Abstract

This study focuses on an analysis of the spray behavior, combustion, and emission characteristics of jet propellant-5 (JP-5) and biodiesel fuels with single-injection timing and multiple split injection strategies in a common rail direct injection (CRDI) single-cylinder diesel engine system. The analysis includes visualization of the spray and combustion. Multiple split injection strategies (e.g., double, triple, quadruple, and quintuple) were considered by equally distributing the fuel injection amount within the single-injection. Injection of biodiesel has a delayed start (0.2 ms) as well as shorter spray tip penetration compared with JP-5. As the fuel injection timing was approached to the top dead center (TDC), the engine performance and combustion efficiency improved. Retarding the injection timing contributed to an increase in carbon dioxide (CO2) (JP-5: max. 2.6% up, BD100: max. 1.5% up) and a decrease in carbon monoxide (CO) (JP-5: max. 93% down, BD100: max. 91% down) and nitrogen oxides (NOx) (JP-5: max. 83% down, BD100: max. 82% down). In comparison with JP-5, biodiesel showed disadvantages from the point of its combustion and emission characteristics for all injection timings. The quadruple-injection strategy, in which fuel injection was performed four times, showed excellent combustion, engine performance, and combustion efficiency. The CO2 emissions were highest with the quadruple-injection strategy (JP-5: 6.6%, BD100: 5.8%). The CO emissions of biodiesel decreased as the pulses of split injection extended, and a significant reduction of 83.8% was observed. NOx increased as the number of split injections increased (JP-5: max. 37% up, BD100: max. 52% up). JP-5 was a longer ignition delay than that of biodiesel from combustion flame visualization results. The final combustion in the multiple-injection strategy showed a typical diffusion combustion pattern.

1. Introduction

The greatest advantage of a diesel engine installed with an electronic fuel injector system and a common rail system is that it is possible to diversify the fuel injection methods through, for example, fuel injection pressure control, timing control, and injection frequency control. Among the various fuel injection methods, controlling the fuel injection timing and injection frequency has remarkable effect on the combustion quality and emission levels under constant engine operating conditions. The fuel injection timing strategy is a very powerful tool that can optimize engine performance and emissions with a constant fuel injection amount. As the fuel injection timing is retarded toward the TDC, higher in-cylinder pressure and in-cylinder temperature are produced. A shorter ignition delay, a reduction in negative work, and a longer combustion period can be achieved under these conditions. Consequently, the engine’s performance and combustion efficiency improve. In terms of emissions, the positive effect of reduced CO and NOx is expected [1,2,3]. Table 1 reviews the results of published research on the influences of fuel injection timing.

Table 1.

Studies on the effects of injection timing.

The multiple-injection strategy is a concept in which the main injection is shared into double or more injections. This method can further expand the reaction area between the air and combustion flame in the combustion chamber. Due to its affection, the distribution of rich regions, which usually occur in single-injection combustion, is reduced inside the combustion chamber. When the multiple-injection strategy is applied to a diesel engine, the combustion generated during the compression stroke increases the in-cylinder pressure and temperature. Therefore, the ignition delay duration of the main injection is shortened, the ROHR is suppressed, and NOx is deceased. Moreover, the application of multiple injection in diesel engines with a low compression ratio can improve their cold-start capability [7,8,9,10]. Table 2 reviews the results of published research on the application of multiple-injection strategies.

Table 2.

Studies on the effects of multiple-injection strategies.

Jet propellant (JP-5) is used for naval aircraft, while JP-8 is used for ground-based military aircraft. Although the physical properties of JP-5 and JP-8 are similar, JP-5 has a higher flash point and is mainly stored in naval vessels. Kerosene-based military jet fuel has a lower density, viscosity, and cetane number compared with conventional diesel fuel. These physicochemical properties increase the ROHR in the premixed combustion stage by lengthening the ignition delay. The higher vaporization of JP-5 results in rapid mixture formation, whereas its low cold flow plugging point (CFPP) ensures fuel supply to the engine in low-temperature environments [15,16]. Table 3 reviews the results of published research on the applications of diesel engines with JP-5 and military jet fuel.

Table 3.

Studies on the effects of JP-5 and military aviation fuel.

Biodiesel is an eco-friendly alternative fuel that has a higher density, viscosity, cetane number, and a lower heating value compared with diesel fuel. A disadvantage of biodiesel is the atomization of fuel droplets, which weakens the formation of the mixture and burns in a locally fuel-rich region, resulting in incomplete combustion. These fuel droplets cause the reduced spray tip penetration and engine power of biodiesel. The oxygen component of biodiesel plays a significant role in shortening the ignition delay; however, more NOx is formed as the addition ratio of biodiesel increases. Various studies have shown that CO decreases and NOx increases when pure biodiesel or biodiesel blend oil is used in a diesel engine [23,24,25]. One study reported that the physical properties of biodiesel at a low injection pressure caused poor spray and atomization, which resulted in incomplete combustion. As a result, CO increased and NOx decreased [26,27,28]. Table 4 reviews the results of published research on biodiesel applications.

Table 4.

Studies on the effects of biodiesel.

Comparative analyses of the combustion and air pollutant characteristics of using JP-5 and biodiesel with various multiple injection strategies in common rail direct injection (CRDI) diesel engines have yielded limited results. These two fuels are believed to be applicable to diesel engines for propulsion and power generation. JP-5 is a fuel used in naval aircraft with limited access to the general public. In particular, previous studies must be considered when JP-5 and biodiesel fuels with large differences in properties are applied to marine diesel engines, including naval vessels equipped with an electronic injector.

The present study was conducted on CRDI single-cylinder diesel engine installed with an electronic injector to evaluate the combustion and emission characteristics of JP-5 and biodiesel fuels. Single-injection timing and multiple split injection strategies were introduced to diversify the fuel injection methods in this experimental study. The multiple split injection strategy was divided into four modes: double, triple, quadruple, and quintuple. The combustion characteristics of JP-5 and biodiesel were analyzed using combustion parameters such as in-cylinder pressure, ROHR, indicated mean effect pressure (IMEP), engine torque, and combustion efficiency. The emission characteristics were analyzed by measuring substances such as oxygen (O2), carbon dioxide (CO2), CO, and NOx emissions. In addition, the spray development and combustion process were visualized in an optically accessible experimental system.

2. Experimental Setup and Strategy

2.1. Experimental System

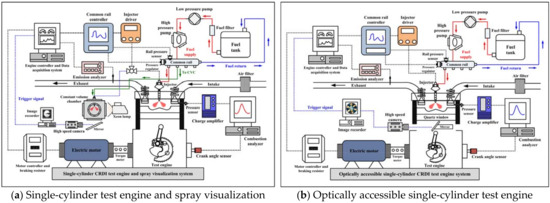

A schematic diagram of the experimental systems used to evaluate the spray behavior, combustion, and emission characteristics of JP-5 and biodiesel fuels is shown in Figure 1. The functions of the main devices that constitute the experimental system are shown in Table 5.

Figure 1.

Schematic of the experimental system: (a) Spray behavior, combustion, and emission characteristics were investigated in this system; (b) visualization of the characteristics of the combustion flame was investigated in this system.

Table 5.

Function of the main devices constituting the experimental system.

A high-performance light source (Xeon 1000, Optical System) was used to obtain a clear image of the spray’s behavior. A high-pressure fuel tube coupled with a sac-type injector mounted in the CVC (constant volume chamber) for spray visualization was directly connected to the common rail of the test engine. In addition, the fuel injection in the spray chamber is synchronized with the test engine. An extended piston, quartz, and 45° mirror were installed to the test engine for visualization of the combustion flame with JP-5 and BD100. The main specifications of the experimental research engine are summarized in Table 6.

Table 6.

Main specifications of the experimental research engine.

2.2. Test Fuels

The JP-5 used for naval aircraft and biodiesel were the test fuels used in this study. JP-5 was supplied by naval vessels carrying aircraft. JP-5 has a lower distillation temperature, density, cetane number, and kinematic viscosity compared with biodiesel, but does not have a lower heating value. In particular, its CFPP shows very low properties below –35 °C. Table 7 lists the main physicochemical properties of the JP-5 and biodiesel fuels.

Table 7.

Main physiochemical properties of the test fuels.

2.3. Injection Strategy and Experimental Conditions

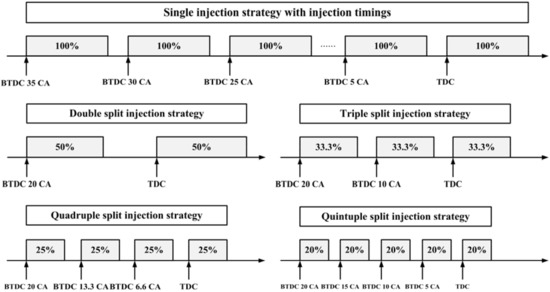

The injection strategies applied in this study were single and multiple split injection. In the case of the single-injection, the fuel injection timing was changed from before top dead center (BTDC) with a crank angle (CA) of 30 to BTDC 5 CA. The amount injected in the single-injection strategy was equally divided according to the number of injections in the multiple split injection strategy. The injected amount of fuel was determined based on the total heating value (mfQLEV = 429.5 J). In the multiple split injection strategy, the first injection timing was selected as BTDC 20 CA, where NOx was formed in large amounts with the single-injection strategy. Figure 2 shows the multiple split injection strategies introduced in this research.

Figure 2.

The multiple split injection strategies.

The injected fuel was supplied by the common rail of the test engine to visualize the spray behavior of the test fuel. The start of energizing (SOE) of the fuel injector and the start of shooting by a high-speed camera were synchronized for accurate analysis of the spray behavior process. The energy generated by the engine was dissipated by a braking resistor connected to an electric motor. The in-cylinder pressure was averaged over 300 cycles to minimize cycle-to-cycle variations. Detailed test conditions, including visualization of the spray behavior process and combustion, are listed in Table 8.

Table 8.

Experimental conditions.

3. Results and Discussions

3.1. Macroscopic Spray Behavior Characteristic

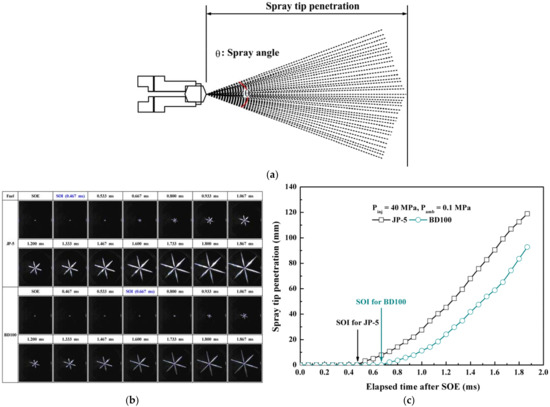

Figure 3b shows images of the spray behavior of the JP-5 and biodiesel. It has been reported that JP-8 has an asymmetric spray shape owing to the strong turbulence of the internal nozzle from a valve orifice covered-type injector [33]. However, it is generally accepted that the sac-type injector has a symmetrical spray [34]. In this study, the spray patterns of the two fuels showed symmetrical results. After the SOE, the start of injection (SOI) of biodiesel was 0.2 ms later than that of JP-5 (JP-5: 0.467 ms; biodiesel: 0.667 ms). Among the physical properties of fuel, it is believed that the physical characteristics of biodiesel, such as higher kinematic viscosity and surface tension, are the main causes of SOI delay. As the spray developed, JP-5 had a longer spray tip penetration. These differences can be attributed to the influence of fuel properties. JP-5 has a lower density, distillation temperature, and kinematic viscosity compared with biodiesel. These properties weaken the surface tension of the fuel more, which causes disequilibrium into the injector hole [17,35].

Figure 3.

Spray behavior process and spray tip penetration of JP-5 and biodiesel. (a) Definition of spray tip penetration. (b) Spray behavior process with JP-5 and BD100. (c) Spray tip penetration with JP-5 and BD100.

Figure 3c shows the results of the spray tip penetration based on the images acquired by the high-speed camera. The spray tip penetration by the definition (Figure 3a) was calculated by analyzing the photos obtained by high speed camera from injection tip to the end of visualization window. Under a constant fuel injection pressure, JP-5 showed longer spray tip penetration than biodiesel. According to the spray model based on momentum theory, the spray tip penetration is strongly dependent on the fuel density and the average injection velocity [36,37]. Biodiesel, with its relatively higher density, can be expected to have longer spray tip penetration owing to this model. However, it is thought that the delayed SOI of biodiesel fuel, which has a greater viscosity and surface tension, leads to shorter spray length.

3.2. Combustion and Emission Characteristics with Single Injection Strategy

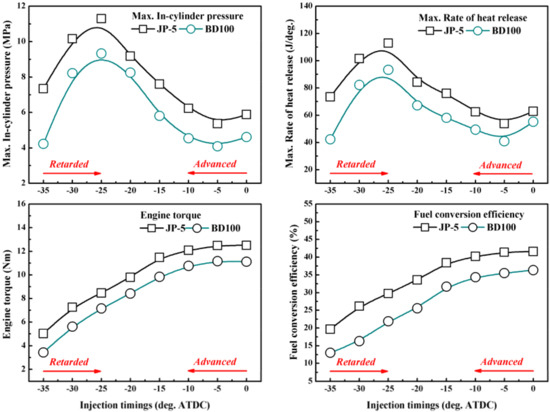

Figure 4 shows the influences of fuel injection timing on the maximum in-cylinder pressure, maximum ROHR, engine torque, and fuel conversion efficiency.

Figure 4.

Maximum in-cylinder pressure, ROHR, engine torque, and fuel conversion efficiency characteristics of JP-5 and biodiesel fuels with different single-injection timings.

As expected, as the fuel injection timing approached toward the TDC and the maximum in-cylinder pressure and ROHR tended to decrease, the engine torque and fuel conversion efficiency increased. The maximum in-cylinder pressure and ROHR decreased because the premixed combustion intensity decreased as the fuel injection timing was delayed. Under advanced injection conditions, the combustion gas acts as the negative work in the compression stroke process, which reduces the engine torque and fuel conversion efficiency. Therefore, it can be concluded that the IMEP and combustion efficiency improved in the retarded injection region. The results for biodiesel shown in Figure 5 were lower than those of JP-5 regardless of the fuel injection timing, even when the total heating value (mfQLEV = 429.5 J) was constant. The lower cetane number of JP-5 lengthened the ignition delay and strengthened the premixed combustion intensity. This has a significant affection on the magnitude of in-cylinder pressure and ROHR. The ignition delay of JP-5 lengthened the combustion period, thus increasing the positive work during the expansion stroke.

Figure 5.

Emission characteristics of JP-5 and biodiesel fuels with different single-injection timings.

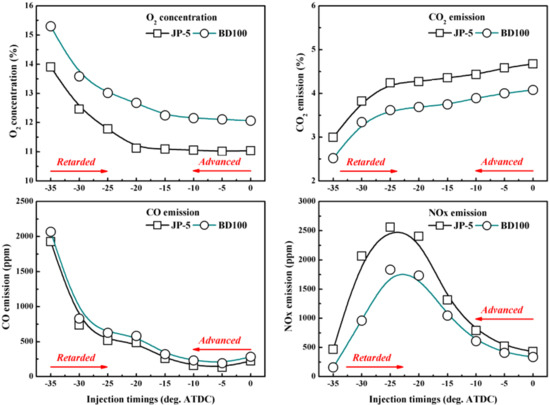

Figure 5 shows the O2, CO2, CO, and NOx characteristics of JP-5 and biodiesel with different fuel injection timings.

Biodiesel contains oxygen, but its spray angle was smaller than that of JP-5; hence, the formation of a mixture with the surrounding air was weakened. This meant that the proportion of air participating in combustion was lower than that of JP-5. Therefore, the O2 level in the exhaust gas of biodiesel was higher than in that of JP-5, regardless of the fuel injection timing. The CO2 emissions increased because the combustion efficiency improved as the fuel injection time was retarded. CO emissions, which are mainly caused by insufficient oxidation reaction and incomplete combustion, decreased as the fuel injection timing moved toward the TDC. Higher in-cylinder pressure and temperature shortened the ignition delay and reduced cylinder wall wetting. This increased the oxidation rate and reduced incomplete combustion, which was a major cause of the CO reductions. Compared with JP-5, the biodiesel produced higher CO emissions. The atomization of fuel droplets and mixture formation were disadvantageous compared with JP-5 because of the high viscosity of biodiesel [37].

For this reason, a locally fuel-rich area is formed in the combustion chamber, which is a major cause of incomplete combustion. NOx is a hazardous substance that is dependent on the combustion gas temperature. As the fuel injection timing was delayed, the maximum in-cylinder pressure and ROHR decreased, which led to a reduction in the combustion gas temperature. The greater vaporization rate and longer ignition delay of JP-5 increased the mixture formation rate, which caused a large amount of heat to be released in the premixed combustion phase. In addition, the faster mixture formation of the high evaporation rate reduced the locally fuel-rich condition, thereby increasing the amount of heat released and the combustion gas temperature.

3.3. Combustion and Emission Characteristics with Multiple Split Injection Strategy

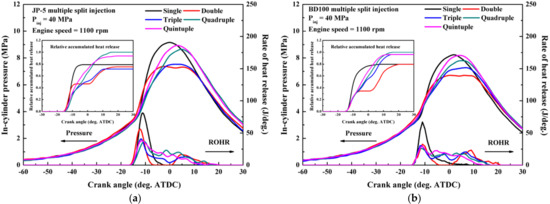

Figure 6 shows the results of the in-cylinder pressure and ROHR curves for JP-5 and biodiesel for the multiple split injection strategies.

Figure 6.

In-cylinder pressure and ROHR curve characteristics of JP-5 and biodiesel fuels with multiple split injection strategies. (a) JP-5. (b) BD100.

It was confirmed that the in-cylinder pressure and ROHR were superior for JP-5, which has an excellent evaporation rate and fast mixture formation. Although the divided injection quantity was reduced, the in-cylinder pressure tended to increase as the number of injection pulses increased. The in-cylinder pressure was higher than that of the single-injection strategy during the expansion stroke owing to the post-combustion effect of the final injection at the TDC. As the number of injections extended, the maximum in-cylinder pressure showed a tendency to increase; however, the maximum ROHR decreased, as expected. In particular, the maximum in-cylinder pressure increased to a level similar to that of single combustion when quintuple split combustion was applied. The increase in the pulse of consecutive fuel injections suppressed the maximum ROHR. However, three or four consecutive injections before the final injection formed a richer mixture that burned rapidly, increasing the in-cylinder pressure.

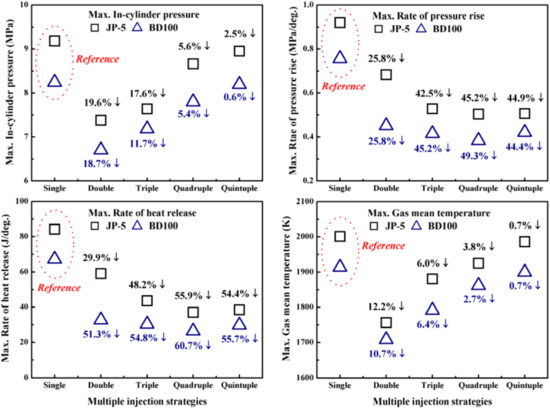

To verify the effects of the multiple split injection strategy, the maximum in-cylinder pressure, the rate of pressure rise (ROPR), the ROHR, and the mean gas temperature were compared with the single-injection strategy, as shown in Figure 7. The maximum in-cylinder pressure increased as the number of equally divided injections increased. Compared with the single-injection strategy, JP-5 and biodiesel were reduced by at least 2.5% and 0.6%, respectively. The ROPR, which is directly related to the combustion noise of the diesel engine, decreased as the number of multiple split injections increased. As a result of using multiple injections, the fuel injection quantity was divided into small portions and the ROHR was suppressed. The maximum mean gas temperature was calculated using the following equation [38,39].

where P(θ), V(θ), and T(θ) are the in-cylinder pressure, cylinder volume, and in-cylinder temperature, respectively, is in-cylinder air mass at the IVO point, is the air density, is the cylinder volume at IVC, is the function of valve lift, is period of IVO, is the duration of EVO, and and are the IVO angle and EVO angle, respectively.

Figure 7.

Maximum in-cylinder pressure, ROPR, ROHR, and GMT of JP-5 and biodiesel fuels with multiple split injection strategies.

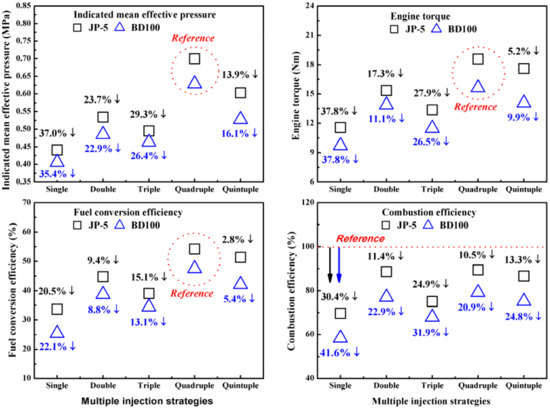

Figure 8 shows the results of the IMEP, engine torque, fuel conversion efficiency, and combustion efficiency for the multiple split injection strategies. Fuel conversion efficiency was simulated as the ratio of fuel chemical energy(mfQLEV) to engine work. In addition, combustion efficiency was defined as the proportion of fuel chemical energy to the heat release generated by combustion. Compared with the single-injection strategy, the quadruple-injection mode showed superior engine performance. Considering that the first fuel injection timing was BTDC 20 CA, the higher heat release during the compression stroke before the TDC changed through heat loss and negative work. This indicates a penalty that cannot be converted into effective work. The accumulated heat release was reduced because the overall combustion duration was shorter than that of the multiple split injection strategy. This reduced the combustion performance, engine performance, and combustion efficiency. As seen in Figure 8, the triple-injection strategy had the lowest results among the multiple-injection strategies for the following reasons. First, the last injection quantity was smaller than that of the double-injection mode, which reduced the combustion period. Each injected mass in the triple-injection strategy was 33.3% of that of the single-injection strategy. Second, each injection quantity of the quadruple and quintuple-injection strategies was smaller than that of the triple-injection strategy; however, the dwell time between fuel injection timings was more reduced than that of the triple-injection strategy. Owing to the shorter dwell time and the increased number of injections, the mixture burned in a rich condition. The results of the quintuple-injection strategy in Figure 8 are considered inferior to those of the quadruple-injection strategy because the fuel injection quantity is less than that of the quadruple strategy.

Figure 8.

IMEP, engine torque, fuel conversion efficiency, and combustion efficiency of JP-5 and biodiesel fuels with multiple split injection strategies.

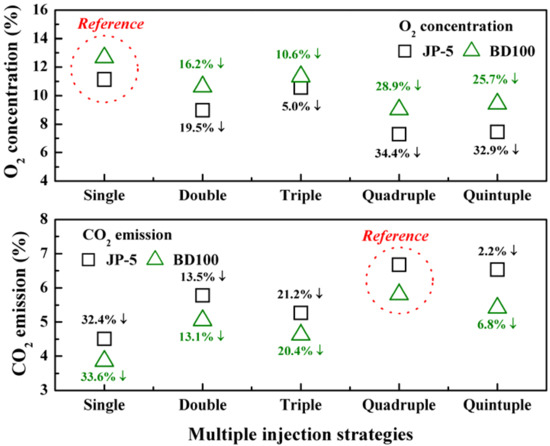

Figure 9 shows the O2 and CO2 emission levels of the multiple-injection strategies. The O2 concentration was measured to be higher in biodiesel than in JP-5, similar to the results of the fuel injection timing research. The low O2 concentration indicated that the oxidation reaction proceeded actively. Compared with the single-injection strategy, the O2 concentration in the multiple split injection strategy was low, with the lowest found in the quadruple strategy. This result proves that the oxidation reaction rate was the highest, with the quadruple strategy. The increase in the number of injections formed a rich mixture and promoted the oxidation reaction with O2, which improved the combustion efficiency. CO2 is proportional to the combustion rate of the injected fuel. The quadruple strategy, which had the lowest O2 level in the exhaust gas, had the highest CO2 emission levels.

Figure 9.

O2 concentration and CO2 emissions of JP-5 and biodiesel fuels with multiple split injection strategies.

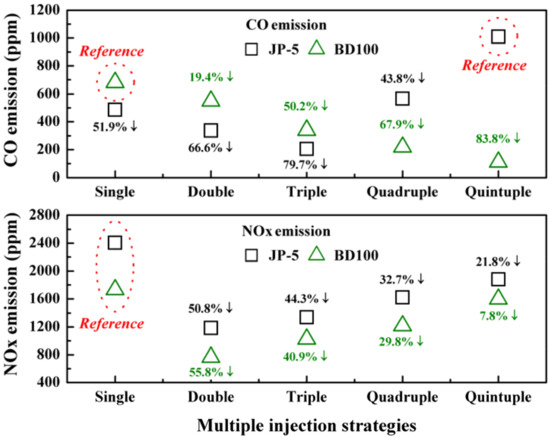

Figure 10 shows the CO and NOx emission levels of the multiple-injection strategies. With the single, double, and triple-injection strategies, the CO emissions of biodiesel were greater than those of JP-5. Interestingly, less CO reduction was observed in the quadruple and quintuple strategies compared with JP-5. As presented in Figure 10, the O2 concentration of biodiesel was higher than that of JP-5 when the multiple split injection strategy was applied. Although biodiesel has a lower carbon and higher oxygen component than JP-5, the increase in CO emissions can be explained by the oxidation reaction rate being lower than that of JP-5. With the quadruple strategy, the mixture became richer, and combustion under richer conditions increased CO emissions. Biodiesel is believed to be more effective at reducing CO than JP-5 through activating oxidation with the oxygen inclusion of the fuel. Thermal NOx from an internal combustion engine is governed on the combustion gas temperature, and the in-cylinder pressure is the dominant parameter in the combustion gas temperature. The results in Figure 7 confirm that the maximum in-cylinder pressure and mean gas temperature increased as the number of split injections increased. With the multiple split injection strategy, a higher maximum ROHR was not identified after the first maximum heat release. The multiple combustion gradually increased the in-cylinder pressure, resulting in the highest in-cylinder pressure after the TDC. This played a major role in increasing the combustion gas temperature. The NOx emissions for the double-injection strategy decreased by up to 50.8% and 55.5% for JP-5 and biodiesel, respectively, compared with the single-injection strategy. NOx emissions were observed to increase gradually with a large amount of fuel injection pulse.

Figure 10.

CO and NOx emissions of JP-5 and biodiesel fuels for multiple split injection strategies.

3.4. Combustion Visualization

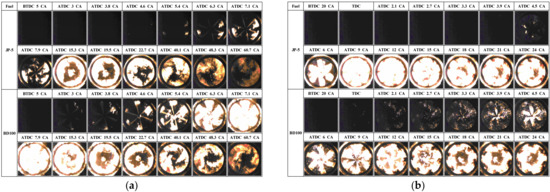

Figure 11 shows continuous images of the combustion flame of JP-5 and biodiesel fuels with the single-injection and double split injection strategies.

Figure 11.

Combustion of JP-5 and biodiesel fuels with the single-injection and double split injection strategies. (a) Single injection strategy (Tinj = BTDC 5 CA). (b) Double spilt injection strategy (1st Tinj = BTDC 20 CA, 2nd Tinj = TDC).

It can be confirmed that the ignition delay of biodiesel was significantly shorter for the single-injection strategy. This is because the SOI of biodiesel is slower than that of JP-5; however, the oxygen component of the fuel promotes rapid ignition. In addition, it was confirmed that the flame of JP-5 spread faster after ignition, with an excellent evaporation rate and rapid mixture formation. In the double split injection mode, the fuel injected from BTDC 20 CA ignited first in the biodiesel in the form of scattered flames. This can be seen as the natural luminosity in the images from after ATDC 4.5 CA. The fuel injected from the TDC has a diffusion combustion form; as a result, the ROHR was suppressed. JP-5 had a longer ignition delay than biodiesel when the natural luminosity was used to define the start of combustion in the images of the combustion process. However, the flame distribution throughout the cylinder after ignition was wider than that of biodiesel because the flame propagation speed was very fast.

4. Conclusions

In this experimental study, the spray behavior, combustion, and emission characteristics of JP-5 and biodiesel and their combustion process were analyzed through visualization in an experiment applying single-injection and multiple split injection strategies in an optically accessible single-cylinder CRDI diesel engine. The following important conclusions were drawn from this study:

I. The sac-type injector spray exhibited a symmetrical pattern, regardless of the fuel properties. The SOI of the fuel was delayed because biodiesel had a higher density, kinematic viscosity, and surface tension than JP-5. JP-5 had better spray tip penetration than biodiesel.

II. Combustion characteristics such as the maximum in-cylinder pressure and ROHR decreased as the injection timing approached the TDC; however, the engine performance improved owing to the increase in the positive work. Combustion under retardation conditions is a direct cause of increased CO2 emissions with a large amount of O2 participation. CO decreased because the oxidation reaction was activated as the injection timing was retarded. NOx reduction was observed as the combustion gas temperature decreased. Biodiesel had disadvantages in terms of combustion and emission characteristics compared with JP-5, regardless of the fuel injection timing.

III. As the number of split injections extended, the maximum in-cylinder pressure and gas mean temperature increased, while the opposite was observed for the maximum ROPR and ROHR. The quadruple-injection strategy showed the best combustion, performance, and efficiency, including the highest O2 consumption and CO2 emissions. The CO emissions of JP-5 decreased for the double and triple-injection strategies; however, an increase in CO with the quadruple strategy was observed again. A significant reduction in CO of up to 83.8% for biodiesel was achieved as split injection pulses increased. An increase in the number of split injections raised the combustion gas temperature, which led to an increase in NOx production from JP-5 and biodiesel.

IV. JP-5, with its excellent evaporation rate, has a longer ignition delay compared with biodiesel, which promotes faster mixture formation inside the cylinder. The rapid flame propagation of JP-5 after ignition enables a combustion process similar to that of biodiesel. Combustion flame by fuel injection was observed to be typical diffusion combustion from the multiple-injection strategy.

Experimental studies on BD100 are working on a CRDI single-cylinder diesel engine to improve the combustion and emission characteristics using multi-stage pre-injection strategies under cold-start conditions. The multi-stage pre-injection strategy can improve the combustion quality and emissions. Combustion quality under the multi-stage injection strategy can be analyzed using RI (ringing intensity) theory. In addition, in the near future, we plan to research the simultaneous reductions in PM and NOx using different injection strategies with a PM analyzer and a urea injection system.

Author Contributions

Writing, investigation and experimental research, and analysis, H.M.B.; conceptualization, methodology, writing—review and editing, and experimental research and analysis, H.M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Acknowledgments

This study was performed by the 2022 Academic Research Project of the Naval Institute for Ocean Research of the Republic of Korea Naval Academy.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| ABDC | After Bottom Dead Center |

| ATDC | After Top Dead Center |

| BBDC | Before Bottom Dead Center |

| BD100 | 100% Biodiesel |

| BTDC | Before Top Dead Center |

| CA | Crank Angle |

| CFPP | Cold Flow Plugging Point |

| CAD | Crank Angle Degree |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| CRDI | Common Rail Direct Injection |

| EVC | Exhaust Valve Closing |

| EVO | Exhaust Valve Opening |

| IMEP | Indicated Mean Effective Pressure |

| IVC | Intake Valve Closing |

| IVO | Intake Valve Opening |

| JP | Jet Propellant |

| LEV | Low Heating Value |

| mf | Fuel Mass |

| NATO | North Atlantic Treaty Organization |

| NOx | Nitrogen Oxides |

| O2 | Oxygen |

| Pinj | Injection pressure |

| RME | Rapeseed Methyl Ester |

| ROHR | Rate of Heat Release |

| ROPR | Rate of Pressure Rise |

| rpm | Revolutions per Minute |

| SOE | Start of Energizing |

| SOI | Start of Injection |

| TDC | Top Dead Center |

| ULSD | Ultra-Low-Sulfur Diesel |

| Tinj | Injection Timing |

| VOC | Valve Orifice Covered |

References

- Kim, H.J.; Jo, S.; Lee, J.T.; Park, S. Biodiesel fueled combustion performance and emission characteristics under various intake air temperature and injection timing conditions. Energy 2020, 206, 118154. [Google Scholar] [CrossRef]

- Gopinath, S.; Devan, P.K.; Mohan, C.; Krishnarao, L.R.; Lokesh kumar, P.; Vara Prasad, S. A review on influence of injection timing and injection pressure on DI diesel engine fueled with low viscous fuel. Mater. Today Proc. 2020, 33, 280–286. [Google Scholar] [CrossRef]

- Karthic, S.V.; Senthil Kumar, M.; Nataraj, G.; Pradeep, P. An assessment on injection pressure and timing to reduce emissions on diesel engine powered by renewable fuel. J. Clean. Prod. 2020, 255, 120186. [Google Scholar] [CrossRef]

- Kulandaivel, D.; Rahamathullah, I.G.; Sathiyagnanam, A.P.; Gopal, K.; Damodharan, D.; Victor, D.P.M. Effect of retarded injection timing and EGR on performance, combustion and emission characteristics of a CRDI diesel engine fueled with WHDPE oil/diesel blends. Fuel 2020, 278, 118304. [Google Scholar] [CrossRef]

- Shareef, S.M.; Mohanty, D.K. Experimental investigation of dairy scum biodiesel in a diesel engine with variable injection timing for performance, emission and combustion. Fuel 2020, 280, 118647. [Google Scholar] [CrossRef]

- Rami Reddy, S.; Murali, G.; Shaik, A.A.; Dhana Raju, V.; Sreekara Reddy, M.B.S. Experimental evaluation of diesel engine powered with waste mango seed biodiesel at different injection timings and EGR rates. Fuel 2021, 285, 119047. [Google Scholar] [CrossRef]

- Sun, Z.; Cui, M.; Wang, H.; Nour, M.; Li, X.; Xu, M.; Hung, D. Effect of split injection timing on combustion and emissions of DISI optical engine under lean burn condition. In Proceedings of the ASME 2020 International Combustion Engine Division Fall Technical Conference, Denver, Colorado, USA, 4–6 November 2020. [Google Scholar] [CrossRef]

- Park, S.H.; Yoon, S.H.; Lee, C.S. Effects of multiple-injection strategies on overall spray behavior, combustion, and emissions reduction characteristics of biodiesel fuel. Appl. Energy 2011, 88, 88–98. [Google Scholar] [CrossRef]

- Yehliu, K.; Boehman, A.L.; Armas, O. Emissions from different alternative diesel fuels operating with single and split fuel injection. Fuel 2010, 89, 423–437. [Google Scholar] [CrossRef]

- Park, S.; Kim, H.J.; Shin, D.H.; Lee, J.T. Effects of various split injection strategies on combustion and emissions characteristics in a single-cylinder diesel engine. Appl. Therm. Eng. 2018, 140, 422–431. [Google Scholar] [CrossRef]

- How, H.G.; Masjuki, H.H.; Kalam, M.A.; Teoh, Y.H. Influence of injection timing and split injection strategies on performance, emission, and combustion characteristics of diesel engine fueled with biodiesel blended fuels. Fuel 2018, 213, 106–114. [Google Scholar] [CrossRef]

- Park, H.; Bae, C.; Ha, C.A. Comprehensive analysis of multiple injection strategies for improving diesel combustion process under cold-start conditions. Fuel 2019, 255, 115762. [Google Scholar] [CrossRef]

- Doll, H.; Barro, C.; Todino, M.; Boulouchos, K. Impact of a split injection strategy on mixing, ignition and combustion behavior in premixed charge compression ignition combustion. Fuel 2021, 294, 120511. [Google Scholar] [CrossRef]

- De la Garza, O.A.; Martínez-Martínez, S.; Avulapati, M.M.; Pos, R.; Megaritis, T.; Gannipa, L. Biofuels and its spray interaction under pilot-main injection strategy. Energy 2021, 219, 119464. [Google Scholar] [CrossRef]

- Arkoudeas, P.; Kalligeros, S.; Zannikos, F.; Anastopoulos, G.; Karnois, D.; Korres, D.; Lois, E. Study of using aviation fuel and biodiesel in CI engines. Energy Convers. Manag. 2003, 44, 1013–1025. [Google Scholar] [CrossRef]

- Korres, D.M.; Karonis, D.; Lois, E.; Linck, M.B.; Gupta, A.K. Aviation fuel JP-5 and biodiesel on a diesel engine. Fuel 2008, 87, 70–78. [Google Scholar] [CrossRef]

- Lee, J.W.; Bae, C.S. Application of JP-8 in a heavy duty diesel engine. Fuel 2011, 90, 1762–1770. [Google Scholar] [CrossRef]

- Lee, J.W.; Oh, H.C.; Bae, C.S. Combustion process of JP-8 and fossil Diesel fuel in a heavy duty diesel engine using two-color thermometry. Fuel 2012, 102, 264–273. [Google Scholar] [CrossRef]

- Uyumaz, A.; Silmaz, H.; Yılmaz, E.; Yamık, H.; Polat, S. Experimental examination of the effects of military aviation fuel JP-8 and biodiesel fuel blends on the engine performance, exhaust emissions and combustion in a direct injection engine. Fuel Process. Technol. 2014, 128, 158–165. [Google Scholar] [CrossRef]

- Lee, J.W.; Lee, J.Y.; Chu, S.H.; Choi, H.M.; Min, K.D. Emission reduction potential in a light-duty diesel engine fueled by JP-8. Energy 2015, 89, 92–99. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S. Combustion phenomenon, performance and emissions of a diesel engine with aviation turbine JP-8 fuel and rapeseed biodiesel blends. Energy Convers. Manag. 2015, 105, 216–229. [Google Scholar] [CrossRef]

- Hissa, M.; Niemi, S.; Sirviö, K.; Niemi, A.; Ovaska, T. Combustion studies of a non-road diesel engine with several alternative liquid fuels. Energies 2019, 12, 2447. [Google Scholar] [CrossRef]

- Shadidi, B.; Najafi, G.; Zolfigol, M.A. A review of the existing potential in biodiesel production in Iran. Sustainability 2022, 14, 3284. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; Nour, M.; Xuan, T.; He, Z.; Hassan, H. Combustion and emission characteristics of a diesel engine working with diesel/jojoba biodiesel/higher alcohol blends. In Proceedings of the ASME 2020 International Combustion Engine Division Fall Technical Conference, Denver, Colorado, USA, 4–6 November 2020. [Google Scholar] [CrossRef]

- Attia, A.M.A.; Kulchitstkiy, A.R.; Nour, M.; EL-Seesy, A.I.; Nada, S.A. The influence of castor biodiesel blending ratio on engine performance including the determined diesel particulate matter composition. Energy 2022, 239, 121951. [Google Scholar] [CrossRef]

- Fontaras, G.; Karavalakis, G.; Kousoulidou, M.; Tzamkiozis, T.; Ntziachristos, L.; Bakeas, E.; Stamoulis, S.; Samara, Z. Effects of biodiesel on passenger car fuel consumption, regulated and non-regulated pollutant emissions over legislated and real-world driving cycles. Fuel 2009, 88, 1608–1617. [Google Scholar] [CrossRef]

- Banapurmath, N.R.; Tewari, P.G.; Hosmath, R.S. Performance and emission characteristics of a DI compression ignition engine operated on Honge, Jatropha and sesame oil methyl esters. Renew. Energy 2008, 33, 1982–1988. [Google Scholar] [CrossRef]

- Alherbawi, M.; McKay, G.; Mackey, H.R.; Al-Ansari, T. A novel integrated pathway for Jet Biofuel production from whole energy crops: A Jatropha curcas case study. Energy Convers. Manag. 2021, 33, 113662. [Google Scholar] [CrossRef]

- Kattimani, S.S.; Topannavar, S.N.; Shivashimpi, M.M.; Dodamani, B.M. Experimental investigation to optimize fuel injection strategies and compression ratio on single cylinder DI diesel engine operated with FOME biodiesel. Energy 2020, 200, 117336. [Google Scholar] [CrossRef]

- Nguyen, T.; Pham, M.; Anh, T.L. Spray, combustion, performance and emission characteristics of common rail diesel engine fueled by fish-oil biodiesel blends. Fuel 2020, 269, 117108. [Google Scholar] [CrossRef]

- Sahoo, P.K.; Das, L.M.; Babu, M.K.G.; Arora, P.; Singh, V.P.; Kumar, N.R.; Varyani, T.S. Comparative evaluation of performance and emission characteristics of jatropha, karanja and polanga biodiesel as fuel in a tractor engine. Fuel 2009, 88, 1698–1707. [Google Scholar] [CrossRef]

- Xue, J.; Grift, T.E.; Hansen, A.C. Effect of biodiesel on engine performance and emissions. Renew. Sust. Energy Rev. 2011, 15, 1098–1116. [Google Scholar] [CrossRef]

- Pickett, L.M.; Hoogterp, L. Fundamental spray and combustion measurements of JP-8 at diesel conditions. SAE Int. J. Commer. Veh. 2008, 1, 108–118. [Google Scholar] [CrossRef]

- Soteriou, C.; Andrews, R.; Smith, M. Direct injection diesel sprays and the effect of cavitation and hydraulic flip on atomization. SAE Tran. J. Eng. 1995, 104, 128–153. [Google Scholar] [CrossRef]

- Myung, K.J.; Suzuki, H.; Sendra, J.; Fujimoto, H. Spray inner structure of evaporating multi-component fuel. Fuel 2007, 87, 202–210. [Google Scholar] [CrossRef]

- Yan, L.; Jiaxing, L.; Tao, Q.; Jianchun, M.; Xianwu, L.; Ning, Z. Effect of injection dynamic behavior on fuel spray penetration of common-rail injector. Energy 2019, 188, 116060. [Google Scholar] [CrossRef]

- Gopinath, S.; Devan, P.K.; Sabarish, V.; Sabharish Babu, B.V.; Sakthivel, S.; Vignesh, P. Effect of spray characteristics influences combustion in DI diesel engine—A review. Mater. Today Proc. 2020, 33, 52–65. [Google Scholar] [CrossRef]

- Septivani, N.; Riyandwita, B.W. Spark ignition engine modeling for in-cylinder pressure and temperature prediction using Simulink. Int. Mech. Ind. Eng. Conf. 2018, 204, 04001. [Google Scholar] [CrossRef][Green Version]

- Maurya, R.K. Reciprocating Engine Combustion Diagnostics-In-Cylinder Pressure Measurement and Analysis; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).