Green Preparation of Aqueous Graphene Dispersion and Study on Its Dispersion Stability

Abstract

1. Introduction

2. Experiment

2.1. Reagents and Equipment

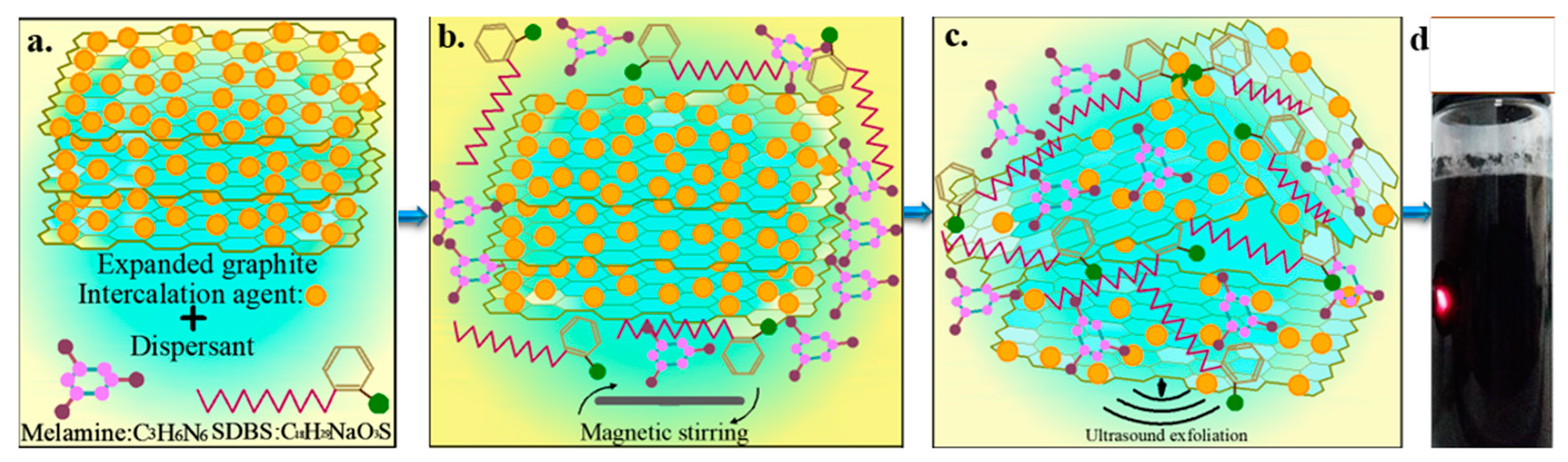

2.2. Experiment Section

3. Results and Discussion

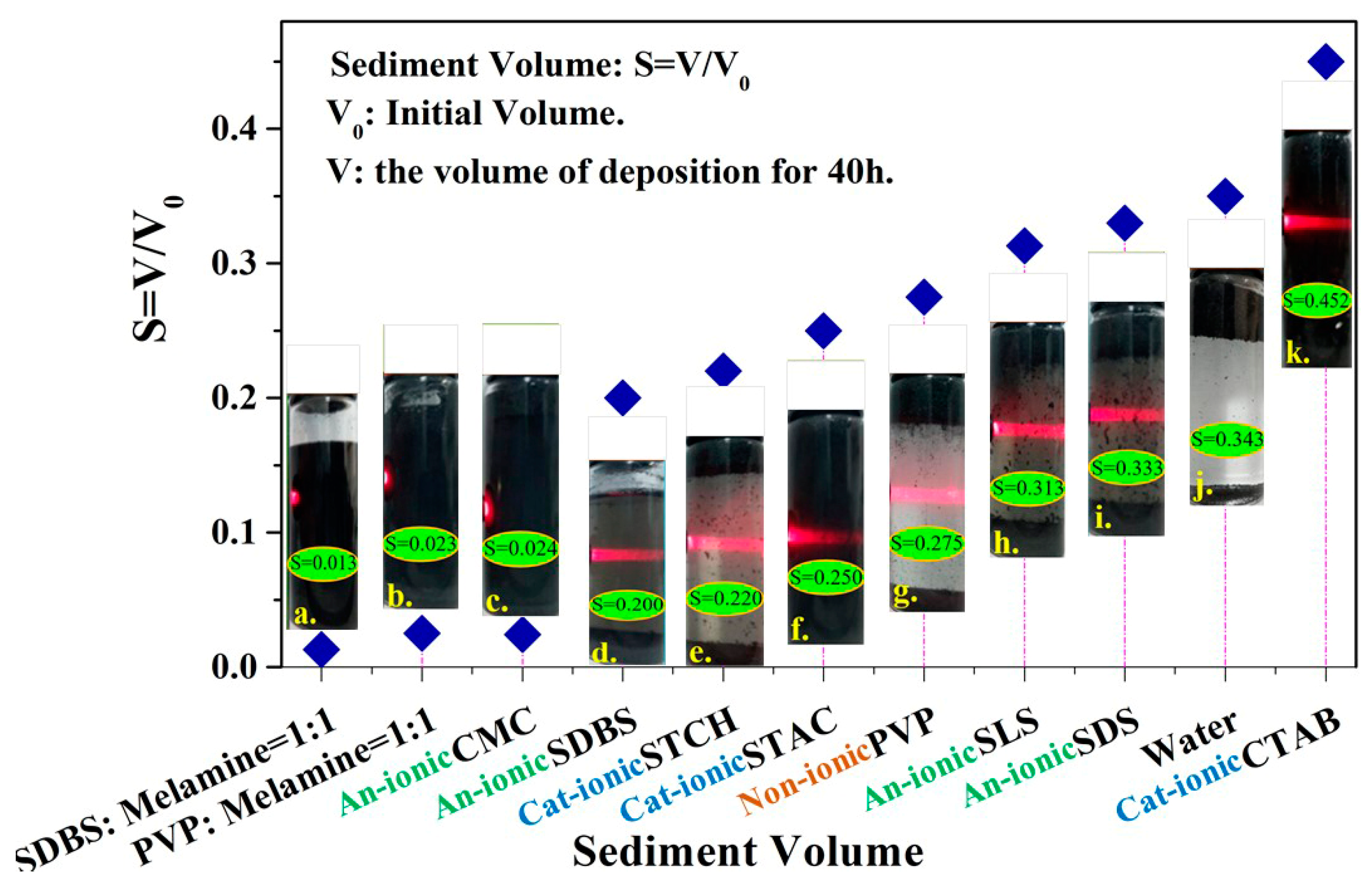

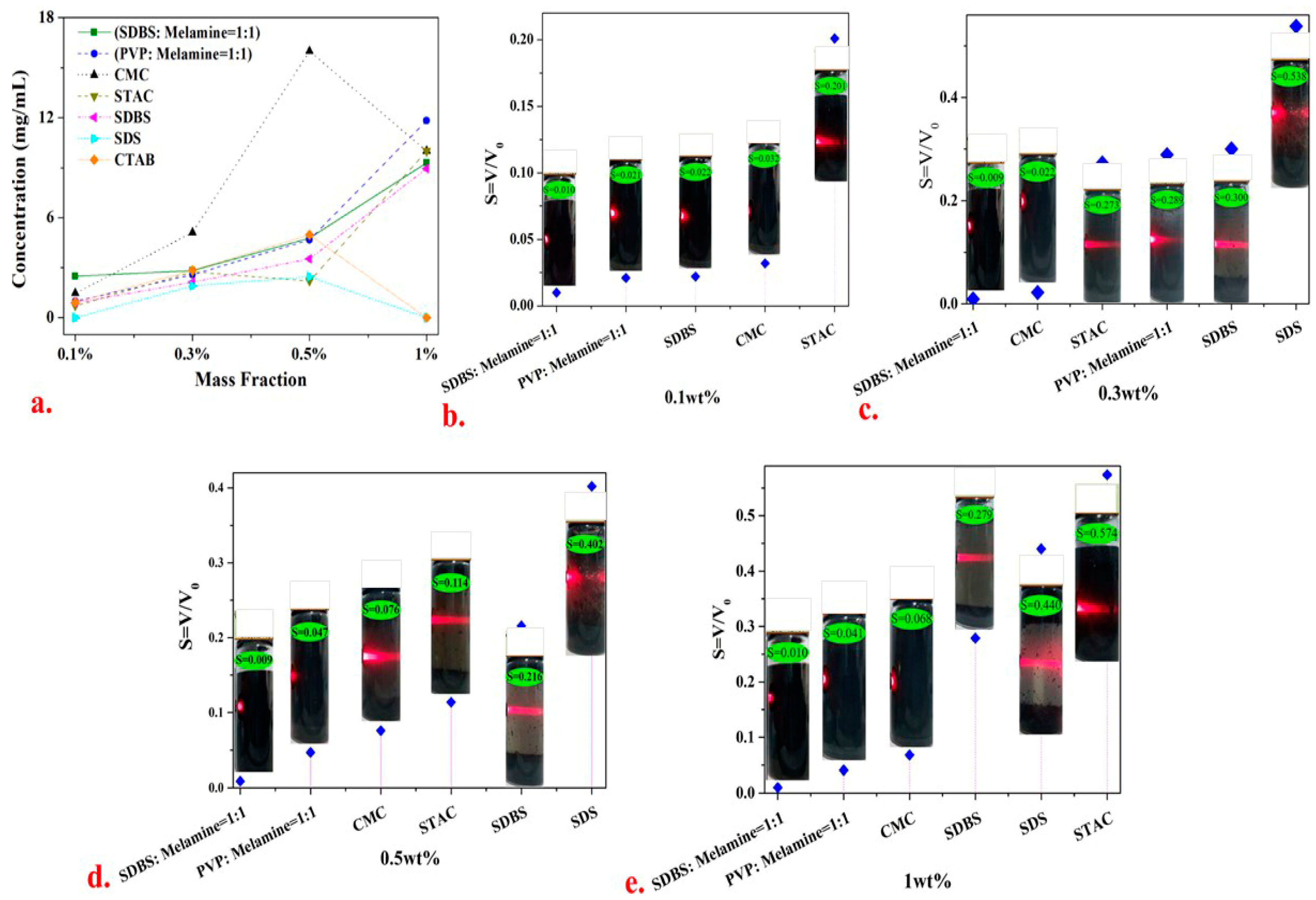

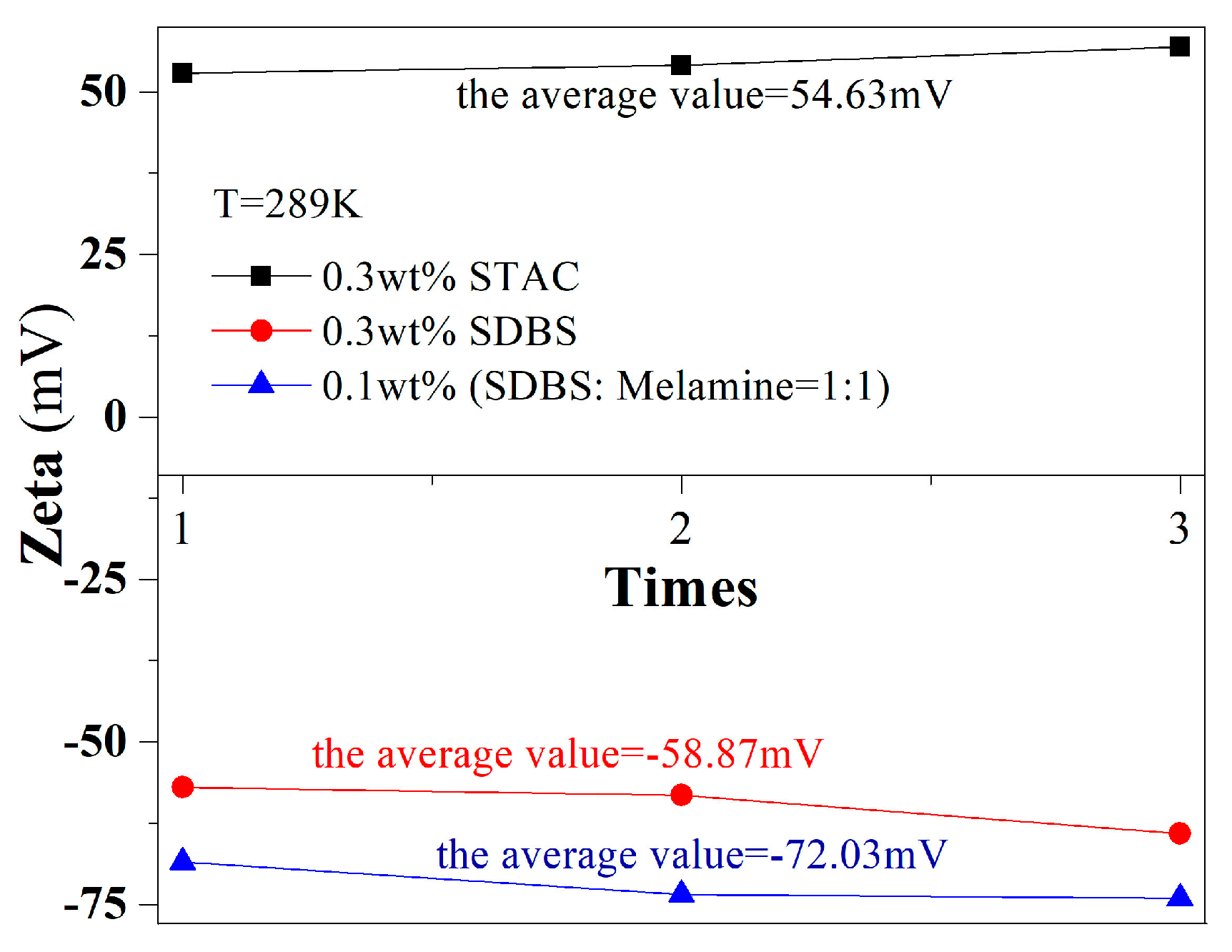

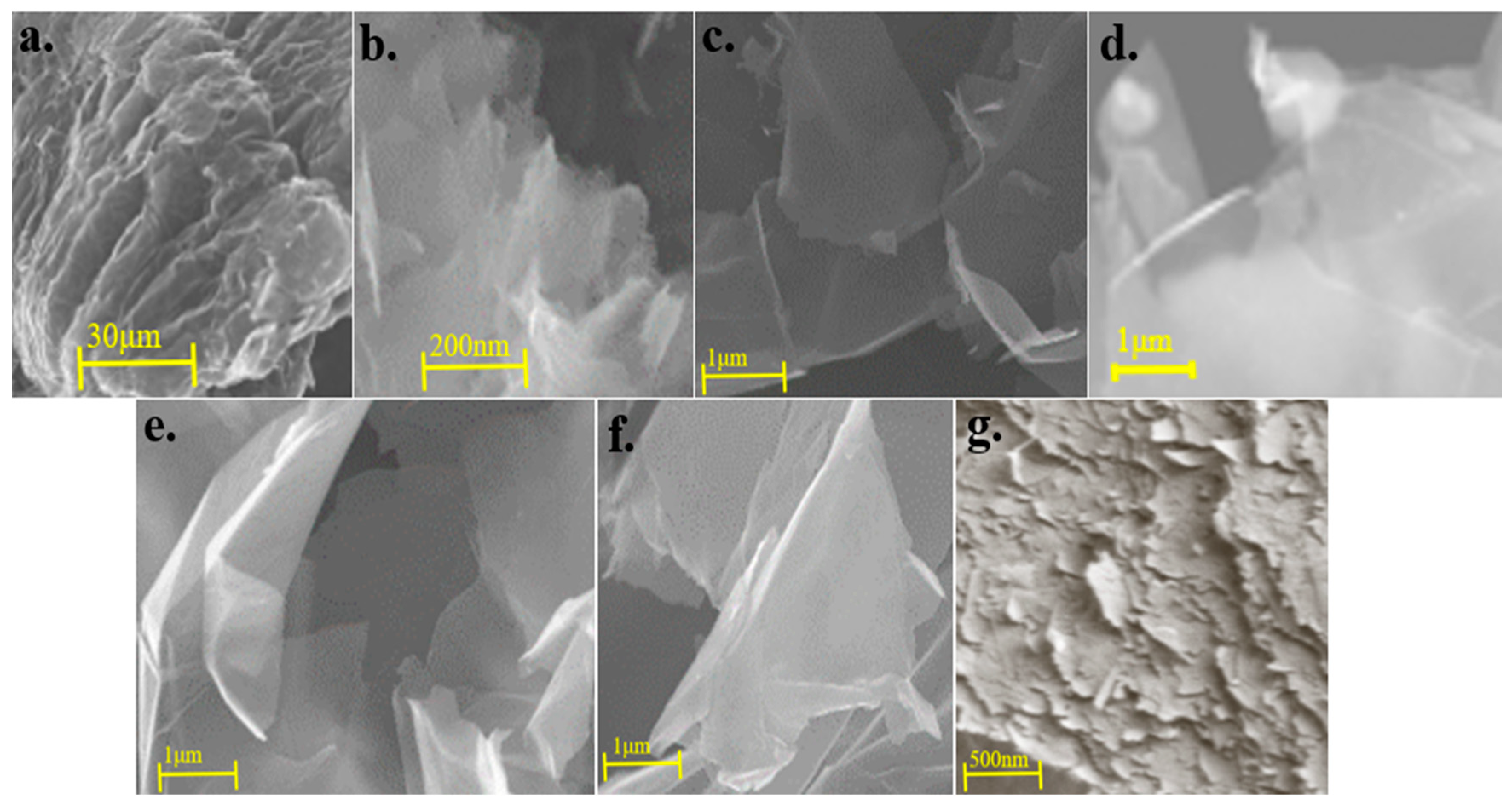

3.1. Analysis of the Exfoliation Grade and Dispersion Stability

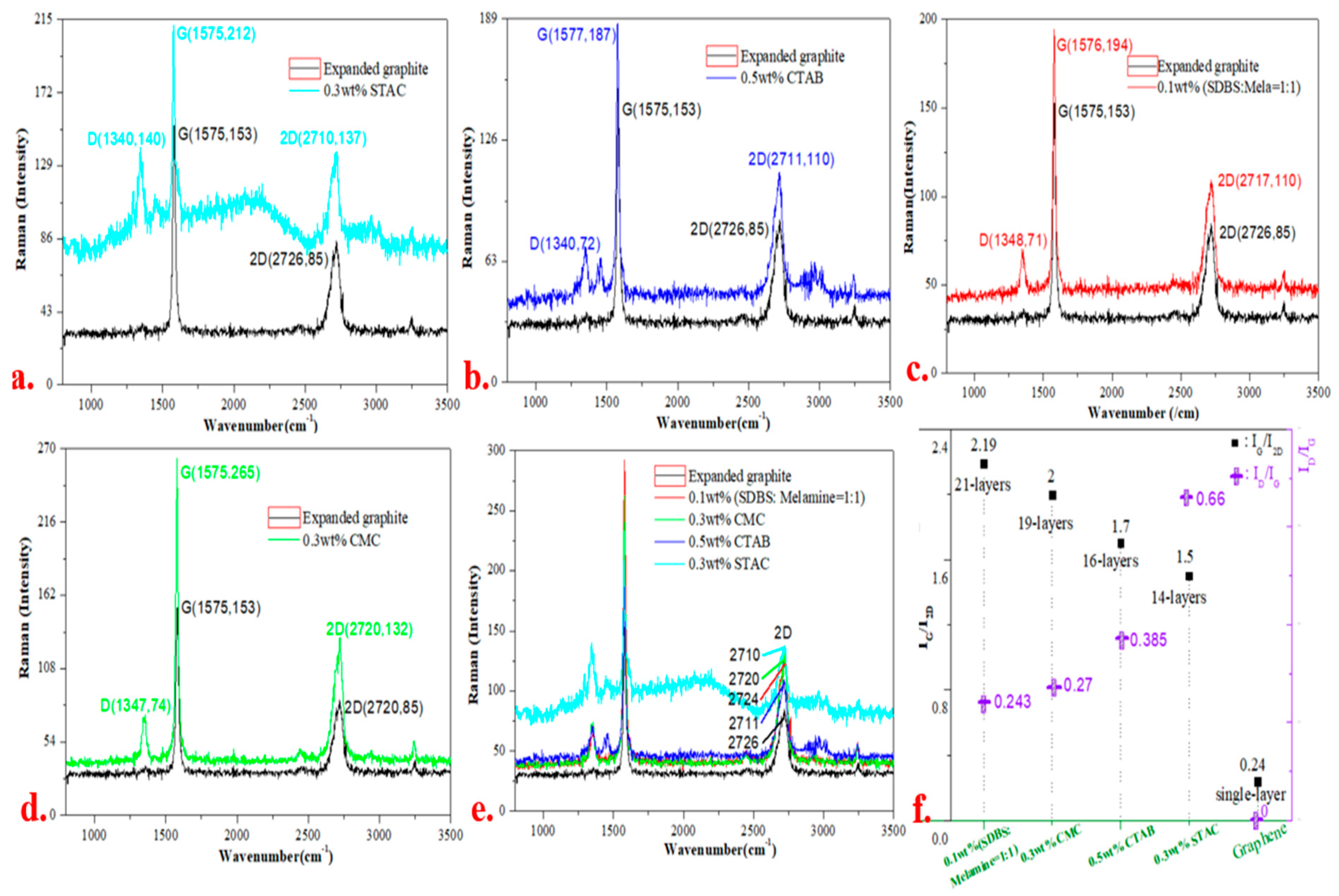

3.2. Graphene Layers

3.3. Defect Density of Graphene

4. Conclusions

- (1)

- The electrostatic repulsion force of the charged particles formed by the ionisation of the quaternary ammonium cationic surfactants in water was greater than the steric resistance generated by the non-ionic surfactants. The former also exerts a strong effect on the van der Waals force between the graphene sheets and enhances the exfoliation ability and dispersion stability. The 0.3 wt.% STAC dispersant system exhibited excellent exfoliation ability and dispersion stability and can exfoliate graphene nanosheets with less than eight layers (the average number of layers was less than 14 layers). In addition, the graphene can be stably dispersed in water and no settlement occurred for 13 days.

- (2)

- The mixed system of cyclic anionic surfactants and heterocyclic non-ionic surfactants exerts a complex dispersion effect on graphene through electrostatic repulsion and π–π action, which was more stable than that of a single dispersant system. The graphene in the 0.1 wt.% (SDBS: melamine = 1:1) system can remain stable in the storage for 22 days without sedimentation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Pérez-Jiménez, A.J.; Sancho-García, J.C. Conductance Enhancement in Nanographene−Gold Junctions by Molecular π-Stacking. J. Am. Chem. Soc. 2009, 131, 14857–14867. [Google Scholar] [CrossRef]

- Allen, M.J.; Tung, V.C.; Kaner, R.B. Honeycomb Carbon: A Review of Graphene. Chem. Rev. 2010, 110, 132–145. [Google Scholar] [CrossRef]

- Lee, H.; Choi, T.K.; Lee, Y.B.; Cho, H.R.; Ghaffari, R.; Wang, L.; Choi, H.J.; Chung, T.D.; Lu, N.; Hyeon, T.; et al. A graphene-based electrochemical device with thermoresponsive microneedles for diabetes monitoring and therapy. Nat. Nanotechnol. 2016, 11, 566–572. [Google Scholar] [CrossRef]

- Long, X.J.; Li, B.; Wang, L.; Huang, J.Y.; Zhu, J.; Luo, S.N. Shock response of Cu/graphene nanolayered composites. Carbon 2016, 103, 457–463. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, F.; Dai, J.; Huang, Z. Effect of Functionalization of Graphene Nanoplatelets on the Mechanical and Thermal Properties of Silicone Rubber Composites. Materials 2016, 9, 92. [Google Scholar] [CrossRef] [PubMed]

- Araujo, K.; Cury, L.A.; Matos, M.; Fernandes, T.; Cancado, L.G.; Neves, B. Electro-optical interfacial effects on a graphene/pi-conjugated organic semiconductor hybrid system. Beilstein J. Nanotechnol. 2018, 9, 963–974. [Google Scholar] [CrossRef] [PubMed]

- An, Y.; Fei, H.; Zeng, G.; Ci, L.; Xi, B.; Xiong, S.; Feng, J. Commercial expanded graphite as a low–cost, long-cycling life anode for potassium–ion batteries with conventional carbonate electrolyte. J. Power Sources 2018, 378, 66–72. [Google Scholar] [CrossRef]

- Shu, K.; Chao, Y.; Chou, S.; Wang, C.; Zheng, T.; Gambhir, S.; Wallace, G.G. A “Tandem” Strategy to Fabricate Flexible Graphene/Polypyrrole Nanofiber Film Using the Surfactant-Exfoliated Graphene for Supercapacitors. ACS Appl. Mater. Inter. 2018, 10, 22031–22041. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yu, J.; Wageh, S.; Al-Ghamdi, A.A.; Xie, J. Graphene in Photocatalysis: A Review. Small 2016, 12, 6640–6696. [Google Scholar] [CrossRef] [PubMed]

- Daud, M.; Kamal, M.S.; Shehzad, F.; Al-Harthi, M.A. Graphene/layered double hydroxides nanocomposites: A review of recent progress in synthesis and applications. Carbon 2016, 104, 241–252. [Google Scholar] [CrossRef]

- Raju, A.P.A.; Lewis, A.; Derby, B.; Young, R.J.; Kinloch, I.A.; Zan, R.; Novoselov, K.S. Wide-Area Strain Sensors based upon Graphene-Polymer Composite Coatings Probed by Raman Spectroscopy. Adv. Funct. Mater. 2014, 24, 2865–2874. [Google Scholar] [CrossRef]

- Ruiyi, L.; Sili, Q.; Zhangyi, L.; Ling, L.; Zaijun, L. Histidine-functionalized graphene quantum dot-graphene micro-aerogel based voltammetric sensing of dopamine. Sens. Actuators B Chem. 2017, 250, 372–382. [Google Scholar] [CrossRef]

- Meng, F.; Wang, H.; Huang, F.; Guo, Y.; Wang, Z.; Hui, D.; Zhou, Z. Graphene-based microwave absorbing composites: A review and prospective. Compos. Part B Eng. 2018, 137, 260–277. [Google Scholar] [CrossRef]

- Liang, A.; Jiang, X.; Hong, X.; Jiang, Y.; Shao, Z.; Zhu, D. Recent Developments Concerning the Dispersion Methods and Mechanisms of Graphene. Coatings 2018, 8, 33. [Google Scholar] [CrossRef]

- Chen, K.; Xue, D. Preparation of Colloidal Graphene in Quantity by Electrochemical Exfoliation. J. Colloid Interf. Sci. 2014, 436, 41–46. [Google Scholar] [CrossRef]

- Cai, Z.; Liu, B.; Zou, X.; Cheng, H. Chemical Vapor Deposition Growth and Applications of Two-Dimensional Materials and Their Heterostructures. Chem. Rev. 2018, 118, 6091–6133. [Google Scholar] [CrossRef] [PubMed]

- Hadi, A.; Zahirifar, J.; Karimi-Sabet, J.; Dastbaz, A. Graphene nanosheets preparation using magnetic nanoparticle assisted liquid phase exfoliation of graphite: The coupled effect of ultrasound and wedging nanoparticles. Ultrason. Sonochem. 2018, 44, 204–214. [Google Scholar] [CrossRef]

- Dong, L.; Chen, Z.; Zhao, X.; Ma, J.; Lin, S.; Li, M.; Bao, Y.; Chu, L.; Leng, K.; Lu, H.; et al. A non-dispersion strategy for large-scale production of ultra-high concentration graphene slurries in water. Nat. Commun. 2018, 9, 76. [Google Scholar] [CrossRef]

- Jin, H.; Guo, C.; Liu, X.; Liu, J.; Vasileff, A.; Jiao, Y.; Zheng, Y.; Qiao, S. Emerging Two-Dimensional Nanomaterials for Electrocatalysis. Chem. Rev. 2018, 118, 6337–6408. [Google Scholar] [CrossRef]

- Lee, T. Quantitative correlation between interlayer distance and shear rate in liquid-based exfoliation of graphene layers. Carbon 2018, 129, 661–666. [Google Scholar] [CrossRef]

- Wang, X.; Liu, X.; Yuan, H.; Liu, H.; Liu, C.; Li, T.; Yan, C.; Yan, X.; Shen, C.; Guo, Z. Non-covalently functionalized graphene strengthened poly (vinyl alcohol). Mater. Des. 2018, 139, 372–379. [Google Scholar] [CrossRef]

- Maleski, K.; Mochalin, V.N.; Gogotsi, Y. Dispersions of Two-Dimensional Titanium Carbide MXene in Organic Solvents. Chem. Mater. 2017, 29, 1632–1640. [Google Scholar] [CrossRef]

- Mukhopadhyay, T.K.; Datta, A. Deciphering the Role of Solvents in the Liquid Phase Exfoliation of Hexagonal Boron Nitride: A Molecular Dynamics Simulation Study. J. Phys. Chem. C 2016, 121, 811–822. [Google Scholar] [CrossRef]

- Xu, X.; Li, P.; Zhang, L.; Liu, X.; Zhang, H.; Shi, Q.; He, B.; Zhang, W.; Qu, Z.; Liu, P. Covalent Functionalization of Graphene by Nucleophilic Addition Reaction: Synthesis and Optical-Limiting Properties. Chem. - An Asian J. 2017, 12, 2583–2590. [Google Scholar] [CrossRef]

- Vera-López, S.; Martínez, P.; San Andrés, M.P.; Díez-Pascual, A.M.; Valiente, M. Study of graphene dispersions in sodium dodecylsulfate by steady-state fluorescence of pyrene. J. Colloid Interf. Sci. 2018, 514, 415–424. [Google Scholar] [CrossRef]

- Liu, C.; Qiu, S.; Du, P.; Zhao, H.; Wang, L. An ionic liquid-graphene oxide hybrid nanomaterial: Synthesis and anticorrosive applications. Nanoscale 2018, 10, 8115–8124. [Google Scholar] [CrossRef]

- Managa, M.; Achadu, O.J.; Nyokong, T. Photophysical studies of graphene quantum dots-Pyrene-derivatized porphyrins conjugates when encapsulated within Pluronic F127 micelles. Dyes Pigments 2018, 148, 405–416. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, L.; Lu, Q.; Kaplan, D.L. Mass Production of Biocompatible Graphene Using Silk Nanofibers. ACS Appl. Mater. Inter. 2018, 10, 22924–22931. [Google Scholar] [CrossRef]

- Wang, S.; Wang, C.; Ji, X.; Lin, M. Surfactant- and sonication- free exfoliation approach to aqueous graphene dispersion. Mater. Lett. 2018, 217, 67–70. [Google Scholar] [CrossRef]

- Hongli, Z.; Wenhao, C.; Li, W.; Jianyuan, Y.; Likun, W. Study on dispersion stability of graphene in surfactants aqueous solutions. J. YanShan Univ. 2018, 42, 377–385. [Google Scholar]

- Poorsargol, M.; Alimohammadian, M.; Sohrabi, B.; Dehestani, M. Dispersion of graphene using surfactant mixtures: Experimental and molecular dynamics simulation studies. Appl. Surf. Sci. 2019, 464, 440–450. [Google Scholar] [CrossRef]

- Sham, A.Y.W.; Notley, S.M. Foam stabilisation using surfactant exfoliated graphene. J. Colloid Interf. Sci. 2016, 469, 196–204. [Google Scholar] [CrossRef]

- Monajjemi, M. Liquid-phase exfoliation (LPE) of graphite towards graphene: An ab initio study. J. Mol. Liq. 2017, 230, 461–472. [Google Scholar] [CrossRef]

- Mateos, R.; García-Zafra, A.; Vera-López, S.; San Andrés, M.; Díez-Pascual, A. Effect of Graphene Flakes Modified by Dispersion in Surfactant Solutions on the Fluorescence Behaviour of Pyridoxine. Materials 2018, 11, 888. [Google Scholar] [CrossRef] [PubMed]

- Nawaz, K.; Ayub, M.; Khan, M.B.; Hussain, A.; Malik, A.Q.; Niazi, M.B.K.; Hussain, M.; Khan, A.U.; Ul-Haq, N. Effect of Concentration of Surfactant on the Exfoliation of Graphite to Graphene in Aqueous Media. Nanomater. Nanotechno. 2016, 6, 14. [Google Scholar] [CrossRef]

- Israelachvili, J.N. Intermolecular and surface forces. Q. Rev. Biol. 2011, 2, 59–65. [Google Scholar]

- Phiri, J.; Gane, P.; Maloney, T.C. High-concentration shear-exfoliated colloidal dispersion of surfactant–polymer-stabilized few-layer graphene sheets. J. Mater. Sci. 2017, 52, 8321–8337. [Google Scholar] [CrossRef]

- Wu, J.B.; Lin, M.; Cong, X.; Liu, H.; Tan, P. Raman spectroscopy of graphene-based materials and its applications in related devices. Chem. Soc. Rev. 2018, 47, 1822–1873. [Google Scholar] [CrossRef]

- Das, A.; Chakraborty, B.; Sood, A.K. Raman spectroscopy of graphene on different substrates and influence of defects. Bull. Mater. Sci. 2008, 31, 579–584. [Google Scholar] [CrossRef]

- Wen, Y.; He, K.; Zhu, Y.; Han, F.; Xu, Y.; Matsuda, I.; Ishii, Y.; Cumings, J.; Wang, C. Expanded graphite as superior anode for sodium-ion batteries. Nat. Commun. 2014, 5, 4033. [Google Scholar] [CrossRef]

| Dispersant | Molecular Formula | Structural Formula | Category |

|---|---|---|---|

| Sodium hydroxide | NaOH | Strong base | |

| 1-Butylpyridinium bis((trifluoromethyl)sulfonyl)imide | C11H14F6N2O4S2 |  | Ionic liquid |

| 1-Butylpyridinium tetrafluoroborate | C9H14BF4N |  | |

| Melamine | C3H6N6 |  | Non-ionic surfactant |

| Triton X-100 | C34H62O11 |  | |

| PVP | (C6H9NO)n |  | |

| Sodium pyrophosphate | Na4P2O7 |  | Dispersant |

| Sodium citrate (anhydrous) | C6H5Na3O7 |  | |

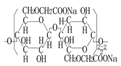

| Sodium taurodeoxycholate hydrate | C26H44NNaO6S |  | Anionic surfactant |

| Sodium lauryl sulfonate (SLS) | C12H25SO3Na |  | |

| SDS | C12H25SO4Na |  | |

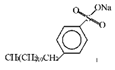

| SDBS | C18H29NaO3S |  | |

| Carboxymethylcellulose sodium (CMC) | C8H16NaO8 |  | |

| CTAB | C19H42NBr |  | Cationic surfactant |

| Octadearyl dimethyl ammonium chloride (STAC) | C21H46NCl |  |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Zhou, M.; Jin, L.; Mo, Y.; Xu, E.; Chen, H.; Liu, L.; Wang, M.; Chen, X.; Zhu, H. Green Preparation of Aqueous Graphene Dispersion and Study on Its Dispersion Stability. Materials 2020, 13, 4069. https://doi.org/10.3390/ma13184069

Li L, Zhou M, Jin L, Mo Y, Xu E, Chen H, Liu L, Wang M, Chen X, Zhu H. Green Preparation of Aqueous Graphene Dispersion and Study on Its Dispersion Stability. Materials. 2020; 13(18):4069. https://doi.org/10.3390/ma13184069

Chicago/Turabian StyleLi, Liangchuan, Ming Zhou, Long Jin, Youtang Mo, Enyong Xu, Huajin Chen, Lincong Liu, Mingyue Wang, Xin Chen, and Hongwei Zhu. 2020. "Green Preparation of Aqueous Graphene Dispersion and Study on Its Dispersion Stability" Materials 13, no. 18: 4069. https://doi.org/10.3390/ma13184069

APA StyleLi, L., Zhou, M., Jin, L., Mo, Y., Xu, E., Chen, H., Liu, L., Wang, M., Chen, X., & Zhu, H. (2020). Green Preparation of Aqueous Graphene Dispersion and Study on Its Dispersion Stability. Materials, 13(18), 4069. https://doi.org/10.3390/ma13184069