1. Introduction

Wind energy has gradually become a key research field of energy development due to its abundant resources, environmental friendliness, and relatively mature technology. In recent years, a number of large-scale and clustered wind farms are also being built rapidly [

1].

In the context of large-scale wind farms, the wake effect of wind farms has received extensive attention, which refers to a decrease in wind speed and an increase in turbulence in the upstream region of wind turbines, resulting in a decrease in power generation and an increase in fatigue load of the downstream wind turbine [

2]. The widely used maximum power point tracking (MPPT) strategy of single wind turbine control ignores the wake interference between wind turbines. Thus, it is gradually being replaced by a collaborative control strategy based on wake regulation [

3].

Accurate wake assessment is the basis for effective wake regulation. The wake evaluation methods include on-site wind measurement and numerical simulations. Numerical simulations can be divided into high-precision simulations, for instance CFD-based simulations, and low-precision fast calculations, for instance engineering wake models. The geometry-resolved CFD simulation is usually used to model a single or very small number of wind turbines [

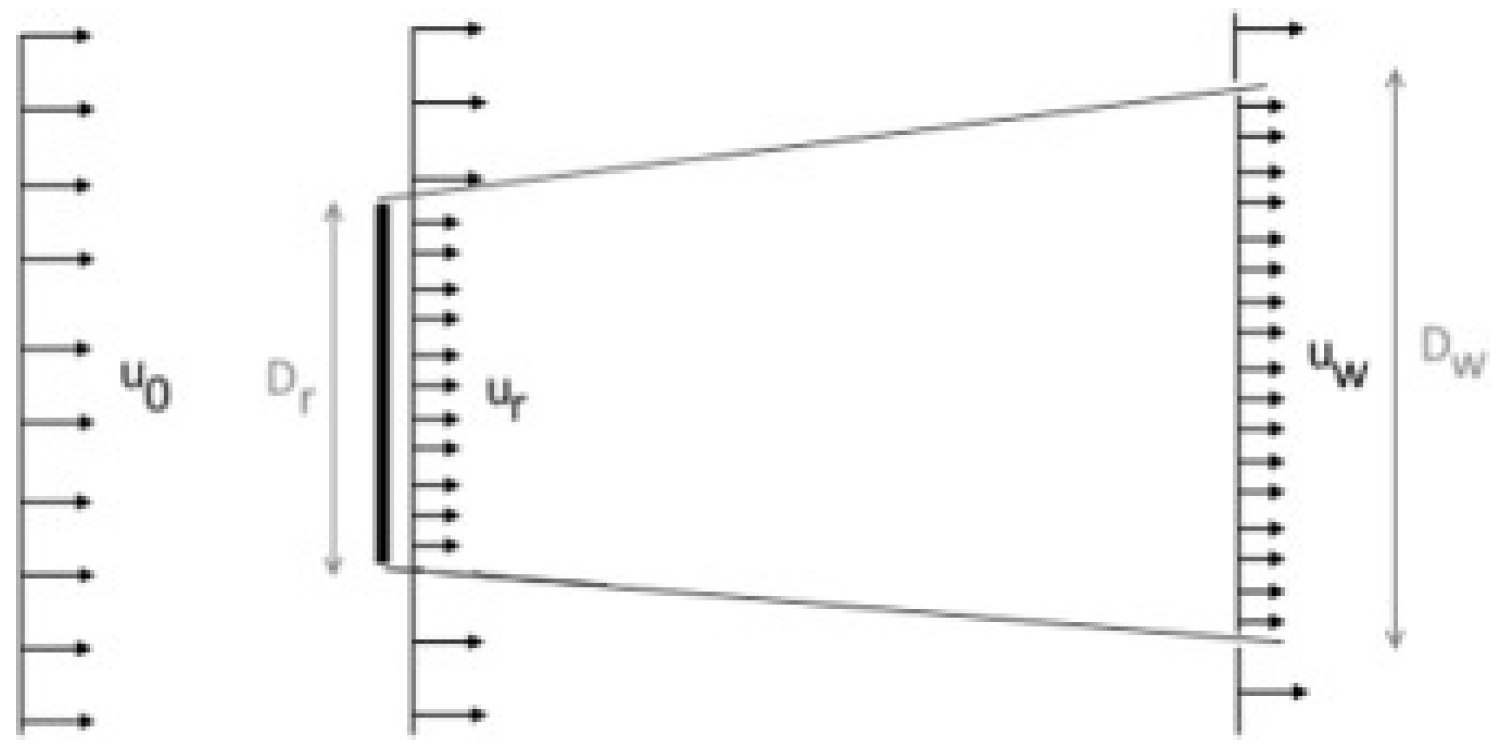

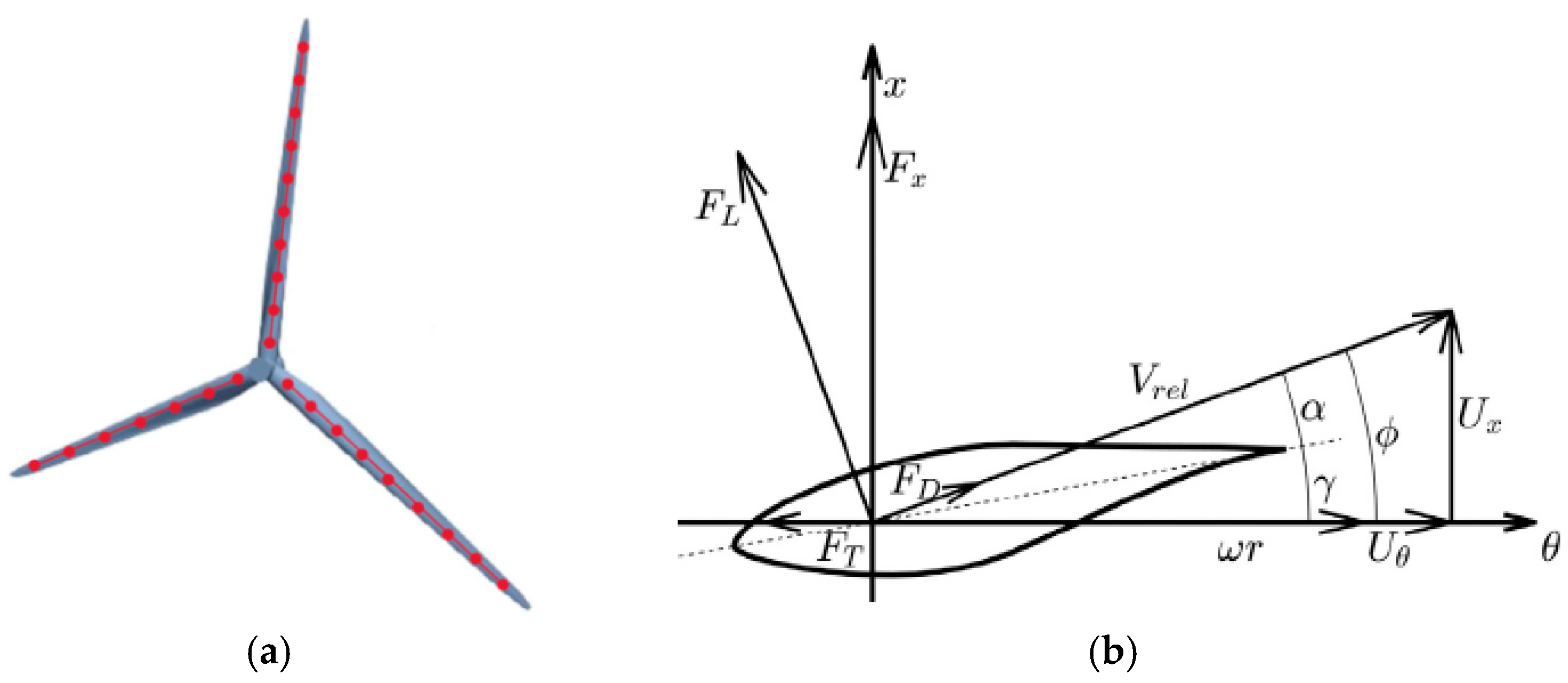

4]. Thus, an actuator model is usually employed to simplify wind turbine modeling, such as the actuator line model (ALM) or actuator disk model (ADM). The actuator line approach represents the aerodynamic loads on a wind turbine blade in terms of these rotational lines by applying volumetric forces distributed along the rotational lines. Since there is no need to use the very fine grid to resolve the boundary layer on the blade surface, it significantly reduces the computational cost [

5]. The ALM, in combination with large eddy simulations, has been often used to study the fundamental characteristics of wake turbulence interactions in wind farms [

6]. Barthelmie et al. [

7] performed CFD simulations of the Horns Rev wind farm based on actuator models, focusing on improvements in wind farm wake modeling. They argued that wake modeling for large wind farms still faces high uncertainties. Weihing et al. [

8] studied the wake characteristics and loads of wind turbines using an ALM-based method. The results showed that the prediction on the wake structure, wake deflection, and wake loss was in good agreement with the results of the geometry-resolved method. Ameur et al. [

9] used ALM, ADM, and RANS simulations to simulate the wind turbine nacelle circumference. It was found that the simulation effect of the actuator line on the recovery rate of the wake is better than that of ADM.

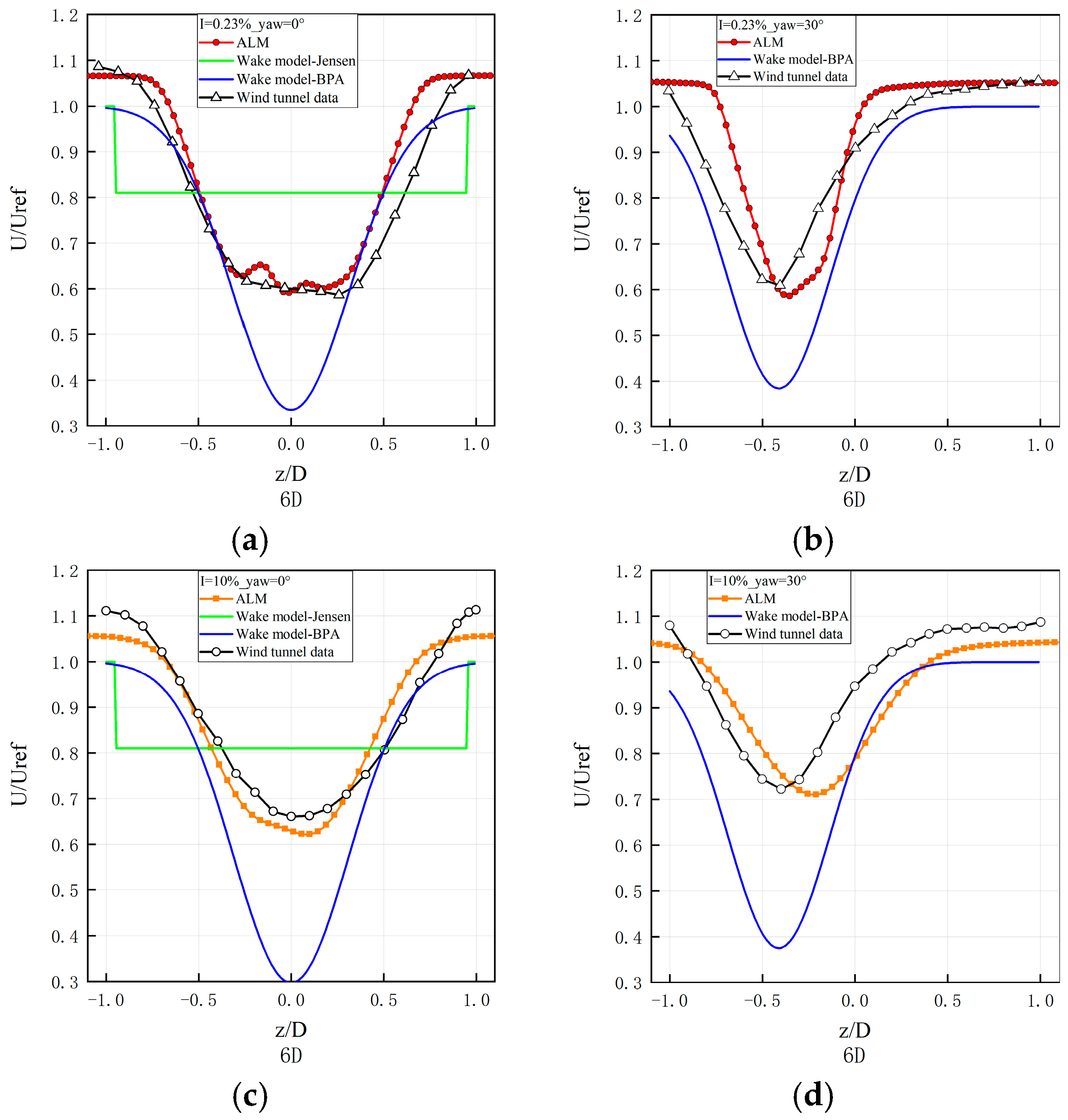

The simulation of wind turbine wake using an actuator model needs to be combined with turbulence-solving methods. Most of the work investigating the characteristics of wake development has used the Large Eddy Simulation (LES) approach. Although the LES method is capable of solving turbulent motions at a finer level, the computational cost of the LES method is too large for wake regulation of a large-scale wind farm. On the other hand, RANS simulations can obtain higher computational efficiency under the premise of guaranteeing a certain computational accuracy, which has a high prospect of practical application in engineering. Van der Laan et al. [

10] proposed a modified k-ε model by limiting the turbulent viscosity based on the velocity gradient and calibrated the model against LESs for eight different single wake scenarios. The results show that the k-ε-fp model compares well with the LESs under low-turbulence conditions. Arabgolarcheh et al. [

11] used the actuator line model coupled with the k-ε turbulence model to study the influence of the wake effect on the downstream turbine caused by the coupling of the longitudinal and longitudinal oscillation of the upstream turbine wake. Li et al. [

12] used the CFD simulation method of the actuator disk model coupled with the k-ε turbulence model to simulate the effects of different working conditions on the wake of wind turbines and compared them with the experimental results, and the correlation coefficients were corrected to improve the accuracy of the simulation.

Due to the fact that the optimal control of wake needs to be calculated and optimized under a large number of working conditions, the engineering wake model with low computational cost and acceptable accuracy has become the primary method of wake prediction [

13]. The most widely used wake model, Jensen wake model [

14], is a linear wake model based on the law of conservation of mass, which considers that the wake loss of downstream wind turbines is linearly related to the distance, and the cross-sectional velocity in the wake region is uniformly distributed. Katic [

15] introduced a one-dimensional momentum theory to improve it. Larsen [

16] constructed the Larsen wake model based on the Prandtl system of turbulent boundary layer equations. The model is able to calculate the diameter during wake expansion and the asymptotic wind speed distribution in the wake region. With the in-depth study of the wake mechanism, scholars have found that the wake velocity loss profile is closer to a Gaussian-type distribution in wind measurement experiments, wind tunnel experiments, and numerical simulations. Bastankhah and Porté-Agel [

17] proposed a Gaussian wake model based on a Gaussian function to describe the wind speed deficit in the far wake region, achieving good accuracy predictions. Relevant academics have researched the mechanism of wake development under yaw conditions of wind turbines and proposed a variety of wake models applicable to yaw conditions. Bastankhah et al. [

18,

19] proposed a wake model for yawing conditions to describe how the wake structure is affected by both the inflow wind shear and the turbine yaw misalignment, and its accuracy was verified by LES results, which can be used for wind farm wake control. Shapiro et al. [

20] also considered the wake characteristics of wind turbines after yawing and formed a yaw wake model by integrating the traverse velocity to obtain the wake offset. Different 3D Gaussian wake models were proposed by considering the wind shear effect and turbulence intensity changes in the vertical direction and made corrections to the turbulence intensity and other parameters in different directions [

21,

22,

23].

The engineering wake models have also been used in wind farm design and wake regulations. Bo et al. [

24] used the classical one-dimensional Jensen wake model to establish a fast calculation method for the wake of the Horse Rev wind farm. The optimal wake regulation strategy under different wind directions and speeds is verified. Dijk et al. [

25] proposed a yaw control method to minimize the wake loss of a wind farm based on an augmented version of the Jensen model. The results showed that the proposed method could increase the overall output power of the wind farm while reducing the impact of load. Zong and Porté-Agel [

26] used a two-dimensional Gaussian wake model to optimize the wake of the Horns Rev wind farm, and the optimization results showed that the power generation can be increased by about 1.8% averaged by each wind direction. Nash R reviews a variety of wake control strategies, including yaw control, pitch control, torque control, and cone angle control. Then, a wake redirection technique is proposed and the effectiveness of the proposed technique is compared with existing wake control techniques [

27]. However, in these engineering wake models used in previous studies, it is often difficult to determine appropriate empirical parameter values for real engineering applications, and differences in application environments and wind turbine models can also have an impact on model accuracy.

Considering the high computational cost of the CFD-based method, it is not suitable for wake regulation of a large-scale wind farm, while the engineering wake model-based method has the problem of parameter uncertainty. In this paper, a coupled method between CFD simulation and engineering wake model based on ALM is proposed, which avoids a significant increase in the computational cost on the CFD simulation method and, at the same time, provides a more accurate wake regulation result, which can effectively calibrate the wake model in practical engineering applications. The paper is organized as follows. The second section introduces the numerical methods, including the wake model and the CFD-based ALM method.

Section 3 presents the validation of the numerical methods.

Section 4 discusses the wake regulation method and test case. Some conclusions are drawn in

Section 5.

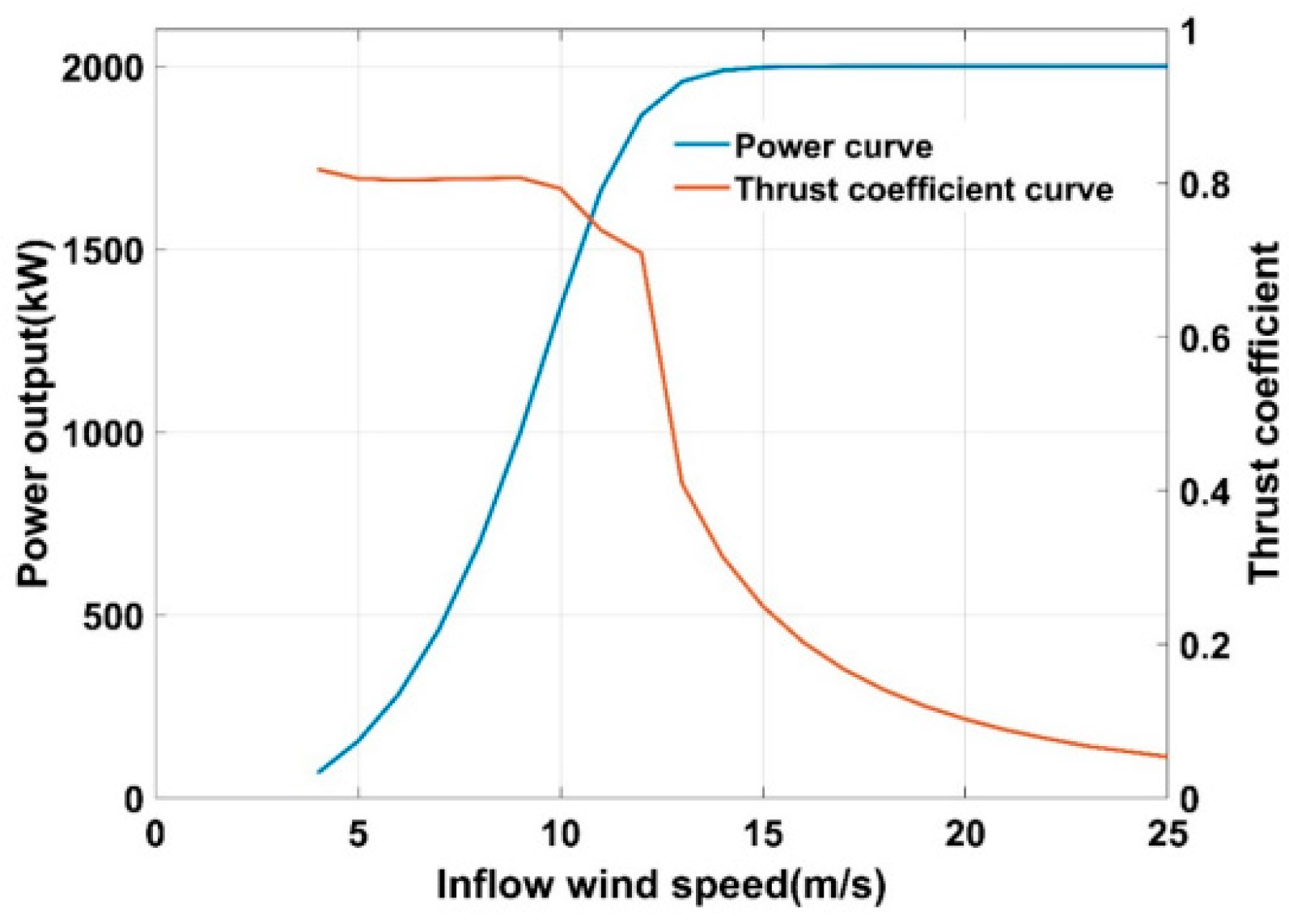

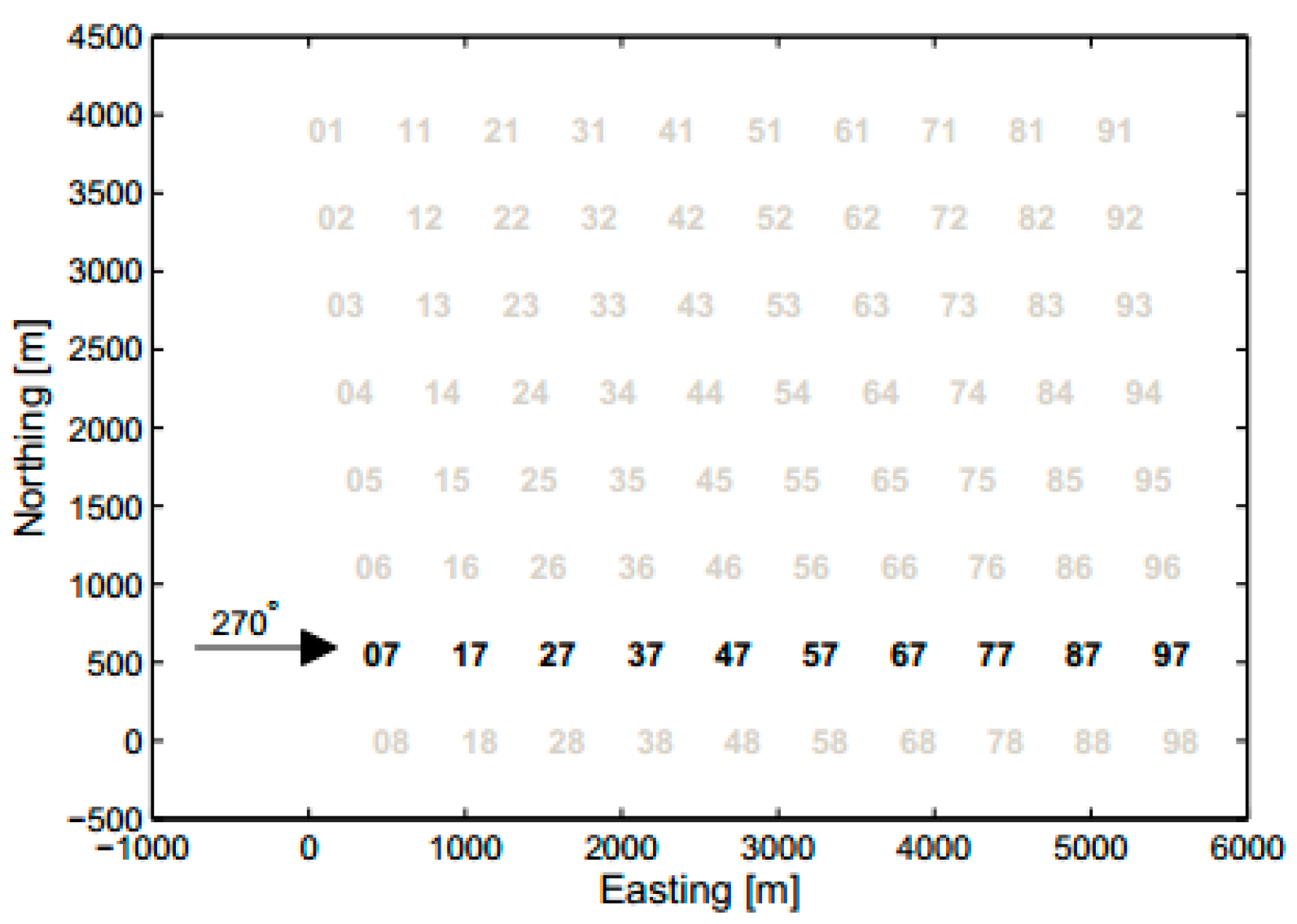

4. Wake Regulation Using the Coupled Method

The Horns Rev wind farm is a large-scale offshore wind farm, which is often used for wake prediction studies around the world because of its long-term observation data. The wind farm consists of 80 Vestas-V80 2 MW wind turbines arranged in a regular array of 8 rows and 10 columns distanced by 7D. The Vestas-V80 2 MW wind turbine has a diameter of 80 m and a hub height of 70 m. The power curve and thrust coefficient curve of the wind turbine are shown in

Figure 7.

When the wind direction is westerly, that is, the incoming flow is 270°, the difference in the average power of rows 2~7 is negligible compared with that of rows 7 alone [

34]. Therefore, as shown in

Figure 8, the 10 wind turbines in the 7th row of the wind farm are used as the simulation objects to study wind farm wake regulation.

4.1. Simulation Settings

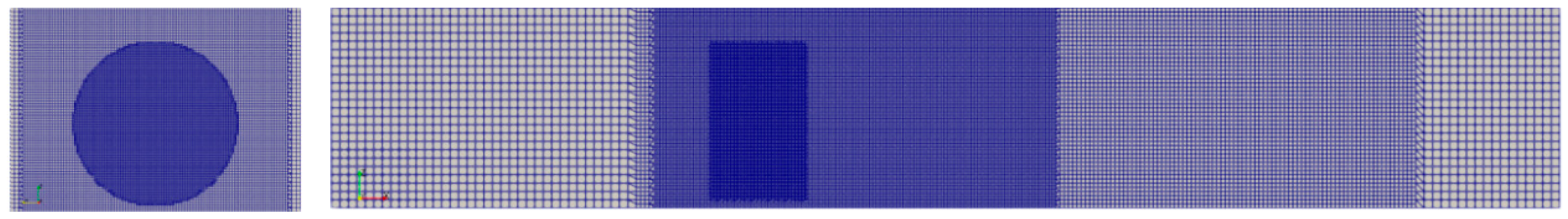

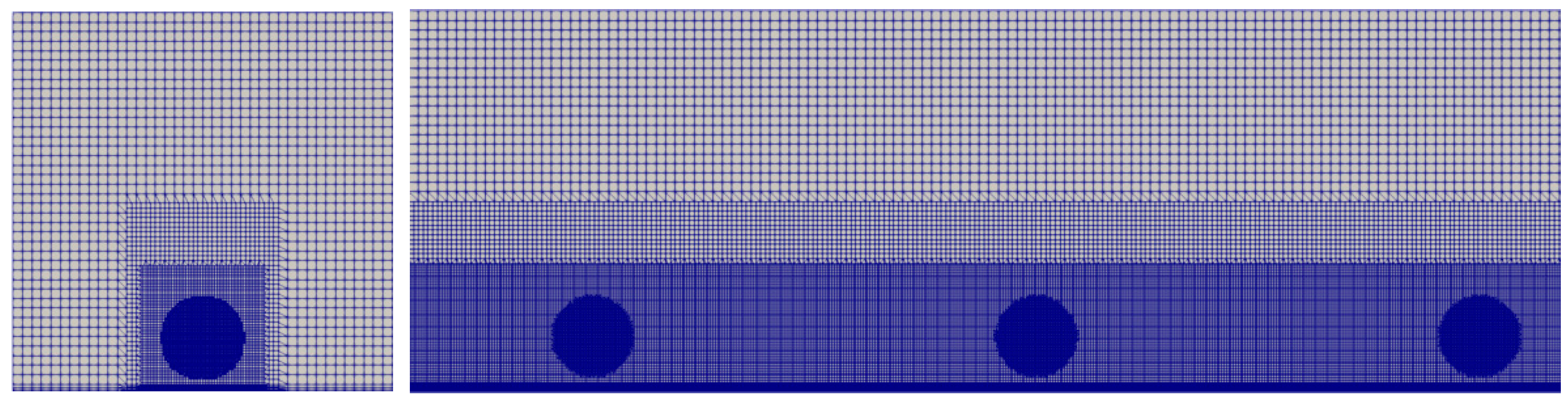

In the ALM method, the size of the calculation domain is set to 6240 m × 480 m × 480 m, that is, 78D × 6D × 6D. The first wind turbine is located downstream of the inlet surface, and the spacing of all wind turbines is 7D. Sarlak et al. [

35] studied the effect of blockage rate on the simulation of wind turbine wake and the results show that when the blockage rate is greater than 5%, it will affect the simulation results of wind turbines, and the blockage rate is usually required to be less than 3%. The blockage rate of this case is 2.2%, which satisfies the corresponding requirements. The open-source structural mesh generator blockMesh is used to generate the background grid, and the snappyHexMesh is used for mesh refinement. The ALM mesh was refined three times, and the minimum mesh size after refinement was 1.5 m, which is less than 1.722 m, in compliance with the requirement that the mesh resolution is less than half of the maximum chord length of the blade [

36]. The final mesh has about 13.02 million grid nodes, and the entire flow field consists of hexahedral cells, ensuring overall good mesh quality. The non-orthogonality, max aspect ratio, max skewness, and face pyramids are shown in

Table 1.

Figure 9 shows a schematic diagram of the partial ALM mesh refinement, only three of the ALM zones are shown along direction.

Reynolds-averaged Navier–Stokes equations have been solved with an extended k-ε turbulence model. A velocity shear distribution in a logarithmic rate profile is set at the inlet of the domain. The wind speed at the hub height is 8.5 m/s, and the turbulence intensity is set at the magnitude of I = 8%. The outlet face boundary is set to the pressure outlet, the lower bottom boundary to the non-slip wall, and the upper and left and right boundaries to the slip boundary.

The simulation time step is set to 0.025 s, with a total simulation time of 2000 s, and the convergence residual is set to 10−6. The minimum mesh size is 1.5 m, and the flow velocity is 8.5 m/s. The calculated maximum CFL number is approximately 0.1417, which is less than 1, indicating a high level of computational stability.

For the wake model calculation, the open-source code, FLORIS, was used to simulate the wake flow, developed by the National Renewable Energy Laboratory (NREL). FLORIS is a low-cost, control-oriented modeling tool used for the calculation of steady-state tail current characteristics of wind farms, with a variety of built-in wake models and optimization algorithms available for a combination of choices, with the visual display of flow field, power generation assessment of wind farms, and optimization of tail current yaw control functions. It has the functions of flow field display, wind farm power generation assessment, wind farm turbine layout optimization, and wake yaw optimization control.

The execution process of yaw optimization firstly uses the velocity loss model, yaw wake model, and wake superposition model in the engineering wake model to describe the distribution of wake loss in the actual wind farm, the yaw wake offset of the yawing wind turbines, and the superposition of wake loss under the influence of upstream multiple wind turbines to achieve the functions of assessing the loss of the wake in the wind farm and the prediction of the output power; and secondly, takes the yaw angle of each unit as the optimization variable, and makes use of the intelligent optimization algorithm to establish a single-objective or multi-objective optimization algorithm. Secondly, the yaw angle of each unit is used as the optimization variable, and the intelligent optimization algorithm is used to establish a single-objective or multi-objective optimization module, which outputs the optimal yaw control strategy for wind farms under different wind conditions and arrangements.

The simulation adopts the BPA wake model and the Bastankhah yaw model built in FLORIS to describe the development of wake under the yaw condition of a single unit, establishes a fast calculation method for the wake of multiple wind turbines using the square and wake superposition model, and then uses the SciPy (Sequential Least Squares Programming)-based SciPy (Sequential Least Squares Programme) optimization controller for the maximum power generation of the whole farm. The optimization controller is used to perform the single-objective optimization calculation for the maximum power generation of the whole field. The main empirical parameter in the wake model, i.e., the wake expansion coefficient, is set to the value k* = 0.38 in reference [

32], and the parameter is calibrated based on the Horns Rev I. wind farm example in the subsequent calculation work.

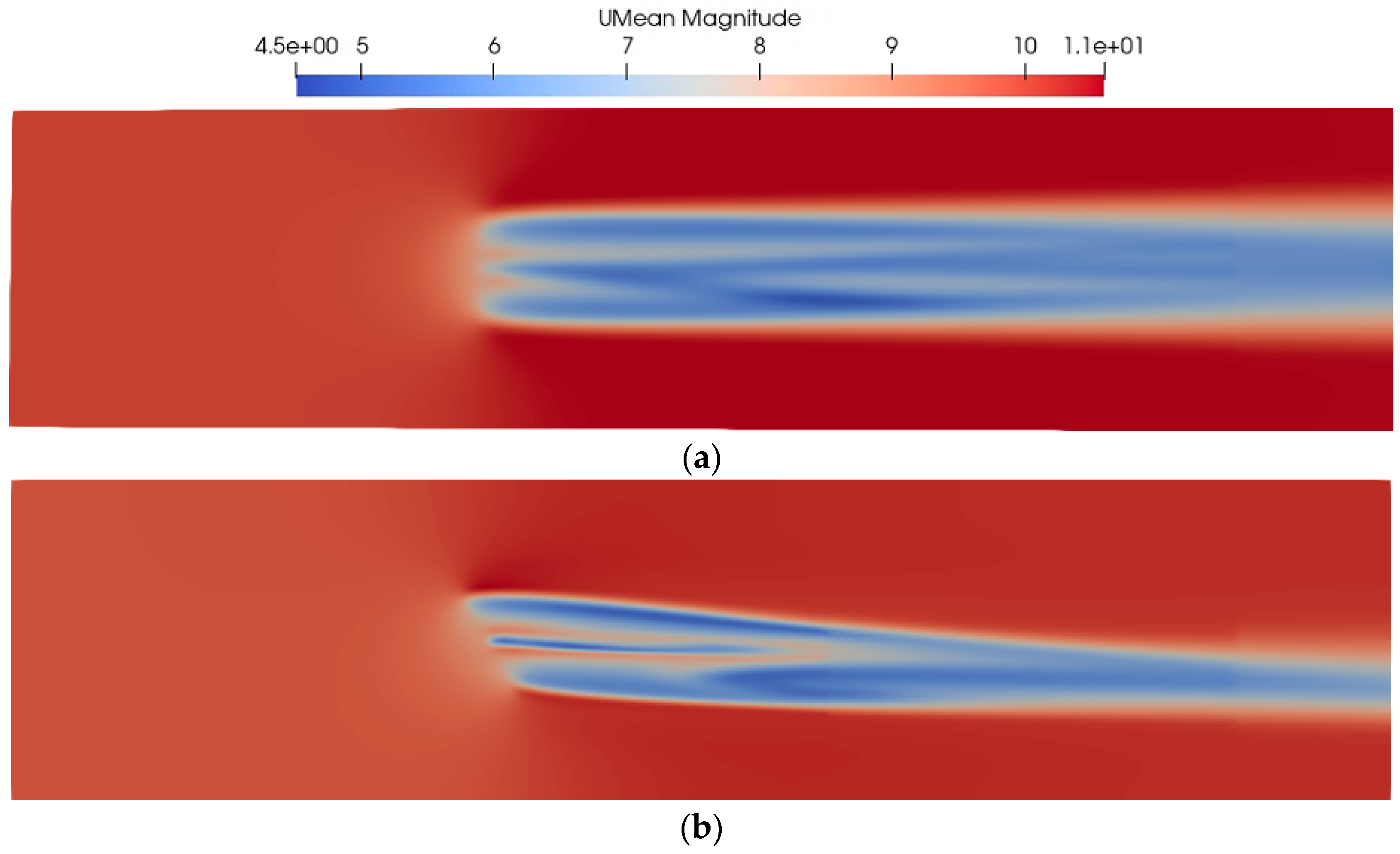

4.2. Without Wake Regulation

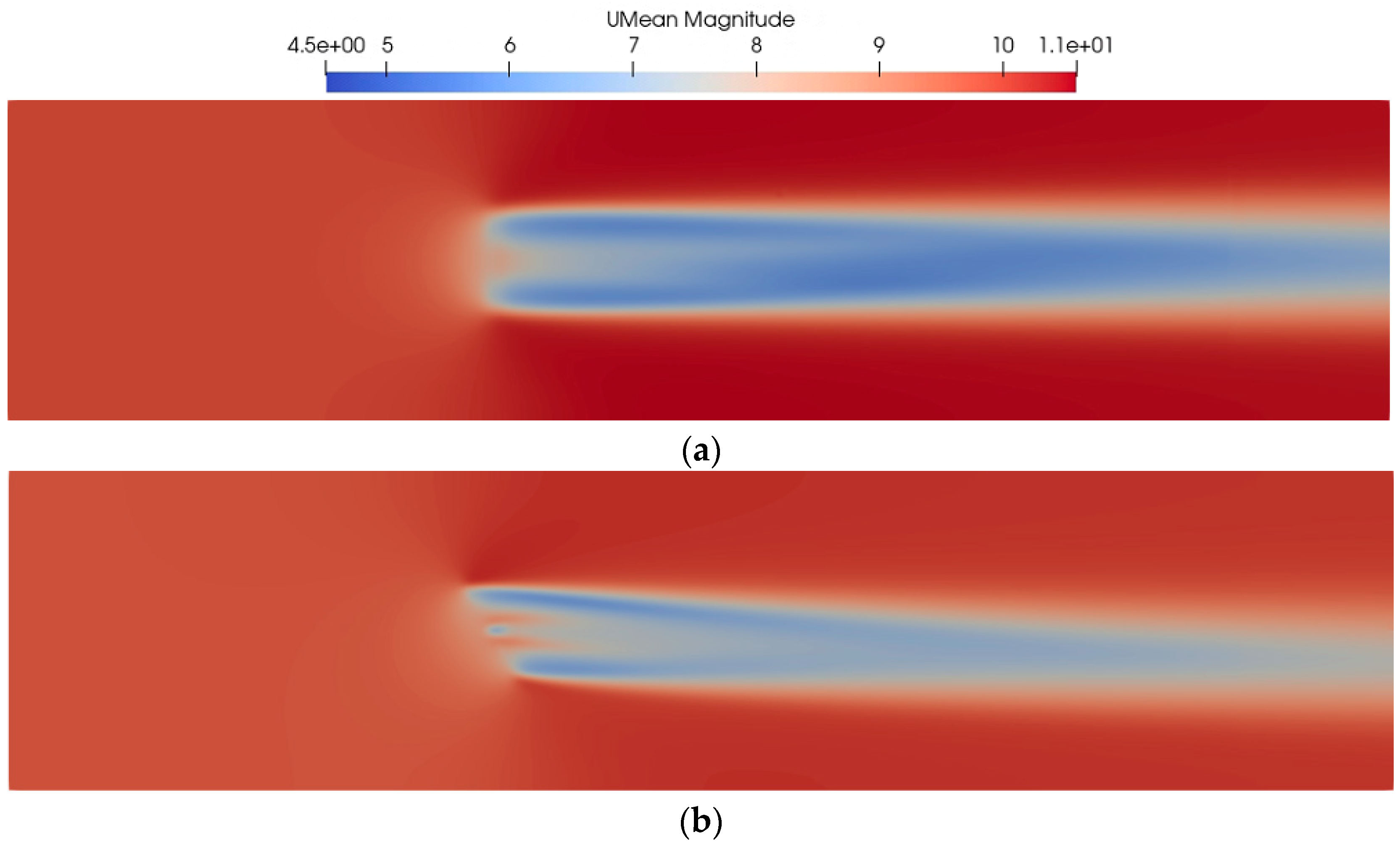

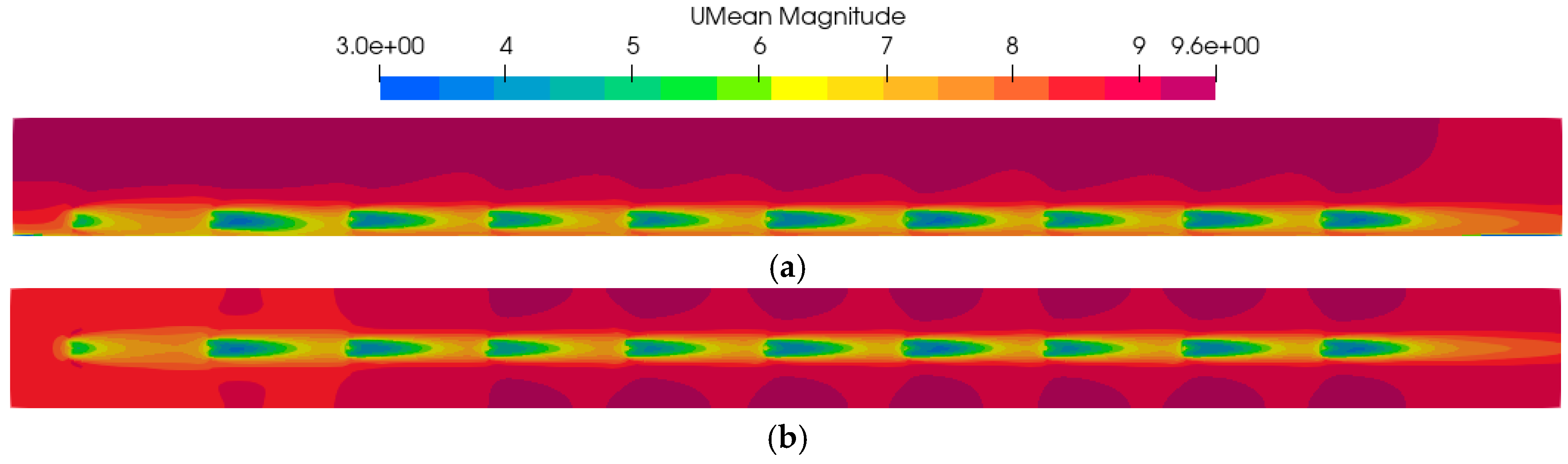

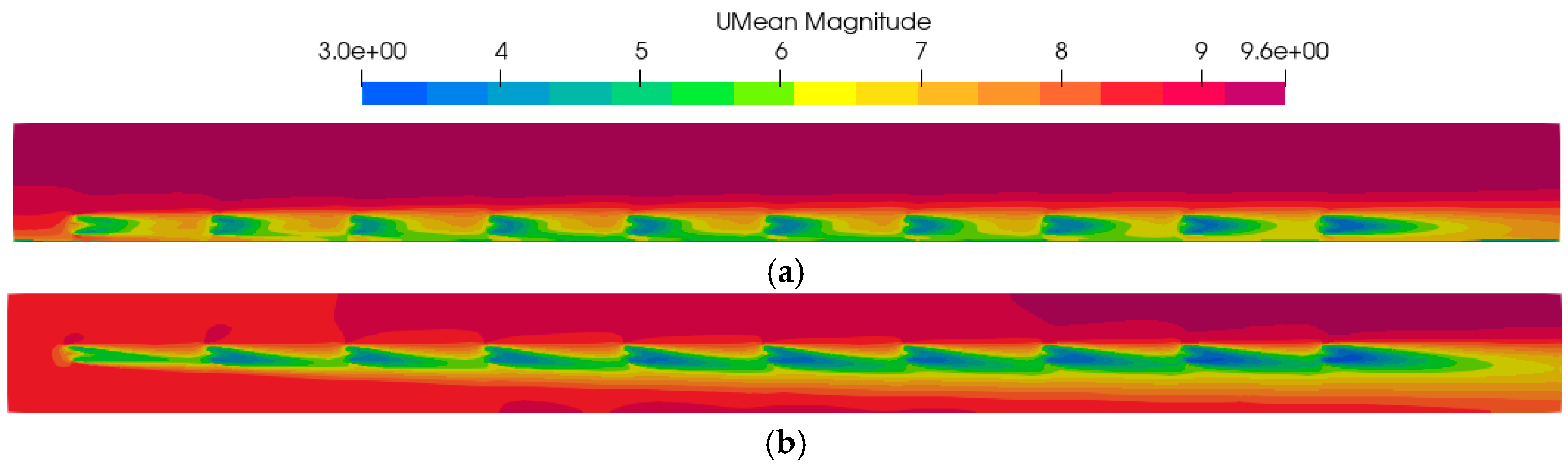

Figure 10 shows the velocity contour of the ALM simulated results at the hub height wind speed of 8.5 m/s. It can be seen from the results that the wind speed behind each wind turbine is the lowest, and gradually recovers with the increase in distance, and the wake can recover to about 7 m/s at about 5D downstream of each wind turbine. The expansion of the wake can be clearly seen from the horizontal velocity profile, and it is found that the shape and area of the wake low-speed area of the first wind turbine are the smallest, and the area of the low-speed area of the wake of the second wind turbine is slightly larger than that of the other wind turbines in the rear row.

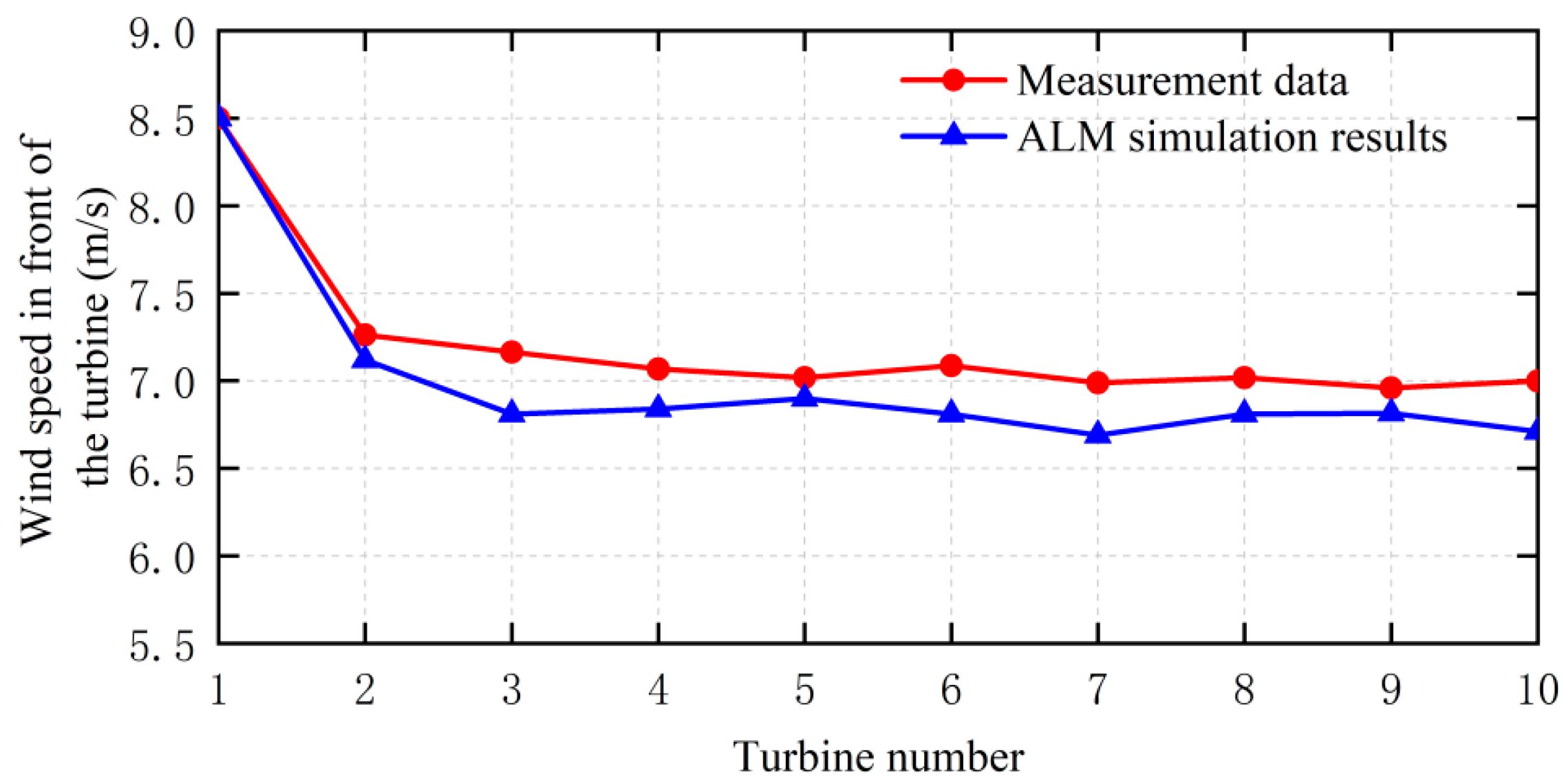

Figure 11 shows the comparison between the ALM simulation results and the measured wind speed data in front of each wind turbine in row 7 of the wind farm. It can be seen that the ALM simulation has satisfied agreement with the measurement data. The maximum relative error is about 4.4%, occurring at the third wind turbine. The relative error is defined by the absolute error normalized by the incoming wind speed, i.e., 8 m/s. It shows that the ALM can predict the recovery of wind speed in the wake of tandem wind turbines with high accuracy.

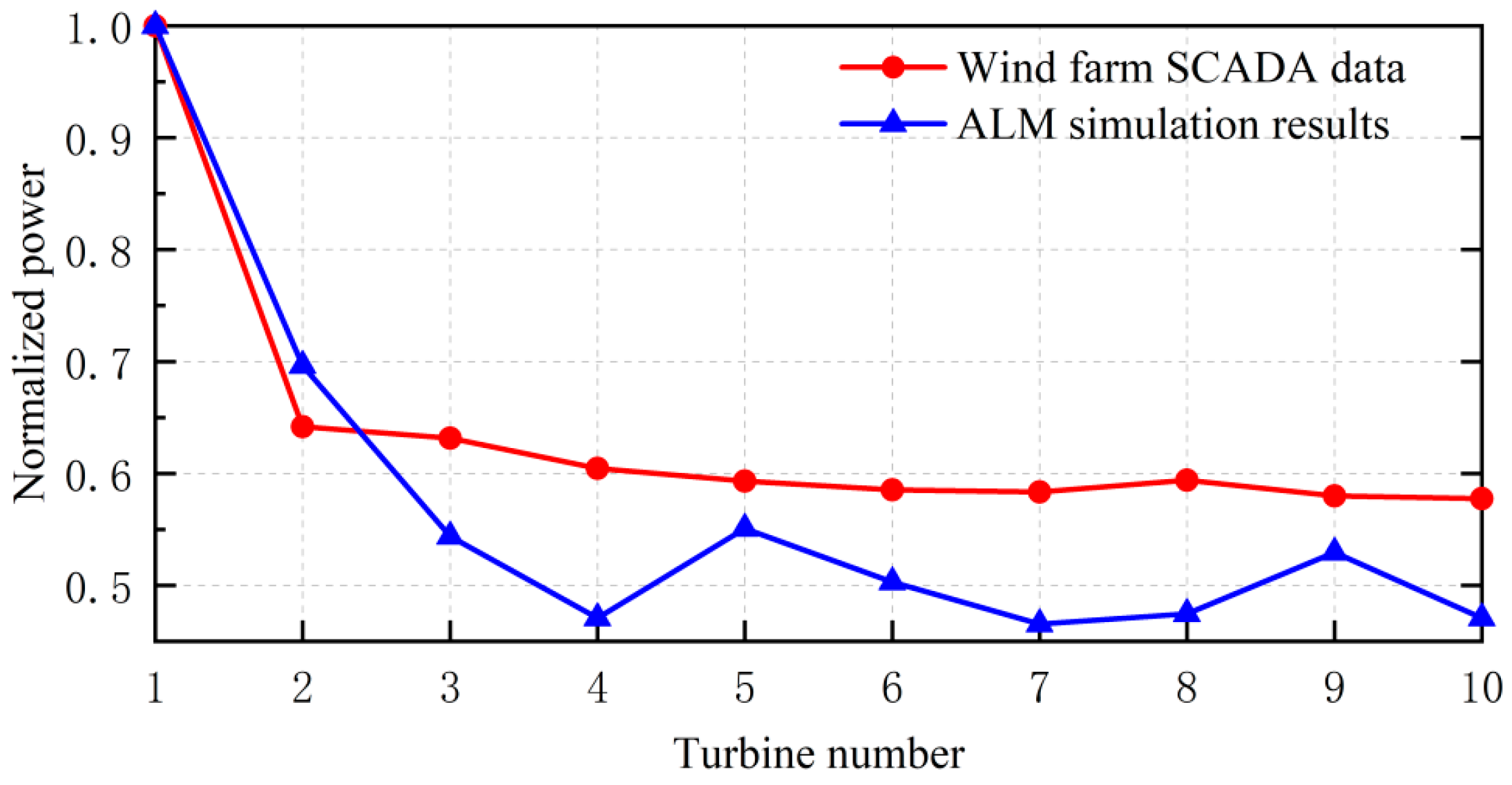

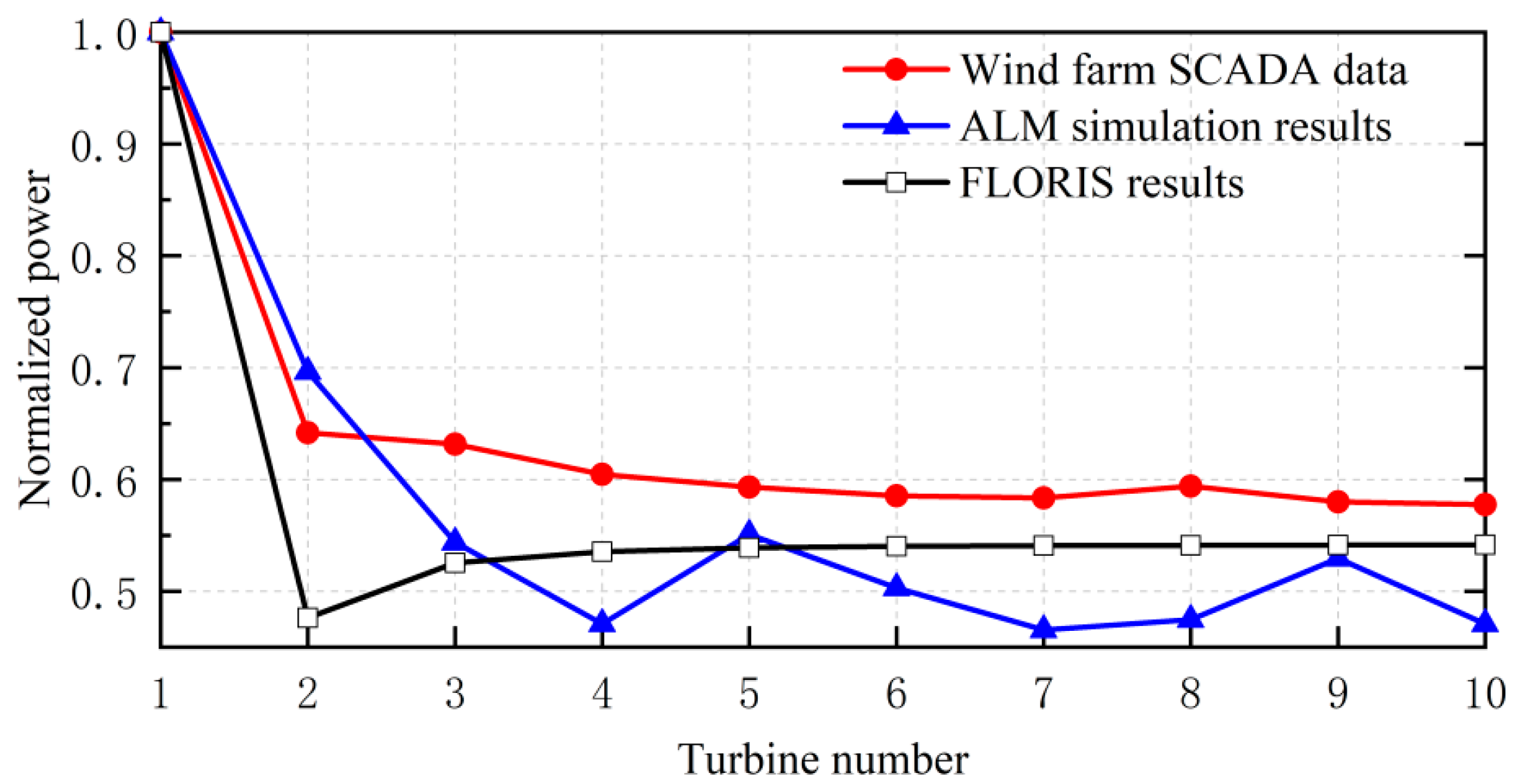

The calculation results of the ALM power are compared with the SCADA data of the wind farm, and the curves are shown in

Figure 12. The SCADA data show that the power of the wind turbines from the 2nd to the 5th unit decreases one by one, and the power of the back row wind turbines is no longer decreasing and basically remains stable. The ALM successfully simulates the decreasing trend of the power of the back row wind turbines of the tandem wind turbines in the wind farm, but among them, the 5th and the 9th wind turbines have an increase in power compared to the previous one because of the sufficient turbulence in the wake stream and the exchange of kinetic energy. Following kinetic energy exchange, the wind speed has recovered, and the power has increased compared to the previous unit. Except for the first two wind turbines, the ALM simulated power output of the back-row wind turbines is overall lower than the measured data published by the wind farm, and the maximum deviation of power between the two is 11.9%, which occurs in the 8th turbine. Since the SCADA data are the averaged results over a period of time and the actuator line is difficult to accurately restore, the control law of the unit itself in the transient simulation leads to a certain degree of error in the calculation of the power coefficient Cp by the ALM. Considering that the power of the wind turbine is proportional to the cubic of the wind speed, it is still enough to consider that the ALM simulation of ten wind turbines established in this paper has high accuracy.

According to the wind farm SCADA data, the total power of the ten wind turbines in row 7 is calculated to be 5682.695 kW. The total power of the ten wind turbines simulated in this paper is 5061.183 kW, and the relation error is 10.94%, which can be considered to be within the allowable error range [

5].

Similarly, the 10 wind turbines in line 7 of Horns Rev I. were modeled using the open-source wind farm wake control software FLORIS—3.5 to verify the accuracy of the wake disturbance simulation of the software.

Figure 13 shows the normalized power calculated by FLORIS, and it is observed that although the error of the second wind turbine reaches 16.56%, it can correctly simulate the trend of decreasing power of the tandem arrangement wind turbines. FLORIS calculates a total power of 4798.354 kW from the SCADA measurement, which is 15.56% off. Relevant studies have shown that due to the existence of more idealistic assumptions and empirical parameters in the derivation of the wake model, the recovery of the wake will be underestimated in the process of practical application, resulting in high results of the calculation of the wake loss [

37]. The comprehensive comparison shows that the engineering wake model is lower than the ALM in the accuracy of wind farm total power prediction, and the use of ALM for correction has guiding significance.

4.3. Wake Regulation Without Parameter Calibration

The wake regulation without parameter calibration is performed first. The improved genetic algorithm is used to optimize the yaw angle in the wake regulation strategy. The maximum yaw angle change is set to ±30°, the wind turbine change in yaw angle was 0.25°, and the optimal yaw matrix of ten wind turbines in row 7 was obtained.

According to the yaw matrix calculated using FLORIS without parameter calibration, the yaw angle of each wind turbine was set separately for CFD-based ALM simulation, the yaw matrix shown in

Table 2. The calculated wake velocity contour is shown in

Figure 14. The cross-section of the deflection of the wake can be observed from the horizontal profile at the hub height. The first wind turbine has the largest yaw angle and the narrowest low-speed area of the wake; the second wind turbine realizes the deflection of the wake at a larger angle from the first wind turbine. Compared with

Figure 9, it is seen that the rear wind turbine is reduced by the influence of the wake, and the area of the wind turbine obtains a relatively higher incoming wind speed.

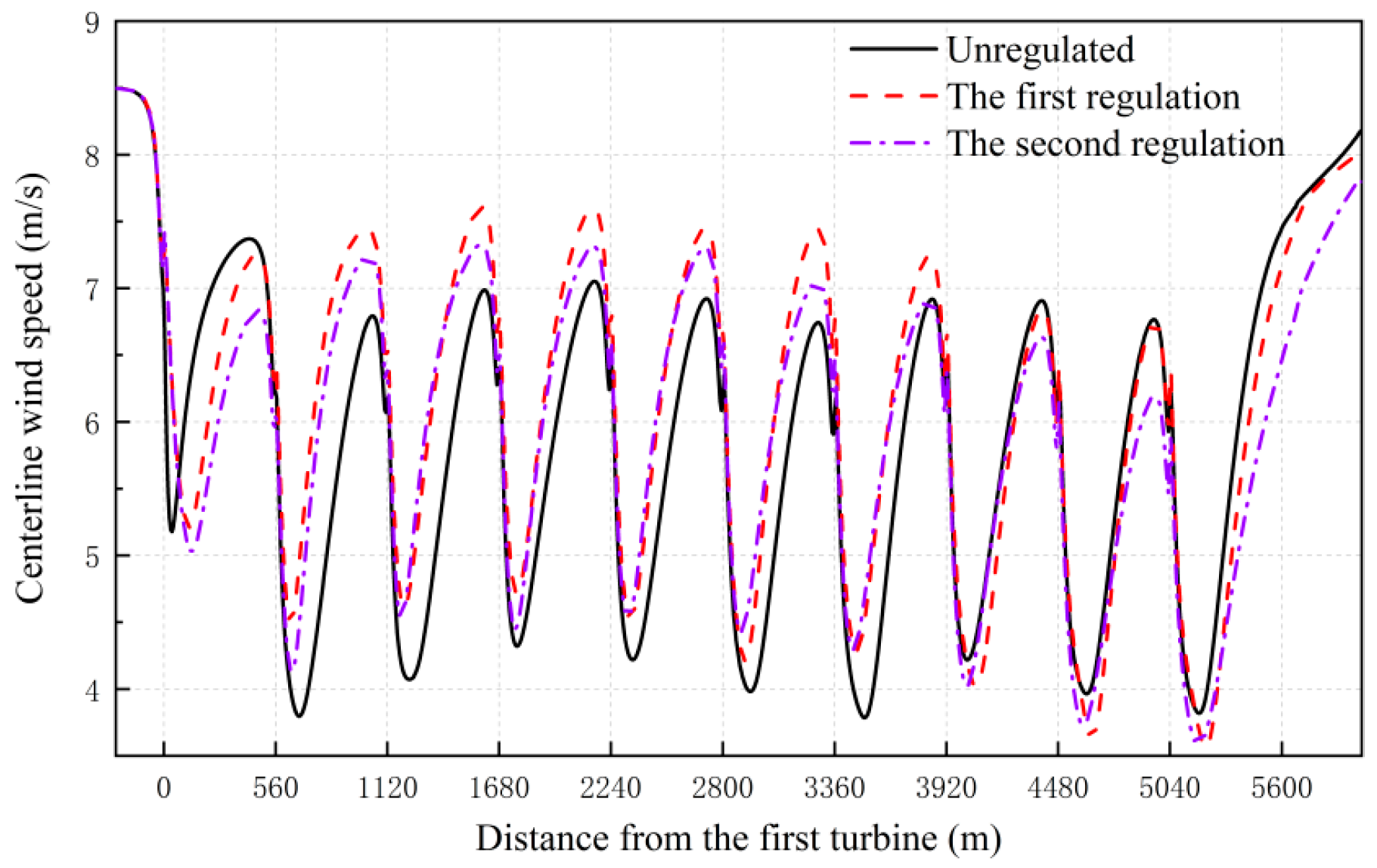

By extracting the wake velocity at the centerline of the contour map, shown in

Figure 15, it can be found that before the implementation of the wake regulation, the inlet wind speed of the third wind turbine is lower than that of the second wind turbine, then increases slightly, then decreases in the 6th and 7th wind turbines, and then the inlet wind speed in front of the 8th wind turbine increases slightly. After the implementation of the active yaw control strategy, the incoming wind speed in front of the 3rd~8th wind turbines increased significantly due to the wake deflection of the upstream wind turbines.

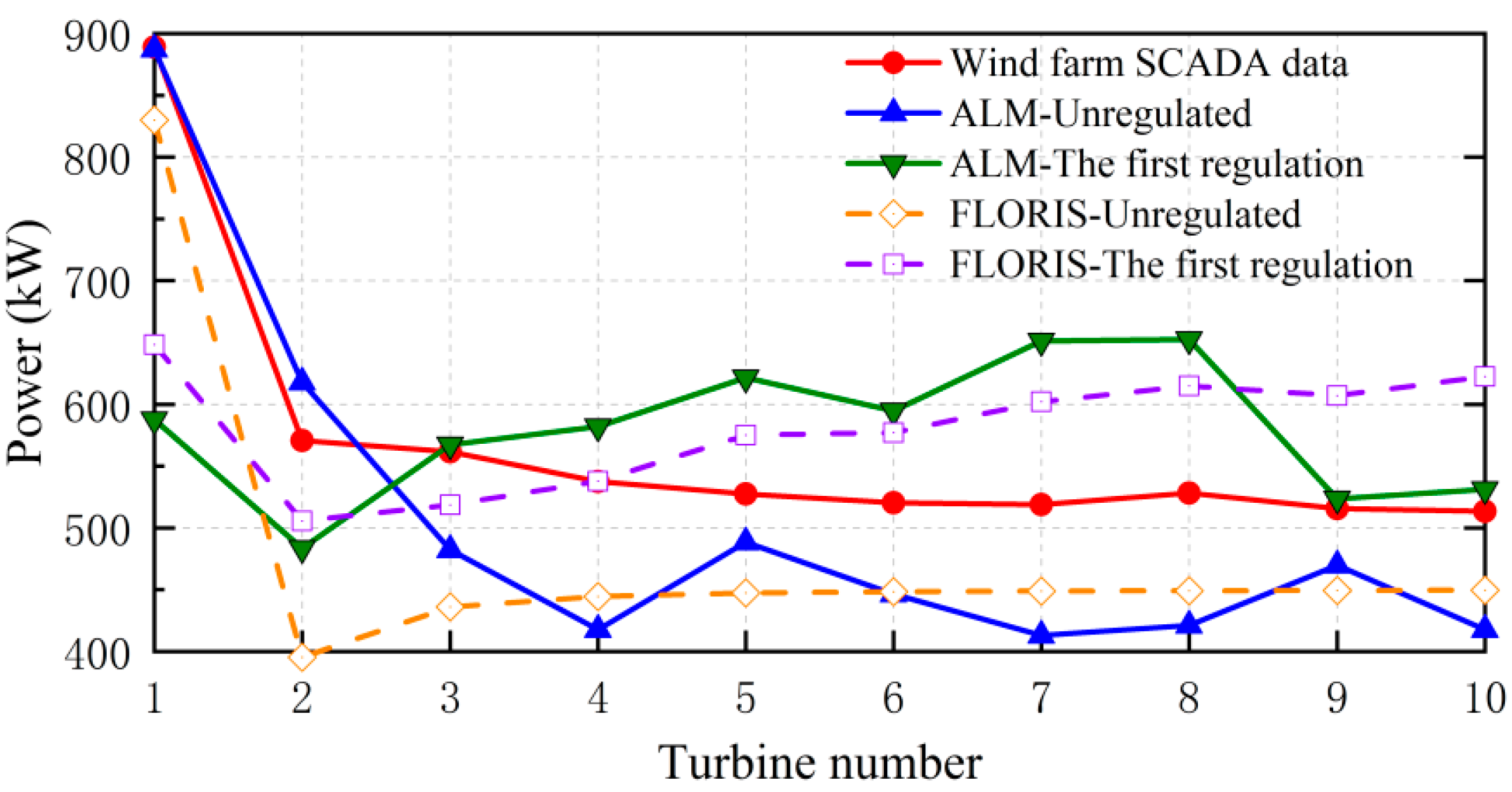

The most direct test criterion for the implementation of active wake regulation is the increase in wind turbine power. It can be intuitively observed from the curve shown in

Figure 16 that the power of the rear wind turbine is greatly increased after the implementation of active wake control. After active yaw control, the total power of the ten wind turbines was 5808.97 kW, which was 21.06% higher than that before the regulation. According to the calculation results of the ALM, the total power is 5794.65 kW, which is 14.49% higher than that before regulation.

4.4. Wake Regulation with Parameter Calibration

As shown in previous section, the wake model results have obvious differences to the ALM results. According to the wake expansion and deflection data obtained by the ALM results and the power calculation results, the parameter k* of the BPA model in FLORIS was corrected to 0.5. Then, adjusting the parameters of the engineering wake model in FLORIS, the updated yaw matrix is obtained as shown in

Table 3.

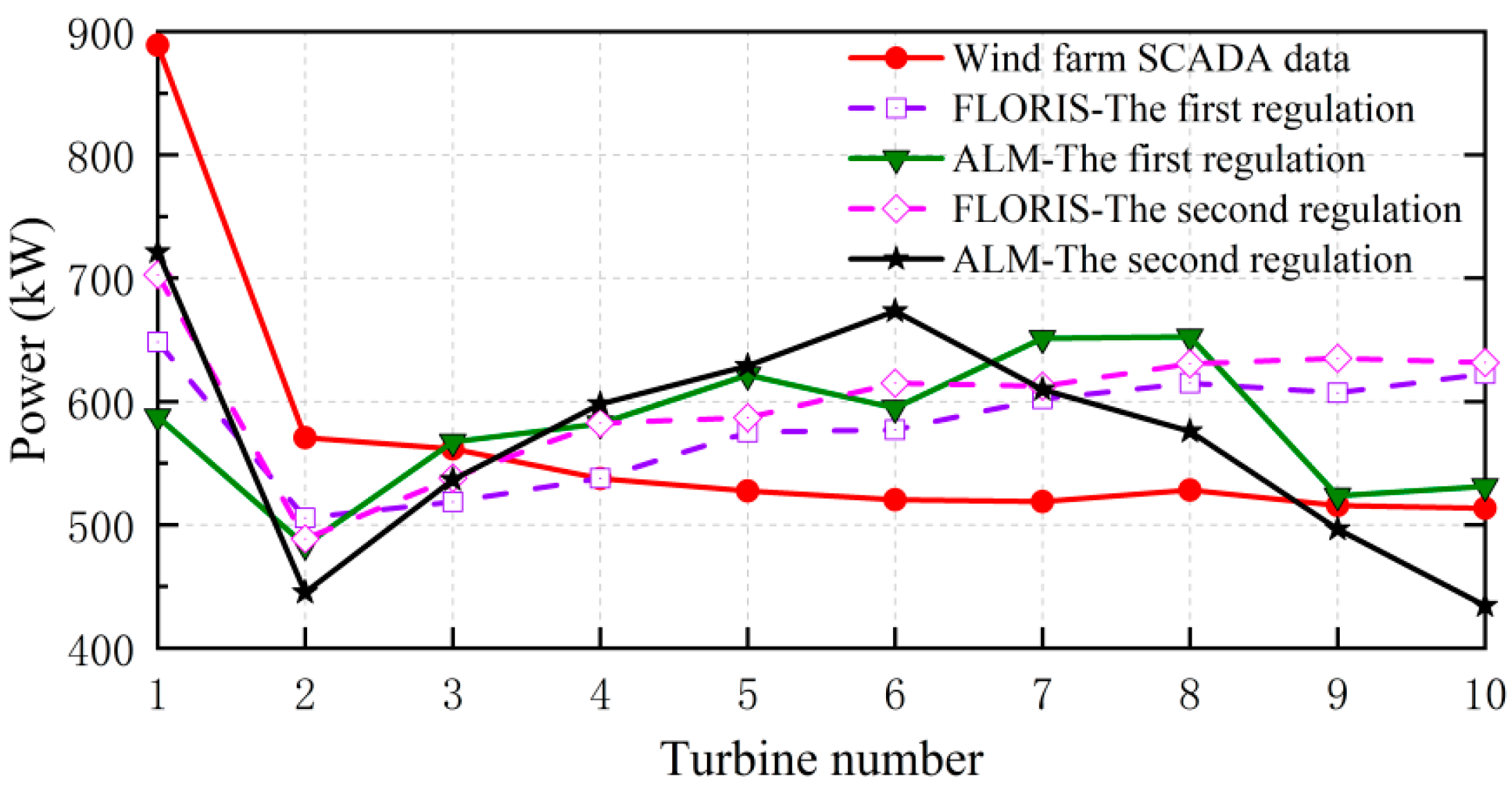

When k* is 0.5, the total power of the wind farm before the implementation of active wake regulation is 5388.04 kW, and the total power after the optimized control is 6050.38 kW, which is increased by 12.29%. The second CFD simulation is performed according to the updated yaw matrix.

Figure 17 shows the change process of wind speed at the centerline of the horizontal profile of the hub height, and it is found that the highest point of the second simulated wake velocity recovery between the two wind turbines is lower than that of the first one, indicating that the overall recovery degree of wake is slightly weaker than that of the first iteration. The simulated power of each wind turbine is shown in

Figure 18, and the power output of each wind turbine has some variations. For example, the power of the first wind turbine increases due to the decrease in its yaw angle, the second wind turbine is affected by the wake of the first wind turbine, the power decreases, and the power of the rear wind turbine gradually increases. The FLORIS simulation results show a steady increase in the rear wind turbines, while the CFD-based ALM simulation results show that the power decreases in the 6th and 8th wind turbines, respectively.

In

Table 4, the total power of the wind farm simulated by the ALM with the second active yaw control strategy is 5719.9 kW, which is 13.02% higher than that before yaw control. The second active yaw control strategy is 1.47% lower than the first strategy, because the yaw angle of the first wind turbine decreases and the yaw angle of other wind turbines changes, resulting in the wind speed of some wind turbines in the back row being lower than that of the first-time yaw strategy, so that the total power is slightly becoming lower.

In the process of the wake regulation for the first time in the previous section, k* = 0.38, and the difference between the ALM results and the wake model results is about 6.57%. Comparing the results of the second active yaw control strategy, the total power increase before and after yaw control was 13.02% and 12.29%, respectively, with a difference of only 0.73%. After two iterative calculations of wake control, the model parameters of the FLORIS software were successfully calibrated using the results of the CFD-based ALM simulation. It proved that the method proposed in this paper by using CFD-based ALM simulation and iterative calculation of engineering wake model can improve the credibility and implementability of the active wake control strategy of wind farms. It should be noted that the calibration could be iterated multiple times till an error tolerance is reached. For the current case, only two CFD-based ALM simulations were performed and, thus, the computational cost increase is neglectable.

Since the accuracy and reliability of the CFD-based ALM simulations and the wake model may have a large difference due to the changes in the application scenario, the actuator line model with less simplification has high confidence in the power calculation results. Moreover, the verification work of the exemplification carried out in this paper is sufficient to confirm the high accuracy of the ALM.