Mechanical Properties of ZTO, ITO, and a-Si:H Multilayer Films for Flexible Thin Film Solar Cells

Abstract

:1. Introduction

2. Experimental Section

2.1. Samples

2.2. Tensile Testing

3. Results and Discussion

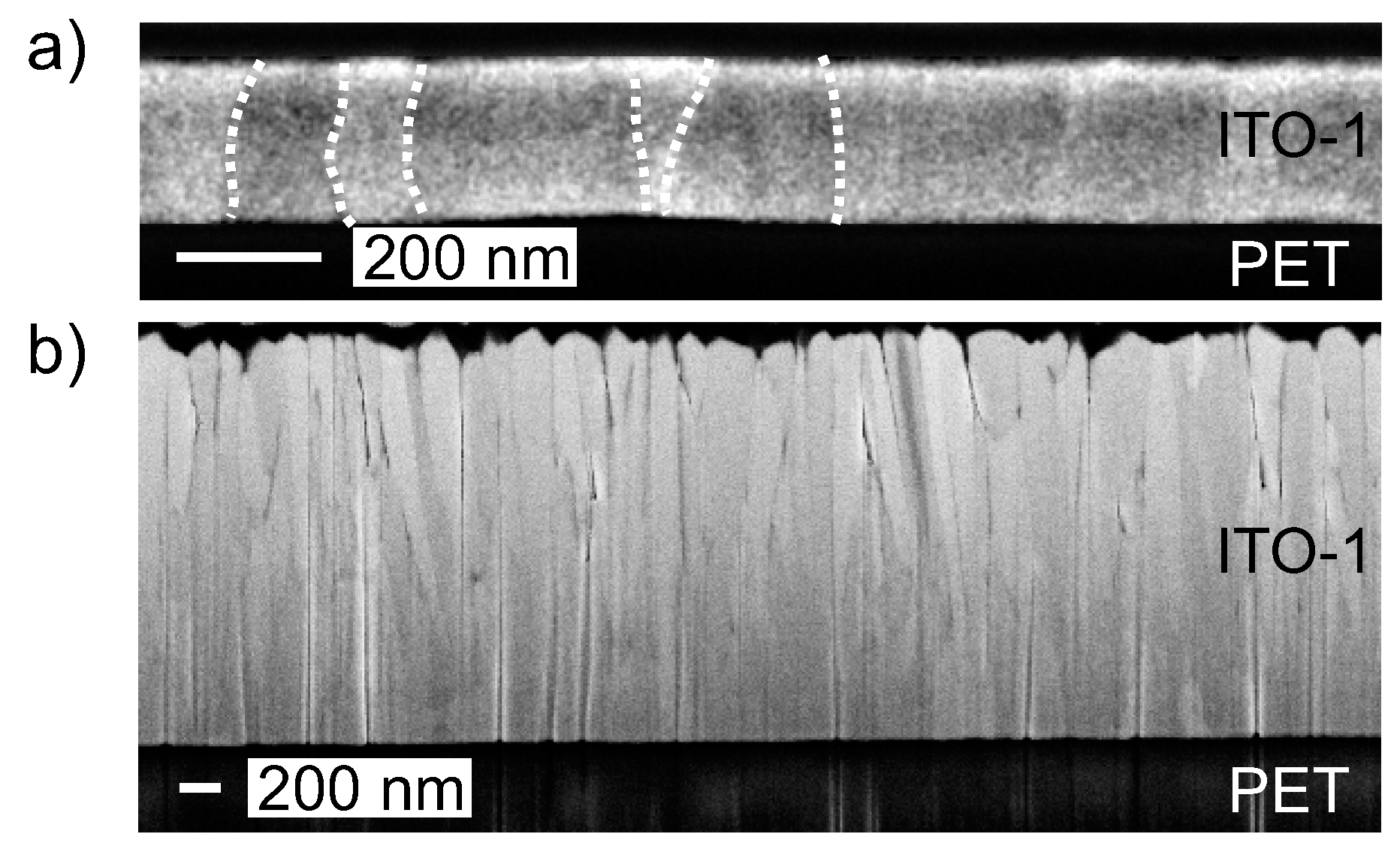

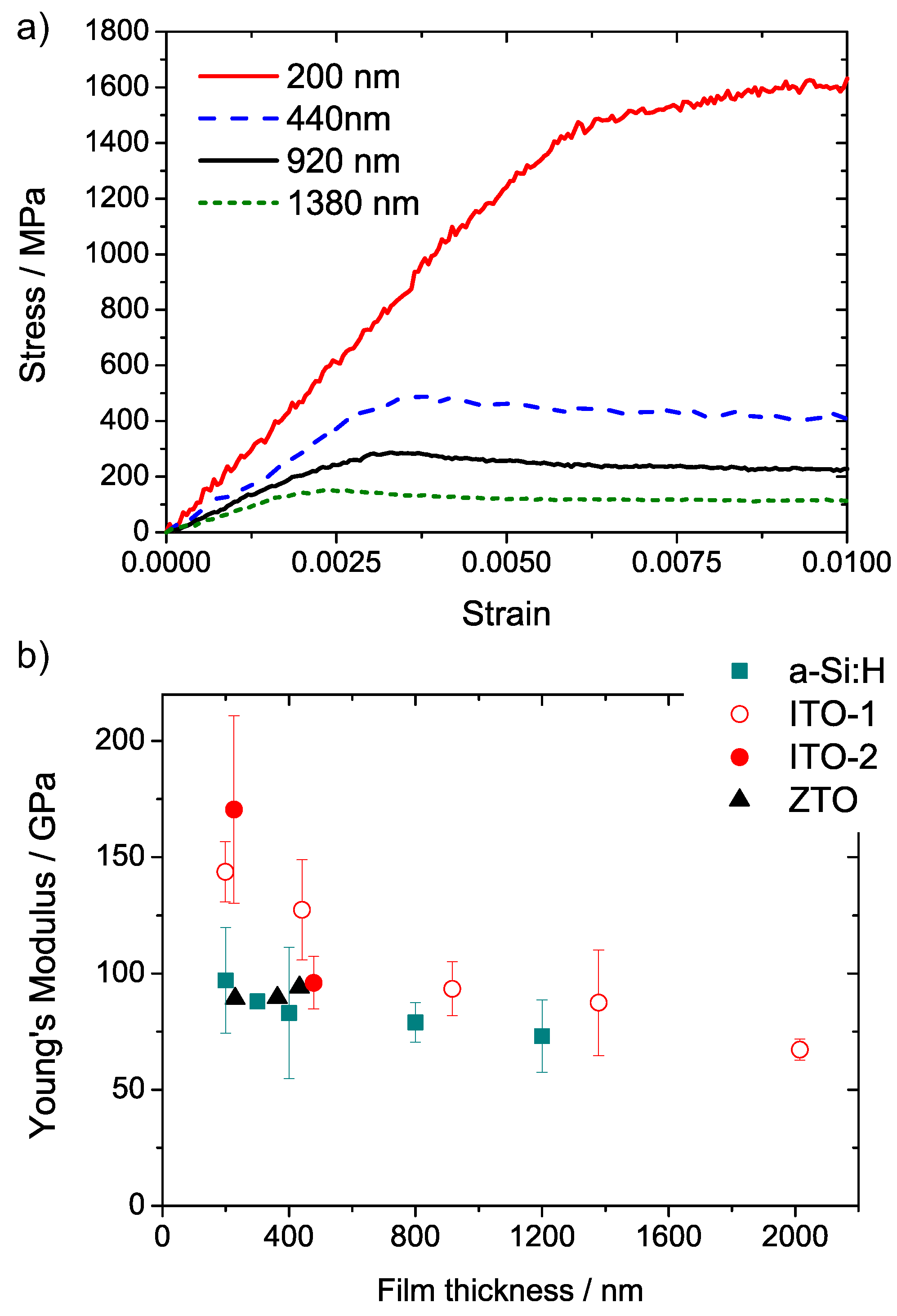

3.1. Film Characterization

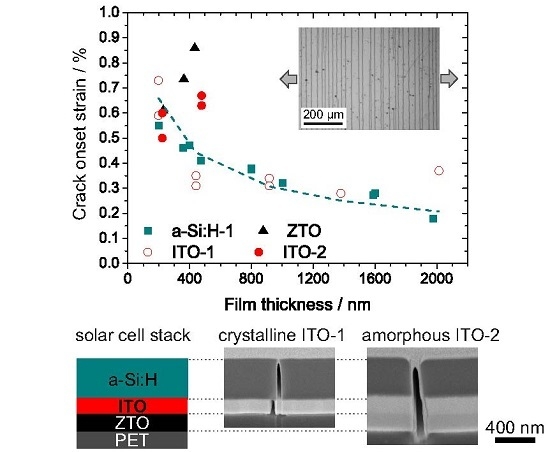

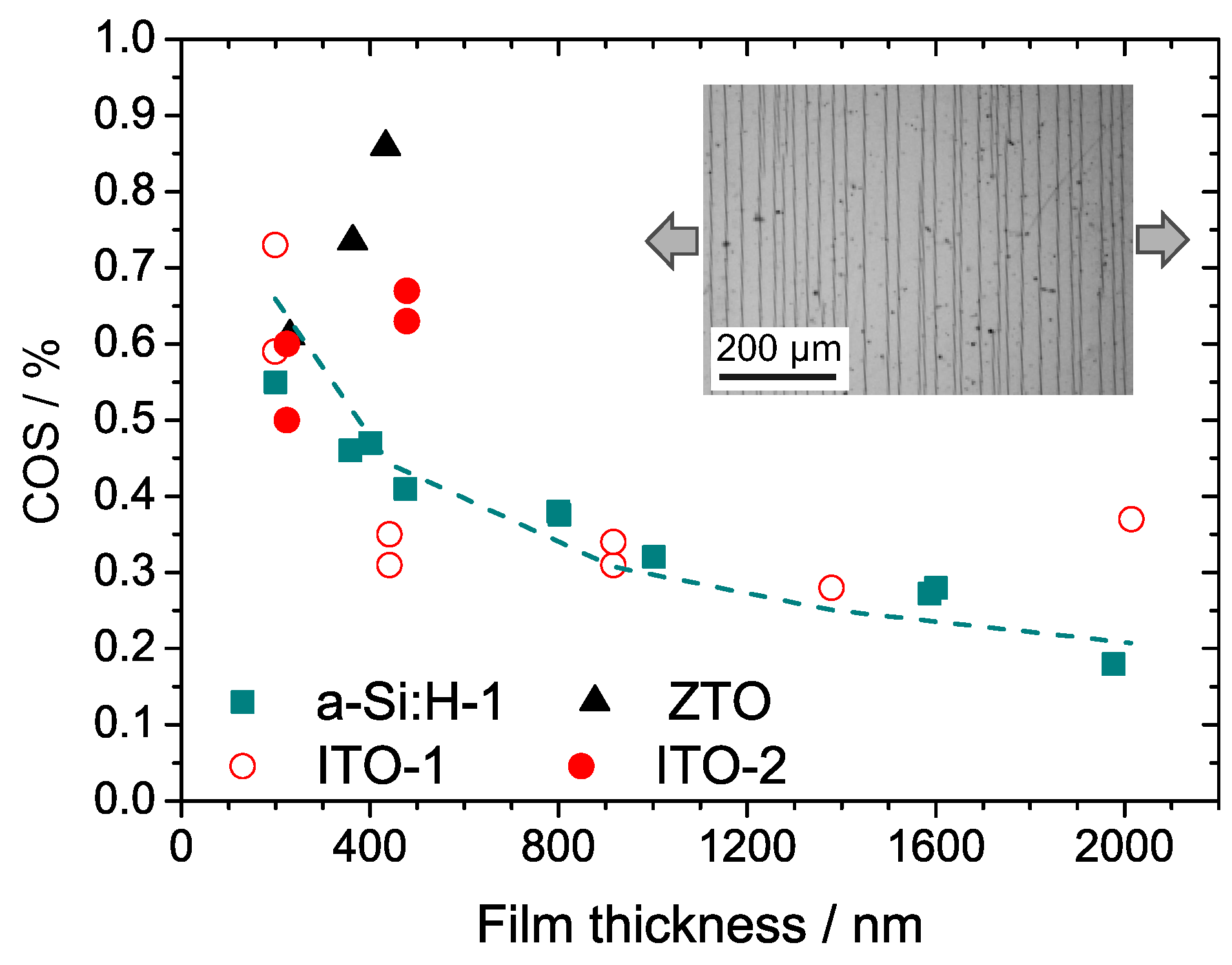

3.2. Failure of Single Films

3.3. Failure of Multilayer Films

4. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Van den Donker, M.N.; Gordijn, A.; Stiebig, H.; Finger, F.; Rech, B.; Stannowski, B.; Bartl, R.; Hamers, E.A.G.; Schlatmann, R.; Jongerden, G.J. Flexible amorphous and microcrystalline silicon tandem solar modules in the temporary superstrate concept. Sol. Energy Mater. Sol. Cells 2007, 91, 572–580. [Google Scholar] [CrossRef]

- Söderström, T.; Haug, F.J.; Terrazzoni-Daudrix, V.; Ballif, C. Optimization of amorphous silicon thin film solar cells for flexible photovoltaics. J. Appl. Phys. 2008, 103, 114509. [Google Scholar] [CrossRef]

- Myong, S.Y.; Jeon, L.S. N-type amorphous silicon-based bilayers for cost-effective thin-film silicon photovoltaic devices. Curr. Appl. Phys. 2014, 14, 151–155. [Google Scholar] [CrossRef]

- Ablayev, G.M.; Abramov, A.S.; Nyapshaev, I.A.; Vygranenko, Y.K.; Yang, R.; Sazonov, A.Y.; Shvarts, M.Z.; Terukov, E.I. Flexible photovoltaic modules based on amorphous hydrogenated silicon. Semiconductors 2015, 49, 679–682. [Google Scholar] [CrossRef]

- Wilken, K.; Paetzold, U.W.; Meier, M.; Prager, N.; Fahland, M.; Finger, F.; Smirnov, V. Nanoimprint texturing of transparent flexible substrates for improved light management in thin-film solar cells. Phys. Status Solidi Rapid Res. Lett. 2015, 9, 215–219. [Google Scholar] [CrossRef]

- Fahlteich, J. Transparente Hochbarriereschichten auf Flexiblen Substraten. Ph.D. Thesis, Technical University Chemnitz, Chemnitz, Germany, 2010. Available online: http://www.qucosa.de/fileadmin/data/qucosa/documents/6451/DissFahlteich_online_A1b.pdf (accessed on 10 February 2011). [Google Scholar]

- Kim, D.-H.; Lee, H.-K.; Na, J.-Y.; Kim, S.-K.; Yoo, Y.-Z.; Seong, T.-Y. ZnSnO/Ag/indium tin oxide multilayer films as a flexible and transparent electrode for photonic devices. Superlattice Microst 2015, 83, 635–641. [Google Scholar] [CrossRef]

- Harris, K.D.; Elias, A.L.; Chung, H.J. Flexible electronics under strain: A review of mechanical characterization and durability enhancement strategies. J. Mater. Sci. 2016, 51, 2771–2805. [Google Scholar] [CrossRef]

- Leterrier, Y.; Medico, L.; Demarco, F.; Manson, J.A.E.; Betz, U.; Escola, M.F.; Olsson, M.K.; Atamny, F. Mechanical integrity of transparent conductive oxide films for flexible polymer-based displays. Thin Solid Films 2004, 460, 156–166. [Google Scholar] [CrossRef]

- Chen, Z.; Cotterell, B.; Wang, W. The fracture of brittle thin films on compliant substrates in flexible displays. Eng. Fract. Mech. 2002, 69, 597–603. [Google Scholar] [CrossRef]

- Ni, J.L.; Zhu, X.F.; Pei, Z.L.; Gong, J.; Sun, C.; Zhang, G.P. Comparative investigation of fracture behaviour of aluminium-doped ZnO films on a flexible substrate. J. Phys. D Appl. Phys. 2009, 42, 175404. [Google Scholar] [CrossRef]

- Sierros, K.A.; Banerjee, D.A.; Morris, N.J.; Cairns, D.R.; Kortidis, I.; Kiriakidis, G. Mechanical properties of ZnO thin films deposited on polyester substrates used in flexible device applications. Thin Solid Films 2010, 519, 325–330. [Google Scholar] [CrossRef]

- Park, J.W.; Lee, S.H.; Yang, C.W. Investigation of the interfacial adhesion of the transparent conductive oxide films to large-area flexible polymer substrates using laser-induced thermo-mechanical stresses. J. Appl. Phys. 2013, 114, 063513. [Google Scholar] [CrossRef]

- Waller, J.H.; Lalande, L.; Leterrier, Y.; Manson, J.A.E. Modelling the effect of temperature on crack onset strain of brittle coatings on polymer substrates. Thin Solid Films 2011, 519, 4249–4255. [Google Scholar] [CrossRef]

- Macionczyk, F.; Bruckner, W.; Pitschte, W.; Reiss, G. Young’s modulus and tensile strength of CuNi(Mn) thin films on polyimide foils by tensile testing. J. Mater. Res. 1998, 13, 2852–2858. [Google Scholar] [CrossRef]

- Yu, D.Y.W.; Spaepen, F. The yield strength of thin copper films on Kapton. J. Appl. Phys. 2004, 95, 2991–2997. [Google Scholar] [CrossRef]

- Kamei, M.; Shigesato, Y.; Takaki, S. Origin of Characteristic Grain-Subgrain Structure of Tin-Doped Indium Oxide-Films. Thin Solid Films 1995, 259, 38–45. [Google Scholar] [CrossRef]

- Krivoglaz, M.A. Theory of X-ray and Thermal Neutron Scattering by Real Crystals; Springer: New York, NY, USA, 1969. [Google Scholar]

- Zeng, K.Y.; Zhu, F.R.; Hu, J.Q.; Shen, L.; Zhang, K.; Gong, H. Investigation of mechanical properties of transparent conducting oxide thin films. Thin Solid Films 2003, 443, 60–65. [Google Scholar] [CrossRef]

- Freund, L.B.; Suresh, S. Thin Film Materials—Stress, Defect Formation and Surface Evolution; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Kuschnereit, R.; Fath, H.; Kolomenskii, A.A.; Szabadi, M. Mechanical and Elastic Properties of Amorphous Hydrogenated Silicon Films Studied by Broad-Band Surface-Acoustic-Wave Spectroscopy. Appl. Phys. A-Mater. 1995, 61, 269–276. [Google Scholar] [CrossRef]

- Pantchev, B.; Danesh, P.; Antonova, K.; Schmidt, B.; Grambole, D.; Baran, J. Effect of film thickness on hydrogen content in a-Si:H. J. Mater. Sci.-Mater. Electron. 2003, 14, 751–752. [Google Scholar] [CrossRef]

- Leterrier, Y.; Andersons, J.; Pitton, Y.; Manson, J.A.E. Adhesion of Silicon Oxide Layers on Poly(ethylene terephthalate). II: Effect of coating thickness on adhesive and cohesive strengths. J. Polym. Sci. Pol. Phys. 1997, 35, 1463–1472. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hengst, C.; Menzel, S.B.; Rane, G.K.; Smirnov, V.; Wilken, K.; Leszczynska, B.; Fischer, D.; Prager, N. Mechanical Properties of ZTO, ITO, and a-Si:H Multilayer Films for Flexible Thin Film Solar Cells. Materials 2017, 10, 245. https://doi.org/10.3390/ma10030245

Hengst C, Menzel SB, Rane GK, Smirnov V, Wilken K, Leszczynska B, Fischer D, Prager N. Mechanical Properties of ZTO, ITO, and a-Si:H Multilayer Films for Flexible Thin Film Solar Cells. Materials. 2017; 10(3):245. https://doi.org/10.3390/ma10030245

Chicago/Turabian StyleHengst, Claudia, Siegfried B Menzel, Gayatri K Rane, Vladimir Smirnov, Karen Wilken, Barbara Leszczynska, Dustin Fischer, and Nicole Prager. 2017. "Mechanical Properties of ZTO, ITO, and a-Si:H Multilayer Films for Flexible Thin Film Solar Cells" Materials 10, no. 3: 245. https://doi.org/10.3390/ma10030245

APA StyleHengst, C., Menzel, S. B., Rane, G. K., Smirnov, V., Wilken, K., Leszczynska, B., Fischer, D., & Prager, N. (2017). Mechanical Properties of ZTO, ITO, and a-Si:H Multilayer Films for Flexible Thin Film Solar Cells. Materials, 10(3), 245. https://doi.org/10.3390/ma10030245