Abstract

This study investigates the effects of varying waste swine oil biodiesel blends on the emission characteristics and efficiency of a compression ignition (CI) engine. Through a series of controlled experiments, the engine was operated under a constant load of 25% across different speeds ranging from 1200 to 1800 rpm. This study meticulously recorded the emissions of carbon monoxide (CO), hydrocarbons (HC), carbon dioxide (CO2), nitrogen oxides (NOx), and particulate matter (PM), along with performance metrics, including Brake Specific Fuel Consumption (BSFC) and Brake Thermal Efficiency (BTE). The results revealed a clear inverse relationship between biodiesel blend percentage and emissions of CO, HC, and PM. CO emissions decreased from 0.76 at 1200 rpm to 0.22 at 1800 rpm for the B80 blend, compared to pure diesel. Similarly, HC emissions showed a decline from 36 to 20 for the B80 blend. Conversely, CO2 and NOx emissions increased in higher biodiesel blends, with CO2 peaking at 2.9 for the B80 blend and NOx emissions rising from 103 for pure diesel to 165 for the B80 blend. PM emissions also decreased with higher blends, from 15 in pure diesel to 10 in the B80 blend. This comprehensive analysis reveals that while biodiesel significantly reduces specific emissions, it also poses challenges in terms of increased fuel consumption and reduced thermal efficiency. The findings emphasize the need for advanced engine technologies and optimization strategies to harness the full potential of biodiesel as a sustainable and environmentally friendly alternative to diesel.

1. Introduction

The transition toward renewable energy sources is a critical component in the global effort to mitigate climate change and reduce reliance on non-renewable resources. Biodiesel, as a renewable, biodegradable, and non-toxic alternative to conventional diesel, has garnered significant attention in this context [1]. Its potential to reduce greenhouse gas emissions and particulate matter makes it a compelling substitute in the transportation and energy sectors [2,3].

Among the diverse sources for biodiesel production, waste swine oil, a by-product of the pork processing industry, offers an intriguing and underexplored opportunity. Its utilization not only addresses the issue of waste management but also aligns with the principles of circular economy and sustainability [4]. Furthermore, waste swine oil is characterized by properties that could favorably impact the combustion process in engines [5].

The application of biodiesel in compression ignition (CI) engines, which are predominant in heavy-duty vehicles and machinery, is pivotal due to their widespread use and significant environmental footprint [6]. While CI engines are lauded for their efficiency, they are also known for their higher emissions of nitrogen oxides (NOx) and particulates compared to gasoline engines, posing environmental and public health concerns [7]. The potential of biodiesel, specifically from waste swine oil, to reduce these emissions is a subject of growing interest.

However, the performance and emission characteristics of CI engines using waste swine oil biodiesel, particularly under variable load conditions, remain inadequately studied. Engine load variations significantly impact fuel consumption, emission rates, and overall engine efficiency [8]. Understanding how these factors interact with biodiesel from waste swine oil is crucial for its practical application and for maximizing its environmental benefits.

This research, therefore, aims to fill this gap by systematically investigating the emission and performance characteristics of a CI engine powered by waste swine oil biodiesel under a spectrum of load conditions. This study is guided by the hypothesis that waste swine oil biodiesel can offer comparable, if not superior, performance while reducing harmful emissions relative to conventional diesel, especially under varied operational scenarios.

The findings of this study have the potential to inform and influence future engine design, fuel formulation, and environmental policy. By providing empirical data on the use of an unconventional biodiesel source, this research seeks to contribute significantly to the scientific understanding of sustainable fuel alternatives and their practical implications in the real world.

This investigation not only addresses a specific gap in renewable energy research but also aligns with broader environmental and sustainability goals. It offers a pathway to enhance the ecological compatibility of CI engines, thereby supporting the transition to more sustainable energy systems.

2. A Literature Review

2.1. Overview of Biodiesel Research

Biodiesel, as an alternative fuel, has been extensively studied for its environmental and economic benefits. Research has predominantly focused on its potential to reduce greenhouse gas emissions and dependence on fossil fuels. Various studies have highlighted biodiesel’s biodegradability, reduced toxicity, and lower emission profile compared to conventional diesel. The compatibility of biodiesel with existing diesel engines, along with its energy efficiency, has also been a subject of significant research, laying the foundation for its broader adoption in the energy sector.

Biodiesel has gained attention as an alternative fuel due to its environmental benefits, energy efficiency, and compatibility with diesel engines. Research has shown that biodiesel production under various conditions can lead to improved environmental performance [9]. Biodiesel, derived from natural fats or vegetable oils, is attractive as an alternative diesel fuel due to its environmental benefits [10]. Studies have demonstrated that biodiesel has the potential to reduce greenhouse gas emissions and inhibit the formation of particulate matter and soot in diesel engines, thus contributing to environmental sustainability [11]. Additionally, biodiesel has been found to have positive environmental impacts by reducing gas emissions and energy consumption when compared to fossil fuels [12].

Furthermore, biodiesel is compatible with diesel engines without the need for significant engine modifications, making it a feasible alternative to traditional diesel fuel [13]. Research has also focused on the performance and combustion of compression ignition engines using biodiesel, demonstrating its potential to reduce environmental pollution and its compatibility with aviation engines [14]. Moreover, biodiesel is a renewable and environmentally friendly alternative fuel with the potential to reduce the use of conventional fuels [15].

In terms of energy efficiency, studies have indicated that biodiesel can be used as a substitute for diesel fuel without compromising engine performance, and it has been shown to emit lower amounts of greenhouse gases [16]. Additionally, biodiesel is a renewable and environmentally friendly alternative fuel suitable for use in compression ignition engines [17].

2.2. Waste Swine Oil as a Biodiesel Source

Waste swine oil, a by-product of the pork industry, has recently gained attention as a biodiesel feedstock. Its abundance and low cost make it an attractive option for biodiesel production [18]. Waste swine oil is a readily available feedstock due to the large amounts of waste oil generated by the swine industry. The oil extracted from swine manure and other waste contains high levels of fatty acids that can be converted into biodiesel. The oil content of waste swine materials ranges from 19.5% to 31.1%, providing a significant source of feedstock [19].

Researchers have explored various transesterification processes to convert waste swine oil into biodiesel. Studies have investigated parameters such as reaction temperature, catalyst type and amount, and methanol ratio to optimize the process [20]. Both acid-catalyzed and base-catalyzed transesterification have been studied [21]. The conversion efficiency of waste swine oil into biodiesel has been found to be high, around 98% [22].

Waste swine oil presents some challenges as a biodiesel feedstock due to the presence of free fatty acids and impurities. Pretreatment steps may be needed to reduce free fatty acids and purify the waste oil before transesterification [23]. However, the low cost of waste swine oil compared to other feedstocks makes it an attractive option for biodiesel production [24].

Waste swine oil shows potential as a feedstock for biodiesel production due to its availability, low cost, and high conversion efficiency. However, challenges related to impurities and free fatty acids require optimization of conversion processes. Further research is needed to improve the quality and yield of biodiesel from waste swine oil.

2.3. Biodiesel in Compression Ignition (CI) Engines

Recent studies have extensively investigated the use of biodiesel in compression ignition (CI) engines, focusing on engine performance, fuel efficiency, and emission characteristics compared to conventional diesel. Reşitoğlu et al. examined the effect of biodiesel derived from waste oil on engine performance and emission characteristics. Their study found that using biodiesel from waste oil as an alternative fuel in CI engines is an efficient way to reduce harmful compounds [25]. Similarly, Ifeanyi-Nze conducted a literature review on the impact of biodiesel engine performance on operations and the environment. The review covered topics related to the direct use of biodiesel in internal combustion engines and its ability to compete with fossil fuel diesel in performance [26].

Bitire et al. analyzed the performance and emission characteristics of a CI engine fueled with parsley biodiesel–diesel blend. Their study addressed issues related to the direct use of biodiesel in internal combustion engines and highlighted that most of these issues can be resolved by blending diesel fuel with biodiesel in various ratios [27].

These studies collectively demonstrate the extensive research conducted on the use of biodiesel in CI engines, emphasizing its impact on engine performance, fuel efficiency, and emission characteristics compared to conventional diesel. The findings underscore the potential of biodiesel as a viable alternative fuel for CI engines, with implications for environmental sustainability and energy efficiency.

2.4. Waste Swine Oil Biodiesel in CI Engines

Research specifically focusing on waste swine oil biodiesel in CI engines is limited but growing. Studies have begun to explore how this biodiesel impacts engine performance and emissions. However, as noted by Cheung et al., there are gaps in understanding the long-term effects on engine wear, maintenance requirements, and emission profiles under varied operational conditions [11].

Mandal et al. specifically investigated the effect of waste cooking oil biodiesel on CI engine pistons. Their study found that using waste cooking oil biodiesel resulted in lower heat transfer to the piston compared to conventional diesel, which could reduce engine wear over time [28]. However, their study focused primarily on thermal effects and did not discuss broader engine performance or emissions.

Reşitoğlu et al. more comprehensively examined the impact of biodiesel derived from waste oil, which could include pork oil, on engine performance and emissions in a CI engine. Their study found that using waste oil biodiesel resulted in lower fuel consumption, torque, and power output compared to diesel fuel [25]. However, waste oil biodiesel also produced significantly lower carbon monoxide, hydrocarbon, and particulate matter emissions. Their study provides insights into both the performance and environmental benefits of using waste oil biodiesel in CI engines.

2.5. Research Gaps and Opportunities

Despite the growing body of research, significant gaps remain, particularly regarding the use of waste swine oil biodiesel under different engine load conditions. These gaps hinder a comprehensive understanding of the fuel’s performance and environmental impact in practical scenarios. There is a critical need for detailed studies that investigate how varying loads affect CI engine performance and emissions when using this biodiesel.

This research aims to fill the identified gaps by conducting an in-depth analysis of the performance and emission characteristics of a CI engine powered by waste swine oil biodiesel under 25% load conditions. By addressing these unexplored areas, this study seeks to contribute valuable insights to the existing literature, potentially influencing the adoption and optimization of waste swine oil biodiesel in CI engines.

3. Research Methodology

3.1. Biodiesel Production from Waste Swine Oil

In biodiesel production from waste swine oil sourced from a BBQ restaurant, the process initiates with heating 500 mL of swine oil to 55 °C. Concurrently, a solution comprising 135 mL of methanol (99.9% pure) and 2.5 gm of Potassium Hydroxide (KOH, 90% reagent grade) is prepared. This mixture is then combined with the preheated oil and stirred continuously for two hours, a crucial step depicted in Figure 1, to transform triglycerides into methyl esters. After this reaction, the mixture is transferred to a separating funnel and left to cool for 24 h, allowing the biodiesel to separate from glycerol (as shown in Figure 1). The biodiesel then undergoes further purification, including washing with warm distilled water and vacuum drying to minimize glycerol content to below 0.02%.

Figure 1.

Process of Biofuel Production from Waste Swine Oil.

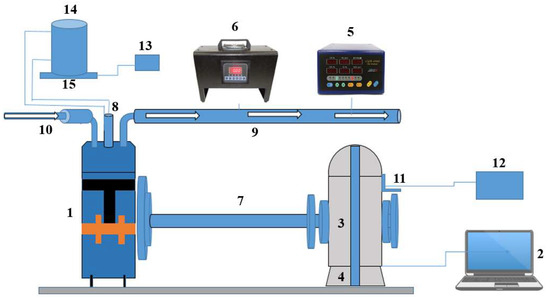

3.2. Engine Specifications and Setup

Figure 2 depicts the experimental setup for a single-cylinder, water-cooled agricultural diesel engine. This engine, manufactured by Daedong Korea Ltd. (Daegu Gwangyeoksi, Republic of Korea), utilizes indirect injection and possesses a rated power output of 7.4 kW. The engine was coupled to an eddy current dynamometer for precise control and measurement of applied load conditions. To record crucial parameters such as fuel consumption rate, exhaust temperature, and engine speed, various sensors and equipment were strategically installed. For detailed engine specifications and data points, please refer to Table 1.

Figure 2.

Experimental setup: (1) single-cylinder engine indirect ignition; (2) torque measurement; (3) eddy-current dynamometer; (4) load cell for torque; (5) gas emission analyzer; (6) smoke analyzer; (7) propeller shaft; (8) injector; (9) exhaust pipe; (10) air intake; (11) rpm sensor; (12) rpm display; (13) fuel weight display; (14) fuel tank; (15) load cell for fuel weight.

Table 1.

Engine specification and data points.

This study utilized a Daedong horizontal, 4-stroke, water-cooled internal combustion engine with a single cylinder, a stroke length of 95 mm, a bore of 95 mm, a compression ratio of 21, a displacement of 673 cc, and an injection pressure of 200 kg/cm2. The choice of this engine, characterized by its unmodified state, was crucial in ensuring the authenticity and applicability of our results. By employing a standard engine configuration typically found in real-world applications, this study offers a realistic evaluation of the performance and emissions of various biodiesel blends compared to standard diesel fuel.

To ensure the authenticity and applicability of the results, this research employed an unmodified internal combustion engine. This approach offers a realistic evaluation of the performance and emissions of various biodiesel blends and standard diesel in standard engine configurations, reflecting the real-world conditions encountered by typical engines. By avoiding any engine modifications, this study maintains the original design characteristics of the engine, leading to findings that are highly relevant and directly applicable to the majority of existing engines in use.

3.3. Test Procedures

Baseline performance was initially established by operating the engine using pure diesel. Stable operation was achieved before switching the fuel to biodiesel derived from waste swine oil. Tests were conducted at 75% load across various speeds: 1200; 1400; 1600; and 1800 rpm. Parameters, such as brake-specific fuel consumption (BSFC), brake thermal efficiency (BTE), and exhaust emissions (CO, CO2, NOx, HC, and PM), were recorded for both fuel types.

Throughout the experiments, the lubricating oil temperature was meticulously maintained between 85 °C and 90 °C. Each test run involved a 15-minute engine operation period, during which all observations and recordings were made with meticulous care. Uncertainty was carefully assessed to minimize potential data errors. Furthermore, precise calibration of all equipment was crucial for ensuring accurate results. To guarantee precision, measurements were recorded at least four times during each experiment, and the arithmetic mean of these readings was subsequently calculated. The range and resolution of the smoke meter and gas analyzer are detailed in Table 2.

Table 2.

Measuring Range and Precision of Smoke Meter and Gas Analyzer.

Engine performance variations were assessed through brake thermal efficiency (BTE) and brake-specific fuel consumption (BSFC). A CGA-4500 gas analyzer, manufactured in the Republic of Korea, was utilized to meticulously analyze engine emissions. This analyzer leverages non-dispersive infrared (NDIR) technology to measure carbon monoxide (CO) concentrations within a range from 0.00% to 10.00% and carbon dioxide (CO2) concentrations within a range from 0.0% to 20.0%. Additionally, the analyzer possesses the capability to measure hydrocarbons (HC) with a range from 0 to 10,000 ppm and oxygen (O2) with an electrochemical sensor within a range from 0.00% to 25.00%. Nitric oxide (NO) concentrations are quantified utilizing another electrochemical sensor within a range from 0 to 5000 ppm. A probe integrated into the exhaust pipe facilitated the acquisition of digital emission data. An exhaust gas temperature sensor consisting of a K-type thermocouple was also utilized, and smoke production was analyzed using a dedicated smoke meter.

3.4. Fuel Properties and Conformity to ASTM Standards

Table 3 presents the fuel properties of both waste swine oil biodiesel and diesel used in the experiment, adhering to the relevant ASTM standards. To clarify, the designations B20, B40, B60, and B80 represent different biodiesel blends, indicating the percentage of biodiesel mixed with conventional diesel fuel:

Table 3.

Fuel Properties of Waste Swine Oil Biodiesel Blends and Standard Diesel Fuel (ASTM Standards).

- B20: 20% biodiesel, 80% conventional diesel;

- B40: 40% biodiesel, 60% conventional diesel;

- B60: 60% biodiesel, 40% conventional diesel;

- B80: 80% biodiesel, 20% conventional diesel.

Understanding these designations is crucial to interpreting the impact of varying biodiesel content on engine performance and emissions in this study.

3.5. Waste Swine Oil Biodiesel Properties

Following transesterification and purification, the waste swine oil biodiesel exhibited the following distinct properties:

- Cetane Number 63 is a strong indicator of efficient and smooth combustion. This value surpasses the typical diesel cetane number range of 40–55, indicating superior ignition quality;

- Density: 893 kg/m3 at 15 °C, slightly higher than standard diesel fuels (800–880 kg/m3). This suggests a slightly heavier mass per unit volume for the biodiesel;

- Viscosity: 5.91 mm2/s at 40 °C, significantly higher than diesel (2.87 cSt). This indicates a thicker, more viscous nature for the biodiesel, potentially impacting fuel atomization and injection.

3.6. Comparison with Diesel

Both fuels exhibit relatively similar densities, falling within the standard range for diesel. However, lard biodiesel’s higher viscosity implies a thicker nature, impacting fuel flow and requiring adjustments to injection settings. Additionally, lard biodiesel’s higher flashpoint (114 °C) indicates lower volatility and potentially safer handling compared to diesel’s 58 °C flashpoint.

Furthermore, lard biodiesel’s significantly higher cetane number (65) demonstrates superior ignition quality compared to diesel (48.7). This advantage translates to smoother combustion and potentially lower emissions.

In terms of energy content, diesel holds an edge with a calorific value of 45.51 MJ/kg compared to lard biodiesel’s 40.21 MJ/kg. This translates to potentially lower fuel efficiency with biodiesel, requiring higher fuel consumption for equivalent power output.

While lard biodiesel possesses some advantages over diesel, such as superior ignition quality and potentially safer handling, its higher viscosity and lower energy content necessitate adjustments to engine settings and may compromise fuel efficiency. Further research is necessary to determine the optimal blend ratio and engine modifications required to optimize performance and minimize emissions utilizing waste swine oil biodiesel.

4. Results and Analysis

4.1. Variation in Carbone Monoxide (CO) with Engine Speed

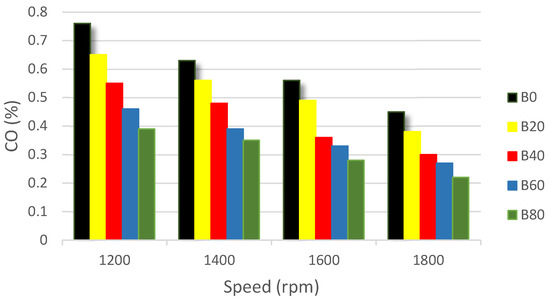

In examining the impact of waste swine oil biodiesel blends on CO emissions in a compression ignition engine, a systematic analysis was conducted under a consistent load of 25% at engine speeds varying from 1200 to 1800 rpm.

Figure 3 indicates a discernible downward trend in CO emissions as the percentage of biodiesel blend increases. Specifically, pure diesel (B0/CO) emitted the highest CO levels across all engine speeds, starting at 0.76 at 1200 rpm and decreasing to 0.45 at 1800 rpm. Introducing the waste swine oil biodiesel blend at 20% (B20/CO) resulted in a significant reduction in emissions, with further improvements being observed in higher blends; the 80% blend (B80/CO) yielded the lowest CO emissions, decreasing from 0.39 at 1200 rpm to 0.22 at 1800 rpm.

Figure 3.

Variation in CO with Engine Speed at 25% Load.

This reduction in CO emissions can be attributed to the higher oxygen content in biodiesel, which facilitates more complete combustion of fuel. Additionally, the unique composition of waste swine oil biodiesel likely leads to altered combustion kinetics, further aiding in the reduction in CO emissions. Compared to findings in similar studies, such as those conducted by Chauhan et al. (2012), our results show a more pronounced decrease in CO emissions with increasing biodiesel blend, especially at higher engine speeds [29]. This suggests that waste swine oil biodiesel may be more effective in reducing emissions than other biodiesel types studied previously. These findings underscore the potential of high-percentage biodiesel blends in mitigating CO emission levels in CI engines and reinforce the reliability of waste swine oil biodiesel as a sustainable alternative fuel. The consistency of this pattern across various engine speeds further highlights its effectiveness in reducing environmental impact in diesel engines.

4.2. Variation in HC with Engine Speed

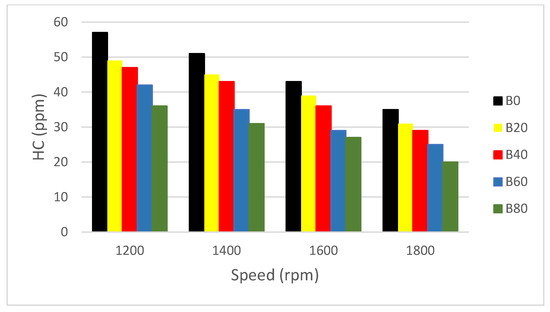

Further to the reductions in carbon monoxide (CO) emissions previously discussed, our investigation extended to hydrocarbon (HC) emissions, revealing a parallel decline as the proportion of waste swine oil biodiesel was augmented.

Figure 4 showcases that the baseline hydrocarbon emissions at B0/HC, representing pure diesel usage, commenced at 57 and exhibited a decrease to 35 with the engine’s increasing rpm. A progression toward environmentally favorable outcomes was observed when the engine was fueled with a 20% biodiesel blend (B20/HC), with emissions ranging from 49 to 31, and this trend continued with higher blend ratios. Notably, the B80/HC blend demonstrated the most significant decrease in HC emissions, starting at 36 and descending to 20, reinforcing the positive environmental implications of high-percentage biodiesel blends.

Figure 4.

Variation in HC with Engine Speed at 25% Load.

The reduction in HC emissions with increasing biodiesel content can be attributed to a better combustion efficiency provided by biodiesel’s higher oxygen content. This results in a more complete combustion of fuel, thus reducing unburnt hydrocarbons. Additionally, the unique fatty acid profile of waste swine oil biodiesel may contribute to more efficient combustion processes compared to conventional diesel, further decreasing HC emissions [28,29]. When compared with findings from other studies, such as those by Zheng et al. (2023), our results align with the general trend of biodiesel leading to lower HC emissions [3]. However, our study indicates a more substantial reduction, particularly with higher biodiesel blends, suggesting that waste swine oil biodiesel might be more effective in mitigating HC emissions than other types of biodiesel.

This consistent reduction across all tested engine speeds suggests that incorporating waste swine oil biodiesel could substantially curtail HC emissions, further validating its efficacy as an alternative fuel with lower environmental impact in comparison to conventional diesel.

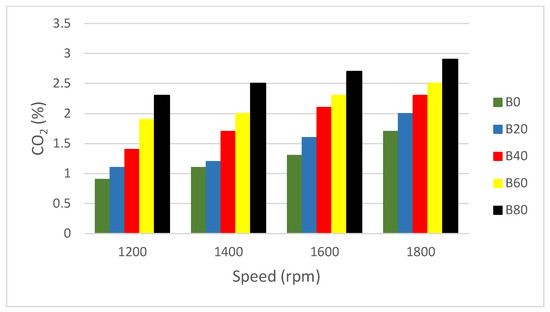

4.3. Variation in CO2 with Engine Speed

In stark contrast to the reductions observed in both CO and HC emissions, the analysis of carbon dioxide (CO2) emissions delineates a contrary trend. Emissions of CO2 are an inevitable outcome of any process that involves the combustion of hydrocarbons or their chemical oxidation, which includes the biological processes of humans and animals. The amount of CO2 released by an engine is directly related to the amount of hydrocarbon fuel it uses. This emission is steadily decreasing due to ongoing advancements in technology [30]. As the engine was operated on escalating percentages of waste swine oil biodiesel, CO2 emissions demonstrated an upward trajectory, according to Figure 5. Starting from a baseline emission value of 0.9 with pure diesel (B0/CO2), there was a noticeable increment in emissions with each subsequent increase in the biodiesel blend ratio.

Figure 5.

Variation in CO2 with Engine Speed at 25% Load.

This increment continued progressively, with the B20/CO2 blend emitting 1.1 and the B40/CO2 emitting 1.4, up to the B80/CO2 blend, which peaked at 2.9. These values escalated uniformly across the engine speed spectrum, indicating that while biodiesel blends could significantly reduce CO and HC emissions, their impact on CO2 emissions was inversely related.

The increase in CO2 emissions with higher percentages of biodiesel can be attributed to the higher oxygen content in biodiesel. This leads to a more complete combustion of carbon into CO2 rather than partial combustion into CO. Additionally, the higher cetane number of biodiesel compared to diesel results in a more efficient combustion process, further contributing to increased CO2 emissions [31]. Mandal et al. (2023) also report reductions in CO and HC emissions with biodiesel usage, and the resultant increase in CO2 emissions aligns with our findings [31].

This suggests that while biodiesel usage contributes positively toward reducing certain pollutants, it may also lead to higher CO2 output, which is an important consideration for the overall environmental footprint of biodiesel fuels.

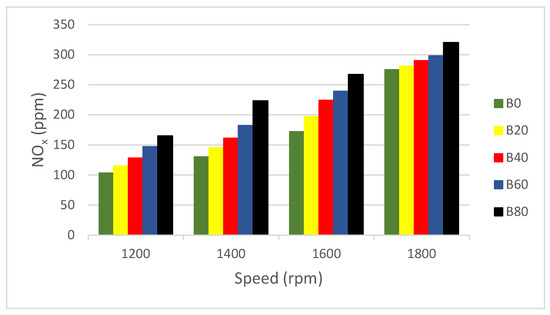

4.4. Variation in NOx with Engine Speed

Figure 6 shows that NOx emissions from the compression ignition (CI) engine operated on various waste swine oil biodiesel blends have unveiled a progressively rising pattern of emissions with increased biodiesel content.

Figure 6.

Variation in NOx with Engine Speed at 25% Load.

Commencing with NOx emissions of 103 for the pure diesel baseline (B0/NOx), each blend exhibited a higher emission level, climbing to 165 for the 80% biodiesel blend (B80/NOx). This upward trend is consistent across the operational speeds, with NOx emissions escalating from 130 to 223 for B20/NOx and B80/NOx, respectively, at intermediate speeds and peaking from 275 to 320 at the highest measured speeds. The data, thus, suggest a proportional relationship between the biodiesel blend percentage and NOx emissions, with higher blends resulting in greater NOx output. This increment in NOx emissions poses a significant challenge, as it contrasts with the concurrent reductions in CO and HC emissions and underlines the complexity of formulating biodiesel fuels that balance the need for reduced carbon emissions with the imperative of minimizing NOx pollutants.

Elsharkawy et al. [32] observed that NOx emissions were increased with higher concentrations of biodiesel in blends. The increase in NOx emissions with higher biodiesel blends can be attributed to several factors. Primarily, biodiesel’s higher oxygen content leads to higher combustion temperatures, which, in turn, facilitate the formation of more NOx [33]. Additionally, the longer ignition delay associated with biodiesel can result in more rapid combustion, further contributing to higher NOx levels [34].

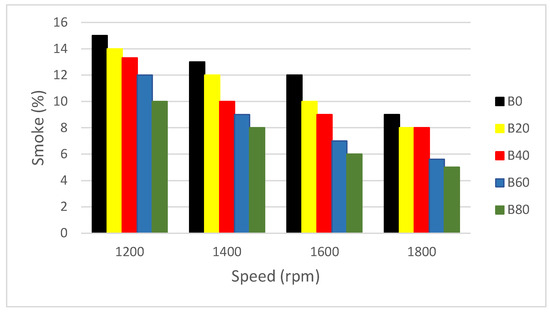

4.5. Variation in Smoke Opacity with Engine Speed

The graph in Figure 7 shows that smoke opacity increases as engine speed increases. This is because the fuel does not have enough time to completely burn at higher engine speeds, resulting in the formation of more smoke particles.

Figure 7.

Variation in Smoke Opacity with Engine Speed at 25% Load.

The trend observed in PM emissions was inversely proportional to the biodiesel blend percentage, with the highest PM emission of 15 recorded at the B0/PM level (pure diesel), which steadily declined to 10 at the B80/PM level (80% biodiesel blend). This decline was consistently observed at different engine speeds, revealing a reduction from 13 to 5 PM emissions when comparing B20/PM to B80/PM at the lower speed settings and a similar reduction from 9 to 5 PM at the higher speed settings.

For instance, research by Ashraful et al. [35] on biodiesel blends from different sources also reported a decrease in PM emissions with increasing biodiesel content. However, our study uniquely demonstrates the effectiveness of waste swine oil biodiesel in this regard, suggesting its higher efficacy in PM reduction compared to other biodiesel types.

These findings delineate the potential of high-percentage biodiesel blends in substantially reducing PM output, a pivotal factor in air quality and public health considerations. These data substantiate the environmental benefits of biodiesel, not only in lowering greenhouse gas and hydrocarbon emissions but also in mitigating particulate pollutants, thereby presenting a compelling case for the adoption of biodiesel as a cleaner alternative to conventional diesel fuel.

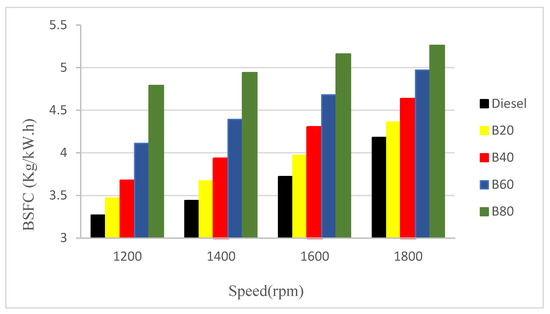

4.6. Brake-Specific Fuel Consumption (BSFC)

As illustrated in Figure 8, the evaluation of BSFC in relation to varying biodiesel blends presents an inverse relationship between fuel efficiency and biodiesel content in the fuel mixture.

Figure 8.

Variation in BSFC with Engine Speed at 25% Load.

This study’s findings indicate that pure diesel (B0/BSFC) exhibits the lowest BSFC, with an initial measurement of 3.27, implying a higher fuel efficiency. As the proportion of waste swine oil biodiesel is increased, a gradual increase in BSFC values is observed, culminating at 4.79 for the B80/BSFC blend, which denotes the least fuel efficiency among the tested blends. This progressive increase in BSFC from 3.44 to 5.26 across the range of biodiesel blends at varying engine speeds suggests that while biodiesel has positive impacts on emissions reduction, it does, however, pose a challenge in terms of fuel consumption efficiency. These data underscore the need for advanced engine calibration and optimization strategies to enhance the fuel economy when higher percentages of biodiesel are used, ensuring that the environmental benefits of emission reduction are not overshadowed by increased fuel consumption.

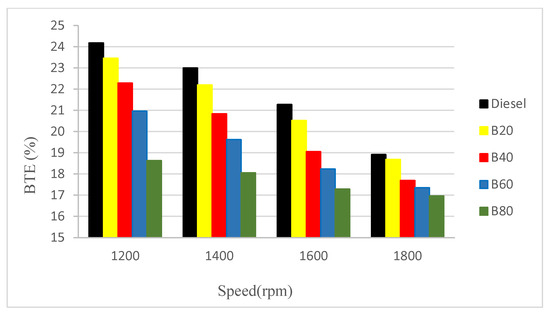

4.7. Brake Thermal Efficiency (BTE)

Figure 9 investigates the impact of varying biodiesel blends on the brake thermal efficiency (BTE) of a compression ignition (CI) engine. The findings demonstrate a clear and consistent inverse relationship between BTE and biodiesel content. In other words, increasing the percentage of biodiesel in the fuel blend leads to a reduction in the engine’s thermal efficiency.

Figure 9.

Variation in BTE with Engine Speed at 25% Load.

Pure diesel fuel (B0) achieved the highest observed BTE of 24.18. As the biodiesel ratio increased, BTE progressively declined, reaching 18.63 for the B80 blend (80% biodiesel). This pattern persisted across all tested engine speeds, with BTE values gradually decreasing as the biodiesel content rose from 20% to 80%.

These results highlight the thermal efficiency challenges associated with utilizing higher biodiesel blends in CI engines. While biodiesel offers significant advantages in reducing emissions, its impact on BTE requires a careful balancing act. This finding emphasizes the critical need for further research and development efforts aimed at optimizing engine design and operation to maximize energy efficiency while reaping the environmental benefits of biodiesel.

5. Conclusions

In conclusion, our study provides a multifaceted view of the implications of incorporating waste swine oil biodiesel blends into CI engine operation. The progression from B0 to B80 biodiesel blends has revealed a consistent reduction in carbon monoxide (CO) and hydrocarbon (HC) emissions, alongside a notable decrease in particulate matter (PM) emissions, which aligns with the global environmental objectives of reducing air pollutants from combustion engines.

Contrariwise, these data indicate an increase in carbon dioxide (CO2) and nitrogen oxide (NOx) emissions with higher biodiesel blends, presenting a complex challenge that underscores the need for a nuanced approach to biodiesel utilization. Furthermore, the observed increase in Brake Specific Fuel Consumption (BSFC) and the decrease in Brake Thermal Efficiency (BTE) with increasing biodiesel content suggest that while biodiesel can effectively reduce certain emissions, it does so at the expense of fuel and thermal efficiency.

This comprehensive analysis suggests that while waste swine oil biodiesel presents a promising alternative to reduce specific pollutants, there are inherent trade-offs that must be addressed. Optimizing engine designs and refining biodiesel formulations could potentially ameliorate the increased fuel consumption and reduced efficiency associated with higher biodiesel blends. As the transportation sector moves toward greener alternatives, the insights garnered from this study could inform future engine technology developments, ensuring that the environmental benefits of biodiesel are maximized without compromising performance.

In our study, we used an unmodified internal combustion engine to realistically evaluate the performance of biodiesel blends, including waste swine oil biodiesel, against standard diesel. While this approach reflects real-world conditions, it also highlights opportunities for future research in engine modifications and operating cycle adjustments for biodiesel. Potential areas for exploration include optimizing fuel injection timing and pressure, adjusting the air intake system, and exploring variable compression ratios to improve combustion efficiency and reduce emissions, particularly NOx. These modifications could enhance the use of biodiesel in both existing and new engines, balancing environmental benefits with operational efficiency.

Author Contributions

Conceptualization, R.K.; methodology, R.K.; software, R.K.; validation, R.K. and H.M.C.; formal analysis, R.K.; investigation, R.K.; resources, H.M.C.; data curation, R.K.; writing—original draft preparation, R.K.; writing—review and editing, R.K. and H.M.C.; visualization, R.K.; supervision, H.M.C.; project administration, H.M.C.; funding acquisition, H.M.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (NRF-2022H1A7A2A02000033)/(NRF-2019R1A2C1010557).

Data Availability Statement

The data presented in this study were collected from the experimental investigation by the first author.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| ppm | parts per million |

| rpm | revolutions per minute |

| KOH | Potassium Hydroxide |

| BSFC | Brake-Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| HC | Hydrocarbon |

| NOX | Nitrogen Oxide |

References

- Ahmad, M.; Elnaggar, A.Y.; Teong, L.K.; Sultana, S.; Zafar, M.; Munir, M.; Hussein, E.E.; Abidin, S.Z.U. Sustainable and eco-friendly synthesis of biodiesel from novel and non-edible seed oil of Monotheca buxifolia using green nano-catalyst of calcium oxide. Energy Convers. Manag. X 2022, 13, 100142. [Google Scholar]

- Liu, Y.H.; Liao, W.Y.; Li, L.; Huang, Y.T.; Xu, W.J.; Zeng, X.L. Reduction measures for air pollutants and greenhouse gas in the transportation sector: A cost-benefit analysis. J. Clean. Prod. 2019, 207, 1023–1032. [Google Scholar] [CrossRef]

- Zheng, F.; Cho, H.M. Investigation of the Impact of Castor Biofuel on the Performance and Emissions of Diesel Engines. Energies 2023, 16, 7665. [Google Scholar] [CrossRef]

- Toldrá-Reig, F.; Mora, L.; Toldrá, F. Trends in biodiesel production from animal fat waste. Appl. Sci. 2020, 10, 3644. [Google Scholar] [CrossRef]

- Ramirez, J.; McCabe, B.; Jensen, P.D.; Speight, R.; Harrison, M.; Van Den Berg, L.; O’Hara, I. Wastes to profit: A circular economy approach to value-addition in livestock industries. Anim. Prod. Sci. 2021, 61, 541–550. [Google Scholar] [CrossRef]

- Douvartzides, S.L.; Charisiou, N.D.; Papageridis, K.N.; Goula, M.A. Green diesel: Biomass feedstocks, production technologies, catalytic research, fuel properties and performance in compression ignition internal combustion engines. Energies 2019, 12, 809. [Google Scholar] [CrossRef]

- Dash, S.K.; Lingfa, P.; Das, P.K.; Saravanan, A.; Dash, D.; Bharaprasad, B. Effect of injection pressure adjustment towards performance, emission and combustion analysis of optimal nahar methyl ester diesel blend powered agricultural diesel engine. Energy 2023, 263, 125831. [Google Scholar] [CrossRef]

- Yin, X.; Li, W.; Zhang, W.; Lv, X.; Yang, B.; Wang, Y.; Zeng, K. Experimental analysis of the EGR rate and temperature impact on combustion and emissions characteristics in a heavy-duty NG engine. Fuel 2022, 310, 122394. [Google Scholar] [CrossRef]

- Tsoutsos, T.; Kouloumpis, V.; Zafiris, T.; Foteinis, S. Life cycle assessment for biodiesel production under greek climate conditions. J. Clean. Prod. 2010, 18, 328–335. [Google Scholar] [CrossRef]

- Ghesti, G.; Macedo, J.; Braga, V.; Souza, A.; Parente, V.; Figuerêdo, E.; Resck, I.S.; Dias, J.A.; Dias, S. Application of raman spectroscopy to monitor and quantify ethyl esters in soybean oil transesterification. J. Am. Oil Chem. Soc. 2006, 83, 597–601. [Google Scholar] [CrossRef]

- Cheung, C.; Man, X.; Fong, K.; Tsang, O. Effect of waste cooking oil biodiesel on the emissions of a diesel engine. Energy Procedia 2015, 66, 93–96. [Google Scholar] [CrossRef]

- Dinh, K.; Duong, H.; Phan, T. Environmental impacts assessment of biodiesel production from jatropha and waste cooking oil (wco). Vietnam J. Sci. Technol. 2019, 57, 606. [Google Scholar] [CrossRef]

- Alex, Y.; Roy, R. Production, quantitative analysis of fatty acids, engine performance and emission characteristics of biodiesel fuel derived from virgin coconut oil. Int. J. Innov. Sci. Res. Technol. 2020, 5, 1397–1404. [Google Scholar] [CrossRef]

- Liu, R.; Zhao, W.; Wang, Z.; Liu, X. Investigation on performance and combustion of compression ignition aviation piston engine burning biodiesel and diesel. Aircr. Eng. Aerosp. Technol. 2020, 93, 384–393. [Google Scholar] [CrossRef]

- Tsanaktsidis, C. Using a biodegradable polymer to reduce the acidity of biodiesel and biodiesel/petroleum diesel fuel blends. Chem. Technol. Fuels Oils 2012, 48, 44–48. [Google Scholar] [CrossRef]

- Ameer, H.; Ameer, M. 4-stroke ci engine: An experimental comparison of performance characteristics for 14% biodiesel & pure diesel. Eur. J. Sustain. Dev. Res. 2020, 4, em0142. [Google Scholar] [CrossRef]

- Santhanakrishnan, S. Performance and emission characteristics of al2o3 coated lhr engine operated with mahua oil biodiesel blend. Int. J. Res. Eng. Technol. 2013, 2, 25–28. [Google Scholar] [CrossRef][Green Version]

- Ejeromedoghene, O.; Oladipo, A.; Okoye, C.O.; Enwemiwe, V.; Anyaebosim, E.V.; Olusola, M.; Adewuyi, S. Green biodiesel based on non-vegetable oil and catalytic ability of waste materials as heterogeneous catalyst. Energy Sources Part A Recovery Util. Environ. Eff. 2022, 44, 7432–7452. [Google Scholar] [CrossRef]

- Yang, S.; Qing-Lan, Z.; Zhang, J.; Zhou, Y.; Liu, Z. Conversion of solid organic wastes into oil via boettcherisca peregrine (Diptera: Sarcophagidae) larvae and optimization of parameters for biodiesel production. PLoS ONE 2012, 7, e45940. [Google Scholar] [CrossRef]

- Astuti, E.; Mufrodi, Z. Optimum condition of biodiesel production from waste cooking oil using continuous stirred tank reactor. Int. J. Smart Grid Clean Energy 2019, 8, 201–205. [Google Scholar] [CrossRef]

- Salehi, A.; Karbassi, A.; Ghobadian, B.; Ghasemi, A.; Doustgani, A. Simulation process of biodiesel production plant. Environ. Prog. Sustain. Energy 2019, 38, e13264. [Google Scholar] [CrossRef]

- Ruhani, B.; Movahedi, P.; Saadi, S.; Ghasemi, A.; Kheradmand, A.; Dibaj, M.; Akrami, M. Comprehensive techno-economic analysis of a multi-feedstock biorefinery plant in oil-rich country: A case study of iran. Sustainability 2022, 14, 1017. [Google Scholar] [CrossRef]

- Vasudevan, P.; Briggs, M. Biodiesel production—Current state of the art and challenges. J. Ind. Microbiol. Biotechnol. 2008, 35, 421–430. [Google Scholar] [CrossRef] [PubMed]

- Sanli, H.; Canakci, M.; Alptekin, E. Characterization of waste frying oils obtained from different facilities. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011. [Google Scholar] [CrossRef]

- Reşitoğlu, İ.; Keskin, A. The effect of biodiesel derived from waste oil on engine performance and emission characteristics. J. Environ. Sci. Stud. 2018, 1, 55. [Google Scholar] [CrossRef]

- Ifeanyi-Nze, F. Impact of biodiesel engine performance on operations and the environment: A literature review. Eur. J. Sustain. Dev. Res. 2022, 6, em0200. [Google Scholar] [CrossRef]

- Bitire, S.; Jen, T. Performance and emission analysis of a ci engine fueled with parsley biodiesel–diesel blend. Mater. Renew. Sustain. Energy 2022, 11, 143–153. [Google Scholar] [CrossRef]

- Mandal, A.; Cho, H.; Chauhan, B. Effect on ci engine piston by waste cooking oil biodiesel. J. Eng. Res 2021, 9, 75–84. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H.M. A study on the performance and emission of a diesel engine fueled with Jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Reitz, R.D.; Ogawa, H.; Payri, R.; Fansler, T.; Kokjohn, S.; Moriyoshi, Y.; Agarwal, A.; Arcoumanis, D.; Assanis, D.; Bae, C.; et al. IJER editorial: The future of the internal combustion engine. Int. J. Engine Res. 2020, 21, 3–10. [Google Scholar] [CrossRef]

- Mandal, A.; Cho, H.; Chauhan, B.S. Experimental investigation of multiple fry waste soya bean oil in an agricultural CI engine. Energies 2022, 15, 3209. [Google Scholar] [CrossRef]

- Elsharkawy, E.A.; Abou Al-Sood, M.M.; El-Fakharany, M.K.; Ahmed, M. Enhancing the impact of biodiesel blend on combustion, emissions, and performance of DI diesel engine. Arab. J. Sci. Eng. 2020, 45, 1109–1123. [Google Scholar] [CrossRef]

- Sui, M.; Zhu, Z.; Li, F.; Wang, H.; Tang, C. Effect of oxidation on the combustion flame characteristics of Jatropha biodiesel. Fuel Process. Technol. 2023, 252, 107972. [Google Scholar] [CrossRef]

- Abdullah, I.S.; Khalid, A.; Jaat, N.; Nursal, R.S.; Koten, H.; Karagoz, Y. A study of ignition delay, combustion process and emissions in a high ambient temperature of diesel combustion. Fuel 2021, 297, 120706. [Google Scholar] [CrossRef]

- Ashraful, A.M.; Masjuki, H.H.; Kalam, M.A. Particulate matter, carbon emissions and elemental compositions from a diesel engine exhaust fuelled with diesel–biodiesel blends. Atmos. Environ. 2015, 120, 463–474. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).