Abstract

To address the problems of complex composition, significant property variations, and difficult and costly harmless treatment of oil-contaminated sludge in oil and gas field development, its good compatibility with the formation is leveraged to formulate it with oilfield water into an oil–water profile control agent. This reduces the cost of harmless treatment and enables resource utilization of hazardous waste. The properties of oil-contaminated sludge were evaluated experimentally. Suspending agents and stabilizers were selected according to the oil–water profile control agent preparation process, the corresponding agents were prepared, and the system was experimentally tested. The experimental results show that the suspending agent carboxymethyl cellulose (CMC) and partially hydrolyzed polyacrylamide (HPAM), and the dispersant Dodecyl dimethyl betaine (BS-12) are used to prepare oil–water profile control agent based on the selected sulfonated mud oily sludge and ground system oily sludge. The optimal formulation of profile control agent is as follows: (1) 50% ground system oily sludge +50% oilfield produced water + 0.2% CMC + 1.0% BS-12; (2) 50% sulfonated mud system oily sludge +50% oilfield produced water + 0.1% HPAM + 1.0% BS-12. The preparation of a profile control agent from oily sludge is a viable low-cost resource treatment strategy for oily sludge, which is of great significance for the environmentally friendly treatment of oil and gas field development.

1. Introduction

Ground system oily sludge from oil and gas gathering, transportation and treatment system refers to the mixture of oil residue and mud and sand generated during the development, storage, transportation, refining and other processes of the oilfield, which mainly comes from the floor sludge, tank bottom sludge, and the bottom sludge of the oil separation tank and the scum of the air flotation tank in the refinery [1]. Sulfonated mud oily sludge is a mixture of sulfonated mud and formation cuttings during drilling. This sludge contains a variety of organic pollutants and heavy metal pollutants, which have strong biological toxicity and belong to the “waste mineral oil and waste containing mineral oil (HW08)” [2] in the national hazardous waste list. However, the hydrocarbon contained in oily sludge is a recoverable resource. According to preliminary statistics, the annual output of oily sludge in China is about 5 × 106 t, which has important resource recovery value. At present, there are the following three kinds of treatment methods for oily sludge [3]: reduction treatment (mechanical separation method [4], sludge thickening method [5], etc.), harmless treatment (high-temperature decomposition method [6], ultrasonic treatment [7], microwave treatment [8], chemical cleaning method, etc.), and resource treatment [9] (reinjection, lubricant manufacturing, etc.). Although the reduction treatment reduces the amount of oily sludge and realizes partial recovery of oily sludge, the sludge after reduction needs further treatment [10,11]. Although harmless treatment reduces the levels of oil and harmful substance, oil-contaminated sludge is characterized by a complex composition and significant variations in moisture content, oil content, and emulsification degree. This results in high difficulty, high energy consumption, and high comprehensive cost in achieving harmless treatment [12,13].

The treatment of oily sludge is a difficult problem in oilfield engineering, but it is an available component for the process of adjusting oil–water profile in oil and gas production [14]. In oil and gas production, the compatibility between the particle size and pore throats is of great importance for controlling the oil–water interface profile [15]. At the same time, the selected profile control agent is required to adapt to the reservoir characteristics in harsh environment, and has high temperature resistance, high salt resistance and other properties [16]. The oily sludge originates from the formation, has good compatibility with the formation, can be effectively plugged, and has the characteristics of high temperature resistance, high salt resistance and shear resistance [17,18]. Using the sludge profile control method to treat oily sludge can not only meet the requirements of oilfield production but also reduce the cost of oilfield waste treatment and oilfield exploitation, and obtain economic benefits [19,20]. During the preparation of profile control agent, oily sludge itself contains plugging particles required for the preparation of profile control agent, and its water and oil contents have met the injection requirements of profile control agent, without pretreatment [21].

The primary objective of this study was to develop an economically reasonable and technically viable resource utilization strategy for collected oil-contaminated sludge. By investigating its composition and properties and considering the preparation process requirements for oil–water interface profile control agents, the formula of oil-contaminated sludge-based profile control and plugging agents was screened and optimized. In order to ensure that oily sludge can reach the corresponding formation smoothly in the profile control process, combined with the properties of oily sludge, a suspension agent and dispersant are usually added to ensure the stability and uniformity of the oily sludge profile control agent. Among these, suspending agents serve to maintain the solid particles in the sludge suspended for longer periods, thereby enhancing the sand-suspending capacity of oil-contaminated sludge, whereas dispersing agents reduce the interfacial tension between the oil, water, and solid phases in the sludge, enabling the formation of a stable emulsion and improving the stability of the sludge.

Therefore, this study focused on the directional resource utilization of oil sludge from the Tarim Oilfield. Based on the basic physical properties of oil-bearing sludge samples, this paper selects suitable suspending agent and dispersant and then carries out a lab test and evaluation on the formed system. In the experimental section focused on optimizing the formula for the oil sludge profile-control agent, we introduce the static layering index method and further propose the Static Stable Stratification Index (SSSI) to evaluate the prepared agents and obtain the formula of profile control agent based on oily sludge. This study is of great significance for oily sludge treatment.

2. Experimental Section

2.1. Materials and Instruments

Oil sludge samples: Ground system oily sludge and sulfonated mud oily sludge produced water are taken from an oil and gas treatment unit in Xinjiang, China. To ensure the representativeness of the evaluation samples, each oil-containing sludge sample was collected using a multi-well sampling method involving five wells, with each well sampled three times.

Reagents: Partially hydrolyzed polyacrylamide (HPAM), dodecyl dimethyl betaine (BS-12), dehydrated sorbitol monooleate polyoxyethylene ether (Tween-80), dehydrated sorbitol monooleate (Span-80), analytical pure, produced by Sinopharm Chemicals Co., Ltd., Shanghai, China. Xanthan gum (XG), carboxymethyl cellulose (CMC), alkylphenol polyoxyethylene ether (OP-10), sodium dodecyl benzene sulfonate (SDBS), analytical pure, produced by Shandong Yousuo Chemical Technology Co., Ltd., Linyi, China.

Instruments: ZNA-A mud solid content tester, manufactured by Qingdao Shande Petroleum Instrument Co., Ltd., Qingdao, China; PHS-3C pH agent, manufactured by Shanghai Jinhuan Instrument Co., Ltd., Shanghai, China. NB-1 Mud Hydrometer, manufactured by Shanghai Luda Experimental Instrument Co., Ltd., Shanghai, China. NDJ-8S heavy oil rotary viscometer, manufactured by Shanghai lichen Instrument Technology Co., Ltd., Shanghai, China. ZNCL-R intelligent magnetic stirrer, manufactured by Zhengzhou yingyu Lingke Instrument Equipment Co., Ltd., Zhengzhou, China GJ-3S high-speed mixer, manufactured by Qingdao Shande Petroleum Instrument Co., Ltd.; GRL-BX roller heating furnace, manufactured by Qingdao Shande Petroleum Instrument Co., Ltd., Qingdao, China; LHG type high temperature aging tank is manufactured by Qingdao Shande Petroleum Instrument Co., Ltd., Qingdao, China.

2.2. Experimental Method

- (1)

- Determination of three-phase content of oily sludge

The ZNG-A mud solid content tester was used for testing. The oily sludge was loaded into the distillation unit and heated in the heating jacket for at least 45 min until no condensate flows out. After that, it was heated for 10 min. The liquid discharged from the condenser was collected, the volume was recorded and the water content and oil content of the oily sludge were calculated. Then the solid content of the oily sludge was calculated according to the formula.

Water content (,%):

Oil content (,%):

Solid particles content (, %):

where denotes water content, and denotes oil content.

- (2)

- Dosage of Suspending Agent Monomer

Three types of suspending agents were selected. A mixture of oily sludge and oilfield produced water at a ratio of 1:1 was weighed, and the suspending agents were added at gradient concentrations (0.1%, 0.4%, 0.7%, 1.0%). The suspension state and duration of the system were observed, and these indicators were used to determine the optimal suspending agent [22].

- (3)

- Dosage of Dispersant Monomer

Five types of dispersants were selected. A mixture of oily sludge and oilfield produced water at a ratio of 1:1 was weighed, and the dispersants were added at gradient concentrations (0.1%, 0.4%, 0.7%, 1.0%). The liquid–solid separation time and the proportion of the water layer after 24 h were observed, and these indicators were used to determine the optimal dispersant [23].

- (4)

- Formulation Experiment of Oily Sludge

A mixture of oily sludge and oilfield-produced water at a ratio of 1:1 was weighed, and a combination of suspending agent and dispersant was added and stirred evenly. The mixture was then heated to 120 °C using a GRL-BX roller (Qingdao Shande Petroleum Instrument Co., Ltd., Qingdao, China) heating furnace and an LHG high-temperature aging tank, followed by static aging for 4 h. After aging, the mixture separated into four layers: supernatant, upper layer (2.5 cm), middle layer, and lower layer (2.5 cm). The volume and density of each layer were recorded. The suspension rate and static stability stratification index [24,25] were calculated using Equations (4) and (5), respectively.

where denotes the initial volume of the suspension system (mL) and denotes the volume of the supernatant separated from the suspension system after standing for 4 h (mL).

Suspension rate ():

where denotes the volume fraction of the i-th layer in the aging tank (%) and denotes the density difference between the oil-contaminated sludge preparation solution of the i-th layer and the initial oil-contaminated sludge preparation solution (g/cm3).

- (5)

- Performance Evaluation of Oily Sludge Profile Control Agent

The technical indicators of the oily sludge profile control agent were measured in accordance with the petroleum and natural gas industry standard SY/T 7625: 2021 [26] (Technical Specifications for Oily Sludge Profile Control), and its performance was evaluated.

The specific test methods for each property are as follows:

Visual observation was employed to evaluate the appearance. Specifically, the prepared and homogenized test sample was placed in a graduated cylinder, and its appearance characteristics, such as color, uniformity, and stratification, were observed after standing.

The pH was determined using a PHS-3C type pH meter (Shanghai Jinhuan Instrument Co., Ltd., Shanghai, China). First, 10 g of the oil-contaminated sludge profile control agent was weighed using an analytical balance, and 90 mL of distilled water was added. After mixing evenly, measurements were performed.

Density measurements were performed using an NB-1 type mud hydrometer (Shanghai Luda Experimental Instrument Co., Ltd., Shanghai, China). The instrument was zeroed, leveled, cleaned, and rinsed with anhydrous ethanol. After the ethanol completely evaporated, the homogenized test sample was injected into the instrument, and the weights were adjusted until balance was achieved to determine the density.

The apparent viscosity was measured using an NDJ-8S heavy oil rotational viscometer (Shanghai lichen Instrument Technology Co., Ltd., Shanghai, China). The test sample was placed in an appropriate container, the instrument was leveled, the rotor protective frame was installed, and a suitable rotor and speed for measurement were selected.

Suspension Stability Index Measurement: After homogenizing the oil-contaminated sludge profile conditioner, 250 mL of the sample was measured using a graduated cylinder, inverted multiple times, and left to stand at room temperature for 24 h. A glass pipette was used to extract half of the suspension volume. The masses of water-insoluble substances in the extracted suspension (m1) and in the remaining suspension in the cylinder (m2) were measured separately. The suspension stability index was then calculated by substituting m1 and m2 into Equation (6), as follows:

3. Results and Discussion

3.1. Morphological and Performance Analysis of Oily Sludge

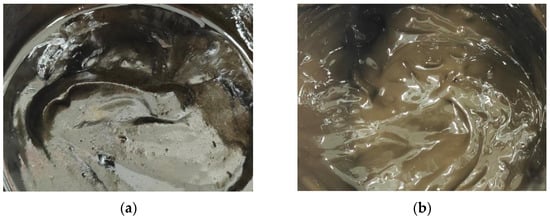

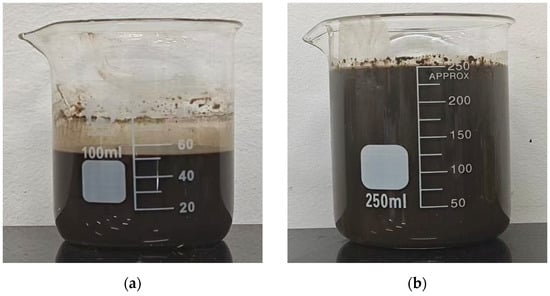

The appearance of the selected ground oily sludge and sulfonated drilling mud oily sludge samples is shown in Figure 1.

Figure 1.

Exterior of oily sludge. (a) Ground system oily sludge; (b) Sulfonated mud oily sludge.

The ground oily sludge sample appeared black and viscous, with large sand particles and a pungent odor. Its pH was 7.98, density was 1.39 g/cm3, and viscosity was 534 mPa·s.

The sulfonated drilling mud oily sludge sample appeared brown, with good fluidity, fine sand particles, and a fishy odor. Its pH was 10.72, density was 1.51 g/cm3, and viscosity was 729 mPa·s.

Based on the average of three repeated experiments, the three-phase composition of the two oily sludge samples is presented in Table 1.

Table 1.

Composition analysis of oily sludge samples.

Based on the test results, both types of oily sludge samples exhibit high water content, ensuring good pumpability and facilitating smooth injection into the formation. Compared to the ground oily sludge, the sulfonated drilling mud oily sludge has lower oil and solid content, which may contribute to its better suspension stability.

3.2. Optimization of Oily Sludge Profile Control Agent Formulation

- (1)

- Selection of Suspending Agents

In the prepared oily sludge solution, the Water content of the oily sludge samples exceeds 50%. After adding oilfield-produced water, the proportion of liquid phase further increases. Due to the density difference between the liquid and solid phases, the solid phase tends to settle, making it necessary to select appropriate suspending agents.

Suspending agents are primarily macromolecular substances that function by modifying the density of the aqueous phase to reduce the density difference between solid and liquid phases. This slows down particle sedimentation, prolongs the suspension time of oily sludge, and enhances its stability. Commonly used suspending agents include HPAM, CMC, and XG.

In the suspending agent optimization experiment, three agents (HPAM, CMC, and xanthan gum) were tested on two types of oily sludge samples under lab temperature conditions with a sludge-to-water ratio of 1:1. Table 2 and Table 3 present the effects of suspending agent dosage on sludge suspension within 24 h.

Table 2.

Effect of the addition of suspending agents on ground system oily sludge.

Table 3.

Effect of adding suspending agent on from sulfonated muds oily sludge.

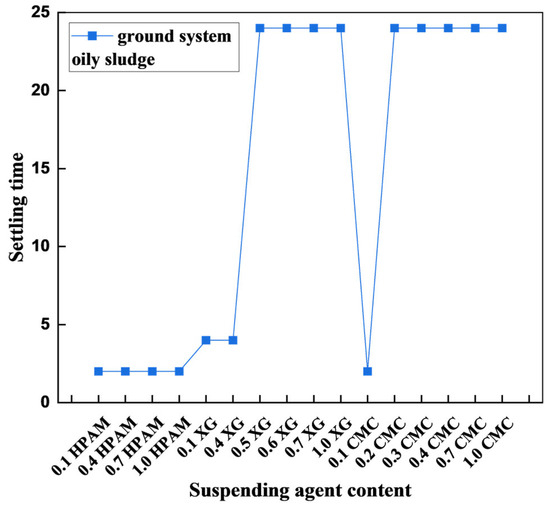

At room temperature, a suspension time of 10 h was used as the reference for suspending agent selection [13]. For ground system oily sludge, as shown in Figure 2, HPAM at 1.0% concentration still showed phase separation within 2 h, failing to meet suspension requirements. In contrast, 0.5% xanthan gum and 0.2% CMC satisfied the requirements and were therefore selected for subsequent formulation studies. Solid particles are prone to sedimentation and stratification owing to gravity, which results in system instability. HPAM is a linear polymer whose mechanism of action primarily relies on charge neutralization and bridging effects. However, these bridging effects are usually disrupted by vibrations, pulse shear, and other factors, leading to a decrease in suspension stability. Both xanthan gum and CMC possess three-dimensional network structures, which can hinder the sedimentation of solid particles. Thus, the performance of HPAM in suspending particles within surface oily sludge is inferior to that of xanthan gum and CMC.

Figure 2.

Relationship between suspension and system layering time.

Compared with surface oily sludge, sulfonated drilling mud oily sludge exhibits a higher water content and strongly alkaline environment. Its high water content and low solid content minimize the impact of solid sedimentation, enabling the three suspending agents to maintain certain structural stability. In a strongly alkaline environment, where anionic HPAM is less affected by alkalinity and xanthan gum and CMC possess excellent acid–base resistance, all three agents are applicable. Thus, 0.1% HPAM, 0.1% xanthan gum, and 0.1% CMC all met the suspension criteria and were chosen for follow-up compatibility experiments.

- (2)

- Optimization of Emulsifiers

The oily sludge contains a small amount of oil phase. The addition of dispersants to the prepared oily sludge solution can reduce the interfacial tension among the water, oil, and solid phases, enabling uniform dispersion of the oil phase in the solution to form a homogeneous and stable dispersion system. Simultaneously, this process ensures appropriate fluidity of the oily sludge, facilitating its injection into formations at certain depths.

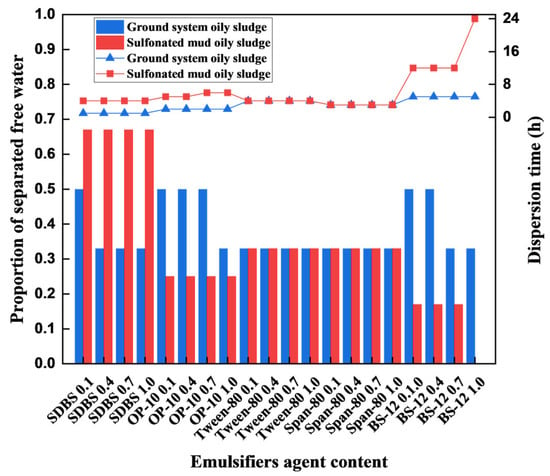

For the dispersant optimization experiment, the following five common agents were selected: SDBS, OP-10, Tween-80, Span-80, and BS-12. The effects of dispersant dosage on the dispersion of two types of oily sludge samples were evaluated under room temperature conditions with a sludge-to-water ratio of 1:1 over 24 h, as shown in Table 4 and Figure 3.

Table 4.

Effect of adding dispersant on ground system oiled sludge.

Figure 3.

Relationship between emulsifiers and the time and condition of system stratification.

Based on the experimental results at ambient temperature, for oil and gas gathering and transportation system oily sludge, SDBS, OP-10, and Span-80 exhibited short dispersion times and poor dispersion performance, whereas Tween-80 and BS-12 demonstrated prolonged dispersion times. Among these, 0.7% Tween-80 and 1.0% BS-12 showed superior emulsification and were selected for subsequent formulation experiments.

For sulfonated drilling mud oily sludge, 1.0% BS-12 achieved a dispersion time exceeding 24 h, representing the best performance, and was thus chosen for follow-up compatibility testing.

Both oily sludge types exhibit high water content and low oil content, requiring additional water during formulation preparation. Thus, the preparation of profile control agents necessitates complete dispersion of the oil phase into the aqueous phase to form O/W emulsions. The hydrophilicity of the hydrophilic groups of the emulsifier must be strong and superior to the lipophilicity of its lipophilic groups. Span-80 is a W/O emulsifier that fails to form an effective interfacial adsorption layer in aqueous systems, leading to rapid stratification and unstable emulsions during the preparation of profile control agents for both types of sludge. In contrast, SDBS, OP-10, Tween-80, and BS-12 have high HLB values and excellent hydrophilicity. SDBS, which is typically found in oily sludge water in oilfields, has high hardness, which can potentially inactivate it. OP-10 exhibits good hydrophilicity and acid–base resistance; however, its emulsion stability decreases above 40 °C owing to weakened hydrogen bonds. Tween-80, a nonionic surfactant, tolerates acids, alkalis, and electrolytes to a certain extent but hydrolyzes under strong acidic/alkaline conditions when subjected to prolonged heating. Consequently, the alkaline environment of sulfonated drilling mud renders it unsuitable, excluding it from the optimal emulsifier selection for this sludge type.

- (3)

- Optimization of Suspending Agent and Dispersant Formulations

To determine the optimal formulation for the oily sludge profile control agent, selected suspending agents and dispersants were systematically combined for both sludge samples. Four formulations were tested for ground oily sludge and three for sulfonated drilling mud oily sludge.

The formulations were heated to reservoir temperature and aged for 4 h, with results shown in Table 5 and Table 6:

Table 5.

Results of Combined Blending of Ground Oil-bearing Sludge.

Table 6.

Sulfonated slurry oiled sludge combination compounding results.

Ground system Oily Sludge: The combination of 0.2% CMC + 1.0% BS-12 exhibited the lowest liquid separation rate and smallest SSSI value (indicating superior high-temperature stability of the suspending agent). The minimal liquid separation confirmed stable emulsion formation under high temperatures, making this the preferred formulation.

Sulfonated Drilling Mud Oily Sludge: The 0.1%XG + 1.0% BS-12 combination had the smallest SSSI but high liquid separation, indicating poor emulsion stability. Both 0.1% HPAM + 1.0% BS-12 and 0.1% CMC + 1.0% BS-12 showed similar separation rates, but the former had a smaller SSSI, demonstrating better high-temperature suspension stability.

Thus, the following optimal formulation was selected: 50% sulfonated drilling mud oily sludge + 50% oilfield produced water + 0.1% HPAM + 1.0% BS-12.

Regarding determination of compound suspending agents, for surface oily sludge a further comparison of the environmental adaptability between xanthan gum and CMC revealed that both exhibited excellent neutral pH stability. However, CMC exhibited higher temperature resistance than xanthan gum, making it the optimal suspending agent for surface oily sludge.

For sulfonated drilling mud oily sludge, the pH of the post-compounding solvent decreased, creating a weakly alkaline environment. Consequently, the hydroxyl groups in HPAM became fully ionized, forming negatively charged hydroxy salts. The repulsion among the charged groups was sufficiently strong to enhance the bridging effect, thereby improving the suspension performance. Therefore, HPAM is the optimal suspending agent for sulfonated drilling mud oily sludge.

The selected emulsifier BS-12, an amphoteric surfactant, dissociates in water to form active moieties with nonionic and anionic properties, ensuring stability across neutral to strongly alkaline conditions. Its coexisting acidic and basic groups also endow it with good stability in hard/high-salinity water, making BS-12 the optimal emulsifier for both types of sludge after compounding.

3.3. Performance Evaluation of Oily Sludge Profile Control Agents

Based on the above experiments and analysis, the formulations for the profile control agents were determined as follows:

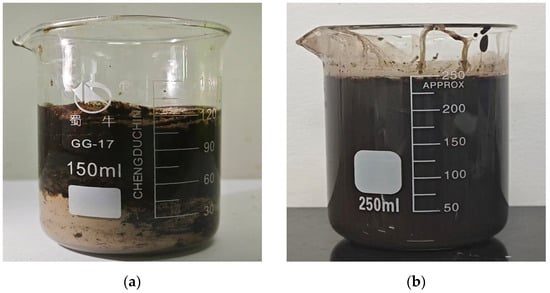

The round system oily sludge profile control agent comprised 50% ground system oily sludge + 50% oilfield produced water + 0.2% CMC + 1.0% BS-12; the sulfonated drilling mud oily sludge profile control agent comprised 50% sulfonated drilling mud oily sludge + 50% oilfield produced water + 0.1% HPAM + 1.0% BS-12. As can be seen from the comparison in Figure 4 and Figure 5.

Figure 4.

Comparison Between Ground Oily Sludge Blank Sample and Profile Control Agent. (a) Blank sample of oily sludge on the ground. (b) Ground oil sludge profile control agent (50% ground system oily sludge + 50% oilfield-produced water + 0.2% CMC + 1.0% BS-12).

Figure 5.

Comparison Between Sulfonated Mud Oily Sludge Blank Sample and Profile Control Agent. (a) Blank sample of sulfonated mud oily sludge. (b) Sulfonated mud oily sludge profile control agent. (50% sulfonated drilling mud oily sludge + 50% oilfield produced water + 0.1% HPAM + 1.0% BS-12).

The two agents were tested according to the industry standard SY/T 7625:2021 [26] (Technical Specifications for Oily Sludge Profile Control), with the results presented in Table 7.

Table 7.

Indoor evaluation of above-ground oily sludge.

For the ground oily sludge profile control agent, its appearance exhibited excellent suspension and dispersion properties. In terms of performance, although the presence of sand particles in oily sludge tends to cause sedimentation and stratification (leading to poor suspension stability), this formulation demonstrated appropriate density and suspension stability index (SSI), confirming its stable suspension characteristics. With regard to compliance, both pH and density met the standard requirements.

For the sulfonated drilling mud oily sludge profile control agent, pH exceeded the specified range of 7–8, though pH has minimal impact on the agent’s performance. Other properties, including density, apparent viscosity, and suspension stability index (SSI), all complied with the standard.

Moreover, after high-temperature treatment, both the surface oiled sludge profile control agent and the sulfonated drilling mud oiled sludge profile control agent maintained good suspension stability.

In conclusion, both formulations satisfy the requirements for use as oily sludge profile control agents.

4. Conclusions

- (1)

- Significant variations in the physicochemical properties were observed between the two types of oiled sludge. The composition of oily sludge on the ground included 51.68% water content, 23.59% oil content, 24.73% solid content, pH value of 7.98, density of 1.39 g/cm3 and viscosity of 534 MPa·s. The components of oily sludge from sulfonated mud included 83.19% water content, 4.25% oil content, 12.57% solid content, pH value of 10.72, density of 1.51 g/cm3, and viscosity of 729 MPa·s.

- (2)

- Based on the property variations between the two oily sludge samples, targeted optimization of oil reservoir profile control agent formulations was achieved through single-factor experiments and orthogonal optimization design. In this optimization process, the SSSI was introduced to evaluate the prepared agents. For the selected ground oily sludge and sulfonated drilling mud oily sludge, the optimized suspending agents for the profile control agents were identified as CMC and HPAM, respectively, while BS-12 was chosen as the dispersant for both. The optimal formulations are ground oily sludge profile control agent with the following characteristics: 50% ground oily sludge + 50% oilfield produced water + 0.2% CMC + 1.0% BS-12; Sulfonated drilling mud oily sludge profile control agent is 50% sulfonated drilling mud oily sludge + 50% oilfield produced water + 0.1% HPAM + 1.0% BS-12.

- (3)

- The complex composition of oily sludge leads to significant variations in properties among different samples, posing considerable challenges for treatment. In this study, by repurposing oily sludge for profile control agent preparation, both resulting products met all standard performance requirements. This approach not only reduces processing workload and costs but also successfully achieves the effective resource utilization of hazardous waste. It plays a significant role in facilitating environmental protection and oilfield development.

- (4)

- This study involved only two types of oily sludge, and further verification is needed to confirm the universality of the proposed formulation. In future studies, the scope of sludge samples should be expanded to optimize formulation adaptability. Additionally, indoor core flooding experiments are recommended to investigate the long-term stability and plugging effect of profile control agents under actual reservoir conditions, providing data support for the large-scale application of this technology.

Author Contributions

Conceptualization, J.Z. and Y.D.; Methodology, J.Z., J.L. and W.W.; Validation, Y.L., H.Y., Y.D. and Z.P.; Formal Analysis, J.L. and W.W.; Investigation, W.W., Y.D. and Z.P.; Resources, Y.L. and H.Y.; Writing—Original Draft Preparation, W.W.; Writing—Review and Editing, J.L.; Visualization, W.W.; Supervision, Y.D. and Z.P.; Project Administration, J.Z. and Y.D.; Funding Acquisition, J.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Science and Technology Research Program [No. 202505]; and the CNPC Major Science and Technology Special Project [2023ZZ17-05].

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

I would like to express my sincere thanks to the State Key Laboratory of Heavy Oil Processing in Karamay, who aided me in the course of writing this paper.

Conflicts of Interest

Authors Jianzhong Zhu and Zhequn Pang were employed by the company Production Technology Research Institute, PetroChina Xinjiang Oilfield Company. Author Yating Ding was employed by the company No. 1 Oil Production Plant of Xinjiang Oilfield Company of China Petroleum. Authors Youwei Li and Hualong Yang were employed by the company Xinjiang Tarim Oilfield Construction Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CMC | Carboxymethyl cellulose |

| HPAM | Partially hydrolyzed polyacrylamide |

| XG | Xanthan gum |

| Tween-80 | Dehydrated sorbitol monooleate polyoxyethylene ether |

| Span-80 | Dehydrated sorbitol monooleate |

| OP-10 | Alkylphenol polyoxyethylene ether |

| SDBS | Sodium dodecyl benzene sulfonate |

| BS-12 | Dodecyl dimethyl betaine |

| SSSI | Static Stable Stratification Index |

| SSI | Suspension Stability Index |

References

- Zhou, L.; Wu, Y.; Liu, L.; Xu, G. Producing way and treatment method of oily sludge in oil field. Mod. Chem. Res. 2021, 100–101. [Google Scholar]

- Sun, X.; Geng, X.; Guo, H.; Wang, C.; Dong, Y. Study on Main Harm and Treatment Process of Oily Sludge. GuangZhou Chem. Ind. 2018, 46, 99–101. [Google Scholar]

- Kang, D.; Lin, H.; Niu, D.; Tian, G.; Xu, R.; Zhang, Z.; Luo, Y.; Zhang, Z. Research progress of processing technology and characteristics of oily sludge. China Environ. Sci. 2023, 43, 4106–4120. [Google Scholar]

- Zheng, S. Application of Sludge Concentration and Dewatering Technology in Oilfield Produced Water Treatment. Energy Conserv. Environ. Prot. 2019, 110–111. [Google Scholar]

- Yan, X.Y.; Qiao, W.Q.; Li, P.L.; Ye, J.Y.; Zhou, Q.Z. Reduction of Oily Sludge by Hydrothermal Method. Environ. Prot. Chem. Ind. 2014, 34, 340–343. [Google Scholar]

- Wang, B.; Hai, L. Research on Incineration Residue of Oil Sludge as Pavement Base Material. Bull. Chin. Ceram. Soc. 2020, 39, 3386–3390. [Google Scholar]

- Sivagami, K.S.; Anand, D.A.; Divyapriya, G.D.; Nambi, I.N. Treatment of petroleum oil spill sludge using the combined ultrasound and Fenton oxidation process. Ultrason. Sonochemistry 2019, 51, 340–349. [Google Scholar] [CrossRef]

- Li, B. Study on the Conversion Process and Technology of Oily Sludge by Microwave Heat Treatment; Beijing University of Chemical Technology: Beijing, China, 2014; 82p. [Google Scholar]

- Cai, C. Analysis on Treatment Technology and Resource Utilization of Oily Sludge in Oilfield. China Resour. Compr. Util. 2022, 73–75. [Google Scholar]

- Li, Z. Research progress on the treatment methods of oily sludge. Chem. Eng. 2023, 37, 83–87. [Google Scholar]

- Long, X.L.; Zhang, G.Z.; Han, L.H.; Meng, Q.M. Dewatering of floated oily sludge by treatment with rhamnolipid. Water Res. 2013, 47, 4303–4311. [Google Scholar] [CrossRef]

- Hochberg, S.H.; Tansel, B.T.; Laha, S.L. Materials and energy recovery from oily sludges removed from crude oil storage tanks (tank bottoms): A review of technologies. J. Environ. Manag. 2022, 305, 114428. [Google Scholar] [CrossRef]

- Teng, Q.T.; Zhang, D.Z.; Yang, C.Y. A review of the application of different treatment processes for oily sludge. Environ. Sci. Pollut. Res. 2021, 28, 121–132. [Google Scholar] [CrossRef]

- Abena, M.A.; Li, T.L.; Shah, M.S.; Zhong, W.Z. Biodegradation of total petroleum hydrocarbons (TPH) in highly contaminated soils by natural attenuation and bioaugmentation. Chemosphere 2019, 234, 864–874. [Google Scholar] [CrossRef]

- Ma, Q.; Jia, Y.; Ma, F.; Xu, L. Preparation and Effect of Oily Sludge Profile Control and Plugging Agent. Petrochem. Ind. Technol. 2023, 30, 10–12. [Google Scholar]

- Jin, X.; Tang, Y.; Liu, L. Study on the Matching Relationship Between Profile Control Particle Size and Permeability of Oil Production Sludge Injection Well. Environ. Prot. Oil Gas Fields 2020, 30, 22–24. [Google Scholar]

- Wang, J.Y.; Jiang, H.G.; Guo, L.Z.; Zhu, Y.; Xuan, Z.L. Development and Performance Evaluation of Oily Sludge Oil Displacement System with Micro-nano Particle. Oilfield Chem. 2023, 40, 684–689. [Google Scholar]

- Cong, S.; Guo, L.; Wang, H.; Liu, W.; Zhang, M. Application of Profile Control Technology for Oily Sludge in Qinghai Oilfield. Energy Conserv. Pet. Petrochem. Ind. 2022, 12, 8. [Google Scholar]

- Niu, L.; He, Z.L. Summary of Application Research of Chemical Water Plugging and Profile Control Agent in Oilfield. Shandong Chem. Ind. 2022, 51, 56–57. [Google Scholar]

- Dai, C.L.; Xu, Z.Z.; Liu, J.W.; Sun, W.; Chen, J.; Zhao, G.; Li, L. Preparation of Oily Sludge Profile Control System and Evaluation of Profile Control Performance. Oilfield Chem. 2021, 38, 58–63. [Google Scholar]

- Hu, K.; Bi, H.; Song, F. The research on profile control technigue of oil-bearing sludge and its applicationg. Drill. Prod. Technol. 2020, 30, 40–43. [Google Scholar]

- Zheng, C.; Zhang, L.; Xu, J.; Zen, M.; Fu, G.; Fu, Y. Construction and performance evaluation of nano microemulsion oil displacement system. Xinjiang Oil Gas 2023, 19, 89–94. [Google Scholar]

- Liang, T.; Yang, C.; Zhang, Y.; Li, P.; Qu, M.; Hou, J. Research and Application Progress of Nanofluid for Enhanced Oil Recovery. Xinjiang Oil Gas 2023, 19, 28–41. [Google Scholar]

- Deng, Z.; Ou, M.; Bai, H.; Jing, Y.; Huang, P.; Shao, P. Development of viscosity reducer for high density water-based drilling fluid and its application. Xinjiang Oil Gas 2023, 19, 33–37. [Google Scholar]

- Li, J.X.; Jiang, S.B.; Yan, Z.H.; Hui, H.J.; Chen, L.; Cui, C.H. Study on the Methods of Evaluating Static Sedimentation Stability of Drill-in Fluids. Drill. Fluid Complet. Fluid 2019, 36, 575–580. [Google Scholar]

- SY/T 7625-2021; Technical Specifications for Oily Sludge Profile Control. Petroleum Industry Press: Beijing, China, 2021.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.