Environmental and Economic Optimisation of Single-Family Buildings Thermomodernisation

Abstract

1. Introduction

2. Research Methodology

- ISO 6946 “Building components and building elements–Thermal resistance and thermal transmittance–Calculation methods”–the standard for calculating thermal transmittance coefficients of multilayer walls [46].

- ISO 13370 “Thermal performance of buildings–Heat transfer via the ground–Calculation methods”–the standard for calculating thermal transmittance of building elements in contact with the ground [47].

- ISO 10077-1 “Thermal performance of windows, doors and shutters–Calculation of thermal transmittance” [48].

- ISO 12831 “Heating systems in buildings. Method for calculation of the design heat load”–the standard for calculating the heat load of a building [49].

- ISO 13788 “Hygrothermal performance of building components and building elements. Internal surface temperature to avoid critical surface humidity and interstitial condensation. Calculation methods”–the standard for analysing the humidity of building elements [50].

- Journal of Laws [Dz. U.] of 2015 item 376: Regulation of the Minister of Infrastructure and Development of 27 February 2015 on the methodology for determining the energy performance of a building or part of a building and certificates [51].

- Journal of Laws [Dz. U.] of 2023 item 697: Regulation of the Minister of Development and Technology of 13 April 2023 changing Regulation of the Minister of Infrastructure and Development of 27 February 2015 on the methodology for determining the energy performance of a building or part of a building and energy performance certificates [52].

2.1. Energy Analysis

2.2. Economic Analysis

2.3. Environmental Analysis

3. Results

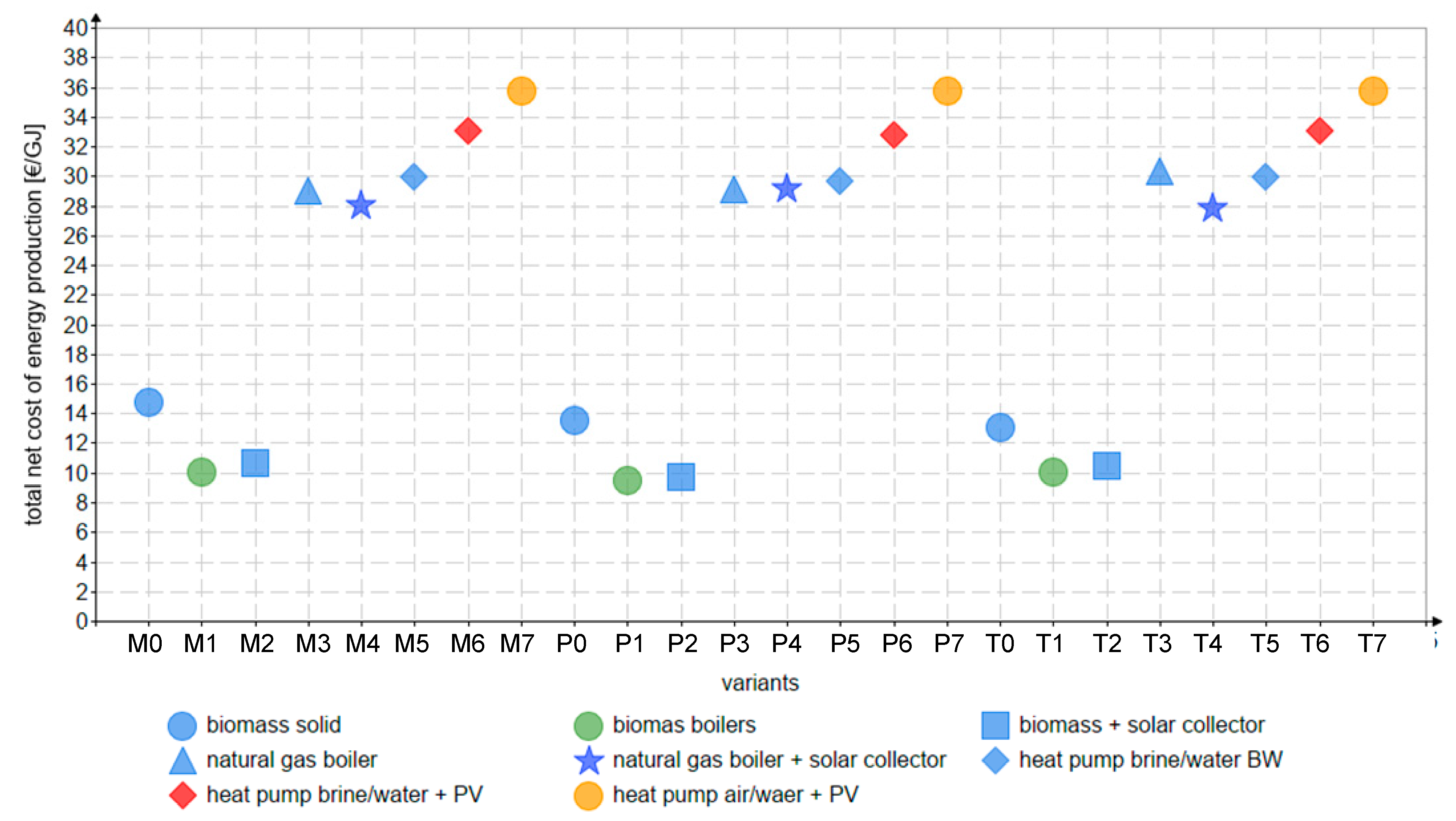

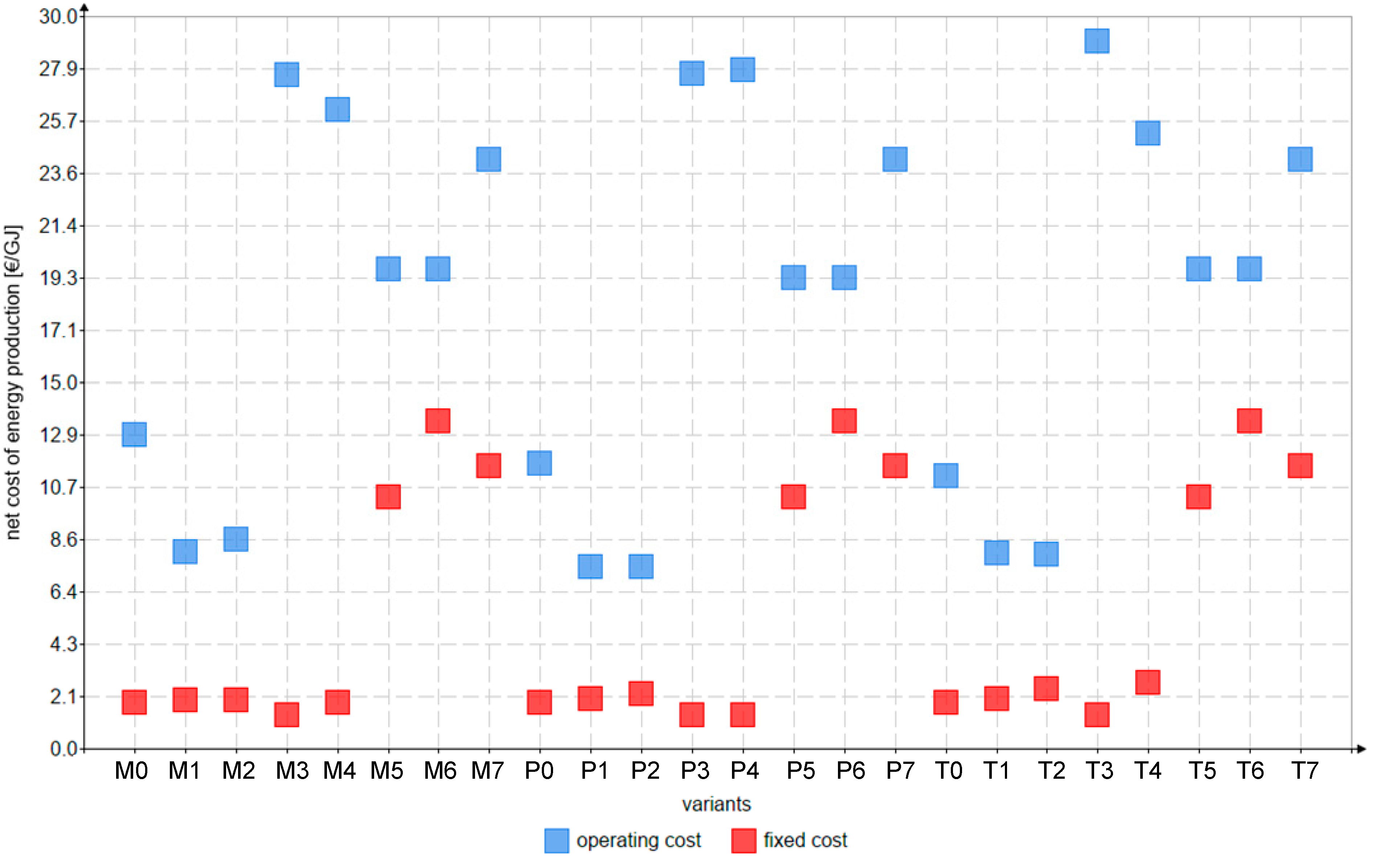

3.1. Economic Analysis Results

3.2. Environmental Analysis Results

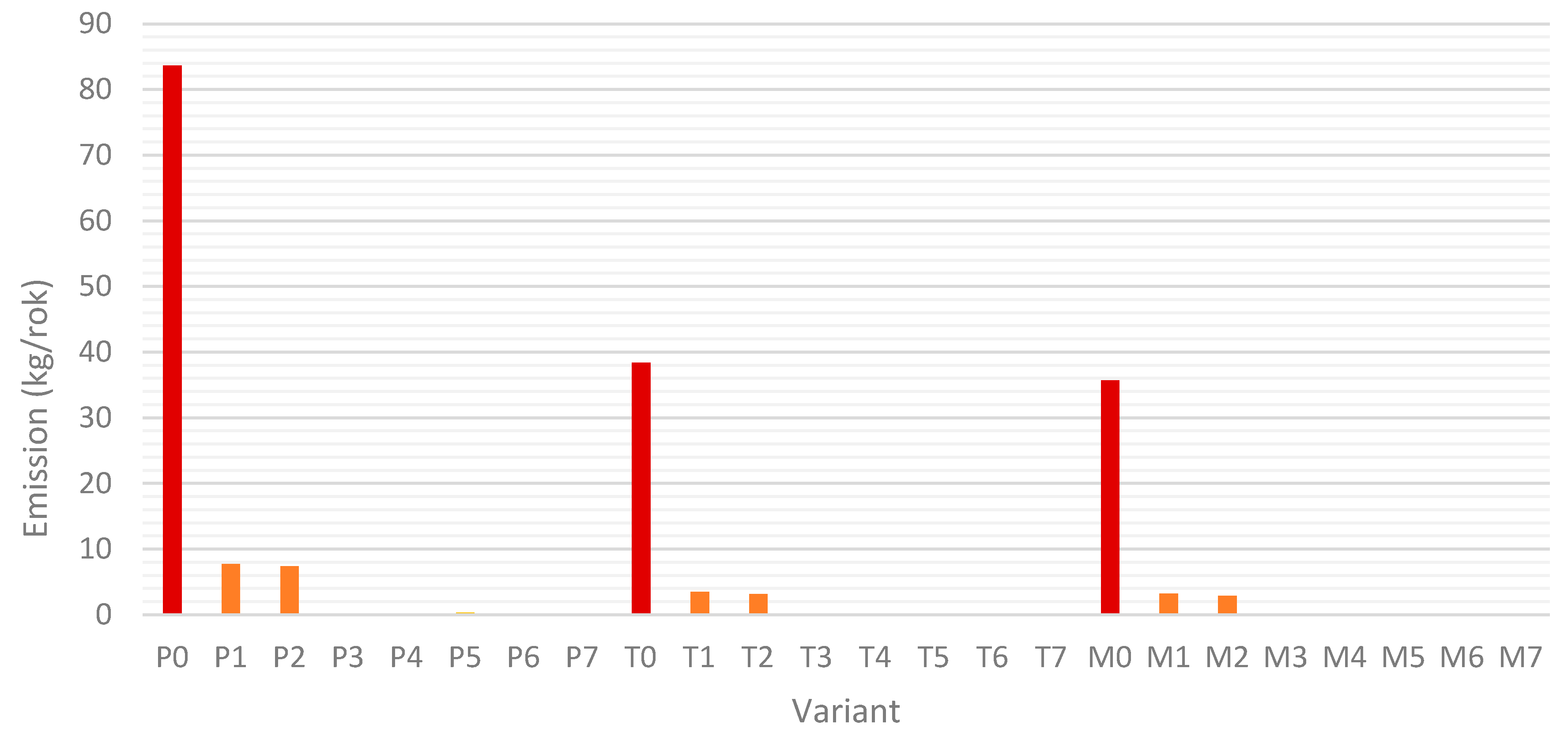

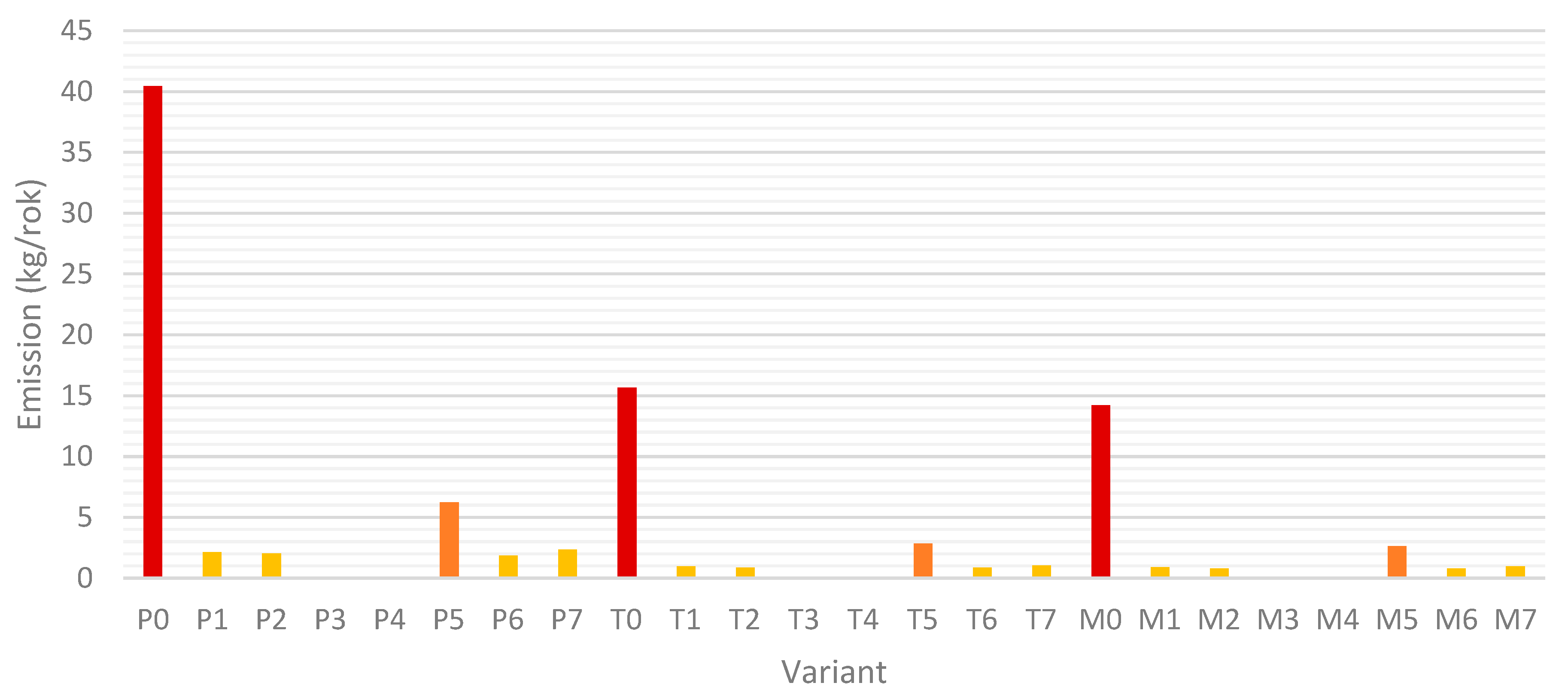

- Total Suspended Particles (TSP): The energy renovation options utilising gas-fired boilers and heat pumps demonstrate the most significant reductions in TSP emissions. Options P3 and P4 achieve a remarkable 99.9% reduction, while options T3, T4, M3, and M4 approach near-total reductions of nearly 100%, as illustrated in Figure 7.

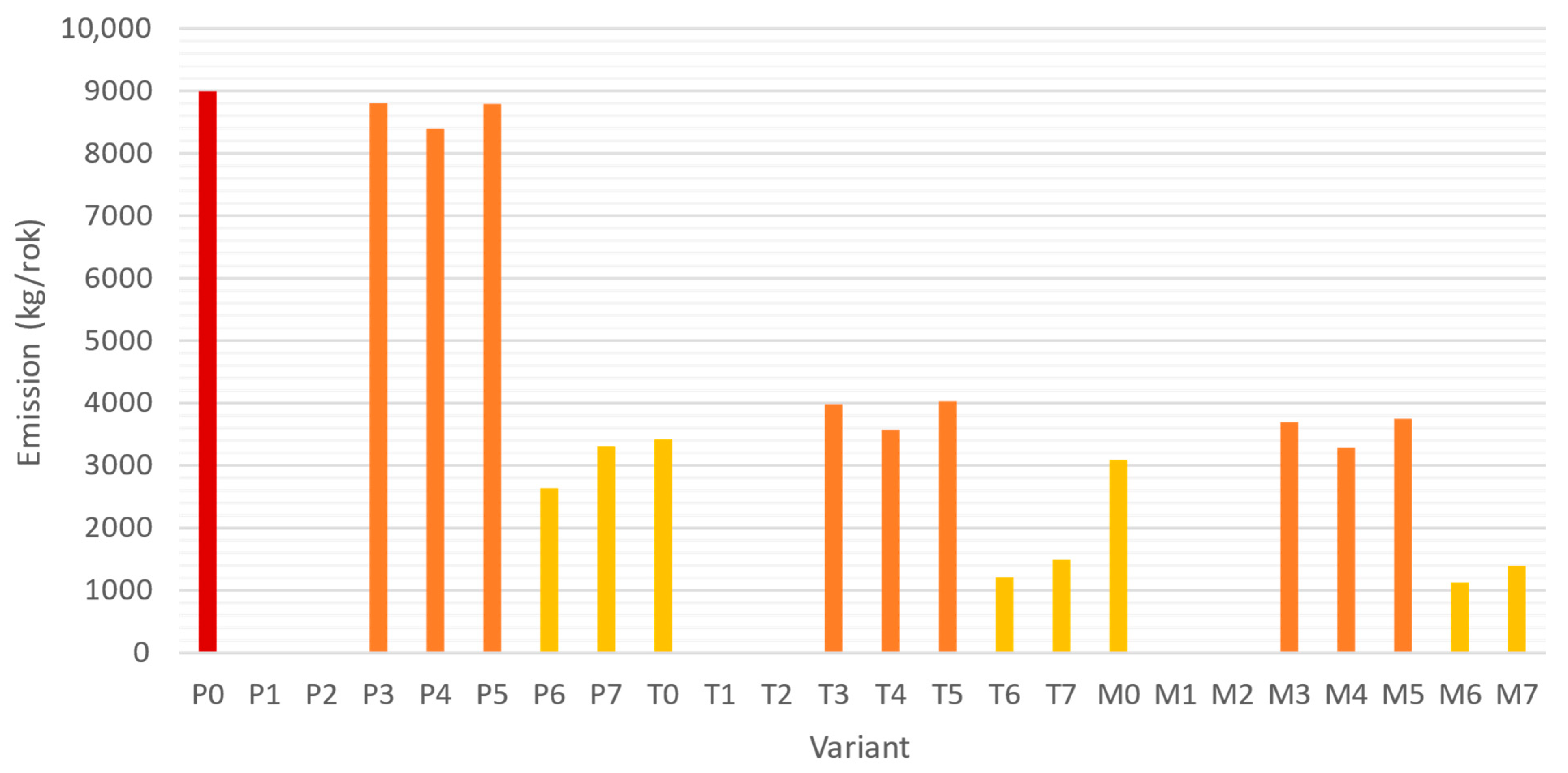

- Carbon Dioxide (CO2): The highest reduction of 100% in CO2 emissions is linked to biomass-fired boiler options (P1–P2, T1–T2, M1–M2). Furthermore, energy renovation options employing heat pumps powered by photovoltaic (PV) installations (P6–P7, T6–T7, M6–M7) result in substantial CO2 reductions, ranging from 63.2% to 87.5% compared to the P0 baseline option. This analysis assumes a 70% contribution of PV electricity to the heat pump operation.

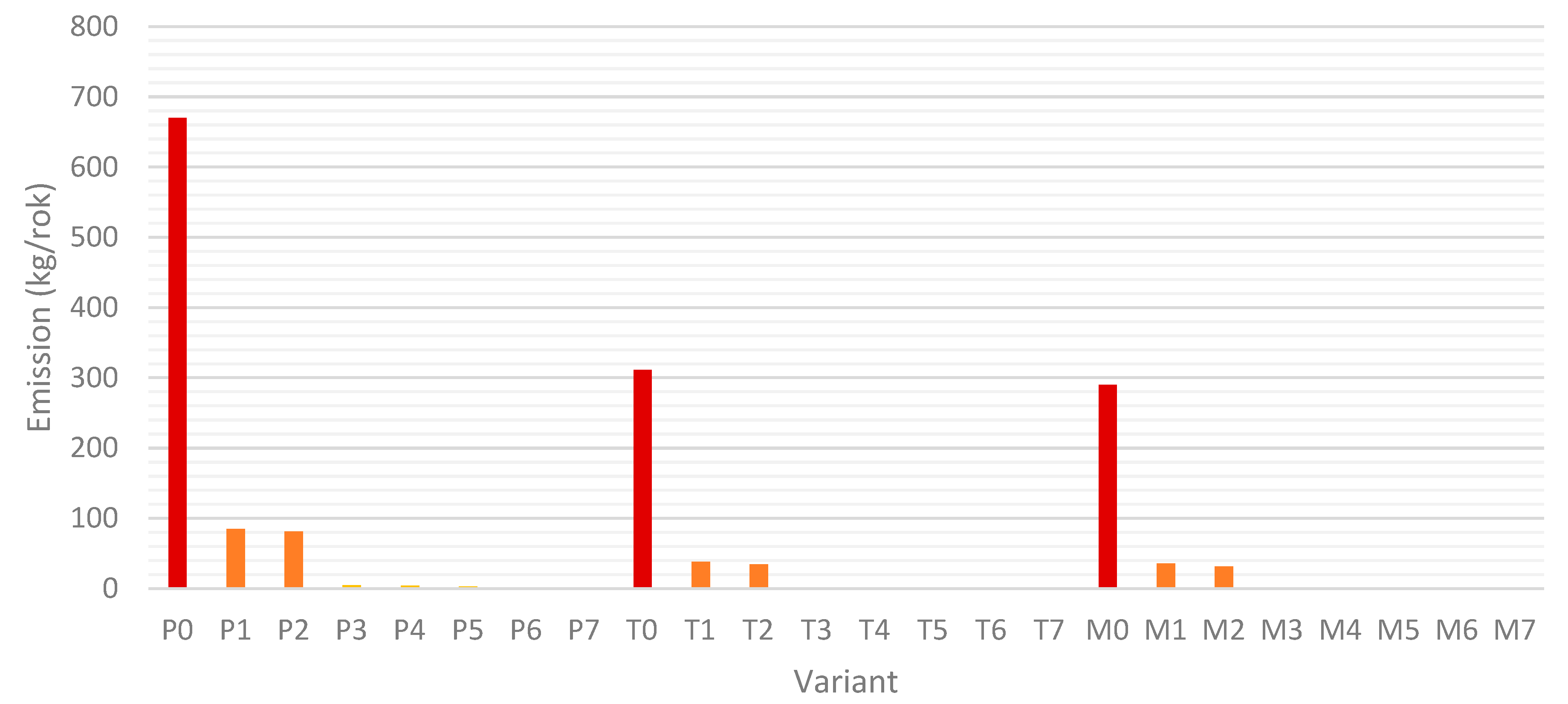

- Carbon Monoxide (CO): All options involving a switch in heat sources exhibit significant reductions in CO emissions, ranging from 87.3% for biomass-fired boilers to 99.9% for heat pumps powered by photovoltaics.

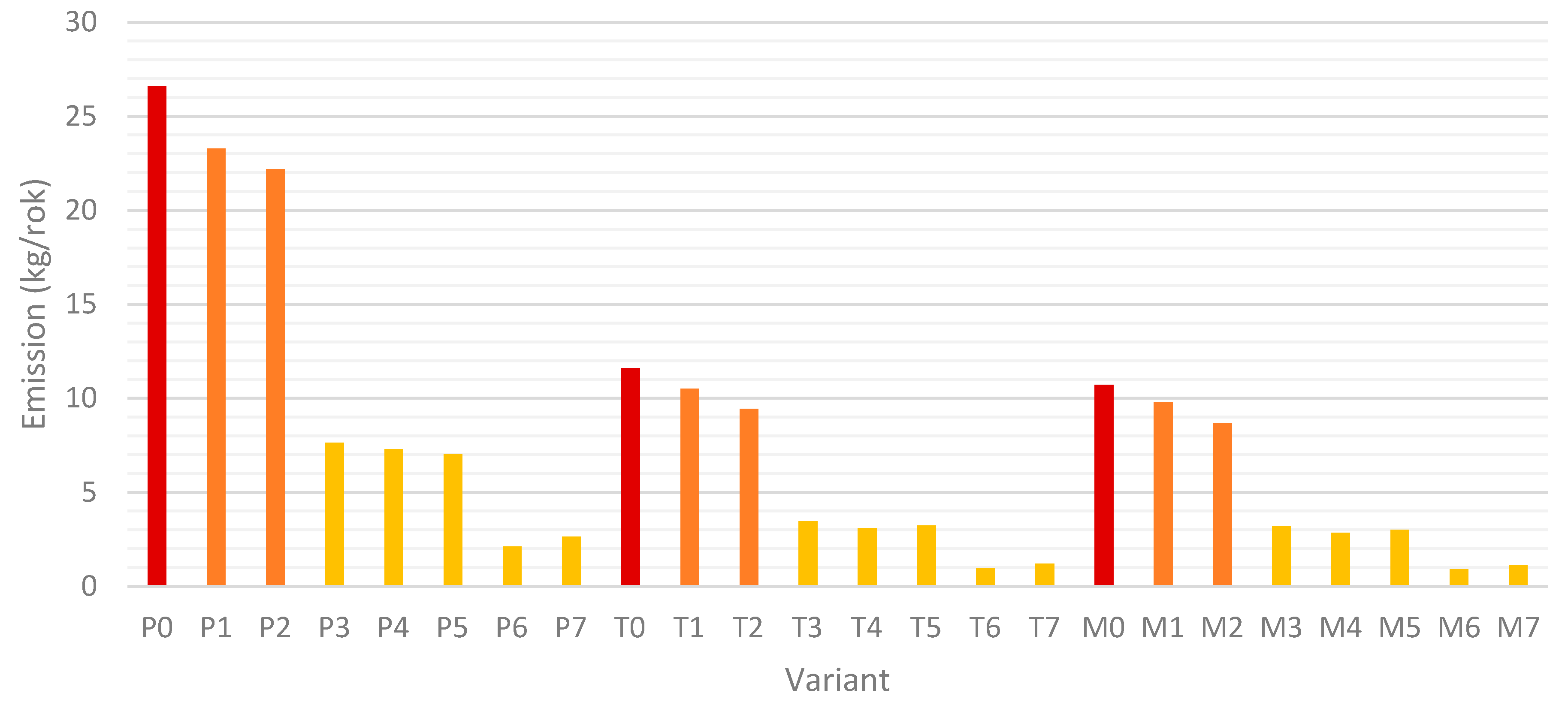

- Nitrogen Oxides (NOx): The most effective options for reducing nitrogen oxide emissions are those that employ heat pumps in conjunction with photovoltaics, achieving reductions between 90% and 96.6%. Options utilising gas-fired boilers (P3, P4, T3, T4, M3, and M4) also yield notable reductions, varying from 71.3% to 87.9%.

- Benzo(a)pyrene (BaP): The analysis indicates that all energy renovation options that involve switching heat sources result in a minimum reduction of 94.4% in BaP emissions for biomass-fired boilers, with reductions reaching up to 100% for gas-fired boilers and heat pumps.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| B(a)P | benzo(a)pyrene |

| CO | carbon monoxide |

| NOx | nitrogen oxides |

| CO2 | carbon dioxide |

| COP | heat pump coefficient of performance |

| ECO2 | carbon dioxide emission |

| EK | final energy |

| EP | primary energy |

| EU | useful energy |

| EPC | Energy Performance Certificate |

| GHG | greenhouse gases |

| LCCA | life cycle cost analysis |

| NPV | net present value |

| PM10 | particulate matter ≤ 10 µg |

| PM2.5 | particulate matter ≤ 2.5 µg |

| PV | photovoltaic |

| RES | renewable energy source |

| SO2 | sulphur dioxide |

| SPBT | simple payback time |

| URES | share of renewable energy sources in annual final energy demand |

| Q | seasonal energy consumption [GJ/year, MWh/year] |

| Qw | calorific value |

| W | emission factor [g/GJ, kg/MWh] |

| WT2021 | technical conditions for new buildings created from 2021 |

| WT2017 | technical conditions for buildings that have been created in 2017–2020 |

References

- Capros, P.; Zazias, G.; Evangelopoulou, S.; Kannavou, M.; Fotiou, T.; Siskos, P.; De Vita, A.; Sakellaris, K. Energy-system modelling of the EU strategy towards climate-neutrality. Energy Policy 2019, 134, 110960. [Google Scholar] [CrossRef]

- Kilkis, S.; Krajacic, G.; Duic, N.; Rosen, M.A.; Al-Nimr, M.A. Advances in integration of energy, water and environment systems towards climate neutrality for sustainable development. Energy Convers. Manag. 2020, 225, 113410. [Google Scholar] [CrossRef]

- Salvia, M.; Reckien, D.; Pietrapertosa, F.; Eckersley, P.; Spyridaki, N.A.; Krook-Riekkola, A.; Olazabal, M.; De Gregorio Hurtado, S.; Simoes, S.G.; Geneletti, D.; et al. Will climate mitigation ambitions lead to carbon neutrality? An analysis of the local-level plans of 327 cities in the EU. Renew. Sustain. Energy Rev. 2021, 135, 11025. [Google Scholar] [CrossRef]

- Oudes, D.; Stremke, S. Spatial transition analysis: Spatially explicit and evidence-based targets for sustainable energy transition at the local and regional scale. Landsc. Urban Plan. 2018, 169, 1–11. [Google Scholar] [CrossRef]

- Kaczmarczyk, M.; Sowiżdżał, A.; Tomaszewska, B. Energetic and Environmental Aspects of Individual Heat Generation for Sustainable Development at a Local Scale—A Case Study from Poland. Energies 2020, 13, 454. [Google Scholar] [CrossRef]

- Kaczmarczyk, M. Building energy characteristic evaluation in terms of energy efficiency and ecology. Energy Convers. Manag. 2024, 306, 118284. [Google Scholar] [CrossRef]

- Tettey, U.; Dodoo, A.; Gustavsson, L. Primary energy implications of different design strategies for an apartment building. Energy 2016, 104, 132–148. [Google Scholar] [CrossRef]

- Guarino, F.; Cellura, M.; Longo, S.; Gulotta, T.; Mistretta, M.; Tumminia, G.; Ferraro, M.; Antonucci, V. Integration of building simulation and life cycle assessment: A TRNSYS application. Energy Procedia 2016, 101, 360–367. [Google Scholar] [CrossRef]

- Jiang, Z.; Risbeck, M.J.; Ramamurti, V.; Murugesan, S.; Amores, J.; Zhang, C.; Lee, Y.M.; Drees, K.H. Building HVAC control with reinforcement learning for reduction of energy cost and demand charge. Energy Build. 2021, 239, 110833. [Google Scholar] [CrossRef]

- Gibbons, L.; Javed, S. A review of HVAC solution-sets and energy performance of nearly zero-energy multi-story apartment buildings in Nordic climates by statistical analysis of environmental performance certificates and literature review. Energy 2022, 238, 121709. [Google Scholar] [CrossRef]

- Zhou, S.L.; Shah, A.A.; Leung, P.K.; Zhu, X.; Liao, Q. A comprehensive review of the applications of machine learning for HVAC. DeCarbon 2023, 2, 100023. [Google Scholar] [CrossRef]

- Zhang, F.; Saeed, N.; Sadeghian, P. Deep learning in fault detection and diagnosis of building HVAC systems: A systematic review with meta analysis. Energy AI 2023, 12, 100235. [Google Scholar] [CrossRef]

- Liang, X.; Chen, K.; Chen, S.; Zhu, X.; Jin, X.; Du, Z. IoT-based intelligent energy management system for optimal planning of HVAC devices in net-zero emissions PV-battery building considering demand compliance. Energy Convers. Manag. 2023, 292, 117369. [Google Scholar] [CrossRef]

- Wang, C.; Ferrando, M.; Causone, F.; Jin, X.; Zhou, X.; Shi, X. An innovative method to predict the thermal parameters of construction assemblies for urban building energy models. Build. Environ. 2022, 224, 109541. [Google Scholar] [CrossRef]

- Askeland, M.; Georges, L.; Korpas, M. Low-parameter linear model to activate the flexibility of the building thermal mass in energy system optimization. Smart Energy 2023, 9, 100094. [Google Scholar] [CrossRef]

- Kaczmarczyk, M. Energy environmental matrix for buildings energy performance certificate evaluation. Energy Build. 2025, 341, 115859. [Google Scholar] [CrossRef]

- Wi, S.; Kang, Y.; Yang, S.; Kim, Y.U.; Kim, S. Hazard evaluation of indoor environment based on long-term pollutant emission characteristics of building insulation materials: An empirical study. Environ. Pollut. 2021, 285, 117223. [Google Scholar] [CrossRef]

- Anh, L.-D.H.; Pasztory, Z. An overview of factors influencing thermal conductivity of building insulation materials. J. Build. Eng. 2021, 44, 102604. [Google Scholar] [CrossRef]

- Edelenbosch, O.Y.; Rovelli, D.; Levesque, A.; Marangoni, G.; Tavoni, M. Long term, cross-country effects of buildings insulation policies. Technol. Forecast. Soc. Change 2021, 170, 120887. [Google Scholar] [CrossRef]

- Lim, T.; Yim, W.S.; Kim, D.D. Evaluation of Daylight and Cooling Performance of Shading Devices in Residential Buildings in South Korea. Energies 2020, 13, 4749. [Google Scholar] [CrossRef]

- Błazy, R.; Błachut, J.; Ciepiela, A.; Łabuz, R.; Papież, R. Thermal Modernization Cost and the Potential Ecological Effect—Scenario Analysis for Thermal Modernization in Southern Poland. Energies 2021, 14, 2023. [Google Scholar] [CrossRef]

- Lis, A.; Ujma, A. Redukcja emisji pyłów zawieszonych w wyniku poprawy izolacyjności cieplnej przegród i zmiany nośnika energii. Reducing of particulate matter emissions as a result of walls thermal insulation improvement and energy carriers changes. Constr. Optimazed Energy Potential 2016, 1, 47–54. [Google Scholar]

- Kim, Y.; Yu, K.H. Study on the certification policy of zero-energy buildings in Korea. Sustainability 2020, 12, 5172. [Google Scholar] [CrossRef]

- Yousefi, M.; Hajizadeh, A.; Soltani, M.N.; Hredzak, B.; Kianpoor, N. Profit assessment of home energy management system for buildings with A-G energy labels. Appl. Energy 2020, 277, 115618. [Google Scholar] [CrossRef]

- Andelkovic, A.S.; Kljajić, M.; Macura, D.; Munćan, V.; Mujan, I.; Tomić, M.; Stepanov, B. Building energy performance certificate—A relevant indicator of actual energy consumption and savings? Energies 2021, 14, 3455. [Google Scholar] [CrossRef]

- Conticelli, E.; Falcioni, S.; Marzani, G.; Morini, G.L.; Tondelli, S. Assessing energy efficiency at urban scale through the use of energy performance certificates: An application in the Emilia-Romagna region, Italy. Cities 2024, 145, 104728. [Google Scholar] [CrossRef]

- Manso-Burgos, A.; Ribo-Perez, D.; Van As, J.; Montagud-Montalva, C.; Royo-Pastor, R. Diagnosis of the building stock using Energy Performance Certificates for urban energy planning in Mediterranean compact cities. Case of study: The city of Valencia. in Spain. Energy Convers. Manag. X 2023, 20, 100450. [Google Scholar] [CrossRef]

- Kaczmarczyk, M.; Sowiżdżał, A. Environmental friendly energy resources improving air quality in urban area. Energy Rep. 2024, 11, 3383–3394. [Google Scholar] [CrossRef]

- Dzikuć, M. Problems associated with the low emission limitation in Zielona Góra (Poland): Prospects challenges. J. Clean. Prod. 2017, 166, 81–87. [Google Scholar] [CrossRef]

- Dzikuć, M.; Piwowar, A.; Szufa, S.; Adamczyk, J.; Dzikuć, M. Potential and Scenarios of Variants of Thermo-Modernization of Single-Family Houses: An Example of the Lubuskie Voivodeship. Energies 2021, 14, 191. [Google Scholar] [CrossRef]

- Piotrowska-Woroniak, J.; Woroniak, G. Redukcja emisji zanieczyszczeń w wyniku termomodernizacji zabytkowych obiektów sakralnych. Reduction of emission pollution as a result of thermomodernisation historic sacral buildings. Civ. Environ. Eng. 2014, 5, 73–77. [Google Scholar]

- Piccardo, C.; Gustavsson, L. Implications of different modelling choices in primary energy and carbon emission analysis of buildings. Energy Build. 2021, 247, 111145. [Google Scholar] [CrossRef]

- Alvarez Florez, L.; Pean, T.; Salom, J. Hourly based methods to assess carbon footprint flexibility and primary energy use in decarbonized buildings. Energy Build. 2023, 294, 113213. [Google Scholar] [CrossRef]

- Ramon, D.; Allacker, K.; Trigaux, D.; Wouters, H.; Lipzig, N.P.M. Dynamic modelling of operational energy use in a building LCA: A case study of a Belgian office building. Energy Build. 2023, 278, 112634. [Google Scholar] [CrossRef]

- Staniunas, M.; Medineckiene, M.; Zavadskas, E.; Kalibatas, D. To modernize or not: Ecological-economical assessment of multi-dwelling houses modernization. Archiv. Civ. Mech. Eng. 2013, 13, 88–98. [Google Scholar] [CrossRef]

- Basińska, M.; Koczyk, H.; Kosmowski, A. Assessment of thermo modernization using the global cost method. Energy Procedia 2015, 78, 2040–2045. [Google Scholar] [CrossRef]

- Szulgowska-Zgrzywa, M.; Piechurski, K.; Stefanowicz, E. Multi-criteria assessment of the scenarios of changing the heating system in apartments in historical buildings in Wroclaw (Poland)—Case study. Energy Build. 2022, 254, 111611. [Google Scholar] [CrossRef]

- Hajto, M.; Kaczmarczyk, M. The potential to improve air quality by increasing the use of deep geothermal energy. Geol. Geophys. Environ. 2022, 48, 147–175. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Q.; Dong, Z.; Li, X.; Li, G.; Li, K. Quantitative evaluation of the building energy performance based on short-term energy predictions. Energy 2021, 223, 120065. [Google Scholar] [CrossRef]

- Andrews, A.; Jain, R.K. Beyond Energy Efficiency: A clustering approach to embed demand flexibility into building energy benchmarking. Appl. Energy 2022, 327, 119989. [Google Scholar] [CrossRef]

- Shimoda, Y.; Yamaguchi, Y.; Iwafune, Y.; Hidaka, K.; Meier, K.; Yagita, Y.; Kawamoto, H.; Nishikiori, S. Energy demand science for a decarbonized society in the context of the residential sector. Renew. Sustain. Energy Rev. 2020, 132, 110051. [Google Scholar] [CrossRef]

- Kaczmarczyk, M.; Kaczmarczyk, M.A.; Pełka, G.; Luboń, W.; Będkowska, A.; Piechowicz, Ł.; Ciapała, B.; Blok, M. Niska Emisja od Przyczyn Występowania do Sposobów Eliminacji [Low-Stack Emissions: Causes and Methods of Elimination]; Geosystem Burek, Kotyza S.C.: Kraków, Poland, 2015. [Google Scholar]

- Kaczmarczyk, M.; Kaczmarczyk, M.A.; Pełka, G.; Luboń, W.; Będkowska, A.; Ciapała, B.; Malik, D.; Podlewska, E.; Zboina, M. Niska Emisja—Efektywność Energetyczna w Gminach i Samorządach [Low-Stack Emissions: Energy Efficiency in Municipalities and Local Governments]; Globenergia Sp. z o.o.: Kraków, Poland, 2017. [Google Scholar]

- POP. Program Ochrony Powietrza Dla Województwa Małopolskiego, Urząd Marszałkowski Województwa Małopolskiego [Air Protection Programme for the Małopolska Province, Marshal’s Office of the Małopolska Province], Kraków. 2017. Available online: https://powietrze.malopolska.pl/program-ochrony-powietrza (accessed on 6 August 2025).

- GUS. 2024: Zużycie Nośników Energii w Gospodarstwach Domowych w 2021 r.; Główny Urząd Statystyczny: Warszawa, Poland, 2024. [Google Scholar]

- ISO 6946; “Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Methods”—The Standard for Calculating Thermal Transmittance Coefficients of Multilayer Walls. ISO: Geneva, Switzerland, 2017.

- ISO 13370; Thermal Performance of Buildings—Heat Transfer via the Ground—Calculation Methods. ISO: Geneva, Switzerland, 2017.

- ISO 10077-1; Thermal Performance of Windows, Doors and Shutters—Calculation of Thermal Transmittance. ISO: Geneva, Switzerland, 2017.

- EN 12831:2006; Heating systems in buildings—Method for calculating the design heat load. ISO: Geneva, Switzerland, 2006.

- ISO 13788; Hydrothermal Performance of Building Components and Building Elements. Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation. Calculation Methods. ISO: Geneva, Switzerland, 2012.

- Journal of Laws [Dz. U.] of 2015 Item 376: Rozporządzenie Ministra Infrastruktury i Rozwoju z Dnia 27 Lutego 2015 r. w Sprawie Metodologii Wyznaczania Charakterystyki Energetycznej Budynku lub Części Budynku oraz Świadectw [Regulation of the Minister of Infrastructure and Development of 27 February 2015 on the Methodology for Determining the Energy Performance of a Building or Part of a Building and Certificates]. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20150000376 (accessed on 6 August 2025).

- Journal of Laws [Dz. U.] of 2023 Item 697: Regulation of the Minister of Development and Technology of 13 April 2023 Changing Regulation of the Minister of Infrastructure and Development of 27 February 2015 on the Methodology for Determining the Energy Performance of a Building or Part of a Building and Energy Performance Certificates. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20230000697 (accessed on 6 August 2025).

- Journal of Laws [Dz. U.] of 2017 Item 2285: Rozporządzenie Ministra Infrastruktury i Budownictwa z Dnia 14 Listopada 2017 r. Zmieniające Rozporządzenie w Sprawie Warunków Technicznych, Jakim Powinny Odpowiadać Budynki i Ich Usytuowanie [Regulation of the Minister of Infrastructure and Construction of 14 November 2017 Amending the Regulation on Technical Conditions to be Met by Buildings and Their Location]. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20170002285 (accessed on 6 August 2025).

- KOBiZE, 2021, Wskaźniki Emisji Zanieczyszczeń ze Spalania Paliw dla Źródeł o Nominalnej Mocy Cieplnej do 5 MW, Zastosowane do Automatycznego Wyliczenia Emisji w Raporcie do Krajowej Bazy za 2020 r. [Emission Factors for Pollutants Produced by Fuel Combustion for Sources with Nominal Thermal Power of up to 5 MW, Used for Automatic Emission Calculation in the Report to the National Database for 2020]. Available online: https://krajowabaza.kobize.pl/docs/MATERIAL_wskazniki_male_kotly_2020.pdf (accessed on 6 August 2025).

- KOBiZE, 2020, Wskaźniki Emisyjności CO2, SO2, NOx, CO i Pyłu Całkowitego dla Energii Elektrycznej na Podstawie Informacji Zawartych w Krajowej Bazie o Emisjach Gazów Cieplarnianych i Innych Substancji za 2019 rok [CO2, SO2, NOx, CO and Total Particulate Matter Emission Factors for Electricity Based on Information Contained in the National Database on Greenhouse Gas and Other Substance Emissions for 2019]. Available online: https://www.kobize.pl/uploads/materialy/materialy_do_pobrania/wskazniki_emisyjnosci/Wskazniki_emisyjnosci_grudzien_2020.pdf (accessed on 6 August 2025).

- Rashad, M.; Żabnieńska-Góra, A.; Norman, L.; Jouhara, H. Analysis of energy demand in a residential building using TRNSYS. Energy 2022, 254, 124357. [Google Scholar] [CrossRef]

- Bergel, T.; Kotowski, T.; Woyciechowska, O. Daily water consumption for household purposes and its variability in a rural household. J. Ecol. Eng. 2016, 17, 47–52. [Google Scholar] [CrossRef]

- Franco, A.; Miserocchi, L.; Test, D. A method for optimal operation of HVAC with heat pumps for reducing the energy demand of large-scale non residential buildings. J. Build. Eng. 2021, 43, 103175. [Google Scholar] [CrossRef]

- Heracleous, C.; Michael, A.; Savvides, A.; Hayles, C. A methodology to assess energy-demand savings and cost-effectiveness of adaptation measures in educational buildings in the warm Mediterranean region. Energy Rep. 2022, 8, 5472–5486. [Google Scholar] [CrossRef]

- Leiria, D.; Johra, H.; Marszal-Pomiarnowska, A.; Pomianowski, M.Z. A methodology to estimate space heating and domestic hot water energy demand profile in residential buildings from low-resolution heat meter data. Energy 2023, 263, 125705. [Google Scholar] [CrossRef]

- Kaczmarczyk, M.; Książek, R.; Hałaj, E.; Gdowska, K.; Kapłan, R.; Pełka, G.; Luboń, W. Assessing discrepancies in heat demand: A case study of diverse energy management systems within the energy performance certificate framework in a student’s dormitory. Energy Builds 2025, 329, 115235. [Google Scholar] [CrossRef]

- Martínez-de-Alegría, I.; Río, R.M.; Zarrabeitia, E.; Alvarez, I. Heating demand as an energy performance indicator: A case study of buildings built under the passive house standard in Spain. Energy Policy 2021, 159, 112604. [Google Scholar] [CrossRef]

- Li, L.; Sun, W.; Hu, W.; Sun, Y. Impact of natural and social environmental factors on building energy consumption: Based on bibliometrics. J. Build. Eng. 2001, 37, 102136. [Google Scholar] [CrossRef]

| Energy Performance Indicator | Rated Building | Requirements for a New Building Pursuant to Technical and Construction Regulations |

|---|---|---|

| Annual useful energy demand | EU = 207.7 kWh/m2year | |

| Annual final energy demand | EK = 389.3 kWh/m2year | |

| Annual primary energy demand | EP = 214.8 kWh/m2year | EP = 70.0 kWh/m2year |

| Unit CO2 emissions | ECO2 = 0.051 t CO2/m2year | |

| Share of renewable energy sources in annual final energy demand | URES = 62.8% |

| Variants | Type of Installation | ||

|---|---|---|---|

| P0 | T0 | M0 | Solid fuel boiler (50% coal, 50% biomass) |

| P1 | T1 | M1 | Biomass boiler |

| P2 | T2 | M2 | Biomass boiler + solar collectors |

| P3 | T3 | M3 | Gas boiler |

| P4 | T4 | M4 | Gas boiler + solar collectors |

| P5 | T5 | M5 | Heat pump brine/water (COP = 3.3) |

| P6 | T6 | M6 | Heat pump brine/water (COP = 3.3) + PV |

| P7 | T7 | M7 | Heat pump air/water (COP 2.6) + PV |

| No. | Type of Thermomodernisation | Uo (Before Thermomodernisation) [W/(m2 K)] | Uo (After Thermomodernisation) [W/(m2 K)] | Umax [W/(m2 K)] |

|---|---|---|---|---|

| 1 | Thermal insulation of the floor on the ground with 10 cm of polystyrene | 0.554 | 0.236 | 0.30 |

| 2 | Thermal insulation of external walls with 15 cm polystyrene | 0.932 | 0.227 | 0.23 |

| 3 | Thermal insulation of the ceiling under the unheated attic with 22 cm mineral wool | 0.729 | 0.179 | 0.18 |

| 4 | Roof thermal insulation with 30 cm mineral wool | 4.946 | 0.176 | 0.18 |

| 5 | Replacement of external doors | 2.500 | 1.500 | 1.50 |

| 6 | Windows replacement | 1.500 | 1.100 | 1.10 |

| No. | Type of Thermomodernisation | Uo (Before Thermomodernisation) [W/(m2 K)] | Uo (After Thermomodernisation) [W/(m2 K)] | Umax [W/(m2 K)] |

|---|---|---|---|---|

| 1 | Thermal insulation of the floor on the ground with 10 cm polystyrene | 0.554 | 0.236 | 0.30 |

| 2 | Thermal insulation of external walls with 18 cm polystyrene | 0.932 | 0.197 | 0.20 |

| 3 | Thermal insulation of the ceiling under the unheated attic with 30 cm mineral wool | 0.729 | 0.140 | 0.15 |

| 4 | Roof thermal insulation with 35 cm mineral wool | 4.946 | 0.150 | 0.15 |

| 5 | Replacement of external doors | 2.500 | 1.100 | 1.10 |

| 6 | Windows replacement | 1.500 | 0.900 | 0.90 |

| No. | Type of Thermomodernisation Single Action | Area [m2] | Cost [EUR/m2] | Total Costs [EUR] |

|---|---|---|---|---|

| 1 | Thermal insulation of the floor on the ground with 10 cm of polystyrene | 67.93 | 43.00 | 2920.99 |

| 2 | Thermal insulation of external walls with 15 cm polystyrene | 96.85 | 57.00 | 5520.45 |

| 3 | Thermal insulation of the ceiling under the unheated attic with 22 cm mineral wool | 77.95 | 57.00 | 4443.15 |

| 4 | Roof thermal insulation with 30 cm mineral wool | 278.12 | 47.50 | 13,210.70 |

| 5 | Replacement of external doors | 1.90 | 276.00 | 524.40 |

| 6 | Windows replacement | 34.95 | 193.50 | 6762.83 |

| 7 | TOTAL | – | – | 33,382.85 |

| No. | Type of Thermomodernisation Single Action | Area [m2] | Cost [EUR/m2] | Total Costs [EUR] |

|---|---|---|---|---|

| 1 | Thermal insulation of the floor on the ground with 10 cm of polystyrene | 67.93 | 43.00 | 9290.99 |

| 2 | Thermal insulation of external walls with 18 cm polystyrene | 96.85 | 58.50 | 5665.73 |

| 3 | Thermal insulation of the ceiling under the unheated attic with 30 cm mineral wool | 77.95 | 59.50 | 4638.03 |

| 4 | Roof thermal insulation with 35 cm mineral wool | 278.12 | 50.00 | 13,906.00 |

| 5 | Replacement of external doors | 1.90 | 276.00 | 524.40 |

| 6 | Windows replacement | 34.95 | 193.50 | 6762.83 |

| 7 | TOTAL | – | 40,787.98 |

| No. | Type of Fuel | Calorific Value Qw | Net Price [EUR] |

|---|---|---|---|

| 1 | firewood, birch, moisture content 0% | 15.6 MJ/kg [m3/(m2year)] | 96.67 per m3 |

| 2 | hard coal | 26 MJ/kg [Mg/(m2year)] | 333.33 per Mg |

| 3 | wood chips with moisture content 20–60%, density 150–400 kg/m3 (275 kg/m3 assumed) [kg/(m2year)] | 6–16 MJ/kg (11 MJ/kg assumed) | 48.33 per Mg |

| 4 | electricity | [kWh/(m2year)] | 0.23 per kWh |

| 5 | solar energy | [kWh/(m2year)] | – |

| 6 | natural gas | 48 TJ/Gg (~34.23 MJ/m3) [m3/(m2year)] | 0.86 per m3 |

| No. | Pollutant | Emission Factor W | ||||

|---|---|---|---|---|---|---|

| Coal–Traditional Boiler with Manual Loading (g/GJ) | Wood–Traditional Boiler with Manual Loading (g/GJ) | Wood–Boiler with Manual Loading–Eco-Design (g/GJ) | Fuel Gas (g/GJ) | Electricity (kg/MWh) | ||

| 1 | TSP | 350 | 350 | 40 | 0.5 | 0.029 |

| 2 | PM10 | 312 | 333 | 38 | 0.5 | No data |

| 3 | PM2,5 | 242 | 315 | 36 | 0.5 | No data |

| 4 | CO2 | 96,370 | 0 | 0 | 57650 | 719 |

| 5 | CO | 2500 | 3000 | 440 | 30 | 0.233 |

| 6 | NOx | 160 | 80 | 120 | 50 | 0.576 |

| 7 | SO2 | 410 | 15 | 11 | 0.4 | 0.511 |

| 8 | BaP | 0.35 | 0.13 | 0.015 | 0.0000008 | No data |

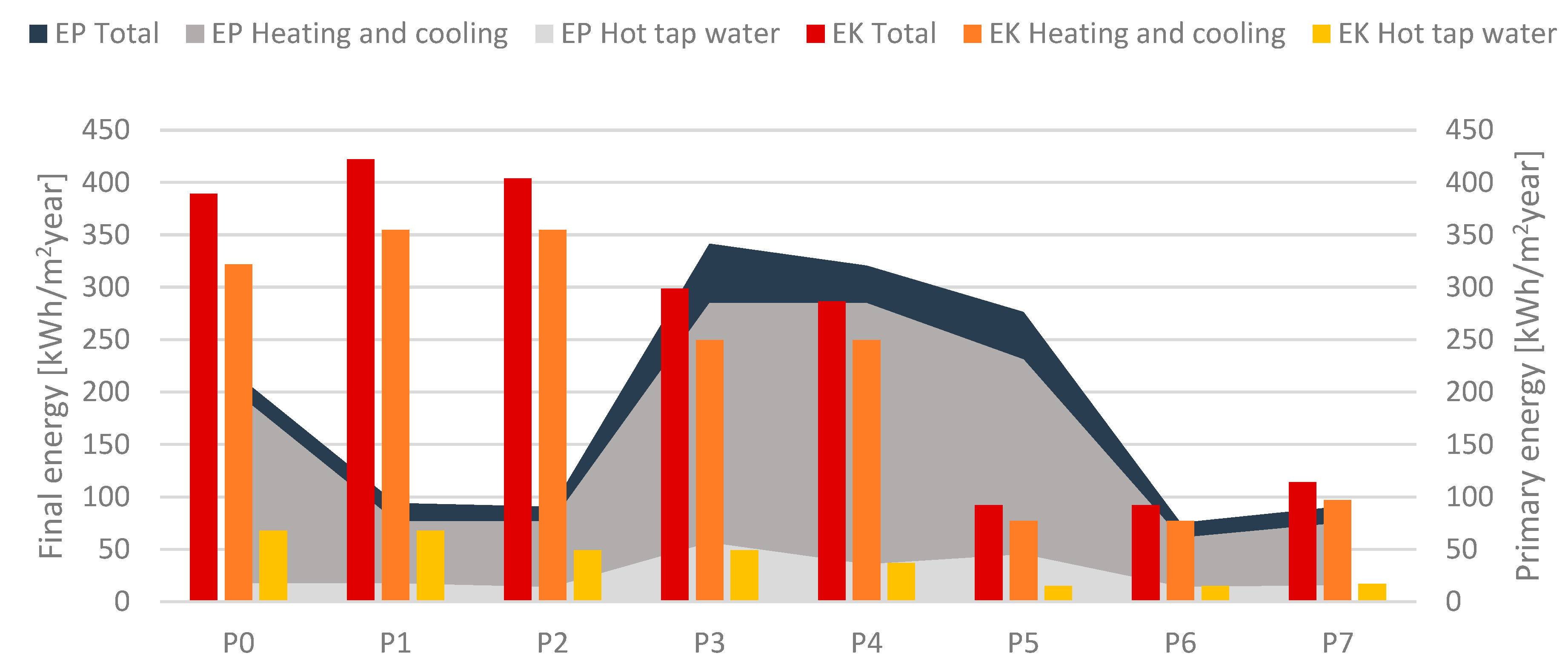

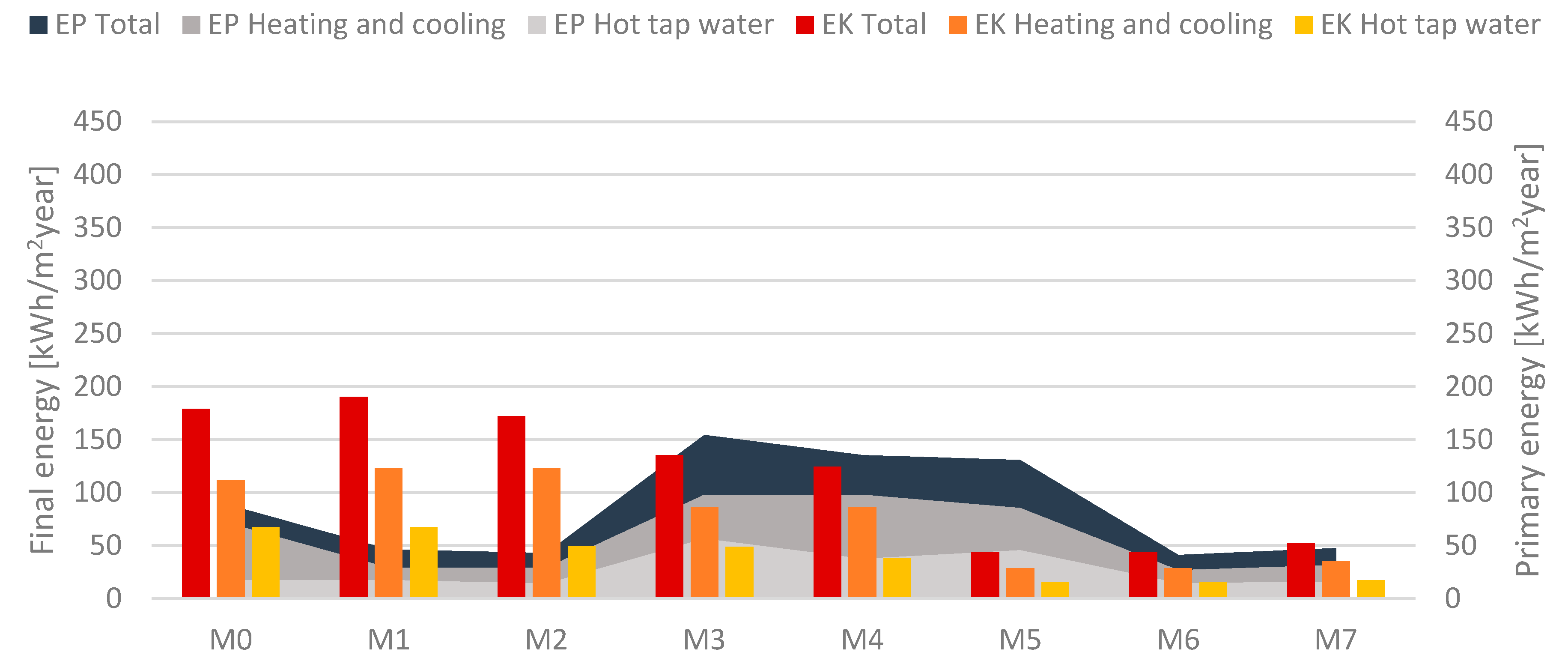

| Variant | Final Energy [kWh/m2year] | Primary Energy [kWh/m2year] | RES Share [%] | ||||

|---|---|---|---|---|---|---|---|

| Total | Heating and Ventilation | Domestic Hot Water | Total | Heating and Ventilation | Domestic Hot Water | ||

| P0 | 389.3 | 321.8 | 67.6 | 214.8 | 197.4 | 17.4 | 62.8 |

| P1 | 422.3 | 354.7 | 67.6 | 94.1 | 76.8 | 17.4 | 99.2 |

| P2 | 403.8 | 354.7 | 49.1 | 90.7 | 76.8 | 13.9 | 99.0 |

| P3 | 298.6 | 249.6 | 49.0 | 341.6 | 285.0 | 56.5 | 0.0 |

| P4 | 286.5 | 249.6 | 36.9 | 320.6 | 285.0 | 35.6 | 2.4 |

| P5 | 92.1 | 77.0 | 15.1 | 276.3 | 231.1 | 45.2 | 65.7 |

| P6 | 92.1 | 77.0 | 15.1 | 75.2 | 61.0 | 14.1 | 94.9 |

| P7 | 114.1 | 97.0 | 17.1 | 90.6 | 75.0 | 15.6 | 95.9 |

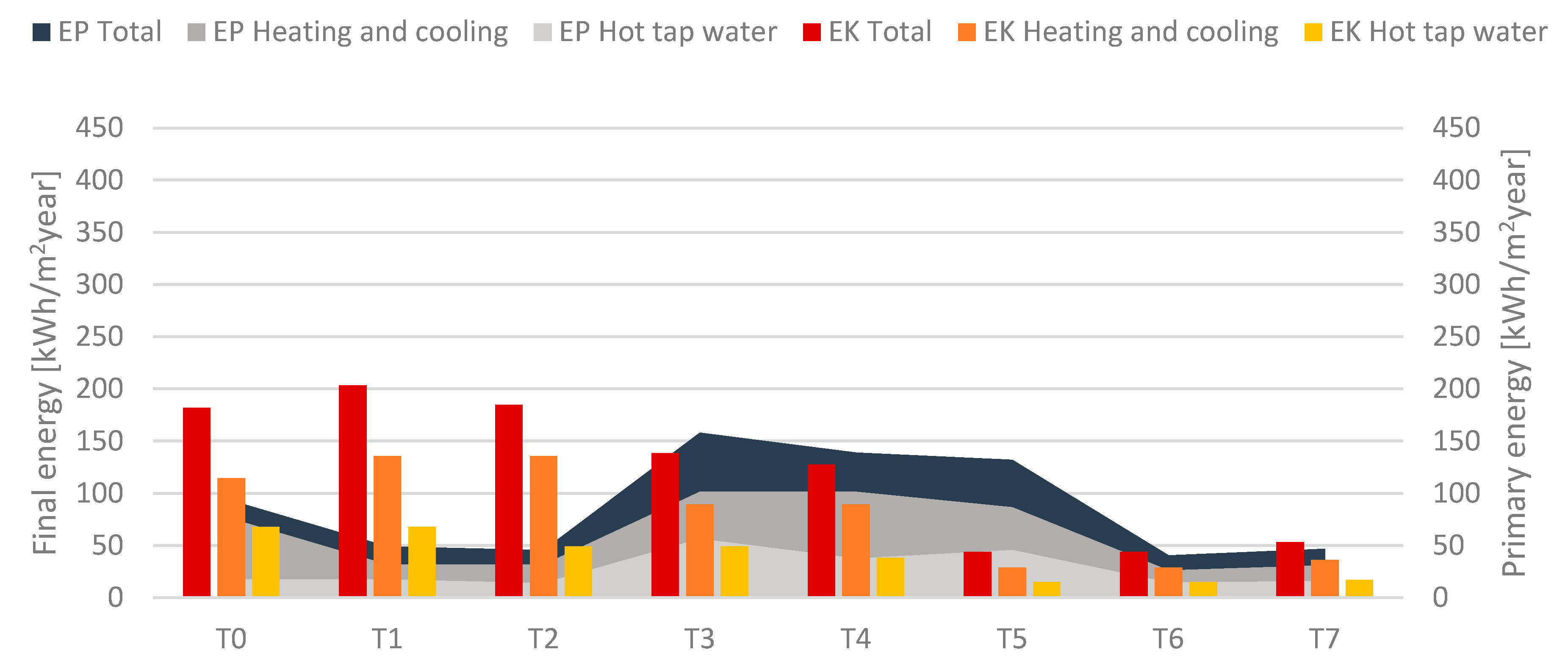

| Variant | Final Energy [kWh/m2year] | Primary Energy [kWh/m2year] | RES Share [%] | ||||

|---|---|---|---|---|---|---|---|

| Total | Heating and Ventilation | Domestic Hot Water | Total | Heating and Ventilation | Domestic Hot Water | ||

| T0 | 181.9 | 114.3 | 67.6 | 93.1 | 75.7 | 17.4 | 68.8 |

| T1 | 203.2 | 135.6 | 67.6 | 49.0 | 31.6 | 17.4 | 98.5 |

| T2 | 184.7 | 135.6 | 49.1 | 45.5 | 31.6 | 13.9 | 98.1 |

| T3 | 138.5 | 89.5 | 49.0 | 158.0 | 101.5 | 56.5 | 0.0 |

| T4 | 127.4 | 89.5 | 38.0 | 138.9 | 101.5 | 37.4 | 5.8 |

| T5 | 44.0 | 28.9 | 15.2 | 132.0 | 86.6 | 45.5 | 62.2 |

| T6 | 44.0 | 28.9 | 15.2 | 40.4 | 26.0 | 14.4 | 90.5 |

| T7 | 53.2 | 36.0 | 17.2 | 46.8 | 30.9 | 15.9 | 92.2 |

| Variant | Final Energy [kWh/m2 year] | Primary Energy [kWh/m2 year] | RES Share [%] | ||||

|---|---|---|---|---|---|---|---|

| Total | Heating and Ventilation | Domestic Hot Water | Total | Heating and Ventilation | Domestic Hot Water | ||

| M0 | 179.0 | 111.4 | 67.6 | 87.7 | 70.4 | 17.4 | 71.2 |

| M1 | 190.3 | 122.8 | 67.6 | 46.3 | 28.9 | 17.4 | 98.5 |

| M2 | 171.8 | 122.8 | 49.1 | 42.8 | 28.9 | 13.9 | 97.9 |

| M3 | 135.3 | 86.3 | 49.0 | 154.4 | 97.9 | 56.5 | 0.0 |

| M4 | 124.3 | 86.3 | 38.0 | 135.3 | 97.9 | 37.4 | 5.9 |

| M5 | 43.5 | 28.4 | 15.2 | 130.6 | 85.2 | 45.5 | 61.3 |

| M6 | 43.5 | 28.4 | 15.2 | 41.1 | 26.7 | 14.4 | 89.4 |

| M7 | 52.5 | 35.2 | 17.2 | 47.4 | 31.5 | 15.9 | 91.2 |

| Variant | Type of Installation | Emission (kg/year) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| TSP | PM 10 | PM 2.5 | CO2 | CO | NOx | SO2 | B(a)P | ||

| P0 | Solid fuel boiler (50% coal, 50% biomass) | 83.64 | 77.62 | 68.46 | 8992.48 | 670.24 | 26.58 | 40.44 | 0.0516 |

| P1 | Biomass boiler | 7.76 | 7.37 | 6.98 | 0.00 | 85.36 | 23.28 | 2.13 | 0.0029 |

| P2 | Biomass boiler + solar collectors | 7.40 | 7.03 | 6.66 | 0.00 | 81.40 | 22.20 | 2.03 | 0.0028 |

| P3 | Gas boiler | 0.08 | 0.08 | 0.08 | 8804.64 | 4.58 | 7.64 | 0.06 | 0.0000 |

| P4 | Gas boiler + solar collectors | 0.07 | 0.07 | 0.07 | 8395.99 | 4.37 | 7.28 | 0.06 | 0.0000 |

| P5 | Heat pump brine/water | 0.35 | 0.00 | 0.00 | 8789.47 | 2.85 | 7.04 | 6.25 | 0.0000 |

| P6 | Heat pump brine/water + PV | 0.11 | 0.00 | 0.00 | 2636.84 | 0.85 | 2.11 | 1.87 | 0.0000 |

| P7 | Heat pump air/water + PV | 0.13 | 0.00 | 0.00 | 3308.37 | 1.07 | 2.65 | 2.35 | 0.0000 |

| T0 | Solid fuel boiler (50% coal, 50% biomass) | 38.37 | 35.76 | 31.94 | 3418.71 | 311.13 | 11.61 | 15.66 | 0.0221 |

| T1 | Biomass boiler | 3.51 | 3.33 | 3.16 | 0.00 | 38.59 | 10.52 | 0.96 | 0.0013 |

| T2 | Biomass boiler + solar collectors | 3.15 | 2.99 | 2.83 | 0.00 | 34.63 | 9.44 | 0.87 | 0.0012 |

| T3 | Gas boiler | 0.03 | 0.03 | 0.03 | 3980.53 | 2.07 | 3.45 | 0.03 | 0.0000 |

| T4 | Gas boiler + solar collectors | 0.03 | 0.03 | 0.03 | 3571.88 | 1.86 | 3.10 | 0.02 | 0.0000 |

| T5 | Heat pump brine/water | 0.16 | 0.00 | 0.00 | 4028.91 | 1.31 | 3.23 | 2.86 | 0.0000 |

| T6 | Heat pump brine/water + PV | 0.05 | 0.00 | 0.00 | 1208.67 | 0.39 | 0.97 | 0.86 | 0.0000 |

| T7 | Heat pump air/water + PV | 0.06 | 0.00 | 0.00 | 1495.70 | 0.48 | 1.20 | 1.06 | 0.0000 |

| M0 | Solid fuel boiler (50% coal, 50% biomass) | 35.70 | 33.29 | 29.79 | 3090.55 | 289.98 | 10.73 | 14.20 | 0.0203 |

| M1 | Biomass boiler | 3.26 | 3.10 | 2.93 | 0.00 | 35.84 | 9.77 | 0.90 | 0.0012 |

| M2 | Biomass boiler + solar collectors | 2.90 | 2.75 | 2.61 | 0.00 | 31.88 | 8.69 | 0.80 | 0.0011 |

| M3 | Gas boiler | 0.03 | 0.03 | 0.03 | 3696.51 | 1.92 | 3.21 | 0.03 | 0.0000 |

| M4 | Gas boiler + solar collectors | 0.03 | 0.03 | 0.03 | 3287.86 | 1.71 | 2.85 | 0.02 | 0.0000 |

| M5 | Heat pump brine/water | 0.15 | 0.00 | 0.00 | 3748.63 | 1.21 | 3.00 | 2.66 | 0.0000 |

| M6 | Heat pump brine/water + PV | 0.05 | 0.00 | 0.00 | 1124.59 | 0.36 | 0.90 | 0.80 | 0.0000 |

| M7 | Heat pump air/water + PV | 0.06 | 0.00 | 0.00 | 1388.98 | 0.45 | 1.11 | 0.99 | 0.0000 |

| Variant | Type of Installation | Emission Reduction in Relation to the Variant P0 (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| TSP | PM 10 | PM 2.5 | CO2 | CO | NOx | SO2 | B(a)P | ||

| P1 | Biomass boiler | 90.7 | 90.5 | 89.8 | 100.0 | 87.3 | 12.4 | 94.7 | 94.4 |

| P2 | Biomass boiler + solar collectors | 91.2 | 90.9 | 90.3 | 100.0 | 87.9 | 16.5 | 95.0 | 94.6 |

| P3 | Gas boiler | 99.9 | 99.9 | 99.9 | 2.1 | 99.3 | 71.3 | 99.8 | 100.0 |

| P4 | Gas boiler + solar collectors | 99.9 | 99.9 | 99.9 | 6.6 | 99.3 | 72.6 | 99.9 | 100.0 |

| P5 | Heat pump brine/water | 99.6 | 100.0 | 100.0 | 2.3 | 99.6 | 73.5 | 84.6 | 100.0 |

| P6 | Heat pump brine/water + PV | 99.9 | 100.0 | 100.0 | 70.7 | 99.9 | 92.1 | 95.4 | 100.0 |

| P7 | Heat pump air/water + PV | 99.8 | 100.0 | 100.0 | 63.2 | 99.8 | 90.0 | 94.2 | 100.0 |

| T0 | Solid fuel boiler (50% coal, 50% biomass) | 54.1 | 53.9 | 53.3 | 62.0 | 53.6 | 56.3 | 61.3 | 57.3 |

| T1 | Biomass boiler | 95.8 | 95.7 | 95.4 | 100.0 | 94.2 | 60.4 | 97.6 | 97.5 |

| T2 | Biomass boiler + solar collectors | 96.2 | 96.1 | 95.9 | 100.0 | 94.8 | 64.5 | 97.9 | 97.7 |

| T3 | Gas boiler | 100.0 | 100.0 | 99.9 | 55.7 | 99.7 | 87.0 | 99.9 | 100.0 |

| T4 | Gas boiler + solar collectors | 100.0 | 100.0 | 100.0 | 60.3 | 99.7 | 88.3 | 99.9 | 100.0 |

| T5 | Heat pump brine/water | 99.8 | 100.0 | 100.0 | 55.2 | 99.8 | 87.9 | 92.9 | 100.0 |

| T6 | Heat pump brine/water + PV | 99.9 | 100.0 | 100.0 | 86.6 | 99.9 | 96.4 | 97.9 | 100.0 |

| T7 | Heat pump air/water + P | 99.9 | 100.0 | 100.0 | 83.4 | 99.9 | 95.5 | 97.4 | 100.0 |

| M0 | Solid fuel boiler (50% coal, 50% biomass) | 57.3 | 57.1 | 56.5 | 65.6 | 56.7 | 59.6 | 64.9 | 60.6 |

| M1 | Biomass boiler | 96.1 | 96.0 | 95.7 | 100.0 | 94.7 | 63.2 | 97.8 | 97.6 |

| M2 | Biomass boiler + solar collectors | 96.5 | 96.5 | 96.2 | 100.0 | 95.2 | 67.3 | 98.0 | 97.9 |

| M3 | Gas boiler | 100.0 | 100.0 | 100.0 | 58.9 | 99.7 | 87.9 | 99.9 | 100.0 |

| M4 | Gas boiler + solar collectors | 100.0 | 100.0 | 100.0 | 63.4 | 99.7 | 89.3 | 99.9 | 100.0 |

| M5 | Heat pump brine/water | 99.8 | 100.0 | 100.0 | 58.3 | 99.8 | 88.7 | 93.4 | 100.0 |

| M6 | Heat pump brine/water + PV | 99.9 | 100.0 | 100.0 | 87.5 | 99.9 | 96.6 | 98.0 | 100.0 |

| M7 | Heat pump air/water + PV | 99.9 | 100.0 | 100.0 | 84.6 | 99.9 | 95.8 | 97.6 | 100.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sowiżdżał, A.; Kaczmarczyk, M.; Pająk, L.; Tomaszewska, B.; Luboń, W.; Pełka, G. Environmental and Economic Optimisation of Single-Family Buildings Thermomodernisation. Energies 2025, 18, 4372. https://doi.org/10.3390/en18164372

Sowiżdżał A, Kaczmarczyk M, Pająk L, Tomaszewska B, Luboń W, Pełka G. Environmental and Economic Optimisation of Single-Family Buildings Thermomodernisation. Energies. 2025; 18(16):4372. https://doi.org/10.3390/en18164372

Chicago/Turabian StyleSowiżdżał, Anna, Michał Kaczmarczyk, Leszek Pająk, Barbara Tomaszewska, Wojciech Luboń, and Grzegorz Pełka. 2025. "Environmental and Economic Optimisation of Single-Family Buildings Thermomodernisation" Energies 18, no. 16: 4372. https://doi.org/10.3390/en18164372

APA StyleSowiżdżał, A., Kaczmarczyk, M., Pająk, L., Tomaszewska, B., Luboń, W., & Pełka, G. (2025). Environmental and Economic Optimisation of Single-Family Buildings Thermomodernisation. Energies, 18(16), 4372. https://doi.org/10.3390/en18164372