A Review of Energy-Efficient Technologies and Decarbonating Solutions for Process Heat in the Food Industry

Abstract

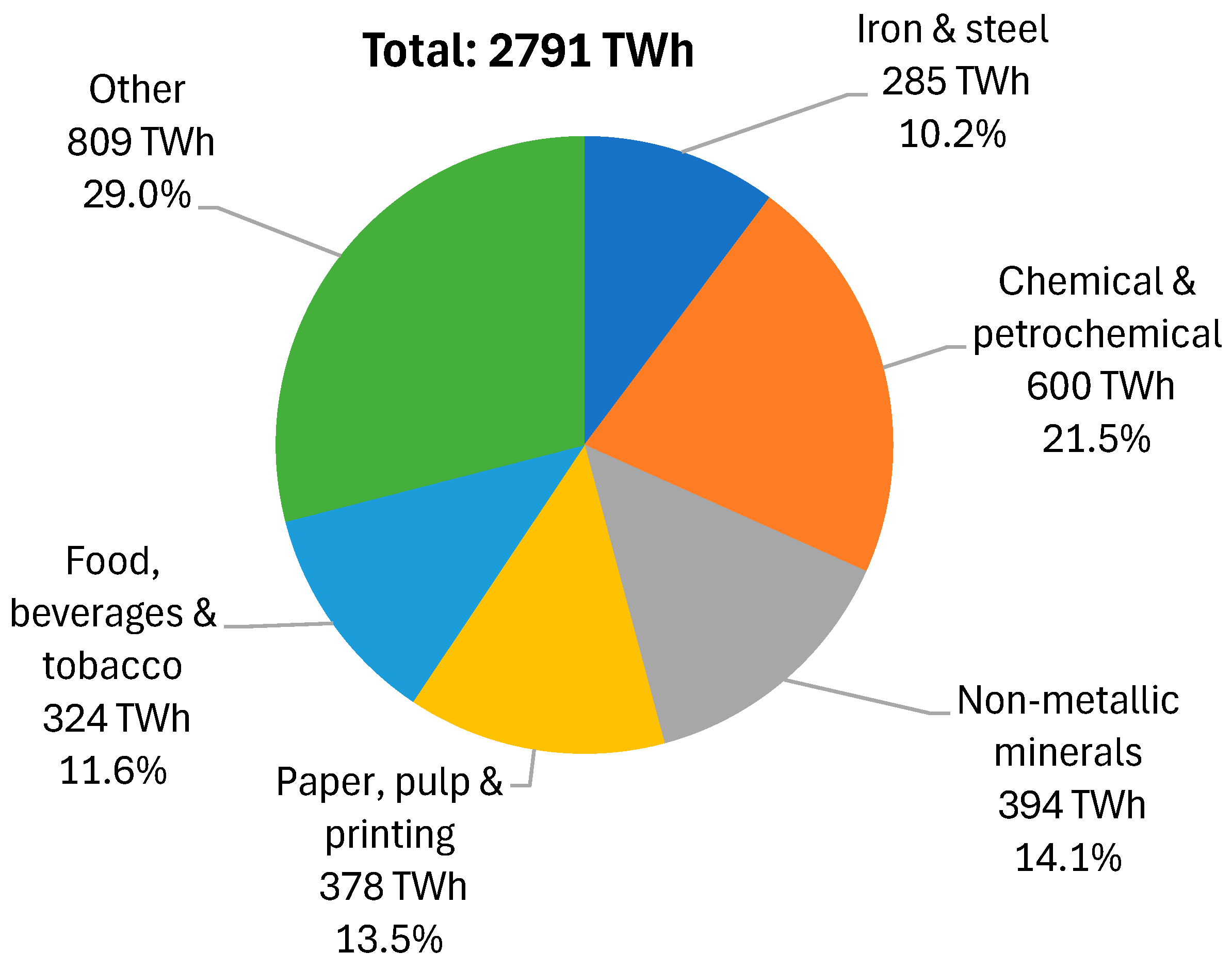

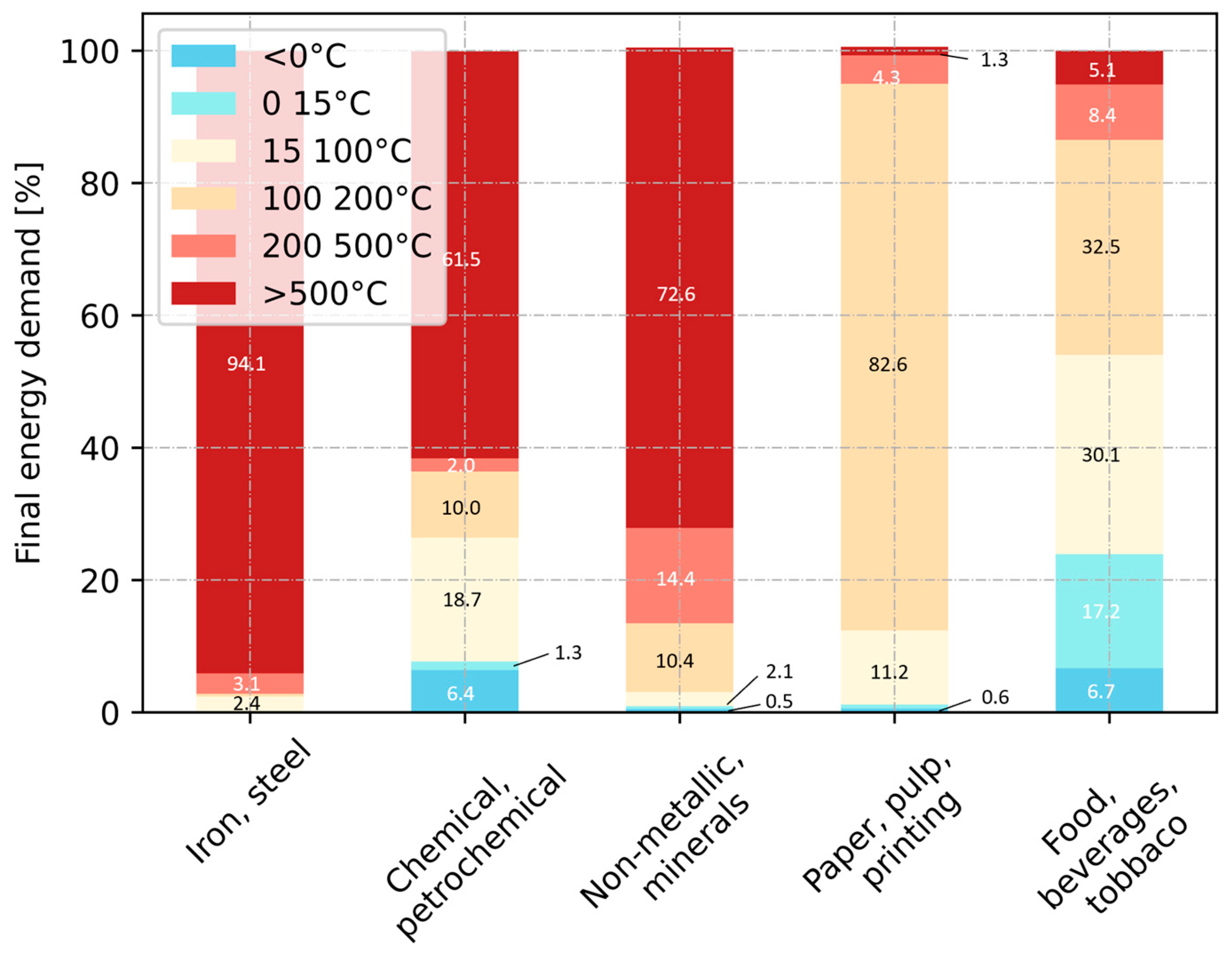

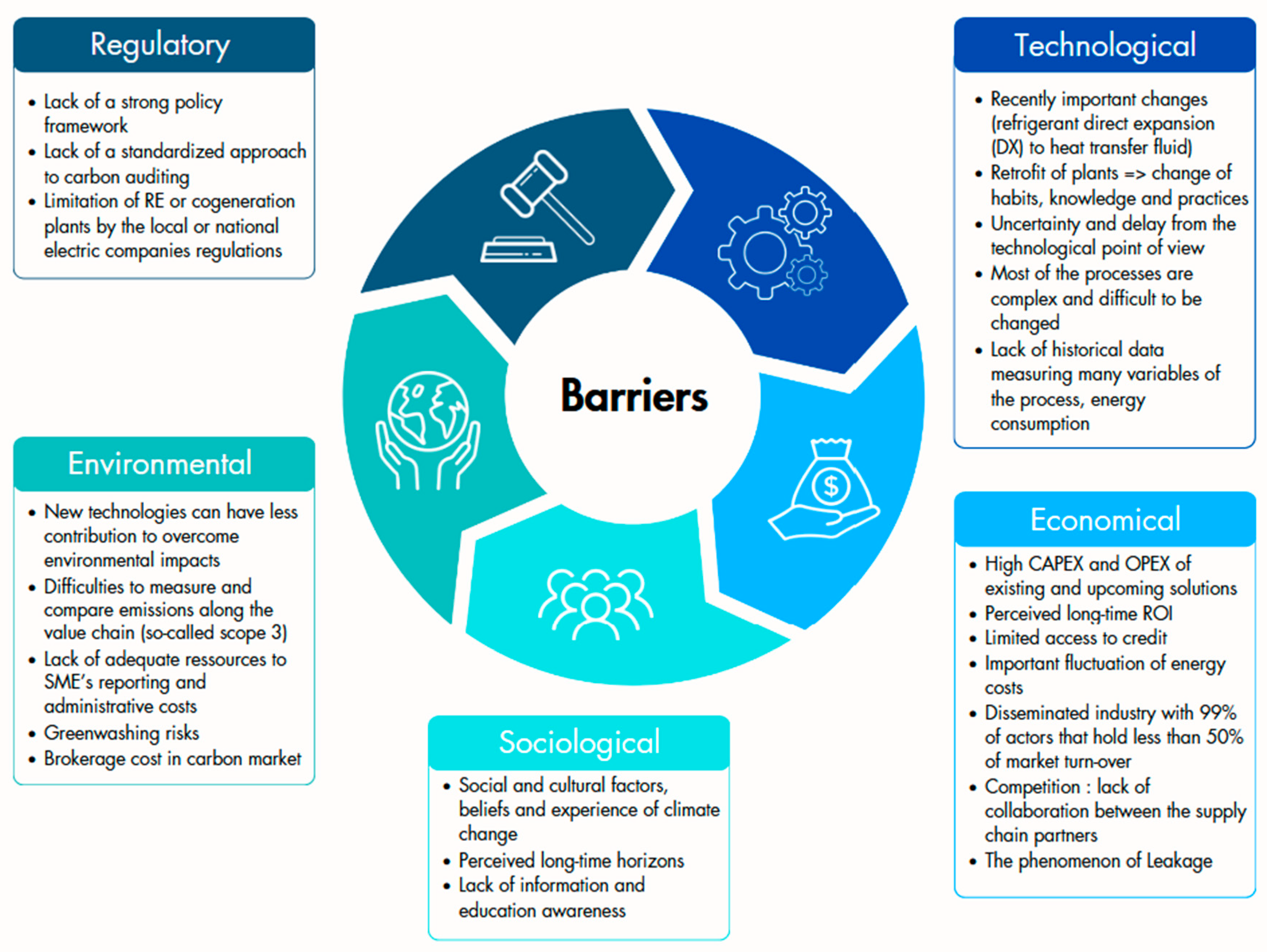

1. Introduction

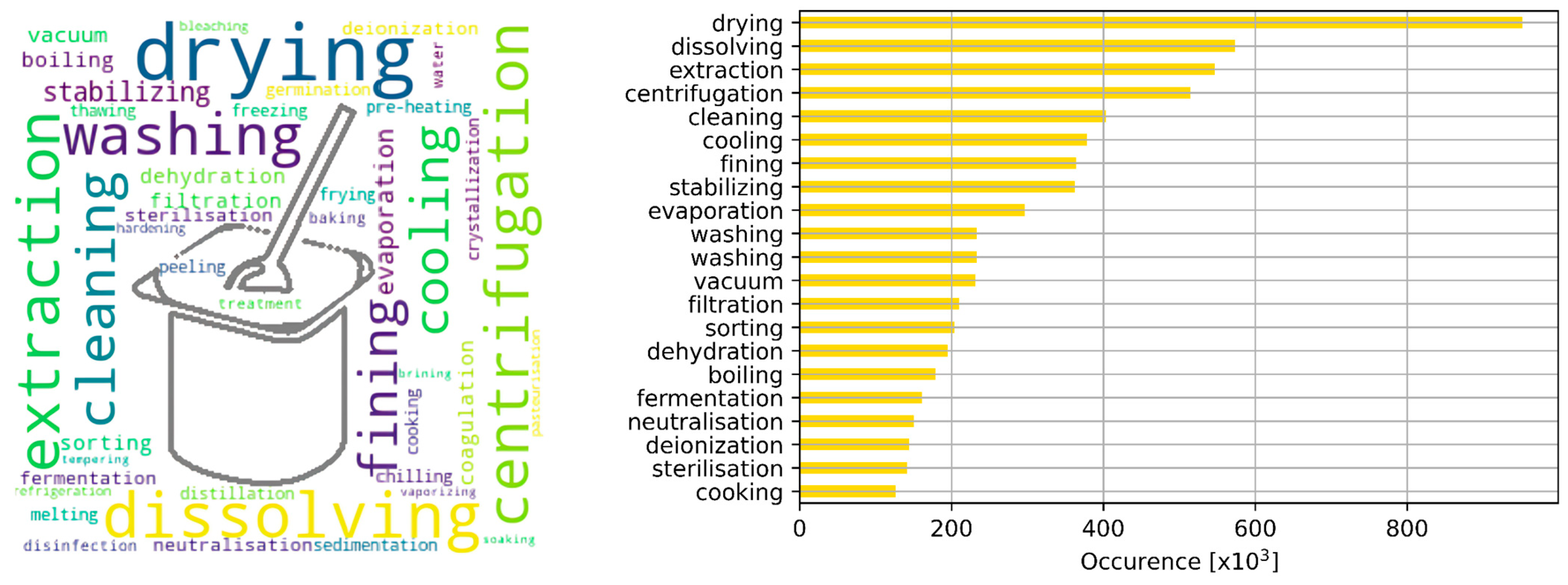

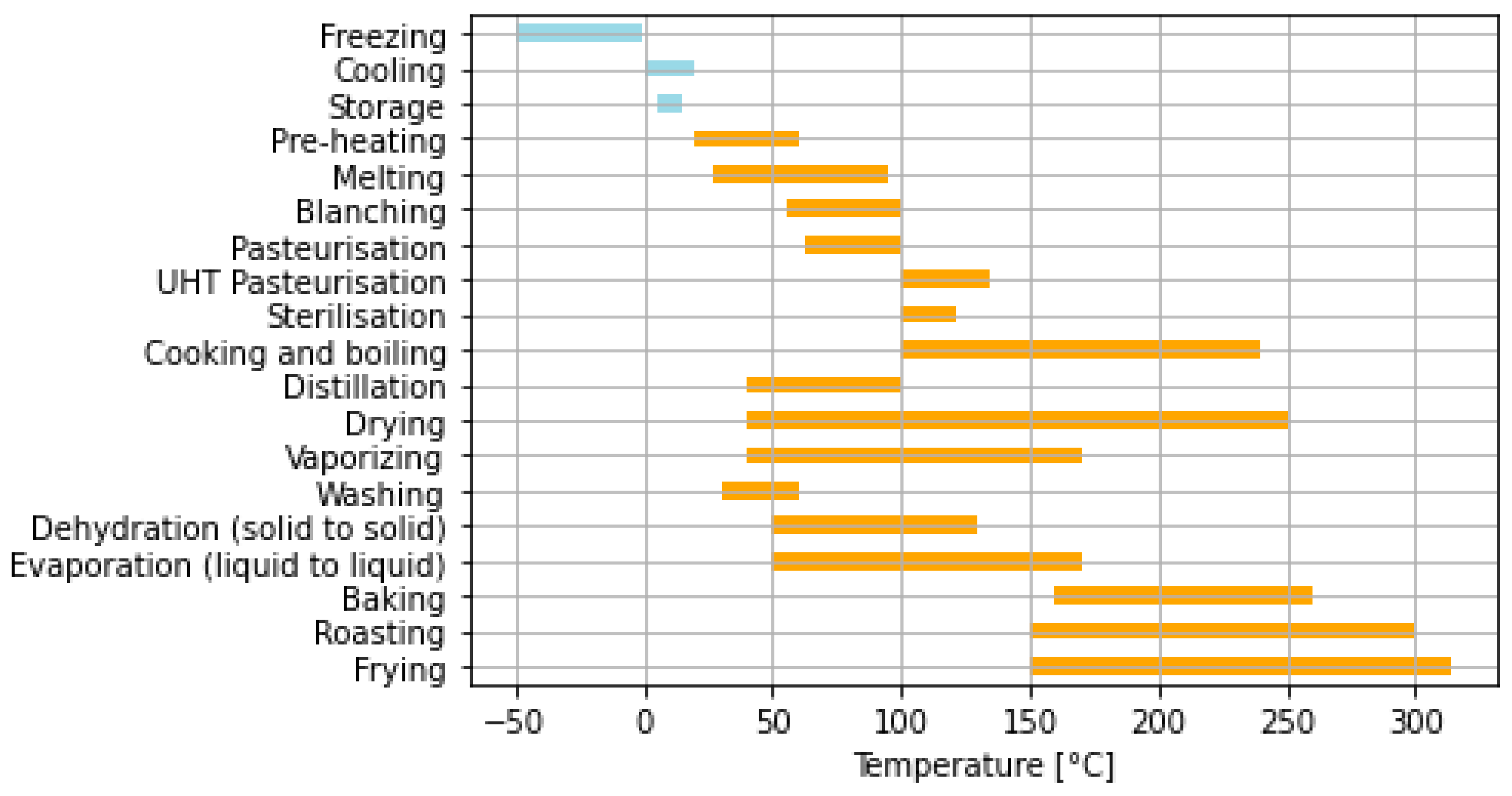

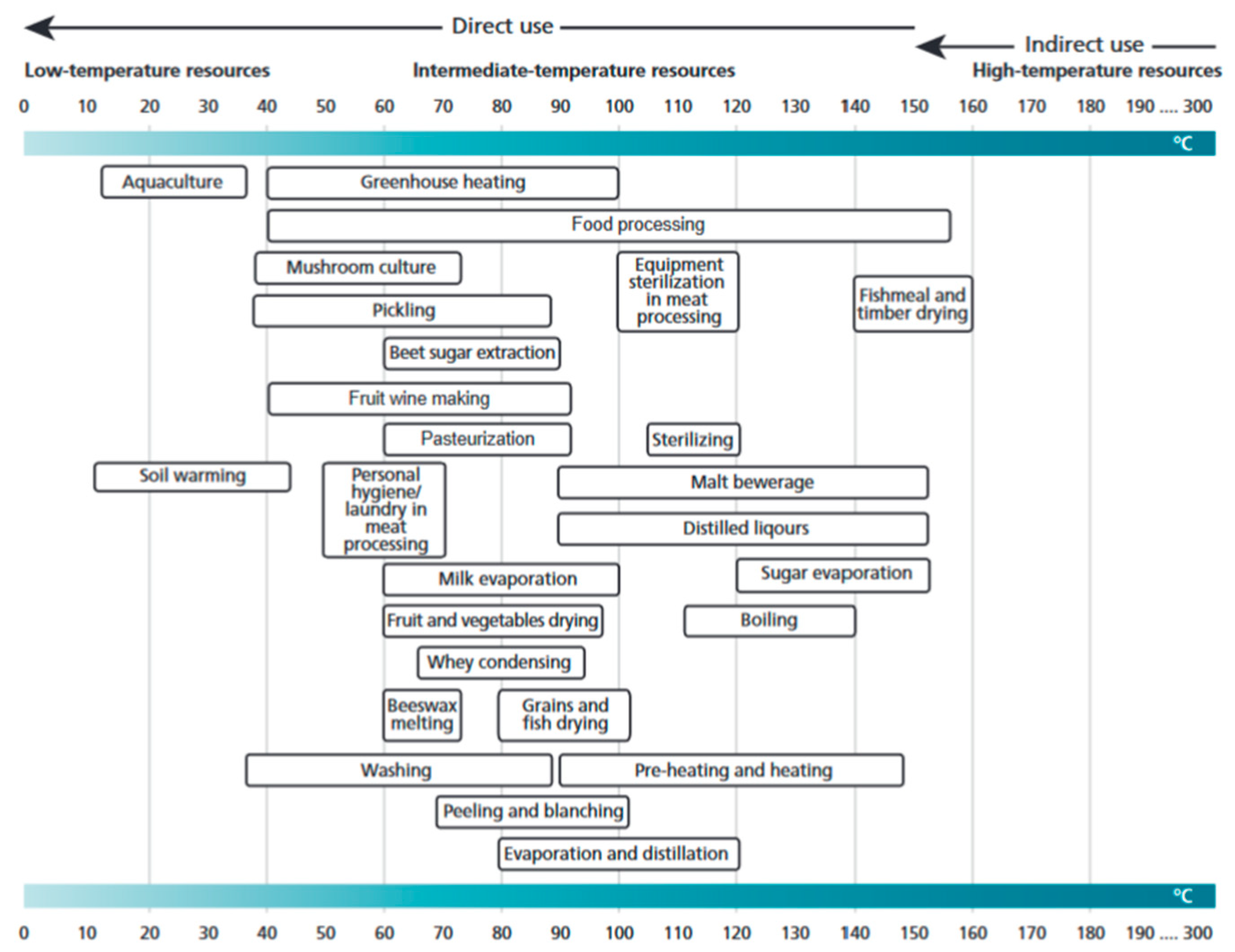

2. Perimeter Definition: Food Processes, Activities, and Temperature Levels

2.1. Dairy Application: Sterilized Milk Powder

| Process | Description | Product Temperature [°C] | Energy Consumption Total: 10.2 MJ/kg |

|---|---|---|---|

| Chilling | Milk cooled down for optional storage before the process | 4 | - |

| Thermization | For 15 s: allows to postpone pasteurization treatment for hours/days | 63–65 | 0.04 [0.4%] |

| Separation | Hot centrifugal separation to separate skimmed milk from cream | 50–52 | 0.08 [0.8%] |

| Pasteurization | Continuous pasteurization for 15–30 s | 72 | 2.1 [20.5%] |

| Chilling | If evaporation and pasteurization are not achieved inline | - | - |

| Evaporation/Concentration | Three-stage evaporation unit between 40 and 70 °C to increase solid content | 70 | 2.7 [26.8%] |

| Homogenization | Decrease fat globule size by two-stage at different pressures for flavor homogenization | - | 0.04 [0.4%] |

| Drying | Spray drying by atomization of concentrated milk at the top of the drying tower | 120–200 | 5.2 [51%] |

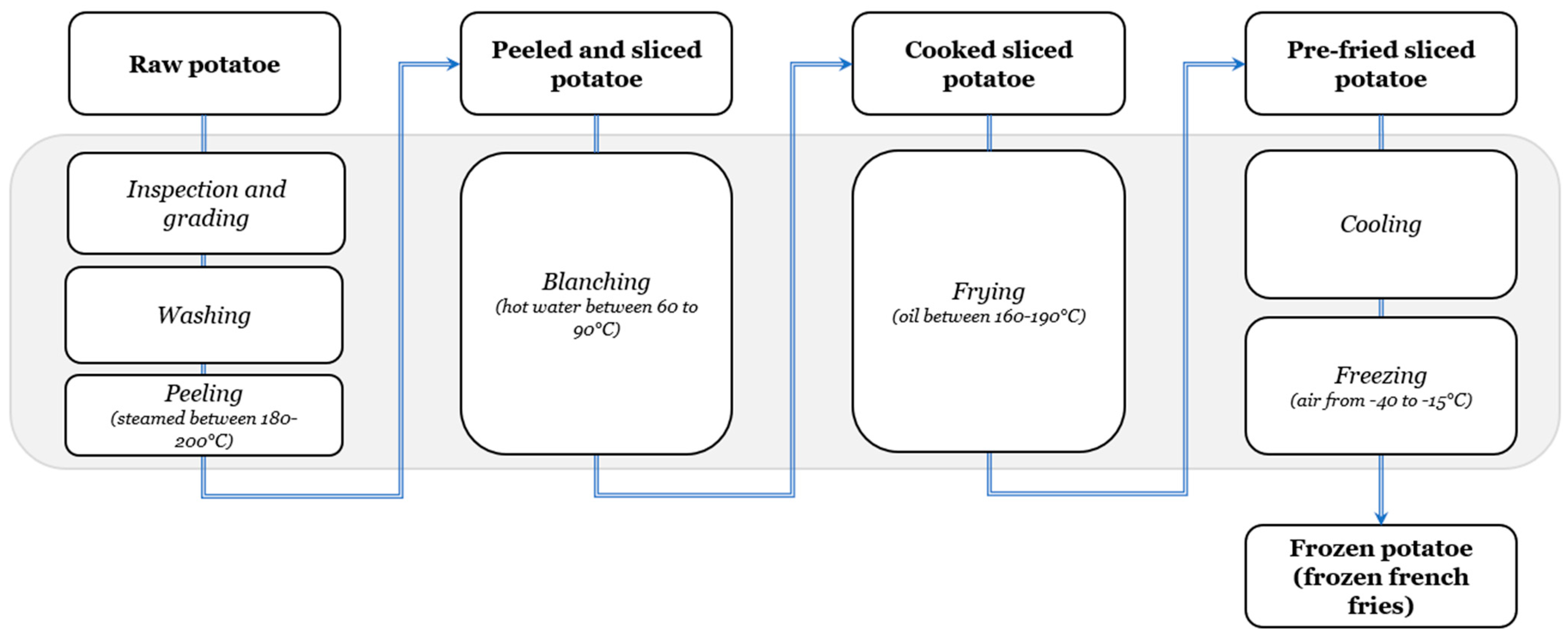

2.2. Frozen Catering: Frozen Potato Manufacture

3. Energy Efficiency and Decarbonation Potential

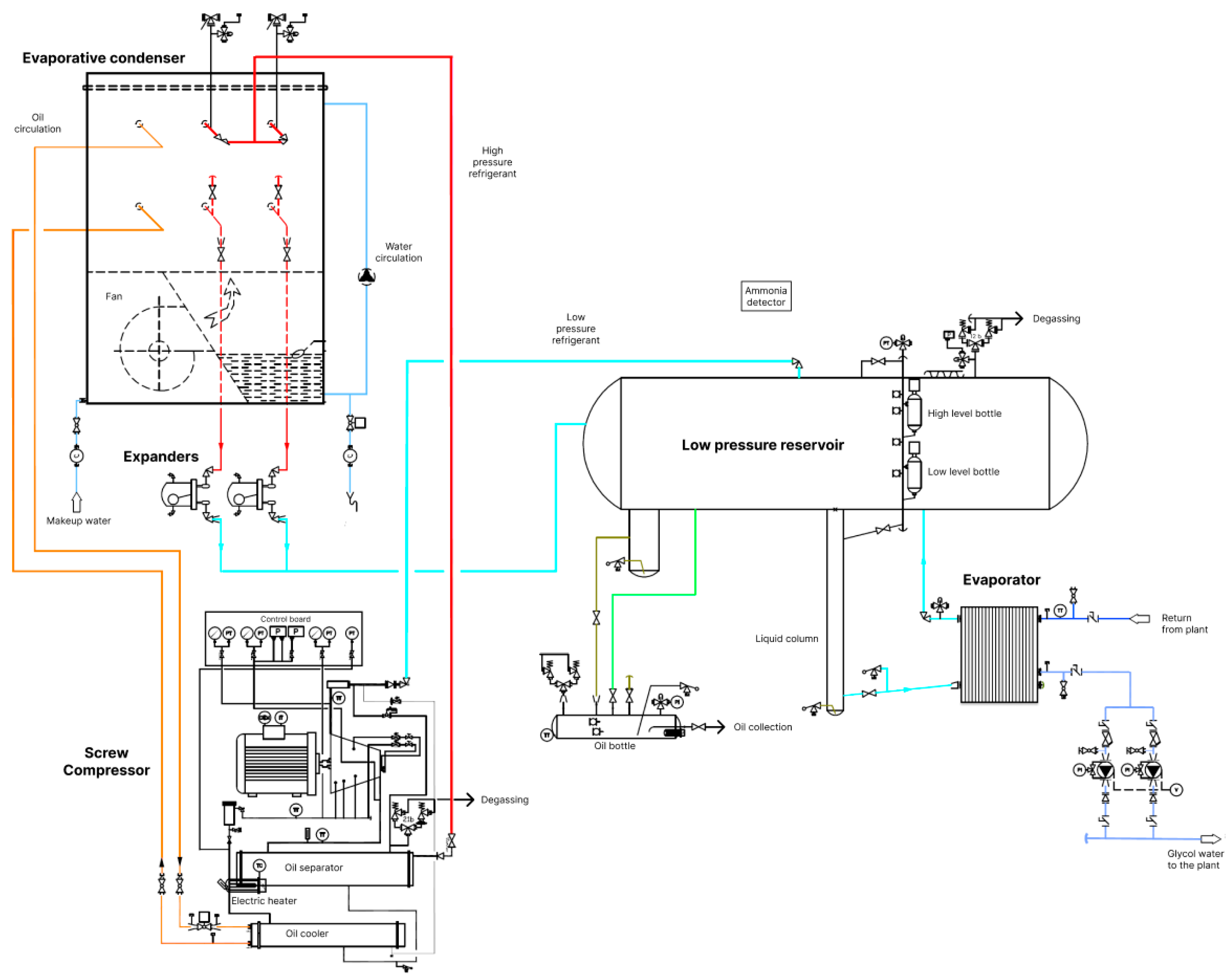

3.1. Refrigeration

3.1.1. Refrigerant Alternatives

3.1.2. Basic Refrigeration System

3.1.3. Enhanced Refrigeration Cycles

3.1.4. Summary of Solutions for Refrigeration Systems

3.2. Heat Generation

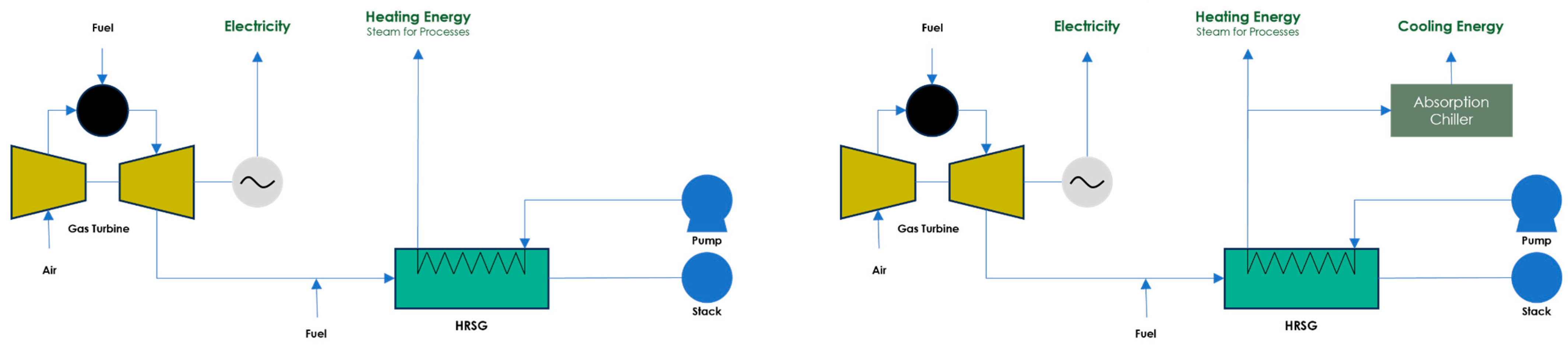

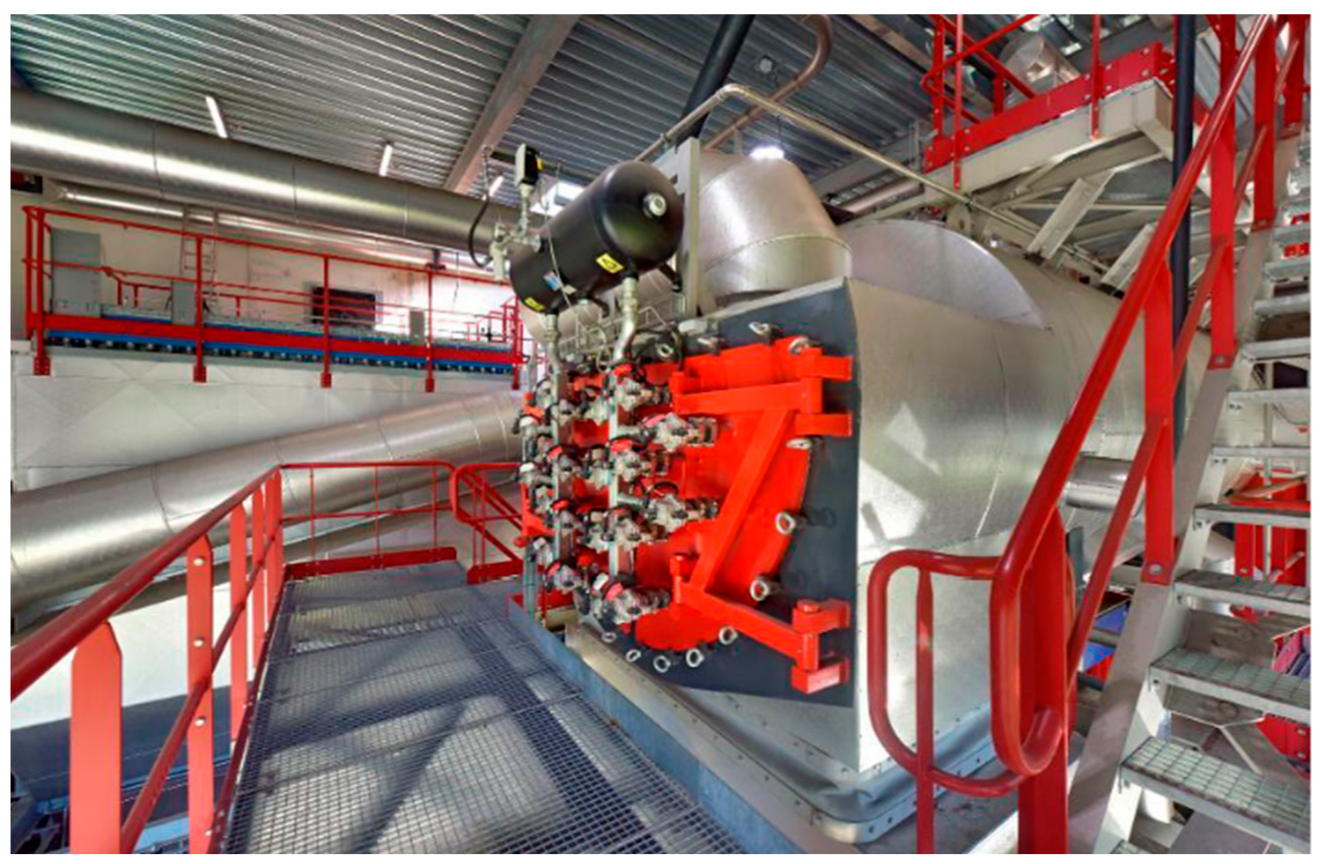

3.2.1. Combined Heat and Power (CHP) Systems

3.2.2. Biofuels and Hydrogen

3.2.3. Electro-Heating Technologies

Electric Immersion Heater

Alternative Thermal Processing

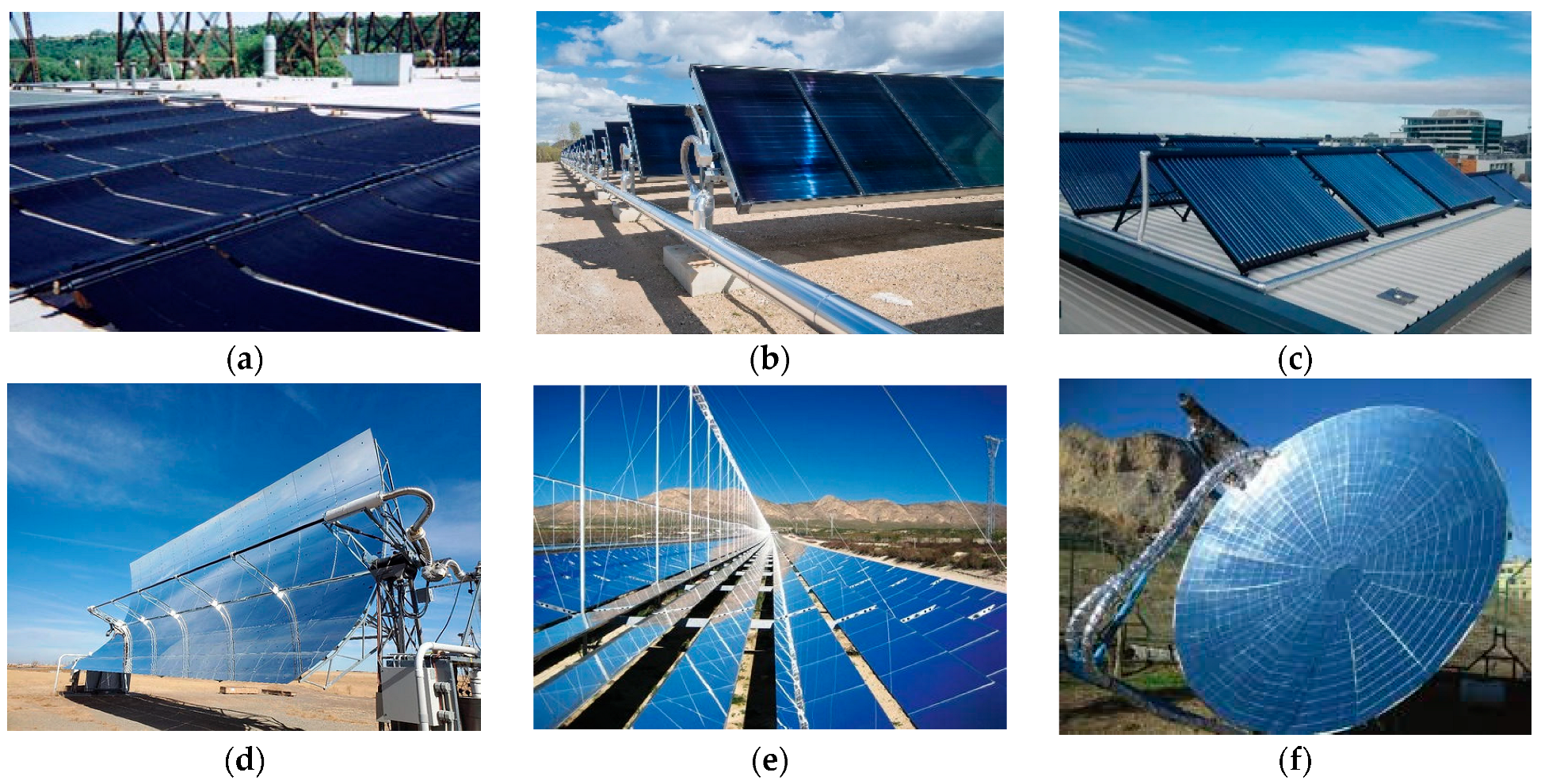

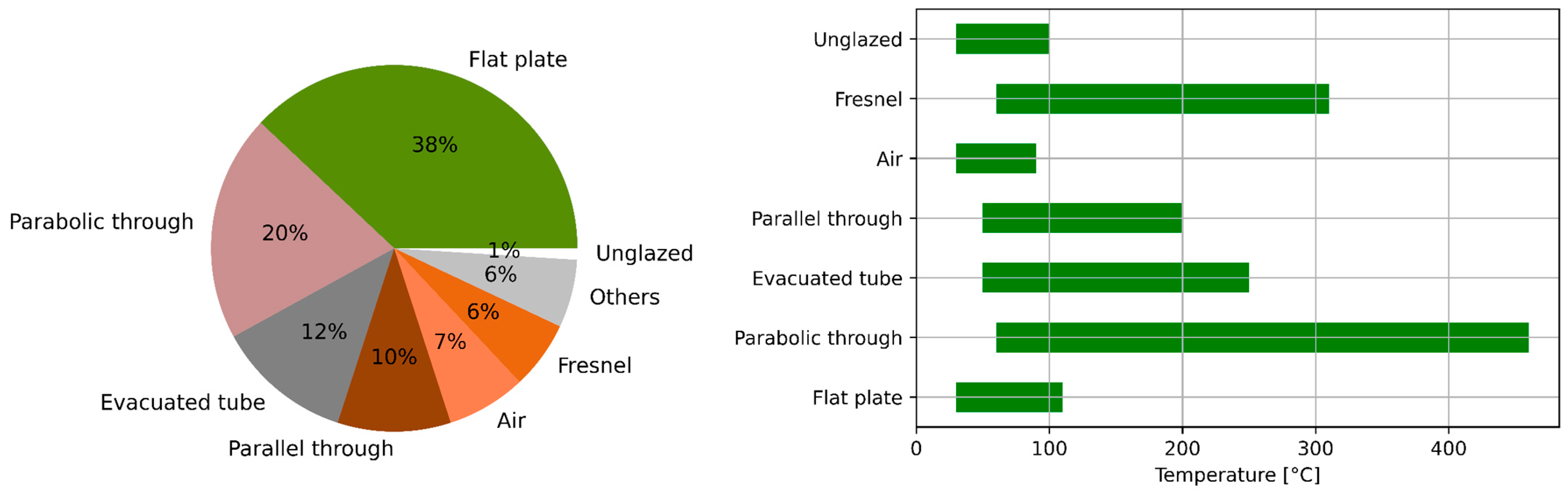

3.2.4. Solar Thermal

3.2.5. Geothermal

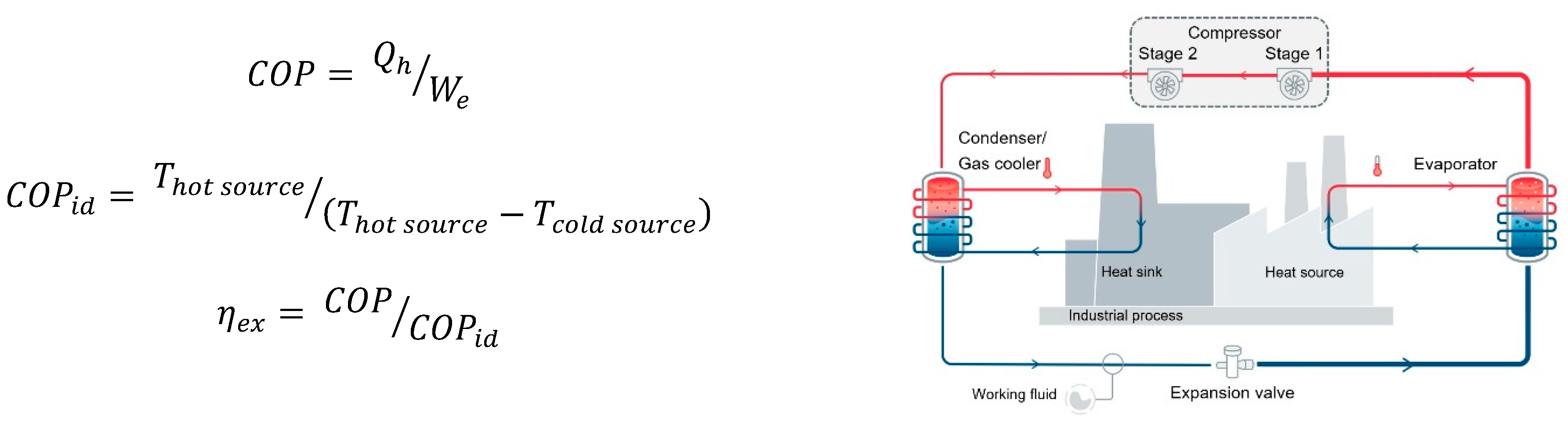

3.2.6. Vapor Compression Heat Pumps

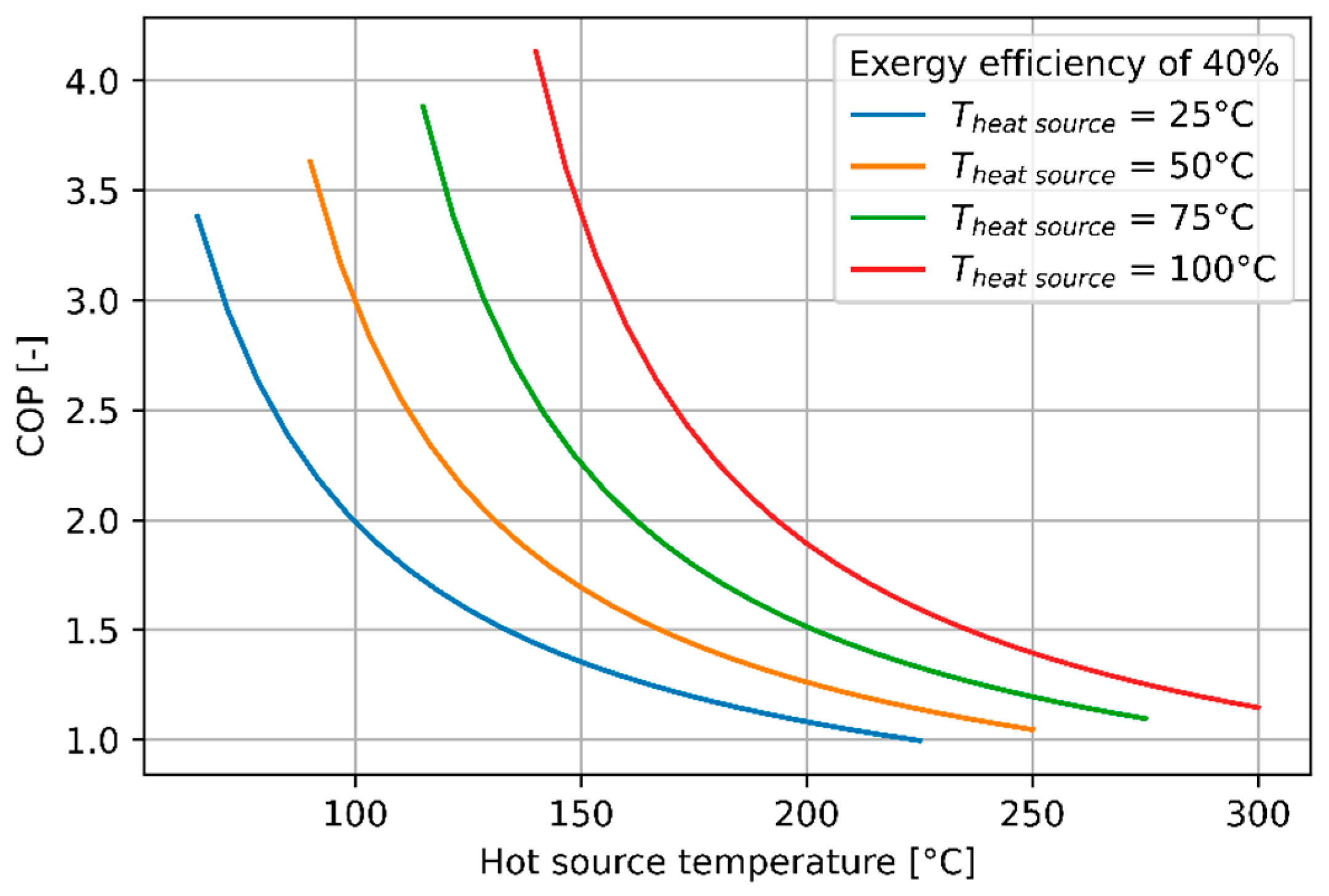

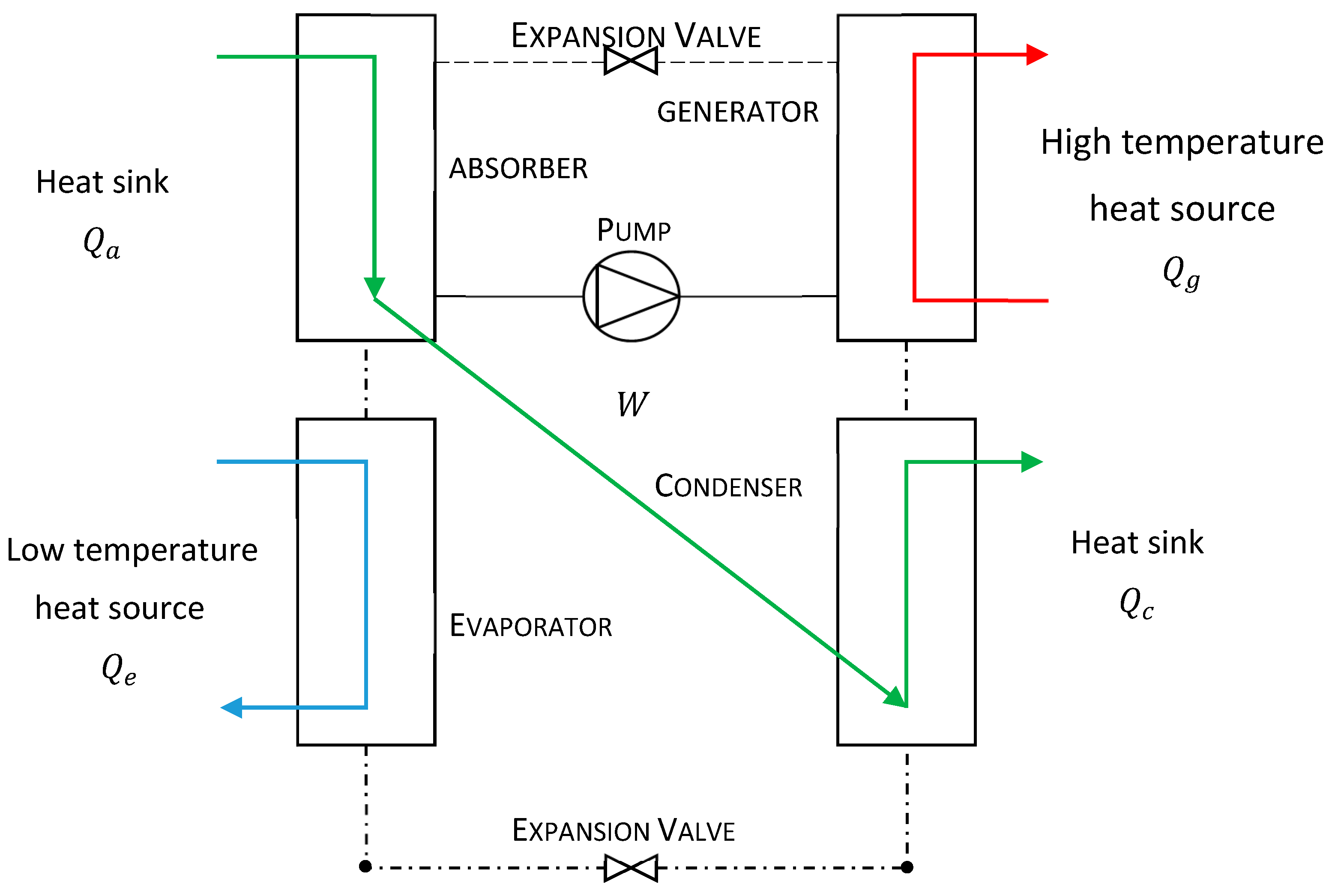

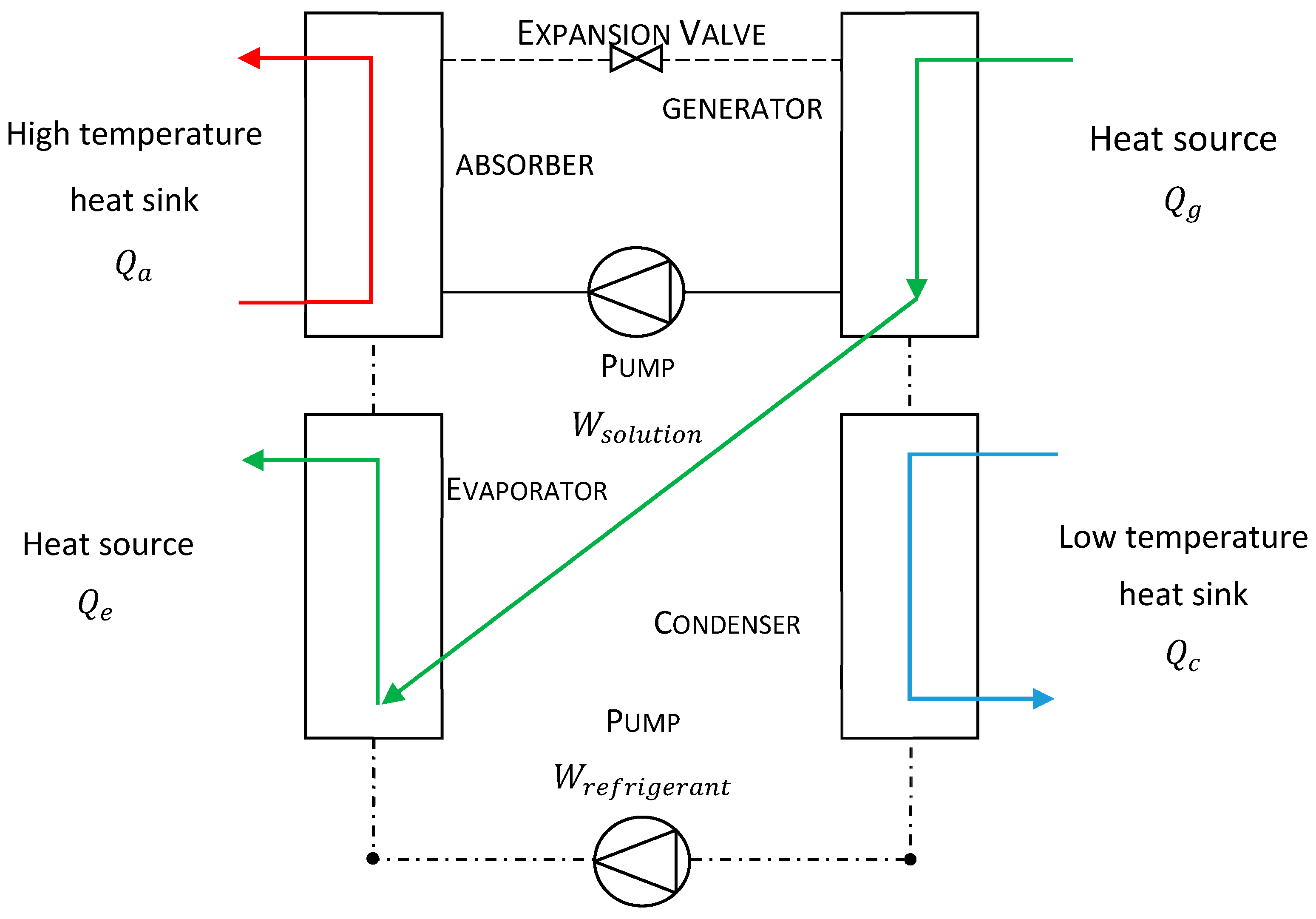

3.2.7. Ab/Adsorption Heat Pump (AHP) and Ab/Adsorption Heat Transformer (AHT)

3.3. Waste Heat Recovery

3.3.1. Direct Heat Recovery

| Location, Company | Application | Technology Modification | Energy Recovered and Energy Savings [MWhth/Year and %] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|

| Regenerative and recuperative burners: Novel designs of burner nozzles | |||||||

| - | Biscuit, chocolate, cake, and wafer manufacturing | Furnace heat recovery on hot exhaust flue gases | 44.9 - | - - | 2.15 | - | [195] |

| - | Wafer manufacturing | Baking oven heat recovery | 232 4.0% | 43 4.0% | - | 2017 | [196] |

| Egypt, Sana Foods | Sweets manufacturing | Heat recovery from the burner’s exhaust | 113.9 3.0% | 30 - | 1.6 | 2021 | [144] |

| Economisers and waste heat boilers: Pre-heating boiler feedwater | |||||||

| - | Biscuit, chocolate, cake, and wafer manufacturing | Furnace heat recovery on hot exhaust flue gases | 136 - | - - | 1.13 | - | [195] |

| - | Biscuit and crackers baking | Heat recovery from natural gas kilns for hot water and steam production | 5627 30% | 1’128 - | 1.5 | 2017 | [197] |

| - | - | Heat recovery from hot exhaust flue gases for air treatment water pre-heating | 53 - | 1100 - | 1.3 | - | [198] |

| - | Canning applications | Heat recovery from natural gas boiler flue gases | 4395 14% | 894 - | 2.5 | 2019 | [197] |

| Air pre-heaters: | |||||||

| United Kingdom | Wafer baking | Single oven air pre-heating | 385 6.7% | 71 - | 5.13 | - | [199] |

| Multiple oven air pre-heating | 1927 34% | 356 - | 1.57 | ||||

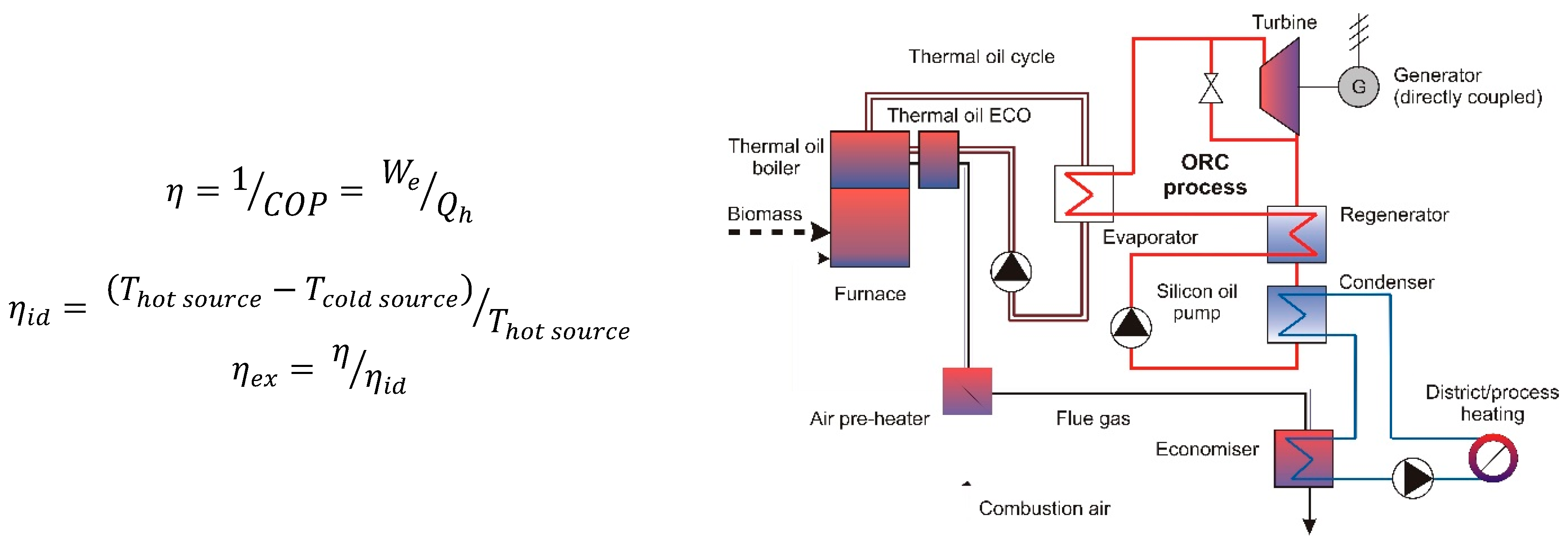

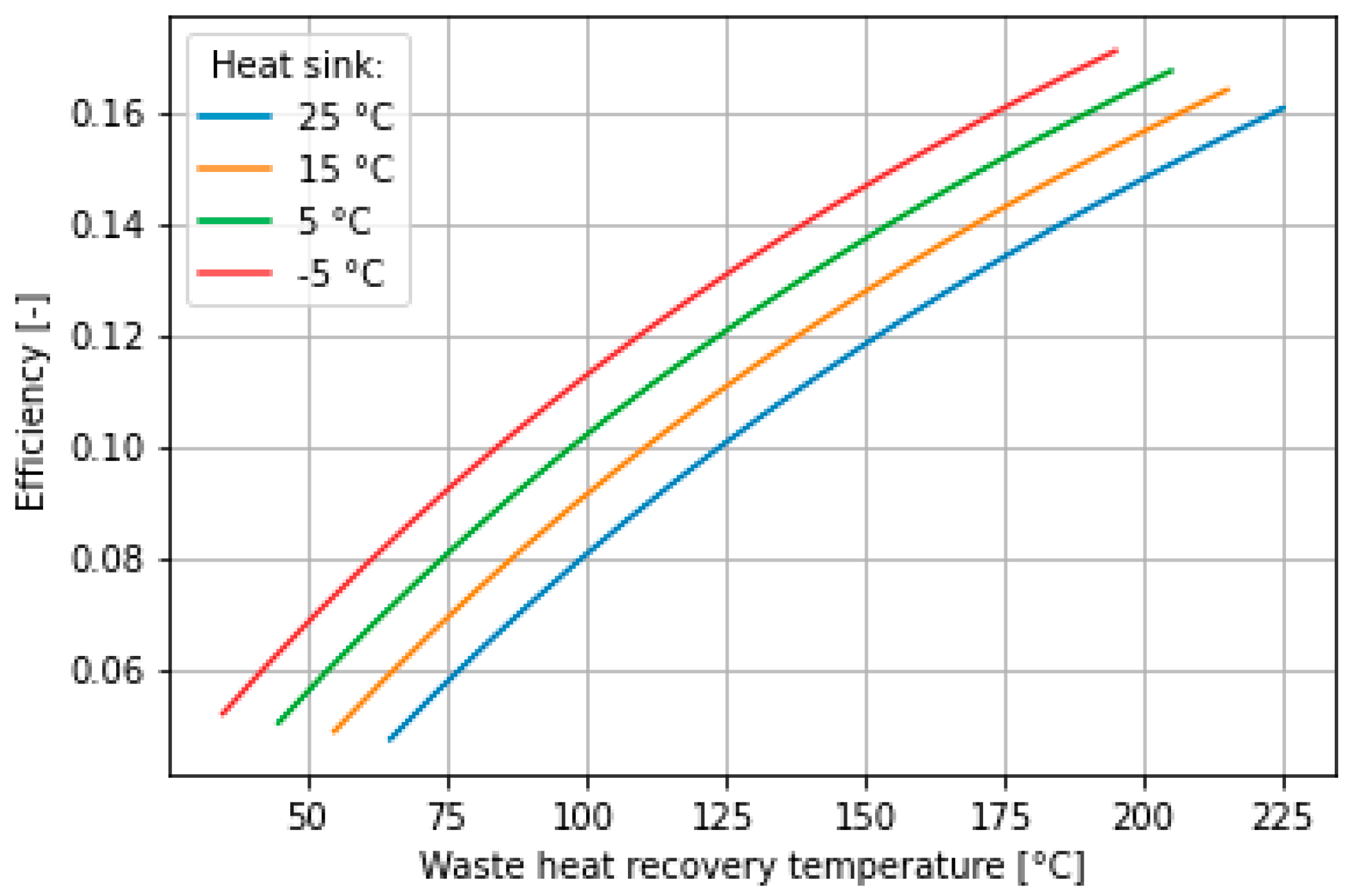

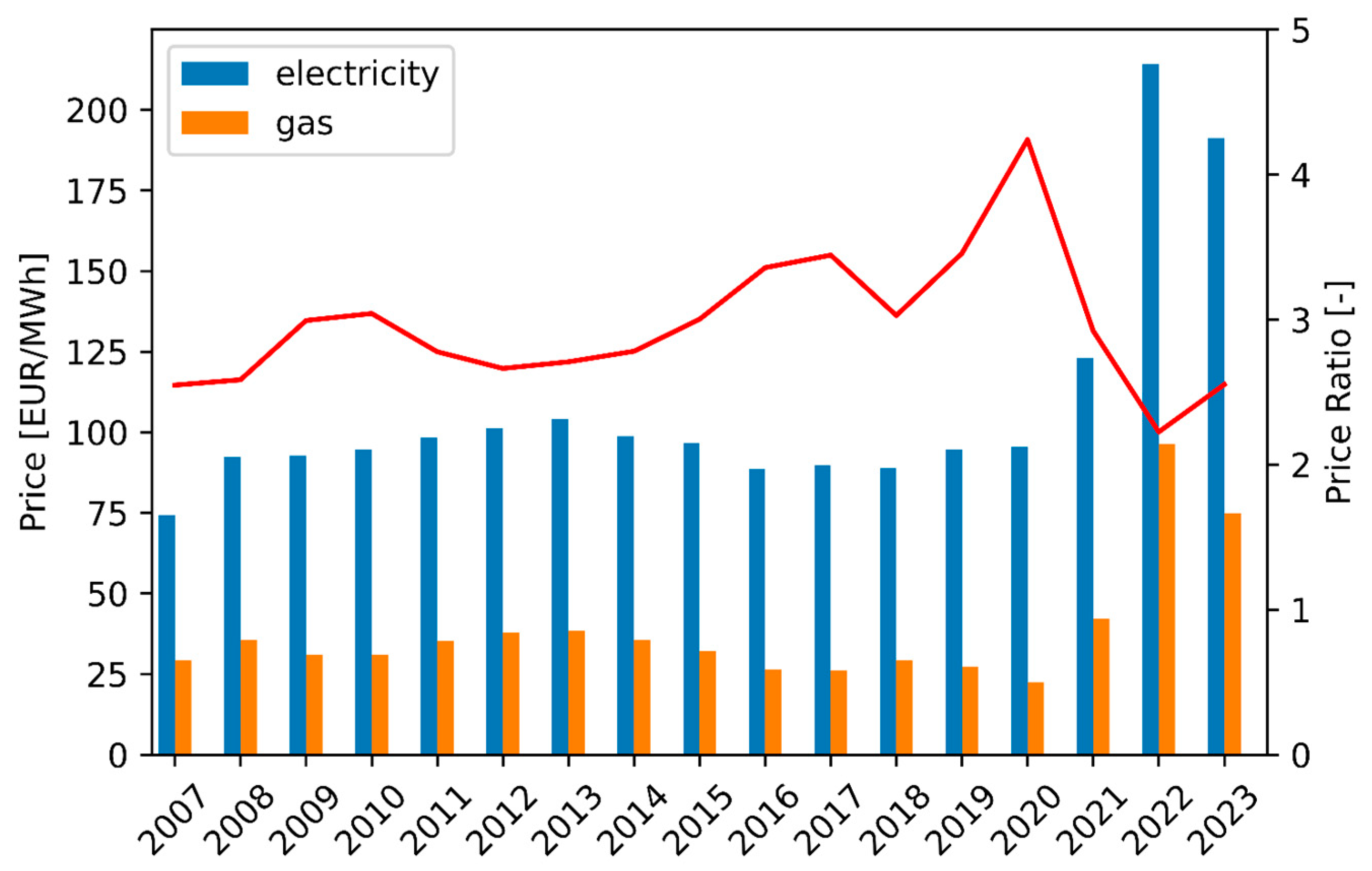

3.3.2. Heat-to-Power Thermodynamic Cycles

3.4. Thermal Energy Storage (TES)

3.4.1. Sensible Heat Storage

3.4.2. Latent Heat Storage

3.4.3. Thermochemical Heat Storage

4. Discussion

5. Conclusions

- The refrigeration sector presents an important consensus on technological options with refrigeration units and absorption chillers;

- Actions taken on the refrigerant replacement have been a great success with the successive and still ongoing phase-down of CFC and HFC fluids;

- Ammonia, CO2, (iso-)butane, and propane refrigerants seem to be the most promising fluids for tomorrow’s refrigeration systems;

- Improved leakage detection systems will significantly decrease direct emissions in the upcoming years;

- Energy efficiency improvements on unit’s components and penetration of renewable sources on the electricity mix will keep decreasing indirect emissions of refrigeration units;

- More advanced decarbonation options are still in the very early stages of development, such as radiation and passive cooling could provide increased performances, but their complex industrialization and economic interest could limit their market penetration.

- Biomass represents a great interest due to its operation similarity with fossil fuels and acceptable decarbonation potential and payback periods, but it only provides solutions when on-site biomass is made available by the product process;

- Solar thermal systems also show great potential for decarbonation due to their renewable aspect but suffer from long payback periods and a lack of reliability that requires them to be implemented in addition to existing systems;

- The most promising technologies for the agri-food sector are heat pumps and high-temperature heat pumps. With short payback periods and important decarbonation potential, their market penetration should be important in the upcoming years, thanks to their recent technological maturity;

- The only limitation highlighted in the reviewed articles is the requirement of waste-heat sources to provide sufficient COP and ensure interesting payback periods. Temperature lifts between 40 and 80 K limit today’s technologies;

- The development of heat pumps with greater efficiencies reaching temperature lifts of 120 to 160 K could provide an extremely interesting option to industrials, as they could cover the major temperature range between −20 °C and 140 °C;

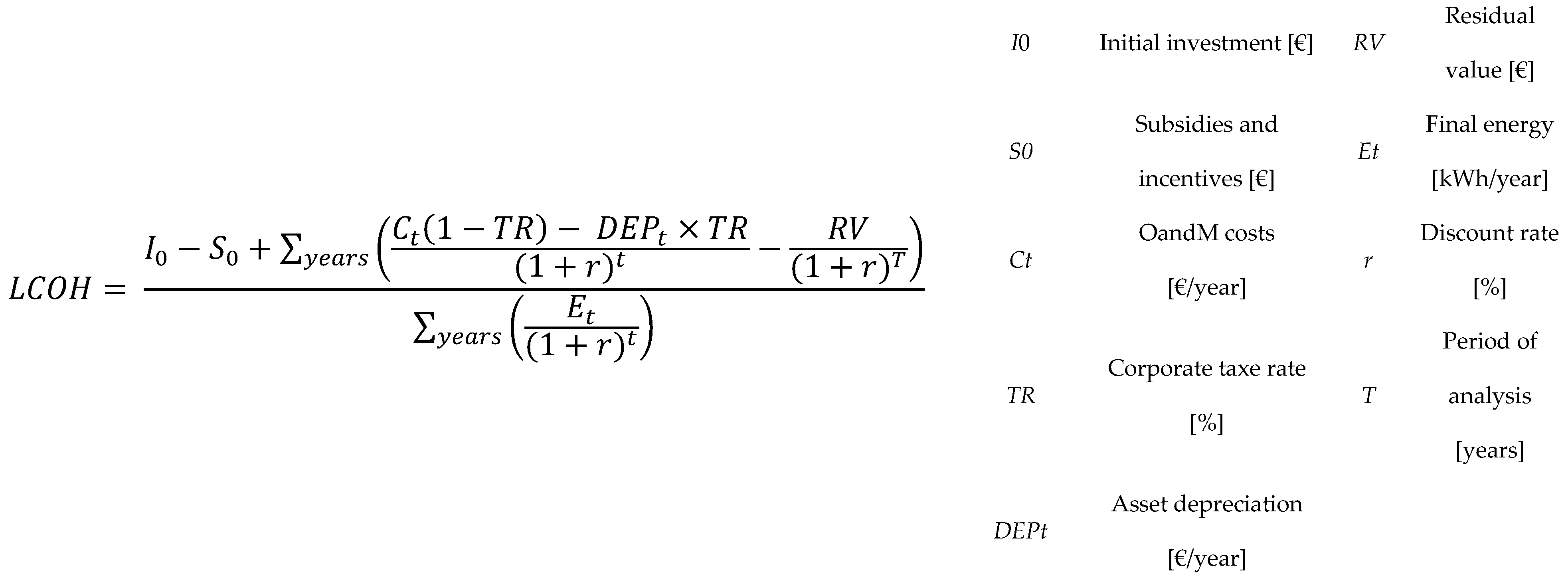

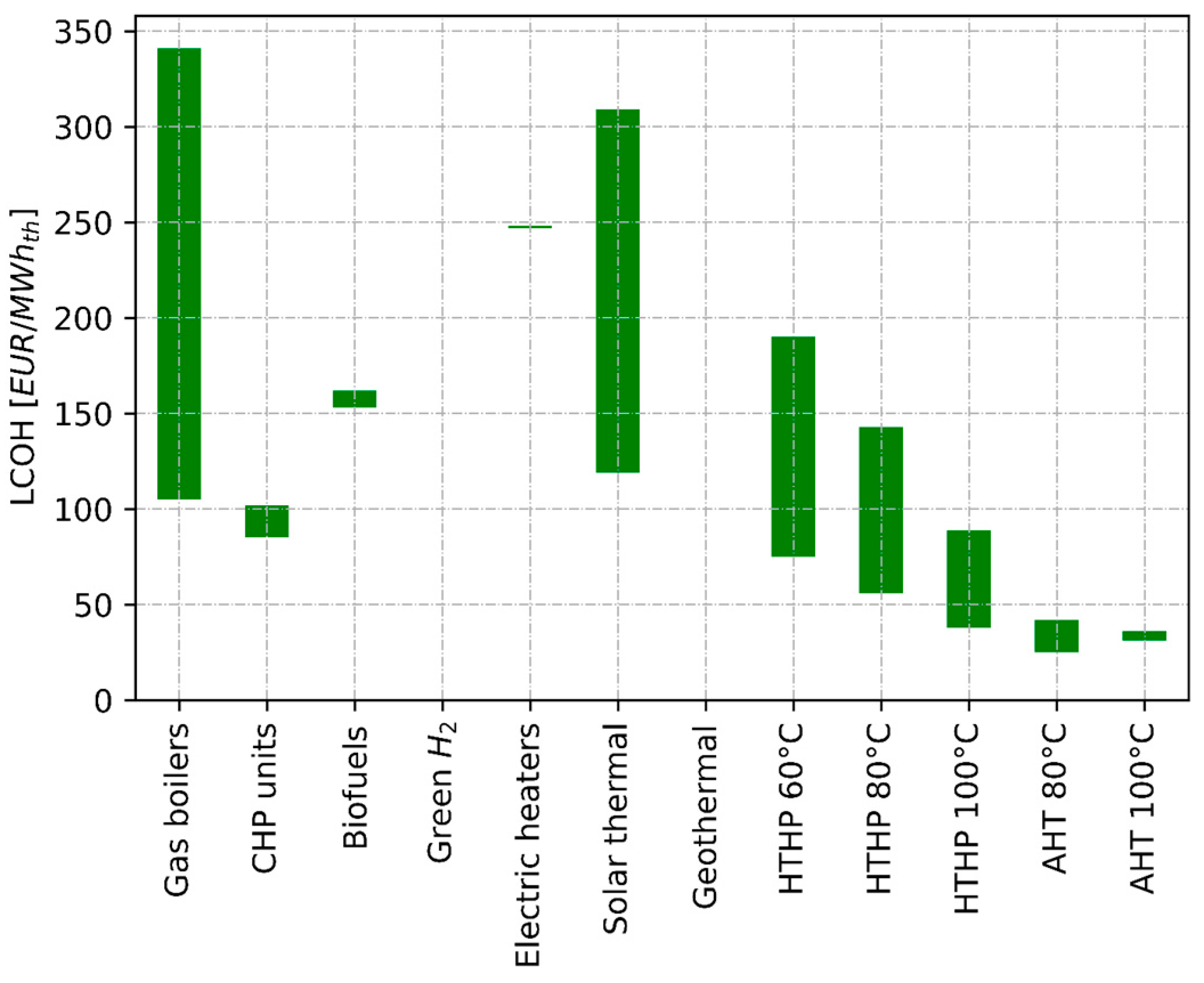

- The LCOH analysis comes in addition to the review of payback periods, as it allows us to compare technologies on similar applications. This analysis presented AHTs and HTHPs as the most interesting technologies;

- The solutions with shorter payback periods are waste heat recovery applications. However, their decarbonation potential remains very limited;

- Storage technologies, possibly coupled with the emerging concepts of “polygeneration systems” and “smart industries”, illustrate the need for complementarity of existing technological solutions;

- Even if technological solutions present a great improvement potential from the economic and emissions points of view, considering all steps, from farm to fork, it appears necessary to redesign the agri-food industry, especially the society diets that provide an incomparable impact on the entire food chain GHG emissions.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pörtner, H.-O.; Roberts, D.C.; Poloczanska, E.S.; Mintenbeck, K.; Tignor, M.; Alegría, A.; Craig, M.; Langsdorf, S.; Löschke, S.; Möller, V.; et al. Climate Change 2022—Impacts, Adaptation and Vulnerability; Cambridge University Press: Cambridge, UK. [CrossRef]

- Olsson, O.; Schipfer, F. Decarbonizing Industrial Process Heat: The Role of Biomass. IEA Bioenergy Task 40: IEA Bioenergy Inter-Task Project on Industrial Process Heat. 2021. Available online: https://www.ieabioenergy.com/wp-content/uploads/2022/02/Role-of-biomass-in-industrial-heat.pdf (accessed on 30 April 2024).

- Hodgson, D.; Vass, T.; Levi, P.; Hugues, P.; Industry. IEA. 2022. Available online: https://www.iea.org/reports/industry (accessed on 30 April 2024).

- Eurostat Database: Simplified Energy Balances. 2023. Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_bal_s/default/table?lang=en (accessed on 30 April 2024).

- Montforti-Ferrario, F.; Pinedo Pascua, I. Energy Use in the EU Food Sector: State of Play and Opportunities for Improvement. JRC Science and Policy Report; Publications Office of the European Union: Luxembourg, 2015. [Google Scholar] [CrossRef]

- Camero, I.; Lopez, A.; Yule, A. Decarbonisation Roadmap for the European Food and Drink Manufacturing Sector—Ricardo Energy. 2021. Available online: https://www.fooddrinkeurope.eu/resource/decarbonising-the-food-and-drink-manufacturing-sector/ (accessed on 30 April 2024).

- Ladha-Sabur, A.; Bakalis, S.; Fryer, P.J.; Lopez-Quiroga, E. Mapping energy consumption in food manufacturing. Trends Food Sci. Technol. 2019, 86, 270–280. [Google Scholar] [CrossRef]

- Li, M.J.; Tao, W.Q. Review of methodologies and polices for evaluation of energy efficiency in high energy-consuming industry. Appl. Energy 2017, 187, 203–215. [Google Scholar] [CrossRef]

- Office for National Statistics. Food and Drink Service Firms Are the Most Likely to Cut Trading to Tackle the Energy Cost, Survey; Office for National Statistics: London, UK, 2022. [Google Scholar]

- Bua, G.; Kapp, D.; Kuik, F.; Lis, E. EU Emissions Allowance Price in the Context of the ECB’s Climate Change Action Plan. ECB Econ. Bull. 2021, 6. Available online: https://www.ecb.europa.eu/pub/economic-bulletin/focus/2021/html/ecb.ebbox202106_05~ef8ce0bc70.en.html (accessed on 30 April 2024).

- European Union Eurostat. Available online: https://ec.europa.eu/eurostat/ (accessed on 13 March 2024).

- Mathieu, Q. Quel impact du choc du prix de l’énergie sur l’industrie agroalimentaire. Brief Ecocoops 2022, 3, 1–4. [Google Scholar]

- GMK Center LLC. Carbon Price in the EU in 2023; GMK Center LLC: Kyiv, Ukraine, 2023. [Google Scholar]

- Fluch, J.; Brunner, C.; Grubbauer, A. Potential for energy efficiencies measures and integration of renewable energy in the European food and beverage industry based on the results of implemented projects. Energy Procedia 2017, 123, 148–155. [Google Scholar] [CrossRef]

- European Commission Website. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 30 April 2024).

- Eurostats Statistics Explained, Final Energy Consumption in Industry—Detailed Statistics. 2023. Data Extracted in May 2023. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Final_energy_consumption_in_industry_-_detailed_statistics#Energy_products_used_in_the_industry_sector (accessed on 30 April 2024).

- Directorate General for Energy, 2016. Mapping and Analyses of the Current and Future (2020–2030) Heating/Cooling Fuel Deployment (Fossil/Renewables). Work Package 1: Final Energy Consumption for the Year 2012. Available online: https://irees.de/wp-content/uploads/2020/06/mapping-hc-final_report_wp1.pdf (accessed on 30 April 2024).

- Ozilgen, M. Energy utilization and carbone dioxide emissions during production of snacks. J. Clean. Prod. 2016, 112, 2601–2612. [Google Scholar] [CrossRef]

- Degerli, B.; Nazir, S.; Sorguven, S.; Hitzmann, B.; Ozilgen, M. Assessement of the energy and exergy efficiencies of farm to fork grain cultivation and bread making processes in Turkey and Germany. Energy 2015, 93, 421–434. [Google Scholar] [CrossRef][Green Version]

- Bartlett, N.; Whittington, E.; Reuvers, S.; Thoday, K. Driving Low-Carbon Growth through Business and Investor Action Overview. Seizing the Global Opportunity: Partnerships for Better Growth and a Better Climate; New Climate Economy: London, UK; Washington, DC, USA, 2016; pp. 1–36. [Google Scholar]

- Clairand, J.M.; Briceno-Leon, M.; Escriva, G.; Marco Pantaleo, A. Review of Energy Efficiency technologies in the food industry: Trends, barriers and opportunities. IEEE Access 2020, 8, 48015–48029. [Google Scholar] [CrossRef]

- Acampora, A.; Ruini, L.; Mattia, G.; Pratesi, C.A.; Lucchetti, M.C. Towards neutrality in the agrifood sector: Drivers and barriers. Resour. Conserv. Recycl. 2023, 189, 106755. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. FAO Statistical Yearbook 2013; Food and Agriculture Organization of the United Nation: Rome, Italy, 2013. [Google Scholar]

- Web of Science. Available online: https://www.webofscience.com/wos/ (accessed on 15 March 2024).

- IEA. Application of Industrial Heat Pumps. Task 1: Heat Pump Energy situation, Energy use, Market overview, Barriers for application. Final Report. IEA Industrial Energy-Related Systems and Technologies Annex 13, IEA Heat Pump Programme Annex 35. Available online: https://jeh-center.org/asset/00032/Annex35/05%20Final%20Report_Task1.pdf (accessed on 30 April 2024).

- Thermal Processing of Foods. Available online: https://ocm.govtsciencecollegedurg.ac.in/Document/638_045450.pdf (accessed on 30 April 2024).

- Safefood 360°. Thermal Processing of Foods, White Paper. Available online: https://www.tiselab.com/pdf/Thermal-Processing-of-Food.pdf (accessed on 30 April 2024).

- Giner Santonja, G.; Karlis, P.; Stubdrup, K.; Brinkmann, T.; Roudier, S. Best Available Techniques (BAT) Reference Document for the Food, Drink and Milk Industries. Industrial Emissions Directive 2010/75/EU (Integrated Pollution Prevention and Control), EUR 29978 EN; Publications Office of the European Union: Luxembourg, 2019; ISBN 978-92-76-13091-8. [Google Scholar] [CrossRef]

- Sruthi, N.U.; Premjit, Y.; Pandiselvam, R.; Kothakota, A.; Ramesh, S.V. An overview of conventional and emerging techniques of roasting: Effect on food bioactive signatures. Food Chem. 2021, 348, 129088. [Google Scholar] [CrossRef]

- Rani, L.; Kumar, M.; Kaushik, D.; Kaur, J.; Kumar, A.; Oz, F.; Proestos, C.; Oz, E. A review on the frying process: Methods, models and their mechanism and application in the food industry. Food Res. Int. 2023, 172, 113176. [Google Scholar] [CrossRef] [PubMed]

- High Temperature Frying. IARC Monographs 95. Available online: https://publications.iarc.fr/_publications/media/download/2887/caae473f264312a90030548ef9c31823f5c7c2a2.pdf (accessed on 30 April 2024).

- Ramirez, C.A.; Patel, M.; Blok, K. From milk to milk powder: Energy use and energy efficiency in the European dairy industry. Energy 2006, 12, 1984–2004. [Google Scholar] [CrossRef]

- Masera, K.; Tannous, H.; Stojceska, V.; Tassou, S. An investigation of recent advances of the integration of solar thermal energy systems in the dairy processes. Renew. Sustain. Energy Rev. 2023, 172, 113028. [Google Scholar] [CrossRef]

- Moejes, S.N.; van Boxtel, A.J.B. Energy potential of emerging technologies in milk powder production. Trends Food Sci. Technol. 2017, 60, 31–42. [Google Scholar] [CrossRef]

- Camci, M. Thermodynamic analysis of a novel integration of a spray dryer and solar collectors: A case study of a milk powder drying system. Dry. Technol. 2020, 38, 350–360. [Google Scholar] [CrossRef]

- Sobulska, M.; Wawrzyniak, P.; Woo, M.W. Superheated Steam Spray Drying as an Energy-Saving Drying Technique: A Review. Energies 2022, 15, 8546. [Google Scholar] [CrossRef]

- Uçal, E.; Yildizhan, H.; Ameen, A.; Erbay, Z. Assessment of Whole Milk Powder Production by a Cumulative Exergy Consumption Approach. Sustainability 2023, 15, 3475. [Google Scholar] [CrossRef]

- Walmsley, T.G.; Atkins, M.J.; Walmsley, M.R.W.; Philipp, M.; Peesel, R.-H. Process and utility system integration and optimization for ultra-low energy milk powder production. Energy 2018, 146, 67–81. [Google Scholar] [CrossRef]

- Shah, H. Integration of Solar Thermal Collectors in the Dairy Industry: A Techno–Economic Assessment—A Case Study of Dubai. Master’s Thesis, Uppsala University, Uppsala, Sweden, 2021. Available online: https://www.diva-portal.org/smash/get/diva2:1568353/FULLTEXT01.pdf (accessed on 30 April 2024).

- Bühler, F.; Zühlsdorf, B.; Nguyen, T.V.; Elmegaard, B. A comparative assessment of electrification strategies for industrial sites: Case of milk powder production. Appl. Energy 2019, 250, 1383–1401. [Google Scholar] [CrossRef]

- Astute Analytica. Global Frozen Food Market; Astute Analytica: Noida, India, 2022. [Google Scholar]

- West, K.J.; de Jonge, J.J.; van Hout, M.; Decarbonisation Options for the Dutch Potato Processing Industry. PBL Netherlands Environmental Agency, Manufacturing Industry Decarbonisation Data Exchange Network. 2021. Available online: https://www.pbl.nl/sites/default/files/downloads/pbl-2021-decarbonisation-options-for-the-dutch-potato-products-industry_3658.pdf (accessed on 30 April 2024).

- Masanet, E.; Worrell, E.; Graus, W.; Galitsky, C. Energy Efficiency Improvement and Cost Saving Opportunities for the Fruit and Vegetable Processing Industry. An ENERGY STAR Guide for Energy and Plant Managers; Office of Scientific and Technical Information, U.S. Department of Energy: Washington, DC, USA, 2008. [Google Scholar] [CrossRef]

- Van Loon, W.A.M. Process innovation and quality aspects of French fries. Ph.D. Thesis, Wageningen University, Wageningen, The Netherlands, 2005. Available online: https://edepot.wur.nl/121683 (accessed on 30 April 2024).

- Van Loon, W.A.M.; Linssen, J.P.H.; Legger, A.; ·Heijmans, R.M.H.; van Deventer, H.C.; ·Burgering, M.J.M.; van Drooge, B.L.; ·Voragen, A.G.J. Study of a new energy efficient process for French fries production. Eur. Food Res. Technol. 2005, 221, 779–786. [Google Scholar] [CrossRef]

- Gary, M. The Rising Threat of HFOs and TFA to Health and the Environment; ATMOsphere: Brussels, Belgium; Brooklyn, NY, USA; Tokyo, Japan, 2022. [Google Scholar]

- Barrault, S.; Mazi, V. Inventaire des Emissions de Fluides Frigorigènes Pour la France Métropole, Résultats 2020 et Estimation Provisoire 2021. Rapport AFCE (2022). Available online: https://www.afce.asso.fr/wp-content/uploads/2022/07/Rapport-AFCE-2022-08-31.pdf (accessed on 30 April 2024).

- European Environment Agency. Available online: https://www.eea.europa.eu/ (accessed on 5 May 2024).

- Mselle, B.D.; Vérez, D.; Zsembinszki, G.; Borri, E.; Cabeza, L.F. Performance Study of Direct Integration of Phase Change Material into an Innovative Evaporator of a Simple Vapour Compression System. Appl. Sci. 2020, 10, 4649. [Google Scholar] [CrossRef]

- Jesper, M.; Pag, F.; Vajen, K.; Jordan, U. Hybrid solar thermal and heat pump systems in industry: Model based development of globally applicable design guidelines. Sol. Energy Adv. 2023, 3, 100034. [Google Scholar] [CrossRef]

- Chikano, M.; Yanagase, Y.; Matsunaga, M.; Tojo, K. Development of high efficiency scroll compressor. In Proceedings of the 7th International Conference on Compressors and their Systems 2011, London, UK, 5–6 September 2011; Woodhead Publishing: Sawston, UK, 2011; pp. 469–475. [Google Scholar] [CrossRef]

- Chao, K.-H.; Chang, L.-Y.; Hung, C.-Y. Design and Control of Brushless DC Motor Drives for Refrigerated Cabinets. Energies 2022, 15, 3453. [Google Scholar] [CrossRef]

- Better buildings solutions center. US Department of Energy. Available online: https://betterbuildingssolutioncenter.energy.gov/better-plants/refrigeration (accessed on 30 April 2024).

- Cirera, J.; Carino, J.A.; Zurita, D.; Ortega, J.A. Improving the Energy Efficiency of Industrial Refrigeration Systems by Means of Data-Driven Load Management. Processes 2020, 8, 1106. [Google Scholar] [CrossRef]

- Arias, J.; Per Lundqvist, P. Heat recovery and floating condensing in supermarkets. Energy Build. 2006, 38, 73–81. [Google Scholar] [CrossRef]

- Ahmed, R.; Mahadzir, S.; Rozali, N.E.M.; Biswas, K.; Matovu, F.; Ahmed, K. Artificial intelligence techniques in refrigeration system modelling and optimization: A multi-disciplinary review. Sustain. Energy Technol. Assess. 2021, 47, 101488. [Google Scholar] [CrossRef]

- Mtibaa, A.; Sessa, V.; Guerassimoff, G.; Alajarin, S. Refrigerant leak detection in industrial vapor compression refrigeration systems using machine learning. Int. J. Refrig. 2024, 161, 51–61. [Google Scholar] [CrossRef]

- Wang, K.; Eisele, M.; Hwang, Y.; Radermacher, R. Review of secondary loop refrigeration systems. Int. J. Refrig. 2010, 33, 212–234. [Google Scholar] [CrossRef]

- Klein, S.A. Engineering Equation Solver, @ 1992–2024; Academic Professional Version V11.823; F-Chart Software: Madison, WI, USA, 2024. [Google Scholar]

- Hu, K.; Zhang, Y.; Liu, Z.; Hu, Y.; Sun, H.; Sun, Z.; Ning, J. Multi-objective (Carbon-Exergy) optimization study of CO2 cascade systems using multiple refrigerant pairs. Int. J. Refrig. 2024, 164, 143–153. [Google Scholar] [CrossRef]

- Khan, A.; Bradshaw, C.R. Quantitative comparison of the performance of vapor compression cycles with compressor vapor or liquid injection. Int. J. Refrig. 2023, 154, 386–394. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Navarro-Esbrí, J.; Barragán-Cervera, A.; Molés, F.; Peris, B.; Verdú, G. Commercial refrigeration—An overview of current status. Int. J. Refrig. 2015, 57, 186–196. [Google Scholar] [CrossRef]

- Andres, L.-N.; Llopis, R.; Sanchez Garcia-Vacas, D.; Gil, J.C.; Cabello, R. Experimental evaluation of a CO2 transcritical refrigeration plant with dedicated mechanical subcooling. Int. J. Refrig. 2016, 69, 361–368. [Google Scholar]

- Rostamzadeh, H.; Gholizadeh, T.; Rostamzadeh, S.; Vosoughi, S.; Farshad, A.A. Role of ejector expander in optimal inherently safety design of cascade NH3/Propane/CO2 vapor compression refrigeration systems. Process Saf. Environ. Prot. 2021, 146, 745–762. [Google Scholar] [CrossRef]

- Murthy, A.A.; Norris, S.; Subiantoro, A. Performance of a four-intersecting-vane expander in a R134a refrigeration cycle. Appl. Therm. Eng. 2022, 209, 118244. [Google Scholar] [CrossRef]

- Bilir Sag, N.; Ersoy, H.K.; Hepbasli, A.; Halkaci, H.S. Energetic and exergetic comparison of basic and ejector expander refrigeration systems operating under the same external conditions and cooling capacities. Energy Convers. Manag. 2015, 90, 184–194. [Google Scholar] [CrossRef]

- Sun, D.; Fei, T.; Liu, Z.; Xu, J.; Qin, J. Performance analysis of a new transcritical R744 refrigeration cycle with expander-mechanical overheating. Appl. Therm. Eng. 2023, 218, 119285. [Google Scholar] [CrossRef]

- Murthy, A.A.; Subiantoro, A.; Norris, S.; Fukuta, M. A review on expanders and their performance in vapour compression refrigeration systems. Int. J. Refrig. 2019, 106, 427–446. [Google Scholar] [CrossRef]

- Erdinc, M.T. Performance simulation of expander-compressor boosted subcooling refrigeration system. Int. J. Refrig. 2023, 149, 237–247. [Google Scholar] [CrossRef]

- Erdinc, M.T. Two-evaporator refrigeration system integrated with expander-compressor booster. Int. J. Refrig. 2023, 154, 349–363. [Google Scholar] [CrossRef]

- Liu, S.; Wang, J.; Dai, B.; Yang, X.; Nian, V.; Li, H.; Yuan, J. Alternative positions of internal heat exchanger for CO2 booster refrigeration system: Thermodynamic analysis and annual thermal performance evaluation. Int. J. Refrig. 2021, 131, 1016–1028. [Google Scholar] [CrossRef]

- Amaris, C.; Tsamos, K.M.; Tassou, S.A. Analysis of an R744 typical booster configuration, an R744 parallel compressor booster configuration and an R717/R744 cascade refrigeration system for retail food applications. Part 1: Thermodynamic analysis. Energy Procedia 2019, 161, 259–267. [Google Scholar] [CrossRef]

- Sacasas, D.; Vega, J.; Cuevas, C. An annual energetic evaluation of booster and parallel refrigeration systems with R744 in food retail supermarkets. A Chilean perspective. Int. J. Refrig. 2022, 133, 326–336. [Google Scholar] [CrossRef]

- Nebot-Andrés, L.; Sanchez, D.; Calleja-Anta, D.; Cabello, R.; Llopis, R. Experimental determination of the optimum intermediate and gas cooler pressures of a commercial transcritical CO2 refrigeration plant with parallel compression. Appl. Therm. Eng. 2021, 189, 116671. [Google Scholar] [CrossRef]

- Lata, M.; Gupta, D.K. Performance evaluation and comparative analysis of trans-critical CO2 booster refrigeration systems with modified evaporative cooled gas cooler for supermarket application in Indian context. Int. J. Refrig. 2020, 120, 248–259. [Google Scholar] [CrossRef]

- Aktemur, C.; Öztürk, I.T. Thermodynamic performance enhancement of booster assisted ejector expansion refrigeration systems with R1270/CuO nano-refrigerant. Energy Convers. Manag. 2022, 253, 115191. [Google Scholar] [CrossRef]

- Aktemur, C.; Öztürk, I.T. Thermodynamic optimisation of a booster-ejector vapour compression refrigeration system using solar energy and R152a/Cu nano-refrigerant. Appl. Therm. Eng. 2023, 229, 120553. [Google Scholar] [CrossRef]

- Paez, A.; Ballot-Miguet, B.; Michel, B.; Tobaly, P.; Revellin, R. Experimental investigation of a new CO2 refrigeration system arrangement for supermarket applications. Int. J. Refrig. 2024, 162, 245–256. [Google Scholar] [CrossRef]

- Pardiñas, A.A.; Selvnes, H.; Banasiak, K.; Hafner, A. Next generation of ejector-supported R744 booster systems for commercial refrigeration at all climates. Int. J. Refrig. 2023, 148, 168–178. [Google Scholar] [CrossRef]

- Banasiak, K.; Hafner, A.; Kriezi, E.; Madsen, K.; Birkelund, M.; Fredslund, K.; Olsson, R. Development and performance mapping of a multi-ejector expansion work recovery pack for R744 vapour compression units. Int. J. Refrig. 2015, 57, 265–276. [Google Scholar] [CrossRef]

- Elbarghthi, A.; Dvorak, V.; Hafner, A.; Banasiak, K. An experimental study of an ejector-boosted transcritical R744 refrigeration system including an exergy analysis. Energy Convers. Manag. 2021, 238, 114102. [Google Scholar] [CrossRef]

- Sarabia Escriva, E.J.; Acha, S.; Le Brun, N.; Soto Francés, V.; Pinazo Ojer, J.M.; Markides, C.N.; Shah, N. Modelling of a real CO2 booster installation and evaluation of control strategies for heat recovery applications in supermarkets. Int. J. Refrig. 2019, 107, 288–300. [Google Scholar] [CrossRef]

- Huang, C.; Zong, Y.; You, S.; Træholt, C.; Thorsen, J.E.; Sloth Larsen, L.F. Economical heat recovery dynamic control and business model for supermarket refrigeration system coupled with district heating system. Sustain. Energy Grids Netw. 2022, 32, 100800. [Google Scholar] [CrossRef]

- Hillphoenix Refrigeration Systems. A Comparative Study of Secondary Glycol and Direct Expansion Refrigeration Systems. Available online: https://www.hillphoenix.com/wp-content/uploads/2018/02/Case-Study-refrigeration-systems-SN-Glycol-DX-Systems-4-26.pdf (accessed on 30 April 2024).

- Efstratiadi, M.; Acha, S.; Shah, N.; Markides, C. Analysis of a closed-loop water-cooled refrigeration system in the food retail industry: A UK case study. Energy 2019, 174, 1133–1144. [Google Scholar] [CrossRef]

- Maté, J.; Papathanasopoulos, C.; Latif, S. Cool Technologies: Working without HFCs; Greenpeace: Amsterdam, The Netherlands, 2010. [Google Scholar]

- McDonald’s, UNEP DTIE, COOL The World’s First HFC-Free McDonald’s Restaurant, a Pilot Project in Vejle/Denmark. 2004. Available online: https://archive.r744.com/files/pdf_506.pdf (accessed on 30 April 2024).

- Star Refrigeration, Case Study: Pinneys of Scotland, R22 Plant Replacement. Available online: https://www.star-ref.co.uk/wp-content/uploads/2020/11/Pinneys-of-Scotland.pdf (accessed on 30 April 2024).

- Star Refrigeration, Case Study: Azanefreezer 2.0. Available online: https://www.star-ref.co.uk/products/packaged-refrigeration-systems/azanefreezer/ (accessed on 30 April 2024).

- Araner, Cogeneration and Trigeneration systems: Advantages and Use Cases. Accessed. Available online: https://www.araner.com/blog/cogeneration-trigeneration-systems (accessed on 1 December 2023).

- Dong, L.; Liu, H.; Riffat, S. Development of small-scale and micro-scale biomass-fuelled CHP systems—A literature review. Appl. Therm. Eng. 2009, 29, 2119–2126. [Google Scholar] [CrossRef]

- Oland, C.B. Guide to Combined Heand Power Systems for Boiler Owners and Operators. 2004. Oak Ridge National Laboratory. Available online: https://api.semanticscholar.org/CorpusID:110098435 (accessed on 30 April 2024).

- Vellini, M.; Gambini, M.; Stilo, T. High-efficiency cogeneration systems for the food industry. J. Clean. Prod. 2020, 260, 121133. [Google Scholar] [CrossRef]

- Bianco, V.; De Rosa, M.; Scarpa, F.; Tagliafico, L.A. Implementation of a cogeneration plan for a food processing facility. A case study. Appl. Therm. Eng. 2016, 102, 500–512. [Google Scholar] [CrossRef]

- 2-G Energy AG, A 5 MW Project for British Sugar. 2016. Available online: https://2-g.com/downloads/en/Case%20Studies/Case-Study-British-Sugar-EN.pdf (accessed on 30 April 2024).

- Food Industry, the Topicality of Cogeneration, Italian FoodTech. 2021. Available online: https://www.italianfoodtech.com/food-industry-the-topicality-of-cogeneration/ (accessed on 1 December 2023).

- Freschi, F.; Giaccone, L.; Lazzeroni, P.; Repetto, M. Economic and environmental analysis of a trigeneration system for food-industry: A case study. Appl. Energy 2013, 107, 157–172. [Google Scholar] [CrossRef]

- Tassou, S.A.; Chaer, I.; Sugiartha, N.; Ge, Y.T.; Marriott, D. Application of tri-generation systems to the food retail industry. Energy Convers. Manag. 2007, 48, 2988–2995. [Google Scholar] [CrossRef]

- Popov, D.; Akterian, S.; Fikiin, K.; Stankov, B. Multipurpose System for Cryogenic Energy Storage and Tri-Generation in a Food Factory: A Case Study of Producing Frozen French Fries. Appl. Sci. 2021, 11, 7882. [Google Scholar] [CrossRef]

- Institut de l’Energie et de l’Environnement de la Francophonie, La Cogeneration–Trigeneration. Français. Thématique: Les Technologies à Haute Performance Energétique. Fiche Technique. Available online: https://www.ifdd.francophonie.org/media/docs/publications/167_Cogeneration.pdf (accessed on 30 April 2024).

- Directorate-General for Energy and Geology, Assessment of the Potential for the Application of High-Efficiency Cogeneration and Efficient District Heating and Cooling. 2021. Available online: https://energy.ec.europa.eu/system/files/2022-01/PT%20CA%202020%20en.pdf (accessed on 30 April 2024).

- Bianchi, M.; Cherubini, F.; De Pascale, A.; Peretto, A.; Elmegaard, B. Cogeneration from poultry industry wastes: Indirectly fired gas turbine applications. Energy 2006, 31, 1417–1436. [Google Scholar] [CrossRef]

- Hasan, N.; Rai, J.N.; Arora, B. Optimisation of CCGT power plant and performance analysis using MATLAB/Simulink with actual operation data. SpringerPlus 2014, 3, 275. [Google Scholar] [CrossRef] [PubMed]

- Amidpour, M.; Manesh, M.H.K. Cogeneration and Polygeneration Systems; Academic Press: Cambridge, MA, USA, 2020. [Google Scholar]

- Ruiz Celma, A.; Lopez Rodriguez, F. Cogeneration plant in an olive sludge industry. Appl. Therm. Eng. 2009, 29, 3394–3400. [Google Scholar] [CrossRef]

- Panno, D.; Messineo, A.; Dispenza, A. Cogeneration plant in a pasta factory: Energy saving and environmental benefit. Energy 2007, 32, 746–754. [Google Scholar] [CrossRef]

- Colley, T. Sustainability Australia, Economic and Technical Potential for Cogeneration in Industry. Meat Livestock Australia Ltd.: North Sydney, Australia, 2010; Available online: https://www.mla.com.au/contentassets/d2c455422ad14190ade9aad1b477e59b/a.env.0102_final_report.pdf (accessed on 30 April 2024).

- Strum, B.; Butcher, M.; Wang, Y.; Huang, Y.; Roskilly, T. The feasibility of the sustainable energy supply from biowastes for a small scale brewery—A case study. Appl. Therm. Eng. 2012, 39, 45–52. [Google Scholar] [CrossRef]

- Le Blog D’écopôle. Available online: http://ecopole.over-blog.com/article-la-boulangerie-riegler-fait-fonctionner-nos-solutions-de-trigeneration-depuis-12-ans-120964049.html (accessed on 30 April 2024).

- Bio Energie International. Available online: https://www.bioenergie-promotion.fr/60811/kogeban-la-centrale-de-trigeneration-a-biomasse-de-nesle-dans-la-somme/ (accessed on 30 April 2024).

- Nussbaumer, T. Industrial Process Heat: Case study 5—Combustion of Wood Chips and Grain Residues for Process Heat Supply in the Largest Bakery in Switzerland, Contribution of Task 32 to the Intertask Project on Industrial Heat; IEA Bioenergy: Didcot, UK, 2021. [Google Scholar]

- Etude ENEA-Quantis, Evaluation des Impacts GES de la Production et L’injection du Biomethane Dans le Reseau de Gaz Naturel—Rapport Synthétique. 2020. Available online: https://www.bioenergie-promotion.fr/wp-content/uploads/2020/04/evaluation-des-impacts-ges-biomethane-_synthese-quantis_2017.pdf (accessed on 30 April 2024).

- International Energy Agency. Global Hydrogen Review 2023; OECD Publishing: Paris, France, 2023. [Google Scholar]

- Kazulis, V.; Vigants, H.; Veidenbergs, I.; Blumberga, D. Biomass and natural gas co-firing—Evaluation of GHG emissions. Energy Procedia 2018, 147, 558–565. [Google Scholar] [CrossRef]

- International Energy Agency Bioenergy. Biomass Combustion; Final Task Report, Triennium 2019–2021; IEA Bioenergy: Didcot, UK, 2022. [Google Scholar]

- West Virginia University, WVU Researchers Develop Hydrogen Technology to Curtail Greenhouse Gases from Food, Beverages Industry. 2023. Available online: https://wvutoday.wvu.edu/stories/2023/07/18/wvu-researchers-develop-hydrogen-technology-to-curtail-greenhouse-gases-from-food-beverage-industry (accessed on 30 April 2024).

- Koppejan, K. Industrial Process Heat: Case Study 1—Combustion of Wood Chips and Composting Residues for Process Steam Generation in a Potato Processing Industry, Contribution of Task 32 to the Intertask Project on Industrial Heat; IEA Bioenergy: Didcot, UK, 2020. [Google Scholar]

- Australian Alliance for Energy Productivity. Renewable Energy for Process Heat, Opportunity Study, Project Report 2020. Available online: https://arena.gov.au/assets/2020/06/renewable-energy-for-process-heat-opportunity-study.pdf (accessed on 30 April 2024).

- ADEME; ENEA Consulting. Intégration des Energies Renouvelables et de Récupération Dans L’industrie: À Chaque Secteur ses Solutions. Rapport 2018. Available online: https://www.actu-environnement.com/media/pdf/news-30913-ademe-enr-recuperation-industrie.pdf (accessed on 30 April 2024).

- Peesel, R.H.; Otte, A.; Stark, M. Transition of steam utility systems to solid biomass-fuelled boilers and biomethane-fuelled fuel cells in the wet pet food processing industry. Chem. Eng. Trans. 2019, 76, 931–936. [Google Scholar] [CrossRef]

- EDF, De la Biomasse Pour Produire de la Vapeur Chez Nestlé. 2015. Available online: https://www.plateformesolutionsclimat.org/wp-content/uploads/2015/11/EDF_Consommer-mieux_Nestle_150_dpi.pdf (accessed on 30 April 2024).

- Sajid, J.; Sajid, M.B.; Ahmad, M.M.; Kamran, M.; Ayub, R.; Ahmed, N.; Mahmood, M.; Abbas, A. Energetic, economic, and greenhouse gas emissions assessment of biomass and solar photovoltaic systems for an industrial facility. Energy Rep. 2022, 8, 12503–12521. [Google Scholar] [CrossRef]

- Atuonwu, J.; Tassou, S. Decarbonisation of food manufacturing by the electrification of heat: A review of developments, technology options and future directions. Trends Food Sci. Technol. 2021, 107, 168–182. [Google Scholar] [CrossRef]

- Zakeri, B.; Staffell, I.; Dodds, P.E.; Grubb, M.; Ekins, P.; Jääskeläinen, J.; Cross, S.; Helin, K.; Castagneto Gissey, G. The role of natural gas in setting electricity prices in Europe. Energy Rep. 2023, 10, 2778–2792. [Google Scholar] [CrossRef]

- Gruber, A.; Biedermann, F.; von Roon, S. Industrial Power-to-Heat Potential. Internationale Energiewirtschaftstagung an der TU Wien IEWT. 2015. Available online: https://docplayer.org/16185960-Industrielles-power-to-heat-potenzial.html#google_vignette (accessed on 20 April 2024).

- Naji, M.; Al-Nimr, M.A. Thermal behavior of a porous electric heater. Appl. Therm. Eng. 2002, 22, 449–457. [Google Scholar] [CrossRef]

- Yilmaz, T.; Basaran, A.; Civi, C. Application of inductive forced heating as a new approach to food industry heat exchangers. J. Therm. Anal. Calorim. 2018, 134, 2265–2274. [Google Scholar] [CrossRef]

- Balthazar, C.; Cabral, L.; Guimaraes, J.; Noronha, M.; Cappato, L.; Cruz, A.; Sant’Anav, A. Conventional and ohmic heating pasteurization of fresh and thawed sheep milk: Energy consumption and assessment of bacterial microbiota during refrigerated storage. Innov. Food Sci. Emerg. Technol. 2022, 76, 102947. [Google Scholar] [CrossRef]

- Aboud, S.; Altemimi, A.; Al-Hilphy, A.; Yi-Chen, L.; Cacciola, F. A comprehensive review on infrared heating applications in food processing. Molecules 2019, 24, 4125. [Google Scholar] [CrossRef] [PubMed]

- ITP Thermal Pty Ltd. Renewable Energy Options for Industrial Process Heat. 2019. Available online: https://arena.gov.au/assets/2019/11/renewable-energy-options-for-industrial-process-heat.pdf (accessed on 30 April 2024).

- Radio Frequency (RF) vs. Microwave (MW), Stalam. Available online: https://www.stalam.com/en/rf-vs-microwaves/ (accessed on 30 April 2024).

- Mariah, S. A Comparative Study of Ohmic and Microwave Heating in Food Processing. Presentation. Available online: https://www.slideshare.net/MariahSadaf/a-comparative-study-between-ohmic-and-microwave-heating-in-food-processing (accessed on 30 April 2024).

- Radoiu, M.; Mello, A. Technical advances, barriers, and solutions in microwave—Assisted technology for industrial processing. Chem. Eng. Res. Des. 2022, 181, 331–342. [Google Scholar] [CrossRef]

- Berteli, M.N.; Marsaioli, A. Evaluation of short cut pasta air dehydration assisted by microwaves as compared to the conventional drying process. J. Food Eng. 2005, 68, 175–183. [Google Scholar] [CrossRef]

- Paya, J.; Cazorla Marin, A.; Arpagaus, C.; Corrales Ciganda, J.L.; Hassan, A. Low-Pressure steam generation with concentrating solar energy and different heat upgrade technologies: Potential in the European Industry. Sustainability 2024, 16, 1733. [Google Scholar] [CrossRef]

- Saini, P.; Ghasemi, M.; Arpagaus, C.; Bless, F.; Bertsch, S.; Zhang, X. Techno-economic comparative analysis of solar thermal collectors and high-temperature heat pumps for industrial steam generation. Energy Convers. Manag. 2023, 277, 116623. [Google Scholar] [CrossRef]

- Sharma, A.; Sharmab, C.; Mullicka, S.; Kandpal, T. Solar industrial process heating: A review. Renew. Sustain. Energy Rev. 2017, 78, 124–137. [Google Scholar] [CrossRef]

- Bandi, S.R.; Anandarao, V. Factors affecting the adoption of solar thermal technology, A study on Food and Chemical Industries. Master’s Thesis, Uppsala University, Uppsala, Sweden, 2021. [Google Scholar]

- SHIP Plants Atlas, AEE Intec. Available online: https://energieatlas.aee-intec.at/index.php/view/map?repository=ship&project=ship_edit (accessed on 30 April 2024).

- Schmitt, B.; Hess, S. “Best Practice” Series of Case Study Reports from Demonstration Projects—Deliverable C4, IEA SHC Task 49, Solar Process Heat for Production and Advanced Applications. 2016. Available online: http://task49.iea-shc.org/data/sites/1/publications/IEA_Task49_Deliverable_C4_Best%20Practice-final-160528.pdf (accessed on 30 April 2024).

- NewHeat, Whey Powder Production Site (Lactalis Group). 2023. Available online: https://newheat.com/en/projects/dairy-industry/ (accessed on 30 April 2024).

- Renewable Thermal Collaborative, Colgate-Palmolive Factory. June 2023. Available online: https://www.renewablethermal.org/wp-content/uploads/2018/06/RTC_Colgate-Palmolive-Case-Study_June-6_2326.pdf (accessed on 30 April 2024).

- Epp, B. Dutch Green Heat Tariff Prompts Record-Size SHIP Plant. Tesselaar Greenhouse, Netherlands. Solarthermalworld.org. Available online: https://solarthermalworld.org/news/dutch-green-heat-tariff-prompts-record-size-ship-plant/ (accessed on 30 April 2024).

- Bolognese, M.; Viesi, D.; Bartali, R.; Crema, L. Modeling study for low-carbon industrial processes integrating solar thermal technologies. A case study in the Italian Alps: The Felicetti Pasta Factory. Sol. Energy 2020, 208, 548–558. [Google Scholar] [CrossRef]

- Dreak, M. Solar Heating in Industrial Processes (SHIP) Project. UNIDO Project Management Unit in Egypt. Available online: https://www.industrialenergyaccelerator.org/wp-content/uploads/UNIDO_SHIP_Summary-Report_Sana-Foods_20210510.pdf (accessed on 30 April 2024).

- FAO. Uses of Geothermal Energy in Food and Agriculture: Opportunities for Developing Countries. 2015. Available online: https://www.fao.org/documents/card/fr/c/045ca001-4849-43b7-/ (accessed on 30 April 2024).

- Dickson, M.H.; Fanelli, M. What is geothermal energy? Renew. Energy 2018, 1, 302–328. [Google Scholar]

- Lim, M.; Lee, C. An experimental study on thermal performance evaluation and effectiveness of geothermal heat exchange system in various standing column well types. Renew. Energy 2021, 179, 1049–1064. [Google Scholar] [CrossRef]

- Goldstein, B.; Hiriart, G.; Bertani, R.; Bromley, C.; Gutiérrez-Negrín, L.; Huenges, E.; Muraoka, H.; Ragnarsson, A.; Tester, J.; Zui, V. Geothermal Energy. In IPCC Special Report on Renewable Energy Sources and Climate Change 2011; Cambridge University Press: Cambridge, UK; New York, NY, USA; Available online: https://www.ipcc.ch/site/assets/uploads/2018/03/Chapter-4-Geothermal-Energy-1.pdf (accessed on 30 April 2024).

- Lund, J.W.; Boyd, T.L. Direct utilization of geothermal energy 2015 worldwide review. Geotherm 2016, 60, 66–93. [Google Scholar] [CrossRef]

- Dalla Longa, F.; Nogueira, L.P.; Limberger, J.; van Wees, J.-D.; van der Zwaan, B. Scenarios for geothermal energy deployment in Europe. Energy 2020, 206, 118060. [Google Scholar] [CrossRef]

- Wawoe, D.; Jette Blangé, J.; den Hartog, D.; Rus, B. Drilling Curved Borehole Heat Exchangers to enable Shallow Geothermal Everywhere. Canopus, IF Technology. 2023. Available online: https://canopusdrillingsolutions.com/wp-content/uploads/2023/06/Whitepaper-Curved-Wells-for-Shallow-Geothermal-Everywhere.pdf (accessed on 30 April 2024).

- Celcius Energy. ZAC Ferney Genève Innovation, The Celsius Energy Consortium Wins Tender for France’s Largest Geothermal Probe Project. Available online: https://www.energaia.fr/wp-content/uploads/2023/12/2023.02-Celsius-Energy-x-PR-Ferney-Geneve-Innovation-ENG.pdf (accessed on 30 April 2024).

- Robins, J.C.; Kesseli, D.; Witter, E.; Rhodes, G. 2022 GETEM Geothermal Drilling Cost Curve Update. In Proceedings of the 2022 Geothermal Rising Conference (GRC), Reno, NV, USA, 28–31 August 2022. [Google Scholar]

- Geothermies, Grand Est, Exemples D’opérations Dans Votre Region. 2017. Available online: https://www.geothermies.fr/outils/operations/la-centrale-geothermique-de-rittershoffen-bas-rhin (accessed on 30 April 2024).

- Climo, M.; Blair, A.; Carey, B.; Bendall, S.; Daysh, S. Driving the Uptake of Geothermal Direct Use in New Zealand: Successful Strategies, Empowered Champions, and Lessons Learnt Along the Way. In Proceedings of the World Geothermal Congress 2020+1, Reykjavik, Iceland, 24–27 October 2021. [Google Scholar]

- Wamanji, E. Aah! GDC Pasteurizes Milk Using Geothermal Heat. The Geo Blog. Available online: https://www.gdc.co.ke/blog/aah-gdc-pasteurizes-milk-using-geothermal-heat/ (accessed on 30 April 2024).

- Kiruja, J. Use of Geothermal Energy in Dairy Processing. Geothermal Training Programme Reports 2011, Reykjavík, Iceland. Available online: https://rafhladan.is/bitstream/handle/10802/23906/UNU-GTP-2011-16.pdf?sequence=1 (accessed on 30 April 2024).

- Bartok, J.W. Geothermal Heat for Greenhouses. Website of University of Massachusetts Amherst. Available online: https://ag.umass.edu/greenhouse-floriculture/fact-sheets/geothermal-heat-for-greenhouses (accessed on 30 April 2024).

- Kälte Klima Actuell. Feasibility of Industrial High-Temperature Heat Pumps up to 250 °C. Available online: https://www.kka-online.info/artikel/kka_-3774194.html (accessed on 30 April 2024).

- Arpagaus, C.; Bless, F.; Uhlmann, M.; Schiffmann, J.; Bertsch, S. High temperature heat pumps: Market overview, state of the art, research status, refrigerants and application potentials. Energy 2018, 152, 985–1010. [Google Scholar] [CrossRef]

- Matheu-Royo, C.; Navarro-Esbri, J.; Mota-Babiloni, A.; Moles, F.; Amat-Albuixech, M. Experimental exergy and energy analysis of a novel high temperature heat pump with scroll compressor for waste heat recovery. Appl. Energy 2019, 253, 113504. [Google Scholar] [CrossRef]

- Byrne, P.; Ghoubali, R. Exergy analysis of heat pumps for simultaneous heating and cooling. Appl. Therm. Eng. 2019, 149, 414–424. [Google Scholar] [CrossRef]

- Mitsopoulos, G.; Syngounas, E.; Tsimpoukis, D.; Bellos, E.; Tzivanidis, C.; Aganostatos, S. Annual performance of a supermarket refrigeration system using different configurations with CO2 refrigerant. Energy Convers. Manag. X 2019, 1, 100006. [Google Scholar] [CrossRef]

- Sarkar, J.; Agrawal, N. Performance optimization of transcritical CO2 cycle with parallel compression economization. Int. J. Therm. Sci. 2010, 49, 838–843. [Google Scholar] [CrossRef]

- Gullo, P.; Elmegaard, B.; Cortella, G. Advanced exergy analysis of a R744 booster refrigeration system with parallel compression. Energy 2016, 107, 562–571. [Google Scholar] [CrossRef]

- Nellissen, P.; Wolf, S. Heat pumps in non-domestic applications in Europe: Potential for an energy revolution, Emerson Climate Technologies. In Proceedings of the Delta-ee 3rd Annual Heat Pumps & Utilities Roundtable, Paris, France, 13 February 2014. [Google Scholar]

- Zühlsdorf, B.; Poulsen, J.L.; Dusek, S.; Wilk, V.; Krämer, J.; Rieberer, R.; Arpagaus, C. IEA HPT Annex 58: High-Temperature Heat Pumps. Task 1 Report: Technologies; IEA Bioenergy: Didcot, UK, 2023. [Google Scholar]

- Kim, Y.J.; Yang, L.; Entchev, E.; Cho, S.; Kang, E.C.; Lee, E.J. Hybrid solar geothermal heat pump system model demonstration study. Process Energy Syst. Eng. 2022, 9, 778501. [Google Scholar] [CrossRef]

- IEA HPT TCP, HTHP for Simultaneous Process Cooling and Heating—SkaleUP. Available online: https://heatpumpingtechnologies.org/annex58/wp-content/uploads/sites/70/2022/07/annex58casehthp-for-simultaneous-process-cooling-and-heating-skaleup.pdf (accessed on 30 April 2024).

- Bantle, M.; Schlemminger, C.; Moen, O.M.; Magnanelli, E. Electrification by High Temperature Heat Pumps; Department Thermal Energy, SINTEF Energy Research: Trondheim, Norway, 2022. [Google Scholar]

- IEA HPT TCP, High Temperature Heat Pumps Demonstrated in Energy Intensive Industries—DryFiciency. Available online: https://heatpumpingtechnologies.org/annex58/wp-content/uploads/sites/70/2022/07/hthpannex58dryfagranafinal.pdf (accessed on 30 April 2024).

- Engie Solutions. Lesaffre Décarbone sa plus Grande Levurerie. Available online: https://www.engie-solutions.com/fr/references/lesaffre-recuperation-chaleur-fatale (accessed on 30 April 2024).

- EDF. Analyse Technico-Economique des Solutions de Récupération de Chaleur Identifiées. Projet Varedia, Rapport Phase 3. Available online: https://www.actalia.eu/wp-content/uploads/2016/01/Analyse-des-solutions-technologiques-.pdf (accessed on 30 April 2024).

- Brückner, S.; Liu, S.; Miró, L.; Radspieler, M.; Cabeza, L.F.; Lävemann, E. Industrial waste heat recovery technologies: An economic analysis of heat transformation technologies. Appl. Energy 2015, 151, 157–167. [Google Scholar] [CrossRef]

- Xie, X.; Yi, Y.; Zhang, H.; Jiang, Y. Theoretical model of absorption heat pump from ideal solution to real solution: Temperature lift factor model. Energy Convers. Manag. 2022, 271, 116328. [Google Scholar] [CrossRef]

- Johnson Controls, York YHAP-C Absorption Heat Pumps. 2016. Available online: https://www.johnsoncontrols.com/en_my/-/media/jci/be/china/hvac-systems/files/water-cooled-chillers-and-heat-pumps/jcib4600_05hp_broch_d15g.pdf (accessed on 30 April 2024).

- Riaz, N.; Sultan, M.; Noor, S.; Sajjadd, U.; Farooq, M.; Khan, M.U.; Hanif, S.; Riaz, F. Recent developments in adsorption heat pumps for heating applications. Adv. Mech. Eng. 2022, 14, 1–32. [Google Scholar] [CrossRef]

- Cudok, F.; Giannetti, N.; Corrales Ciganda, J.L.; Aoyama, J.; Babu, P.; Coronas, A.; Fujii, T.; Inoue, N.; Saito, K.; Yamaguchi, S.; et al. Absorption heat transformer—State-of-the-art of industrial applications. Renew. Sustain. Energy Rev. 2021, 131, 110757. [Google Scholar] [CrossRef]

- Döll, J.; Bentaher, H.; Morgenstern, A. First results of a pilot installation of a solar thermally driven cold store. Int. J. Refrig. 2014, 39, 77–85. [Google Scholar] [CrossRef]

- Weber, C.; Berger, M.; Mehling, F.; Heinrich, A.; Núñez, T. Solar cooling with water–ammonia absorption chillers and concentrating solar collector—Operational experience. Int. J. Refrig. 2014, 39, 57–76. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, H.; Cui, L.; Wang, J.; Lee, C.; Dong, Y. Simulation study of an open compression absorption heat pump in water and heat recovery of low-temperature and high-humidity flue gas. Energy Convers. Manag. 2022, 269, 116180. [Google Scholar] [CrossRef]

- Shamim, J.A.; Auti, G.; Kimura, H.; Fei, S.; Hsu, W.-L.; Daiguji, H.; Majumdar, A. Concept of a hybrid compression-adsorption heat pump cycle. Cell Rep. Phys. Sci. 2022, 3, 101131. [Google Scholar] [CrossRef]

- Mohammed, R.H.; Radwan, A.; Rezk, A.; Olabi, A.G.; Sharma, V.; Hossain, A.K.; Alaswad, A.; Abdelkareem, M.A. Energy and exergy study of the integrated adsorption-absorption system driven by transient heat sources for cooling and desalination. Energy Convers. Manag. 2023, 277, 116614. [Google Scholar] [CrossRef]

- Jutsen, J.; Pears, A.; Hutton, L. High Temperature Heat Pumps for the Australian for Industry: Opportunities Assessment; Australian Alliance for Energy Productivity: Sydney, Australia, 2017. [Google Scholar]

- Coolplanet. Absorption Chiller Technology Creates €267,375 in Savings. Available online: https://www.coolplanet.io/case-studies/absorption-chiller-case-study (accessed on 30 April 2024).

- Ayou, D.S.; Corberán, J.M.; Coronas, A. Current status and new developments on high temperature heat pumps. In Proceedings of the 25th IIR International Congress of Refrigeration, Montréal, QC, Canada, 24–30 August 2019. [Google Scholar] [CrossRef]

- Grastim. Baronia Flumeri. Available online: https://www.grastim.com/en/pasta_baronia.html (accessed on 30 April 2024).

- ADEME. La Chaleur Fatale, Faits et Chiffres. ©ADEME Éditions. 2017. Available online: https://librairie.ademe.fr/ged/2321/chaleur_fatale-8821-2018-06_pdf.pdf (accessed on 30 April 2024).

- Simeone, A.; Luo, Y.; Woolley, E.; Rahimifard, S.; Boër, C. A decision support system for waste heat recovery in manufacturing. CIRP Ann. 2016, 65, 21–24. [Google Scholar] [CrossRef]

- Luberti, M.; Gowans, R.; Finn, P.; Santori, G. An estimate of the ultralow waste heat available in the European Union. Energy 2022, 238, 121967. [Google Scholar] [CrossRef]

- Law, R.; Harvey, A.; Reay, D. Opportunities for low-grade heat recovery in the UK food processing industry. Appl. Therm. Eng. 2013, 53, 188–196. [Google Scholar] [CrossRef]

- Zuberi, M.J.S.; Hasanbeigi, A.; Morrow, W.R. Electrification of Boilers in U.S. Manufacturing. Report from Lawrence Berkeley National Laboratory and Global Efficiency Intelligence. 2021. Available online: https://escholarship.org/content/qt98r4r9r5/qt98r4r9r5_noSplash_016278e60333f3f05ce150b89cc9f28f.pdf (accessed on 30 April 2024).

- Gourmelon, S.; Théry Hétreux, R.; Floquet, P. A systematic approach: Combining process optimisation exergy analysis and energy recovery for a better efficiency of industrial processes. Int. J. Exergy 2017, 23, 298–329. [Google Scholar] [CrossRef]

- Rusen, S.E.; Topcu, M.A.; Celtek, S.A.; Karanfil Celep, G.; Rusen, A. Investigation of energy saving potentials of a food factory by energy audit. J. Eng. Res. Appl. Sci. 2018, 7, 848–860. Available online: https://journaleras.com/index.php/jeras/article/view/116 (accessed on 30 April 2024).

- Mukherjee, S.; Asthana, A.; Howarth, M.; Mcniell, R. Waste heat recovery from industrial baking ovens. Energy Procedia 2017, 123, 321–328. [Google Scholar] [CrossRef]

- Renovis Rational Energy Solutions. Available online: https://www.renovisenergy.com/en/free-heat-from-baking-ovens.htm (accessed on 30 April 2024).

- C-Nergie. Une Entreprise Manufacturière Récupère la Chaleur du Procédé. Available online: https://www.c-nergie.com/realisation/1-34-une-entreprise-manufacturiere-recupere-la-chaleur-du-procede.html (accessed on 30 April 2024).

- Mukherjee, S.; Asthana, A.; Howarth, M.; Chowdhury, J.I. Techno-Economic Assessment of Waste Heat Recovery Technologies for the Food Processing Industry. Energies 2020, 13, 6446. [Google Scholar] [CrossRef]

- Kuraa, B. Case Study—Heat Recovery in a Food Company. BKU Consul. 2018. Available online: https://palast.ps/sites/default/files/inline-files/13%20Case%20study_Heat%20recovery_EE.pdf (accessed on 30 April 2024).

- Ásgeirsdóttir, M.O. Increasing Energy Efficiency in Industry Applying Pinch Analysis. A Dairy Plant Case Study. Master’s Thesis, University of Iceland, Reykjavik, Iceland, 2010. Available online: https://rafhladan.is/bitstream/handle/10802/15142/Orkusjodur-104-RES_MasterThesis_MargretOrmslevAsgeirsdottir_july2010-29-2010.pdf?sequence=1 (accessed on 30 April 2024).

- Mateu-Royo, C.; Mota-Babiloni, A.; Navarro-Esbrí, J.; Peris, B.; Molés, F.; Amat-Albuixech, M. Multi-objective optimization of a novel reversible High-Temperature Heat Pump-Organic Rankine Cycle (HTHP-ORC) for industrial low-grade waste heat recovery. Energy Convers. Manag. 2019, 197, 111908. [Google Scholar] [CrossRef]

- Bios-Bioenergysysteme Gmbh. ORC System. Available online: https://www.bios-bioenergy.at/index.php/en/technology-info/electricity-from-biomass/orc-process (accessed on 30 April 2024).

- Wieland, C.; Schifflechner, C.; Dawo, F.; Astolfi, M. The organic Rankine cycle power systems market: Recent developments and future perspectives. Appl. Therm. Eng. 2023, 224, 119980. [Google Scholar] [CrossRef]

- Turboden. Cereal Docks. Available online: https://www.turboden.com/case-histories/1463/cereal-docks (accessed on 30 April 2024).

- ADEME. Etude D’opportunité du Mix Energétique bas Carbone Laiterie Saint-Père. Librairie ADEME 2021. Available online: https://librairie.ademe.fr/7104-etude-d-opportunite-du-mix-energetique-bas-carbone-laiterie-saint-pere.html (accessed on 30 April 2024).

- Biglia, A.; Enrico Fabrizio, E.; Maria Ferrara, M.; Paolo Gay, P.; Davide Ricauda Aimonino, D. Performance Assessment of a Multi-energy System for a Food Industry. Energy Procedia 2015, 82, 540–545. [Google Scholar] [CrossRef]

- Kyotherm. Available online: https://kyotherm.com/en/projets/case-study-heatcube-tisza-2/ (accessed on 30 April 2024).

- Bauer, T.; Steinmann, W.D.; Laing, D.; Tamme, R. Thermal energy storage materials and systems. Annu. Rev. Heat Transf. 2012, 15, 131–177. [Google Scholar] [CrossRef]

- Seyitini, L.; Belgasim, B.; Chintua Enweremadu, C. Solid state sensible heat storage technology for industrial applications—A review. J. Energy Storage 2023, 62, 106919. [Google Scholar] [CrossRef]

- Rahimi-Khoigani, S.; Hamdami, N.; Dalvi-Isfahan, M. Application of an improved latent heat storage system in the food packaging. J. Food Eng. 2023, 341, 111351. [Google Scholar] [CrossRef]

- Fallahi, A.; Guldentops, G.; Tao, M.; Granados-Focil, S.; Van Dessel, S. Review on solid-solid phase change materials for thermal energy storage: Molecular structure and thermal properties. Appl. Therm. Eng. 2017, 127, 1427–1441. [Google Scholar] [CrossRef]

- Anant Kishore, R.; Mahvi, A.; Singh, A.; Woods, J. Finned-tube-integrated modular thermal storage systems for HVAC load modulation in buildings. Cell Rep. Phys. Sci. 2023, 4, 101704. [Google Scholar] [CrossRef]

- Ren, F.; Du, J.; Cai, Y.; Guo, J.; Liu, Y.; Zhang, D.; Li, M. Study on thermal performance of a new optimized snowflake longitudinal fin in vertical latent heat storage. J. Energy Storage 2022, 50, 104165. [Google Scholar] [CrossRef]

- Yedmel, M.A.; Hunlede, R.; Lacour, S.; Alvarez, G.; Delahaye, A.; Leducq, D. A novel approach to integrate cold energy storage in a vapour compression cycle. In Proceedings of the ICR2023, 26th International Congress of Refrigeration, Paris, France, 21–25 August 2023. [Google Scholar] [CrossRef]

- Sp.Ice. Available online: https://sp-icestorage.com/ (accessed on 30 April 2024).

- FAFCO. Icebat. Available online: https://fafco.fr/icebat-technologie-exclusive-fafco/ (accessed on 30 April 2024).

- Byrne, P.; Tiffonnet, A.L.; Filippidis, M.; Abdullah, N.; Lalanne, P.; Yatim, A.; Estellé, P.; Alhamid, I.; Maré, T.; Putra, N. Study of a phase change material storage for the solar air-conditioning system of a net-zero energy hotel in a tropical region. In Proceedings of the 6th IIR Conference on Sustainability and the Cold Chain, ICCC 2020, Nantes, France, 26–28 August 2020. [Google Scholar] [CrossRef]

- Hee Choi, D.; Lee, J.; Hong, H.; Tae Kang, Y. Thermal conductivity and heat transfer performance enhancement of phase change materials (PCM) containing carbon additives for heat storage application. Int. J. Refrig. 2014, 42, 112–120. [Google Scholar] [CrossRef]

- Islam, A.; Pandey, A.K.; Saidur, R.; Aljafari, B.; Tyagi, V.V. Advancements in foam-based phase change materials: Unveiling leakage control, enhanced thermal conductivity, and promising applications. J. Energy Storage 2023, 74, 109380. [Google Scholar] [CrossRef]

- Hu, X. Study of the thermal performance of metal foam and PCM composite for thermal energy storage. Ph.D. Thesis, UTT, Université Technologique de Troyes, Troyes, France, 2021. [Google Scholar]

- Cristopia, Stockage D’énergie Thermique. Available online: https://thermofin.net/fr/produits/cristopia-stockage-denergie-thermique/ (accessed on 30 April 2024).

- Allouhi, A. Latent Thermal Energy Storage for Solar Industrial Drying Applications. Sustainability 2023, 15, 13254. [Google Scholar] [CrossRef]

- Samah, W.; Clain, P.; Rioual, F.; Fournaison, L.; Delahaye, A. Review on ice crystallization and adhesion to optimize ice slurry generators without moving components. Appl. Therm. Eng. 2023, 223, 119974. [Google Scholar] [CrossRef]

- Hauer, A. IEA-ETSAP and IRENA © Technology-Policy Brief E17. January 2013. Available online: https://iea-etsap.org/E-TechDS/PDF/E17IR%20ThEnergy%20Stor_AH_Jan2013_final_GSOK.pdf (accessed on 30 April 2024).

- Artelys Optimzation Solutions. Towards an Efficient, Integrated and Cost-Effective Net-Zero Energy System in 2050. The Role of Cogeneration. 2020. Available online: https://www.cogeneurope.eu/images/Artelys-Presentation-Key-Findings---Study-Commissioned-by-CE-final.pdf (accessed on 30 April 2024).

- Badouard, T.; Moreira de Oliveira, D.; Yearwood, J.; Torres, P. Enerdata, Trinomics. LCOE & LCOH: Energy Costs, Taxes and the Impact of Government Interventions on Investments. Final Report. Available online: https://energy.ec.europa.eu/system/files/2020-10/final_report_levelised_costs_0.pdf (accessed on 30 April 2024).

- Giordano, L.; Furlan, G.; Puglisi, G.; Cancellara, F.A. Optimal design of a renewable energy-driven polygeneration system: An application in the dairy industry. J. Clean. Prod. 2023, 405, 136933. [Google Scholar] [CrossRef]

- Selvnes, H.; Jenssen, S.; Sevault, A.; Widell, K.N.; Ahrens, M.; Ren, S.; Hafner, A. Integrated CO2 refrigeration and heat pump systems for dairies. In Proceedings of the 15th IIR-Gustav Lorentzen conference on Natural Refrigerants (GL2022), Trondheim, Norway, 13–15 June 2022. [Google Scholar]

- Selvnes, H.; Jenssen, S.; Sevault, A.; Widell, K.N.; Ahrens, M.; Ren, S.; Hafner, A. Integrated CO2 refrigeration and heat pump system for a dairy plant: Energy analysis and potential for cold thermal energy storage. In Proceedings of the ICR2023, 26th International Congress of Refrigeration, Paris, France, 21–25 August 2023. [Google Scholar] [CrossRef]

- Burke, D.T.; Hynds, P.; Priyadarshini, A. Quantifying farm-to-fork greenhouse gas emissions for five dietary patterns across Europe and North America: A pooled analysis from 2009 to 2020. Resour. Environ. Sustain. 2023, 12, 100108. [Google Scholar] [CrossRef]

| Process | Description | Product Temperature [°C] | Energy Consumption Total | |

|---|---|---|---|---|

| 3.3 MJ/kg [42] | 3.0 MJ/kg [43] | |||

| Washing | Removal of all dirt, stones, and other (non) organic elements issued from crops | Ambient | <1% | 14.1% |

| Peeling | Usually achieved by steam peeling, where the skin is removed after short exposure to high-temperature steam and light mechanical pressure to remove the skin. Can also be made mechanically, which is less precise but much less energy-intensive (1/10) | 180–200 °C | 15% | <1% |

| Blanching | Exposure to hot water to reduce bacterial and enzymatic activity | 60–90 °C | 10% | 12.7% |

| Frying | Potatoes are cooked in high-temperature oil. It can be performed multiple times or during variable times | 160–190 °C | 65% | 25.7% |

| Cooling | This step is performed quickly to stop the cooking process but does not represent an important energy step | N.A. | 2% | <1% |

| Freezing | Most of the refrigeration energy produced is used during the freezing phase, where sliced and fried potatoes are exposed to cold air | −15 to −40 °C | 8% | 46.3% |

| Location, Company | Application | Previous Technology | Novel Technology | Power | COP and Energy Savings [- and %] | Annual CO2 Emissions Savings [% and tCO2/Year] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| United States, Lowes Food | Climatic chamber for food storage | Conventional R404A DX system | Secondary propylene glycol secondary circuit for commercial refrigeration (and VFD control on compressors) | 319 kW | - 5.2% (and 10.2%) | - | - | 2010 | [84] |

| United Kingdom, - | Refrigeration in food retail | DX CO2 transcritical booster with an air-cooled condenser | DX CO2 transcritical booster with a hybrid condenser (water-cooled and air-cooled condensers in parallel) | - | 2.4–2.9 40 6% | 11 - | 4.8 | 2021 | [85] |

| Denmark, McDonald’s | Refrigeration in food retail | HFC refrigeration units with R404a, R134a, R407C | Natural refrigerant units with R290, R600a, and R744 | - | - - 12% | - 27% | - | 2003 | [86,87] |

| Scotland, Youngs Seafood Group | Slamon processing | Two refrigeration units working with R22 | Air-cooled low-charge ammonia refrigeration unit | 111–650 | - - 15–20% | 453–815 - | - | - | [88] |

| United Kingdom, Blakemans | Sausages and meat-based products manufacturer | Six separate units working with R404A | Low-charge ammonia refrigeration units | 290 | - - 77.3% | 350 - | - | - | [89] |

| Location, Company | Application | Previous Technology | Novel Technology | Power [MWe] | Efficiency and Primary Energy Savings [% and %] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Sicily, Italy - | Wheat pasta drying | Separate production with grid and natural gas | CHP gas turbine operating with natural gas working in (dis)continuous mode | 0.8 | 70% (th: 46 e: 24) 5–9% | 271–481 6–9% | 14.8–16.1 | 2007 | [106] |

| Italy | Soft drinks bottling | Separate production with grid and natural gas | CHP gas turbine operating with natural gas | 1.8–2.2 | - 10.2–11.3% | - - | 2.4–5.7 | 2016 | [94] |

| Belgium | Aquatic center | Separate production with grid and natural gas | CHP-ICE operating with natural gas | 0.2 | 85% (th: 51 e: 34) - - | - - | 3–10 | - | [100] |

| Spain | Olive sludge—hot water and drying process | Separate production with grid and natural gas | CHP-ICE operating with natural gas | - | - 16% | 753 - | 4.5 | 2006 | [105] |

| Australia, Midfield | Beef, lamb, veal, and mutton sterilization | - | CHP-reciprocating gas engine operating with biogas and natural gas co-combustion | 1.5 MWe | 89% (th: 47 e: 42) - | - - | +/−5 | 2009 | [107] |

| Location, Company | Application | Previous Technology | Novel Technology | Power [MWe] | Efficiency and Primary Energy Savings [% and %] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Italy, Brunel University | University test for food applications | Electricity from the grid and natural gas boiler | Microturbine, gas absorption chiller, and natural gas boiler | 0.294 | 88.1% (th: 50.5 e: 37.6) - | - 0–12.5% | 4.51 | 2007 | [98] |

| United Kingdom | Brewery | Oil boiler and diesel generator | Biogas boiler from brewery waste and cattle slurry, water–ammonia absorption chiller | - | 88.4% (th: 69.4 e: 30.6) | - - | 5.4 | 2012 | [108] |

| Brazil, - | Soluble coffee manufacturing | Coffee ground and firewood biomass boiler | Biomass boiler, water–ammonia absorption chiller, steam turbine | 5.3 | - - | - - | >2 | 2001 | [109] |

| France, Nestlé | Starch, wheat product manufacturing | - | Turbine, absorption chiller, and biomass boiler | 16 | - - | 90,000 - | - | 2016 | [110] |

| Fuel | Carbon Intensity [gCO2/kWh] | Fuel | Carbon Intensity [gCO2/kWh] |

|---|---|---|---|

| Natural gas | 266.9–586.2 | Grey hydrogen | 303.0–393.9 |

| Pulverized solid biomass | 16.8–93.4 | Yellow hydrogen | 60.6 |

| Biogas from methanisation | 23.4–44 |

| Location, Company | Application | Previous Technology | Novel Technology | Power [MWth] | Efficiency and Energy Savings [% and % or m3] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Netherlands, ProBiomass BV | Potato industry steam generation | Natural gas boilers | Woodchip and composting residues boiler | 10 | - 8.2 × 106 m3 | 14,500 - | - | 2020 | [117] |

| Australia, Simplot | Vegetable processing for cleaning, blanching, defrosting | Natural gas boiler | Wood waste or woodchips biomass boiler + heat recovery | 5 | - - | - 33% | - | 2020 | [118] |

| France, Tereos | Sugar manufacturing and distillation | Natural gas boiler | Biogas and natural gas co-combustion boiler | 8.3 | - 5 × 106 m3 | 11,200 - | <5.0 | 2013 | [119] |

| United Kingdom, British Sugar | Sugar manufacturing | - | Biogas and biomethane CHP | 2 × 2.8 | 86% (th: 48.2 e: 37.8) - | - - | - | 2016 | [95] |

| Spain, Spain | Wet pet food manufacturing for steam generation | Natural gas boiler 2 × 5.4 MWth | Solid-biomass fuelled boiler | 2.05 | - | - 42% | - | 2019 | [120] |

| Biomethane fuelled boiler | - | - 27% | - | ||||||

| France, Nestlé | Sugar refining evaporation process | Natural gas boiler | Solid biomass boiler | 20 + 5 | - 8% | 40,000 - | - | 2013 | [121] |

| Switzerland, Coop Group | Large bakery process | - | Woodchips and grain residue pellets biomass boiler | 2.9 | - - | 4000 - | - | 2015 | [111] |

| - - | Rice processing plant | Coal boiler | 100% Rice husk, 50% Rice husk and wood, 100% wood combustion | - | - 19–22% | 11,612 98 | 1.6–2.0 | [122] |

| Electro-Heating Technology | Description | Efficiency | References |

|---|---|---|---|

| Infrared (IR) | Bring electric heaters at very high temperatures (650–1200 °C) to produce radiation for uniform and oriented surface heating Drying, baking, roasting | 40–70% | [129,130] |

| Induction (IH) | Heating pipe or magnetic element in contact with food product with a magnetic field generated by an electrical coil All processes, including liquid or slurry heating | 70–95% | [127] |

| Radiofrequency (RF) | Placing food between two electrodes and generating an electromagnetic field through capacitors at low frequency (10–50 MHz) | 60–65% | [131] |

| Ohmic (OH) | Placing conductive food in direct contact with two electrodes leading to alternating electric current passing through the volume at low frequency (50 or 60 MHz) | 90% | [128,132] |

| Microwave (MW) | Applying an electromagnetic field at high frequency (0.3–300 GHz) to polar molecules leads to friction/rotation converted into heat | 10–85% | [133,134] |

| Location, Company | Application | Previous Technology | Novel Technology | Power, Footprint and Solar Irradiance [MWth, m2, W/m2] | Energy Produced and Energy Savings [MWhth and %] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Austria, Goess Heineken | Hot water and steam for drying. Cleaning, pasteurizing, and mashing | Natural gas boiler | Standard flat plate solar collectors + biomass boiler for complement | 1.0 1500 666 | 471 30% | 500 - | - | 2013 | [140] |

| France, Lactalis Group | Milk powder manufacturing | Natural gas boiler | Standard flat plate solar collector | 10.7 14,843 713 | 8000 11% | 2000 7% | - | 2023 | [141] |

| Switzerland, Emmi AG | Dairy plant for steam generation | Fuel oil boiler | Parabolic trough solar collectors and linear Fresnel reflectors | 0.44 627 700 | 255 - | - - | - | 2012 | [33] |

| Greece, Colgate Palmolive | Household products manufacturing | Natural gas boiler | Parabolic trough solar collectors with rotation mechanism | - - - | 163 - | - 39% | - | 2018 | [142] |

| Italy, Nuova Sarda | Dairy, cheese plant for steam generation | Fuel oil steam generation | Linear Fresnel reflectors | 0.47 995 474 | 500 - | - - | - | 2015 | [33] |

| Netherlands, Tesselaar Greenhouse | Flower greenhouse heating for hot water production | Natural gas boilers | Flat plate solar collectors | 6.5 9300 698 | 5000 - | CO2 neutral - | - | 2019 | [143] |

| France, SARL Cavet | Cheese maturing for hot water production for heating and cleaning | - | Flat plate solar collectors | - 90 450 | 57 33% | - 16% | 6 | 2005 | [119] |

| Italy, La Felicetti Pasta Factory | Pasta drying for | Natural gas boiler and cogenerator | Parabolic collectors, troughs, reflectors | - - 600–900 | - - | 99 - | 9 | - | [144] |

| Egypt, Sana Foods | Sweets manufacturing | Natural gas steam boiler | Solar flat plate collectors | - 110 - | 189.7 3.0% | 51 - | 5.4 | 2021 | [145] |

| Location, Company | Application | Previous Technology | Novel Technology | Power, Depth [MWth, m] | Energy Produced and Energy Savings [GWhth, %] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| France, Roquette Frères | Starch extraction EGS | Wood biomass and natural gas boiler | Geothermal double borehole | 27 2500 | 180 25% | 41,000 - | - | 2017 | [155] |

| Australia, Midfields Meats | Beef, lamb, veal, and mutton sterilization | Natural gas boiler | Geothermal borehole | - - | 7.7 - | 1800 - | - | 2009 | [130] |

| New Zealand, Rogue Bore Brewery | Brewery | - | - | 3 - | - - | - - | - | 2020 | [156] |

| Costa Rica | Vegetables and grain drying | - | - | 1 - | 5.8 - | - - | - | 2005 | [150] |

| Kenya, GDC | Dairy pasteurization | - | Geothermal borehole | - | - 40% | - - | - | 2021 | [157,158] |

| New England, - | Greenhouse heating | - | Geothermal borehole | - 75–500 | - - | - - | < 10 | 2008 | [159] |

| Location, Company | Application | Previous Technology | Novel Technology | Power, COP, Tsource/Tsink [MWth, -, °C/°C] | Energy Produced and Energy Savings [MWhth, %] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Norway, TINE SA | Dairy products for cold, hot water, and steam | Natural gas boilers | HTHP cascade R290 (LT) and R600 (HT) | 0.30 2.5 20/115 | - 62% | - <94% | 2.5 | 2021 | [25,170,171] |

| Austria, Agrana | Starch drying | - | HTHP twin cycle R1336mzz | 0.37 2.8–3.2 80/160 | 2200 20–80% | 660 40–90% | - | 2020 | [172] |

| Ireland, Ahascragh | Distillery whisky | - | HTHP | 1.0 5 60/120 | - 50% | 736 70% | <3 | 2023 | [167] |

| Denmark, Arlan Arinco | Natural gas boiler | Milk powder drying and air pre-heating | HTHP hybrid R717 R744 | 1.25 4.6 45/85 | 7200 - | 1400 - | 1.5 | 2012 | [25] |

| Switzerland, Slaughter-house Zurich | Hot water generation in a slaughterhouse | Fossil fuel boiler | HTHP R744 | 0.80 3.4 30/90 | 2590 75% | 510 30% | - | 2011 | [25] |

| France, Lesaffre | Yeast production | Waste heat recovery for performance increase in yeast production | HTHP | 19 - 28/90 | - 70 | 30,000 70% | - | 2025 | [173] |

| France, Actalia | Pasteurization for milk, cream, and serum manufacturing | Natural gas | HP single stage | 0.64 5.6 28/50 | 4310 - | 890 - | 2.5–2.9 | 2014 | [174] |

| Location, Company | Application | Previous Technology | Novel Technology | Power COP [kWth, -] | Energy Produced and Energy Savings [MWhth, %] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| - - | Poultry processing plant | - | Ammonia/water absorption for cooling/heating demand | 350 - | - - | - - | - | 2006 | [185] |

| Spain, - | Edible oils processing | CHP operating with natural gas | Trigeneration based on absorption chiller | 2400 - | - - | - - | 1.3 | - | [186] |

| Egypt, Sana Foods | Sweets manufacturing | Natural gas steam boiler | Furnace exhaust heat recovery absorption chiller | - - | 113.6 4% | 30 - | 2.4–3.2 | [144] | |

| Japan, Alcohol industry | Alcohol industry | - | Single-stage absorption heat transformer (H20/LiBr) | 2475 0.45 | - - | - - | - | - | [187] |

| Italy, Baronia Flumeri | Pasta dough pre-heating and superheated water production | CHP operating with natural gas engines | Single-stage absorption heat transformer (H2O/LiBr) | 1202 0.46 | - - | - - | - | 2013 | [187,188] |

| Location, Company | Application | Technology Modification | Energy Recovered and Energy Savings [MWhth/Year and %] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|

| Waste heat recovery on refrigeration units | |||||||

| France, Haagen Dazs | Pasteurization processes for ice cream manufacturing | Heat recovery compressor’s oil and flue gases | 51 - | - | - | 2013 | [119] |

| France, Actalia | Pasteurization processes for milk, cream, and serum manufacturing | Heat recovery on condensation waste heat recovery of refrigeration unit | 3450 | 710 - | 0.07–0.28 | 2014 | [174] |

| Waste heat recovery on processes (pinch analysis) | |||||||

| Danemark, Star Food Ltd. | Paté production facility | Recovery of used cleaning water | 19 - | 0.42 | 2018 | [200] | |

| Iceland, MS dairy plant | Cream and processing milk facility | Heat exchanger network construction after pinch analysis | 4.4 - | - - | - | 2010 | [201] |

| Location, Company | Application | Previous Technology | Novel Technology | Power, Efficiency, Tsource/Tsink [kWe, -] | Electricity Produced and Electricity Savings [MWhth, %] | Annual CO2 Emissions Savings [tCO2/Year and %] | Payback Period [Years] | Year | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Italy, Cereal Docks | Heat recovery from diesel engines used in grain and oilseed processing | - | ORC | 600 - - | - - | - | - | 2012 | [205] |

| United Kingdom, Pilot scale unit | Heat recovery on wafer baking oven | - | Regenerative ORC working with R245fa | 23 13.8 165/- | - 6 | - | 15.7 | - | [199] |

| France, Laiterie Saint Père | Dairy industry, implementation pre-study | Fossil fuel (natural gas, fuel oil, propane) boilers | ORC module coupled with novel wood biomass boiler | 500 - -/- | - 16 | 4140 42% | 10–15 | 2021 | [206] |

| LCOH [€/MWhth] | References | |

|---|---|---|

| Gas boilers | 105–341 | [50,135,136,137,138,139,140,141,142,143,144,145,146,147,148,149,150,151,152,153,154,155,156,157,158,159,160,161,162,163,164,165,166,167,168,169,170,171,172,173,174,175,176,177,178,179,180,181,182,183,184,185,186,187,188,189,190,191,192,193,194,195,196,197,198,199,200,201,202,203,204,205,206,207,208,209,210,211,212,213,214,215,216,217,218,219,220,221,222,223,224,225,226] |

| CHP—Co/Trigeneration units | 85–102 | [226,227] |

| Biofuels | 153–162 | [227] |

| Green Hydrogen boilers | Not found | Not found |

| Electric immersion heaters | 247 | [135] |

| Solar thermal | 119–309 | [135] |

| Geothermal | N.A. | N.A. |

| HTHP 60 °C | 75–190 | [135] |

| HTHP 80 °C | 56–143 | [135] |

| HTHP 100 °C | 38–89 | [135] |

| AHT 80 °C | 25–42 | [135] |

| AHT 100 °C | 21–36 | [135] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faraldo, F.; Byrne, P. A Review of Energy-Efficient Technologies and Decarbonating Solutions for Process Heat in the Food Industry. Energies 2024, 17, 3051. https://doi.org/10.3390/en17123051

Faraldo F, Byrne P. A Review of Energy-Efficient Technologies and Decarbonating Solutions for Process Heat in the Food Industry. Energies. 2024; 17(12):3051. https://doi.org/10.3390/en17123051

Chicago/Turabian StyleFaraldo, François, and Paul Byrne. 2024. "A Review of Energy-Efficient Technologies and Decarbonating Solutions for Process Heat in the Food Industry" Energies 17, no. 12: 3051. https://doi.org/10.3390/en17123051

APA StyleFaraldo, F., & Byrne, P. (2024). A Review of Energy-Efficient Technologies and Decarbonating Solutions for Process Heat in the Food Industry. Energies, 17(12), 3051. https://doi.org/10.3390/en17123051