Abstract

Growing global energy demand and limited reserves of traditional energy resources are causing a growing energy shortage. In order to meet future energy needs, new energy resources must be continuously explored. Deepwater drilling research has emerged as one of the key ways to address this issue, and well structure slimming is an effective way to increase drilling speed and reduce costs. The hole size of the second section of deepwater wells decreases from a conventional 660.4 mm to 444.5 mm and increases from 500–800 m to 800–1200 m, creating problems where the conventional 660.4 mm cone bit cannot be used, the rate of penetration (ROP) of the cone bit is low, and the service life is short. To solve these problems, a 444.5 mm artificial polycrystalline diamond compact (PDC) was designed for the first time for use at home or abroad, and according to the characteristics and operation requirements of the 914.4 mm conductor jetting process, a unique anti-collision gauge protector was designed, an innovative bypass nozzle was configured, and a hydraulic design to prevent bit balling in shallow soft mudstone was formulated. PDC jetting bit-drilling technology based on well structure slimming was successfully applied to eight deepwater wells in the eastern South China Sea, which successfully jetted a 914 mm conductor and greatly improved the ROP of their second-section holes. When the below-mudline depth of the second-section hole increased by 37.01%, the average ROP increased by 227.84%. These technical achievements have successfully realized deep drilling with seawater, increased speed and efficiency, achieved good application results, and accumulated valuable experiences that can be used for reducing the cost and increasing the efficiency of offshore drilling operations.

1. Introduction

In the contemporary era, energy is the vital lifeblood of our global society, serving as the foundational pillar upon which the multifarious sectors of the world’s economy pivot and flourish. Nevertheless, the inexorable rise in global energy demand—driven by burgeoning population dynamics, the relentless march of industrialization, and the ascendancy of emerging economies—portends a looming specter of depletion of conventional energy resources. This precipitates a pressing inquiry: how can we satiate future energy exigencies while concurrently alleviating our reliance on the finite reservoirs of traditional energy sources? The realm of deepwater drilling emerges as a beacon of hope in grappling with this exigency [1,2]. Deepwater regions enshroud vast, untapped reservoirs of petroleum and natural gas. Through the meticulous inquiry and extraction endeavors of deepwater drilling, we are poised to unearth and exploit these reservoirs, potentially extending the temporal bounds of conventional energy resource provisioning. Deepwater drilling, therefore, proffers a conduit toward diversifying our energy supply matrix, ameliorating the proclivity toward dependence on specific regions or sources, and bolstering the global energy supply’s resilience and security.

One of the main reasons for the rapid spread and wide application of surface conductor jetting technology, as an advanced method for operating the upper well section of deepwater wells, is its excellent adaptability and efficiency [3]. Oil and gas exploration and development in deepwater environments urgently require innovative technologies, and studies by scholars such as Jeanjean [4] and Yan [5] have shown that the introduction of surface conductor jetting technology provides a practical solution to meet this need. Wang et al. [6,7,8] revealed the effect of fluid phase transition on multiphase flow in deepwater wellbore and proposed a multiphase flow model by considering fluid phase transition, which lays an important foundation for the safety of deepwater drilling. Domestic and international deepwater surface conductor jetting technology utilizes well-designed combinations of drilling tools. It is common for these combinations to use a cone bit to drill a 914 mm diameter conduit and then move to a 660.4 mm cone bit to jet and complete the lowering of the second-opening 660.4 mm borehole, which is ultimately combined with a 508 mm surface casing [2,9]. This well structure design has been widely verified in the international deepwater well development field and has achieved remarkable success. Similarly, China’s self-operated deepwater drilling project in the South China Sea also adopted this proven form of wellbore structure in its initial stage to ensure stable downhole operations in the complex deepwater environment [10].

The control of the surface conductor in deepwater wells in terms of mud depth is crucial. Usually, based on the geological conditions of the deepwater seabed and the stability requirements of the submerged wellhead, the mud depth of the surface casing is controlled to be around 80 m. Wei et al. [11] found that the mud depth of the 508 mm surface casing for the design of a second-opening 660.4 mm wellbore is generally between 500 and 800 m. This strategy is designed to effectively seal off the shallow, unformed formations in deepwater from the complex third-opening borehole. The purpose of this well-designed mud entry depth strategy is to effectively seal the deepwater shallow, unformed formation in order to meet the requirements of complex three-opening borehole operations. Applying surface conduit injection technology to the upper section of deepwater wells is a well-established technique and plays a vital role in international and domestic deepwater oil and gas exploration and development projects. Its high adaptability, operational efficiency, and strong suitability for deepwater environments make it one of the formidable tools that can be used in addressing future challenges in deepwater exploration and development.

Jin and other scholars [12] have shown that streamlining and slimming the design of the wellbore structure is a key initiative in realizing cost savings and efficiency improvements in oil and gas well drilling operations. With the continuous advancement in self-operated deepwater drilling projects in the South China Sea, a useful way to reduce the cost of deepwater well drilling is carefully designing and slimming down the wellbore structure of the upper well section of deepwater wells to improve speed and efficiency. In deepwater well drilling, the high cost has always been a challenge, and Lukawski [13] found that the cost mainly covers several aspects, such as equipment, manpower, operating time, and resources. Therefore, by slimming down the design of the well structure, the time and resources required for drilling operations can be effectively reduced, thus increasing productivity while reducing the overall cost. In this process, the wellbore structure of the upper well section of a deepwater well plays a key role. By optimizing the wellbore design, not only can the efficiency of the drilling operation be improved, but unnecessary resistance and friction during the drilling process can also be reduced, equipment wear and tear can be reduced, and equipment life can be extended, which further reduces the burden of operating costs. This design concept has been widely used in self-operated deepwater drilling projects in the South China Sea, providing solid support for continued advancement in the project and the realization of economic benefits. Slimming down the well structure of the upper section of deepwater wells is one of the key strategies that can be used to reduce costs and improve efficiency in deepwater drilling operations. This useful technique not only helps to meet challenges in deepwater oil and gas exploration and development, but also contributes positively to improving the competitiveness and sustainability of deepwater drilling projects.

Currently, deepwater well drilling technology research mainly focuses on the analysis of the risk of dynamic positioning of deepwater drilling platforms [14], subsea casing technology [15], design of the surface casing entry depth [16], verification of subsea wellhead stability [17], drill string mechanics analysis [18], low-temperature/low-density cement slurries [19], and low-temperature drilling fluid systems [20]. A series of studies by Wang et al. [6,21] and Zhang et al. [22,23] showed that the problem of hydrate formation control is also very important for the deepwater drilling process. However, research has not covered the slimming down of wellbore structures and polycrystalline diamond compact (PDC) jetting bit-drilling technology [24,25]. Therefore, conducting an analysis on the slimming design of wellbore structures in the upper wellbore section of deepwater wells and innovatively researching matching small-sized PDC jetting bit-drilling technology is of significant importance. This endeavor will promote the practical application of the technology, contributing to the acceleration and cost reduction of deepwater drilling. Simultaneously, this research will continue to play a crucial role in addressing global energy shortages and contributing to the sustainability of future energy resources.

2. Materials and Methods

2.1. Deepwater Well Structure Slimming Technology

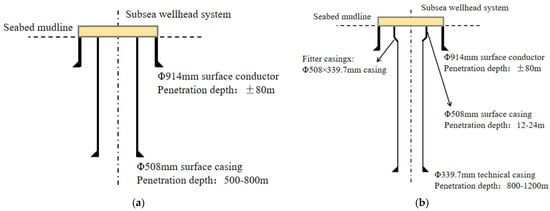

With advancements in deepwater self-operated drilling operations and the deepening of the understanding of the geological conditions of the deepwater seabed in the South China Sea and deepwater drilling technology, in order to reduce the operating costs of deepwater wells and improve operational efficiency, starting in 2020, the deepwater wells’ second-section borehole design was optimized. A comparison of the slimmed-down upper-section well structure of the deepwater well with the conventional upper-section well structure of the deepwater well is shown in Figure 1, which is slimmed from a conventional 660.4 mm borehole to 444.5 mm (with the use of a 339.7 mm casing instead of the original 508 mm surface casing). The penetration depth of the second section was deepened from the conventional 500–800 m to 800–1200 m for seawater deep drilling. In order to meet the requirement of a 476.25 mm high-pressure wellhead head (HPWH) sitting on a 914 mm low-pressure wellhead head (LPWH), the top of the 339.7 mm casing was connected with 1–2 pcs of 508 mm surface casing via a fitter casing, and the top of the 508 mm surface casing was welded with a 476.25 mm HPWH. This method of connecting a 508 mm casing at the top of a fitter casing and a 339.7 mm casing at the bottom is called a composite casing string. Because of this well structure design, the 508 mm surface casing is only installed in 1–2 pcs, the length of which is within 24 m. In comparison, the depth of the first opening of the 914 mm surface conductor is ±80 m, so the 508 mm surface casing is located inside of the 914 mm surface conductor after it is installed in the well. The size of the 444.5 mm wellbore’s second section will not affect its installation into the well.

Figure 1.

Slimmed-down upper-well section of the well structure of deepwater wells and conventional upper-well section structure of deepwater wells. (a) Upper-section well structure of conventional deepwater well; (b) Upper-section well structure of slimmed-down deepwater well.

The slimmed-down design of the second-section borehole in the upper section of deepwater wells has multiple technical advantages: (1) The size of the borehole is reduced from the conventional 660.4 mm borehole to 444.5 mm, which reduces the volume of rock breakage and rock cuttings. According to the calculation, under the same penetration depth, the cuttings volume of 444.5 mm borehole is only 45% of the 660.4 mm borehole, which reduces the energy required for drilling in the second section and is conducive to speeding up the drilling process and reducing the wear and tear on the drill bit. (2) The operation of the upper section of the deepwater wells is carried out via seawater drilling and the cuttings are returned from the seabed to be discharged into the sea, so after the structure of the second section has been slimmed and the penetration has been deepened, it can conduct deep seawater drilling. After slimming down the structure of the second section and increasing the penetration depth, deep drilling with seawater is realized, and the amount of drilling fluid system required for the lower well section is reduced. Deepwater wells are affected by low temperatures in the seabed, the polyammonium drilling fluid system has good rheology, and hydrate inhibition is generally used [15], which is expensive.

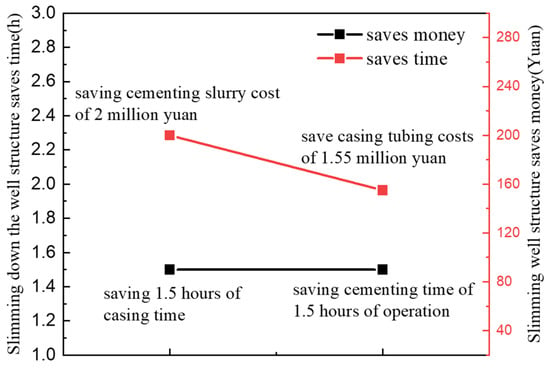

(3) After the well structure is slimmed down, the conventional 508 mm surface casing is replaced with 508 mm + 339.7 mm composite casing strings, which saves the cost of casing tubing, and the small-size casing connection is more efficient. Compared with the conventional cementing method of a 508 mm surface casing in a 660.4 mm borehole, a 339.7 mm casing in a 444.5 mm borehole can significantly reduce the cost of cementing slurry and additives and reduce the time of cementing operation. After calculations, we determined that the second section reaches a penetration depth of 800 m; for example, the use of slimming after the well structure compared to the conventional design of the pair is shown in Figure 2. This design can save casing tubing costs up to 1.55 million CNY, 1.5 h of casing time, cementing slurry costs up to 2 million CNY, and up to 1.5 h of cementing time. (4) The reduction in the size of the second section is conducive to correcting the deviation correction operation, and in the early stage in a number of deepwater wells, a second open 660.4 mm borehole drilling well deviation occurs. In the previous period, there were many deepwater wells with 660.4 mm boreholes where well deviation occurred, and it was difficult and inefficient to deviate correction using the motor and large-size cone bit. (5) Due to the reduction in the borehole size, there is no need to use the conventional 241.3 mm drill collars and measuring tools in the bottom drilling tools, and it is possible to use the 203.2 mm collars and measuring tools, which can be used directly in the drilling derrick after the completion of the operation of the upper section and in the subsequent lower section of the 311.3 mm collars and measuring tools. After completing the upper section, these drilling tools can stand directly on the drilling platform derrick and be reused in the subsequent 311.15 borehole of the lower section, saving the time required for dismantling and reassembling the drilling tools.

Figure 2.

Comparison of the structure of the slimmed-down borehole with the conventional design after the second section at a penetration depth of 800 m.

2.2. Innovative Design of PDC Jetting Bit

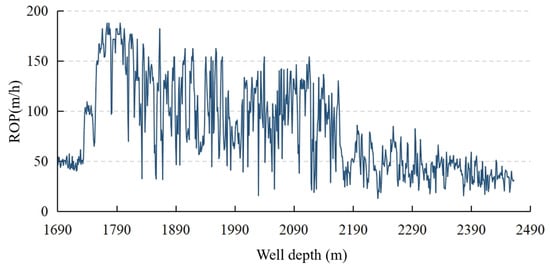

The first problem introduced by the slimming of the size of the second-section borehole in the upper section of the deepwater well is that the conventional 660.4 mm cone bit is unable to perform continuous drilling of the second-section 444.5 mm borehole after the conductor jetting is in place. It is necessary to design a 444.5 mm drill bit to drill the second-section 444.5 mm borehole and perform the first-opening conduit jetting operation simultaneously. Subsequently, there is an increase in the penetration depth of the second section, which leads to an increase in the formation strength and a decrease in drilling ability, and the use of a cone bit will result in a slow rate of penetration (ROP) and low drilling efficiency, which has been demonstrated in the second open drilling operation using a conventional 660.4 mm cone bit. For example, in a deepwater well in Liwan, South China Sea, with a water depth of 1583.6 m, a 914 mm conductor depth of 80.4 m, and a 660.4 mm borehole depth of 853.4 m (starting depth of 1690 m, ending depth of 2463 m, and footage of 773 m), a conventional 660.4 mm cone bit is used to perform the conductor jetting and the second section of the borehole drilling. As can be seen in Figure 3, the mechanical drilling speed of the second section of the well can be reduced from an average of about 100 m/h to an average of about 50 m/h 550 m below the mudline. In the last 100 m of drilling, it is even reduced to about 30 m/h, a significant reduction, resulting in an average ROP of 61.2 m/h in the second section of the borehole, which is less than the expected operational efficiency.

Figure 3.

ROP diagram of a deepwater well with second section.

In addition, since the cone bit consists of movable parts such as wheel carriers and bearings, it has a limited service life under deep seawater drilling operations, with increased drilling pressure, risk of dropping the parts into the well, and subsequent complications.

Based on the above-mentioned problems of slimming the well structure in the upper section of deepwater wells—combined with the geological characteristics wherein the shallow stratum of deepwater wells in the eastern part of the South China Sea is poorly formed and the lithology is mainly a large set of mudstones, as well as the mechanism of cutting and breaking the rock by the teeth of the PDC bit—an innovative 444.5 mm PDC jetting bit design was developed. The advantages of the innovatively designed PDC jetting drill bit over the conventional cone bits used at home and abroad are shown in Table 1 below.

Table 1.

Comparison of advantages of PDC jetting drill bits over conventional cone bits.

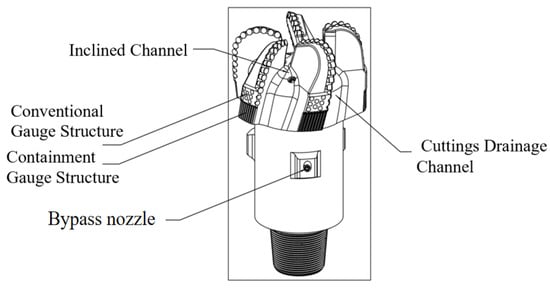

The structure of the innovatively designed 444.5 mm PDC jetting drill bit is shown in Figure 4, and the hole is designed with five cutter blades and a single row of teeth. In order to support smooth jetting operation in a 914 mm large-size conductor, this bit has two obvious design features compared with the conventional PDC bit:

Figure 4.

Schematic structure of 444.5 mm PDC jetting drill bit.

- (1)

- Unique anti-collision design. Due to the smaller size of the drill bit and the increased gap between the drill bit and the surface conductor ring, the drill bit is prone to swinging and collision at the conductor’s shoe position during the jetting operation, resulting in damage to the drill bit. In order to solve this problem, an anti-collision retainer is designed at the conventional retainer, and anti-collision retainer vertical bars are arranged. In order to take into account the abrasion resistance of the drill bit and the high feed rate, combined with the theoretical analysis of the length of the drill bit extending from the conductor shoe [26,27], the length of the drill bit extending from the bottom end of the conductor shoe is designed to be in the range of 150–200 mm, ensuring that the lower edge of the conductor shoe is within the length of the drill bit’s anti-collision retaining diameter.

- (2)

- Innovative bypass nozzle configuration. The increase in annular space between the drill bit and the conductor will lead to two problems: one is that it is more difficult to return the cuttings in the annular space of the conductor, and the other is that a stratigraphic step surface can easily form at the conductor shoe, which may lead to a low injection efficiency or the accumulation of cuttings to block the annular space of the conductor, resulting in a failed operation. Therefore, a bypass nozzle with a 45° inclination angle toward the bottom of the drill bit and an inner diameter of 11.1 mm was designed to hydrodynamically flush the stratum step between the drill bit and the conductor shoe and assist in the hydrodynamic return of cuttings through the design of a reasonable bit space.

In addition to the above two technical features, in terms of the characteristics of deepwater shallow soft mudstone, in order to prevent bit balling, the height of the cutter blade at the crown of the bit and the space of the drill flute were increased, and the depth of the drill flute was designed to be 95–130 mm. Different from conventional drilling, where rock breaking is mainly accomplished by the mechanical cutting or milling action of the teeth of the bit [28], the conductor jetting process relies on the water jets in the water eye of the bit to flush the soft mud to form a hole, so the hydrodynamic design of the jetting bit is the key. Based on the hydrodynamic parameter design, the innovatively designed PDC jetting drill bit has nine Φ11.11 mm nozzles in the crown of the drill bit, of which four small-angle nozzles are arranged near the center of the drill bit and five large-angle inclined nozzles are positioned near the shoulder of the drill bit. As measured by the mud pump displacement of 5200 m/L on the offshore platform, the total hydraulic force of the drill bit reaches 490 hp, and the impact strength of the water jet is over 60 kpa, which meets the requirements of deepwater surface conductor jetting operation.

3. Field Applications

The PDC jetting bit-drilling technology based on the slimming of well structures has been implemented and applied in eight deepwater wells in the eastern South China Sea; these eight wells all use the innovatively designed 444.5 mm PDC jetting bit to jet down the 914 mm conductor, and the second-section drilling operation process is safe and smooth.

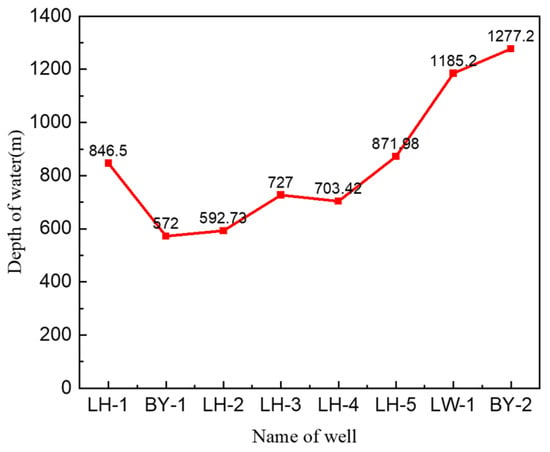

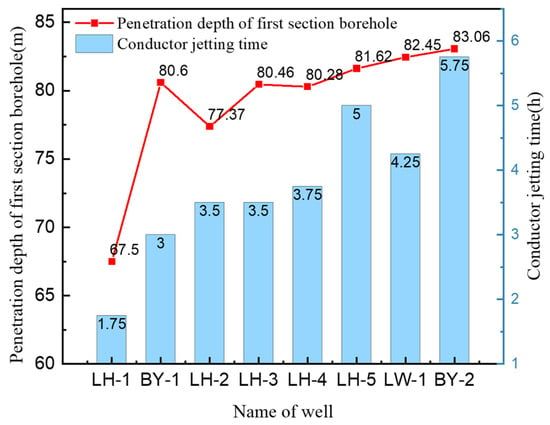

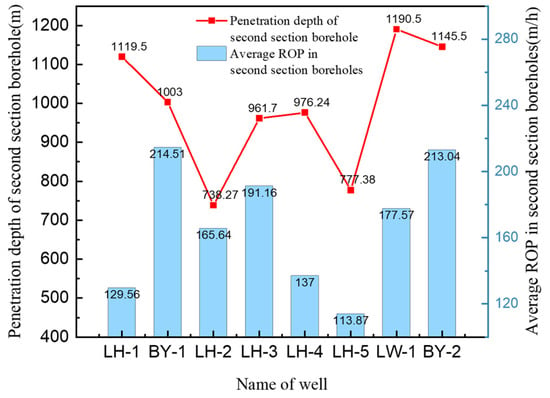

The operating water depth of the technology application well is shown in Figure 5, and the operating data of the first-section borehole and the second-section borehole of the technology application well are shown in Figure 6 and Figure 7. The operation data of the eight wells are shown in Table 2; the water depth range is 572–1277.2 m, the penetration depth of the 914 mm surface conductor is 67.5–83.06 m, and the penetration depth of the 444.5 mm borehole is 738.27–1190.5 m. The maximum penetration depth of the second borehole is 1190.50 m, the average mechanical drilling speed of the second borehole exceeds 200 m/h, and the maximum is 214.51 m/h, which is the record for the highest mechanical drilling speed of the second borehole in the deepwater drilling operation.

Figure 5.

Operational water depth of technical application wells.

Figure 6.

Operational data of the technical application well’s first-section borehole.

Figure 7.

Operational data of the technical application well’s second-section borehole.

Table 2.

Statistical table of operational data of wells where the technology is applied.

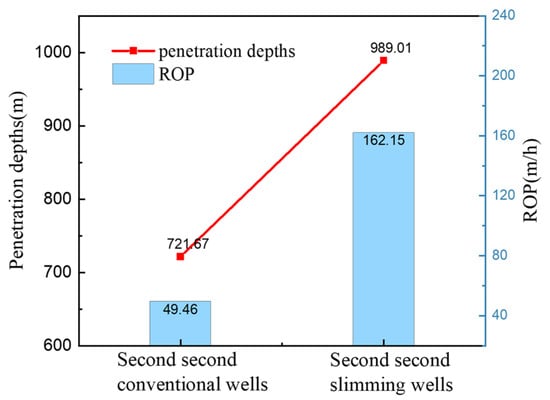

The average time for conductor jetting in the eight wells is 3.81 h, compared with the average of 5 h in the previous operation. This result is 23.8% faster, among which the time for conductor jetting of LH-1 well is only 1.75 h, which sets a new record for the shortest time for deepwater conductor jetting in China. As shown in Figure 8 below, after the deepwater well structure is slimmed down, the average depth below the mudline in the eight wells’ second-section 444.5 mm boreholes reaches 989.01 m, compared with 721.67 m, the average depth below the mudline in the conventional 660.4 mm boreholes in the previous operation; overall, this is an increase of 37.01%. After adopting the innovatively designed 444.5 mm PDC jetting bit, the average mechanical drilling speed of the eight wells’ second section was 162.15 m/h, compared with the average mechanical drilling speed of 49.46 m/h of the conventional 660.4 mm bit in the previous operation. The average mechanical drilling speed was increased by 227.84%, with an increase in penetration depth of 37.01%, realizing the increase in speed and efficiency.

Figure 8.

Comparison of conventional and slimmed-down technologies for deepwater well body structures.

On site, one innovatively designed 444.5 mm PDC jetting drill bit was used to complete the drilling of the upper section of all eight deepwater wells, and the drill bit was only slightly worn and could be used again. If a cone bit was used, only one bit could be used for a maximum of three wells, and three cone bits were needed to complete the eight wells. Considering the operating time saved by speeding up drilling, the cost of cementing slurry and casing materials saved by the slimming of the well body, and the cost of drilling fluid materials saved by the deep drilling of seawater, the operating cost saved for a single well exceeded 4 million CNY, and the cumulative economic benefit of the eight deepwater wells exceeded 30 million CNY, a great reduction in the cost of deepwater operations.

4. Conclusions

Deepwater drilling research is critical to solving the world’s energy shortages. Deepwater drilling provides critical support to meet the growing global energy demand by discovering new hydrocarbon reserves, diversifying energy supplies, and supporting technological innovation and economic development. Research on deepwater PDC jetting bit-drilling technology with lean well structures can contribute to future energy sustainability.

The innovatively designed 444.5 mm PDC jetting bit substantially increased the ROP of the second section in deepwater wells compared with the conventional cone bit, met the design requirements of slimming the structure of deepwater wells, realized deep drilling with seawater, and saved time in the operation period and drilling material costs.

The small-size 444.5 mm PDC jetting bit and large-size 914.4 mm surface conductor have the problem of a small bit in the conductor shoe position swinging back and forth, as well as low jetting efficiency and other problems. Unique anti-collision to protect the diameter of the design, innovative configuration of the bypass nozzle, and improving the jetting displacement and other methods can effectively solve these problems to ensure that the conductor’s surface is safe and smooth jetting operations are performed.

The deepwater well’s second-section borehole size is reduced after slimming, reducing the stability of the subsea wellhead. The need for target well field investigation information, as well as operating conditions and strict calibration of the stability of the subsea wellhead, can ensure that the energy extraction of deepwater wells is safe and reliable and provides the necessary guarantee for a sustainable energy supply.

Author Contributions

Conceptualization, W.Z.; methodology, D.G.; formal analysis, W.Z.; resources, Y.Z.; data curation, D.Y.; writing—original draft, W.Z., D.G., Y.Z. and D.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Major Scientific and Technological Project “Deepwater Drilling and Completion Engineering Technology” (2016ZX0528-001) in China, as well as the National Natural Science Foundation of China (NSFC) Key Project “Basic Theory Research on Key Technology of Deepwater and Shallow Drilling” (51434009).

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Amadi, K.; Iyalla, I. Application of mechanical specific energy techniques in reducing drilling cost in deepwater development. In Proceedings of the SPE Deepwater Drilling and Completions Conference, OnePetro, Galveston, TX, USA, 20–21 June 2012. [Google Scholar]

- Akers, T.J. Jetting of structural casing in deepwater environments: Job design and operational practices. SPE Drill. Complet. 2008, 23, 29–40. [Google Scholar] [CrossRef]

- D’Ambrosio, P.; Prochaska, E.; Bouska, R.; Tinsley, D.; Hart, S. Cost Effective Ultra-Large Diameter PDC Bit Drilling in Deepwater Gulf of Mexico. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 5–7 March 2013. [Google Scholar]

- Jeanjean, P. Innovative design method for deepwater surface casings. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 29 September–2 October 2002; p. 77357. [Google Scholar]

- De, Y.A.; Bin, C.H.; Ruirui, T.I.; Lingan, S.O.; Biao, W.A.; Baobo, L.I. Research on Increasing Drilling Speed for Deepwater conductor Jetting. Drill. Prod. Technol. 2021, 44, 36. [Google Scholar]

- Wang, Z.; Sun, B. Annular multiphase flow behavior during deep water drilling and the effect of hydrate phase transition. Pet. Sci. 2009, 6, 57–63. [Google Scholar] [CrossRef]

- Wang, Z.; Sun, B.; Sun, X.; Li, H.; Wang, J. Phase state variations for supercritical carbon dioxide drilling. Greenh. Gases Sci. Technol. 2016, 6, 83–93. [Google Scholar] [CrossRef]

- Wang, Z.; Lou, W.; Sun, B.; Shaowei, P.; Xinxin, Z.; Hui, L. A model for predicting bubble velocity in yield stress fluid at low Reynolds number. Chem. Eng. Sci. 2019, 201, 14815. [Google Scholar] [CrossRef]

- Syazwan, M.; Shafei, A.; Paimin, M.R.; Su’if, M.Z.; Abidin, H.Z.; Ismail, Y.; Natarajan, S. Enhancement of Structural conductor Design and Execution of Jetting Operations for Ultra-Deepwater Wells in Brunei. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 25–27 October 2016; p. 182427. [Google Scholar]

- Liu, S.; Xie, R.; Tong, G.; Wu, Y.; Xu, G. Progress and prospect of deepwater well drilling and completion technique of CNOOC. Acta Pet. Sin. 2019, 40, 168. [Google Scholar]

- Wei, H.; Yang, J.; Liu, Z.; Ye, J.; Zhang, J.; Yan, D.; Li, S.; Zhang, K.; Wang, W. Study on safety control technology of surface conductor jetting penetration in ultra-deep water soft formation drilling. In Proceedings of the ISOPE International Ocean and Polar Engineering Conference, ISOPE, Honolulu, HI, USA, 16–21 June 2019. [Google Scholar]

- Jin, X.; Wen, J.; Li, L.; Guo, W.; Zhou, G. Analysis of the emergency disconnection range of dynamically positioned platforms in deepwater drilling operations. China Offshore Oil Gas 2017, 29, 116–121. [Google Scholar]

- Lukawski, M.Z.; Anderson, B.J.; Augustine, C.; Capuano, L.E., Jr.; Beckers, K.F.; Livesay, B.; Tester, J.W. Cost analysis of oil, gas, and geothermal well drilling. J. Pet. Sci. Eng. 2014, 118, 1–14. [Google Scholar] [CrossRef]

- Shen, Y.; Zhao, L. Safety emergency response measures for out of control drift of offshore dynamic positioning drilling platform. Drill. Prod. Technol. 2013, 36, 118–120. [Google Scholar]

- Zhou, J.L.; Xu, L.B. Research progress of key technologies for deepwater drilling risers. China Offshore Oil Gas 2018, 30, 135–143. [Google Scholar]

- Jin, Y. Calculation method of surface conductor setting depth in deepwater oil and gas wells. Acta Pet. Sin. 2019, 40, 1396. [Google Scholar]

- Wang, L.; Yang, J.; Li, L.; Hu, Z.; Ke, K.; Zang, Y.; Sun, T. Wellhead stability in gas hydrate formation during deep-water drilling. Chin. J. Geotech. Eng. 2022, 44, 2312–2318. [Google Scholar]

- Gao, D.L.; Wang, Y.B. Progress in tubular mechanics and design control techniques for deepwater drilling. Pet. Sci. Bull. 2016, 1, 61–80. [Google Scholar]

- Feng, Y.; Song, M.; Zhang, H.; Li, H. Liquid cementing fluid reduced lightened deepwater light-weight cement slurry. Drill. Fluid Complet. Fluid 2017, 34, 80–84. [Google Scholar]

- Geng, T.; Ziu, Z.; Tang, Z.; Zhao, X.; Miao, H. The development and application of high temperature resistant and strong inhibitive water-based drilling fluid for deepwater drilling. Pet. Drill. Tech. 2019, 47, 82–88. [Google Scholar]

- Wang, Z.; Sun, B. Deepwater gas kick simulation with consideration of the gas hydrate phase transition. J. Hydrodyn. Ser. B 2014, 26, 94–103. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Liu, S.; Meng, W.; Sun, B.; Sun, J.; Wang, J. A method for preventing hydrates from blocking flow during deep-water gas well testing. Pet. Explor. Dev. 2020, 47, 1256–1264. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, Z.; Sun, B.; Sun, X.; Liao, Y. An integrated prediction model of hydrate blockage formation in deep-water gas wells. Int. J. Heat Mass Transf. 2019, 140, 187–202. [Google Scholar] [CrossRef]

- Hu, H.; Guan, Z.; Wang, B.; Liang, D.; Sun, M.; Wang, X.; Chen, W. Weight-on-bit self-adjusting dual-diameter bit leads a step change in drilling bit technology. In Proceedings of the International Petroleum Technology Conference, IPTC, Beijing, China, 26–28 March 2019. [Google Scholar]

- Eustes, A.; Bourdon, N.; Joshi, D.; McKenna, K.; Uzun, O.; Zody, Z.; Alhaidari, S.; Amer, A. 4 Onshore Drilling. In Advances in Terrestrial and Extraterrestrial Drilling: Ground, Ice, and Underwater; CRC Press: Boca Raton, FL, USA, 2021; Volume 63. [Google Scholar]

- Yang, J.; Yan, D.; Tian, R.; Zhou, B.; Liu, S.; Zhou, J.; Tang, H. Bit stick-out calculation for the deepwater conductor jetting technique. Pet. Explor. Dev. 2013, 40, 394–397. [Google Scholar] [CrossRef]

- Zhou, B.; Yang, J.; Liu, Z.; Zhou, R. Model and experimental study on jetting flow rate for installing surface conductor in deep-water. Appl. Ocean. Res. 2016, 60, 155–163. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, D.; Zhao, Y.; Zhou, Y.; Tang, Q.; Han, J. Simulation and experimental study on temperature and stress field of full-sized PDC bits in rock breaking process. J. Pet. Sci. Eng. 2020, 186, 106679. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).