Research on the Resource-Allocation-Optimization Strategy for Offshore Wind Power Construction Considering Complex Influencing Factors

Abstract

1. Introduction

2. Optimization of Strategies Under Complex Influencing Factors

2.1. Key Parameters of the Process

2.2. Construction Resources

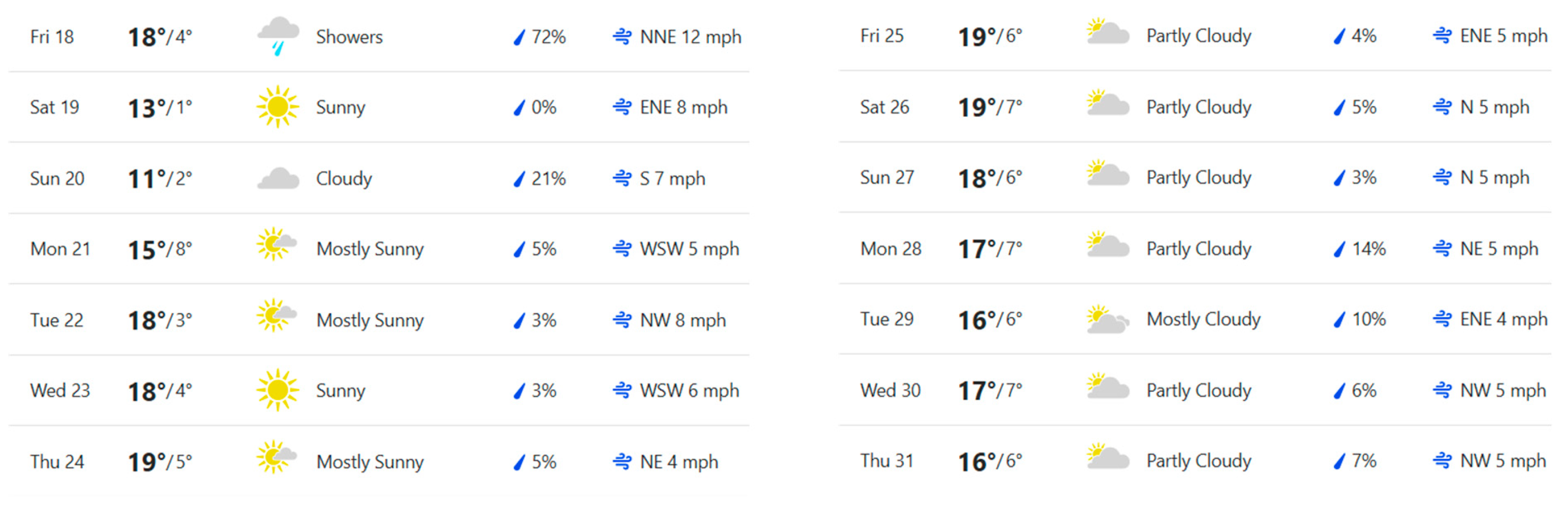

2.3. Meteorological Conditions

3. Resource-Allocation-Optimization Indicators

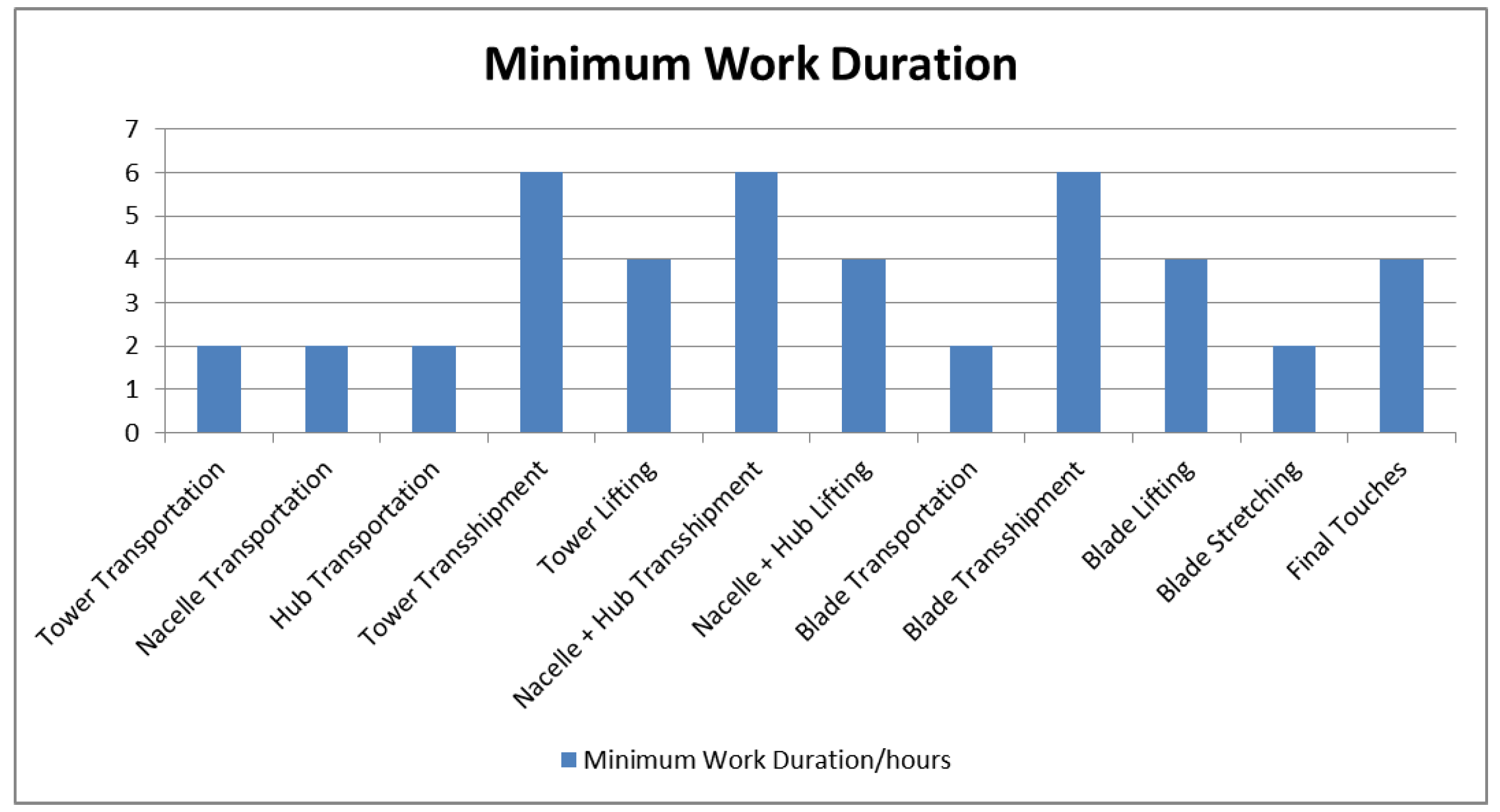

3.1. Minimum Working Hours

3.2. Window Period Utilization

3.3. Rate of Optimization of Resource Allocation

3.4. Cost–Benefit Ratio

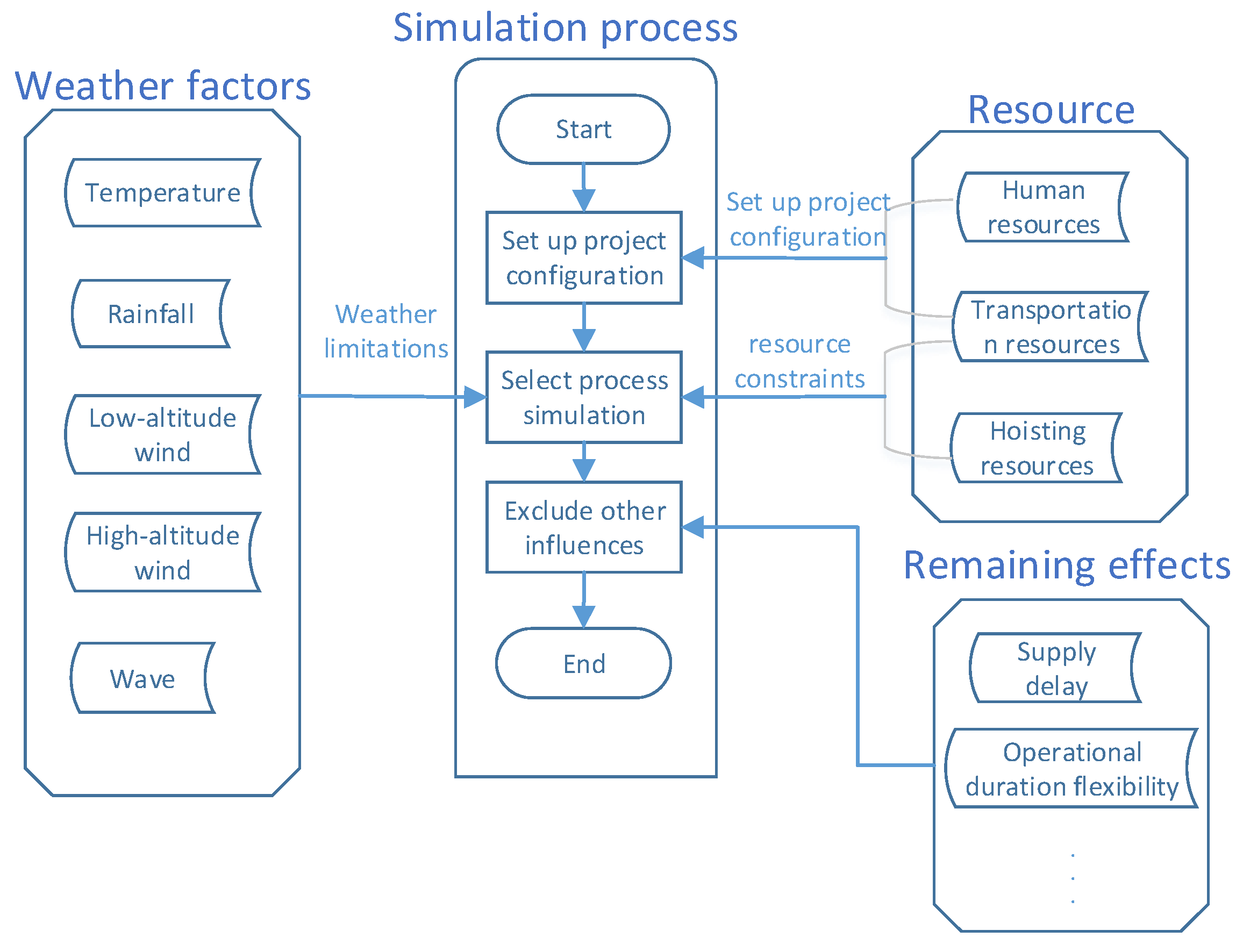

4. Resource-Allocation-Optimization Simulation System

4.1. Weather Module of System

4.2. Process Module of System

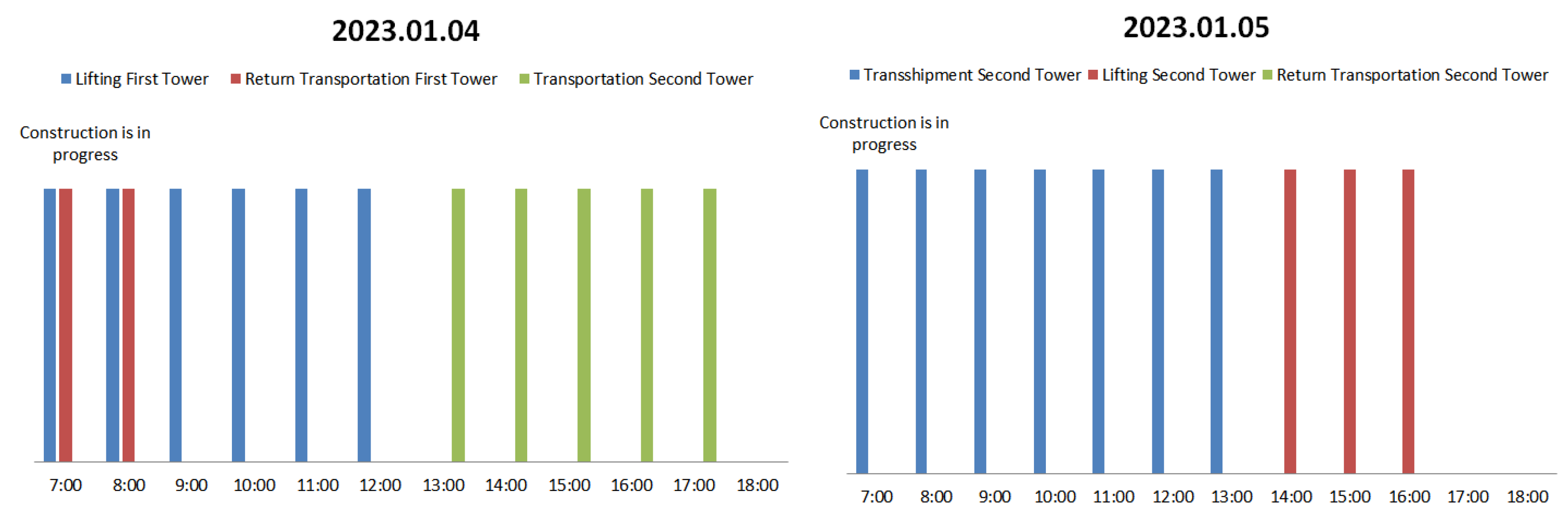

4.3. Simulation Result

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, B.W.; Zhang, Z.B.; Li, G.D.; Yang, D.S.; Santos, M. Review of Key Technologies for Offshore Floating Wind Power Generation. Energies 2023, 16, 710. [Google Scholar] [CrossRef]

- Ayub, M.W.; Hamza, A.; Aggidis, G.A.; Ma, X.D. A Review of Power Co-Generation Technologies from Hybrid Offshore Wind and Wave Energy. Energies 2023, 16, 550. [Google Scholar] [CrossRef]

- Serri, L.; Airoldi, D.; Lanni, F.; Naldi, R.; Castorrini, A.; Rispoli, F.; Soukissian, T.; Santos, L.C.; Le Boulluec, M.; Maisondieu, C. Technical and economic challenges for floating offshore wind deployment in Italy and in the Mediterranean Sea. Wiley Interdiscip. Rev. Energy Environ. 2024, 13, e533. [Google Scholar] [CrossRef]

- Chen, Y.H.; Lin, H.Y. Overview of the development of offshore wind power generation in China. Sustain. Energy Technol. Assess. 2022, 53, 102766. [Google Scholar] [CrossRef]

- Luo, K.; Cheng, Y.; Wang, T.; Qi, H. Review of Offshore Wind Power Reliability Analysis and Assessment. In Proceedings of the 2023 International Conference on Power System Technology (PowerCon), Jinan, China, 21–22 September 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Snyder, B.; Kaiser, M.J. Ecological and economic cost-benefit analysis of offshore wind energy. Renew. Energy 2009, 34, 1567–1578. [Google Scholar] [CrossRef]

- Song, D.R.; Shen, G.Y.; Huang, C.E.; Huang, Q.; Yang, J.; Dong, M.; Joo, Y.H.; Duic, N. Review on the Application of Artificial Intelligence Methods in the Control and Design of Offshore Wind Power Systems. J. Mar. Sci. Eng. 2024, 12, 424. [Google Scholar] [CrossRef]

- Díaz, H.; Soares, C.G. Review of the current status, technology and future trends of offshore wind farms. Ocean Eng. 2020, 209, 107381. [Google Scholar] [CrossRef]

- Salvacao, N.; Soares, C.G.; Bentamy, A. Offshore Wind Energy Assessment for the Iberian Coasts Using Remotely Sensed Data; Taylor & Francis Group: London, UK, 2015. [Google Scholar]

- Díaz, H.; Soares, C.G. Cost and financial evaluation model for the design of floating offshore wind farms. Ocean Eng. 2023, 287, 115841. [Google Scholar] [CrossRef]

- Edwards, E.C.; Holcombe, A.; Brown, S.; Ransley, E.; Hann, M.; Greaves, D. Evolution of floating offshore wind platforms: A review of at-sea devices. Renew. Sustain. Energy Rev. 2023, 183, 113416. [Google Scholar] [CrossRef]

- Salvacao, N.; Soares, C.G. Resource Assessment Methods in the Offshore Wind Energy Sector. In Floating Offshore Wind Farms; Springer Nature: Cham, Switzerland, 2016; pp. 121–141. [Google Scholar]

- Su, X.; Wang, X.D.; Xu, W.L.; Yuan, L.Q.; Xiong, C.H.; Chen, J.M. Offshore Wind Power: Progress of the Edge Tool, Which Can Promote Sustainable Energy Development. Sustainability 2024, 16, 7810. [Google Scholar] [CrossRef]

- Cheneka, B.R.; Watson, S.J.; Basu, S.; IOP. The impact of weather patterns on offshore wind power production. In Proceedings of the Conference on Science of Making Torque from Wind (TORQUE), Delft University of Technology, TU Delft Wind Energy Institute, ELECTR NETWORK, Virtual, 28 September–2 October 2020. [Google Scholar]

- Zhao, W.; Zou, H.; Li, L.; Guo, Z. Cloud-Edge-End Collaboration for Intelligent Management in Offshore Wind Farms. In Proceedings of the 2024 6th International Conference on Communications, Information System and Computer Engineering (CISCE), Guangzhou, China, 10–12 May 2024; pp. 1–5. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, A.; Shan, K.; Yu, X. Economic assessment of new type foundation for offshore wind turbines. J. Hydroelectr. Eng. 2023, 42, 27–34. [Google Scholar]

- Santos, A.; Fagerholt, K.; Soares, C.G. A stochastic optimization algorithm for the supply vessel planning problem under uncertain demand and uncertain weather conditions. Ocean Eng. 2023, 278, 114428. [Google Scholar] [CrossRef]

- Santos, A.; Fagerholt, K.; Laporte, G.; Soares, C.G. A stochastic optimization approach for the supply vessel planning problem under uncertain demand. Transp. Res. Part B Methodol. 2022, 162, 209–228. [Google Scholar] [CrossRef]

- Scholz-Reiter, B.; Lutjen, M.; Heger, J.; Schweizer, A. Planning and control of logistics for offshore wind farms. Advances in Mathematical and Computational Methods. In Proceedings of the 12th WSEAS International Conference on Mathematical and Computational Methods in Science and Engineering (MACMESE 2010), Faro, Portugal, 3–5 November 2010; pp. 242–247. [Google Scholar]

- Ait-Alla, A.; Quandt, M.; Lütjen, M.; Bremer, B. Aggregate Installation Planning of Offshore Wind Farms. Int. J. Energy 2013, 7. [Google Scholar]

- Sarichloo, Z.; Murphy, A.; Butterfield, J.; Doran, W.J.; Hannigan, P.; Desmond, C. Modelling port and offshore installation operations for floating wind farms. In Proceedings of the 2022 Annual Wind Energy Ireland Conference, Dublin, Ireland, 14 February 2022. [Google Scholar]

- Levitt, A.C.; Kempton, W.; Smith, A.P.; Musial, W.; Firestone, J. Pricing offshore wind power. Energy Policy 2011, 39, 6408–6421. [Google Scholar] [CrossRef]

- Yong, L.; Ping, Z.; Min, F. Research on construction system of large scale non-grid-connected wind power offshore wind farms. In Proceedings of the 2010 World Non-Grid-Connected Wind Power and Energy Conference (WNWEC), Nanjing, China, 5–7 November 2010; p. 5. [Google Scholar] [CrossRef]

- Lin, Y.; Yang, Z.; Liu, Y.; Wang, X.; Lu, P.; Dong, S. Analysis of weather window and construction efficiency for wind power development in offshore China. Acta Energiae Solaris Sin. 2023, 44, 273–280. [Google Scholar]

- Ge, Q. Design of Offshore Wind Power ROI Energy Analysis Model Using XGBoost Algorithm. In Proceedings of the 2024 IEEE 2nd International Conference on Sensors, Electronics and Computer Engineering (ICSECE), Jinzhou, China, 29–31 August 2024; pp. 1440–1444. [Google Scholar] [CrossRef]

| Events | Duration | Direct Predecessor | Interruptibility | Min Interruption Time | Personnel Required | Cost of Process | Attributes |

|---|---|---|---|---|---|---|---|

| A1 | T A1 | A0 | Yes | 1 | 4 | 0.15M ¥ | Transportation |

| A2 | T A2 | A0, A1 | No | / | 6 | 0.20M ¥ | Lifting |

| … | … | … | … | … | … | … | … |

| Z1 | T Z1 | Y1 | Yes | 2 | 4 | 0.15M ¥ | Other |

| Equipment | Vessel | Crane | |

|---|---|---|---|

| Attributes | |||

| Load Capacity/(kg) | — | — | |

| Wave Resistance/(m/s) | |||

| Wind Resistance/m | |||

| Cost | |||

| Maximum Speed (m/s) | — | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, N.; He, R.; Jin, C.; Xu, Y.; Pan, G.; Qi, L. Research on the Resource-Allocation-Optimization Strategy for Offshore Wind Power Construction Considering Complex Influencing Factors. Energies 2024, 17, 6006. https://doi.org/10.3390/en17236006

Wu N, He R, Jin C, Xu Y, Pan G, Qi L. Research on the Resource-Allocation-Optimization Strategy for Offshore Wind Power Construction Considering Complex Influencing Factors. Energies. 2024; 17(23):6006. https://doi.org/10.3390/en17236006

Chicago/Turabian StyleWu, Ning, Rongrong He, Chunwei Jin, Yuan Xu, Guobing Pan, and Lianzhen Qi. 2024. "Research on the Resource-Allocation-Optimization Strategy for Offshore Wind Power Construction Considering Complex Influencing Factors" Energies 17, no. 23: 6006. https://doi.org/10.3390/en17236006

APA StyleWu, N., He, R., Jin, C., Xu, Y., Pan, G., & Qi, L. (2024). Research on the Resource-Allocation-Optimization Strategy for Offshore Wind Power Construction Considering Complex Influencing Factors. Energies, 17(23), 6006. https://doi.org/10.3390/en17236006