Abstract

With coal mines’ mining depth increasing, the stress environment in deep mining (including key factors such as high ground stress, strong disturbance, and complex geological structures, as well as stress redistribution after deformation of surrounding roadway rock) is complex, which leads to increasingly prominent deformation and failure problems for goaf-side roadways in thick coal seams. Surrounding rock deformation is difficult to control, and mine pressure behavior is violent, making traditional support technologies no longer able to meet the mining safety requirements of roadways in deep thick coal seams. Taking the 6311 working face of Tangkou Coal Mine as the engineering research background, this paper systematically summarizes the deformation and failure characteristics of goaf-side roadways in deep thick coal seams through field monitoring, borehole peeping, and other means, and conducts in-depth analysis of their failure mechanisms and influencing factors. Aiming at these problems, a synergistic support–unloading control method for goaf-side roadways is proposed, which integrates roof blasting pressure relief, coal pillar grouting reinforcement, and constant-resistance energy-absorbing anchor cable support. The effects of the unsupported scheme, original support scheme, and synergistic support–unloading control scheme are compared and analyzed through FLAC3D numerical simulation. Further verification through field application shows that it has remarkable effects in controlling roadway convergence deformation, roof separation, and bolt (cable) stress. Specifically, compared with the original support schemes, the horizontal displacement on the coal pillar side is reduced by 89.5% compared with the original support scheme, and the horizontal displacement on the solid coal side is reduced by 79.3%; the vertical displacement on the coal pillar side is reduced by 45.8% and the vertical displacement on the solid coal side is reduced by 42.4%. Compared with the original support scheme, the maximum deformation of the roadway’s solid coal rib, roof, and coal pillar rib is reduced by 76%, 83%, and 88%, respectively, while the separation between the shallow and deep roof remains at a low level. The coal stress continues fluctuating stably during the monitoring period; the force on the bolts (cables) does not exceed the designed anchoring force, with sufficient bearing reserve space (47% remaining), and no breakage occurs, which fully proves the feasibility and effectiveness of the synergistic support–unloading control technology scheme. This technology realizes the effective control of on-site roadways and provides technical reference for the support engineering of coal mine goaf-side roadways under similar conditions.

1. Introduction

After years of exploitation, coal resources in the shallow part of the Earth are gradually depleting. As mining depth has extended to over 1000 m, the environmental conditions of the surrounding rock have undergone significant changes compared to those in shallow regions, accompanied by numerous problems that are difficult to control effectively, such as the “three highs and one disturbance” (i.e., high in situ stress, elevated temperature, high groundwater pressure, and intense mining disturbance). These factors induce changes in various properties of rock masses, including mechanical behaviors, surrounding rock deformation, and rock mass strength, leading to a series of disasters such as uncontrollable surrounding rock deformation and intense mine pressure behavior in mining areas. Drawing on relevant research findings, it is widely recognized that superimposed mining stress, triggered by the substantial mining thickness of coal seams and intense movement of overlying strata, can exacerbate the deformation and instability failure of roadways with thick coal roofs [1], concomitantly leading to a gradual reduction in the performance and efficacy of their supporting systems [2,3]. These issues seriously threaten the occupational safety of miners and efficient production, posing challenges to the future development of the entire coal industry toward deeper horizons.

Based on this, scholars at home and abroad have conducted extensive research and obtained numerous innovative conclusions. In terms of the failure mechanism of roadway surrounding rocks, Wang, X et al. [4], through MATLAB numerical analysis, verified the mechanical response mechanisms underlying bending deformation, elasto-plastic transformation, and unloading failure of surrounding rocks in deep soft rock roadways, with the spatiotemporal evolution characteristics of soft rock deformation and failure being simultaneously revealed; Feng, J et al. [5], by employing numerical simulation software, analyzed the influence law of the magnitude and direction of principal stress on the plastic zone of mining roadways, and the deformation and failure mechanism of surrounding rocks in mining roadways was thereby revealed; and Zang, C et al. [6] evaluated rock mass properties using field data and mechanical parameters of rock specimens, while a numerical model of deep roadway surrounding rocks was established through microparameter calibration. Furthermore, the deformation characteristics and cracking behavior of roadways were examined in detail: Zheng, L et al. [7], leveraging numerical simulation technology, investigated the impact of various factors on roadway stability, and a high-strength composite support system consisting of “anchor cable + fiber-reinforced shotcrete + metal mesh + friction bolt + resin bolt + cement grouting” was put forward; Wang, M et al. [8] established multiple numerical models to study the deformation, stress distribution, and surrounding rock failure zones of roadways under different working conditions; Zeng, C et al. [9] modified model parameters using nonlinear fitting methods, analyzed the failure characteristics of deep-buried soft rock roadways, and proposed a comprehensive, step-by-step combined support control strategy based on numerical simulation results; Hengbin C et al. [10] established a FLAC3D numerical calculation model to compare the stress, deformation, and failure laws of surrounding rocks in mining roadways under initial support and phased support with the same support strength; and Ping L et al. [11] established a linear relationship model to explore the quantitative association between unloading and variations in deformation modulus and cohesion, which was further extended to tensile strength parameters. Their findings indicate that the degradation of cohesion and tensile strength constitute key factors contributing to large-scale deformation in tunnels. HaoJie X et al. [12] analyzed the structural characteristics and stress distribution of automatic roadway formation via roof cutting (AFR), and the pressure relief and energy reduction mechanisms of this technology were clarified. This approach effectively reduces the peak stress and energy acting on roadways while eliminating the need for reserved coal pillars. Chongyan L et al. [13], using a true triaxial rock test system, acoustic emission (AE) monitoring system, and micro-camera monitoring system, explored the failure patterns of roadway surrounding rocks under varying in situ stress environments; Wang, J et al. [14] placed emphasis on the characteristics of ground subsidence during rock mass displacement, with a particular focus on in-depth analysis of thin bedrock fragmentation and alluvial layer collapse; Vladimir Demin et al. [15] studied mining engineering reinforcement technology in high-stress areas behind longwall faces in Kazakhstan, focusing on reinforcement measures to maintain roadway stability, and clarified the influence mode of stress on the stability of mining operations based on the technical parameters of mining operations; and Tien Trung Vu [16] delimited the rock mass displacement zone in Nui Beo Coal Mine, Vietnam, using numerical simulation methods, providing a reference method for the analysis of stress–strain behavior in longwall mining environments.

In terms of support control technology for deep roadway surrounding rocks, Zhang, X et al. [17], in their research on maintaining soft thick coal seam roadways under intense mining influences, proposed a novel “bolt (cable) support-pre-splitting-grouting” technology, and an equivalent load calculation model for stress distribution in roadway surrounding rocks was established accordingly; Peng W et al. [18] established a mechanical model of roadways with broken surrounding rocks using classical rock mechanics theory; Houqiang Y et al. [19] studied and put forward an efficient excavation–support coordination technology for the surrounding rocks of roadways adjacent to goafs; and Gong H et al. [20] constructed an ultrasonic wave velocity prediction model via laboratory tests, numerical simulation, and on-site monitoring methods. A corresponding prediction module was further developed using the Fish language, enabling accurate simulation of ultrasonic wave velocity evolution characteristics during the deformation and failure process of surrounding rocks. Jucai C et al. [21], based on surrounding rock stability indexes and deformation data, analyzed the stability of surrounding rocks under unsupported and bolt-supported conditions, verifying the rationality of using such indexes to describe instability characteristics; Yongliang H et al. [22] determined the evolution of surrounding rock fractures using borehole images captured by a digital panoramic borehole camera, while the evolution and control of surrounding rocks in rock burst-prone mine roadways under varied pressure relief and support conditions were investigated; Xueyuan Q et al. [23] carried out numerical simulation analysis and engineering application research out on the deformation and failure characteristics of surrounding rocks, and an asymmetric high-prestress pressure relief coupling control technology was proposed; HaoJie X et al. [24] proposed a method of pressure relief and energy absorption through roof cutting through their research; Zhumabekova et al. [25] formulated technical premises for the anchoring of marginal rock and soil considering the state of rock mass around the excavation area, and determined parameters for mine bolt support operations; Zhe X et al. [26] discussed the control problem of hard roofs in extra-thick coal seams, proposed a new surrounding rock control strategy, optimized the stress environment of roadway surrounding rocks, inhibited damage to anchoring structures, and provided ideas for the safety control of roadway roofs under extra-thick coal seam conditions; Wang, S et al. [27] studied the synergistic control effect of pressure relief and long-bolt support in deep roadways, revealing that the combined scheme of pressure relief and long-bolt support exhibits significant efficacy in mitigating high-stress environments and controlling roadway deformation; and Zhu L et al. [28] studied the plastic zone range, horizontal displacement, and bearing capacity of floor coal pillars, and a technology for reinforcing floor coal pillars through grouting to fill goafs was proposed.

Existing studies have focused on numerical simulations, field tests, and theoretical analyses of failure mechanisms in deep roadway surrounding rocks, as well as the exploration of various support and pressure relief technologies. Significant achievements have been made in revealing the deformation laws of deep rock masses and applying single support/pressure relief measures. However, these studies are mostly concentrated on general deep roadway contexts. For the specific scenario of gob-side roadways in deep thick coal seams, which are significantly affected by high ground stress and strong disturbances, targeted and adaptive research remains insufficient. In fact, current control methods for gob-side roadways mainly adopt single or simple combinations of support or pressure relief measures such as bolt (cable) support, cement grouting, and roof pre-splitting/blasting. Although these measures can alleviate local problems to a certain extent, in-depth research and engineering practice cases of support–pressure relief collaborative control methods that truly integrate support strength enhancement with pressure relief energy release, considering the complex geological and mining conditions of gob-side roadways in deep thick coal seams, are still relatively scarce. Based on this, taking the 6311 working face of Tangkou Coal Mine as the engineering background, this paper conducts an in-depth analysis of the failure mechanism of gob-side roadways in deep thick coal seams and proposes a support–pressure relief collaborative control technology for such roadways. Its application in the 6311 working face of Tangkou Coal Mine has effectively ensured efficient and safe mine production, while providing an important technical reference and practical experience for the support engineering of coal mine gob-side roadways under similar conditions.

2. Engineering Overview

2.1. Engineering Geological Conditions

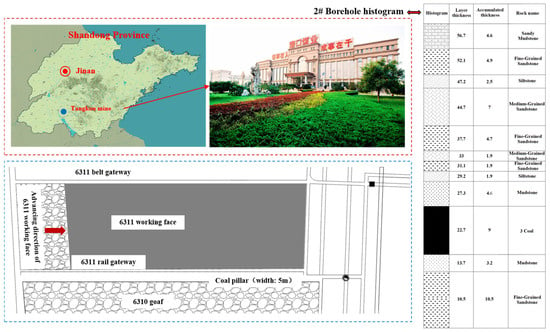

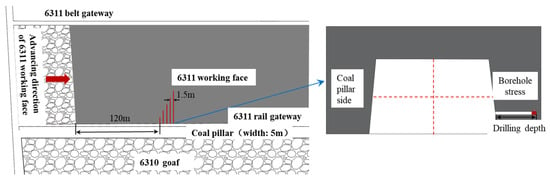

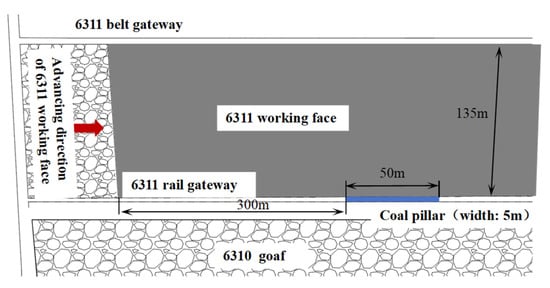

The 6311 working face of Tangkou Coal Mine is situated on the south side of the return airway in the sixth mining area, with an average depth of approximately 920 m. The 6311 working face extracts the No. 3 coal seam, where the dip angle of the coal (rock) seam ranges from 0~5° (with an average of 3°) and the dip direction is 30~330°. The coal seam thickness varies from 7.5~10.0 m, with an average thickness of about 9.3 m. The layout and comprehensive borehole histogram of the 6311 working face are presented in Figure 1.

Figure 1.

Layout schematic and borehole columnar diagram of 6311 working face.

2.2. On-Site Original Support Design of Goaf-Side Roadways

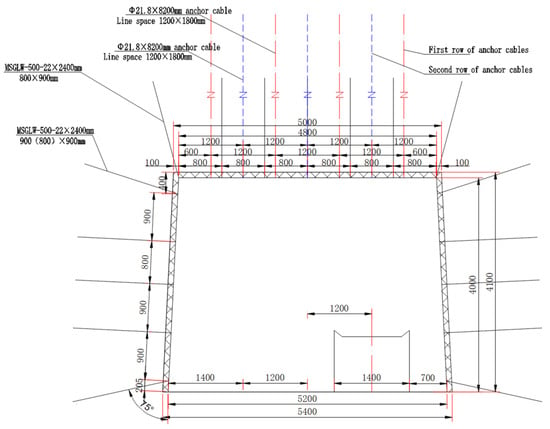

- (1)

- Roof Support

Each row is equipped with seven high-strength bolts, which are used in combination with W-shaped steel belts and bolt trays. The spacing between bolts and the row spacing are 800 × 900 mm. Each bolt is anchored with an extended length using one MSK2590 resin anchoring agent. The anchor cables are designed with a row spacing of 900 mm and arranged adjacent to the bolts. Specifically, one row consists of four anchor cables with a spacing of 1800 mm, and another row consists of three anchor cables with the same spacing. The specifications of the anchor cables are Φ21.8 × 8200 mm, and the anchoring depth into stable rock strata must not be less than 1 m; if anchoring into stable rock strata is not achievable, the support anchor cables should be extended promptly. Each anchor cable is subjected to extended anchoring using two MSK2590 resin anchoring agents. The M-shaped steel belts have specifications of 4000 × 330 × 5 mm and 2800 × 330 × 5 mm.

- (2)

- Two-Rib Support

The design scheme for high-strength bolts includes five bolts per row, with a spacing and row spacing of 900 (800) × 900 mm. Each bolt is designed for extended anchoring using one MSK2590 resin anchoring agent, and the bolt steel belts are W-shaped steel belts with specifications of 1300 × 280 × 3 mm and 2200 × 280 × 3 mm. The specific support measures are illustrated in Figure 2 below.

Figure 2.

Support cross-section diagram of rail gateway in 6311 working face.

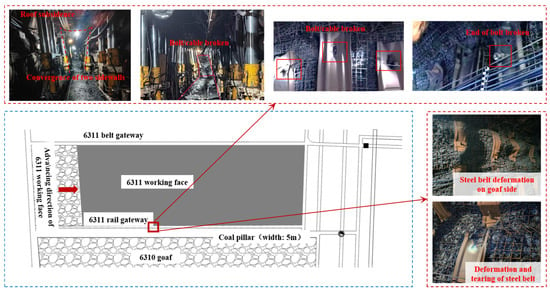

Before mining operations in the 6311 working face were initiated, the surrounding rock mass of the goaf-side roadway was impacted by tunneling activities, leading to the development of initial fractures in the coal and rock masses surrounding the roadway. Particularly in the weaker parts of the sidewalls, the coal mass exhibits flake spalling, gradually forming a loose and fragmented state with local collapses. At this stage, the fracture process is incomplete, allowing for temporary stability. After the completion of initial support measures, the surrounding rock of the roadway maintained overall stability for a certain period. However, as time progresses, stress redistribution leads to gradual damage to the surrounding rock: the upper loose rock mass fractures due to insufficient load-bearing capacity, and as the bulking volumes of the coal and rock masses increase, the metal mesh used in the initial support is bulged or even torn by the deformed coal mass, forming an obvious pocket-like structure. Under the influence of deep high ground stress, the coal mass in the middle of the roadway sidewall experiences shear failure, causing the entire sidewall to bulge outward in a noticeable arc. This kind of deformation not only impacts the safety of roadway passage but also endangers the overall stability of the surrounding rock during the service period of working face mining. Thus, it is essential to conduct in-depth research on the failure mechanism and support scheme optimization of goaf-side roadways. The deformation and failure of the goaf-side roadway in the 6311 working face are illustrated in Figure 3.

Figure 3.

Schematic of deformation and failure of rail gateway.

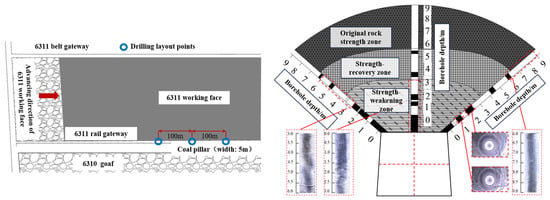

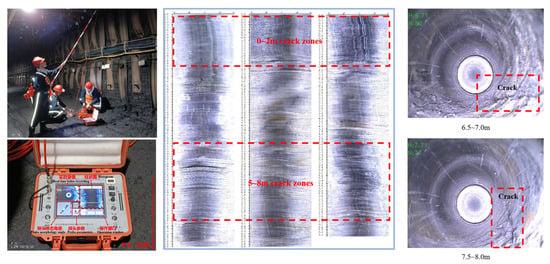

2.3. Borehole Peeping Conditions

The borehole locations are arranged in front of the working face, with three typical cross-sections selected. The distance between each cross-section is approximately 100 m, depending on the specific conditions. The on-site borehole drilling depth is 8~12 m for the roof and 5~8 m for the sidewalls. The roof boreholes are drilled perpendicular to the roof or at a 45° angle, while the sidewall boreholes are horizontal or set at a 5° downward angle. Figure 4 shows the layout of the roadway borehole peeping scheme and the roof borehole peeping conditions.

Figure 4.

Layout of borehole peeping scheme and schematic of peeping zones.

As shown in Figure 4 and Figure 5, the rock mass is almost completely fragmented at a borehole depth of 2 m, making the borehole highly susceptible to deformation. At a depth of 5~8 m, numerous fractures are still observed in the rock mass. The number of fractures decreases up to a depth of 8 m, but relatively obvious fractures are still visible. Based on the overall peeping results of the roadway roof, the upper surrounding rock can be roughly divided into three zones: the strength-weakened, strength-recovery, and original rock strength zone. From near to far, the number and development degree of fractures continuously decrease, while the integrity of the original rock gradually improves.

Figure 5.

Borehole peeping conditions of roof.

3. Analysis of Failure Mechanism of Roadway Surrounding Rock

3.1. Monitoring and Analysis of Surrounding Rock Deformation

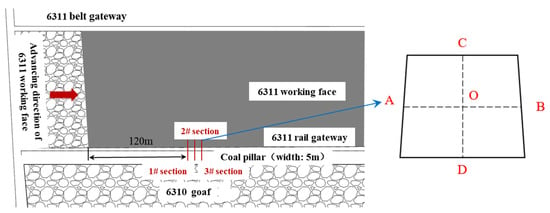

To analyze the actual deformation law of the surrounding rock in the rail gateway, multiple monitoring sections were arranged at appropriate positions ahead of the working face in the roadway to monitor the deformation of the two sidewalls, roof, and floor. These monitoring sections were placed approximately 120 m in front of the actual mining line, with three monitoring sections set at an interval of about 5 m. The layout of the monitoring sections is shown in Figure 6.

Figure 6.

Layout diagram of surrounding rock deformation-monitoring sections in rail gateway of 6311 working face.

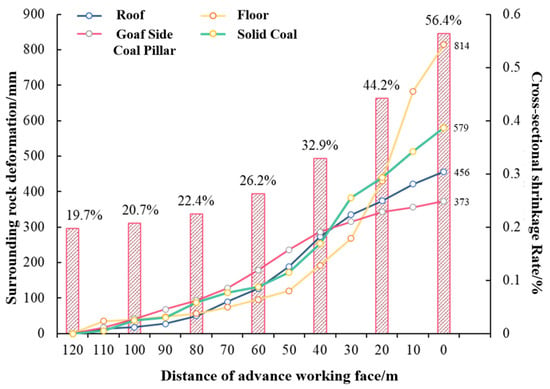

Data collation reveals the surrounding rock deformation of the rail gateway in the 6311 working face. As indicated by the curves in Figure 7, the maximum deformation characteristics of each part of the roadway follow the order of floor > production sidewall > roof > goaf side. The final deformation amounts at the four points are 814 mm, 579 mm, 456 mm, and 373 mm, respectively. The convergence of the roof and floor exceeds that of the two sidewalls, with the cross-sectional shrinkage rate reaching 56.4%.

Figure 7.

Statistical chart of deformation monitoring in rail gateway of 6311 working face.

As shown in Figure 8, with the progress of mining, the originally designed trapezoidal cross-section of the roadway is transformed into an irregular shape.

Figure 8.

Schematic of cross-sectional deformation of roadway in 6311 working face.

3.2. Analysis of Stress Variation in Surrounding Rock

To analyze the stress variation process of the surrounding rock in the rail gateway of the 6311 working face, we arranged a 120 m monitoring section for stress data collection. Boreholes with different depths (3 m, 6 m, 9 m, 12 m, and 15 m) were drilled in the solid coal sidewall, with a spacing of 1.5 m between adjacent boreholes. Each borehole was located 1.5 m above the roadway floor, and the layout is shown in Figure 9.

Figure 9.

Layout diagram of surrounding rock stress-monitoring sections in rail gateway of 6311 working face.

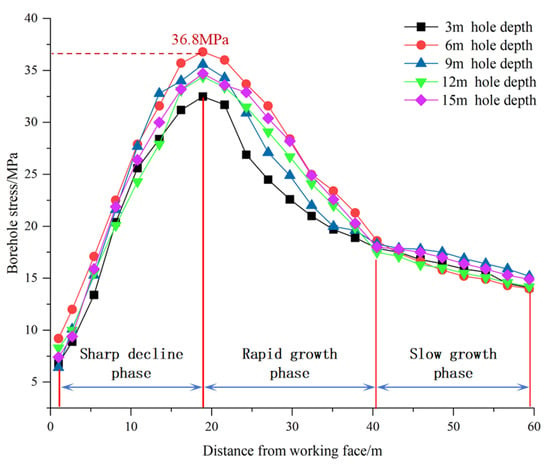

By organizing the data, the stress-monitoring curves of the surrounding rock in the rail gateway can be obtained (Figure 10). According to the data variation trend, the stress variation process of the monitoring section can be roughly divided into three stages: the slow growth stage (40~60 m), the rapid growth stage (20~40 m), and the sharp decline stage (0~20 m). The maximum stress of 36.8 MPa occurs within the 6 m borehole position.

Figure 10.

Stress variation curves of surrounding rock in monitoring sections of 6311 working face.

3.3. Stress Analysis of Bolts (Cables)

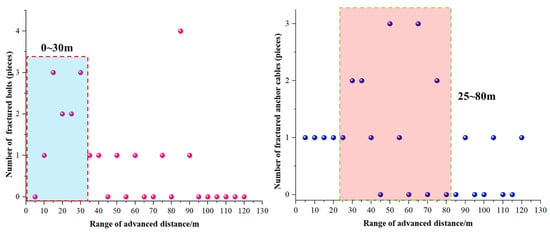

Statistics on the number and distribution of fractured bolts/cables on-site are presented in Figure 11.

Figure 11.

Statistical chart of bolt/cable fracture conditions in roadway.

The data in the figure indicate that a total of 21 bolts fractured within the 120 m range ahead of the working face, with the highest number of fractures (11 cases) occurring within the 30 m range ahead. For anchor cables, a total of 24 fractured within the 120 m range ahead, with the majority (14 cases) concentrated in the 25~80 m range ahead. The fracture positions of bolts/cables are mainly concentrated at the upper shoulder corners of the two roadway sidewalls, and the forms of fracture include rod body fracture, end failure, and steel strip tearing, among other types.

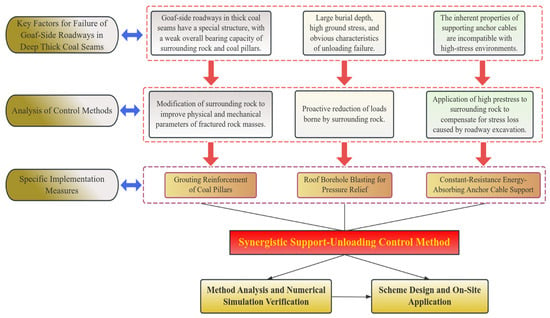

3.4. Analysis of Failure Mechanism of Goaf-Side Roadways in Deep Thick Coal Seams

Based on the above materials analysis, the key factors affecting the goaf-side roadways can be identified.

- (1)

- Owing to the structural uniqueness of goaf-side roadways in thick coal seams, the overall bearing capacity of the surrounding rock and coal pillars is relatively low. Field monitoring shows that the convergence of the roof and floor is greater than that of the two sidewalls, with a cross-sectional shrinkage rate reaching 56.4%. Borehole peeping reveals the severe fragmentation of shallow rock masses, and that the sidewalls are prone to arc-shaped outward bulging. These phenomena indicate that it is difficult for the structure to form a stable bearing system, and that it is susceptible to deformation and failure.

- (2)

- With a large burial depth and high ground stress, the characteristics of unloading failure are obvious. Stress monitoring presents three-stage changes, with the maximum stress reaching 36.8 MPa, and significant stress concentration occurs in the sidewalls. This stress distribution characteristic makes the sidewalls a failure-sensitive zone, increasing the possibility of roadway deformation and failure.

- (3)

- Bolt/cable fractures are concentrated in specific areas: most bolts fracture within 30 m ahead of the working face, while anchor cables are mainly fractured in the range of 25–80 m ahead, with fracture positions primarily at the upper shoulder corners of the two sidewalls. This indicates that the original support has insufficient deformation resistance in high-stress disturbance zones and cannot adapt to the demand of intense roadway deformation.

4. Analysis of Synergistic Support–Unloading Prevention and Control Method

4.1. Design of Prevention and Control Method

Targeting the complex stress environment faced by goaf-side roadways in deep thick coal seams and the key factors affecting their deformation and failure, a synergistic support–unloading control method more adaptable to the deep thick coal seam environment is proposed on this basis, with the technical road map shown in Figure 12.

Figure 12.

Technical roadmap of synergistic support–unloading prevention and control method.

This scheme achieves the effective improvement of the surrounding rock stability of the roadway through reasonable management, control, and synergistic regulation of various factors affecting roadway stability. The reliability of the scheme is first verified by means of numerical simulation.

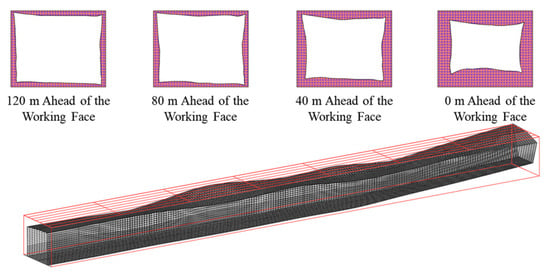

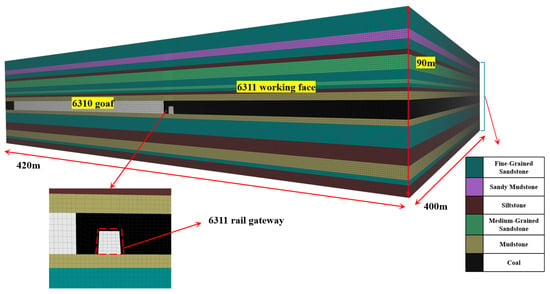

4.2. Numerical Simulation Analysis of Synergistic Support–Unloading Control Method

According to the actual engineering geological parameters, we built a numerical calculation model with FLAC3D finite difference software, as shown in Figure 13. The model has geometric dimensions of 420 m × 400 m × 90 m, and the roadway features a trapezoidal cross-section with a 4.8 m roof width, 5.2 m floor width, 4 m height, and 9.3 m thick coal seam. A 19.5 MPa uniform load is applied to the top to simulate the self-weight pressure of overlying strata, with corresponding pressure on the model’s side surfaces. Vertical displacement constraints are set at the model’s bottom, and horizontal displacement constraints are set on the left and right sides. The Mohr–Coulomb model is used for rock blocks in calculations, with the model discretized into eight-node hexahedral elements for structured meshing. Local mesh refinement was conducted for the roadway and working face mining areas to ensure calculation accuracy.

Figure 13.

Overview of numerical calculation model.

Based on the geological overview of the 6311 working face in Tangkou Coal Mine and laboratory test data, the main rock mechanical parameters of each rock stratum were set as follows. (Table 1)

Table 1.

Mechanical parameters of roof and floor rock strata in roadway.

4.2.1. Scheme Design

Herein, through numerical modeling, the deformation and failure characteristics of goaf-side roadways under multiple variables, including different ground stress levels, different coal pillar widths, and different roof strengths, are analyzed to further clarify the actual influence laws of each factor variable on the roadway surrounding rock at engineering sites.

Different ground stress levels are designated as Group A, with serial numbers Ak (where k = 1~5) corresponding to ground stress levels of 0.75, 1.00, 1.25, 1.50, and 1.75, respectively. The scheme design is shown in Table 2 below.

Table 2.

Scheme of different ground stress levels.

Different coal pillar widths are designated as Group B, with serial numbers Bk (where k = 1–4) corresponding to coal pillar widths of 3 m, 5 m, 8 m, and 14 m, respectively. The scheme design is shown in Table 3 below.

Table 3.

Scheme of different coal pillar widths.

Different roof surrounding rock strengths are designated as Group C, with serial numbers Ck (where k = 1–5) corresponding to roof surrounding rock strength coefficients of 1.0, 1.1, 1.2, 1.3, and 1.4, respectively. The scheme design is shown in Table 4 below.

Table 4.

Scheme of surrounding rock strength of different roofs.

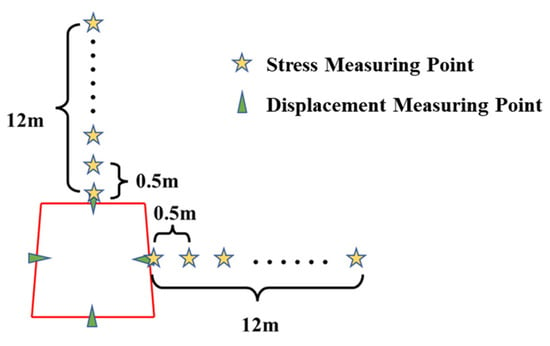

In this section, the roadway surrounding rock is taken as the research object, and the monitoring contents include the stress distribution and deformation magnitude around the roadway. A measuring line is arranged at the midline of the roadway roof and the solid coal rib, respectively, with measuring points placed on the measuring lines. The specific layout of the measuring points is shown in Figure 14.

Figure 14.

Monitoring scheme of numerical simulation.

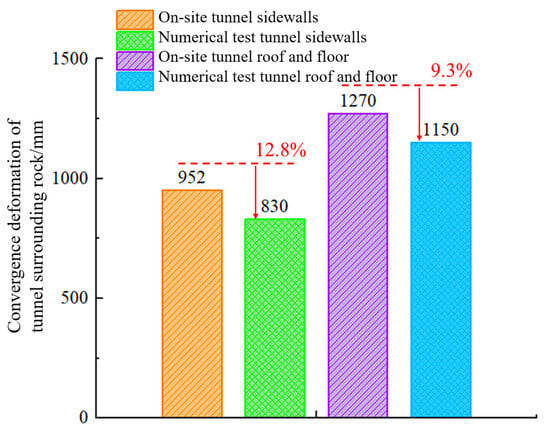

4.2.2. Numerical Simulation Verification and Analysis of Influencing Factors

The test data were compared with the on-site-measured data, as shown in Figure 15. The difference rate of each value is within 13%, indicating that the model test is credible and consistent with the actual on-site conditions.

Figure 15.

Difference rate between numerical simulation and actual site.

On this basis, an analytical study was conducted on each influencing factor, with details as follows:

- (1)

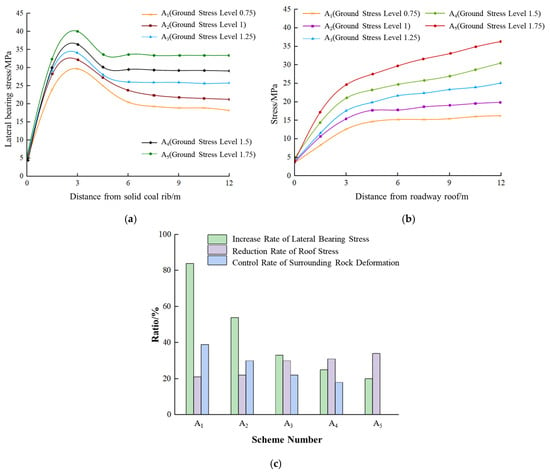

- Analysis of the influence of different ground stress levels.

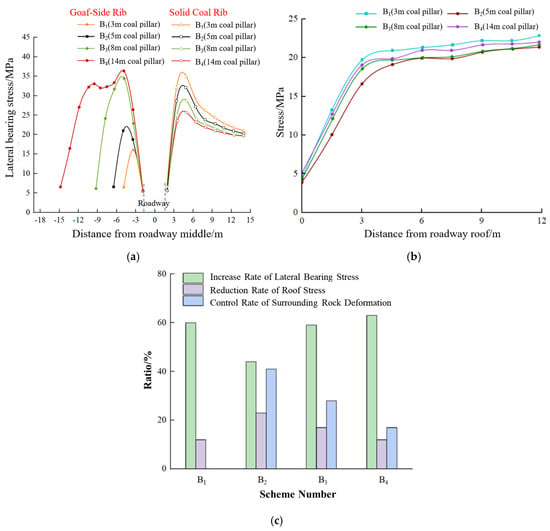

After completing the simulation of the scheme, the monitoring data were statistically analyzed to obtain the corresponding simulation results. The statistical data show the stress changes inside the solid coal rib in Figure 16a, the roof stress changes in Figure 16b, and the various evaluation indices of the roadway in Figure 16c.

Figure 16.

Schematic diagram of lateral bearing stress, roof stress, and index changes in roadways under different ground stress levels. (a) Variation diagram of roadway lateral bearing stress; (b) variation diagram of roadway roof stress; (c) schematic diagram of changes in evaluation indicators in different schemes.

As the ground stress level increases from 0.75 to 1.75, the maximum lateral bearing stress of the solid coal rib increases from 29 MPa to 40 MPa, with an increase rate of 37.9%. The roof stress at 12 m from the roof increases from 15 MPa to 35 MPa, with an increase rate of 133%. Meanwhile, as the ground stress level increases, the deformation of the surrounding rock roof gradually increases, with an increase rate of 66.7%. Elevated ground stress exacerbates stress concentration within the roadway surrounding rock, significantly increasing the difficulty of support. It is necessary to adopt enhanced support measures and effective pressure relief measures to improve the stress environment of the surrounding rock.

- (2)

- Analysis of the influence of different coal pillar widths.

Similarly, the stress changes inside the coal pillar and solid coal are shown in Figure 17a, the roof stress changes in Figure 17b, and the various evaluation indices of the roadway in Figure 17c.

Figure 17.

Schematic diagram of lateral bearing stress, roof stress, and index changes in roadways with different coal pillar widths. (a) Variation diagram of roadway lateral bearing stress; (b) variation diagram of roadway roof stress; (c) schematic diagram of changes in evaluation indicators in different schemes.

As the coal pillar width increases from 3 m to 14 m, the stress distribution on both sides exhibits asymmetry. On the solid coal rib side, the maximum stress of each group gradually decreases from 35 MPa to 25 MPa; in contrast, the maximum stress on the small coal pillar side rises from 15 MPa to 40 MPa, with the location of peak stress gradually shifting toward the deep rock mass. When the coal pillar is too wide (e.g., exceeding 14 m), two stress peaks appear inside the rock mass on the small coal pillar side, increasing the risk of coal pillar instability. Either too narrow or too wide a coal pillar width will have adverse effects on the site. It is important to reasonably select the on-site coal pillar width, and at the same time pay attention to strengthening the support of the coal pillar to improve its bearing capacity, which is of great significance for controlling roadway stress and deformation.

- (3)

- Analysis of the influence of different roof surrounding rock strengths.

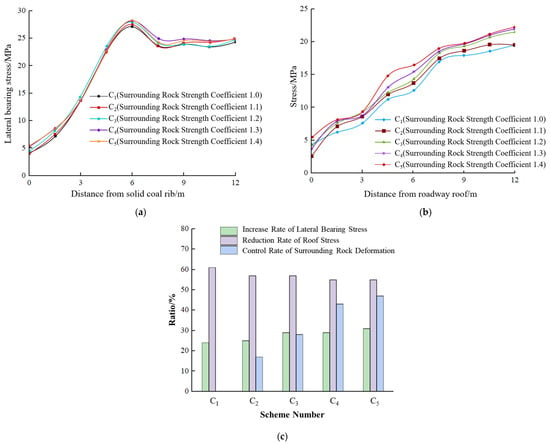

The stress changes inside the solid coal are shown in Figure 18a, the roof stress changes in Figure 18b, and the various evaluation indices of the roadway in Figure 18c.

Figure 18.

Schematic diagram of lateral bearing stress, roof stress, and index changes in roadways with different roof surrounding rock strengths. (a) Variation diagram of roadway lateral bearing stress; (b) variation diagram of roadway roof stress; (c) schematic diagram of changes in evaluation indicators in different schemes.

As the roof surrounding rock strength coefficient increases from 1.0 to 1.4, the rib stress under different variables shows an overall stable increasing trend, but the stress difference at the same position under different conditions is not obvious. As the distance from the roadway roof increases, the stress measured by each scheme shows an increasing trend, and the increase process is relatively uniform. Meanwhile, the higher the roof surrounding rock strength coefficient, the greater the stress value at the same distance. With the reduction in residual weak coal seams in the roof and the increase in surrounding rock strength coefficient, the deformation and failure of the roadway roof gradually decrease. It is necessary to focus on designing the height of on-site goaf-side roadways, pay attention to the problem of weak roofs in thick coal seams, and reasonably strengthen the support of surrounding rock according to actual conditions.

4.2.3. Synergistic Support–Unloading Control Method

Building on the research in the previous section, this section proposes targeted solutions to the various issues mentioned above, reasonably supplements the original on-site support scheme, and continues to use numerical simulation to simulate and analyze the various methods’ effects, thereby providing a basis for solving on-site problems. The details are as follows.

The content of this simulation is a comparative analysis of the synergistic support–unloading control scheme with the unsupported roadway scheme and the original support scheme, with the implementation schemes shown in Table 5.

Table 5.

Scheme implementation plan.

Specifically, the implementation methods of the synergistic support–unloading control scheme are as follows:

- (1)

- The roof blasting borehole scheme involves deep-hole pre-splitting blasting along the dip direction of the working face in the 6311 rail gateway, treated approximately as slitting measures in this test.

- (2)

- For the grouting reinforcement scheme of small coal pillars, the numerical simulation scheme for grouting reinforcement refers to relevant previous research results; i.e., the elastic modulus, cohesion, tensile strength, etc., are set to 1.5 times the original parameters, the internal friction angle is increased by 2°, and Poisson’s ratio is reduced by 0.02 for numerical analysis.

- (3)

- The support scheme involves constructing constant-resistance energy-absorbing anchor cables on the solid coal side and roof of the 6311 rail gateway.

Through the above simulation schemes, the stress and displacement changes in the roadway under unsupported conditions, the original support scheme, and different control measures are analyzed to determine the actual effect of the control scheme.

4.3. Analysis of Numerical Experiment Results

4.3.1. Analysis of Vertical Stress Variation in Roadway Surrounding Rock

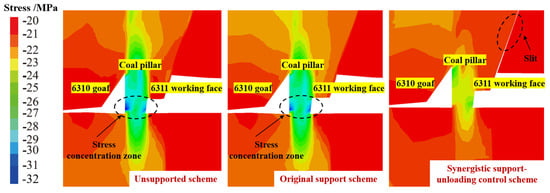

To explore the surrounding rock control effect and deformation failure characteristics of the goaf-side roadway under the unsupported scheme, original support scheme, and synergistic support–unloading control scheme, simulation analysis of the roadway under the three schemes was conducted. Figure 19 shows the vertical stress distribution near the small coal pillar under the three schemes.

Figure 19.

Schematic of vertical stress distribution in roadway under three schemes.

As shown in Figure 19, under the unsupported condition, obvious stress concentration occurs in the small coal pillar of the goaf-side roadway in the 6311 working face, with the maximum stress reaching approximately 32 MPa. Severe stress concentration in the surrounding rock of the roadway makes it prone to deformation and failure; stress concentration in the sidewalls indicates more severe fragmentation there, eventually leading to arc-shaped protrusion of the sidewalls.

After applying the on-site support scheme, stress concentration is alleviated, with no significant change in the peak stress value but a reduced distribution area. Obvious stress concentration still exists near the small coal pillar, indicating that the original supports can play a certain role in improving stress distribution and help the surrounding rock passively resist external pressure, but their actual effect is limited, and the stress concentration problem is not fundamentally solved.

After applying the synergistic support–unloading control scheme, the stress transfer path is effectively changed, the stress concentration near the coal pillar is significantly alleviated, the maximum stress in the sidewalls is reduced, and the area of the increased- stress region is decreased, resulting in a more reasonable overall stress distribution. This indicates that the synergistic support–unloading control scheme effectively blocks stress transfer between the goaf and the roadway through roof blasting boreholes to form slits, reduces external pressure on the roadway, and enhances the bearing capacity of the coal pillar itself. This scheme effectively controls roadway deformation and improves overall stability.

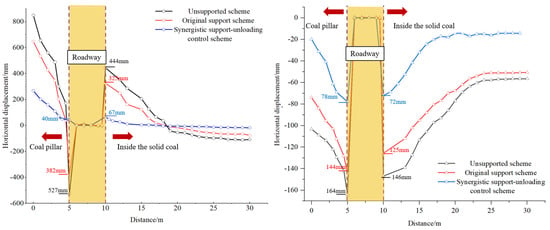

4.3.2. Comparative Analysis of Deformation Results Under Three Schemes

In Figure 20, the left diagram presents the horizontal displacement at various positions along the horizontal line through the center of the roadway sidewall, while the right diagram shows the vertical displacement at these positions. The positive and negative values indicate the direction of surrounding rock deformation and displacement: positive (negative) horizontal displacement represents leftward (rightward) direction, and positive (negative) vertical displacement represents upward (downward) direction.

Figure 20.

Horizontal (Left) and vertical (Right) displacement variation curves of roadway.

Regarding the horizontal displacement of the roadway, under the original support scheme, the maximum horizontal displacement on the coal pillar side reaches 382 mm, with a reduction amplitude of 27.5%, and that on the solid coal side reaches 325 mm, with a reduction amplitude of 26.8%. Under the synergistic support condition, the maximum horizontal displacement on the coal pillar side is 40 mm, and that on the solid coal side is 67 mm. The horizontal displacement at all positions of the roadway decreases significantly under synergistic support: compared with the original support scheme, the horizontal displacement on the coal pillar side is reduced by approximately 89.5%, and that on the solid coal side by 79.3%. Additionally, the horizontal displacement on the solid coal side stabilizes more rapidly.

For vertical displacement, under the original support scheme, the maximum vertical displacement on the coal pillar side reaches 144 mm (a 12.2% reduction), while that on the solid coal side is 125 mm (a 14.4% reduction). In general, vertical displacement on the coal pillar side exceeds that on the solid coal side. Under the synergistic support condition, the maximum vertical displacement on the coal pillar side is 78 mm, and that on the solid coal side is 72 mm. The vertical displacement at all positions decreases significantly under synergistic support: compared with the original support scheme, the vertical displacement on the coal pillar side is reduced by approximately 45.8%, and that on the solid coal side by 42.4%. Similarly, the vertical displacement in the solid coal side stabilizes more rapidly.

4.4. Engineering Recommendations

Based on the proposed synergistic support–unloading control approach and the comparison of numerical test results under three scenarios, combined with practical engineering experience, engineering recommendations for the on-site synergistic support–unloading control method could be put forward.

- (1)

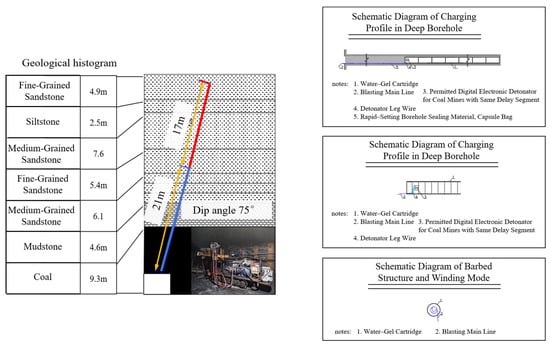

- Roof blasting borehole scheme: Specifically, in the rail gateway of the 6311 working face, deep-hole pre-splitting blasting measures were carried out along the dip direction of the working face. The borehole length is 38 m, the borehole angle is 75°, the borehole spacing is 15 m, the borehole diameter is 75 mm, and the distance from the borehole opening to the production side is 1 m.

- (2)

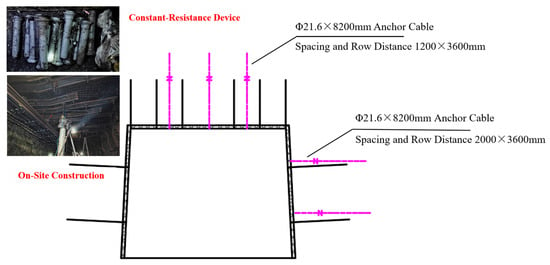

- Constant-resistance energy-absorbing anchor cable support scheme: Corresponding anchor cables were constructed on the solid coal side and roof of the 6311 rail gateway. The layout of the constant-resistance energy-absorbing anchor cables on the roof is with a spacing and row spacing of 1200 × 3600 mm, and the anchor cable parameters are Φ21.6 × 8200 mm; the anchor cable layout on the solid coal side is two anchor cables per section, 1000 mm from the roof and floor, respectively, with a spacing of 3600 mm, in the same section as the roof support anchor cables.

- (3)

- Small coal pillar grouting reinforcement scheme: Grouting boreholes were constructed on the non-production side of the 6311 rail gateway.

5. Scheme Design and On-Site Application

As can be seen from the above engineering recommendations, under the conditions of deep thick coal seams, the synergistic support–unloading control scheme is an effective method to control the deformation and failure of goaf-side roadways. This scheme has been applied in the field at the 6311 working face of Tangkou Coal Mine. The post-construction data were tracked and monitored to verify the actual effect of the synergistic support–unloading control system, providing an important reference for solving the problem of surrounding rock control in goaf-side roadways of deep thick coal seams.

5.1. On-Site Scheme Design

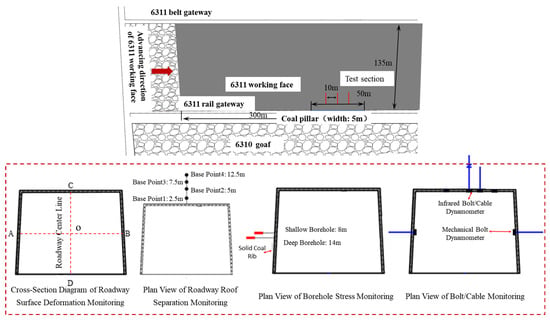

The on-site test section starts at 300 m ahead of the goaf-side roadway in the 6311 working face rail gateway, with a total length of 50 m. Within the test section, coal pillar grouting reinforcement, constant-resistance anchor cable support, and roof blasting borehole pressure relief are implemented on-site. A schematic diagram of the specific test section is shown in Figure 21.

Figure 21.

Schematic of on-site test section.

5.1.1. Deep-Hole Blasting for Pressure Relief

Deep-hole blasting pressure relief was carried out in the test section of the 6311 working face goaf-side roadway. The parameters for the layout of roof pre-splitting blasting boreholes above the production rib side of the roadway are as follows: the boreholes are directed along the dip of the working face, with a spacing of 15 m, a diameter of 75 mm, a depth of 38 m, an opening position 1 m from the roadway rib, and an elevation angle of 75°. The charge quantity per blasthole is 59.5 kg, and the borehole sealing length is 13 m. A schematic diagram of deep-hole blasting pressure relief at the top of the production rib side in the 6311 working face rail gateway is shown in Figure 22.

Figure 22.

Deep-hole blasting parameters diagram (Left) and profile diagram (Right).

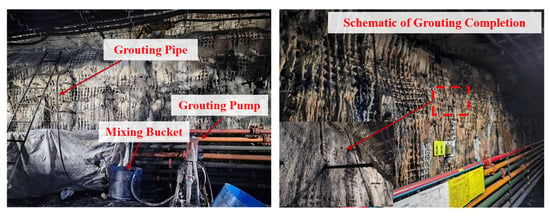

5.1.2. Grouting Reinforcement of Coal Pillars

To better reinforce the small coal pillar of the goaf-side roadway by grouting, improve its bearing capacity, and form a grouting reinforcement scheme for the small coal pillar, Figure 23 shows a schematic diagram of on-site grouting operations.

Figure 23.

On-site grouting operation diagram.

5.1.3. Constant-Resistance Anchor Cable Support

The on-site constant-resistance energy-absorbing anchor cable support scheme for the test section roadway is as follows: high-strength constant-resistance energy-absorbing anchor cables of Φ21.6 × 8200 mm are used for the roadway roof, with a spacing and row distance of 1200 × 3600 mm. For the solid coal rib side, two anchor cables are arranged per cross-section, with a spacing of 3600 mm, located in the same cross-section as the roof anchor cables. The upper and lower anchor cables are 1000 mm from the roof and floor, respectively, arranged perpendicular to the roadway rib, and the designed pre-tightening force of the anchor cables is 175 kN, consistent with the original on-site support. Figure 24 shows the on-site support layout of the roadway.

Figure 24.

Schematic of support layout.

5.2. On-Site Effect Monitoring

To monitor the changes in the surrounding rock of the 6311 working face rail gateway after the application of the synergistic support–unloading control scheme, a monitoring cross-section was arranged in the middle of the test section, with two additional monitoring cross-sections set 10 m apart from it (one inside and one outside). The monitoring involved arranging corresponding monitoring cross-sections to monitor indicators such as roadway surface displacement, roof separation displacement, coal and rock mass stress, and bolt/cable force after the completion of relevant engineering measures, and analyzing the changes in the collected data. The layout of the monitoring scheme is shown in Figure 25.

Figure 25.

Layout schematic of on-site monitoring scheme.

- (1)

- Convergence deformation monitoring.

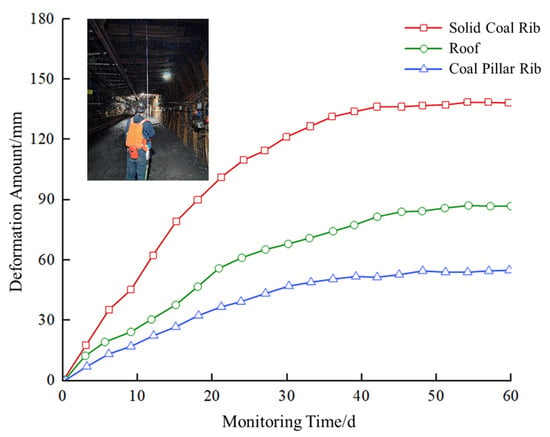

The cross-measuring-point method was used for long-term monitoring in the monitoring section. The surface displacement changes in the roadway at different positions are shown in Figure 26.

Figure 26.

Deformation curves of roadway surrounding rock.

As can be seen from the figure, after implementing the on-site support scheme, the deformation of the roof, solid coal rib, and coal pillar rib all increased, but the total amount was small, with a slow increase basically occurring within 30 days, after which it entered a stable state without significant fluctuations. By position, the deformation of the solid coal rib > the deformation of the roof > the deformation of the coal pillar rib. The maximum deformation of the solid coal rib was 130 mm, the roof was 79 mm, and the coal pillar rib was 45 mm, all far less than the deformation data of the roadway surrounding rock measured at the early monitoring section on-site.

- (2)

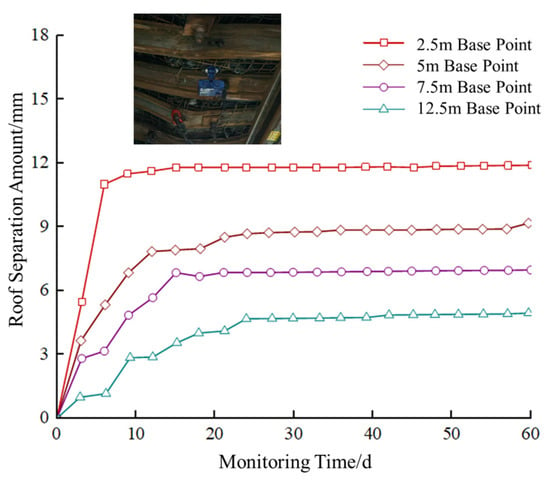

- Roof separation monitoring.

To monitor and statistically analyze the displacement of the roof strata in the test section after implementing the synergistic support–unloading control scheme, a multi-point extensometer was used for long-term monitoring in the monitoring section. The deep displacement changes are shown in Figure 27.

Figure 27.

Deep displacement variation curves of roadway roof.

- (3)

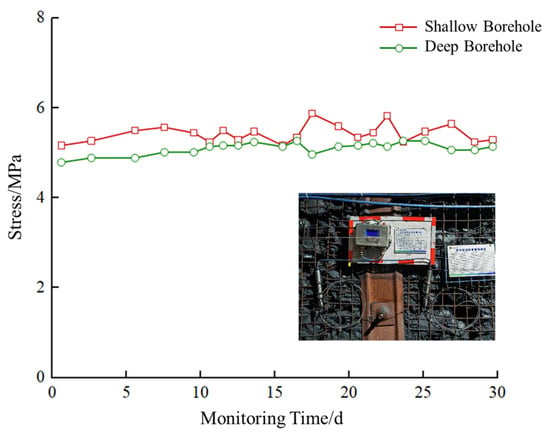

- Coal stress monitoring.

To monitor and statistically analyze the stress changes in the solid coal rib of the test section after implementing the synergistic support–unloading control scheme, borehole stress meters were used for long-term monitoring in the monitoring section. The stress changes in the solid coal rib of the roadway are shown in Figure 28.

Figure 28.

Stress variation curves of roadway solid coal rib.

As can be seen from the figure, after completing all measures on-site, the monitoring data of the borehole stress meters installed at depths of 8 m and 14 m inside the solid coal rib at the monitoring section showed little change during the monitoring period, maintaining a small fluctuation state (the maximum difference rate between shallow boreholes and deep boreholes is only about 15%) without significant stress increase or decrease. This indicates that the measures improved the stress environment around the roadway surrounding rock as a whole, avoiding the harm caused by high stress to roadway supports and deformation. At the same time, it can be observed that the shallow-hole stress is generally greater than the deep-hole stress, indicating that the shallow coal body is more significantly affected by stress.

- (4)

- Bolt/cable force monitoring.

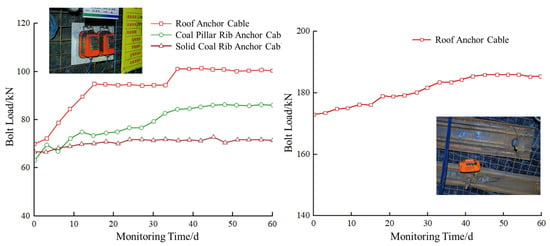

To monitor and statistically analyze the force changes in the bolts/cables in the test section after implementing the synergistic support–unloading control scheme, bolt/cable axial force meters were used to collect long-term data statistics in the monitoring section. The force changes in the roadway bolts/cables are shown in Figure 29.

Figure 29.

Axial force variation curves of bolts (Left) and anchor cables (Right).

As can be seen from the figure, for the on-site monitored bolts, the designed initial pre-tightening force was 60~70 kN. The load of the roof bolts increased rapidly in the initial monitoring stage, slowed down after about 10 days, gradually stabilized, and had another significant increase at about 37 days, finally stabilizing at about 100 kN. The bolts on the coal pillar rib fluctuated and increased in the early stage, slowed down after about 30 days, and finally stabilized at about 82 kN. The bolts on the solid coal rib showed little overall change during the entire monitoring period and finally stabilized at about 69 kN. The final stable loads of the above three are all far less than the designed anchorage force of 190 kN for the bolts, indicating a high bearing reserve. For the on-site-monitored anchor cables, the initial designed pre-tightening value was 175 kN, which gradually increased slowly during the entire monitoring period and finally reached 185 kN. Relative to the designed anchorage force of 350 kN for the anchor cables, there is still considerable bearing reserve space; the remaining bearing reserve space is 47%.

6. Discussion

This study aims to solve the deformation and failure problem of gob-side entries in deep thick coal seams caused by the complex stress environment in deep areas.

By revealing its failure mechanism, a suitable coordinated support and unloading control method is proposed to provide technical support and practical reference for roadway support engineering under similar conditions.

To achieve the research objectives, at the on-site level, monitoring sections were arranged in the 6311 working face of Tangkou Coal Mine to monitor the deformation of the roadway roof, floor, and two ribs; the changes in surrounding rock stress; and the force on bolts (cables). Combined with borehole peeping technology, the internal fragmentation characteristics of the surrounding rock were analyzed, and data on roadway deformation laws and stress evolution were obtained. At the theoretical and numerical simulation level, a FLAC3D numerical model was constructed based on on-site geological parameters, and the characteristics of surrounding rock stress distribution under the conditions of no support, original support, and coordinated support–unloading control schemes were compared and analyzed to verify the effectiveness of the control method. At the on-site application level, a 50 m test section was selected to implement roof blasting for pressure relief, coal pillar grouting reinforcement, and constant-resistance energy-absorbing cable support. The actual effect of the technical scheme was tested by monitoring indicators such as convergence deformation, roof separation, coal stress, and the force on the bolts (cables).

This study still has certain limitations: First, the research was carried out based on the 6311 working face of Tangkou Coal Mine (burial depth: 920 m; coal seam thickness: 9.3 m). The applicability of the conclusions under conditions of greater burial depth (such as more than 1000 m), thicker coal seams (such as more than 10 m), or different lithological combinations needs to be further verified. Second, the parameters for coal pillar grouting reinforcement (elastic modulus, cohesion, etc.) in the numerical simulation refer to previous studies and have not been dynamically corrected in full combination with on-site-measured data for grouting diffusion, which may lead to deviations from the actual reinforcement effect.

Future research can be deepened through the following approaches: (1) Establishing a correlation model between control parameters and geological conditions for different burial depths, coal seam thicknesses, and lithologies to improve the technical universality. (2) Optimizing the method for determining the mechanical parameters of rock strata/coal pillars in numerical simulations to improve the prediction accuracy of the model. (3) Conducting long-term monitoring of the test roadway, studying the mechanical response law of the support system under long-term mining influence, and proposing time-dependent maintenance strategies.

7. Conclusions

(1) Through on-site monitoring and borehole peeping of the track gateway in the 6311 working face of Tangkou Coal Mine, it is found that the roadway deformation shows decreases in the order of floor, production rib, roof, and gob side. The displacement of the roof and floor is greater than the two ribs, and the section shrinkage rate is relatively high, reaching 56.4%. The surrounding rock stress change has three stages: slow growth, rapid growth, and sharp decline. The breakage of bolts (cables) is concentrated at 0~30 m/25~80 m, and the failure mechanism mainly stems from key factors such as the weak overall bearing capacity of the surrounding rock and coal pillar caused by the special structure of the gob-side entry into the thick coal seam, significant unloading failure, and the insufficient adaptability of the support cables under the high-stress environment.

(2) Aiming at the failure mechanism and deformation problem of gob-side entries in deep thick coal seams, the proposed coordinated support and unloading control method has significant effectiveness. According to the comparative analysis of FLAC3D numerical simulation, compared with the original support schemes, the coordinated support–unloading control scheme can effectively change the stress transfer path and alleviate the stress concentration near the coal pillar. The horizontal displacement on the coal pillar side is reduced by 89.5% compared with the original support scheme, and the horizontal displacement on the solid coal side is reduced by 79.3%; the vertical displacement on the coal pillar side is reduced by 45.8%, and the vertical displacement on the solid coal side is reduced by 42.4%. The approach significantly improves the stress distribution and stress state of the surrounding rock, and its control effect is better than that of a single support or pressure relief measure, reflecting the advantage of the synergistic effect of “pressure relief” and “support”.

(3) The on-site application of the coordinated support and unloading control method in the 6311 working face of Tangkou Coal Mine has achieved good actual results, verifying the feasibility and applicability of the technical scheme. On-site monitoring results show that after implementing this method, compared to the original support scheme, the maximum deformations of the solid coal rib, the roof, and the coal pillar rib of the roadway are reduced by 76%, 83%, and 88%, respectively; the shallow and deep roof separation is at a low level; the coal stress continues fluctuating stably during the monitoring period; and the force on the bolts (cables) does not exceed the designed anchoring force, with sufficient bearing reserve space (47% remaining), with no breakage occurring, effectively ensuring the stability of the roadway. This achievement not only realizes the effective control of the on-site roadway, but also provides an important technical reference and practical experience for the support engineering of gob-side entries in deep thick coal seams under other similar conditions.

Author Contributions

Conceptualization, C.Z., Y.S. and Y.H.; methodology, C.Z., Y.S., Y.Z.,Y.H., H.Y., C.C. and H.T.; investigation, C.Z., Y.S., Y.Z.,Y.H., H.Y., Z.Z., C.C. and H.T.; resources, Y.S. and Z.Z.; writing—original draft preparation, Y.Z. and H.Y.; writing—review and editing, Y.H.; supervision, Y.H.; project administration, C.Z.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key R&D Program of China (2024YFC2909504) and National Natural Science Foundation of China (NSFC) Project (42177130, 42307213).

Data Availability Statement

The original contributions presented in this study are included in this article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhu, C.L.; Zhang, J.X.; Li, M.; He, Z.; Wang, Y.; Lan, Y. Effect mechanism of strata breakage evolution on stope deformation in extra-thick coal seams. Alex. Eng. J. 2022, 61, 5003–5020. [Google Scholar] [CrossRef]

- Xu, Y.; Zhou, X.K.; Gong, W.M.; Zhang, Z. Mechanism and control of cable breakage in a roadway with thick top coal in a rockburst mine. Adv. Civ. Eng. 2021, 2021, 2275820. [Google Scholar] [CrossRef]

- Yu, Y.; Lu, J.F.; Chen, D.C.; Pan, Y.; Zhao, X.; Chen, C.; Gao, S. Research on mechanisms and control measures of surrounding rock disaster in large section roadway with top coal under the influence of tectonic stress. Shock. Vib. 2021, 2021, 4474895. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, Y.; Zhang, Q.; Wei, Y.; Liu, W.; Jiang, T. Space-time evolution characteristics of deformation and failure of surrounding rock in deep soft rock roadway. Sustainability 2022, 14, 12587. [Google Scholar] [CrossRef]

- Feng, J.; Yin, S.; Cheng, Z.; Shi, J.; Shi, H.; Xu, H.; Guo, S.; Wang, H. Deformation and failure mechanism of surrounding rock in mining-influenced roadway and the control technology. Shock. Vib. 2021, 2021, 5588314. [Google Scholar] [CrossRef]

- Zang, C.; Chen, M.; Zhang, G.; Wang, K.; Gu, D. Research on the failure process and stability control technology in a deep roadway: Numerical simulation and field test. Energy Sci. Eng. 2020, 8, 2297–2310. [Google Scholar] [CrossRef]

- Zheng, L.; Zuo, Y.; Hu, Y.; Wu, W. Deformation mechanism and support technology of deep and high-stress soft rock roadway. Adv. Civ. Eng. 2021, 2021, 6634299. [Google Scholar] [CrossRef]

- Wang, M.; Ding, F.; Niu, Z.; Gao, Y.; Jiao, H.; Chen, Z. Numerical investigation with failure characteristic analysis and support effect evaluation of deep-turning roadways. Appl. Sci. 2024, 14, 10075. [Google Scholar] [CrossRef]

- Zeng, C.; Zhou, Y.; Xiao, Y.; Zhou, X.; Zhu, C.; Xu, Y. Research on soft rock damage softening model and roadway deformation and failure characteristics. Materials 2022, 15, 5886. [Google Scholar] [CrossRef]

- Chu, H.; Li, G.; Liu, Z.; Liu, X.; Wu, Y.; Yang, S. Multi-Level Support Technology and Application of Deep Roadway Surrounding Rock in the Suncun Coal Mine, China. Materials 2022, 15, 8665. [Google Scholar] [CrossRef]

- Liu, P.; Wang, H.; Liu, Q.; Li, X.; Dong, Y.; Xie, X. FDEM numerical study on the large deformation mechanism of layered rock mass tunnel under excavation-unloading disturbance. Tunn. Undergr. Space Technol. 2025, 159, 106497. [Google Scholar] [CrossRef]

- Xue, H.; Jiang, B.; He, M.; Zhang, C.; Wang, Y.; Zhang, S.; Deng, Y. Mechanism and validation of pressure relief and energy reduction of automatically formed roadway by roof cutting in deep coal mines. Bull. Eng. Geol. Environ. 2025, 84, 77. [Google Scholar] [CrossRef]

- Liu, C.; Cheng, P.; Zhao, G.; Xu, W.; Meng, X.; Liu, W.; Cheng, X. Experimental study on the failure mechanism of roadway surrounding rock under true triaxial loading: Insights from acoustic emission (AE) characteristics. Measurement 2025, 246, 116727. [Google Scholar] [CrossRef]

- Wang, J.; Wu, S.; Wang, Z.; Barbaryka, A.; Tost, M.; Li, M. New Prediction Method of Subsidence Based on the Numerical Displacement Analysis: A Study Case of Deep-Buried Thick Alluvial Layer and Thin Bedrock. Rock Mech. Rock Eng. 2025, 58, 6723–6744. [Google Scholar] [CrossRef]

- Demin, V.; Khalikova, E.; Rabatuly, M.; Amanzholov, Z.; Zhumabekova, A.; Syzdykbaeva, D.; Bakhmagambetova, G.; Yelzhanov, Y. Research into mine working fastening technology in the zones of increased rock pressure behind the longwall face to ensure safe mining operations. Min. Miner. Deposits 2024, 18, 27–36. [Google Scholar] [CrossRef]

- Vu, T.T.; Do, S.A. Determination of the Rock Mass Displacement Zone by Numerical Modeling Method When Exploiting the Longwall at the Nui Beo Coal Mine, Vietnam. Min. Miner. Deposits 2023, 17, 59–66. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, F.; Qu, H.; Liu, C.; Li, Z.; Hao, W. Surrounding rocks deformation mechanism and roof cutting-grouting joint control technology for soft and thick coal seam roadway. Sustainability 2023, 15, 15415. [Google Scholar] [CrossRef]

- Peng, W.; Feng, S. Research on the Support Technology for Deep Large-Section Refuge Chambers in Broken Surrounding Rock in a Roadway. Appl. Sci. 2024, 14, 7527. [Google Scholar] [CrossRef]

- Yang, H.; Han, C.; Zhang, N.; Li, X.; Liu, Y.; Liu, W.; Song, K.; Guo, Y.; Yao, W. Efficient Excavation and Support Cooperation Technology for Surrounding Rock of Deep Buried Long-Distance and Large Section Gob-Side Roadway: A Case Study. Geofluids 2022, 2022, 6895887. [Google Scholar] [CrossRef]

- Gong, H.; Li, D.; Ru, W.; Luo, P.; Zhang, G.; Liu, Y. Characteristics of damage deterioration and strategy of zonal support for surrounding rock in deep mine roadway. Eng. Fail. Anal. 2025, 170, 170109316. [Google Scholar] [CrossRef]

- Chang, J.; He, K.; Yin, Z.; Li, W.; Li, S.; Pang, D. Study on the Instability Characteristics and Bolt Support in Deep Mining Roadways Based on the Surrounding Rock Stability Index: Example of Pansan Coal Mine. Adv. Civ. Eng. 2020, 2020, 8855335. [Google Scholar] [CrossRef]

- He, Y.; Gao, M.; Xu, D.; Yu, X. Investigation of the evolution and control of fractures in surrounding rock under different pressure relief and support measures in mine roadways prone to rockburst events. R. Soc. Open Sci. 2021, 8, 202044. [Google Scholar] [CrossRef]

- Qi, X.; Wang, R.; Mi, W. Failure Characteristics and Control Technology of Surrounding Rock in Deep Coal Seam Roadway with Large Dip Angle under the Influence of Weak Structural Plane. Adv. Civ. Eng. 2020, 2020, 6623159. [Google Scholar] [CrossRef]

- Xue, H.; Wang, Q.; Jiang, B.; Jiang, Z.; Wang, Y.; Huang, Y.; He, M. Study on the method of pressure relief by roof cutting and absorbing energy in deep coal mines. Bull. Eng. Geol. Environ. 2023, 82, 298. [Google Scholar] [CrossRef]

- Aila, Z.; Vladimir, D.; Bekzhan, I.; Tatiana, D.; Gaukhar, A. Evaluating the Efficiency of the Mine Workings Supporting Technology Application to Increase Contour Stability. Tr. Univ. 2024, 185, 1609–1825. [Google Scholar]

- Xiang, Z.; Zhang, N.; Xie, Z.; Guo, F.; Zhang, C. Cooperative Control Mechanism of Long Flexible Bolts and Blasting Pressure Relief in Hard Roof Roadways of Extra-Thick Coal Seams: A Case Study. Appl. Sci. 2021, 11, 4125. [Google Scholar] [CrossRef]

- Wang, S.; Xiang, Z.; Deng, J.; Yang, H.; Yang, X.; Jin, S. Analysis of Cooperative Control Effect of Pressure Relief and Long Bolt Support for Deep Roadway Under Strong Mining Disturbance of Adjacent Working Face. Geotech. Geol. Eng. 2021, 39, 2259–2268. [Google Scholar] [CrossRef]

- Zhu, L.; Feng, G.; Cui, J. Research on the Influence of Slurry Filling on the Stability of Floor Coal Pillars during Mining above the Room-and-Pillar Goaf: A Case Study. Geofluids 2020, 2020, 8861328. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).