Abstract

This study investigated the integration of perovskite solar cells (PSCs) on stainless steel (SS) substrates for application in building-integrated photovoltaics (BIPV). Using advanced atomic force microscopy measurements, we confirmed that enhanced substrate roughness increased the reflectance along an interface. Consequently, a remarkable final efficiency of 11.9% was achieved. Notably, PSCs, known for their exceptional efficiency of 26.1%, can overcome the inherent efficiency limitations of SS-based thin-film solar cells. In this study, a PSC with an efficiency of 14% was fabricated on a flexible SS substrate. This study is a significant step towards advancing sustainable energy solutions for BIPV applications. The global shift towards renewable energy sources has catalyzed intensive research and development efforts, rendering the exploration of alternative materials and manufacturing processes a priority. The success of PSCs on SS substrates underscores their promise to achieve a balance between efficiency and versatility in BIPV solutions. Moreover, our findings reveal that controlling the substrate surface characteristics can significantly enhance the performance of PSCs, offering a pathway toward greater energy efficiency and sustainability in the construction industry.

1. Introduction

The ever-increasing global demand for sustainable energy sources has propelled the relentless search for highly efficient solar cells, particularly those adaptable to diverse applications [1,2,3,4]. Two primary areas where solar energy seamlessly converges with architectural and transportation solutions are building-integrated photovoltaics (BIPV) and vehicle-integrated photovoltaics (VIPV) [5,6,7,8,9,10,11,12]. Thin-film solar cells, which can be manufactured on various substrates rather than on rigid crystalline silicon, have been extensively used in BIPV and VIPV. Among these, perovskites, capable of high efficiency, are currently being researched [13,14,15].

With the evolution of photovoltaic technologies, various solar-cell technologies have been meticulously tailored to function on flexible substrates. This endeavor spans a spectrum of materials, including amorphous silicon (a-Si:H), copper zinc tin sulfur selenide (CZTSSe), copper indium gallium selenide (CIGS), cadmium telluride (CdTe), dye-sensitized solar cells (DSSC), and organic photovoltaics (OPV) [16,17,18,19]. The development of solar cells on flexible substrates is a turning point in this field, facilitating innovative applications.

The quest for sustainable energy sources has sparked dynamic exploration of alternative substrates for photovoltaic applications. Among the several types of materials, stainless steel (SS) substrates have emerged as a compelling choice, boasting a constellation of unique advantages. These substrates are characterized by exceptional flexibility, proven durability against environmental stressors, and robust resistance to corrosion. With these advantages, SS substrates are applied in many fields. In the field of construction and architecture, SS panels play a crucial role in shaping structural elements, external facades, and roofing structures. The enduring stability they provide contributes significantly to the longevity of buildings. Also, in the automotive industry, stainless steel is integrated into vehicles as components and exterior materials. Its resilience against corrosion becomes particularly valuable in maintaining the overall lifespan and appearance of automobiles. Finally, in the field of electronics, stainless steel becomes an ally in providing durability and stability. It is employed in the outer casings and components of various electronic products. Therefore, applying solar cells to SS substrates makes it possible to utilize them in the above fields.

Consequently, SS substrates are considered the optimal choice for solar installations that require versatility and resilience, thereby fostering the prospect of innovative solar energy solutions.

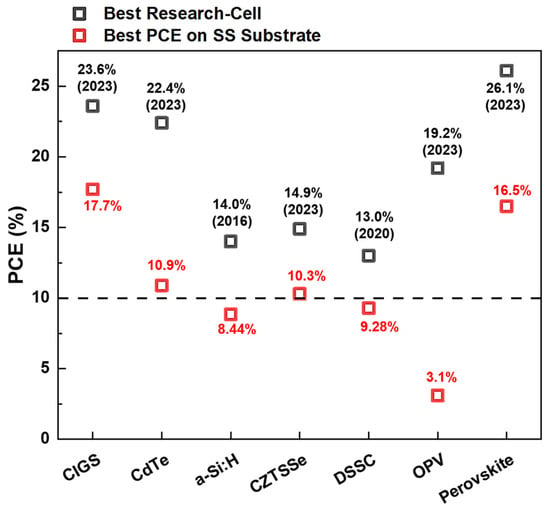

The best research-cell efficiencies and power conversion efficiencies (PCE) of SS substrates for thin-film solar cells, including a-Si:H, CZTSSe, CIGS, CdTe, DSSC, and OPV, are graphically shown in Figure 1 [20,21,22,23,24,25,26].

Figure 1.

PCE of best research-cell and best on SS substrate in thin film solar cells: Best Research-Cell PCE from NREL chart; Best PCE on SS Substrate from published paper.

Although SS substrates hold great promise, the historical challenge has been achieving high-efficiency solar cells that exceed the elusive 10% threshold for this unconventional material. However, this formidable endeavor has gained momentum with the advent of perovskite solar cells (PSCs). Notably, perovskite technology currently has the highest known efficiency in the solar cell realm (26.1%) [26]. PSCs have been effectively applied to steel substrates with a reported efficiency of 16.5% [27,28,29,30]. While previous studies have focused on the fabrication of perovskite solar cells (PSCs) on rigid SS substrates to achieve high efficiency, this paper distinguishes itself by successfully extending the fabrication of these cells to flexible substrates. Unlike the existing literature that predominantly addresses PSCs on rigid SS platforms, our work emphasizes the novel aspect of producing PSCs on flexible substrates, marking a significant departure from the conventional paradigm. This shift not only expands the scope of perovskite solar cell applications but also addresses the growing demand for flexible and lightweight photovoltaic technologies. In our study, while achieving a lower efficiency than this benchmark, we demonstrated a substantial efficiency of 11.9% by substituting the substrate with a steel substrate instead of a glass substrate. Furthermore, by extending our investigation to flexible substrates, the efficiency was enhanced to 14%. Additionally, we explored the effects of increased reflectance on current density when using SS substrates in future applications.

While PSCs demonstrate high efficiency on SS substrates, their practical application in BIPV, VIPV, etc., poses significant challenges. The potential leakage of lead (Pb) from PSCs raises environmental and human health concerns. In response to this issue, recent research has focused on developing robust strategies for immobilizing and capturing Pb, aiming to mitigate the associated risks [31,32]. These advancements in Pb immobilization and capture technologies are pivotal steps towards overcoming a critical barrier, thereby enhancing the viability of integrating PSCs into BIPV and VIPV systems in the near future.

2. Materials and Methods

2.1. Preparation of Materials

SS and polished SS substrates were obtained from POSCO. The polishing was carried out by rotating a buff with polished paper in the range of 240 to 320 mesh. Tin(4) oxide (SnO2) 15% in H2O colloidal dispersion was purchased from Alfa Aesar. N,N-Dimethylformamide (anhydrous, 99.8%) (DMF), dimethyl sulfoxide (anhydrous, 99.9%) (DMSO), Diethyl ether, chlorobenzene (anhydrous, 99.9%), acetonitrile (anhydrous, 99.8%), 4-tere-butylpyridine (96%), and bis (trifluoromethane) sulfonamide lithium salt (Li-TFSI) were purchased from Sigma-Aldrich. Methylammonium iodide (MAI) was purchased from Dyesol. Lead (2) iodide (PbI2) was purchased from TCI. 2,2′,7,7′-Tetrakis [N,N-di(4-methoxyphenyl)amino]-9,9′-spirobifluorene (spiro-OMeTAD) was purchased from Lumtec.

2.2. Perovskite Solar Cell Fabrication

The SS substrates were rinsed with acetone, ethanol, and isopropanol for 15 min each under sonication, followed by an ultraviolet (UV)-ozone treatment for 30 min. For the diffusion barrier, 1 μm SiO2 was deposited by PECVD on the SS substrate.

After the RF sputtering of Indium Tin Oxide (ITO) of approximately 150 nm, the substrate was annealed at 400 °C for 30 min. To deposit an electron transport layer (ETL), SnO2 15% in H2O colloidal dispersion was diluted with deionized water (1:7). It was then spin-coated onto ITO at 4000 rpm (dynamic spin coating). To prepare the MAPbI3 perovskite precursor solution, MAI (159 mg) and PbI2 (481 mg) were dissolved in DMF (636.6 μL)/DMSO (71 μL). Diethyl ether was dropped during spin coating. The substrate was dried on a hot plate at 60 °C for 1 min and then at 100 °C for 5 min. A spiro-OMeTAD solution was used as a hole transport layer (HTL). Spiro-OMeTAD (72.3 mg) powder was dissolved in 4-tertbutylpyridine (28.8 μL), Li-TFSI solution (520 mg in 1 mL of acetonitrile), and chlorobenzene (1 mL). The solution was then spin-coated onto a substrate. For the substrate configuration, a 20 nm MoOx sputter buffer layer and an ITO transparent electrode were deposited successively. Finally, a 100 nm Au electrode was thermally evaporated from the sample.

2.3. Measurement

The depth profile of the SS substrate was determined using dynamic secondary ion mass spectrometry (D-SIMS) (IMS-4fE7). The roughness of each substrate surface was measured using atomic force microscopy (AFM) (XE-100). The solar cell parameters of the devices were measured using a Xe lamp solar simulator (WACOM WXS-155S-10 class AAA) at 25 °C, with an airmass (AM) of 1.5, and 100 mW/cm2 irradiation under a standard test condition (STC). Calibration was performed prior to the measurement using a modulated reference silicon solar cell. We measured the photocurrent as a function of the voltage using a source meter (Keithley 2400). All light I–V measurements were performed using a 0.075 cm2 mask. The scan voltage setting time was 200 ms. X-ray diffraction (XRD) patterns were measured using an X-ray diffractometer (Rigaku) with a Cu Kα source (1.54 nm). Scanning electron microscopy (SEM) was performed using a Quanta 250 FEG microscope (FEI). To evaluate the electrical properties of the device, external quantum efficiency (EQE) measurements were performed using a 150 W Xe lamp (QEX7, PV measurement, Point Roberts, WA, USA) and a monochromator to provide monochromatic light in the wavelength range from 300 to 850 nm. The absorbance and reflectance were measured using UV–vis spectroscopy (JASCO V-670).

3. Results and Discussion

3.1. Confirmation of SiO2 Film for Diffusion Barrier

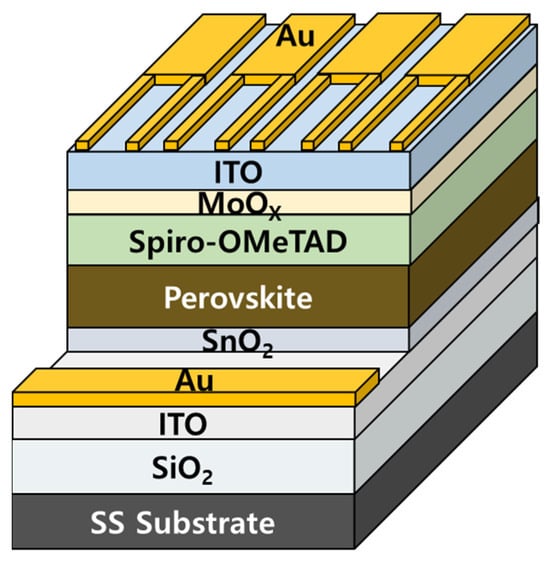

In this study, we constructed a PSC structure, illustrated in Figure 2, on an SS substrate using a substrate configuration. Notably, during the fabrication process, a 1 µm SiO2 layer was meticulously deposited between the rear transparent electrode and SS substrate. The SiO2 layer augmented the conductivity of the rear transparent electrode, ITO, via sputter deposition and subsequent annealing at 400 °C for 30 min. Notably, this annealing process, marked by a temperature of 400 °C, was the highest point in the solar cell fabrication sequence, primarily undertaken to thwart any potential impurity diffusion from the SS substrate.

Figure 2.

Perovskite solar cell structure on an SS substrate.

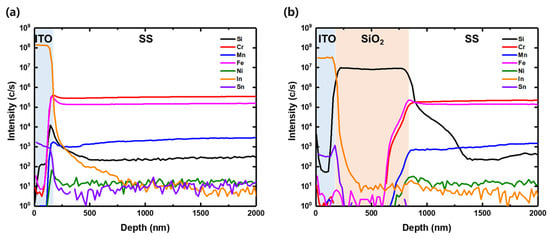

This specific technique parallels practices in the fabrication of CZTSSe or CIGS solar cells, where processing temperatures typically fall in the range of 450–550 °C [20,33]. To substantiate the effectiveness of our impurity diffusion barrier, we conducted ITO deposition and annealing with and without SiO2, followed by D-SIMS measurements. As shown in Figure 3, the outcomes confirmed that in the absence of SiO2, impurities including Fe and Cr infiltrated the ITO layer. In contrast, in the presence of SiO2, it acted as a robust diffusion barrier, successfully preventing impurities from infiltrating the ITO layer. This highlights the pivotal role of SiO2 as an effective inhibitor of impurity diffusion in solar cells.

Figure 3.

D-SIMS results after annealing ITO film (a) without diffusion barrier SiO2; (b) with diffusion barrier SiO2.

3.2. Perovskite Solar Cells on SS Substrates

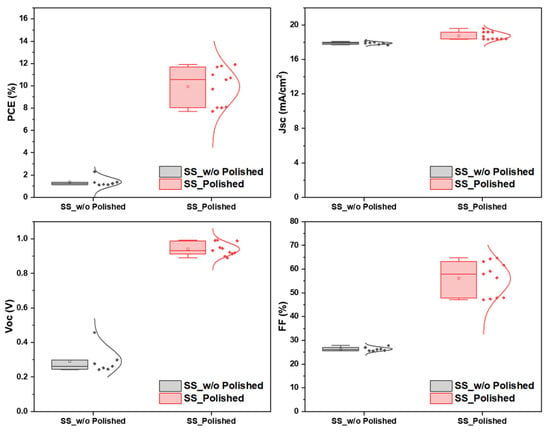

Following the successful validation of our impurity diffusion barrier, we fabricated solar cells on an SS substrate by employing the same approach as that applied to glass substrates, that is, utilizing a substrate configuration. To streamline the fabrication process, a rigid substrate of equivalent thickness to glass, denoted as 1.1 t, was used. In this case, two types of SS substrates were prepared, differing in whether they were polished or not, and cells were subsequently manufactured. The outcomes of these cells are visually presented in a numerical distribution graph for each parameter, as depicted in Figure 4. Notably, the PSCs on w/o polished substrates demonstrated the highest efficiency, as low as 2.3% (Table 1). This low efficiency is attributed to the roughness of the SS substrate. If the substrate is rough, the series resistance increases, resulting in low open-circuit voltage (VOC) and fill factor (FF).

Figure 4.

Parameters extracted from light J–V curve of perovskite solar cells on w/o polished and polished SS substrates. The parameters of each cell are indicated with dots, and their distribution is indicated with lines and boxes.

Table 1.

Best parameters of PSCs on w/o polished and polished SS substrates.

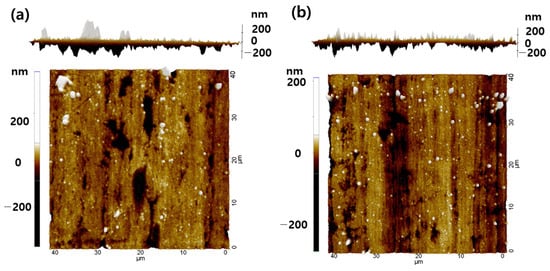

To address this challenge, solar cells were fabricated on polished substrates, leading to a substantial increase in efficiency of up to 11.9% (Figure 4). The most notable enhancements were observed in VOC and FF, primarily attributed to the improved smoothness of the SS substrate, as confirmed by AFM measurements shown in Figure 5. Through AFM measurements, the roughness and morphology of the sample surface can be confirmed. Upon examining Figure 5a,b, a discernible vertical pattern is evident. This particular configuration aligns with findings in the literature [34], leading to the conclusion that the polishing process for this sample was exclusively conducted in the vertical direction. In particular, a detailed roughness analysis considering the peak roughness (Rp = peak height–valley depth), roughness variation (RMS), and average roughness (Ra) revealed that the polished substrate exhibited a roughness level more than double that of the original substrate (Table 2).

Figure 5.

AFM results (a) w/o polished SS substrate; (b) polished SS substrate.

Table 2.

Roughness of w/o polished and polished SS substrates.

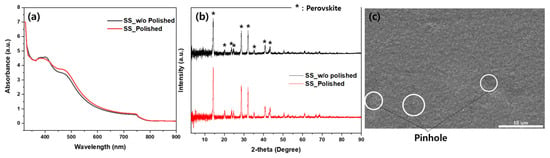

We conducted absorbance, XRD, and SEM measurements to investigate the properties of the perovskite thin film (Figure 6). The results indicate that the perovskite thin film is well-formed, as evidenced by the absorbance and XRD analyses. However, SEM images reveal the presence of pinholes in the perovskite thin film. These pinholes are observed to act as defects, exerting an influence on both VOC and FF. This suggests that the defects introduced by the pinholes have a discernible impact on the electrical characteristics of the perovskite solar cells, affecting both VOC and FF. Consequently, SS substrate roughness is a critical fact, highlighting its significance in shaping the overall performance of perovskite solar cells.

Figure 6.

Perovskite on SS substrates (a) absorbance; (b) XRD; (c) SEM image.

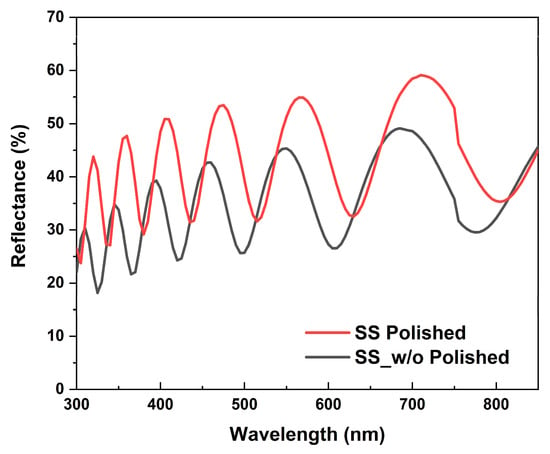

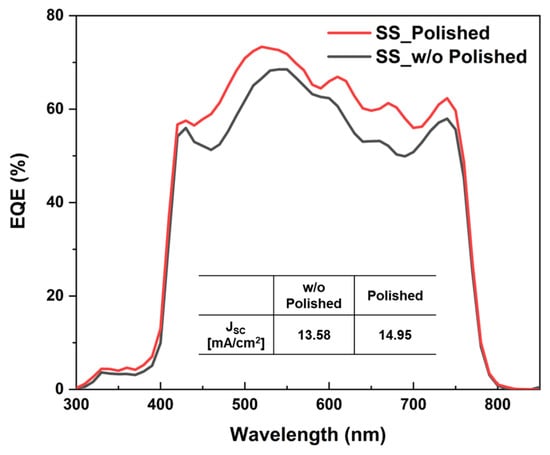

This smoother surface facilitated improved thin-film coating, minimized defects, and enhanced junction formation, resulting in an anticipated increase in Voc and FF. Notably, the short-circuit current density (JSC) increased even when the substrate configuration was considered. In Figure 7, the reflectance measurements demonstrate that the polished substrate exhibited over 10% higher reflectance across the entire wavelength range than the unpolished substrate. Figure 8 shows that the EQE results yielded higher EQE values for the polished substrate in the 400–800 nm wavelength range than for the substrate without polishing. The difference in JSC between the two cells in this range amounted to 1.37 mA/cm2. When the JSC values obtained through light current-voltage (LIV) measurements were compared, the difference was found to be 1.5 mA/cm2.

Figure 7.

Reflectance results of w/o polished and polished SS substrates.

Figure 8.

EQE results of perovskite solar cells on w/o polished and polished SS substrates.

Thus, employing an SS substrate with a roughness level similar to that of a glass substrate can produce PSCs with VOC and FF values on par with those of substrate configuration cells manufactured using high-efficiency glass substrates or other transparent flexible substrates, such as polyethylene terephthalate (PET) or polyimide. This indicates the feasibility of achieving high-efficiency cells with a significantly higher current density using SS substrates.

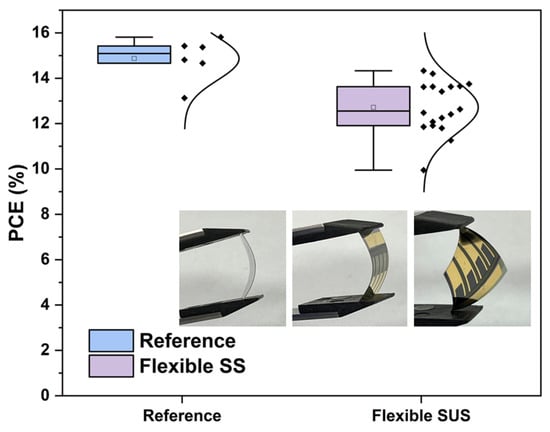

Additionally, this study extended the investigation to include flexible SS substrates with a thickness of 0.05 t. Solar cells were fabricated on these flexible substrates, yielding the following efficiency results. As shown in Figure 9 for reference, solar cells on glass substrates, which served as the benchmark, achieved an efficiency of approximately 15%. In contrast, solar cells on flexible SS substrates exhibited efficiencies with a range of 10–14%. The improved efficiency of the Perovskite Solar Cells (PSC) on flexible substrates compared to rigid substrates can be attributed to several factors.

Figure 9.

PCE results of reference (glass substrate) and flexible substrates. The PCE values of each cell are indicated with dots, and their distribution is indicated with lines and boxes.

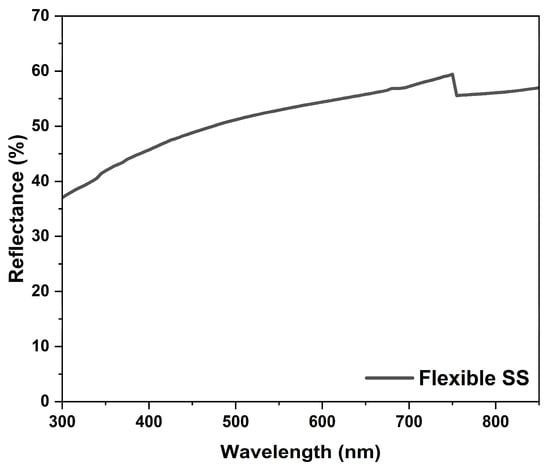

First, flexible stainless steel (SS) substrates undergo a planarization process during manufacturing through a roll-to-roll method. This process leads to a notable improvement in surface roughness. Specifically, it has been reported that the roughness is reduced to Rp = 8.9 nm [35]. Additionally, studies on the fabrication of Copper Indium Gallium Selenide (CIGS) solar cells on flexible SS substrates indicate RMS of approximately 13.6 nm [36]. An examination of the actual reflectance of the flexible SS substrate utilized in our experiments revealed consistently high reflectance across the entire wavelength spectrum, as shown in Figure 10. The high efficiency of flexible SS substrates is thought to be due to the following reasons. This diversification in substrate options underscores the adaptability of perovskite solar cell technology and its potential for tailoring solutions for various applications.

Figure 10.

Reflectance of a flexible substrate.

4. Conclusions

Aiming at efficient solar cells adaptable to various applications, we investigated the potential of SS substrates. These substrates offer unique advantages such as flexibility, durability, and corrosion resistance, rendering them promising for photovoltaics, particularly BIPV and VIPV. Historically, SS substrates have encountered challenges in achieving efficiencies exceeding 10%. However, we harnessed the power of perovskite solar cells, which are known for their remarkable efficiency of 26.1%. By substituting glass with SS substrates, we achieved a substantial efficiency of 11.9%, which was further improved to 14% with flexible SS substrates.

Our study revealed that a smoother substrate is essential for enhancing parameters such as VOC and FF. The polished SS substrate facilitated a better thin-film coating, reduced defects, and promoted efficient junction formation. This resulted in an increased JSC and higher reflectance. Furthermore, our exploration of flexible SS substrates demonstrated their adaptability, with efficiencies in the range of 10–14%. This diversity in substrates underscores the versatility of the PSC technology.

In summary, our research revealed the potential of SS substrates for perovskite solar cells, offering high efficiency and high current density. This represents a critical step toward enriching the sustainable energy landscape, where SS substrates play a pivotal role in broader solar power integration.

Author Contributions

Conceptualization, S.L. and S.-W.L.; methodology, S.B. and J.-K.H.; validation, W.L.; formal analysis, D.P.; investigation, S.-H.J.; resources, K.K.; data curation, J.-S.H.; writing—original draft preparation, S.L.; writing—review and editing, S.B.; visualization, S.C.; supervision, Y.K.; project administration, D.K.; funding acquisition, H.-S.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the “Human Resources Program in Energy Technology” of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) and was granted financial resources from the Ministry of Trade, Industry, and Energy, Republic of Korea (No. 20204010600470). This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) from the Ministry of Trade, Industry, and Energy (No. 20214000000680).

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ostfeld, A.E.; Arias, A.C. Flexible photovoltaic power systems: Integration opportunities, challenges and advances. Flex. Print. Electron. 2017, 2, 013001. [Google Scholar] [CrossRef]

- Lacerda, J.S.; Van Den Bergh, J.C. Diversity in solar photovoltaic energy: Implications for innovation and policy. Renew. Sustain. Energy Rev. 2016, 54, 331–340. [Google Scholar] [CrossRef]

- Alaaeddin, M.; Sapuan, S.; Zuhri, M.; Zainudin, E.; Al-Oqla, F.M. Photovoltaic applications: Status and manufacturing prospects. Renew. Sustain. Energy Rev. 2019, 102, 318–332. [Google Scholar] [CrossRef]

- Meddeb, H.; Götz-Köhler, M.; Neugebohrn, N.; Banik, U.; Osterthun, N.; Sergeev, O.; Berends, D.; Lattyak, C.; Gehrke, K.; Vehse, M. Tunable photovoltaics: Adapting solar cell technologies to versatile applications. Adv. Energy Mater. 2022, 12, 2200713. [Google Scholar] [CrossRef]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; Del Cano, T.; Rico, E. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858. [Google Scholar] [CrossRef]

- Heinstein, P.; Ballif, C.; Perret-Aebi, L.-E. Building integrated photovoltaics (BIPV): Review, potentials, barriers and myths. Green 2013, 3, 125–156. [Google Scholar] [CrossRef]

- Kuhn, T.E.; Erban, C.; Heinrich, M.; Eisenlohr, J.; Ensslen, F.; Neuhaus, D.H. Review of technological design options for building integrated photovoltaics (BIPV). Energy Build. 2021, 231, 110381. [Google Scholar] [CrossRef]

- Yang, R.J.; Zou, P.X. Building integrated photovoltaics (BIPV): Costs, benefits, risks, barriers and improvement strategy. Int. J. Constr. Manag. 2016, 16, 39–53. [Google Scholar] [CrossRef]

- Duigou, T.; Boichon, V.; Brancaz, X.; Chabuel, F.; Francescato, P.; Gaume, J.; Habchi, G.; Lagache, M.; Saffré, P.; Tenchine, L. VIPV: Process development of integrated photovoltaic cells in a double-curved composite structure for automotive application. In Proceedings of the 37th European Photovoltaic Solar Energy Conference and Exhibition, Online, 7–11 September 2020; pp. 7–12. [Google Scholar]

- Araki, K.; Ota, Y.; Lee, K.-H.; Yamada, N.; Yamaguchi, M. Curve correction of the energy yield by flexible photovoltaics for VIPV and BIPV applications using a simple correction factor. In Proceedings of the 2019 IEEE 46th Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; 2019; pp. 1584–1591. [Google Scholar]

- Commault, B.; Duigou, T.; Maneval, V.; Gaume, J.; Chabuel, F.; Voroshazi, E. Overview and perspectives for vehicle-integrated photovoltaics. Appl. Sci. 2021, 11, 11598. [Google Scholar] [CrossRef]

- Samadi, H.; Ala, G.; Lo Brano, V.; Romano, P.; Viola, F. Investigation of Effective Factors on Vehicles Integrated Photovoltaic (VIPV) Performance: A Review. World Electr. Veh. J. 2023, 14, 154. [Google Scholar] [CrossRef]

- Green, M.A.; Ho-Baillie, A.; Snaith, H.J. The emergence of perovskite solar cells. Nat. Photonics 2014, 8, 506–514. [Google Scholar] [CrossRef]

- Correa-Baena, J.-P.; Saliba, M.; Buonassisi, T.; Grätzel, M.; Abate, A.; Tress, W.; Hagfeldt, A. Promises and challenges of perovskite solar cells. Science 2017, 358, 739–744. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.S.; Park, N.G. Perovskite solar cells: From materials to devices. Small 2015, 11, 10–25. [Google Scholar] [CrossRef] [PubMed]

- Kang, D.-W.; Ryu, J.; Konagai, M. High-performance amorphous silicon thin film solar cells prepared at 100 C: Toward flexible building-integrated photovoltaics. Electron. Mater. Lett. 2019, 15, 623–629. [Google Scholar] [CrossRef]

- Kim, S.; Hoang, V.Q.; Bark, C.W. Silicon-based technologies for flexible photovoltaic (Pv) devices: From basic mechanism to manufacturing technologies. Nanomaterials 2021, 11, 2944. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Van Quy, H.; Bark, C.W. Photovoltaic technologies for flexible solar cells: Beyond silicon. Mater. Today Energy 2021, 19, 100583. [Google Scholar] [CrossRef]

- Ramanujam, J.; Bishop, D.M.; Todorov, T.K.; Gunawan, O.; Rath, J.; Nekovei, R.; Artegiani, E.; Romeo, A. Flexible CIGS, CdTe and a-Si: H based thin film solar cells: A review. Prog. Mater. Sci. 2020, 110, 100619. [Google Scholar] [CrossRef]

- Ahn, K.; Kim, S.-Y.; Kim, S.; Son, D.-H.; Kim, S.-H.; Kim, S.; Kim, J.; Sung, S.-J.; Kim, D.-H.; Kang, J.-K. Flexible high-efficiency CZTSSe solar cells on stainless steel substrates. J. Mater. Chem. A 2019, 7, 24891–24899. [Google Scholar] [CrossRef]

- Jung, K.H.; Yun, S.J.; Lee, S.H.; Lee, Y.J.; Lee, K.-S.; Lim, J.W.; Kim, K.-B.; Kim, M.; Schropp, R. Double-layered Ag–Al back reflector on stainless steel substrate for a-Si: H thin film solar cells. Sol. Energy Mater. Sol. Cells 2016, 145, 368–374. [Google Scholar] [CrossRef]

- Kranz, L.; Gretener, C.; Perrenoud, J.; Schmitt, R.; Pianezzi, F.; La Mattina, F.; Blösch, P.; Cheah, E.; Chirilă, A.; Fella, C.M. Doping of polycrystalline CdTe for high-efficiency solar cells on flexible metal foil. Nat. Commun. 2013, 4, 2306. [Google Scholar] [CrossRef]

- Kumar, V.; Wang, H. Selection of metal substrates for completely solution-processed inverted organic photovoltaic devices. Sol. Energy Mater. Sol. Cells 2013, 113, 179–185. [Google Scholar] [CrossRef]

- Pianezzi, F.; Chirilă, A.; Blösch, P.; Seyrling, S.; Buecheler, S.; Kranz, L.; Fella, C.; Tiwari, A. Electronic properties of Cu (In, Ga) Se2 solar cells on stainless steel foils without diffusion barrier. Prog. Photovolt. Res. Appl. 2012, 20, 253–259. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Y.; Su, Y.; Yang, Z.; Zhang, Y. Carbon/F-doped SnO2 nanowires array counter electrode for dye sensitized solar cell. Optoelectron. Adv. Mater. Rapid Commun. 2010, 4, 1332–1335. [Google Scholar]

- National Renewable Energy Laboratory (NREL). Available online: https://www.nrel.gov/pv/assets/pdfs/best-research-cell-efficiencies.pdf (accessed on 7 December 2023).

- Feleki, B.T.; Bouwer, R.K.; Wienk, M.M.; Janssen, R.A. Perovskite Solar Cells on Polymer-Coated Smooth and Rough Steel Substrates. Sol. RRL 2022, 6, 2100898. [Google Scholar] [CrossRef]

- Feleki, B.T.; Bouwer, R.K.; Zardetto, V.; Wienk, M.M.; Janssen, R.A. p–i–n perovskite solar cells on steel substrates. ACS Appl. Energy Mater. 2022, 5, 6709–6715. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Anadkat, N.; Avasthi, S. Nip Perovskite Solar Cells on Opaque Flexible Stainless-Steel Substrate. In Proceedings of the 2022 IEEE International Flexible Electronics Technology Conference (IFETC), Qingdao, China, 21–24 August 2022; IEEE: New York, NY, USA, 2022. [Google Scholar]

- Kumar, S.; Palariya, A.K.; Mohapatra, A.A.; Patil, S.; Avasthi, S. Acetamidinium-substituted methylammonium lead iodide based perovskite solar cell on flexible stainless-steel substrate. In Proceedings of the 2021 IEEE 48th Photovoltaic Specialists Conference (PVSC), Virtual, 20–25 June 2021; pp. 939–941. [Google Scholar]

- Valastro, S.; Smecca, E.; Mannino, G.; Bongiorno, C.; Fisicaro, G.; Goedecker, S.; Arena, V.; Spampinato, C.; Deretzis, I.; Dattilo, S. Preventing lead leakage in perovskite solar cells with a sustainable titanium dioxide sponge. Nat. Sustain. 2023, 6, 974–983. [Google Scholar] [CrossRef]

- Zhang, H.; Lee, J.-W.; Nasti, G.; Handy, R.; Abate, A.; Grätzel, M.; Park, N.-G. Lead immobilization for environmentally sustainable perovskite solar cells. Nature 2023, 617, 687–695. [Google Scholar] [CrossRef] [PubMed]

- Hamtaei, S.; Brammertz, G.; Poortmans, J.; Vermang, B. A review on barrier layers used in flexible stainless-steel based CIGS photovoltaic devices. npj Flex. Electron. 2023, 7, 36. [Google Scholar] [CrossRef]

- Gadwal, M.S.M.; Sartale, S.D.; Mathe, V.L.; Pathan, H.M. Substrate assisted electrochemical deposition of patterned cobalt thin films. Electrochem. Commun. 2009, 11, 1711–1713. [Google Scholar] [CrossRef]

- Okagata, Y. Design Technologies for Railway Wheels and Future Prospects. Nippon. Steel Sumitomo Met. Tech. Rep. 2013, 105, 26–33. [Google Scholar]

- Liu, W.-S.; Hu, H.-C.; Pu, N.-W.; Liang, S.-C. Developing flexible CIGS solar cells on stainless steel substrates by using Ti/TiN composite structures as the diffusion barrier layer. J. Alloys Compd. 2015, 631, 146–152. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).