Research Progress and Technical Challenges of Geothermal Energy Development from Hot Dry Rock: A Review

Abstract

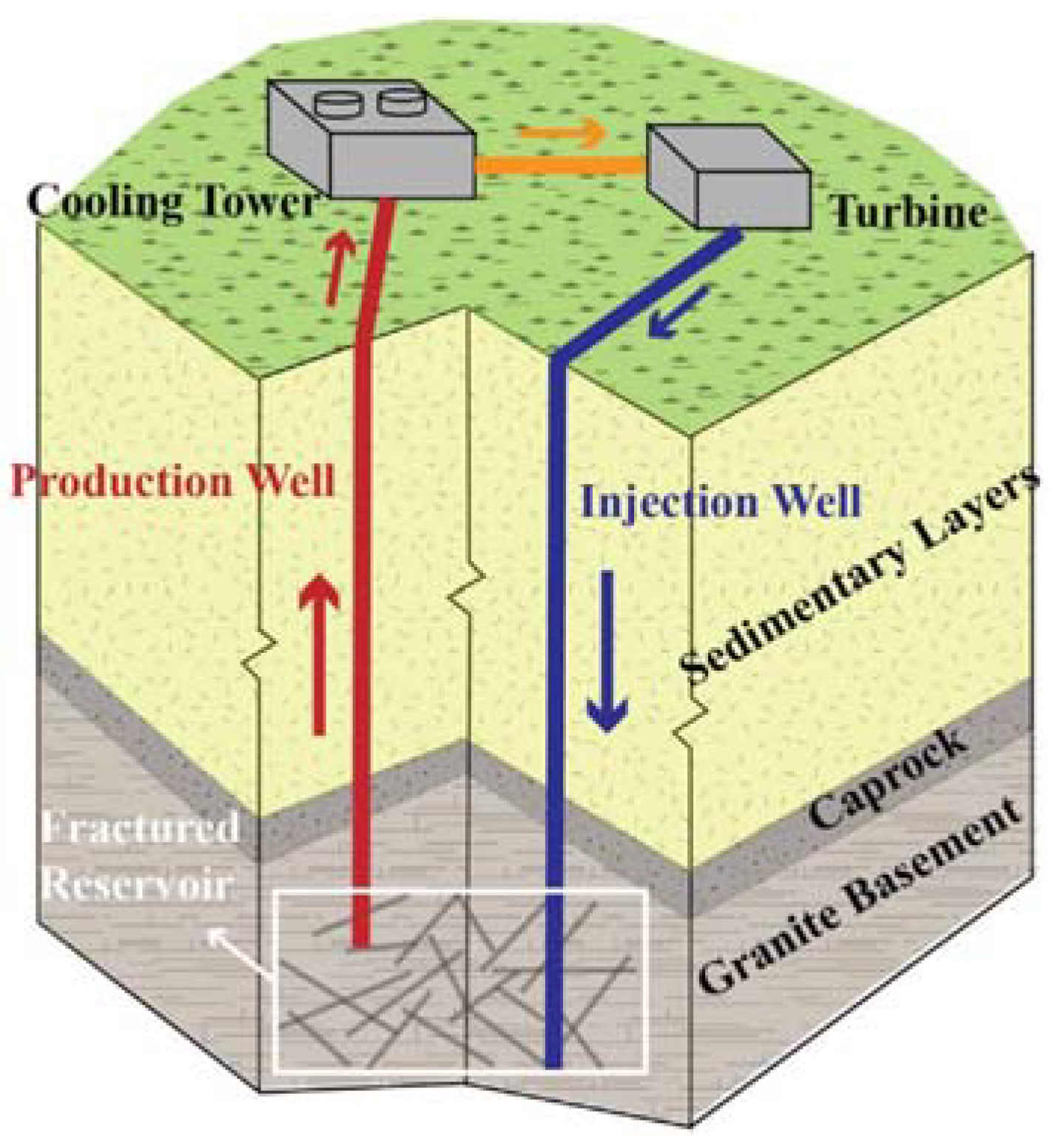

1. Introduction

2. Development Progress and Trend of HDR in the World

2.1. The Progress and Trend in USA

2.2. The Progress and Trend in China

2.3. The Progress and Trend in Europe

2.4. The Progress and Trend in Korea

2.5. The Progress and Trend in Japan

3. Technical Challenges and Evaluation of HDR

3.1. The Base Technology of HDR Geothermal Development

- (1)

- Evaluation and site selection

- (2)

- Efficient and low-cost drilling

- (3)

- Efficient geothermal utilization

3.2. The Key Technology of HDR Geothermal Development

- (1)

- High-resolution exploration and characterization of HDR

- (2)

- Efficient and complex fracture network reservoir creation

- (3)

- Effective microseismic control

- (4)

- Fracture network connectivity and reservoir characterization

3.3. The Game-Changing Technology of HDR Geothermal Development

- (1)

- Downhole liquid explosion fracture creation

- (2)

- Downhole in situ efficient heat transfer and power generation

- (3)

- CO2 and other working fluid for high-efficient power generation

3.4. Technical Level Assessment of HDR Development in China and the United States

4. Research Suggestions for HDR

4.1. Combined Heating and Power Generation

4.2. Industry–University–Research Cooperation

4.3. Increasing Government Investment in R&D and Demonstration

5. Conclusions

Funding

Acknowledgments

Conflicts of Interest

References

- Lu, S.M. A global review of enhanced geothermal system (EGS). Renew. Sustain. Energy Rev. 2018, 81, 2902–2921. [Google Scholar] [CrossRef]

- Nath, F.; Mahmood, M.N.; Ofosu, E.; Khanal, A. Enhanced geothermal systems: A critical review of recent advancements and future potential for clean energy production. Geoenergy Sci. Eng. 2024, 243, 213370. [Google Scholar] [CrossRef]

- Olasolo, P.; Juárez, M.C.; Morales, M.P.; D’Amico, S.; Liarte, I.A. Enhanced geothermal systems (EGS): A review. Renew. Sustain. Energy Rev. 2016, 56, 133–144. [Google Scholar] [CrossRef]

- Tester, J.W.; Anderson, B.J.; Batchelor, A.S.; Blackwell, D.D.; DiPippo, R.; Drake, E.M.; Garnish, J.; Livesay, B.; Moore, M.C.; Nichols, K.; et al. The Future of Geothermal Energy: Impact of Enhanced Geothermal Systems [EGS] on the United States in the 21st Century; Massachusetts Institute of Technology: Cambridge, MA, USA, 2006. [Google Scholar]

- Gong, L.; Han, D.; Chen, Z.; Wang, D.; Jiao, K.; Zhang, X.; Yu, B. Research status and development trend of key technologies for enhanced geothermal systems. Nat. Gas Ind. B 2023, 10, 140–164. [Google Scholar] [CrossRef]

- Qiao, M.; Jing, Z.; Feng, C.; Li, M.; Chen, C.; Zou, X.; Zhou, Y. Review on heat extraction systems of hot dry rock: Classifications, benefits, limitations, research status and future prospects. Renew. Sustain. Energy Rev. 2024, 196, 114364. [Google Scholar] [CrossRef]

- Yuan, Y.L.; Xu, T.F.; Moore, J.; Lei, H.W.; Feng, B. Coupled Thermo-Hydro-Mechanical Modeling of Hydro-Shearing Stimulation in an Enhanced Geothermal System in the Raft River Geothermal Field, USA. Rock Mech. Rock Eng. 2020, 53, 5371–5388. [Google Scholar] [CrossRef]

- Li, S.; Wang, S.; Tang, H. Stimulation mechanism and design of enhanced geothermal systems: A comprehensive review. Renew. Sustain. Energy Rev. 2022, 155, 111914. [Google Scholar] [CrossRef]

- Olasolo, P.; Juarez, M.C.; Olasolo, J.; Morales, M.P.; Valdani, D. Economic analysis of Enhanced Geothermal Systems (EGS). A review of software packages for estimating and simulating costs. Appl. Therm. Eng. 2016, 104, 647–658. [Google Scholar] [CrossRef]

- Laughlin, A.W.; Eddy, A.C.; Laney, R.; Aldrich, M.J. Geology of the Fenton Hill, New Mexico, hot dry rock site. J. Volcanol. Geotherm. Res. 1983, 15, 21–41. [Google Scholar] [CrossRef]

- Xing, P.; Damjanac, B.; Moore, J.; McLennan, J. Flowback Test Analyses at the Utah Frontier Observatory for Research in Geothermal Energy (FORGE) Site. Rock Mech. Rock Eng. 2022, 55, 3023–3040. [Google Scholar] [CrossRef]

- Xing, P.; McLennan, J.; Moore, J. In-Situ Stress Measurements at the Utah Frontier Observatory for Research in Geothermal Energy (FORGE) Site. Energies 2020, 13, 5842. [Google Scholar] [CrossRef]

- Xing, P.; McLennan, J.; Moore, J. Minimum in-situ stress measurement using temperature signatures. Geothermics 2022, 98, 102282. [Google Scholar] [CrossRef]

- Aghajannezhad, P.; Sellier, M. Modelling the Flow in the Utah FORGE Wells Disrete Fracture Network. Fluids 2024, 9, 229. [Google Scholar] [CrossRef]

- Zeinabady, D.; Clarkson, C.R. Reservoir and Fracture Characterization for Enhanced Geothermal Systems: A Case Study Using Multifractured Wells at the Utah Frontier Observatory for Research in Geothermal Energy Site. SPE J. 2024, 29, 592–605. [Google Scholar] [CrossRef]

- Horalek, J.; Jechumtalova, Z.; Dorbath, L.; Sileny, J. Source mechanisms of micro-earthquakes induced in a fluid injection experiment at the HDR site Soultz-sous-Forets (Alsace) in 2003 and their temporal and spatial variations. Geophys. J. Int. 2010, 181, 1547–1565. [Google Scholar] [CrossRef]

- Portier, N.; Hinderer, J.; Riccardi, U.; Ferhat, G.; Calvo, M.; Abdelfettah, Y.; Bernard, J.-D. New results on the gravity monitoring (2014–2017) of Soultz-sous-Forets and Rittershoffen geothermal sites (France). Geotherm. Energy 2018, 6, 19. [Google Scholar] [CrossRef]

- Portier, N.; Hinderer, J.; Riccardi, U.; Ferhat, G.; Calvo, M.; Abdelfettah, Y.; Heimlich, C.; Bernard, J.-D. Hybrid gravimetry monitoring of Soultz-sous-Forets and Rittershoffen geothermal sites (Alsace, France). Geothermics 2018, 76, 201–219. [Google Scholar] [CrossRef]

- Javani, D.; Schmittbuhl, J.; Cornet, F. Pressure propagation during hydraulic stimulation: Case study of the 2000 stimulation at Soultz-sous-Forêts. Geotherm. Energy 2025, 13, 1–24. [Google Scholar] [CrossRef]

- Feng, C.; Gao, G.; Zhang, S.; Sun, D.; Zhu, S.; Tan, C.; Ma, X. Fault slip potential induced by fluid injection in the Matouying enhanced geothermal system (EGS) field, Tangshan seismic region, North China. Nat. Hazards Earth Syst. Sci. 2022, 22, 2257–2287. [Google Scholar] [CrossRef]

- Zhong, C.; Xu, T.; Yuan, Y.; Feng, B.; Yu, H. The feasibility of clean power generation from a novel dual-vertical-well enhanced geothermal system (EGS): A case study in the Gonghe Basin, China. J. Clean. Prod. 2022, 344, 131109. [Google Scholar] [CrossRef]

- Zhong, C.; Xu, T.; Gherardi, F.; Yuan, Y. Comparison of CO2 and water as working fluids for an enhanced geothermal system in the Gonghe Basin, northwest China. Gondwana Res. 2023, 122, 199–214. [Google Scholar] [CrossRef]

- Feng, B.; Cui, Z.; Liu, X.; Shangguan, S.; Qi, X.; Li, S. Effects of Water-Rock Interaction on the Permeability of the Near-Well Reservoir in an Enhanced Geothermal System. Energies 2022, 15, 8820. [Google Scholar] [CrossRef]

- Yuan, Y.; Xu, T.; Jiang, Z.; Feng, B. Prospects of power generation from the deep fractured geothermal reservoir using a novel vertical well system in the Yangbajing geothermal field, China. Energy Rep. 2021, 7, 4733–4746. [Google Scholar] [CrossRef]

- Pandey, S.N.; Vishal, V.; Chaudhuri, A. Geothermal reservoir modeling in a coupled thermo-hydro-mechanical-chemical approach: A review. Earth-Sci. Rev. 2018, 185, 1157–1169. [Google Scholar] [CrossRef]

- Chen, Y.; Huang, L.; Ajo-Franklin, J.; Bauer, S.J.; Baumgartner, T.; Beckers, K.; Blankenship, D.; Bonneville, A.; Boyd, L.; Brown, S.T.; et al. Optimal design of 3D borehole seismic arrays for microearthquake monitoring in anisotropic media during stimulations in the EGS collab project. Geothermics 2019, 79, 61–66. [Google Scholar] [CrossRef]

- Lu, J.; Ghassemi, A. Coupled Thermo-Hydro-Mechanical-Seismic Modeling of EGS Collab Experiment 1. Energies 2021, 14, 446. [Google Scholar] [CrossRef]

- Feng, Z.; Huang, L.; Chi, B.; Gao, K.; Li, J.; Ajo-Franklin, J.; Blankenship, D.A.; Kneafsey, T.J.; Team, E.G.S.C. Monitoring spatiotemporal evolution of fractures during hydraulic stimulations at the first EGS collab testbed using anisotropic elastic-waveform inversion. Geothermics 2024, 122, 103076. [Google Scholar] [CrossRef]

- Kneafsey, T.; Dobson, P.; Blankenship, D.; Schwering, P.; White, M.; Morris, J.P.; Huang, L.; Johnson, T.; Burghardt, J.; Mattson, E.; et al. The EGS Collab project: Outcomes and lessons learned from hydraulic fracture stimulations in crystalline rock at 1.25 and 1.5 km depth. Geothermics 2025, 126, 103178. [Google Scholar] [CrossRef]

- Moraga, J.; Duzgun, H.S.; Cavur, M.; Soydan, H. The Geothermal Artificial Intelligence for geothermal exploration. Renew. Energy 2022, 192, 134–149. [Google Scholar] [CrossRef]

- Xing, P.; Moore, J.; Damjanac, B.; McLennan, J. Investigation of thermal cooling effect of long-term circulation in Raft River enhanced geothermal system. Geothermics 2024, 120, 103026. [Google Scholar] [CrossRef]

- Jeanne, P.; Rutqvist, J.; Rinaldi, A.P.; Dobson, P.F.; Walters, M.; Hartline, C.; Garcia, J. Seismic and aseismic deformations and impact on reservoir permeability: The case of EGS stimulation at The Geysers, California, USA. J. Geophys. Res. -Solid Earth 2015, 120, 7863–7882. [Google Scholar] [CrossRef]

- Garcia, J.; Hartline, C.; Walters, M.; Wright, M.; Rutqvist, J.; Dobson, P.F.; Jeanne, P. The Northwest Geysers EGS Demonstration Project, California Part 1: Characterization and reservoir response to injection. Geothermics 2016, 63, 97–119. [Google Scholar] [CrossRef]

- Niemz, P.; McLennan, J.; Pankow, K.L.; Rutledge, J.; England, K. Circulation experiments at Utah FORGE: Near-surface seismic monitoring reveals fracture growth after shut-in. Geothermics 2024, 119, 102947. [Google Scholar] [CrossRef]

- Mindygaliyeva, B.; Uzun, O.; Amini, K.; Kazemi, H.; Fleckenstein, W. Assessment of two recent hot dry rock thermal energy production projects. Geothermics 2024, 122, 103075. [Google Scholar] [CrossRef]

- Xu, T.; Yuan, Y.; Jia, X.; Lei, Y.; Li, S.; Feng, B.; Hou, Z.; Jiang, Z. Prospects of power generation from an enhanced geothermal system by water circulation through two horizontal wells: A case study in the Gonghe Basin, Qinghai Province, China. Energy 2018, 148, 196–207. [Google Scholar] [CrossRef]

- Xu, T.; Moore, J.; Jiang, Z. The Special Issue on Hot Dry Rock Resource Exploration and Enhanced Geothermal Engineering. Acta Geol. Sin. -Engl. Ed. 2021, 95, I–IV. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Jiang, G.; Hu, J.; Shi, Y.; Wang, S.; Hu, S. A Method for Determining Target Areas of Hot Dry Rock Resources: A Case Study in Continental China. Energies 2024, 17, 2435. [Google Scholar] [CrossRef]

- Xie, J.; Li, L.; Wen, D.; Peng, S.; Zheng, J.; Fu, G. Experiments and Analysis of the Hydraulic Fracture Propagation Behaviors of the Granite with Structural Planes in the Gonghe Basin. Acta Geol. Sin. -Engl. Ed. 2021, 95, 1816–1827. [Google Scholar] [CrossRef]

- Zhang, E.-y.; Wen, D.-g.; Wang, G.-l.; Jin, X.-p.; Zhang, L.-y.; Wu, H.-d.; Wang, W.-s.; Ye, C.-m.; Weng, W.; Li, K.; et al. Two stages power generation test of the hot dry rock exploration and production demonstration project in the Gonghe Basin, northeastern Qinghai-Tibet plateau, China. China Geol. 2024, 7, 409–421. [Google Scholar] [CrossRef]

- Niu, Q.; Ma, K.; Wang, W.; Pan, J.; Wang, Q.; Du, Z.; Wang, Z.; Yuan, W.; Zheng, Y.; Shangguan, S.; et al. Multifactor analysis of heat extraction performance of coaxial heat exchanger applied to hot dry rock resources exploration: A case study in matouying uplift, Tangshan, China. Energy 2023, 282, 128277. [Google Scholar] [CrossRef]

- Niu, Q.; Yao, M.; Yuan, J.; Chang, J.; Qi, X.; Shangguan, S.; Wang, Q.; Wang, W.; Yuan, W. Mechanism and Influencing Factor Analysis of Near-Well Stimulation for Hot Dry Rock Reservoirs by Liquid CO2 Phase Transition Blasting: Applied to Matouying Uplift. ACS Omega 2025, 10, 2819–2832. [Google Scholar] [CrossRef] [PubMed]

- Schill, E.; Genter, A.; Cuenot, N.; Kohl, T. Hydraulic performance history at the Soultz EGS reservoirs from stimulation and long-term circulation tests. Geothermics 2017, 70, 110–124. [Google Scholar] [CrossRef]

- Gerard, A.; Genter, A.; Kohl, T.; Lutz, P.; Rose, P.; Rummel, F. The deep EGS (Enhanced Geothermal System) project at Soultz-sous-Forets (Alsace, France). Geothermics 2006, 35, 473–483. [Google Scholar] [CrossRef]

- Baria, R.; Baumgärtner, J.; Gérard, A.; Jung, R.; Garnish, J. European HDR research programme at Soultz-sous-Forets (France) 1987–1996. Geothermics 1999, 28, 655–669. [Google Scholar] [CrossRef]

- Held, S.; Genter, A.; Kohl, T.; Kölbel, T.; Sausse, J.; Schoenball, M. Economic evaluation of geothermal reservoir performance through modeling the complexity of the operating EGS in Soultz-sous-Forêts. Geothermics 2014, 51, 270–280. [Google Scholar] [CrossRef]

- Baujard, C.; Genter, A.; Dalmais, E.; Maurer, V.; Hehn, R.; Rosillette, R.; Vidal, J.; Schmittbuhl, J. Hydrothermal characterization of wells GRT-1 and GRT-2 in Rittershoffen, France: Implications on the understanding of natural flow systems in the rhine graben. Geothermics 2017, 65, 255–268. [Google Scholar] [CrossRef]

- Reinecker, J.; Gutmanis, J.; Foxford, A.; Cotton, L.; Dalby, C.; Law, R. Geothermal exploration and reservoir modelling of the United Downs deep geothermal project, Cornwall (UK). Geothermics 2021, 97, 102226. [Google Scholar] [CrossRef]

- Gan, Q.; Feng, Z.; Zhou, L.; Li, H.; Liu, J.; Elsworth, D. Down-dip circulation at the united downs deep geothermal power project maximizes heat recovery and minimizes seismicity. Geothermics 2021, 96, 102204. [Google Scholar] [CrossRef]

- Paulillo, A.; Cotton, L.; Law, R.; Striolo, A.; Lettieri, P. Geothermal energy in the UK: The life-cycle environmental impacts of electricity production from the United Downs Deep Geothermal Power project. J. Clean. Prod. 2020, 249, 119410. [Google Scholar] [CrossRef]

- Paulillo, A.; Cotton, L.; Law, R.; Striolo, A.; Lettieri, P. Life-cycle inventory data and impacts on electricity production at the United Downs Deep Geothermal Power project in the UK. Data Brief 2020, 29, 105117. [Google Scholar] [CrossRef]

- Chamorro, C.R.; Garcia-Cuesta, J.L.; Mondejar, M.E.; Perez-Madrazo, A. Enhanced geothermal systems in Europe: An estimation and comparison of the technical and sustainable potentials. Energy 2014, 65, 250–263. [Google Scholar] [CrossRef]

- Dalla Longa, F.; Nogueira, L.P.; Limberger, J.; van Wees, J.-D.; van der Zwaan, B. Scenarios for geothermal energy deployment in Europe. Energy 2020, 206, 118060. [Google Scholar] [CrossRef]

- Chelle-Michou, C.; Do Couto, D.; Moscariello, A.; Renard, P.; Rusillon, E. Geothermal state of the deep Western Alpine Molasse Basin, France-Switzerland. Geothermics 2017, 67, 48–65. [Google Scholar] [CrossRef]

- Agemar, T.; Weber, J.; Schulz, R. Deep Geothermal Energy Production in Germany. Energies 2014, 7, 4397–4416. [Google Scholar] [CrossRef]

- Lee, Y.; Park, S.; Kim, J.; Kim, H.C.; Koo, M.-H. Geothermal resource assessment in Korea. Renew. Sustain. Energy Rev. 2010, 14, 2392–2400. [Google Scholar] [CrossRef]

- Kim, K.-I.; Min, K.-B.; Kim, K.-Y.; Choi, J.W.; Yoon, K.-S.; Yoon, W.S.; Yoon, B.; Lee, T.J.; Song, Y. Protocol for induced microseismicity in the first enhanced geothermal systems project in Pohang, Korea. Renew. Sustain. Energy Rev. 2018, 91, 1182–1191. [Google Scholar] [CrossRef]

- Terakawa, T.; Seo, W.; Kim, K.-H.; Ree, J.-H. Three-Dimensional Pore Fluid Pressures in Source Region of 2017 Pohang Earthquake Inferred From Earthquake Focal Mechanisms. Geophys. Res. Lett. 2020, 47, e2019GL085964. [Google Scholar] [CrossRef]

- McGarr, A.; Majer, E.L. The 2017 Pohang, South Korea, Mw 5.4 main shock was either natural or triggered, but not induced. Geothermics 2023, 107, 102612. [Google Scholar] [CrossRef]

- Kim, K.-H.; Ree, J.-H.; Kim, Y.; Kim, S.; Kang, S.Y.; Seo, W. Assessing whether the 2017 Mw 5.4 Pohang earthquake in South Korea was an induced event. Science 2018, 360, 1007–1009. [Google Scholar] [CrossRef]

- Ellsworth, W.L.; Giardini, D.; Townend, J.; Ge, S.; Shimamoto, T. Triggering of the Pohang, Korea, Earthquake (Mw 5.5) by Enhanced Geothermal System Stimulation. Seismol. Res. Lett. 2019, 90, 1844–1858. [Google Scholar] [CrossRef]

- Yasukawa, K. Geothermal Energy Use and Its Related Technology Development in Japan. J. Energy Resour. Technol. -Trans. ASME 2021, 143, 100802. [Google Scholar] [CrossRef]

- Hori, Y.; Kitano, K.; Kaieda, H.; Kiho, K. Present status of the Ogachi HDR Project, Japan, and future plans. Geothermics 1999, 28, 637–645. [Google Scholar] [CrossRef]

- Kuriyagawa, M.; Tenma, N. Development of hot dry rock technology at the Hijiori test site. Geothermics 1999, 28, 627–636. [Google Scholar] [CrossRef]

- Yanagisawa, N.; Matsunaga, I.; Sugita, H.; Sato, M.; Okabe, T. Temperature-dependent scale precipitation in the Hijiori Hot Dry Rock system, Japan. Geothermics 2008, 37, 1–18. [Google Scholar] [CrossRef]

- Oka, D.; Tamura, M.; Mogi, T.; Nakagawa, M.; Takahashi, H.; Ohzono, M.; Ichiyanagi, M. Conceptual model of supercritical geothermal system in Shiribeshi Region, Hokkaido, Japan. Geothermics 2023, 108, 102617. [Google Scholar] [CrossRef]

- Muraoka, H.; Asanuma, H.; Tsuchiya, N.; Ito, T.; Mogi, T.; Ito, H. The Japan Beyond-Brittle project. Sci. Drill. 2014, 17, 51–59. [Google Scholar]

- Yanagisawa, N.; Masuda, Y.; Asanuma, H.; Osato, K.; Sakura, K. Estimation of casing material corrosion rates for supercritical geothermal development. Geothermics 2021, 96, 102149. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, G.; Zhu, X.; Li, T. Occurrence of geothermal resources and prospects for exploration and development in China. Energy Explor. Exploit. 2021, 39, 536–552. [Google Scholar] [CrossRef]

- Wang, Y.; Yuan, Y.; Guo, B.; Lei, H.; Zhu, H.; Tian, H.; Xu, T. Numerical simulation of hydro-shearing stimulation in the enhanced geothermal system at the Utah FORGE site. Eng. Geol. 2024, 343, 107823. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, F.; Xu, Y.; He, J.; Deng, D.; Zhan, S.; Zhang, C. Dynamics study of hot dry rock percussive drilling tool based on the drill string axial vibration. Geoenergy Sci. Eng. 2025, 246, 213599. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, F.; Yan, D.; Liao, H.; Niu, J. Characteristic analysis of a HDR percussive drilling tool with sinusoidal impact load. Geoenergy Sci. Eng. 2024, 238, 212847. [Google Scholar] [CrossRef]

- Leslie, M. Geothermal Power Potential Heats Up. Engineering 2024, 43, 14–16. [Google Scholar] [CrossRef]

- Mokhtari, H.; Hadiannasab, H.; Mostafavi, M.; Ahmadibeni, A.; Shahriari, B. Determination of optimum geothermal Rankine cycle parameters utilizing coaxial heat exchanger. Energy 2016, 102, 260–275. [Google Scholar] [CrossRef]

- Ahmadi, A.; Assad, M.E.H.; Jamali, D.H.; Kumar, R.; Li, Z.X.; Salameh, T.; Al-Shabi, M.; Ehyae, M.A. Applications of geothermal organic Rankine Cycle for electricity production. J. Clean. Prod. 2020, 274, 122950. [Google Scholar] [CrossRef]

- Chen, J.; Xu, T.; Liang, X.; Jiang, Z. Stochastic inversion of tracer test data with seismicity constraint for permeability imaging in enhanced geothermal reservoirs. Geophysics 2022, 87, M307–M319. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, S.; Turnadge, C.; Xu, T. Combining autoencoder neural network and Bayesian inversion to estimate heterogeneous permeability distributions in enhanced geothermal reservoir: Model development and verification. Geothermics 2021, 97, 102262. [Google Scholar] [CrossRef]

- Peacock, J.R.; Earney, T.E.; Mangan, M.T.; Schermerhorn, W.D.; Glen, J.M.; Walters, M.; Hartline, C. Geophysical characterization of the Northwest Geysers geothermal field, California. J. Volcanol. Geotherm. Res. 2020, 399, 106882. [Google Scholar] [CrossRef]

- Fu, P.; Schoenball, M.; Ajo-Franklin, J.B.; Chai, C.; Maceira, M.; Morris, J.P.; Wu, H.; Knox, H.; Schwering, P.C.; White, M.D.; et al. Close Observation of Hydraulic Fracturing at EGS Collab Experiment 1: Fracture Trajectory, Microseismic Interpretations, and the Role of Natural Fractures. J. Geophys. Res. -Solid Earth 2021, 126, e2020JB020840. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, G.; Zhou, J.; Liu, J. Fracture Network Volume Fracturing Technology in High-temperature Hard Formation of Hot Dry Rock. ACTA Geol. Sin. -Engl. Ed. 2021, 95, 1828–1834. [Google Scholar] [CrossRef]

- Jia, Y.; Tsang, C.-F.; Hammar, A.; Niemi, A. Hydraulic stimulation strategies in enhanced geothermal systems (EGS): A review. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 211. [Google Scholar] [CrossRef]

- Na, J.; Xu, T.; Jiang, Z.; Bao, X.; Wu, Y.; Feng, B. A study on the interaction of mud acid with rock for chemical stimulation in an enhanced geothermal system. Environ. Earth Sci. 2016, 75, 1025. [Google Scholar] [CrossRef]

- Portier, S.; Vuataz, F.D. Developing the ability to model acid-rock interactions and mineral dissolution during the RMA stimulation test performed at the Soultz-sous-Forets EGS site, France. Comptes Rendus Geosci. 2010, 342, 668–675. [Google Scholar] [CrossRef]

- Hu, Z.; Xu, T.; Moore, J.; Feng, B.; Liu, Y.; McLennan, J.; Yang, Y. Investigation of the effect of different injection schemes on fracture network patterns in hot dry rocks—A numerical case study of the FORGE EGS site in Utah. J. Nat. Gas Sci. Eng. 2022, 97, 104346. [Google Scholar] [CrossRef]

- Cheng, Y.; Liu, W.; Xu, T.; Zhang, Y.; Zhang, X.; Xing, Y.; Feng, B.; Xia, Y. Seismicity induced by geological CO2 storage: A review. Earth-Sci. Rev. 2023, 239, 104369. [Google Scholar] [CrossRef]

- He, M.; Li, Q.; Li, X.; Zhang, Y. Traffic light system regulation of induced seismicity under multi-well fluid injection. Energy Geosci. 2025, 6, 100368. [Google Scholar] [CrossRef]

- Trutnevyte, E.; Wiemer, S. Tailor-made risk governance for induced seismicity of geothermal energy projects: An application to Switzerland. Geothermics 2017, 65, 295–312. [Google Scholar] [CrossRef]

- Kassem, M.A.; Moscariello, A.; Hollmuller, P. Navigating risk in geothermal energy projects: A systematic literature review. Energy Rep. 2025, 13, 696–712. [Google Scholar] [CrossRef]

- Baisch, S.; Koch, C.; Muntendam-Bos, A. Traffic Light Systems: To What Extent Can Induced Seismicity Be Controlled? Seismol. Res. Lett. 2019, 90, 1145–1154. [Google Scholar] [CrossRef]

- Ader, T.; Chendorain, M.; Free, M.; Saarno, T.; Heikkinen, P.; Malin, P.E.; Leary, P.; Kwiatek, G.; Dresen, G.; Bluemle, F.; et al. Design and implementation of a traffic light system for deep geothermal well stimulation in Finland. J. Seismol. 2020, 24, 991–1014. [Google Scholar] [CrossRef]

- Luginbuhl, M.; Rundle, J.B.; Turcotte, D.L. Statistical physics models for aftershocks and induced seismicity. Philos. Trans. R. Soc. A-Math. Phys. Eng. Sci. 2019, 377, 20170397. [Google Scholar] [CrossRef]

- Cloetingh, S.; van Wees, J.D.; Ziegler, P.A.; Lenkey, L.; Beekman, F.; Tesauro, M.; Foerster, A.; Norden, B.; Kaban, M.; Hardebol, N.; et al. Lithosphere tectonics and thermo-mechanical properties: An integrated modelling approach for Enhanced Geothermal Systems exploration in Europe. Earth-Sci. Rev. 2010, 102, 159–206. [Google Scholar] [CrossRef]

- Porter, R.T.J.; Striolo, A.; Mahgerefteh, H.; Walker, J.F. Addressing the risks of induced seismicity subsurface energy operations. Wiley Interdiscip. Rev. -Energy Environ. 2019, 8, e324. [Google Scholar] [CrossRef]

- Horne, R.; Genter, A.; McClure, M.; Ellsworth, W.; Norbeck, J.; Schill, E. Enhanced geothermal systems for clean firm energy generation. Nat. Rev. Clean Technol. 2025, 1, 148–160. [Google Scholar] [CrossRef]

- Chugunova, T.; Corpel, V.; Gomez, J.P. Explicit Fracture Network Modelling: From Multiple Point Statistics to Dynamic Simulation. Math. Geosci. 2017, 49, 541–553. [Google Scholar] [CrossRef]

- Rathnaweera, T.D.; Wu, W.; Ji, Y.; Gamage, R.P. Understanding injection-induced seismicity in enhanced geothermal systems: From the coupled thermo-hydro-mechanical-chemical process to anthropogenic earthquake prediction. Earth-Sci. Rev. 2020, 205, 103182. [Google Scholar] [CrossRef]

- Dorn, C.; Linde, N.; Le Borgne, T.; Bour, O.; Klepikova, M. Inferring transport characteristics in a fractured rock aquifer by combining single-hole ground-penetrating radar reflection monitoring and tracer test data. Water Resour. Res. 2012, 48, W11521. [Google Scholar] [CrossRef]

- Chatzopoulos, G.; Michas, G.; Vallianatos, F. Fracture network organization with continuation of injections in the Habanero field (Cooper Basin, Australia) disclosed by coda wave fluctuations. Geomech. Energy Environ. 2023, 36, 100510. [Google Scholar] [CrossRef]

- Follin, S.; Hartley, L.; Rhen, I.; Jackson, P.; Joyce, S.; Roberts, D.; Swift, B. A methodology to constrain the parameters of a hydrogeological discrete fracture network model for sparsely fractured crystalline rock, exemplified by data from the proposed high-level nuclear waste repository site at Forsmark, Sweden. Hydrogeol. J. 2014, 22, 313–331. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Zhang, S.; Yang, X.; Wang, Y.; Khan, J. Characteristics of micron-scale pore-fracture modification in marine shale reservoirs with different combustion explosion energy. Geoenergy Sci. Eng. 2024, 237, 212780. [Google Scholar] [CrossRef]

- Wei, X.; Wang, X.; Cao, M.; Zhang, Y.; Shi, J.; Zhang, Y.; Zhang, Y. Study on rock fracture mechanism based on the combustion and explosion characteristics of high-energy expansive agent. Eng. Fract. Mech. 2023, 289, 109428. [Google Scholar] [CrossRef]

- Kalam, S.; Afagwu, C.; Al Jaberi, J.; Siddig, O.M.; Tariq, Z.; Mahmoud, M.; Abdulraheem, A. A review on non-aqueous fracturing techniques in unconventional reservoirs. J. Nat. Gas Sci. Eng. 2021, 95, 104223. [Google Scholar] [CrossRef]

- Wang, W.; Wang, W.; Yuan, W.; Zhou, G.; Feng, X.; Liang, X. Numerical simulation of the effect of water-decoupling charge blasting on reservoir permeability enhancement. Geomat. Nat. Hazards Risk 2022, 13, 2356–2384. [Google Scholar] [CrossRef]

- Xu, P.; Cheng, Y.F.; Zhang, Y.T.; Zhang, X.C.; Jia, J.H. A Study on Low Permeability Formation’s Permeability Variation Induced by Explosive Fracturing Technology. Pet. Sci. Technol. 2013, 31, 2541–2547. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, L.; Li, X.; Liu, Z.; Chen, J. Numerical investigations of mechanical behavior and permeability evolution in mine geothermal reservoir with blasting fractures using fully coupled thermal–hydraulic-mechanical modeling. Appl. Therm. Eng. 2024, 252, 123596. [Google Scholar] [CrossRef]

- Jeong, H.; Jeon, B.; Choi, S.; Jeon, S. Fracturing behavior around a blasthole in a brittle material under blasting loading. Int. J. Impact Eng. 2020, 140, 103562. [Google Scholar] [CrossRef]

- Yin, H.; Zayed, M.E.; Li, Y.; Yang, L.; Fan, Y.; Wang, Z.; Yin, L.; Zhao, J.; Al-Kbodi, B.H.; Rehman, S. Thermo-economic performance of a leaky downhole coaxial geothermal system for maximizing geothermal energy production: Numerical investigation. Renew. Energy 2024, 232, 121082. [Google Scholar] [CrossRef]

- Wang, G.; Song, X.; Shi, Y.; Sun, B.; Zheng, R.; Li, J.; Pei, Z.; Song, H. Numerical investigation on heat extraction performance of an open loop geothermal system in a single well. Geothermics 2019, 80, 170–184. [Google Scholar] [CrossRef]

- Agson-Gani, P.H.; Zueter, A.C.; Xu, M.P.; Ghoreishi-Madiseh, S.A.; Kurnia, J.C.; Sasmito, A.P. Thermal and hydraulic analysis of a novel double-pipe geothermal heat exchanger with a controlled fractured zone at the well bottom. Appl. Energy 2022, 310, 118407. [Google Scholar] [CrossRef]

- Zhao, W.; Yuan, Y.; Jing, T.; Zhong, C.; Wei, S.; Yin, Y.; Zhao, D.; Yuan, H.; Zheng, J.; Wang, S. Heat Production Performance from an Enhanced Geothermal System (EGS) Using CO2 as the Working Fluid. Energies 2023, 16, 7202. [Google Scholar] [CrossRef]

- Cong, L.; Lu, S.; Jiang, P.; Zheng, T.; Yu, Z.; Lu, X. Research Progress on CO2 as Geothermal Working Fluid: A Review. Energies 2024, 17, 5415. [Google Scholar] [CrossRef]

- Bongole, K.; Sun, Z.; Jun, Y.; Mehmood, A.; Wang, Y.; Mboje, J.; Ying, X. Multifracture response to supercritical CO2-EGS and water-EGS based on thermo-hydro-mechanical coupling method. Int. J. Energy Res. 2019, 43, 7173–7196. [Google Scholar] [CrossRef]

- Antoneas, G.; Koronaki, I. Geothermal Solutions for Urban Energy Challenges: A Focus on CO2 Plume Geothermal Systems. Energies 2024, 17, 294. [Google Scholar] [CrossRef]

- Xu, R.; Zhang, L.; Zhang, F.; Jiang, P. A review on heat transfer and energy conversion in the enhanced geothermal systems with water/CO2 as working fluid. Int. J. Energy Res. 2015, 39, 1722–1741. [Google Scholar] [CrossRef]

- Wang, E.; Peng, N.; Zhang, M. System Design and Application of Supercritical and Transcritical CO2 Power Cycles: A Review. Front. Energy Res. 2021, 9, 723875. [Google Scholar] [CrossRef]

| Technological Type | Technological Name | Technological Development Gap | Technical Application |

|---|---|---|---|

| Base technologies | Evaluation and site selection | Synchronization | Industrialization |

| Efficient and low-cost drilling | Run after | Industrialization | |

| Efficient geothermal utilization | Run after | Industrialization | |

| Key technologies | High-resolution exploration and characterization of HDR | Run after | Pilot |

| Efficient and complex fracture network reservoir creation | Run after | Pilot | |

| Effective microseismic control | Synchronization | Pilot | |

| Fracture network connectivity and reservoir characterization | Synchronization | Pilot | |

| Game-changing technologies | Downhole liquid explosion fracture creation | Synchronization | Laboratory |

| Downhole in situ efficient heat transfer and power generation | Synchronization | Pilot | |

| CO2 and other working fluid for high-efficient power generation | Synchronization | Laboratory |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Y.; Zhang, X.; Yu, H.; Zhong, C.; Wang, Y.; Wen, D.; Xu, T.; Gherardi, F. Research Progress and Technical Challenges of Geothermal Energy Development from Hot Dry Rock: A Review. Energies 2025, 18, 1742. https://doi.org/10.3390/en18071742

Yuan Y, Zhang X, Yu H, Zhong C, Wang Y, Wen D, Xu T, Gherardi F. Research Progress and Technical Challenges of Geothermal Energy Development from Hot Dry Rock: A Review. Energies. 2025; 18(7):1742. https://doi.org/10.3390/en18071742

Chicago/Turabian StyleYuan, Yilong, Xinli Zhang, Han Yu, Chenghao Zhong, Yu Wang, Dongguang Wen, Tianfu Xu, and Fabrizio Gherardi. 2025. "Research Progress and Technical Challenges of Geothermal Energy Development from Hot Dry Rock: A Review" Energies 18, no. 7: 1742. https://doi.org/10.3390/en18071742

APA StyleYuan, Y., Zhang, X., Yu, H., Zhong, C., Wang, Y., Wen, D., Xu, T., & Gherardi, F. (2025). Research Progress and Technical Challenges of Geothermal Energy Development from Hot Dry Rock: A Review. Energies, 18(7), 1742. https://doi.org/10.3390/en18071742