Assessment Methods for DC Stray Current Corrosion Hazards in Underground Gas Pipelines: A Review Focused on Rail Traction Systems

Abstract

1. Introduction

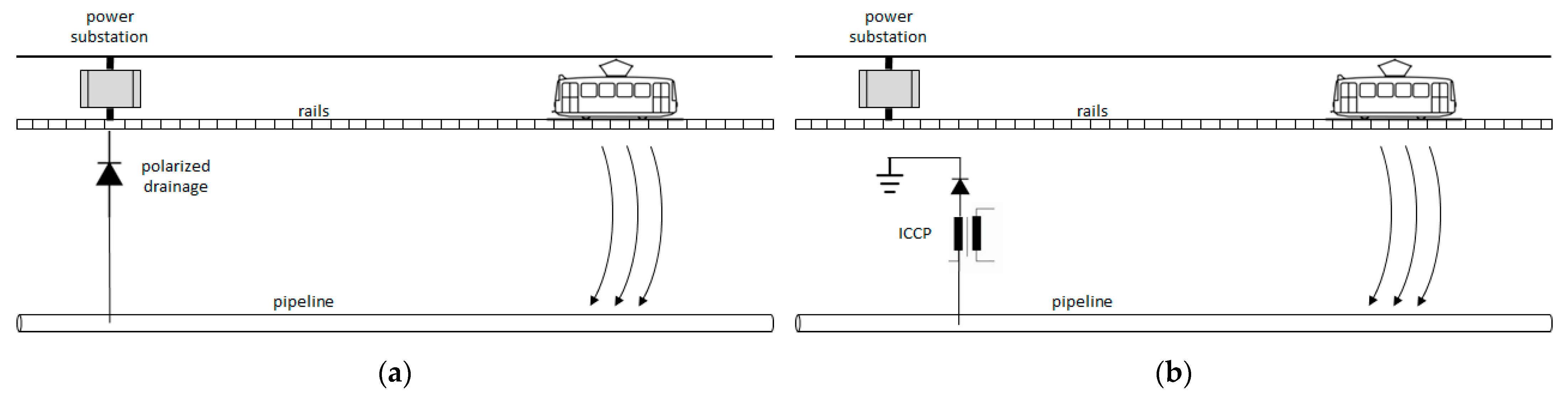

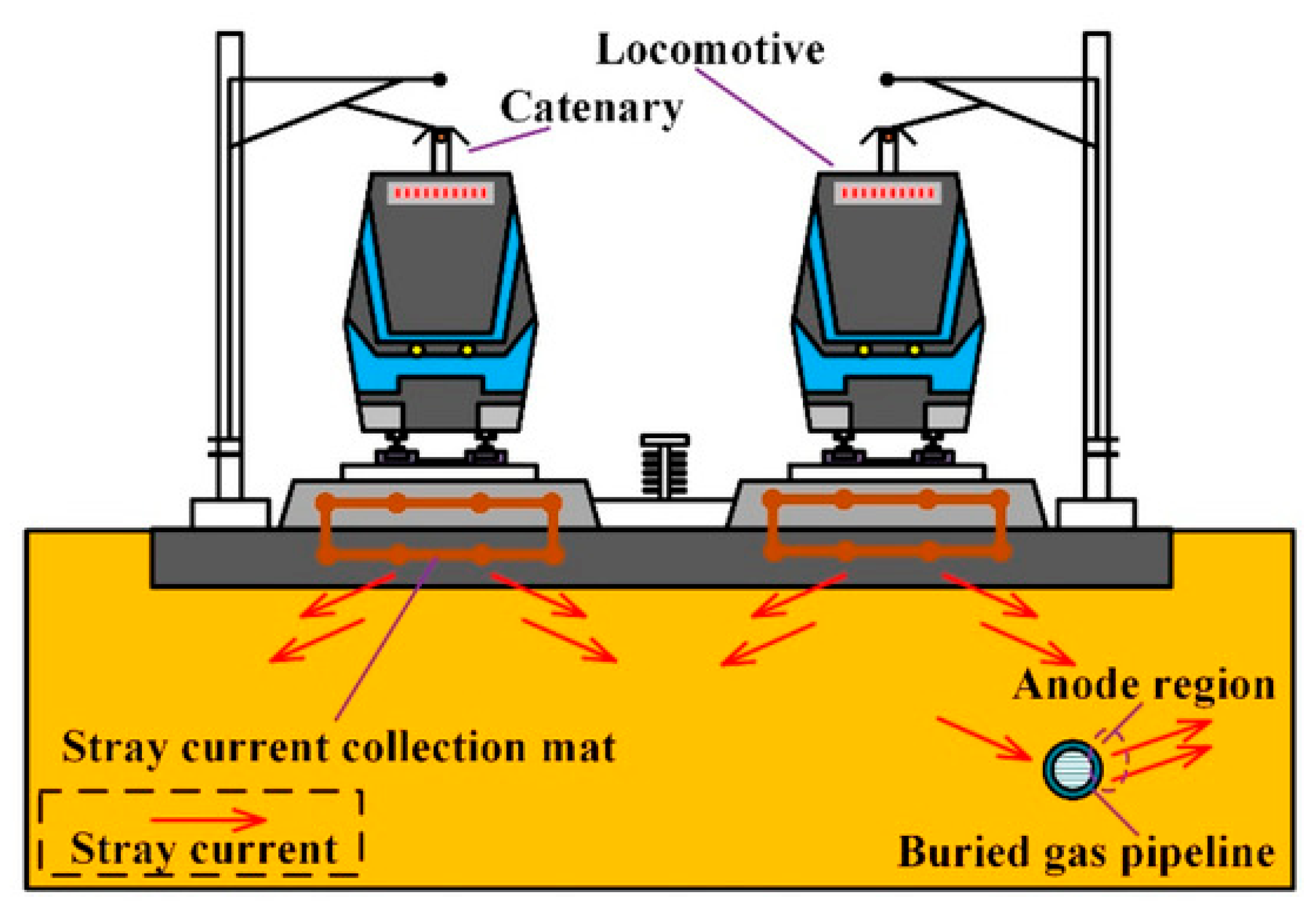

2. Corrosive Impact of Stray Currents Leaking from DC Electric Rail Traction Systems on Gas Pipelines

3. Methods for Testing Gas Pipelines for Electrolytic Corrosion

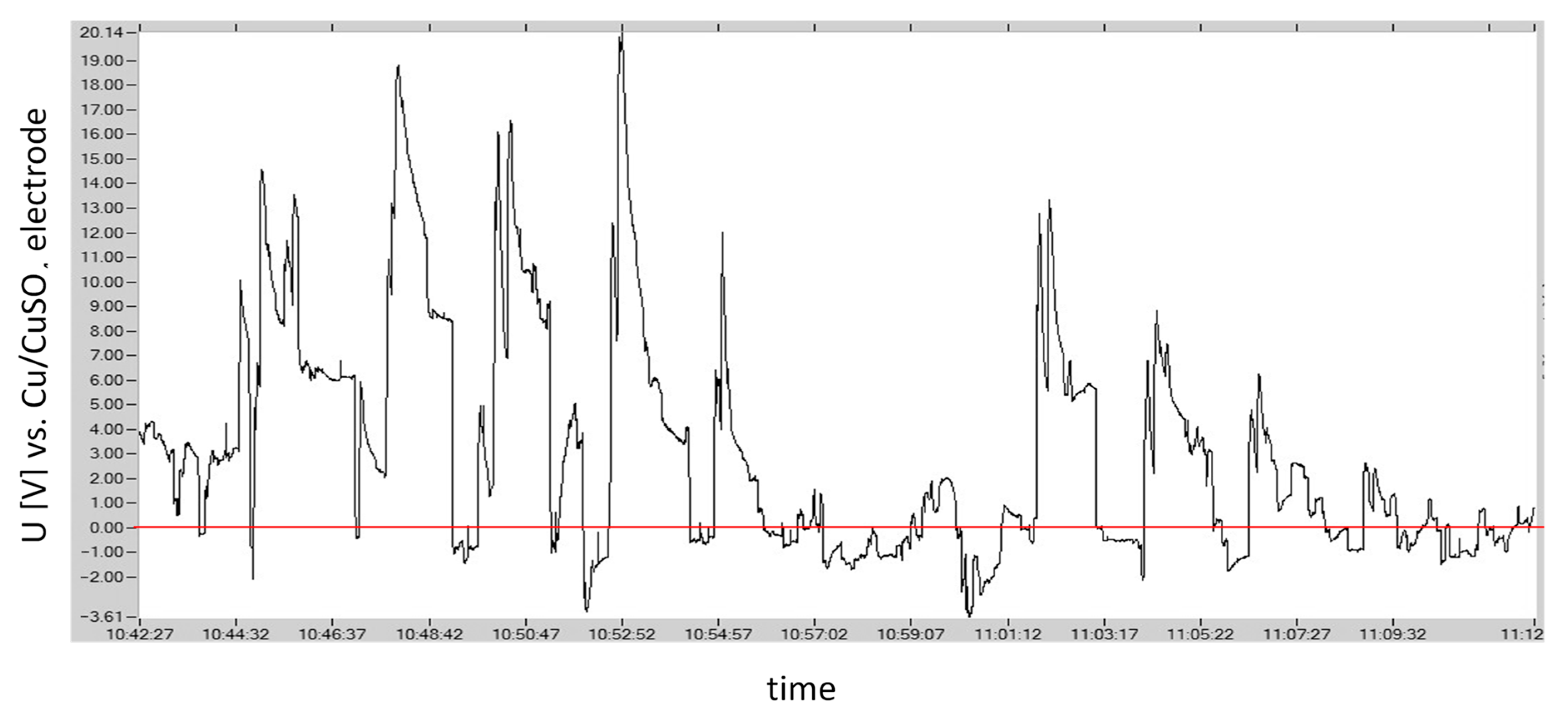

3.1. Rails Potential Testing Method

| Method summary | |

| measured quantity: | potential of railway or tram rails |

| measuring equipment: | voltage recorder, Cu/CuSO4 reference electrode, cable connection to the rail |

| what conclusion can be drawn: | determining whether there is an anodic or cathodic zone on the gas pipeline near the rails based on the rails’ potential |

3.2. Method for Determining Electric Field Gradients on the Ground Surface

| Method summary | |

| measured quantity: | potential gradient on the ground surface |

| measuring equipment: | voltage recorder, two Cu/CuSO4 reference electrodes |

| what conclusion can be drawn: | determining the locations where stray currents flow from the pipeline into the ground (anodic zones on the pipeline) based on the potential gradient direction |

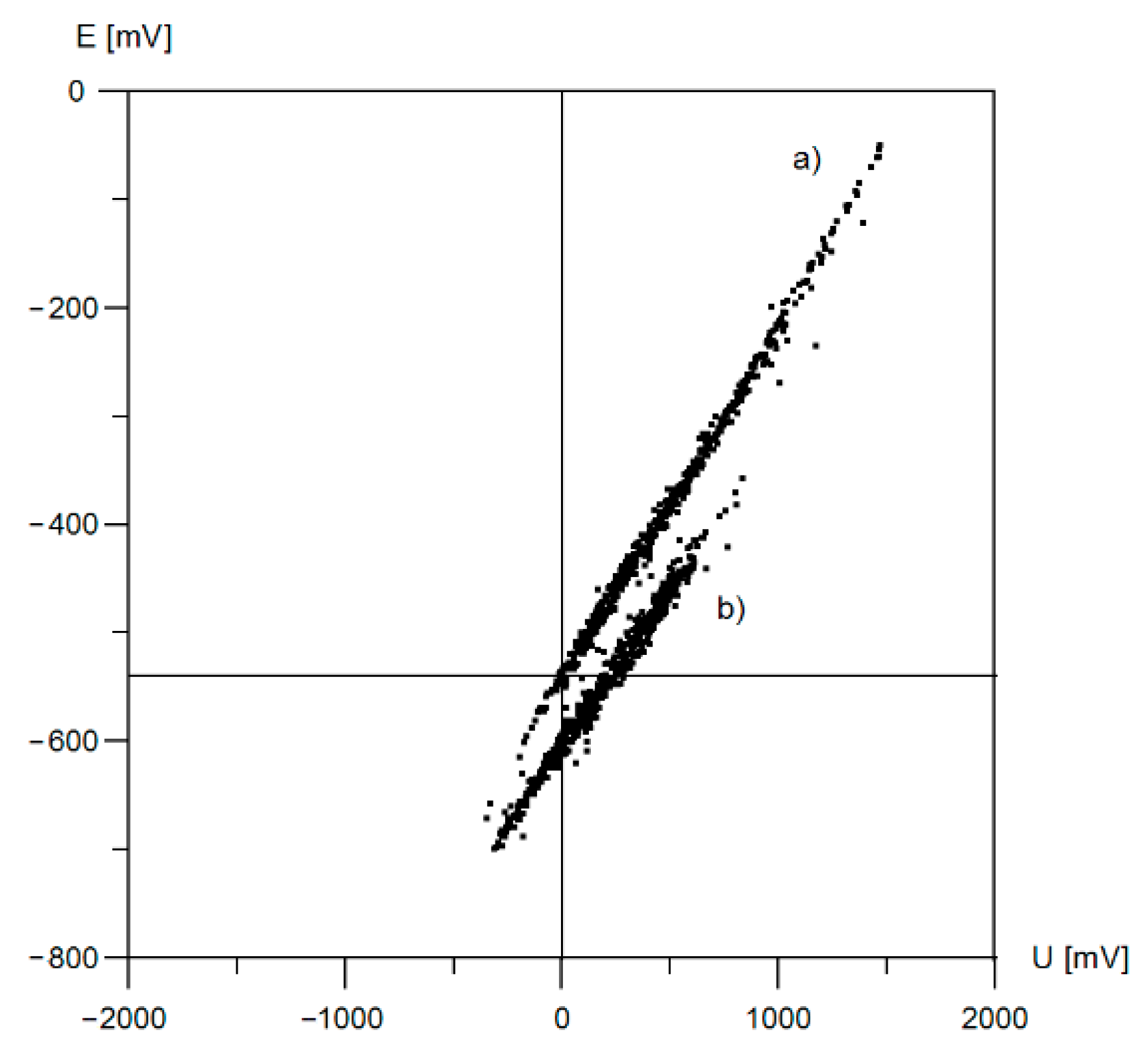

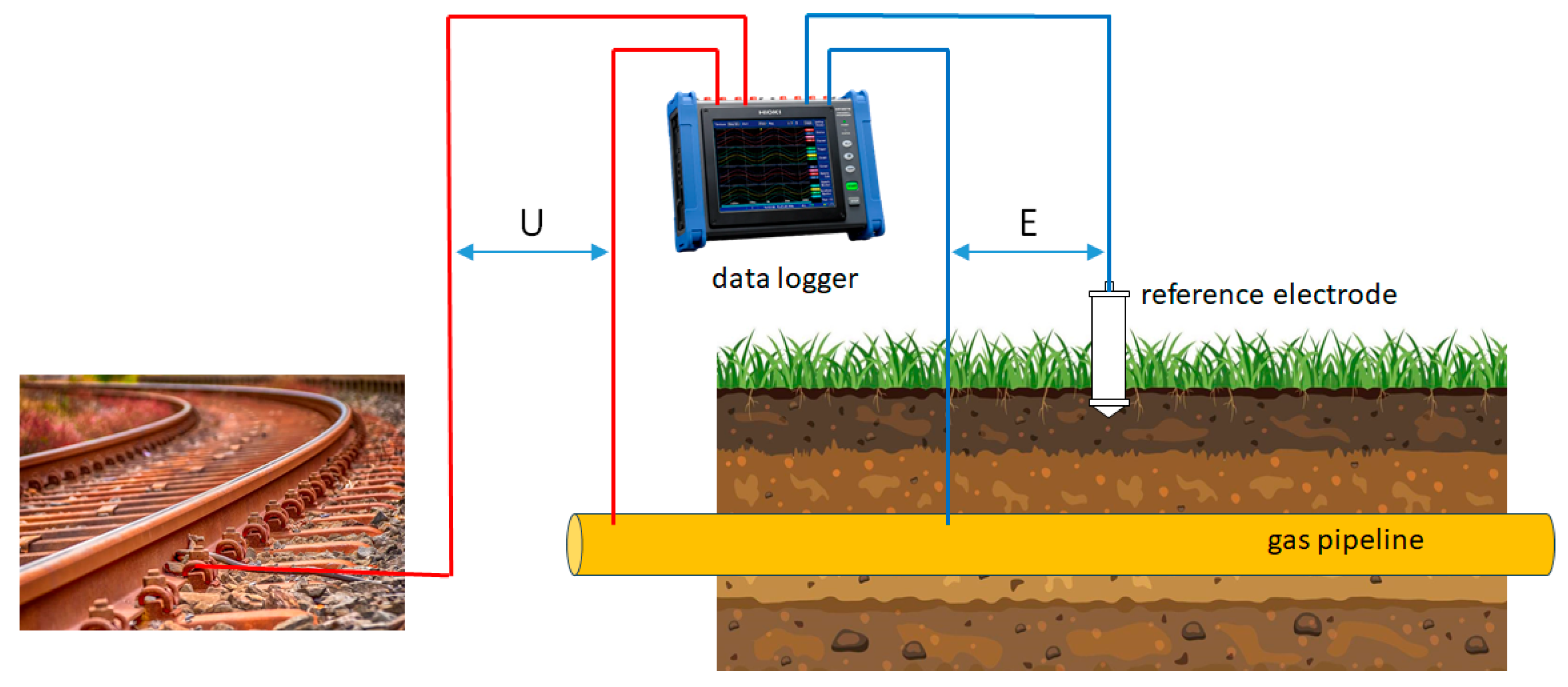

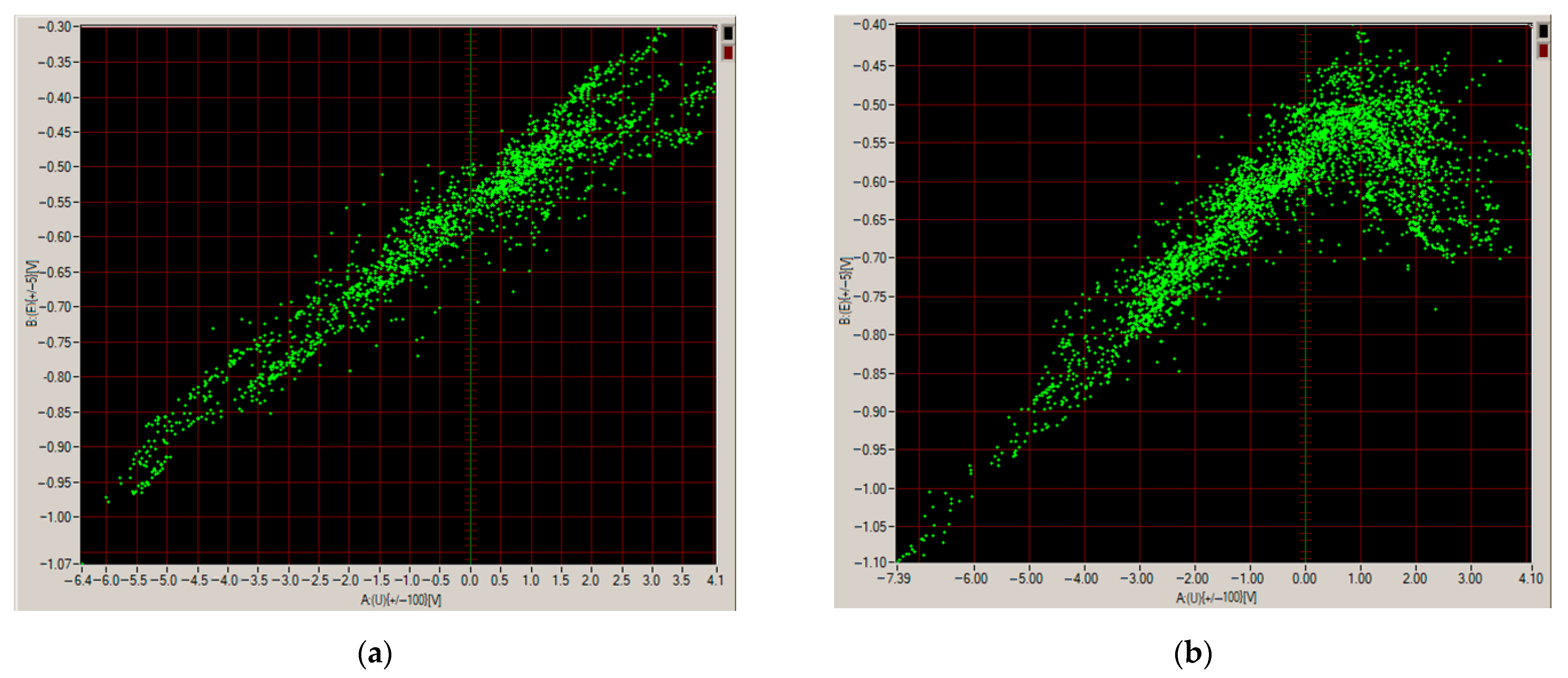

3.3. Correlation Method ‘E = f(U)’ for Testing the Impact of Stray Currents on Gas Pipelines

| Method summary | |

| measured quantity: | simultaneous measurement: potential of the gas pipeline and voltage of the gas pipeline relative to the rails |

| measuring equipment: | two-channel voltage recorder, Cu/CuSO4 reference electrode, cable connection to the gas pipeline, cable connection to the rail |

| what conclusion can be drawn: | - assessment of the magnitude of the stray current hazard based on the value of the gas pipeline potential asymmetry coefficient at the measurement site, - assessment of the effectiveness of the gas pipeline’s electrochemical protection system based on the shape of the correlation graph E = f(U) and the value of the asymmetry coefficient |

3.4. Correlation Method ‘U = f(E)’ for Testing the Impact of Stray Currents on Gas Pipelines

| Method summary | |

| measured quantity: | simultaneous measurement: voltage of the gas pipeline relative to the rails and potential of the gas pipeline |

| measuring equipment: | two-channel voltage recorder, Cu/CuSO4 reference electrode, cable connection to the gas pipeline, cable connection to the rail |

| what conclusion can be drawn: | intensity of the impact of stray currents on the gas pipeline based on the slope of the correlation graph U = f(E) |

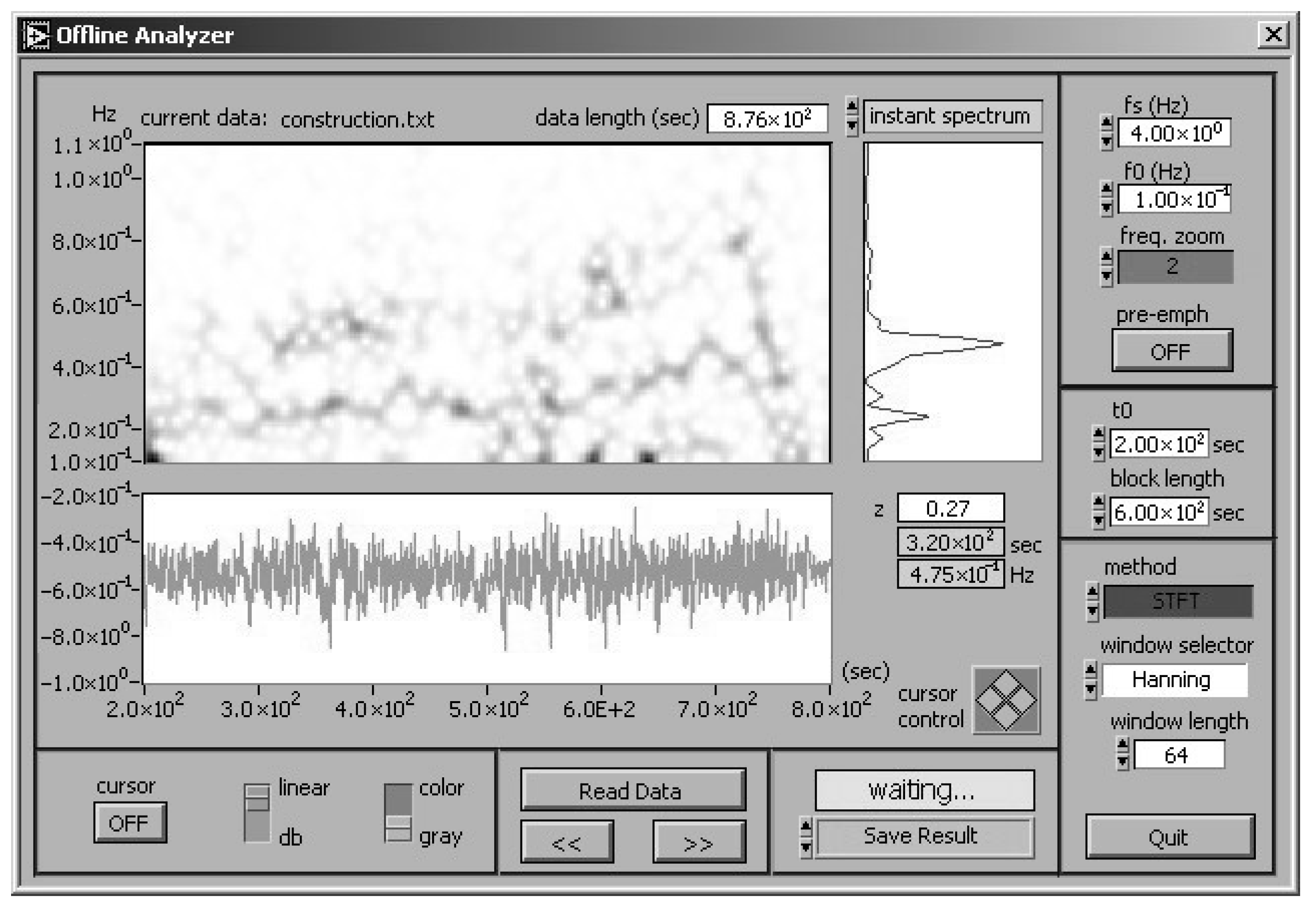

3.5. Time-Frequency Detection Method of Stray Current Interference on Gas Pipeline

| Method summary | |

| measured quantity: | simultaneous measurement: potential of gas pipeline and potential of rails |

| measuring equipment: | two-channel voltage recorder, two Cu/CuSO4 reference electrodes, cable connection to the gas pipeline, cable connection to the rail |

| what conclusion can be drawn: | whether rail traction affects the gas pipeline, or there is no impact, based on a comparison of the energy spectra of both measured signals in the joint time and frequency domain |

4. Discussion

5. Conclusions

- measurements of the potential of electric traction rails or the electric field gradient on the ground surface, which allow identification of the possibility of electrolytic corrosion based on the direction of current flow,

- studies of the correlation between the potential of the gas pipeline and its voltage relative to the electric traction rails, which provide information on the corrosion hazard from anodic areas on the pipeline,

- frequency domain analysis of the pipeline potential, which unequivocally identifies the stray current source that impacts the pipeline.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dakwar, N.; Papavinasam, S.; Hammoud, A. Evaluation of Prediction Techniques in Corrosion Management of Pipelines External Corrosion. In Proceedings of the AMPP Annual Conference + Expo 2025, Nashville, TN, USA, 6–10 April 2025; AMPP: Houston, TX, USA, 2025; pp. 1–14. [Google Scholar] [CrossRef]

- ISO 22426; Assessment of the Effectiveness of Cathodic Protection Based on Coupon Measurements. CENELEC: Brussels, Belgium, 2020.

- Lin, S.; Tang, Z.; Chen, X.; Liu, X.; Liu, Y. Analysis of Stray Current Leakage in Subway Traction Power Supply System Based on Field-Circuit Coupling. Energies 2024, 17, 3121. [Google Scholar] [CrossRef]

- ISO 21857; Petroleum, Petrochemical and Natural Gas Industries—Prevention of Corrosion on Pipeline Systems Influenced by Stray Currents. CENELEC: Brussels, Belgium, 2021.

- Szeliga, M.J. Rail transit stray current control: Then and now. Mater. Perform. 1993, 32, 35–39. [Google Scholar]

- Chen, Z.; Koleva, D.; van Breugel, K. A review on stray current-induced steel corrosion in infrastructure. Corros. Rev. 2017, 35, 397–423. [Google Scholar] [CrossRef]

- Tzeng, Y.; Lee, C. Analysis of rail potential and stray currents in a direct-current transit system. IEEE Trans. Power Deliv. 2010, 25, 1516–1525. [Google Scholar] [CrossRef]

- Zaboli, A.; Vahidi, B.; Yousefi, S.; Hosseini-Biyouki, M.M. Evaluation and control of stray current in DC-electrified railway systems. IEEE Trans. Veh. Technol. 2017, 66, 974–980. [Google Scholar] [CrossRef]

- Wang, C.; Li, W.; Xin, G.; Wang, Y.; Xu, S.; Fan, M. Novel method for prediction of corrosion current density of gas pipeline steel under stray current interference based on hybrid LWQPSO-NN model. Measurement 2022, 200, 111592. [Google Scholar] [CrossRef]

- Lucca, G. Estimating stray current interference from DC traction lines on buried pipelines by means of a Monte Carlo algorithm. Electr. Eng. 2015, 97, 277–286. [Google Scholar] [CrossRef]

- Kim, Y.S.; Jeong, G.J.; Sohn, H.J. Mathematical modeling on the corrosion of unprotected structure due to stray current resulting from cathodic protection system. Met. Mater. Int. 1999, 5, 93–99. [Google Scholar] [CrossRef]

- Wang, C.; Li, W.; Wang, Y.; Xu, S.; Fan, M. Stray Current Distributing Model in the Subway System: A review and outlook. Int. J. Electrochem. Sci. 2018, 13, 1700–1727. [Google Scholar] [CrossRef]

- Vranesic, K.; Serdar, M.; Lakusic, S.; Kolár, V.; Mariscotti, A. Dynamic stray current measuring methods in urban areas. Balt. J. Road Bridge Eng. 2022, 17, 146–170. [Google Scholar] [CrossRef]

- Machczyński, W.; Budnik, K.; Szymenderski, J. Assessment of D.C. traction stray currents effects on nearby pipelines. COMPEL 2016, 35, 1468–1477. [Google Scholar] [CrossRef]

- Ogunsola, A.; Mariscotti, A.; Sandrolini, L. Estimation of stray current from a DC-electrified railway and impressed potential on a buried pipe. IEEE Trans. Power Deliv. 2012, 27, 2238–2246. [Google Scholar] [CrossRef]

- Du, G.; Wang, J.; Jiang, X.; Zhang, D.; Yang, L.; Hu, Y. Evaluation of Rail Potential and Stray Current with Dynamic Traction Networks in Multitrain Subway Systems. IEEE Trans. Transp. Electrif. 2020, 6, 784–796. [Google Scholar] [CrossRef]

- Zaboli, A.; Vahidi, B.; Yousefi, S.; Hosseini Biyouki, M.M. Effect of control methods on calculation of stray current and rail potential in DC-electrified railway systems. In Proceedings of the 4th International Conference on Recent Advances in Railway Engineering (ICRARE2015), Tehran, Iran, 17–18 May 2015. [Google Scholar]

- Vranešić, K.; Lakusic, S.; Kolar, V.; Placek, J. Stray current measurement at the tramway infrastructure in Ostrava, Czech Republic. In Proceedings of the 6th International Conference on Road and Rail Infrastructure, Online, 20–21 May 2021; pp. 575–582. [Google Scholar] [CrossRef]

- Peabody, A.W. Peabody’s Control of Pipeline Corrosion, Ronald, L., Bianchetti, P.E., Eds.; 3rd ed.; NACE International: Houston, TX, USA, 2018. [Google Scholar] [CrossRef]

- Szeliga, M.J. Stray Current Corrosion: The Past, Present, and Future of Rail Transit Systems; NACE International: Houston, TX, USA, 1994. [Google Scholar]

- Siranec, M.; Regula, M.; Otcenasova, A.; Altus, J. Measurement and analysis of stray currents. In Proceedings of the 2019 20th International Scientific Conference on Electric Power Engineering (EPE), Kouty nad Desnou, Czech Republic, 15–17 May 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Zakowski, K.; Darowicki, K.; Orlikowski., J.; Jazdzewska, A.; Krakowiak, S.; Gruszka, M. Electrolytic corrosion of water pipeline system in the remote distance from stray currents—Case study. Case Stud. Constr. Mater. 2016, 4, 116–124. [Google Scholar] [CrossRef]

- Alamuti, M.M.; Nouri, H.; Jamali, S. Effects of earthing systems on stray current for corrosion and safety behaviour in practical metro systems. IET Electr. Syst. Transp. 2011, 1, 69–79. [Google Scholar] [CrossRef]

- Juybari, E.Z.; Keypour, R.; Niasati, M. Voltage distribution indices method to analyse the performance of various structures of stray current collectors in direct current transit lines. IET Electr. Syst. Transp. 2021, 11, 322–332. [Google Scholar] [CrossRef]

- Cotton, I.; Charalambous, C.A.; Aylott, P.; Ernst, P. Stray current control in DC mass transit systems. IEEE Trans. Veh. Technol. 2005, 54, 722–730. [Google Scholar] [CrossRef]

- EN 50122-2; Railway Applications—Fixed Installations—Electrical Safety, Earthing and the Return Circuit. Part 2: Provisions against the Effects of Stray Currents Caused by DC Traction Systems. CENELEC: Brussels, Belgium, 2022.

- Vranesic, K.; Bhagat, S.; Mariscotti, A.; Vail, R. Measures and Prescriptions to Reduce Stray Current in the Design of New Track Corridors. Energies 2023, 16, 6252. [Google Scholar] [CrossRef]

- Liu, W.; Li, T.; Zheng, J.; Pan, W.; Yin, Y. Evaluation of the Effect of Stray Current Collection System in DC-Electrified Railway System. IEEE Trans. Veh. Technol. 2021, 70, 6542–6553. [Google Scholar] [CrossRef]

- Yang, X.; Wang, M.; Zheng, T.Q.; Sun, X. Modelling and Simulation of Stray Current in Urban Rail Transit—A Review. Urban Rail Transit 2024, 10, 189–199. [Google Scholar] [CrossRef]

- Zhu, Q.; Cao, A.; Zaifend, W.; Song, J.; Shengli, C. Stray current corrosion in buried pipeline. Anti-Corros. Methods Mater. 2011, 58, 234–237. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Xu, S.; Li, W.; Wang, Y.; Xing, F. Assessment of interference scope induced by stray current in the metro depot for the corrosion risk of buried metal pipeline. Electr. Eng. 2024, 106, 4277–4296. [Google Scholar] [CrossRef]

- Wang, C.; Qin, G. Corrosion of underground infrastructures under metro-induced stray current: A review. Corros. Commun. 2024, 14, 23–38. [Google Scholar] [CrossRef]

- Xu, W.; Li, Y.; Li, H.; Wang, K.; Zhang, C.; Jiang, Y.; Qiang, S. Corrosion mechanism and damage characteristic of steel fiber concrete under the effect of stray current and salt solution. Constr. Build. Mater. 2022, 314, 125618. [Google Scholar] [CrossRef]

- Peng, X.; Huang, Z.; Chen, B.; Liu, D.; Li, H. On the interference mechanism of stray current generated by DC tram on pipeline corrosion. Eng. Fail. Anal. 2020, 116, 104760. [Google Scholar] [CrossRef]

- Lin, S.; Wang, A.; Liu, M.; Lin, X.; Zhou, Q.; Zhao, L. A Multiple Section Model of Stray Current of DC Metro Systems. IEEE Trans. Power Deliv. 2021, 36, 1582–1593. [Google Scholar] [CrossRef]

- Zhou, Q.; Lin, S.; Wu, J. Dynamic stray current evaluation model of metro system considering reversible DC traction power system. Int. J. Rail Transp. 2023, 12, 492–513. [Google Scholar] [CrossRef]

- EN 50162:2004; Protection Against Corrosion by Stray Current from Direct Current Systems. CENELEC: Brussels, Belgium, 2004.

- Liang, H.; Wu, Y.; Han, B.; Lin, N.; Wang, J.; Zhang, Z.; Guo, Y. Corrosion of Buried Pipelines by Stray Current in Electrified Railways: Mechanism, Influencing Factors, and Protection. Appl. Sci. 2025, 15, 264. [Google Scholar] [CrossRef]

- Allahkaram, S.R.; Isakhani-Zakaria, M.; Derakhshani, M.; Samadian, M.; Sharifi-Rasaey, H.; Razmjoo, A. Investigation on corrosion rate and a novel corrosion criterion for gas pipelines affected by dynamic stray current. J. Nat. Gas Sci. Eng. 2015, 26, 453–460. [Google Scholar] [CrossRef]

- Du, G.; Zhang, D.; Li, G.; Wang, C.; Liu, J. Evaluation of rail potential based on power distribution in DC traction power systems. Energies 2016, 9, 729. [Google Scholar] [CrossRef]

- Chuchit, T.; Kulworawanichpong, T. Stray current assessment for DC transit systems based on modelling of earthing and bonding. Electr. Eng. 2019, 101, 81–90. [Google Scholar] [CrossRef]

- Gu, J.; Yang, X.; Zheng, T.; Xia, X.; Chen, M. Rail potential and stray current mitigation for the urban rail transit with multiple trains under multiple conditions. IEEE Trans. Transp. Electrif. 2022, 8, 1684–1694. [Google Scholar] [CrossRef]

- Ormellese, M.; Beretta, S.; Brugnetti, F.; Brenna, A. Effects of non-stationary stray current on carbon steel buried pipelines under cathodic protection. Constr. Build. Mater. 2021, 281, 122645. [Google Scholar] [CrossRef]

- Szymenderski, J.; Machczyński, W.; Budnik, K. Modeling Effects of Stochastic Stray Currents from D.C. Traction on Corrosion Hazard of Buried Pipelines. Energies 2019, 12, 4570. [Google Scholar] [CrossRef]

- Memon, S.A.; Fromme, P. Stray Current Corrosion and Mitigation: A synopsis of the technical methods used in dc transit systems. IEEE Electrif. Mag. 2014, 2, 22–31. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Li, W.; Yang, X.F.; Ye, G.; Fan, Q.G.; Zhang, L.P. Modeling and simulation the distribution of metro stray current. In Proceedings of the 2010 International Conference on Computer Application and System Modeling (ICCASM 2010), Taiyuan, China, 22–24 October 2010; IEEE: Piscataway, NJ, USA, 2010. [Google Scholar] [CrossRef]

- EN ISO 15257:2017-10; Cathodic Protection—Competence Levels of Cathodic Protection Persons—Basis for a Certification Scheme. CENELEC: Brussels, Belgium, 2017.

- Zakowski, K.; Darowicki, K. Methods of evaluation of the corrosion hazard caused by stray currents to metal structures containing aggressive media. Pol. J. Environ. Stud. 2000, 9, 237–241. [Google Scholar]

- Yan, J.; Bai, E.; Xu, J. The calculation of rail potential considering stray current. J. Phys. Conf. Ser. 2024, 2797, 012046. [Google Scholar] [CrossRef]

- Vranešić, K.; Serdar, M.; Lakušić, S. Analysis of electrical potential and stray currents at DC transit system. In Proceedings of the International Conference on Sustainable Materials, Systems and Structures (SMSS 2019), Rovinj, Croatia, 20–22 March 2019. [Google Scholar]

- Wang, C.; Li, W.; Wang, Y.; Xu, S.; Li, K. Evaluation Model for the Scope of DC Interference Generated by Stray Currents in Light Rail Systems. Energies 2019, 12, 746. [Google Scholar] [CrossRef]

- Zhang, J.; Cao, X.; Jin, W.; Zhang, S.; Zhang, B.; Zhang, Y. The Influence of Relative Position on Ground Potential and Electric Field Based on Interfacial Charge Accumulation in HVDC. IEEJ Trans. Elec. Electron. Eng. 2025, 20, 29–40. [Google Scholar] [CrossRef]

- Steinmetz, T.; Helias, M.; Wimmer, G.; Fichte, L.O.; Clemens, M. Electro-Quasistatic Field Simulations Based on a Discrete Electromagnetism Formulation. IEEE Trans. Magn. 2006, 42, 755–758. [Google Scholar] [CrossRef]

- Regula, M.; Siranec, M.; Otcenasova, A.; Hoger, M. Possibilities of the stray current measurement and corrosive risk evaluation. Electr. Eng. 2022, 104, 2497–2513. [Google Scholar] [CrossRef]

- Zhiguang, C.; Chaokui, Q.; Jixu, T.; Yu, Z. Analyzing of Stray Current Interference on Buried Gas Pipeline from Shanghai Urban Rail Transit. Res. J. Appl. Sci. Eng. Technol. 2013, 5, 4421–4426. [Google Scholar] [CrossRef]

- Zakowski, K.; Sokolski, W. 24-hour characteristic of interaction on pipelines of stray currents leaking from tram tractions. Corros. Sci. 1999, 41, 2099–2111. [Google Scholar] [CrossRef]

- Buchler, M.; Joos, D. Assessing the corrosion risk caused by DC interference on cathodically protected pipelines. In Proceedings of the EUROCORR 2019 The Annual Congress of the European Federation of Corrosion, Seville, Spain, 9–13 September 2019. [Google Scholar]

- Chen, Y.; Wang, F.; Zou, G.; Sun, W.; Li, C. Study on corrosion behaviour of X65 steel of buried pipeline under dynamic stray current interference. AIP Adv. 2025, 15, 065005. [Google Scholar] [CrossRef]

- Qin, H.; Du, Y.; Lu, M.; Liu, J.; Zhu, X. Accelerated corrosion of pipeline steel under dynamic DC stray current interference. Corros. Eng. Sci. Technol. 2020, 55, 670–680. [Google Scholar] [CrossRef]

- Vranešić, K.; Lakušić, S.; Serdar, M. Corrosion and stray currents at urban track infrastructure. GRADEVINAR 2020, 72, 593–600. [Google Scholar] [CrossRef]

- Darowicki, K.; Zakowski, K. A new time-frequency detection method of stray current field interference on metal structures. Corros. Sci. 2004, 46, 1061–1070. [Google Scholar] [CrossRef]

- Zakowski, K. The determination and identification of stray current source influences on buried pipelines using time/frequency analysis. Anti-Corros. Methods Mater. 2009, 56, 330–333. [Google Scholar] [CrossRef]

- Mujezinović, A.; Martinez, S. Application of the continuous wavelet cross-correlation between pipe-to-soil potential and pipe-to-rail voltage influenced by dynamic stray current from DC train traction. IEEE Trans. Power Deliv. 2021, 36, 1015–1023. [Google Scholar] [CrossRef]

- Quian, S.; Chen, D. Join Time-Frequency Analysis. Methods and Applications; Prentice Hall PTR: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Ramirez, R. The FFT Fundamentals and Concepts; Tektronix Inc.: Englewood Cliffs, NJ, USA, 1985. [Google Scholar]

- Allen, R.L.; Mills, D.W. Signal Analysis. Time, Frequency, Scale, and Structure; IEEE Press (Wiley-Interscience): New York, NY, USA, 2004. [Google Scholar]

- Carmona, R.; Hwang, W.-L.; Torresani, B. Practical Time-Frequency Analysis. In Wavelet Analysis and Its Applications; Academic Press: New York, NY, USA, 1998. [Google Scholar]

- Sun, X.; Yang, X.; Zhao, R.; Wang, Z.; Chen, M.; Zheng, T.Q. S-Transform Based Time-Frequency Evaluation of Dynamic Stray Current in Zero-Resistance Converter System. Energies 2025, 18, 1594. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, S.; Gan, T.; Qiu, Y.; Song, Q.; Zhao, Y. Frequency characteristics analysis of pipe-to-soil potential under metro stray current interference using continuous wavelet transform method. Constr. Build. Mater. 2023, 407, 133453. [Google Scholar] [CrossRef]

- Machczyński, W. Simulation model for drainage protection of earth-return circuits laid in stray currents area. Electr. Eng. 2002, 84, 165–172. [Google Scholar] [CrossRef]

- Zakowski, K.; Darowicki, K. Detection of stray current field interference on metal constructions using STFT. In Proceedings of the 6th International Conference on Damage Assessment of Structures (DAMAS 2005), Gdansk, Poland, 4–6 July 2005; Volume 293–294, pp. 785–791. [Google Scholar]

- Guo, Y.; Ding, J.; Li, X.; Li, J. Study of Impressed Current Cathodic Protection (ICCP) on the Steel Pipeline under DC Stray Current Interference. Int. J. Electrochem. Sci. 2021, 16, 210547. [Google Scholar] [CrossRef]

- Kolbadinejad, M.; Zabihollah, A.; Khayyat, A.; Mahmoud, M.O. An equivalent electrical circuit design for pipeline corrosion monitoring based on piezoelectric elements. J. Mech. Sci. Technol. 2013, 27, 799–804. [Google Scholar] [CrossRef]

- EN 13509:2003; Cathodic Protection Measurement Techniques. CENELEC: Brussels, Belgium, 2003.

- Thakur, A.; Kumar, A.; Kumar, A.; Pushpa, S. Prediction and mitigation of AC interference on the pipeline system. Corros. Rev. 2022, 40, 149–157. [Google Scholar] [CrossRef]

- Farahani, E.M.; Su, Y.; Chen, X.; Wang, H.; Laughorn, T.R.; Onesto, F.; Zhou, Q.; Huang, Q. AC corrosion of steel pipeline under cathodic protection: A state-of-the-art review. Mater. Corros. 2024, 75, 290–314. [Google Scholar] [CrossRef]

- Thakur, A.; Kumar, A.; Kumar, A.; Pushpa, S. The science of alternating current-induced corrosion: A review of literature on pipeline corrosion induced due to high-voltage alternating current transmission pipelines. Corros. Rev. 2020, 38, 463–472. [Google Scholar] [CrossRef]

- ISO 18086; Corrosion of Metals and Alloys—Identification of Corrosion Induced by Alternating Current—Protection Criteria. CENELEC: Brussels, Belgium, 2019.

| Method and Time for Obtaining Conclusions | Typical Application Case | Advantages | Disadvantages |

|---|---|---|---|

| Rails’ Potential Testing immediate conclusions | preliminary identification of the risk of stray currents when: - designing the gas pipeline route, - it is impossible to connect the measuring cables to the pipeline. | - no complicated measuring equipment is required, - the measurements are simple to perform, - the method can be used by basic cathodic protection personnel, - low cost of testing. | - information obtained is for exploratory purposes only, - it only determines the probability of harmful impacts, which may differ depending on actual pipelines (unknown distribution of stray currents in the field after the construction of the gas pipeline network). |

| Electric Field Gradients on the Ground Surface immediate conclusions | determining the anodic zones of the gas pipeline along its route | - no complicated measuring equipment is required, - the measurements are simple to perform, - the method can be used by basic cathodic protection personnel, - low cost of testing. | - sensitivity of measurement results to foreign electric fields, - non-homogeneous soil resistivity has the potential to affect electric field gradients. |

| Correlation E = f(U) conclusions after analyzing the data in the laboratory | - determining the magnitude of electrolytic corrosion risk of the gas pipeline at the measurement site, - determining whether electrochemical protection of the gas pipeline at the measurement site is necessary, - evaluating the effectiveness of the gas pipeline’s stray current protection system: polarized drainage, ICCP, or sacrificial anodes. | - it provides clear results regarding the magnitude of the stray current hazard (potential change asymmetry coefficient), - the hazard criterion is related to the time domain, not to potential values; therefore, changes in ground resistivity do not affect the obtained results. | - application of this method requires specialized training, - proper analysis of correlation graphs requires extensive experience, - the costs are higher than in previous methods due to the need to use two-channel recorders and software for analyzing the results. |

| Correlation U = f(E) conclusions after analyzing the data in the laboratory | determining the place of greatest impact on the section of the gas pipeline running along the traction line | - measurements easy to perform by trained personnel, - no need for specialized software. | - sensitivity of measurement results to changes in soil resistivity along the tested section of the gas pipeline, - in the case of gas pipelines with high insulation tightness, the measurement results are closely related to the location of insulation defects—there is a possibility of misinterpretation of the beta profile. |

| Time-Frequency Analysis conclusions only after analyzing the data in the laboratory | - determining which stray current source is affecting the gas pipeline (e.g., tram or railway traction), - determining the range of the stray current source’s impact on the gas pipeline (testing remote pipeline sections). | - ease of performing field measurements. | - high costs associated with the equipment recording the measured signals and the software for time-frequency analysis, - advanced post-processing, complicated time-frequency analysis procedures, - obtained results do not provide information about the type of stray current interaction (anodic or cathodic). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żakowski, K.; Szociński, M.; Krakowiak, S. Assessment Methods for DC Stray Current Corrosion Hazards in Underground Gas Pipelines: A Review Focused on Rail Traction Systems. Energies 2025, 18, 5570. https://doi.org/10.3390/en18215570

Żakowski K, Szociński M, Krakowiak S. Assessment Methods for DC Stray Current Corrosion Hazards in Underground Gas Pipelines: A Review Focused on Rail Traction Systems. Energies. 2025; 18(21):5570. https://doi.org/10.3390/en18215570

Chicago/Turabian StyleŻakowski, Krzysztof, Michał Szociński, and Stefan Krakowiak. 2025. "Assessment Methods for DC Stray Current Corrosion Hazards in Underground Gas Pipelines: A Review Focused on Rail Traction Systems" Energies 18, no. 21: 5570. https://doi.org/10.3390/en18215570

APA StyleŻakowski, K., Szociński, M., & Krakowiak, S. (2025). Assessment Methods for DC Stray Current Corrosion Hazards in Underground Gas Pipelines: A Review Focused on Rail Traction Systems. Energies, 18(21), 5570. https://doi.org/10.3390/en18215570