Abstract

This paper presents the jig operating properties of the selected final parameters of the hard coal concentrate. The quality parameters of the product, such as the yield and ash content, were evaluated in terms of the technical and hydrodynamic parameters of the jig’s operation. The research program included a series of experiments in which the efficiency and the amount of hutch water were changed. The variables selected and analyzed were divided into two categories, i.e., one related to the characteristics of the concentrate produced, and the other to the characteristics of the jig operation. Models were built for narrowed particle size fractions based on concentrate yield and ash content in the concentrate. In addition, a multidimensional analysis was performed, considering variables such as machine throughput, which was determined by the flow rate of the material, the amount of hutch water, the quality of the concentrate, and the amount of concentrate, as well as the accuracy of the jig operation expressed by the imperfection. Two main parameters were taken into account for modeling the operation to examine their significance of influence on the final responses in terms of the possibility of adjusting the value of independent settings of the jig operation. The presented approach to modeling the operation of the jig can be extended by considering the impact of other parameters, taking into account the variability of the final effect, as long as it is allowed under the industrial conditions of machine operation and the assumed production requirements. The approach presented in this paper is a new technique, which was not found in the literature.

1. Introduction

According to sources, 70% of the world’s steel production is based on coal. It is the basis of both the steel and cement industries [1] and, most importantly, it is considered a fuel with a good calorific value among fuels burned in the energy sector through traditional furnaces and rotary kilns with piston charging. Coal is also used in various industrial plants, gardening and district heating. It is also used in many households, which further increases the demand for this type of fuel. Its good calorific value ensures that the furnace reaches a high temperature quickly, which in turn, reduces the amount of carbon product used, resulting in less ash. From a technological point of view, coal accounts for about 90% of the mined quantity. The production of coal concentrates based on energy and coking coal is mainly based on the enrichment by a jig. Therefore, this process is one of the most important nodes in the technological chain in the processing of hard coals.

The efficiency of particle separation in the jig is influenced by many practical and hydrodynamic variables, as well as factors related to the feed characteristics, such as the coal’s physical and textural properties (particle shape, hardness, surface roughness), granulometric and densimetric composition, and chemical features. Hydrodynamic variables include water consumption (hutch water, transport water, and general water), water pressure, and rheological properties of the medium in terms of its density, viscosity, and solids content. There are also aerodynamic variables affecting the operational performance, such as the frequency and amplitude of the pulsation motion, along with the air pressure used to generate the pulsation [2,3]. The amount of material fed into the jig and its densimetric composition play an important role in the quantity and quality of the coal concentrate produced (i.e., calorific value, ash, and sulfur contents). Due to changes in the flow rate of the enrichment material, there are changes in the absolute position of the density layers of the bed. For instance, if the flow rate of the bottom product (tailings) is constant, it leads to fluctuations in density separation and, consequently, to a deterioration in the concentrate quality when the separation density is higher than the set point. If may also result in a loss of concentrate in the waste when the separation density is lower than the set point [4]. In addition, the use of jig feed stabilization systems should ensure stable conditions for coal-particle loosening in subsequent pulsation cycles and minimize coal particle dispersion in the jig bed [5]. The results of the experiments showed that the amount of additional water needed to properly loosen the jig bed during pulsating motion was necessary to occupy the appropriate equilibrium layers by the particles according to their density. These results were related to the grouping of particles by density from the heaviest in the lower layers of the bed to the lightest in the upper layers, and thus the separation into products: concentrate, excess, and tailings [6,7].

The type and water pulsation cycle are other key variables affecting coal separation efficiency using a jig [8,9]. In most used jigs, the pulsating motion is generated by compressed air and additional hutch water, which is introduced to augment the rising water stream. Through this, a better bed layer loosening can be obtained leading to a faster stratification and a shorter separation time [10,11,12]. However, hutch water without a pulsating motion can effectively loosen only small particles, as its velocity in most cases does not exceed 0.007 m/s [13]. The occurrence of optimal conditions for the amplitude and frequency of pulsations to generate different waveforms and its effect on particle stratification is shown in a mathematical model using the discrete element method. This technique is used to study particle stratification during deposition [14]. The mathematical model was developed by combining computational fluid dynamic (CFD) for liquid flow with the discrete element method (DEM) for particle flow where the effects of variables, such as vibration frequency, amplitude, and the size and density of ragging particles on the flow and separation efficiency were studied [15,16]. In many studies, the optimization of the jig operation is carried out mainly in terms of determining the density separation and identifying imperfections based on the distribution curves separation [17,18,19,20]. Optimization using Yates’ statistical analysis showed that the orderly based influential factors on the recovery of coal and grade in a synthetic mixture of coal and quartz separated in a jig at narrow particle size fractions were piston stroke > bed thickness > water level > particle size [21,22]. Tripathy and others [23,24] predicted the quality and quantity of concentrate of non-cooking coal using a multidimensional Nelder–Mead pattern. However, these studies were limited to selected particle size fractions separated in laboratory conditions.

A dynamic model for the removal of coal products in the jig based on the principle of conservation of mass for coal density layers transported in the jig bed was developed in the work of Cierpisz [4]. It was used for the design of product unloading control systems from the jig in real-world conditions. In another study, the celestite grade and recovery were correlated to operating variables in the jig, i.e., separation time at a fixed water flow rate and stroke length. For evaluating the separation results, the jig regression analysis of experimental data and analysis of variance (ANOVA) were used to estimate the statistical parameters [25]. The approach aimed at improving the efficiency of fine coal production, in terms of quality and quantity, should take into account all stages of the process that affect the final result, i.e., the product for the recipient.

Many authors in their works studied the issue of modeling the separation process in a jig on the basis of empirical experiences, as well as theoretical works using various types of mathematical models: discrete element method, numerical, phenomenological, heuristic, and other modelings. Following this, they developed a mathematical model for the probability of the useful fraction distribution in the volume of the jig bed [26]. The problem of loosening the jig bed under the influence of pulsating movements and the modeling of this issue was dealt with, in particular, by Mishra and Mehrotra [27,28]. A DEM-based technique was used to statistically describe particle movements in the jig bed, and the dynamic modeling of the deposition system [29]. Modeling of the dynamics of fluid motion as a function of the amplitude and frequency of pulsation of the medium in the jig was developed to better explain the phenomenon of particle stratification [30]. The particle-stratification model was also developed based on the assumption that differences in particle settling velocity cause their stratification [31]. The kinetics of particle stratification is influenced primarily by operational variables such as: pulse time, the pulse hold time, the amplitude of the jig cycle, and the depth of the particle bed in the jig [32]. In spite of this, under ideal conditions for homogeneous particles in terms of geometrical and densimetric features, particle stratification occurs in accordance with the King model [33]. On the basis of heuresis, the dependence on the settling velocity of spherical and irregular particles in the jig bed was derived using the distributions of geometrical and physical features of particles [34,35]. It was found that size stratification is not driven by a reduction in the potential energy of the particle bed in jigs [36]. The phenomenological model of bed stratification in connection with the DEM model, showed the mechanism of particle settlements in the bed, specifically the relationship between bed porosity and stratification rate [37]. The use of neural networks to model the operation of the jig in real conditions can describe a complex non-linear, time-varying dynamic system with an acceptable approximation of the jig’s operating conditions [38]. Numerical studies on multiphase flows were presented elsewhere [15,16], and the jig frequency was examined by Ferreira et al. [12]. An empirical equation based on experiments on a laboratory jig model showed that the influence of air cycle, inlet period, exhaust period, and air pressure on bed loosening are closely correlated [39]. Optimization of the iron ore enrichment process in the jig was carried out in order to determine the optimal height of the jig bed for various feed characteristics [40].

The analysis of separation efficiency in jig, according to the narrow particle fractions, allowed us to notice that in the case of fine particles, the separation efficiency is lower than in the case of coarse ones, especially for an experiment with the amount of additional water being equal to 35 m3/h [7,41]. For these particles, the hydrodynamic conditions of jig work connected with the amount of hutch water have the biggest influence on beneficiation effects. For coarser particles, the amount of hutch water does not have such a big influence on separation efficiency, but the separation density grows significantly. For these reasons, the authors decided to check whether the influence of hydrodynamic and process conditions can be explained using mathematical modeling in narrow-size fractions and whether it is related to the quantity and quality of produced coal concentrates. Thus far, no such studies have been found in the literature on the subject.

In this article, a statistical analysis was carried out and models for the operation of a jig in the technological line of coal enrichment were presented. However, it is important to mention that the quality of the final product is also influenced by other sub-processes and additional operations, such as fines dewatering. The optimization of the operation of the jig within narrow particle size fractions was performed for two selected operating parameters. In this way, it is possible to observe to what extent and under what conditions the particle sizes affect the operation of the jig and to extend the model as needed, taking into account other measured factors. The described method of mathematical modeling and optimization of the process creates new possibilities in the field of control and optimization of the enrichment process. This is extremely important not only for mining companies, but above all from the environmental point of view under the scope of quality of the final product.

2. Materials and Methodology

2.1. Experiment

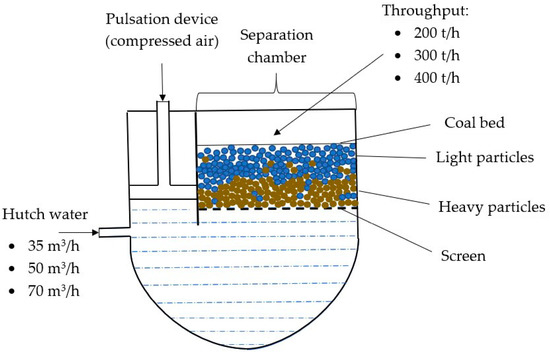

Experimental studies were conducted in a coal jig, in which coal with a particle size of 2.0–20.0 mm was separated. This is done for type 32 steam coal, according to Polish classification. The ash grade in industrial conditions during sampling for each experiment was on the level of 40–47% in the feed and mean sulfur content 2.2% in all experiments. The series of experiments consisted of testing an industrial jig with three products and a working area of 17 m2, operating in a mechanical preparation plant of one of the coal mines. The trials were performed with a constant number of pulsations, i.e., 26 cycles per minute. The system throughput, i.e., the feed flow rate, was varied at three levels of 200, 300, and 400 t/h. Samples of products were taken from the jig at three variable settings of the hutch water flow rate for the set jig throughput, which were 35, 50, and 70 m3/h. A schematic illustration of the studied jig separator is presented in Figure 1. At these parameters, after stabilization of the process, samples of concentrate, midllings and tailings were collected simultaneously within 3 min, following the procedures of representativeness. Subsequently, each of the separation products was subjected to densimetric and granulometric analyses. The flow and sink analysis was performed in zinc chloride solutions with densities of 1.3, 1.4, 1.5, 1.6, 1.7, 1.8, and 2.0 t/m3, respectively. It was used to determine the accuracy of the jig’s work separation. Additionally, the samples were sieved on screens with mesh sizes of 2.0, 3.15, 5.0, 6.3, 8.0, 10.0, 12.5, 16.0, and 20.0 mm to determine the effect of variable machine operating conditions on separation efficiency. In all size fractions obtained as a result of flow-sink and granulometric analyses, the yields of the products and ash content were determined. The scheme of the performed tests is presented in Table 1.

Figure 1.

Scheme of a jig separator.

Table 1.

Scheme of factor experiment.

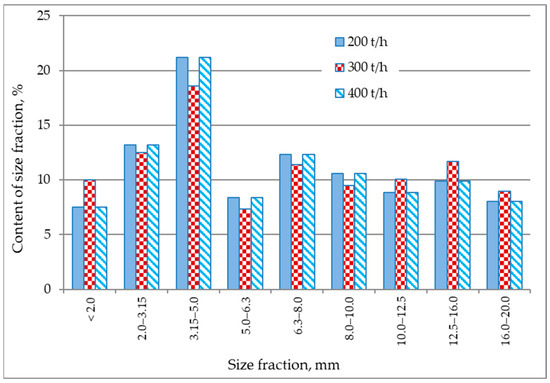

The following factors were used to evaluate the jig’s efficiency: the quality, expressed by the ash content in the concentrate; the amount of product-concentrate yield; and the accuracy of the separation process itself, measured by the imperfection index in each narrow particle size fraction. When changing the settings of the jig operation, i.e., changing the amount of material supplied for enrichment, samples of the feed were taken and sieved on the same screens as the enrichment products to check the uniformity of the feed in terms of its particle size distribution. The particle size distribution of the feeds is shown in Figure 2. A significant increase in the content of particles was observed in the 3.15–5.0 mm feed size fraction, while the content of the corresponding particle size fraction in the feeds differed from each other in the range of 0.6–3.0% in the individual trials. When analyzing the variability of particle size for size fractions in individual trials at different performances, a constant level of the content of the finest particles <2.0 mm and size fractions above 5.0 mm was observed. The relative standard deviation was used to determine the degree of uniformity of the feed:

where: σ is the standard deviation and represents the average particle size.

Figure 2.

Particle size fractions in investigated coal plant for individual experiments.

The calculated relative standard deviation for each feed indicated that the material was uniform in terms of granulometric properties in the individual particle size fractions and for each feed it was about 12%.

2.2. Model

The obtained experimental results in terms of quantity and quality of produced concentrate and accuracy of jig operation were subjected to mathematical analysis, taking into account technological conditions of machine work and hydrodynamic parameters. The analyzed variables can be divided into two categories: characteristics of the produced concentrate (yield, ash content) and characteristics of the jig’s work (throughput, hutch water). Thus, the general form of the mathematical model is as follows:

where: y is the dependent value, which was defined either as concentrate yield or ash content in concentrate.

y = f (throughput, hutch water)

The series of experiments were designed and conducted as a factorial experiment, using different levels of variability depending on the nature of the variables. Two important technological parameters for jig operation (variable 1 and variable 2) were selected as independent variables with three levels of variability in each of the respective models. For variable 1 (jig throughput), experiments were conducted at 200, 300, and 400 t/h, while for variable 2 (the amount of hutch water), amounts of 35, 50, and 70 m3/h were selected. When each test variable has the same number of variability levels, the total number of individual experiments required can be written as follows:

where: n is the number of levels of volatility and k shows the number of variables.

For such assumptions, nine individual experiments on coal enrichment were carried out to verify its feasibility enrichment. After spreading the collected concentrate on narrow particle size fractions, nine particle size fractions were obtained, in which quantitative and qualitative parameters were determined, which also made it possible to check the enrichment potential of the material as a function of particle size. Since a series of tests, in which the jig was tested under real conditions, was carried out in one work shift, it was assumed that the coal used for preparation was qualitatively homogeneous and characterized by constant ash content. A complete series of N = 9 tests were performed for an industrial jig for the enrichment of coal. As defined in Equation (2), the working models of the jig were calculated separately for γc and A. According to the above and in relation to (2), it can be written as follows:

where: γc is concentrate yield, and A denotes ash content in the concentrate.

Y(γc, A) = f (throughput, amount of hutch water)

All variables were determined for each particle size fraction in all concentrates from the nine experiments.

3. Results

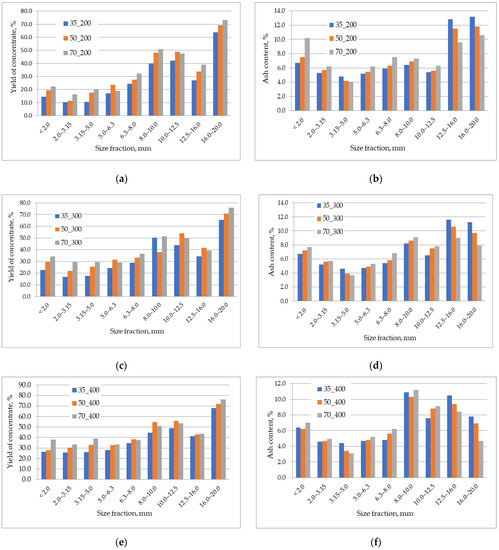

Figure 3 shows the dependency of the quality and quantity of the concentrate produced in each particle size fraction on the variable operating conditions. It was observed that as the particle size increased, the yield of concentrates in each size fraction improved, except for the 12.5–16.0 mm size fraction, but for the lowest throughput of 200 t/h (Figure 3a). At higher throughputs, the maximum concentrate yields were obtained for the coarsest size fraction 16.0–20.0 mm (Figure 3c,e). By analyzing the quality of the concentrates, it can be evidently seen that the ash content increased in the smallest size fraction < 2.0 mm and in the biggest size fractions > 12.5 mm at the lowest throughput (Figure 3b). In the case of an average throughput of 300 t/h, the distribution of ash grade in concentrate was at lower levels with the maximum amount of hutch water for size fractions coarser than 3.15 mm.

Figure 3.

Concentrate yield and ash contents in the concentrate as a function of particle size fraction: (a) yield of concentrate—throughput 200 t/h, (c) yield of concentrate—throughput 300 t/h, (e) yield of concentrate—throughput 400 t/h, (b) ash content—throughput 200 t/h, (d) ash content—throughput 300 t/h, (f) ash content—throughput 400 t/h.

On the other hand, for the jig throughput of 400 t/h, the highest amount of hutch water improved the quality of the concentrate for particles coarser than 8.0 mm (Figure 3f). The inflow of hutch water caused a movement with approximately constant velocity in the working bed, which aimed to optimally loosen the bed layer, since the amount of hutch water could regulate the degree of loosening of the material more precisely than with compressed air [2,42].

Multi-Factor Analysis of Variables Affecting the Effects of Coal Separation in a Jig

When considering more than two factors affecting separation efficiency in a jig, particle size and density as well as partition coefficient are usually taken into account. As a result, the partition surface can be plotted and a stochastic model can be used to describe the operation of the jig [43,44,45,46]. Multidimensional methods can also be used to assess the coal processing effects. Such methods as the observational tunnels method [47], principal component analysis [48,49], relevance maps [50], self-organizing Kohonen maps [51], multidimensional scaling [52], and autoassociative neural networks [53] were used in this matter. The evaluation of these methods’ efficiency can be found in [54].

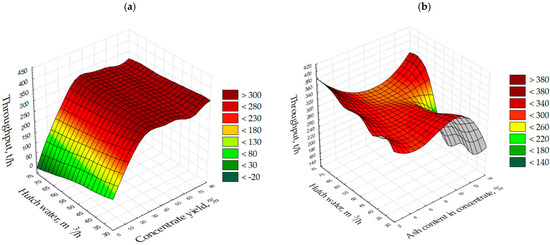

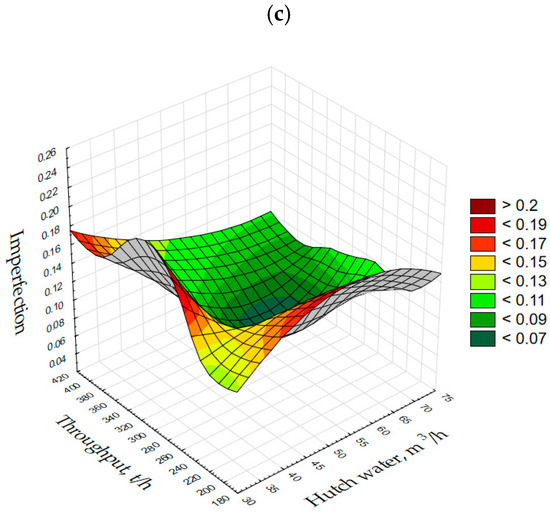

Meanwhile, in the enrichment process of coal in a jig with a pulsating work bed in a water medium, there are a number of variables that determine its progress. These are related to the properties of the feed, machine settings, and the hydrodynamics of the process [55]. Therefore, to illustrate how and to what extent the analyzed parameters determine the separation in the jig, a multi-parameter analysis was performed. The analysis considered variables such as the jig throughput, which is determined by the material flow rate, the amount of hutch water, the quality of the concentrate and the amount of concentrate, and the imperfection. A three-parameter analysis was performed over the entire range of variability, which also allows predicting, within a certain range of variability of individual parameters, the results of separation for individual variables. Figure 4a–c presented three-dimensional diagrams of the variability of the system Figure 4a (concentrate yield-axis x, hutch water-axis y, throughput-axis z), Figure 4b (ash content-axis x, hutch water axis y, throughput axis z), and Figure 4c (hutch water-axis x, throughput-axis y, imperfection- axis z). Figure 4a clearly shows that the yield of concentrate also enhanced with increasing the throughput. It depends to a lesser extent on the amount of hutch water added. Figure 4b shows that it was difficult to obtain a consistent trend in the variability of ash content in the concentrate as a function of yield and amount of hutch water. Therefore, the obtained surface was wavy and the analysis of the influence of the independent variables on the dependent variable should be performed separately for each particle size fraction. Figure 4c shows that the highest value of imperfection was obtained at higher values of the amount of hutch water and jig throughput. This relationship was also not homogeneous and it can be assumed that the quality of the feed can have a great influence on the obtained results.

Figure 4.

Three-dimensional surfaces of the analyzed variables for all cases: (a) influence of throughput and hutch water on concentrate yield, (b) influence of throughput and hutch water on ash content in concentrate, (c) influence of throughput and hutch water on imperfection.

4. Discussion

4.1. Modeling Results

The results of the research allowed us to establish the general dependencies of the operating variables of the jig in order to determine the parameters of the produced concentrates in terms of quantitative and qualitative characteristics and the accuracy of the operation of the machine. The models described were related to concentrate yield (γc) and ash content in the concentrate (A). The significance of each independent variable in the model was tested at a confidence level of 1 − α = 0.95. The significance coefficient R2 was calculated separately for each model. Table 2 shows the calculated models for each particle size fraction and the values of R2.

Table 2.

Models specified for each particle size.

The modeling results for the individual particle size fraction showed that both types of models were characterized by high significance and high values of the R2 coefficient. In particular, the models for ash content indicated a high degree of explanation of the dependent variable by the variables water amount and yield of concentrate. For the fine particle size fraction, a positive influence of the amount of hutch water can generally be observed. This means that as the amount of added hutch water increased, the ash content in the concentrate also increased. This trend was different for the coarse size fractions and for the 3.15–5.00 mm. In the case of jig throughput, it was clear that the relationship was usually inversely proportional, i.e., as it increased, the ash content increased. Uniform feeding is a prerequisite for the normal operation of the jig. An increase or fluctuation in the amount of feed supplied or interruptions in the supply will result in a loss of coal in the tailings and a decrease in the quality of the concentrate. On the other hand, with an incomplete load with the feed, the throughput of the jig was not fully used and particles of tailings or intergrowth entered the concentrate. An inverse relationship can be seen for the 8.0–10.0 and 10.0–12.5 mm size fractions, but the values of the coefficients for the variable t are not high. A high value of the R2 coefficient proved that these observations were significant. Somewhat worse models were obtained for the amount of concentrate yield, although the parameters of the model are still statistically significant. In this case, the effect of hutch water amount and throughput on the amount of yield was generally positive, i.e., the relationships were directly proportional.

Only for the 8.0–10.0 and 10.0–12.5 mm size fraction was a different type of relationship found, which is also probably related to other values of the equation coefficients for ash content in the concentrate in these size fractions. The quality of the model related to the ash content in the concentrate increased with particle size, starting with the class above 6.3 mm. In general, coarse particles were enriched more than fine particles, whose separation was difficult to predict from a statistical point of view. The dependent variables and parameters in the models were found to be significant based on the selected significance level of α = 0.05. The previously performed heuristic modeling allowed the development of a physical model of the separation function that takes into account the interactions between the particles in the work bed of the jig [56]. The analysis of the correlation between the ash and sulfur content in the feed and the particles size fractions, as well as the methodology of the upgrading curves in the work [57,58], shows the range of possibilities for the choice of an effective tool for the evaluation of upgrading, which allows the process control to optimize the results obtained for the industrial upgrading of raw materials. However, models for narrow particle size fractions that can be extended by introducing additional variables have not yet been presented in the literature.

Limitations of the presented model can be defined as each model based on the empirical results of its application is limited to a certain type of coal. As other tests showed, for various coals the results can be different. The value of the R2 coefficient showed that the quality of most of the equations was statistically good. However, the natural variation of the feed in industrial conditions may cause some discrepancies from the results obtained during the test. However, it is worth noting that the experiments were conducted in industrial conditions—so the results can be treated as representative of an industrial practice. Anther limitation is that the preparation of coal from a certain narrow particle density-size fraction in industrial condition is very hard. However, the results may help in the appropriate preparation of the feed.

4.2. Validation

The models presented in Section 4.1 show a fairly high level of determination and thus a high degree of explanation of the values of the dependent variables by the independent variables, especially for the models on ash content in the concentrate.

All models are statistically significant at the 1 − α = 0.95 probability level. The mean square error MSE, defined by Equation (5), was also calculated for each model from each particle size fraction.

where: is ab empirical value obtained from experience and ŷ is a value calculated from the model.

Table 3 presents the MSE values calculated for each grain class separately for the models for γc and A.

Table 3.

The MSE value defines the average deviation of the model from the empirical data.

As can be seen from Table 3, the indicators of concentrate production obtained from the model deviate on average from the actual values in the range of 1.32% to 16.97%. The ash content in the concentrate was in the range of 0.16% to 1.57%. The modeling results for concentrate quality, i.e., ash content in the concentrate, proved to be much better.

5. Conclusions

Processing in a jig is a mineral separation method that has been used successfully for several centuries, but there is no theory or mathematical model that would accurately and unambiguously explain the mechanism of the separation process. The working chamber of the setting machine has always been treated as a “black box” through which the feed layer passed and after its passage two or more separation products were obtained. Visually, it is impossible to observe the movement of the particles in the working chamber of the jig, except for the upper layer of the bed and the particles located near the walls of the chamber.

The research presented in this article is a different approach to modeling the work of the jig. A new way was shown to evaluate the influence of dependent variables on the parameters of the produced concentrate in terms of its quantity and quality in particle size fractions using simple modeling tools. A high level of model fit was obtained, especially for the case with ash content in the concentrate, for which only in one case was the value of the coefficient of determination R2 less than 80% for the smallest particle size fraction, i.e., less than 2 mm. Lower coefficients of determination were obtained for models with a variable such as a concentrate yield, which in four cases were below 80%, proving the poorer quality of the model. Validation of the obtained model with real operating results for concentrate quality shows a high level of accuracy. This proves that the chosen approach to modeling was correct. On the other hand, the validation of the model for concentrate production, especially in the 8.0–10.0 and 10.0–12.5 mm size fractions, showed a low degree of accuracy. The analysis of the results and the developed mathematical models in narrow particle size fractions of the concentrate showed that for particles of 2.0–8.0 mm and in the size fraction 10.0–12.5 mm, at a throughput of 200 t/h and a small addition of hutch water, it is possible to obtain a very good quality concentrate, in which ash is about 6%. For these size fractions, the values of the coefficients of variable 1 (throughput) and variable 2 (hutch water) are very low. However, a similar relationship between the model in particle size fraction and concentrate yield cannot be observed.

As a result of observations and developed models, it was found that in the case of outflows, the influence of the amount of hutch water and throughput is relatively greater, which is evidenced not only by high R2 values, but also by higher values of the coefficients of the regression equations. For the finer size fraction, the influence of both of these parameters is positive, similarly for the smallest size fraction. Only in the 8.0–10.0 and 10.0–12.5 mm size fractions is this relationship inverse, but the quality of the models for these classes is the worst, which may be the reason for the not fully correct assessment of the process. One can also pay attention to the small values of these coefficients, which, taking into account the confidence intervals, may change their sign in the model. In the case of models for ash content, their quality is very high, but the relative effect of hutch water and yield is small in terms of the value of the measured random variable. The values of the coefficients are close to zero, which means that despite the significant dependence, their influence on the ash content is relatively small.

The multi-variant analysis allowed us to determine the optimal areas for the operation of the jig to produce coal concentrate in terms of quantity and quality, as well as the settings for the operation of the machine: throughput and amount of hutch water and accuracy of the operation of the jig. The presented working models of the jig refer to a specific machine used in a plant for the enrichment of coal. The proposed approach can be implemented in the coal enrichment plant for another type of jig; however, special care should be taken in sampling to ensure that the samples are representative.

The statistical methodology of optimizing the process using regression modeling presented in this manuscript is different from the traditionally used methods and tools for assessing the beneficiation process in a jig, and above all, it allows for a close look at the results of coal separation in narrow particle size fractions. The multifaceted development of the research material, both based on regression models and multidimensional analysis, indicated the diversity in the beneficiation of fine and coarse particles in the range of particle size directed to beneficiation in the jig, which is a generally known fact but not necessarily used in industrial practice.

Author Contributions

Conceptualization, writing—original draft and writing—review and editing, A.S. and T.N.; methodology, validation, and formal analysis, A.S.; investigation, resources, and data curation, A.S.; writing—review and editing and supervision, M.W. and A.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to ethical restrictions.

Conflicts of Interest

The authors declare no conflict of interest.

References

- World Coal Association. Available online: https://www.worldcoal.org/coal-facts/ (accessed on 9 December 2022).

- Nawrocki, J. Budowa i Eksploatacja Osadzarek; Skrypt uczelniany nr 408; Politechnika Śląska: Gliwice, Poland, 1972. (In Polish) [Google Scholar]

- Wills, B.A.; Napier-Munn, T. Wills’ Mineral Processing Technology, 7th ed.; Butterworth-Heinemann: Oxford, UK, 2006. [Google Scholar]

- Cierpisz, S. A Dynamic model of coal products discharge in a jig. Miner. Eng. 2017, 105, 1–6. [Google Scholar] [CrossRef]

- Cierpisz, S.; Joostberens, J. Impact of feed control on the coal bed stability in a jig. Arch. Min. Sci. 2019, 64, 639–653. [Google Scholar]

- Brożek, M.; Surowiak, A. Effect of particle shape on jig separation efficiency. Physicochem. Probl. Miner. Process. 2007, 41, 397–413. [Google Scholar]

- Surowiak, A. The analysis of coal fines separation precision exposed to changeable hydrodynamic parameters of jig work. Arch. Min. Sci. 2018, 63, 437–448. [Google Scholar]

- Cierpisz, S.; Kryca, M.; Sobierajski, W. Control of coal separation in a jig using a radiometric mete. Miner. Eng. 2016, 95, 59–65. [Google Scholar] [CrossRef]

- Cierpisz, S.; Joostberens, J. Nonlinear control of refuse discharge in a three-product coal jig. IFAC-PapersOnLine 2022, 55, 132–137. [Google Scholar] [CrossRef]

- Xia, Y.F.; Peng, F.F.; Wolfe, E. CFD simulation of fine coal segregation and stratification in jigs. Int. J. Miner. Process. 2007, 82, 164–176. [Google Scholar] [CrossRef]

- Sampaio, C.H.; Cazacliu, B.G.; Miltzarek, G.L.; Huchet, F.; le Guen, L.; Petter, C.O.; Paranhos, R.; Ambros, W.M.; Oliveira, M.L.S. Stratification in air jigs of concrete/brick/gypsum particles. Constr. Build. Mater. 2016, 109, 63–72. [Google Scholar] [CrossRef]

- Ferreira Feil, N.; Sampaio, C.H.; Wotruba, H. Influence of jig frequency on the separation of coal from the Bonito-seam. Santa Catarina, Brazil. Fuel Process. Technol. 2012, 96, 22–26. [Google Scholar] [CrossRef]

- Povarov, A.I.; Rapolov, K.I.; Malova, N.N.; Movszovicz, S.A. Promyszlennyje ispytanija obrazcov vysokoproizvoditielnych otsadocznych maszin. Obogaszczenie Rud. 1966, 6, 44–50. (In Russian) [Google Scholar]

- Srinivasan, R.; Mishra, B.K.; Mehrotra, S.P. Simulation of particle stratification in jigs. Coal Prep. 1999, 20, 41–72. [Google Scholar] [CrossRef]

- Dong, K.J.; Kuang, S.B.; Vince, A.; Hughes, T.; Yu, A.B. Numerical simulation of the in-line pressure jig unit in coal preparation. Miner. Eng. 2010, 23, 301–312. [Google Scholar] [CrossRef]

- Constant, M.; Coppin, N.; Dubois, F.; Artoni, R.; Lambrechts, J.; Legat, V. Numerical investigation of the density sorting of grains using water jigging. Powder Technol. 2021, 393, 705–721. [Google Scholar] [CrossRef]

- Tromp, K.F. Neue Wege für Beurteilung der Aufbereitung von Steinkohlen. Glückauf 1937, 73, 125–131. [Google Scholar]

- Terra, A. Essai d’une théorie de lavage. In Revue de l’Industrie Minérale; Columbia University: New York, NY, USA, 1938. [Google Scholar]

- Pielot, J. Production value optimization with intermediate jig product recirculation. E3S Web Conf. 2016, 8, 1046. [Google Scholar] [CrossRef]

- Surowiak, A. Investigation and evaluation of jigging separation features. Arch. Min. Sci. 2018, 63, 839–851. [Google Scholar]

- Ahmed, M.M. Optimiztion of jigging proces using statistical technique. J. Eng. Sci. 2010, 38, 807–818. [Google Scholar] [CrossRef]

- Ahmed, M.M. Optimiztion of A jigging proces using statistical technique. Int. J. Coal Prep. Util. 2011, 31, 112–123. [Google Scholar] [CrossRef]

- Tripathy, A.; Panda, L.; Sahoo, A.K.; Biswal, S.K.; Dwari, R.K.; Sahu, A.K. Statistical optimization study of jigging process on beneficiation of fine size high ash Indian non-coking coal. Adv. Powder Technol. 2016, 27, 1219–1224. [Google Scholar] [CrossRef]

- Panda, L.; Sahoo, A.K.; Tripathy, A.; Biswal, S.K.; Sahu, A.K. Application of artificial neural network to study the performance of jig for beneficiation of non-coking coal. Fuel 2012, 97, 151–156. [Google Scholar] [CrossRef]

- Sobhy, A.; El-Midany, A.A.; Ibrahim, S.S. Celestite upgrading by jigs in presence of steel balls as ragging material. Physicochem. Probl. Miner. Process. 2021, 57, 118–128. [Google Scholar] [CrossRef]

- Nikiforova, L.V.; Matveev, A.I.; Sleptsova, E.E.; Boris, V.; Yakovlev, B.V. Mathematical modeling of the jigging process in mineral processing. In Proceedings of the 8th International Conference on Mathematical Modeling (ICMM-2017); AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2017; Volume 1907, p. 030037. [Google Scholar]

- Mishra, B.K.; Mehrotra, S.P. Modeling of particle stratification in jigs by the discrete element method. Miner. Eng. 1998, 11, 511–522. [Google Scholar] [CrossRef]

- Mishra, B.K.; Mehrotra, S.P. A jig model based on the discrete element method and its experimental validation. Int. J. Miner. Process. 2001, 63, 177–189. [Google Scholar] [CrossRef]

- Li, M.; Gong, D.W.; Xu, S.F. Research on applications of three layers neural network in dynamic modeling of jig system. In Proceedings of the 3rd World Congress on Intelligent Control and Automation, Hefei, China, 28 June–2 July 2000; IEEE: Piscatvie, NJ, USA, 2000; pp. 1176–1177. [Google Scholar]

- Mishra, B.K.; Adhikari, B. Analysis of fluid motion during jigging. Miner. Eng. 1999, 12, 1469–1477. [Google Scholar] [CrossRef]

- Woollacott, L.C. Accounting for the effect of particle density and size on stratification in mineral jigs: A preliminary model based on particle settling rates. Miner. Eng. 2022, 178, 107404. [Google Scholar] [CrossRef]

- Woollacott, L.C.; Tripathy, A.; Potgieter, H. The effect of operating conditions on density stratification in a batch jig I: The influence on the equilibrium stratification profile. Miner. Eng. 2021, 170, 106838. [Google Scholar] [CrossRef]

- Woollacott, L.C.; Bwalya, M.; Mabokela, L. A validation study of the King stratification model. J. S. Afr. Inst. Min. Metall. 2015, 115, 2. [Google Scholar] [CrossRef]

- Surowiak, A.; Brożek, M. Methodology of calculation the terminal settling velocity distribution of spherical particles for high values of the Reynold’s number. Arch. Min. Sci. 2014, 59, 269–282. [Google Scholar] [CrossRef]

- Surowiak, A.; Brożek, M. Methodology of calculation the terminal settling velocity distribution of irregular particles for values of the Reynold’s number. Arch. Min. Sci. 2014, 59, 553–562. [Google Scholar] [CrossRef]

- Woollacott, L.C. The impact of size segregation on packing density in jig beds: An X-ray tomographic study. Miner. Eng. 2019, 131, 98–110. [Google Scholar] [CrossRef]

- Crespo, E.F. Modeling segregation and dispersion in jigging beds in terms of the bed porosity distribution. Miner. Eng. 2016, 85, 38–48. [Google Scholar] [CrossRef]

- Gong, D.W.; Xu, S.F.; Wang, X.S. Research on application of recurrent neural network in modelling jigging system of coal preparation plant. Procedings of the 3rd World Congress on Intelligent Control and Automation, Hefei, China, 28 June–2 July 2000; IEEE: Piscatvie, NJ, USA, 2000; pp. 1147–1150. [Google Scholar]

- Zhang, J.; Tao, Y.J.; Kuang, Y.L.; Gui, X.H. Research on the impact of model jig test device operation factors on material bed. Energy Sources A Recovery Util. Environ. Eff. 2019, 41, 779–789. [Google Scholar]

- Shukla, V.; Kumar, C.R.; Chakraborty, D.P.; Kumar, A. Optimization of jigging process parameters to beneficiate iron ore fines—A case study of Tatasteel. Inzynieria Miner. 2019, 2, 165–170. [Google Scholar]

- Surowiak, A. Evaluation of the results of coal jigging process. In Proceedings of the E3S Web of Conferences, MEC 2017 Mineral Engineering Conference, Wisła, Poland, 20–23 September 2017; Volume 18, p. 01030. [Google Scholar]

- Brożek, M.; Surowiak, A. Argument of separation at upgrading in the JIG. Arch. Min. Sci. 2010, 55, 21–40. [Google Scholar]

- Rao, B.V.; Jeelan, G.; Shirke, S.; Gopalkrishna, S.J. Experimental validation of extended stratification model part B: Coal-ash segregation studies in a batch jig operation. Trans. Indian Inst. Met. 2017, 70, 375–394. [Google Scholar] [CrossRef]

- Rao, B.V.; Jeelan, G.; Shirke, S.; Gopalkrishna, S.J. Experimental Validation of Extended Stratification Model: Part A—Ore with Tracer Particle Studies in a Batch Jig Operation. Trans. Indian Inst. Met. 2017, 70, 359–373. [Google Scholar] [CrossRef]

- Rao, B.V. An improved stochastic model to describe partition surfaces of entire segregated batch jig bed. Miner. Eng. 2021, 170, 107064. [Google Scholar]

- Kumar, S.; Venugopal, R. Coal cleaning using jig and response surface approach for determination of quality of clean coal. Int. J. Coal Prep. Util. 2020, 40, 107–115. [Google Scholar] [CrossRef]

- Jamróz, D.; Niedoba, T. Application of Observational Tunnels Method to Select Set of Features Sufficient to Identify a Type of Coal. Physicochem. Probl. Miner. Process. 2014, 50, 185–202. [Google Scholar]

- Niedoba, T. Multi-parameter data visualization by means of principal component analysis (PCA) in qualitative evaluation of various coal types. Physicochem. Probl. Miner. Process. 2014, 50, 575–589. [Google Scholar]

- Jamróz, D.; Niedoba, T.; Surowiak, A.; Tumidajski, T. The use of the visualisation of multidimensional data using PCA to evaluate possibilities of the division of coal samples space due to their suitability for fluidised gasification. Arch. Min. Sci. 2016, 61, 523–535. [Google Scholar] [CrossRef]

- Niedoba, T. Application of relevance maps in multidimensional classification of coal types. Arch. Min. Sci. 2015, 60, 93–106. [Google Scholar]

- Jamróz, D.; Niedoba, T. Application of multidimensional data visualization by means of self-organizing Kohonen maps to evaluate classification possibilities of various coal types. Arch. Min. Sci. 2015, 60, 39–50. [Google Scholar]

- Jamróz, D. Application of multidimensional scaling to classification of various types of coal. Arch. Min. Sci. 2014, 59, 413–425. [Google Scholar]

- Jamróz, D. Application of multi-parameter data visualization by means of autoassociative neural networks to evaluate classification possibilities of various coal types. Physicochem. Probl. Miner. Process. 2014, 50, 719–734. [Google Scholar]

- Jamróz, D.; Niedoba, T. Comparison of selected methods of multi-parameter data visualization used for classification of coals. Physicochem. Probl. Miner. Process. 2015, 51, 769–784. [Google Scholar]

- Gawenda, T.; Surowiak, A.; Krawczykowska, A.; Stempkowska, A.; Niedoba, T. Analysis of the aggregate production process with different geometric properties in the light fraction separator. Materials 2022, 15, 4046. [Google Scholar] [CrossRef] [PubMed]

- Surowiak, A.; Brożek, M. A physical model of separation process by means of JIGS. Physicochem. Probl. Miner. Process. 2016, 52, 228–243. [Google Scholar]

- Surowiak, A.; Foszcz, D.; Niedoba, T. Evaluation of jig work on the basis of granulometric analysis of particle size fractions of benefication products in purpose of process optimization. IOP Conf. Ser. Mater. Sci. Eng. 2019, 641, 012006. [Google Scholar] [CrossRef]

- Surowiak, A.; Foszcz, D.; Niedoba, T. Optimisation of coal beneficiation in a jig in changing hydrodynamic conditions of its operation. Acta Montan. Slovaca. 2022, 27, 1–10. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).