Abstract

Tests during methane hydrate (MH) production in Japan have shown that excessive water production is a primary challenge in MH development. It can lead to sand production, inhibit effective reservoir depressurization, and hinder gas production. This study investigated the ability of a reactive grout, produced by the in situ reaction of CO2 with sodium silicate (SS), to inhibit water generation from unconsolidated sand layers by forming a water-blocking gel barrier. The performance of this grout was evaluated through laboratory experiments using silica sand as a porous medium. Under controlled conditions, diluted SS and CO2 were sequentially injected. The injection and gelation processes were monitored in real time using CT scanning, and SEM was employed to analyze the microstructure of the reaction products. The results indicated that SS exhibited piston-like flow, with elevated concentrations increasing viscosity and promoting more uniform injection. CO2 injection resulted in successful in situ gel formation. A homogeneous gel distribution decreased permeability by ~98% when the SS concentration was 25 wt%. However, at 50 wt%, rapid localized gelation caused preferential flow paths and reduced sealing efficiency. These findings highlight the potential of CO2 reactive grouting for water management in MH exploitation and the importance of optimizing injection parameters.

1. Introduction

As the global primary energy demand continues to rise and the urgency to control the increase in global temperatures intensifies, clean energy sources, particularly natural gas, have garnered considerable attention and have experienced a significant increase in demand in recent years [1]. One of the most abundant natural sources of methane, MH, is considered to have substantial potential to meet the growing demand for natural gas in the future [2,3]. Consequently, research on MH has been actively pursued by various countries worldwide.

Over the past decade, Japan has conducted two offshore MH production tests at the Daini Atsumi Knoll in the Eastern Nankai Trough. These tests have revealed several challenges in MH development, with excessive water production being a key issue [4,5]. The depressurization method, widely used to produce methane gas from MH, works by lowering the reservoir pressure, thereby destabilizing MH and causing it to decompose into methane gas and water [6]. However, excessive water production can hinder further pressure reduction. Moreover, MH-bearing sediments are typically unconsolidated, making them more susceptible to sand production, which ultimately reduces productivity or even causes production to stall [7]. An analysis of production test data indicates that this excessive water mainly originates from formation water [4,5,7]. Both experimental studies [8] and numerical simulations [9] have demonstrated that formation water intrusion significantly reduces the effectiveness and gas production capacity of the depressurization method. Therefore, effective depressurization requires blocking the flow of water from the formation water.

Early research on MH development studied the reservoir’s overburden and underburden as impermeable seals. However, with further investigation, it has been found that potentially mobile water may exist not only within the overburden and underburden but also along the lateral boundaries [10]. To prevent water from entering the reservoir, extensive research has been conducted to address this issue. Among various approaches, reservoir reformation using CO2 hydrates has garnered particular attention [11,12,13,14]. However, this method typically requires continuous CO2 injection over several years [14], which poses challenges with regard to maintaining the long-term effectiveness of CO2-CH4 replacement and in reducing operational costs. Additionally, the potential risk of CO2 leakage remains a significant concern [11]. In addition, the use of water-blocking agents is also a common method for achieving effective water shutoff. However, commonly available agents such as Relative Permeability Modifiers (RPMs) have relatively high initial viscosity, which leads to poor injectivity and difficulty penetrating deep formations. Given the uncertain distance between the water-bearing zone and the production well, plugging agents must possess effective deep sealing capabilities. Due to the permeability of reservoir boundary layers, plugging only the adjacent water-bearing formations is insufficient to effectively prevent continuous water infiltration into the MH reservoir, where the infiltrated water is subsequently produced during extraction. This infiltration becomes more pronounced under depressurization conditions. Therefore, conventional water-blocking agents often exhibit limited efficacy in mitigating this issue.

On the other hand, in carbon capture and storage (CCS) research, we previously proposed and validated a CO2-reactive grout based on the reaction between CO2 and sodium silicate [15]. The plugging mechanism of sodium silicate (SS) arises from its reaction with dissolved CO2, leading to the formation of amorphous silica (SiO2 (am)) precipitates, as shown in the following reactions:

Na2O·3SiO2 + H2CO3 → Na2CO3 + 3SiO2 (am) + H2O

Na2O·3SiO2 + 2H2CO3 → 2NaHCO3 + 3SiO2 (am) + H2O

Na2O·3SiO2 + 2H2CO3 → 2NaHCO3 + 3SiO2 (am) + H2O

The amorphous silica formed during the reaction can clog pores and fractures in situ, thereby contributing to effective plugging performance. We simulated reservoir flow paths using glass beads. Microscopic observations inside the pressure vessel revealed CO2 reaction products adhering to the bead surfaces, clearly demonstrating the pore-clogging effect of amorphous silica precipitates. Even in samples with permeability up to several darcies, permeability was reduced to less than 1% of the original value, and these findings were further validated by numerical simulations. In addition, reports have indicated that the application of CO2 in reservoirs has been receiving increasing attention [16]. For MH reservoirs, owing to the extremely low viscosity of CO2, CO2 exhibits excellent permeability and is capable of penetrating deeply into the reservoir. Sequential injection of SS and CO2 into the water-bearing formation induces an in situ chemical reaction, resulting in the formation of gelation products that establish extensive blocking barriers. This strategy overcomes the limitations associated with traditional plugging agents in deep formation.

However, because of different application purposes, the previous method cannot be directly applied to seal the water-bearing zone. In our 2014 CCS laboratory study, we assumed that CO2 naturally migrated upward along leakage paths in the storage reservoir due to gravity and buoyancy forces, reacting with the pre-injected sodium silicate solution to form sealing structures. In contrast, the present study targeting methane hydrate (MH) reservoirs requires forced injection of sodium silicate solution and CO2 into horizontal layers. The difference in injection methods of the solution and CO2 may influence the related phenomena. For example, buoyancy-driven accumulation of CO2 above the horizontal layer might affect the spatial distribution of the reaction products and their plugging performance. An excessively rapid reaction may lead to premature blockage at the injection site, impeding the deep penetration of CO2 and consequently restricting the effective sealing zone. In view of these issues, systematic experimental studies are needed to verify the feasibility of applying CO2-reactive grouting materials in unconsolidated sand formations.

To evaluate the water-blocking performance of CO2 reactive grout, core plugging tests were conducted under simulated MH reservoir conditions. To investigate the injection and mixing process of SS and CO2, X-ray computed tomography (CT) was employed to continuously monitor and record the internal structure of the cores. After the tests, core samples were extracted for scanning electron microscopy (SEM) analysis to determine the primary distribution and degree of gelation of the gel products. This study serves as fundamental research aimed at investigating the flow trajectories of SS and CO2 and the spatial distribution of the resulting water-blocking agents in unconsolidated sand formations. It should be noted that the sand samples used in this experiment do not contain methane hydrate.

2. Laboratory Experiments

Laboratory experiments were conducted to evaluate the permeability changes in core samples simulating MH reservoirs. Sodium chloride (NaCl) brine was injected into the cores both before and after grouting to measure the variation in permeability. During the grouting process, CT imaging was employed to monitor and visualize the flow paths of saline solution and CO2 within the samples. The following sections provide detailed descriptions of the materials used, the experimental system setup, and the procedures followed.

2.1. Experimental Materials and Preparation

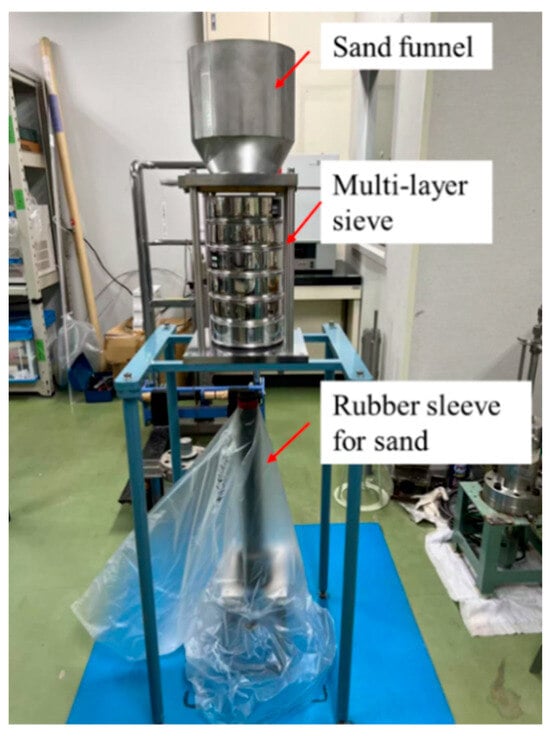

To minimize the impact of heterogeneity in natural formations on internal flow behavior, uniform-grained Tohoku silica sand No. 8 (average particle diameter: ~0.12 mm) was selected as the experimental sand specimen. This sand meets the Japanese Industrial Standards (JIS), and its particle size is comparable to that of typical reservoir sands. Previous studies have used Tohoku silica sand No. 8 to simulate the fine sand characteristics of MH reservoirs [17], indicating that it can effectively represent actual reservoir conditions. The cores were prepared using the Multiple Sieving Pluviation (MSP) method (as shown in Figure 1) to ensure uniform sand deposition and a controllable relative density. Dry sand was first poured into a funnel equipped with multiple sieves, which regulated the falling speed and flow rate of the sand particles to achieve uniform deposition while minimizing segregation and agglomeration. The sand particles were allowed to fall freely from a fixed height and were uniformly deposited into the rubber sleeve below, forming the sand-packed core used in subsequent experiments.

Figure 1.

Experimental setup for preparing sand-packed cores using the Multiple Sieving Pluviation (MSP) method. Dry sand passes through a sand funnel and multi-layer sieves to control particle flow and ensure uniform deposition.

The sand-filled rubber sleeve was then inserted into the core holder, as illustrated in Figure 2. Stainless steel mesh and end caps were attached at both ends of the sleeve to secure the core and prevent sand leakage. The right side of Figure 2 depicts a cross-sectional view of the end cap at positions A and B, indicated by dashed lines in the left schematic. A specially designed spiderweb-patterned groove structure was applied to the face of the core support plug, which is in direct contact with the end surface of the core sample. This design ensures uniform fluid distribution across the entire core face, both when entering and exiting the core. Such grooves are highly effective in mitigating capillary inlet and outlet effects. The core holder was constructed with a carbon-fiber-reinforced polymer (CFRP) outer shell and an aluminum inner lining. Water was injected into the annular space between the aluminum lining and the rubber sleeve to apply confining pressure to the sample. As CT scanning was required during the experiment, the selection of materials was particularly critical. CFRP offers an excellent compressive strength and is semi-transparent to X-rays, helping to reduce imaging artifacts. Aluminum provides high structural strength and a favorable strength-to-weight ratio, enabling it to withstand high pressure while minimizing interference with CT imaging. The combination of these two materials ensures both the mechanical stability of the core holder and improved CT image quality.

Figure 2.

(Left): Schematic of the core holder with a rubber sleeve containing the sand core, secured by end caps and stainless-steel mesh; water is injected into the annular space to provide uniform confining pressure. (Right): Detailed view of the spiderweb-patterned grooves on the inlet and outlet plugs, designed to ensure even fluid distribution and minimize capillary inlet and outlet effects.

The grouting agent used in this study was JIS-standard No. 3 sodium silicate (JIS K 1408:1966 [18]) with a Na2O·3SiO2 concentration of 1.46 mol/L (Caili Ceramics Co., Ltd., Guangzhou, China). To control the reaction rate and viscosity and prevent rapid gelation near the injection port, the solution was diluted to 12.5–50 wt%. Apparent viscosity was measured at room temperature using a Viscometer SV-10 (AND Co., Ltd., Takayama, Japan). As illustrated in Figure 3, dilution significantly reduced the viscosity to approximately 1 to 4 times that of water, compared to approximately 200 mPa·s for the undiluted solution. Additionally, 3 wt% sodium iodide (NaI), a neutral reagent-grade salt (≥99.5%, Wako Pure Chemical Industries, Ltd., Osaka, Japan), was added to the diluted solution as a contrast agent. Viscosity measurements indicated that the addition of NaI had a minimal impact on the fluid’s viscosity. NaI is a neutral salt that does not react with CO2 or SS and does not significantly change the pH, so it does not affect gelation.

Figure 3.

Relationship between sodium silicate (SS) concentration and apparent viscosity at room temperature. Viscosity was measured for JIS-standard No. 3 SS (1.46 mol/L Na2O·3SiO2) diluted from 12.5 to 50 wt%.

CO2 gas (≥99.5%, Toyo High-Pressure Gas Co., Ltd., Chiba, Japan) was first pressurized into a syringe pump using a commercially available CO2 pump (TELEDYNE ISCO 500D, Lincoln, NE, USA), then injected at a constant rate by advancing the syringe pump piston. Absolute permeability was calculated using Darcy’s law with a 3 wt% NaCl brine injection.

where is the water viscosity, A is the cross-sectional area, and L is the core length. ∆P is the pressure drop across the core, and Q is the injection flow rate.

2.2. Experimental System

Figure 4 illustrates the core sample sealed in a rubber sleeve with end caps (left), and CT system control console (right). The CT scanner used in this study was manufactured by Siemens. During scanning, the sample was placed into the core holder shown in Figure 2 and positioned horizontally on the scanning bed, with its axis aligned with the direction of scanner movement. Circular cross-sectional images perpendicular to the core axis were acquired at 0.5 mm intervals.

Figure 4.

(Left): Core sample sealed in a rubber sleeve with end caps. (Right): CT system control console.

The structure and materials of the core holder have been detailed in the previous section, with the design of the pressure vessel carefully considering the requirements for CT imaging. Although the in situ pressure of MH reservoirs typically exceeds 10 MPa, the confining pressure in this study was set to 400 psi (around 2.76 MPa) to balance material safety and CT image quality. It is worth noting that increasing pressure can enhance the plugging efficiency of the CO2 and SS system, mainly by increasing the solubility of CO2 and accelerating the reaction rate, thereby forming a denser gel structure. Consequently, in practical applications, CO2-reactive grout is expected to demonstrate superior plugging performance. All experiments were conducted at room temperature (20 °C), which is close to the temperature of methane hydrate (MH) reservoirs (approximately 10 °C).

The core holder was placed horizontally during scanning, with the core axis aligned to the scanner movement. Cross-sectional images were taken at 0.5 mm intervals perpendicular to the core axis.

The experimental flow is depicted in Figure 5, with a photograph of the actual setup shown in Figure 6. A back pressure regulator (BPR; Swagelok, Solon, OH, USA) was installed downstream of the core to maintain a stable system pressure. Pressure gauges (Kyowa PGS-50KA, Tokyo, Japan) were positioned both upstream and downstream to continuously monitor injection and back pressures. To reduce errors potentially caused by clogging upstream, a differential pressure gauge (Kyowa PDU-A-1 MPa) was incorporated into the system. Liquid injection was performed using a TELEDYNE ISCO syringe pump of the same model as that used for CO2 gas. Stainless-steel tubing and fittings (1/8 inch), manufactured by Swagelok, were primarily used for pressure gauge connections in the experimental system. To ensure pressure resistance, a larger-diameter stainless steel tube was employed for the CO2 inlet. In contrast, PTFE (Teflon) tubing, renowned for its exceptional chemical resistance, was utilized for liquid injection lines. Additionally, to prevent CO2 and liquid from mixing during injection, multiple valves were installed to keep their flow paths separate.

Figure 5.

Schematic of experimental setup highlighting the positions of valves. For a detailed view of the core holder, see Figure 2.

Figure 6.

Photograph of the experimental setup with labeled components, including the core holder, accumulator, helium porosimeter, back pressure regulator (BPR), pressure gauges, and syringe pumps.

2.3. Experimental Procedures

After preparing the material, connecting the pipeline, and applying a 2.76 MPa confining pressure, the experimental procedures were conducted in the following sequence.

- ①

- Porosity measurements

CT scanning was performed on the core in its dry state. Core porosity was measured using a helium porosimeter (Core Laboratories Inc., Houston, TX, USA) equipped with a Bourdon-type pressure gauge. The pore volume was determined by subtracting the pre-measured volumes of the connecting pipes (v1 to v5) from the total system volume (see Figure 5). Porosity was then calculated by combining this pore volume with the core volume evaluated from CT imaging. To ensure the accuracy of the measurements, porosity was also cross-validated using the true density of the sand, which had been measured in advance with a pycnometer manufactured by Bel Japan, Inc., Tokyo, Japan.

- ②

- Core saturation with NaCl brine

The specimen and the piping system were first saturated with CO2, followed by evacuation under vacuum. Upon completion of the vacuum process and exposure of the system to atmospheric pressure, the core was immediately saturated with a NaCl brine solution. To displace any remaining dissolved CO2, 1 pore volume (1 PV) of NaCl brine was injected at a flow rate of 1.0 mL/min. Simultaneously, BPR was adjusted to approximately 500 kPa and maintained at this setting throughout the subsequent experiments. CT scanning was performed on the core in its NaCl brine-saturated state.

- ③

- Permeability measurement (prior to grouting test)

NaCl brine was injected into the core at incrementally increasing flow rates (1 → 2 → 3 → 4 mL/min), each maintained for 10 min. The pressure difference across the core was measured, and the permeability prior to the grouting experiment was calculated based on Darcy’s law.

- ④

- SS injection

The fluid in the accumulator was switched from NaCl brine to SS. Approximately 0.5 PV of SS was injected into the core from the upstream inlet, with the injection rate initially set at 0.5 mL/min and later increased to 1.0 mL/min. CT scans were performed on the core saturated with both SS and NaCl brine. Scanning was conducted immediately after the SS injection and subsequently every 0.05 PV until a volume of 0.5 PV was reached. After the SS injection, an additional 10 mL of NaCl brine was injected at 1.0 mL/min to flush out residual SS remaining in the inlet tubing. CT scans were taken during the valve switching process and subsequently at 5 min intervals.

- ⑤

- CO2 injection

During the experiment, the fluid in the accumulator was switched from SS to CO2. To prevent a sudden CO2 influx into the core, the CO2 line pressure was set approximately 10 kPa below the core pressure prior to valve switching, ensuring that injection would not occur until the pressure rose after the CO2 pump was started. CT scanning was performed on the core saturated with water glass, NaCl brine, and CO2 throughout the injection process. Scans were conducted immediately after CO2 injection, then every 3 min until 0.3 PV had been injected; thereafter, scans were performed every 0.05 PV until the total injection reached 1.0 PV (approximately one scan every 12 min). Injection was terminated if a CO2 breakthrough was detected in the CT images. The injection rate was maintained at 0.5 mL/min, with an injection pressure limit set at 1 MPa. Additionally, the volume of produced water was monitored regularly at every 0.05 PV increment to track fluid dynamics.

- ⑥

- Waiting period for SS-CO2 reaction

After the CO2 was injected, the system pressure was allowed to decrease naturally to 0.5 MPa. Valves V2 and V4 (Figure 2) were then opened, and a constant pressure of 0.5 MPa was maintained using a pump. CT scans were scheduled at 15 min, 30 min, and 1 h after injection, followed by hourly scans up to approximately 3 h. Finally, the sample was left to stand undisturbed overnight, allowing the reaction to proceed.

- ⑦

- Permeability measurement (post-grouting experiment)

Prior to the measurement, CT scans were performed on the core saturated with water glass, NaCl brine, and CO2. The fluid in the accumulator was then switched to NaCl brine. NaCl brine was injected into the core at incrementally increasing flow rates of 1.1, 1.2, 1.3, and 1.4 mL/min, each maintained for 10 min. Water permeability was calculated after the experiment based on the pressure difference between the upstream and downstream sides, with a back pressure maintained at 0.5 MPa. CT scans were conducted at the beginning and end of each flow rate stage to monitor the core condition.

3. Experimental Results

Table 1 summarizes the physical properties of the core samples used in this study, along with the reduction in permeability observed after grouting for each experimental run. Here, Vb and Vp represent the bulk volume and pore volume of the cores, respectively, while Kw1 and Kw2 denote the permeability before and after grouting. CT imaging confirmed that the physical properties of the core samples were consistent across all test groups, with an average core length of approximately 28 cm and a diameter of about 3.7 cm. Except for Run A, the porosity in the other test runs was around 45%, and the initial water permeability (Kw1) was approximately 3200 mD. The SS solutions used in the experiments were diluted by factors ranging from 2 to 8, corresponding to concentrations of 12.5 to 50 wt%.

Table 1.

Experimental conditions, core sample properties, and permeability reduction after grouting.

Run A represents the formal experiment conducted under a set of finalized conditions, established based on a series of preliminary tests. These preliminary tests mainly investigated the effects of different combinations of sample preparation methods, injection rates, and experimental pressures on the outcomes. The core sample used in this experiment exhibited relatively low porosity and initial permeability, likely due to localized compaction of the sand during sample preparation.

Figure 7 presents CT images obtained during the Run A experiment. Each scan generated more than 600 cross-sectional images of the core. For example, Figure 7a displays a cross-sectional image taken 1.15 cm from the upstream end of the core, with the bottom of the image corresponding to the lower side in the direction of gravity. To better visualize internal structural changes, a contrast-enhanced version is presented in Figure 7b. All subsequent CT images were processed in the same manner and displayed using the same contrast adjustment settings. Figure 7c displays a reconstructed axial view of the core based on the full set of cross-sectional images, with the bottom corresponding to the upstream inlet of the core. CT image reconstruction and analysis were performed using Fiji, a commonly used distribution of ImageJ version 1.54f, for image visualization and grayscale processing. The horizontal axis of the “A” view corresponds to the left and right directions in Figure 7a, while the horizontal axis of the “L” view corresponds to the vertical directions in Figure 7a. Brighter regions in the CT images indicate areas of higher density. In this experiment, the SS solution mixed with sodium iodide (NaI), along with its reaction products, exhibited the highest brightness, as evidenced by the intense high-grayscale region in the lower part of Figure 7c.

Figure 7.

CT images of the core during Run A. (a) Representative cross-sectional image acquired 1.15 cm from the upstream inlet. (b) Contrast-enhanced view to improve visualization of internal structures. (c) Axial reconstruction from all cross-sectional CT images, showing density distribution and accumulation of SS-NaI reaction products near the lower inlet region.

Figure 8 presents the reconstructed axial view CT images of the core in Run A, covering the entire process from SS injection to the post-gelation permeability measurement. During SS injection, a high-grayscale region gradually expanded downstream in the CT images (Figure 8a). Once this region extended beyond half the core length, corresponding to the 0.5 PV threshold described in Step ④, the injection was stopped, and the system was flushed with NaCl brine. Approximately 120 mL of CO2 was injected in Run A. In Figure 8b, the slightly darker area near the inlet indicates that the brine continued to advance deeper into the core, with the SS solution exhibiting piston-like displacement behavior.

Figure 8.

High-contrast axial CT images of the core during Run A. (a,b): SS injection phase at 25 wt%, showing progressive downstream expansion of high-density regions and piston-like displacement behavior. (c,d): CO2 injection phase, with scattered low-density channels forming within the SS zone. (e,f): NaCl brine injection state, showing high-density regions concentrated in the upper section.

In the subsequent CO2 injection phase (Figure 8d), scattered black spots appeared within the SS-occupied zone, indicating the formation of CO2 flow channels within the core. When these black areas reached the outlet, gas release was observed from the outlet (the cylinder shown in Figure 5). Figure 8e shows the state of the core after being left overnight to complete gelation. In Figure 8f, high-grayscale regions are predominantly concentrated in the upper part of the image, with a smaller amount also visible in the lower part. These are presumed to be well-gelled and structurally stable SS remnants. The results of Run A demonstrate that at a 25 wt% concentration, the SS gel exhibits excellent plugging performance, resulting in a reduction of approximately 98% in permeability.

To investigate the effect of SS concentration on plugging performance, a series of consecutive experiments, Run B, were conducted by varying the dilution ratio of SS. Initially, the SS concentration was reduced to 12.5 wt% for the first experiment. In Run B1, approximately 107 mL of CO2 was injected, resulting in a permeability reduction of about 80%. Similarly to Figure 8, Figure 9 presents CT images that capture the entire process, from SS injection to permeability measurement. When the SS solution was displaced by NaCl brine, it exhibited piston-like displacement behavior similar to that observed in Run A, although the displacement front was less stable compared to Run A. During the CO2 injection stage (Figure 9d), numerous black speckled features appeared within the SS region, clearly illustrating the CO2 flow paths through the gel. Figure 9f shows that, under the flushing effect of NaCl brine, high-grayscale regions were mainly concentrated in the downstream portion of the core, while a portion remained in the middle section. These residual materials in the midsection are likely to have more strongly gelled reaction products that resisted brine displacement and exhibited some degree of water-blocking capability.

Figure 9.

High-contrast CT images of the core during Run B1. (a,b): SS injection phase at 12.5 wt%, showing downstream propagation with less stable displacement front compared to Run A. (c,d): CO2 injection phase, with numerous low-density flow paths forming within the SS zone. (e,f): NaCl brine injection state, showing high-density regions concentrated downstream and partially retained in the midsection.

Run B2 was a repeat experiment using a 25 wt% SS concentration, and its permeability result was similar to that of Run B1. Approximately 194 mL of CO2 was injected during the experiment, resulting in a permeability reduction of approximately 98%, comparable to that observed in Run A. The CT images acquired during the injection process are shown in Figure 10. Compared to Run A, the CO2 flow paths were more clearly observed in this experiment. In comparison with Run B1, the CO2 was distributed more uniformly during injection. Similarly, after the final NaCl brine injection, a greater number of high-grayscale regions remained in the middle section of the core, and the width of this residual zone was noticeably larger than that in Run B1.

Figure 10.

High-contrast CT images of the core during Run B2. (a,b): SS injection phase at 25 wt%, showing uniform downstream propagation of the SS solution. (c,d): CO2 injection phase, with clearer and more uniformly distributed low-density flow paths compared to Run A and Run B1. (e,f): NaCl brine injection state, showing a wider residual high-density zone concentrated in the middle section of the core.

Run B3 was conducted using a 50 wt% SS concentration. Under this condition, CO2 more readily reacted with the residual SS, resulting in pipeline clogging and increased experimental complexity. After injecting approximately 15 mL of CO2, gas was released from the downstream end, and the final permeability of the core decreased by about 60%. It is speculated that the back pressure regulator failed to maintain the set pressure of 500 kPa during this experiment, resulting in a pressure differential slightly higher than expected during CO2 injection. The CT images obtained during the experiment are shown in Figure 11. In Figure 11b, a distinct interface is observed at the displacement front of the SS flow, indicating a relatively stable piston-like displacement behavior. As shown in Figure 11d, a broad black region was observed forming within the sample during CO2 injection. Compared to previous experiments, the contact area between CO2 and SS was significantly smaller in this test. As shown in Figure 11f, the high-grayscale region appeared near the upstream inlet, and its brightness was noticeably lower than in earlier experiments. This suggests that CO2 reacted rapidly with SS at the inlet; however, due to the limited contact area, the resulting reaction products exhibited a lower degree of cementation than those observed in the previous experiments.

Figure 11.

High-contrast CT images of the core during Run B3. (a,b): SS injection phase at 50 wt%, showing a distinct displacement front and relatively stable piston-like behavior. (c,d): CO2 injection phase, with a broad low-density region forming inside the core, indicating limited CO2-SS contact area. (e,f): NaCl brine injection state showing a high-density region near the upstream inlet with lower brightness.

Experimental observations indicated that the use of highly concentrated SS solutions introduced operational challenges, such as pipeline clogging, thereby impeding the stability of experimental procedures. Consequently, the SS concentration was reduced in subsequent experiments, with Run B4 utilizing an SS solution of 33.3 wt%. CO2 began to flow out from the downstream end after approximately 63 mL had been injected. Compared to previous experiments, the flow rate of CO2 increased noticeably with rising SS concentration. The permeability of the core decreased by only 47% after the grouting process was completed. Figure 12 presents the CT images acquired during the experiment. As shown in Figure 12d, the CO2 flow pattern closely resembles that observed in Run B3, with the flow primarily concentrated in the central region of the sample. In Figure 12f, a high-grayscale region, similar to that observed in previous experiments, is visible in the front to middle sections of the sample. However, this region appears significantly narrower, resulting in a reduced sealing area, which may explain the relatively limited permeability reduction observed in this experiment.

Figure 12.

High-contrast CT images of the core during Run B4. (a,b): SS injection phase with 33.3 wt% concentration, showing CO2 breakthrough after ~63 mL injection. (c,d): CO2 injection phase, displaying flow concentrated mainly in the core’s central region, similar to Run B3. (e,f): NaCl brine injection state revealing a narrower high-density region in the front to midsections.

The experimental results revealed the diffusion behavior of SS solution within the sand layer, as well as the diffusion characteristics of CO2 in the SS-saturated sand. Regardless of variations in dilution ratio and viscosity, the diffusion process of the SS solution in the sand layer remained fundamentally consistent. However, as the dilution ratio decreased and viscosity increased, the interface between the SS solution and brine became more distinct, and the flow exhibited a more pronounced piston-like displacement behavior. During the CO2 injection process, CO2 did not flow exclusively along the upper part of the sand layer as previously anticipated. Instead, it successfully penetrated the SS solution and mixed with it. In the following section, we present a detailed analysis of the diffusion behavior of CO2 within the sand layer, examining the underlying mechanisms responsible for the observed reduction in permeability.

To verify that the material at the core center corresponds to reaction products of SS, supplementary experiments were conducted. In this study, SS solution concentrations of 25 wt% were selected. SEM analysis was performed using a Helios NanoLab 650 (manufactured by FEI, Hillsboro, OR, USA). Sample preparation followed the same blocking procedure described above. After grouting, the rubber sleeve containing the sample was removed and cut open longitudinally along the axis to extract the sand-packed core. Guided by CT images, the core was cut in the cross-sectional direction at the corresponding heights to obtain sand samples from designated locations. The sand samples were mounted on SEM stubs and air-dried for approximately one week prior to observation. The SEM images are presented in Figure 13, with a uniform horizontal field width (HFW) of 111 μm applied.

Figure 13.

SEM images of the core sample treated with 25 wt% SS solution. (A): Dense and well-defined needle-like crystals are observed, indicating the formation of a strong silicate gel network near the sample center. (B): No needle-like crystals were observed near the sample inlet.

In Figure 13A, a large number of densely arranged needle-like crystals can be observed. Previous studies have indicated that during the dehydration and crystallization of silicate gels, once the silicate concentration reaches saturation, the system undergoes a rapid and random nucleation process that promotes the radial growth of needle-like crystals in multiple directions [19,20]. The crystals observed in Figure 13A exhibit these characteristics, allowing us to conclude that CO2 reaction products are present in this region. Combined with earlier CT analysis, this area is located near the center of the core, where significant gel accumulation was observed. The dense gel structures effectively block the main flow channels, resulting in a substantial reduction in overall permeability. This microscopic evidence further supports a strong correlation between macroscopic plugging performance and microscopic gel structure. Figure 13B shows the surface morphology near the injection inlet, where well-developed needle-like crystals as seen in Figure 13A are absent, and the corresponding CT image displays relatively low grayscale values. This indicates that varying grayscale levels in CT images can represent the presence or absence of CO2 reaction products.

4. Discussions

As noted in the previous section, a higher SS concentration led to an increase in the actual CO2 flow rate. Although partial blockage in the pipeline during B3 may have caused inaccuracies in the measured pressure, thereby affecting the setting of the initial pressure differential and subsequently influencing the CO2 flow rate, this trend was still clearly confirmed in B4. The underlying reason for this variation in flow rate can be elucidated from Figure 14. Figure 14 presents a series of CT images obtained after the injection of NaCl brine during the permeability measurement stage. Although the high-grayscale region—presumed to be SS or their reaction products—was displaced toward the outlet by the injected brine and could be observed exiting the core, the water-blocking performance varied significantly across the different experimental runs. This suggests that the key factor influencing blocking efficiency is the presence and spatial distribution of the high-grayscale region in the middle section of the core, which is considered to represent the formed water-blocking barriers. In Runs B1 and B2, the gel was relatively uniformly distributed across the cross-section, indicating the formation of a more continuous and complete barrier structure inside the sample. This uniform distribution likely enhanced the gel’s ability to obstruct flow channels and improve overall sealing effectiveness. In contrast, in Runs B3 and B4, the gel was primarily concentrated near the center of the core, with significantly less gel formation observed in the peripheral regions. This non-uniform distribution implies that during CO2 injection, the gas preferentially flows through the central part of the sample, forming dominant flow paths, which exhibit clear channeling behavior. As a result, the gel tended to accumulate mainly within these central flow paths and failed to effectively seal the entire cross-sectional area. Such a segregated distribution of the water-blocking barrier significantly reduced its overall capacity to inhibit fluid migration. Incomplete sealing in the peripheral regions may allow for bypass flow along the wall boundaries or through zones of higher porosity, thus diminishing the overall water-blocking efficiency of the system. These findings underscore the critical importance of achieving a uniform spatial distribution of gels in porous media to ensure long-term and effective barrier performance.

Figure 14.

CT images after NaCl brine injections during permeability tests. High-grayscale regions, representing SS or reaction products, were displaced toward the outlet. Runs B1 and B2 show uniform gel distribution forming effective barriers, while B3 and B4 have localized gel accumulation, resulting in weaker blocking.

It should be noted that the above analysis based on CT images is qualitative. To further verify the channeling phenomenon associated with high-concentration SS solutions, we conducted a quantitative analysis of the CO2 distribution inside the samples immediately after CO2 injection by comparing the CT values from the original CT images. Figure 15, Figure 16, Figure 17 and Figure 18 (panel a) show the original CT scan images of the Run B samples with enhanced contrast, captured immediately after CO2 injection—corresponding to the time points shown in Figure 9, Figure 10, Figure 11 and Figure 12 (panel d). The scanning position was located 100 mm from the inlet, near the center of the core, as indicated in Figure 9, Figure 10, Figure 11 and Figure 12 (panel d). Panel b in each figure presents the CT values of each pixel along the horizontal cross-section from left to right within the CT image shown in panel a. The CT images have a resolution of 512 × 512 pixels. Since the CT scan range was manually adjusted for each experiment, the actual length represented by each pixel varies slightly, fluctuating around approximately 0.13 mm. The range of CT value variations within the sample is indicated by the purple dashed line in the right panel.

Figure 15.

(a): CT cross-sectional image at a depth of 100 mm from the injection inlet, immediately after CO2 injection for Run B1 (12.5 wt% sodium silicate group); (b): CT value distribution curve along the horizontal diameter (pixel-wise) of the left image for Run B1.

Figure 16.

(a): CT cross-sectional image at a depth of 100 mm from the injection inlet, immediately after CO2 injection for Run B1 (25 wt% sodium silicate group); (b): CT value distribution curve along the horizontal diameter (pixel-wise) of the left image for Run B2.

Figure 17.

(a): CT cross-sectional image at a depth of 100 mm from the injection inlet, immediately after CO2 injection for Run B1 (50 wt% sodium silicate group); (b): CT value distribution curve along the horizontal diameter (pixel-wise) of the left image for Run B3.

Figure 18.

(a): CT cross-sectional image at a depth of 100 mm from the injection inlet, immediately after CO2 injection for Run B1 (33.3 wt% sodium silicate group); (b): CT value distribution curve along the horizontal diameter (pixel-wise) of the left image for Run B4.

After CO2 injection, SS containing sodium iodide in the pores is displaced, leading to decreased CT values at those locations, which appear as darker regions in the images. For example, the low CT value near pixel 320 in Figure 15b corresponds to the dark area near the center-right in Figure 15a. Figure 15 presents Run B1 (12.5 wt% SS solution), with an average CT value of 1164.4 along the horizontal diameter and relatively small fluctuations, indicating a uniform distribution. Run B2 (25 wt% SS solution, Figure 16) shows a similar pattern with an average CT value of 1190.0. Figure 17 depicts Run B3 (50 wt% SS), where CT values between pixels 220 and 320 are notably lower than average (1151.7), while other regions show greater fluctuations and higher values than B1 and B2. Similarly, Run B4 (33.3 wt%, Figure 18) displays a centrally concentrated low CT value region, resembling B3, with an average of 1158.2 and slightly less intense fluctuations.

Overall, the CT values exhibit two distinct patterns: relatively uniform variation across the sample (Figure 15 and Figure 16), and a pronounced central dip with elevated values at the sides (Figure 17 and Figure 18). These correspond to two CO2 flow regimes illustrated in Figure 19: uniform flow and channeling. Runs B1 and B2 used lower concentration, lower viscosity SS solutions (Figure 3), enabling uniform CO2 flow and resulting in the structures seen in Figure 14 (Runs B1 and B2). In contrast, the higher viscosity solutions in Runs B3 and B4 hindered CO2 flow, causing channeling and reaction localization near the sample center, as shown in Figure 14 (Runs B3 and B4).

Figure 19.

Schematic comparison of CO2 flow patterns in sand layers injected with low-viscosity SS (uniform flow) versus high-viscosity SS (centered flow).

5. Conclusions

This study systematically evaluated the water-blocking performance of gel barriers formed in situ through the reaction between SS and CO2 in unconsolidated sand layers representative of MH reservoirs. The main experimental findings are summarized as follows.

- SS solution exhibited consistent diffusion behavior within the sand, with clear interfaces and piston-like displacement characteristics. CO2 effectively penetrated and mixed with SS solution.

- Under ambient temperature conditions, SS gel demonstrated excellent water-blocking performance in core flooding experiments. When the sodium silicate concentration increased to 25 wt%, the water-blocking efficiency rose to over 98%. CT images and the SEM results showed that the gel was primarily concentrated in the middle section of the sand core, playing a key role in reducing permeability. CT analysis revealed that under low-viscosity SS solution conditions, CO2 was more uniformly injected into the porous medium, which is crucial for achieving homogeneous gel distribution

- When the concentration of SS exceeds 25 wt%, CO2 flow exhibits significant channeling behavior, reducing its contact with the silicate, leading to incomplete reactions and consequently lowering the plugging efficiency. When the sodium silicate concentration exceeds 25 wt%, the gel formed in the middle section of the sample tends to concentrate near the center, making effective water blockage difficult. CT value analysis indicates that under high-viscosity SS solution conditions, CO2 flow exhibits significant channeling behavior, which reduces its contact with the silicate, leads to incomplete reactions, and consequently lowers the overall plugging efficiency.

- For effective plugging using SS gelation, prioritizing the uniform spatial distribution of reaction products is more important. Enhancing injection strategies and tailoring solution formulations to achieve consistent colloid dispersion and deposition within the porous structure are essential for improving the overall plugging performance.

Author Contributions

Conceptualization, data curation, investigation, and writing—original draft, R.Z.; conceptualization, data curation, methodology, supervision, and writing—review and editing, T.I.; conceptualization, investigation, project administration, supervision, and writing—review and editing, S.A.; investigation, methodology and experimental supervision, T.U. All authors have read and agreed to the published version of the manuscript.

Funding

Funded by the Ministry of Economy, Trade and Industry, Japan.

Data Availability Statement

The data presented in this study are available upon request from the corresponding author.

Acknowledgments

This study was conducted as part of the research by the MH21-S R&D consortium as funded by the Ministry of Economy, Trade and Industry. All experiments were conducted at the JOGMEC Technology & Research Center in cooperation with the Research Laboratory division of the Technology Department. We would like to express our gratitude to this facility.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Yin, Z.; Linga, P. Methane Hydrates: A Future Clean Energy Resource. Chin. J. Chem. Eng. 2019, 27, 2026–2036. [Google Scholar] [CrossRef]

- Li, Q.; Wu, J.; Li, Q.; Wang, F.; Cheng, Y. Sediment Instability Caused by Gas Production from Hydrate-Bearing Sediment in Northern South China Sea by Horizontal Wellbore: Sensitivity Analysis. Nat. Resour. Res. 2025, 34, 1667–1699. [Google Scholar] [CrossRef]

- Li, Q.; Liu, J.; Wang, S.; Guo, Y.; Han, X.; Li, Q.; Cheng, Y.; Dong, Z.; Li, X.; Zhang, X. Numerical Insights into Factors Affecting Collapse Behavior of Horizontal Wellbore in Clayey Silt Hydrate-Bearing Sediments and the Accompanying Control Strategy. Ocean Eng. 2024, 297, 117029. [Google Scholar] [CrossRef]

- Yamamoto, K.; Terao, Y.; Fujii, T.; Ikawa, T.; Seki, M.; Matsuzawa, M.; Kanno, T. Operational Overview of the First Offshore Production Test of Methane Hydrates in the Eastern Nankai Trough. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5 May 2014; OTC: Houston, TX, USA, 2014; p. D031S034R004. [Google Scholar]

- Yamamoto, K.; Wang, X.-X.; Tamaki, M.; Suzuki, K. The Second Offshore Production of Methane Hydrate in the Nankai Trough and Gas Production Behavior from a Heterogeneous Methane Hydrate Reservoir. RSC Adv. 2019, 9, 25987–26013. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.-S.; Zhang, X.; Liu, J.-W.; Lee, Y.; Li, X.-S. Natural Gas Hydrate Resources and Hydrate Technologies: A Review and Analysis of the Associated Energy and Global Warming Challenges. Energy Environ. Sci. 2021, 14, 5611–5668. [Google Scholar] [CrossRef]

- Konno, Y.; Fujii, T.; Sato, A.; Akamine, K.; Naiki, M.; Masuda, Y.; Yamamoto, K.; Nagao, J. Key Findings of the World’s First Offshore Methane Hydrate Production Test off the Coast of Japan: Toward Future Commercial Production. Energy Fuels 2017, 31, 2607–2616. [Google Scholar] [CrossRef]

- Li, N.; Zhang, J.; Xia, M.-J.; Sun, C.-Y.; Liu, Y.-S.; Chen, G.-J. Gas Production from Heterogeneous Hydrate-Bearing Sediments by Depressurization in a Large-Scale Simulator. Energy 2021, 234, 121183. [Google Scholar] [CrossRef]

- Li, G.; Li, X.-S.; Zhang, K.; Li, B.; Zhang, Y. Effects of Impermeable Boundaries on Gas Production from Hydrate Accumulations in the Shenhu Area of the South China Sea. Energies 2013, 6, 4078–4096. [Google Scholar] [CrossRef]

- Boswell, R.; Yamamoto, K.; Tamaki, M.; Collett, T.S.; Moridis, G.; Myshakin, E. New Insights into the Occurrence and Implications of Mobile Water in Gas Hydrate Systems. Energy Fuels 2022, 36, 2447–2461. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, F.; Lipiński, W. Research Progress and Challenges in Hydrate-Based Carbon Dioxide Capture Applications. Appl. Energy 2020, 269, 114928. [Google Scholar] [CrossRef]

- Li, N.; Sun, Z.; Jia, S.; Sun, C.; Liu, B.; Yang, L.; Chen, G. A Novel Method to Greatly Increase Methane Hydrate Exploitation Efficiency via Forming Impermeable Overlying CO2 Cap. Energy Procedia 2019, 158, 5975–5981. [Google Scholar] [CrossRef]

- Sun, Y.-F.; Cao, B.-J.; Zhong, J.-R.; Kan, J.-Y.; Li, R.; Niu, J.-S.; Chen, H.-N.; Chen, G.-J.; Wu, G.-Z.; Sun, C.-Y.; et al. Gas Production from Unsealed Hydrate-Bearing Sediments after Reservoir Reformation in a Large-Scale Simulator. Fuel 2022, 308, 121957. [Google Scholar] [CrossRef]

- Guo, Y.; Li, S.; Sun, H.; Wu, D.; Liu, L.; Zhang, N.; Qin, X.; Lu, C. Enhancing Gas Production and CO2 Sequestration from Marine Hydrate Reservoirs through Optimized CO2 Hydrate Cap. Energy 2024, 303, 131821. [Google Scholar] [CrossRef]

- Ito, T.; Xu, T.; Tanaka, H.; Taniuchi, Y.; Okamoto, A. Possibility to Remedy CO2 Leakage from Geological Reservoir Using CO2 Reactive Grout. Int. J. Greenh. Gas Control 2014, 20, 310–323. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wang, F.; Xu, N.; Wang, Y.; Bai, B. Settling Behavior and Mechanism Analysis of Kaolinite as a Fracture Proppant of Hydrocarbon Reservoirs in CO2 Fracturing Fluid. Colloids Surf. A Physicochem. Eng. Asp. 2025, 724, 137463. [Google Scholar] [CrossRef]

- Nakayenga, J.; Hata, T.; Saracho, A.C.; Haigh, S.K. Effects of High Pressure on Microbiologically Induced Calcium Carbonate Precipitation of Methane Hydrate-Bearing Sand Layers. Soils Found. 2025, 65, 101651. [Google Scholar] [CrossRef]

- JIS K 1408:1966; Sodium Silicate. Japanese Standards Association: Tokyo, Japan, 1966.

- Puel, F.; Verdurand, E.; Taulelle, P.; Bebon, C.; Colson, D.; Klein, J.-P.; Veesler, S. Crystallization Mechanisms of Acicular Crystals. J. Cryst. Growth 2008, 310, 110–115. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, Y.; Huang, J.; Chen, G. Mechanical Properties, Microstructure and Consolidation of Sand Modified with Sodium Silicate. Eng. Geol. 2022, 310, 106875. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).