Abstract

The transition toward a renewable-based energy structure has significantly accelerated the advancement of energy storage technologies. Compressed air energy storage (CAES) is regarded as a highly promising long-duration energy storage solution due to the advantages of its large scale and long service life. However, the efficiency of conventional compressed air energy storage (CAES) systems remains limited due to the inadequate utilization of thermal energy. Isothermal compressed CAES (ICAES) technology, based on liquid pistons, can overcome the efficiency bottleneck by enabling temperature control during air compression. However, the operation of liquid pistons under high-pressure storage conditions remains a challenge because of the high compression ratio. To enhance the utilization rate of the two-stage liquid piston unit by using the synchronous operations of compression and discharge processes, this paper proposes a coordinated operation scheme. Then, a multi-stage ICAES system under constant-pressure air storage is proposed. Mathematical models and energy efficiency analysis methods of the multi-stage ICAES system are also established. Finally, the operational characteristics are analyzed in combination with the ICAES at 200 kWh. The results show that the proposed system can achieve an overall efficiency of 68.0%, under 85% and 90% efficiencies for low-pressure and linear equipment, respectively. The coordinated operation of the two-stage liquid piston unit can be further extended to multi-stage operations, demonstrating broad application prospects in ICAES systems.

1. Introduction

Amid the global transition toward low-carbon development, the installed capacity of renewable energy, primarily wind and solar power, continues to expand globally [,]. However, the intermittency and volatility of renewable energy have led to challenges in supply–demand imbalances and insufficient frequency regulation capability for power systems []. According to statistics from the International Energy Agency (IEA), the global curtailment rate of renewable energy reached 8% in 2022, indicating that the large-scale integration of renewable energy is facing difficulty []. As a key enabling technology to achieve a high penetration of renewable energy and to ensure the flexibility of power systems, the critical role of energy storage has become increasingly prominent []. Among mainstream energy storage technologies, pumped hydro storage is limited by geographical constraints and long construction periods. Lithiumion batteries face challenges of high costs, short lifespans, and resource constraints []. Compressed air energy storage (CAES) has the advantages of a large scale, long lifespan, and moderate cost, and isconsidered a highly promising solution for long-duration energy storage [].

Traditional CAES uses air compressors to compress air into high-pressure storage during off-peak load periods and release it for power generation during peak load periods in combination with natural gas combustion for expansion []. Two commercial CAES plants have been established, based on traditional CAES: the Huntorf plant in Germany in 1978 and the McIntosh plant in the United States in 1991, both with an efficiency of only around 50% [,]. Two research directions have emerged to improve the operational efficiency of CAES plants. One is the Advanced Adiabatic CAES (AA-CAES) technology, which focuses on how to efficiently utilize heat during the adiabatic compression process. AA-CAES enhances thermal utilization and eliminates natural gas combustion by using multi-stage compression with intercooling, multi-stage expansion, and intermediate reheating [,,]. The other is Isothermal CAES (I-CAES) technology, without high-temperature heat during the compression and expansion processes. By using liquid media with high specific heat in the compression and expansion processes, I-CAES can significantly increase the heat transfer coefficient, limit the temperature fluctuations of the air, reduce compression power consumption, and increase the output power [,].

Liquid piston technology is one of the common techniques in I-CAES systems []. It can achieve more efficient and compact air compression and expansion processes by replacing traditional mechanical pistons with liquids (such as water, oil, or liquid metals) []. The efficiency of traditional mechanical pistons is limited due to frictional losses and sealing issues. Liquid pistons can significantly reduce leakage risks and improve energy transfer efficiency by leveraging the incompressibility and flexible contact characteristics of fluids [,]. Studies have shown that liquid pistons can rapidly dissipate compression heat through the high thermal conductivity of the liquid during the isothermal compression process, reducing thermodynamic losses and increasing overall system efficiency to over 70% [,]. However, liquid piston technology has challenges regarding the stability of liquids under high-pressure conditions, dynamic sealing technology, and system operation optimization [,]. Although high-pressure air storage can increase the energy storage density, the high compression ratio also leads to the volume of the liquid piston increasing, raising costs and potentially causing air dissolution [].

Therefore, adopting a multi-stage operation scheme for I-CAES systems based on liquid pistons is imperative. However, current research on the coordinated operation of multi-stage liquid piston units (LPUs) remains limited. The main challenge lies in the fact that during compression in an enclosed environment, the liquid piston unit cannot simultaneously perform the exhaust process, making it difficult to coordinate with the next-stage liquid piston unit [,,]. One possible solution is to activate the high-pressure LPU only after the low-pressure liquid piston has completed compression. However, this approach inevitably reduces the utilization rate of the high-pressure liquid piston, thereby lowering the overall power output of the plant. Alternatively, introducing a buffer tank between the two liquid piston stages could help maintain constant pressure dynamically, improving system coordination at the expense of higher costs.

To address the above issues, this paper proposes a coordinated operation scheme for a two-stage LPU, in which the compression and exhaust processes in the first-stage LPU (FS_LPU) are carried out simultaneously. The air is compressed while being discharged into the second-stage LPU (SS_LPU), enabling coordinated operation between the two stages. The proposed method enhances system power output while ensuring high heat transfer efficiency. The remainder of this paper is organized as follows: in Section 2, the coordinated operation scheme for LPUs is introduced. In Section 3, the constant-pressure I-CAES system, based on two-stage LPUs, is proposed. The system’s pre-charging, energy storage, and power generation processes are described. The mathematical model of the system and the analysis of its operational characteristics based on a 200 kWh case study are developed in Section 4 and Section 5. Finally, Section 6 provides the conclusions.

2. Coordinated Operation Scheme of Liquid Piston Units

2.1. Liquid Piston Units

ICAES systems typically employ a single LPU. Due to the inherent compression ratio limitations of single-stage liquid pistons, conventional ICAES systems generally operate at lower air storage pressures. Alternatively, they may integrate with adiabatic compression technology—initially pressurizing air to higher levels via adiabatic methods, followed by secondary compression through an LPU to elevate the pressure of air storage. Multi-stage liquid piston configurations remain uncommon in ICAES applications, with the primary challenge lying in the coordinated operation between stages. Before introducing the coordinated operation of two-stage LPUs, the fundamental concept and components of LPUs are defined as below.

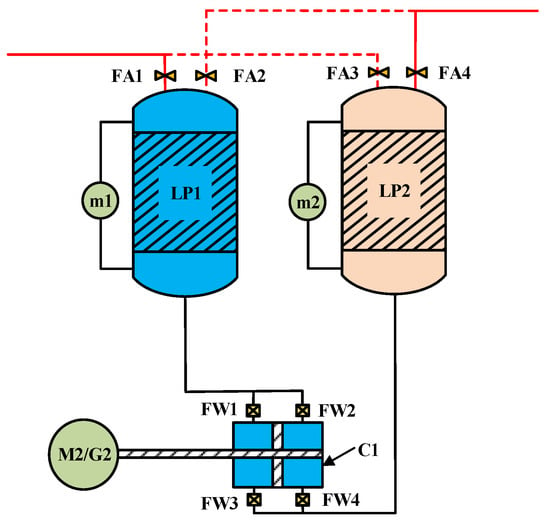

As shown in Figure 1, LPUs consist of two liquid pistons with identical volumes, filled with an air–water mixture, and a reversible drive mechanism. Integral packing materials are installed inside the liquid pistons to increase the gas–liquid heat transfer surface area, while external water pumps are used to draw water from the bottom to the top for spraying. This forced liquid circulation enhances the gas–liquid heat transfer coefficient, enabling an isothermal process as the air alternately undergoes compression or expansion within the two liquid pistons. During the energy storage and power generation processes, the LPU functions as the liquid piston compressor (LPC) and the liquid piston expander (LPE), respectively.

Figure 1.

Schematic diagram of the liquid piston unit structure.

The drive mechanism of LPUs can take various forms. The hydraulic cylinder is selected in this paper due to its ability to accommodate wide pressure variations, combined with a reversible linear motor to drive the energy storage and power generation processes. Each hydraulic cylinder is equipped with four valves, and the flow direction of the liquid is controlled by the opening and closing of these valves. When the hydraulic cylinder moves to the left, valves FW2 and FW3 open, allowing liquid to flow from LP1 to LP2, while valves FW1 and FW4 open to enable liquid flow from LP2 to LP1. When the hydraulic cylinder moves to the right, the valve operation strategy is reversed from the aforementioned process.

2.2. Coordinated Operation of Two-Stage Liquid Piston Units

In the series operation of two-stage LPUs, the FS_LPU typically undergoes three phases during the compression process in ignorance of clearance: constant-pressure intake, sealed compression, and constant-pressure discharge. During the sealed compression phase, the air discharge flow rate is zero, which prevents the SS_LPU from operating normally. To enable the coordinated operation between the two stages, merging the sealed compression and constant-pressure discharge phases of the FS_LPU synchronously is proposed. In this way, the FS_LPU can transfer air to the SS_LPU while compressing. As a result, the FS_LPU operates in two phases: constant-pressure intake and simultaneous compression discharge, while the SS_LPU operates through variable-pressure intake, sealed compression, and constant-pressure discharge.

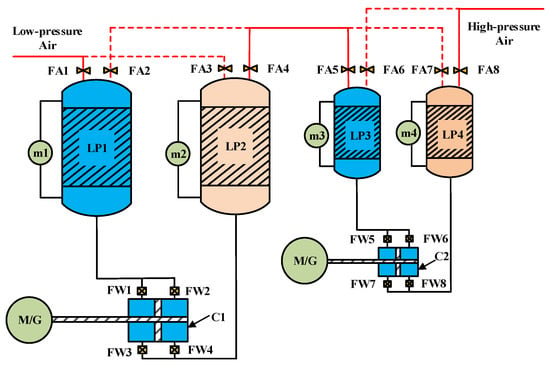

Figure 2 illustrates a schematic diagram of the coordinated operation of two-stage LPUs. The FS_LPU consists of LP1, LP2, and a reversible drive mechanism, while the SS_LPU is composed of LP3, LP4, and another reversible drive mechanism. Low-pressure air enters LP1 at a constant rate. Under the drive of the motor, hydraulic cylinder C1 moves reciprocally, pumping liquid into LP2. Simultaneously, valves FA4 and FA5, between LP2 and LP3, are opened, establishing a direct connection between them. The air within the combined space of LP2 and LP3 is compressed simultaneously, while the liquid in LP3 is pumped into LP4 through hydraulic cylinder C2, further compressing the air in LP4. Once the air reaches the designated pressure level, valve FA8 opens to discharge the high-pressure air.

Figure 2.

Schematic diagram of the coordinated operation of the two-stage liquid piston units.

When all the liquid in LP1 is transferred to LP2, the air inside LP2 is also fully moved into LP3, achieving a synchronous compression and discharge process. Meanwhile, LP4 becomes filled with liquid. At this point, LP1~2 and LP3~4 swap roles and proceed to the next compression cycle.

Through this scheme, the two-stage LPUs can operate in a coordinated and continuous manner. The air is always compressed within the LPUs, ensuring an isothermal compression process. The expansion process is considered the reverse process of compression, which can also be realized with synchronized operation.

3. A Novel Isothermal Compressed Air Energy Storage System

3.1. System Structure

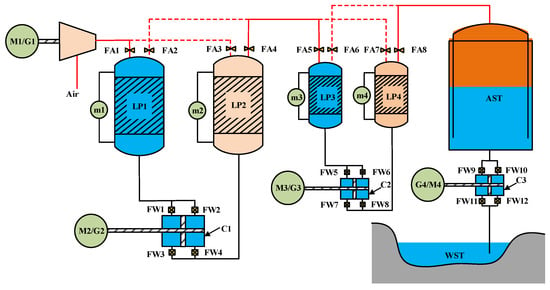

The multi-stage I-CAES system with constant-pressure air storage can be developed based on the coordinated operation of two-stage LPUs. As is shown in Figure 3, the system consists of a low-pressure compressor/expander and two-stage LPUs. The air storage tank (AST) uses a pressure vessel filled with an air–water mixture, and a set of hydraulic cylinders at the bottom controlling the liquid volume from the water storage tank (WST) to the AST, ensuring a constant-pressure storage process. To simplify the analysis, all of the drive motors in the system are assumed to be reversible. M1/G1 is the drive motor/generator for the low-pressure compressor/expander, M2/G2 is the linear motor/linear generator for the first-stage liquid piston compressor/expander, M3/G3 is the linear motor/linear generator for the second-stage liquid piston compressor/expander, and G4/M4 is the external linear generator/motor for the air storage tank. C1, C2, and C3 are the three sets of hydraulic cylinders. FA1~FA6 are the gas valves, and FW1~FW12 are the liquid valves.

Figure 3.

I-CAES system based on coordinated operation of two-stage LPUs.

3.2. Preset Process

The low-pressure compressor injects low-pressure air into LP1, while LP2 and LP4 are filled with water. The FS_LPU drives the liquid from LP2 to LP1, and both LP1 and LP4 work together to compress low-pressure air into LP4 for storage. Simultaneously, the low-pressure compressor injects air into LP2, while the SS_LPU transfers liquid from LP4 to LP3, with LP3 connected to the external atmosphere. Upon completion of this process, LP1 and LP3 are water-filled, LP2 contains low-pressure air, and LP4 holds medium-pressure air, thereby finalizing the preset configuration.

The energy storage and power generation processes, excluding the air storage tank, have the same preset state, meaning the system only requires one preset operation. Before the energy storage process, the air storage tank needs to be filled with water.

3.3. Energy Storage Process

During the first compression cycle, the low-pressure compressor M1 injects low-pressure air into LP1. The linear motor M2 of the FS_LPU drives the hydraulic cylinder C1 to transfer liquid from LP1 to LP2. The valve between LP2 and LP3 is opened, forming a connected space, and the air is compressed within the connected space. At the same time, the linear motor M3 of the SS_LPU drives the hydraulic cylinder C2 to transfer liquid from LP3 to LP4, compressing the air in LP4 to the specified pressure. Then, the valve between LP4 and the AST is opened to transfer the air at a constant pressure into the storage chamber. At this point, the liquid in the AST is driven by the external hydraulic cylinder C3, which enables the linear generator G4 to generate electricity.

After the above process is completed, the roles of LP1 and LP2 are swapped, as well as the roles of LP3 and LP4, and the system enters the next compression cycle until the energy storage process is completed.

3.4. Power Generation Process

During the first expansion cycle, the linear motor M4 drives the hydraulic cylinder C3 to pump water into the AST. A certain volume of high-pressure air from the AST enters LP3. After that, the valve between the storage chamber and LP3 is closed, and the air expands within LP3. The liquid in LP3 is continuously transferred to LP4 via the hydraulic cylinder C3, driving the linear generator G3 of the SS_LPU to generate electricity. The valve between LP4 and LP1 is opened, forming a connected space, and the air in LP4 expands within this space. Simultaneously, the liquid in LP1 is forced into LP2 by the expanding air through the hydraulic cylinder C1, driving the linear generator G2 of the FS_LPU to generate electricity. The low-pressure air in LP2 enters the low-pressure expander G1 for further expansion and power generation.

After the process is completed, the roles of LP1 and LP2 are swapped, as well as the roles of LP3 and LP4, and the system enters the next expansion cycle until the power generation process is finished.

4. Mathematical Model of the Proposed System

When conducting the mathematical model analysis for the proposed system, the following assumptions are made:

- The air is treated as an ideal gas, and the process is assumed to be isothermal due to the rapid heat transfer between air and water inside the liquid pistons.

- The action time of valve switching is neglected, and the starting and stopping processes of the linear motors are not considered, assuming a constant speed operation model.

- The transmission liquid is considered incompressible, and air dissolution is ignored. The volume of the liquid piston’s clearance is neglected, and pressure losses and kinetic energy losses during the flow process are ignored, as well.

- The effects of the actual height difference of the liquid on the pressure in the liquid pistons and the storage tank are neglected.

4.1. The Process of Energy Storage

4.1.1. The Low-Pressure Compressor

The low-pressure compressor compresses atmospheric air into low-pressure and alternately delivers it into LP1 and LP2. By neglecting the valve switching time, the airflow rate can be considered constant. Combined with the liquid flow in the FS_LPU, a constant low-pressure air pressure can be maintained. The specific work performed by M1 is expressed as:

where is the mass flow rate of the intake air, Rg is the specific gas constant for air, T0 is the ambient temperature, p1 is the low-pressure air pressure, and p0 is the ambient air pressure. Considering the efficiency of the low-pressure compressor, the actual specific compression work is:

4.1.2. First-Stage Liquid Piston Compressor

The first-stage liquid piston compressor compresses the air from low pressure to medium pressure. Let the medium pressure be p2, then the compression ratio is a1 = p2/p1, which is also referred to as the volumetric compression ratio in the isothermal process. During the first compression cycle , LP1 is in the intake state, and the internal pressure remains constant, that is:

LP1 is initially filled with water. Under the isobaric condition, LP1 must maintain equilibrium between the air inflow rate and the liquid outflow rate as follows:

where represents the air inflow rate into LP1, and represents the liquid outflow rate from LP1. and the air density in LP1 satisfy . Since the air density and the pressure in LP1 satisfy , can be expressed as:

The water in LP1, reciprocally actuated by linear motor M2, is displaced through the hydraulic cylinder C1 into LP2 to compress the enclosed air. Let vc1 be the operating speed of the linear motor M2, and D1, d1, and S1 represent the diameter, rod diameter, and effective area of the hydraulic cylinder C1, respectively. The liquid flow rate discharged from LP1 satisfies

According to Equations (4) and (6), when considering the dimensions of the hydraulic cylinder, the mass flow rate of the intake air is:

After one compression cycle, the liquid in LP1 is evacuated. Equation (8) represents the minimum volume VLP_1 that the FS_LPU needs to satisfy. In practice, considering the impact of spraying, a sufficient amount of liquid should be left at the bottom. Therefore, the actual liquid piston volume may retain a certain margin.

LP2 and LP3 undergo joint compression, and the air compression process in LP2 is simultaneously influenced by the liquid flow rates of both the FS_LPU and SS_LPU. Let the liquid piston volume in the SS_LPU be VLP_2, the operating speed of the linear motor M3 be vc2, and the diameter, connecting rod diameter, and effective area of the hydraulic cylinder C2 be D2, d2, and S2, respectively. The liquid piston volume in the SS_LPU satisfies

The liquid flow rate in LP3 of the SS_LPU is:

The liquid flow rate and air pressure in LP2 are:

The unit power consumption of the linear drive motor M2 is:

Considering the efficiency of the linear motor , its actual unit compression power consumption is:

In subsequent cycles, the liquid volume and gas pressure variations in LP1 and LP2 follow the same pattern, with their roles reversed. The modeling procedure is repeated and will not be elaborated further in this work.

4.1.3. The Second-Stage Liquid Piston Compressor

The second-stage liquid piston compressor compresses air from medium pressure to high pressure. Let the high-pressure air pressure be p3, then the compression ratio is a2 = p3/p2. During the first compression cycle , the pressures in LP3 and LP2 of the second-stage liquid piston compressor are equal, and the liquid flow rate in LP4 is as follows:

In one compression cycle, the compression process in LP4 is divided into two periods: one is the closed air compression process, and the other is the constant-pressure air migration process. Let the closed air compression time be , and the time and compression ratio satisfy the relationship.

The air pressure in LP4 can be expressed in segments as:

The unit power consumption of the linear drive motor M3 is:

Considering the efficiency of the linear motor as , its actual unit compression power consumption is:

In subsequent cycles, the liquid volume and air pressure variation patterns of LP3 and LP4 are swapped. The modeling procedure is repeated and will not be elaborated further in this work.

4.1.4. Air Storage Tank

During the first compression cycle Δtc, the pressure in the AST remains constant. The AST remains stationary before air is transferred from LP4, and the linear generator G4 is not in operation. When the air is transferred, the liquid in the AST flows at a constant rate, and the hydraulic cylinder C3 drives the linear generator G4 to generate electricity. Let the operating speed of the linear generator G3 be vc3, and the diameter, rod diameter, and effective area of the hydraulic cylinder C3 be D3, d3, and S3, respectively. The airflow in the AST satisfies

When the AST is filled with air at a constant pressure, the airflow in the AST should match the airflow from the SS_LPU:

The unit work output of the linear generator G4 is:

Considering the efficiency of the linear generator , the actual unit power output is:

4.2. The Generation Process

4.2.1. The Low-Pressure Expander

The low-pressure air in the liquid pistons LP1 and LP2 alternately enters the low-pressure expander. Under isothermal expansion conditions, the work performed by G1 is:

where is the mass flow rate of the exhaust air. Considering the efficiency of the low-pressure expander , the actual unit expansion output work is:

4.2.2. The First-Stage Liquid Piston Expander

The first-stage liquid piston expander expands air from a medium-pressure p2 to a low-pressure p1, so the expansion ratio remains as a1. During the first expansion cycle , LP2 is in the exhaust state with the internal pressure maintained constant. Let the operating speed of the linear generator G2 be ve1, then the liquid flow rate and air pressure in LP2 are as follows:

Under the isobaric model, LP2 satisfies the relationship between the exhaust mass flow rate and the operating speed, as follows:

The medium-pressure air in LP4 enters LP1, and the air expands jointly in both. The air pressure in LP1 is influenced by the linear drive speeds of the two-stage LPUs. Let the operating speed of the linear generator G3 in the SS_LPU be ve2, and the liquid flow rate in LP4 is:

The volumes of the liquid pistons in the two stages satisfy

The liquid flow rate and air pressure in LP1 are:

The unit work performed by the linear generator G2 is:

Considering the efficiency of the linear generator , its actual unit power output is:

In subsequent cycles, the liquid volume and air pressure variation patterns of LP1 and LP2 are exchanged. The modeling process will not be repeated.

4.2.3. The Second-Stage Liquid Piston Expander

The second-stage liquid piston expander achieves the expansion of air from high-pressure p3 to medium-pressure p2, with an expansion ratio of a2. During the first expansion cycle, the pressures in LP4 and LP1 within the second-stage liquid piston expander remain equal, and the liquid flow rate in LP3 satisfies:

During an expansion cycle, the expansion process in LP3 is divided into two periods: a constant-pressure air transfer process from the AST and a closed air expansion process. Let the duration of the constant-pressure air transfer process be , then the time and expansion ratio satisfy

The air pressure in LP3 can be expressed in a piecewise form as follows:

The unit work output of the linear generator G3 is:

Considering the efficiency of the linear generator, the actual unit power generation is:

In subsequent cycles, the variation patterns of liquid volume and air pressure in LP3 and LP4 are interchanged. The repetitive modeling process is not elaborated further.

4.2.4. Air Storage Tank

During the expansion cycle, the pressure in the AST remains constant. Firstly, the liquid driven by the linear motor M4 is injected into the AST, while a certain amount of high-pressure air is transferred into LP3. Afterward, M4 stops operating, and the AST remains static, with the high-pressure air undergoing closed expansion in LP3. Assuming the operating speed of the linear motor M4 is ve3, the airflow rate in the AST satisfies

During the constant-pressure air discharge, the airflow rate from the AST should match the airflow rate of the SS_LPU:

The unit power consumption of the linear motor M4 is:

Considering the efficiency of the linear motor , its actual unit power consumption is:

4.3. Calculate the Efficiency

Based on the mathematical models of the energy storage and power generation processes mentioned above, the operating efficiency of the I-CAES system can be calculated. Let the total energy storage time be tc, and the total electricity consumption during the energy storage process is:

Let the total power generation time be te, and the total power generation during the power generation process is:

The system efficiency is expressed as:

5. Case Analysis

5.1. Parameter Setting

In this section, based on the mechanism of the two-stage LPU coupled operation of the I-CAES system, the system parameters for a 200 kWh energy storage capacity are configured to analyze the operational characteristics of the system [,,]. As is shown in Table 1, the parameters for the energy storage and power generation processes are set as follows:

Table 1.

System parameter settings.

5.2. Energy Storage Process

The energy storage time tc is 2 h, with a cycle compression time Δtc of 0.25 h, requiring eight rotations of the liquid piston. The low-pressure compressor compresses the air from atmospheric pressure to 0.6 MPa of low-pressure air and alternately feeds it into LP1 and LP2. The inflow mass flow rate is 0.33 kg/s.

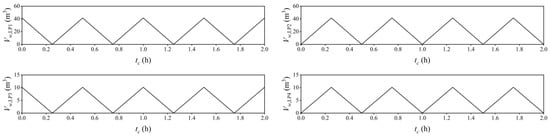

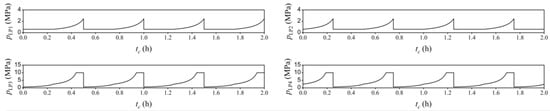

Figure 4 shows the liquid volume variation curve in the two-stage LPUs during the energy storage process. Since the linear drive motors in both liquid piston units operate at a constant speed, the liquid volume of the liquid pistons changes linearly within each cycle. The liquid flow rate exchanged between LP1 and LP2 is 46.1 L/s, while the liquid flow rate exchanged between LP3 and LP4 is 11.3 L/s. The flow ratio is the same as the compression ratio a1. The liquid volume of the liquid pistons during the entire energy storage process exhibits a triangular wave variation characteristic.

Figure 4.

Liquid volume variation curves in the two-stage LPUs during the energy storage process.

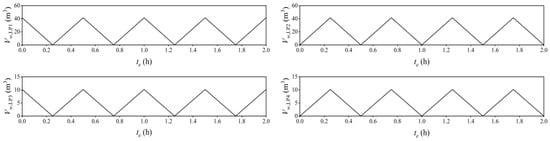

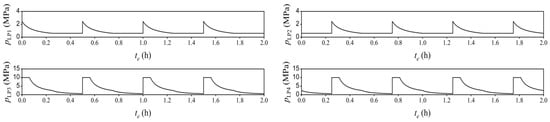

Figure 5 shows the air pressure variation curve within the two-stage LPUs during the energy storage process. During the first compression cycle, LP1 maintains low-pressure air intake, with the pressure remaining constant at 0.6 MPa. The low-pressure air in LP2 is compressed within the connected volume formed by LP2 and LP3, and the pressure rises from 0.6 MPa to 2.45 MPa as the air moves from LP2 to LP3. In the first 0.19 h, LP4 compresses the medium-pressure air, increasing the pressure from 2.45 MPa to 10 MPa. Afterward, for the next 0.06 h, the air enters the AST at a constant pressure, so the pressure remains constant. From Figure 5, the pressure operating range of the FS_LPU is between 0.6 MPa and 2.54 MPa, while the SS_LPU operates in the pressure range of 0.6 MPa to 10 MPa. This is due to the combined operation of the two-stage LPUs, which increases the operating range of the SS_LPU.

Figure 5.

Air pressure variation curves in the two-stage LPUs during the energy storage process.

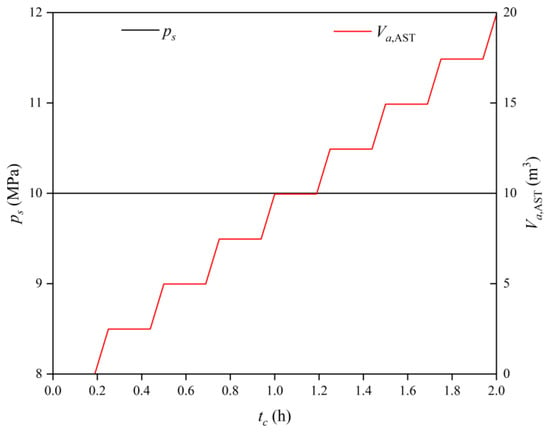

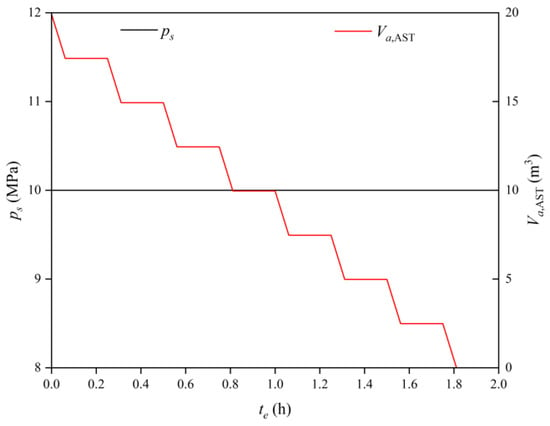

Figure 6 shows the air pressure and volume variation curves in the AST during the energy storage process. The pressure remains constant at 10 MPa, with intermittent changes during the charging process, because the charging flow is discontinuous. During the last 0.06 h of each compression cycle, the charging occurs with a flow rate of 11.3 L/s.

Figure 6.

Air pressure and volume variation curves in the air storage tank during the energy storage process.

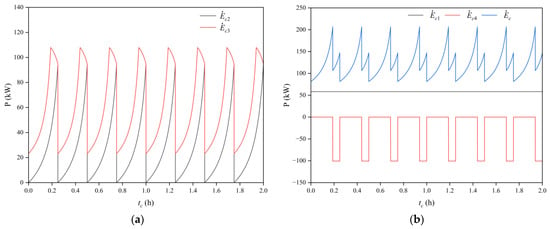

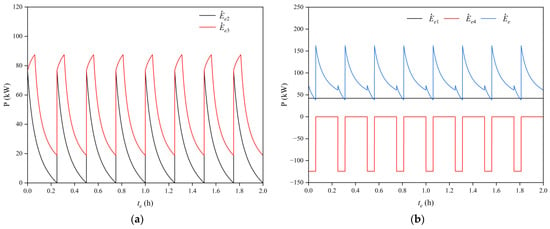

Figure 7 shows the power variation curve during the energy storage process. Figure 7a shows the driving power curves of the two-stage liquid pistons M2 and M3. During the first compression cycle, when the linear motor M2 starts running, the pressure at both ends is 0.6 MPa, and the initial power is 0. As the air pressure in LP2 increases, the power of M2 gradually rises to 94.7 kW. The initial power of the linear motor M3 is 23.2 kW, and during the first 0.19 h, it gradually increases to 108.0 kW. In the subsequent 0.06 h, the power drops back to 94.7 kW because LP4 is in a constant-pressure state, while the pressure in LP3 is still rising. This reduces the pressure difference on both sides and decreases the operating power of M3.

Figure 7.

The power variation curve during the energy storage process. (a) The power curves of M2 and M3. (b) The power curves of M1, G4, and the system.

Figure 7b shows the power curves of the low-pressure compressor M1, the linear generator G4, and the total system. The power of the low-pressure compressor M1 is constant at 58.3 kW, while the linear generator G4 only operates during the last 0.06 h of each cycle, with a generation power of 100.6 kW due to the large pressure difference. The total power of the entire system experiences two fluctuations during each compression cycle: one occurs in the first 0.19 h, where the power increases from 81.5 kW to 207.0 kW, and the other occurs in the last 0.06 h, where the power increases from 106.4 kW to 147.2 kW. The linear generator G4 also helps reduce the overall power fluctuation of the system to some extent.

5.3. The Power Generation Process

The power generation time te is 2 h, with a cycle expansion time of 0.25 h, requiring eight cycles of liquid piston rotation. The low-pressure air pressure in LP1 and LP2 is 0.6 MPa, which is alternately fed into the low-pressure expansion machine G1, with an exhaust mass flow rate of 0.33 kg/s.

Figure 8 shows the liquid volume change curve inside the two-stage LPUs during the power generation process. Similar to the energy storage process, when the operation speeds of the linear generators G2 and G3 are constant, the liquid flow exchanged between the two-stage liquid pistons remains unchanged, at 46.1 L/s and 11.3 L/s, respectively, exhibiting a triangular wave variation characteristic.

Figure 8.

Liquid volume variation curves in the two-stage LPUs during the energy generation process.

Figure 9 shows the air pressure change curve inside the two-stage LPUs during the power generation process. In the first expansion cycle, LP2 continuously delivers low-pressure air at 0.6 MPa to the low-pressure expander. LP4 and LP1 are connected, and the medium-pressure air in LP4 expands from 2.45 MPa to 0.6 MPa in the connected space. LP3 continuously obtains 10 MPa high-pressure air from the air storage chamber for 0.06 h, with the pressure remaining constant. In the subsequent 0.19 h, the high-pressure air expands from 10 MPa to 2.45 MPa in LP4. Similarly, the SS_LPU operates in the pressure range of 0.6 to 10 MPa.

Figure 9.

The air pressure variation curve inside the two-stage liquid pistons during the power generation process.

Figure 10 shows the air pressure and volume change curves in the AST during the power generation process. The pressure in the AST remains constant at 10 MPa, with the high-pressure air intermittently migrating to the SS_LPU. The exhaust occurs during the first 0.06 h of each cycle, with an exhaust flow rate of 11.3 L/s.

Figure 10.

The air pressure and volume variation curves in the air storage tank during the power generation process.

Figure 11 shows the power variation curve during the power generation process. Figure 11a is the driving power curve of the two-stage liquid pistons G2 and G3. During the first expansion cycle, the power generation of the linear generator G2 decreases from 76.7 kW to 0 due to the pressure drop in LP1. The power generation of the linear generator G3 experiences a process of first rising and then falling, increasing from 76.7 to 87.4 kW, and then dropping to 18.8 kW. The increase in power for the linear generator G3 is due to the constant-pressure exhaust from the AST. As the pressure in LP3 remains constant, LP4’s pressure decreases during its joint expansion with LP1, causing the pressure difference in the SS_LPU to increase gradually, resulting in a rise in power generation.

Figure 11.

The power variation curve during the power generation process. (a) The power curves of G2 and G3. (b) The power curves of G1, M4, and the system.

Figure 11b shows the power curves for the low-pressure expander G1, the linear motor M4, and the system. The power of the low-pressure expander G1 is constant at 42.1 kW, and the linear motor M4 operates only for the first 0.06 h of each cycle, with a power consumption of 124.2 kW. The total power generation of the power station experiences two fluctuations during each expansion cycle: one in the first 0.06 h, where the power drops from 71.4 to 38.4 kW, and another in the last 0.19 h, where the power drops from 162.6 to 60.9 kW.

5.4. Energy Efficiency Analysis

In the above case, during the 2-h energy storage process, the low-pressure compressor M1 consumes 116.6 kWh, linear motor M2 consumes 53.1 kWh, linear motor M3 consumes 119.9 kWh, and linear generator G4 generates 49.3 kWh, with a total energy consumption of 240.3 kWh.

During the 2-h power generation process, the low-pressure expander G1 generates 84.3 kWh, linear generator G2 generates 43.0 kWh, linear generator G3 generates 97.1 kWh, and linear motor M4 consumes 60.9 kWh, with a total power generation of 163.5 kWh.

The storage capacity of the system is set to 200 kWh, so the efficiency of energy storage is 83.2%, the efficiency of power generation is 81.7%, and the overall efficiency of the system is 68.0%. The reason why the efficiency of energy storage and power generation is lower than that of the single-drive equipment is that during the energy storage process, G4, associated with the AST, is used for power generation, while M4, associated with the AST, is used for power consumption. The internal consumption of electrical energy damages the efficiency of the entire system. This is also the drawback of using this constant-pressure air storage solution in this system.

Compared to traditional ICAES systems based on single-stage liquid pistons, ICAES systems based on the cooperative operation of two-stage liquid pistons can achieve higher pressure output and thus obtain higher energy density. The main cost of CAES is the cost of air storage. As the energy storage density increases, the required storage volume will significantly decrease, resulting in an overall economic improvement. Taking the case above as an example, as shown in Table 2, for a 200 kWh energy storage capacity of the ICAES, the output pressure of the compressed air energy storage system using a traditional single-stage liquid piston is 2.45 MPa, and the required energy storage volume is 131.3 m3. The case above only requires 19.9 m3, accounting for only 15.2% of the volume. On the basis of the cooperative operation of two-stage liquid pistons, constructing three-stage or higher order liquid pistons will further reduce the storage volume, but higher storage pressure requires higher pressure resistance of the storage material.

Table 2.

Analysis of characteristics of ICAES systems with different liquid piston stages.

6. Conclusions

To achieve the multi-stage synchronous operation process in the I-CAES system, a coordinated operation strategy for the two-stage LPUs is proposed in this paper. During the energy storage process, the compression and exhaust processes of the FS_LPU are carried out simultaneously, with air being continuously fed into the SS_LPU, achieving joint compression of air between the two LPUs. At this point, the SS_LPU can synchronize the air compression, thereby avoiding the issue of stopping operation due to insufficient airflow.

Based on the coordinated operation strategy of the two-stage LPUs, a multi-stage I-CAES system with constant-pressure air storage is constructed. The low-pressure compressor is responsible for compressing the air to low pressure, while the two-stage LPUs are responsible for compressing the air to medium pressure and high pressure. The preset process, energy storage process, and power generation process of the system are analyzed through detailed description. A mathematical model of the system is established based on the operation process, and the operational characteristics of the liquid piston, AST, motor/generator, and other components were analyzed using the case of a 200 kWh energy storage system.

Simulation analysis found that the pressure operating range of the SS_LPU is increased from 2.45~10 MPa to 0.6~10 MPa due to the coordinated compression in the two-stage LPUs, which imposes higher safety requirements for the liquid piston in the high-pressure stage. In both the energy storage and power generation processes, the power of the system fluctuates twice per cycle. During the energy storage process, the liquid in the AST works on the outside during constant-pressure air storage, which reduces the energy storage capacity of the system. In the power generation process, the liquid in the AST needs to consume energy during constant-pressure exhaust, which reduces the power generation capacity. Additionally, due to the constant-pressure air storage process, the drive power of the SS_LPUs also experiences peak power, where the energy storage process and power generation process reach 108.0 kW and 87.4 kW, respectively.

Under the condition that the efficiency of the low-pressure compressor/expander is 85% and the efficiency of the linear motor/generator is 90%, the overall efficiency of the system can reach 68.0%. The main reasons for the efficiency reduction are the power generation state during the energy storage process and the energy consumption state during the power generation process, which is an inevitable problem with this constant-pressure air storage solution. The overall efficiency can be further improved by optimizing the constant-pressure air storage scheme. In general, the multi-stage I-CAES system is the future development trend in the isothermal field. Based on the coordinated operation of the two-stage LPU scheme, it is possible to expand the analysis to three-stage, four-stage, or even more stages of system operation processes, which can help reduce the pressure fluctuation range of each stage and is likely to be a significant field for future research.

Author Contributions

Conceptualization, T.J. and Y.C.; methodology, Y.C.; validation, T.J.; formal analysis, Y.C.; investigation, H.H.; resources, H.H.; data curation, H.H.; writing—original draft preparation, Y.C.; writing—review and editing, H.H.; supervision, T.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are contained within the article.

Acknowledgments

The authors acknowledge the support of the State Key Laboratory of Alternate Electrical Power System with Renewable Energy Sources and the technical support of the Shanghai Investigation, Design and Research Institute.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Gong, L.; Li, Y.; Wang, Y.; Zhang, Y. Study on the peak shaving performance of coupled system of compressed air energy storage and coal-fired power plant. J. Energy Storage 2025, 107, 114954. [Google Scholar] [CrossRef]

- Huang, L.; Hou, Z.; Fang, Y.; Luo, J.; Wu, L.; Wang, Q.; Guo, Y.; Zhang, X.; Shi, T.; Liu, J. The development, frontier and prospect of Large-Scale Underground Energy Storage: A bibliometric review. J. Energy Storage 2024, 103, 114293. [Google Scholar] [CrossRef]

- Bogdanov, D.; Ram, M.; Aghahosseini, A.; Gulagi, A.; Oyewo, A.S.; Child, M.; Caldera, U.; Sadovskaia, K.; Farfan, J.; De Souza Noel Simas Barbosa, L.; et al. Low-cost renewable electricity as the key driver of the global energy transition towards sustainability. Energy 2021, 227, 120467. [Google Scholar] [CrossRef]

- Downie, C. Strategies for Survival: The International Energy Agency’s response to a new world. Energy Policy 2020, 141, 111452. [Google Scholar] [CrossRef]

- Wang, G.; Verleysen, K.; De Meulenaere, R.; Blondeau, J. Multi-objective optimization of hybrid energy storage systems under uncertainty. J. Energy Storage 2025, 111, 115218. [Google Scholar] [CrossRef]

- Li, Z.; Deusen, D. Role of energy storage technologies in enhancing grid stability and reducing fossil fuel dependency. Int. J. Hydrog. Energy 2025, 102, 1055–1074. [Google Scholar] [CrossRef]

- Chen, H.; Cong, T.N.; Yang, W.; Tan, C.; Li, Y.; Ding, Y. Progress in electrical energy storage system: A critical review. Prog. Nat. Sci. Mater. 2009, 19, 291–312. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Jin, P.; Cai, X.; Du, J.; Zhang, W.; Wang, H.; Li, R.; Cheng, Z. Design and thermodynamic performance analysis of a novel adiabatic compressed air energy storage system based on liquid piston re-pressurization. J. Energy Storage 2025, 105, 114675. [Google Scholar] [CrossRef]

- Li, R.; Tao, R.; Feng, X.; Yao, E.; Zhang, H.; Ling, L.; Wang, H. Energy distributing and thermodynamic characteristics of a coupling near-isothermal compressed air energy storage system. J. Energy Storage 2023, 58, 106314. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, Y.; Yu, B.; Liao, Z.; Xu, C. Thermodynamic analysis of an advanced adiabatic compressed air energy storage system integrated with a high-temperature thermal energy storage and an Organic Rankine Cycle. J. Energy Storage 2024, 100, 113773. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Yang, S.; Hooman, K.; Yang, X. Assessment evaluation of a trigeneration system incorporated with an underwater compressed air energy storage. Appl. Energy 2021, 303, 117648. [Google Scholar] [CrossRef]

- Han, Z.; Sun, Y.; Li, P. Research on energy storage operation modes in a cooling, heating and power system based on advanced adiabatic compressed air energy storage. Energy Convers. Manag. 2020, 208, 112573. [Google Scholar] [CrossRef]

- Chen, L.; Zheng, T.; Mei, S.; Xue, X.; Liu, B.; Lu, Q. Review and prospect of compressed air energy storage system. J. Mod. Power Syst. Clean Energy 2016, 4, 529–541. [Google Scholar] [CrossRef]

- Zhang, L.; Xie, M.; Ye, K.; Li, S.; Chen, L. Compressed air energy storage based on variable-volume air storage: A review. J. Energy Storage 2025, 110, 115361. [Google Scholar] [CrossRef]

- Hu, S.; Zhang, X.; Xu, W.; Cai, M.; Xu, Y.; Chen, H. Experimental study of tube-array-based liquid piston air compressor for near-isothermal compressed air energy storage system. Appl. Energy 2024, 373, 123979. [Google Scholar] [CrossRef]

- Hao, F.; Mu, A.; Lv, Z.; Zhou, H. A comprehensive review of liquid piston compressed air energy storage for sustainable renewable energy integration. J. Energy Storage 2024, 98, 113071. [Google Scholar] [CrossRef]

- Li, H.; Dong, C.; Mao, Y.; Gu, H.; Ye, Y.; Ye, C.; Bu, Z.; Zhong, Y.; Ye, T. Performance discussion of a compressed air energy storage system based on compression and expansion dual-purpose compressor with water spray cooling function. J. Energy Storage 2024, 103, 114327. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, W.; Nian, Y. Liquid-gas heat transfer characteristics of near isothermal compressed air energy storage based on Spray Injection. Int. J. Heat Mass Transf. 2023, 215, 124530. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, X.; Li, X.; Xu, Y.; Chen, H. Thermodynamic analysis of isothermal compressed air energy storage system with droplets injection. Energy 2023, 284, 129304. [Google Scholar] [CrossRef]

- Sangdani, M.H.; Tavakolpour-Saleh, A.R. Assessment of frequency and stroke in three-stage liquid-piston thermoacoustic Stirling engines via a new approach: Analysis and experiment. Energy 2025, 315, 134315. [Google Scholar] [CrossRef]

- Van de Ven, J.D.; Li, P.Y. Liquid piston gas compression. Appl. Energy 2009, 86, 2183–2191. [Google Scholar] [CrossRef]

- Luo, G.; He, T.; Wang, C.; Zhao, K.; Luo, Y.; Qin, Y. A novel variable liquid-properties thermal network model for researching on thermodynamic characteristics of ethylene glycol piston pump. Int. Commun. Heat Mass Transf. 2024, 150, 107185. [Google Scholar] [CrossRef]

- Ahn, B.; Ro, P.I. Spray cooling technique in liquid piston gas compression and impact of air dissolution on efficiency evaluation at different pressure levels. J. Energy Storage 2024, 81, 110460. [Google Scholar] [CrossRef]

- Hashemi-Tilehnoee, M.; Tsirin, N.; Stoudenets, V.; Bushuev, Y.G.; Chorążewski, M.; Li, M.; Li, D.; Leão, J.B.; Bleuel, M.; Zajdel, P.; et al. Liquid piston based on molecular springs for energy storage applications. J. Energy Storage 2023, 68, 107697. [Google Scholar] [CrossRef]

- Zhou, H.; Ooi, K.T.; Dong, P.; Yang, Z.; Zhou, S.; Zhao, S. Dynamic and energy analysis of a liquid piston hydrogen compressor. Int. J. Hydrog. Energy 2023, 48, 20694–20704. [Google Scholar] [CrossRef]

- Gouda, E.M.; Neu, T.; Benaouicha, M.; Fan, Y.; Subrenat, A.; Luo, L. Experimental and numerical investigation on the flow and heat transfer behaviors during a compression–cooling–expansion cycle using a liquid piston for compressed air energy storage. Energy 2023, 277, 127622. [Google Scholar] [CrossRef]

- Neu, T.; Subrenat, A. Experimental investigation of internal air flow during slow piston compression into isothermal compressed air energy storage. J. Energy Storage 2021, 38, 102532. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).