, O.V.; Postolnyi, B.O.; Zaleski, K.; Coy, E.; Jurga, S.; Lisovenko, M.O.; Konarski, P.; Rebouta, L.; et al. Superhard CrN/MoN coatings with multilayer architecture. Mater. Des. 2018, 153, 47–59. [Google Scholar] [CrossRef]

- Postolnyi, B.O.; Bondar, O.V.; Zaleski, K.; Coy, E.; Jurga, S.; Rebouta, L.; Araujo, J.P. Multilayer Design of CrN/MoN Superhard Protective Coatings and Their Characterisation. In Advances in Thin Films, Nanostructured Materials, and Coatings; Pogrebnjak, A.D., Novosad, V., Eds.; Springer: Singapore, 2019; pp. 17–29. [Google Scholar] [CrossRef]

- Bagdasaryan, A.A.; Pshyk, A.V.; Coy, L.E.; Kempiński, M.; Pogrebnjak, A.D.; Beresnev, V.M.; Jurga, S. Structural and mechanical characterization of (TiZrNbHfTa)N/WN multilayered nitride coatings. Mater. Lett. 2018, 229, 364–367. [Google Scholar] [CrossRef]

- Lin, Y.; Zia, A.W.; Zhou, Z.; Shum, P.W.; Li, K.Y. Development of diamond-like carbon (DLC) coatings with alternate soft and hard multilayer architecture for enhancing wear performance at high contact stress. Surf. Coat. Technol. 2017, 320, 7–12. [Google Scholar] [CrossRef]

- Zha, X.; Jiang, F.; Xu, X. Investigating the high frequency fatigue failure mechanisms of mono and multilayer PVD coatings by the cyclic impact tests. Surf. Coat. Technol. 2018, 344, 689–701. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chiu, W.-T.; Hung, J.-P. Mechanical properties and high temperature oxidation of CrAlSiN/TiVN hard coatings synthesized by cathodic arc evaporation. Surf. Coat. Technol. 2016, 303, 18–24. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Weng, S.-Y.; Chen, C.-H.; Fu, F.-X. High temperature oxidation and cutting performance of AlCrN, TiVN and multilayered AlCrN/TiVN hard coatings. Surf. Coat. Technol. 2017, 332, 494–503. [Google Scholar] [CrossRef]

- Chang, Y.-Y.; Chang, H.; Jhao, L.-J.; Chuang, C.-C. Tribological and mechanical properties of multilayered TiVN/TiSiN coatings synthesized by cathodic arc evaporation. Surf. Coat. Technol. 2018, 350, 1071–1079. [Google Scholar] [CrossRef]

- Kong, Y.; Tian, X.; Gong, C.; Chu, P.K. Enhancement of toughness and wear resistance by CrN/CrCN multilayered coatings for wood processing. Surf. Coat. Technol. 2018, 344, 204–213. [Google Scholar] [CrossRef]

- Beake, B.D.; Fox-Rabinovich, G.S. Progress in high temperature nanomechanical testing of coatings for optimising their performance in high speed machining. Surf. Coat. Technol. 2014, 255, 102–111. [Google Scholar] [CrossRef]

- Chowdhury, S.; Beake, B.; Yamamoto, K.; Bose, B.; Aguirre, M.; Fox-Rabinovich, G.; Veldhuis, S. Improvement of Wear Performance of Nano-Multilayer PVD Coatings under Dry Hard End Milling Conditions Based on Their Architectural Development. Coatings 2018, 8, 59. [Google Scholar] [CrossRef]

- Kursuncu, B.; Caliskan, H.; Guven, S.Y.; Panjan, P. Improvement of cutting performance of carbide cutting tools in milling of the Inconel 718 superalloy using multilayer nanocomposite hard coating and cryogenic heat treatment. Int. J. Adv. Manuf. Technol. 2018, 97, 467–479. [Google Scholar] [CrossRef]

- Rezapoor, M.; Razavi, M.; Zakeri, M.; Rahimipour, M.R.; Nikzad, L. Fabrication of functionally graded Fe-TiC wear resistant coating on CK45 steel substrate by plasma spray and evaluation of mechanical properties. Ceram. Int. 2018, 44, 22378–22386. [Google Scholar] [CrossRef]

- Narasimhan, K.; Boppana, S.P.; Bhat, D.G. Development of a graded TiCN coating for cemented carbide cutting tools—a design approach. Wear 1995, 188, 123–129. [Google Scholar] [CrossRef]

- Miao, H.; Shi, F.; Peng, Z.; Yang, S.; Liu, C.; Qi, L. Nanometer grain titanium carbonitride coatings with continuously graded interface onto silicon nitride cutting tools by pulsed high energy density plasma. Mater. Sci. Eng. A 2004, 384, 202–208. [Google Scholar] [CrossRef]

- Damerchi, E.; Abdollah-zadeh, A.; Poursalehi, R.; Mehr, M.S. Effects of functionally graded TiN layer and deposition temperature on the structure and surface properties of TiCN coating deposited on plasma nitrided H13 steel by PACVD method. J. Alloy. Compd. 2019, 772, 612–624. [Google Scholar] [CrossRef]

- Bell, T.; Dong, H.; Sun, Y. Realising the potential of duplex surface engineering. Tribol. Int. 1998, 31, 127–137. [Google Scholar] [CrossRef]

- Lembke, M.I.; Lewis, D.B.; Titchmarsh, J.M. Joint Second Prize Significance of Y and Cr in TiAlN Hard Coatings for Dry High Speed Cutting. Surf. Eng. 2001, 17, 153–158. [Google Scholar] [CrossRef]

- Schönjahn, C.; Ehiasarian, A.P.; Lewis, D.B.; New, R.; Münz, W.-D.; Twesten, R.D.; Petrov, I. Optimization of in situ substrate surface treatment in a cathodic arc plasma: A study by TEM and plasma diagnostics. J. Vac. Sci. Technol. A Vac. Surf. Film. 2001, 19, 1415–1420. [Google Scholar] [CrossRef]

- Lattemann, M.; Ehiasarian, A.P.; Bohlmark, J.; Persson, P.Å.O.; Helmersson, U. Investigation of high power impulse magnetron sputtering pretreated interfaces for adhesion enhancement of hard coatings on steel. Surf. Coat. Technol. 2006, 200, 6495–6499. [Google Scholar] [CrossRef]

- Stoiber, M.; Wagner, J.; Mitterer, C.; Gammer, K.; Hutter, H.; Lugmair, C.; Kullmer, R. Plasma-assisted pre-treatment for PACVD TiN coatings on tool steel. Surf. Coat. Technol. 2003, 174–175, 687–693. [Google Scholar] [CrossRef]

- El-Hossary, F.M.; Negm, N.Z.; El-Rahman, A.M.A.; Hammad, M. Duplex treatment of 304 AISI stainless steel using rf plasma nitriding and carbonitriding. Mater. Sci. Eng. C 2009, 29, 1167–1173. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhong, J.; Lv, X.; Zhao, Y.; Zhou, W.; Zhang, Y. Microstructure and performance of functionally graded Ti(C,N)-based cermets prepared by double-glow plasma carburization. Int. J. Refract. Met. Hard Mater. 2014, 44, 109–112. [Google Scholar] [CrossRef]

- Yang, Y.; Yan, M.F.; Zhang, Y.X. Tribological behavior of diamond-like carbon in-situ formed on Fe3C-containing carburized layer by plasma carburizing. Appl. Surf. Sci. 2019, 479, 482–488. [Google Scholar] [CrossRef]

- Glühmann, J.; Schneeweiß, M.; Van den Berg, H.; Kassel, D.; Rödiger, K.; Dreyer, K.; Lengauer, W. Functionally graded WC–Ti(C,N)–(Ta,Nb)C–Co hardmetals: Metallurgy and performance. Int. J. Refract. Met. Hard Mater. 2013, 36, 38–45. [Google Scholar] [CrossRef]

- Garcia, J.; Pitonak, R. The role of cemented carbide functionally graded outer-layers on the wear performance of coated cutting tools. Int. J. Refract. Met. Hard Mater. 2013, 36, 52–59. [Google Scholar] [CrossRef]

- Chen, J.; Deng, X.; Gong, M.; Liu, W.; Wu, S. Research into preparation and properties of graded cemented carbides with face center cubic-rich surface layer. Appl. Surf. Sci. 2016, 380, 108–113. [Google Scholar] [CrossRef]

- Rech, J.; Battaglia, J.L.; Moisan, A. Thermal influence of cutting tool coatings. J. Mater. Process. Technol. 2005, 159, 119–124. [Google Scholar] [CrossRef]

- Rech, J.; Kusiak, A.; Battaglia, J. Tribological and thermal functions of cutting tool coatings. Surf. Coat. Technol. 2004, 186, 364–371. [Google Scholar] [CrossRef]

- Shalaby, M.A.; Veldhuis, S.C. Wear and Tribological Performance of Different Ceramic Tools in Dry High Speed Machining of Ni-Co-Cr Precipitation Hardenable Aerospace Superalloy. Tribol. Trans. 2019, 62, 62–77. [Google Scholar] [CrossRef]

- Song, W.; Wang, Z.; Deng, J.; Zhou, K.; Wang, S.; Guo, Z. Cutting temperature analysis and experiment of Ti–MoS2/Zr-coated cemented carbide tool. Int. J. Adv. Manuf. Technol. 2017, 93, 799–809. [Google Scholar] [CrossRef]

- Gengler, J.J.; Hu, J.; Jones, J.G.; Voevodin, A.A.; Steidl, P.; Vlček, J. Thermal conductivity of high-temperature Si–B–C–N thin films. Surf. Coat. Technol. 2011, 206, 2030–2033. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Michailidis, N.; Skordaris, G.; Bouzakis, E.; Biermann, D.; M’Saoubi, R. Cutting with coated tools: Coating technologies, characterization methods and performance optimization. Cirp Ann. 2012, 61, 703–723. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, J.; Chen, M. Enhancing the machining performance by cutting tool surface modifications: A focused review. Mach. Sci. Technol. 2019, 1–33. [Google Scholar] [CrossRef]

- Oliaei, S.N.B.; Karpat, Y.; Davim, J.P.; Perveen, A. Micro tool design and fabrication: A review. J. Manuf. Process. 2018, 36, 496–519. [Google Scholar] [CrossRef]

- Swan, S.; Abdullah, M.S.B.; Kim, D.; Nguyen, D.; Kwon, P. Tool Wear of Advanced Coated Tools in Drilling of CFRP. J. Manuf. Sci. Eng. 2018, 140, 111018. [Google Scholar] [CrossRef]

- Volosova, M.; Grigoriev, S.; Metel, A.; Shein, A. The Role of Thin-Film Vacuum-Plasma Coatings and Their Influence on the Efficiency of Ceramic Cutting Inserts. Coatings 2018, 8, 287. [Google Scholar] [CrossRef]

- Mitterer, C. PVD and CVD Hard Coatings. In Compr Hard Mater; Elsevier: Amsterdam, The Netherlands, 2014; pp. 449–467. [Google Scholar] [CrossRef]

- Rokni, M.R.; Nutt, S.R.; Widener, C.A.; Champagne, V.K.; Hrabe, R.H. Review of Relationship Between Particle Deformation, Coating Microstructure, and Properties in High-Pressure Cold Spray. J. Spray Technol. 2017, 26, 1308–1355. [Google Scholar] [CrossRef]

- Abukhshim, N.A.; Mativenga, P.T.; Sheikh, M.A. Heat generation and temperature prediction in metal cutting: A review and implications for high speed machining. Int. J. Mach. Tools Manuf. 2006, 46, 782–800. [Google Scholar] [CrossRef]

- Jaworska, L.; Cyboron, J.; Cygan, S.; Laszkiewicz-Lukasik, J.; Podsiadlo, M.; Novak, P.; Holovenko, Y. New materials through a variety of sintering methods. IOP Conf. Series Mater. Sci. Eng. 2018, 329, 012004. [Google Scholar] [CrossRef]

- Billman, E.R.; Mehrotra, P.K.; Shuster, A.F.; Beechly, C.W. Machining with Al2O3-Sic Whisker Cutting Tools. In Proceedings of the 12th Annual Conference on Composites and Advanced Ceramic Materials: Ceramic Engineering and Science Proceedings, Cocoa Beach, FL, USA, 1 January 1988; Wachtman, J.B.J., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA; pp. 543–552. [Google Scholar]

- McMillan, P.F. New materials from high-pressure experiments. Nat. Mater. 2002, 1, 19–25. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, J.; Jiang, W. Recent development in reactive synthesis of nanostructured bulk materials by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2013, 39, 103–112. [Google Scholar] [CrossRef]

- Grasso, S.; Hu, C.; Maizza, G.; Sakka, Y. Spark Plasma Sintering of Diamond Binderless WC Composites. J. Am. Ceram. Soc. 2012, 95, 2423–2428. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Y.; Li, T.; Li, X.; Cheng, X.; Dong, L.; Yuan, Y.; Zang, J.; Lu, J.; Yu, Y.; et al. Fabrication of diamond–SiC–TiC composite by a spark plasma sintering-reactive synthesis method. J. Eur. Ceram. Soc. 2015, 35, 69–76. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E.; Tay, B.Y.; Zhao, Z.; Zhao, L.; Tian, Z.; Yang, S. Direct selective laser sintering and melting of ceramics: A review. Rapid Prototyp. J. 2017, 23, 611–623. [Google Scholar] [CrossRef]

- Klimczyk, P.; Cura, M.E.; Vlaicu, A.M.; Mercioniu, I.; Wyżga, P.; Jaworska, L.; Hannula, S.-P. Al2O3 –cBN composites sintered by SPS and HPHT methods. J. Eur. Ceram. Soc. 2016, 36, 1783–1789. [Google Scholar] [CrossRef]

- Wozniak, J.; Cygan, T.; Petrus, M.; Cygan, S.; Kostecki, M.; Jaworska, L.; Olszyna, A. Tribological performance of alumina matrix composites reinforced with nickel-coated grapheme. Ceram. Int. 2018, 44, 9728–9732. [Google Scholar] [CrossRef]

- Cygan, T.; Wozniak, J.; Kostecki, M.; Petrus, M.; Jastrzębska, A.; Ziemkowska, W.; Olszyna, A. Mechanical properties of graphene oxide reinforced alumina matrix composites. Ceram. Int. 2017, 43, 6180–6186. [Google Scholar] [CrossRef]

- Broniszewski, K.; Wozniak, J.; Kostecki, M.; Czechowski, K.; Jaworska, L.; Olszyna, A. Al2O3–V cutting tools for machining hardened stainless steel. Ceram. Int. 2015, 41, 14190–14196. [Google Scholar] [CrossRef]

- Benedicto, E.; Carou, D.; Rubio, E.M. Technical, Economic and Environmental Review of the Lubrication/Cooling Systems Used in Machining Processes. Procedia Eng. 2017, 184, 99–116. [Google Scholar] [CrossRef]

- Putyra, P.; Figiel, P.; Podsiadło, M.; Klimczyk, P. Alumina composites with solid lubricant participations, sintered by SPS-method. Kompozyty 2011, 11, 107–110. [Google Scholar]

- Deng, J.; Cao, T. Self-lubricating mechanisms via the in situ formed tribofilm of sintered ceramics with CaF2 additions when sliding against hardened steel. Int. J. Refract. Met. Hard Mater. 2007, 25, 189–197. [Google Scholar] [CrossRef]

- Deng, J.; Can, T.; Sun, J. Microstructure and mechanical properties of hot-pressed Al2O3/TiC ceramic composites with the additions of solid lubricants. Ceram. Int. 2005, 31, 249–256. [Google Scholar] [CrossRef]

- Wu, G.; Xu, C.; Xiao, G.; Yi, M.; Chen, Z.; Xu, L. Self-lubricating ceramic cutting tool material with the addition of nickel coated CaF2 solid lubricant powders. Int. J. Refract. Met. Hard Mater. 2016, 56, 51–58. [Google Scholar] [CrossRef]

- Katzman, H.; Libby, W.F. Sintered Diamond Compacts with a Cobalt Binder. Science 1971, 172, 1132–1134. [Google Scholar] [CrossRef]

- Hibbs, L.E., Jr.; Wentorf, R.E., Jr. High pressure sintering of diamond by cobalt infiltration. High Temp.-High Press. 1974, 6, 409–413. [Google Scholar]

- Griffin, N.D.; Hughes, P.R. Polycrystalline Diamond Partially Depleted of Catalizing Material, US6592985B2, 2003. Available online: https://patents.google.com/patent/US6592985B2/en (accessed on 17 March 2020).

- Bertagnolli, K.E.; Vail, M.A. Polycrystalline Diamond Compact (PDC) Cutting Element Having Multiple Catalytic Elements, US8342269B1, 2013. Available online: https://patents.google.com/patent/US8342269 (accessed on 17 March 2020).

- Osipov, A.S.; Klimczyk, P.; Cygan, S.; Melniychuk, Y.A.; Petrusha, I.A.; Jaworska, L.; Bykov, A.I. Diamond-CaCO 3 and diamond-Li 2 CO 3 materials sintered using the HPHT method. J. Eur. Ceram. Soc. 2017, 37, 2553–2558. [Google Scholar] [CrossRef]

- Jaworska, L.; Szutkowska, M.; Klimczyk, P.; Sitarz, M.; Bucko, M.; Rutkowski, P.; Figiel, P.; Lojewska, J. Oxidation, graphitization and thermal resistance of PCD materials with the various bonding phases of up to 800 °C. Int. J. Refract. Met. Hard Mater. 2014, 45, 109–116. [Google Scholar] [CrossRef]

- Sumiya, H. Novel Development of High-Pressure Synthetic Diamonds Ultra-Hard Nano-Polycrystalline Diamonds. Sei Tech. Rev. 2012, 15–23. Available online: https://global-sei.com/technology/tr/bn74/pdf/74-03.pdf (accessed on 17 March 2020).

- Morris, D.G.; Muñoz-Morris, M.A. The stress anomaly in FeAl–Fe3Al alloys. Intermetallics 2005, 13, 1269–1274. [Google Scholar] [CrossRef]

- Novák, P.; Nová, K. Oxidation Behavior of Fe–Al, Fe–Si and Fe–Al–Si Intermetallics. Materials 2019, 12, 1748. [Google Scholar] [CrossRef] [PubMed]

- Grabke, H.J. Oxidation of Aluminides. Mater. Sci. Forum 1997, 251–254, 149–162. [Google Scholar] [CrossRef]

- Novák, P.; Šotka, D.; Novák, M.; Michalcová, A.; Šerák, J.; Vojtěch, D. Production of NiAl–matrix composites by reactive sintering. Powder Metall. 2011, 54, 308–313. [Google Scholar] [CrossRef]

- Sheng, L.Y.; Yang, F.; Xi, T.F.; Guo, J.T. Investigation on microstructure and wear behavior of the NiAl–TiC–Al2O3 composite fabricated by self-propagation high-temperature synthesis with extrusion. J. Alloy. Compd. 2013, 554, 182–188. [Google Scholar] [CrossRef]

- Choo, H.; Nash, P.; Dollar, M. Mechanical properties of NiAl–AlN–Al2O3 composites. Mater. Sci. Eng. A 1997, 239–240, 464–471. [Google Scholar] [CrossRef]

- Furushima, R.; Shimojima, K.; Hosokawa, H.; Matsumoto, A. Oxidation-enhanced wear behavior of WC-FeAl cutting tools used in dry machining oxygen-free copper bars. Wear 2017, 374–375, 104–112. [Google Scholar] [CrossRef]

- Mottaghi, M.; Ahmadian, M. Comparison of the wear behavior of WC/(FeAl-B) and WC-Co composites at high temperatures. Int. J. Refract. Met. Hard Mater. 2017, 67, 105–114. [Google Scholar] [CrossRef]

- Ahmadian, M.; Wexler, D.; Chandra, T.; Calka, A. Abrasive wear of WC–FeAl–B and WC–Ni3Al–B composites. Int. J. Refract. Met. Hard Mater. 2005, 23, 155–159. [Google Scholar] [CrossRef]

- Subramanian, R.; Schneibel, J.H. FeAl–TiC and FeAl–WC composites—melt infiltration processing, microstructure and mechanical properties. Mater. Sci. Eng. A 1998, 244, 103–112. [Google Scholar] [CrossRef]

- Buchholz, S.; Farhat, Z.N.; Kipouros, G.J.; Plucknett, K.P. The reciprocating wear behaviour of TiC–Ni3Al cermets. Int. J. Refract. Met. Hard Mater. 2012, 33, 44–52. [Google Scholar] [CrossRef]

- Robertson, S.W.; Pelton, A.R.; Ritchie, R.O. Mechanical fatigue and fracture of Nitinol. Int. Mater. Rev. 2013, 57, 1–37. [Google Scholar] [CrossRef]

- Baumann, M.A. Nickel-titanium: Options and challenges. Dent. Clin. N. Am. 2004, 48, 55–67. [Google Scholar] [CrossRef] [PubMed]

- Novák, P.; Kristianová, E.; Valalik, M.; Darme, C.; Salvetr, P. New Composite Materials Based on NiTi. Manuf. Technol. 2015, 15, 644–647. [Google Scholar]

- Novák, P.; Kříž, J.; Průša, F.; Kubásek, J.; Marek, I.; Michalcová, A.; Voděrová, M.; Vojtěch, D. Structure and properties of Ti–Al–Si-X alloys produced by SHS method. Intermetallics 2014, 39, 11–19. [Google Scholar] [CrossRef]

- Mochizuki, N.; Takasugi, T.; Kaneno, Y.; Oki, S.; Hirata, T. Friction stir welding of 430 stainless steel and pure titanium using Ni3Al-Ni3V dual two-phase intermetallic alloy tool. In Proceedings of the 1st International Joint Symposium on Joining and Welding; Woodhead Publishing: Sawston, Cambridge, UK, 2013; pp. 465–471. [Google Scholar]

- Knaislová, A.; Novák, P.; Cabibbo, M.; Průša, F.; Paoletti, C.; Jaworska, L.; Vojtěch, D. Combination of reaction synthesis and Spark Plasma Sintering in production of Ti-Al-Si alloys. J. Alloy. Compd. 2018, 752, 317–326. [Google Scholar] [CrossRef]

- Holmström, E.; Linder, D.; Salmasi, A.; Wang, W.; Kaplan, B.; Mao, H.; Larsson, H.; Vitos, L. High entropy alloys: Substituting for cobalt in cutting edge technology. Appl. Mater. Today 2008, 12, 322–329. [Google Scholar] [CrossRef]

- Arragó, J.M.; Ferrari, C.; Reig, B.; Coureaux, D.; Schneider, L.; Llanes, L. Mechanics and mechanisms of fatigue in a WC–Ni hardmetal and a comparative study with respect to WC–Co hard metals. Int. J. Fatigue 2015, 70, 252–257. [Google Scholar] [CrossRef]

- Viswanadham, R.K.; Lindquist, R.G. Transformation-Toughening in Cemented Carbides: Part I. Binder Composition Control. Met. Trans. A 1987, 18, 2163–2173. [Google Scholar] [CrossRef]

- Schubert, W.D.; Fugger, B.M.; Wittmann, R. Useldinger, Aspects of sintering of cemented carbides withFe-based binders. Int. J. Refract. Met. Hard Mater. 2015, 49, 110–123. [Google Scholar] [CrossRef]

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Reck, B.K. On the materials basis of modern society. Proc. Natl. Acad. Sci. 2015, 112, 6295–6300. [Google Scholar] [CrossRef] [PubMed]

- Provis, J.L. Grand Challenges in Structural Materials. Front. Mater. 2015, 2. [Google Scholar] [CrossRef]

- Materials Genome Initiative Homepage. Available online: https://www.mgi.gov (accessed on 4 March 2020).

- Psi-k Homepage. Available online: http://psi-k.net/ (accessed on 4 March 2020).

- Overview of the EU funded Centres of Excellence for Computing Applications. Available online: https://ec.europa.eu/programmes/horizon2020/en/news/overview-eu-funded-centres-excellence-computing-applications (accessed on 4 March 2020).

- EXDCI Homepage. Available online: https://exdci.eu (accessed on 4 March 2020).

- NIMS. 2019. Available online: https://www.nims.go.jp/eng/index.html (accessed on 4 March 2020).

- The Novel Materials Discovery (NOMAD) Laboratory Homepage. Available online: https://nomad-coe.eu/ (accessed on 4 March 2020).

- FAIR-DI (Data Infrastructure). Pillar, A, Computational Materials Science–NOMAD. Available online: https://fairdi.eu/index.php?page=pillar-a (accessed on 4 March 2020).

- AiiDA (Automated Interactive Infrastructure and Database for Computational Science) Homepage. Available online: http://www.aiida.net/ (accessed on 4 March 2020).

- MaterialsCloud Homepage. Available online: https://www.materialscloud.org/ (accessed on 4 March 2020).

- CMR (Computational Materials Repository) Homepage. Available online: https://cmr.fysik.dtu.dk/ (accessed on 4 March 2020).

- MPDS (Materials Platform for Data Science) Homepage. Available online: https://mpds.io/ (accessed on 4 March 2020).

- OMD (Open Materials Database) Homepage. Available online: http://openmaterialsdb.se/ (accessed on 4 March 2020).

- ESL (Electronic Structure Library) Homepage. Available online: https://esl.cecam.org/ (accessed on 4 March 2020).

- ESP (Electronic Structure Project) Homepage. Available online: http://gurka.fysik.uu.se/ESP/ (accessed on 4 March 2020).

- Materials Project Homepage. Available online: https://www.materialsproject.org/ (accessed on 4 March 2020).

- AFLOW (Automatic-FLOW for Materials Discovery) Homepage. Available online: http://www.aflow.org/ (accessed on 4 March 2020).

- OQMD (Open Quantum Materials Database) Homepage. Available online: http://oqmd.org/ (accessed on 4 March 2020).

- MatNavi (NIMS Materials Database) Homepage. Available online: https://mits.nims.go.jp/index_en.html (accessed on 4 March 2020).

- factsage Homepage. Available online: http://www.factsage.com/ (accessed on 4 March 2020).

- Computherm Homepage. Available online: https://computherm.com/ (accessed on 4 March 2020).

- Thermocalc Homepage. Available online: https://www.thermocalc.com/ (accessed on 4 March 2020).

- Opencalphad Homepage. Available online: http://www.opencalphad.com/ (accessed on 4 March 2020).

- MMM@HPC (Multiscale Materials Modelling on High Performance Computing Architectures) Homepage. Available online: http://www.multiscale-modelling.eu/ (accessed on 4 March 2020).

- EUDAT Homepage. Available online: https://eudat.eu/ (accessed on 4 March 2020).

- Kaye and Laby. Available online: http://www.npl.co.uk/resources (accessed on 4 March 2020).

- MEDEA Homepage. Available online: https://www.materialsdesign.com/ (accessed on 4 March 2020).

- NanoHUB Homepage. Available online: http://nanohub.org/ (accessed on 4 March 2020).

- Pymatgen Homepage. Available online: http://pymatgen.org/ (accessed on 4 March 2020).

- Imeall Homepage. Available online: https://github.com/kcl-tscm/imeall (accessed on 4 March 2020).

- MPInterfaces Homepage. Available online: https://github.com/henniggroup/MPInterfaces (accessed on 4 March 2020).

- pylada Homepage. Available online: https://github.com/pylada/pylada-defects (accessed on 4 March 2020).

- Jain, A.; Ong, S.P.; Hautier, G.; Chen, W.; Richards, W.D.; Dacek, S.; Cholia, S.; Gunter, D.; Skinner, D.; Ceder, G.; et al. Commentary: The Materials Project: A materials genome approach to accelerating materials innovation. APL Mater. 2013, 011002. [Google Scholar] [CrossRef]

- Massalski, T.B.; Okamoto, H.; Subramanian, P.R.; Kacprzak, L. (Eds.) Binary Alloy Phase Diagrams, 2nd ed.; ASM International: Cleveland, OH, USA, 1990. [Google Scholar]

- Villars, P.; Prince, A.; Okamoto, H. (Eds.) Handbook of Ternary Alloy Phase Diagrams; ASM International: Cleveland, OH, USA, 1995. [Google Scholar]

- NIST-ASM (National Institute of Standards and Technology – Materials Data Repository) Homepage. Available online: https://materialsdata.nist.gov (accessed on 4 March 2020).

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: Challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Fu, X.; Schuh, C.A.; Olivetti, E.A. Materials selection considerations for high entropy alloys, Scr. Mater. 2017, 138, 145–150. [Google Scholar] [CrossRef]

- Abu-Odeh, A.; Galvan, E.; Kirk, T.; Mao, H.; Chen, Q.; Mason, P.; Malak, R.; Arróyave, R. Efficient exploration of the High Entropy Alloy composition-phase space. Acta Mater. 2018, 152, 41–57. [Google Scholar] [CrossRef]

- Ikeda, Y.; Grabowski, B.; Körmann, F. Ab initio phase stabilities and mechanical properties of multicomponent alloys: A comprehensive review for high entropy alloys and compositionally complex alloys. Mater. Charact. 2019, 147, 464–511. [Google Scholar] [CrossRef]

- Gorbachev, I.; Popov, V.; Katz-Demyanetz, A.; Popov, V.V., Jr.; Eshed, E. Prediction of the Phase Composition of High-Entropy Alloys Based on Cr–Nb–Ti–V–Zr Using the Calphad Method. Phys. Met. Metallogr. 2019, 120, 378–386. [Google Scholar] [CrossRef]

- USPEX (Universal Structure Predictor: Evolutionary Xtallography) Homepage. Available online: http://uspex-team.org/en/ (accessed on 4 March 2020).

- GASP (Genetic Algorithm for Structure and Phase Prediction) Homepage. Available online: http://gasp.mse.ufl.edu/ (accessed on 4 March 2020).

- CALYPSO (Crystal structure AnaLYsis by Particle Swarm Optimization) Homepage. Available online: http://www.calypso.cn/ (accessed on 4 March 2020).

- ATAT (Alloy Theoretic Automated Toolkit) Homepage. Available online: https://www.brown.edu/Departments/Engineering/Labs/avdw/atat/ (accessed on 4 March 2020).

- UNCLE-MEDEA. Available online: https://www.materialsdesign.com/products (accessed on 4 March 2020).

- RuNNer Homepage. Available online: http://www.uni-goettingen.de/de/560580.html (accessed on 4 March 2020).

- AIRSS (Ab Initio Random Structure Searching) Homepage. Available online: https://www.mtg.msm.cam.ac.uk/Codes/AIRSS (accessed on 4 March 2020).

- Kvashnin, A.G.; Zakaryan, H.A.; Zhao, C.; Duan, Y.; Kvashnina, Y.A.; Xie, C.; Dong, H.; Oganov, A.R. New tungsten borides, their stability and outstanding mechanical properties. J. Phys. Chem. Lett. 2018, 9, 3470. [Google Scholar] [CrossRef]

- Mikhail Kuklin. Available online: https://wiki.aalto.fi/display/IMM/USPEX+guide (accessed on 4 March 2020).

- Atomistica Homepage. Available online: http://www.atomistica.org/ (accessed on 4 March 2020).

- Atomicrex Homepage. Available online: https://atomicrex.org/ (accessed on 4 March 2020).

- Potfit Homepage. Available online: https://www.potfit.net (accessed on 4 March 2020).

- OpenKIM (Knowledgebase of Interatomic Models) Homepage. Available online: https://openkim.org/ (accessed on 4 March 2020).

- GAP (Gaussian Approximation Potentials) Homepage. Available online: http://www.libatoms.org/Home/Software (accessed on 4 March 2020).

- SNAP (Spectral Neighbor Analysis Potential) Homepage. Available online: https://github.com/materialsvirtuallab/snap (accessed on 4 March 2020).

- González, C.; Panizo-Laiz, M.; Gordillo, N.; Guerrero, C.L.; Tejado, E.; Munnik, F.; Piaggi, P.; Bringa, E.; Iglesias, R.; Perlado, J.M.; et al. H trapping and mobility in nanostructured tungsten grain boundaries: A combined experimental and theoretical approach. Nucl. Fusion. 2015, 55, 113009. [Google Scholar] [CrossRef]

- Valles, G.; Panizo-Laiz, M.; González, C.; Martin-Bragado, I.; González-Arrabal, R.; Gordillo, N.; Iglesias, R.; Guerrero, C.L.; Perlado, J.M.; Rivera, A. Influence of grain boundaries on the radiation-induced defects and hydrogen in nanostructured and coarse-grained tungsten. Acta Mater. 2017, 122, 277–286. [Google Scholar] [CrossRef]

- The Minerals, Metals & Materials Society (TMS). Advanced Computation and Data in Materials and Manufacturing: Core Knowledge Gaps and Opportunities; TMS: Pittsburgh, PA, USA, 2018. [Google Scholar]

- Bessa, M.A.; Glowacki, P.; Houlder, M. Bayesian Machine Learning in Metamaterial Design: Fragile Becomes Supercompressible. Adv. Mater. 2019, 31, 1904845. [Google Scholar] [CrossRef] [PubMed]

- White Paper on Gaps and Obstacles in Materials Modelling. Available online: https://emmc.info/wp-content/uploads/2019/12/EMMC-CSA-whitepaper-DRAFTV20191220v2.pdf (accessed on 4 March 2020).

- Shin, S.-H.; Kim, H.-Y.; Rim, K.-Y. Worker Safety in the Rare Earth Elements Recycling Process from the Review of Toxicity and Issues. Saf. Health Work 2019, 10, 409–419. [Google Scholar] [CrossRef] [PubMed]

- Dominik, B.; Kleinert, F.; Imiela, J.; Westkämper, E. Life Cycle Management of Cutting Tools: Comprehensive Acquisition and Aggregation of Tool Life Data. Procedia Cirp 2017, 61, 311–316. [Google Scholar]

- Ishida, T.; Itakura, T.; Moriguchi, H.; Ikegaya, A. Development of technologies for recycling cemented carbidescrap and reducing tungstenuse in cemented carbide tools. SEI Tech. Rev. 2012, 75, 38–46. [Google Scholar]

- Hayashi, T.; Sato, F.; Sasaya, K.; Ikegaya, A. Industrialization of Tungsten Recovering from Used Cemented Carbide Tools. SEI Tech. Rev. 2016, 82, 33–38. [Google Scholar]

- Freemantle, C.; Sacks, N. Recycling of cemented tungsten carbide mining tool scrap. J. South. Afr. Inst. Min. Metall. 2015, 115, 1207–1213. [Google Scholar] [CrossRef]

- Angelo, P.C.; Subramanian, R. Powder Metallurgy: Science, Technology and Applications; PHI Learning Pvt. Ltd.: New Delhi, India, 2008. [Google Scholar]

- Altuncu, E.; Ustel, F.; Turk, A.; Ozturk, S.; Erdogan, G. Cutting-tool recycling process with the zinc-melt method for obtaining thermal-spray feedstock powder (wc-co) mtaec9. UDK 2013, 47, 115. [Google Scholar]

- Lee, J.; Kim, S.; Kim, B. A New Recycling Process for Tungsten Carbide Soft Scrap That Employs a Mechanochemical Reaction with Sodium Hydroxide. Metals 2017, 7, 230. [Google Scholar]

- Popov, V., Jr.; Katz-Demyanetz, A.; Garkun, A.; Bamberger, M. The effect of powder recycling on the mechanical properties and microstructure of electron beam melted Ti-6Al-4 V specimens. Addit. Manuf. 2018, 22, 834–843. [Google Scholar] [CrossRef]

- Joost, R.J.; Pirso, J.; Letunovitš, S.; Juhani, K. Recycling of WC-Co Hardmetals by Oxidation and Carbothermal Reduction in Combination with Reactive Sintering. Est. J. Eng. 2012, 18, 127. [Google Scholar] [CrossRef]

- Malyshev, V.; Shakhnin, D.; Gab, A.; Uskova, N.; Gudymenko, O.; Glushakov, V.; Kushchevska, N. Tungsten Resource-Saving: Cobalt Cermets Wastes Recycling and Concentrates Extraction. J. Env. Sci. Eng. B 2015, 4. [Google Scholar] [CrossRef]

- Gregor, K.; Luidold, S.; Czettl, C.; Storf, C. Successful Control of the Reaction Mechanism for Semi-Direct Recycling of Hard Metals. Int. J. Refract. Met. Hard Mater. 2020, 86, 105131. [Google Scholar]

- Liu, H.; Hanyu, H.; Murakami, Y.; Kamiya, S.; Saka, M. Recycling Technique for CVD Diamond Coated Cutting Tools. Surf. Coat. Technol. 2001, 137, 246–248. [Google Scholar] [CrossRef]

- Van Staden, A.C.; Hagedorn-Hansen, D.; Oosthuizen, G.A.; Sacks, N. Characteristics of single layer selective laser melted tool grade cemented tungsten carbide. In Proceedings of the Competitive Manufacturing, International Conference on Competitive Manufacturing (COMA ’16), Stellenbosch University, Stellenbosch, South Africa, 27–29 January 2016; Stellenbosch University: Stellenbosch, South Africa. [Google Scholar]

| Work Material | Cutting Parameters Used | Oscillation Parameters (Frequency (f), Amplitude (a)) | Cutting Force Comparison with Conventional Turning | Additional Conclusions |

|---|---|---|---|---|

| Ti6Al2Sn4Zr6Mo (α + β Ti alloy) [69] | fr = 0.1 mm/rev; v = 10–60 m/min; d = 0.2 mm | f = 20 kHz; a = 10 µm | Reduction by 74% | Surface roughness improved by 50% |

| Ti-15333 (β alloy) [70] | fr = 100 µm/rev; v = 10 m/min; d = 100–500 µm | F = 20 kHz a = 8 µm | Reduction by 80%–85% | Surface roughness improved by 50% while heat was applied during ultrasonic assisted machining |

| Ti6Al4V [71] | fr = 0.1 mm/rev; v = 10–300 m/min d = 0.1mm | f = 20 kHz a = 20 µm | Reduction by 40%–45% | Surface roughness improved by 40% |

| Ti 15-3-3-3 (β Ti-alloy) [72] | Fr = 0.1 mm/rev; v = 10–70 m/min; d = 50–500 µm | f = 17.9 kHz a = 10 µm | Reduction by 71%–88% | Surface roughness improved by 49% |

| Low alloy steel (DF2) [73] | Fr = 0.1 mm/rev; v = 50 m/min; d = 0.2 mm | F = 19 kHz; a = 15 µm | Reduction by 50% | Tool wear 20% less |

| S.No. | Theoretical Approach | Experimental Realization |

|---|---|---|

| Modification of the process | ||

| 1 | Reduction of chemical reaction rate between the tool and workpiece | Cryogenic turning [79] |

| 2 | Reduction of contact time between tool and workpiece | Vibration-assisted cutting [68,69,73,80,81,82,83,84,85,86] |

| 3 | Lowering of temperature rise and chemical contact | Usage of appropriate coolant [87,88] |

| Modification of the cutting tool | ||

| 4 | Building a diffusion barrier on the cutting tool | Use of protective coatings [89] |

| 5 | Modifying the cutting tool geometry | Providing nanogrooves on the cutting tool |

| 6 | Use of alternative cutting tool material | Use of cBN |

| Workpiece modification | ||

| 7 | Surface layer modification of the workpiece prior to cutting | Ion implantation |

| 8 | Surface defect machining | Pre-drilled laser holes in the workpiece reduce the shear strength, which is evident by observing a lower shear plane angle [90,91,92] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rizzo, A.; Goel, S.; Luisa Grilli, M.; Iglesias, R.; Jaworska, L.; Lapkovskis, V.; Novak, P.; Postolnyi, B.O.; Valerini, D. The Critical Raw Materials in Cutting Tools for Machining Applications: A Review. Materials 2020, 13, 1377. https://doi.org/10.3390/ma13061377

Rizzo A, Goel S, Luisa Grilli M, Iglesias R, Jaworska L, Lapkovskis V, Novak P, Postolnyi BO, Valerini D. The Critical Raw Materials in Cutting Tools for Machining Applications: A Review. Materials. 2020; 13(6):1377. https://doi.org/10.3390/ma13061377