Abstract

The production of orange (Citrus sinensis) generates many residues, and the few that are used are usually by-products of the fruit juice processing industry. Among the residues, wood is potentially advantageous for use in bioenergy, but with few records in the literature. In this sense, this study sought to evaluate the feasibility of using orange wood for energy purposes by performing chemical characterization, immediate analysis, FTIR, calorific value, thermogravimetry and bulk and energetic densities for three compositions: 100% trunk (100T), 90% trunk + 10% bark (90T10B) and 100% bark (100B). 100T showed a higher fixed carbon content (16.76%) and equality with 90T10B in lignin, holocellulose, useful calorific value and volatile materials. 100B presented higher extractives and ash contents of 19.67% and 10.35%, respectively. The FTIR spectra and thermogravimetric curves were similar in 100T and 90T10B. 100B showed more stages of degradation and a higher incidence of peaks in the range 780–612 cm−1. The bulk density was equal in 100T and 90T10B, but the energy density was higher in 100T (6.16 Gj.m−3). 100T and 90T10B are good options for bioenergy and the chemical composition and thermal degradation of 100B point to new investigations in this composition.

1. Introduction

Orange (Citrus sinensis) had a world production estimated for 2022–2023 of 47.8 million tons [1]. In Brazil, in 2022, orange production was 16.3 million tons [2], numbers that make the country the world’s largest producer of this fruit, it being the largest destination of this production and juice processing [1]. Given this scenario, it is possible to infer that there is a high generation of residues ranging from whole trees that are discarded because they have reached the end of the productive cycle or because of diseases, in addition to disposal from the juice industry as the peels and bagasse of the fruit.

Given the need for new trends in environmental and economic terms, as well as a better use of production and industrialization, it is necessary to develop waste management, considering its possibilities to extend the life of the residues. Orange bagasse has nutritional value, is investigated for its high content of phenolic compounds and antioxidant action, in addition to being a rich source of fiber, and can be used by the food industry and health promotion areas [3,4,5]. Orange peel is also a nutritional source of minerals and carbohydrates and can be used in the production of unicellular proteins [6]. Due to the high content of pectin, it can be used as a reinforcement in the composition of urea formaldehyde resin for bonding agglomerated panels of lignocellulosic materials [7] and even as an energy source [8]. Pruning residues from orange trees can also be used for energy production [9] and as an adjunct to the stability of organic matter in soils with high salinity [10].

In the case of orange wood and bark, there is a rich source of lignocellulosic matter with the potential to be used in bioenergy. This use of orange wood has scarce records in the literature. Much of this is due to the cultivation that is being carried out only for the production of fruits intended for the juice industry, as well as for marketing. However, it is necessary to review some positions in the energy scenario due to the worldwide decarbonization trend that drives the cultivation and mobilization of research aimed at the area of new raw materials for use in bioenergy [11]. Thus, orange residual wood is a high-value biomass for studies focused on bioenergy, evaluating its technical feasibility, risks and benefits.

This study of technical feasibility is intended to evaluate the orange wood and bark through its chemical characterization, energy, physical properties and thermal behavior and, with the knowledge of these variables, to make comparisons with biomasses that are already consolidated, as well as other lignocellulosic residues that, as well as orange residues, especially wood, were not studied or evaluated in terms of bioenergy. It is also necessary to evaluate the combustion of the material in relation to the emission of polluting gases. Therefore, if it has been found that the waste adds energy value, its use should take into account the environmental risks that are inserted in the conditions established because bioenergy projects should be based not only on the economy provided by the associated benefits but also on sustainability risks [11].

The strategies related to the technology to be used for the biomass conversion of orange wood into high-value products should be described in the literature for other lignocellulosic residues since the energy use of these residues is still recent. Thus, the most consolidated technological options in terms of bioenergy are the production of solid biofuels (briquettes and pellets) and coal [12]. These technologies aim to increase the energy density, avoiding the direct burning of waste, configuring themselves as a form of treatment of the waste, corroborating with the decrease in its flow and avoiding inadequate disposal.

2. Materials and Methods

The biomass used was obtained on a rural property located in the city of Jerônimo Monteiro, Brazil (20°45′30.6″ S, 41°23′50.6″ W). A tree was selected at the end of the productive cycle and after approximately 30 years. The tree was cut into disks with random dimensions, and they were arranged in natural drying at room temperature for a period of seven days. The trunk and bark were crushed in a Marconi/Piracicaba-SP knife mill, sieved and separated into fractions that passed the 40-mesh sieve (opening 0.42 mm) and were retained in the 60-mesh sieve (opening 0.25 mm), in addition to the sawdust that exceeded the 270-mesh sieve (opening 0.053 mm) for further analysis in the compositions 100T (100% trunk), 90T10B (90% trunk + 10% bark) and 100B (100% bark). The procedures described were performed according to [13].

2.1. Chemical Analysis and Immediate Analyses

To determine the extractive content of the wood, we used a 2.0 g dry sample with an accuracy of 0.0001 g according to [13,14], placed in the Gooch crucible, a 30 mL sintered disc, G-2 porosity, and borosilicate glass, previously dried in an oven at 105 ± 2 °C. The lignin content was determined according to [15,16]. In this method, H2SO4 was used at 72% (m/v) with a mass of 0.3 g dry extractives-free sample with an accuracy of 0.0001 g. The determination of holocellulose was performed according to the procedure described by [17]. In this method, the oxidation of lignin occurs with a sodium chlorite reagent. It used 1.0 g of dry sample extractives with an accuracy of 0.0001 g. The immediate chemical analysis was performed in single gear using 1.0 g of sample with an accuracy of 0.0001 g [18].

2.2. Fourier Transform Infrared (FTIR)

The sawdust fraction that exceeded the 270-mesh sieve (opening 0.053 mm) was used. The equipment used was an FTIR spectrometer, Bruker, Tensor 27, 400–4000 cm−1 (Billerica, MA, USA).

2.3. Calorific Value

For determination of the higher calorific value (HHV), the samples were dried in an oven at 105 ± 2 °C for 24 h. It was a 0.5 g dry sample with an accuracy of 0.0001 g for the measurement of the HHV, which was measured in a Calorimeter IKA C200 according to [19]. The useful calorific value (UHV) was estimated according to the methodology suggested in [20], assuming an average hydrogen content of 6% and moisture estimated before the test according to [18].

2.4. Bulk Density and Energy Density

Bulk density (kg.m−3) was performed according to [21]. The energy density (GJ.m−3) was estimated according to that described by [22,23,24].

2.5. Thermogravimetric Analysis (TGA and DTG)

For this analysis, a fraction was used that exceeded the 270-mesh sieve (opening 0.053 mm). The equipment used was Setaran, LabSys Evo model, under N2 atmosphere at a heating rate of 5 °C.min−1 and a temperature range of 25 to 650 °C.

2.6. Data Analysis

In the chemical analysis, immediate and calorific values were performed with five repetitions for the compositions 100T, 90T10B and 100B, similar in bulk density but only in the compositions 100T and 90T10B. The analysis of holocellulose was performed in triplicate. The Tukey test was used to determine the means, and uncertainty was verified with 95% probability.

3. Results and Discussions

3.1. Chemical Characterization

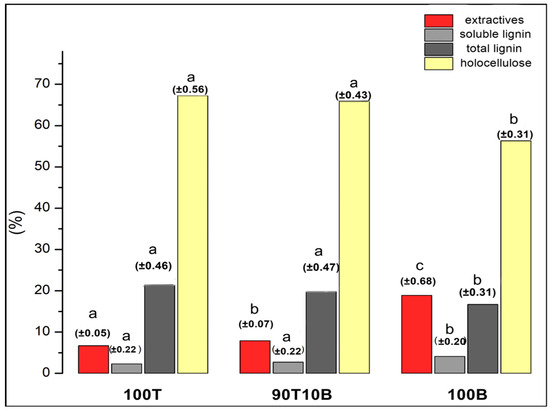

The results obtained in chemical characterization are illustrated in Figure 1.

Figure 1.

Data were obtained from compositions 100T, 90T10B and 100B. The values in parentheses correspond to the confidence intervals with a 95% probability. Equal letters in superscript indicate statistical equality according to the Tukey test.

The extractive content (EC) in the 100T composition was lower than in 90T10B (6.34 and 7.48%, respectively). With this, it is possible to infer that there was an influence of 10% of the bark because the value found for extractives in the composition 100B was 19.67%. High values in the EC are usually expected for bark [25,26,27].

Refs. [28,29] found in their studies that the content of extractives decreases with the increasing age of the tree. In [30], EC for the trunk of a 22-year-old orange tree was 12.41%, a value well above that found in the present study. In addition, conditions related to soil type, management and fertilization can also influence the extractive content [31,32].

EC in wood is an important influence on energy use due to its carbon content. The solubility in several solvents, water among them, exerts influence on the moisture content of the material, which influences the reduction in calorific value and the effective biomass burning [33,34,35]. However, there is a positive relationship between extractive content and calorific value [36,37]. The most volatile extractives and low molecular mass are degraded more quickly with an increasing temperature [38], which contributes to burning in order to optimize the combustion of the material [39]. Extractives can also be formed by breaking the hemicellulose chains, giving these new compounds higher degradation temperatures [40,41,42].

Refs. [39,43] describe in their studies that extractive contents in the range of 10–25% are configured as having an attractive and appropriate chemical characteristic for burning. However, these values are high compared to compositions 100T and 90L10B. High levels of extractives tend to accelerate the combustion of the material, and this decrease in burning time is not desirable in terms of better energy use [40]. Refs. [34,44] observed smaller extractive content ranges (5–8%) and (7–11.5%), respectively, which are closer to those found in the materials of the present study.

The contents of total lignin in 100T and 90T10B were close (22.83 and 22.69%, respectively), with no influence of 10% of the bark. However, in 100B, the value of total lignin was the lowest among the analyzed compositions (17.38%). It was also found that 100B obtained a higher content of soluble lignin (4.24%), and 100T and 90T10B obtained values of 2.16 and 2.56%, respectively. This is probably due to the existence of higher syringyl groups than guaiacyl in shells and chemical reactivity to the material [45]. Ref. [30] obtained a total lignin content of 19.8% using the trunk of a younger tree, which would explain the lower total lignin content since the molecule is the last to be formed in the cell wall [46]. Although some studies do not show a strong correlation in several species, some studies show an increase or decrease in lignin levels with age [29].

The lignin content is the main constituent of wood with regard to the use of biomass for energy, to the point of being isolated and increased in biomass to further enhance the product [47]. This is due to this macromolecule contributing to the largest fraction of carbon in biomass, having a direct relationship with the calorific value, in addition to providing mechanical durability to wood, a desirable quality in cases of biomass compaction and thermal resistance. It is the last lignocellulosic compound to be degraded [31,37,41,46], giving the material higher levels of fixed carbon [47], and greater thermal resistance to biomass [48].

Ref. [49] found values close to the previous ones (27.64 and 23.30%) using residues of the fruit of Bertholletia excelsa (Brazil nut tree) and Lecythis pisonis (Castanheira-de-sapucaia), respectively. Ref. [50] found in residues of urban pruning, bark, and sawdust of the hybrid Eucalyptus urophylla x Eucalyptus grandi, 24.42, 16.80, and 24.41% lignin, respectively, which, according to the author, can be used for energy use. This value is close to that obtained in the present study for two of the studied compositions, but still slightly lower than [35], which, using sugarcane bagasse, found 27.95%. Ref. [51] used various wastes, from construction wood to agro-industrial waste, and controlled the values of total lignin in the range of 23–36%.

Holocellulose contents were statistically equal in 100T and 90T10B with 68.67% and 67.27%, respectively. There was no significant influence on 10% of the bark, although this composition was the one with the lowest content (58.71%). The holocellulose content is a relevant factor from the point of view of moisture because the higher the holocellulose content, the greater the tendency to absorb moisture, directly influencing the energy yield of the material [52,53]. The contents found are close to what was found by [9], who obtained 73.20% using residues of orange tree pruning. Values similar to the present study were found for bean straw and corn cob (70.17 and 74.37%, respectively) according to [36], and lower values were found by [49] between 56.56 and 57.27% of holocellulose using Bertholletia excelsa (Brazil nut tree) and Lecythis pisonis (Castanheira-de-sapucaia), respectively. Holocellulose is of fundamental importance because the degradation of the molecules that compose it occurs in an extensive temperature range, approximately 150–450 °C, which gives thermal stability in the burning of biomass [52], although, according to [49], there is an inverse relationship with the fixed carbon content, which is corroborated by [44], who obtained higher levels of holocellulose and, consequently, lower levels of lignin by studying various wood residues.

3.2. Immediate Analyses

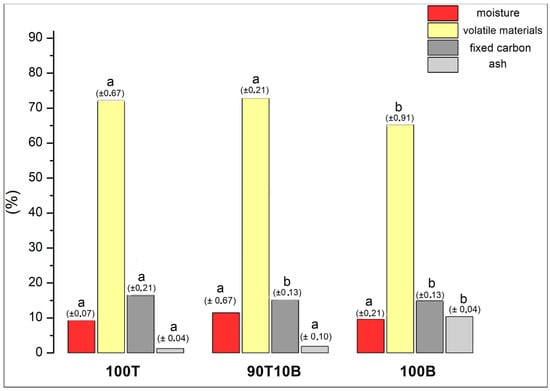

The results of the immediate analysis of the compositions studied are illustrated in Figure 2.

Figure 2.

Data on moisture, volatile materials, fixed carbon and ash of the studied compositions. The values in parentheses correspond to the confidence intervals with a 95% probability. Equal letters in superscript indicate statistical equality according to the Tukey test.

According to the data obtained in the immediate chemical analysis, the percentage moisture contents were 9.56% for the 100T composition, 10.26% for 90T10B and 9.83% for 100B. The values found, according to the literature, are close to the biomass expected to be used for energy use in relation to the compaction of the material, in which moisture should be between 8 and 15% [50,54,55]. Moisture is a parameter used to qualify the biomass that mainly influences the calorific value of the material because it reduces the mass fraction of carbonaceous compounds and, consequently, reduces the heat capacity, causing greater endothermy in the process that involves burning the material, mainly in cases of large volumes of biomass. Therefore, this influences production costs and leads to a loss of useful energy [36,55,56,57].

The contents of volatile materials (VMs) were higher in 100T and 90T10B, which were statistically equal at 72.57 and 73.10%, respectively. 100B presented the lowest value, at 66.16%. The contents obtained for 100T and 90T10B are in accordance with the literature [55,56,58,59,60] for residues of different biomass, such as Eucalyptus sp. sawdust, Pinus sp. sawdust, sugarcane bagasse and açaí stone residues, which were obtained in their studies and had values in the range of 70–81%. A higher value was found in [61], who obtained 87.49% for Andropogon gayanus grass. VM is an important parameter in the quality of biomass for energy purposes because the release of these gases is essential to maintaining the burning of the material, generating ignition. However, it should be noted that a large production of volatiles can accelerate mass loss [35,36,48]. This loss is accentuated in the degradation of cellulose, and although it is a natural succession of thermochemical reactions in the biomass combustion process, very accentuated conditions may not be desirable in terms of the best possible energy utilization [62,63].

The fixed carbon content (FC) was higher in 100T, which presented 16.76%. In the compositions 90T10B and 100B, the contents were 14.95 and 14.68%, respectively, an indication that the addition of 10% of the bark did not influence the FC content in 90T10B. The values obtained in this study are in accordance with the literature for wood biomass [35,50,55,64]. Ref. [55] found values close to this study using the sawdust of Pinus and Eucalyptus, at 18.6 and 17.9%, respectively. Higher contents were found by [59,65], who used açaí and jatropha seeds and obtained 24.6 and 26.7%, respectively. Lower values than the present study were obtained by [66,67], which found 14.0 and 13.3% for residues of banana leaf and rice husk, respectively. FC directly influences the values of calorific value [55,62], although in some cases this relationship may not occur, according to age [68] and separate parts of the tree (wood, branch and bark), as found by [58], which obtained an inverse relation comparing the analyzed parts. In addition, the FC content can be influenced by the way the biomass to be used is found, because impurities contained in the biomass can compromise the FC values [36].

As for the ash content, in the material 100T, it was 1.11%, and in 90T10B, it was 1.69%, demonstrating that there was no significant influence of the 10% of the bark. The highest value obtained was in 100B, at 9.33%; this value is high and expected for bark [39,50,58]. Ash has a very complex nature, and in cases of high contents, biomass is not desirable in terms of bioenergy. However, as a by-product of burning large amounts of biomass, ash can be used in the production of silicon carbide, pure silica, mortars and alkaline activators, among others [69,70,71,72]. The values found in compositions 100T and 90T10B are in accordance with the literature with regard to the amount of ash that biomass can present to be used energetically [56,73], except for composition 100B, although the bark can be used in blends [39,50]. The ash contents found in 100T and 90T10B were lower compared to those obtained by [30], which, using the trunk of the orange tree that was aged less than the present study, obtained an ash content of 2.8%, which is expected for tree age according to studies by [32,74]. Ref. [9] used pruning residues from orange tree branches and obtained 3.34% of ash. In addition, these values for the two compositions are in accordance with those found in studies with some species of eucalyptus, which is the biomass most used in energy use, obtaining values in the range of 0.68–2.82% of ash in [22,75], although contents below these were found, more precisely between 0.35 and 0.50% in the studies of [58,76]. Intermediate values are found in several biomasses, as found in the studies of [59], who obtained 1.44% using açai seeds, and [55], who found a content of 1.42% using sugarcane bagasse.

The ash content in biomass refers to its inorganic content that is oxidized in the combustion process of elements such as calcium, potassium, phosphorus, magnesium, iron, sodium and silicon, among others [36,77]. The quantification of ash is of fundamental importance because it is a fraction not used energetically and has an inverse relation with the calorific value [64,65]. Ash contents in reused biomass may also be associated with the type of collection and storage of the material that can contaminate the biomass [36].

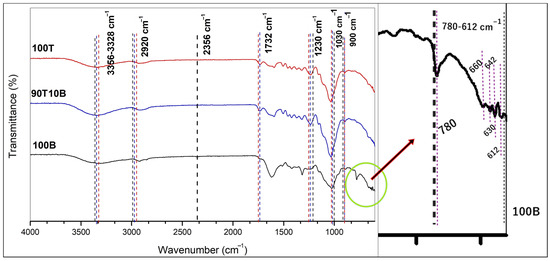

3.3. Fourier Transform Infrared (FTIR)

Figure 3 shows the absorption spectra of the compositions analyzed (left). The right corresponds to a cut with the highest incidence of peaks in the composition 100B.

Figure 3.

Spectra of compositions 100T, 90T10B and 100B. On the right, a cut shows the highest incidence of peaks in 100B.

The compositions analyzed showed few differences in their spectra, except for the range 780–612 cm−1 in 100B. It is observed that the samples of compositions 100T and 90T10B showed greater similarity between their spectra, while 100B showed more absorption peaks than the other two compositions. All compositions presented an absorption range of 3356–3328 cm−1 attributed to phenolic groups present in lignin [30,78,79]. The peak at 2920 cm−1 refers to C-H bonds that are associated with cellulose [30,78,80]. At 100B only, a peak occurs at 2356 cm−1. This peak corresponds to atmospheric CO2, detected at the time of analysis. In the range of 1732–1230 cm−1 of materials 100T and 90T10B (in 100B from 1621 cm−1), there is the presence of carbonyl groups at points at 1732 cm−1, indicating the presence of aldehydes [81,82], characteristic in lignin [52,83], and indicative of hemicelluloses [84], C=C (1680–1620 cm−1), which may be associated with unsaturated cyclic compounds [78], which is the case of some extractives, and =CH2 (1485–1445 cm−1) associated with aromatic rings [30], C-O links (1327–1267 cm−1) present in lignin guaiacyl and syringyl, respectively [30], and hemicelluloses [85].

There is the occurrence of characteristic peaks of ether groups in 1033 cm−1 (1025 cm−1 in 100B) that are present in the structure of lignin [30,81]. In the range of 900–612 cm−1, they are present in the spectrum of compositions 100T and 90T10B only in their extreme values and absent in the range of 780–630 cm−1, and present only in 100B. In 897 cm−1, typical peaks of primary carbon bonds are observed, indicating cellulose and hemicellulose, and in 667 cm−1 as well, referring to the -COH out-of-plane characteristic of cellulose [85].

The range of 900–612 cm−1, with strong incidence in the composition 100B, is closely associated with aromatic groups mono or di-substitutes [78] and may indicate the presence of several species of extractives, a hypothesis that is corroborated by the chemical analysis in 100B that indicated 19.67% of total extractive content in this composition.

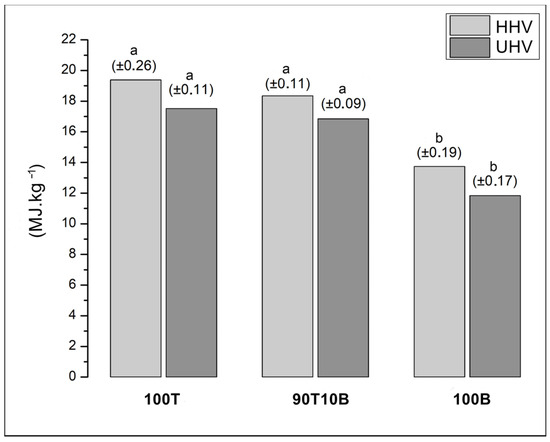

3.4. Calorific Value

The values found for useful heating value (UHV) and higher heating value (HHV) (Figure 4) in the study are the main parameters used to evaluate the potential for reuse of a biomass in terms of energy per unit mass or volume [86,87]; mainly the useful energy, which is obtained by estimating the UHV in order to discount the energy involved in water formation and condensation by hydrogen combustion and water evaporation from the intrinsic moisture in the material [50,88].

Figure 4.

HHV and UHV of compositions 100T, 90T10B and 100B. Equal letters in superscript indicate statistical equality according to the Tukey test.

The compositions 100T and 90T10B showed equal values of UHV from a statistical point of view: 17.51 MJ.kg−1 and 16.84 MJ.kg−1, respectively. Thus, the 10% of the bark, which obtained the UHV value of 11.83 MJ.kg−1, did not influence the value obtained in 90T10B. However, it is important to be aware that if biomass is used as an energy source in which there is a mixture of substrates with different calorific values, useful heat loss may occur. The UHV found in 100B can be considered as expected, since this composition was the one that presented a high ash content and extractives, in addition to lower levels of lignin and holocellulose, factors that directly influence the energy value of the material [50,58,77,89]. The data obtained in this study for the compositions containing the trunk of the orange tree are potential sources of energy use in relation to various biomasses, as indicated in the works of [39], who found HHV values in the range of 17.35–19.39 MJ.kg−1 using ten different types of biomass, as well as in [59], who obtained the HHV of 19.6 MJ.kg−1 using açaí seeds, [55], who, using sugarcane bagasse, obtained 18.5 MJ.kg−1, and [90], who obtained 18.2 MJ.kg−1, in addition to higher values as in [87], who, using canjiqueira and cambará, obtained 20.07 and 19.54 MJ.kg−1, respectively.

3.5. Bulk Density and Energy Density

The values of bulk density and energy density performed in compositions 100T and 90T10B are shown in Table 1.

Table 1.

Bulk density and energy density values of compositions 100T and 90T10B. Values in parentheses correspond to confidence intervals with 95% probability. Equal letters in superscript indicate statistical equality according to the Tukey test.

As can be seen in Table 1, the averages obtained for the studied compositions are in a state of statistical equality. However, there are intrinsic characteristics to each biomass that, when crushed, can present several different particle sizes within the same range and allow for varied conditioning, causing higher or lower values of bulk density in the case of blends [36,91,92,93]. This understanding of the particularities of each biomass should be considered in cases of high quantities.

The bulk density results found in the literature have an immense diversity in the values for different types of biomass for the reasons mentioned above, which, in this case, includes the data obtained in this work as intermediates and within what is expected for biomass for energy use. Values lower than the compositions studied were found by [94] for corn stover (157.9 kg.m−3), wheat straw (151.8 kg.m−3) and sorghum (223.7 kg.m−3). Ref. [36], studying several biomasses, found lower values than those of the present study for bean husks (77.3 kg.m−3) and corn cobs (197.3 kg.m−3) and a higher value for coffee husks (389.2 kg.m−3). Lower and higher values were also obtained by [95] with peanut shell (76.9 kg.m−3) and cashew nut shell (452.7 kg.m−3) and [96] with pine nut residues (87 kg.m−3). High bulk density values are more desirable for lignocellulosic residues, as they are an important indicator for energy density and biomass transport [24,36,97]. In addition, according to [98], the increase in this parameter directly influences the yield in the roasting and carbonization of biomass. Low densities impair the logistics process by requiring volume to be stored, and, in this case, the most indicated is the pelletization of biomass [96,99,100].

Although the means of the bulk density and calorific value of the compositions were statistically equal to each other, regarding energy density, it was observed that the composition 100T presented the highest average (6.16 GJ.m−3), and the composition 90T10B was 5.85 GJ.m−3. The values found in the two compositions were higher than those obtained by [36] with coffee bark (5.66 GJ.m−3), wood waste from the timber industry (3.20 GJ.m−3) and civil construction disposal (2.82 GJ.m−3). High values are also found in [29] using Bambusa vulgaris, in which the effect of stem positions and age was analyzed, obtaining values in the range of 9.4–12.1 GJ.m−3.

3.6. Thermogravimetric Analysis (TGA and DTG)

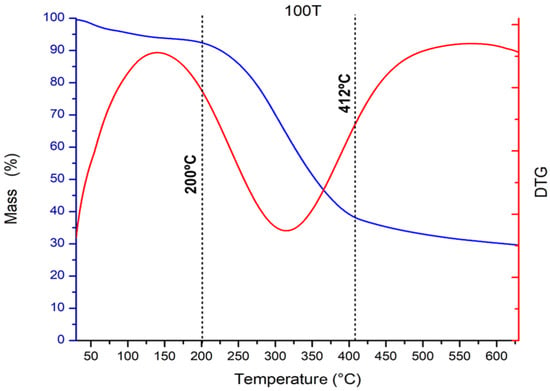

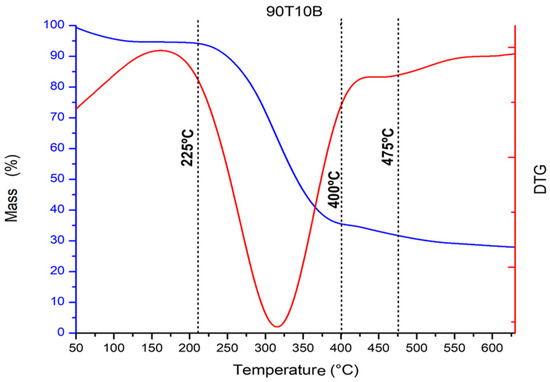

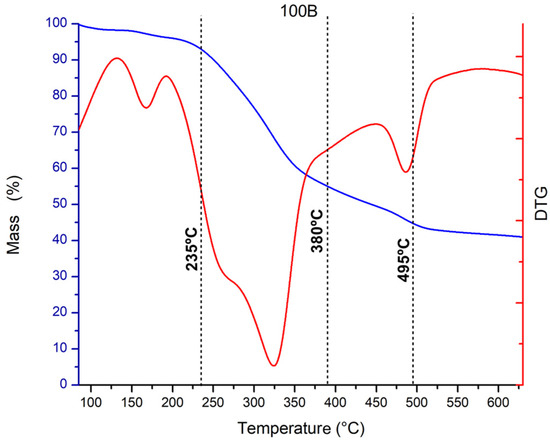

The TGA and DTG graphs of the studied compositions are presented in Figure 5, Figure 6 and Figure 7.

Figure 5.

TG and DTG curves of 100T composition.

Figure 6.

TG and DTG curves of 90T10B composition.

Figure 7.

TG and DTG curves of 100B composition.

Analyzing Figure 5, Figure 6 and Figure 7, 100T and 90T10B have similar thermogravimetric profiles, and 100B has a unique profile compared to the other compositions. All compositions have different phases of degradation of the lignocellulosic components. In the experimental conditions, the residual was approximately 38% in 100T, 32% in 90T10B composition and 45% in 100B composition, recalling that the latter consists only of the shell, a material of more complex chemical composition [77,101]. The hypothesis that justifies that the composition 100B presented a higher residual is due to the high ash content in 100B, since the inorganic content is oxidized in a temperature range more extensive than lignocellulosic materials and can slow the burning of the carbonaceous fraction [102,103].

For all compositions, the initial mass losses were around 150 °C due to the evaporation of water and the detachment of some light volatile compounds [104,105,106,107]. Light volatile compounds are also eliminated at temperatures up to approximately 200 °C and are mainly formed by terpenes, aldehydes of various molecular weights, esters and organic acids such as formic acid and acetic acid, among others [107]. These compounds come from extractives [103] and are part of the decomposition of hemicelluloses, in addition to lignin, whose degradation begins at around 200 °C [108,109]. After this period, the most significant mass losses occur for all materials in terms of cellulose and lignin.

In the 100T composition, the degradation phase was 225 °C to 412 °C. In this temperature range, there is continuity in the degradation of hemicelluloses, and the degradation of almost all cellulose occurs [110]. In this phase, there is about a 54% mass loss in the 100T composition. According to the literature, there is still lignocellulosic material to decompose beyond 412 °C, such as hemicelluloses and cellulose; these two can be degraded up to 450 °C [41,62,111]. In addition, there is also the degradation of lignin, which has greater thermal stability compared to other components, with degradation up to 600 °C [32,112], and, in an isolated condition, its decomposition can reach up to 900 °C [111].

For the 90T10B composition, two phases of degradation occurred. The first one was from 225 to 400 °C. In this phase, there was a mass loss of approximately 58%. There was a second degradation phase, from 380 °C to 475 °C, which did not occur in 100T. In this phase, there was a mass loss of approximately 4%. The presence of this second phase of degradation is due to the presence of 10% of the bark, which allowed for a greater degradation of lignocellulosic components since its percentage of residue was the lowest.

In composition 100B, there were also two phases of degradation. The first phase is between 235 °C and 380 °C; this phase is shorter than in compositions 100T and 90T10B. The fact that this phase began at a higher temperature than the previous compositions is due to the high content of extractives, which, according to chemical characterization, was the highest among the analyzed compositions. In this phase, there was a 38% mass loss. The second phase of degradation occurred between temperatures of 380 °C and 495 °C, with 13% of mass loss. This composition presented the highest degradation temperature compared to the compositions 100T and 90T10B. This was probably due to the greater amount of extractives to be degraded and mainly due to the inorganic fraction contained in the material, which, due to its high specific heat, absorbs more heat and slows its transfer in the direction of carbonaceous compounds [113,114].

The DTG peaks observed between temperatures of 200 and 380 °C signify the initial stages of thermal degradation for distinct constituents such as lignin, hemicellulose and cellulose. Due to their closely proximate degradation temperatures, these constituents may exhibit overlapping DTG peaks. Another noteworthy consideration is the thermal degradation of extractives. Owing to their complex nature, these extractives may manifest degradation peaks within the DTG curve spanning temperatures from 150 to 500 °C. The detection and analysis of these peaks are crucial in understanding the intricate thermal behavior of the components within the studied material.

Further studies are needed with other heating rates to draw a more clarifying profile of the degradation of the components of the materials studied. It is also essential to perform thermogravimetry in an oxidizing atmosphere, which provides different profiles of curves that demonstrate a greater decomposition of lignocellulosic materials.

4. Conclusions

According to the results obtained, the compositions 100T and 90T10B did not show significant differences, except for the chemical characterization, where the composition 100T presented the lowest extractive content (6.34%), fixed carbon content (16.76%) and energy density (6.16 Gj.m−3). The composition 100B presented higher extractives (19.67%) and ash (9.33%) and lower UHV (11.83 Mj.kg−1). In the FTIR and thermogravimetric analyses, 100T and 90T10B were similar. However, 100B presented a higher incidence of peaks and more phases of thermal degradation.

The values obtained in the analyses are compatible with several biomasses used in bioenergy, for which comparisons were made. The study showed that 10% of the bark significantly influenced the values of fixed carbon, extractives and energy density. This was due to the high content of ash and extractives present in the bark. The higher incidence of peaks in 100B was due to the higher extractive content in this material. The extractives also influenced the largest number of thermal degradation phases, along with the inorganic content present in this material.

To reproduce better results, new analyses are necessary, but due to the limitations of the research, they were not performed. Elemental analysis is an important parameter combined with chemical characterization and thermogravimetric analysis in the oxygen atmosphere, and with other heating rates and higher temperatures, larger samples and new proportions of compositions can be included in the new research.

Through this study, it is possible to conclude that orange wood can be used as bioenergy in regions where there is high fruit production. Biomass compaction is a great option as it increases the energy density of the material and prolongs the life of the waste. The bark (100B), due to the low caloric value, is not suitable for energy. However, studies should be performed to verify the potential of its extractives, which is corroborated by the unique characteristics demonstrated in the absorption and thermal degradation spectra.

Author Contributions

Conceptualization and writing original draft, L.C.D.; methodology, supervision and formal analysis, D.G.; validation, supervision and resources, A.F.D.J.; writing—review and editing and supervision, M.P.O.; project administration and funding acquisition, M.P.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Fundação de Amparo à Pesquisa e Inovação do Espírito Santo/Espírito Santo Research and Innovation Support Foundation (FAPES)–<T.O. 45132.706.31102.30042021>.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- United States Department of Agriculture (USDA). Citrus: World Markets and Trade. 2023. Available online: https://apps.fas.usda.gov/psdonline/circulars/citrus.pdf (accessed on 22 September 2023).

- Brazilian Institute of Geography and Statistics (IBGE). Orange Production. 2023. Available online: https://www.ibge.gov.br/explica/producao-agropecuaria/laranja/br (accessed on 22 September 2023).

- Dennis-Wall, J.C.; Burns, A.M.; Solch, R.J.; Ukhanova, M.; Dahl, W.J.; Christman, M.C.; Boileau, T.; Brauchla, M.; Shin, J.-E.; Nieves, C.; et al. A Beverage Containing Orange Pomace Improves Laxation and Modulates the Microbiome in Healthy Adults: A Randomised, Blinded, Controlled Trial. J. Funct. Foods 2019, 60, 103438. [Google Scholar] [CrossRef]

- Guzman, G.; Xiao, D.; Liska, D.; Mah, E.; Sanoshy, K.; Mantilla, L.; Replogle, R.; Boileau, T.W.; Burton-Freeman, B.M.; Edirisinghe, I. Addition of Orange Pomace Attenuates the Acute Glycemic Response to Orange Juice in Healthy Adults. J. Nutr. 2021, 151, 1436–1442. [Google Scholar] [CrossRef] [PubMed]

- Asif, M.; Khan, M.K.; Khan, M.I.; Maan, A.A.; Helmick, H.; Kokini, J.L. Effects of Citrus Pomace on Mechanical, Sensory, Phenolic, Antioxidant, and Gastrointestinal Index Properties of Corn Extrudates. Food Biosci. 2023, 55, 103012. [Google Scholar] [CrossRef]

- Carranza-Méndez, R.; Chávez-González, M.L.; Sepúlveda-Torre, L.; Govea-Salas, M.; Ramos-González, R.; Aguilar, C.N. Production of Single Cell Protein from Orange Peel Residues by Candida Utilis. Biocatal. Agric. Biotechnol. 2022, 40, 102298. [Google Scholar] [CrossRef]

- Moutousidis, D.; Karidi, K.; Athanassiadou, E.; Stylianou, E.; Giannakis, N.; Koutinas, A. Reinforcement of Urea Formaldehyde Resins with Pectins Derived from Orange Peel Residues for the Production of Wood-Based Panels. Sustain. Chem. Environ. 2023, 4, 100037. [Google Scholar] [CrossRef]

- Vamvuka, D.; Sfakiotakis, S.; Kotronakis, M. Fluidized Bed Combustion of Residues from Oranges’ Plantations and Processing. Renew. Energy 2012, 44, 231–237. [Google Scholar] [CrossRef]

- Gonzalez, Z.; Rosal, A.; Requejo, A.; Rodríguez, A. Production of Pulp and Energy Using Orange Tree Prunings. Bioresour. Technol. 2011, 102, 9330–9334. [Google Scholar] [CrossRef] [PubMed]

- García-Franco, N.; Wiesmeier, M.; Colocho, C.; Fella, F.; Martínez-Mena, M.; Almagro, M.; Martínez, E.G.; Kögel-Knabner, I. Pruning Residues Incorporation and Reduced Tillage Improve Soil Organic Matter Stabilization and Structure of Salt-Affected Soils in a Semi-Arid Citrus Tree Orchard. Soil Tillage Res. 2021, 213, 105129. [Google Scholar] [CrossRef]

- Welfle, A.J.; Almena, A.; Arshad, M.N.; Banks, S.W.; Butnar, I.; Chong, K.J.; Cooper, S.G.; Daly, H.; Garcia Freites, S.; Güleç, F.; et al. Sustainability of Bioenergy—Mapping the Risks & Benefits to Inform Future Bioenergy Systems. Biomass Bioenergy 2023, 177, 106919. [Google Scholar] [CrossRef]

- Amorim, E.P.; Pimenta, A.S.; Souza, E.C. Use of Forest Harvest Waste: State of the Art and Opportunities. Res. Soc. Dev. 2021, 10, e4410212175. [Google Scholar] [CrossRef]

- T264 cm-97; Preparation of Wood for Chemical Analysis. Technical Association of Pulp and Paper Industry (TAPPI): Atlanta, GA, USA, 1997.

- T204 cm-97; Solvent Extractives of Wood and Pulp. Technical Association of Pulp and Paper Industry (TAPPI): Atlanta, GA, USA, 1997.

- T 222 om-02; Acid-Insoluble Lignin in Wood and Pulp. Technical Association of Pulp and Paper Industry (TAPPI): Atlanta, GA, USA, 2002.

- T um 250; Acid-Soluble Lignin in Wood and Pulp. Technical Association of Pulp and Paper Industry (TAPPI): Atlanta, GA, USA, 1991.

- Morais, J.P.S.; Rosa, M.F.; Marconcini, J.M. Procedures for Lignocellulosic Analysis, 1st ed.; Campina Grande, Brazil, 2010; pp. 35–42. [Google Scholar]

- ASTM D1762-84; Standard Test Method for Chemical Analysis of Wood Charcoal. Reapproved 2007; American Society for Testing and Materials: West Conshohocken, PA, USA, 2007.

- ASTM E870; Standard Test Methods for Analysis of Wood Fuels. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- D. I. N. EM 14918; Determination of Calorific Value. Deutsches Institut Für Normung: Berlim, Germany, 2010.

- ASTM E873-82; Standard Test Method for Bulk Density of Densified Particulate Biomass Fuels. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Jesus, M.S.; Costa, L.J.; Ferreira, J.C.; Freitas, F.P.; Santos, L.C.; Rocha, M.F.V. Energy Characterization of Different Eucalyptus Species. Floresta 2017, 47, 11. [Google Scholar] [CrossRef]

- Souza, F.D.; Vale, A.T. Energy Density of Lignocellulose Biomass Briquettes and their Relation to Briqueting Parameters. Pesqui. Florest. Bras. 2017, 36, 405. [Google Scholar] [CrossRef]

- Protásio, P.; Cristina, I.; Trugilho, P.F.; Silva, V.O.; Elisa, A. Compression of plant biomass for the production of solid biofuels. Pesqui. Florest. Bras. 2011, 31, 273–283. [Google Scholar] [CrossRef]

- Edislan, F.; Maia, J.H.; Souza, L.S.; Martins, T.; Gomes, V. Physical Characterization and Determination of Embiratanha Wood Extracts Contents. Adv. For. Sci. 2019, 6, 755. [Google Scholar] [CrossRef]

- Pedrazzi, C.; Dick, R.; Coldebella, M.G.; Giesbrecht, B.M.; Rosa, R.C. Wood Chemistry. Collection Rural Sciences (27), 1st ed.; Santa Maria, Brazil, 2019; pp. 11–20. [Google Scholar]

- Routa, J.; Brännström, H.; Laitila, J. Effects of Storage on Dry Matter, Energy Content and Amount of Extractives in Norway Spruce Bark. Biomass Bioenergy 2020, 143, 105821. [Google Scholar] [CrossRef]

- Moulin, J.C.; Arantes, M.D.C.; Vidaurre, G.B.; Paes, J.B.; Carneiro, A.d.C.O. Effect of Spacing, Age and Irrigation on the Chemical Components of Eucalyptus Wood. Rev. Árvore 2015, 39, 199–208. [Google Scholar] [CrossRef][Green Version]

- Vale, A.T.; Moreira, A.C.O.; Martins, I.S. Evaluation of the Energy Potential of Bamboo Vulgaris by Age. Floresta Ambiente 2017, 24, e00123314. [Google Scholar] [CrossRef][Green Version]

- Porto, D.S.; Forim, M.R.; Costa, E.S.; Fernandes, J.B.; Silva, M.F.G.F. Evaluation of Lignins of Trunk and Roots from Citrus sinensis L. Osbeck: A Large Available Brazilian Biomass. J. Braz. Chem. Soc. 2021, 32, 29–39. [Google Scholar] [CrossRef]

- Sette, C.R.; Tomazello Filho, M., Jr.; Silva, F.G.d., Jr.; Laclau, J.P. Changes in the Chemical Properties of Wood with the Substitution of K by Na in Eucalyptus Plantations. Rev. Árvore 2014, 38, 569–578. [Google Scholar] [CrossRef]

- Garcia, D.P.; Caraschi, J.C.; Ventorim, G. Thermal Decomposition of Wooden Pellets by TGA. Holos 2016, 1, 327. [Google Scholar] [CrossRef]

- Pereira, A.A.; Lima, M.D.R.; Patrício, E.P.S.; Numazawa, S.; Goulart, S.L.; Protásio, T.d.P. Sustainable Forestry Waste Grouping for Bioenergy Generation. Sci. For. 2020, 48, e3157. [Google Scholar] [CrossRef]

- Zaque, L.A.M.; Mendoza, Z.M.S.H.; Borges, P.H.M.; Ferreira, M.D.; Morais, P.H.M. Extractive Contents in Brazilian Mahogany Wood. Braz. Appl. Sci. Rev. 2021, 5, 1871–1880. [Google Scholar] [CrossRef]

- Grotto, C.G.L.; Costa, A.M.F.; Colares, C.J.G.; Pereira, D.H. Characterization of Sugar Cane Bag Biomass with Energy Views. ForScience 2021, 9, e00928. [Google Scholar] [CrossRef]

- Dionizio, A.F.; Teixeira, A.; Oliveira, G.; Chaves, B.M. Adding Value to Agro-Industrial Waste for Energy Purposes. Rev. Ciências Agrárias 2019, 42, 528–538. [Google Scholar] [CrossRef]

- Irawati, D.; Higeta, S.; Wedatama, S.; Ishiguri, F.; Yokota, S. Characterization of Branch Waste of Several Tropical Fruit Tree Species as Considerations for Bioenergy Resources. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Yogyakarta, Indonesia, 16–17 October 2019; Volume 449, p. 012019. [Google Scholar] [CrossRef]

- Ferreira, K.A.C.; Mendoza, Z.M.S.H.; Ribeiro, E.S.; Batista, B.M.F.; Silva, J.C. Analysis of Accidental Compounds in Tectona grandis Wood L. F. Biodiversidade 2015, 14, 105–116. [Google Scholar]

- Saccol, A.F.O.; Welter, C.A.; Rosa, R.C.; Coldebella, R.; Longhi, S.J.; Farias, J.A.; Pedrazzi, C. Analysis of Accidental Compounds in Tectona grandis Wood. Matéria 2020, 25, e12634. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Santana, R.M.C. Thermal Decomposition of Wood: Kinetics and Degradation Mechanisms. Bioresour. Technol. 2012, 126, 7–12. [Google Scholar] [CrossRef]

- Canal, W.D.; Carvalho, A.M.M.L.; Oliveira, A.C.; De Magalhães, M.A.; Cândido, W.L.; Fialho, L.d.F. Thermal Behavior, Emission of Condensable and Non-Condensable Gases in the Carbonization Process of Wood. Pesqui. Florest. Bras. 2016, 36, 261–267. [Google Scholar] [CrossRef]

- Juizo, C.G.F.; Zen, L.R.; Klitzke, W.; França, M.C.; Cremonez, V.G.; Klitzke, R.J. Technological Properties of Thermal Treated Eucalyptus Wood. Nativa 2018, 6, 537–542. [Google Scholar] [CrossRef]

- De Souza, H.J.P.L.; Arantes, M.D.C.; Vidaurre, G.B.; Andrade, C.R.; Carneiro, A.C.O.; De Souza, D.P.L.; Protásio, T.P. Pelletization of Eucalyptus Wood and Coffee Growing Wastes: Strategies for Biomass Valorization and Sustainable Bioenergy Production. Renew. Energy 2020, 149, 128–140. [Google Scholar] [CrossRef]

- Santos, A.M.; Melo, A.A.; Queiroz, A.; Guimarães, L.; Consolaro, H.N.; Sarmento, A.P. Recovery of Wood Wastes for Bioenergy Generation. Rev. Process. Químicos 2020, 13, 51–56. [Google Scholar] [CrossRef]

- Brumano, G.C.B.; Barbosa, B.M.; Colodette, J.L.; Fernandes, S.A. Study of structures present in lignin soluble in lignocellulose materials by pyrolysis associated with gas chromatography and mass spectrometry. In Proceedings of the 49th International Pulp and Paper Congress, São Paulo, Brazil, 25–27 October 2016. [Google Scholar]

- Cao, Z.; Zhang, S.; Huang, X.; Liu, H.; Sun, M.; Lyu, J. Correlations between the Compressive Strength of the Hydrochar Pellets and the Chemical Components: Evolution and Densification Mechanism. J. Anal. Appl. Pyrolysis 2020, 152, 104956. [Google Scholar] [CrossRef]

- Ndumbo, M.; De Conti, A.C.; Brienzo, M. New Process of Producing Briquettes with Greater Durability Using 593 Sugarcane Fractions and Additives; Briquets and Their Use. BR 102021003264-2 A2, 30 August 2022. [Google Scholar]

- Silveira, J.H.; Dorneles, R.H.T.; Sebbem, V.H.A.; Gasparin, F.P.; Ries, L.A.S. Characterization of residual biomass from saline eucalyptus harvest for thermal conversion processes. In Natural Resources: Forest Biomass Energy, 1st ed.; Oliveira, R.J., Ed.; Editora Científica Digital: São Paulo, Brazil, 2021; Volume 2, pp. 12–31. [Google Scholar] [CrossRef]

- Carmona, I.N.; Sampaio, J.d.S.; Luz, P.A.S.A.d.; Andrade, F.W.C. Tannin Quantification and Chemical-Energetic Characterization of Biomass Residues of Bertholletia spp. and Lecythis’ spp. Fruits. Matéria 2021, 26, e13070. [Google Scholar] [CrossRef]

- Carvalho, N.; Barros, J.; Silva, D.; Nakashima, G.; Yamaji, F. Physical and Chemical Characterization of Biomass Used as Solid Fuel in a Boiler. Química Nova 2021, 44, 35–40. [Google Scholar] [CrossRef]

- Orellana, B.B.M.A.; do Vale, A.T.; Orellana, J.B.P.; Chaves, B.S.A.; de Oliveira Moreira, A.C. Characterization of Agroindustrial Wastes of the Federal District Region for Energy Purposes. Energ. Na Agric. 2020, 35, 46–61. [Google Scholar] [CrossRef]

- Rowell, R.M. Moisture Properties. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 75–97. ISBN 978-1-4398-5381-8. [Google Scholar]

- Neves, T.A.; Protásio, T.P.; Trugilho, P.F.; Vale, M.L.A.; Souza, L.C.; Vieira, C.M.V. Eucalyptus Clone Wood Quality in Different Ages for Bioenergy Production. Rev. Ciências Agrárias 2013, 56, 139–148. [Google Scholar] [CrossRef]

- Ribeiro, R.M.; Bahia, M.A.M.; Caetano, M.Z.G.; Sousa, P.H.C.V.; Fernandes, R.L.O.; Franco, M.P.; Sette Júnior, C.R. Eucalyptus Clone Wood Quality in Different Ages for Bioenergy Production. Rev. Virtual Química 2022, 14, 465–477. [Google Scholar] [CrossRef]

- Silva, D.A.; Nakashima, G.T.; Barros, J.L.; Da Roz, A.L.; Yamaji, F.M. Biomass Characterization for Briqueting. Floresta 2015, 45, 713. [Google Scholar] [CrossRef]

- Fortaleza, A.P.; Filho, J.J.P.N.; Ceretta, R.P.S.; Barros, D.S.; Silva, S.S. Biomass of forest species for the production of plant coal. Ciência Florest. 2019, 29, 1436–1451. [Google Scholar] [CrossRef]

- Denadai, M.S.; Mendes, C.R.L.G.; Bueno, O.C.; Silva, M.A.; Guerra, S.P.S.; Seiko, M. Impact of Humidity of Sweetened Sugar Cane Straw on Shipping Cost. In Proceedings of the 10th International Bioenergy Congress, São Paulo, Brazil, 15–16 July 2015. [Google Scholar]

- Watzlawick, L.F.; Wionzek, F.B.; Silva, S.V.K.; Benin, C.C. Biomass production and energy properties of Eucalyptus benthamii maiden et cambage. In Resources Woodworking Industrial Engineering: Technology, Research and Trends, 1st ed.; Gonçalves, F.G., Ed.; Editora Científica Digital: São Paulo, Brazil, 2020; pp. 267–285. [Google Scholar] [CrossRef]

- Oliveira, P.R.S.; Trugilho, P.F.; de Oliveira, T.J.P. Briquettes of Acai Seeds: Characterization of the Biomass and Influence of the Parameters of Production Temperature and Pressure in the Physical-Mechanical and Energy Quality. Environ. Sci. Pollut. Res. 2021, 29, 8549–8558. [Google Scholar] [CrossRef]

- Teixeira, C.M.; Martins, M.P.; Yamamoto, H.; Chrisostomo, W.; Yamaji, F.M. Chemical Characterization of Eucalyptus sp. Short-Rotation Forest Waste for Bioenergy Production. Rev. Virtual Química 2016, 8, 1693–1701. [Google Scholar] [CrossRef]

- Pedrosa, A.L.; Pedroza, M.M.; Cardoso, C.P.; Negre, S.M.S. Characterization of the plant andropogon gayanus kunth aimed at the production of biofuels in the northern region of Brazil. In Proceedings of the 7th Scientific Initiation and Extension Journey, Palmas, Brazil, 19–21 October 2016. [Google Scholar]

- Araújo, A.C.C.; Costa, L.J.; Braga, P.P.C.; Neto, R.M.G.; Rocha, M.F.V.; Trugilho, P.F. Energy Properties of Cenostigma macrophyllum Wood and Vegetable Coal: Subsidies for Sustainable Use. Pesqui. Florest. Bras. 2018, 38, e201701546. [Google Scholar] [CrossRef]

- Santos, C.P.S.; Costa, S.E.L.; Rodrigues, I.; Gomes, F.; Dos Santos, R.C.; De Castro, V.R. Thermal decomposition of wood of two species of caatinga: Caesalpinia pyramidalis e Aspidosperma pyrifolium. In Proceedings of the 3rd International Congress of Agricultural Sciences, João Pessoa, Brazil, 8–13 December 2018. [Google Scholar]

- Brun, E.J.; Bersch, A.P.; Periera, F.A.; Silva, D.A.; Barba, Y.R.D.; Dorini Junior, J.R. Characterization of three genetic materials of Eucalyptus Sp. Rev. Floresta 2018, 48, 87–92. [Google Scholar] [CrossRef]

- Tomeleri, J.O.P.; Valentim, L.B.; Silva, J.P.; Yamaji, F.M.; Pádua, F.A. Chemical and Energetic Characterization of Pinhão Manso Residual Epicarp (Jatropha curcas L.) and Briquette Produced. Rev. Virtual Química 2017, 9, 942–952. [Google Scholar] [CrossRef]

- Maia, B.; Souza, O.; Marangoni, C.; Hotza, D.; Oliveira, A.; Sellin, N. Production and Characterization of Fuel Briquettes from Banana Leaves Waste. Chem. Eng. Trans. 2014, 37, 439–444. [Google Scholar] [CrossRef]

- Rodrigues, D.S.; Alexandrino, I.C.A.; Souza, M.C.; Toneli, J.T.C.L.; Antônio, G.C. Immediate analysis of agricultural biomasses: A comparative study. In Proceedings of the 6th Technical Scientific Congress of Engineering and Agronomy (CONTECC), Palmas, Brazil, 17–19 September 2019. [Google Scholar]

- Soares, V.C.; Bianchi, M.L.; Trugilho, P.F.; Pereira, A.J.; Höfler, J. Correlations Between the Properties of Wood and Eucalyptus Hybrids Vegetable Coal. Rev. Arvore 2014, 38, 543–549. [Google Scholar] [CrossRef]

- Foletto, E.L.; Hoffmann, R.; Hoffmann, R.S.; Portugal, U.L., Jr.; Jahn, S.L. Applicability of The Ashes of The Rice Shell. Química Nova 2005, 28, 1055–1060. [Google Scholar] [CrossRef]

- Centenaro, S.H.; Silva, J.A.G.; Paulino, R.S. Use of Biomass Ash Generated in the Malt Agro Industry for Argamass Production. Rev. Int. Ciências 2021, 11, 158–176. [Google Scholar] [CrossRef]

- Assis, L.F. Biomass Ash Characterization and Application Potential as Pozolanic Material or Alkaline Activator; “Júlio de Mesquita Filho”; Paulista State University: São Paulo, Brazil, 2023; pp. 37–39. [Google Scholar]

- Kieling, A.G.; Brehm, F.A.; Kulakowski, M.P.; Moraes, C.A.M. Influence of The Burning Process on The Characteristics of Rice Shell Ash. Braz. J. Anim. Environ. Res. 2020, 3, 2106–2116. [Google Scholar] [CrossRef]

- Brand, M.A.; Cunha, A.; Carvalho, A.F.; Brehmer, D.R.; Küster, L.C. Analysis of the quality of wood and charcoal produced from the species Miconia cinnamomifolia (De Candolle) Naudin (Jacatirão-açu) in family farming, in Biguaçu. Sci. Florest. 2013, 41, 401–410. [Google Scholar]

- Protásio, T.d.P.; Neves, T.A.; dos Reis, A.A.; Trugilho, P.F. Effect of Age and Clone on Eucalyptus spp Wood Quality for Bioenergy Production. Ciência Florest. 2014, 24, 465–477. [Google Scholar] [CrossRef]

- Barreiros, R.M.; Ribeiro, G.P.; Dias, K.B.; Gouvêa, C.S.; Reis, A.M.F.; Silva, G.C. Energy potential of wood of three species of eucalyptus. In Natural Resources: Forest Biomass Energy, 1st ed.; Oliveira, R.J., Moreira, R.C., Eds.; Editora Científica Digita: São Paulo, Brazil, 2021; pp. 146–164. [Google Scholar] [CrossRef]

- Vivian, M.A.; Silva, A.M.O.; Modes, K.S.; Dobner Júnior, M.; Silva Júnior, F.G. Features of the wood Cunninghamia lanceolata (Chinese fir). Sci. For. 2021, 49, e3581. [Google Scholar] [CrossRef]

- Sjöström, E. Wood Chemistry: Fundamentals and Applications, 2nd ed.; Academic Press: Cambridge, MA, USA, 1993; pp. 107–113. [Google Scholar] [CrossRef]

- Pavia, D.L.; Lampman, G.M.; Kriz, G.S.; Vyvyan, J.R. Introduction to Spectroscopy, 4th ed.; Cengage Learning: Belmont, CA, USA, 2010; p. 716, ISBN-13:9788522107087.

- Haqiqi, E.E. Analisis FTIR (Fourier Transform InfraRed) Adsorbents Coloring Substances from Chicken Egg Shell Residues Combined Biomass Seals Pad. In Proceedings of the National Seminar on Chemistry: Exploration of Natural Materials as Science Innovation for Progress, Jatinangor, Indonésia, 9–10 November 2018. [Google Scholar]

- Xu, F.; Zhang, X.; Zhang, F.; Jiang, L.; Zhao, Z.; Li, H. TG-FTIR for Kinetic Evaluation and Evolved Gas Analysis of Cellulose with Different Structures. Fuel 2020, 268, 117365. [Google Scholar] [CrossRef]

- Silva, A.L.L.; Araujo, M.G.S.; Bastos, M.L.A.; Bernardo, T.H.L.; Oliveira, J.F.S.; Silva-Junior, E.F.; Santos-Junior, P.F.S.; Araujo, M.V.; Alexandre-Moreira, M.S.; Araújo-Júnior, J.X.; et al. Evaluation of Antibacterial, Cytotoxic and Antioxidant Activity of Plant Species Opuntia cochenillifera (L.) Mill. Rev. Bras. Plantas Med. 2016, 18, 307–315. [Google Scholar] [CrossRef]

- Candelier, K.; Dibdiakova, J.; Volle, G.; Rousset, P. Study on Chemical Oxidation of Heat Treated Lignocellulosic Biomass under Oxygen Exposure by STA-DSC-FTIR Analysis. Thermochim. Acta 2016, 644, 33–42. [Google Scholar] [CrossRef]

- Lopes, W.A.; Fascio, M. Scheme for Interpreting Organic Substance Spectrals in the Infrared Region. Química Nova 2004, 27, 670–673. [Google Scholar] [CrossRef]

- Cadermatori, P.H.G.; Missio, A.L.; Mattos, B.D.; Gatto, D.A. Effect of Thermal Treatments on Technological Properties of Wood from Two Eucalyptus Species. Agrar. Sci. 2015, 87, 471–481. [Google Scholar] [CrossRef]

- Evans, P.D. Weathering of Wood and Wood Composites. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 163–165. ISBN 978-1-4398-5381-8. [Google Scholar]

- Tang, J.P.; Lam, H.L.; Aziz, M.K.A.; Morad, N.A. Enhanced Biomass Characteristics Index in Palm Biomass Calorific Value Estimation. Appl. Therm. Eng. 2016, 105, 941–949. [Google Scholar] [CrossRef]

- Galvani, F.; Okamura, L.A.; Salis, S.M. Energy Potential of the Biomasses of Canjiqueira E Do Cambará. 2021. Available online: http://www.infoteca.cnptia.embrapa.br (accessed on 10 September 2022).

- Reis Portilho, G.; Resende de Castro, V.; de Cássia Oliveira Carneiro, A.; Cola Zanuncio, J.; José Vinha Zanuncio, A.; Gabriella Surdi, P.; Gominho, J.; de Oliveira Araújo, S. Potential of Briquette Produced with Torrefied Agroforestry Biomass to Generate Energy. Forests 2020, 11, 1272. [Google Scholar] [CrossRef]

- Habitzreiter, T.L.; Adami, P.F.; Brun, E.J.; Batista, V.V.; Ferreira, M.L.; Giacomel, C.L. Caloric Power and Economic Analysis of Total or Partial Use of Eucalyptus Biomass. Sci. Agrar. Parana. 2020, 18, 282. [Google Scholar] [CrossRef]

- Lima, M.J. Determination of Reaction Kinetics and Operating Conditions of Coffee Bark Pyrolysis in Fixed Bed; Federal University of Espírito Santo: Vitória, Spain, 2018; pp. 43–44. [Google Scholar]

- Haykiri-Acma, H.; Baykan, A.; Yaman, S.; Kucukbayrak, S. Effects of Fragmentation and Particle Size on the Fuel Properties of Hazelnut Shells. Fuel 2013, 112, 326–330. [Google Scholar] [CrossRef]

- Casara, V.P.; Bohn, L.R.; Dresch, A.P.; Mibielli, G.M.; Bender, J.P. Physico-chemical characterization of Maize biomass. In Proceedings of the 12th Brazilian Congress of Chemical Engineering in Scientific Initiation (COBEQ-IC), São Carlos, Brazil, 16–19 July 2017. [Google Scholar] [CrossRef]

- Dresch, A.P.; Bender, J.P.; Führ, J.F.; Vargas, A.C.G.; Mibielli, G.M. Physico-chemical characterization of millet biomass (Pennisetum glaucum). In Proceedings of the 13th Brazilian Congress of Chemical Engineering in Scientific Initiation (COBEQ-IC), Uberlândia, Brazil, 21–24 July 2019, ISSN 2359-1757. [Google Scholar]

- Tumuluru, J.S. Effect of Pellet Die Diameter on Density and Durability of Pellets Made from High Moisture Woody and Herbaceous Biomass. Carbon Resour. Convers. 2018, 1, 44–54. [Google Scholar] [CrossRef]

- Gadelha, A.M.T.; Rodrigues, D.S.; Alexandrino, I.C.A.; Toneli, J.T.C.L.; Antônio, G.C. Biomasses with energy potential for briqueting: Comparative density. In Proceedings of the 7th Technical-Scientific Congress of Engineering and Agronomy (CONTECC), Online, 16–17 September 2021, ISSN 2358117-4. [Google Scholar]

- Jacinto, R.C.; Brand, M.A.; Cunha, A.B.; Souza, D.L.; Silva, M.V. Use of Waste from the Pinhão Production Chain for the Production of Pellets for Energy Generation. Floresta 2017, 47, 353–363. [Google Scholar] [CrossRef]

- Moraes, S. Biomass and Densing Technologies for Energy Application. Rev. IPT Tecnol. Inovação 2021, 5, 353–363. [Google Scholar]

- Campbell, W.A.; Coller, A.; Evitts, R.W. Comparing Severity of Continuous Torrefaction for Five Biomass with a Wide Range of Bulk Density and Particle Size. Renew. Energy 2019, 141, 964–972. [Google Scholar] [CrossRef]

- Agar, D.A.; Rudolfsson, M.; Kalén, G.; Campargue, M.; Silva Perez, D.; Larsson, S.H. A Systematic Study of Ring-Die Pellet Production from Forest and Agricultural Biomass. Fuel Process. Technol. 2018, 180, 47–55. [Google Scholar] [CrossRef]

- Mudryk, K.; Jewiarz, M.; Wróbel, M.; Niemiec, M.; Dyjakon, A. Evaluation of Urban Tree Leaf Biomass-Potential, Physico-Mechanical and Chemical Parameters of Raw Material and Solid Biofuel. Energies 2021, 14, 818. [Google Scholar] [CrossRef]

- Wiedenhoeft, A.C. Structure and Function of Wood. In Handbook of Wood Chemistry and Wood Composites, 2nd ed.; Rowell, R.M., Ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 9–30. ISBN 978-1-4398-5381-8. [Google Scholar]

- Macedo, L.A.; Commandré, J.M.; Rousset, P.; Valette, J.; Pétrissans, M. Influence of Potassium Carbonate Addition on the Condensable Species Released during Wood Torrefaction. Fuel Process. Technol. 2018, 169, 248–257. [Google Scholar] [CrossRef]

- González Martínez, M.; Anca Couce, A.; Dupont, C.; da Silva Perez, D.; Thiéry, S.; Meyer, X.; Gourdon, C. Torrefaction of Cellulose, Hemicelluloses and Lignin Extracted from Woody and Agricultural Biomass in TGA-GC/MS: Linking Production Profiles of Volatile Species to Biomass Type and Macromolecular Composition. Ind. Crops Prod. 2022, 176, 114350. [Google Scholar] [CrossRef]

- Corradi, L.A.; Carvalho, A.M.; Trugilho, P.F.; Melo, I.M.; Oliveira, A.C. Study of Thermal Degradation of Eucalyptus Wood Through Thermogravimetry and Calorimetry. Rev. Arvore 2013, 37, 567–576. [Google Scholar] [CrossRef]

- Zanetti, A.; Benevides, L.C.; Xavier, T.P.; Lira, T.P. Assessment of drying kinetics in thermogravimetric analysis of orange bagasse. In Proceedings of the 12th Brazilian Congress of Chemical Engineering in Scientific Initiation (COBEQ-IC), São Carlos, Brazil, 16–19 July 2017. [Google Scholar]

- Romero, M.J.A.; Duca, D.; Maceratesi, V.; Di Stefano, S.; De Francesco, C.; Toscano, G. Preliminary Study on the Thermal Behavior and Chemical-Physical Characteristics of Woody Biomass as Solid Biofuels. Processes 2023, 11, 154. [Google Scholar] [CrossRef]

- Adamová, T.; Hradecký, J.; Pánek, M. Volatile Organic Compounds (VOCs) from Wood and Wood-Based Panels: Methods for Evaluation, Potential Health Risks, and Mitigation. Polymers 2020, 12, 2289. [Google Scholar] [CrossRef] [PubMed]

- Machado, G.O.; Vogel, F.; Silva, M.M. Influence of the Final Carbonization Temperature on the Physical, Chemical and Energy Characteristics of Cinnamon Coal (Melia azedarach L.) Influence of Temperature Carbonization in Physical, Chemical and Energy of Charcoal from Cinamomo. Ambiência 2014, 10, 83–96. [Google Scholar] [CrossRef]

- Figueroa, M.J.M.; Moraes, P.D. Wood Behaviour at High Temperatures. Ambiente Construído 2009, 9, 157–174. [Google Scholar] [CrossRef]

- Andrade, C.; Mayer, S.L.S.; Ferraz, F.A.; Marchesan, R.; Rossi, L.; Silva, D.A. Energy Properties of Hovenia dulcis Thunberg Wood and Coal. Ciência Madeira Braz. J. Wood Sci. 2019, 10, 166–175. [Google Scholar]

- Carneiro, A.C.O.; Santos, R.C.; Castro, R.V.O.; Castro, A.F.N.M.; Pimenta, A.S.; Pinto, E.M.; Alves, I.C.N. Thermal Decomposition Study of Eight Species of Wood from the Seridó Region, Rio Grande do Norte. Rev. Árvore 2013, 37, 1153–1163. [Google Scholar] [CrossRef]

- Schulz, H.R.; Acosta, A.P.; Barbosa, K.T.; Gatto, D.A. Chemical, Mechanical, Thermal and Optical Properties of Thermal Treated Wood of Pinus elliottii Planted in Brazil. Quebracho Rev. Cienc. For. 2021, 29, 122–131. [Google Scholar]

- Magalhães, A.S.; Silva, T.M.M.; Castro, V.G. Production and characterization of Briquettes from Solid Waste and Semi-Manual Pressing. Adv. For. Sci. 2019, 6, 705. [Google Scholar] [CrossRef]

- Alcântara, G.; Cuccia, V. Methods for treatment of NORM waste from the oil and gas industry. In Proceedings of the 10th Nuclear Atlantic Conference (INAC 2021), Virtual, 29 November–2 December 2021; ISBN 978-65-594-1256-3. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).